Patents

Literature

319results about "Silicon hydrides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

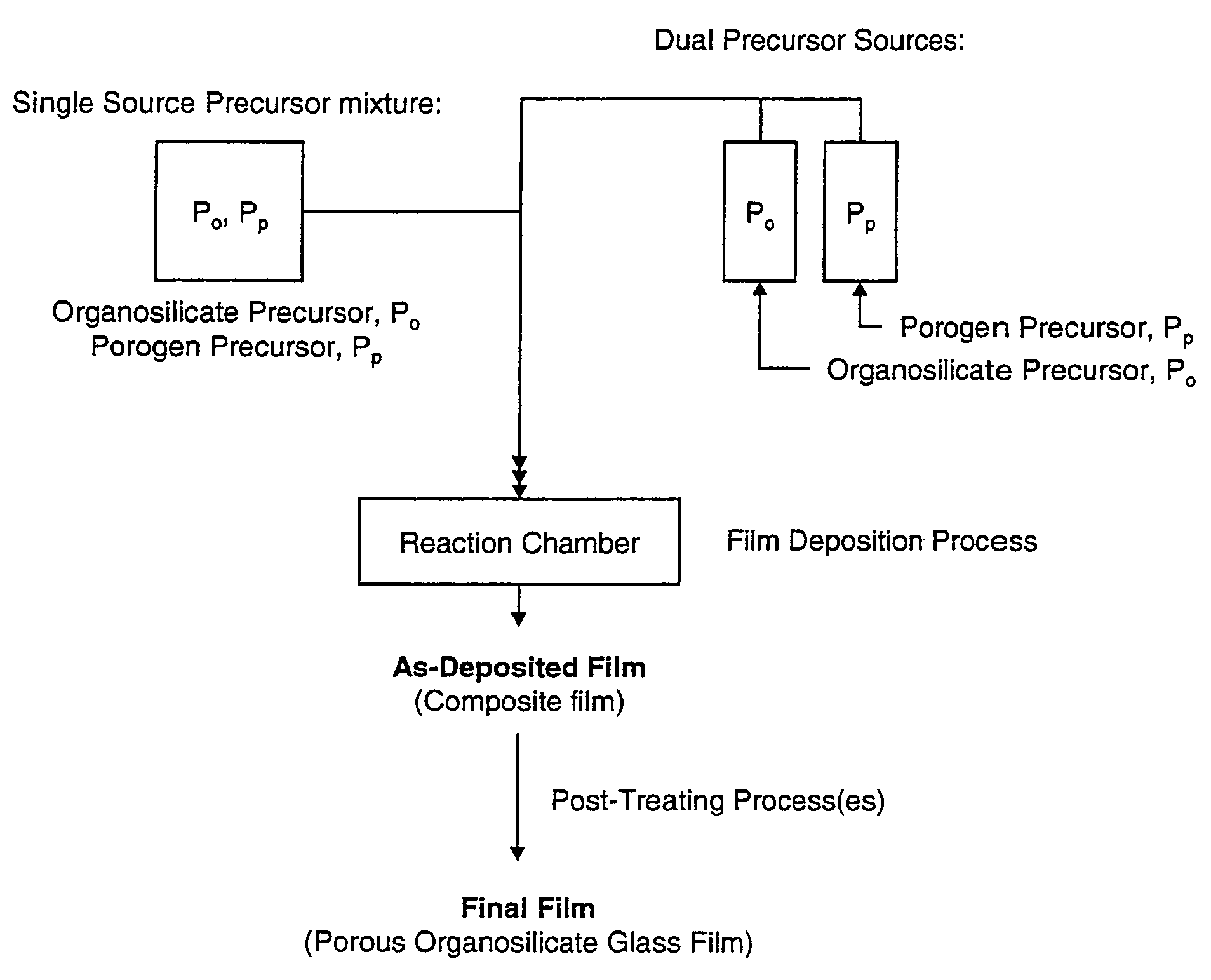

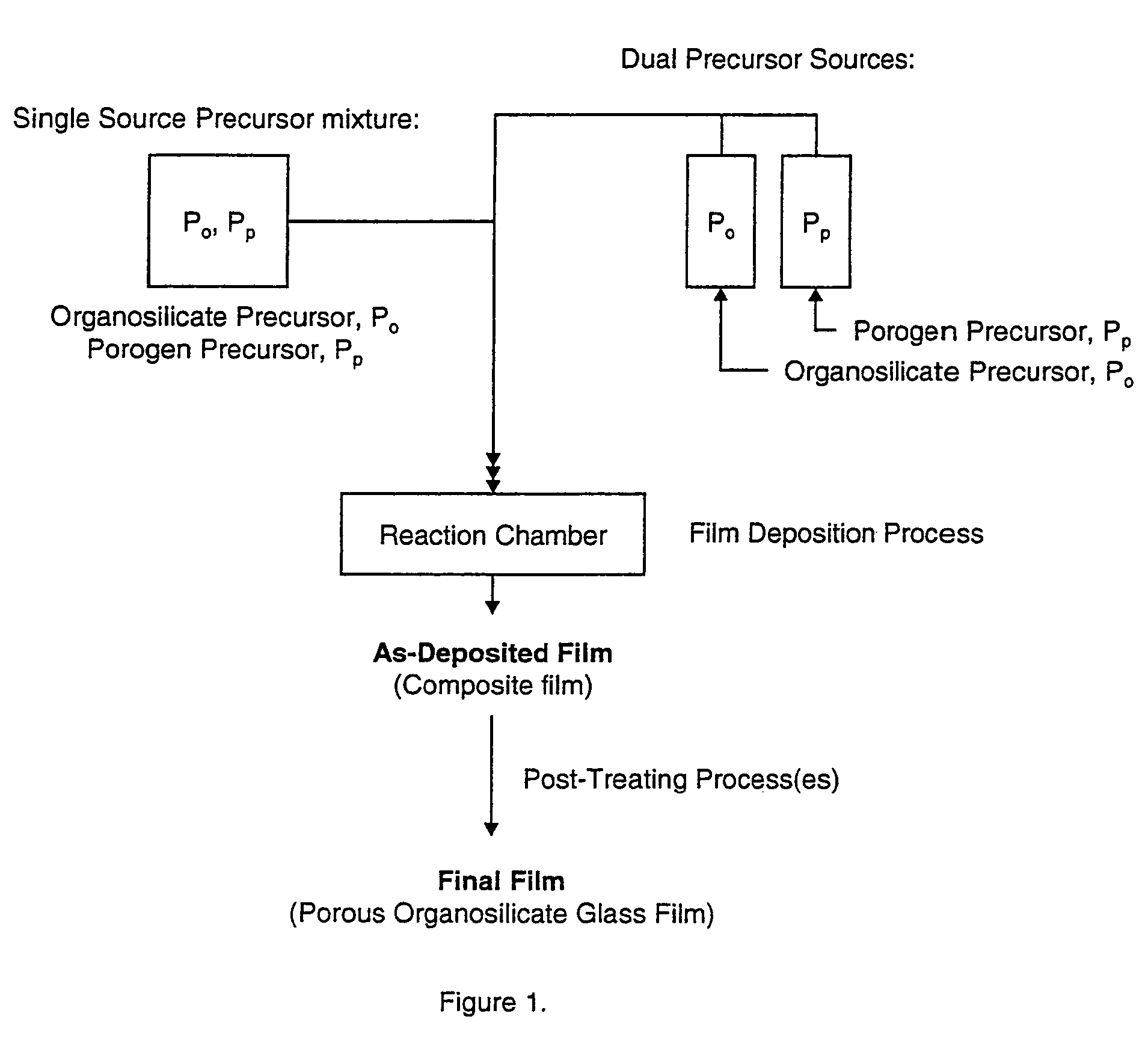

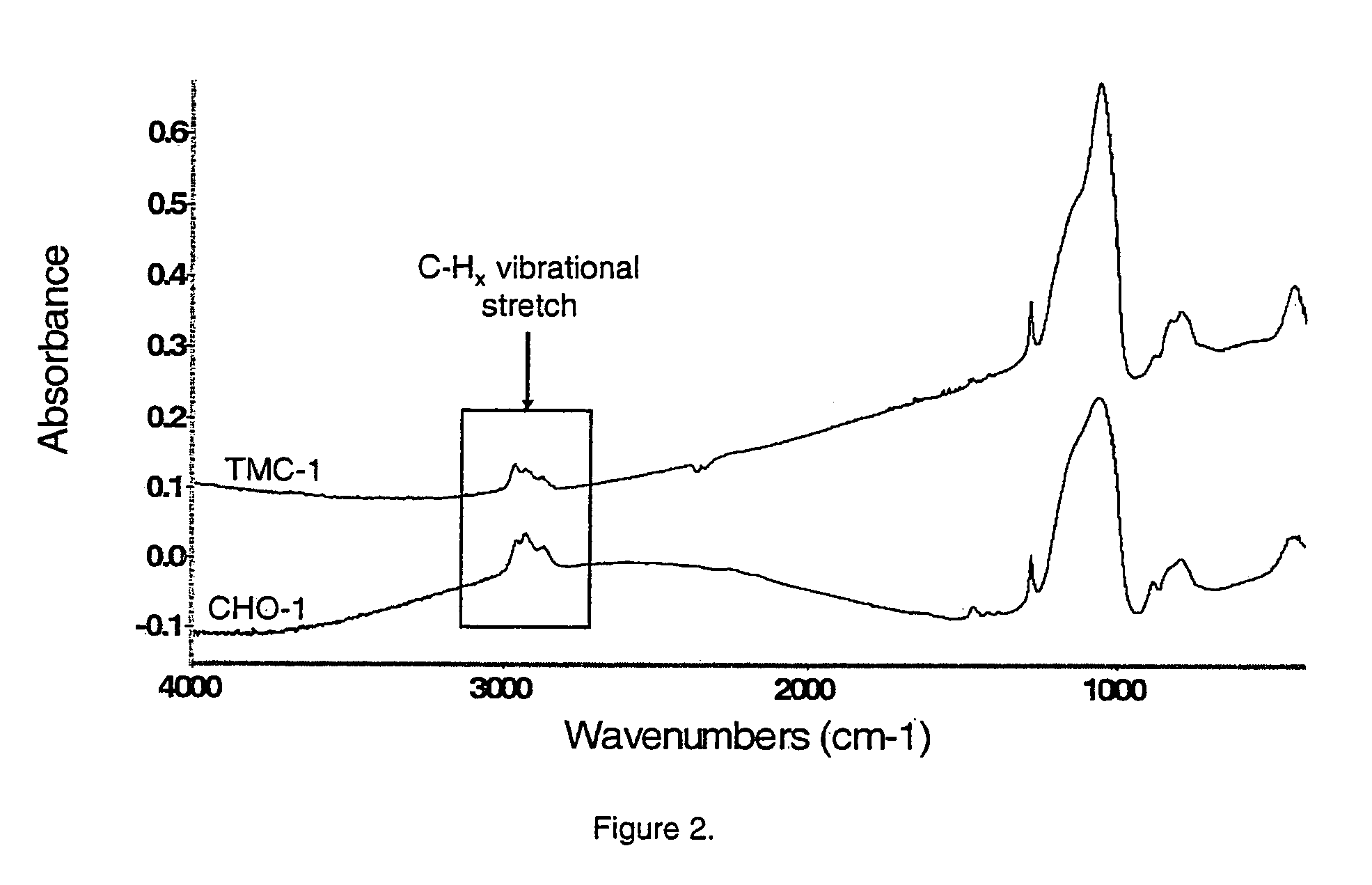

Porous low dielectric constant compositions and methods for making and using same

ActiveUS20060078676A1Semiconductor/solid-state device manufacturingPretreated surfacesConstant compositionCarboxylic acid

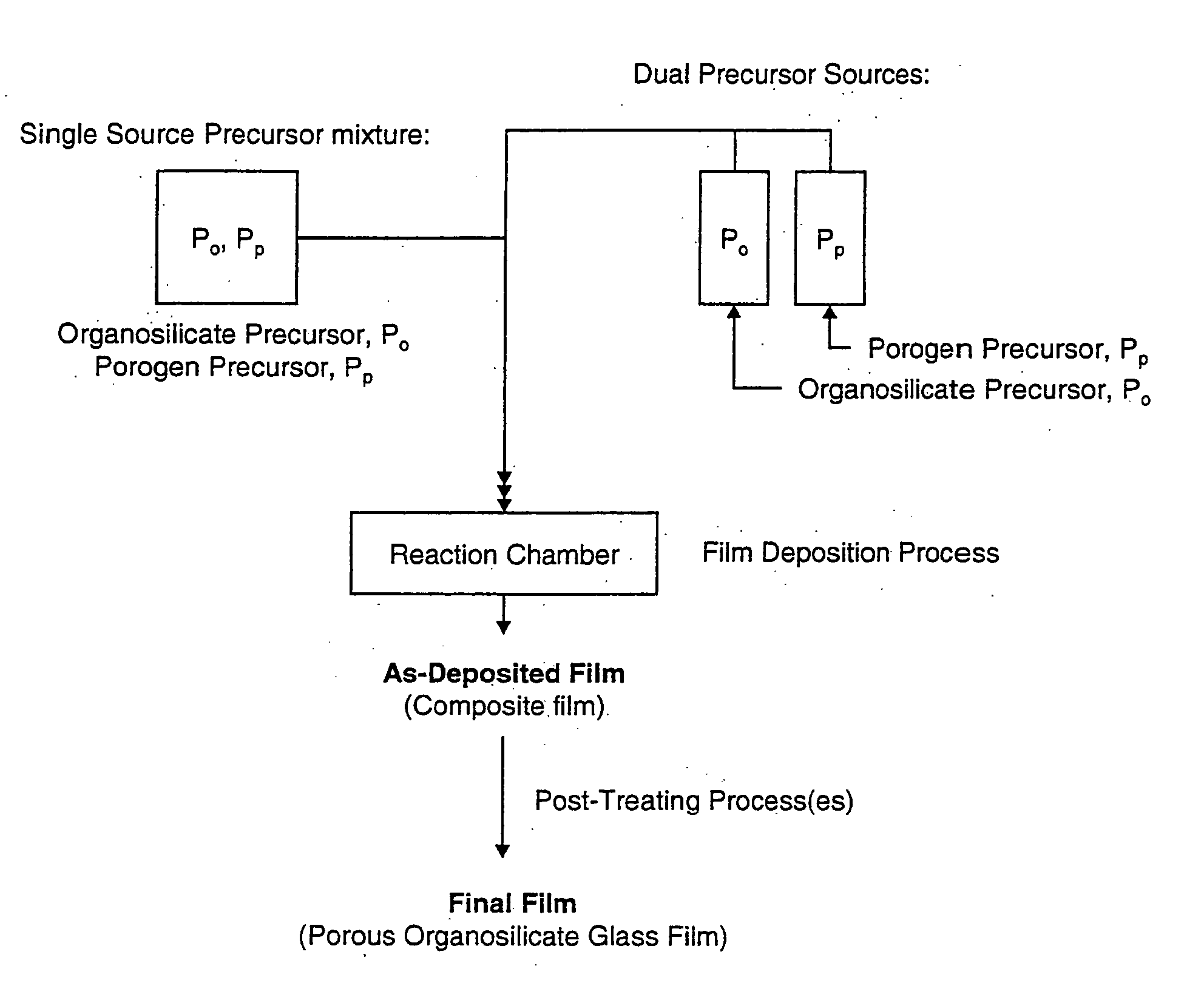

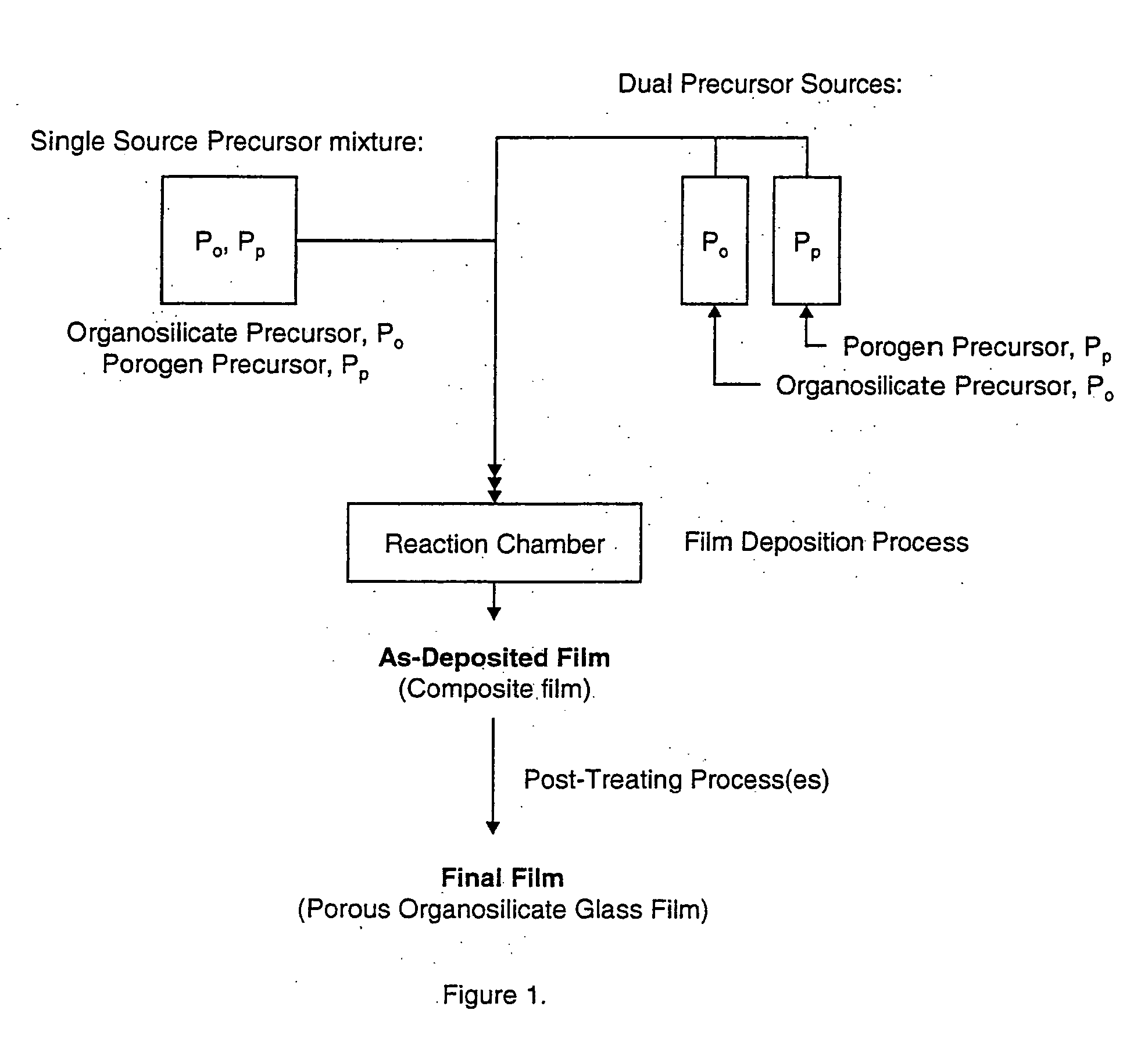

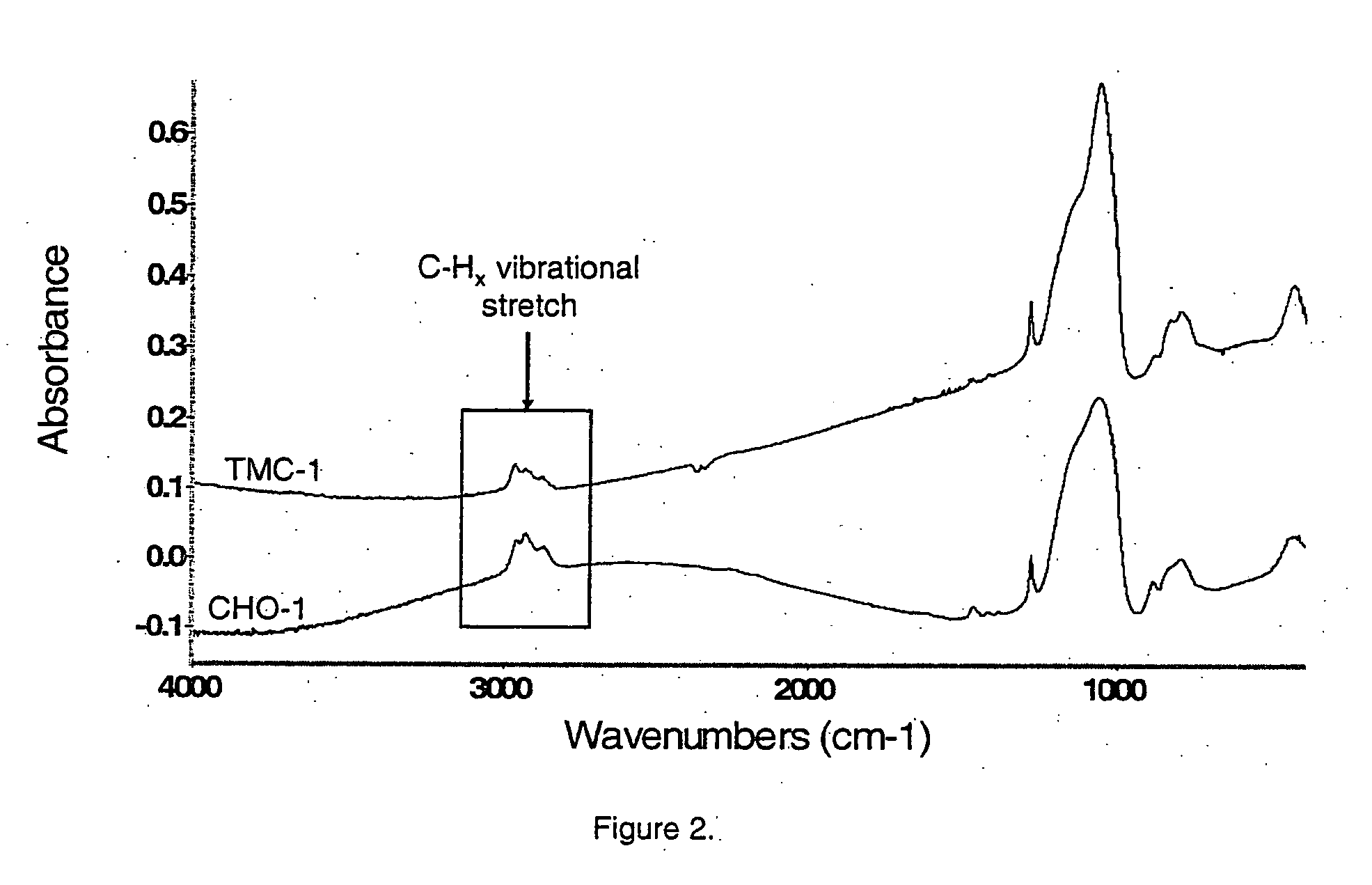

A porous organosilicate glass (OSG) film: SivOwCxHyFz, where v+w+x+y+z=100%, v is 10 to 35 atomic %, w is 10 to 65 atomic %, x is 5 to 30 atomic %, y is 10 to 50 atomic % and z is 0 to 15 atomic %, has a silicate network with carbon bonds as methyl groups (Si—CH3) and contains pores with diameter less than 3 nm equivalent spherical diameter and dielectric constant less than 2.7. A preliminary film is deposited by a chemical vapor deposition method from organosilane and / or organosiloxane precursors, and independent pore-forming precursors. Porogen precursors form pores within the preliminary film and are subsequently removed to provide the porous film. Compositions, film forming kits, include organosilane and / or organosiloxane compounds containing at least one Si—H bond and porogen precursors of hydrocarbons containing alcohol, ether, carbonyl, carboxylic acid, ester, nitro, primary amine, secondary amine, and / or tertiary amine functionality or combinations.

Owner:VERSUM MATERIALS US LLC

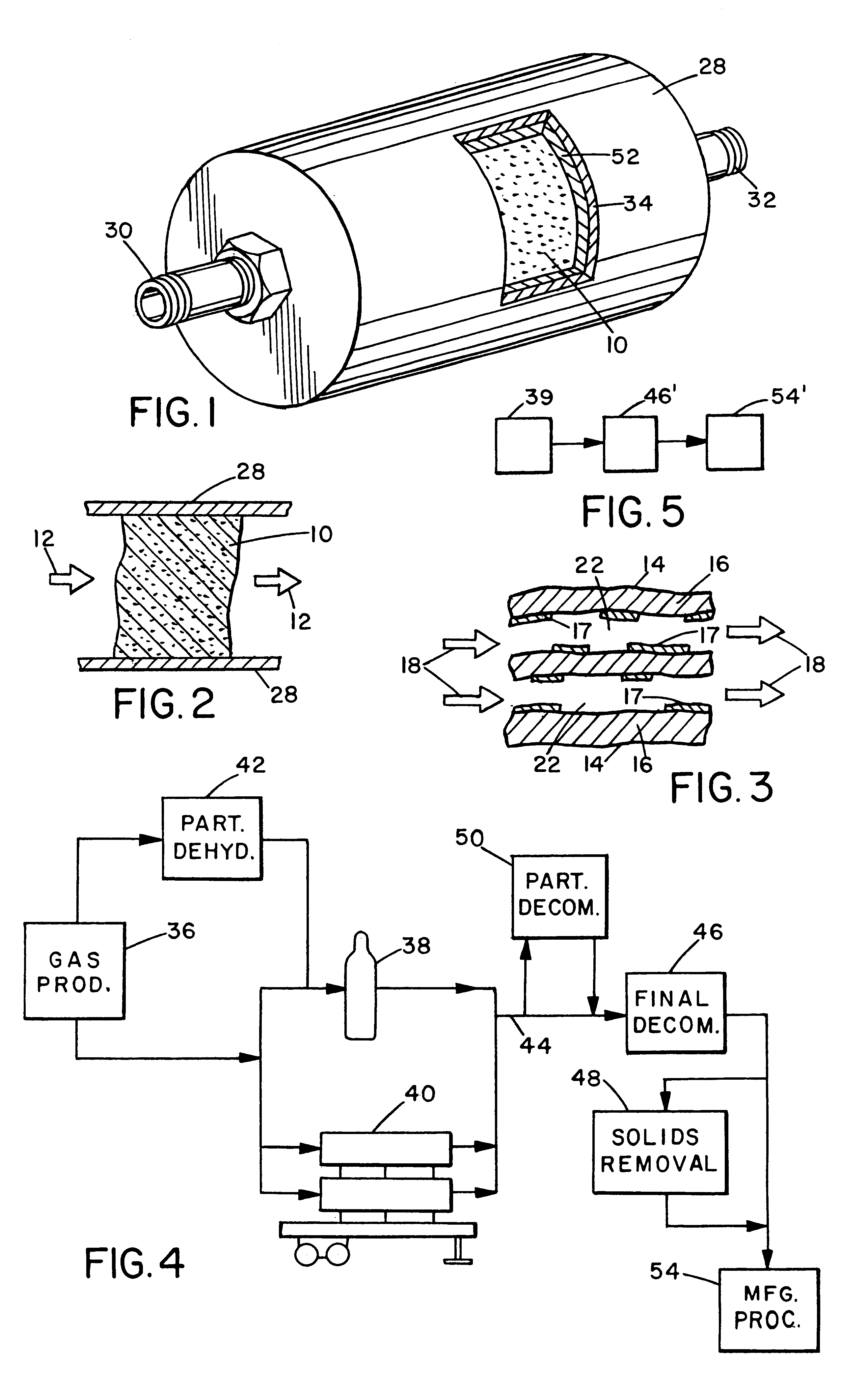

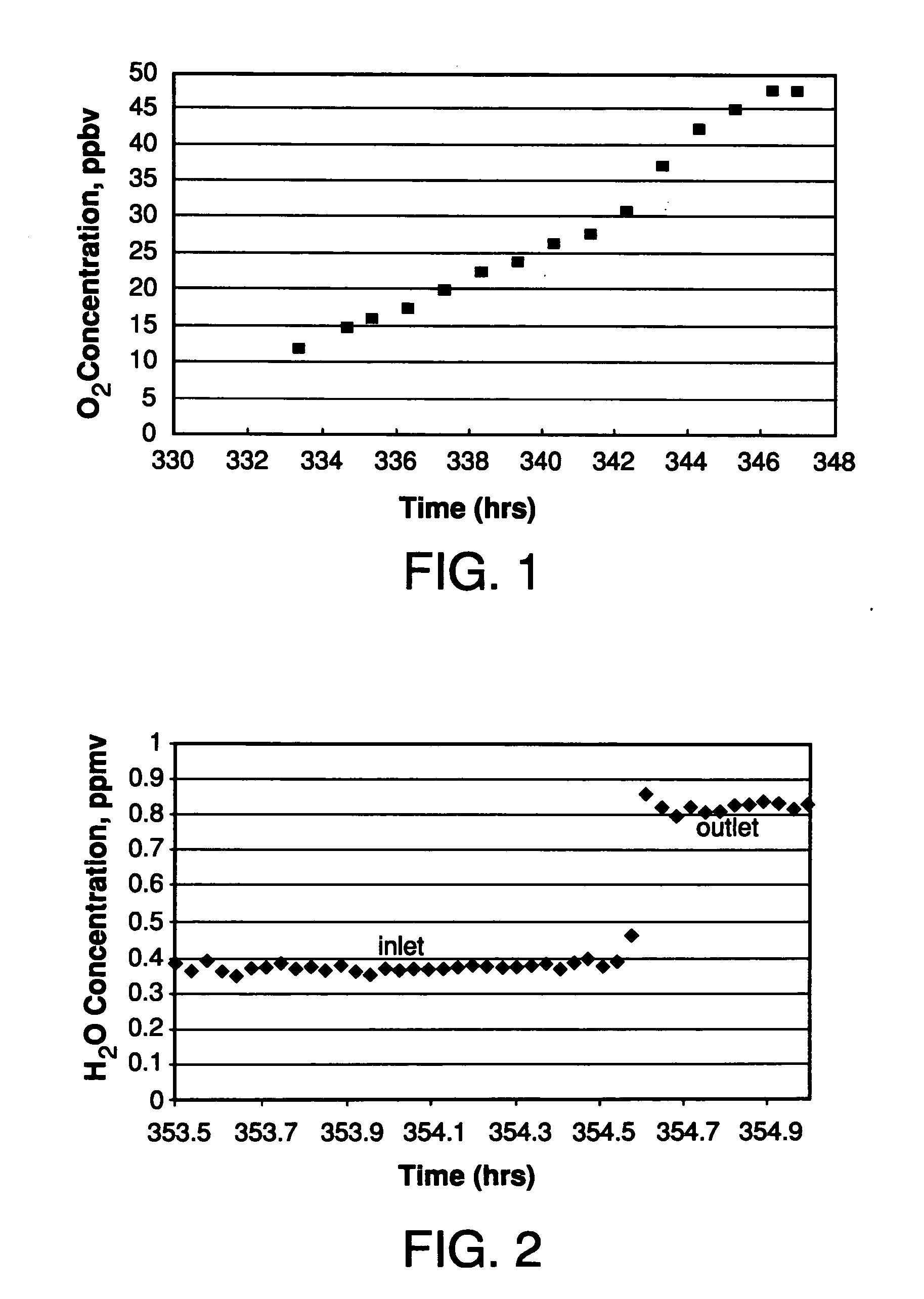

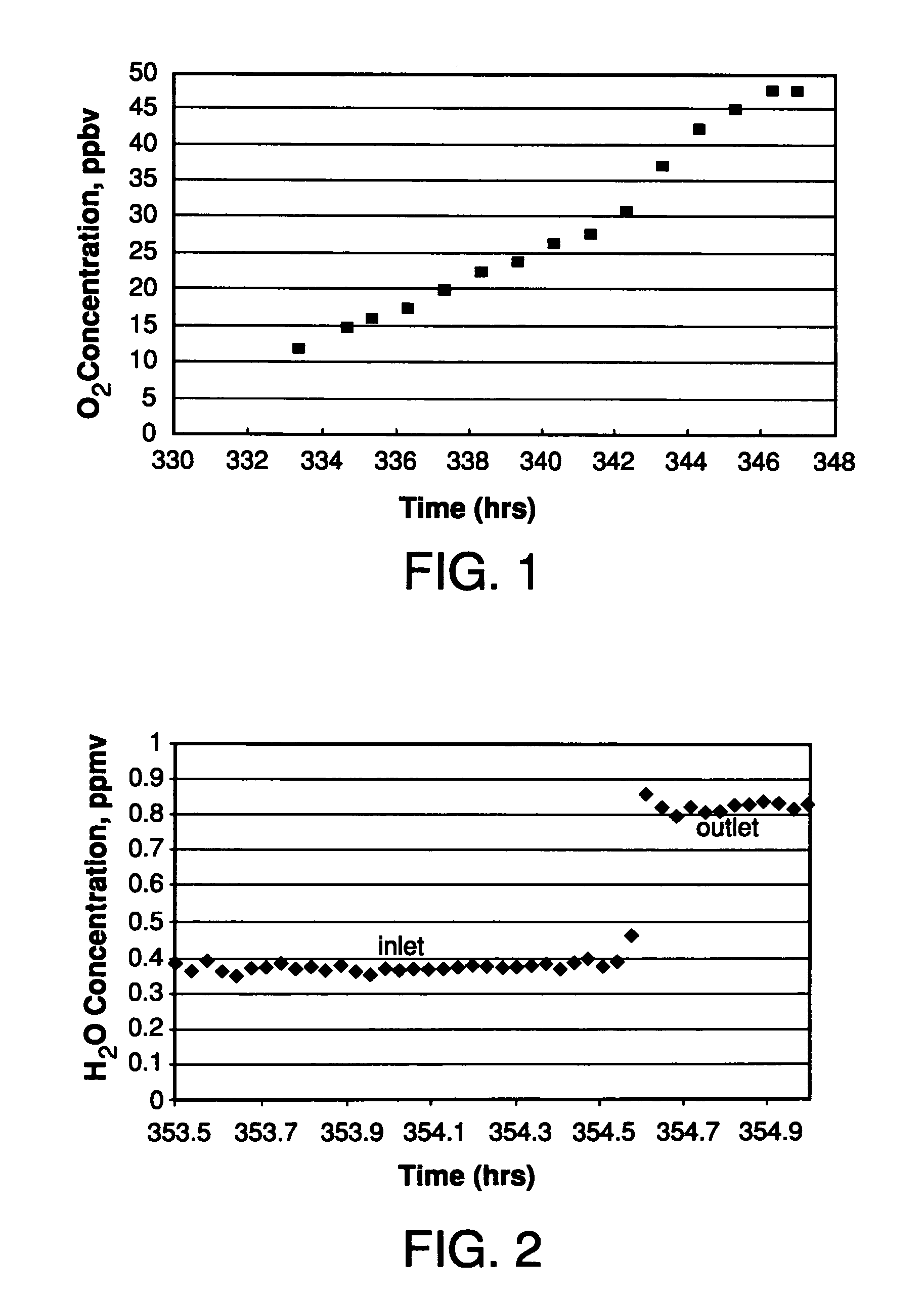

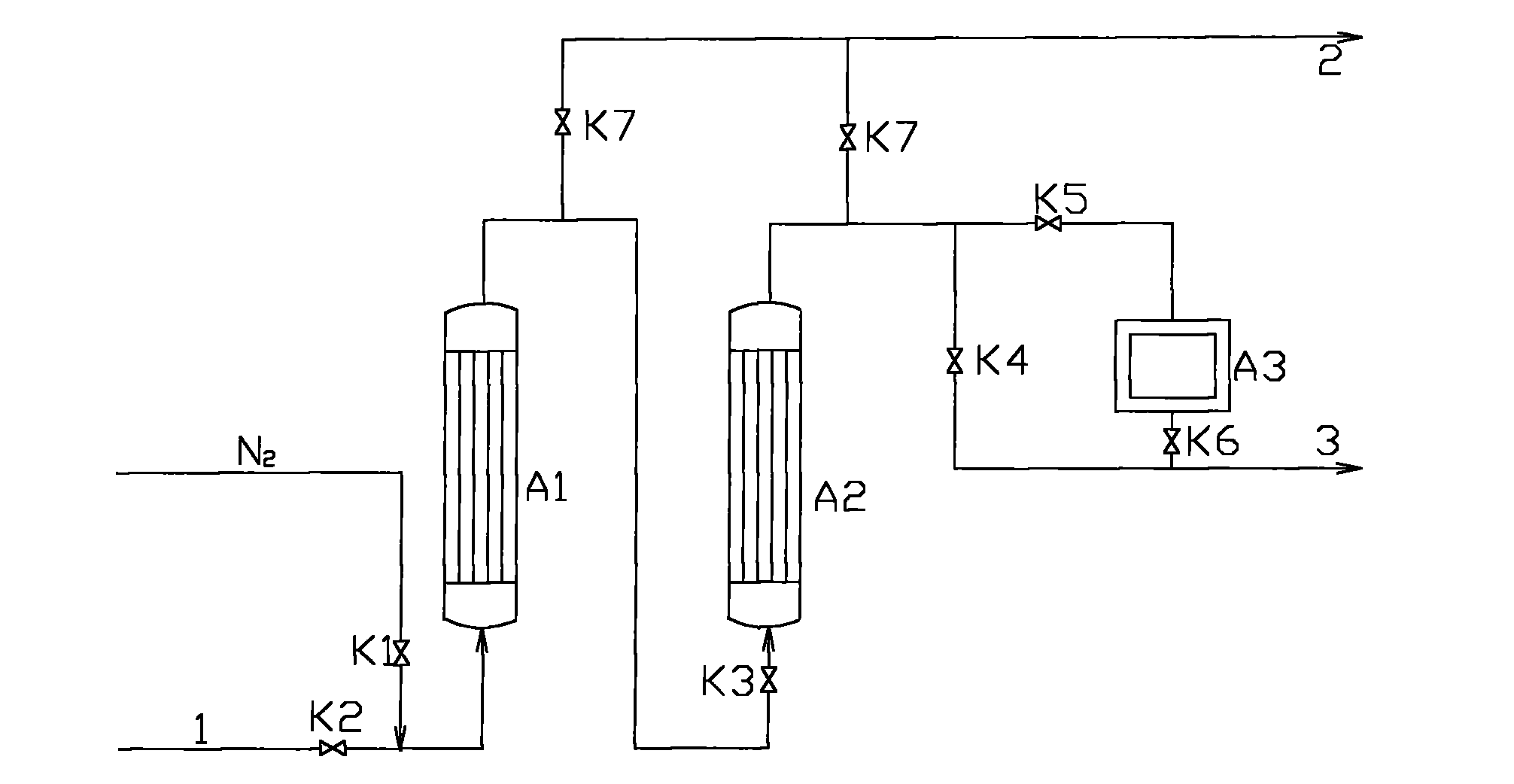

Method and apparatus for purification of hydride gas streams

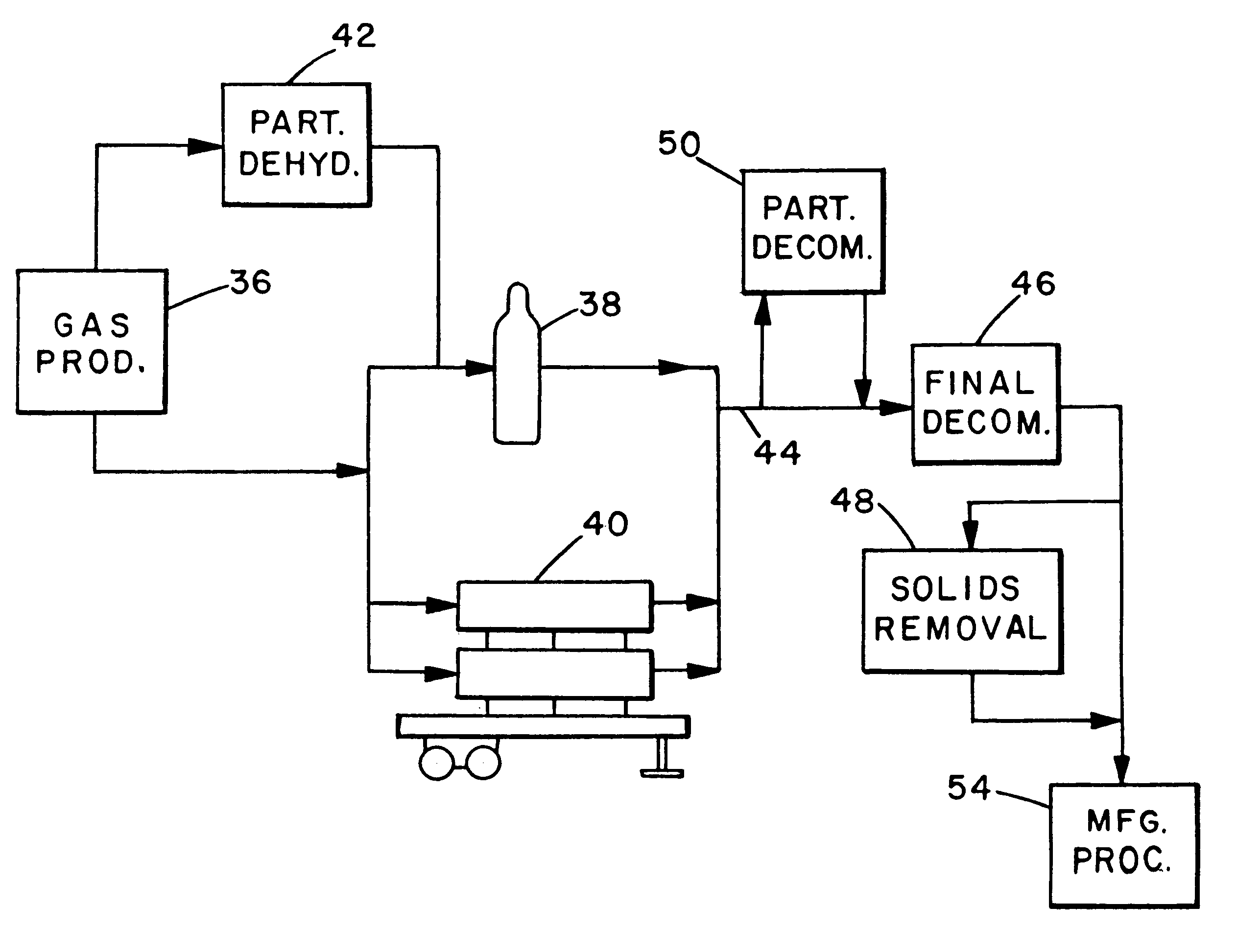

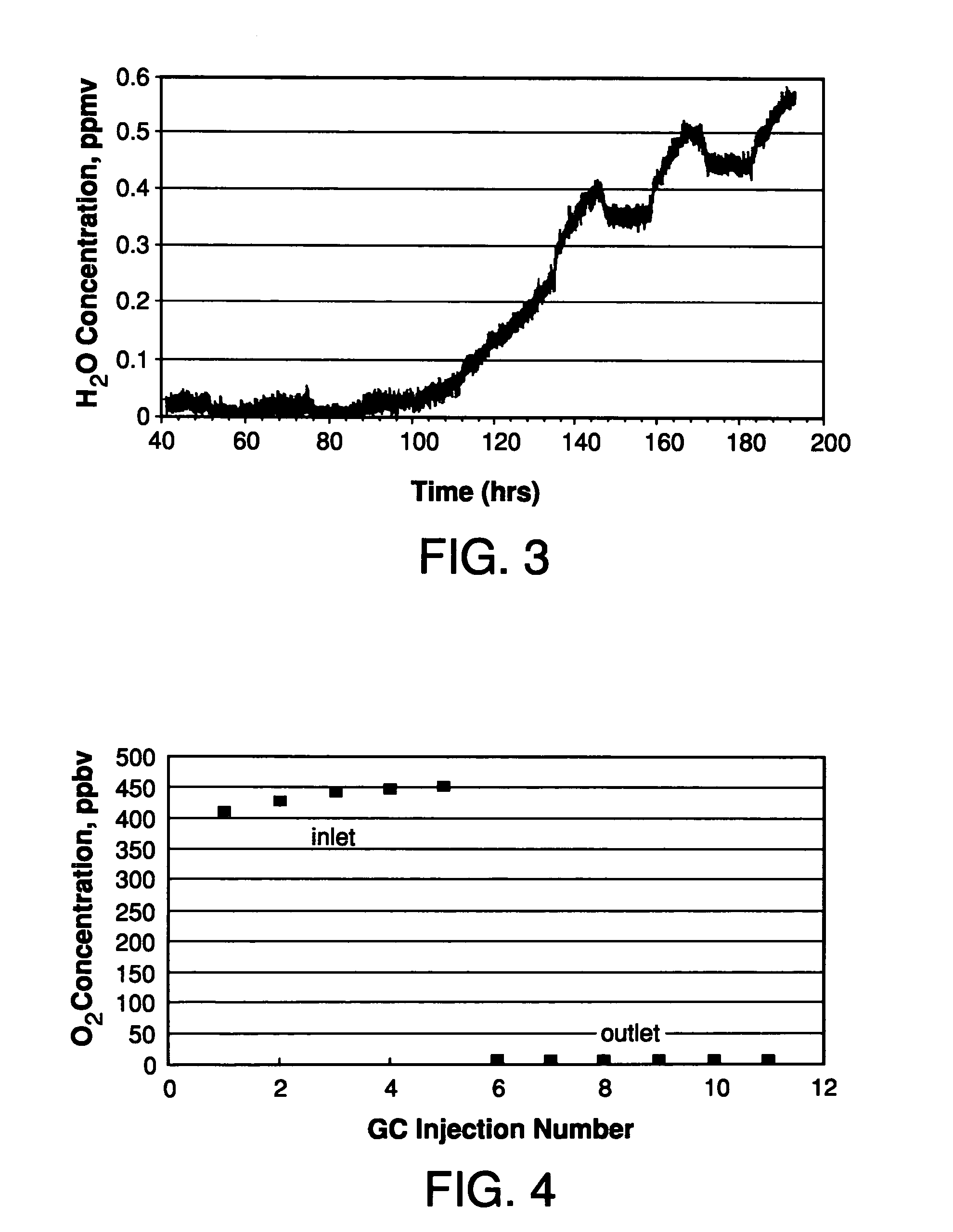

A process and apparatus for the decontamination of gaseous contaminants (especially oxygen, carbon dioxide and water vapor) from hydride gases (including their lower alkyl analogs) down to <=100 ppb contaminant concentration are described. The critical component is a high surface area metal oxide substrate with reduced metal active sites, which in various physical forms is capable of decontaminating such gases to <=100 ppb, <=50 ppb or <=10 ppb level without being detrimentally affected by the hydride gases. The surface area of the substrate will be >=100 m2 / g, and preferably 200-800 m2 / g. Oxides of various metals, especially manganese or molybdenum, can be used, and mixtures of integrated oxides, or one type of oxide coated on another, may be used. The substrate is preferably retained in a hydride-gas-resistant container which is installed in a gas supply line, such as to a gas- or vapor-deposition manufacturing unit. The invention provides final decontamination for hydride gas streams intended for gas- or vapor-deposition formation of high purity LED, laser (especially blue laser), electronic, optical or similar products, and can be used in combination with upstream preliminary decontamination process and / or upstream or downstream solid particulate removal units.

Owner:SAES PURE GAS

Porous low dielectric constant compositions and methods for making and using same

Owner:VERSUM MATERIALS US LLC

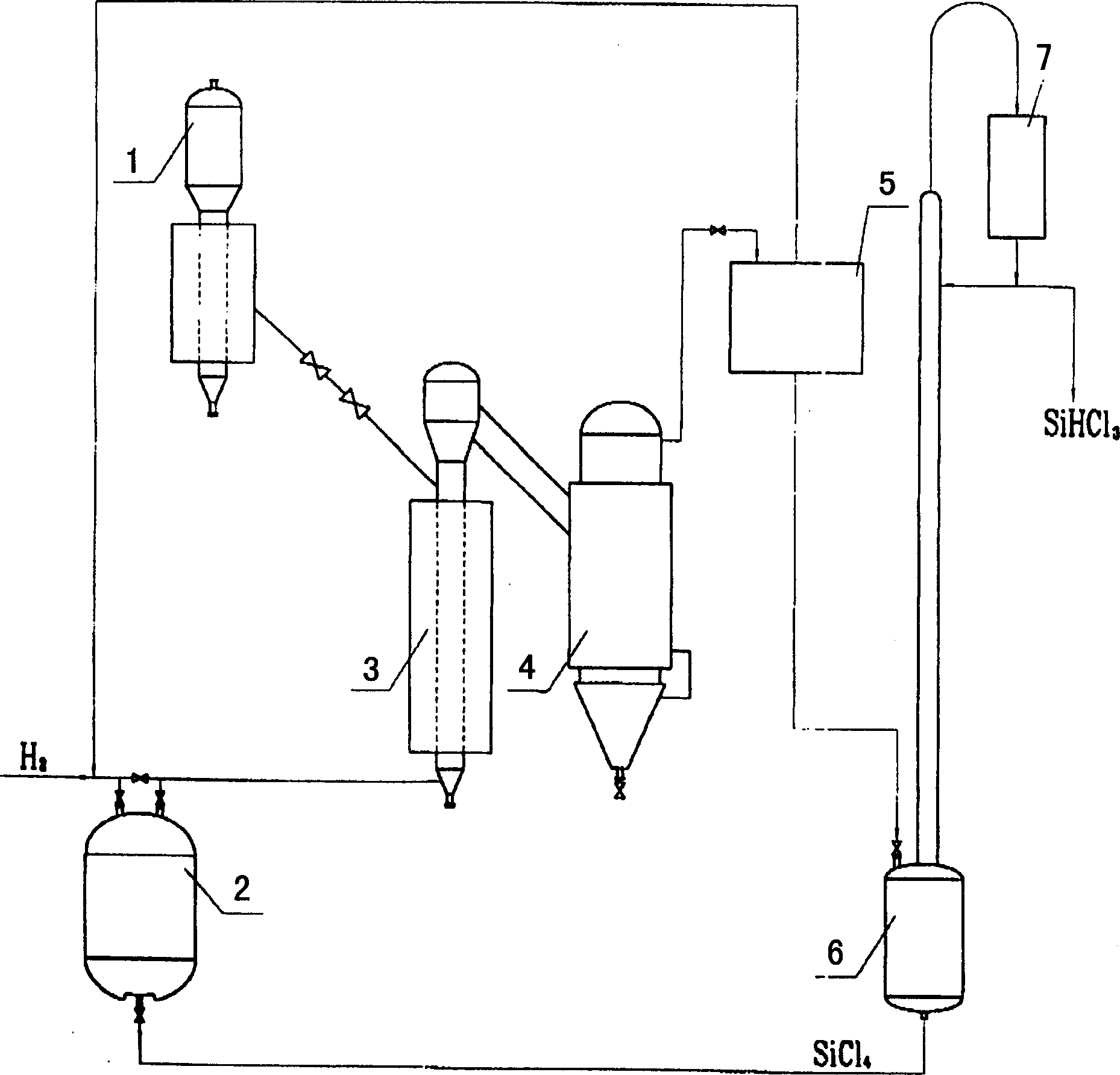

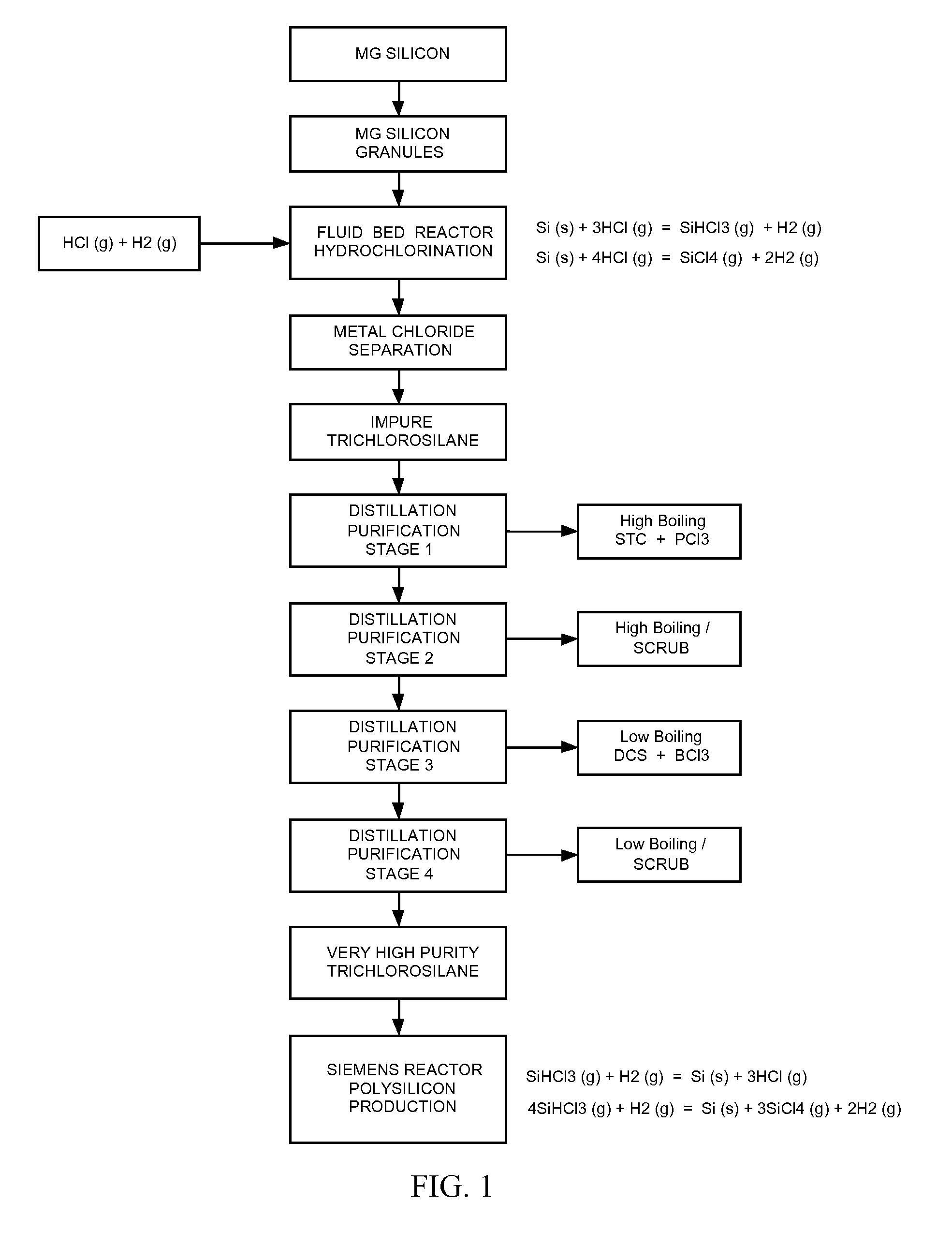

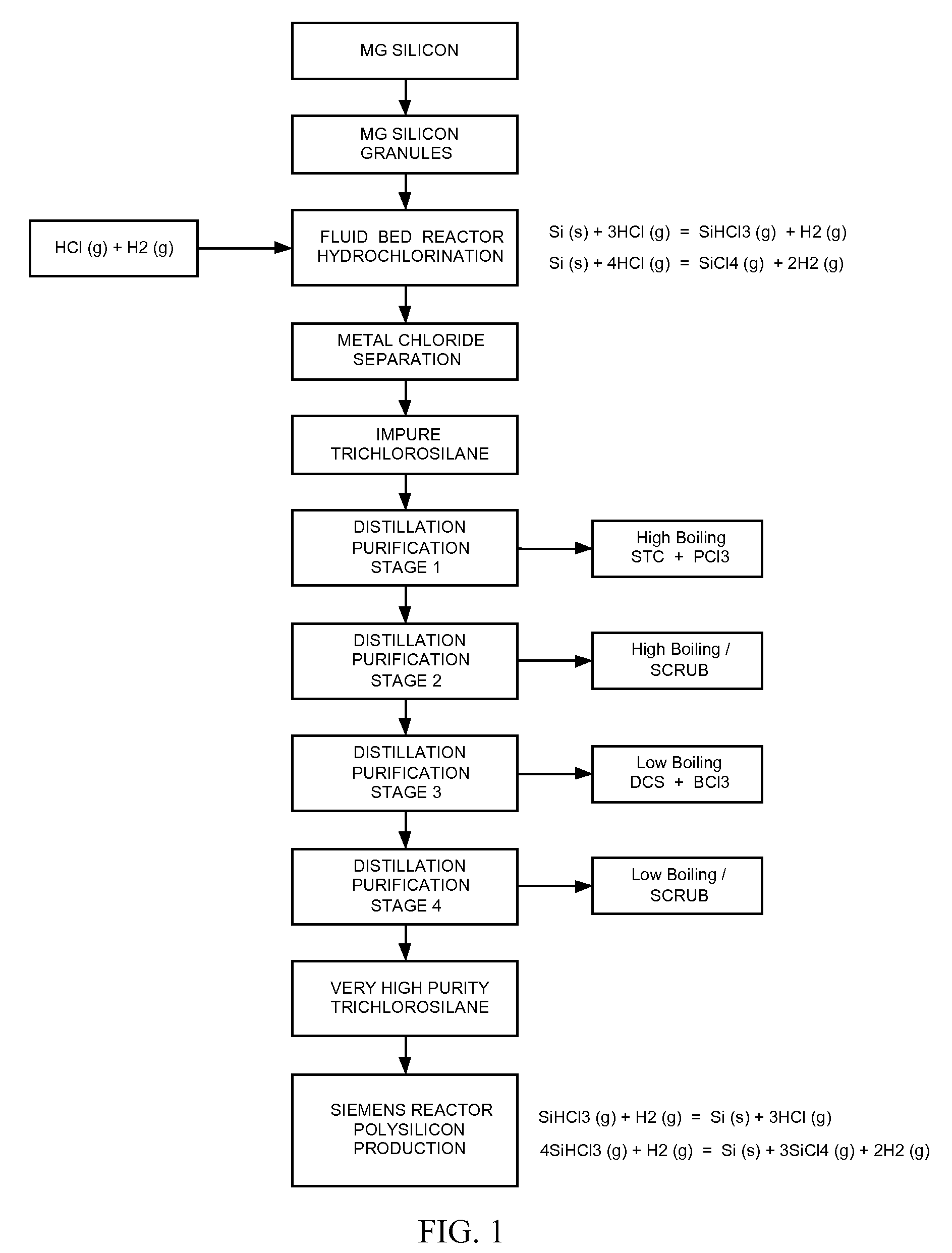

Silicon tetrachloride hydrogenating process of producing trichloro hydrosilicon

InactiveCN1436725ANo pollution in the processEasy to controlSilicon hydridesHalogenated silanesNickel catalystHydrogen atmosphere

The silicon tetrachloride hydrogenating process of producing trichloro-hydrosilicon includes: mixing powdered nickel catalyst and silicon powder in the mass ratio of 1-10 and activating the mixture in hydrogen atmosphere and at the temperature of continuously change from 20 deg.C to 420 deg.c; and making mixed gas of hydrogen and SiCl4 in the molar ratio of 1-10 pass through the activated catalyst and silicon powder layer for hydrogenating SiCl4 continuously at 400-500 deg.c temperature and 1.2-1.5 MPa pressure. The equipment, system and operation of the present invention has high once SiCl4 converting rate and low power consumption and may be used in large-scale production.

Owner:CHINA ENFI ENG CO LTD

Negative-electrode active material for nonaqueous electrolyte secondary battery, and negative electrode and nonaqueous electrolyte secondary battery using the same

InactiveUS20070207381A1Excellent cycle characteristicsIncrease energy densityNegative electrodesSilicon hydridesLithiumHydrogen

A negative-electrode active material for nonaqueous electrolyte secondary battery, comprising a silicon compound capable of inserting and extracting lithium ion, wherein the silicon compound contains silicon-hydrogen bonds and the silicon-hydrogen bonds are introduced into the compound by reduction of at least one compound selected from the group consisting of silicon oxide, silicon nitride and silicon carbide with hydrogen, and a negative electrode for nonaqueous electrolyte secondary battery having a layer containing the negative-electrode active material in the above arrangement formed on a current collector.

Owner:PANASONIC CORP

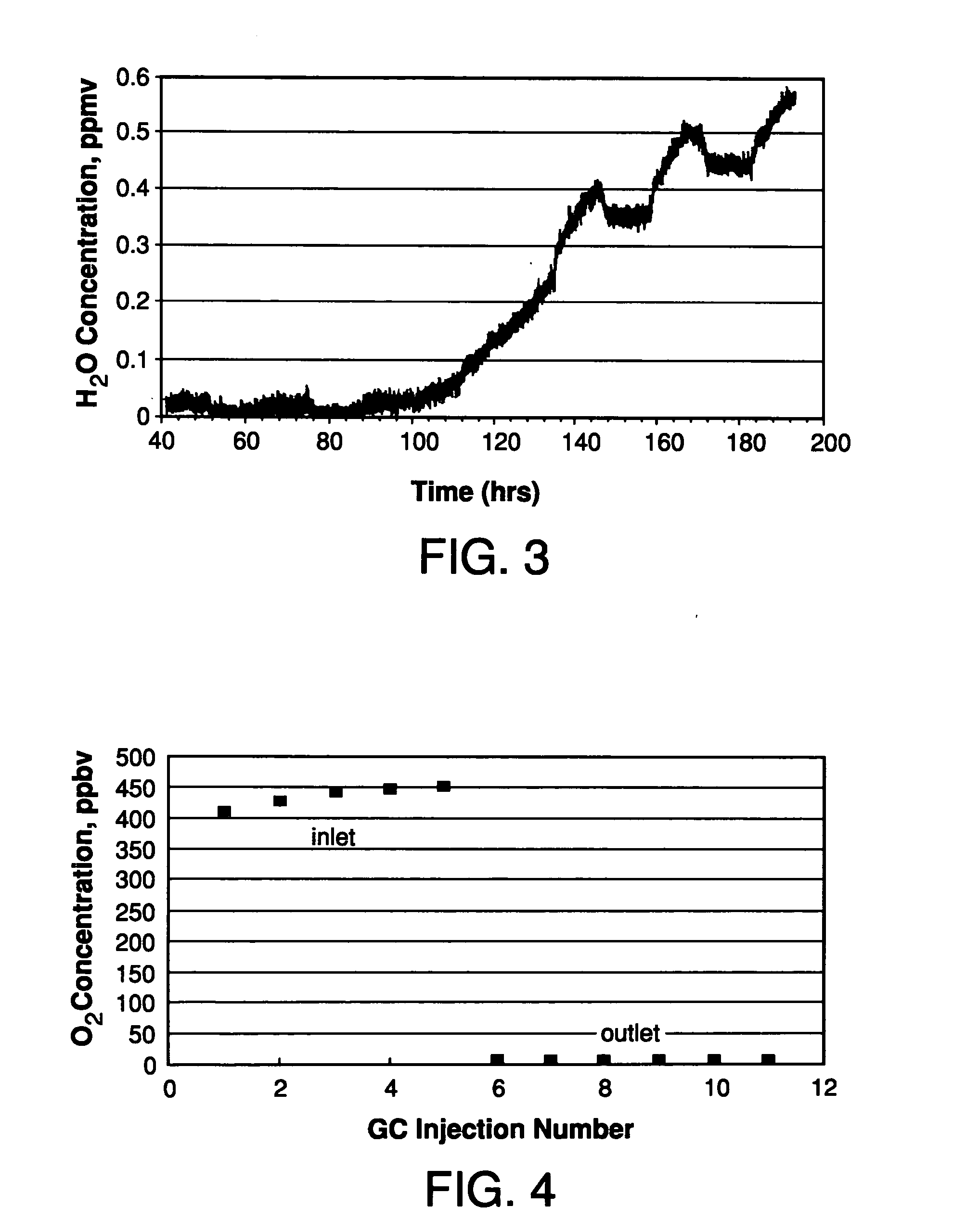

Purification of hydride gases

Purification material for removing a contaminant from an impure hydride gas comprising an adsorbent comprising a reduced metal oxide on a porous support and a desiccant. The porous support may be selected from the group consisting of activated carbon, alumina, silica, zeolite, silica alumina, titania, zirconia, and combinations thereof. The reduced metal oxide may comprise one or more metals selected from the group consisting of Group I alkali metals (lithium, sodium, potassium, rubidium, and cesium), Group II alkaline earth metals (magnesium, calcium, strontium, and barium), and transition metals (manganese, nickel, zinc, iron, molybdenum, tungsten, titanium, vanadium, cobalt, and rhodium). The desiccant may be selected from the group consisting of hygroscopic metal salts, zeolites, single metal oxides, mixed metal oxides, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

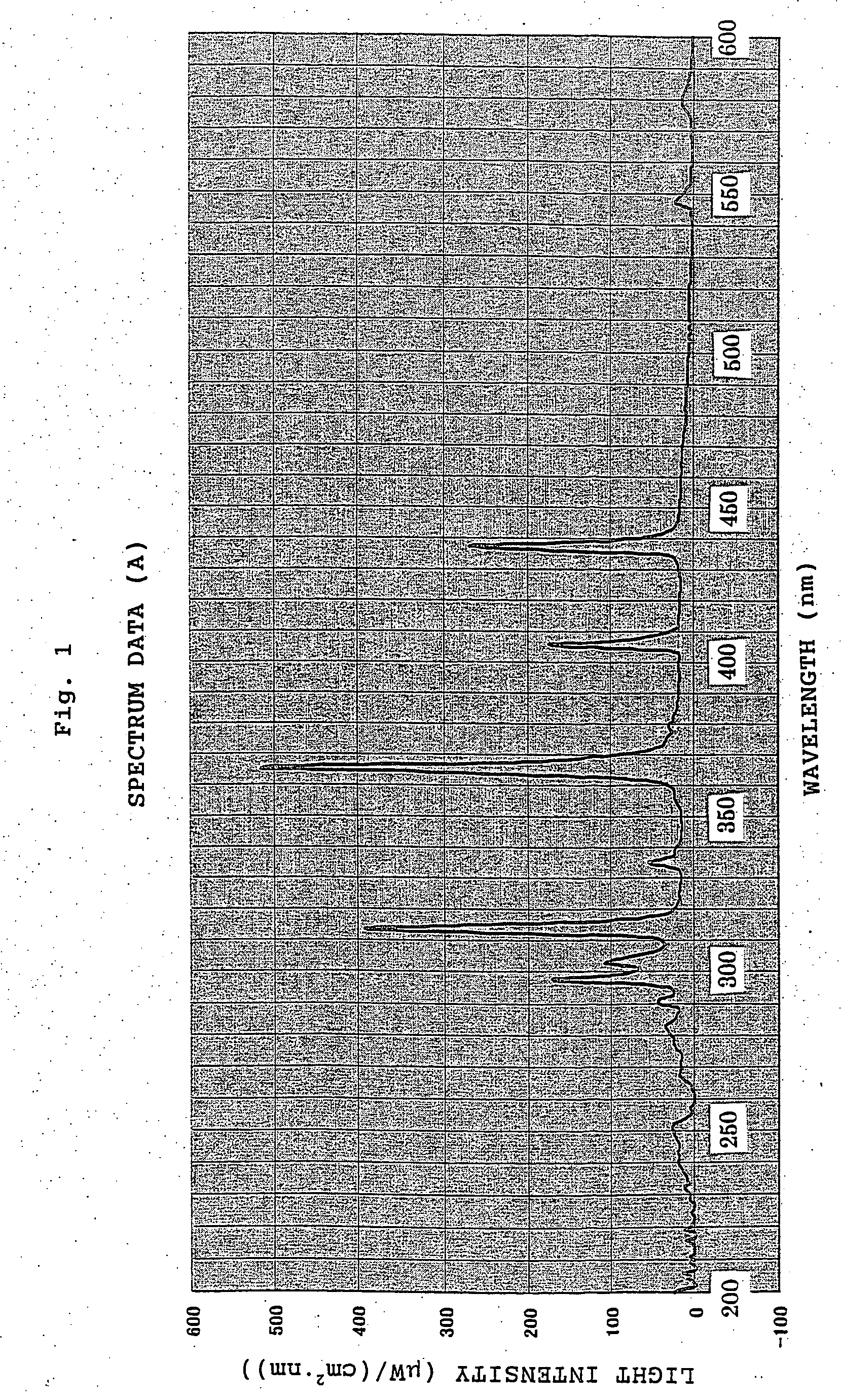

Silane polymer and method for forming silicon film

InactiveUS20060159859A1High molecular weightSilicon organic compoundsSiliconSilane compoundsBoiling point

There are provided a silane polymer having a higher molecular weight from the viewpoints of wettability when applied to a substrate, a boiling point and safety, a composition which can form a high-quality silicon film easily, a silicon film forming composition which comprises a silane polymer obtained by irradiating a photopolymerizable silane compound with light of specific wavelength range to photopolymerize it, and a method for forming a silicon film which comprises applying the composition to a substrate and subjecting the coating film to a heat treatment and / or a light treatment.

Owner:JSR CORPORATIOON

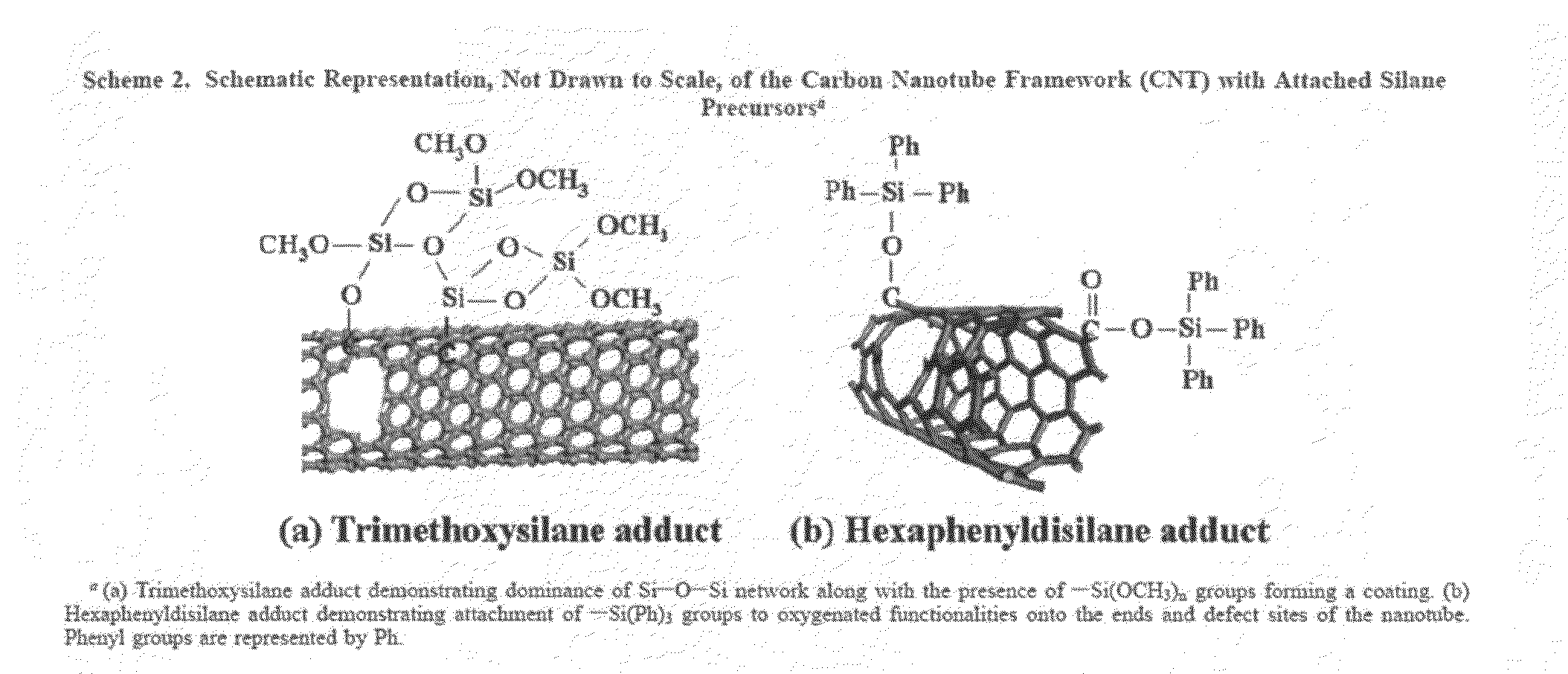

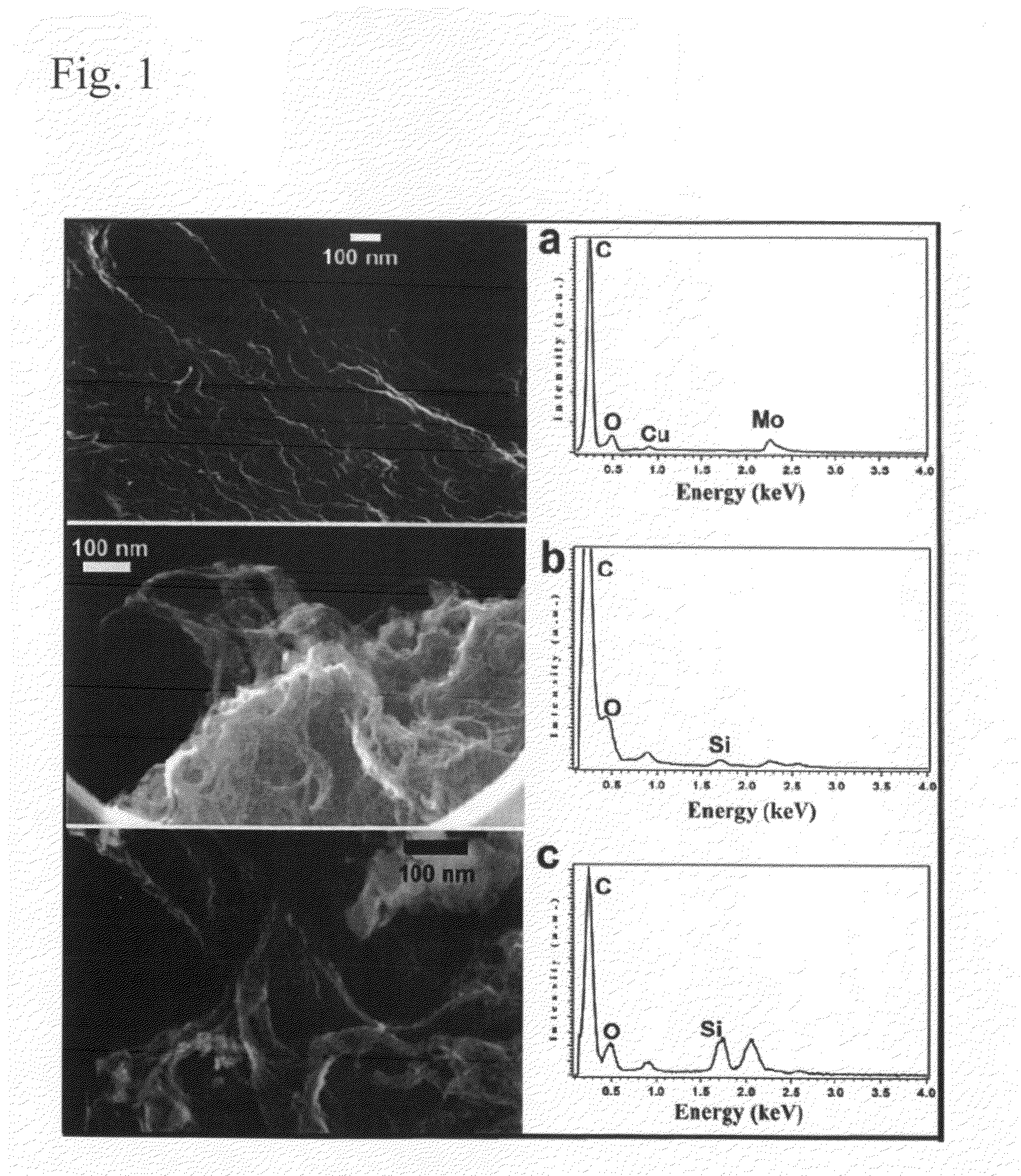

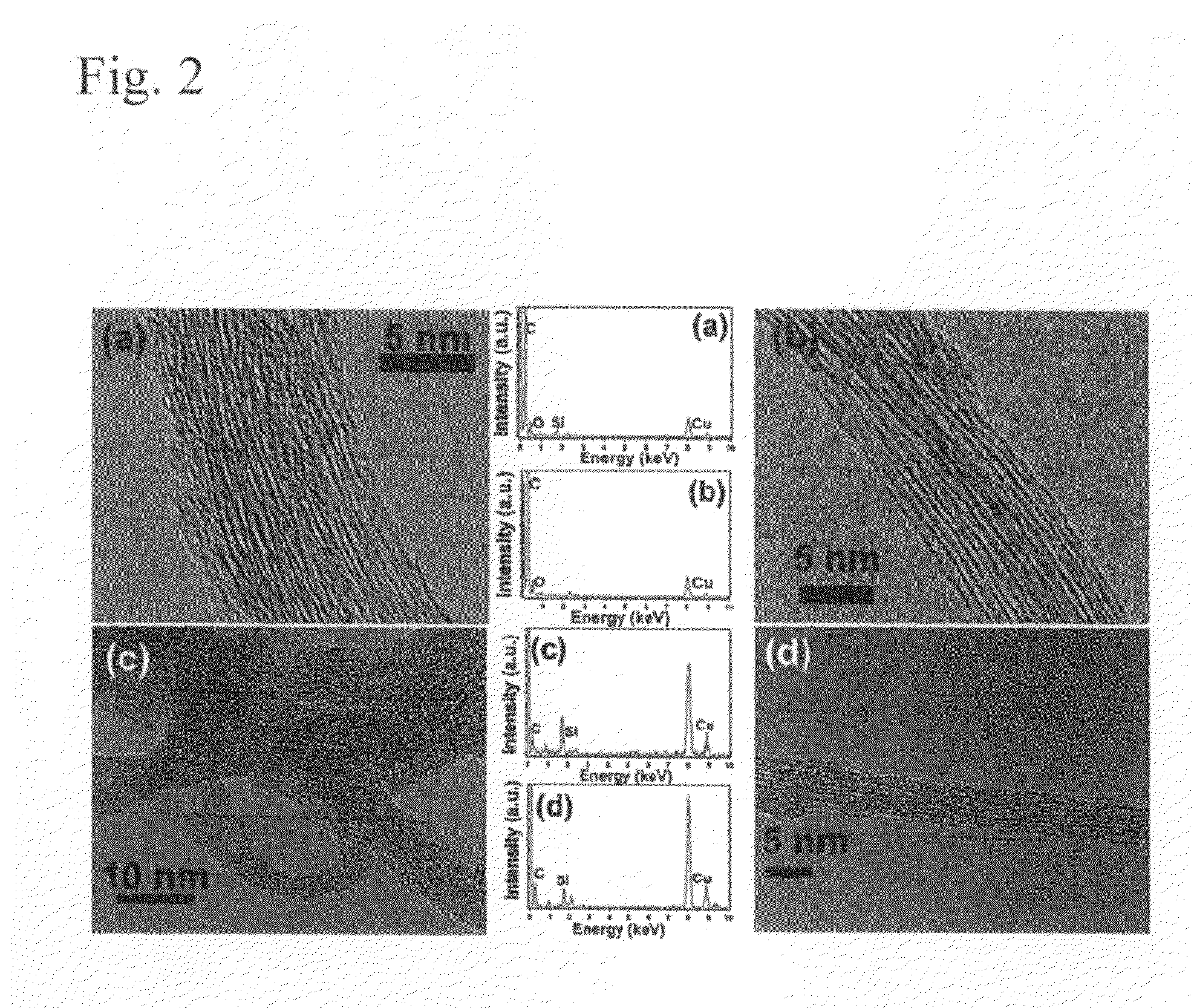

Silylated carbon nanotubes and methods of making same

InactiveUS20090060815A1Silicon organic compoundsMaterial nanotechnologyTert-butyldimethylsilaneBis(trimethylsilyl)amine

The invention provides adducts comprising a carbon nanotube with covalently attached silane moieties, and methods of making such adducts. Examples of silane moieties include trimethoxysilane; hexaphenyldisilane; silylphosphine; 1,1,1,3,5,5,5-heptamethyltrisiloxane; polydimethylsiloxane, poly(N-bromobenzene-1,3-disulfonamide); N,N,N′,N′-tetrabromobenzene-1,3-disulfonamide; hexamethyldisilazane (HMDS); chlorotrimethylsilane (TMCS); trichloromethylsilane (TCMS); an alkyl(alkylamino)silane; a tri(alkoxy)silane; tert-butyldimethylsilane; monochloroaminosilane; dichloroaminosilane; trichloroaminosilane; and dimethylaminosilane.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

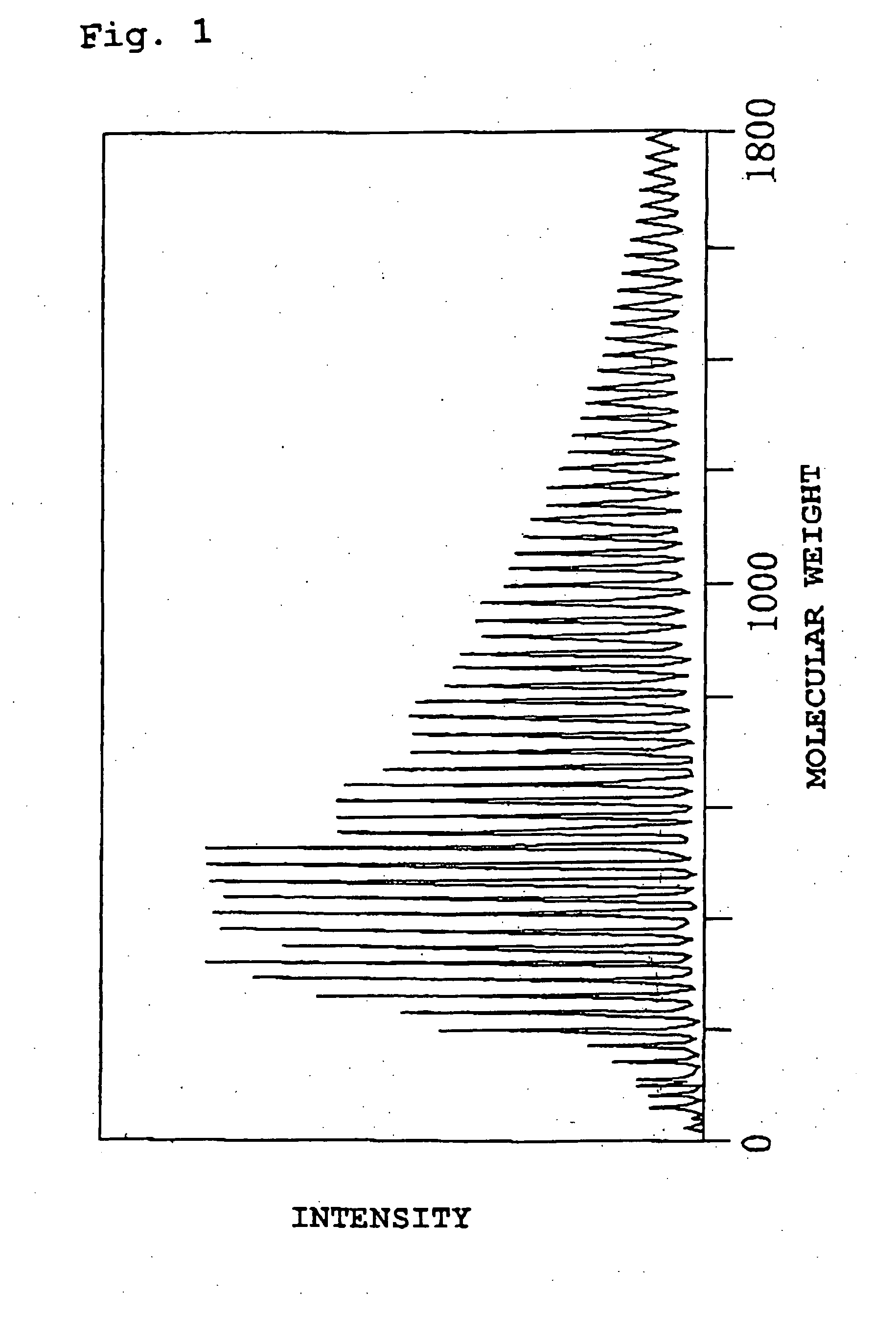

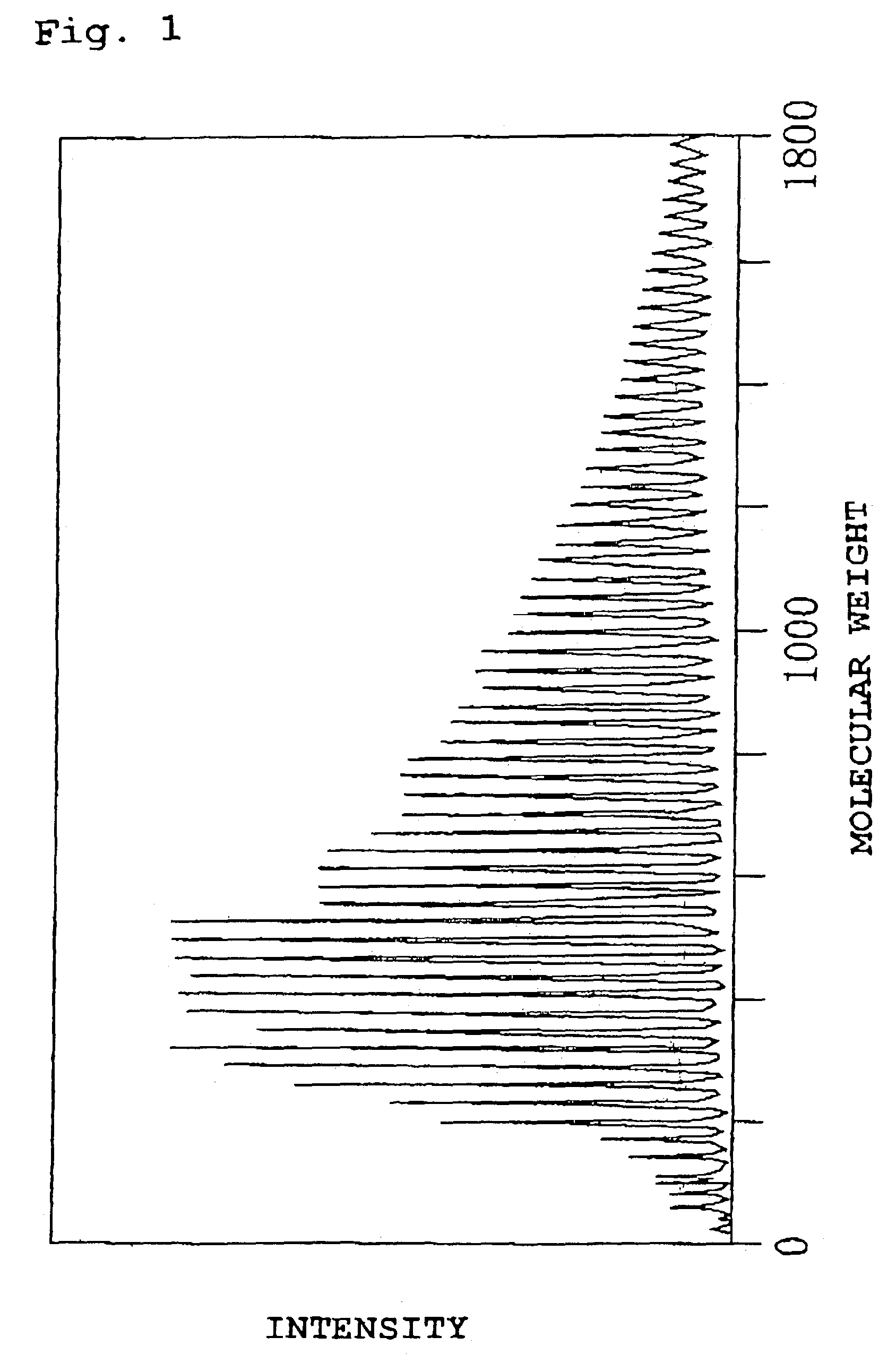

High order silane composition, and method of forming silicon film using the composition

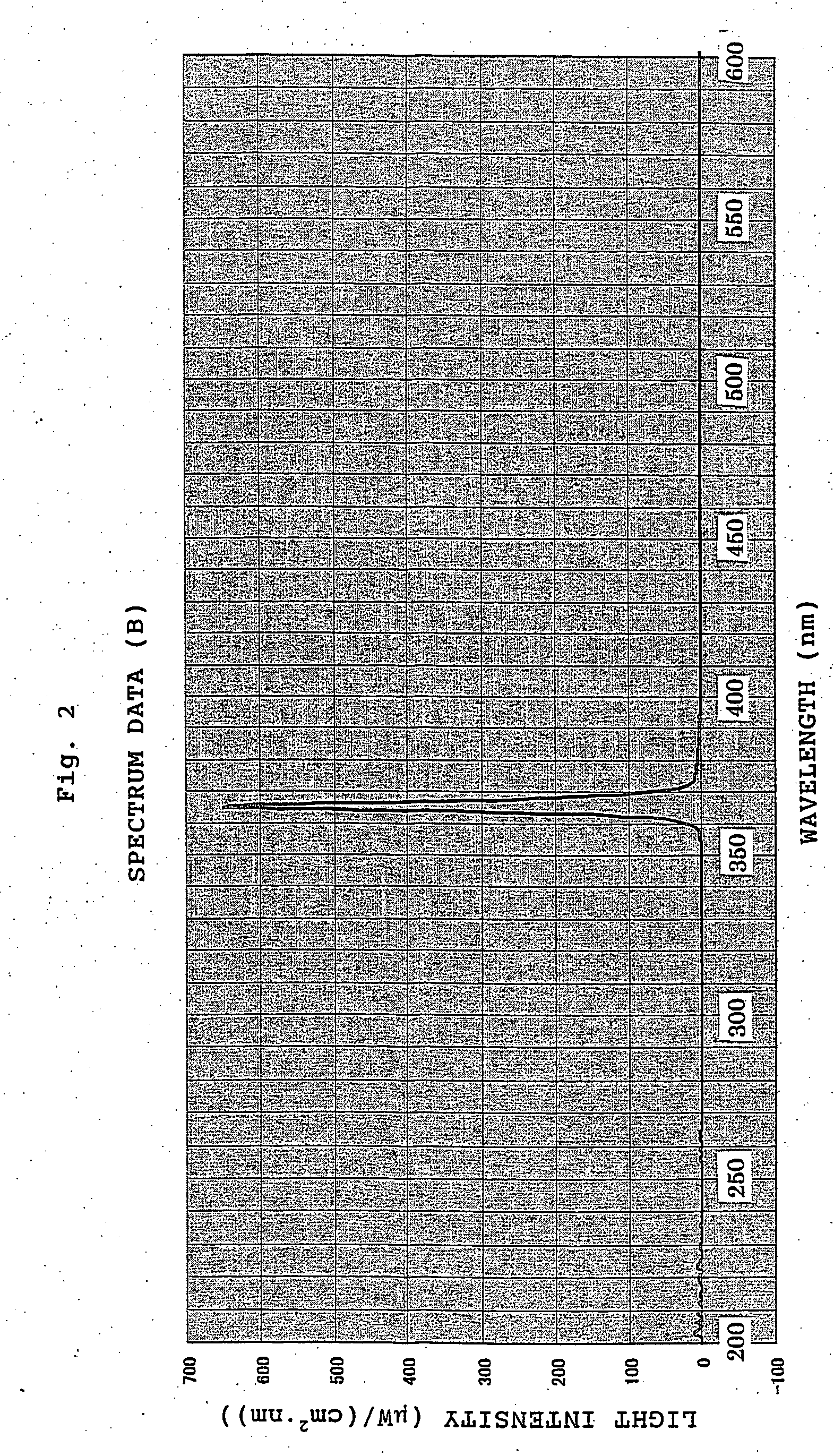

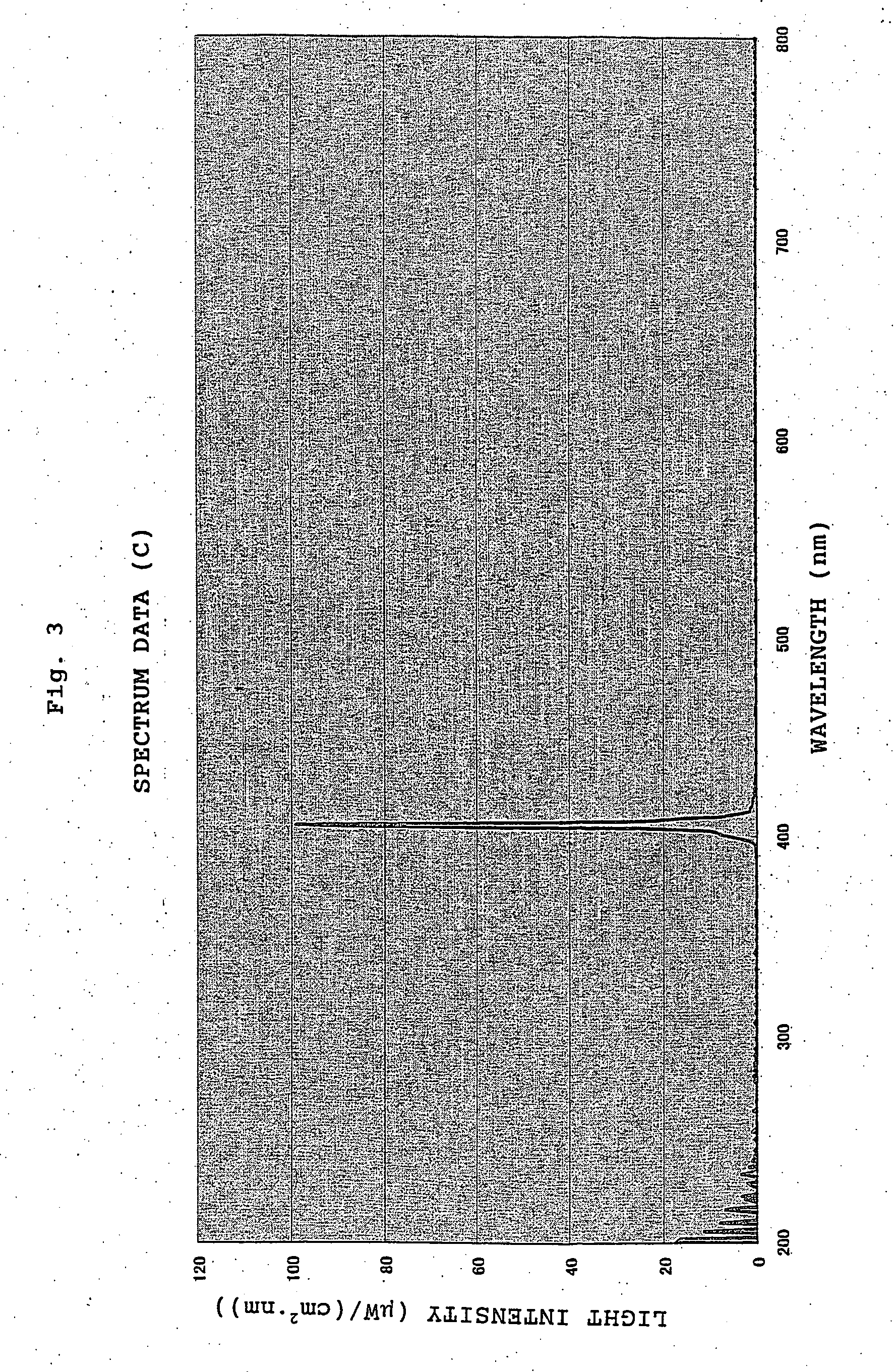

InactiveUS20070190265A1Well formedHigh molecular weightPretreated surfacesSilicon hydridesBoiling pointUltraviolet lights

It is an object of the present invention to provide a high order silane composition that contains a polysilane having a higher molecular weight than conventionally, this being from the viewpoints of wettability when applying onto a substrate, boiling point and safety, and hence in particular enables a high-quality silicon film to be formed easily, and also a method of forming an excellent silicon film using the composition. The present invention attains this object by providing a high order silane composition containing a polysilane obtained through photopolymerization by irradiating a solution of a photopolymerizable silane or a photopolymerizable like-liquid silane with ultraviolet light. Moreover, the present invention provides a method of forming a silicon film comprising the step of applying such a high order silane composition onto a substrate.

Owner:AOKI TAKASHI +4

Semiconductor having large volume fraction of intermediate range order material

A high quality non-single-crystal silicon alloy material including regions of intermediate range order (IRO) silicon alloy material up to but not including the volume percentage required to form a percolation path within the material. The remainder of the material being either amorphous or a mixture of amorphous and microcrystalline materials. The materials were prepared by CVD using differing amounts of hydrogen dilution to produce materials containing differing amounts of IRO material. Preferably the material includes at least 8 volume percent of IRO material.

Owner:BEKAERT ECD SOLAR SYST

Conversion of direct process high-boiling residue to monosilanes

InactiveUS6013235APromote conversionSilicon organic compoundsPhysical/chemical process catalystsHydrogenBoiling point

A process for the production of monosilanes from the high-boiling residue resulting from the reaction of hydrogen chloride with silicon metalloid in a process typically referred to as the "direct process." The process comprises contacting a high-boiling residue resulting from the reaction of hydrogen chloride and silicon metalloid, with hydrogen gas in the presence of a catalytic amount of aluminum trichloride effective in promoting conversion of the high-boiling residue to monosilanes. The present process results in conversion of the high-boiling residue to monosilanes. At least a portion of the aluminum trichloride catalyst required for conduct of the process may be formed in situ during conduct of the direct process and isolation of the high-boiling residue.

Owner:DOW SILICONES CORP

High order silane composition, and method of forming silicon film using the composition

InactiveUS7223802B2Well formedHigh molecular weightSilicon hydridesSemiconductor/solid-state device manufacturingBoiling pointUltraviolet lights

It is an object of the present invention to provide a high order silane composition that contains a polysilane having a higher molecular weight than conventionally, this being from the viewpoints of wettability when applying onto a substrate, boiling point and safety, and hence in particular enables a high-quality silicon film to be formed easily, and also a method of forming an excellent silicon film using the composition. The present invention attains this object by providing a high order silane composition containing a polysilane obtained through photopolymerization by irradiating a solution of a photopolymerizable silane or a photopolymerizable like-liquid silane with ultraviolet light. Moreover, the present invention provides a method of forming a silicon film comprising the step of applying such a high order silane composition onto a substrate.

Owner:SEIKO EPSON CORP

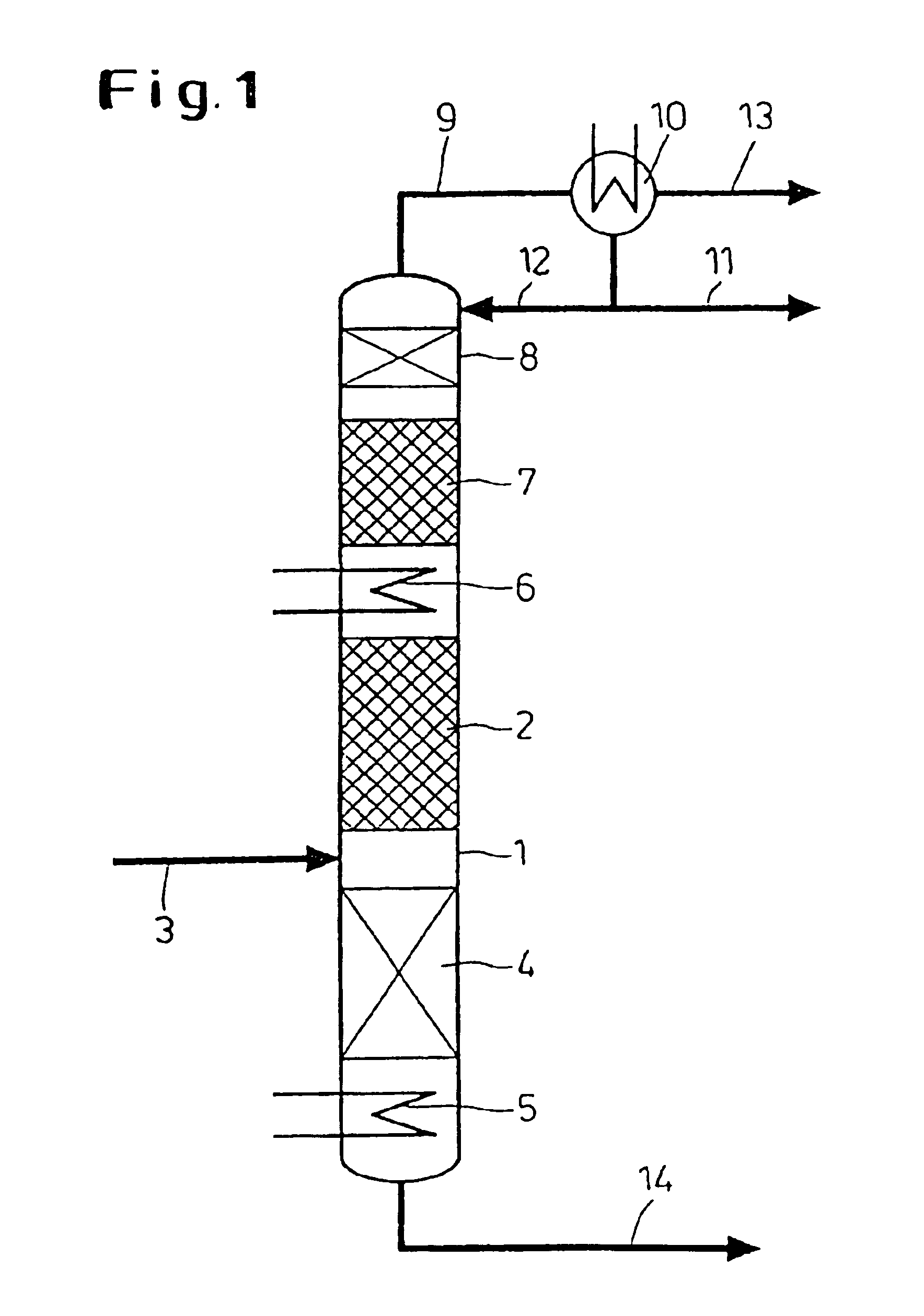

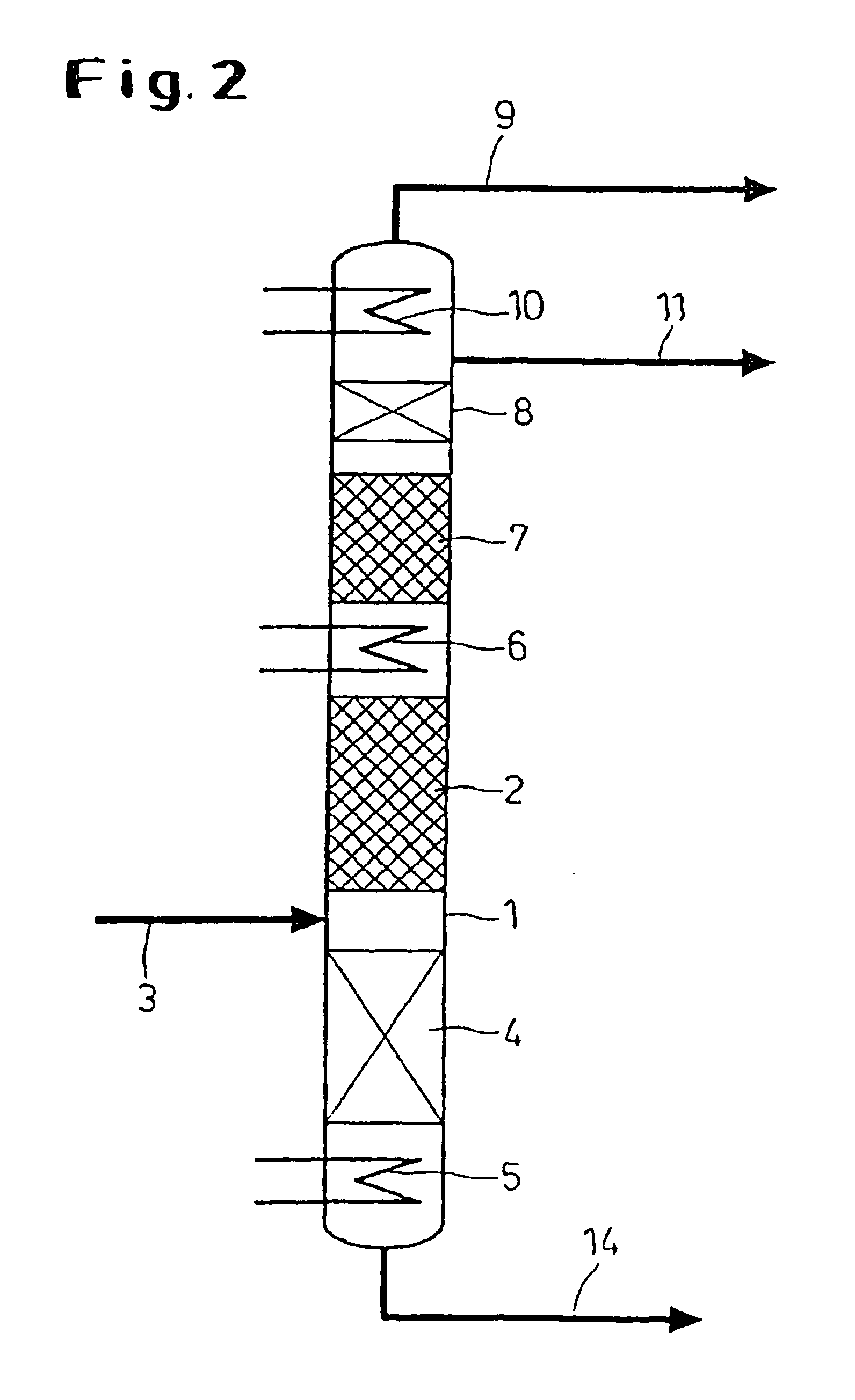

Method and facility for producing silane

InactiveUS6942844B2Weaken energyReduce equipmentSilicon hydridesLiquid solutions solvent extractionChemistryDistillation

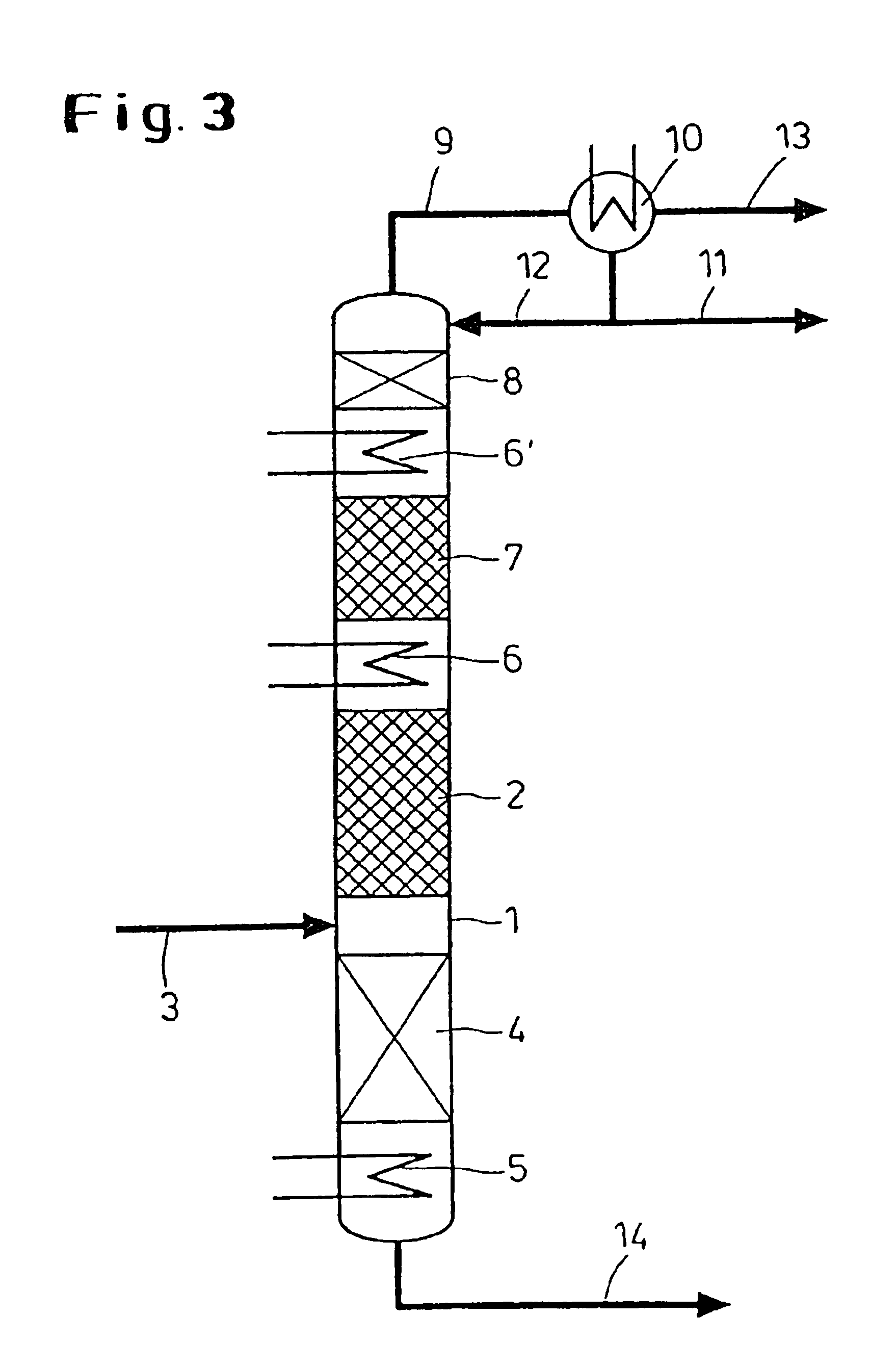

Silane is produced in a continuous process by disproportionating trichlorsilane in at least 2 recreation areas for reaction / distillation, which are run through by a countercurrent of steam and liquid in the presence of catalytically active solid under a pressure which ranges between 500 mbar and 50 bar.

Owner:EVONIK DEGUSSA GMBH

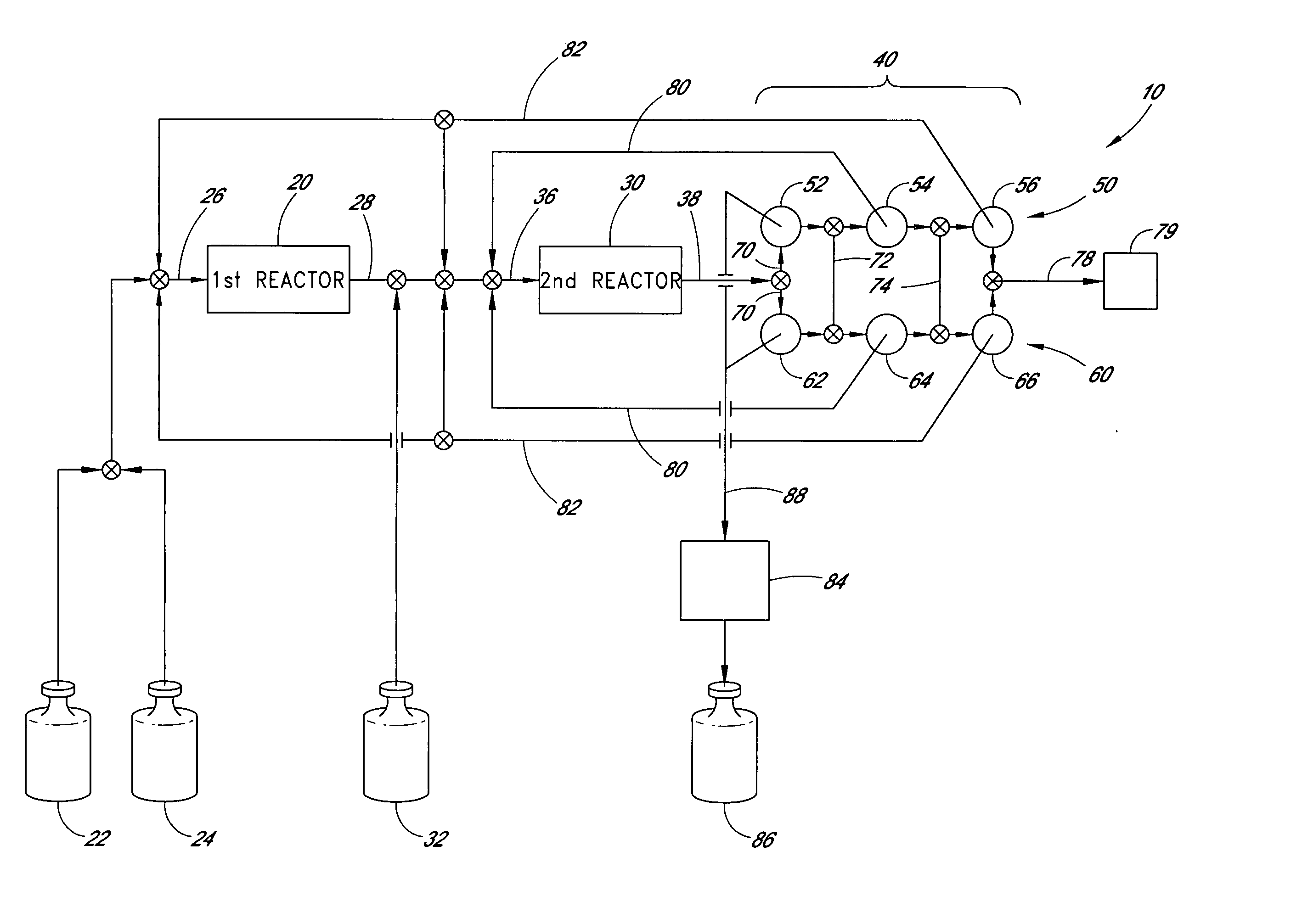

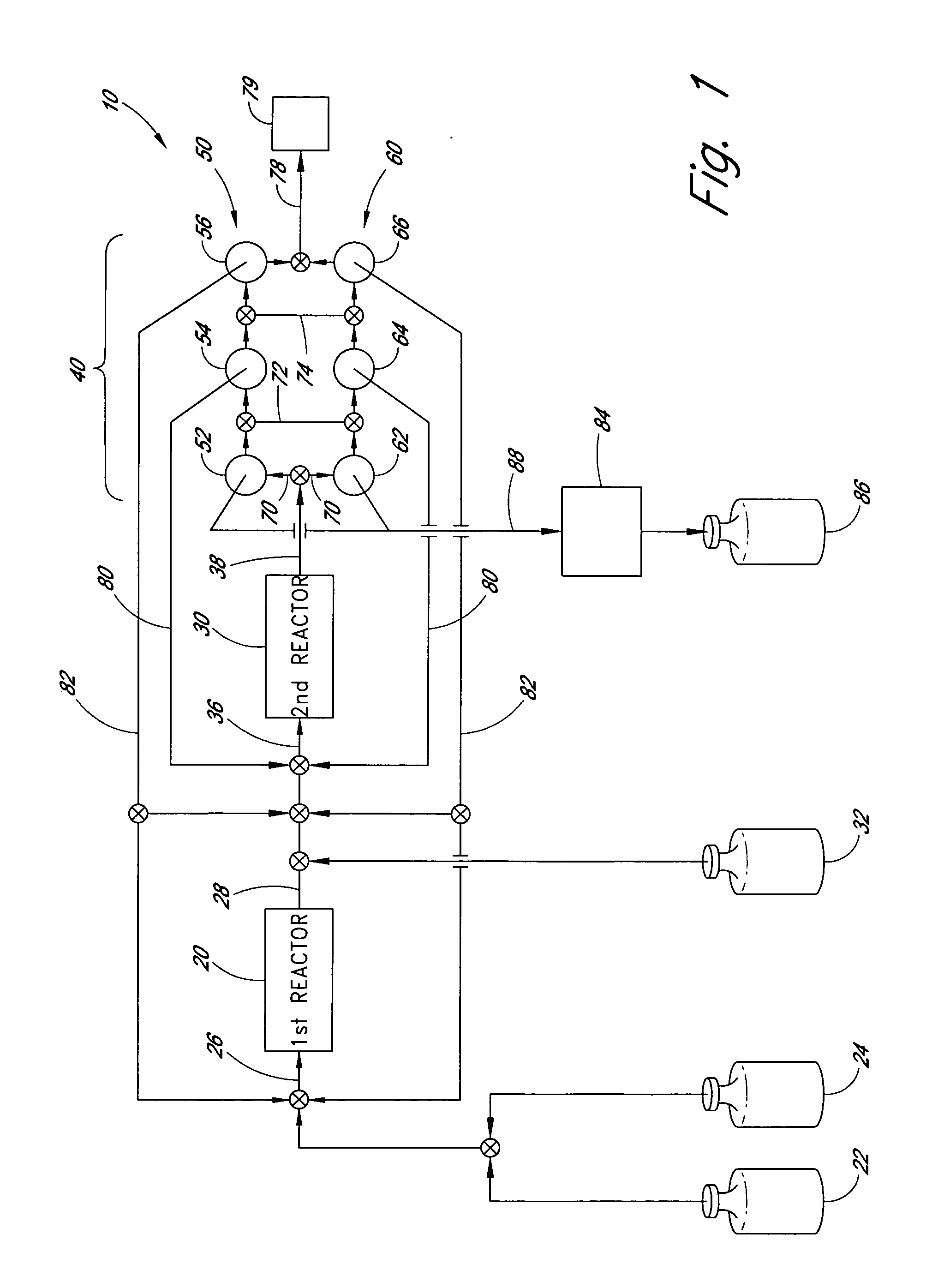

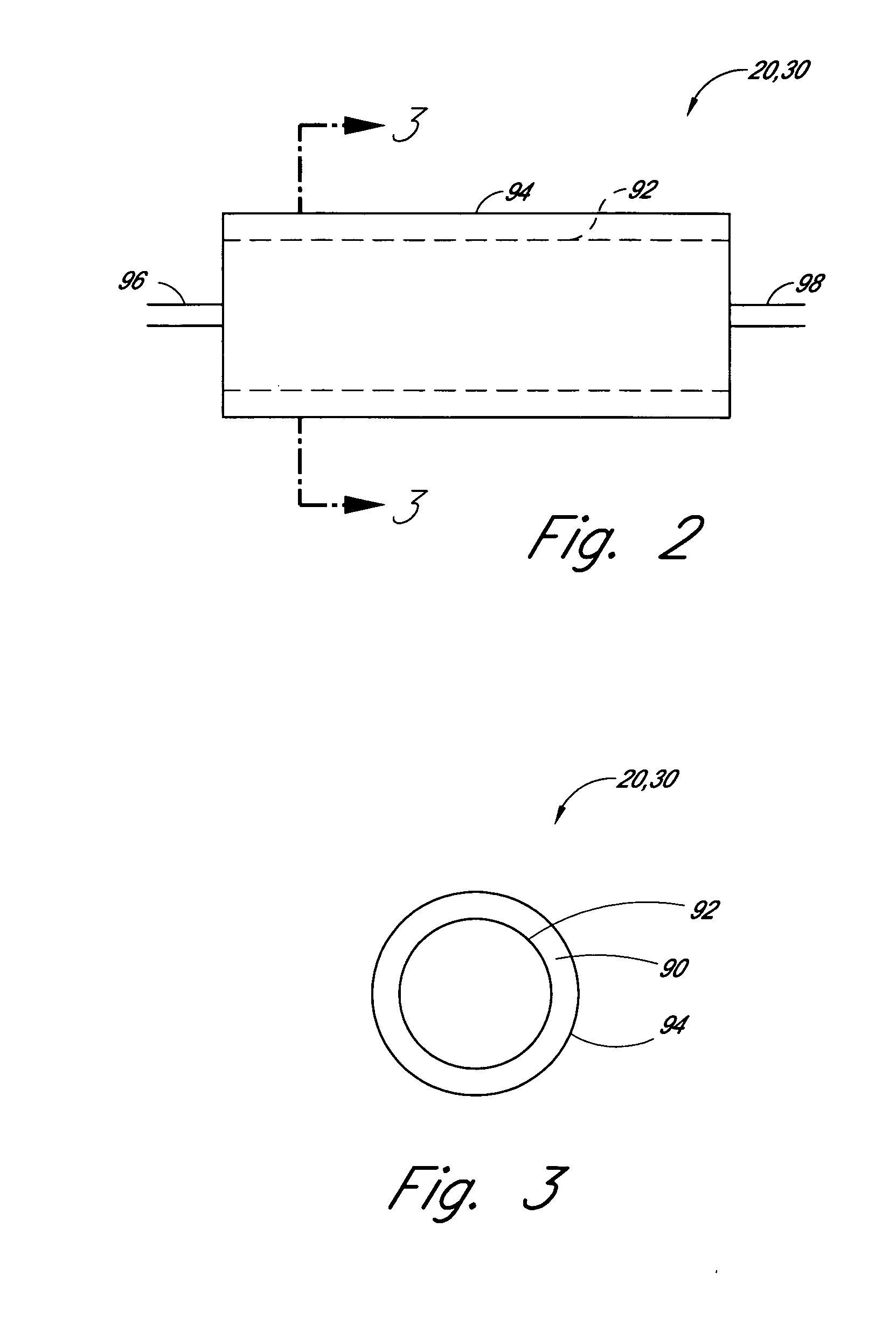

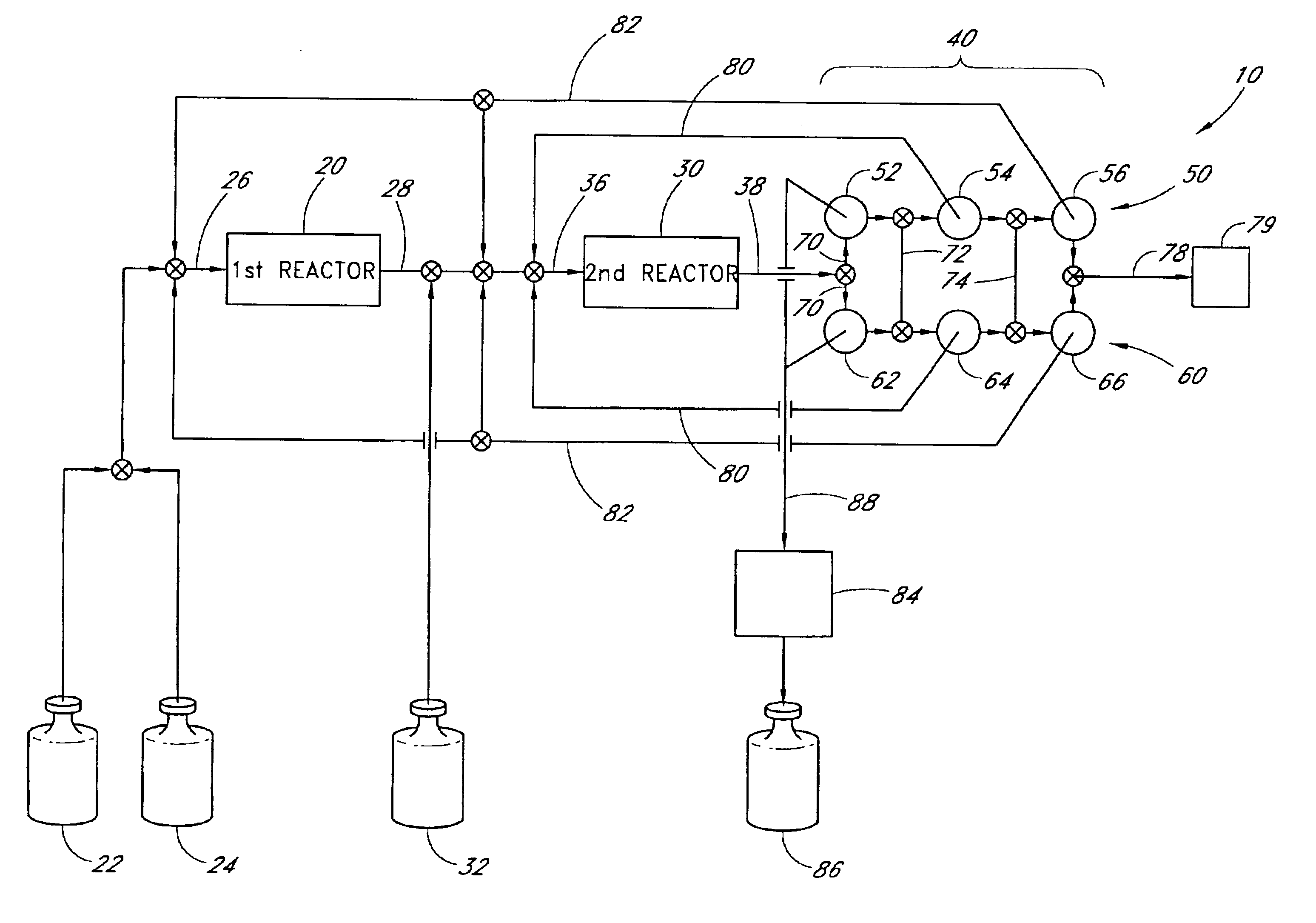

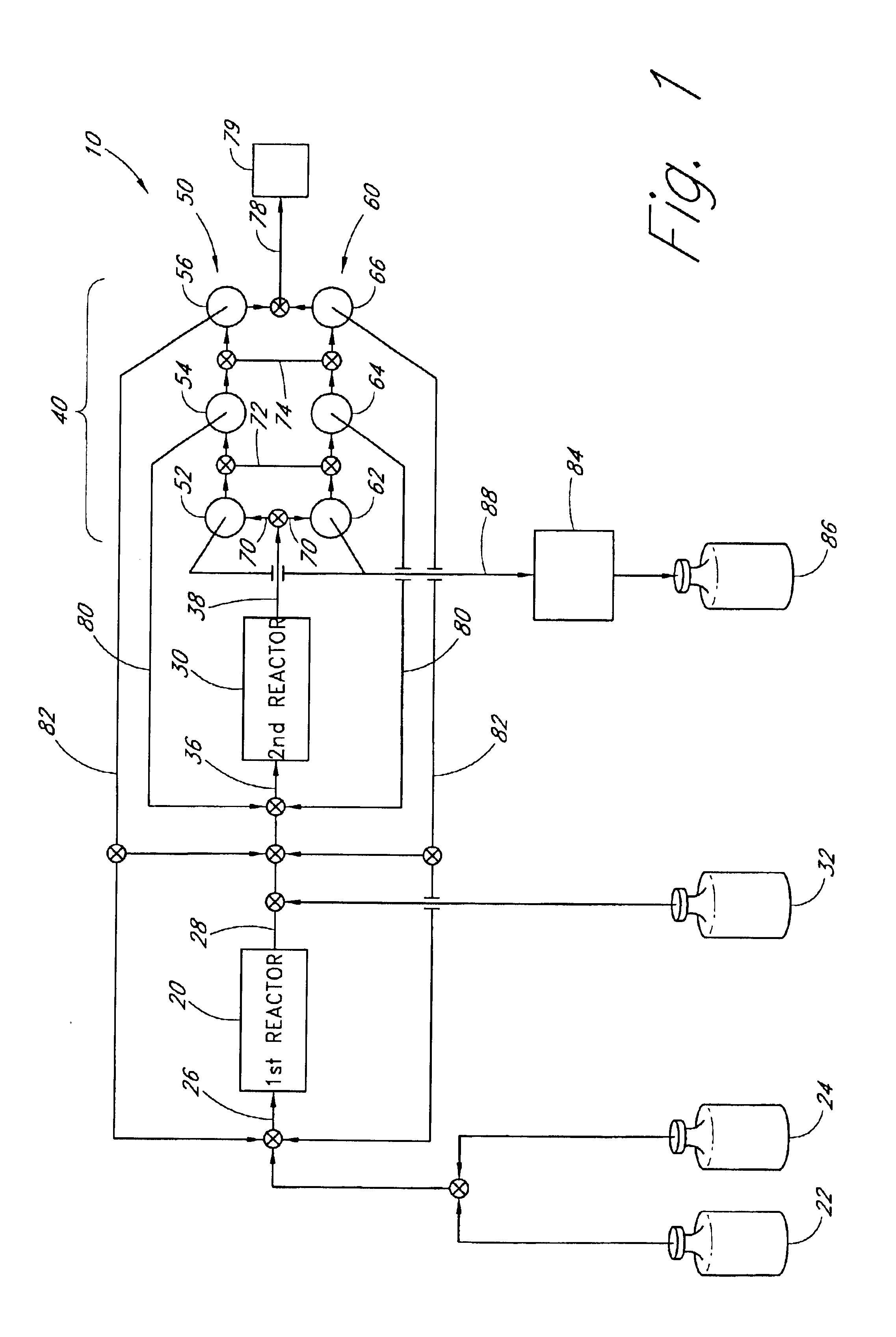

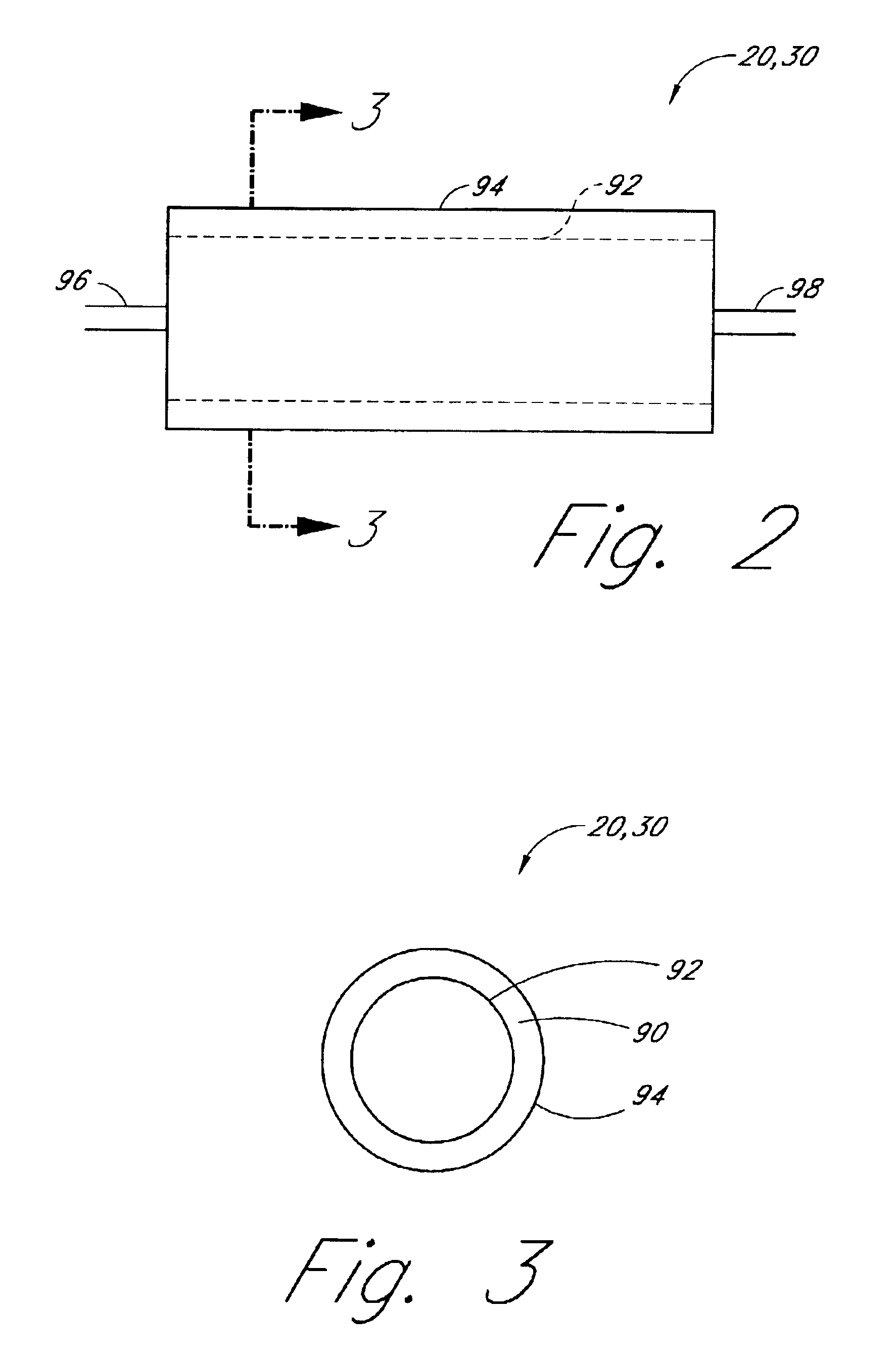

Method and apparatus for chemical synthesis

InactiveUS20050142046A1Silicon hydridesEnergy based chemical/physical/physico-chemical processesChemical synthesisCondensation trap

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM AMERICA INC

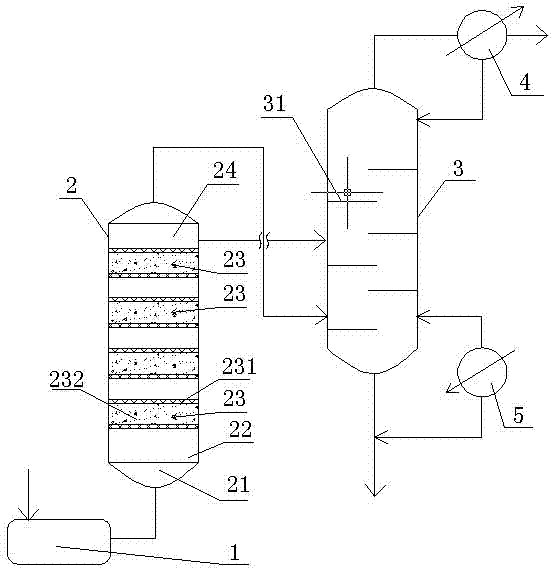

Production method of silane

The invention discloses a production method of silane. The production method comprises the following steps of: heating trichlorosilane to 70-90 DEG C by using a preheater; feeding heated trichlorosilane into a first reaction region of a reaction rectifying tower, and performing a first step catalytic disproportionation reaction of trichlorosilane in the first reaction region to generate dichlorosilane and silicon tetrachloride; feeding silicon tetrachloride generated in the first reaction region into the stripping section of the reaction rectifying tower, separating, purifying and discharging from a tower kettle; raising dichlorosilane generated in the first reaction region to a second reaction region of the reaction rectifying tower, and performing a second step catalytic disproportionation reaction to generate trichlorosilane and silane; refluxing the trichlorosilane generated in the second reaction region into the first reaction region, mixing with trichlorosilane heated by using the preheater, and continually performing the first step catalytic disproportionation reaction; and raising silane generated in the second reaction region into the rectifying section of the reaction rectifying tower, separating, purifying and discharging from the tower top of the reaction rectifying tower to obtain silane.

Owner:覃攀

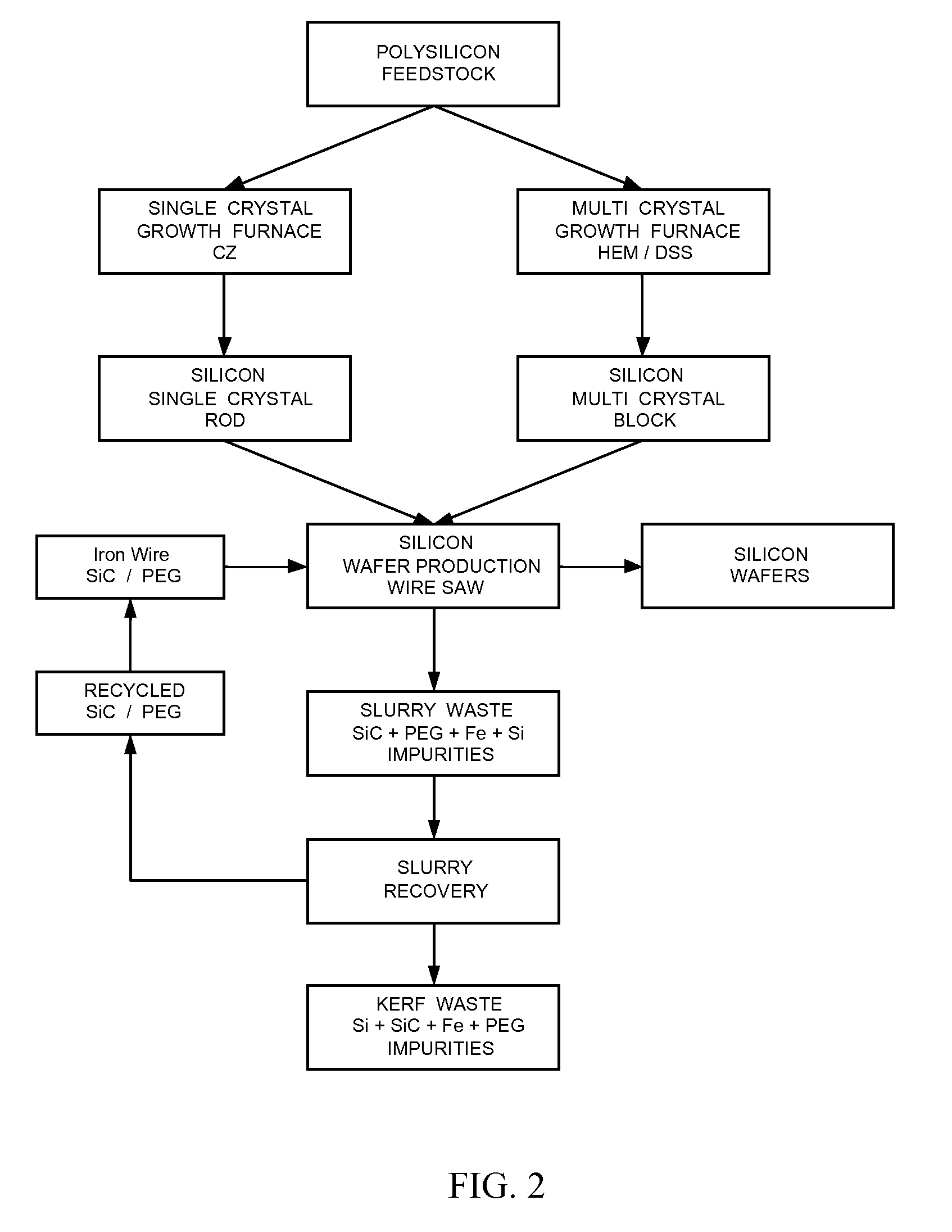

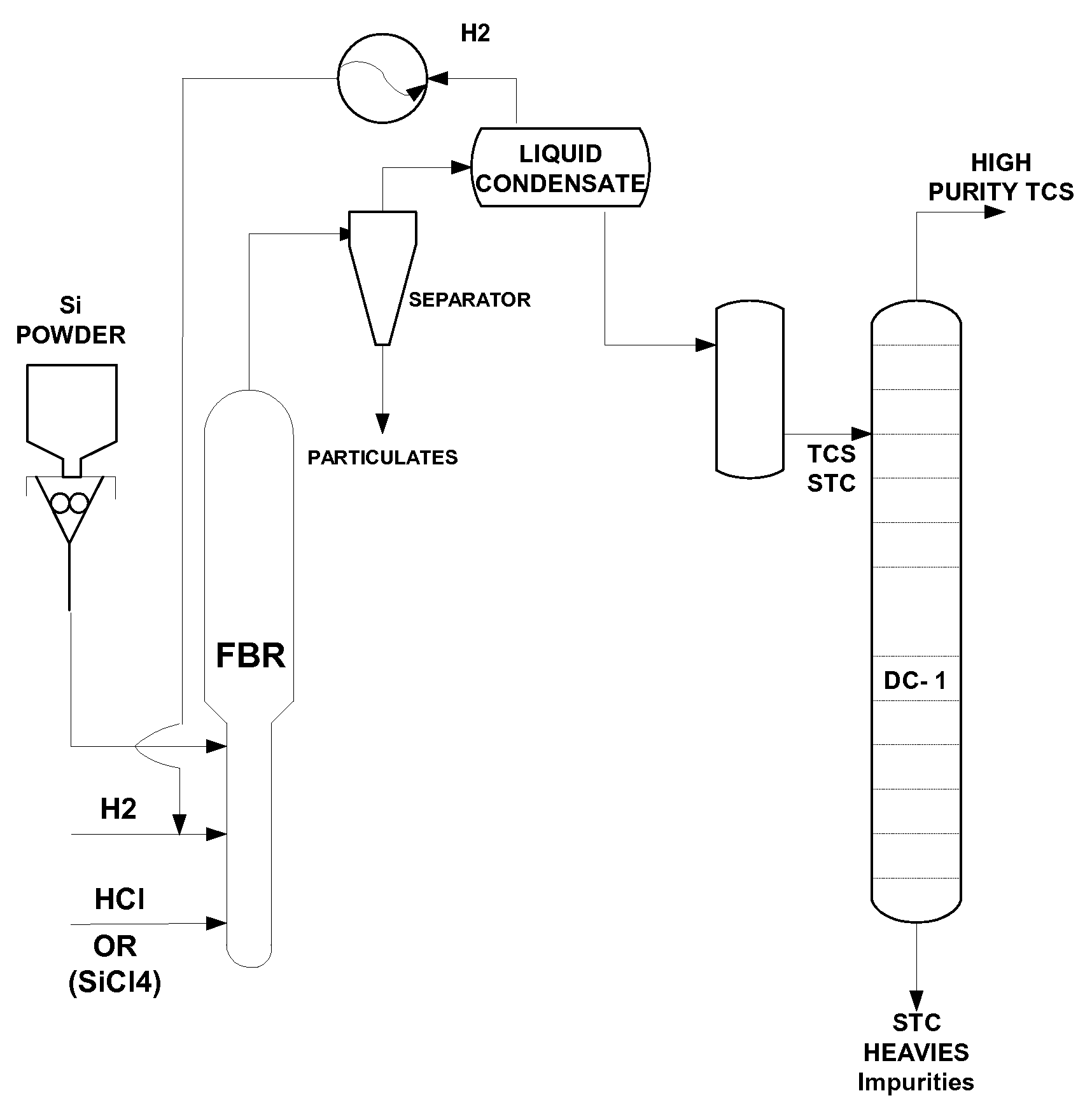

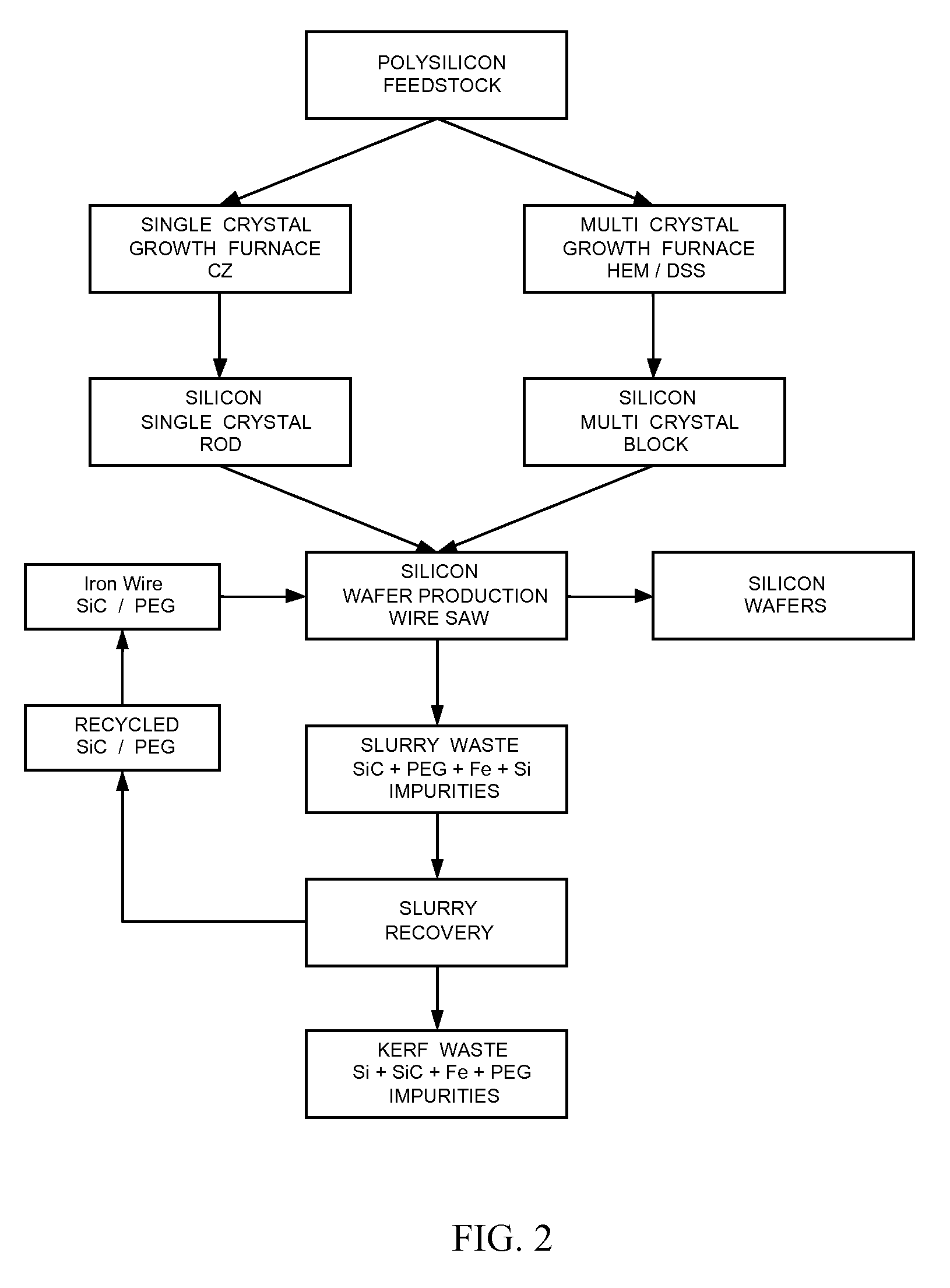

Method to convert waste silicon to high purity silicon

A process for the recovery of silicon includes providing silicon-containing solids recovered from a silicon manufacturing process, said recovered silicon-containing solids being substantially free of semiconductor dopants; converting the recovered silicon-containing solids into gaseous silicon forms; subjecting to purification by minimal distillation; collecting the gaseous silicon forms as a condensed liquid of silicon-containing compounds; and utilizing the silicon-containing compounds for silicon deposition.

Owner:HARIHARAN ALLEPPEY V +1

Silicon-Containing Particle, Process For Producing The Same, Organic-Polymer Composition, Ceramic, And Process For Producing The Same

InactiveUS20110033708A1Small particle sizeGood dispersionMaterial nanotechnologySilicaSurface-active agentsDissolved phase

A process for producing silicon-containing particles having an extremely small particle diameter by a simple process without using surface-active agents or the like. The process is characterized by forming silicon-containing particles as a result of phase separation from an organic polymer, wherein the phase separation is achieved by an addition reaction, condensation reaction, ring-opening reaction, or a radical reaction of a curable silicon-containing compound or a curable composition that contains said compound, and the silicon-containing compound or the composition is maintained in a uniform liquid, fused, or dissolved phase with the organic polymer that is free of silicon and does not participate in the curing reaction of the silicon-containing compound or the composition.

Owner:DOW CORNING TORAY CO LTD

Method for producing higher silanes

Owner:EVONIK OPERATIONS GMBH

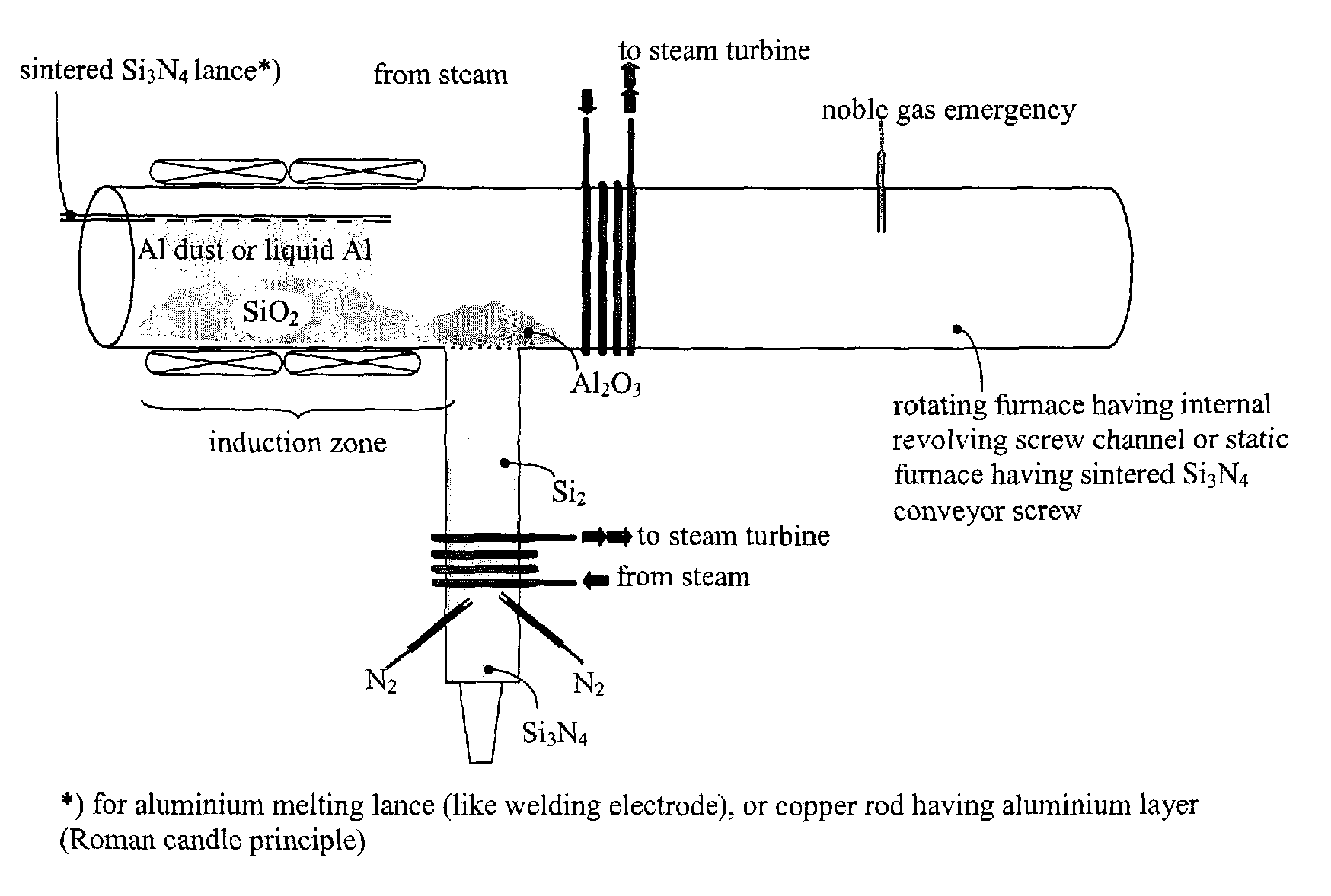

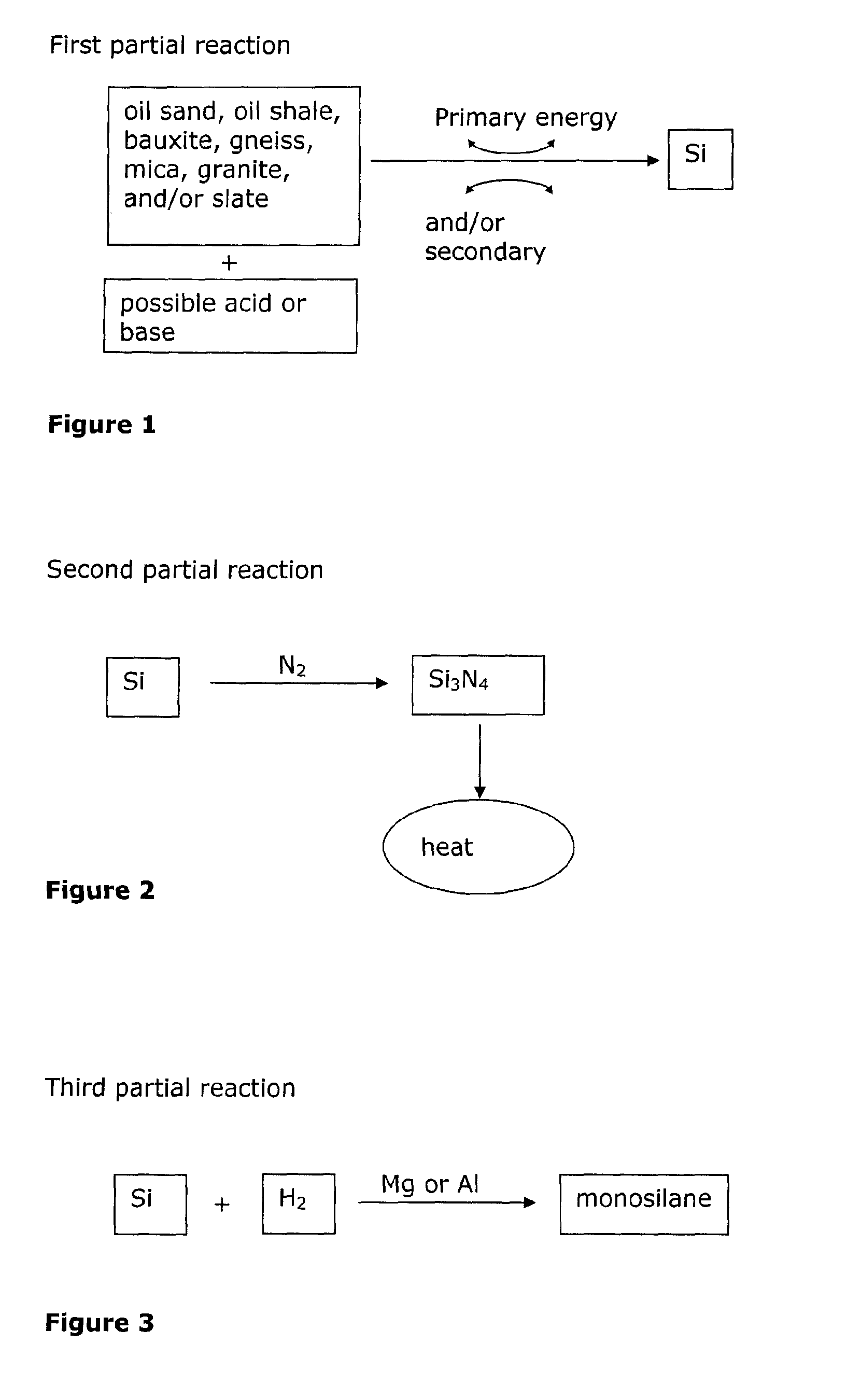

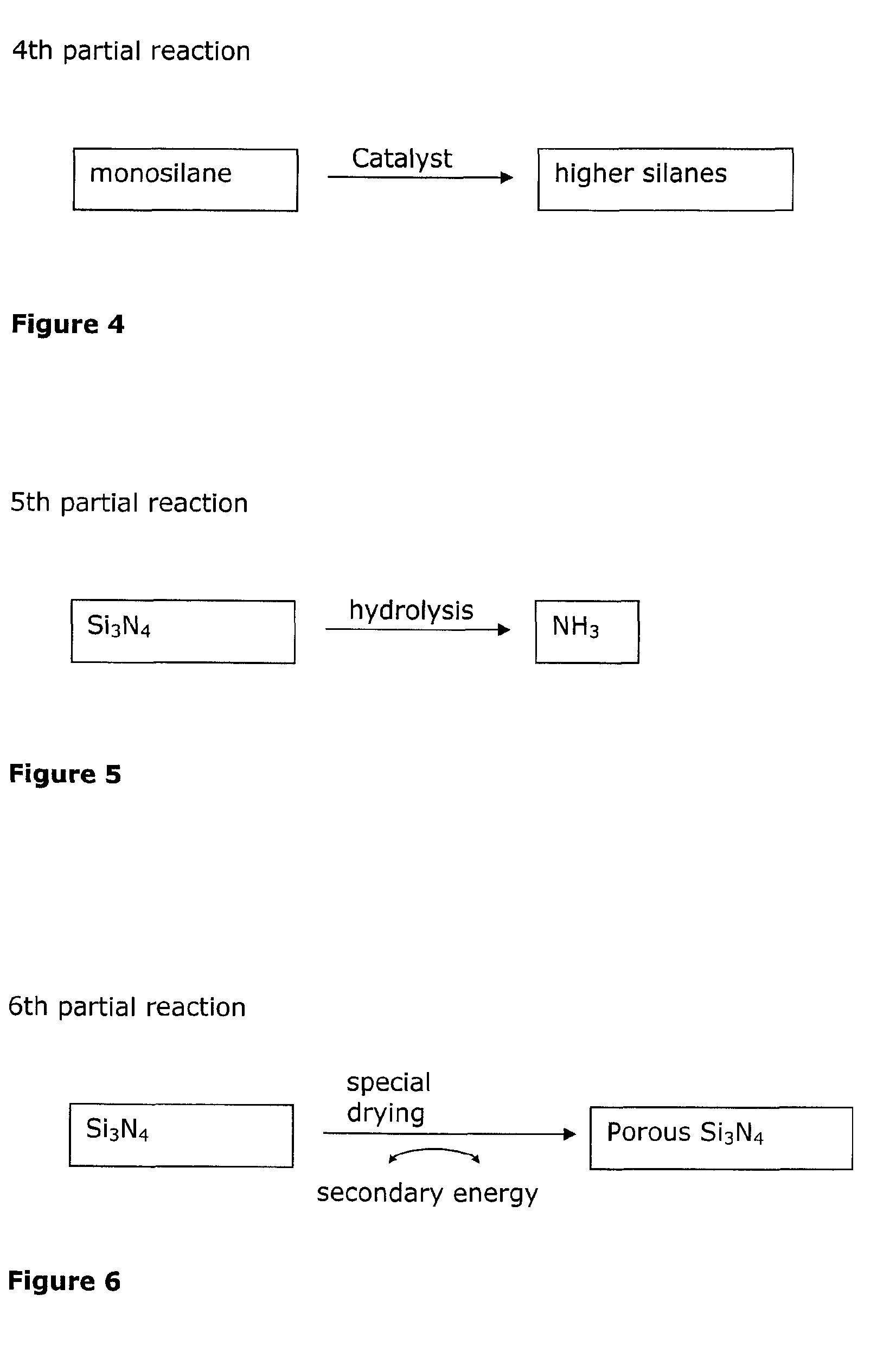

Cascaded power plant process and method for providing reversibly usable hydrogen carriers in such a power plant process

Owner:SILICON FIRE AG

Purification of hydride gases

Purification material for removing a contaminant from an impure hydride gas comprising an adsorbent comprising a reduced metal oxide on a porous support and a desiccant. The porous support may be selected from the group consisting of activated carbon, alumina, silica, zeolite, silica alumina, titania, zirconia, and combinations thereof. The reduced metal oxide may comprise one or more metals selected from the group consisting of Group I alkali metals (lithium, sodium, potassium, rubidium, and cesium), Group II alkaline earth metals (magnesium, calcium, strontium, and barium), and transition metals (manganese, nickel, zinc, iron, molybdenum, tungsten, titanium, vanadium, cobalt, and rhodium). The desiccant may be selected from the group consisting of hygroscopic metal salts, zeolites, single metal oxides, mixed metal oxides, and combinations thereof.

Owner:VERSUM MATERIALS US LLC

Method of high purity silane preparation

InactiveUS6103942AHigh purityIncrease productionSilicaOrganic compound preparationLiquid productSilanes

A process for the preparation of high purity silane, suitable for forming thin layer silicon structures in various semiconductor devices and high purity poly- and single crystal silicon for a variety of applications, is provided. Synthesis of high-purity silane starts with a temperature assisted reaction of metallurgical silicon with alcohol in the presence of a catalyst. Alcoxysilanes formed in the silicon-alcohol reaction are separated from other products and purified. Simultaneous reduction and oxidation of alcoxysilanes produces gaseous silane and liquid secondary products, including, active part of a catalyst, tetra-alcoxysilanes, and impurity compounds having silicon-hydrogen bonds. Silane is purified by an impurity adsorption technique. Unreacted alcohol is extracted and returned to the reaction with silicon. Concentrated mixture of alcoxysilanes undergoes simultaneous oxidation and reduction in the presence of a catalyst at the temperature -20 DEG C. to +40 DEG C. during 1 to 50 hours. Tetra-alcoxysilane extracted from liquid products of simultaneous oxidation and reduction reaction is directed to a complete hydrolysis. Complete hydrolysis of tetra-alcoxysilane results in formation of industrial silica sol and alcohol. Alcohol is dehydrated by tetra-alcoxysilane and returned to the reaction with silicon.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

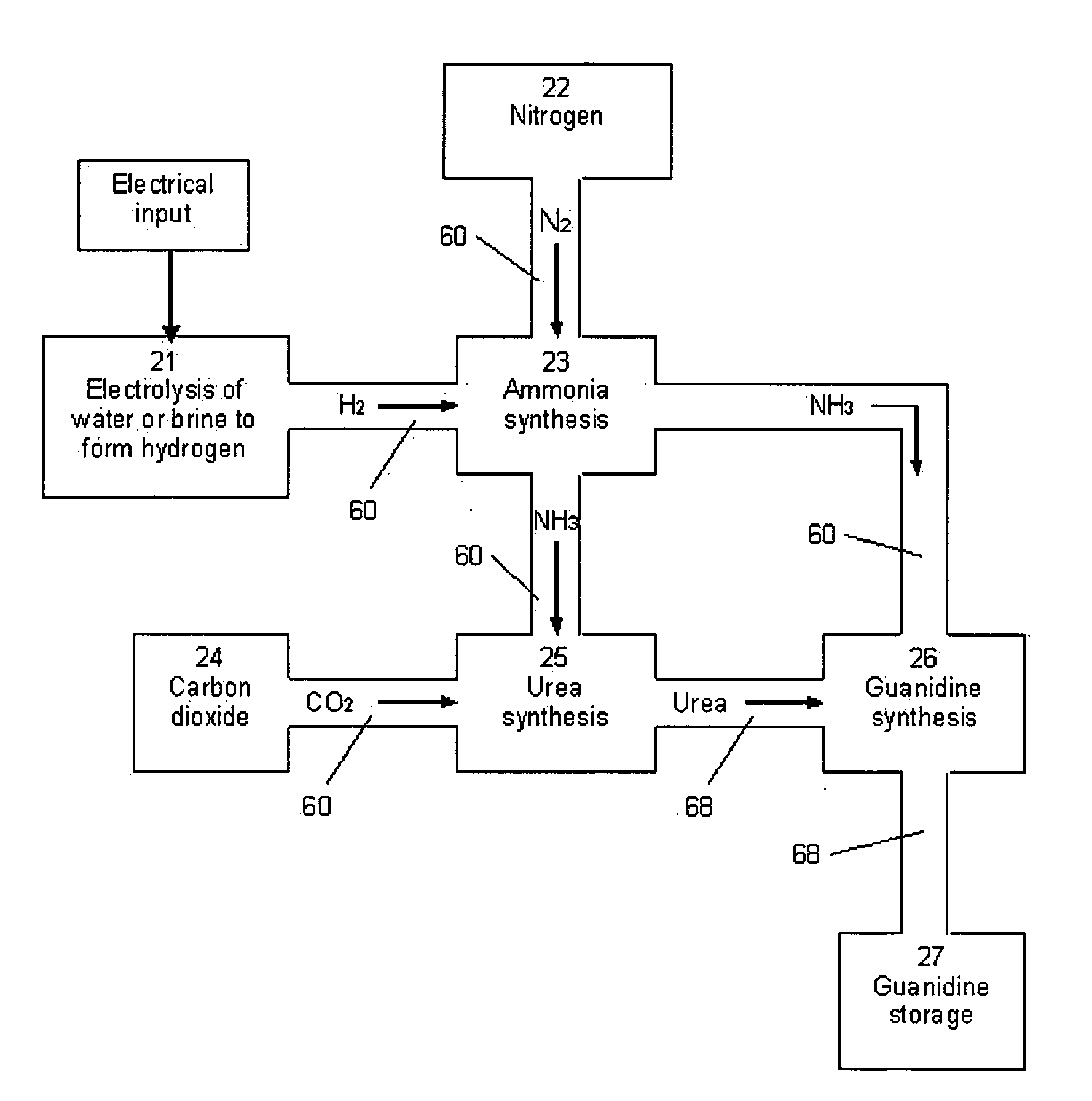

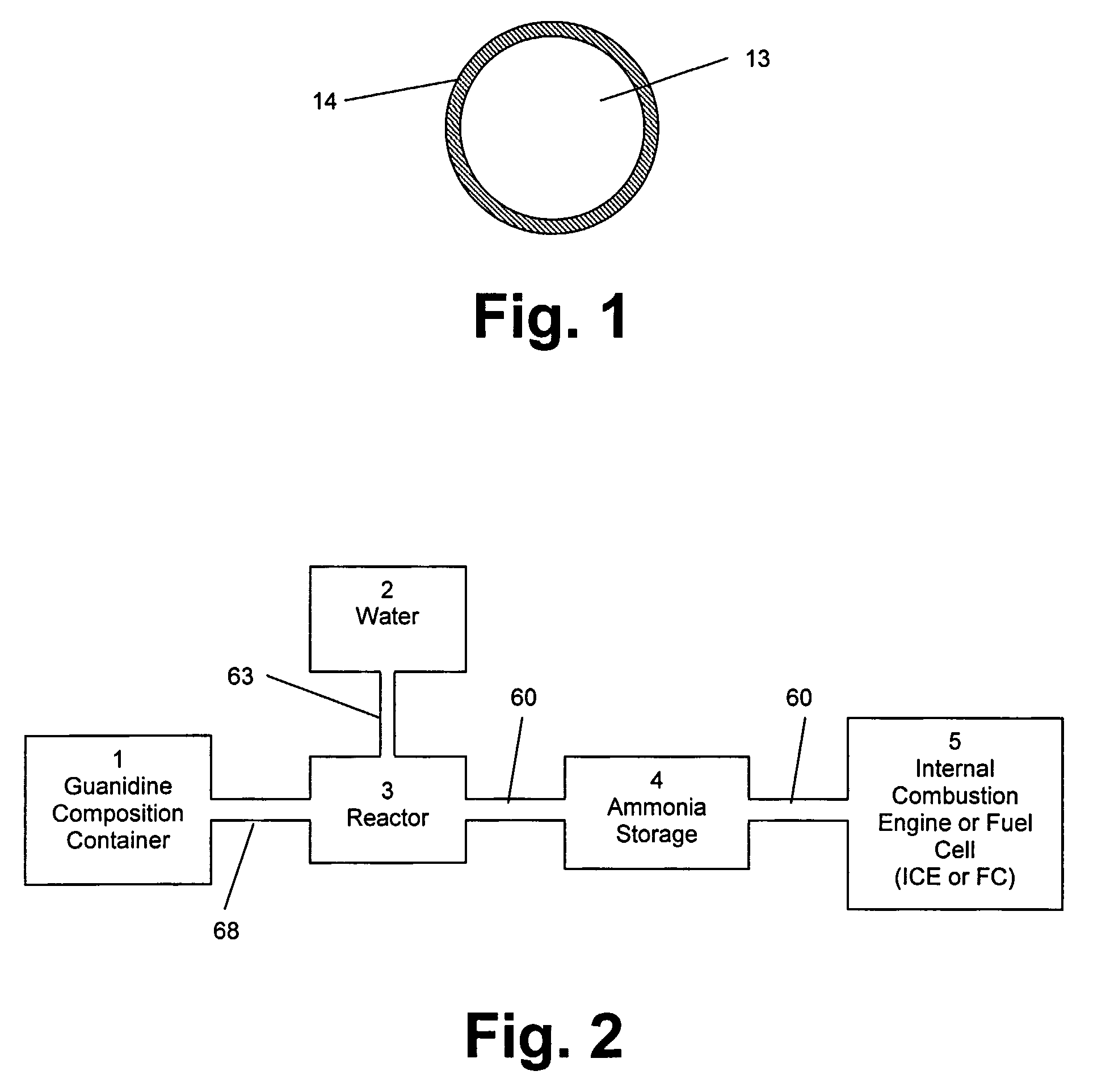

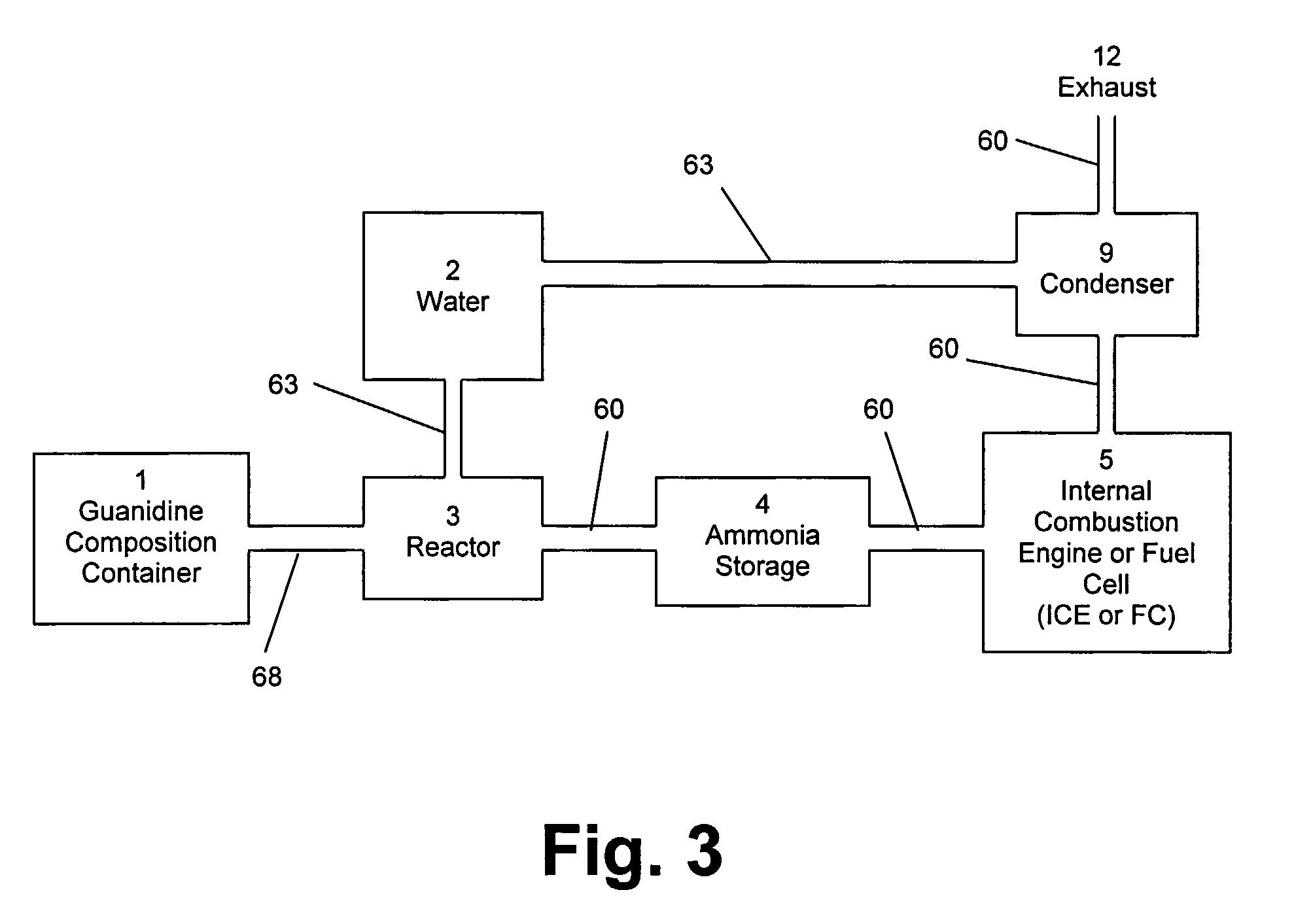

Guanidine Based Composition and System for Same

InactiveUS20080286165A1High specific energyIncrease energy densityOrganic chemistryOrganic compound preparationBuffer tankNitrogen

A method and apparatus for generating energy from a composition containing guanidine and a method for providing the composition containing guanidine. The apparatus includes a container such as tank (1) for providing the composition, and a container such as tank (2) for providing water. The composition is delivered from tank (1) to a container such as reactor (3) for reacting the guadinine composition with water, supplied from tank (2), to form ammonia. The apparatus may also include buffer tank (4) for storing the ammonia produced by the reactor. The ammonia produced from the reactor of the guadinine composition with water is delivered from the buffer tank (4) to a container such as chamber (5) for oxidizing ammonia to form water and nitrogen generating energy

Owner:GRAUPNER ROBERT K +2

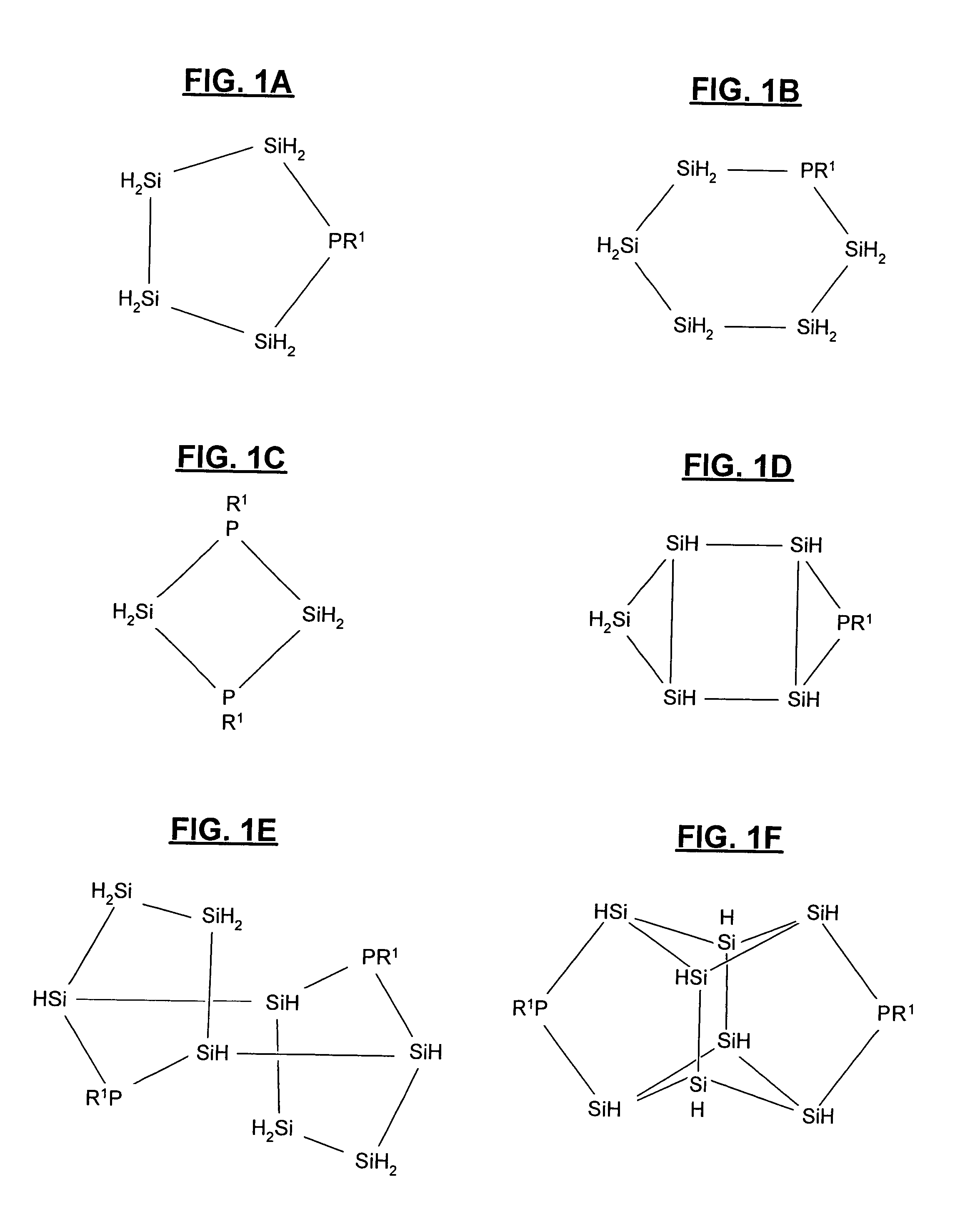

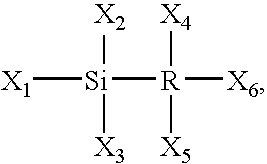

Heterocyclic semiconductor precursor compounds, compositions containing the same, and methods of making such compounds and compositions

Heterocyclosilane compounds and methods for making the same. Such compounds (and / or ink compositions containing the same) are useful for printing or spin coating a doped silane film onto a substrate that can easily be converted into a doped amorphous silicon film (that may also be hydrogenated to some extent) or doped polycrystalline semiconductor film suitable for electronic devices. Thus, the present invention advantageously provides commercial qualities and quantities of doped semiconductor films from a “doped liquid silicon” composition.

Owner:ENSURGE MICROPOWER ASA

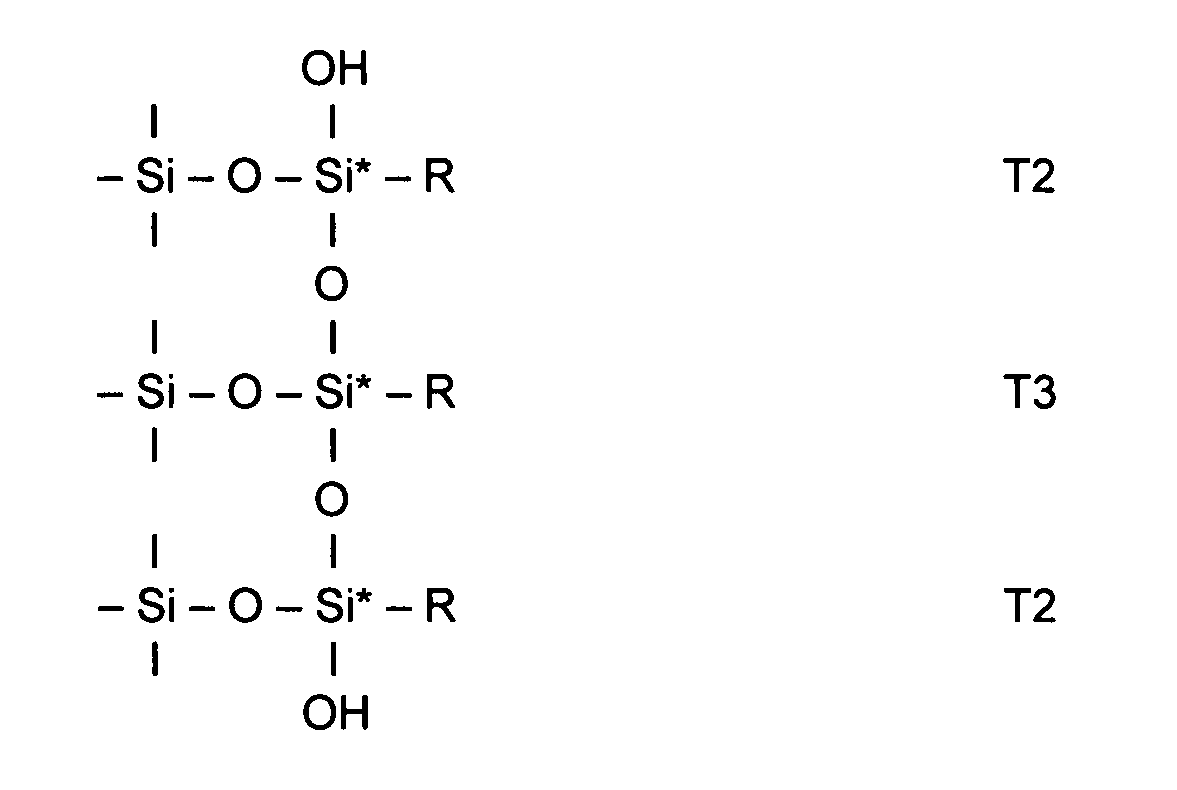

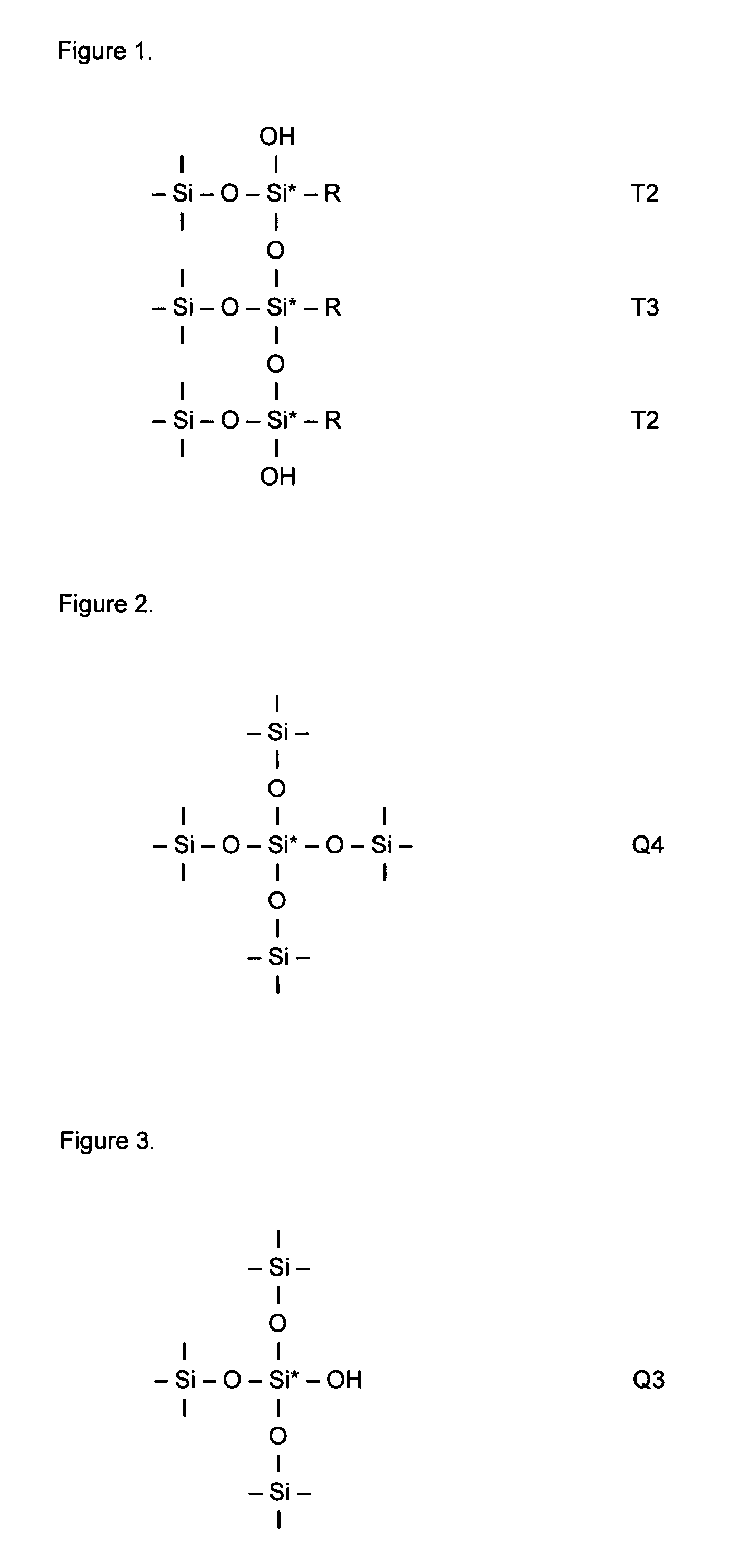

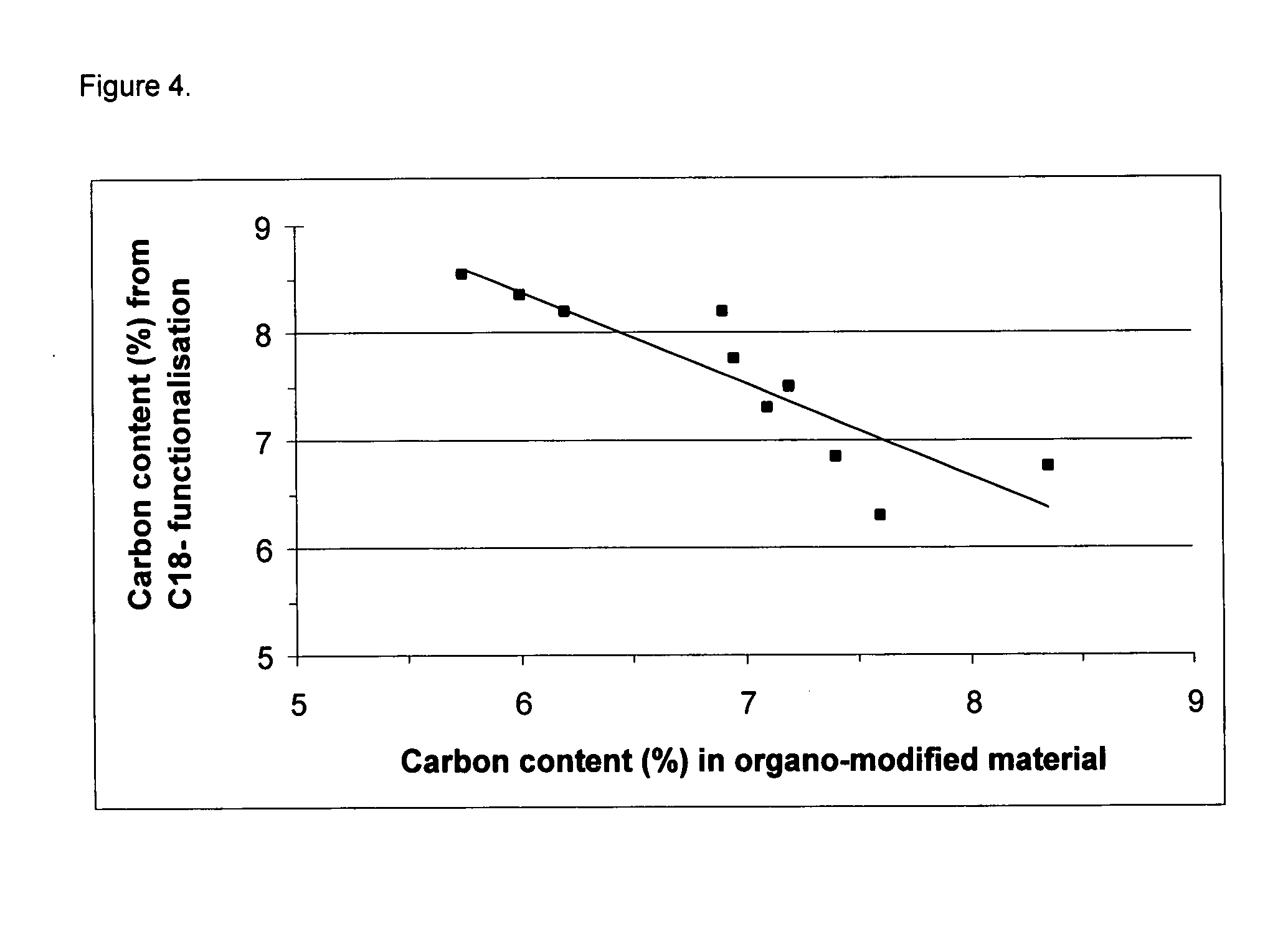

Silica based material

ActiveUS20070187313A1Good chemical stabilityMinimise unfavourable interactionIon-exchange process apparatusOther chemical processesStationary phaseFluid phase

An organo-modified silica based material to be used for making a stationary phase for liquid chromatography comprising a part which is unmodified silica, and a part which is silica comprising organic groups bonded to the silica. A method for preparing an organo-modified silica based material comprising mixing in an aqueous medium a silica based material and an organosilane compound, and reacting the mixture. A stationary phase separation material prepared by functionalising the organo-modified silica based material is also disclosed.

Owner:AKZO NOBEL CHEM INT BV

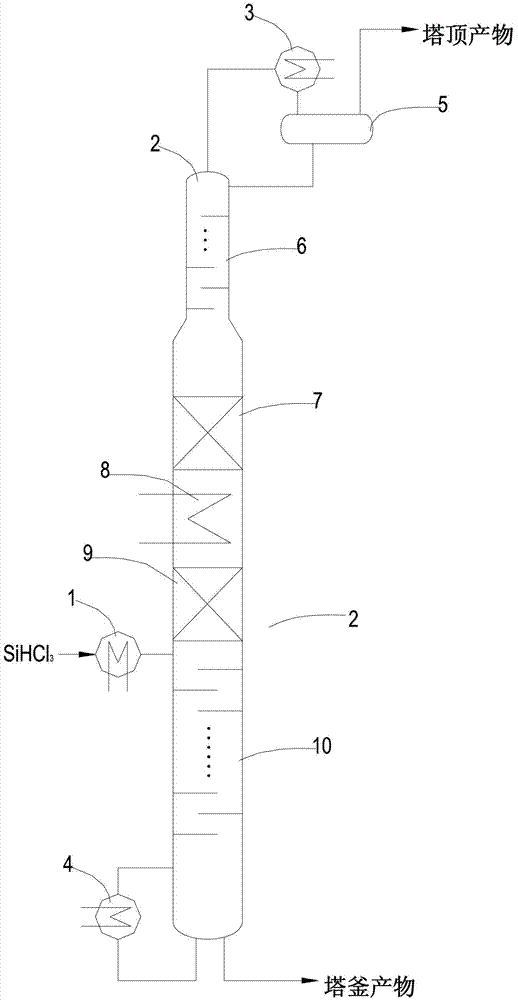

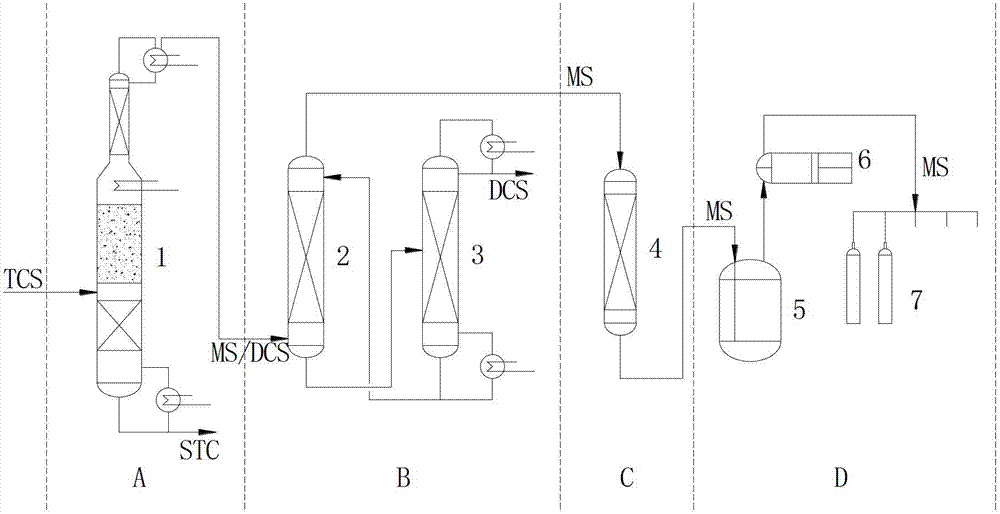

Device and method for preparing high-purity silane through disproportionation reactive distillation of trichlorosilane

ActiveCN103172071ASimple process equipmentRealization of multi-step disproportionation processChemical industrySilicon hydridesProcess equipmentGas phase

The invention relates to a device and a method for preparing high-purity silane through disproportionation reactive distillation of trichlorosilane. The method comprises a disproportionation reactive distillation process (A), a silicon tetrachloride absorption process (B), a fixed bed absorption process (C) and a product filling process (D). The method comprises the steps that: two-step disproportionation reaction is adopted, and the distillation separation action of a reactive distillation column is utilized to finally obtain a mixed gas of silane and dichlorosilane on a column top to be used as non-condensable gas of a condenser to be extracted, and a silicon tetrachloride product is obtained at a column bottom after reaction formation; a gaseous product which is recovered through a disproportionation reactive distillation column enters into a silicon tetrachloride absorption column, wherein the main ingredient of an absorbed gas is silane, an absorption liquid is filled into a silicon tetrachloride desorption column, the desorbed dichlorosilane is recovered on the column top, and the desorption liquid of the column reflows back to the silicon tetrachloride absorption tower; the absorbed gas is filled into a fixed bed to absorb so as to obtain a high-purity silane product; and the silane product is filled into a buffer tank under the pressurization condition. Technological equipment is simple, and the obtained silane product has high purity.

Owner:TIANJIN UNIV

Method and apparatus for chemical synthesis

InactiveUS6858196B2Easy to operate continuouslyHighly orderedNitrogen compoundsMetal silicidesCondensation trapChemical synthesis

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM IP HLDG BV

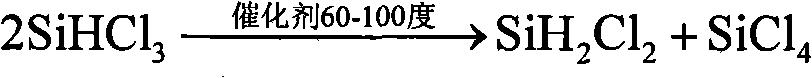

Catalyst used in preparation of silane by disproportionation, preparation method for catalyst and method for preparing SiH4 by disproportionating SiH2C12

InactiveCN101987296AHigh activityImprove stabilitySilicon hydridesCatalyst activation/preparationCationic exchangeSilanes

The invention provides a catalyst used in preparation of silane by disproportionation, a preparation method for the catalyst and a process for preparing SiH4 by disproportionating SiH2C12. The catalyst is used for preparing higher hydrogen-containing halogeno silane and silane by disproportionating halogeno silane. The catalyst is M / acid cation exchange resin, wherein M may be one or more of Ru, Rh, Fe, Co, Ni, Pd, Cd, Cu, Zn, Ag, Pt and Au. The catalyst has higher activity and high-temperature resistance during preparation of silane, and particularly has the maximum service temperature up to 150 DEG C in large-scale production, thereby improving disproportionation temperature and contributing to improving primary conversion efficiency of the reaction. A carrier has no adsorbability to a silane product, thereby contributing to catalyst stability and yield improvement. In addition, the preparation method is simple, easy, and highly stable.

Owner:BYD CO LTD

Method for preparing silane by disproportionating dichlorosilane

ActiveCN102874817AIncrease profitReduce the discharge of three wastesSilicon hydridesSocial benefitsSilanes

The invention relates to the technical field of preparation and purification of silane, in particular to a method for preparing silane by disproportionating dichlorosilane. The method comprises the following steps of: putting chlorosilane of which the main component is the dichlorosilane into a disproportionation reaction tower; and feeding a reaction product into a catalytic reaction and then fed into section rectification column for separating to obtain silane gas at the temperature of 30 to 100 DEG C, wherein macroporous anion exchange resins and organic amine composite catalyst are filled in the catalytic reaction section. By the method, the conversion rate of the dichlorosilane is greatly improved and up to over 25 percent; and a by-product, namely the dichlorosilane produced during polysilicon production is converted to the silane, so that the utilization rate of raw materials is increased, emission of waste water, waste residues and waste gas is reduced, and economic benefits and social benefits are improved during polysilicon production.

Owner:ZHEJIANG JINGGONG NEW MATERIAL TECH

Silicon-containing layer deposition with silicon compounds

InactiveUS20070240632A1Silicon organic compoundsPolycrystalline material growthSelective depositionSilicon

Embodiments of the invention relate to methods for depositing silicon-containing materials on a substrate. In one example, a method for selectively and epitaxially depositing a silicon-containing material is provided which includes positioning and heating a substrate containing a crystalline surface and a non-crystalline surface within a process chamber, exposing the substrate to a process gas containing neopentasilane, and depositing an epitaxial layer on the crystalline surface. In another example, a method for blanket depositing a silicon-containing material is provide which includes positioning and heating a substrate containing a crystalline surface and feature surfaces within a process chamber and exposing the substrate to a process gas containing neopentasilane and a carbon source to deposit a silicon carbide blanket layer across the crystalline surface and the feature surfaces. Generally, the silicon carbide blanket layer contains a silicon carbide epitaxial layer selectively deposited on the crystalline surface.

Owner:APPLIED MATERIALS INC

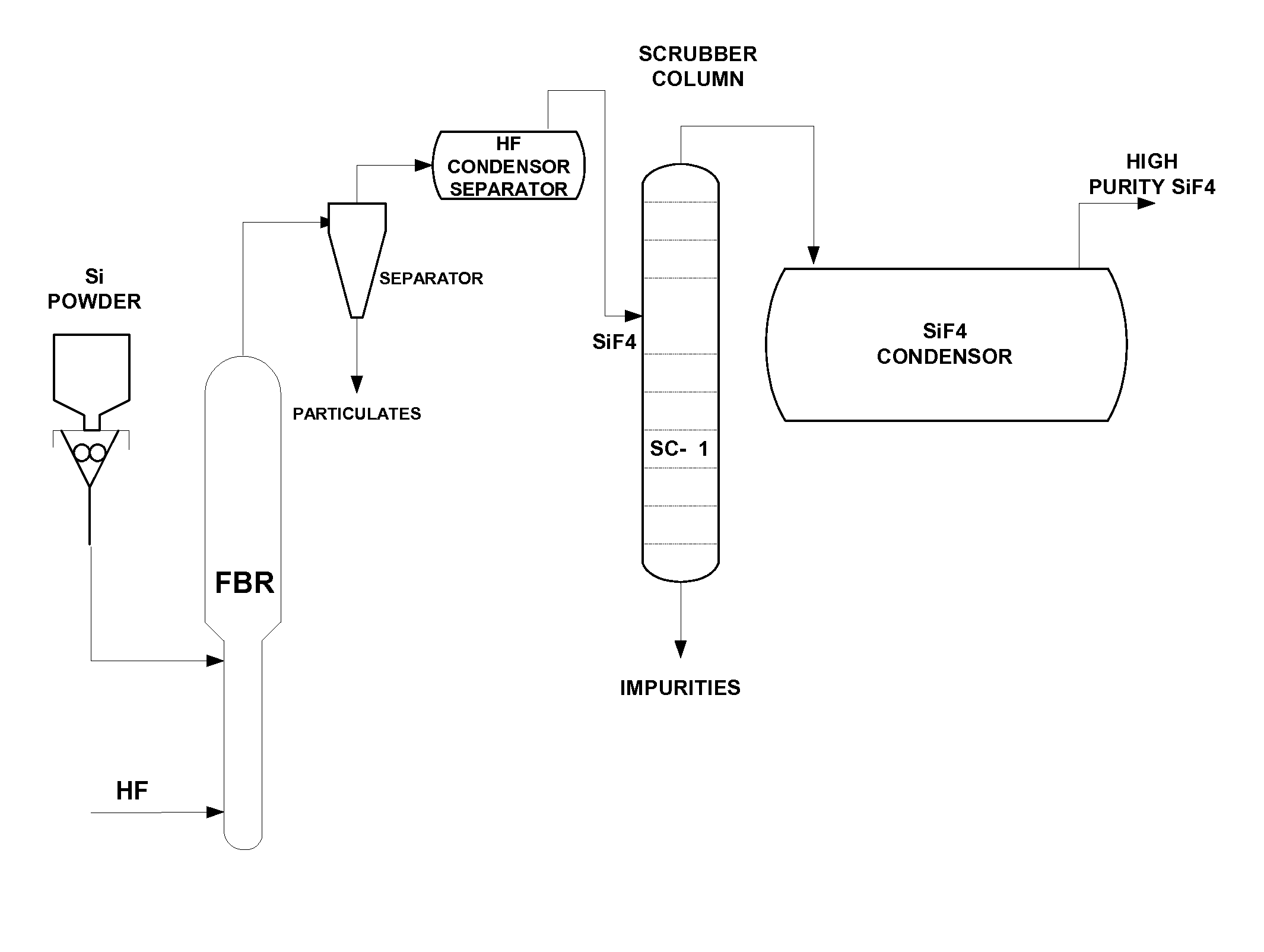

METHOD TO CONVERT SILICON POWDER TO HIGH PURITY POLYSILICON THROUGH INTERMEDIATE SiF4

InactiveUS20100061911A1High purityRobust and practicalSilicon hydridesFine working devicesDopantDistillation

A process for the recovery of silicon includes providing silicon-containing solids recovered from a silicon manufacturing process, said recovered silicon-containing solids being substantially free of semiconductor dopants; converting the recovered silicon-containing solids into gaseous silicon forms; subjecting to purification by minimal distillation; collecting the gaseous silicon forms as a condensed liquid of silicon-containing compounds; and utilizing the silicon-containing compounds for silicon deposition.

Owner:HARIHARAN ALLEPPEY V +1

Popular searches

Solid state diffusion coating Glass/slag layered products Natural mineral layered products Chemical vapor deposition coating Water-setting substance layered product Thin material handling Using liquid separation agent Alkali metal oxides/hydroxides Chemical/physical processes Oxygen/ozone/oxide/hydroxide

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com