Method for producing higher silanes

A technology of silicon compound and general formula, applied in the device for implementing the method, in the field of preparing silicon halide compound and preparing corresponding germanium compound, can solve the problems of impure crude product and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

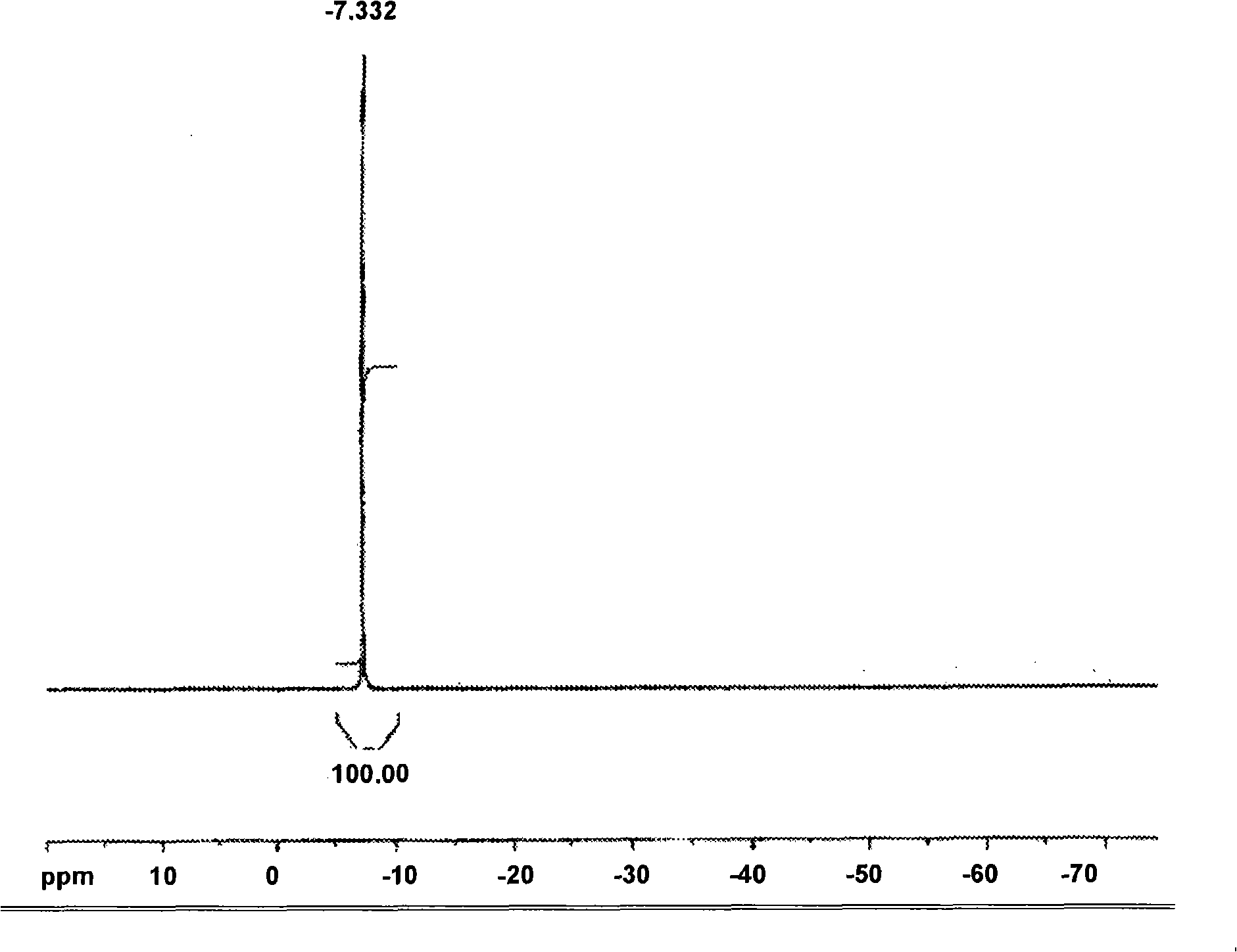

[0059] enriched with methyltrichlorosilane (MeSiCl) in which silicon tetrachloride is preferably present in excess 3 ) of silicon tetrachloride (SiCl 4 ) is continuously evaporated and introduced into the non-thermal plasma in the gas discharge section of the quartz glass reactor. The gas phase was passed through the reactor at a rate of about 250 ml / h. An AC voltage with a frequency of 1.9 kHz and an amplitude of 35 kV "peak-to-peak" was applied while the gas phase was flowing through the reactor. The power input into the reactor was about 40W. Adjust the working pressure to about 300mbar. After passing through the reactor, the liquid reaction mixture is collected in a collection vessel. The gas chromatogram of the reaction mixture gave only one signal for the higher molecular weight silicon compound and could be attributed to hexachlorodisilane. The distillation was carried out discontinuously in a distillation apparatus equipped with a 50 cm column with Sulzer metal la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com