Quick-curing silicon PU material and preparation method thereof

A fast-curing, PU material technology, applied in the field of polyurethane, can solve the problems of long construction period and achieve the effect of improving curing speed, excellent strength and anti-settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

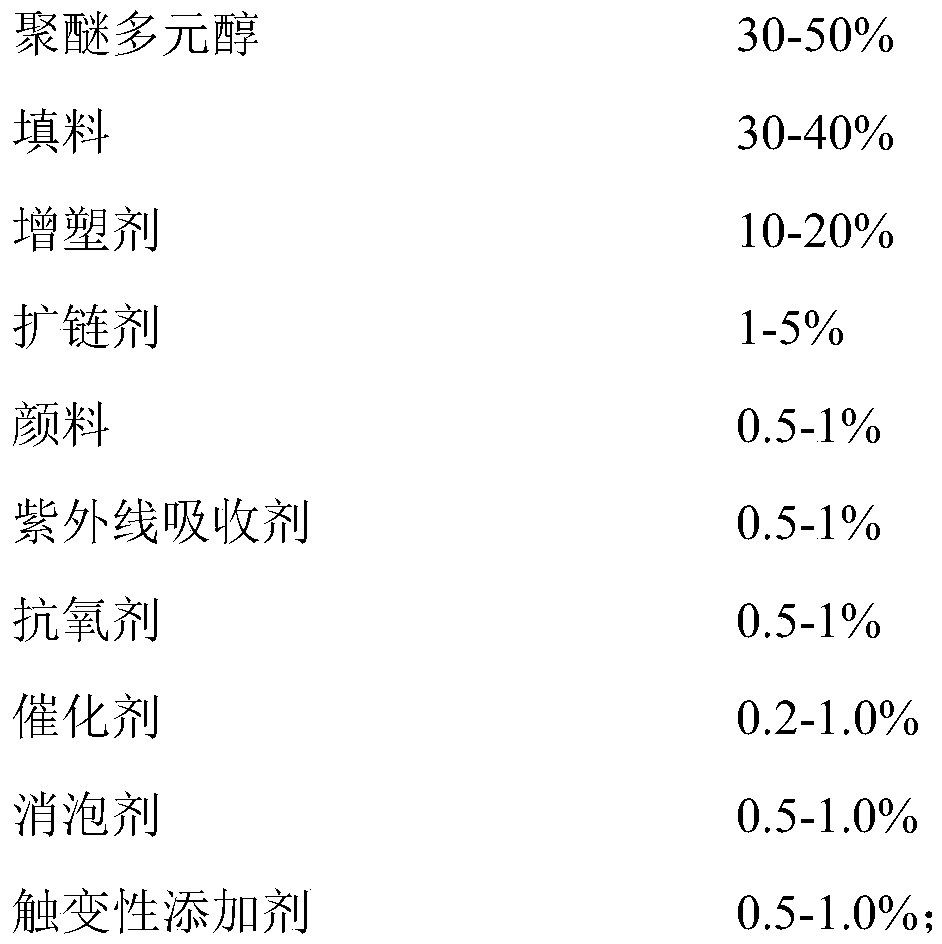

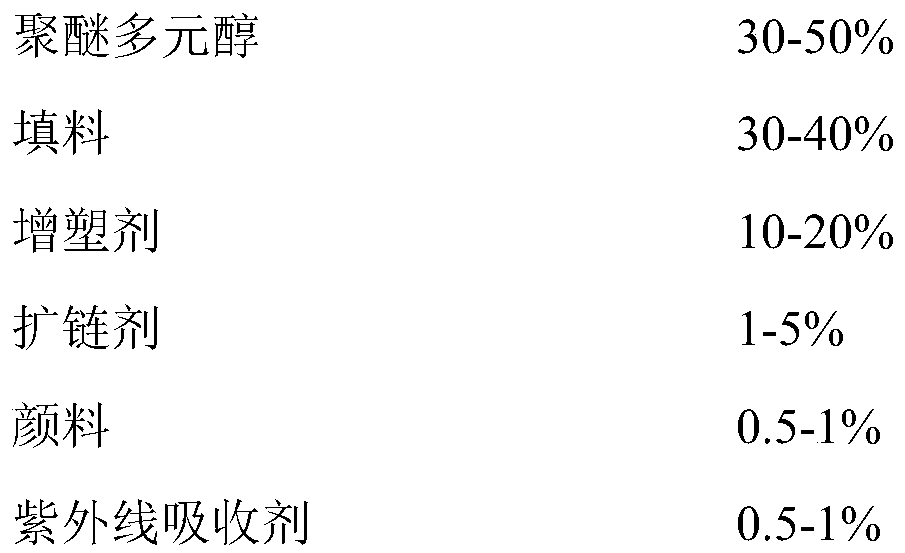

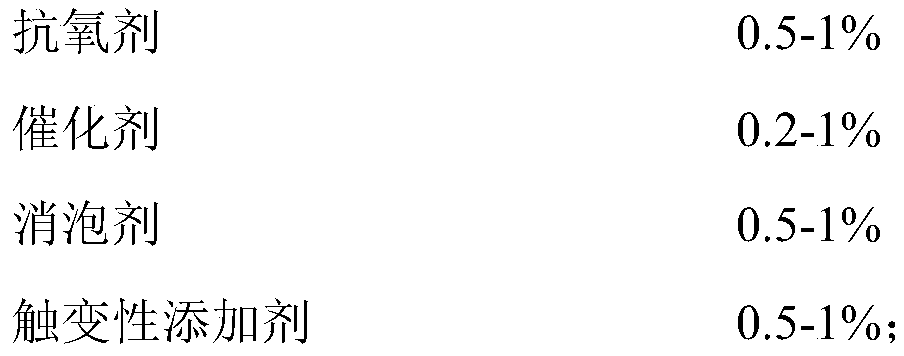

Method used

Image

Examples

Embodiment 1

[0037] Preparation of component A materials: first put 50% of MN700, 30% of 400 mesh talc powder, 0.5% of iron oxide green, 10% of dioctyl phthalate, 5% of XYlink 740M, and 1% of MT PLUS into the kettle and stir evenly. Raise the temperature to 85°C, dehydrate under the condition of vacuum degree -0.1MPa, make the moisture below 0.1%, drop the temperature to 60°C, add 2-(2'-hydroxy-3',5'-di-tert-butylphenyl)benzene 1% triazole, 1% isooctyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate, 1% CUCAT-TM, 0.5% BYK-066N and stir for 20 minutes to obtain the product of component A;

[0038] Preparation of component B material: add DL-1000 65% to the reaction kettle, stir and heat up to 95°C, dehydrate at -0.1MPa, use moisture below 0.05%, then cool down to 50°C, add M20S 35% at 85°C React for 2 hours, lower the temperature to 50°C, add 20ppm phosphoric acid, stir for 20 minutes, and then pack into barrels to obtain the product of component B;

[0039] When using, mix components A and B ...

Embodiment 2

[0041] Preparation of component A materials: first put DV125 40%, 400 mesh talc powder 32%, iron oxide green 1%, dimethyl adipate 20%, TDMA-02 3%, MT PLUS 1% into the kettle and stir evenly. Raise the temperature to 85°C, dehydrate under the condition of vacuum degree -0.1MPa, make the moisture below 0.1%, drop the temperature to 70°C, add 2-(2'-hydroxy-3',5'-di-tert-butylphenyl)benzene 0.7% triazole, 0.8% isooctyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate, 1% BYK-024, 0.5% CUCAT-TM and stirred for 20 minutes to obtain the product of component A;

[0042] Preparation of component B materials: add DL-2000 60% to the reaction kettle, stir and raise the temperature to 95°C, dehydrate under the condition of -0.1MPa, and use moisture below 0.05%. Then cool down to 50°C, add liquefied MDI 40% and react at 80°C for 2.5 hours, cool down to 50°C, add phosphoric acid 20ppm, stir for 20min, and then pack into barrels to obtain component B product;

[0043] When using, mix components A...

Embodiment 3

[0045] Preparation of component A materials: first put MN-500 32%, 400 mesh talc powder 40%, iron oxide green 1%, dibutyl phthalate 20%, XYlink 740M 4%, MT PLUS 0.5% into the kettle and stir Evenly, heat up to 90°C, dehydrate under the condition of vacuum degree -0.1MPa, make the moisture below 0.1%, drop the temperature to 60°C, add 2-(2'-hydroxy-3',5'-di-tert-butylphenyl ) 0.5% benzotriazole, 0.5% isooctyl 3,5-di-tert-butyl-4-hydroxyphenylpropionate, 0.8% BYK-024, 0.7% CUCAT-TM and stir for 30 minutes to obtain the product of component A;

[0046] Preparation of component B materials: add DL-2000 70% to the reaction kettle, stir and heat up to 100°C, dehydrate under the condition of -0.1MPa, and use moisture below 0.05%. Then cool down to 50°C, add HDI biuret polyisocyanate 30%, react at 85°C for 2 hours, cool down to 50°C, add 20 ppm of benzoyl chloride, stir for 20 minutes, and then pack into barrels to obtain component B product;

[0047] When using, mix components A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com