Coating composition and coated paper and coated paperboard

a technology of coating composition and coating paper, applied in the field of coating composition, can solve the problems of affecting the mechanical strength of the substrate, affecting the barrier properties, and affecting the application of significant strain on the paper or paperboard substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

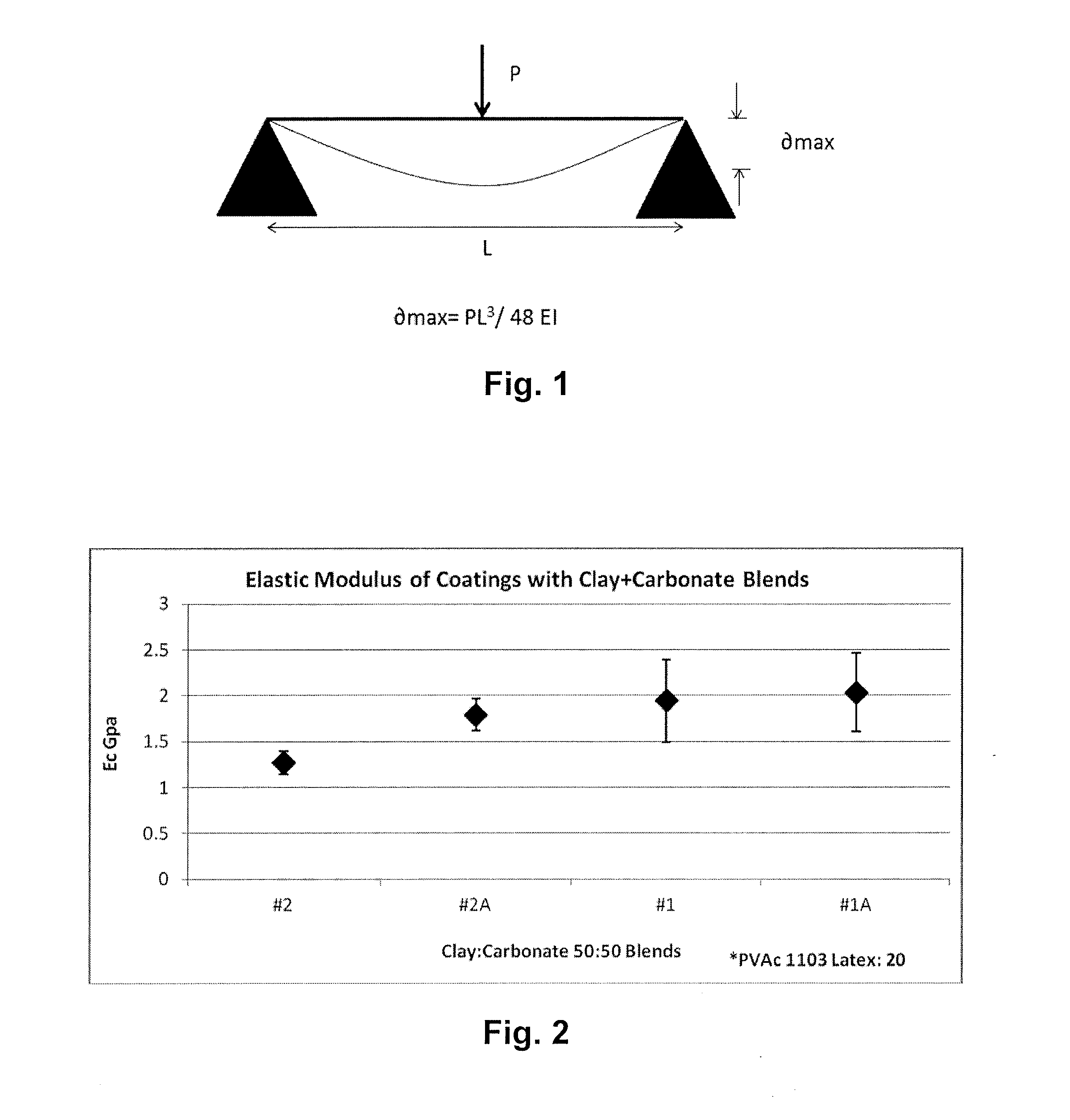

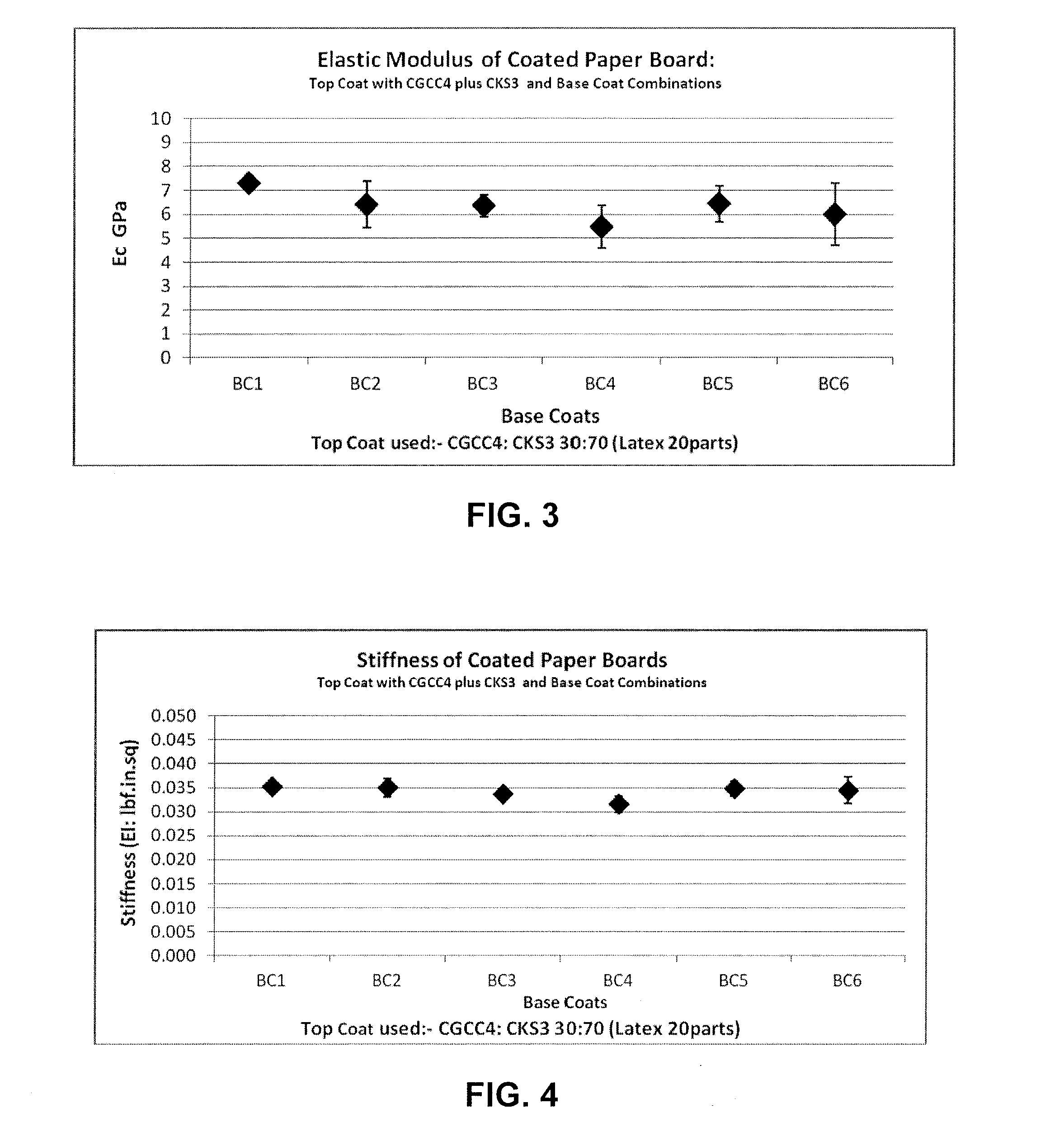

[0104]In order to evaluate coating compositions, typical paperboard used in the packaging industry was used as a substrate or base stock. Sample coating compositions containing selected platy clay and carbonate pigments were applied to the paperboards using a CLC (Cylindrical Lab Coater) machine. The sample coating compositions were applied on one side of the paperboard, and the samples were double-coated (i.e., a base coat and a top coat). The coated sample paperboards were then calendered, and bending modulus and stiffness tests were conducted on the coated and calendered paperboard samples. The samples were creased along machine and cross direction using a CreaseStream. Thereafter, the creased samples were folded using a rubber roller to mimic the creasing and folding in an industrial or manufacturing environment.

[0105]The failure occurring at the creased or folded path was observed under a microscope, and images were taken so that visual ratings of the flaked and cracked areas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| equivalent spherical diameter | aaaaa | aaaaa |

| mean particle size | aaaaa | aaaaa |

| mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com