Upper insulating plate of cylindrical-structured lithium battery

A technology for insulating plates and lithium batteries, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of uneven liquid absorption of cells, uneven electrolyte injection and absorption, and poor electrolyte absorption, etc. Solve the absorption problem and improve the effect of the absorption problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

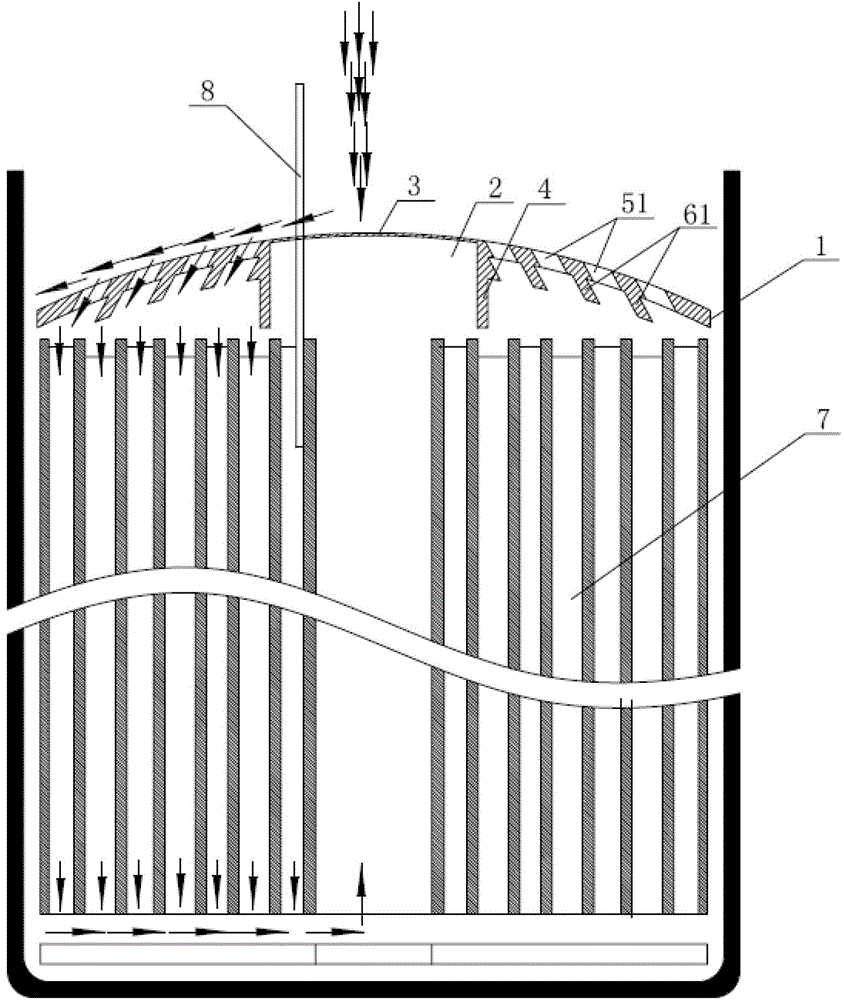

[0022] In this embodiment, the upper insulating plate of the present invention is applied to a 14500 lithium battery with a cylindrical structure of a wound cell.

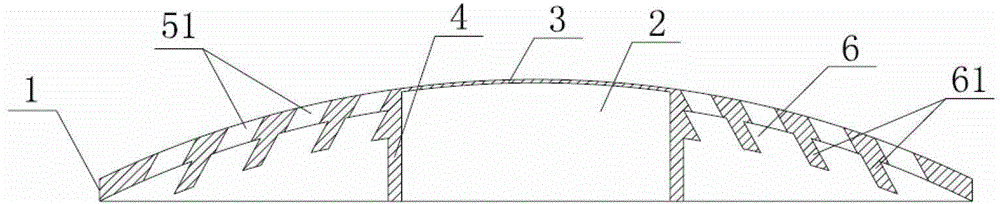

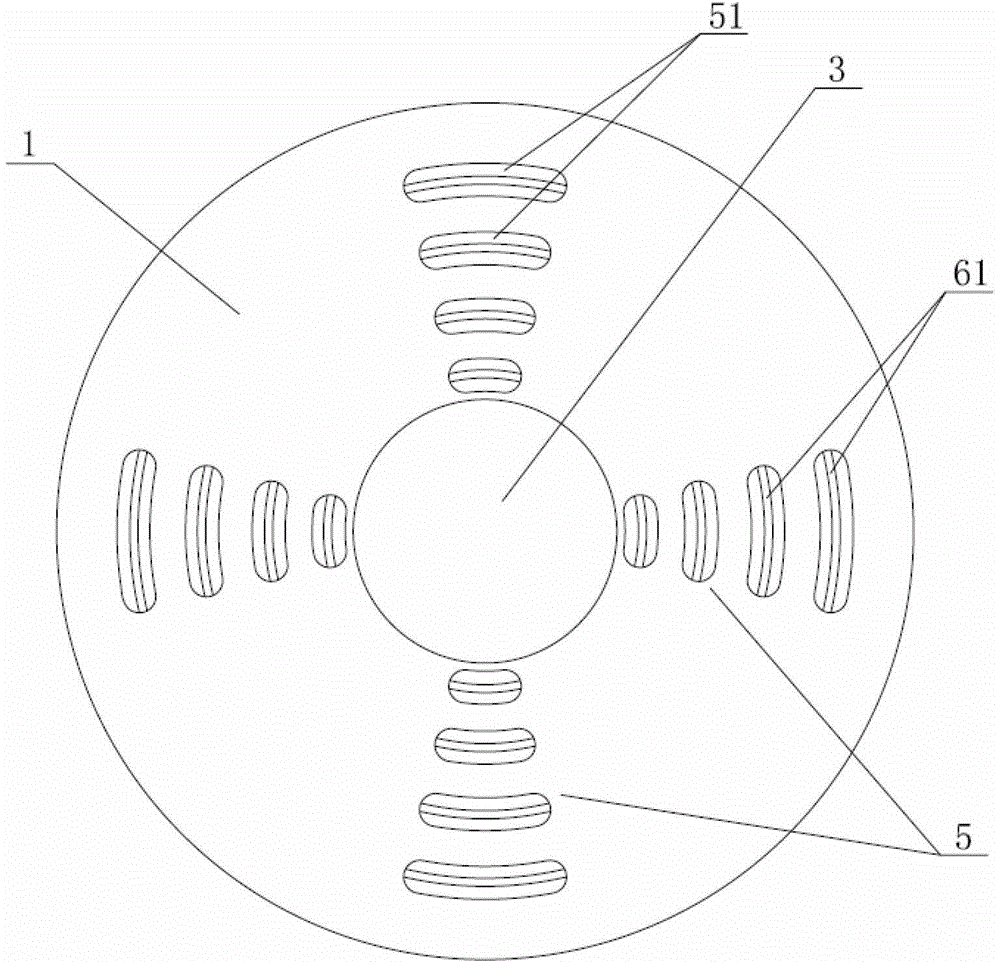

[0023] The upper insulating plate is made of nylon material by injection molding process. Its structure is shown in the figure. The upper insulating plate includes an arched upper insulating plate body 1 with a spherical surface. The upper insulating plate body 1 is provided with lithium supply The central hole 2 through which the battery positive electrode tab 8 passes. The upper part of the central hole 2 is covered with a film 3 for the lithium battery positive electrode tab 8 to pierce; a cylindrical baffle 4 is provided downwards along the circumferential direction of the central hole 2. The insulating plate main body 1 is provided with a plurality of sets of diffusion oblique hole groups 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com