Composite purification device and process suitable for dusty gas

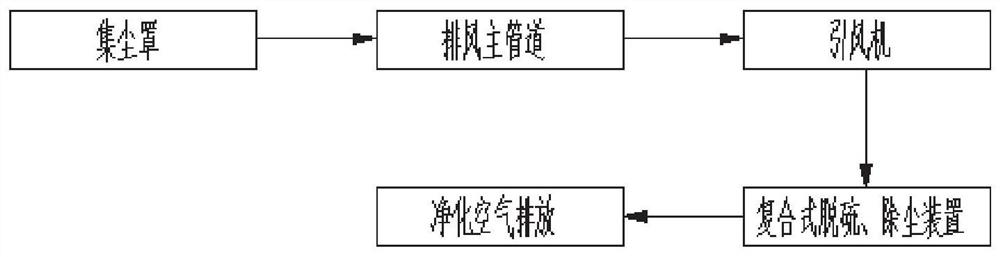

A purification device and a composite technology, applied in the direction of gas treatment, use of liquid separation agent, chemical instruments and methods, etc., can solve the problems of smoke and dust without purification treatment, air pollution, and the inability to use local exhaust hoods, etc., to reduce operation Maintenance cost, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

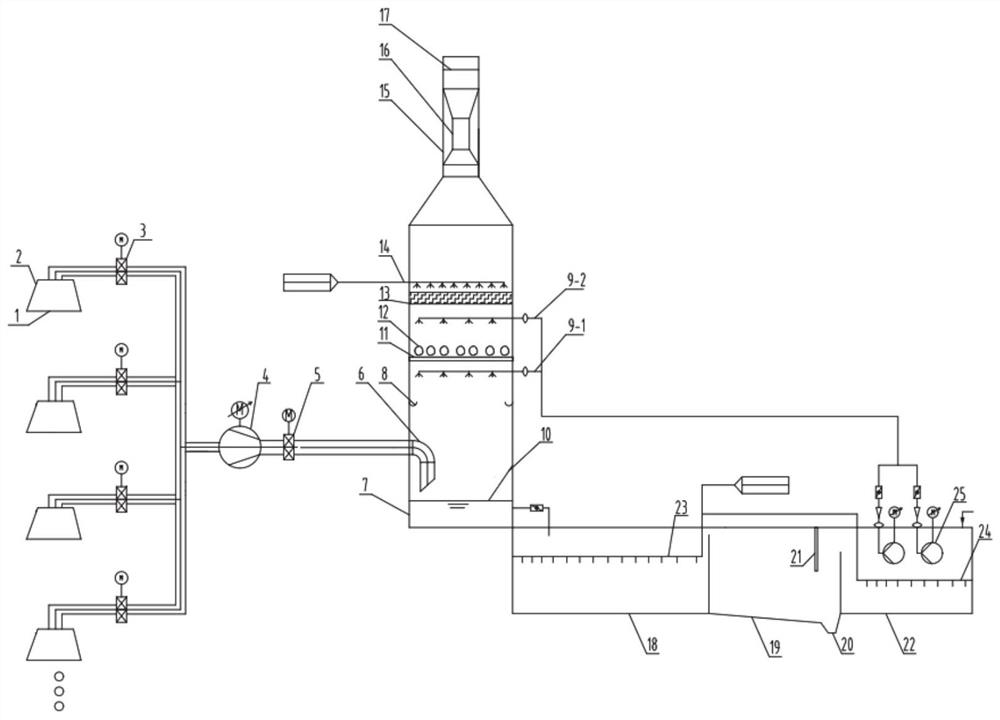

[0062] Such as figure 2 As mentioned above, a composite purification device suitable for dusty gas, comprising: anti-aspiration grille 1, dust collection cover 2, induced draft fan inlet baffle 3, induced draft fan 4, induced draft fan outlet baffle door 5, gas Introduction pipe 6, half-pipe type turbulence device 8, first spray layer 9-1, liquid retaining turbulence 11, second spray layer 9-2, droplet primary catcher 13, droplet secondary catcher 16 And anti-blocking grid 17, the structure of anti-blocking grid 17 is as Figure 5 shown. The droplet secondary catcher 16 and the anti-blocking grille 17 are arranged in the straight exhaust air duct at the upper part of the purification tower.

[0063] The half-pipe type turbulence device 8, the first spray layer 9-1, the liquid holding turbulence device 11, the second spray layer 9-2, and the primary droplet catcher 13 are arranged inside the composite purification tower.

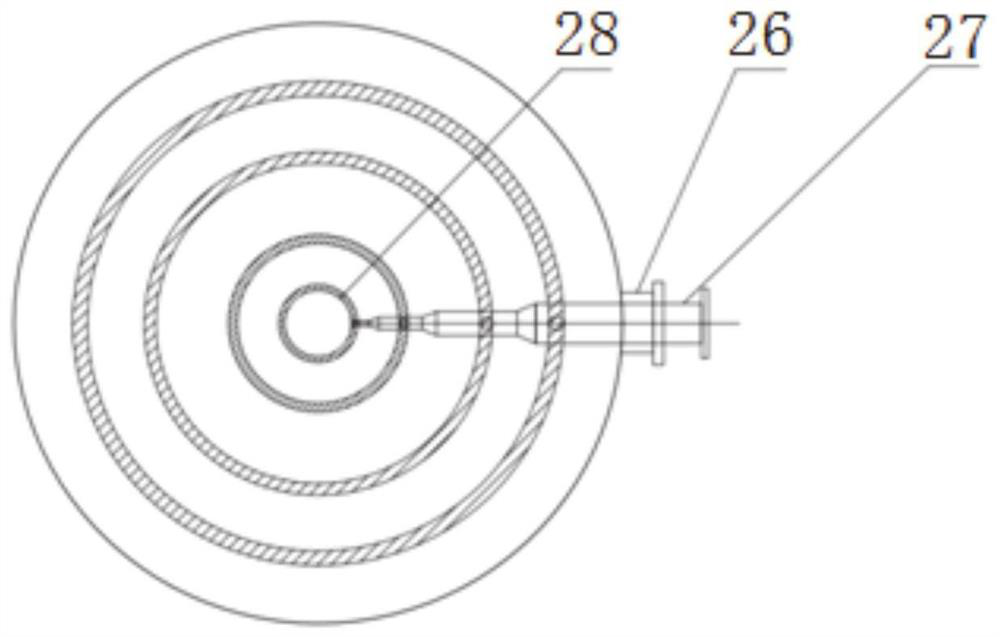

[0064] Such as image 3 As shown, the water distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com