Patents

Literature

105results about How to "Improve dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

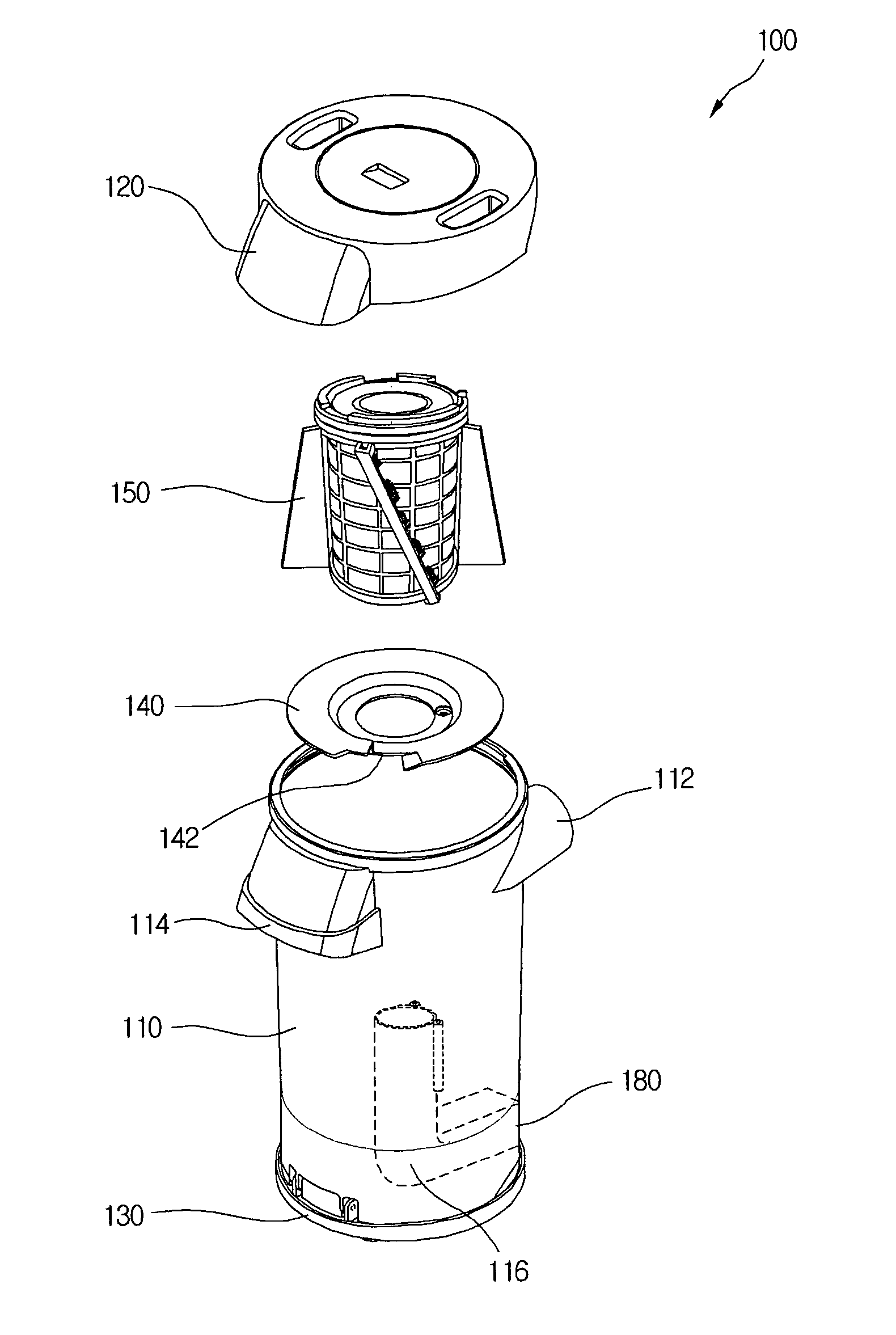

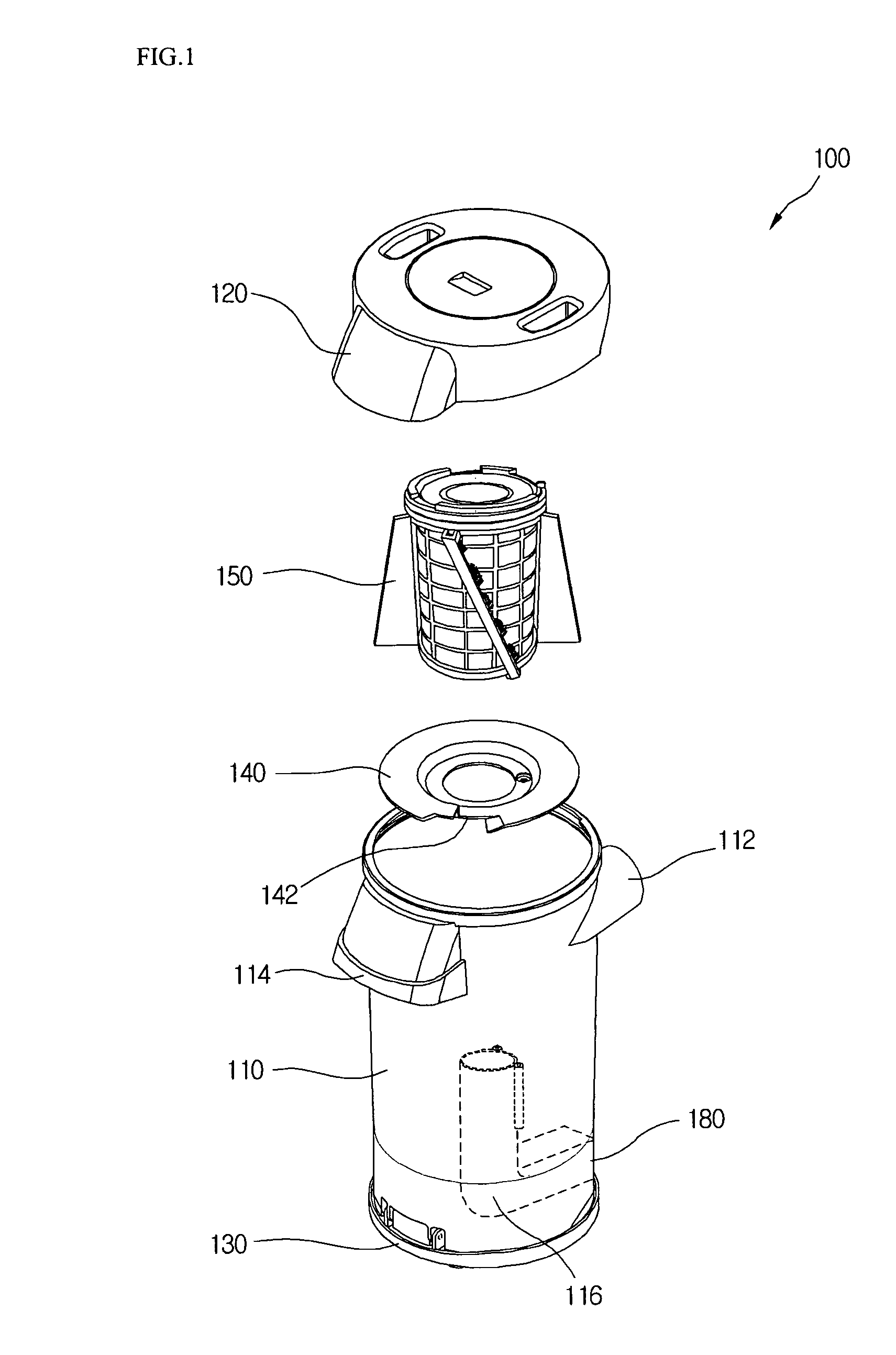

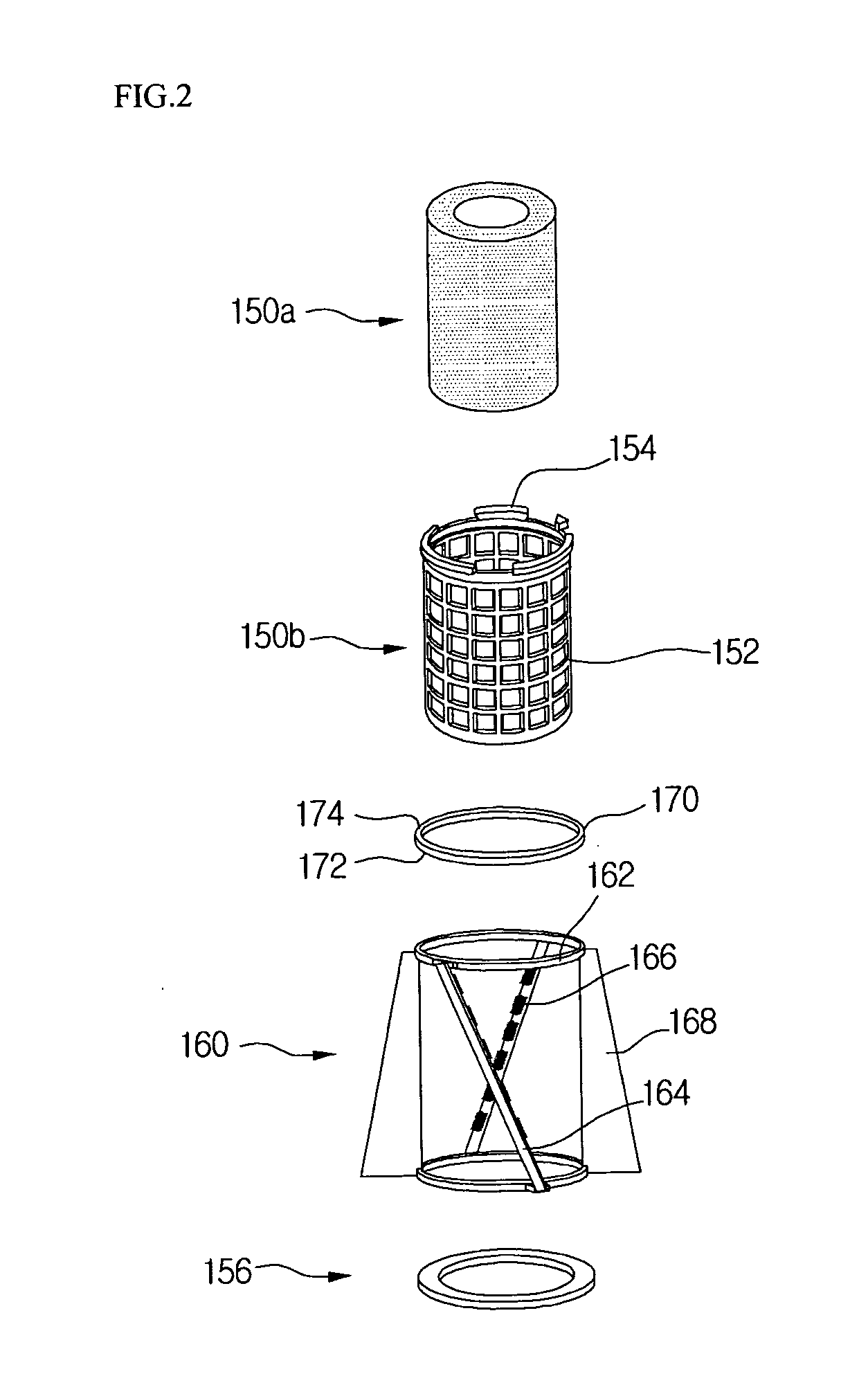

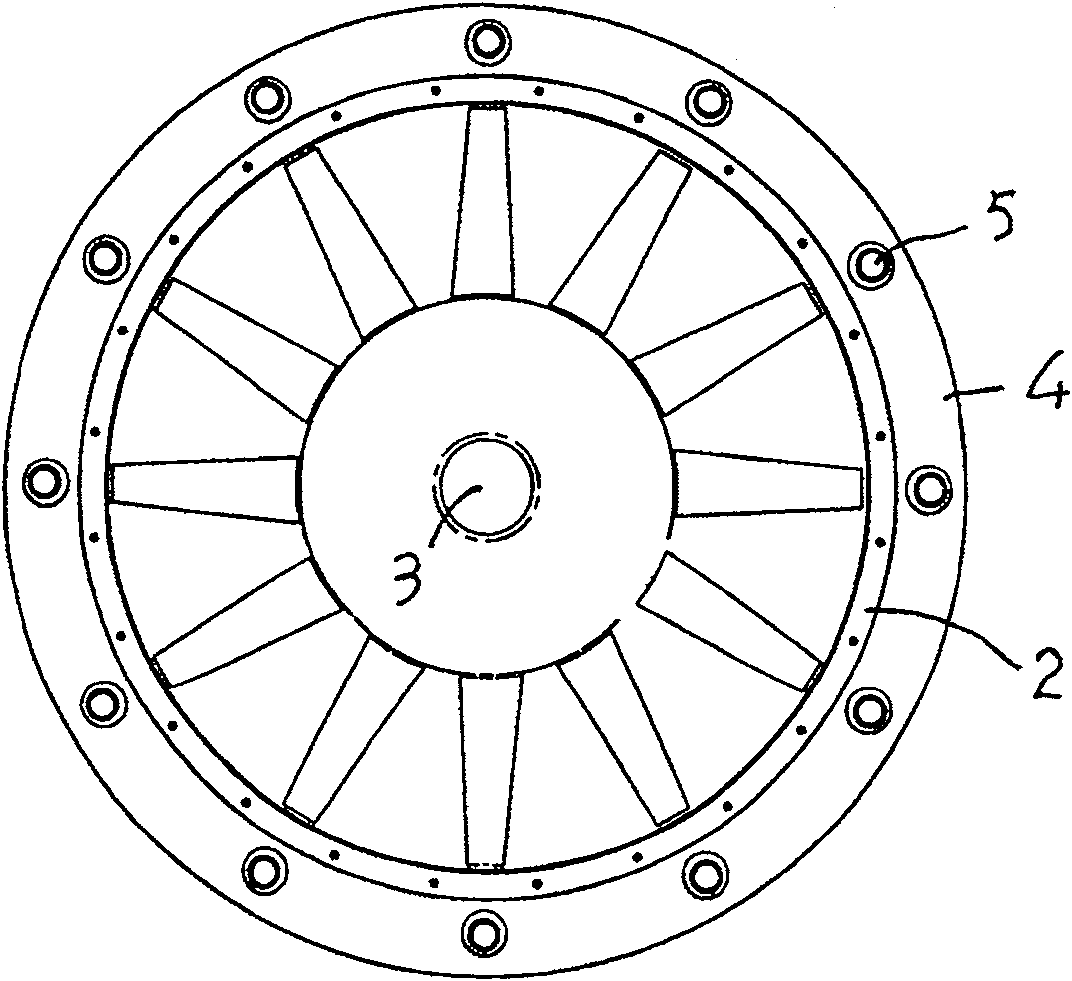

Dust collection unit and vacuum cleaner with the same

ActiveUS20060042202A1Improve dust removalPrevent overloadCleaning filter meansCombination devicesEngineeringForeign matter

A dust collection unit for a vacuum cleaner includes a dust collection container for collecting foreign objects contained in air introduced therein, covers defining a top and bottom of the dust collection container, and a filter-cleaning unit having a plurality of brushes rotating around the porous filter unit to remove the foreign objects clogging the outer surface of the porous filter unit.

Owner:LG ELECTRONICS INC

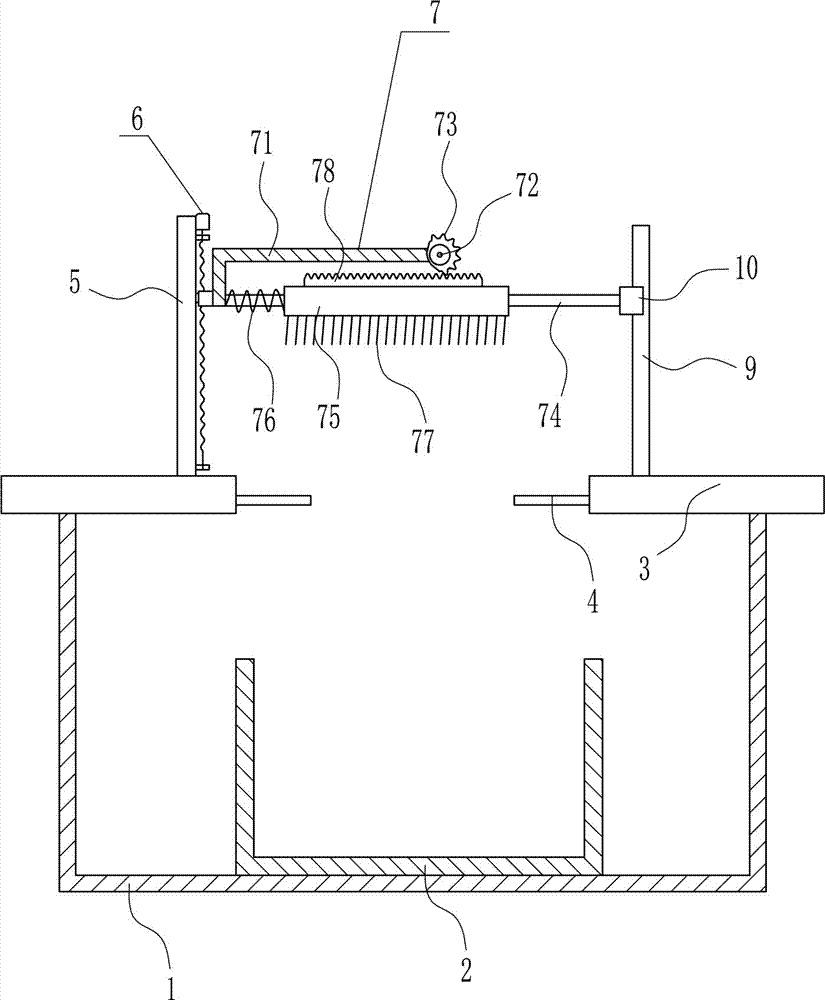

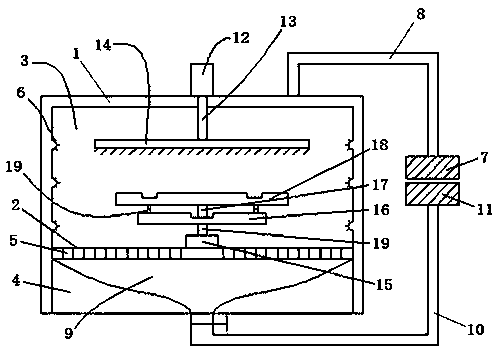

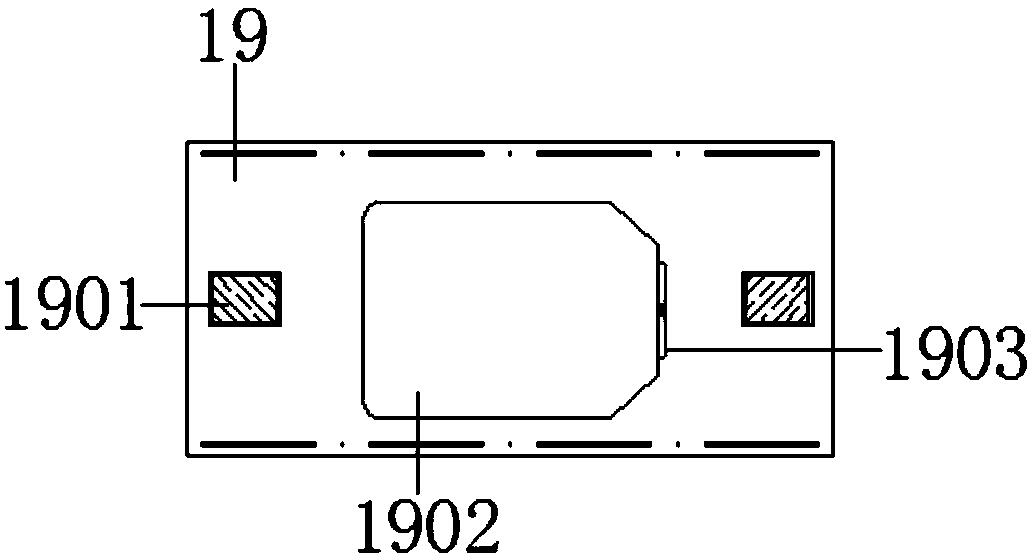

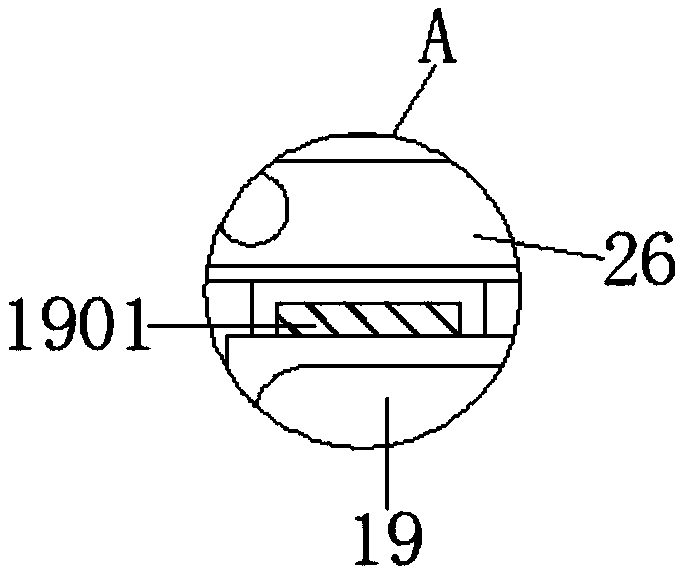

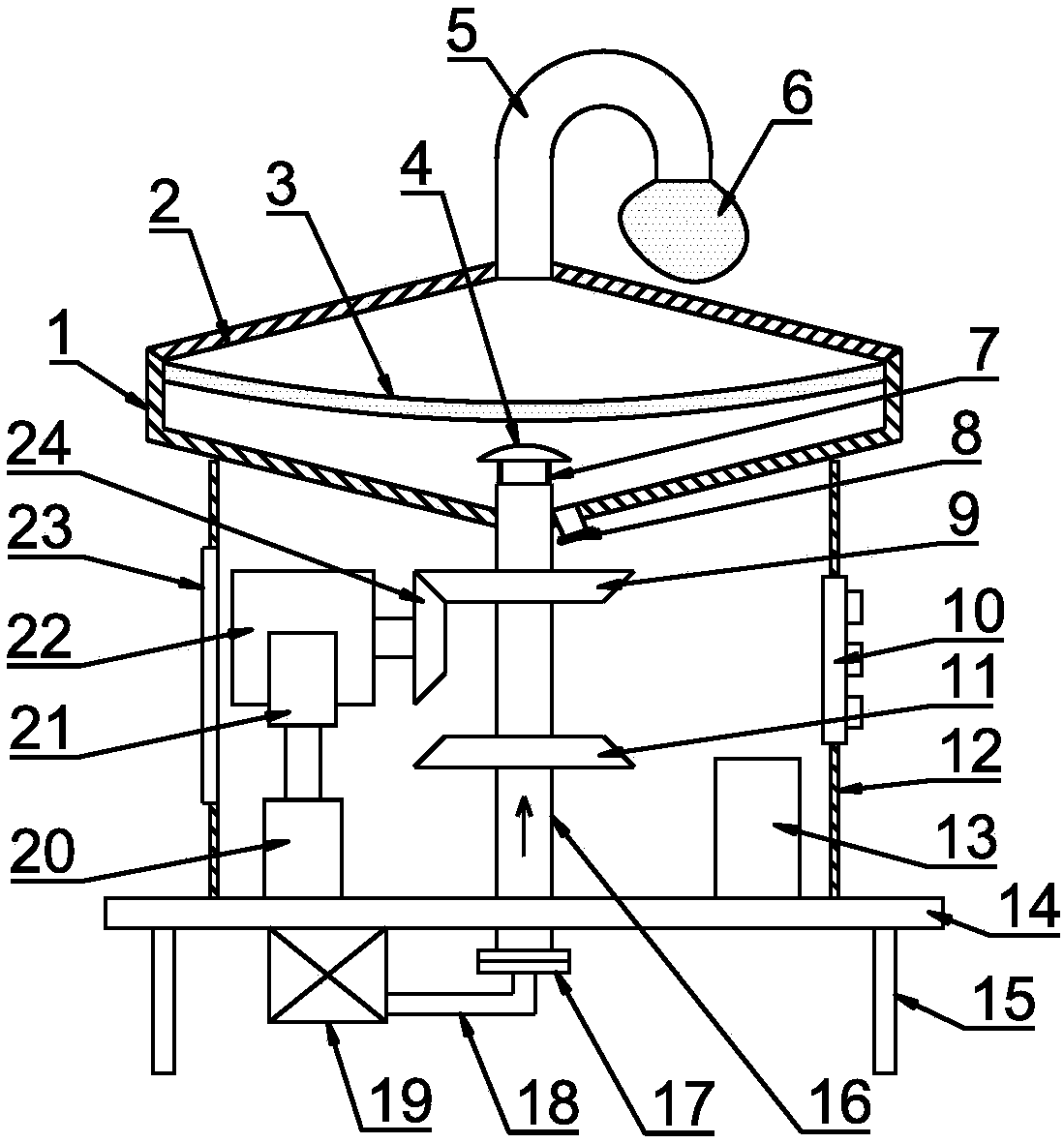

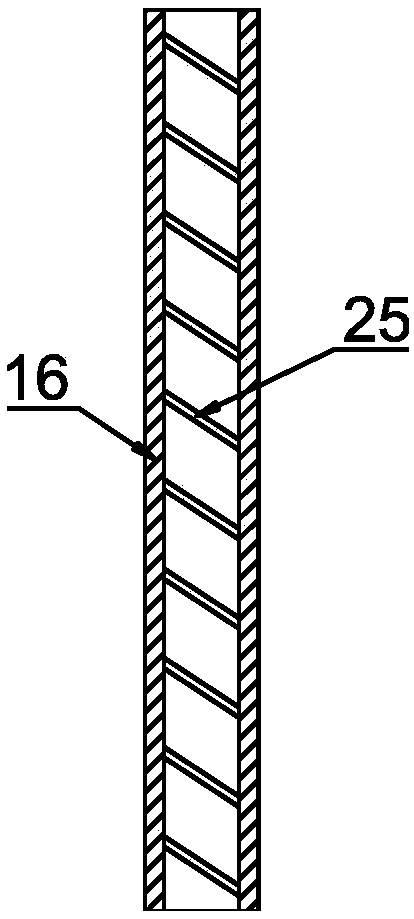

High-efficiency dust removal device for circuit board

InactiveCN106944376AImprove dust removalImprove dust removal effectCleaning using toolsCleaning using gasesEngineeringBolt connection

The invention relates to a dust removal device for a circuit board, particularly to a high-efficiency dust removal device for the circuit board. The invention technically aims to provide a high-efficiency dust removal device for the circuit board, with the advantages of time and labor saving, high dust removal speed and capability of collecting falling dust in the dust removal process but without influence on surrounding environment. According to the above technical scheme, the invention provides a high-efficiency dust removal device for the circuit boards, comprising a frame, a collection box, fixed blocks, a holding plate, etc.; the collection box is installed in the middle of the inner bottom of the frame through bolted connection, and the fixed blocks are symmetrically installed at the left and right sides of the frame top through bolted connection. In the invention, the circuit board can be cleaned through moving a brush right and left; at the same time, air is ejected from an air outlet pipe to blow dust on the circuit board to speed up dust removal of the circuit board.

Owner:刘养青

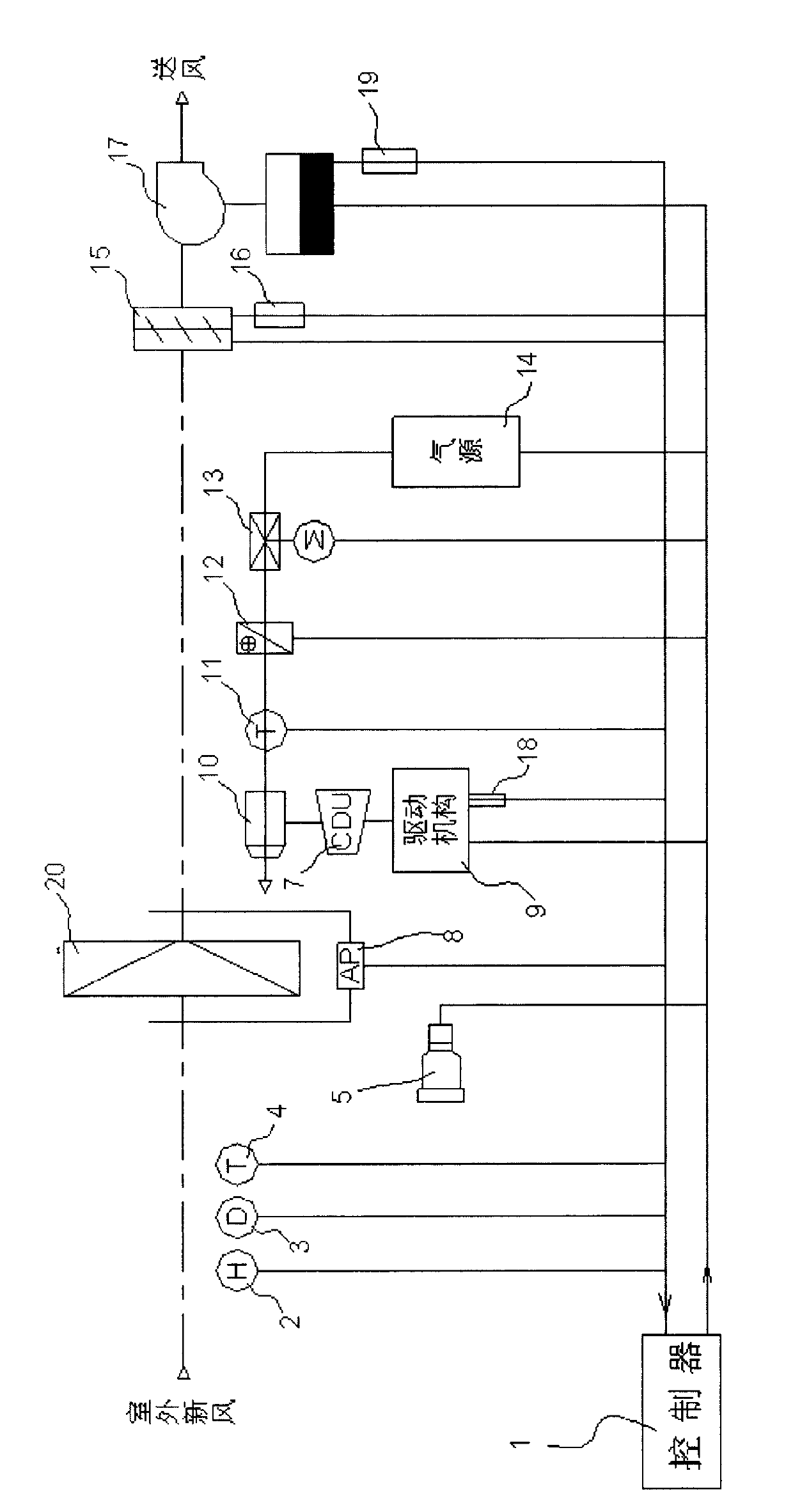

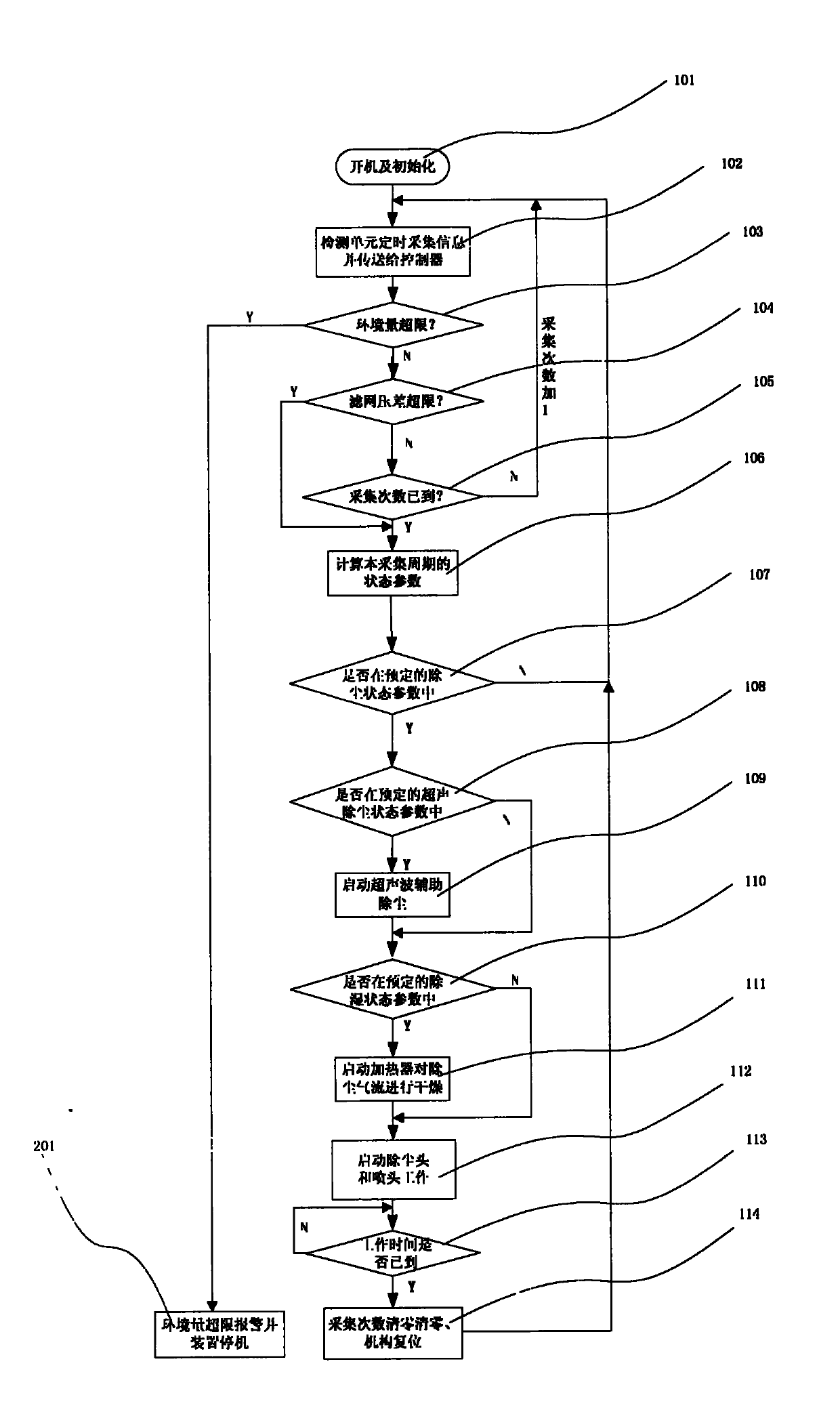

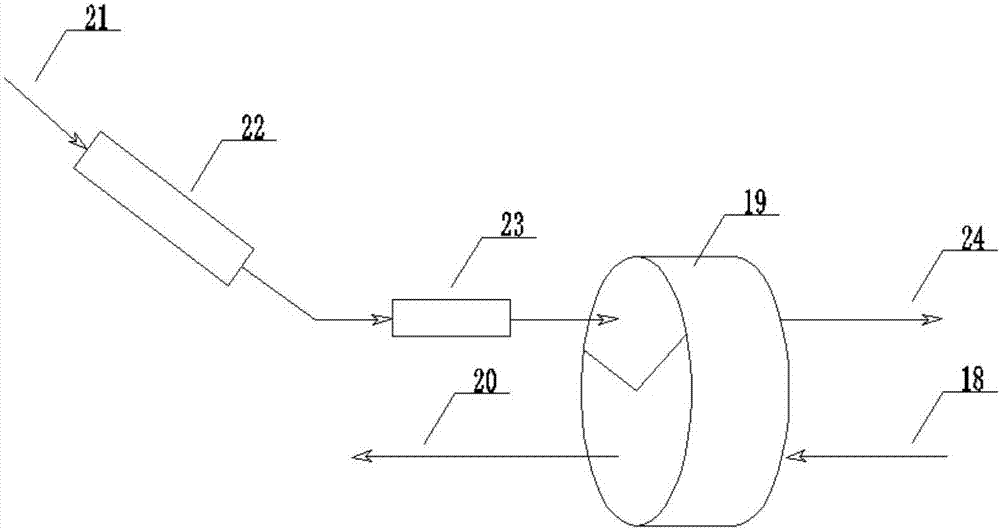

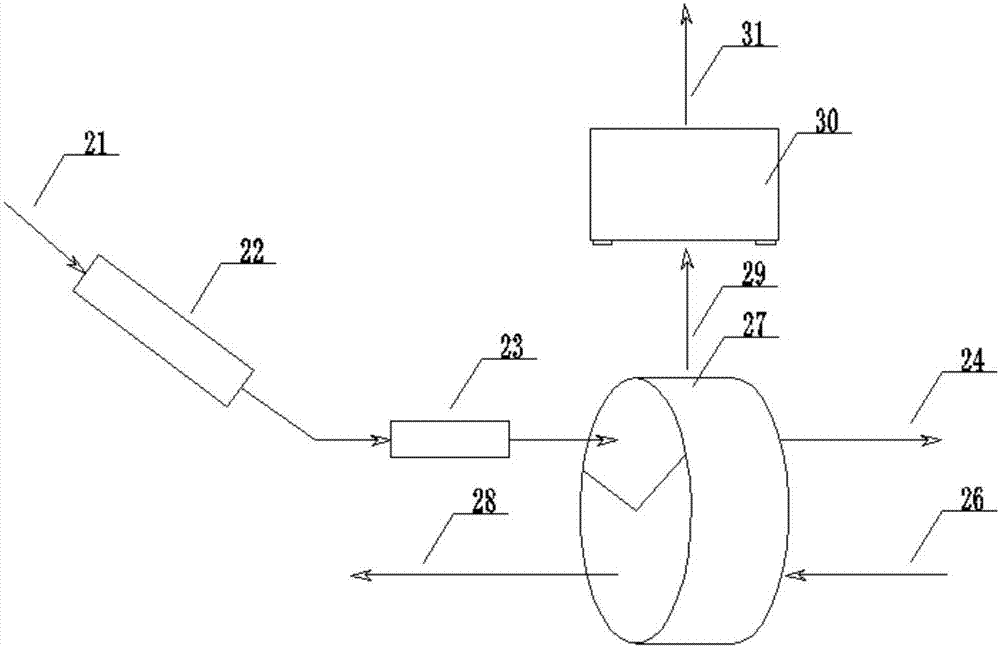

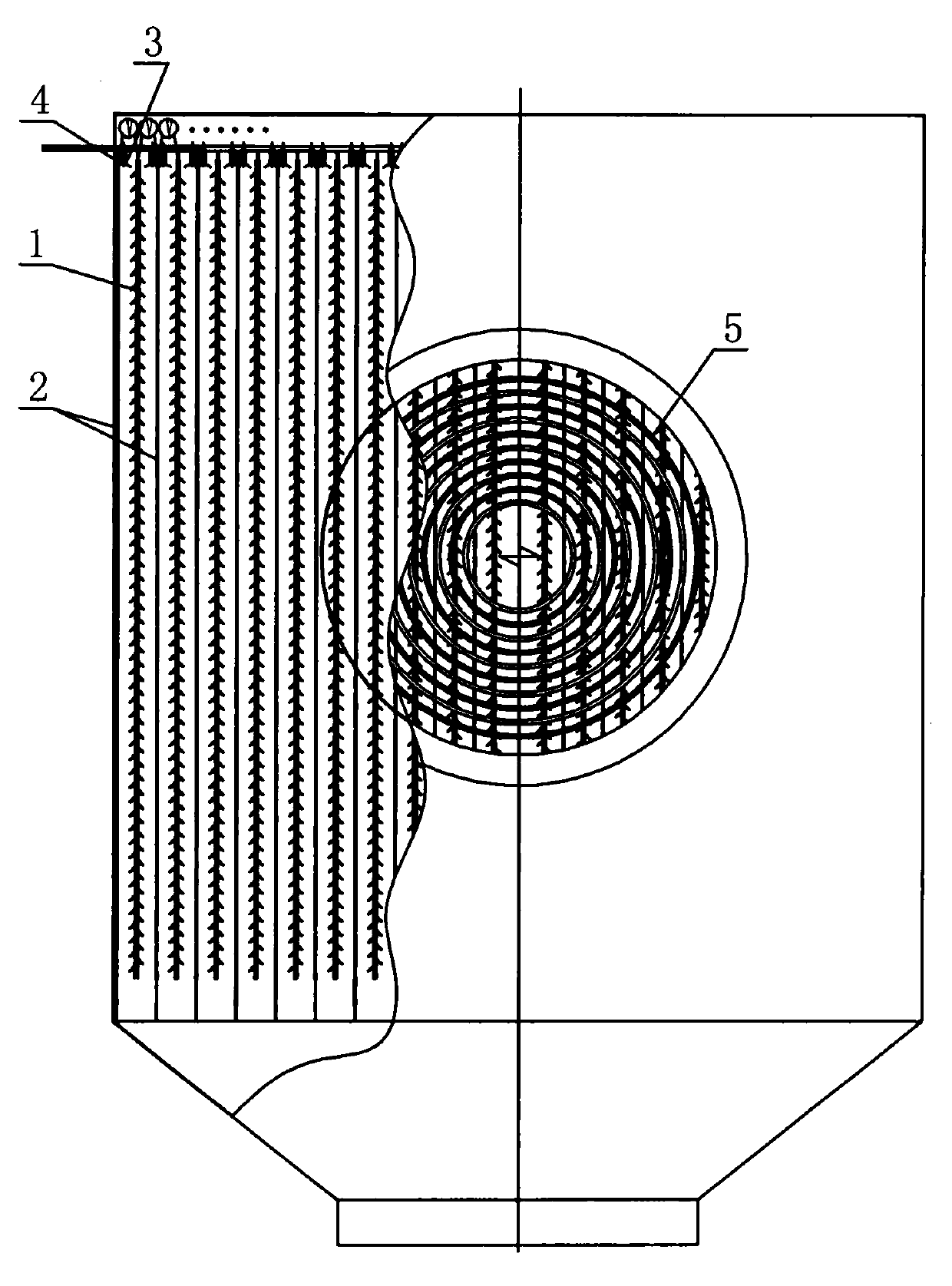

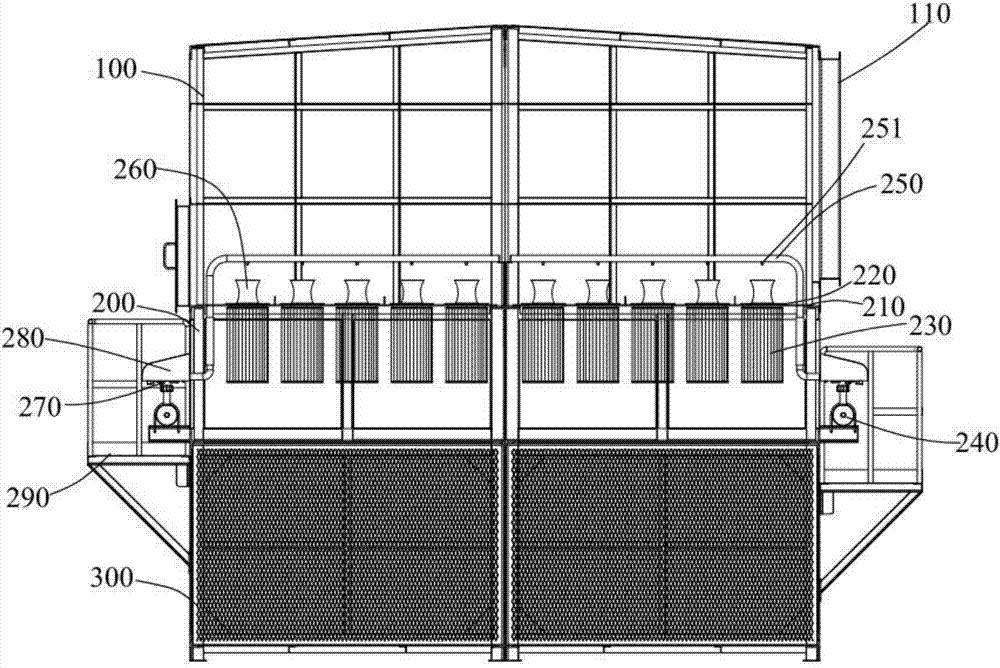

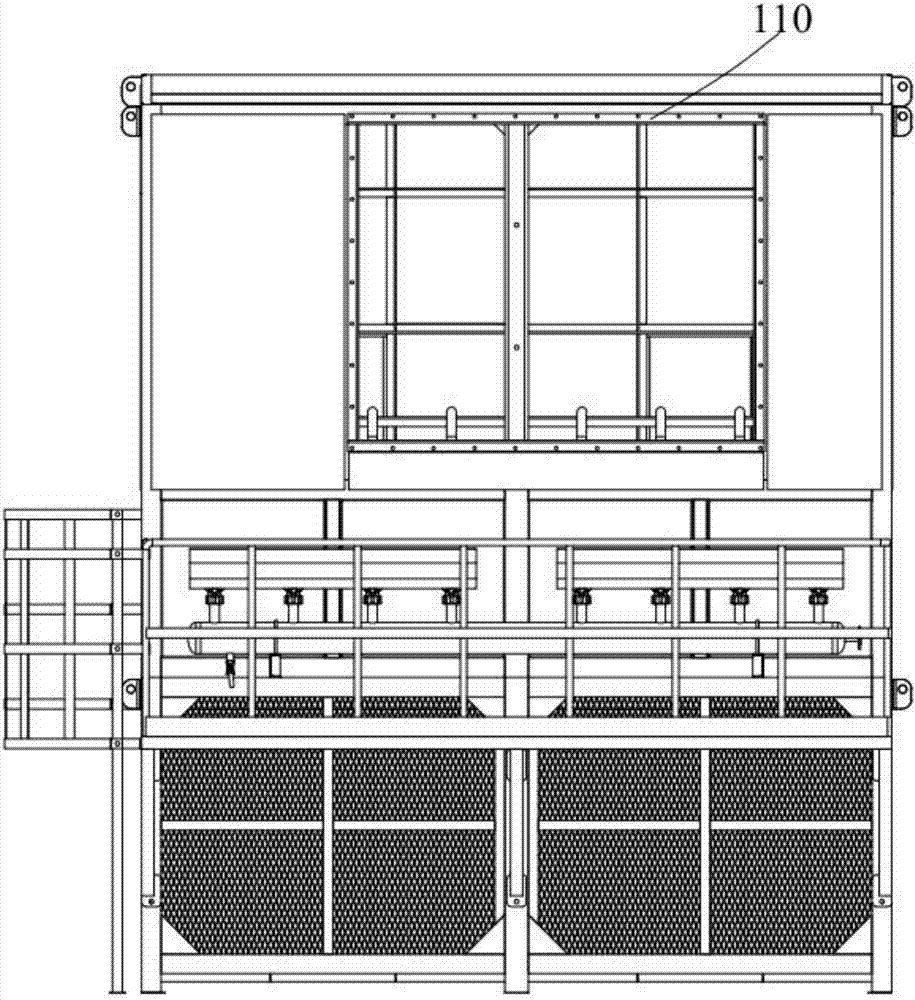

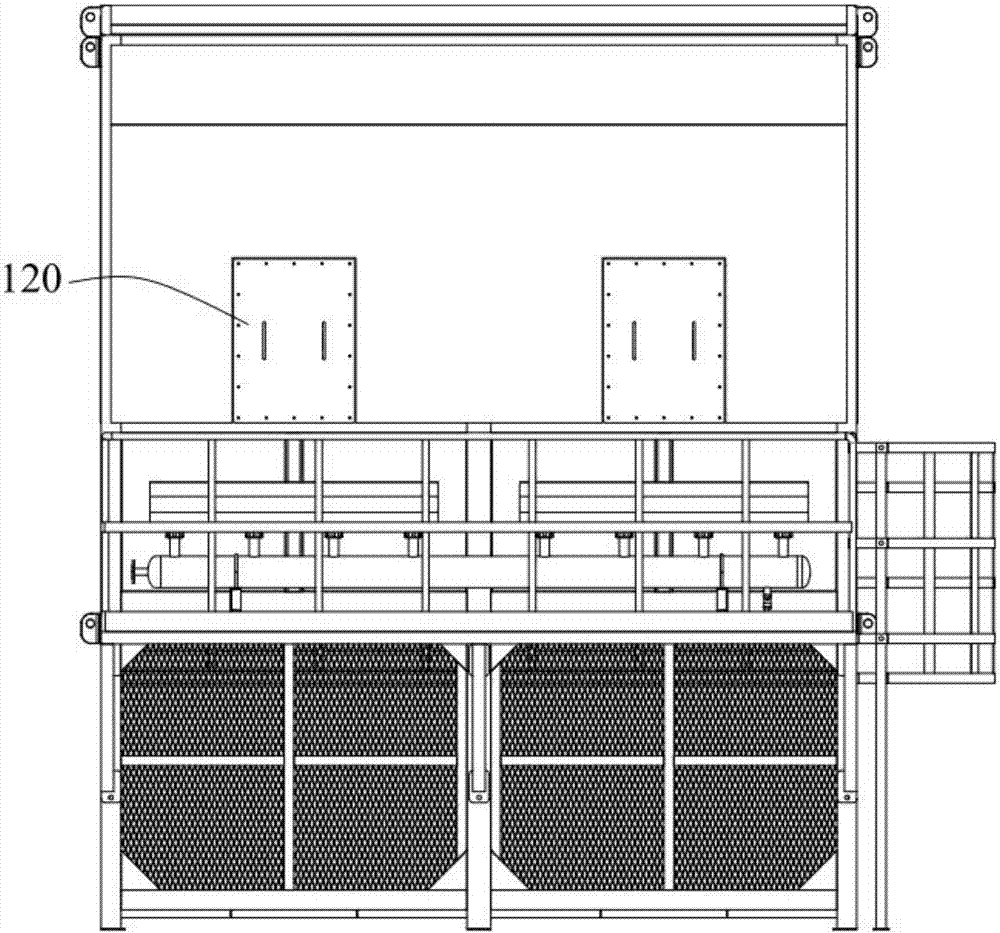

Fresh air ventilating device with self cleaning and dedusting function and dedusting method of fresh air ventilating device

InactiveCN104180465AAvoid accelerated degradationReduce maintenance frequencySpace heating and ventilation safety systemsLighting and heating apparatusFresh airEngineering

The invention relates to the field of ventilation, and discloses a fresh air ventilating device with a self cleaning and dedusting function. The fresh air ventilating device comprises an execution unit, a detection unit, a controller and an air source unit, wherein the detection unit is used for converting the environment quantity related to self cleaning and dedusting and the working state physical quantity of a system component into electric quantity and conditioning the electric quantity into an electric quantity signal which is compatible with the controller for being transmitted to the controller; the execution unit refers to execution components related to the self cleaning and dedusting, a driving circuit and a driving mechanism of the execution components, the execution unit is mainly used for enabling all execution components to work cooperatively according to an operation result of a control strategy under the regulation action of the controller and realizing the self cleaning and dedusting function on a filter screen; the controller is a microprocessor and has the main functions of collecting and processing the environment quantity and the system work state information of the detection unit at regular times, carrying out operation evaluation on a trend and a result of a dust accumulation process of the filter screen according to a dedusting strategy and outputting different dedusting control modes to filter screen dust accumulation situations in different degrees or different types. The invention also discloses a self cleaning and dedusting method using the fresh air ventilating device. The fresh air ventilating device and the self cleaning and dedusting method, disclosed by the invention, have the advantages that in-time and efficient dedusting can be carried out, and the energy source is saved.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

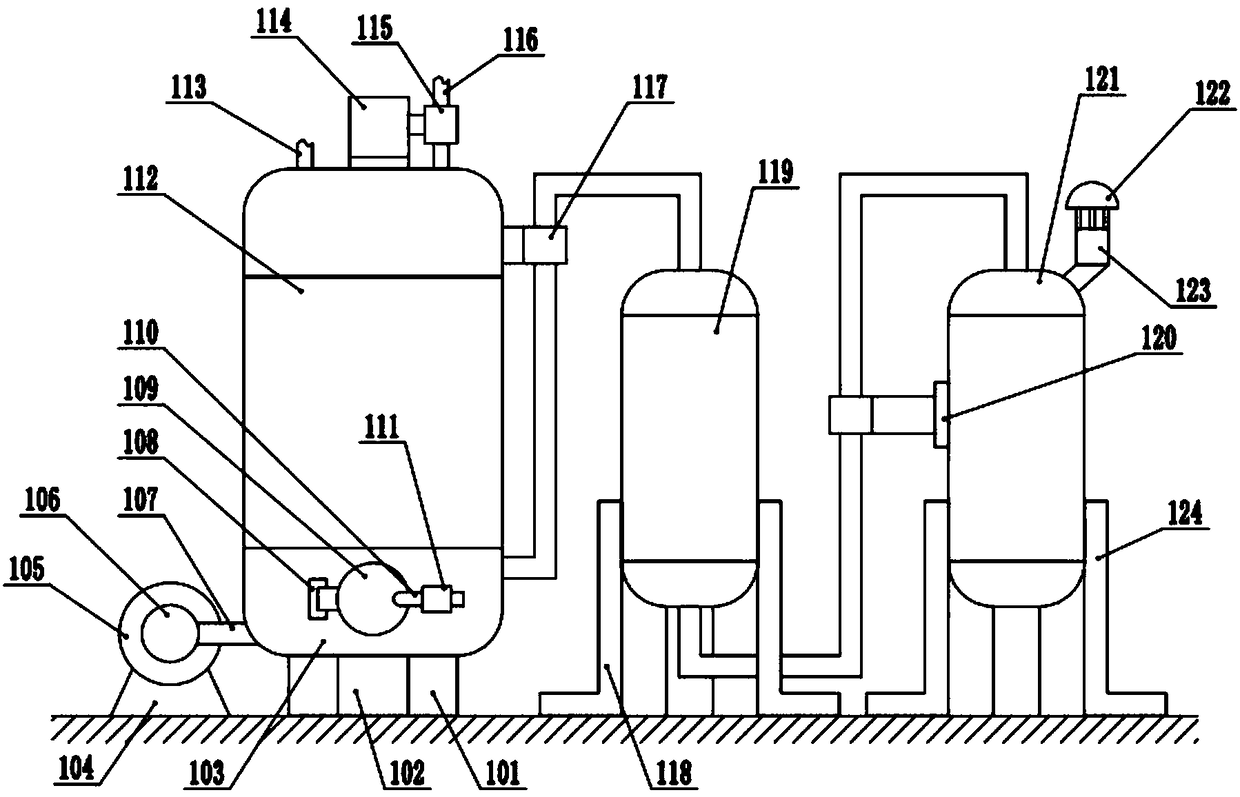

Desulfurization dust removing method of industrial furnace

InactiveCN101362043AIncrease contact timeImprove dust removal efficiencyUsing liquid separation agentFlue gasLiquid water

The invention discloses a desulfurization and dust removal method for an industrial furnace, which comprises the followings steps: 1. a flue gas inlet of a desulfurization and dust removal device of the industrial furnace is communicated with a flue gas outlet of the industrial furnace; 2. cooling water is pumped into a water inlet pipe, enters a contact type cooling spraying device through a flow partitioning device, falls into a spraying area in spraying shape and then is discharged along a blowdown pipe; 3. flue gas generated from the industrial furnace enters the desulfurization and dust removal device of the industrial furnace from bottom to top from the flue gas inlet of a shell, is contacted with cooling water between a barrier cap and an annular bottom plate firstly and then with the cooling water in the spraying shape and falling down from the contact type cooling spraying device to carry out heat exchange; 4. after the heat exchange, phase change is carried out to steam so as to cause the steam to turn into liquid water drops, during the phase change, adjacent sulfur dioxide is absorbed by the water drops and adjacent minimal dust grains are adsorbed by the water drops effectively. The desulfurization and dust removal method for the industrial furnace has good dust removal effect, high desulfurization efficiency, as well as low energy consumption, low equipment investment and low operation cost.

Owner:姚立猛

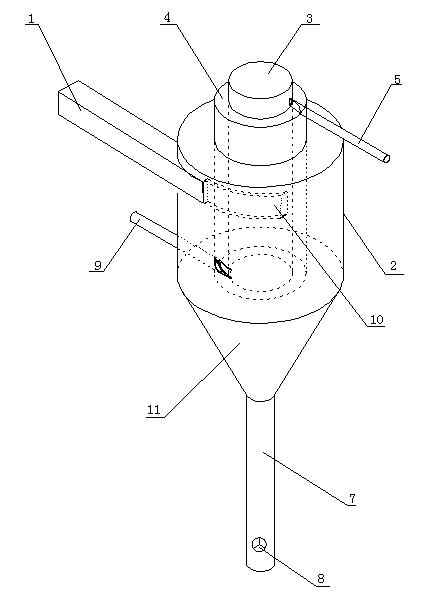

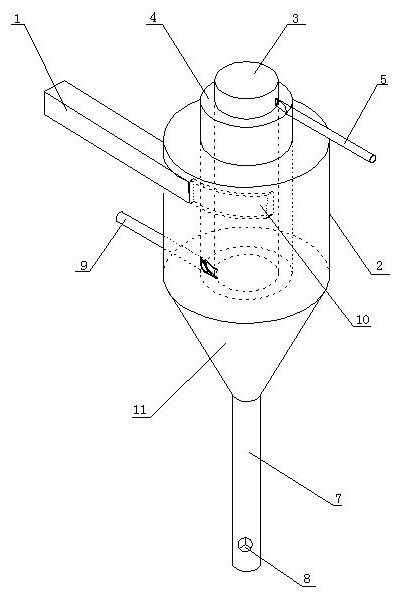

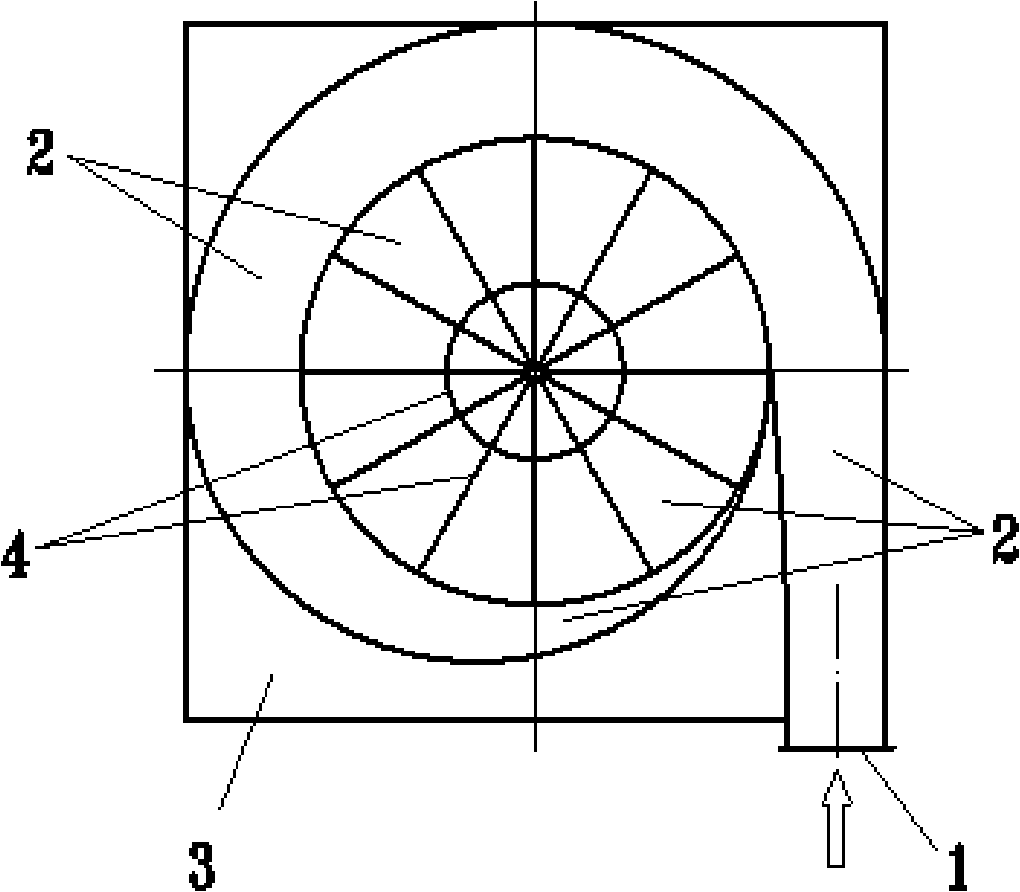

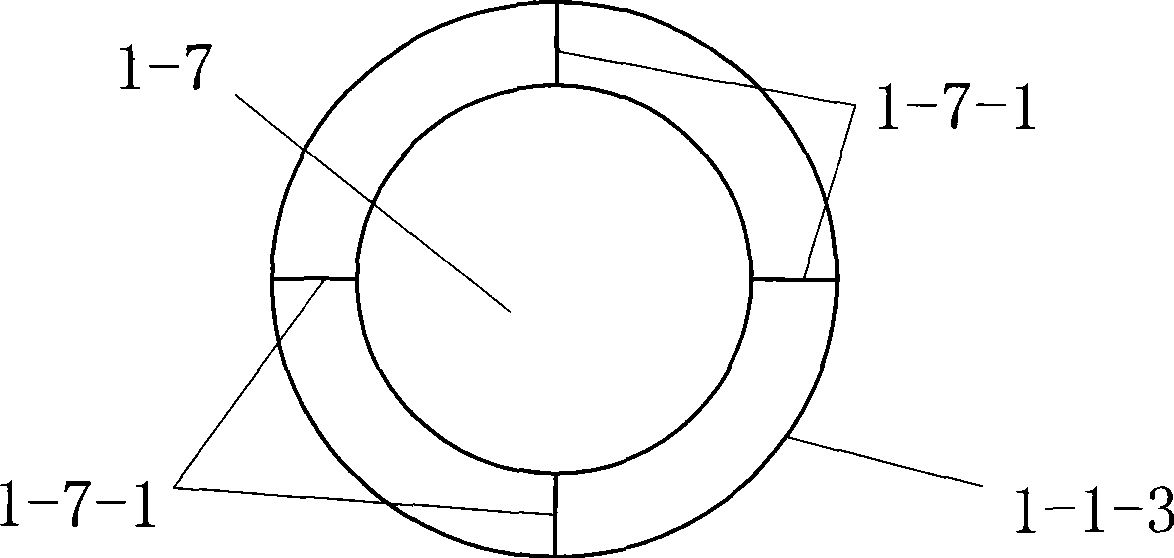

Dust collecting and air cooling heat exchanger

InactiveCN101920228AImprove heat transfer efficiencyContinuous ash dischargeReversed direction vortexStationary tubular conduit assembliesBiomassSmall footprint

The invention discloses a dust collecting and air cooling heat exchanger, relating to a gas purification device, in particular to the dust collecting and air cooling heat exchanger which is used for a biomass fluidized bed and fulfills the functions of dust collection and air cooling heat exchange. The dust collecting and air cooling heat exchanger mainly comprises a cyclone dust collector, wherein the cyclone dust collector consists of a cylinder, a cone, a gas inlet pipe and a gas outlet pipe, the cone is arranged below the cylinder, the lower part of the cone is connected with an ash discharge pipe, the gas inlet pipe is communicated with the upper part of the cylinder along a tangent direction of the cylinder, and the gas outlet pipe is arranged in the cylinder. The dust collecting and air cooling heat exchanger is characterized in that a round pipe with both closed ends is also arranged in the cylinder of the cyclone dust collector and is sleeved on the gas outlet pipe, an interlayer between the inner wall of the round pipe and the outer wall of the gas outlet pipe is a heat exchange chamber, an air inlet is arranged at the upper end of the round pipe, and an air outlet is arranged at the lower end of the round pipe. Compared with the traditional equipment, the invention has six advantages that firstly, the functions of dust collection and air cooling heat exchange are simultaneously realized; secondly, the efficiency of dust collection and air cooling heat exchange is high; thirdly, ashes can be continuously discharged in the work process; fourthly, the structure is simple, and the operation is convenient; fifthly, the occupied area is small; and sixthly, the cost is low.

Owner:KUNMING DIANYAN NEW ENERGY TECH DEV

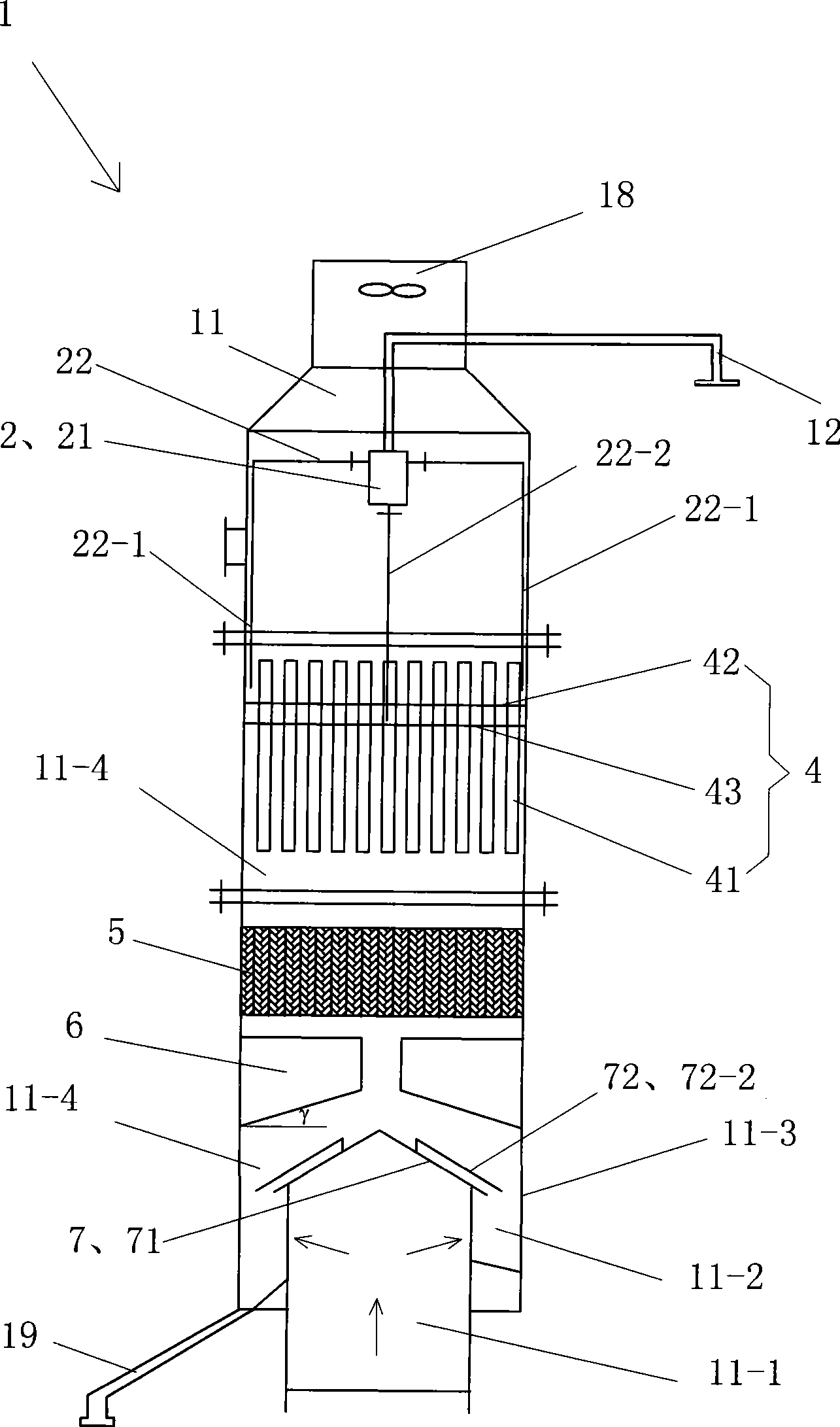

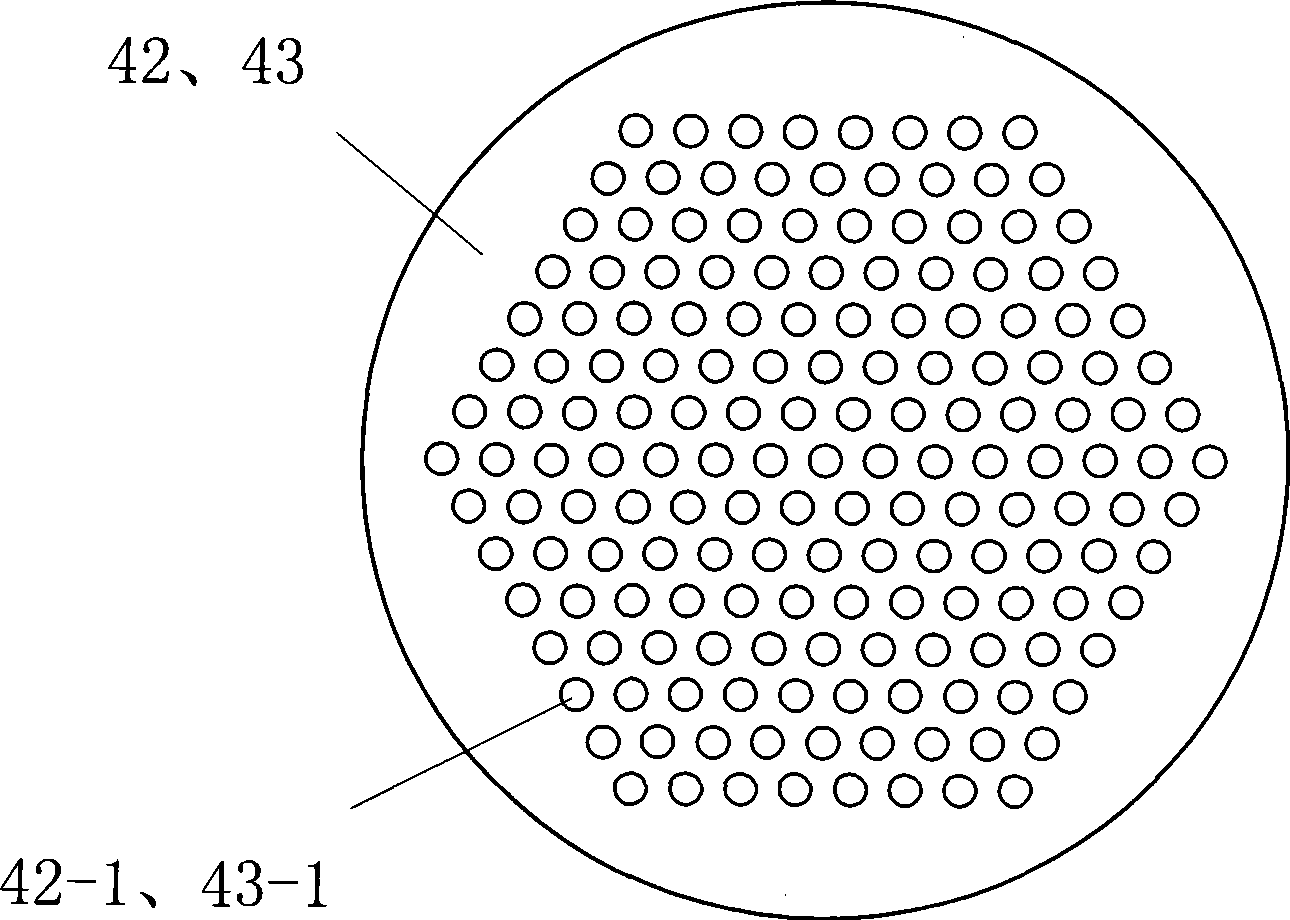

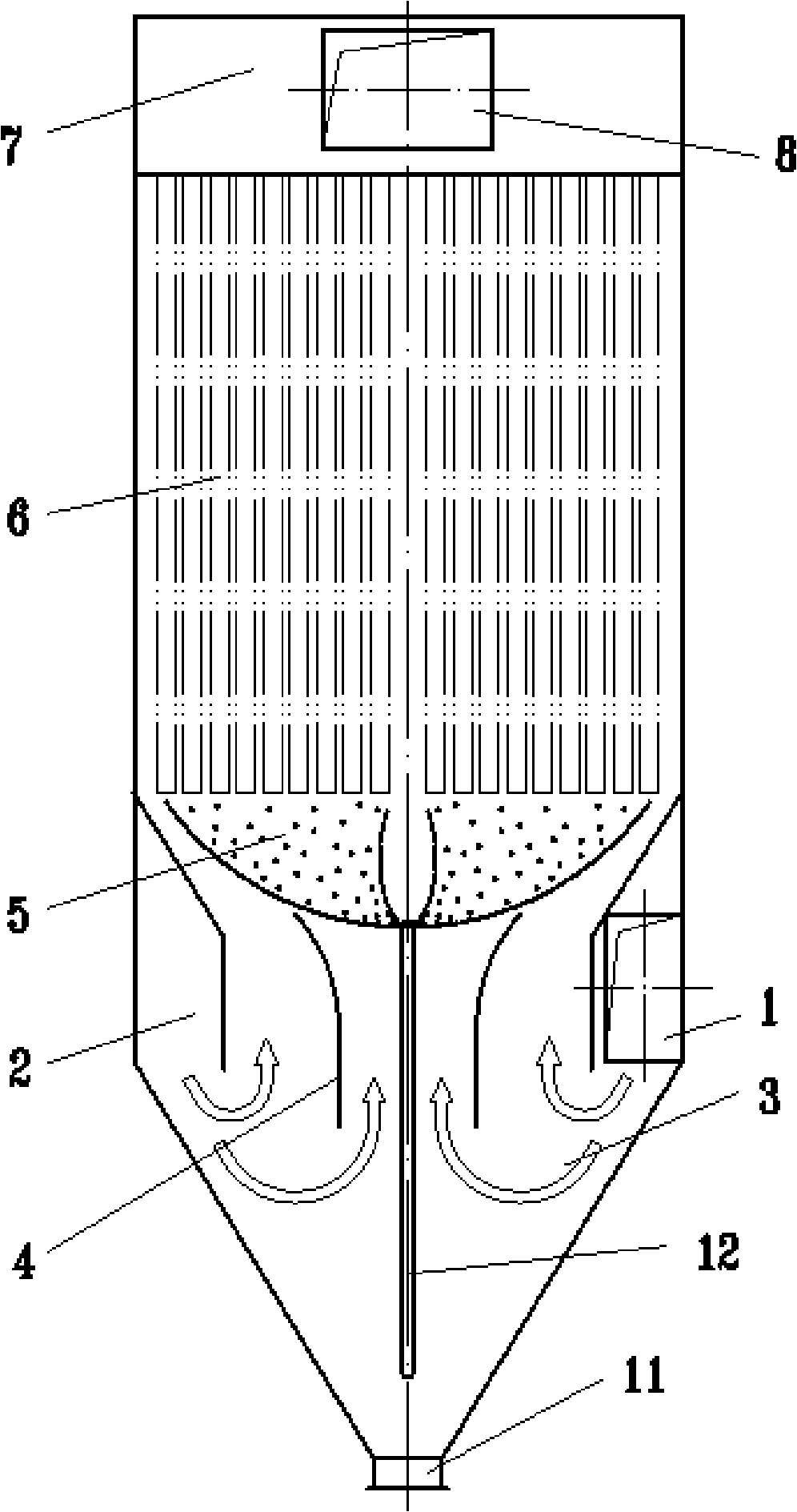

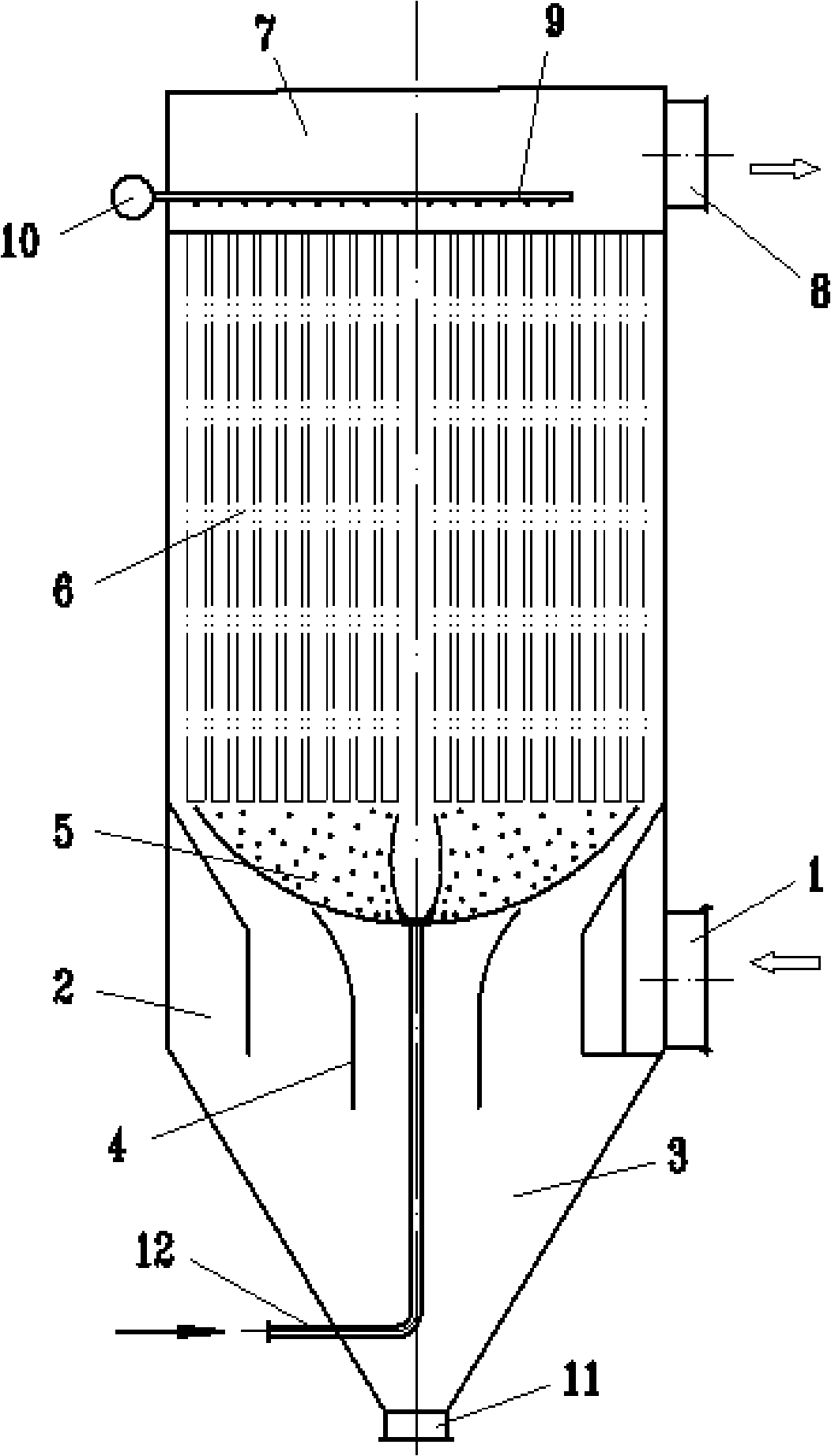

Combined purifying method and device

The invention discloses a combined purifying method and the device; wherein, the method is characterized in that: the cyclone dedusting and filter bag dedusting are combined into a whole, and two-grade dedusting method is adopted. The first grade is the cyclone dedusting; the air with dust enters a rotary flue along the wall of a purifier and rotates at a high speed in the annular rotary flue; under the action of the centrifugal force, the solid particles in the dust air are separated from the air at first, and deposit at the bottom of a dust hopper arranged below the purifier. The second grade is filter bag dedusting; the dust air undergoing the first grade cyclone dedusting enters a filter bag chamber through a plurality of ring holes in the annular rotary flue from the bottom up; the filter bag is arranged in the filter bag chamber and used for fending the fine particles remained in the dust air outside the filter bag; the purified air enters a clean air chamber and is exhausted out from an air outlet of the clean air chamber. The combined dedusting method has the advantages of improved dedusting efficiency and / or purifying efficiency of the air with dust, and reducing the maintenance workload and the floor area of the equipment.

Owner:GUIYANG AL-MG DESIGN & RES INST

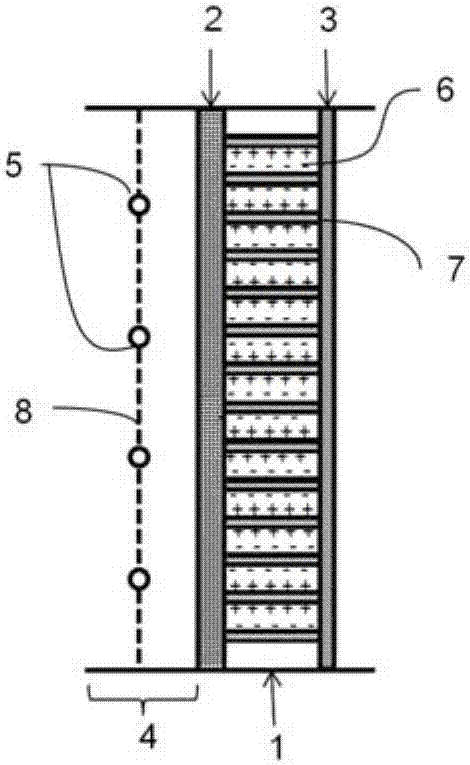

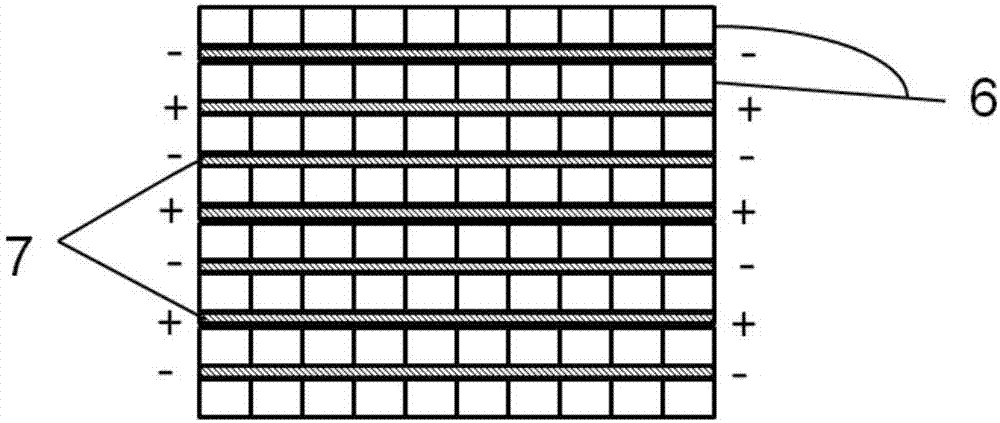

Multifunctional air purifying device

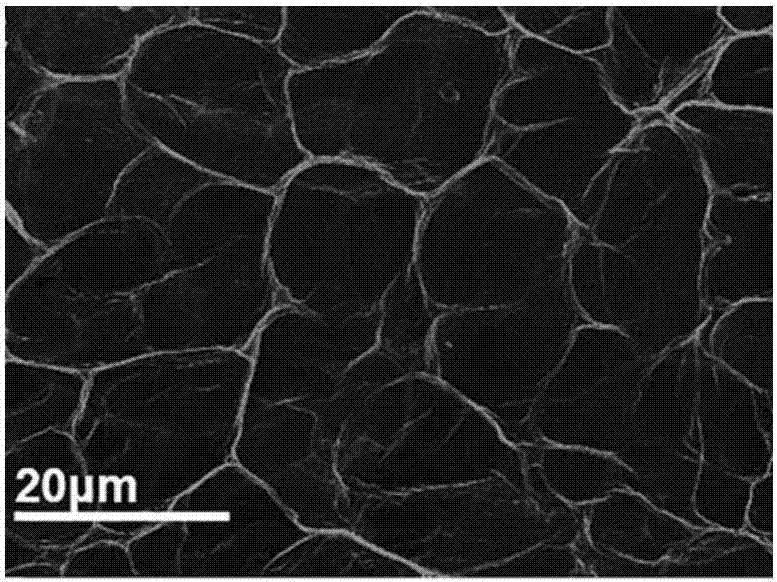

ActiveCN106861340AIncrease loadImprove load stabilityCombination devicesGas treatmentAir cleaningDust particles

The invention relates to a multifunctional air purifying device. The device comprises a dust particle charging area (4), a prefilter screen (2), a strong parallel electric field dust-collecting part (1) and a photocatalytic decomposition layer (3) which are in sequential arrangement, wherein the dust particle charging area (4) is composed of corona electrodes (5) and a metal plate (8) with pore channels; the strong parallel electric field dust-collecting part (1) is a parallel strong electric field composed of electrode layers (7) and grid plastic plates (6) in alternate permutation distribution; and the photocatalytic decomposition layer (3) is arranged at the rear of the strong parallel electric field dust-collecting part (1). Compared with the prior art, the device provided by the invention is small, exquisite and compact, and has high efficiency of removing dust and bacteria; a graphene aerogel layer has strong adsorption capacity, is easy to functionalize, and can effectively absorb organic pollutants like formaldehyde; meanwhile, graphene aerogel has large pore specific surface area, high photocatalyst loading capacity and higher photocatalyst loading stability in air flow, and also can eliminate ozone generated in the process of electrostatic dust collection.

Owner:SHANGHAI JIAO TONG UNIV

Fire-fighting vehicle-mounted vortex jetting fire extinguisher

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

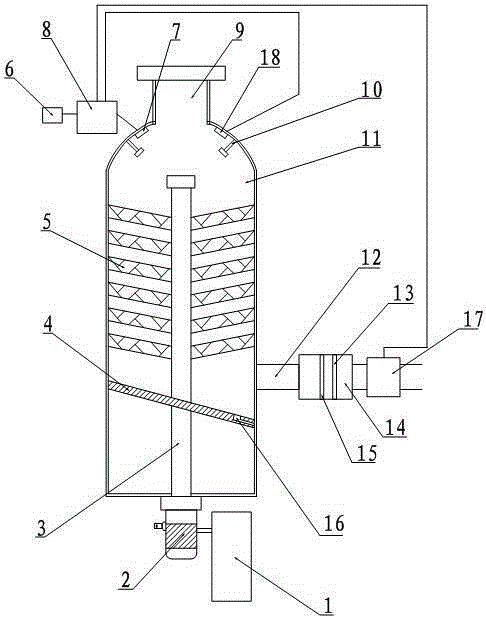

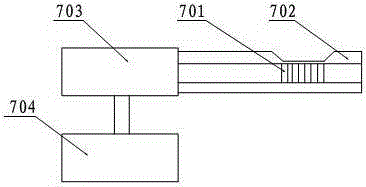

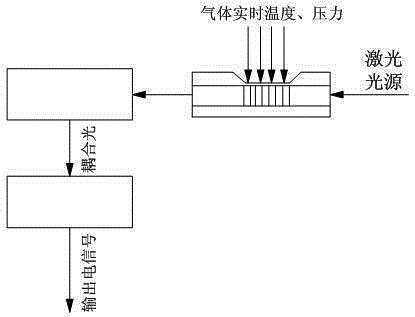

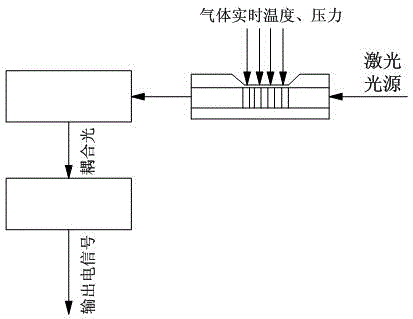

Water spray purifying system applied to industrial flue gas dedusting

InactiveCN105396404AReasonable designSimple structureHuman health protectionCombination devicesLaser transmitterSprayer

The invention discloses a water spray purifying system applied to industrial flue gas dedusting. The water spray purifying system applied to industrial flue gas dedusting comprises a machine body, a sprayer, a filtering screen, a flue gas charge pipeline, a drive mechanism, a temperature and pressure data acquiring device, a gas pressure regulating valve, an alarm, a laser transmitter 1, a laser transmitter 2, a sewage diversion baffle and a primary filtering device, wherein the top of the machine body is provided with a clean air discharge pipeline; the sprayer and the filtering screen are both arranged in the machine body; the flue gas charge pipeline is communicated with the side wall of the machine body; the drive mechanism is connected with the machine body and is used for controlling the filtering screen to drive; the temperature and pressure data acquiring device stretches into the machine body and is connected with a PLC; the gas pressure regulating valve, the alarm and the laser transmitter 1 are all connected with the PLC; the laser transmitter 2 is connected with the temperature and pressure data acquiring device and the PLC; the sewage diversion baffle is arranged in the machine body and is positioned below the filtering screen; the sprayer is positioned above the filtering screen; the sewage diversion baffle is of a slope structure, and the bottom of the slope is provided with a water drainage channel; light sources of the laser transmitters are directed to the temperature and pressure data acquiring device. The water spray purifying system applied to industrial flue gas dedusting is reasonable in design, is simple in structure, effectively enhances the flue gas purifying effect, and enhances the dedusting efficiency.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

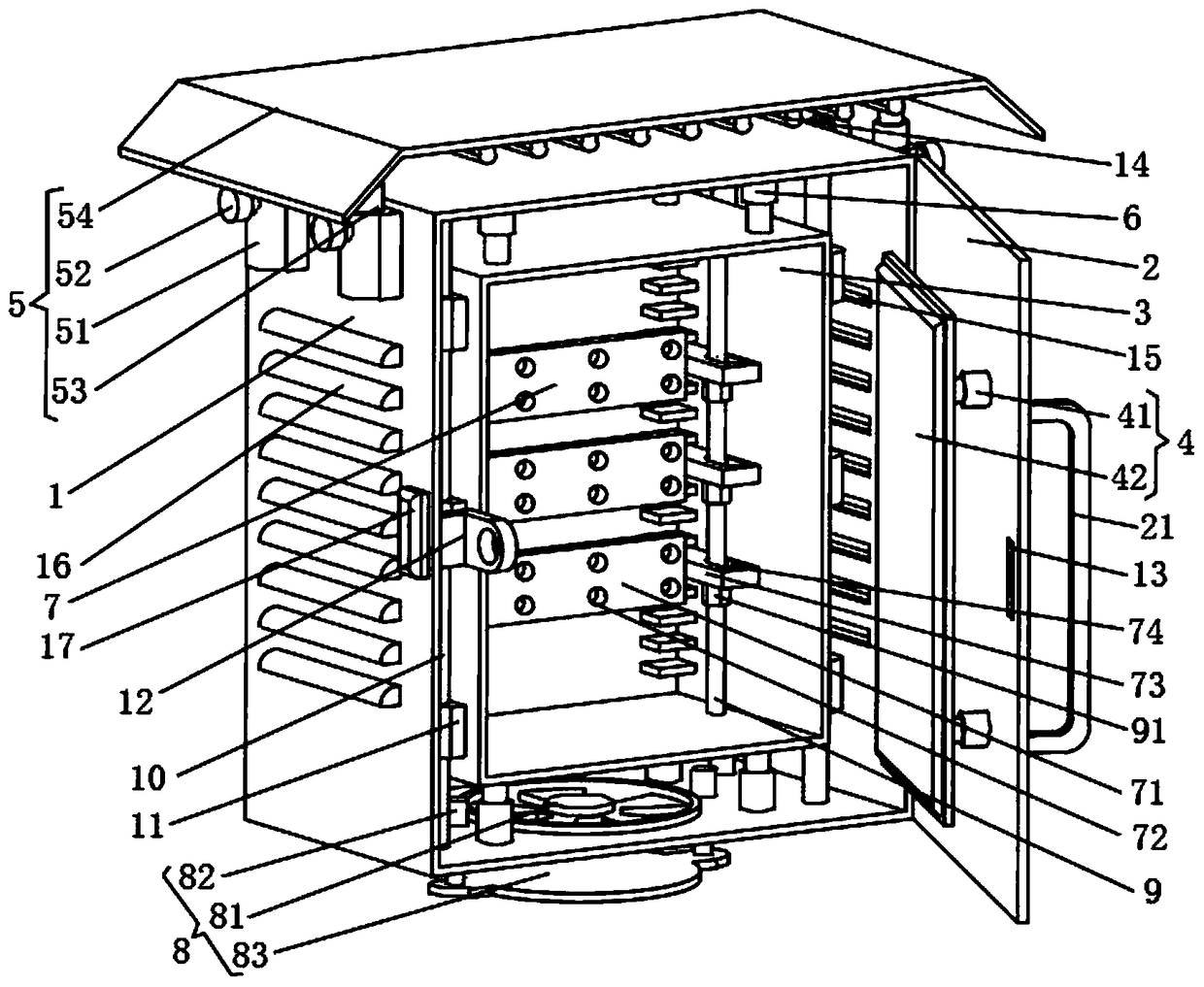

An intelligent low-voltage integrated distribution box

InactiveCN109038296APlay the role of shock absorberImprove impact resistanceSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsLow voltageEngineering

The invention discloses an intelligent low-voltage integrated distribution box, include an outer case, An upper surface of that out box body is provided with a protective device, The left side surfaceand the right side surface of the outer box body are provided with evenly distributed ventilation holes, the side surface of the outer box body corresponding to the ventilation holes is provided withan arc plate, the lower surface of the outer box body is provided with a dust removing device, the inner upper end surface and the lower end surface of the outer box body are provided with a third shock absorber, and the third shock absorber is fixedly connected with the inner box body at one end away from the outer box body. The intelligent low-voltage integrated distribution box, the position of the mounting plate can be adjusted and fixed, easy to adjust the position of the electric device, The utility model can effectively improve the space utilization rate of the inner box body, can alsoprotect the outer box body through the protective device, and can improve the shock absorption effect of the inner box body through the third shock absorber, and can improve the dust removal and heatdissipation effect of the whole distribution box through the dust removal device, thereby prolonging the service life of the distribution box and being convenient to use.

Owner:江苏国明浩辰科技有限公司

Chemical waste gas integrated treatment device

InactiveCN107670443AImprove dust removalImprove the effect of desulfurization and denitrificationCombination devicesGas treatmentElectrostatic precipitatorAqueous solution

The invention discloses a chemical waste gas integrated treatment device, comprising a desulfurization and denitrification dedusting box; the bottom of the desulfurization and denitrification dedusting box is connected with a setting tank through a communicating pipe, a demister is arranged on the upper side of the interior of the desulfurization and denitrification dedusting box, and a liquid distribution device is arranged on the lower side of the demister and is provided with a liquid inlet tube; the liquid inlet tube is provided with a booster pump, and the other end of the liquid inlet tube is connected with a desulfurization aqueous solution tank; a plurality of atomizers are installed on the lower side of the liquid distribution device, and a silk screen is arranged on the lower side of the liquid distribution device; a variable frequency motor is installed on the middle part of a motor rack at the lower side of the silk screen, a baffle plate is installed on the upper side output shaft of the variable frequency motor, a flue gas inlet pipe is also arranged on the lower part of the left side of the desulfurization and denitrification dedusting box and is provided with a wetelectrostatic precipitator. The chemical waste gas integrated treatment device is simple in structure, low in manufacture and running cost, good in flue gas desulfurization and denitrification effect,high in efficiency and easy to popularize.

Owner:龙里县逸轩生产力促进中心

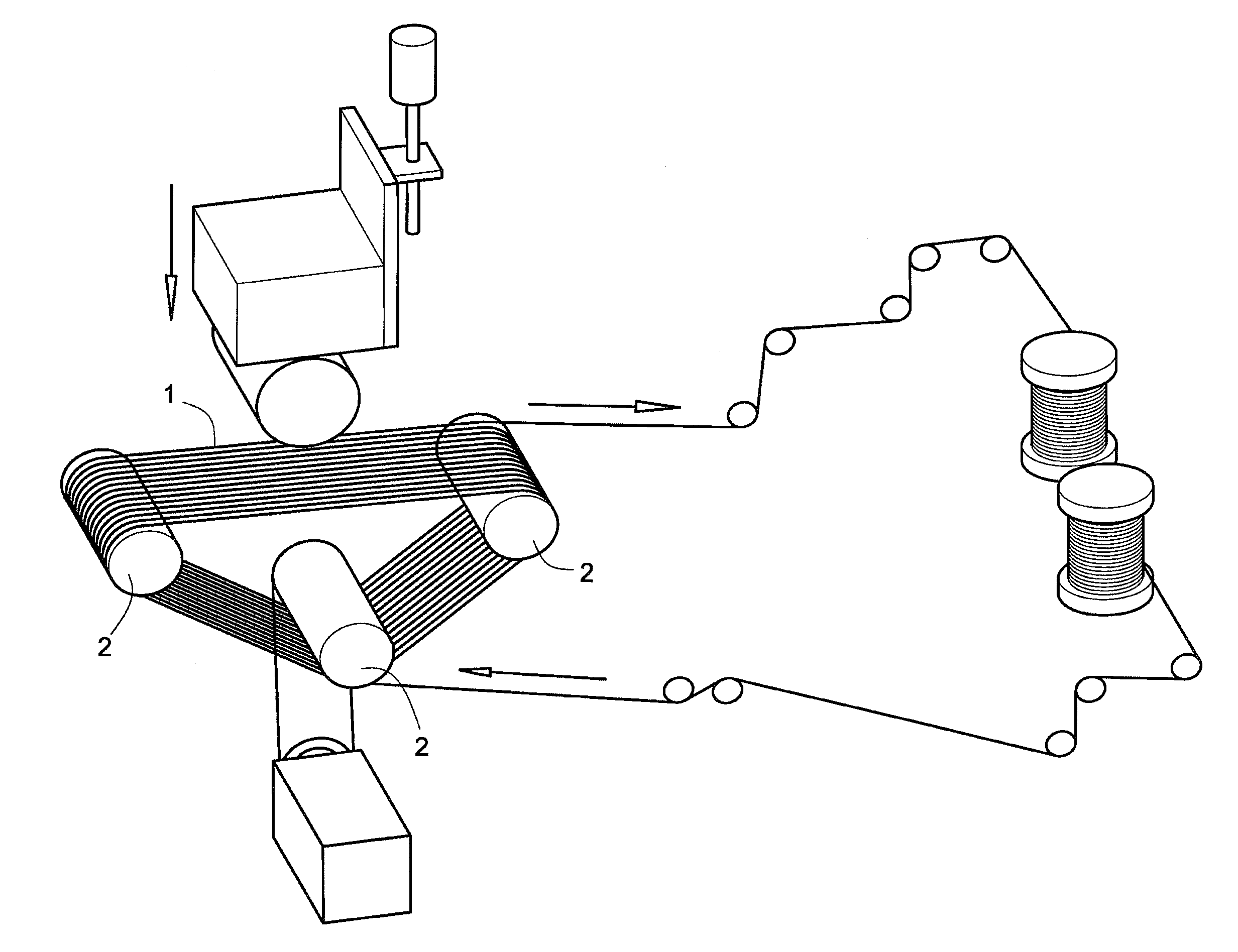

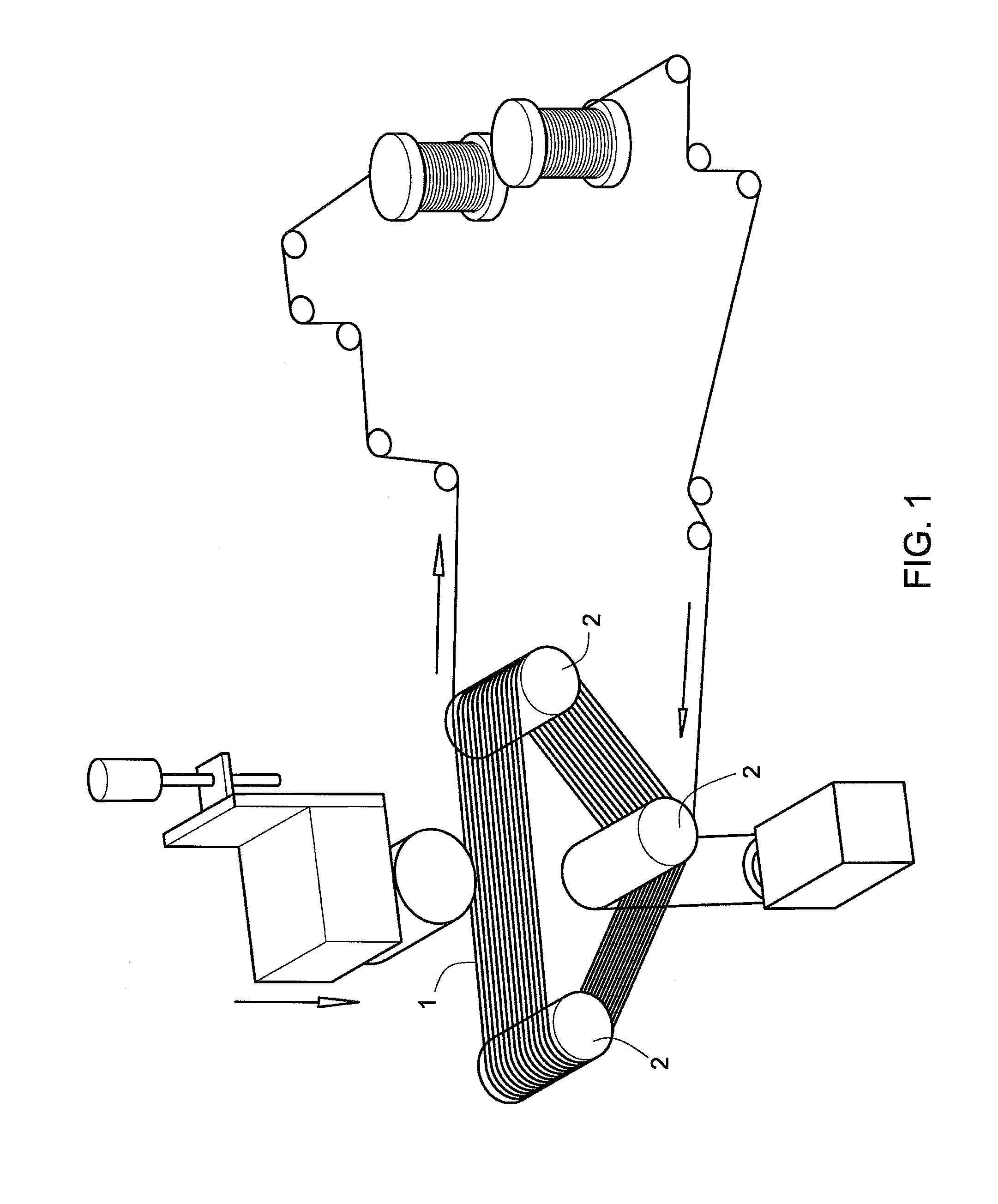

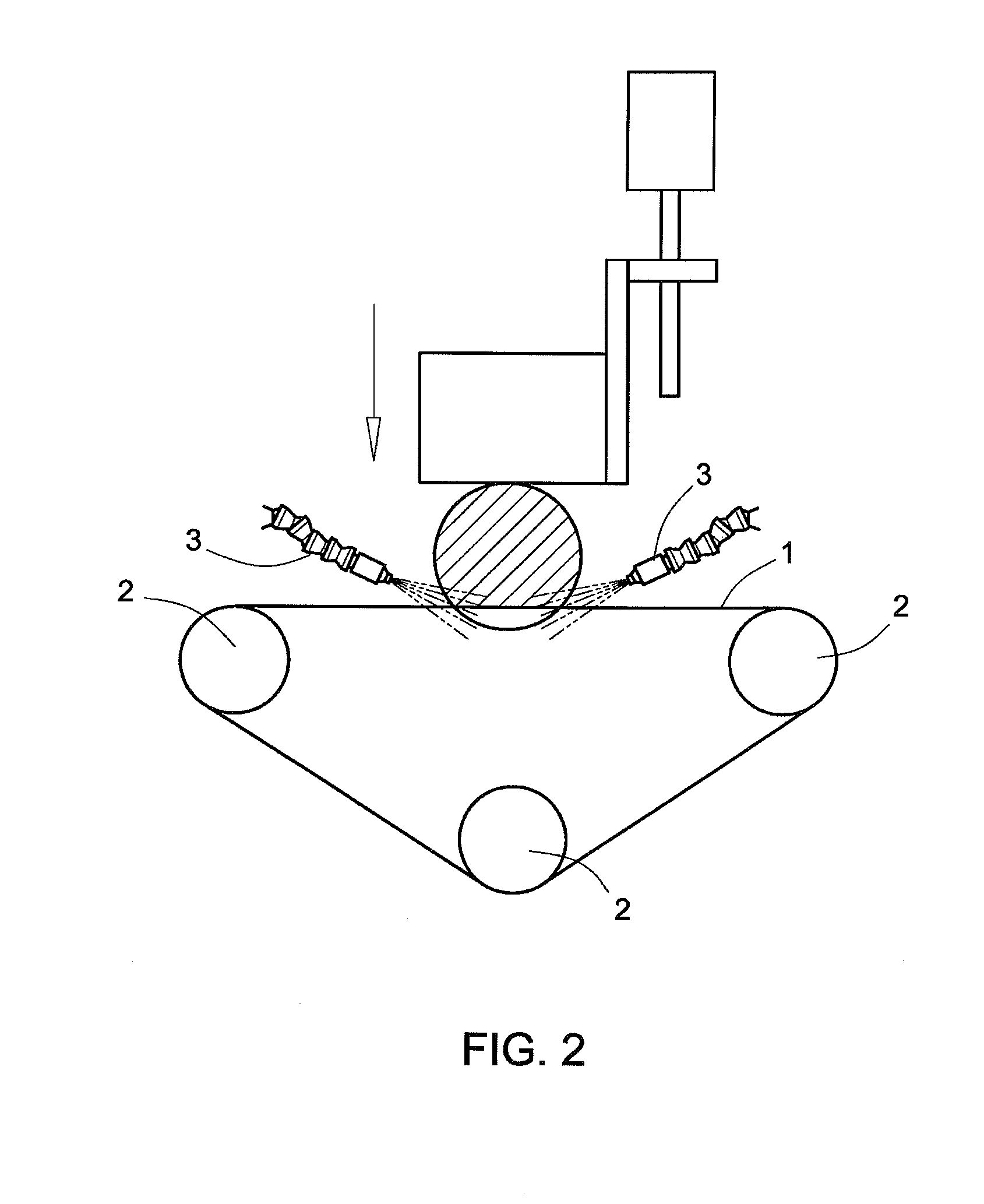

Cooling Device for Diamond-Wire Cutting System

InactiveUS20120167733A1Improve dust removalImprove cooling effectSemiconductor/solid-state device manufacturingMetal sawing toolsWire cuttingEngineering

A cooling device for a diamond-wire cutting system includes a fluid retarding space as a cooling tank enclosed and defined by one or more surfaces for temporarily holding a cooling fluid. The surfaces provide a closed or semi-open sidewall that allows a cutting part of a diamond wire for cutting a workpiece to pass through the cooling tank and get immersed in the cooling fluid. A sorting collector is connected to the cooling tank. Thereby, cutting the hard-brittle workpiece is always performed in the cooling fluid, so as to prevent the cooling fluid and cutting chips from splashing, and improve heat dissipation and dust removal, thereby enhancing the cutting capability and efficiency. The tooled workpiece has cut surfaces with improved smoothness. The sorting collector performs solid-liquid separation to the cooling fluid containing cutting chips, so that the cutting chips and the cooling fluid can be recycled.

Owner:MICRON DIAMOND WIRE & EQUIP

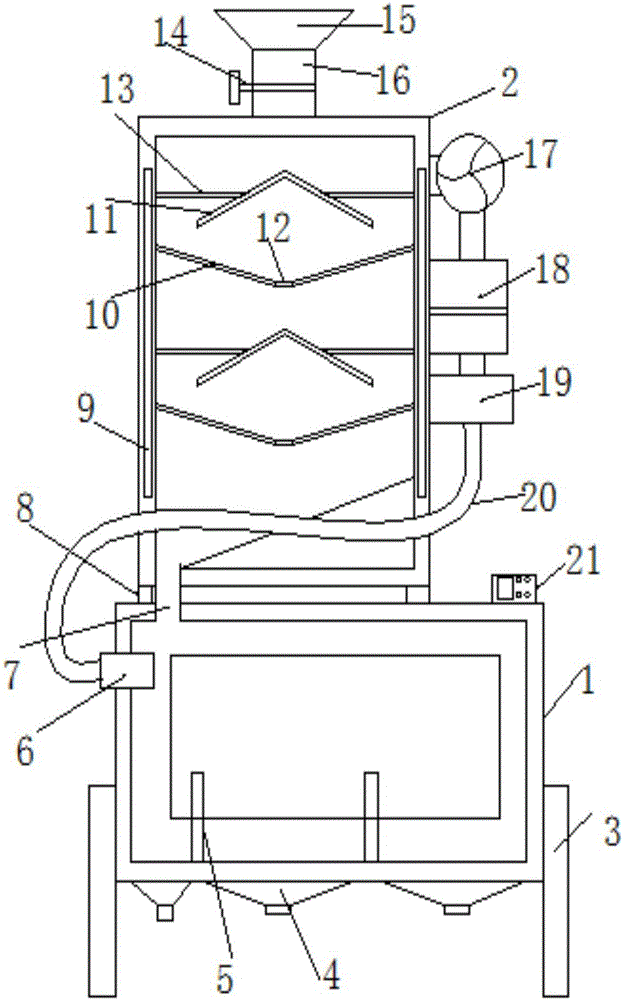

Simple agricultural grain winnowing machine

InactiveCN106423866AImprove winnowing effectSimple structureGas current separationDrying gas arrangementsAgricultural engineeringElectromagnetic heating

The invention discloses a simple agricultural grain winnowing machine which comprises a winnowing box and a de-dusting drying oven. The simple agricultural grain winnowing machine is characterized in that support legs are symmetrically arranged on left and right sides of the winnowing box; the winnowing box is arranged as a rectangular box; the de-dusting drying oven is arranged on the left side at the upper end of the winnowing box; the de-dusting drying oven is arranged as a cylindrical drum; an electromagnetic heating coil is clamped in a wall of the de-dusting drying oven; the bottom left side of the drying oven is communicated with the winnowing box through a connecting pipe; a blanking pipe is arranged in the middle of the top of the de-dusting drying oven; an adjusting valve is arranged on the blanking pipe; a feeding hopper is arranged at the upper end of the blanking pipe; a material collecting hopper is arranged in the de-dusting drying oven; an edge at the upper end of the material collecting hopper is connected with an inner wall of the winnowing box; a blanking hole is formed in a middle position at the lower end of the material collecting hopper; and a material distributing hopper is arranged above the material collecting hopper. The simple agricultural grain winnowing machine has the advantages of simple and reasonable structure, good winnowing effect, good de-dusting and drying effects, capability of reducing production cost of the device and high practicability.

Owner:郑州莉迪亚医药科技有限公司

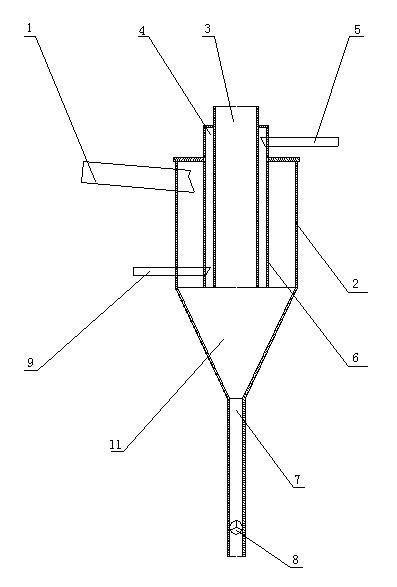

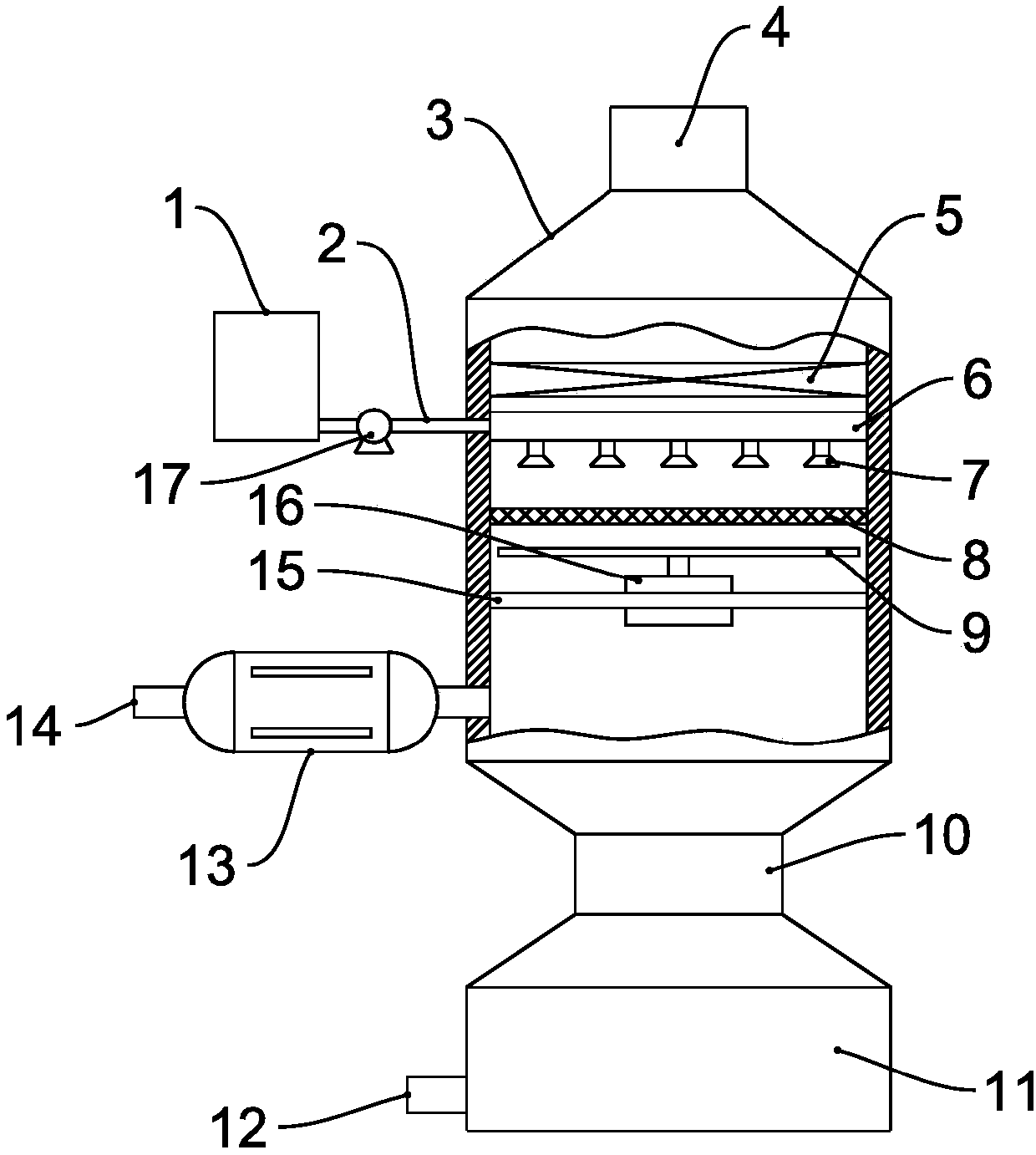

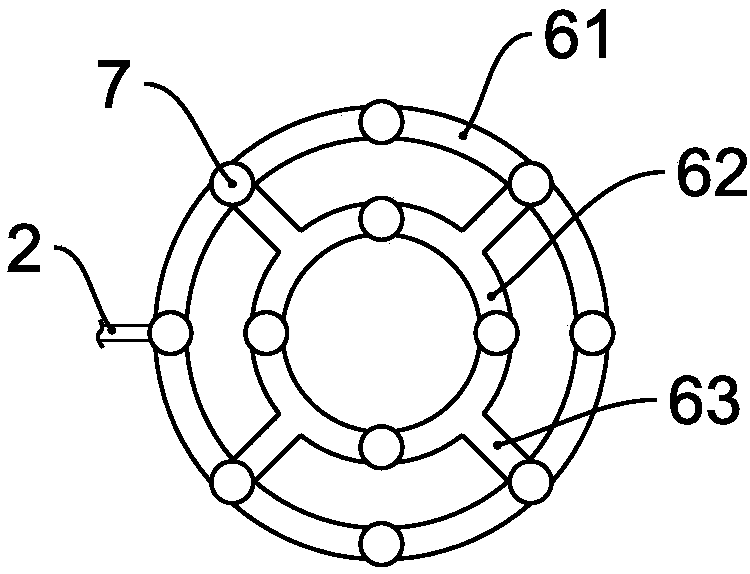

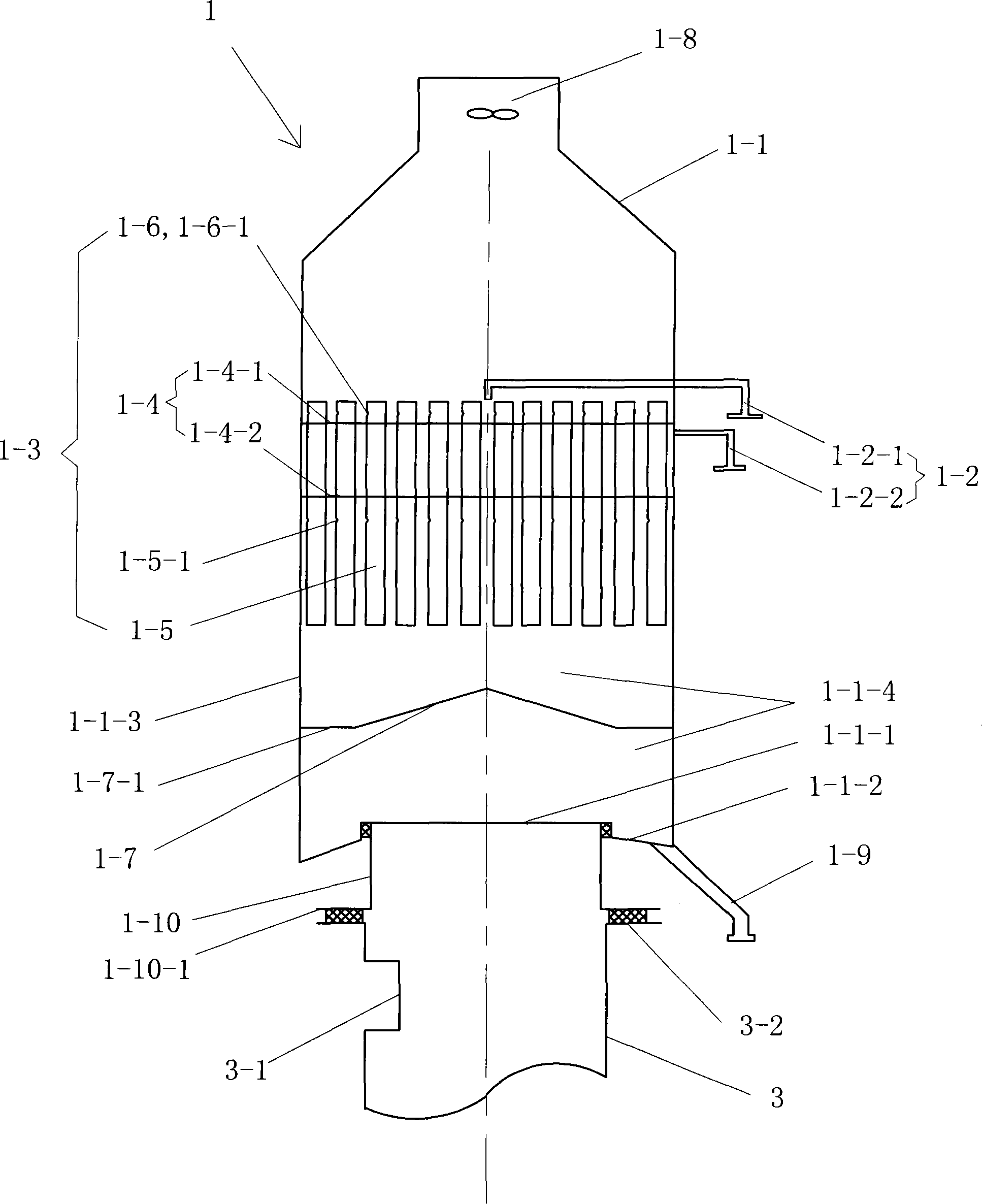

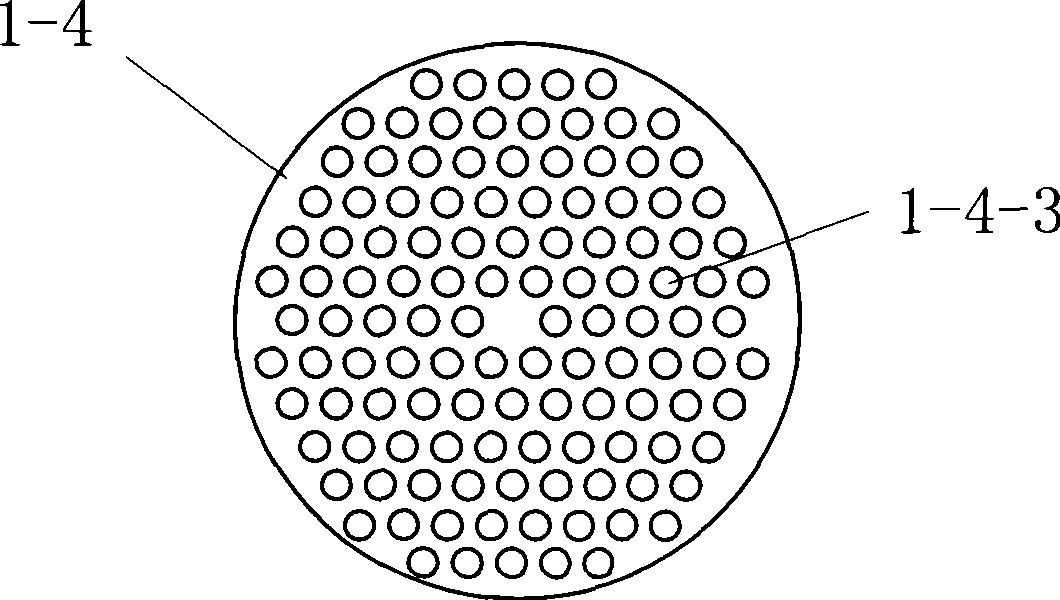

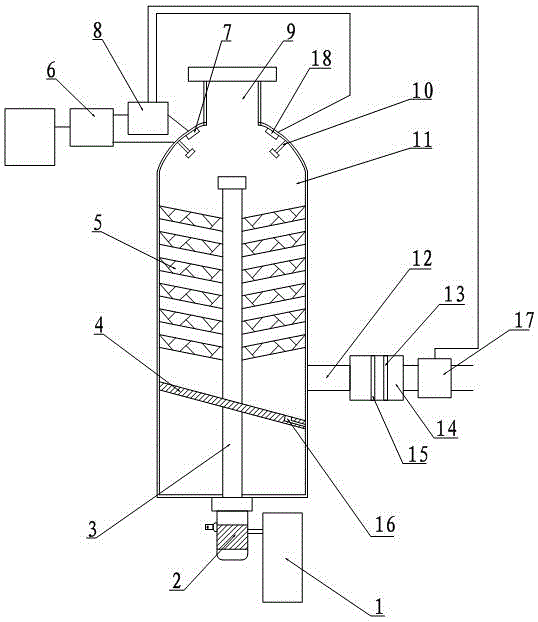

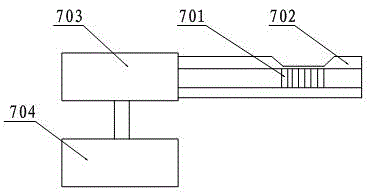

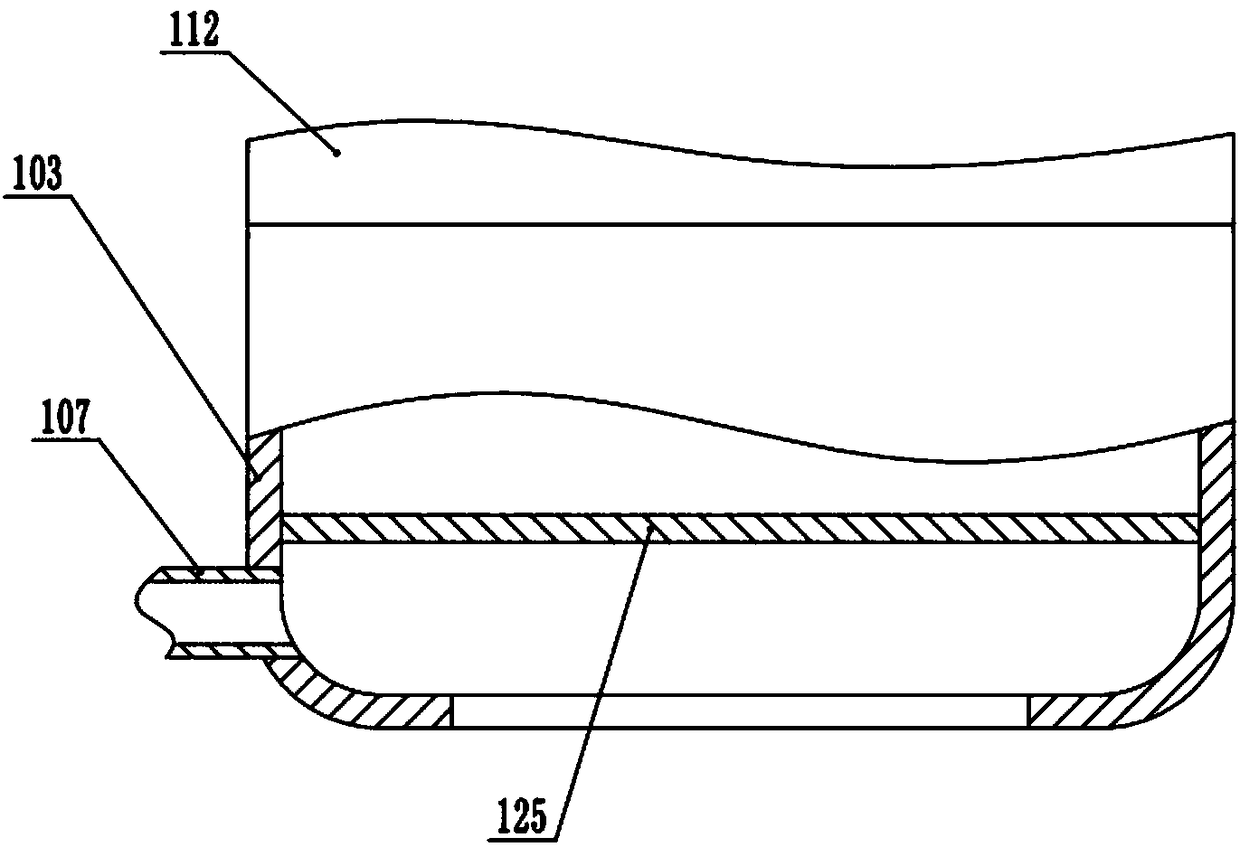

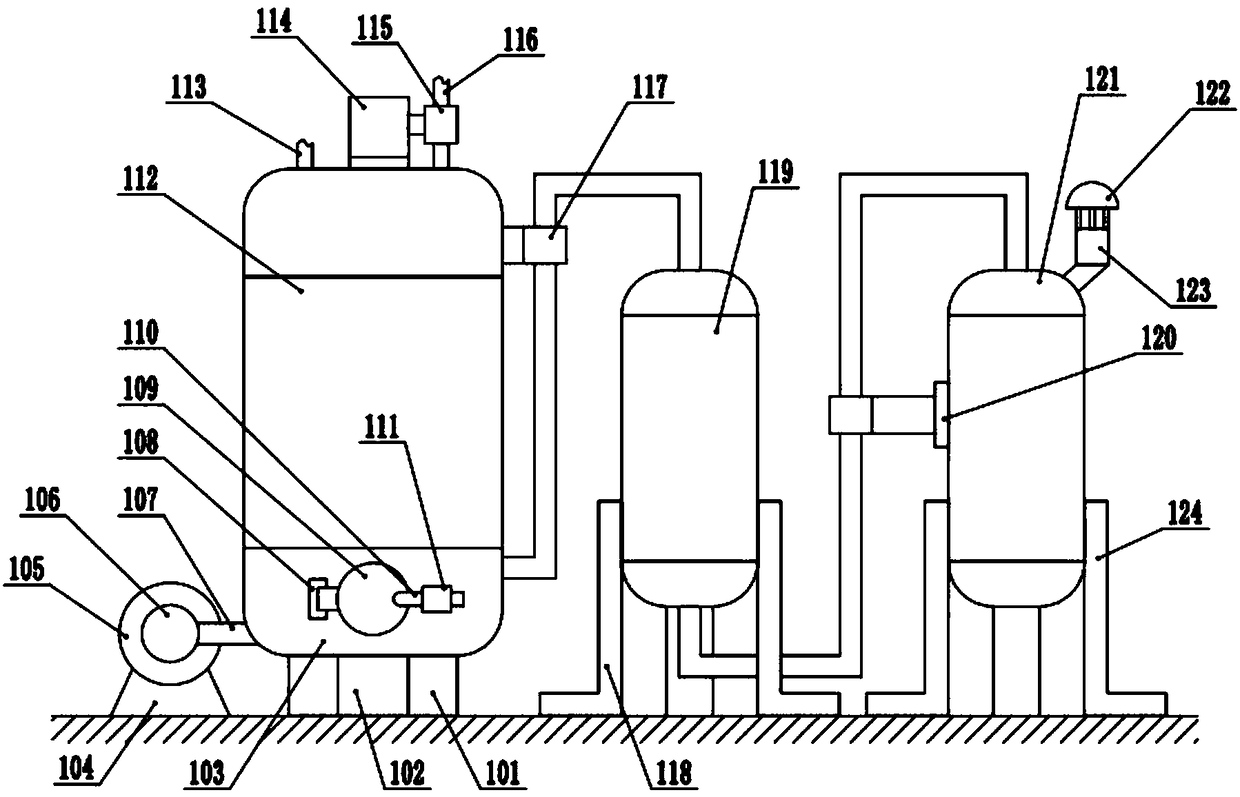

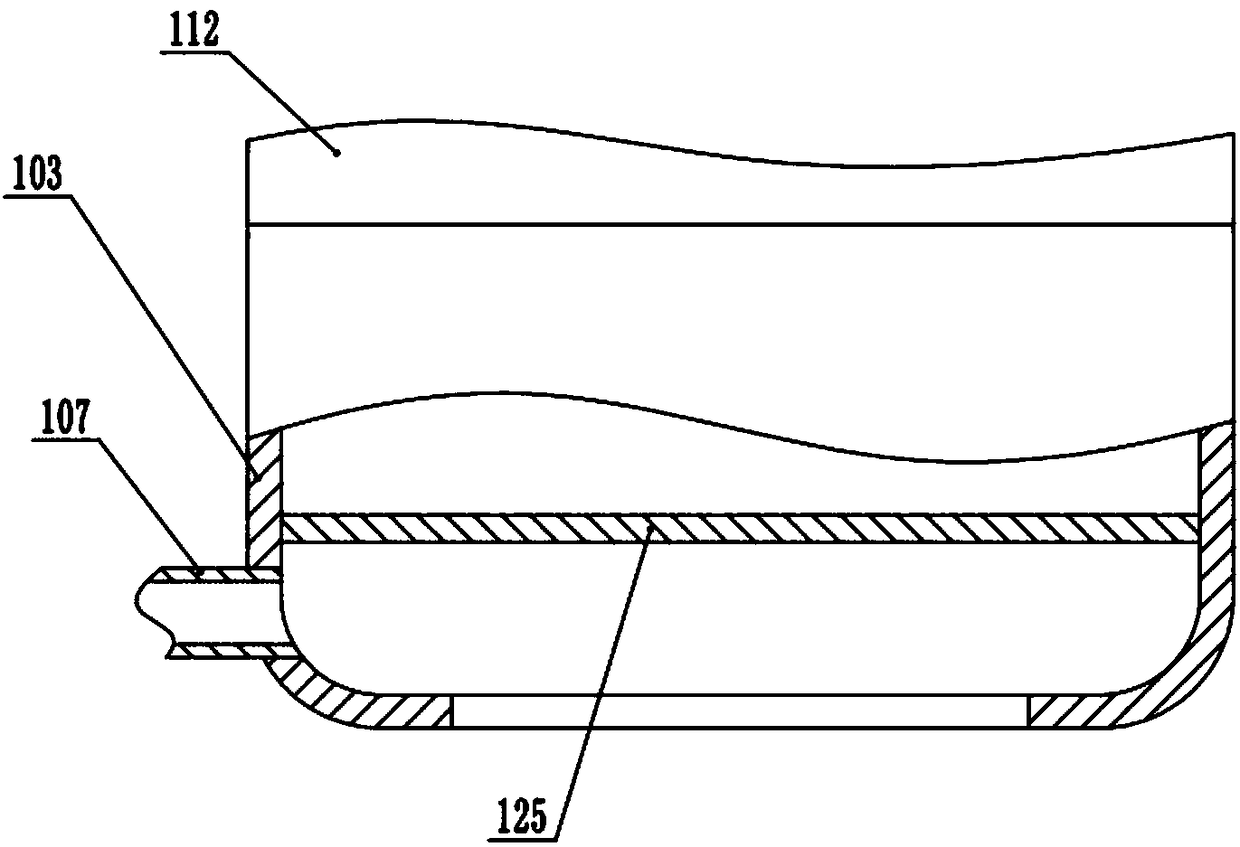

Desulfurization dust collector for industrial furnace

InactiveCN101391175AIncrease contact timeImprove dust removal efficiencyUsing liquid separation agentVertical furnacesFlue gasEngineering

The invention discloses a desulfurization and dust removal device for an industrial furnace, the device has a desulfurization dust remover, and the desulfurization dust remover comprises a shell as well as a contact type cooling spray device, a drain pipe, a barrier cap and a water inlet pipe fixed on the shell. The shell is provided with a flue gas inlet, an annular bottom plate and an annular side plate. The contact type cooling spray device is a tube array contact type cooling spray device, and the tube array contact type cooling spray device has a tube array and a tube plate, each single pipe of the tube array penetrates through the corresponding tube hole in the tube plate, and is fixed on the tube plate, each single pipe of the tube array is vertically arranged and is parallel to other pipes, an opening is arranged at the lower end of the body of each single pipe, and a water inlet part is arranged at the upper end head of the pipe body. The invention has advantages that the desulfurization and dust removal efficiency of the device can reach above 98 percent, the equipment investment is less, the running cost and the energy consumption are low, and the device is suitable for large-area promotion and application.

Owner:姚立猛

Method of preparing manganese sulfate solution by reducing pyrolusite

PendingCN110396612AEasy to handleProcess environmental protectionManganese sulfatesPyrolusiteElectrolysis

The invention discloses a method of preparing a manganese sulfate solution by reducing pyrolusite. The method comprises the following steps: (1) crushing the pyrolusite to obtain a product a; (2) adding a sulfuric acid solution into the product a, uniformly stirring the solution, and heating and insulating the solution to obtain a product b; (3) adding a reducer into the product b, and controllingthe temperature to react to obtain a product c; and (4) transferring the product c to a leaching tank, supplementing an electrolytic manganese anode solution to maintain a liquid-solid ratio, controlling the temperature, stirring the solution to react, and filtering the solution to obtain the manganese sulfate solution. Compared with an existing method of reducing carbon and acid leaching, the method has the beneficial effect of obvious cost advantage and environmental-friendly advantage.

Owner:GUIZHOU UNIV

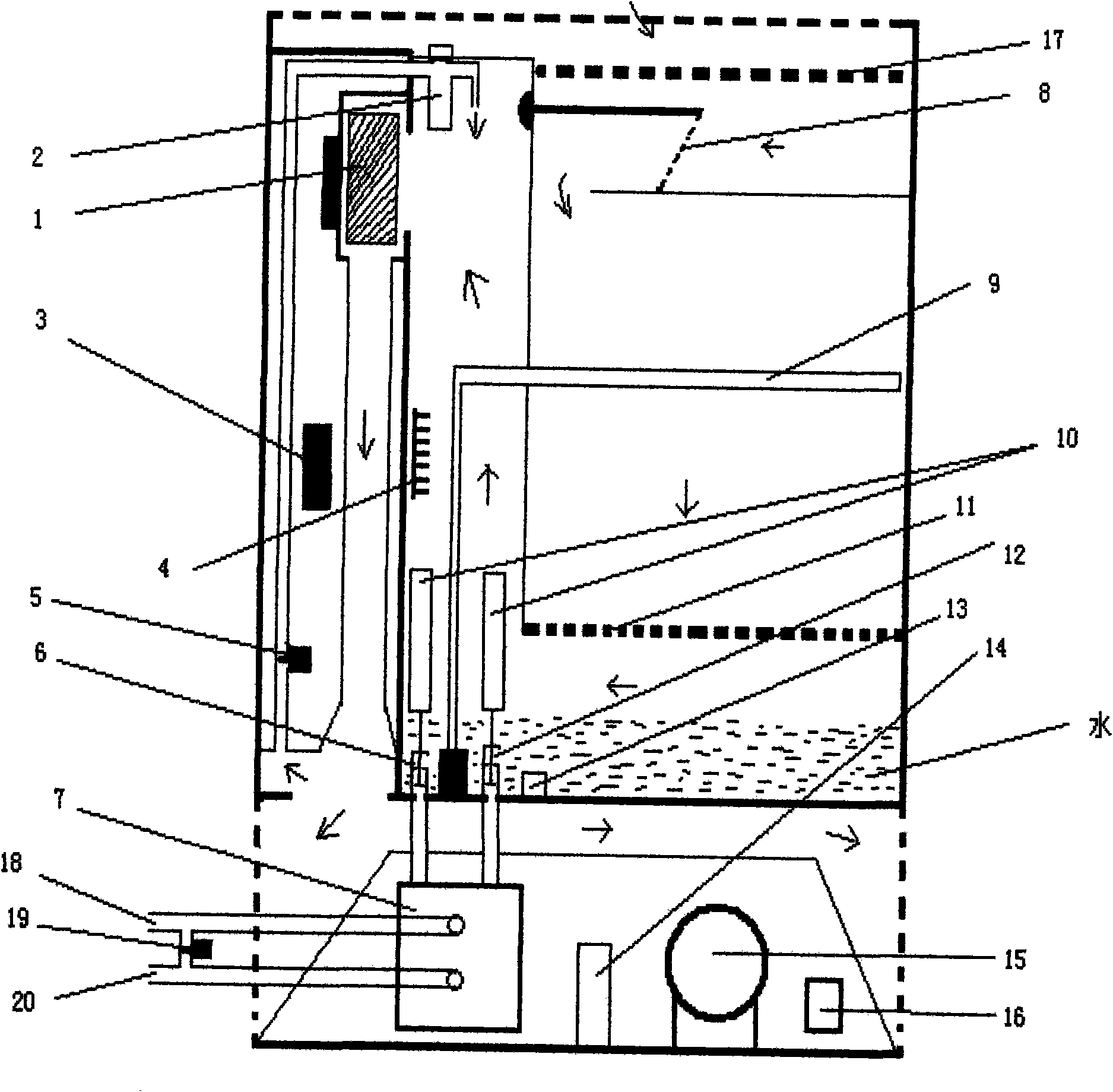

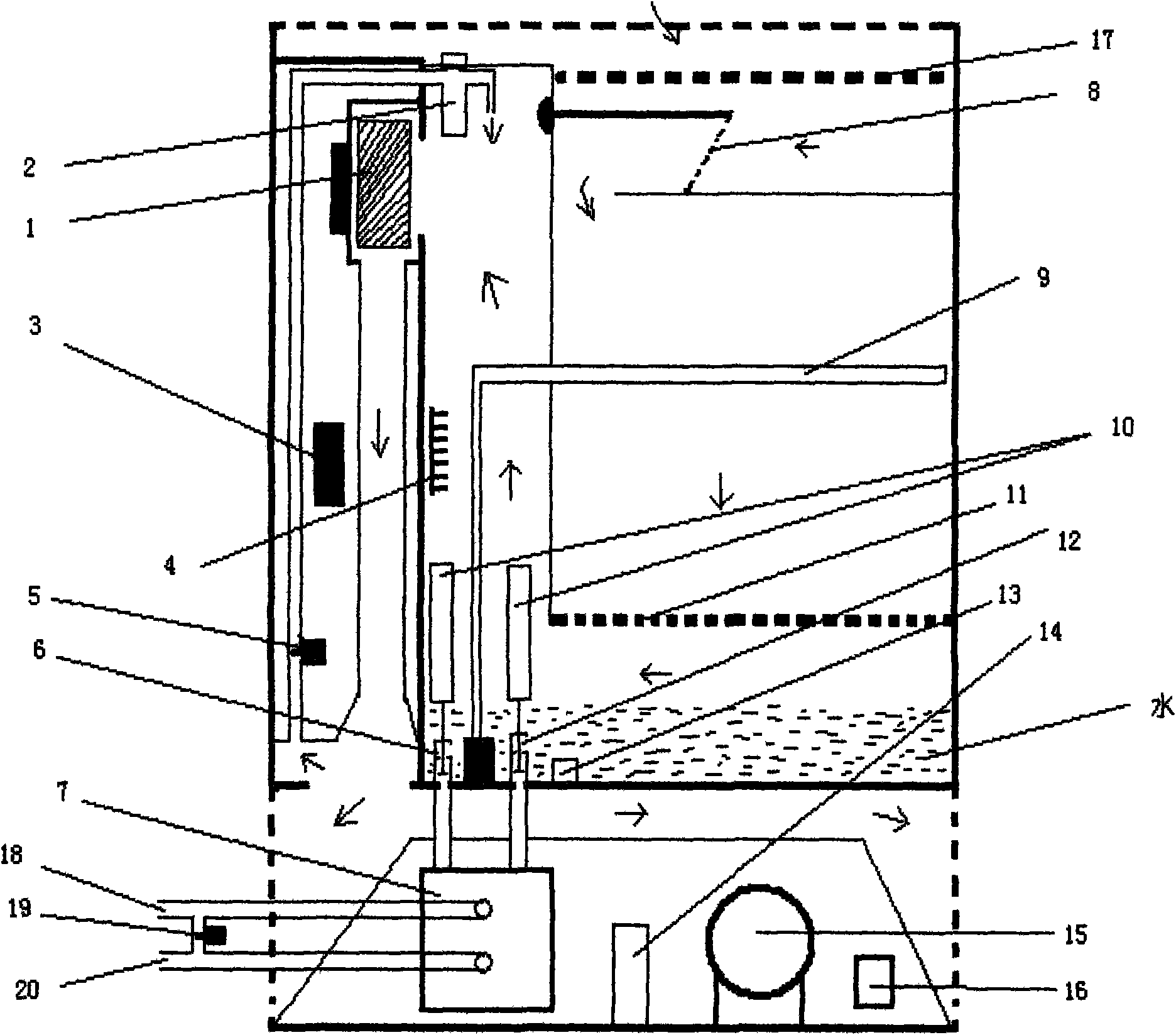

Full-automatic washing type air purifier

InactiveCN102338419AAutomatic control of aroma concentrationImprove dust removalHuman health protectionSpace heating and ventilation safety systemsAutomatic controlElectrostatic precipitator

The invention provides a full-automatic washing type air purifier which takes tap water as a purifying material, is capable of automatically controlling indoor fragrance concentration, humidifies air in an heating manner, realizes dehumidification through refrigeration of a compressor and does not consume water. The air purifier is internally provided with electrostatic precipitation and overflowing prevention devices. The air purifier is characterized in that a water inlet is connected with tap water, a water outlet is connected with water equipment with low requirement on water quality; an auxiliary filter screen and a subsidiary filter screen with water can absorb tiny dust and harmful substances soluble and insoluble in water, and filtered water can be supplied to a toilet or other water equipment which has low requirement on water quality.

Owner:徐世友

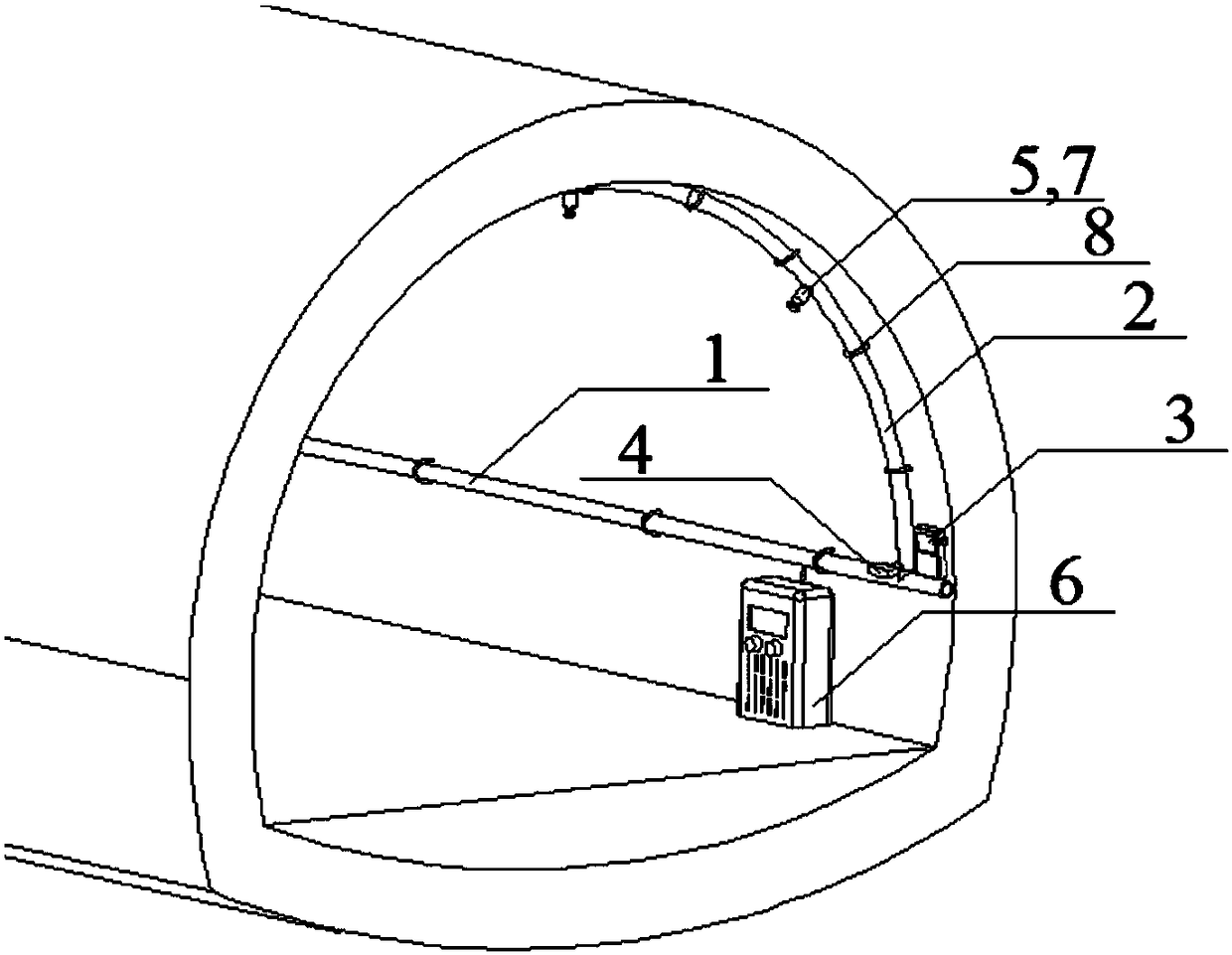

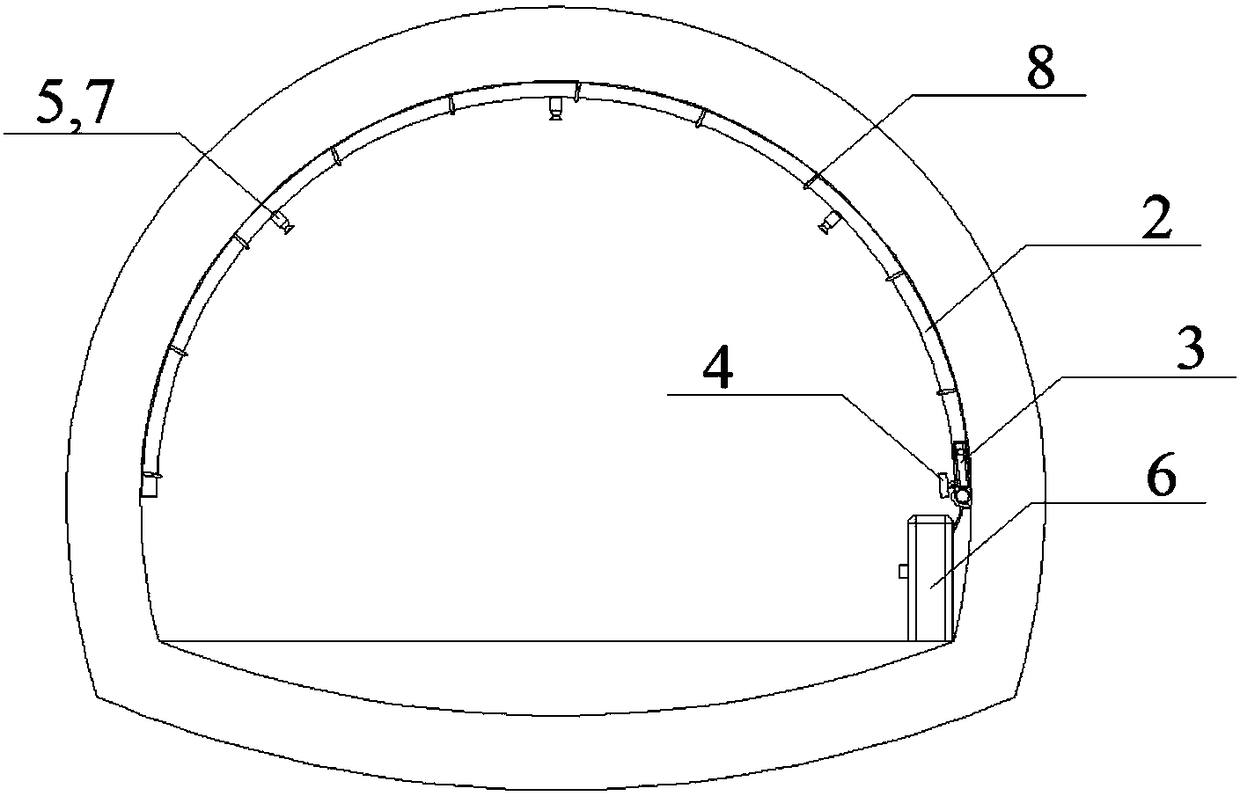

Automatic fog lowering, dedusting and cooling system and method in tunnel construction process

ActiveCN108150214AEasy to get materialsEasy to makeDust removalFire preventionPipeflowCooling effect

The invention discloses an automatic fog lowering, dedusting and cooling system and method in tunnel construction process. The system comprises a water guiding main pipe, water guiding pipes, a sensor, a valve, atomization devices, a cooling device, water outlets, and pipe clamps; the water guiding pipe is arranged in full profile along a tunnel vault; the pipes are fixed on the inner wall of a tunnel by the pipe clamps, and a circle of water guiding pipes are arranged every 3-5m; the water outlets of the water guiding pipes are all provided with atomization devices; the atomization devices can convert water in the water guiding pipes into an atomizing state to carry out fog lowering and dedusting, and the dedusting effect is improved; and the cooling device is arranged at an appropriate location of the water guiding main pipe, the water in the water guiding pipes is cooled and injected by the cooling device, and the cooling effect is improved. The automatic fog lowering, dedusting andcooling system and method in the tunnel construction process solve the problem of high temperature and high dust concentration in the process of tunnel construction work.

Owner:SHANDONG UNIV +1

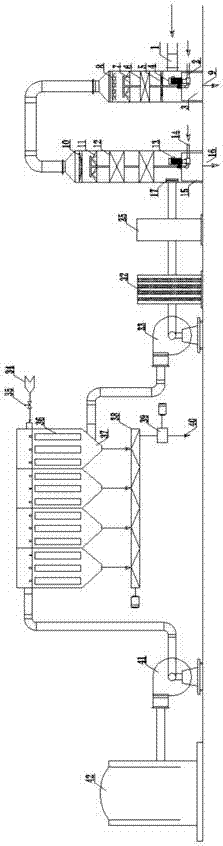

Deodorization and purification treatment system of biological sludge pyrolysis synthesis gas

InactiveCN107297112AReduce pressure drop resistanceIncreased number of spinsCombination devicesGas treatmentCycloneSludge

The invention relates to a deodorization and purification treatment system of biological sludge pyrolysis synthesis gas. The system comprises a cyclone plate water spraying tower module, a spraying reaction acid removal tower module, a solar energy-rotary wheel dehumidification module, a sludge base activated carbon absorption module and a pulse bag type dust remover module in sequential connection, wherein the cyclone plate water spraying tower module comprises a pyrolysis tail gas inlet, a cyclone plate, a filling material layer, a circulation water pump, a water supplementing opening, a first sedimentation pool, a clean water spray head, a first screen defogging device and a sludge outlet; the spraying reaction acid removal tower module comprises a cyclone device, an atomization device, a two-stage filling material layer, a metering circulation pump, a second sedimentation pool, a liquid supplementing pipe and a second screen defogging device; the sludge base activated carbon absorption module consists of a solar heat collector, an electric heater, a sludge base activated carbon rotary wheel, a photocatalysis waste gas treatment device and the like. The deodorization and purification treatment system has the advantages that the structure is reasonable; fetor gas in the pyrolysis tail gas can be controlled in a national standard range; in addition, the pyrolysis synthesis gas is purified; the synthesis gas fuel gas quality is improved.

Owner:ZHEJIANG UNIV OF TECH

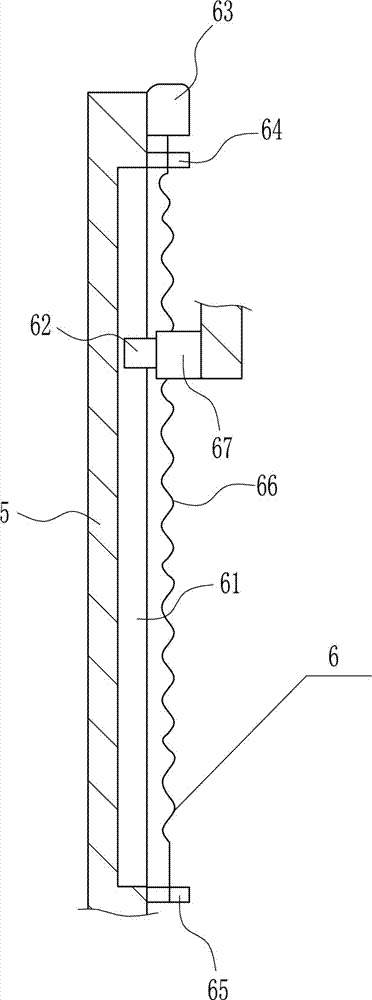

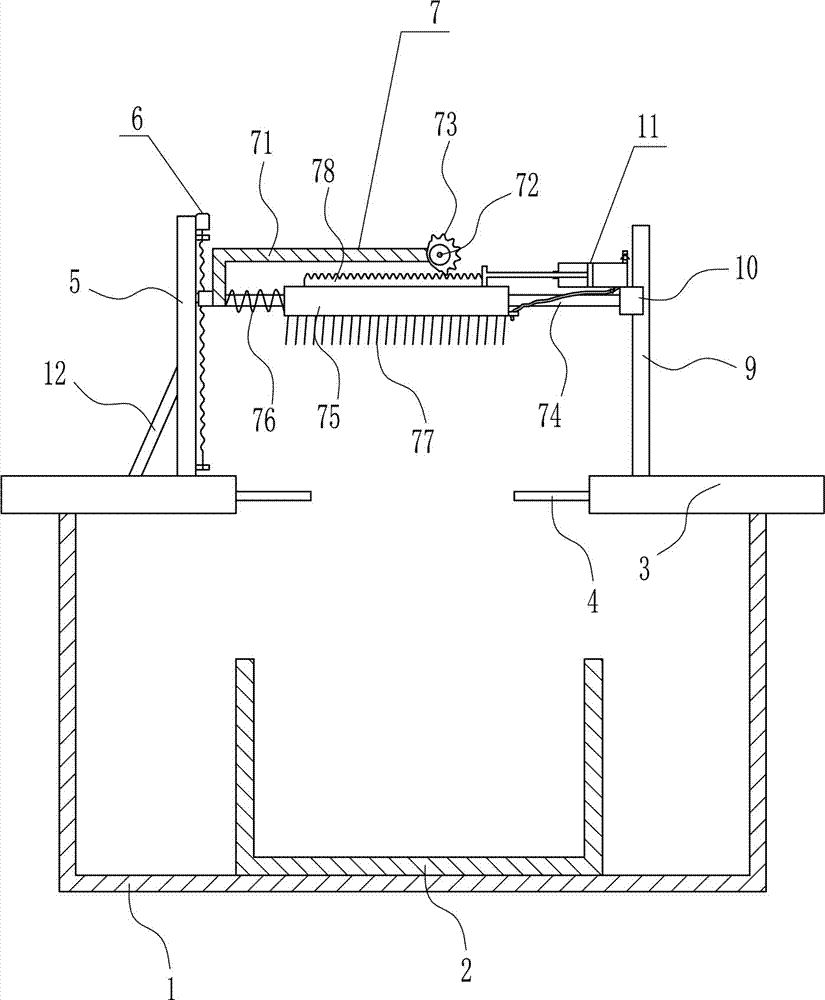

Clothes hanger with swinging function and clothes care machine comprising clothes hanger

PendingCN110130080AImprove the bactericidal effectImprove dust removalMechanical cleaningPressure cleaningEngineeringClothes hanger

The invention discloses a clothes hanger with a swinging function. The clothes hanger comprises fixing blocks, a swinging clothes hanger and a motor, wherein the fixing blocks are fixedly arranged ina box and connected with pull rods; two ends of the swinging clothes hanger are connected with the pull rods respectively, and a hollowed-out structure is arranged on the swinging clothes hanger; themotor is fixedly arranged in the box, a power output shaft of the motor is fixedly connected with a rotating shaft rocker arm, the rotating shaft rocker arm and the hollowed-out structure are closelyattached, and one end of the rotating shaft rocker arm extends out of the hollowed-out structure. The hollowed-out structure is arranged on the swinging clothes hanger, rotational movement of the rotating shaft rocker arm can be converted into left and right swinging and forward and backward swinging of the swinging clothes hanger by the structure; a rotary hanging block for hanging clothes is mounted at the lower end of the rotating shaft rocker arm. The structure rotates with a motor spindle synchronously, clothes rotate by 360 degrees after being hung on the structure, high-temperature steam can directly act on every angle of the clothes, so that the sterilization, dust removal, wrinkle removal and shaping effects during clothes caring are improved.

Owner:合肥品冠科技有限公司

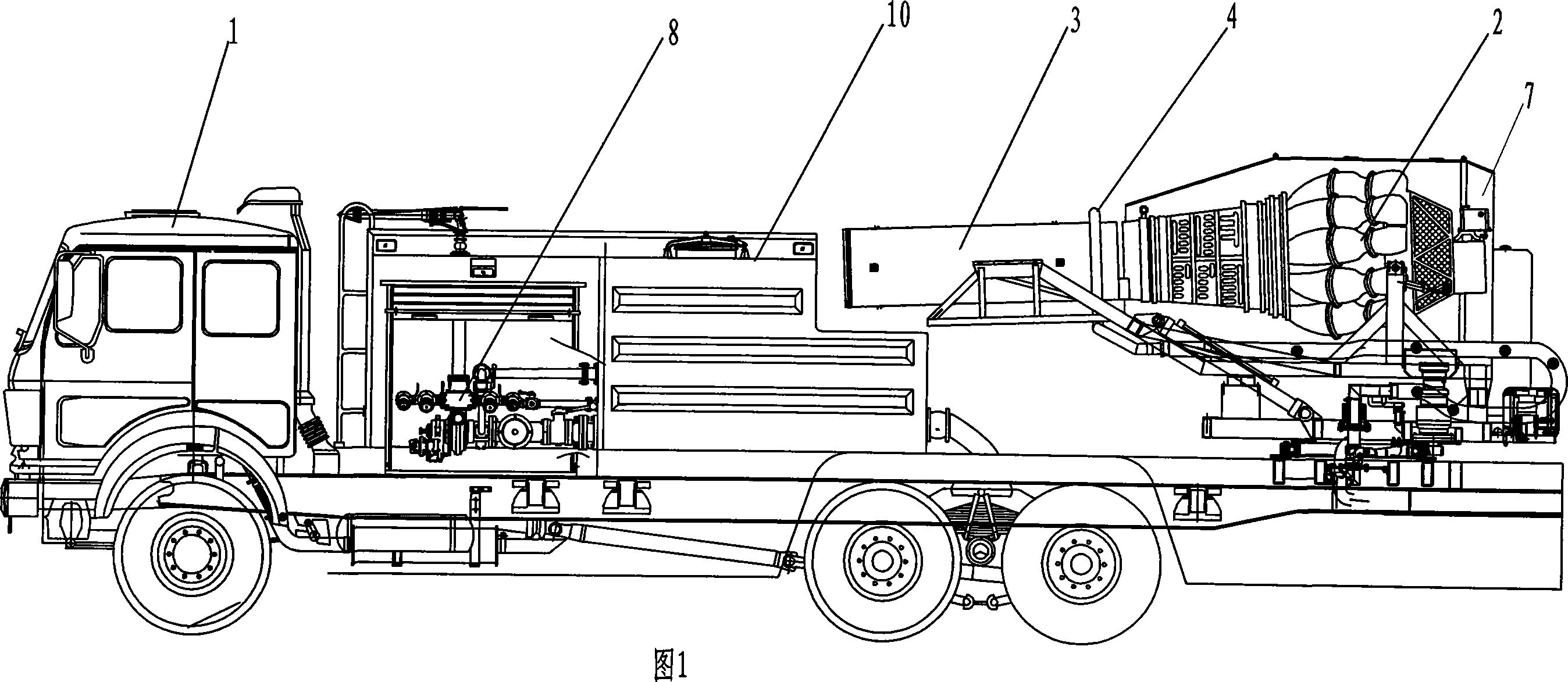

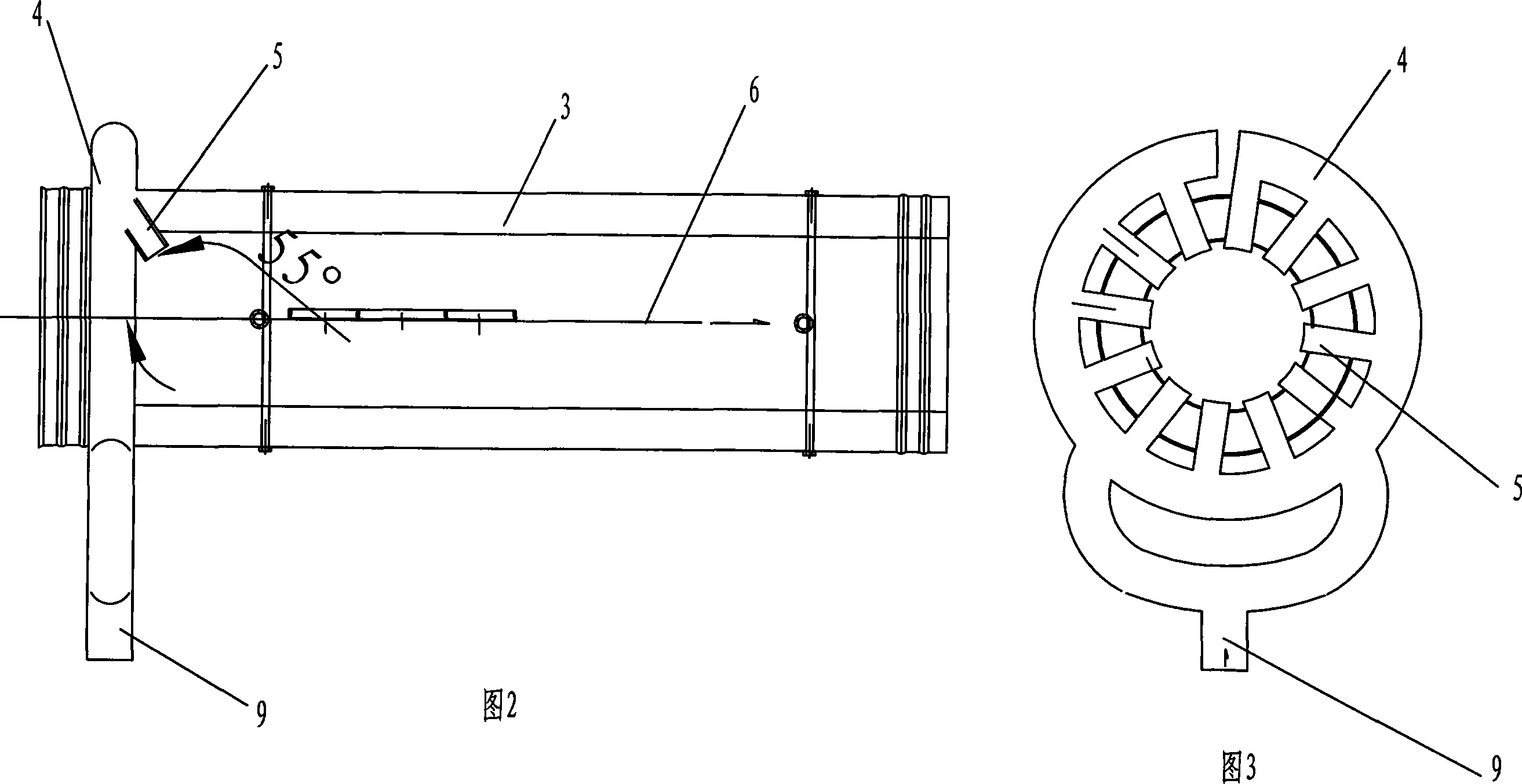

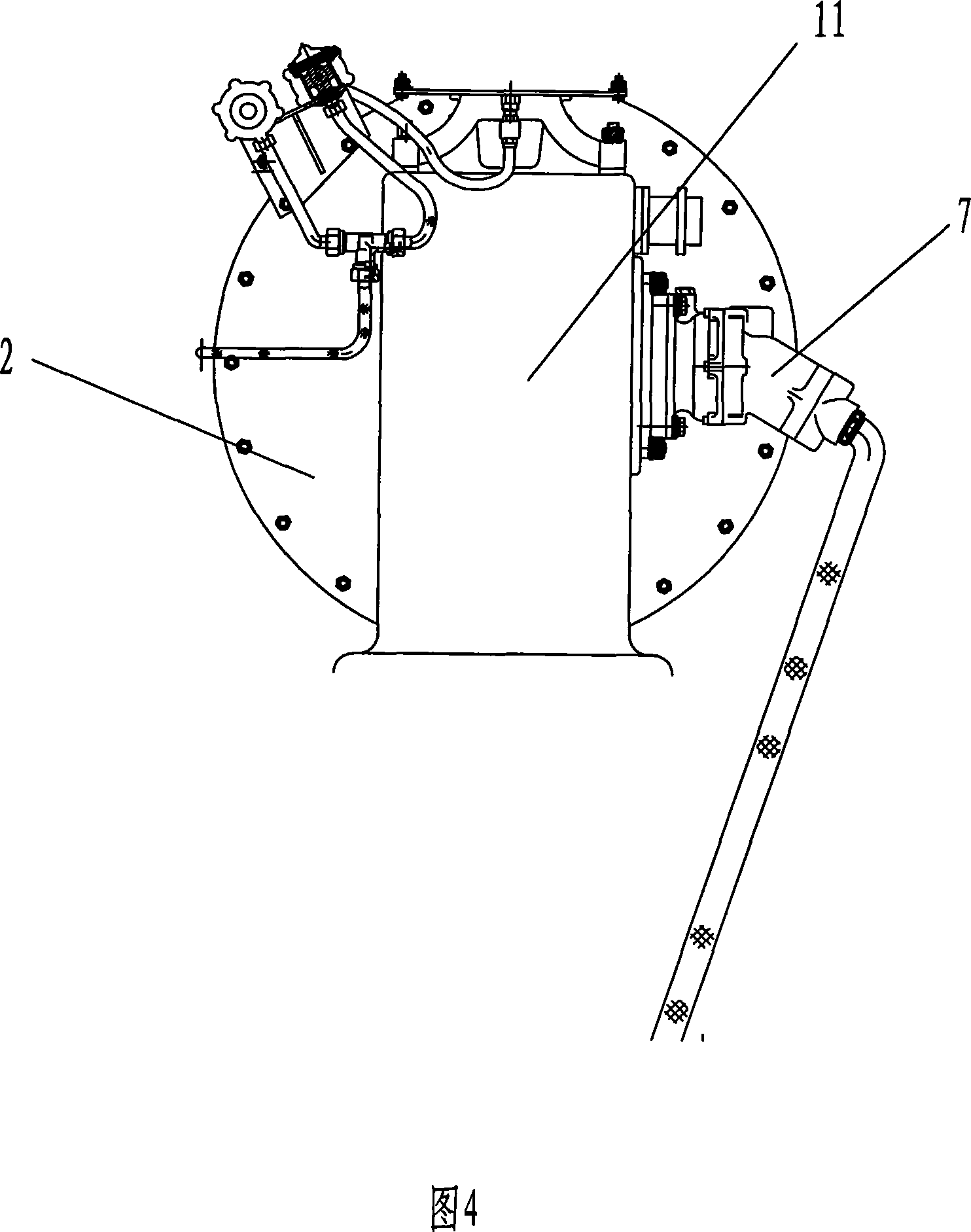

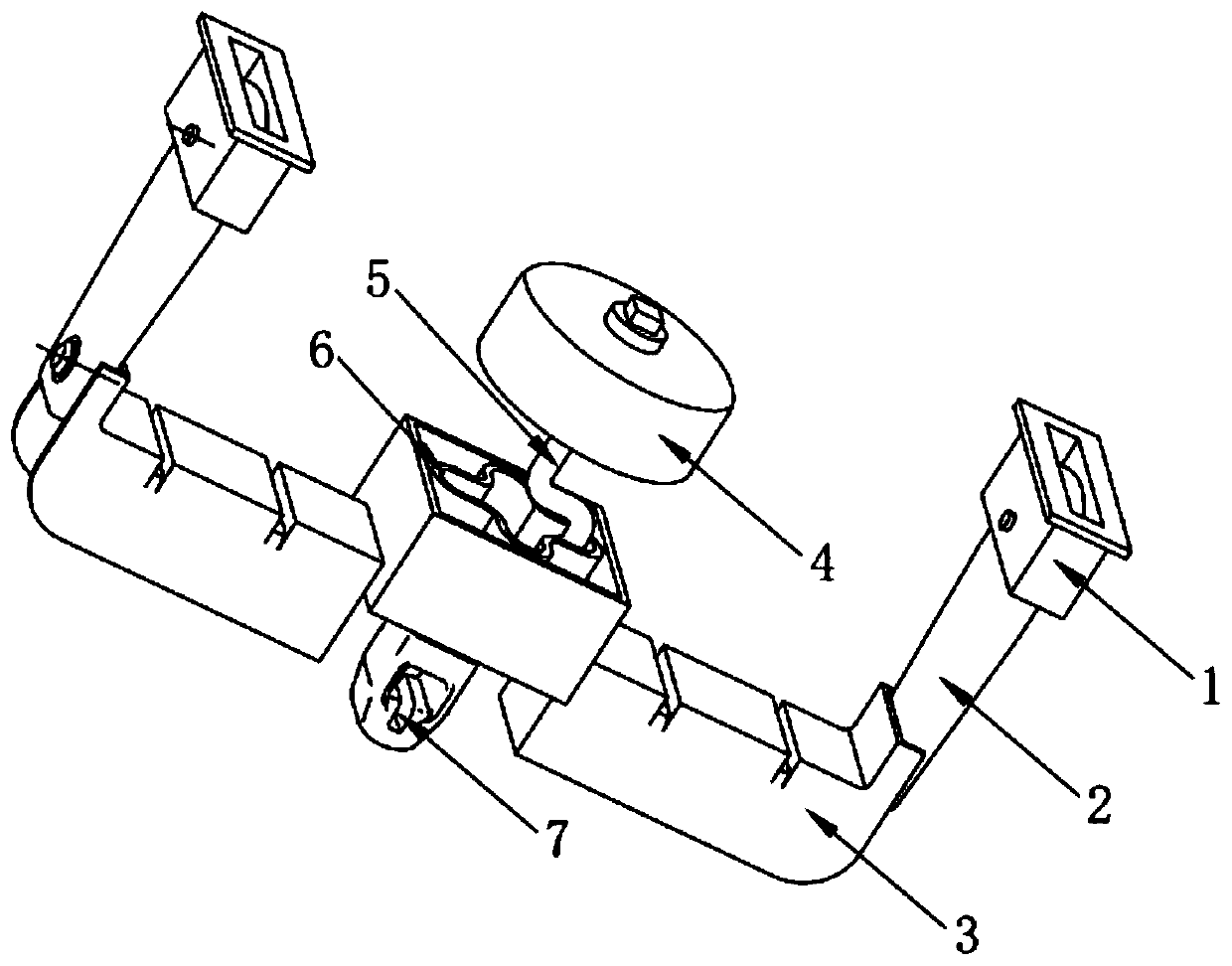

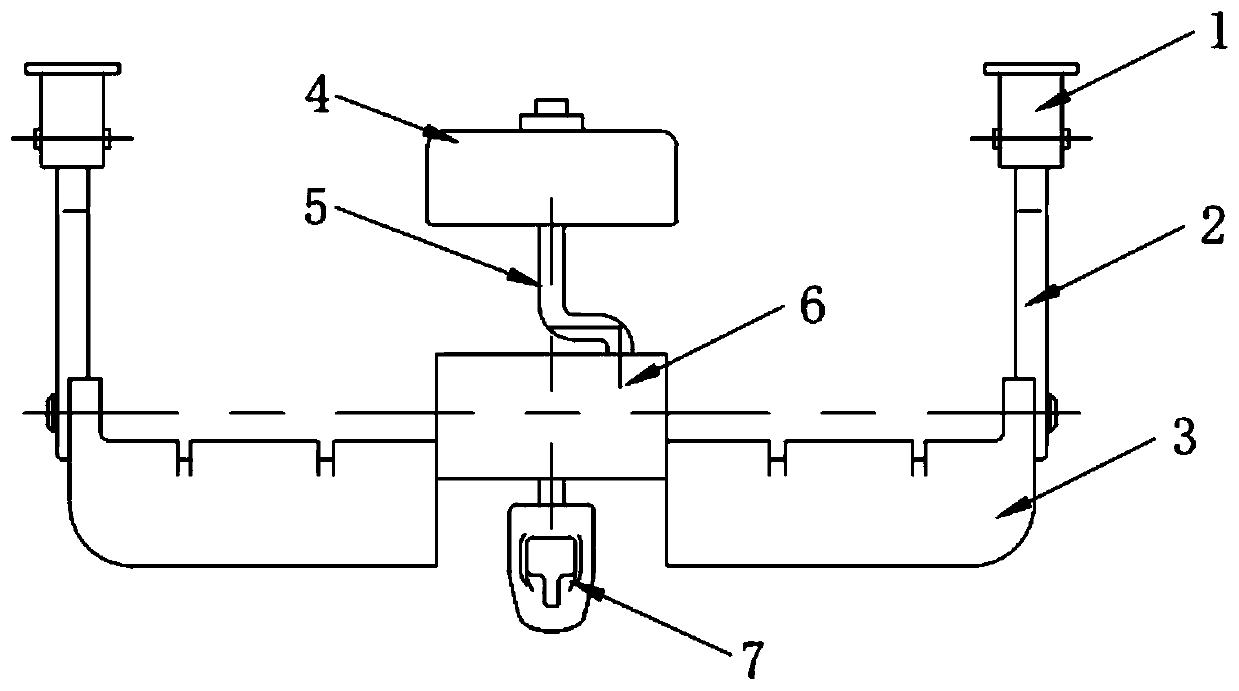

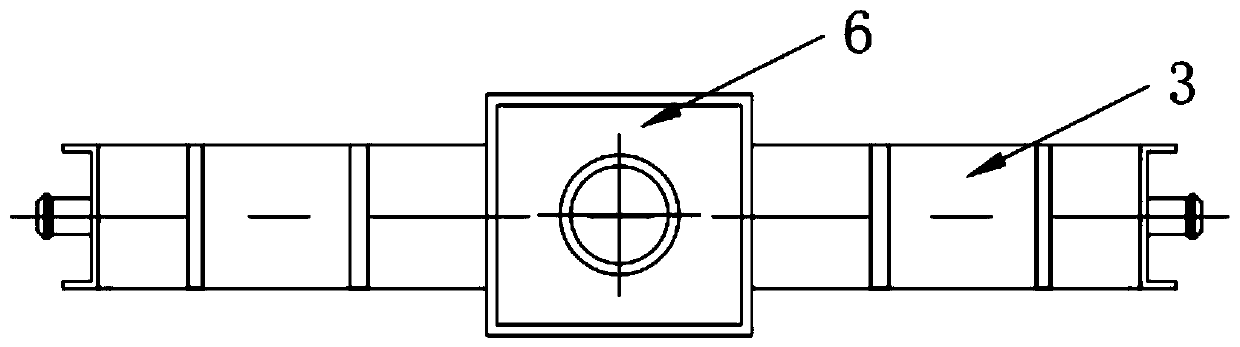

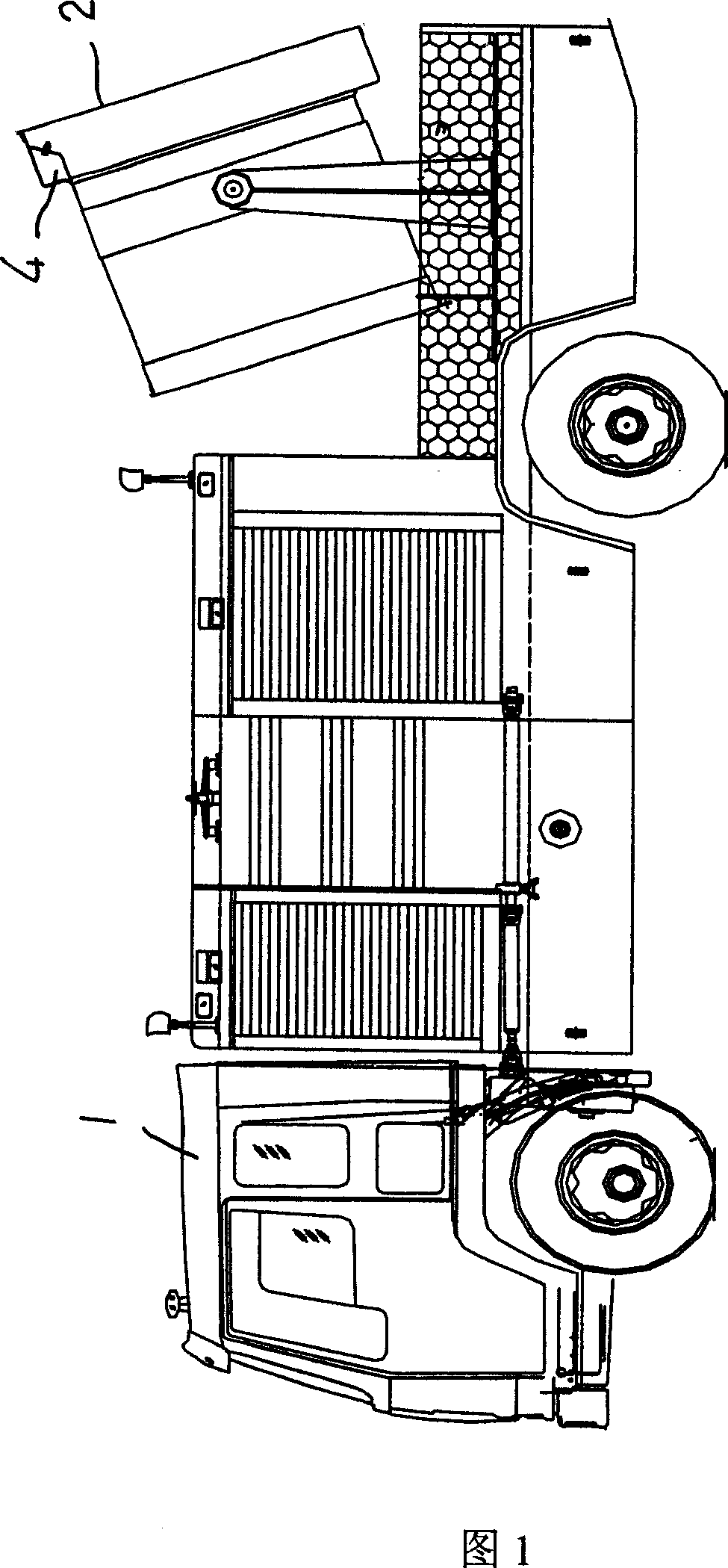

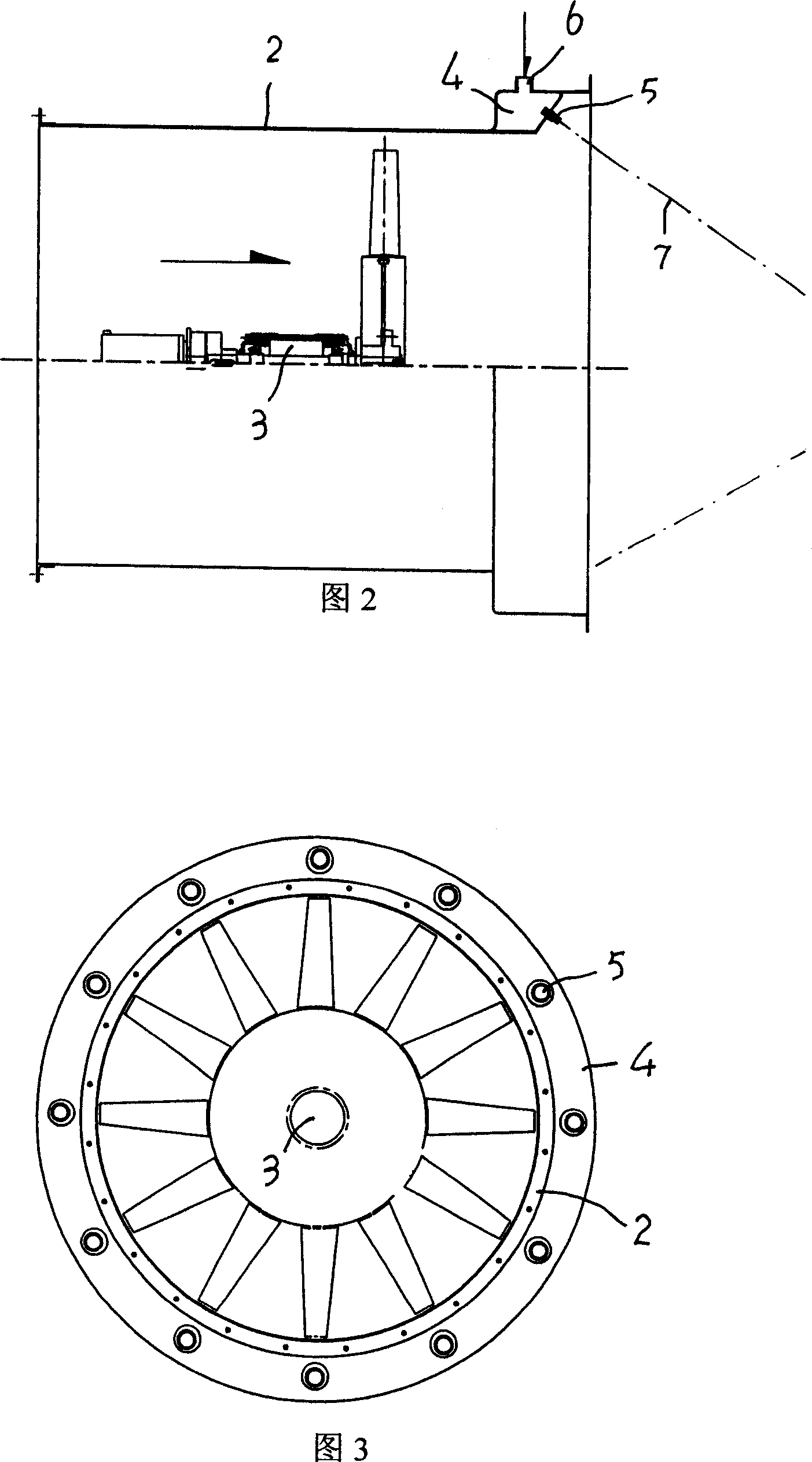

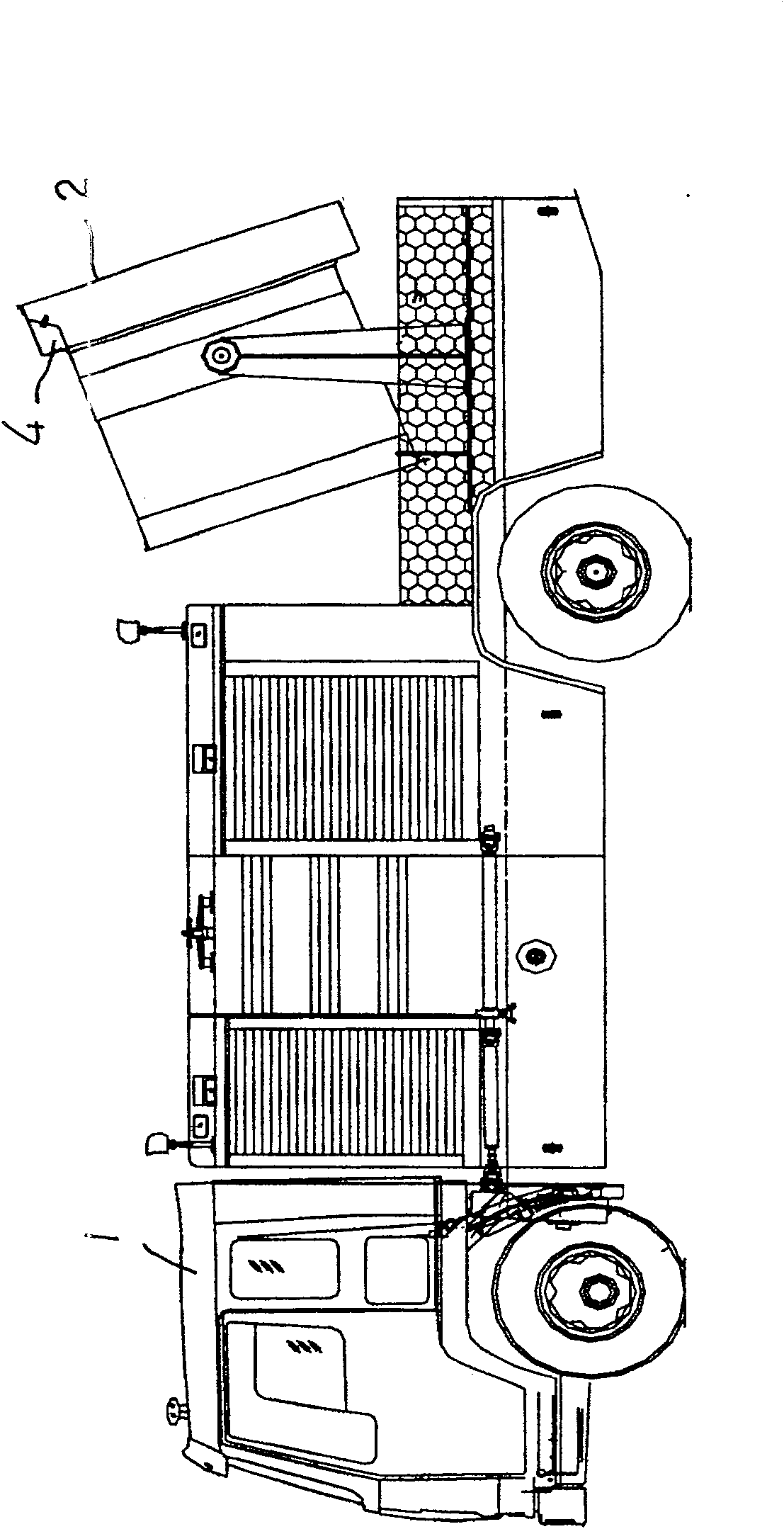

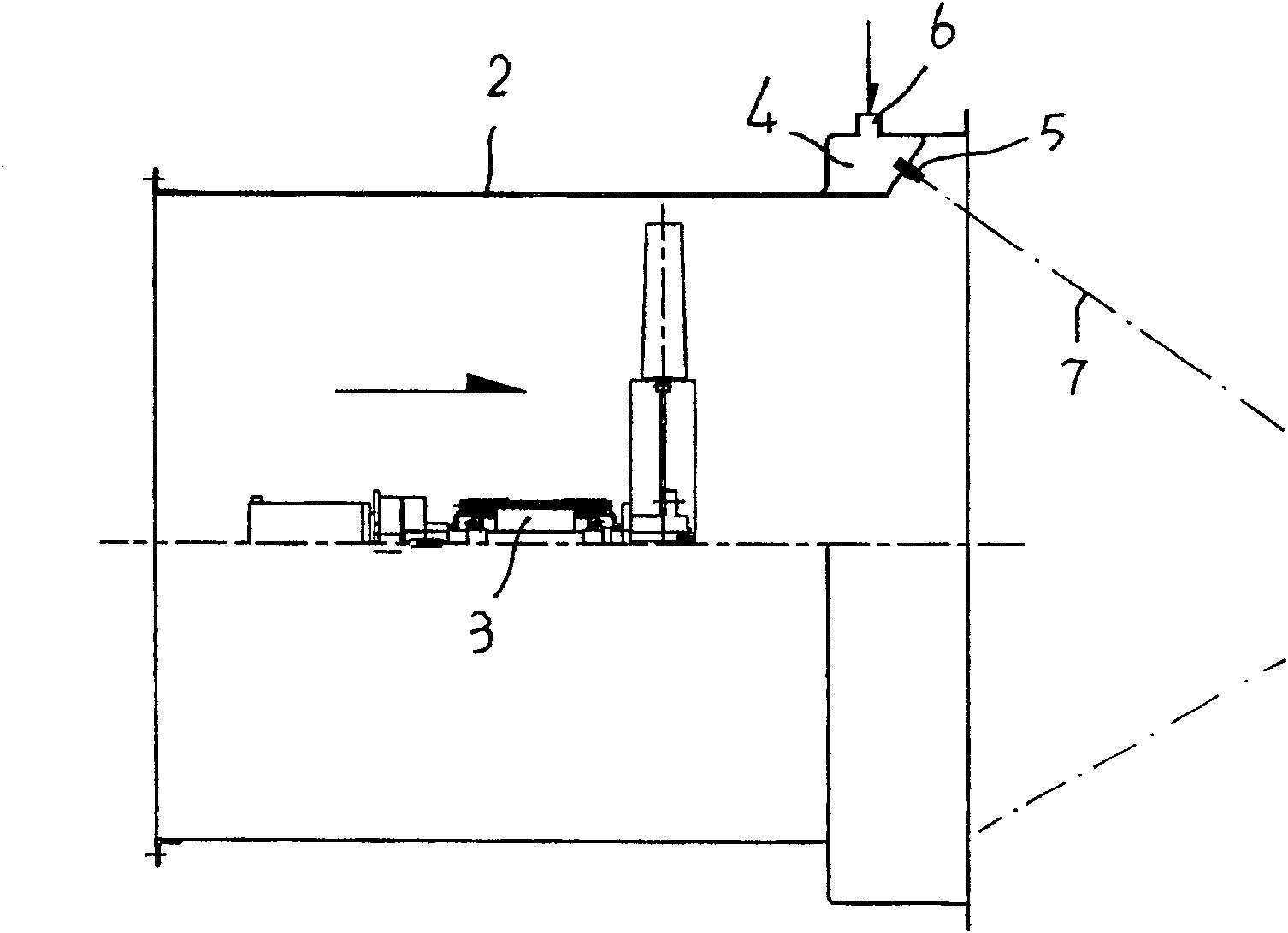

Fire control on-board fine-spray fire extinguishing smoke-discharging apparatus

The present invention relates to a fire-fighting vehicle mounted water mist fire-suppressing and smoke-removing equipment. It is characterized by that it uses the fire-fighting vehicle as carrier, on the fire-fighting vehicle an air barrel is set, in the air barrel interior an axial-flow blower is set; in the barrel mouth position of said air barrel, along the periphery of said air barrel a ring-shaped conduit is set, along said ring-shaped conduit uniformly distributed are water mist nozzles. Said invention integrates vehicle mounting, fire-fighting, ventilation, smoke-removing and dust-removing functions into one body, and can quickly eliminate smoke, lower temperature and remove dust.

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

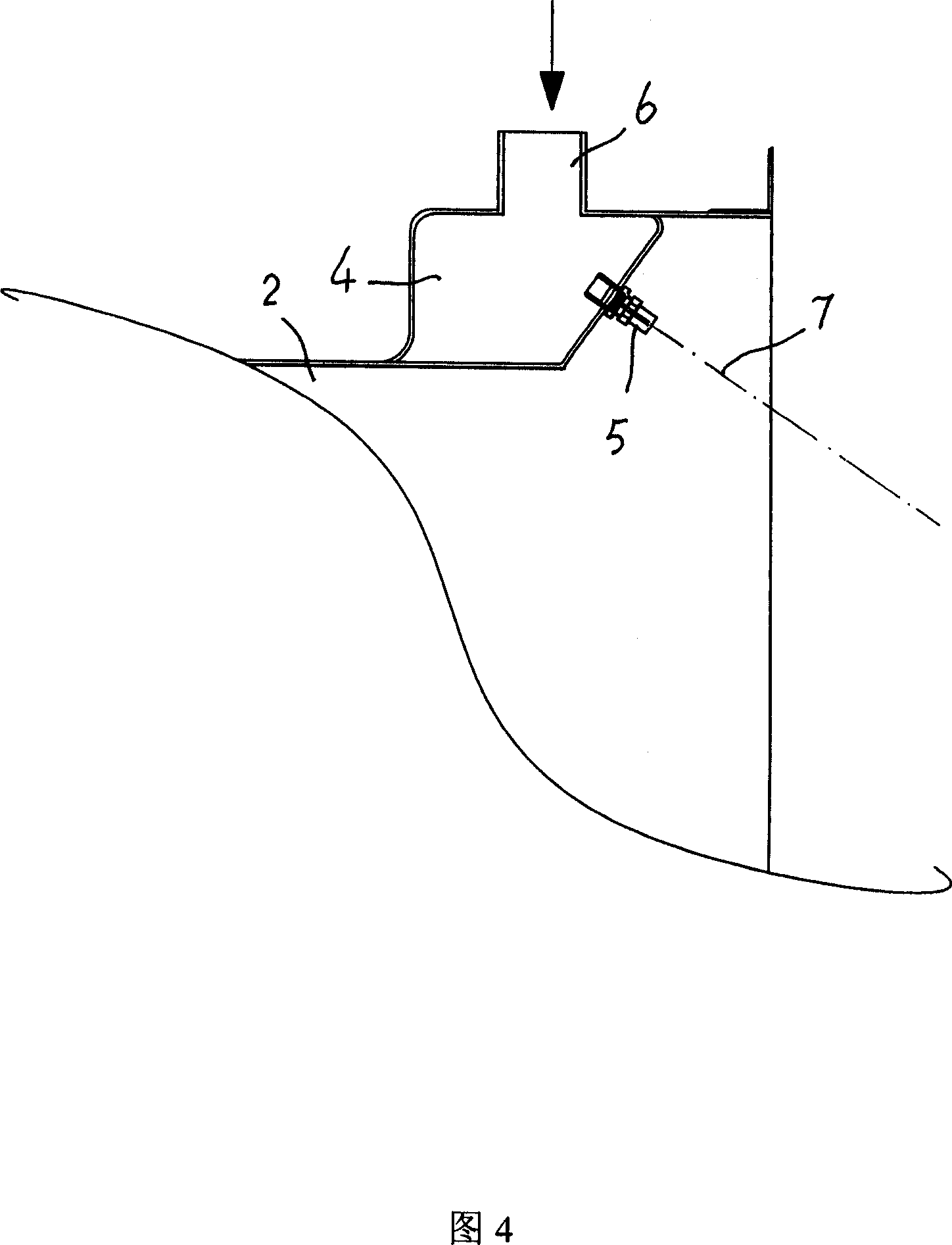

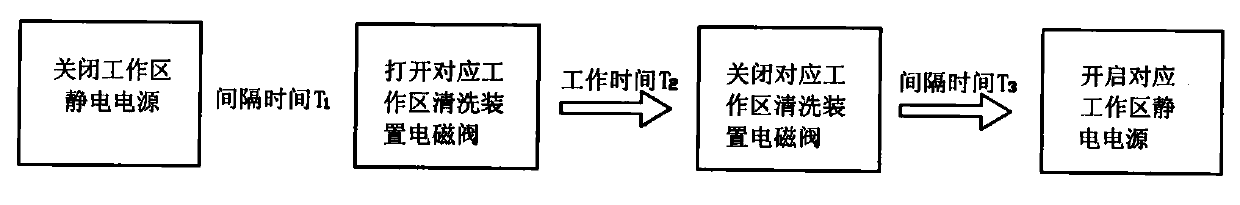

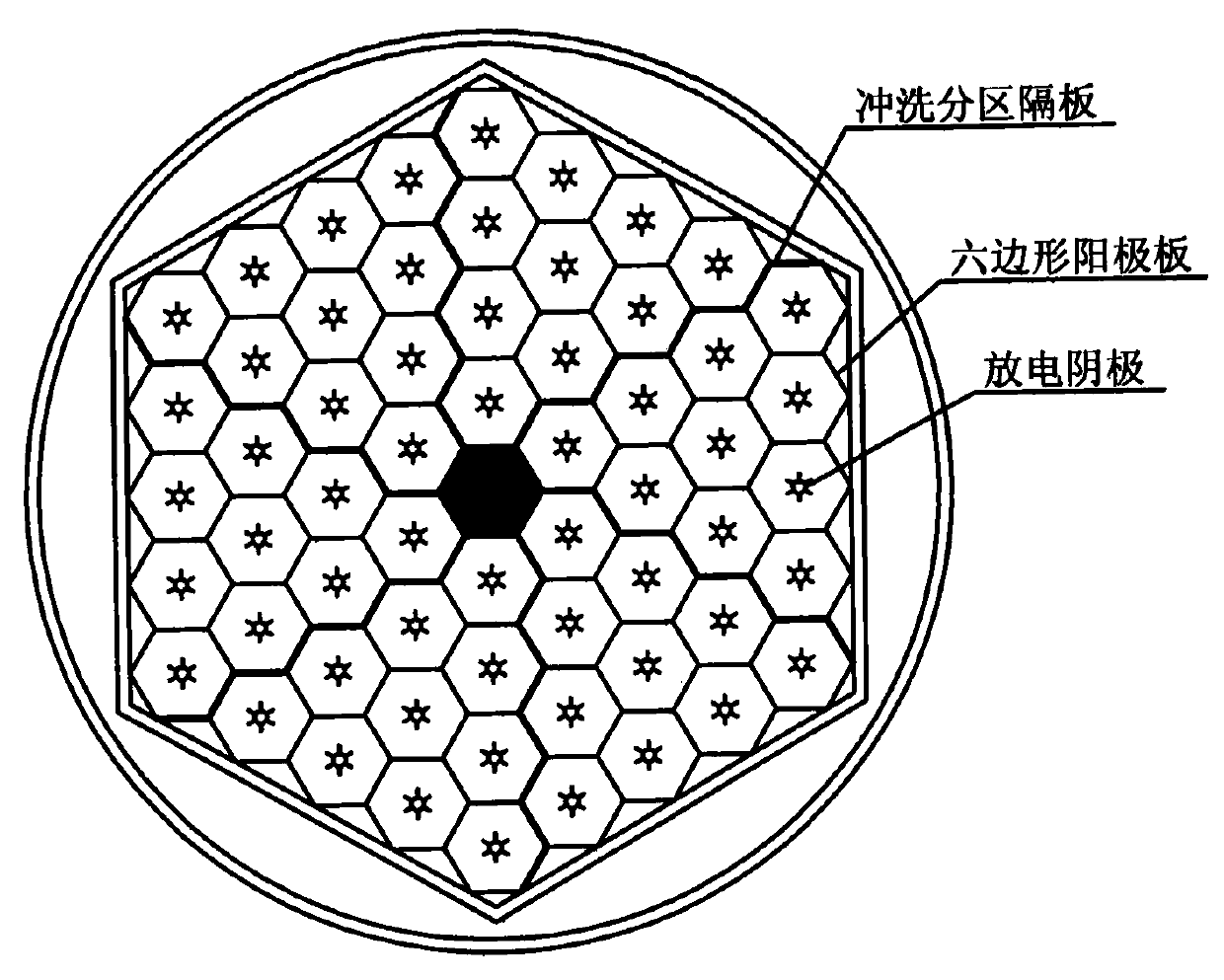

Self-cleaning wet type electrostatic precipitation demister capable of working continuously

InactiveCN103341299AContinuous dust removal workSave flushing waterCombination devicesGas heaterFine particulate

The invention discloses a self-cleaning wet type electrostatic precipitation demister capable of working continuously. The electrostatic precipitation demister comprises discharge electrodes, fixed anodes, an atomizing device, a first water spraying washing device and a second water spraying washing device, wherein the first water spraying washing device is installed at the upper parts of the discharge electrodes, the second water spraying washing device is installed at two sides of the fixed anodes, the atomizing device is installed at a smoke inlet and is used for guaranteeing the humidity of smoke, and the water spraying washing devices enable a washing area to be powered off temporarily and a non-washing area to be powered normally for work according to the control sequence of an automatic program. The electrostatic precipitation demister can remove extra over 90% of dust (containing fine particulate matters), gypsum rain and acidic materials in the smoke without improving an existing deduster and desulfurizer, and can remove part of heavy metals in the smoke, the processed smoke satisfies the newest national environment protection standards, the requirement of a chimney on anticorrosion is lowered, a GGH(gas-gas heater) is omitted, and water, electricity and capitals are saved.

Owner:冯万春 +1

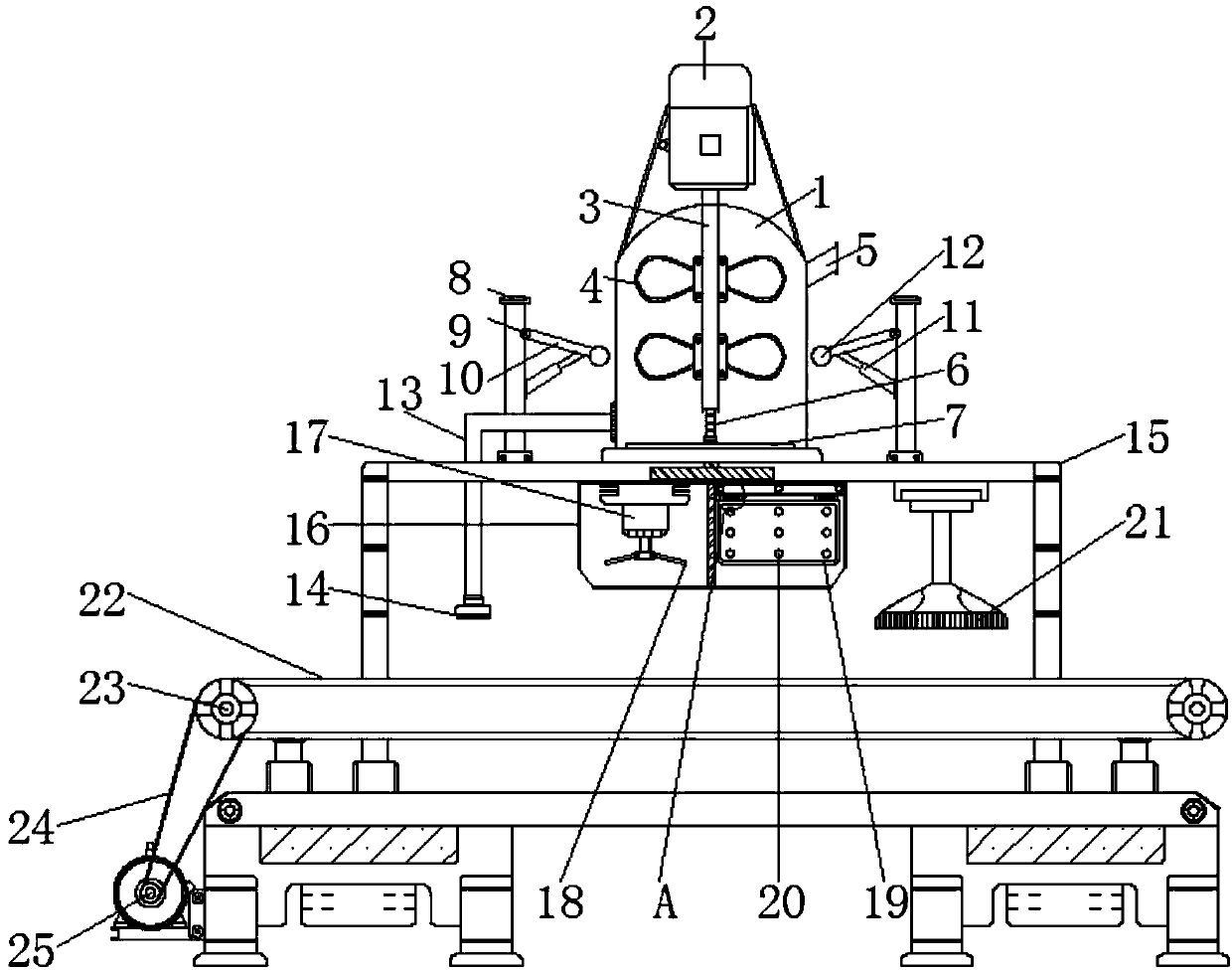

Dust removal device for lithium batteries

PendingCN109092735ASimple structureEasy maintenanceCleaning using toolsCleaning using gasesElectrical batteryEngineering

The invention relates to a dust removal device for lithium batteries. The dust removal device for the lithium batteries comprises an outer shell, a blowing dust removal unit, an air-induced dust collection unit, a rotary dust sweeping unit and a battery bracket unit. The outer shell is divided into a dust removal cavity and a dust collection cavity through a division plate, a plurality of dust fall holes are formed in the division plate, the battery bracket unit is arranged on the upper end surface of the division plate and in the dust removal cavity, the lithium batteries for dust removal canbe arranged on the battery bracket unit, the battery bracket unit can extend and retract in the vertical direction, the rotary dust sweeping unit is arranged directly above the battery bracket unit,and the rotary dust sweeping unit is arranged on the outer shell. The air-induced dust collection unit is arranged in the dust collection cavity, and the blowing dust removal unit is arranged in the dust removal cavity. The dust removal device for the lithium batteries solves the problems that an existing dust removal device cannot clean dust adhering to the surfaces of the lithium batteries, andthe dust on the whole lithium batteries is further difficult to be removed.

Owner:XIAN TECH UNIV

Automatic cleaning and drying integrated painting equipment

InactiveCN107930965AImprove practicalityFunction increaseRotary stirring mixersTransportation and packagingEngineeringConveyor belt

The invention relates to automatic cleaning and drying integrated painting equipment. The automatic cleaning and drying integrated painting equipment comprises a stirring barrel, a connection rod, fulcrum bars, a pipeline, a support, an adsorption box and a conveyor belt. A first motor is arranged above the stirring barrel, and the bottom end of the first motor is connected with a stirring shaft.The stirring shaft is provided with stirring blades, and a feed port is arranged on the right sides of the stirring blades. The connection rod is connected to the bottom end of the stirring shaft, anda rotary table is arranged below the connection rod. The inner wall of each fulcrum bar is connected with a rotating shaft, the inner side of each rotating shaft is provided with a knocking rod, thebottom of each knocking rod is connected with a hydraulic air cylinder, and the inner wall of each knocking rod is fixedly provided with a knocking ball. The pipeline is arranged at the left end of the stirring barrel, and a brush is arranged below the pipeline. The automatic cleaning and drying integrated painting equipment has the beneficial effects that painting, drying, air freshening and cleaning are combined well, and the problems which cannot be solved by ordinary painting equipment are solved.

Owner:蓝旭辉

Automatic industrial flue gas purifying system

InactiveCN105344194AReasonable designSimple structureHuman health protectionCombination devicesLaser transmitterControl system

The invention discloses an automatic industrial flue gas purifying system. The automatic industrial flue gas purifying system comprises a body, and the top of the body is equipped with clean air discharging pipe. The automatic industrial flue gas purifying system comprises a spray thrower and a filtering screen, and the spray thrower and the filtering screen are arranged in the body. The automatic industrial flue gas purifying system comprises a flue gas input pipe communicated with the side wall of the body, a transmission mechanism connected with the body and used for controlling rotation of the filtering screen, a temperature and pressure data collection device extending into the body and connected with a PLC controller, a gas pressure regulating valve, a liquid flow control system and a laser emitter. The gas pressure regulating valve, the liquid flow control system and the laser emitter are connected with the PLC controller. The automatic industrial flue gas purifying system also comprises a spray water box connected with the liquid flow control system, a laser emitter connected with the temperature and pressure data collection device and the PLC controller, a sewage drainage separation plate arranged inside the body and located under the filtering screen and a primary filtering device. The automatic industrial flue gas purifying system is reasonable in design, is simple in structure, improves flue gas purifying effects effectively and raises the dedusting efficiency.

Owner:CHENGDU ZHONGHENG ZHIHE INFORMATION TECH CO LTD

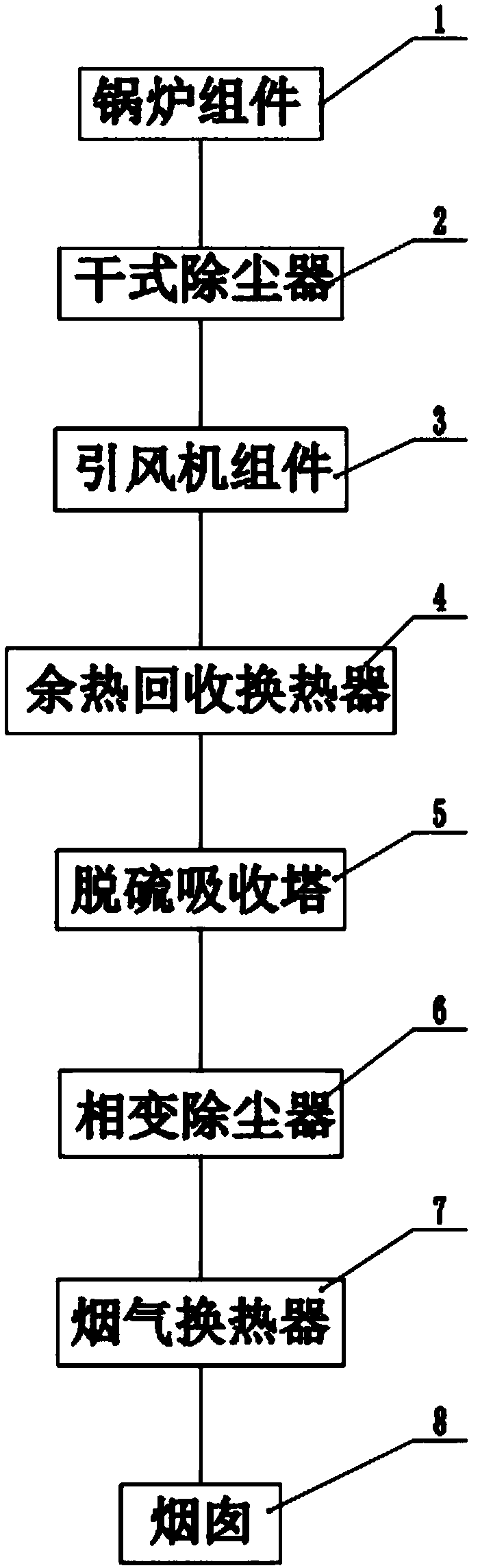

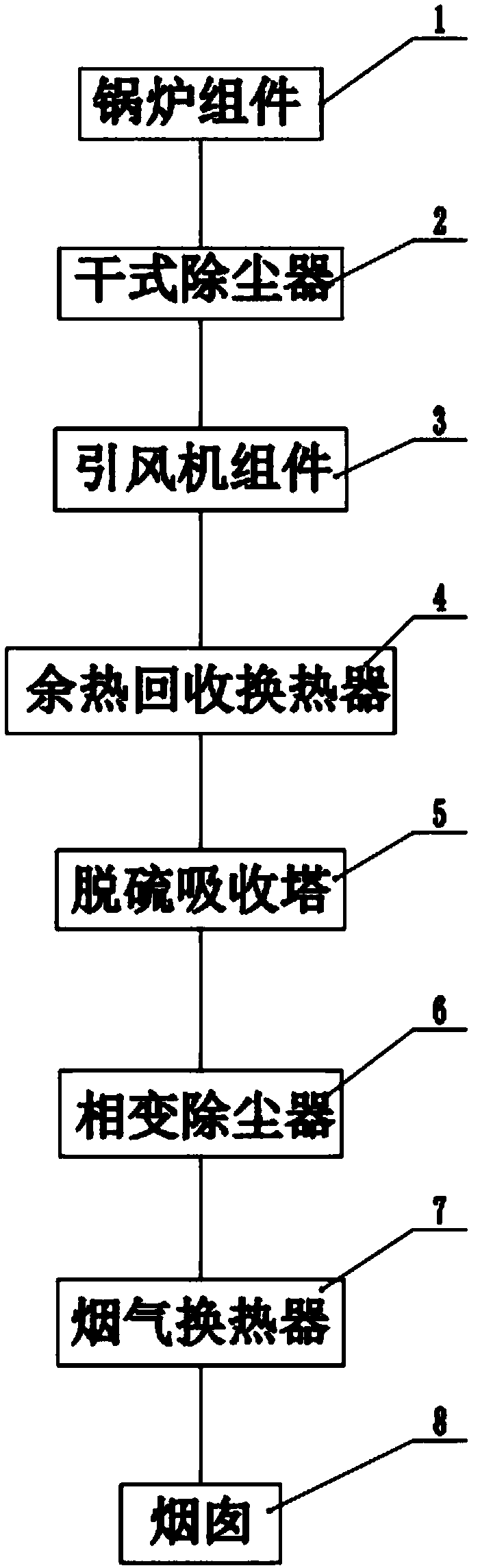

Desulfurization flue gas treatment method

InactiveCN108176179ASimple structureThe principle is simpleCombination devicesGas treatmentFlue gasTherapeutic effect

The invention discloses a desulfurization flue gas treatment method, and belongs to the field of environmental protection equipment. The desulfurization flue gas treatment method is realized by a desulfurization flue gas treatment system. The desulfurization flue gas treatment system comprises a boiler component, a dry dust collector, an induced draft fan component, a waste heat recovery heat exchanger, a desulfurization absorption tower, a phase change dust collector, a flue gas heat exchanger and a chimney which are connected in sequence. The structure and principle of the desulfurization flue gas treatment system are simple, the perfect desulfurization flue gas treatment is realized through the cooperation of each part, and the treatment effect is good.

Owner:苏州浩长空环保科技有限公司

Nut drying and dust removing device

InactiveCN108562124AGood dust removal and drying effectImproved dust removal and dryingDrying gas arrangementsDrying chambers/containersTelescopic cylinderDrive motor

The invention discloses a nut drying and dust removing device. The nut drying and removing device comprises a lower box body, an upper box body and a base; a screen is installed on the inner side of the lower box body, an exhaust pipe is installed in the middle of the top of the upper box body, and a dust collecting cloth bag is installed at the end of the exhaust pipe; a vertical rotating pipe isfixedly installed in the middle of the bottom of the lower box body, the lower end of the vertical rotating pipe extends to the lower side of the base, the lower end of the vertical rotating pipe isconnected to a gas conveying pipe through a rotating joint, and the other end of the gas conveying pipe is connected to a hot fan arranged at the bottom of the base; and an upper bevel gear and a lower bevel gear are installed on the vertical rotating pipe between the lower box body and the base from top to bottom respectively, a telescopic cylinder is installed on the base, a driving motor is fixedly installed on a motor support at the upper end of the telescopic cylinder, the end part of the output shaft of the driving motor is provided with a side bevel gear which can be in meshed connection with the upper bevel gear and the lower bevel gear. According to the nut drying and dust removing device, the structural design is reasonable, the dust removal and drying effects of the nuts are good, the efficiency is high, and the popularization and application value is high.

Owner:黄锦山

Fire control on-board fine-spray fire extinguishing smoke-discharging apparatus

The present invention relates to a fire-fighting vehicle mounted water mist fire-suppressing and smoke-removing equipment. It is characterized by that it uses the fire-fighting vehicle as carrier, on the fire-fighting vehicle an air barrel is set, in the air barrel interior an axial-flow blower is set; in the barrel mouth position of said air barrel, along the periphery of said air barrel a ring-shaped conduit is set, along said ring-shaped conduit uniformly distributed are water mist nozzles. Said invention integrates vehicle mounting, fire-fighting, ventilation, smoke-removing and dust-removing functions into one body, and can quickly eliminate smoke, lower temperature and remove dust.

Owner:MINGGUANG HAOMIAO SECURITY PROTECTION TECH

Self-cleaning filter

PendingCN107569946AImprove dust removalImprove efficiencyDispersed particle filtrationHuman health protectionEngineeringWire mesh

The invention discloses a self-cleaning filter. The self-cleaning filter comprises an upper box, a filter layer and a lower box which are sequentially arranged from top to bottom, wherein an air outlet is formed in the side face of the upper box; a horizontally arranged mounting plate is arranged in the filter layer; a plurality of flange plates in a rectangular matrix manner in equal distance areembedded into the mounting plate; filter cartridges are respectively arranged at the bottoms of the plurality of flange plates; blowback air pockets are respectively arranged on two parallel outer walls of the filter layer; the blowback air pockets are connected with blowback pipes corresponding to the filter cartridges; nozzles corresponding to the filter cartridges are arranged at the bottom ends of the blowback pipes; and a steel wire mesh is made on the side wall of the lower box. According to the self-cleaning filter, the dust removal and self-cleaning efficiency is improved, the filtercartridges can be automatically cleaned in groups, the other filter cartridges can also normally work, and the working efficiency is improved.

Owner:ZHANGJIAGANG AIER ENVIRONMENTAL PROTECTION ENG CO LTD

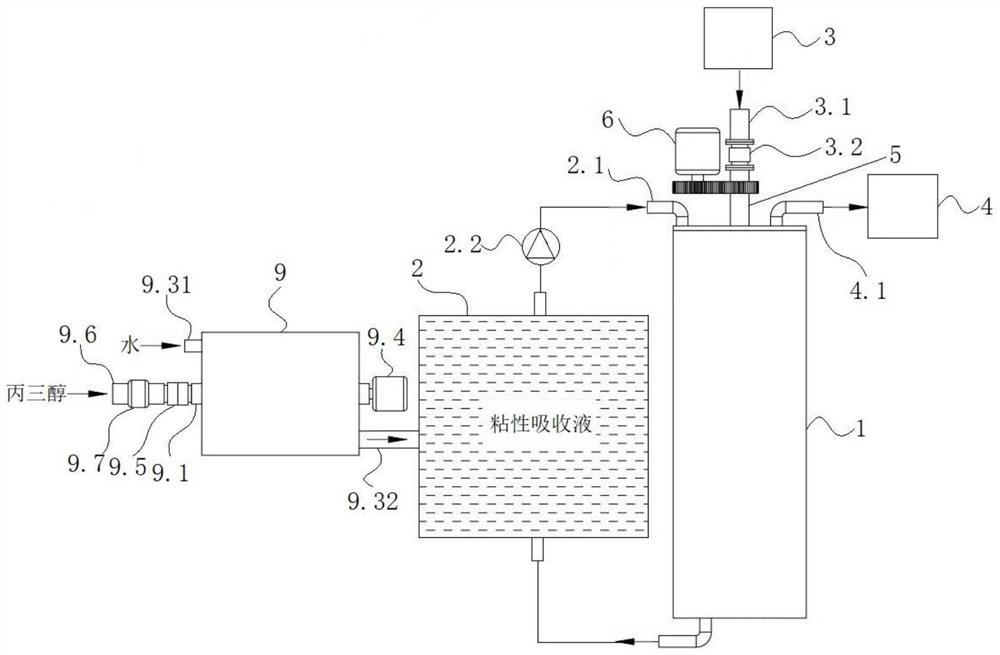

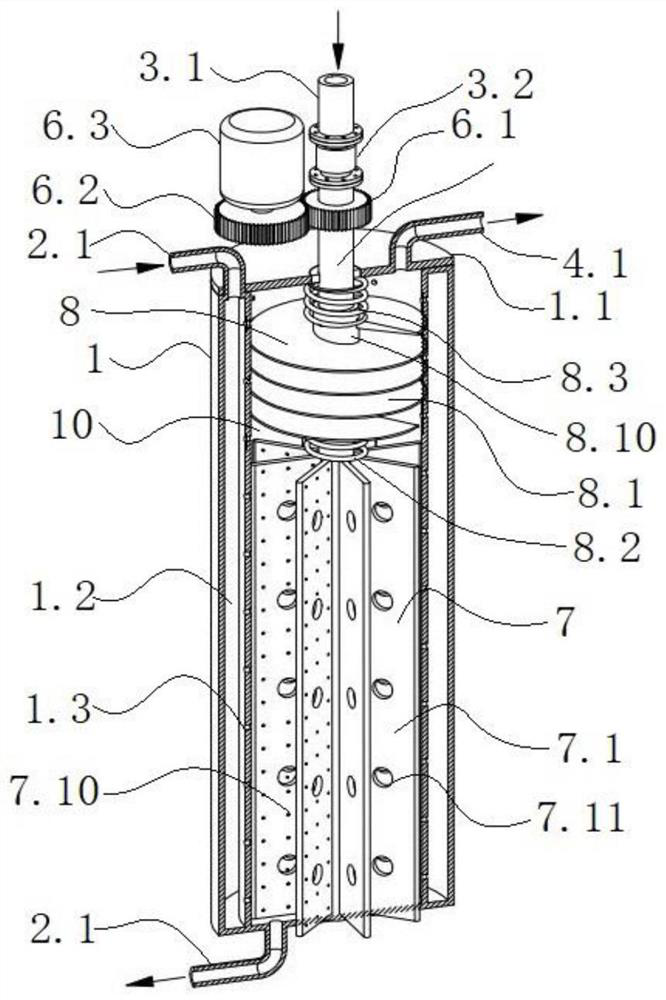

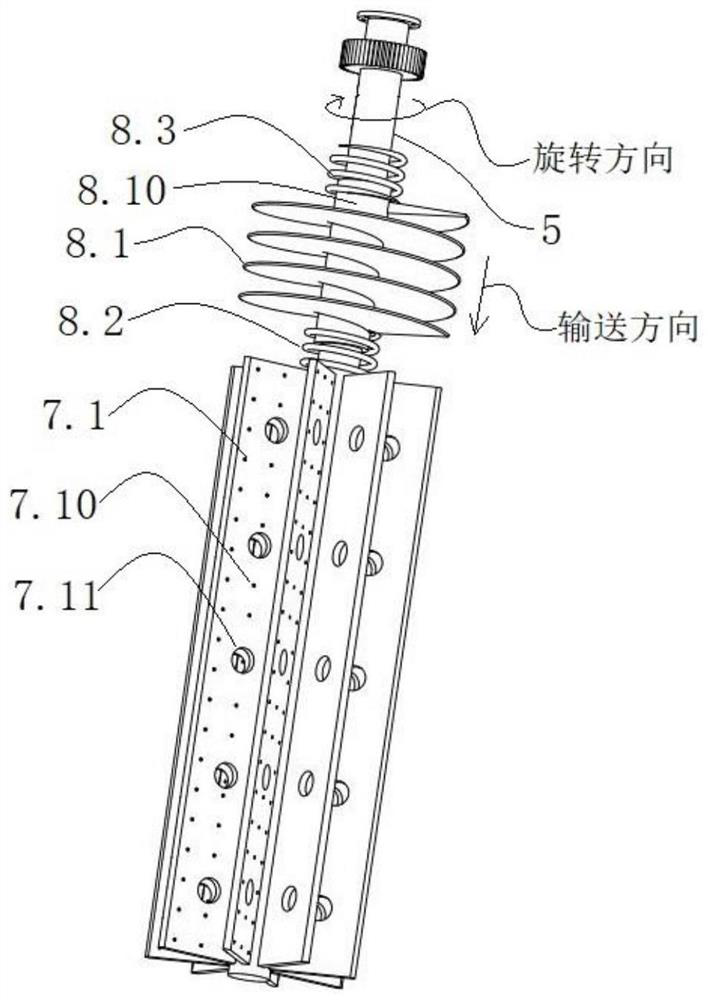

Dust removal and desulfurizing system for treating industrial waste gas by using viscous absorption liquid and treatment method

InactiveCN112452115AExtended flow timeImprove liquidityTransportation and packagingMixing methodsThermodynamicsExhaust fumes

The invention discloses a dust removal and desulfurizing system for treating industrial waste gas by using viscous absorption liquid and a treatment method. The dust removal and desulfurizing system comprises a dust removal and desulfurizing container, a viscous absorption liquid circulating tower, an industrial waste gas source and a gas receiving tower, the viscous absorption liquid circulatingtower circularly supplies the viscous absorption liquid to the dust removal and desulfurizing container, the industrial waste gas source conveys industrial waste gas to the dust removal and desulfurizing container, and the industrial waste gas subjected to dust removal and desulfurizing is received by the gas receiving tower; the dust removal and desulfurizing container is provided with a cylindrical dust removal and desulfurizing cavity and an annular liquid distribution cavity from inside to outside, the cylindrical dust removal and desulfurizing cavity is inserted into a vertical pipe, thevertical pipe is provided with a gas distribution stirring assembly and an elastic spiral choked flow blade assembly from top to bottom, and viscous absorption liquid is stirred while the gas distribution stirring assembly distributes gas; and the elastic spiral choked flow blade assembly conveys the viscous absorption liquid downwards to chock flow of industrial waste gas and generates vertical elastic vibration under flow impact of the viscous absorption liquid at the same time. The dust removal and desulfurizing system integrates industrial waste gas dedusting and desulfurizing, and dedusting and desulfurizing are thorough and efficient.

Owner:崔小勤

Comprehensive treatment system for desulfurized flue gas and treatment method adopting comprehensive treatment system

InactiveCN108211690ASimple structureThe principle is simpleCombination devicesGas treatmentFlue gasEnvironmental engineering

The invention discloses a comprehensive treatment system for desulfurized flue gas and a treatment method adopting the comprehensive treatment system and belongs to the field of environmental protection equipment. The treatment system comprises a boiler assembly, a dry type dust collector, an induced draft fan assembly, a waste heat recovery heat exchanger, a desulfurizing absorption tower, a phase change dust collector, a gas-gas heater and a chimney which are connected sequentially. The comprehensive treatment system is simple in structure, adopts simple principle, perfect desulfurization offlue gas is realized through coordination of all parts, and the treatment effect is good.

Owner:苏州浩长空环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com