Patents

Literature

40 results about "Equivalent spherical diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In science, the equivalent spherical diameter (or ESD) of an irregularly shaped object is the diameter of a sphere of equivalent volume. According to the IUPAC definition, the equivalent diameter of a non-spherical particle is equal to a diameter of a spherical particle that exhibits identical properties (e.g., aerodynamic, hydrodynamic, optical, electrical) to that of the investigated non-spherical particle. For particles in non-turbulent motion, the equivalent diameter is identical to the diameter encountered in the Stokes' law.

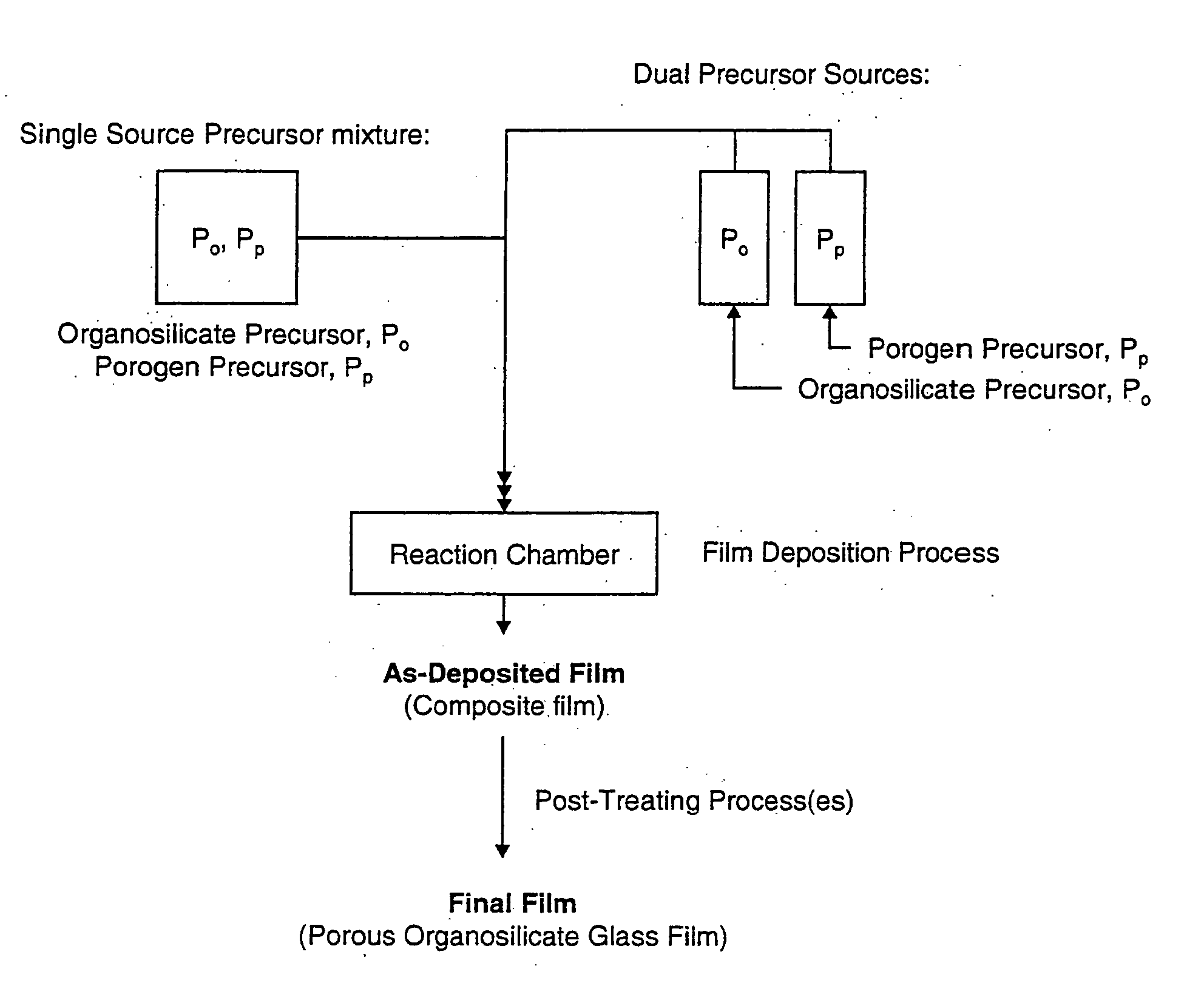

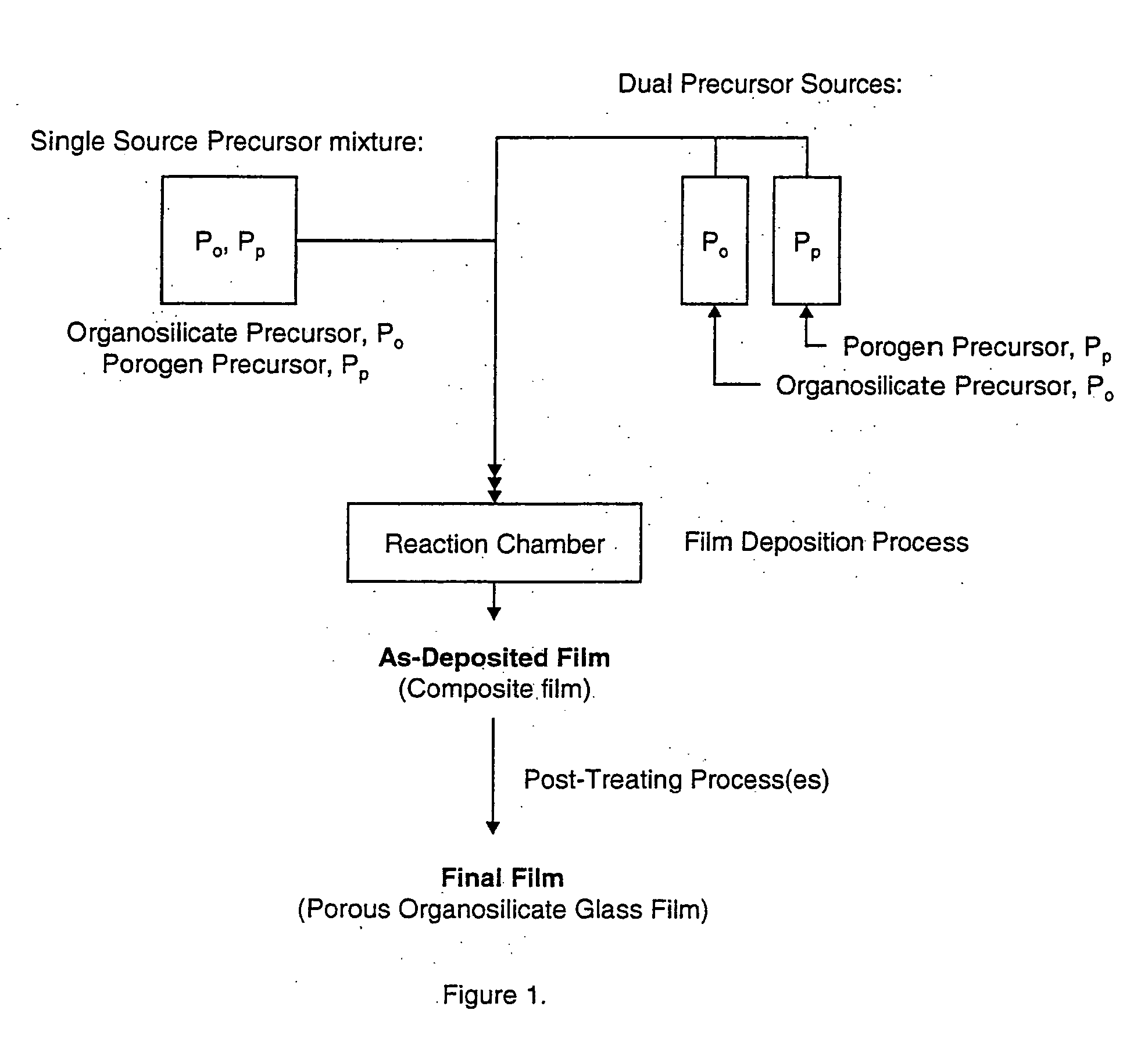

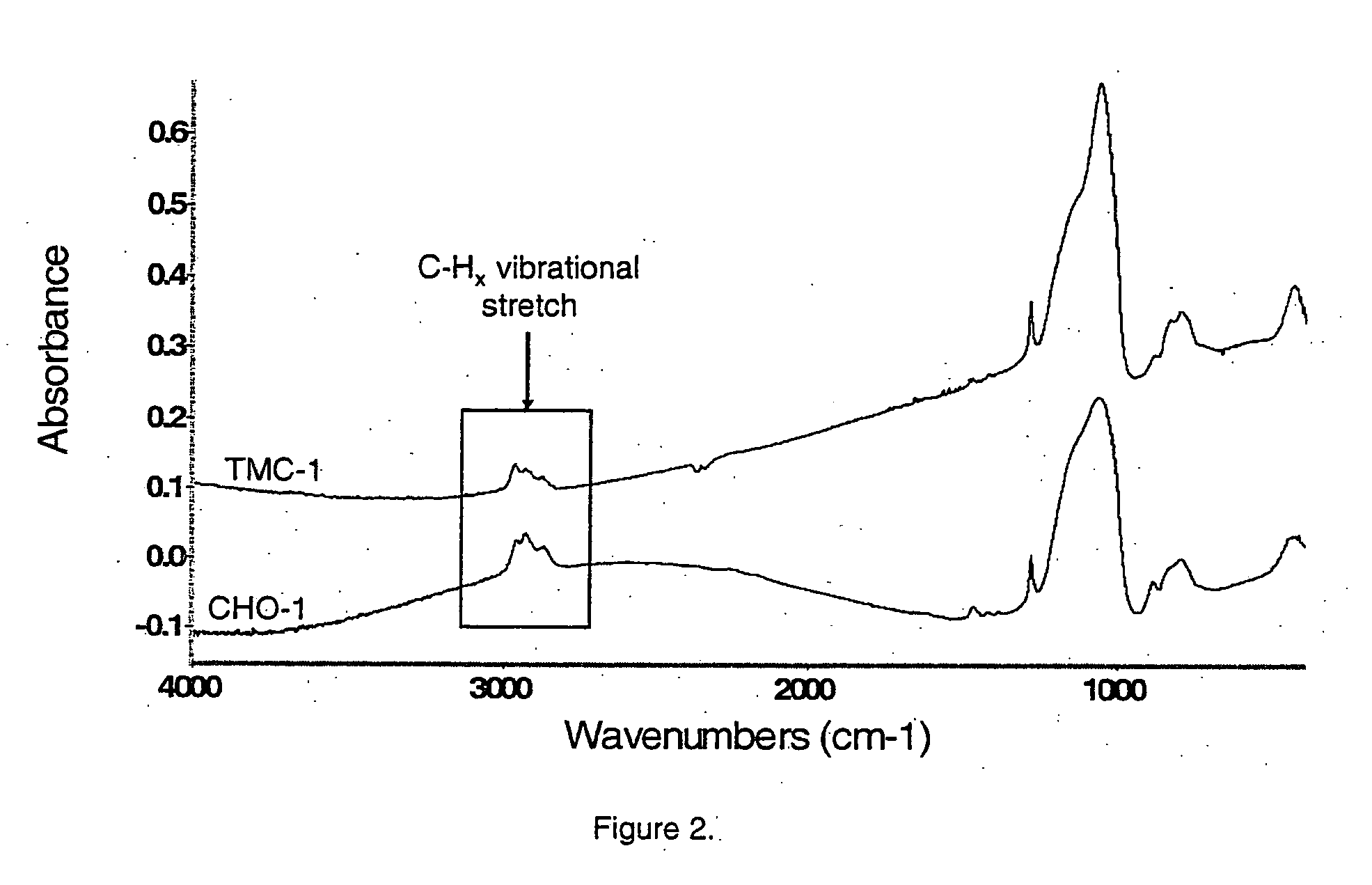

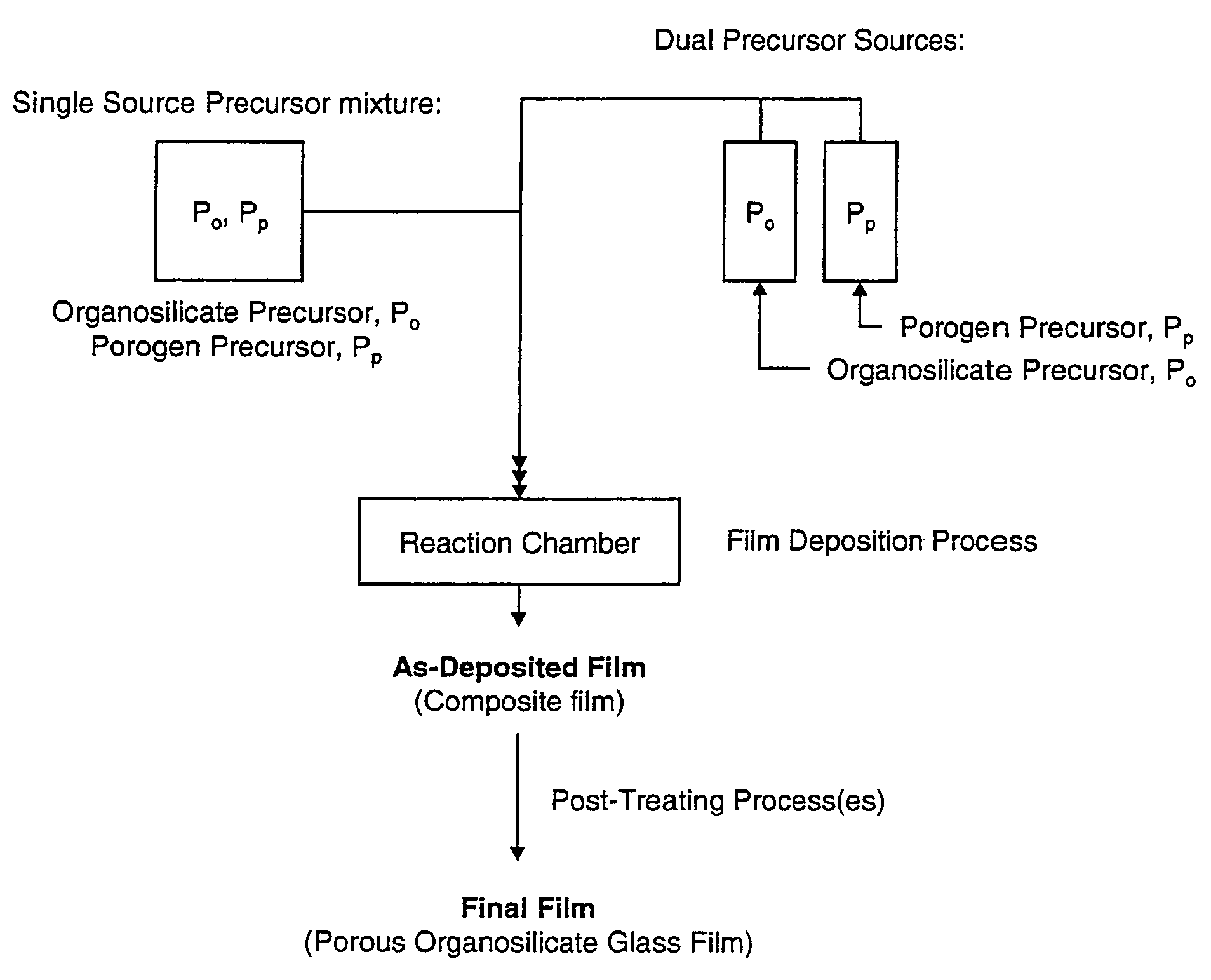

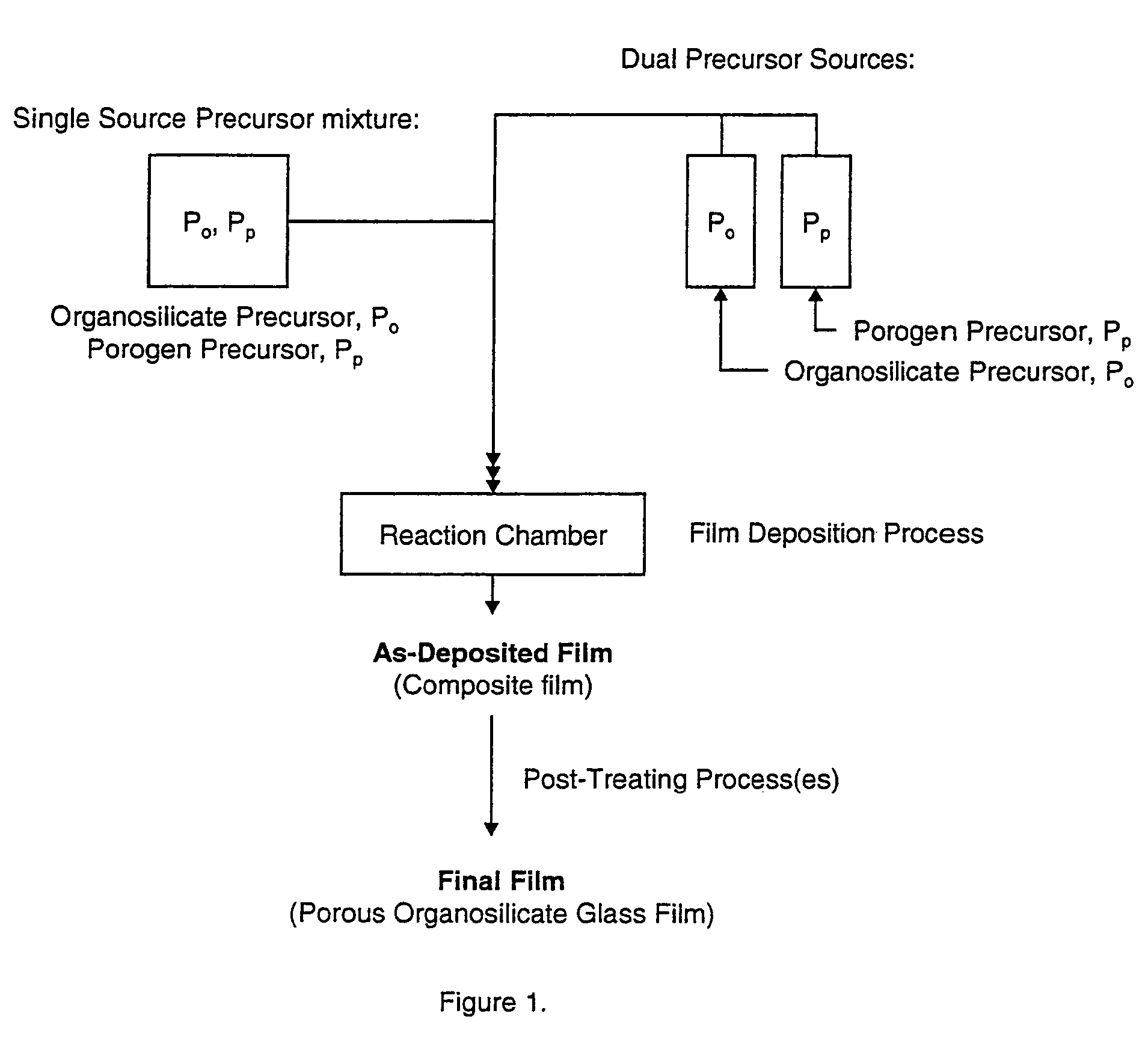

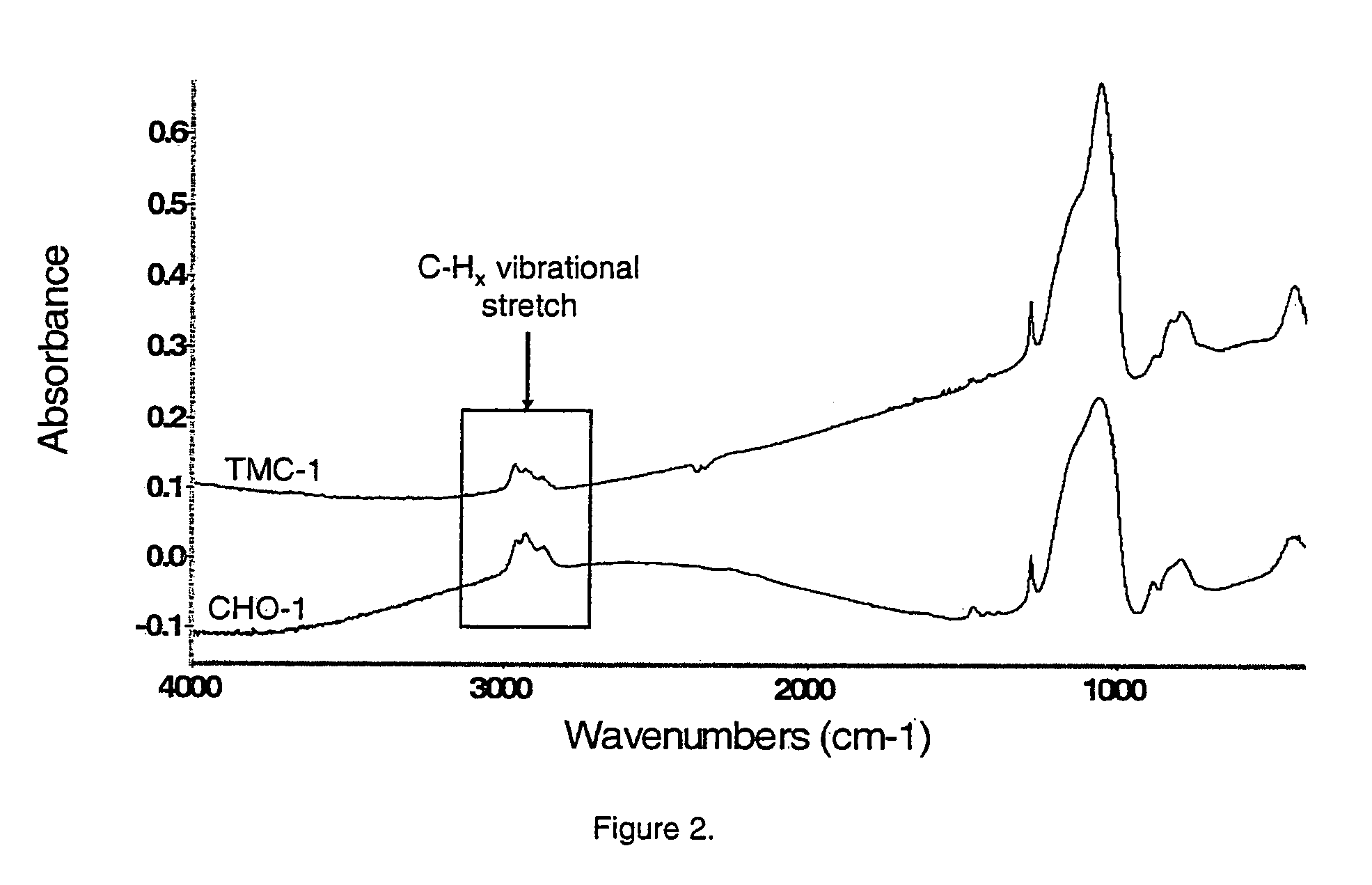

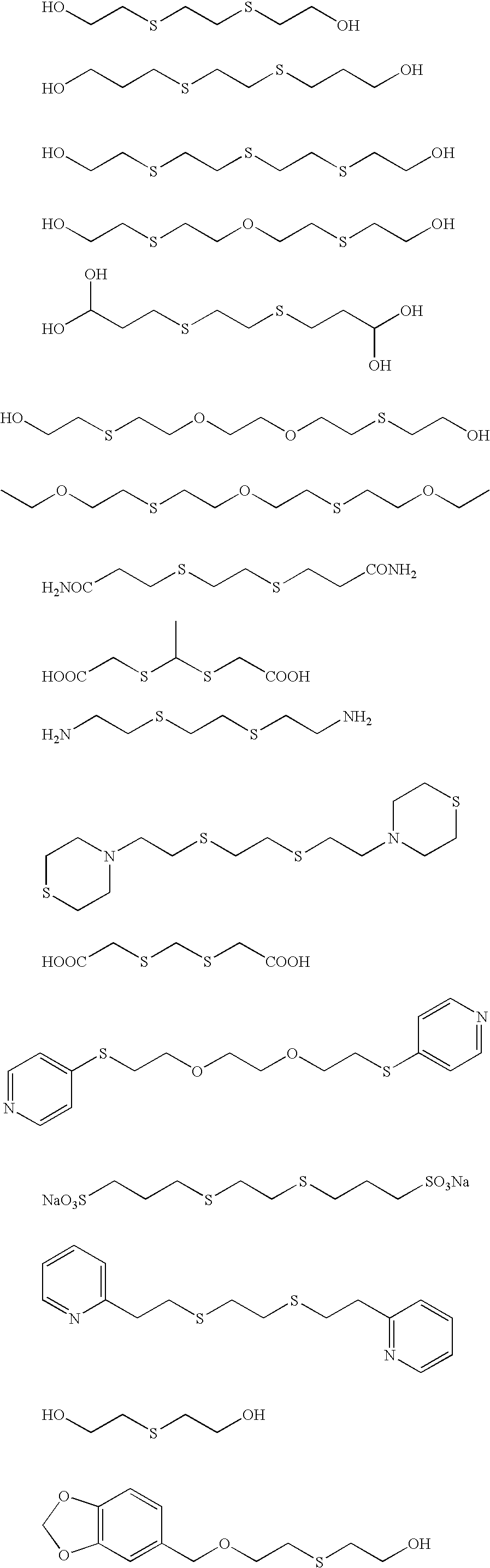

Porous low dielectric constant compositions and methods for making and using same

ActiveUS20060078676A1Semiconductor/solid-state device manufacturingPretreated surfacesConstant compositionCarboxylic acid

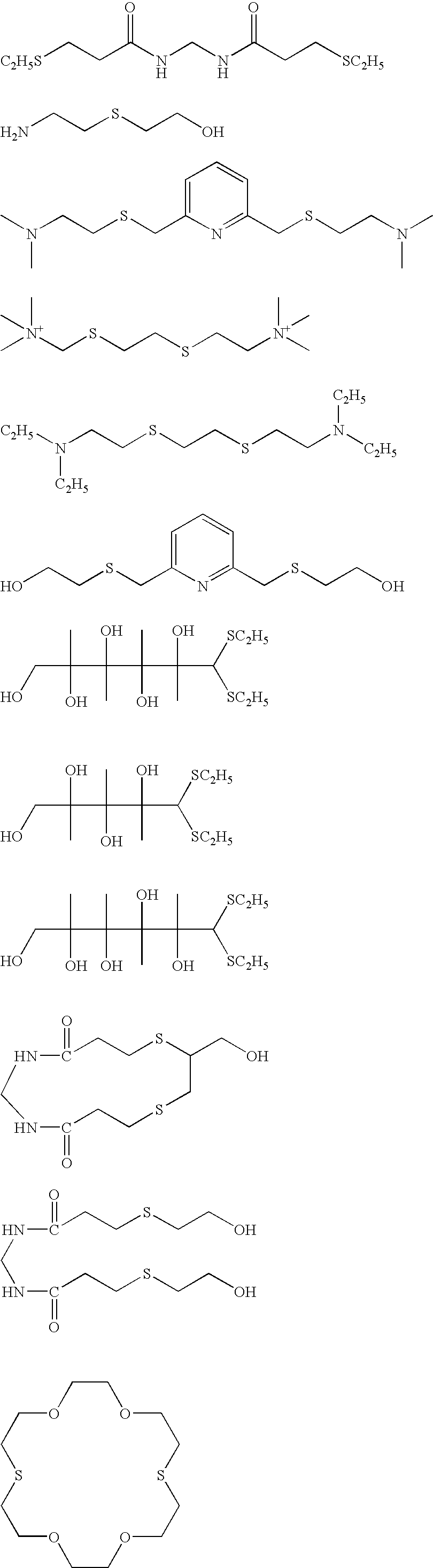

A porous organosilicate glass (OSG) film: SivOwCxHyFz, where v+w+x+y+z=100%, v is 10 to 35 atomic %, w is 10 to 65 atomic %, x is 5 to 30 atomic %, y is 10 to 50 atomic % and z is 0 to 15 atomic %, has a silicate network with carbon bonds as methyl groups (Si—CH3) and contains pores with diameter less than 3 nm equivalent spherical diameter and dielectric constant less than 2.7. A preliminary film is deposited by a chemical vapor deposition method from organosilane and / or organosiloxane precursors, and independent pore-forming precursors. Porogen precursors form pores within the preliminary film and are subsequently removed to provide the porous film. Compositions, film forming kits, include organosilane and / or organosiloxane compounds containing at least one Si—H bond and porogen precursors of hydrocarbons containing alcohol, ether, carbonyl, carboxylic acid, ester, nitro, primary amine, secondary amine, and / or tertiary amine functionality or combinations.

Owner:VERSUM MATERIALS US LLC

Porous low dielectric constant compositions and methods for making and using same

Owner:VERSUM MATERIALS US LLC

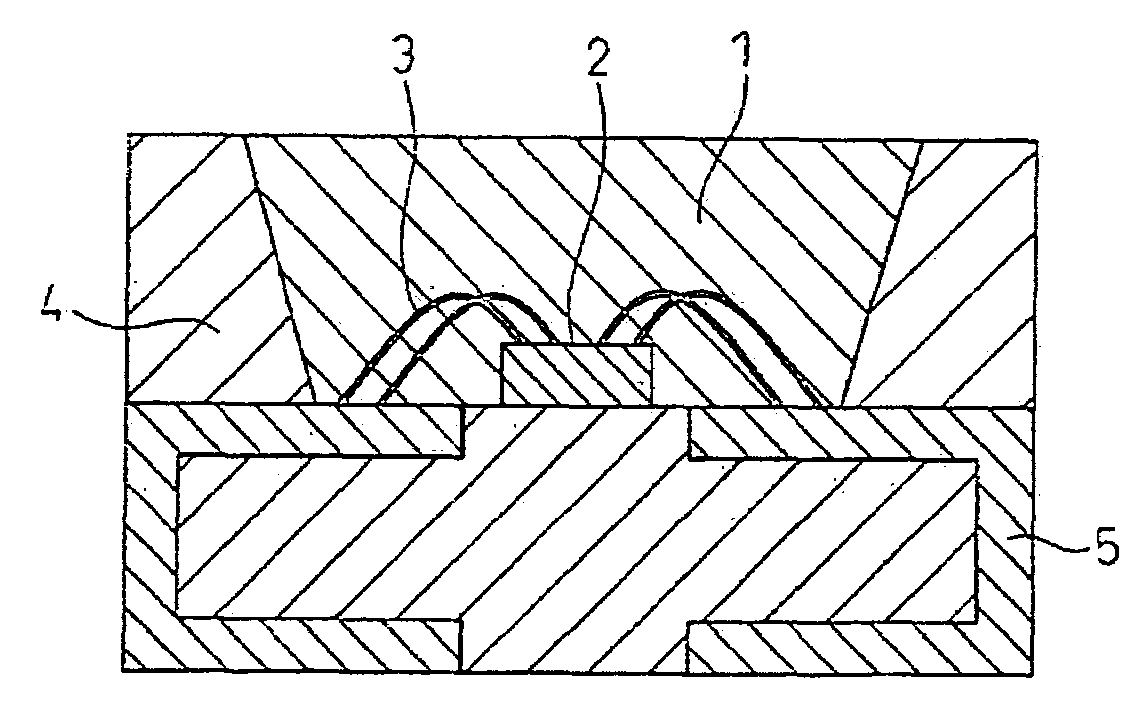

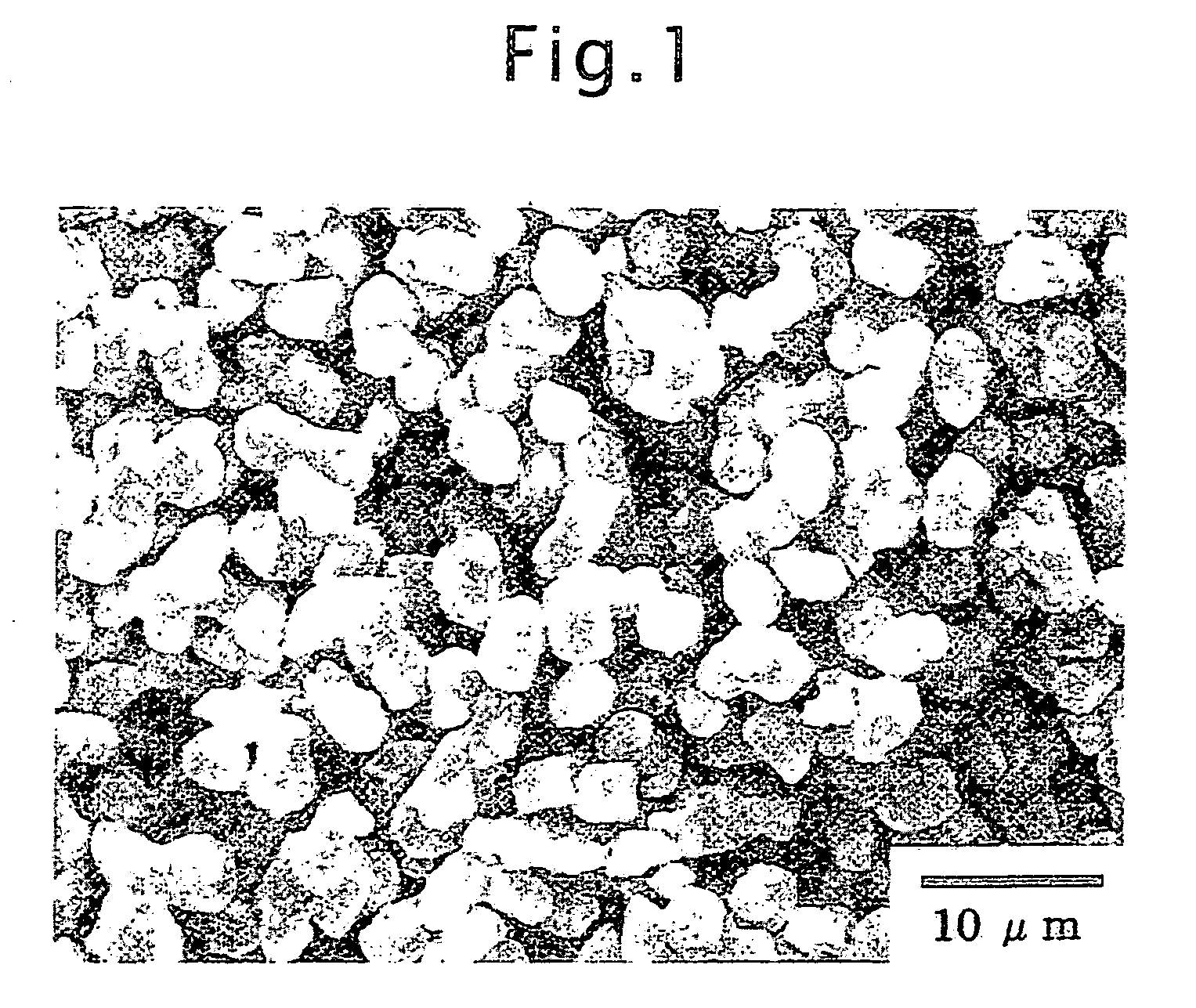

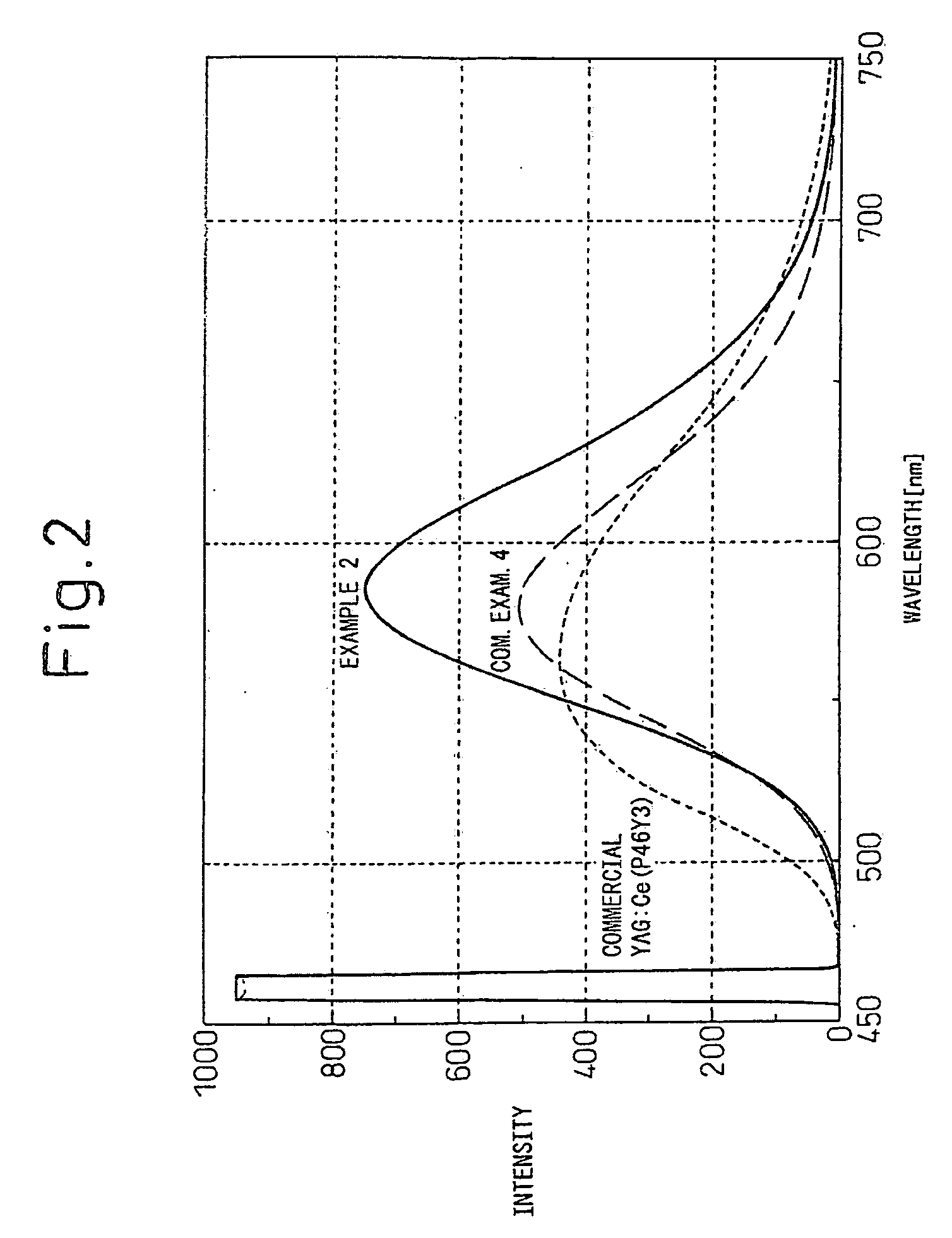

Sialon-based oxynitride phosphor and production method thereof

InactiveUS20090284948A1Prevent excessive aggregationLess fusionDischarge tube luminescnet screensElectric discharge tubesLanthanideElectron

The present invention relates to an oxynitride phosphor comprising an α-sialon as the main component, which is represented by the general formula: MxSi12−(m+n)Al(m+n)OnN16−n:Lny (wherein 0.3≦x+y<1.5, 0<y<0.7, 0.3≦m<4.5, 0<n<2.25, and assuming that the atomic valence of the metal M is a and the atomic valence of the lanthanide metal Ln is b, m=ax+by) and in which the aggregation index, A1=D50 / DBET≦3.0 or the aggregation index A2=D50 / Dparticle≦3.0; and a production method and usage of the phosphor.The phosphor of the present invention has less aggregation and a narrow particle size distribution, and therefore is easy to uniformly mix with a resin or the like, and a high-brightness white LED can be easily obtained.D50 [μm]: The median diameter in the grain size distribution curve.DBET [μm]: The equivalent-sphere diameter calculated on the basis of a BET specific surface area.Dparticle [μm]: The primary particle diameter measured by the image analysis of a scanning electron micrograph.

Owner:UBE IND LTD

Weight material for drilling fluids and method of creating and maintaining the desired weight

InactiveUS6180573B1Prevent inflowImprove performanceOther chemical processesFlushingVolumetric Mass DensityEquivalent spherical diameter

Drilling fluid additives are designed to increase the density of drilling fluids while minimizing the increase in the resistance to flow of the drilling fluid. In particular, barite particles are added to the drilling fluid as a weight material where the barite particles include at least 85% by weight particles less than 75 microns and greater than 6 microns in equivalent spherical diameter.

Owner:HALLIBURTON ENERGY SERVICES INC

Weight material for drilling fluids and method of creating and maintaining the desired weight

InactiveUS6548452B1Prevent inflowImprove performanceDrilling compositionBorehole/well accessoriesVolumetric Mass DensityEquivalent spherical diameter

Owner:HALLIBURTON ENERGY SERVICES INC

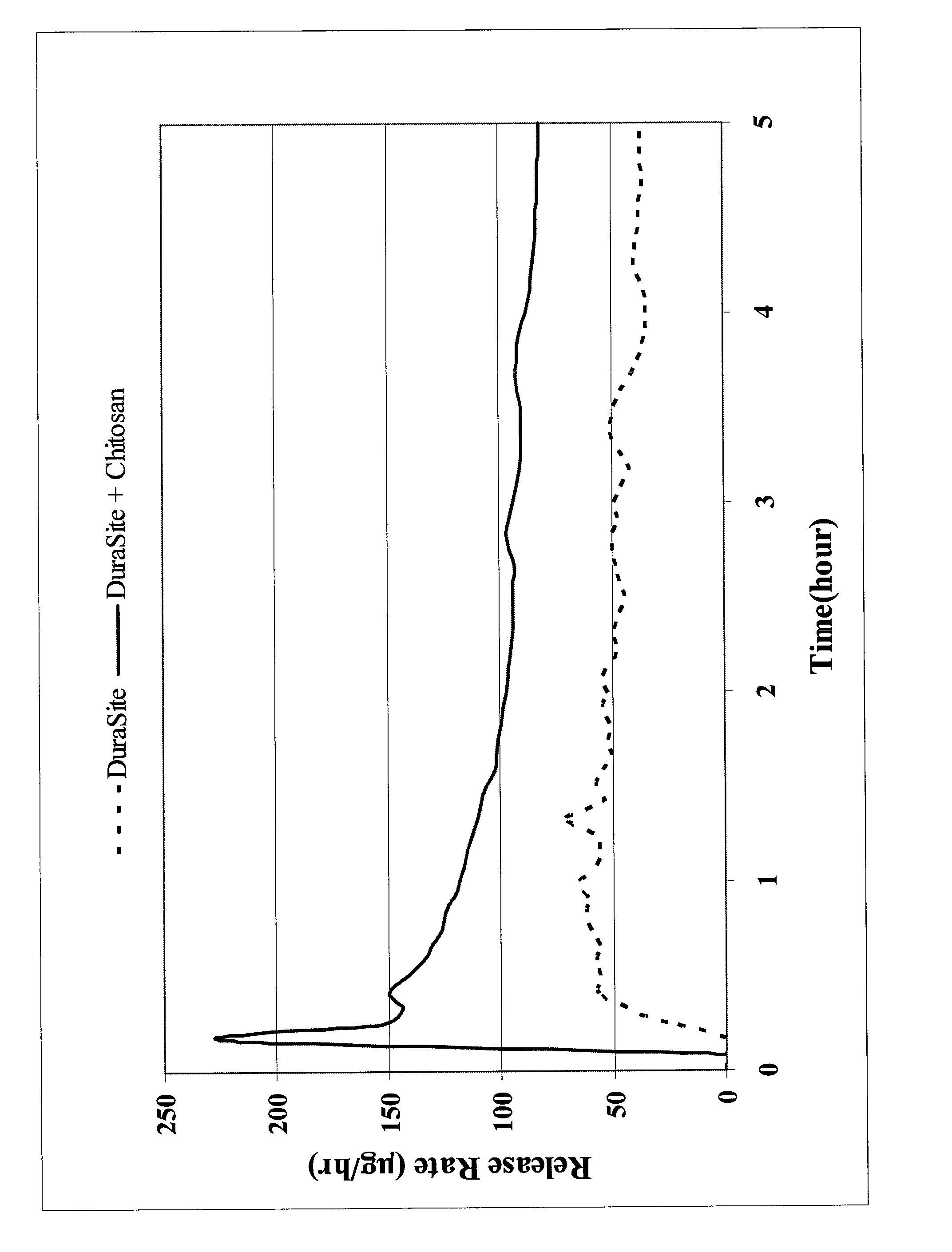

Controlled-release ophthalmic vehicles

An ophthalmically acceptable vehicle includes an aqueous suspension having a first viscosity. The suspension includes about 0.1% to about 6.5% by weight of a carboxyl-containing polymer prepared by polymerizing one or more carboxyl-containing monoethylenically unsaturated monomers and less than about 5% by weight of a cross-linking agent. The polymer has average particle size of not more than about 50 μm in equivalent spherical diameter. The vehicle includes a second polymer that allows the carboxyl-containing polymer to remain suspended. Upon contact with tear fluid, the vehicle gels to a second viscosity which is greater than the first viscosity. A method of administering a medicament to the eye of a subject includes applying a composition that includes this ophthalmically acceptable vehicle and a medicament contained for treatment of a disease or disorder for which ophthalmic delivery is indicated. The medicament is released from the vehicle in a sustained release manner.

Owner:SUN PHARMA GLOBAL FZE

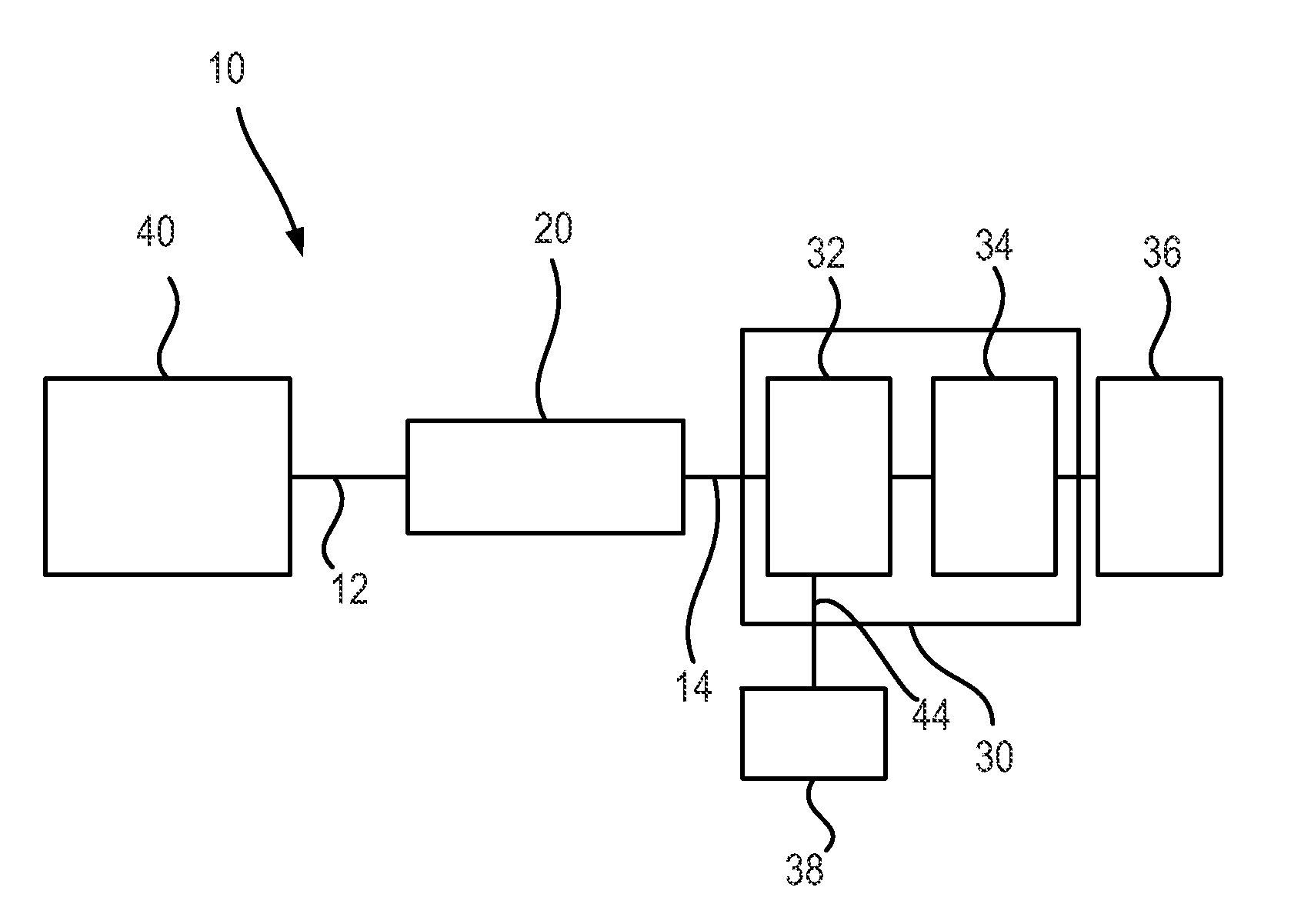

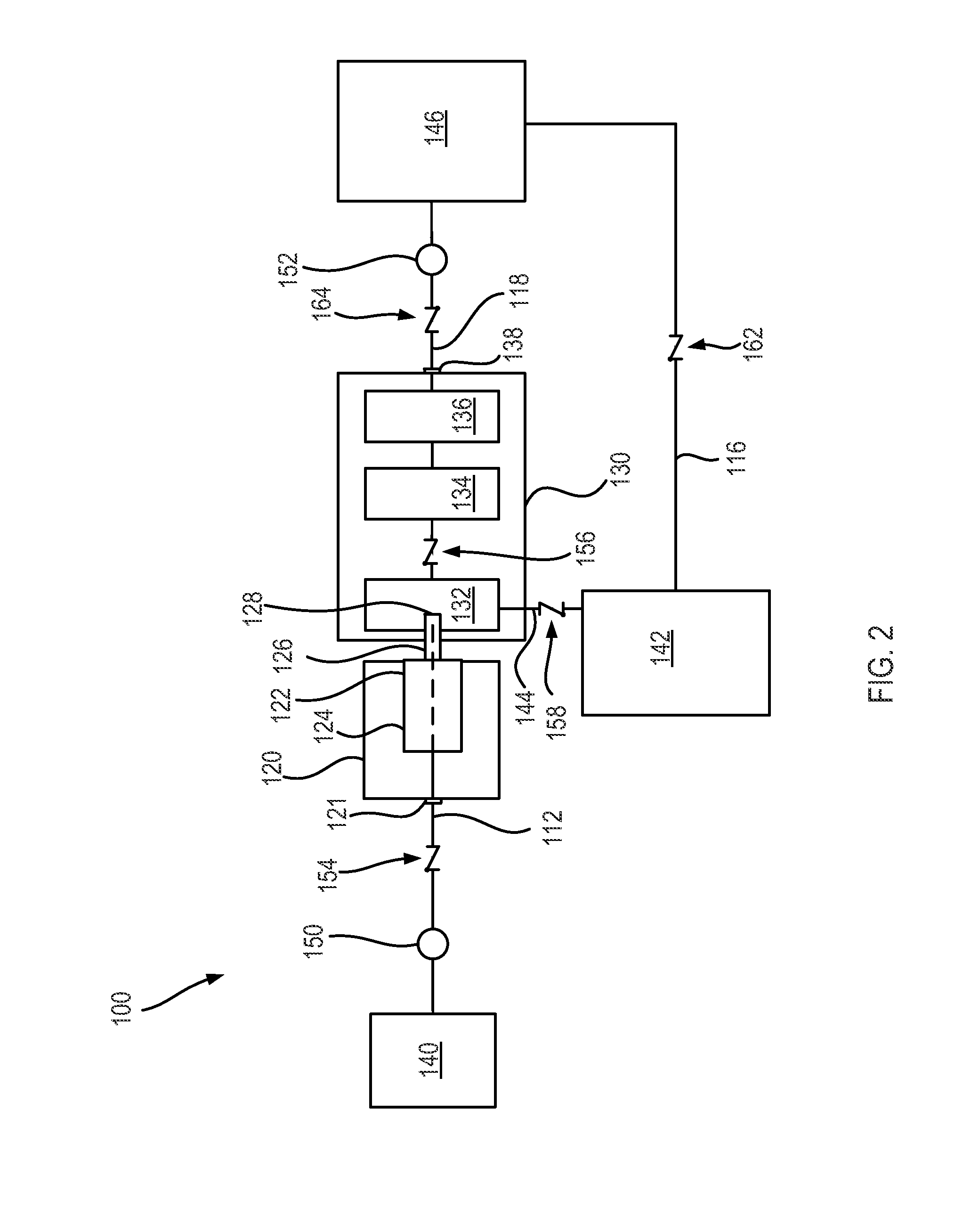

Methods and devices for controlling particle size and particle size distribution

Methods and apparatus for continuously preparing a particulate material are provided. One method of the invention includes mixing a first solution comprising a solute dissolved in a solvent, with a second solution, thereby providing a first solution-second solution mixture; and introducing the mixture into the high-energy zone of a high shear dispersion system and dispersing the first solution-second solution mixture prior to significant particulate growth, whereby the dispersed mixture forms a suspension of particles of the solute; and wherein significant particulate growth has occurred when the average equivalent spherical diameter of at least one particle in the solution is greater than 10 micrometer. Integrated apparatuses for performing methods of the invention are also provided.

Owner:TRAVERS WILLIAM A

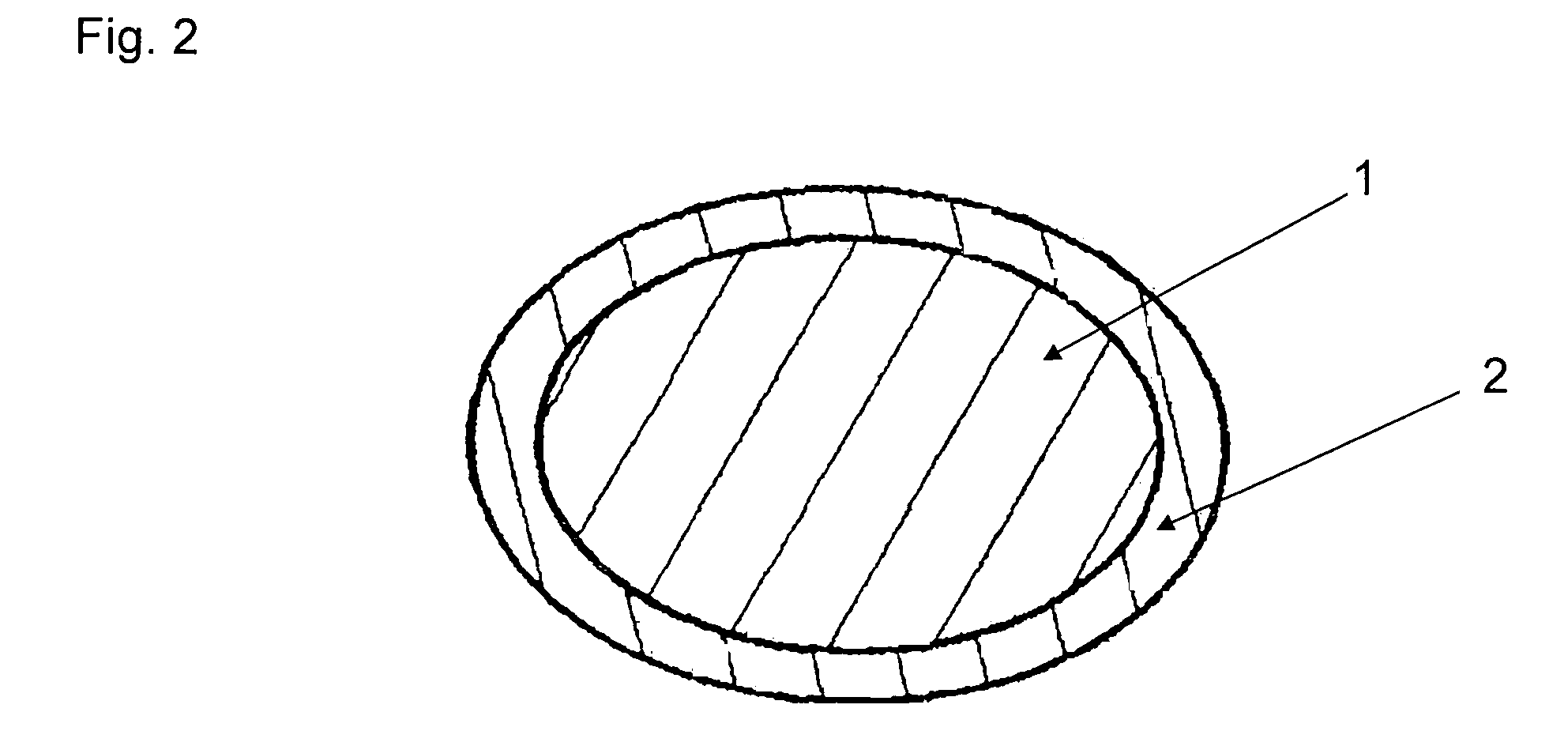

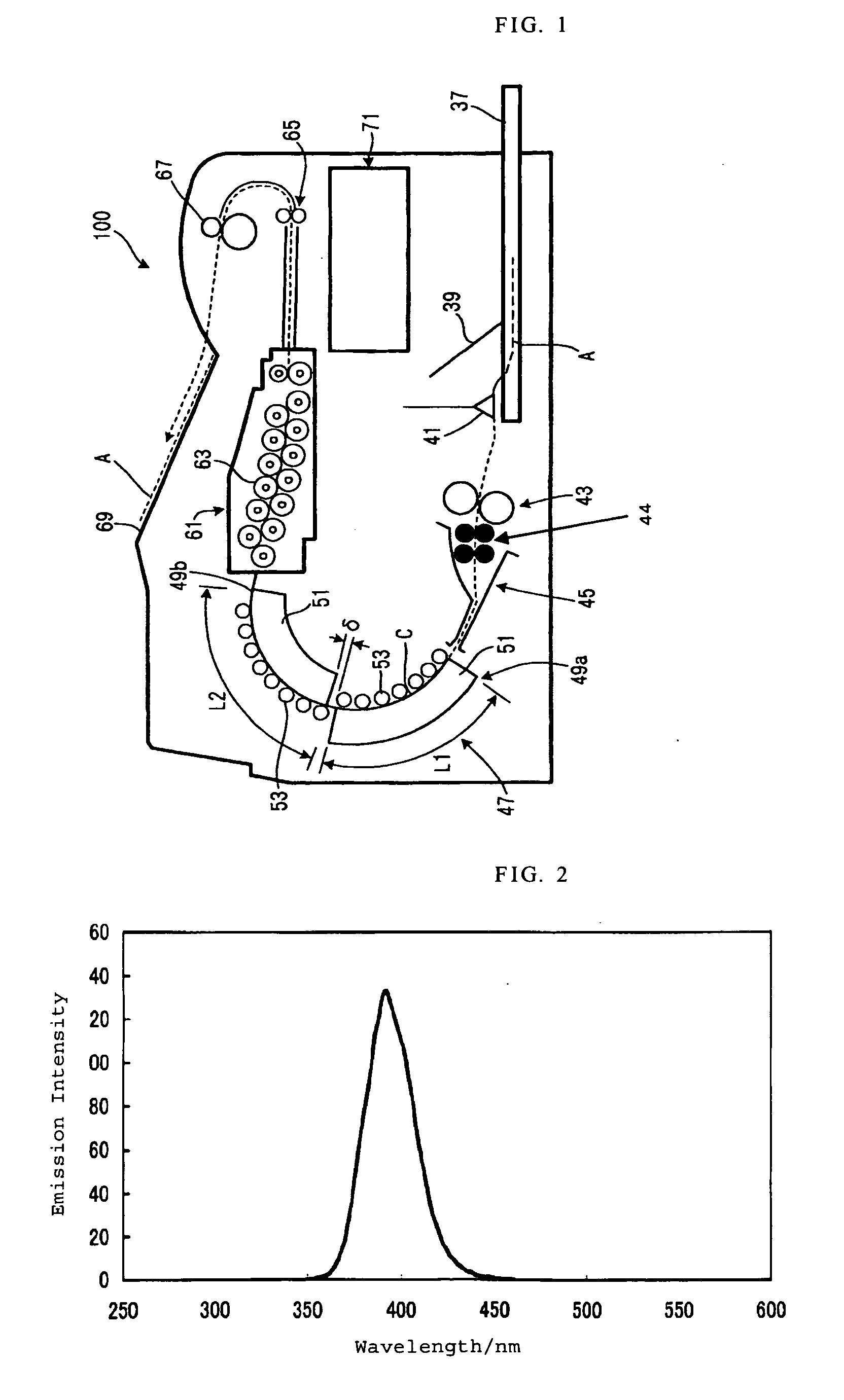

Electroluminescence device having phosphor particles which give donor-acceptor type luminescence

ActiveUS7176616B2Discharge tube luminescnet screensElectroluminescent light sourcesPhosphorEquivalent spherical diameter

An electroluminescence device, including phosphor particles, which phosphor particles give donor-acceptor type luminescence, and have an average equivalent sphere diameter of 1.0 μm or more and 12.0 μm or less and a coefficient of variation of equivalent sphere diameters of 3% or more and 30% or less.

Owner:FUJIFILM CORP +1

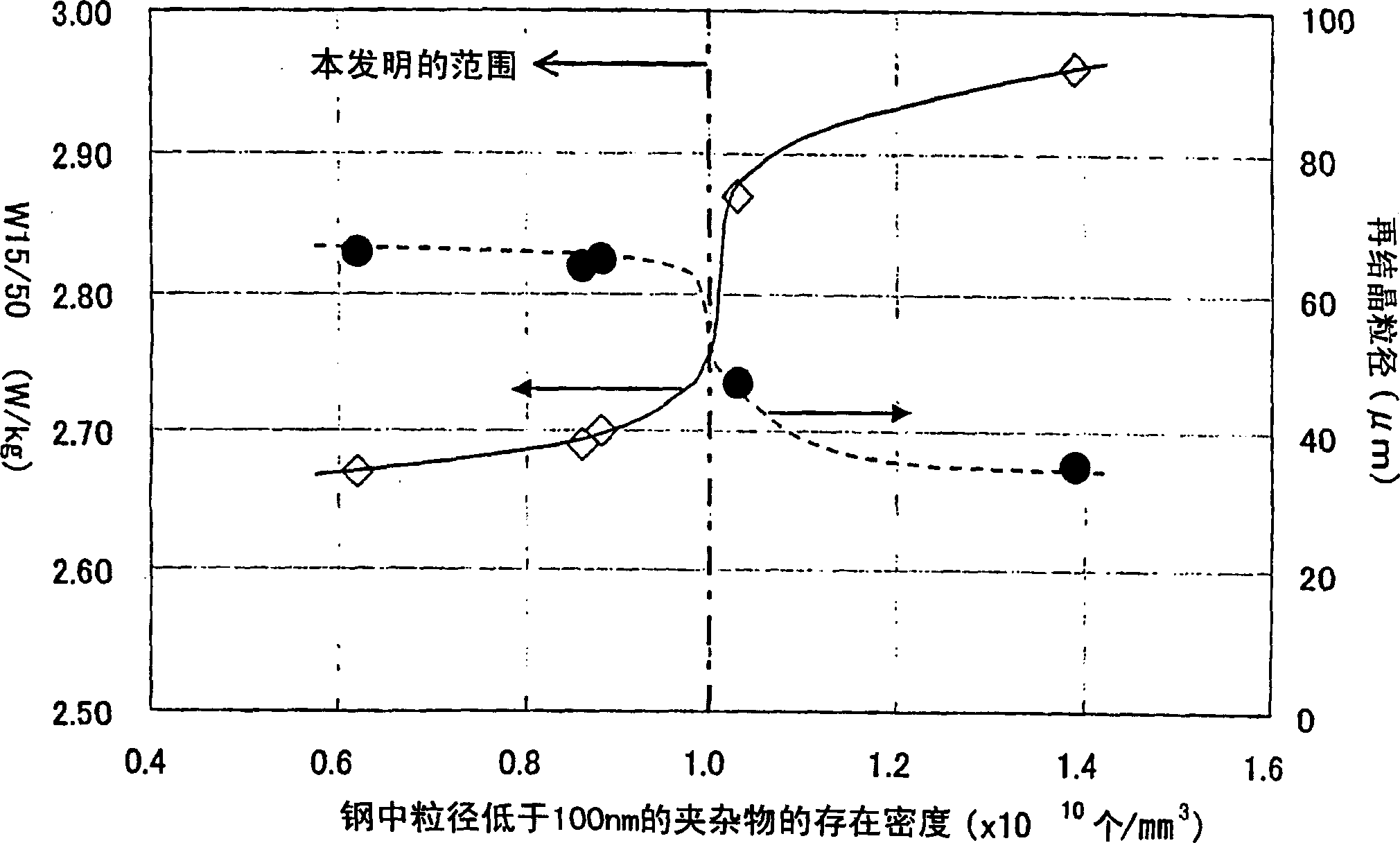

Non-oriented silicon steel sheet having excellent core loss and its production method

ActiveCN1784504AAchieve low iron lossInorganic material magnetismFurnace typesEquivalent spherical diameterSheet steel

A non-oriented electrical steel sheet, characterized in that the number density of inclusions contained in the steel sheet with an equivalent spherical diameter of less than 100 nm is 1 x 1010 [pieces / mm3] or less; furthermore, in mass %, Contains C: 0.01% or less, Si: 0.1% to 7.0%, Al: 0.1% to 3.0%, Mn: 0.1% to 2.0%, REM: 0.0003% to 0.05%, Ti: 0.02% or less, S: 0.005 % or less, and N: 0.005% or less, the balance is composed of Fe and unavoidable impurities, and the mass % of Al represented by [Al], the mass % of N represented by [N], and the mass % of N represented by [Ti ] The mass % of Ti represented by ] satisfies the following formula (1).

Owner:NIPPON STEEL CORP

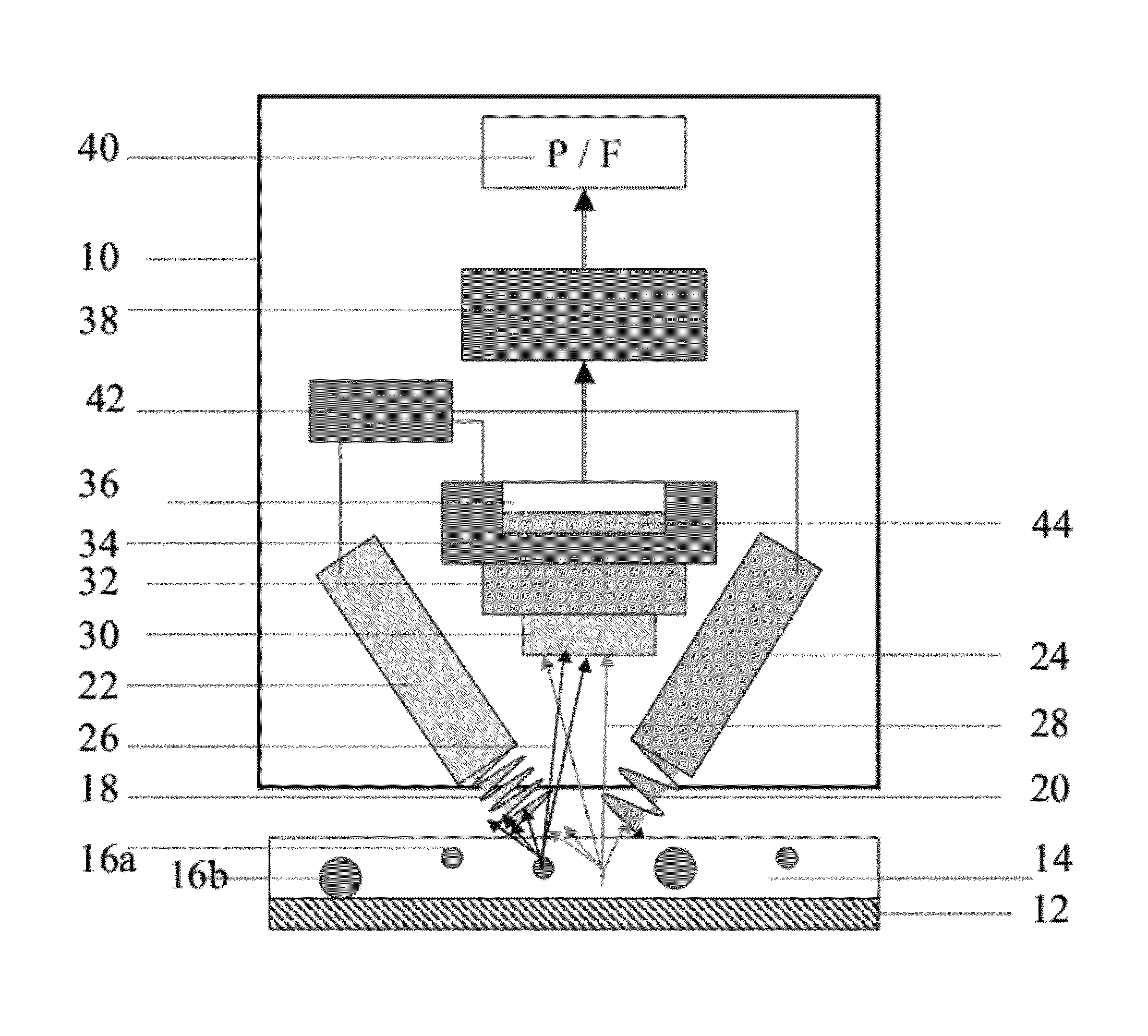

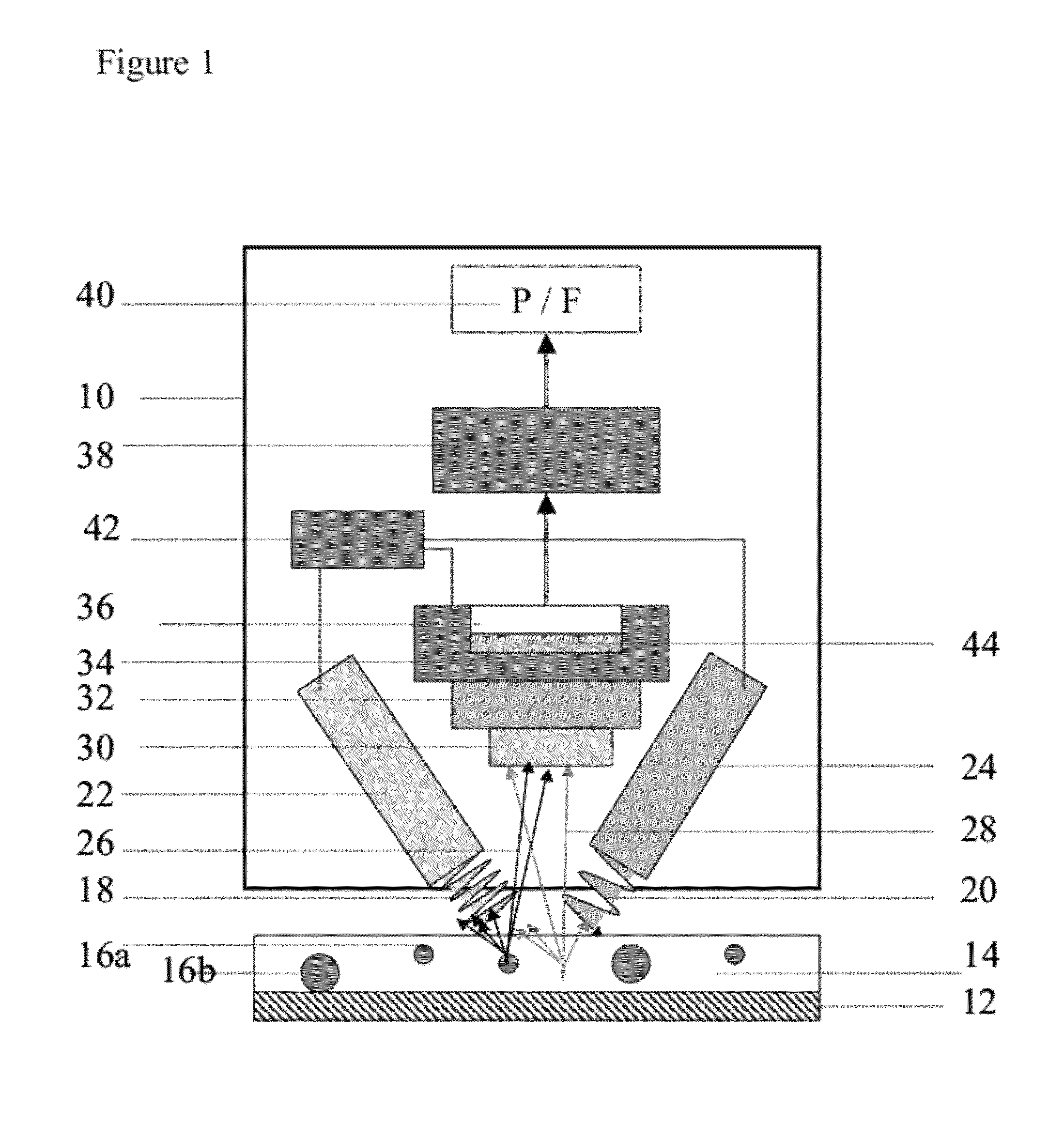

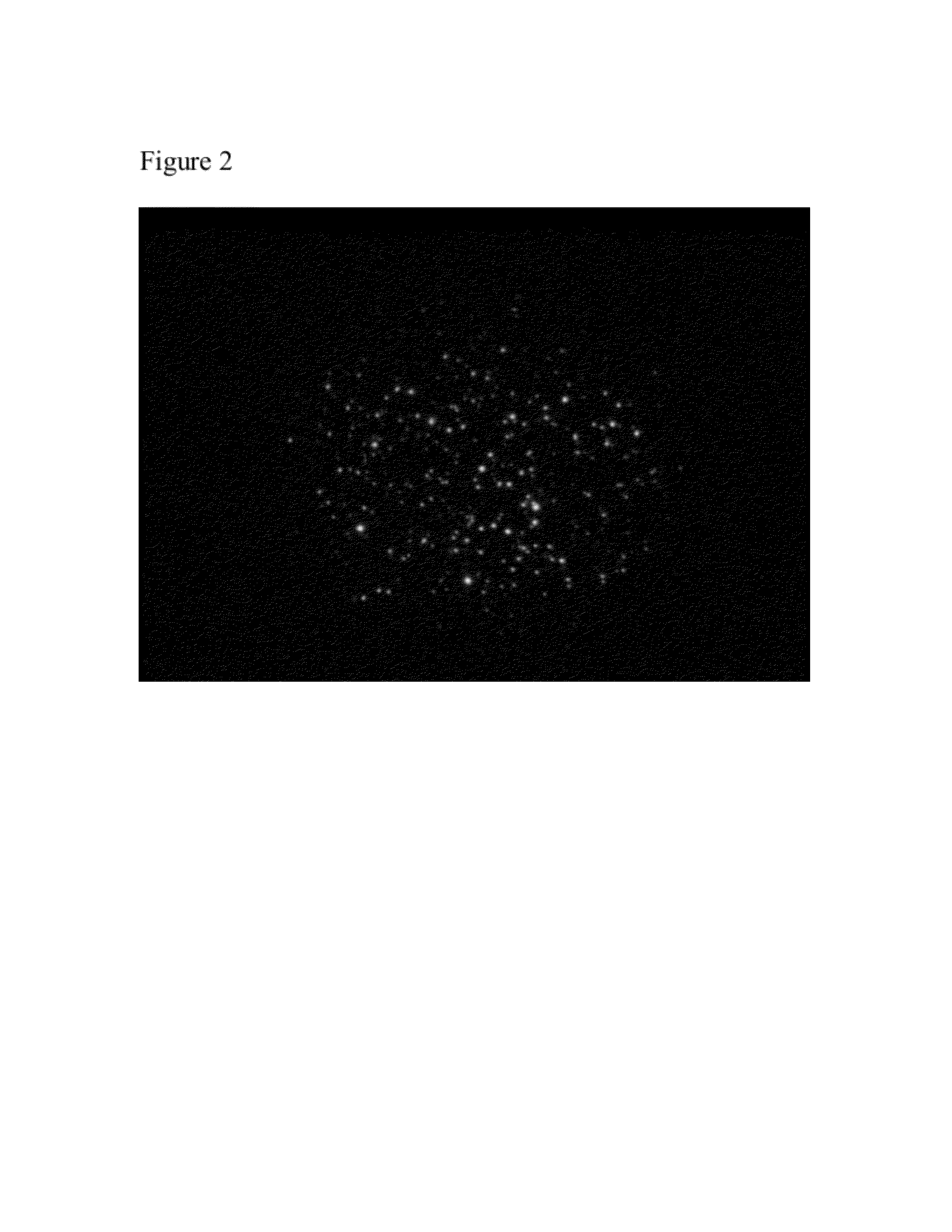

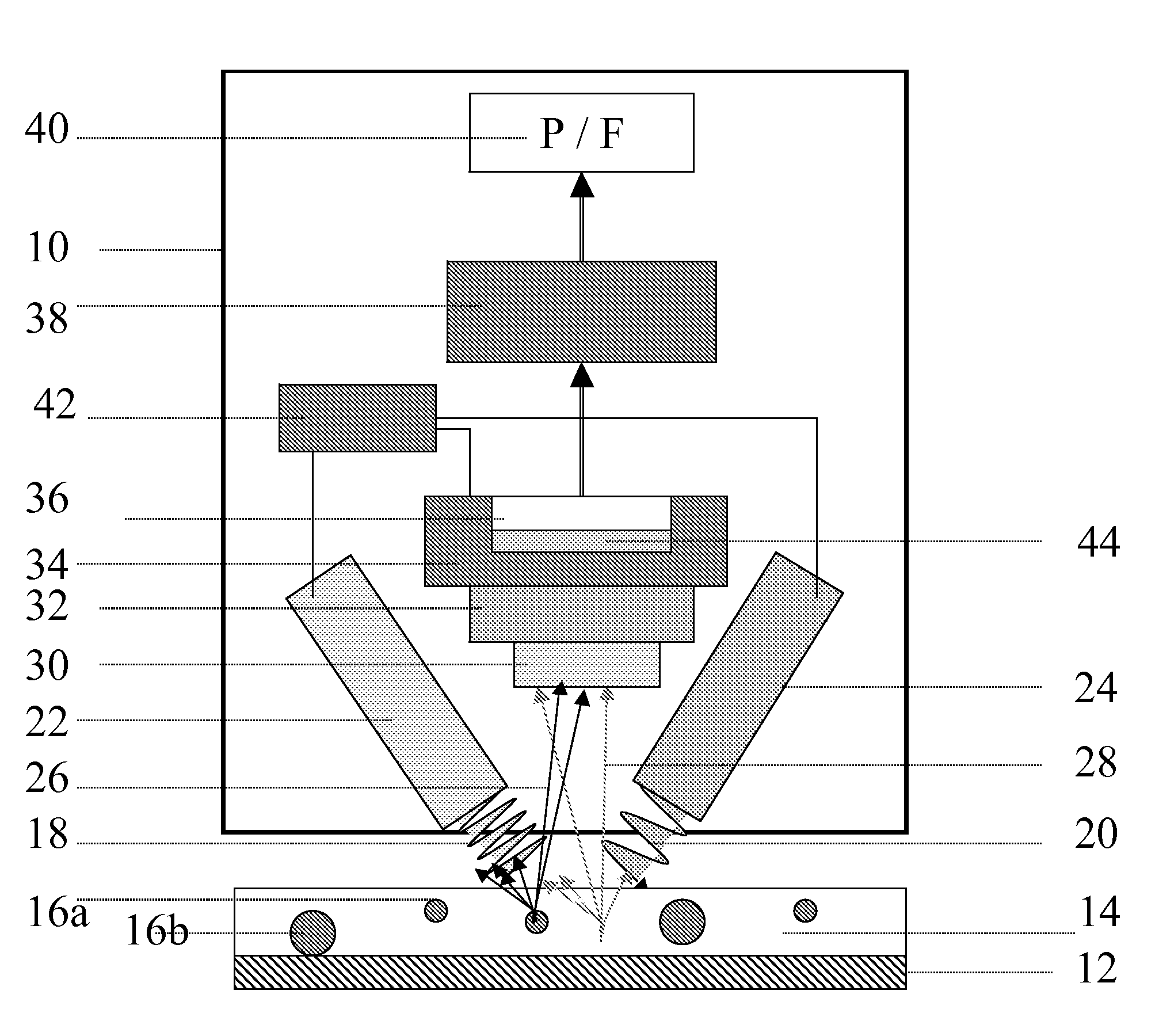

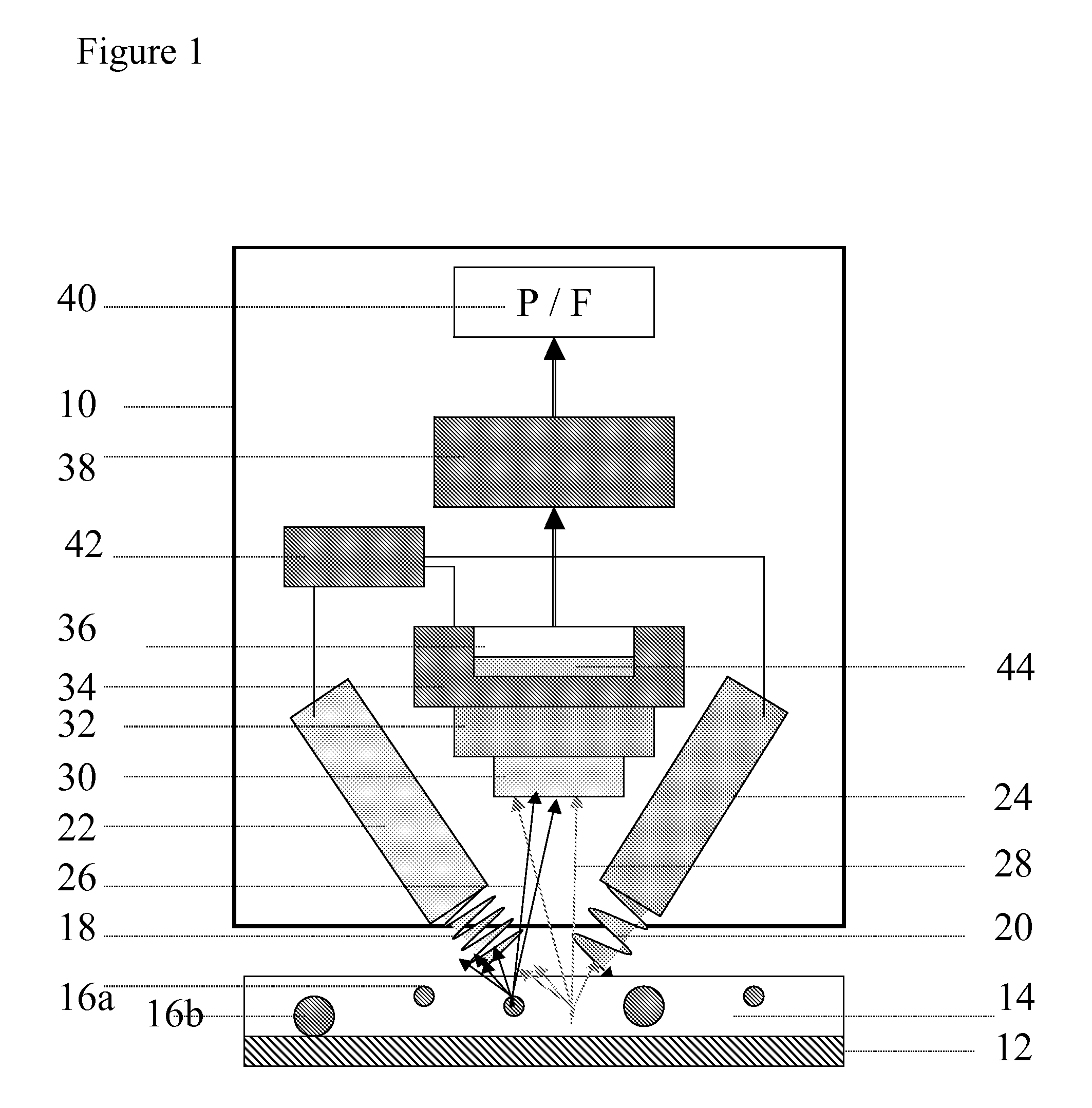

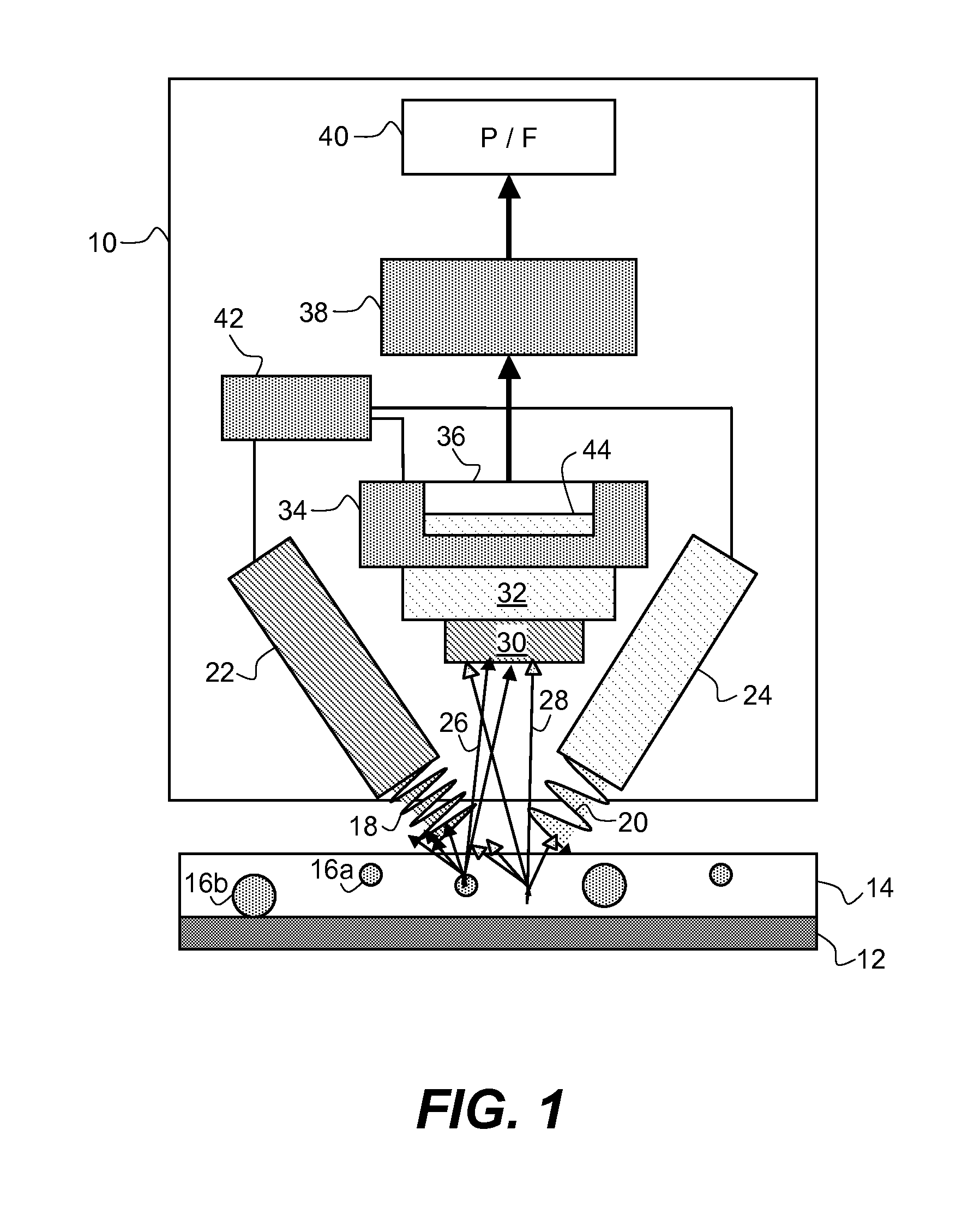

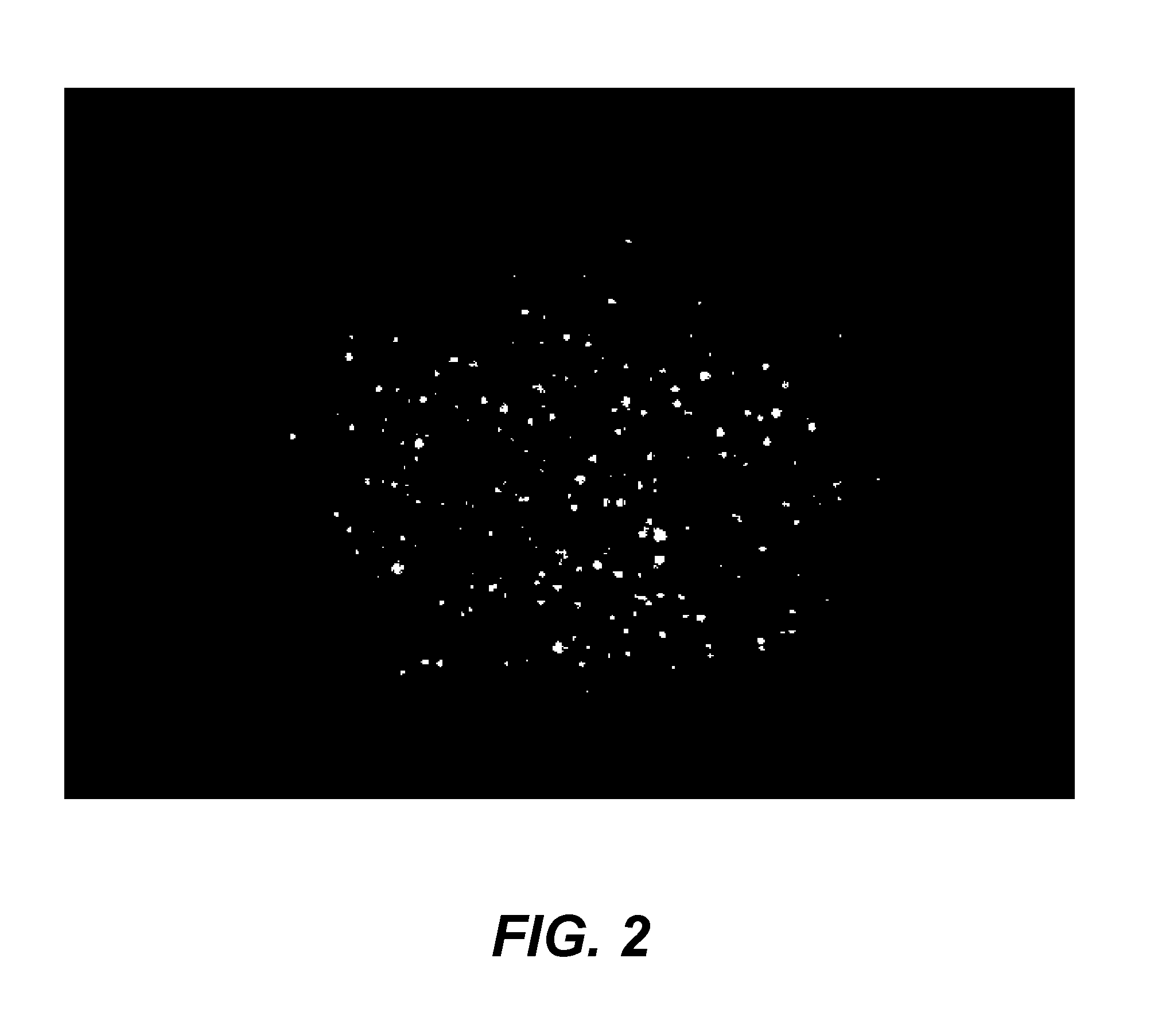

Security system with different size emissive particles

ActiveUS8153984B2Less expensivePhotosensitive materialsPaper-money testing devicesSpectral bandsEquivalent spherical diameter

A security marker material comprising emissive particles selected from at least two groups with different size distributions and the size distributions satisfy the formula:[(x−z)2 / (Sx2 +Sz2)]1 / 2 >1 wherein x and z are the volume-weighted mean equivalent-spherical diameters of the two particle distributions and Sx and Sz are the standard deviations of the same two distributions. The emissive materials are placed in or on an item. The emissive materials are excited with electromagnetic radiation in one or more specified spectral bands. The electromagnetic radiation is detected in one or more spectral bands from the emissive materials in an image-wise fashion. The attributes of the image are analyzed and characterized and are compared to authentication criteria to determine the authenticity of the marked item.

Owner:AUTHENTIX INC

Size dependent marker codes

ActiveUS20100155679A1Less expensivePhotosensitive materialsPaper-money testing devicesEquivalent spherical diameterComputer science

A security marker material comprising emissive particles and the emissive particles can be grouped into at least two groups with different size distributions and the size distributions satisfy the formula:[(x−z)2 / (Sxs+Sz2)]1 / 2>1where x and z are the volume-weighted mean equivalent-spherical diameters of the two particle distributions and Sx and Sz are the standard deviations of the same two distributions. The security marker material is part of a security system and authentication is based on criteria which include responses related to marker size and size distribution. This invention provides a less expensive method of generating a more complex, difficult-to-replicate security code.

Owner:AUTHENTIX INC

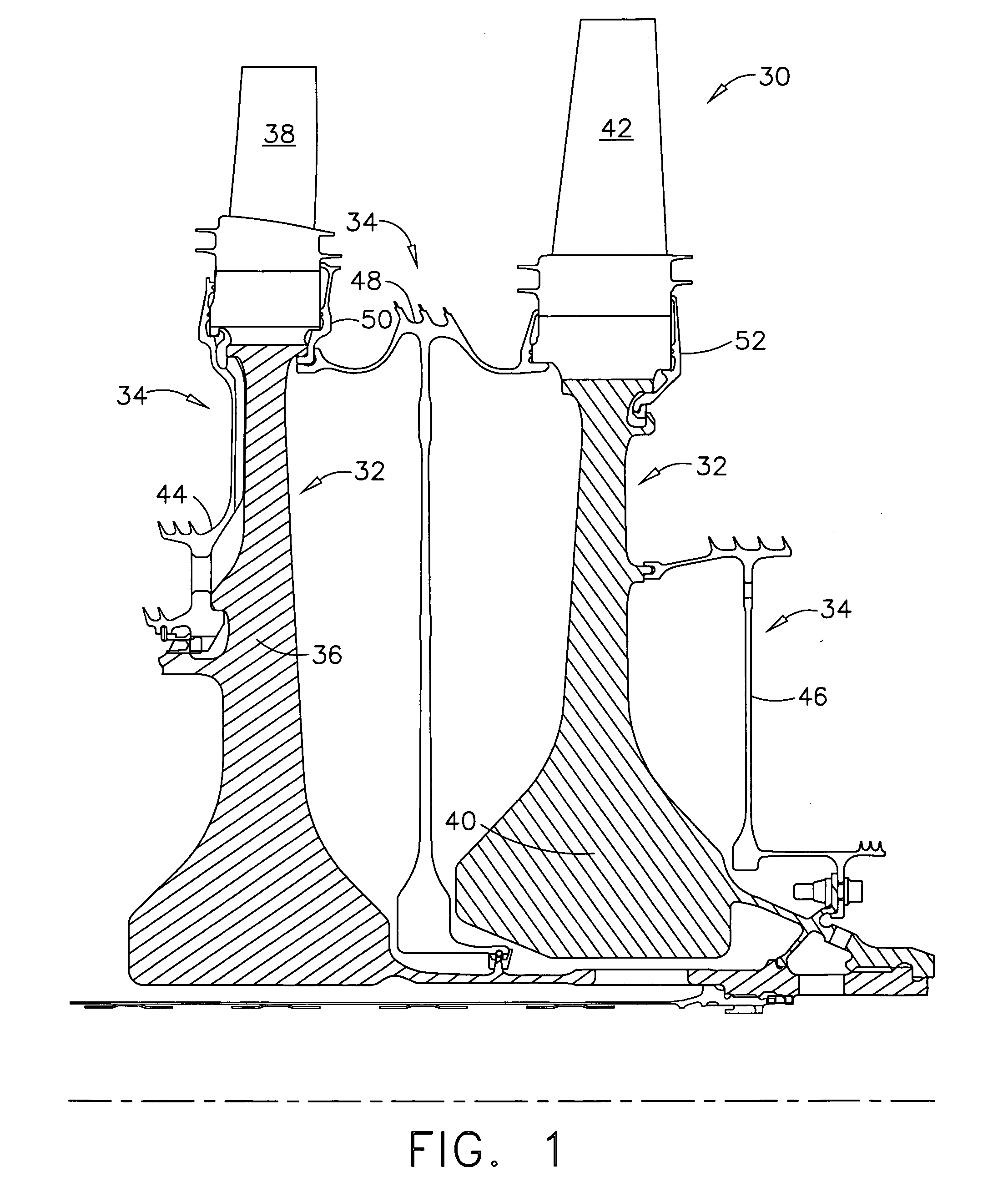

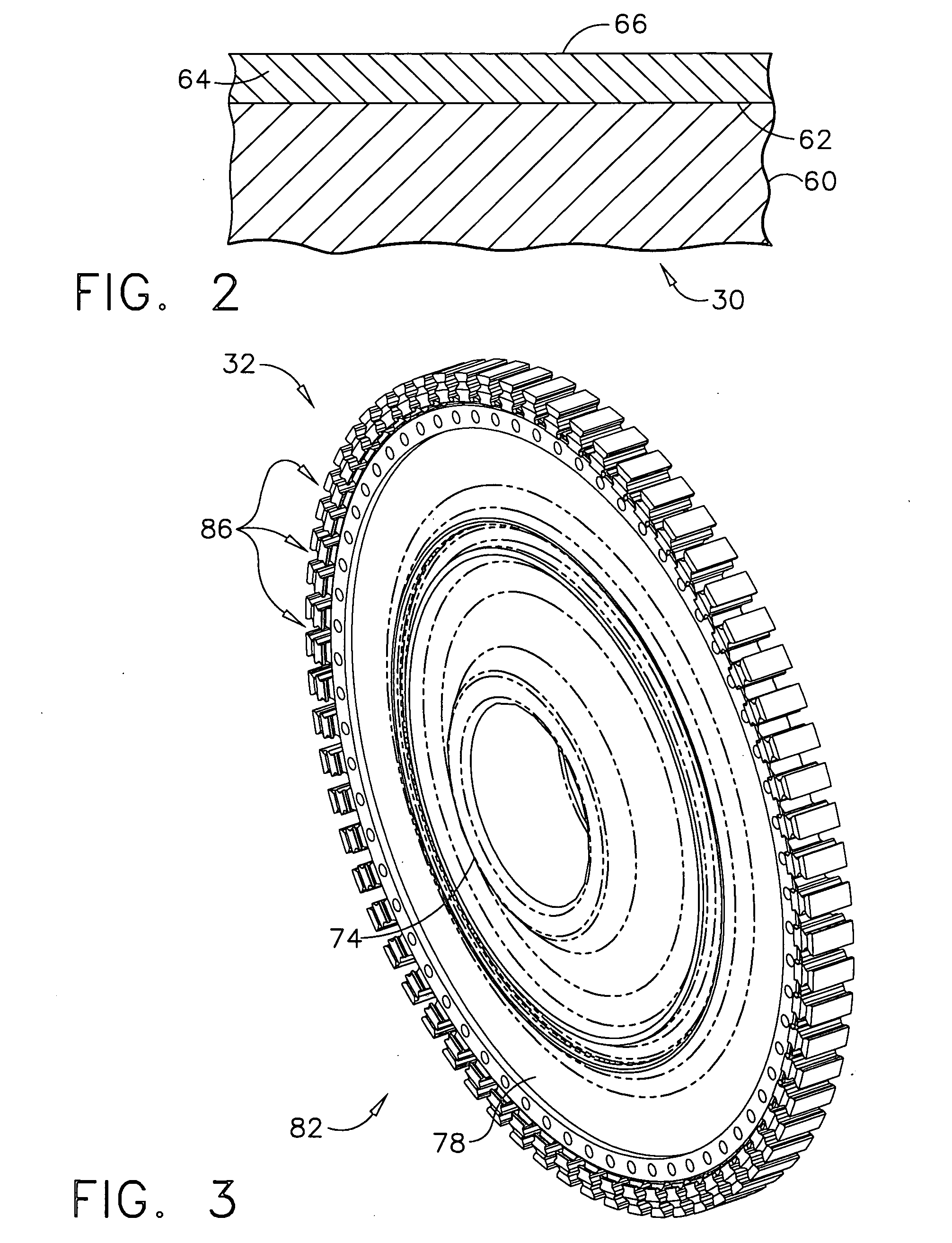

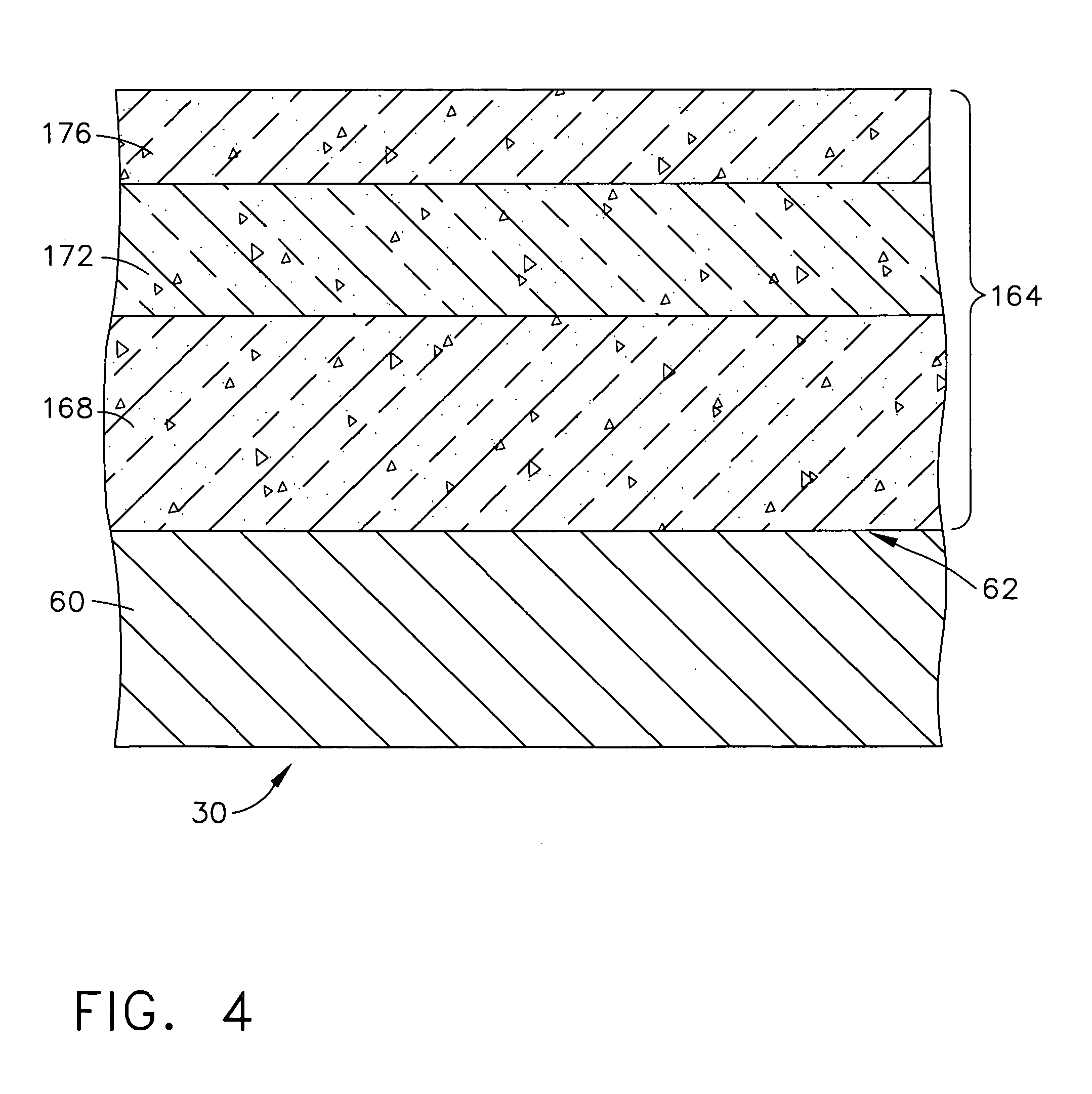

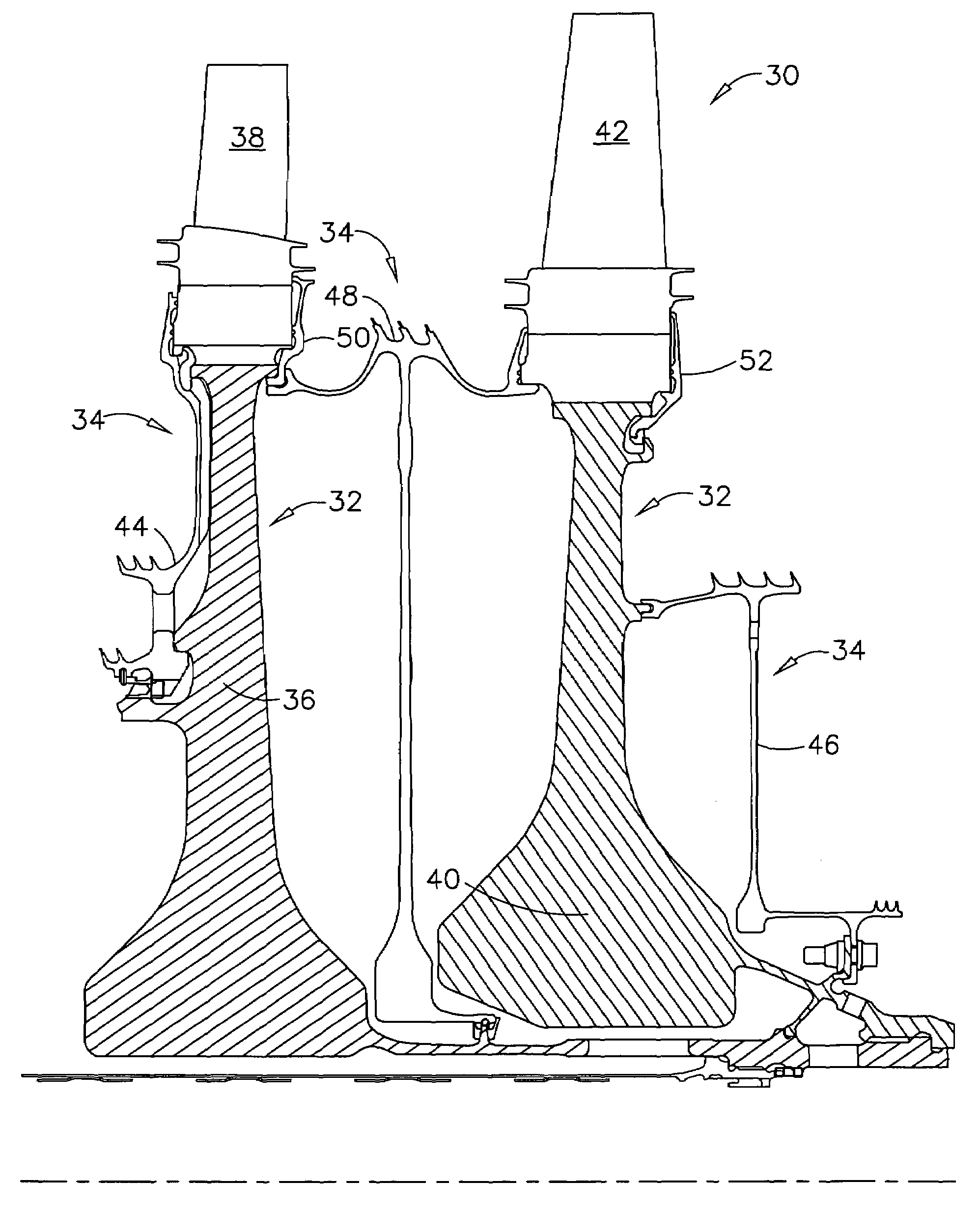

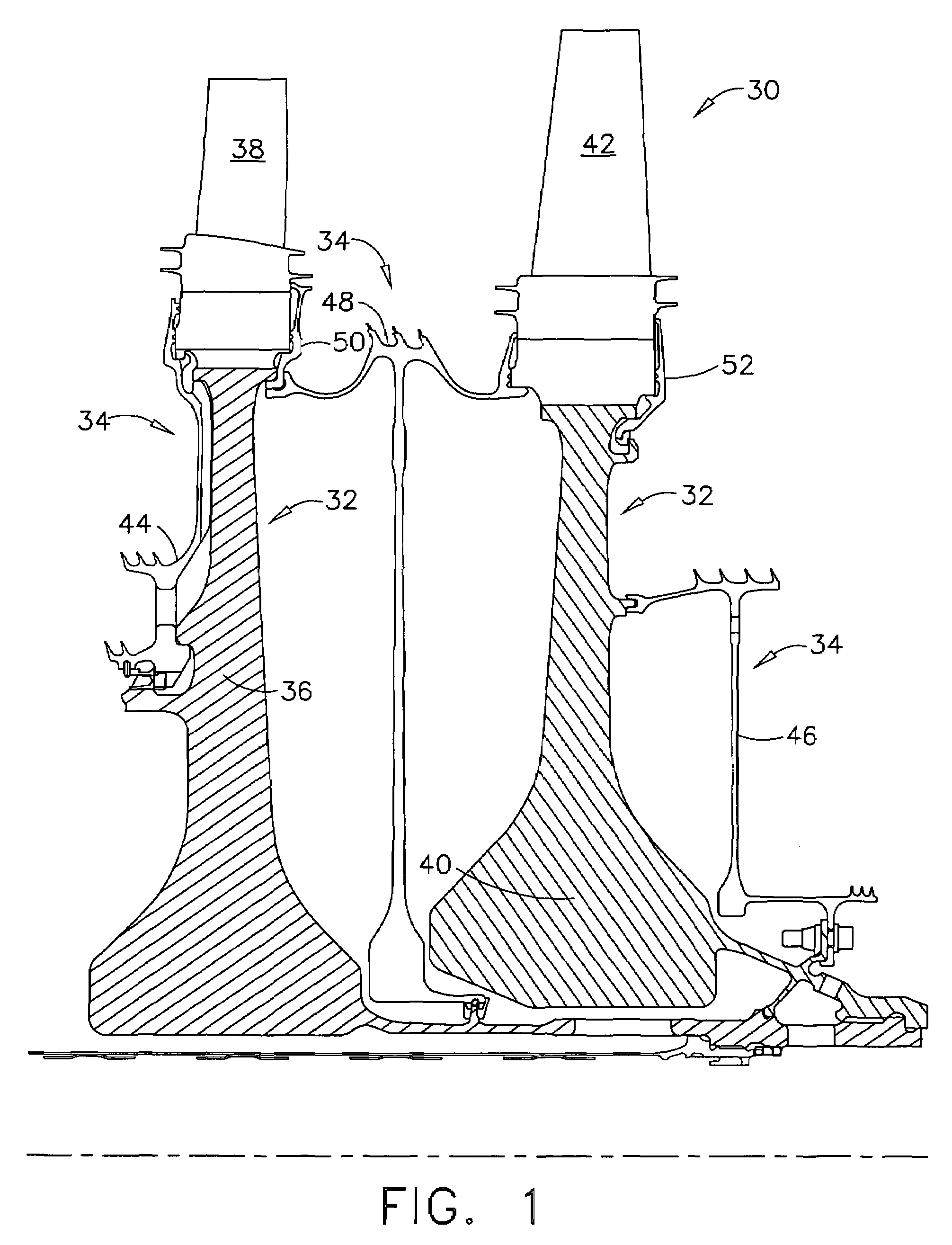

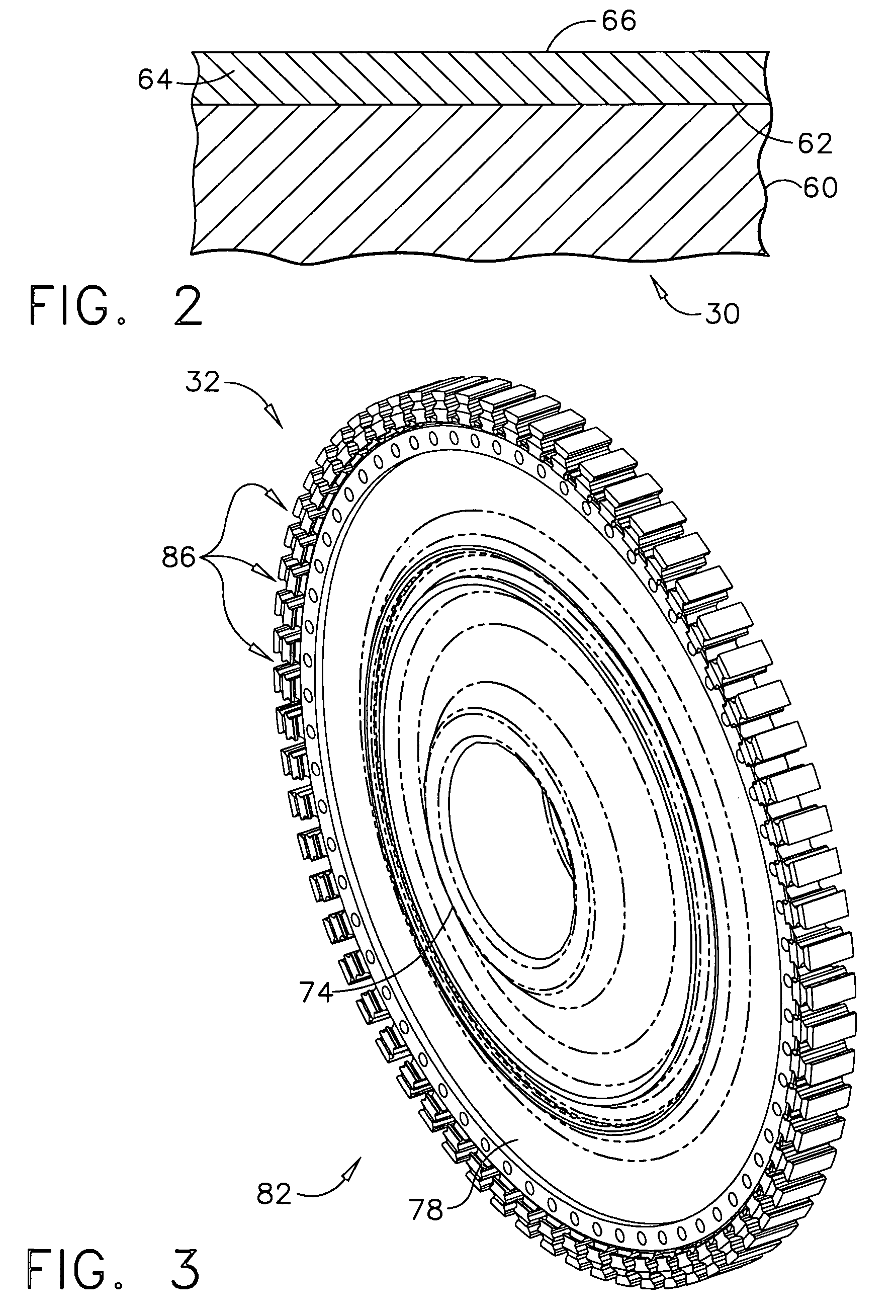

Particulate corrosion resistant coating composition, coated turbine component and method for coating same

ActiveUS20070141371A1Increased strain toleranceNot easy to peel offRecord information storageCeramic layered productsParticulatesEquivalent spherical diameter

A composition comprising a glass-forming binder component and a particulate corrosion resistant component. The particulate corrosion resistant component comprises corrosion resistant particulates having: a CTEp of at least about 4 and being solid at a temperature of about 1300° F. (704° C.) or greater; and a maximum median particle size defined by one of the following formulas: (a) for a CTEp of 8 or less, an Mp equal to or less than (4.375×CTEp)−10; and (b) for a CTEp of greater than 8, an Mp equal to or less than (−4.375×CTEp)+60, wherein CTEp is the average CTE of the corrosion resistant particulates and wherein Mp is the median equivalent spherical diameter (ESD), in microns, of the corrosion resistant particulates. Also disclosed is an article comprising a turbine component comprising a metal substrate and a corrosion resistant coating overlaying the metal substrate, as well as a method for forming at least one layer of the corrosion resistant coating adjacent to the metal substrate. The corrosion resistant coating has a maximum thickness defined by one of the following formulas: (3) for a CTEp of 8 or less, an Tc equal to or less than (1.5×CTEp)−3.5; and (4) for a CTEp of greater than 8, an Tc equal to or less than (−1.5×CTEp)+20.5, wherein Tc is the thickness, in mils, of the corrosion resistant coating.

Owner:GENERAL ELECTRIC CO

Particulate corrosion resistant coating composition, coated turbine component and method for coating same

ActiveUS7604867B2Increased strain toleranceNot easy to peel offRecord information storageCeramic layered productsParticulatesEquivalent spherical diameter

A composition comprising a glass-forming binder component and a particulate corrosion resistant component. The particulate corrosion resistant component comprises corrosion resistant particulates having: a CTEp of at least about 4 and being solid at a temperature of about 1300° F. (704° C.) or greater; and a maximum median particle size defined by one of the following formulas: (a) for a CTEp of 8 or less, an Mp equal to or less than (4.375×CTEp)−10; and (b) for a CTEp of greater than 8, an Mp equal to or less than (−4.375×CTEp)+60, wherein CTEp is the average CTE of the corrosion resistant particulates and wherein Mp is the median equivalent spherical diameter (ESD), in microns, of the corrosion resistant particulates. Also disclosed is an article comprising a turbine component comprising a metal substrate and a corrosion resistant coating overlaying the metal substrate, as well as a method for forming at least one layer of the corrosion resistant coating adjacent to the metal substrate. The corrosion resistant coating has a maximum thickness defined by one of the following formulas: (3) for a CTEp of 8 or less, an Tc equal to or less than (1.5×CTEp)−3.5; and (4) for a CTEp of greater than 8, an Tc equal to or less than (−1.5×CTEp)+20.5, wherein Tc is the thickness, in mils, of the corrosion resistant coating.

Owner:GENERAL ELECTRIC CO

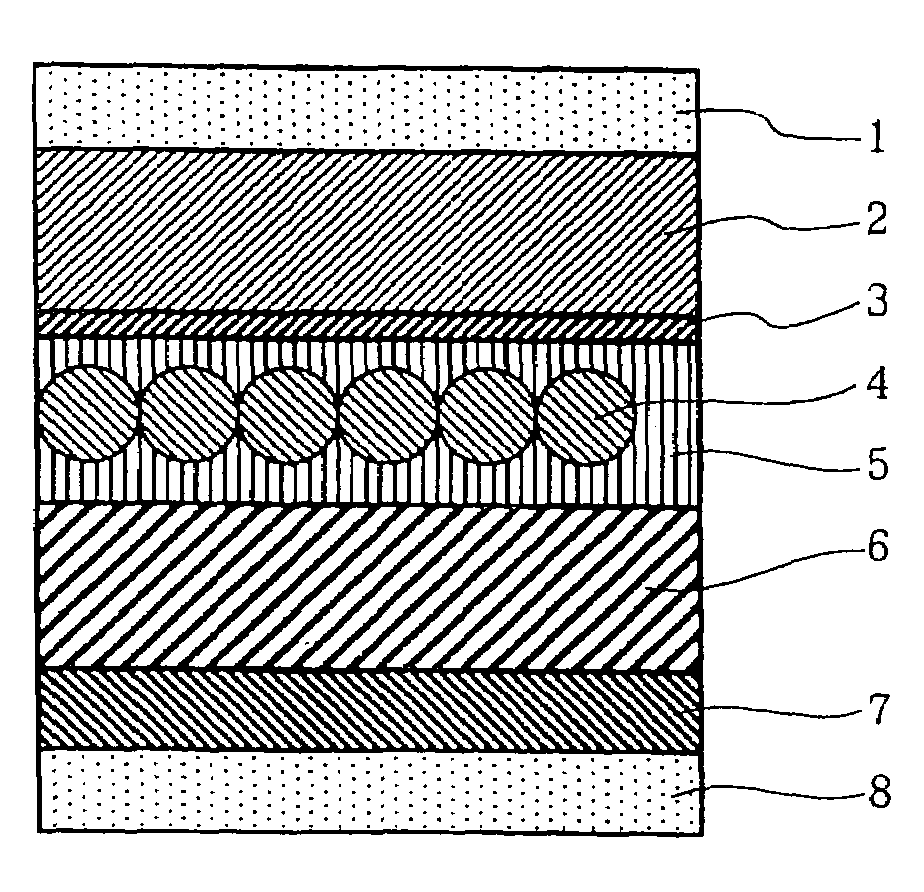

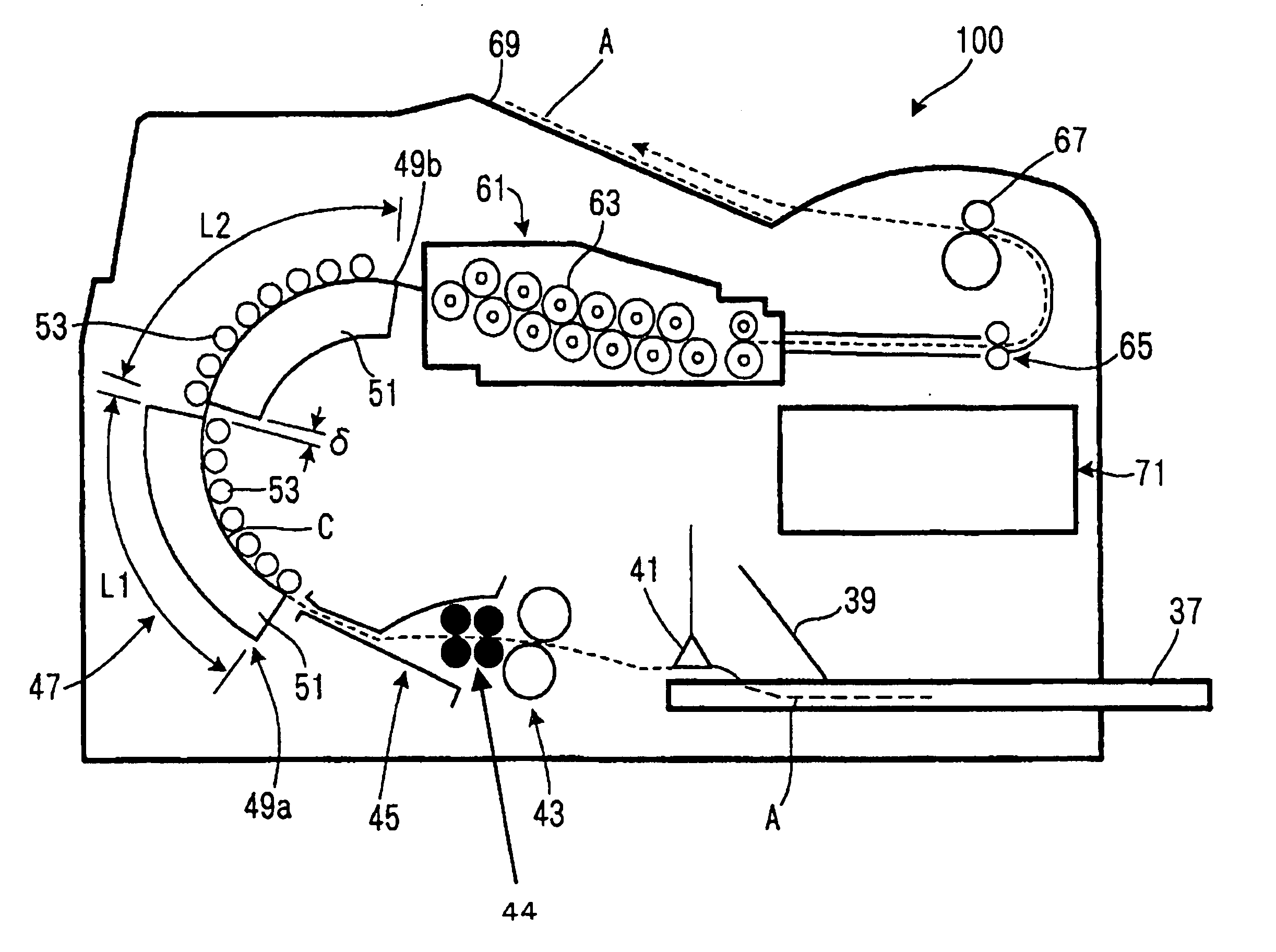

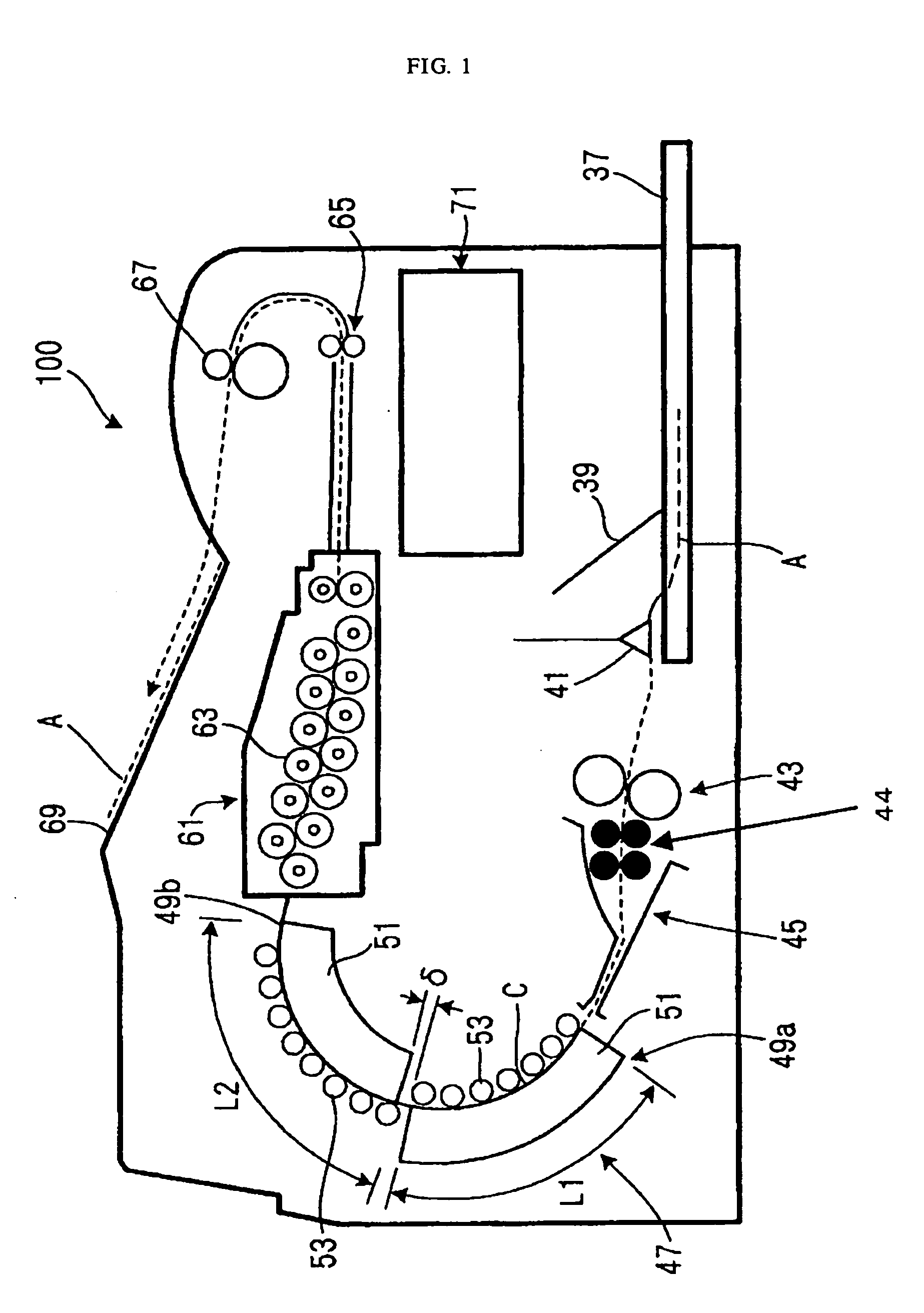

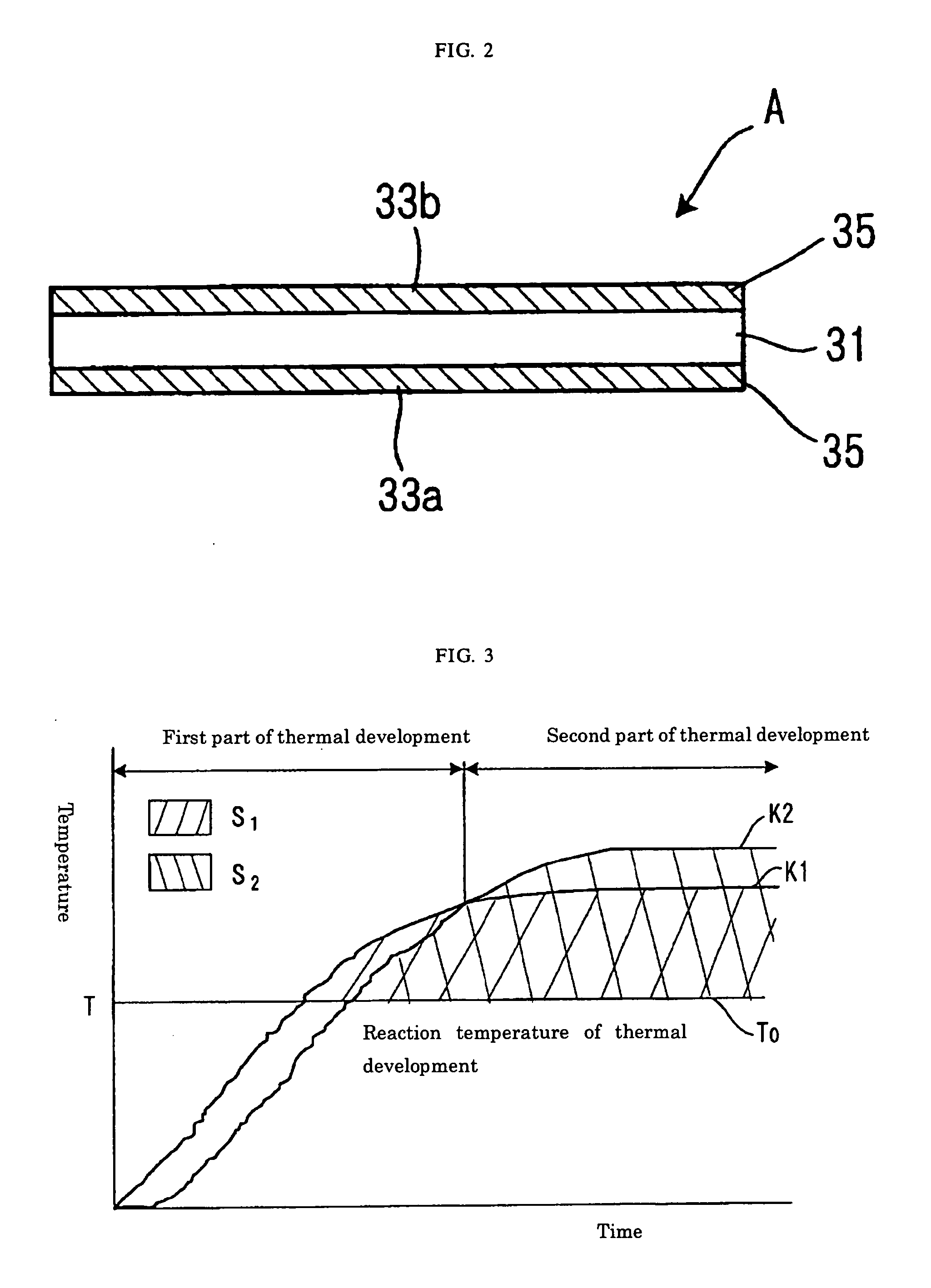

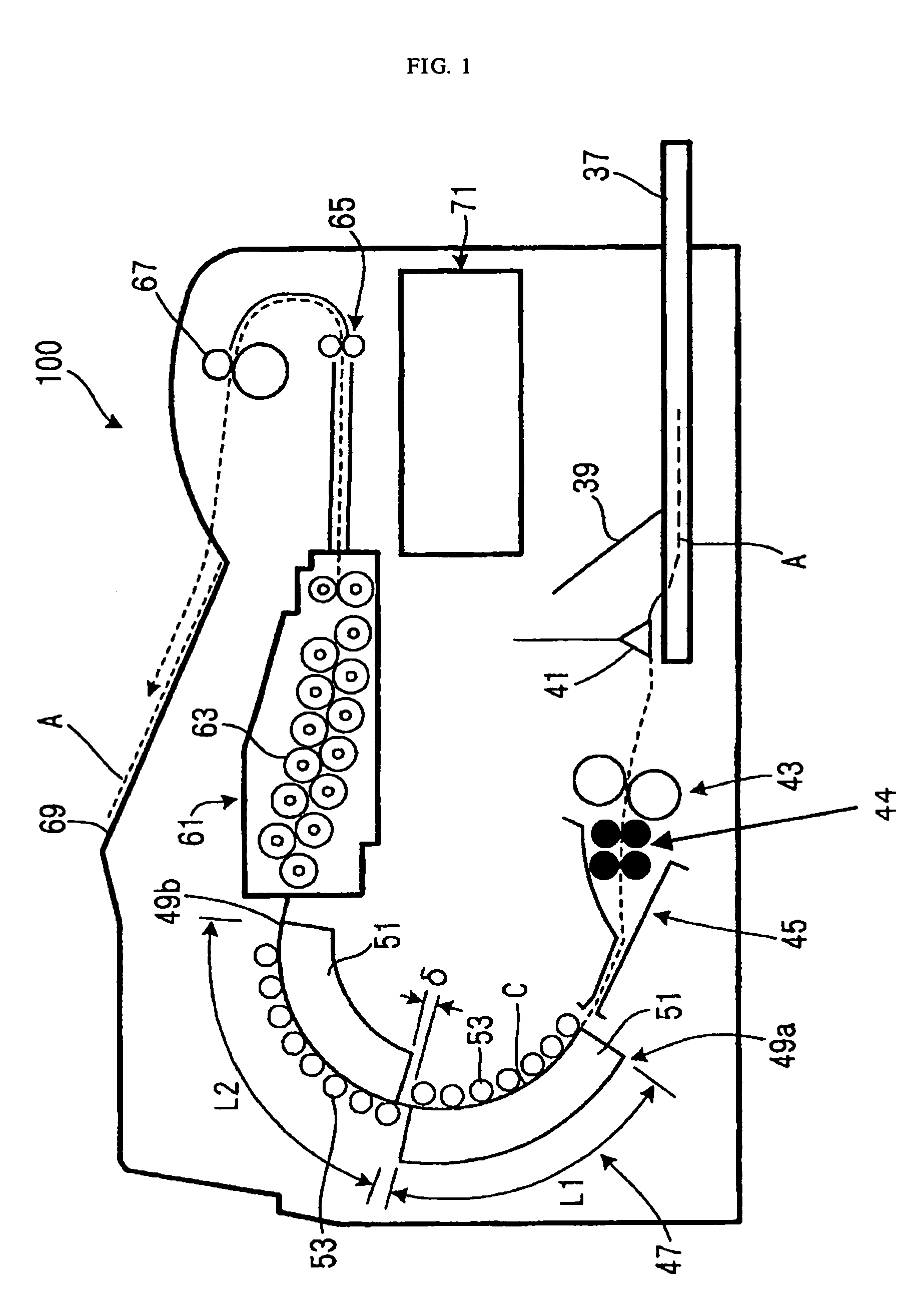

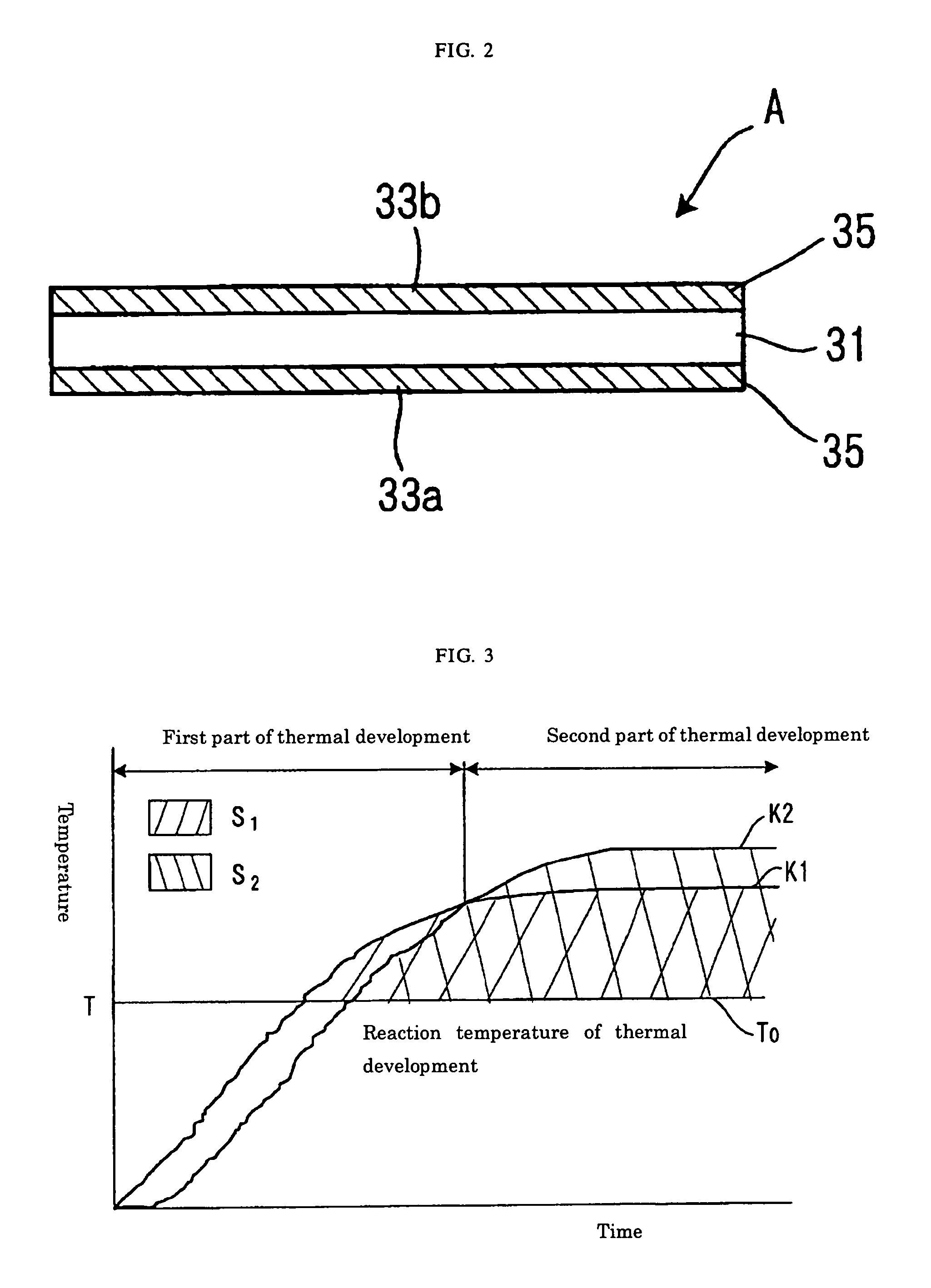

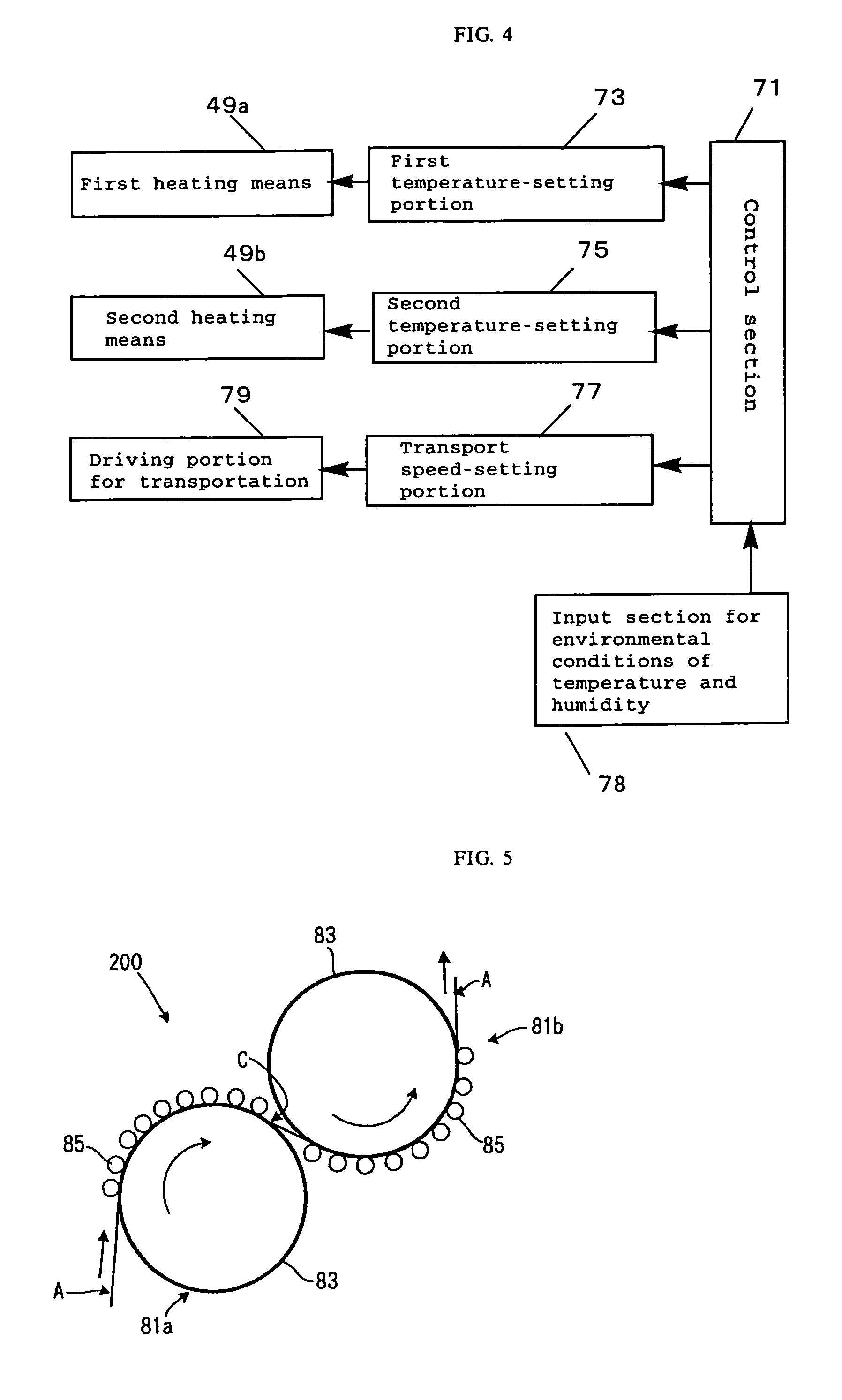

Photothermographic material and method for preparing photosensitive silver halide emulsion

InactiveUS20050079457A1Reduce light absorptionLight absorptionX-ray/infra-red processesPhotoprinting processesSilver iodideEquivalent spherical diameter

The invention provides a photothermographic material containing a tabular photosensitive silver halide having an average silver iodide content of 40 mol % or higher, 50% or more of a total projected area of the photosensitive silver halide being occupied by tabular grains having an aspect ratio of 2 or more, the photosensitive silver halide grains having a mean equivalent spherical diameter of from 0.2 μm to 5 μm and a variation coefficient of an equivalent spherical diameter distribution of 30% or less. Further, a method for preparing the photosensitive silver halide used in the photothermographic material is characterized in that grains are formed in the presence of at least one selected from a silver halide solvent and an amino group-modified gelatin. A high-sensitivity photothermographic material exhibiting a low fog and a high optical density is provided.

Owner:FUJIFILM HLDG CORP +1

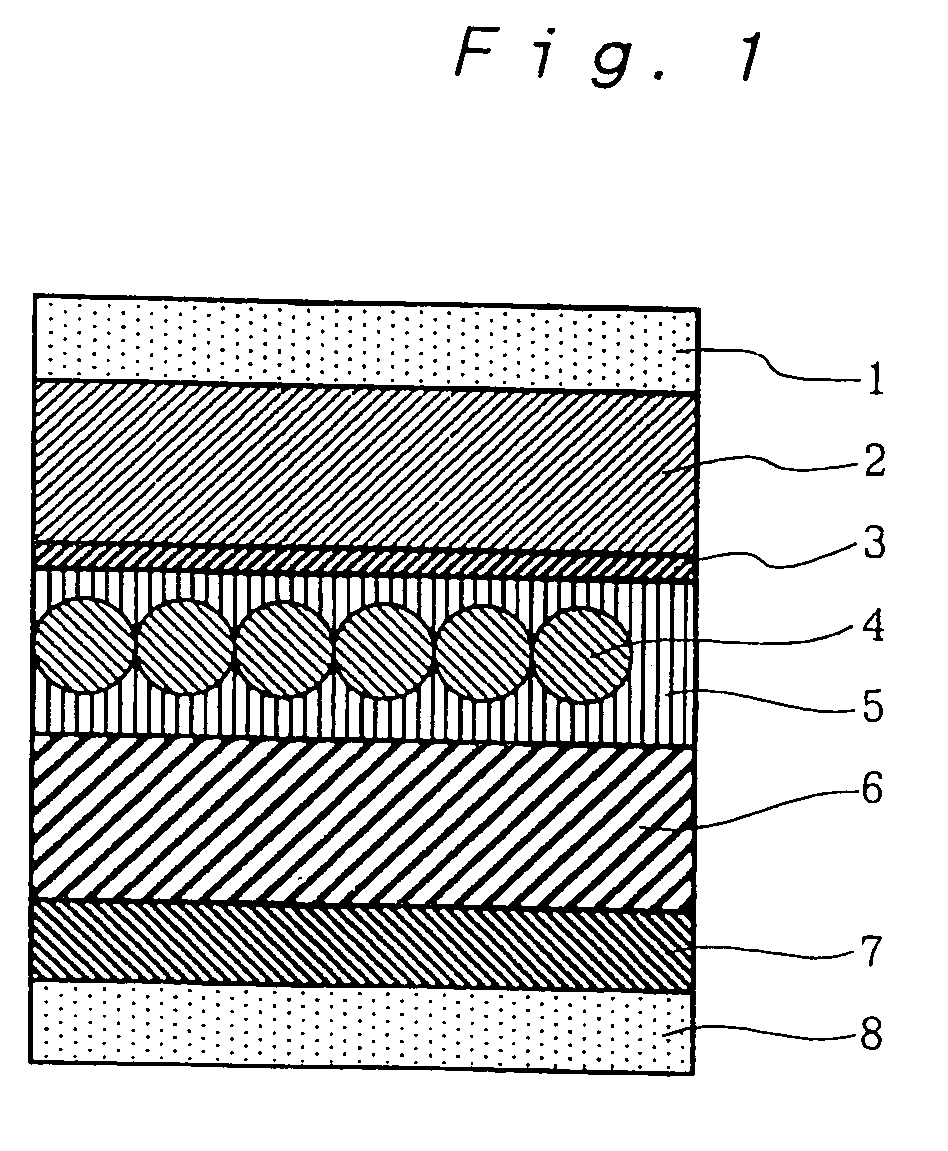

Photothermographic material and image forming method

InactiveUS20050277072A1Low costDiffusion transfer processesX-ray/infra-red processesFluorescenceX-ray

Provided are a photothermographic material which includes, on at least one side of a support, an image forming layer containing at least a photosensitive silver halide, a non-photosensitive organic silver salt, a reducing agent, and a binder, and is X-ray exposed with a fluorescent intensifying screen, wherein (1) the photosensitive silver halide includes tabular grains having a mean aspect ratio of 2 to 100 and a mean equivalent spherical diameter of 0.3 μm to 10 μm, (2) an exposure value necessary for obtaining an image density of fog+0.5 after exposing the photothermographic material with monochromatic light having the same wavelength as the main emission peak wavelength of the fluorescent intensifying screen and having a half width of 15 nm±5 nm and thermally developing the photothermographic material is from 1×10−6 watt·sec·m−2 to 1×10−3 watt·sec·m−2, and (3) haze of the photothermographic material after thermal devolpment is less than 80% of that before thermal development; and an image forming method using the same.

Owner:FUJIFILM CORP +1

Coating composition and coated paper and coated paperboard

A coating composition may include kaolin having a shape factor less than about 70 and calcium carbonate, wherein less than about 90% by weight and greater than about 60% by weight of particles of the calcium carbonate have an equivalent spherical diameter (esd) less than 2 microns. The coating composition may include a thickener present in an amount ranging from about 0.1% to about 0.9% by active dry weight of the composition. A coating composition may include kaolin having a shape factor less than about 70 and calcium carbonate having a mean particle size (d50) of at least about 2.4 microns and a steepness factor of at least about 30. The coating composition may be a paper basecoat composition or a paperboard basecoat composition. A paper or paperboard product may include the coating composition on at least one surface of the paper product or paperboard product.

Owner:IMERYS USA INC

Cover body, electronic device and cover body processing method

ActiveCN110167296AImprove qualityImprove appreciationOrnamental structuresCasings/cabinets/drawers detailsEquivalent spherical diameterLED lamp

The invention discloses a cover body, an electronic device and a cover body processing method. The cover body includes a substrate including an outer surface and an inner surface opposite to the outersurface, and a luminous layer disposed on at least one of the outer surface and the inner surface of the substrate, wherein the luminous layer includes luminous powder, the equivalent spherical diameter of the luminous powder is d1, the d1 satisfies that the d1 is not smaller than 60 mum and is not greater than 160 mum, when the luminous layer is disposed on the inner surface of the substrate, the substrate is a transparent member. The cover body is advantaged in that the luminous powder of the cover flickers in the dark and forms a plurality of fine illuminating patterns, the starry look canbe created, enhancing the product texture and the ornamental degree of the cover body is facilitated, setting light emitting devices such as LED lamps is not needed, additional power consumption canbe avoided, and the cost is low.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

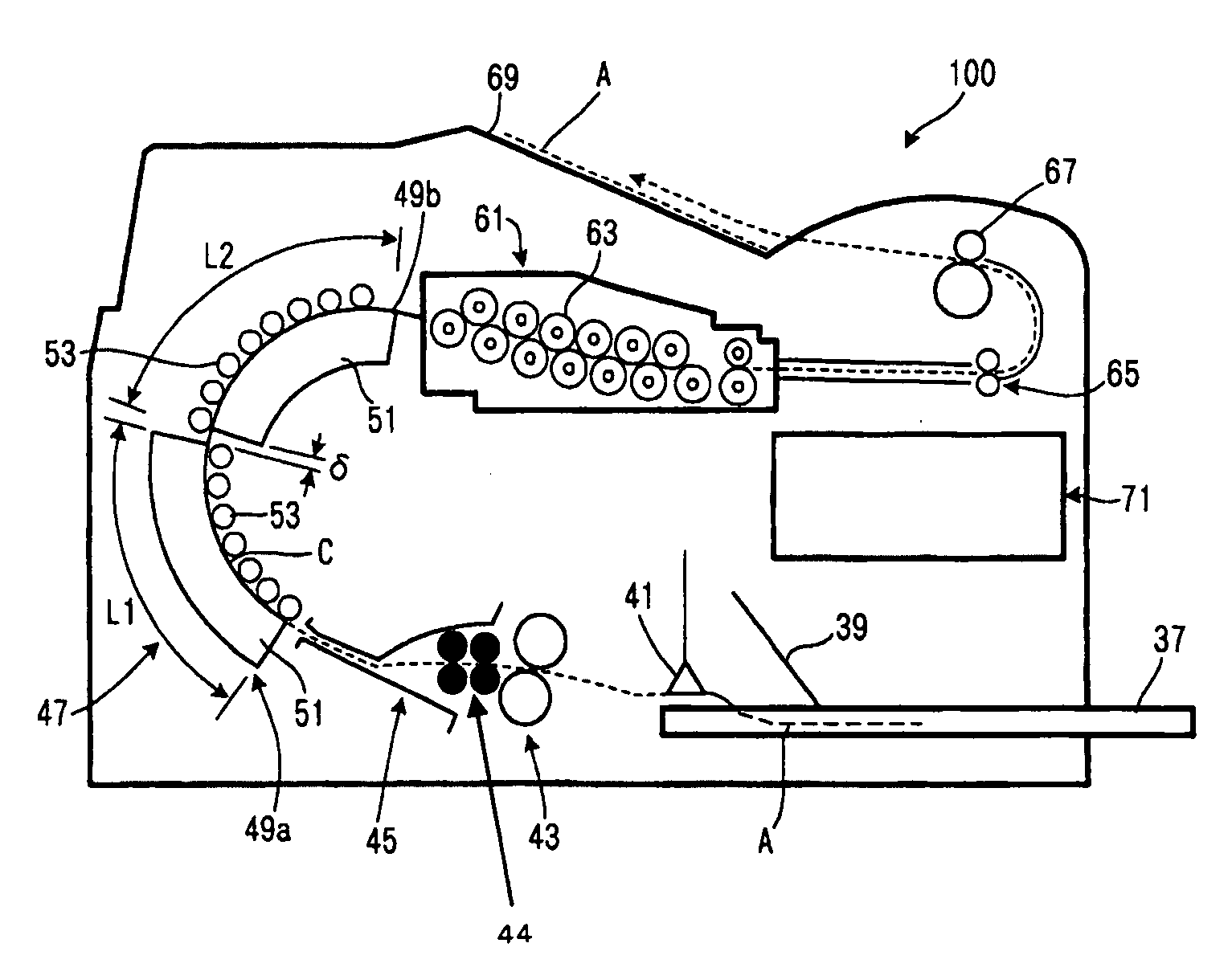

Electrostatic latent image developing toner, electrostatic latent image developer, image forming apparatus, and apparatus for manufacturing electrostatic latent image developing toner

An electrostatic latent image developing toner has an average sphericity of at least 0.94 but no more than 0.98, the particles for which the accumulated equivalent spherical diameter on a number basis is at least 90% and the sphericity is less than 0.92 account for less than 3% of the entire toner, the proportion of particles having a sphericity of at least 0.90 but less than 0.95 is at least 20% but no more than 40% of the entire toner, and a proportion of particles having a sphericity of at least 0.95 but no more than 1.00 is at least 60% but no more than 80% of the entire toner.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Kaolin pigment products

InactiveUS20060096501A1High glossIncrease brightnessPigmenting treatmentNon-fibrous pulp additionParticulatesEquivalent spherical diameter

A pigment product for use in a coating composition to provide a gloss coating on paper, the pigment product comprising a processed particulate kaolin having a particle size distribution such that at least about 80% by weight of the particles have an equivalent spherical diameter less than about 2 p,m and in the range of from about 10% to about 20% by weight of the particles have an equivalent spherical diameter less than about 0.25 wm, the particles have a shape factor in the range of from about 20 to about 36 and the particles have a particle steepness in the range of about greater than about 35, more preferably in the range of about 35 to about 40, and wherein the kaolin is derived from a secondary kaolin source.

Owner:IMERYS RIO CAPIM CAULIM

Photothermographic material and image forming method

Provided are a photothermographic material which includes, on at least one side of a support, an image forming layer containing at least a photosensitive silver halide, a non-photosensitive organic silver salt, a reducing agent, and a binder, and is X-ray exposed with a fluorescent intensifying screen, wherein (1) the photosensitive silver halide includes tabular grains having a mean aspect ratio of 2 to 100 and a mean equivalent spherical diameter of 0.3 μm to 10 μm, (2) an exposure value necessary for obtaining an image density of fog+0.5 after exposing the photothermographic material with monochromatic light having the same wavelength as the main emission peak wavelength of the fluorescent intensifying screen and having a half width of 15 nm±5 nm and thermally developing the photothermographic material is from 1×10−6 watt·sec·m−2 to 1×10−3 watt·sec·m−2, and (3) haze of the photothermographic material after thermal devolpment is less than 80% of that before thermal development; and an image forming method using the same.

Owner:FUJIFILM CORP +1

Size dependent marker codes

ActiveUS20120138857A1Less expensivePhotosensitive materialsPaper-money testing devicesEquivalent spherical diameterSize dependent

Owner:AUTHENTIX INC

Polyester resin composition, process for producing the same, and polyester film

InactiveCN1961020AExcellent toneIncrease production capacitySynthetic resin layered productsGeneral purposePolyester resin

A polyester resin composition having an equivalent spherical diameter of 1 mm to 50 mm, a degree of crystallization of not less than 65% and less than 99%, an intrinsic viscosity of not more than 0.7 dl / g and a cyclic trimer content of not more than 0.4% by weight. This polyester resin composition has an excellent color tone, causes no significant viscosity lowering or viscosity rise, and can withstand a process which is exposed to a long-term heat history. A polyester resin composition having a viscosity suitable for extrusion in a general-purpose manner, a production process thereof, and a polyester film are also provided.

Owner:TORAY IND INC

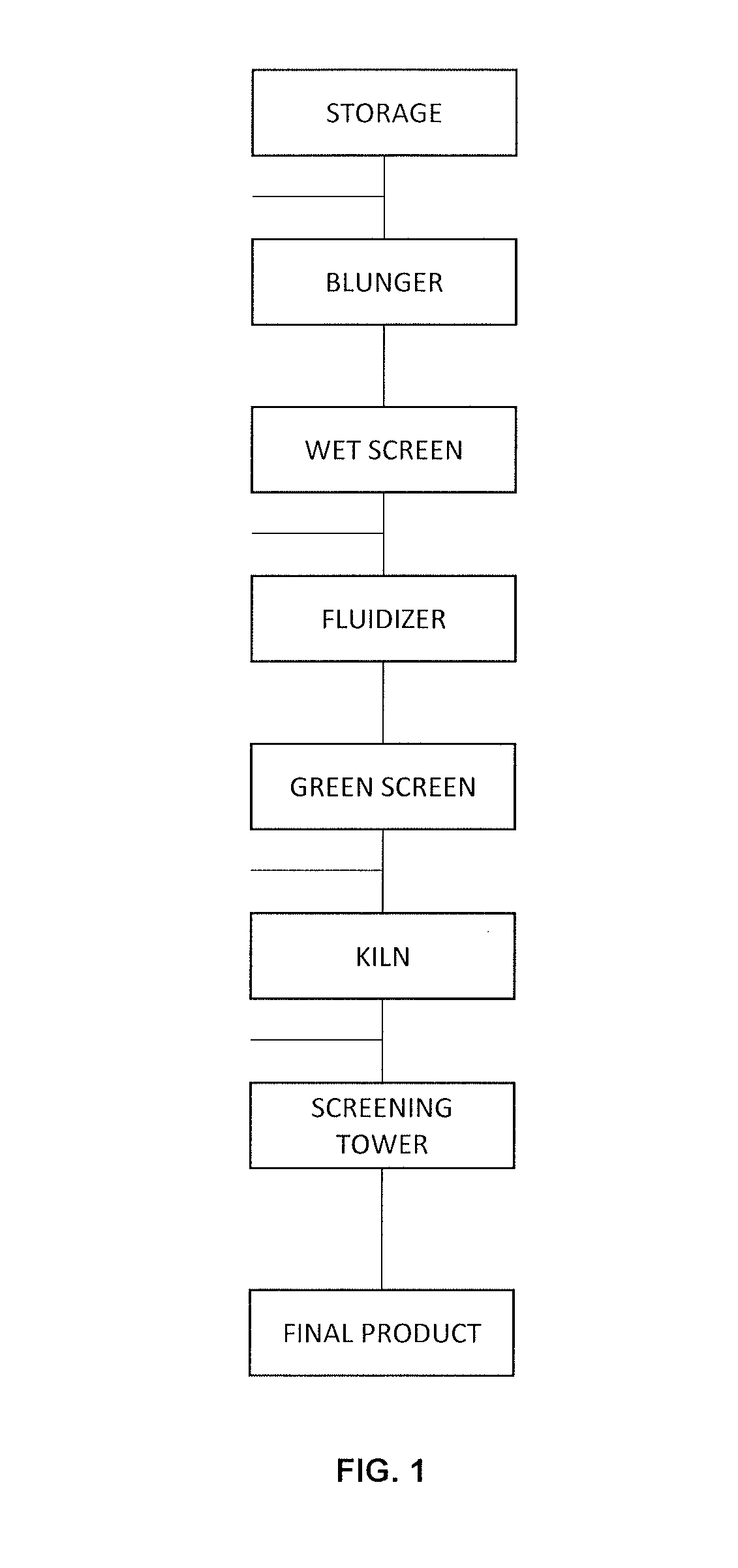

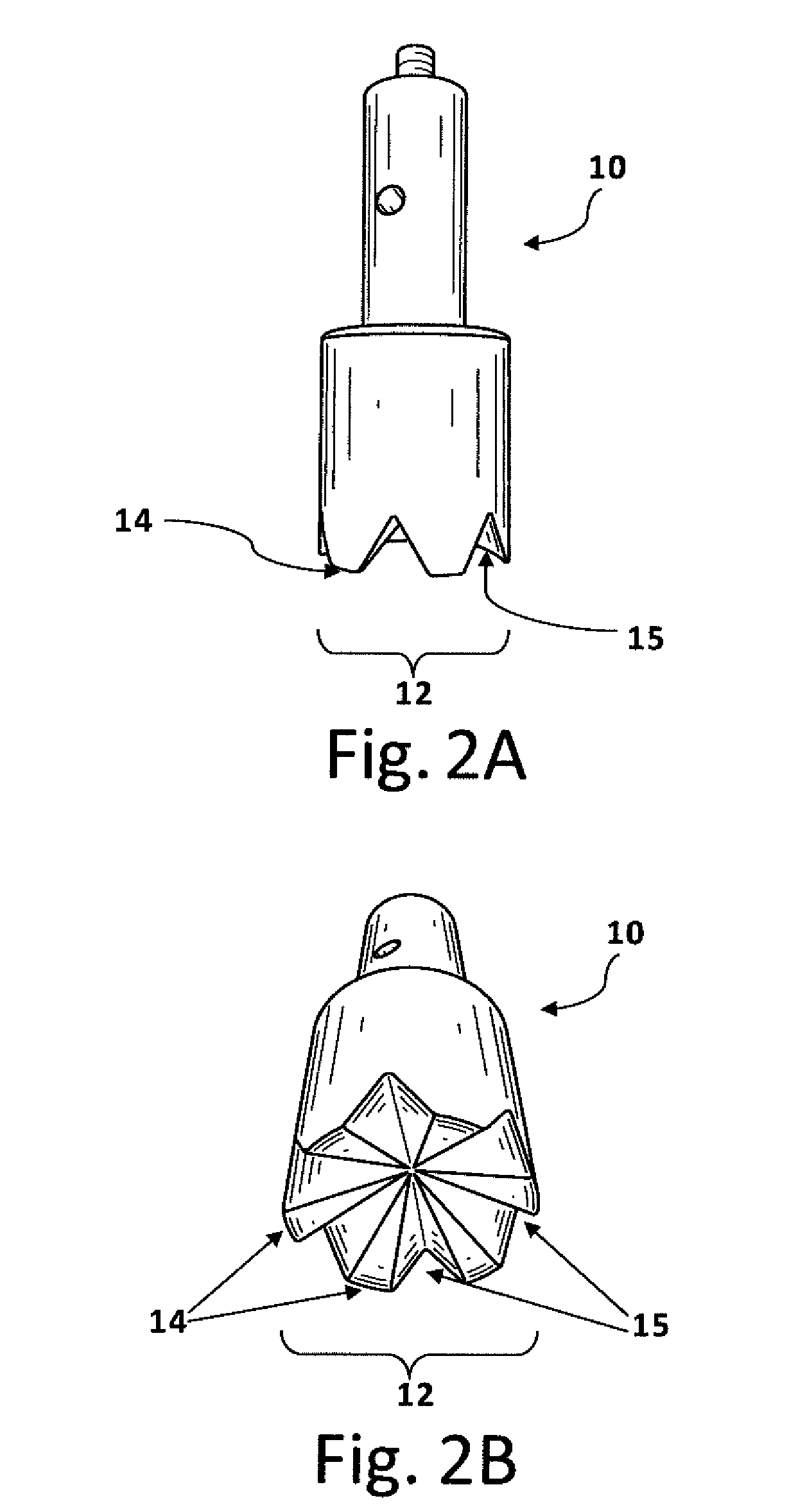

Proppants and Anti-flowback additives including kaolin clay

A method of making a sintered ceramic proppant may include providing a kaolin clay. The kaolin clay may include an Al2O3 content no greater than about 46% by weight, and a K2O content no greater than 0.1% by weight. The kaolin clay may have a particle size distribution such that greater than 70% of the particles have an equivalent spherical diameter of less than 0.5 microns as measured by Sedigraph, and a shape factor less than about 18. The method may further include blunging the kaolin clay, agglomerating the kaolin clay, and sintering the agglomerated kaolin clay to produce a sintered ceramic proppant. The kaolin clay may have an A-bob Hercules viscosity of at least about 3,300 rpm at 18 kilodyne-cm and 70% solids.

Owner:US CERAMICS LLC

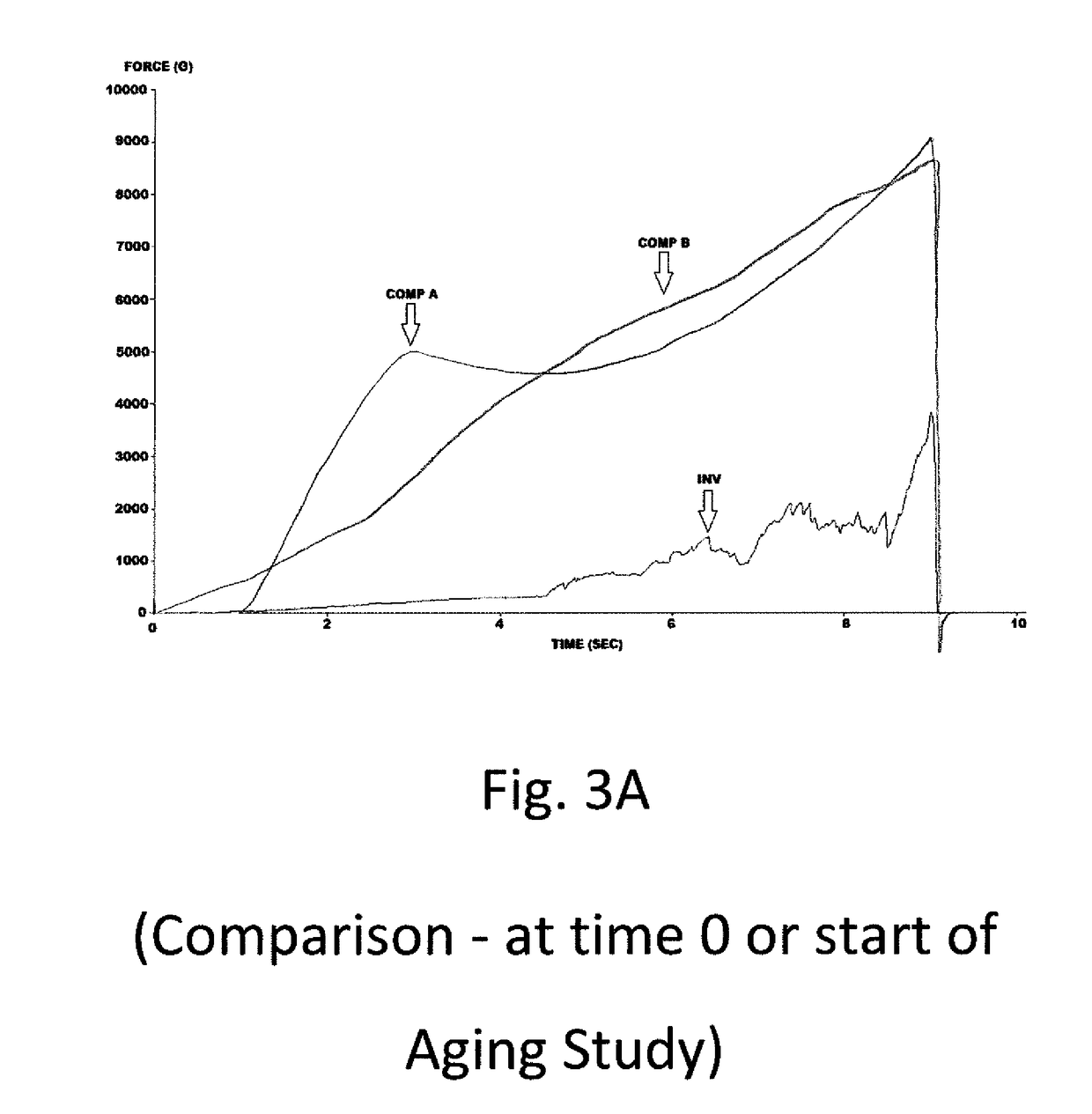

Coated bite-sized snacks

The invention relates to small edible portions (i.e., bite-sized snacks) comprising a soft nut butter inner core coated with a crunchy grain-based outer coating. The bite-sized snacks have an equivalent spherical diameter of about 1 to 3 cm. Texture analysis of the bite-sized snacks determines that the bite-sized snacks have a soft texture with an average peak force in the range of about 800-5,000 g and an average positive area in the range of about 2,000-15,000 g*sec. The bite-sized snacks unexpected have both a soft and crunchy texture and are surprisingly shelf stable.

Owner:THE J M SMUCKER CO

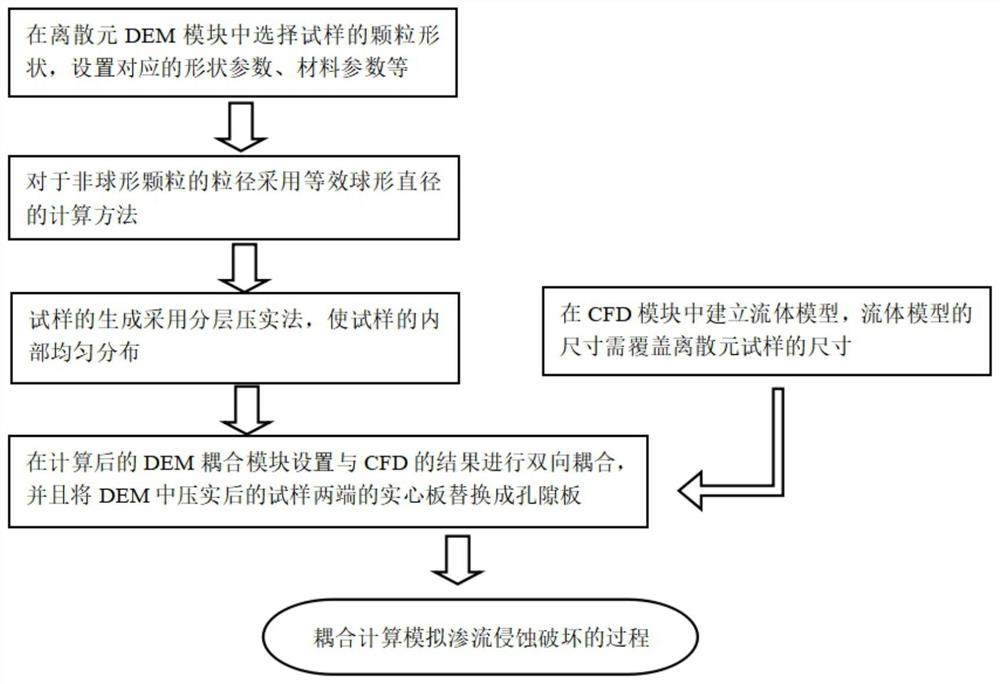

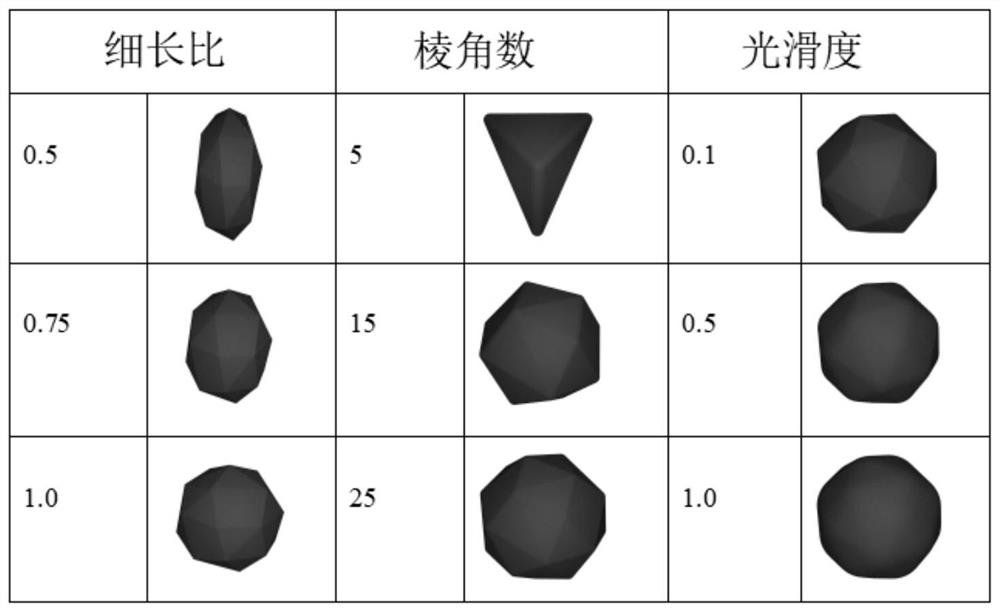

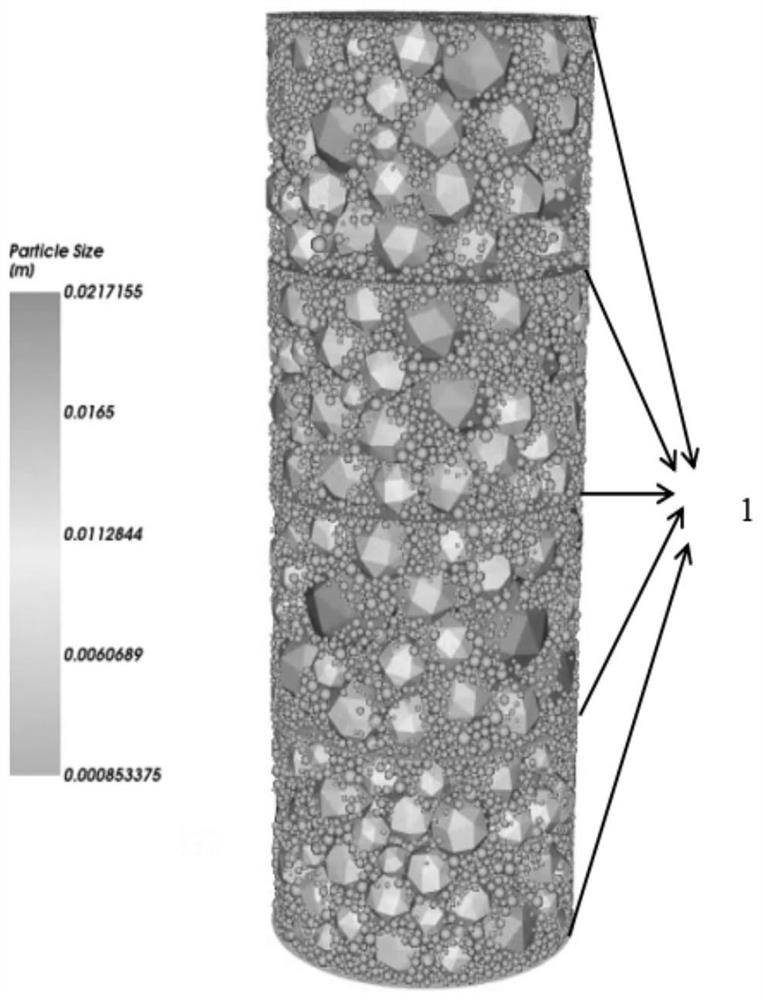

CFD-DEM seepage erosion damage simulation method considering particle shape

ActiveCN113221474AImprove accuracyAppropriate engineering practiceSustainable transportationDesign optimisation/simulationSpherical granuleComputational simulation

The invention discloses a CFD-DEM seepage erosion damage simulation method considering particle shapes, which comprises the following steps: determining particle shape parameters of a sample in a DEM module, and calculating the particle size of non-spherical particles by using an equivalent spherical diameter method; configuring at least two preset spaces in the DEM module, and generating samples in the preset spaces by adopting a layered compaction method, wherein a solid plate is adopted between every two adjacent preset spaces; establishing a fluid model in the CFD module; carrying out bidirectional coupling on the coupling module in the DEM module and the CFD module, replacing solid plates at the two ends of a sample with pore plates, and simulating the process of seepage erosion damage through coupling calculation. A sample of the non-spherical particles is established through discrete elements, bidirectional coupling calculation is carried out on the sample and a CFD module, the interaction mechanism of the particles and fluid can be further researched from macro and micro angles, the influence of the particle shape on seepage erosion damage is considered, the accuracy is higher, and the method is more suitable for engineering practice.

Owner:SHENZHEN UNIV

Polyester Resin Composition, Process For Producing The Same , And Polyester Film

ActiveUS20080076863A1Low costReduce the amount requiredConductive materialSynthetic resin layered productsGeneral purposePolymer science

A polyester resin composition having an equivalent spherical diameter of 1 mm to 50 mm, a degree of crystallization of not less than 65% and less than 99%, an intrinsic viscosity of not more than 0.7 dl / g and a cyclic trimer content of not more than 0.4% by weight. This polymer resin composition has an excellent color tone, causes no significant viscosity lowering or viscosity rise, and can withstand a process which is exposed to a long-term thermal history. A polyester resin composition having a viscosity suitable for extrusion in a general-purpose manner, a production process thereof, and a polyester film are also provided.

Owner:TORAY IND INC

Polyester resin composition, process for producing the same, and polyester film

ActiveUS8299158B2Reduce the amount requiredExcellent toneConductive materialSynthetic resin layered productsGeneral purposePolymer science

A polyester resin composition having an equivalent spherical diameter of 1 mm to 50 mm, a degree of crystallization of not less than 65% and less than 99%, an intrinsic viscosity of not more than 0.7 dl / g and a cyclic trimer content of not more than 0.4% by weight. This polymer resin composition has an excellent color tone, causes no significant viscosity lowering or viscosity rise, and can withstand a process which is exposed to a long-term thermal history. A polyester resin composition having a viscosity suitable for extrusion in a general-purpose manner, a production process thereof, and a polyester film are also provided.

Owner:TORAY IND INC

Photothermographic material and image forming method

InactiveUS20070020566A1Low costX-ray/infra-red processesMulticolor photographic processingCoated surfaceImaging quality

A photothermographic material having, on at least one side of a support, an image forming layer containing at least a photosensitive silver halide, a non-photosensitive organic silver salt, a reducing agent, and a binder, wherein (1) the photosensitive silver halide comprises tabular grains having a mean aspect ratio of 2 to 100 and a mean equivalent spherical diameter of 0.3 μm to 10 μm; (2) 50% by weight or more of the binder is a hydrophilic binder; (3) the photothermographic material comprises a means for nucleation; and (4) an average gradient of a photographic characteristic curve of the photothermographic material is from 1.8 to 4.3. An X-ray image forming method using the above photothermographic material is also disclosed. A photothermographic material that is improved in coated surface state and has high sensitivity and high image quality, and an X-ray image forming method using the same are provided.

Owner:FUJIFILM HLDG CORP +1

Method of improving the corrosion resistance of a metal substrate

ActiveUS20190390358A1Improved salt spray corrosion resistanceImprove corrosion resistancePaints with biocidesElectrophoretic coatingsHydrogenEquivalent spherical diameter

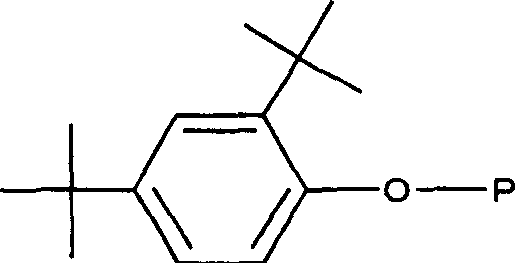

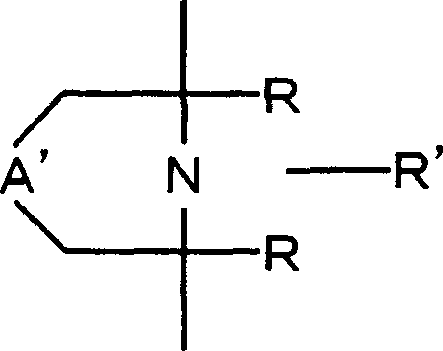

The invention provides a method of improving the corrosion resistance of a metal substrate. The method comprises:(a) electrophoretically depositing on the substrate a curable electrodepositable coating composition to form a coating over at least a portion of the substrate, and(b) heating the substrate to a temperature and for a time sufficient to cure the coating on the substrate. The electrodepositable coating composition comprises a resinous phase dispersed in an aqueous medium, the resinous phase comprising:(1) an ungelled active hydrogen-containing, cationic salt group-containing resin electrodepositable on a cathode;(2) an at least partially blocked polyisocyanate curing agent; and(3) a pigment component comprising an inorganic, platelike pigment having an average equivalent spherical diameter of at least 0.2 microns. The electrodepositable coating composition demonstrates a pigment-to-binder ratio of at least 0.5. The coating composition contains less than 8 percent by weight of a grind vehicle.

Owner:PPG IND OHIO INC

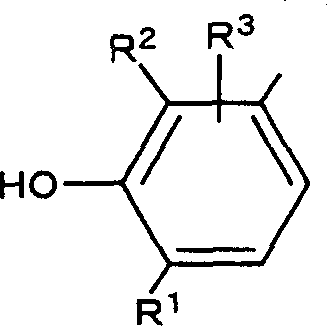

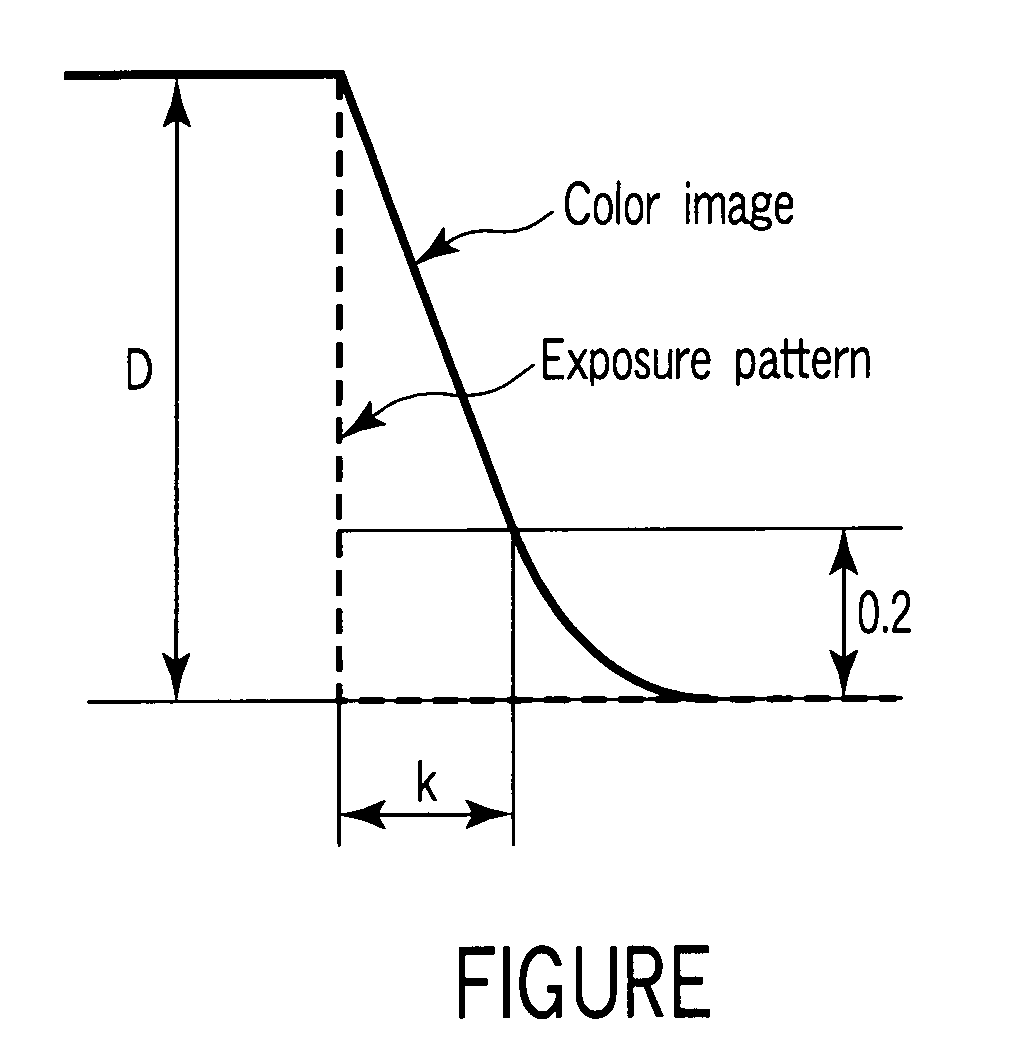

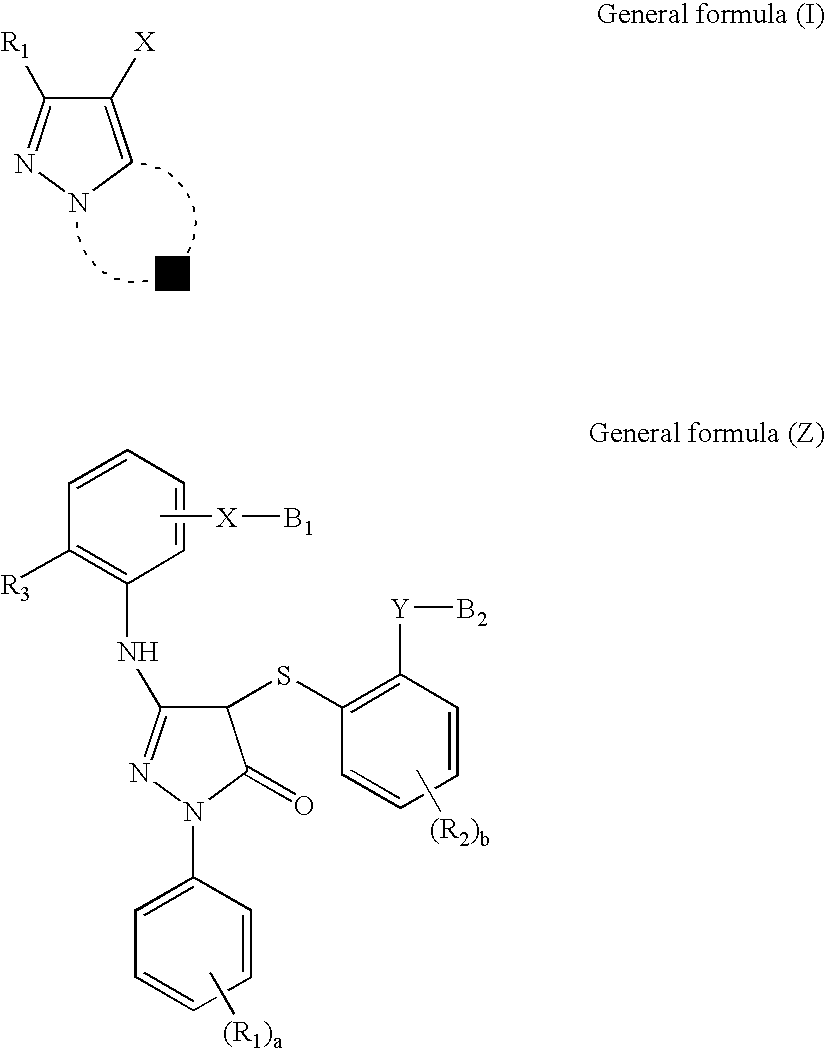

Silver halide photosensitive material and image-forming method using the same

InactiveUS20080026333A1High resolutionLittle deteriorationSilver halide emulsionsSilver halide subtractive colour processesImage formationEquivalent spherical diameter

A silver halide photosensitive material having at least one blue-sensitive layer, at least one green-sensitive layer, and at least one red-sensitive layer, on a transparent support, wherein at least one of the green-sensitive layers contains a coupler represented by general formula (I) or general formula (Z), and all of the green-sensitive layers contain silver halide emulsion having an average equivalent-spherical diameter of 0.35 μm or less:

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com