Dust removal and desulfurizing system for treating industrial waste gas by using viscous absorption liquid and treatment method

A technology of industrial waste gas and desulfurization system, which is applied in the direction of mixing method, separation method and use of liquid separating agent, etc. It can solve the problems of insufficient mixing and contact, large residual amount of sulfur dioxide, and low efficiency of waste gas treatment, so as to improve the efficiency of dust removal and desulfurization, Strong adhesion ability and effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further technical detail below in conjunction with the accompanying drawings.

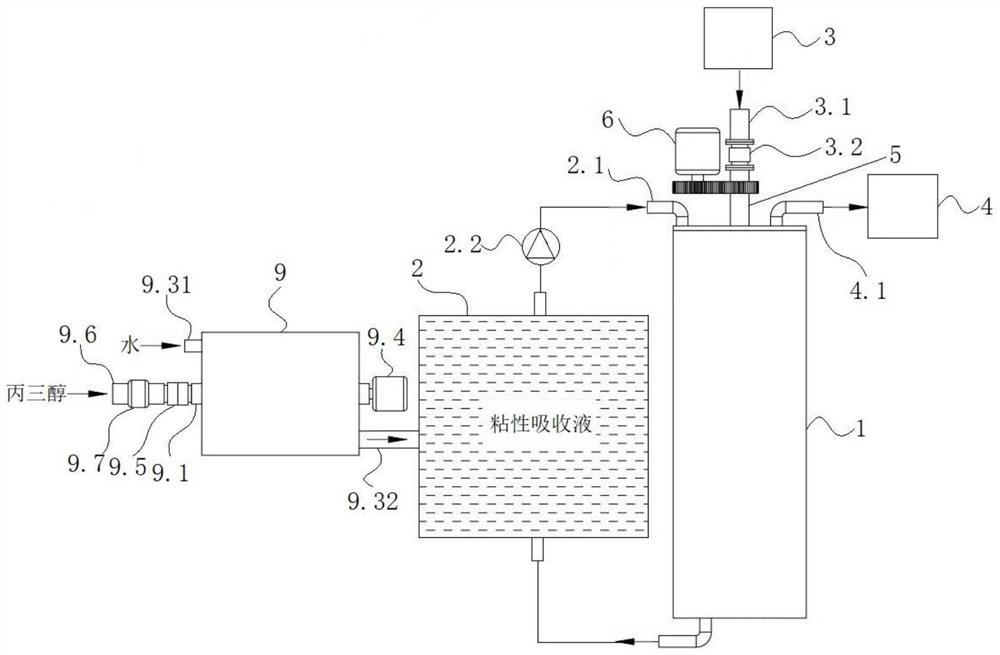

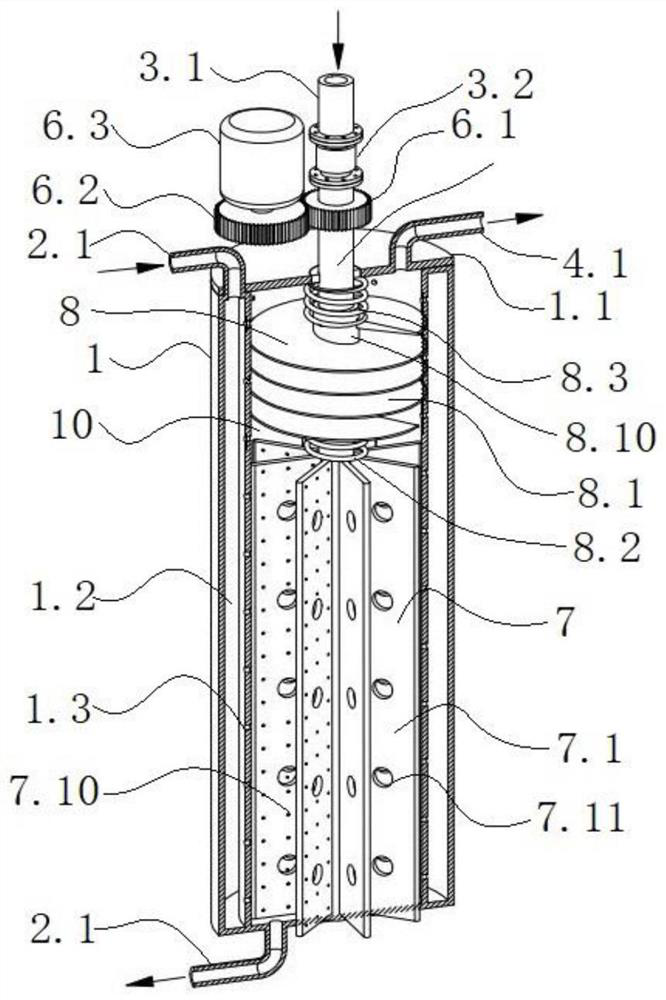

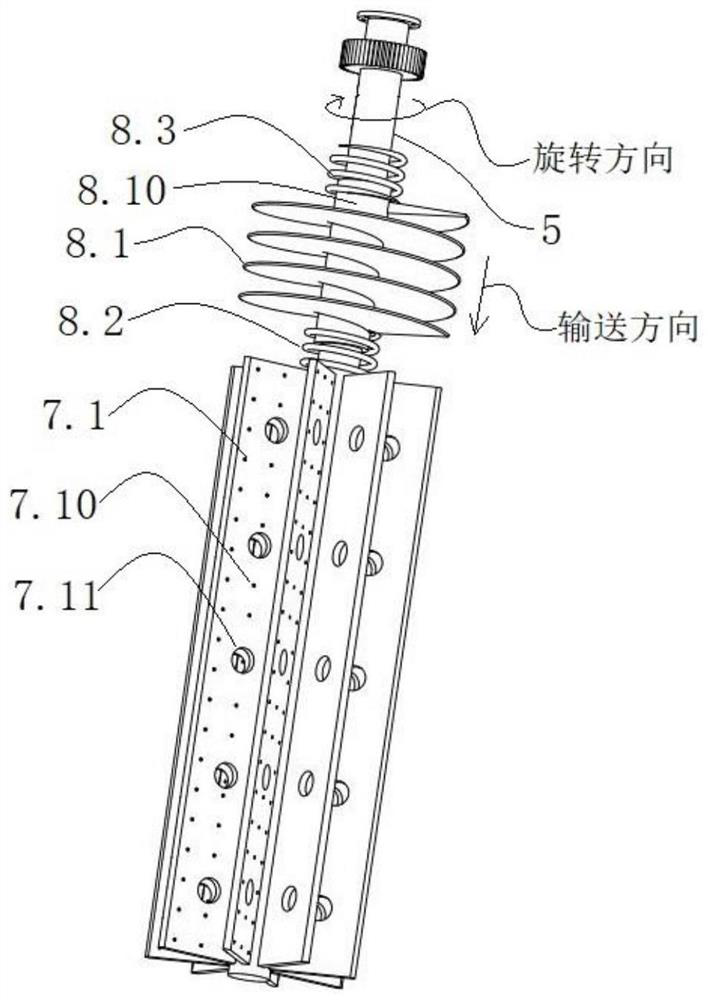

[0036] as attached figure 1As shown, the dust removal and desulfurization system using viscous absorption liquid to treat industrial waste gas includes a dust removal and desulfurization container 1, a viscous absorption liquid circulation tower 2, an industrial waste gas source 3 and a gas receiving tower 4; the viscous absorption liquid circulation tower 2 passes through the liquid circulation pipeline 2.1 Circulating supply of viscous absorption liquid to the dust removal and desulfurization container 1, a circulation pump 2.2 is installed on the liquid circulation pipeline 2.1, the viscous absorption liquid is formed by mixing glycerol and water with a mixing device 9, the The industrial waste gas source 3 transports the industrial waste gas to the dust removal and desulfurization container 1 through the intake pipe 3.1, and the industrial waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com