Improved textile machine with dust removal function

An improved, textile machine technology, applied in textiles and papermaking, mechanical cleaning, dispersed particle separation, etc., can solve problems such as worker health hazards, impact on workers' working environment, and inability to achieve better control of dust adsorption and removal effects. Achieve the effect of reducing employee workload and speeding up production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

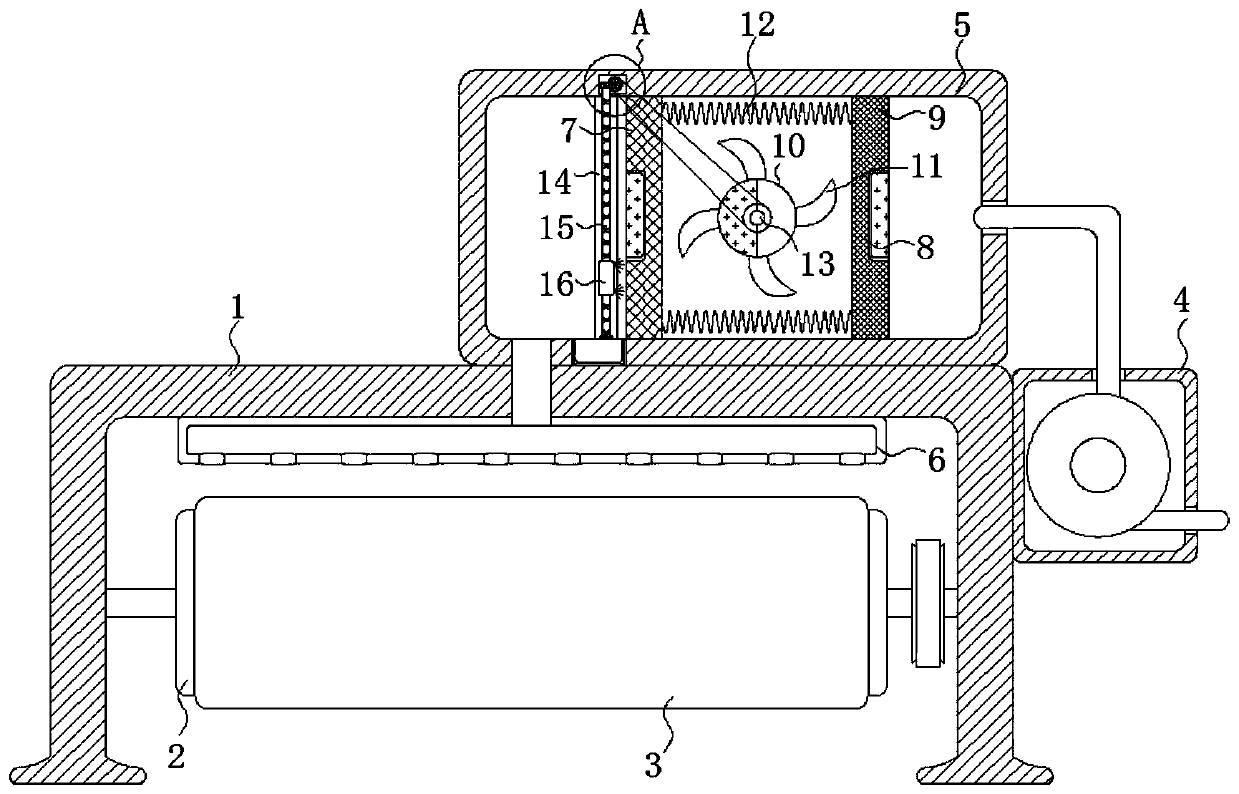

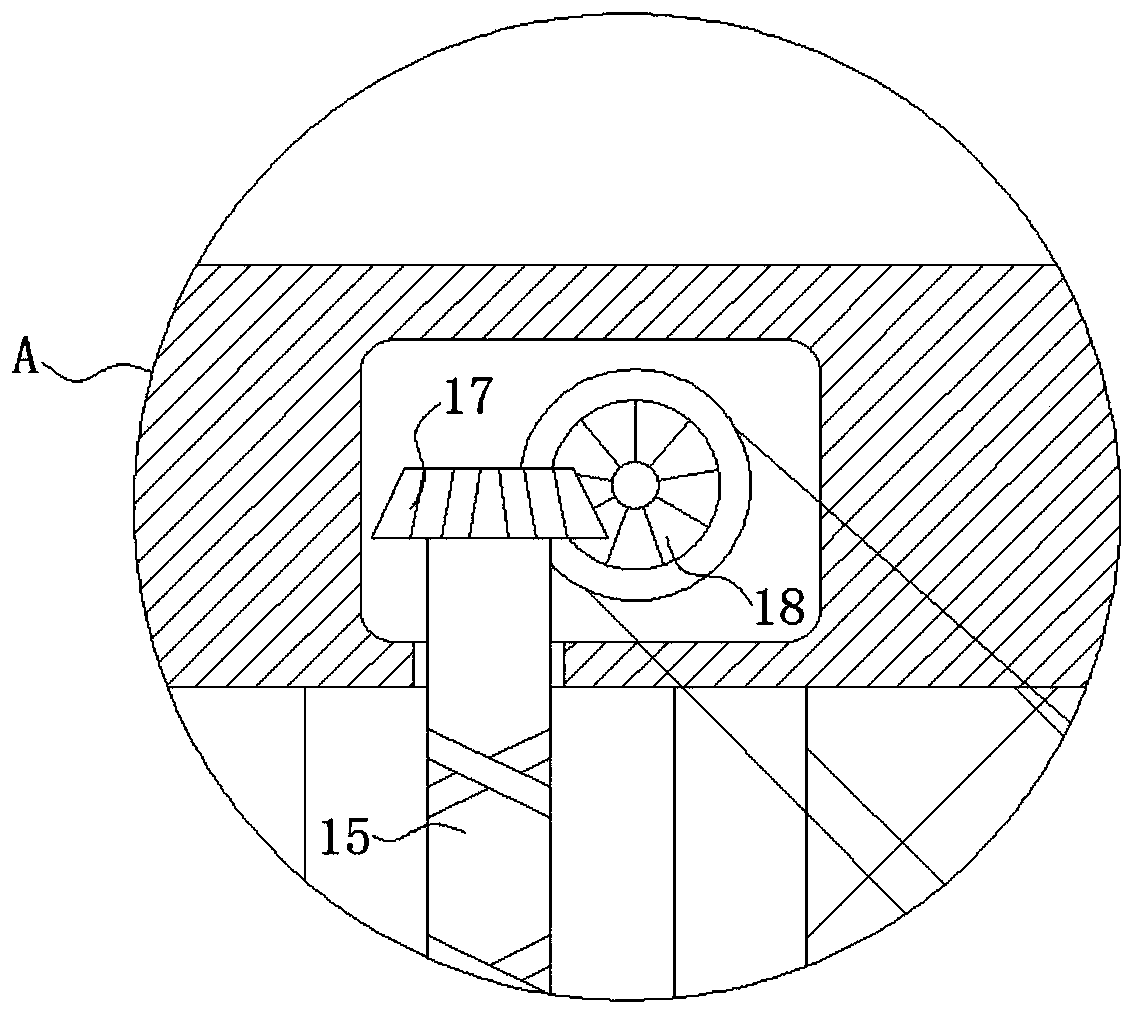

[0029] refer to Figure 1-4 , an improved textile machine with dust removal function, comprising a frame 1, a driving roller 2 is rotatably connected to the inner side wall of the frame 1, an air conveyor 4 is fixedly connected to the outer side wall of the frame 1, and an upper end side of the frame 1 is fixedly connected There is a dust removal box 5, and the airflow conveyor 4 communicates with the side wall of the dust removal box 5 through two connecting pipes. The two connecting pipes are close to the side wall of the dust removal box 5. Located directly above the textile cloth 3, the inner wall of the dust removal box 5 is symmetrically slidingly connected with a first filter screen 7 and a second filter screen 9, the mesh of the first filter screen 7 is larger than that of the second filter screen 9, and the second filter screen 9 Fine dust can be adsorbed and cleaned to prevent it from floating into the air. The opposite side walls of the first filter screen 7 and the...

Embodiment 2

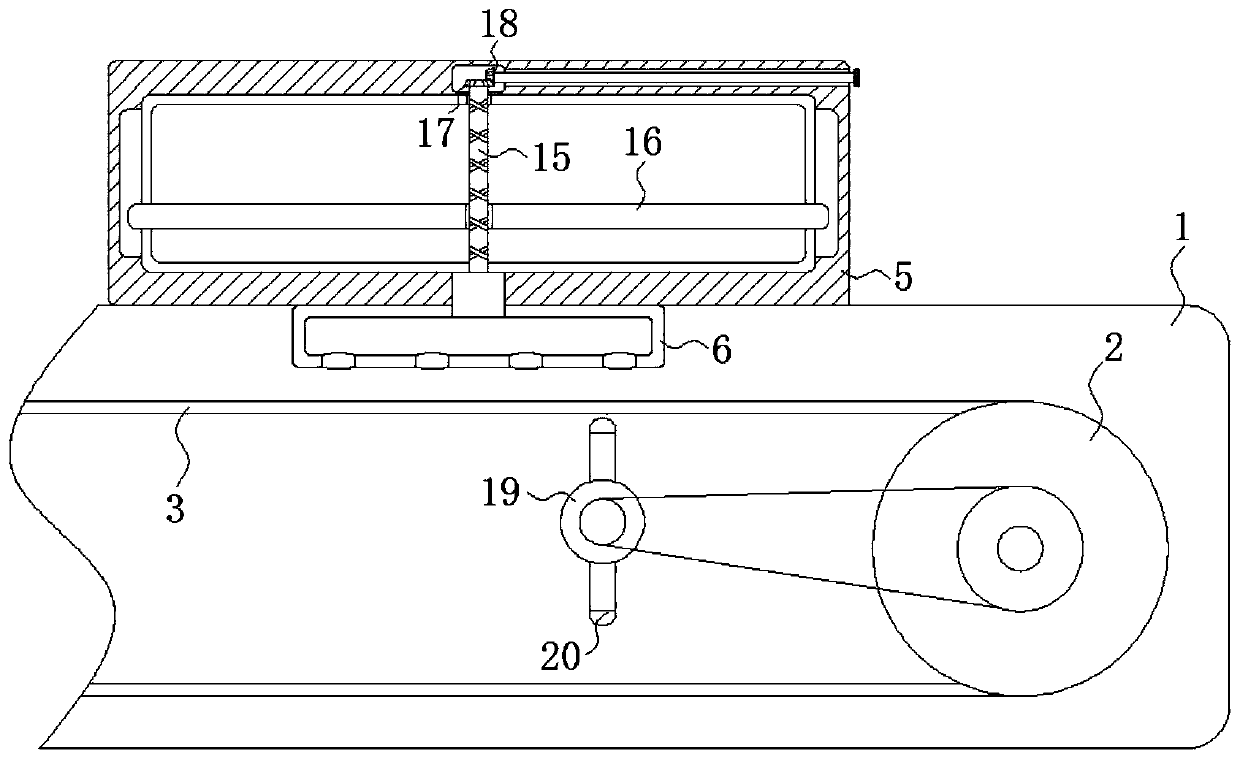

[0036] refer to Figure 5-6 , and the difference from Embodiment 1 is that the opposite inner wall of the dust removal box 5 is fixedly connected with the adsorption cylinder 21, and the adsorption cylinder 21 is coaxially sleeved on the connecting rod 13, and the inner wall of the adsorption cylinder 21 is embedded with a glass plate. The rod 13 is located on the side wall of the adsorption cylinder 21 and is fixedly connected with a plurality of crossbars 23 at equal intervals along its circumference. Block 22, the bonding surface of arc-shaped block 22 and the glass plate wraps the silk layer, and the friction between the silk layer and the glass block can generate static electricity to absorb the fine dust flowing out from the mesh of the first filter screen 7. On the connecting rod 13 A second cleaning device for cleaning the adsorption cylinder 21 is installed. The second cleaning device includes two L-shaped brackets 24 that are symmetrically fixedly connected to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com