Patents

Literature

63results about "Germanium halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing higher silanes

Owner:EVONIK OPERATIONS GMBH

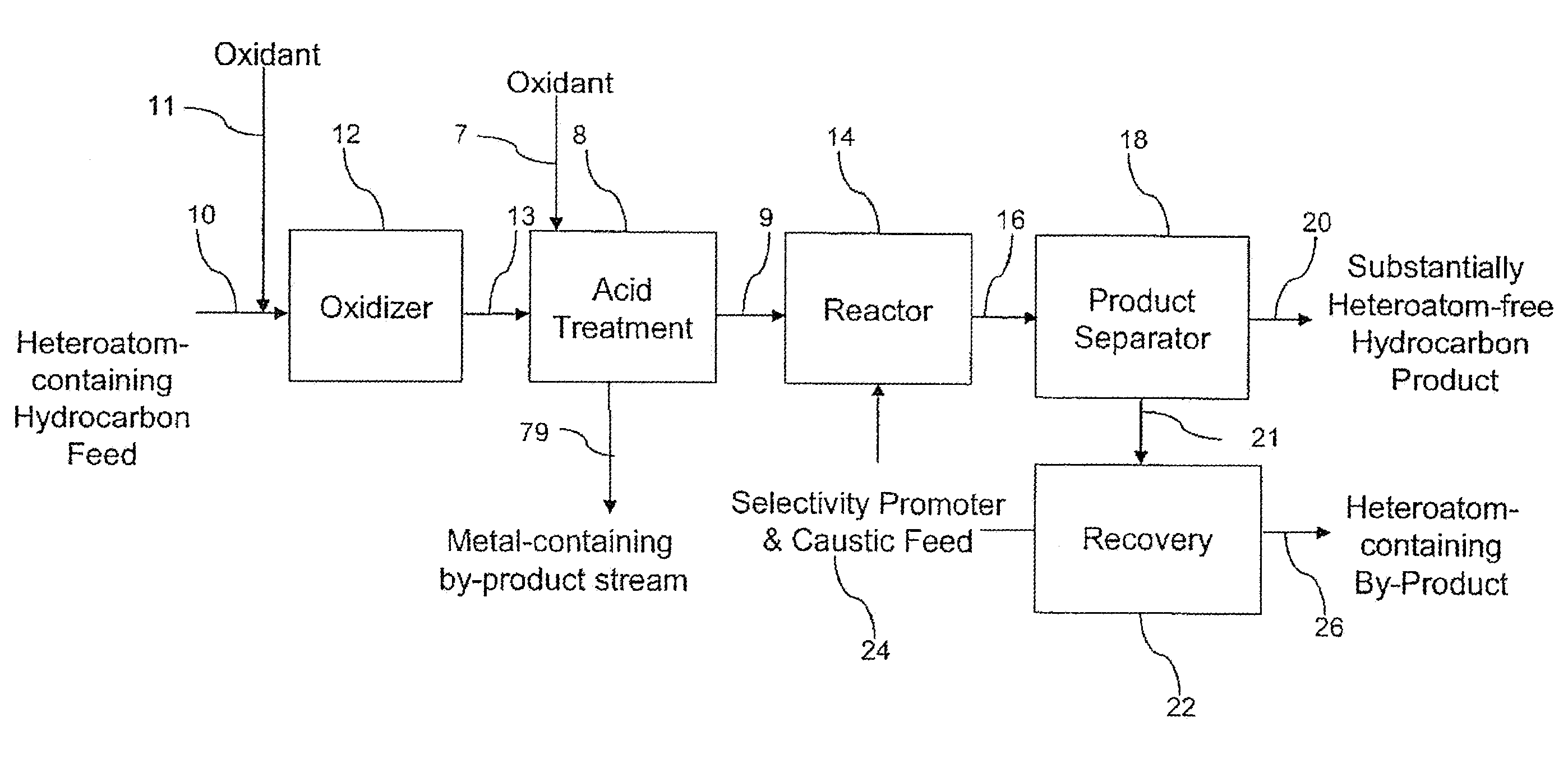

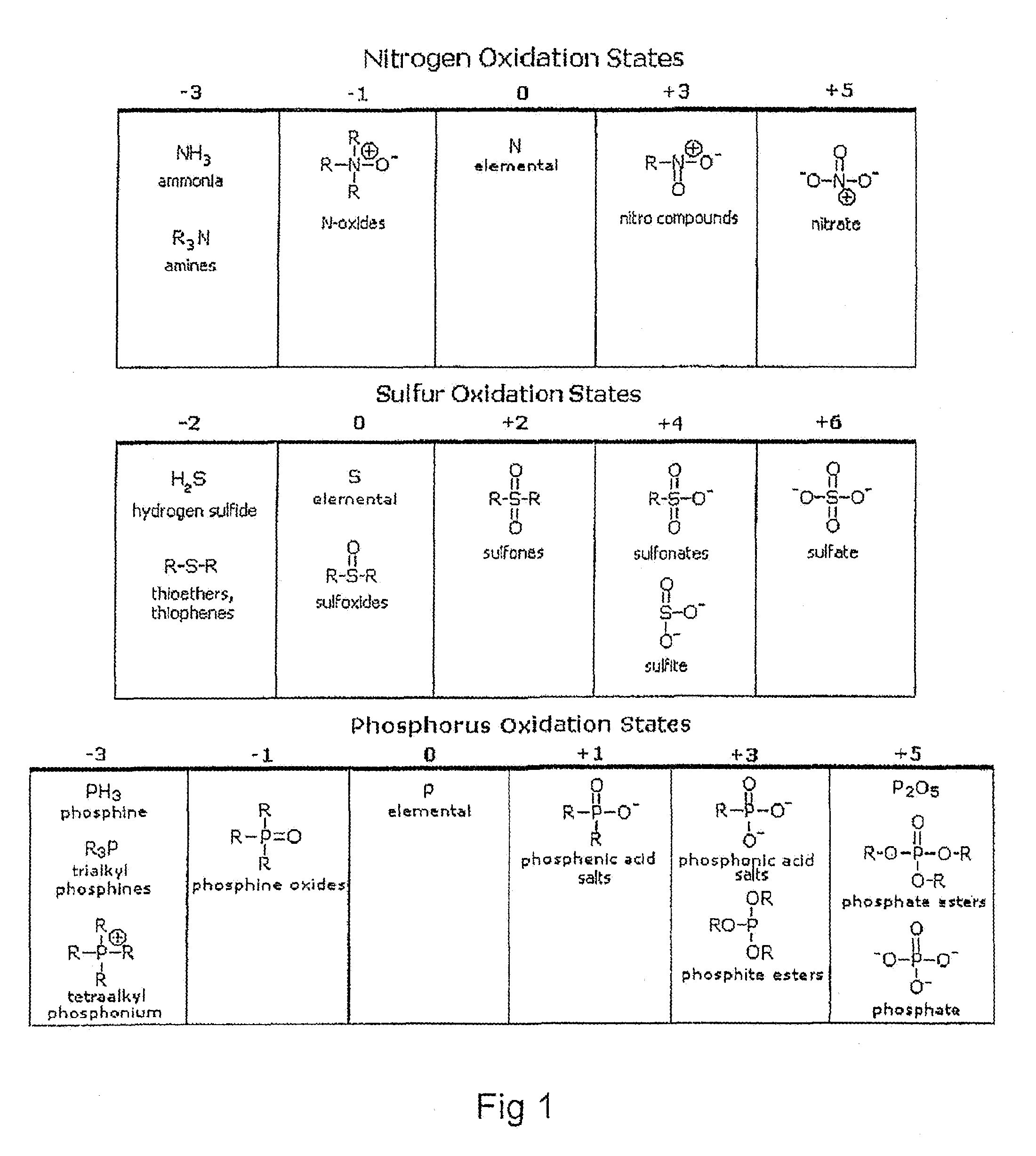

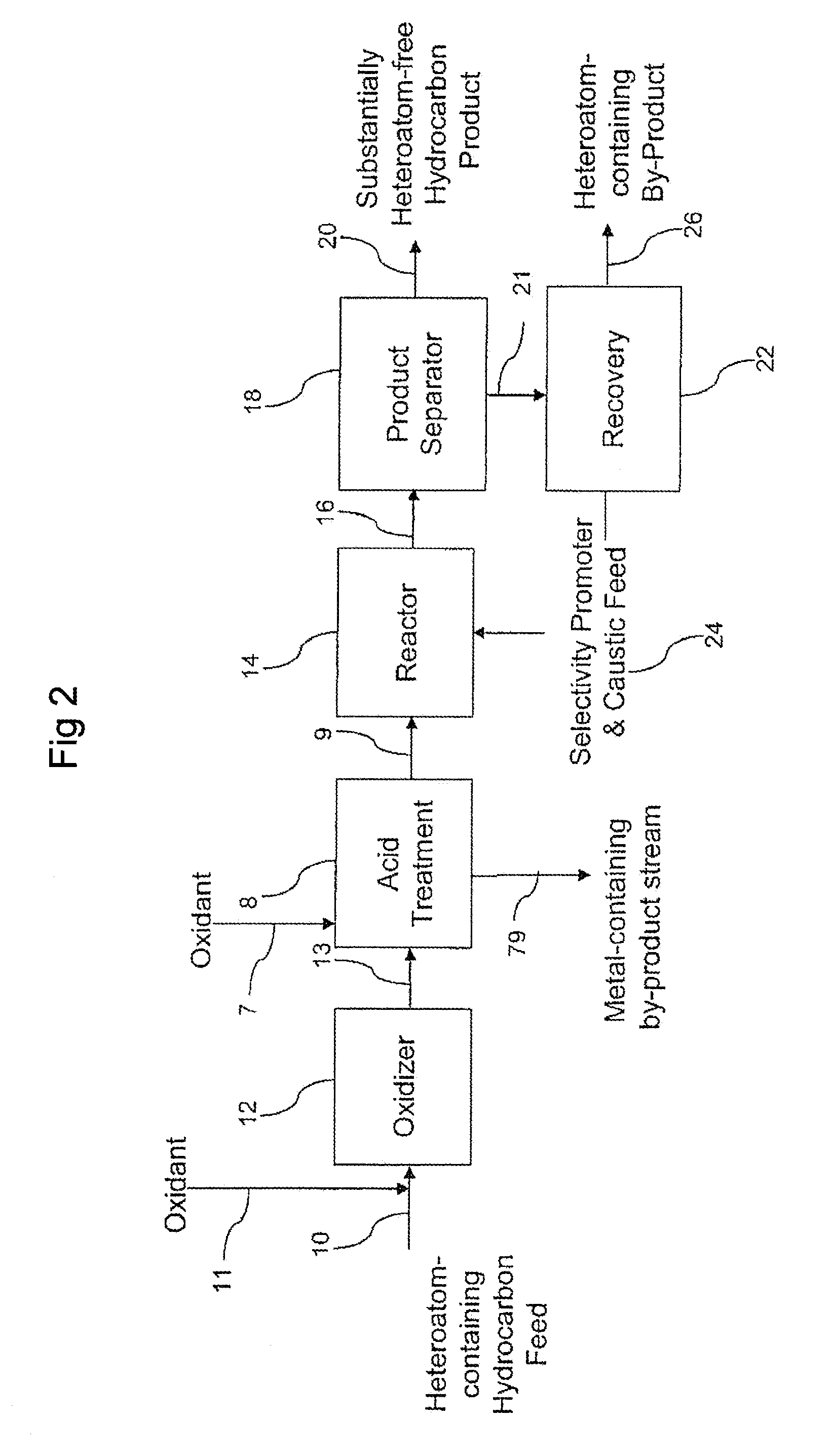

Methods for upgrading of contaminated hydrocarbon streams

ActiveUS8197671B2Hydrocarbon distillationRefining with acid-containing liquidsHeteroatomOxidizing agent

A method of upgrading a heteroatom-containing hydrocarbon feed by removing heteroatom contaminants is disclosed. The method includes contacting the heteroatom-containing hydrocarbon feed with an oxidant and an immiscible acid to oxidize the heteroatoms, contacting the oxidized-heteroatom-containing hydrocarbon feed with caustic and a selectivity promoter, and removing the heteroatom contaminants from the heteroatom-containing hydrocarbon feed. The oxidant may be used in the presence of a catalyst.

Owner:AUTERRA INC

Preparation purification method of germanium tetrachloride for optical fiber

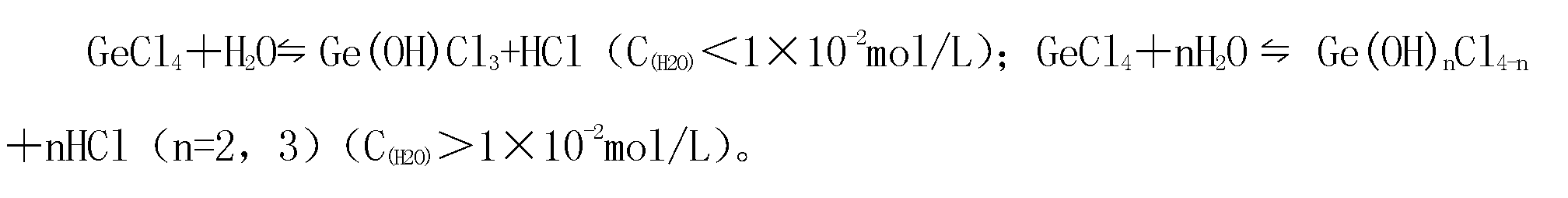

InactiveCN103183375AMeet the requirements of germanium tetrachlorideSuitable for mass production applicationsGermanium halidesPurification methodsDistillation

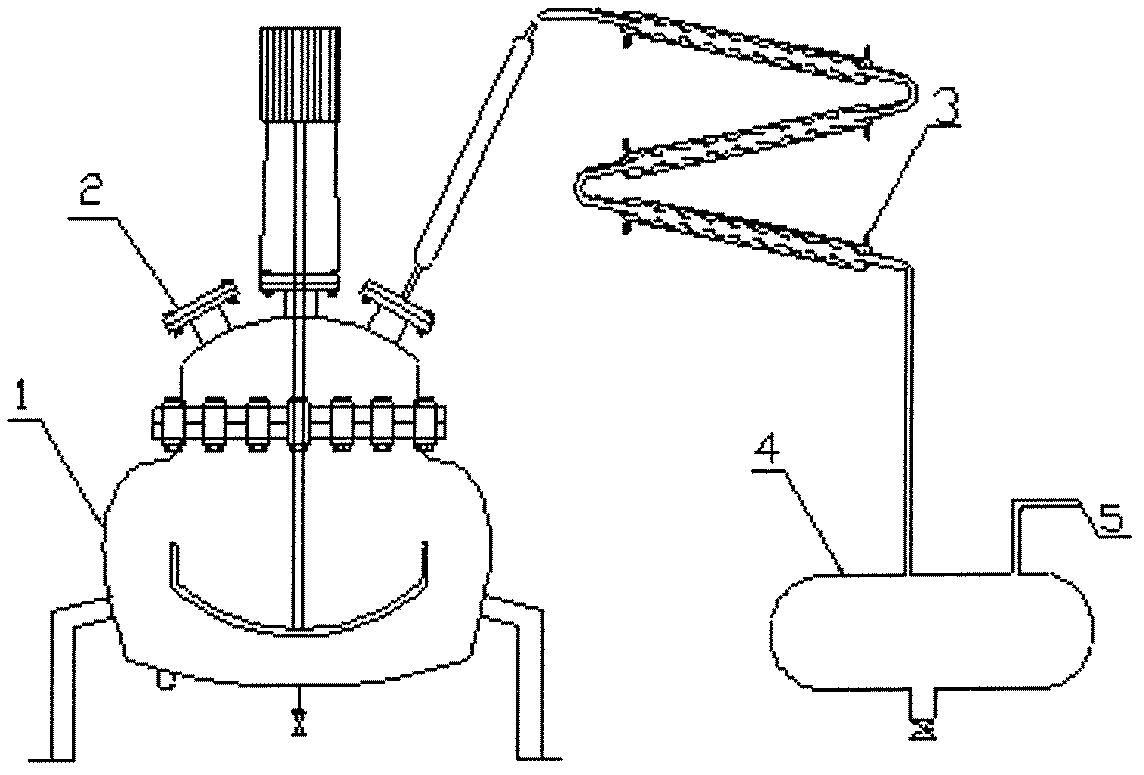

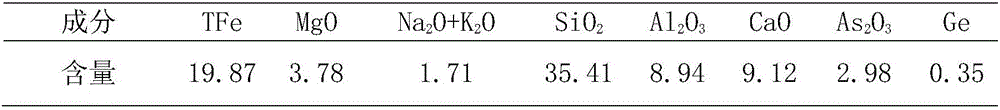

The invention provides a preparation purification method of germanium tetrachloride for optical fibers, which adopts germanium concentrate as a raw material; hydrochloric acid, sulfuric acid, and ferric trichloride are added into a chlorination reaction vessel according to a certain proportion for reaction to prepare crude germanium tetrachloride; the crude germanium tetrachloride is fully mixed with hydrochloric acid and manganese dioxide according to a certain proportion in a repeated distillation reaction vessel for distillation and purification to obtain preliminarily purified germanium tetrachloride; the germanium tetrachloride after repeated distillation purification is processed in a quartz rectifying tower in inert atmosphere by controlling a tower bottom temperature to be 75-95 DEG C, a tower column temperature to be 30-95 DEG C, and a reflux ratio of 4:1-14:1, so as to obtain high-purity germanium tetrachloride. The high-purity germanium tetrachloride prepared through three procedures of chlorination distillation, repeated distillation, and rectification purification, has a content of transition metal impurities of less than 3 ppb, a content of hydrogen-containing impurities of less than 1 ppm, and meets the requirements for perform rod germanium tetrachloride for optical fibers.

Owner:GRINM ELECTRO OPTIC MATERIALS

Method for recycling germanium, gallium, indium and selenium in waste diode

ActiveCN102951618AReduce pollutionHigh recovery rateZinc halidesSolid waste disposalIndiumMineral Sources

The invention relates to treatment of waste metal materials, and in particular relates to a method for recycling germanium, gallium, indium and selenium in a waste diode. The recycling method comprises the following steps of: (1) crushing the waste diode; (2) separating plastic powder from metal powder; (3) oxidizing roasting; (4) recycling selenium; and (5) recycling gallium, indium and germanium. By using the method, the pollution of the diode on the environment is reduced, valuable elements of selenium, indium, gallium and germanium are recycled, and mineral resources are saved; and the method is simple to operate, lower in cost, high in recycling rate of selenium, indium, gallium and germanium elements and very high in purity of recycling products.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

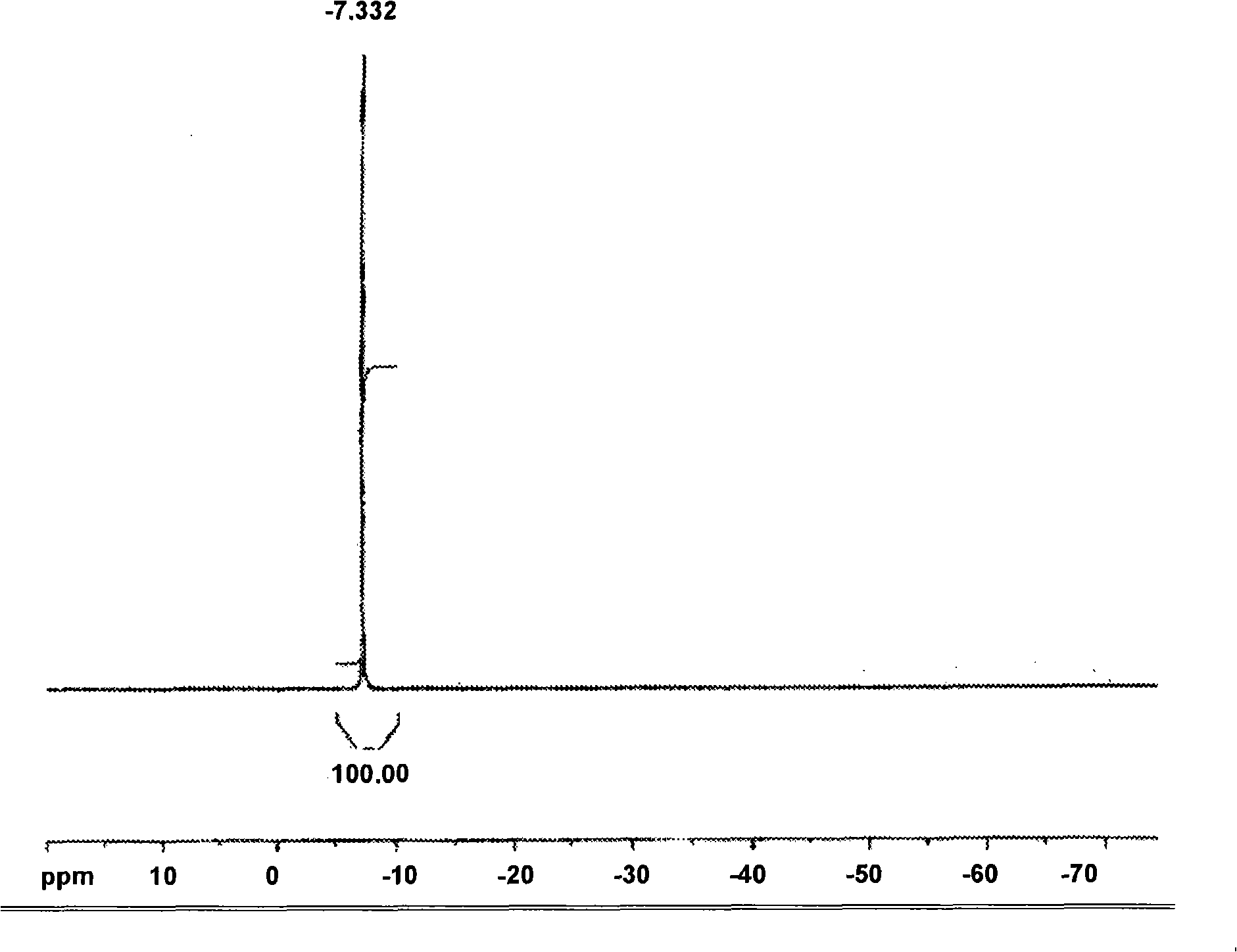

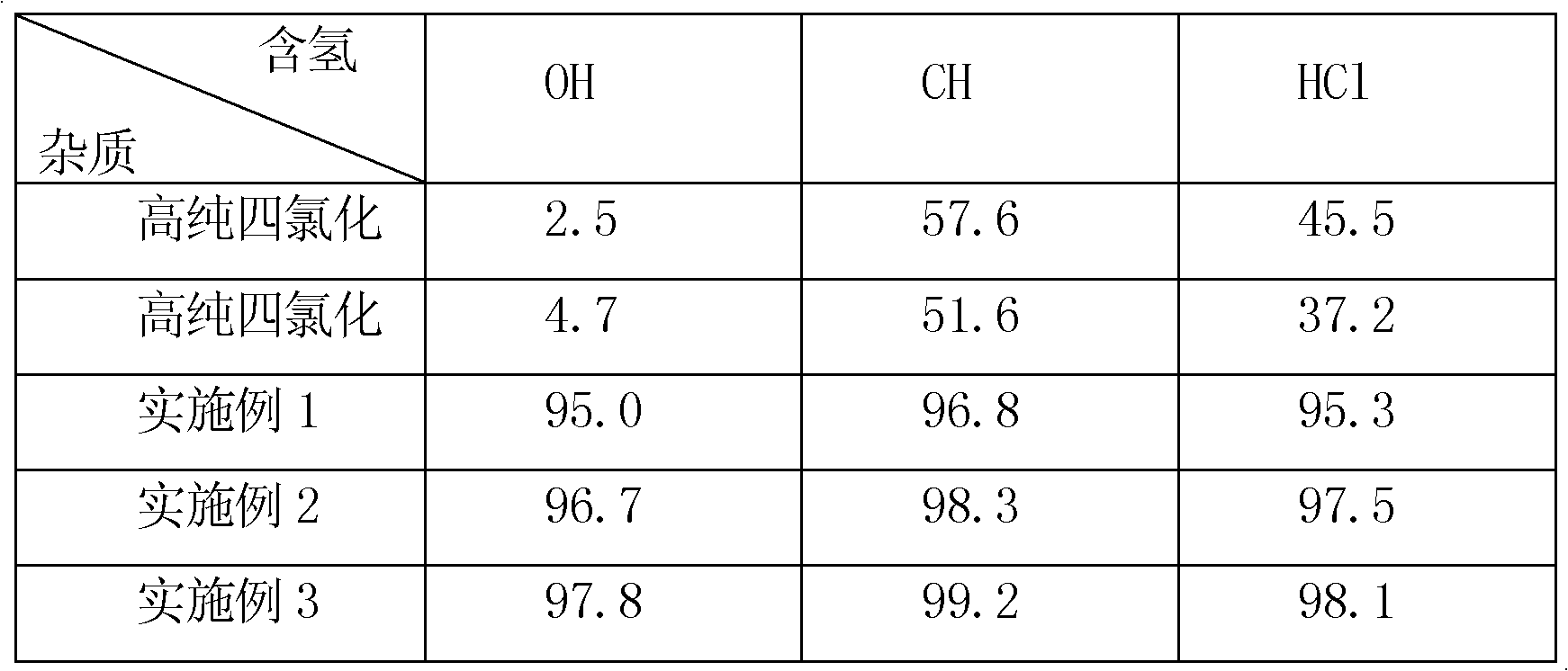

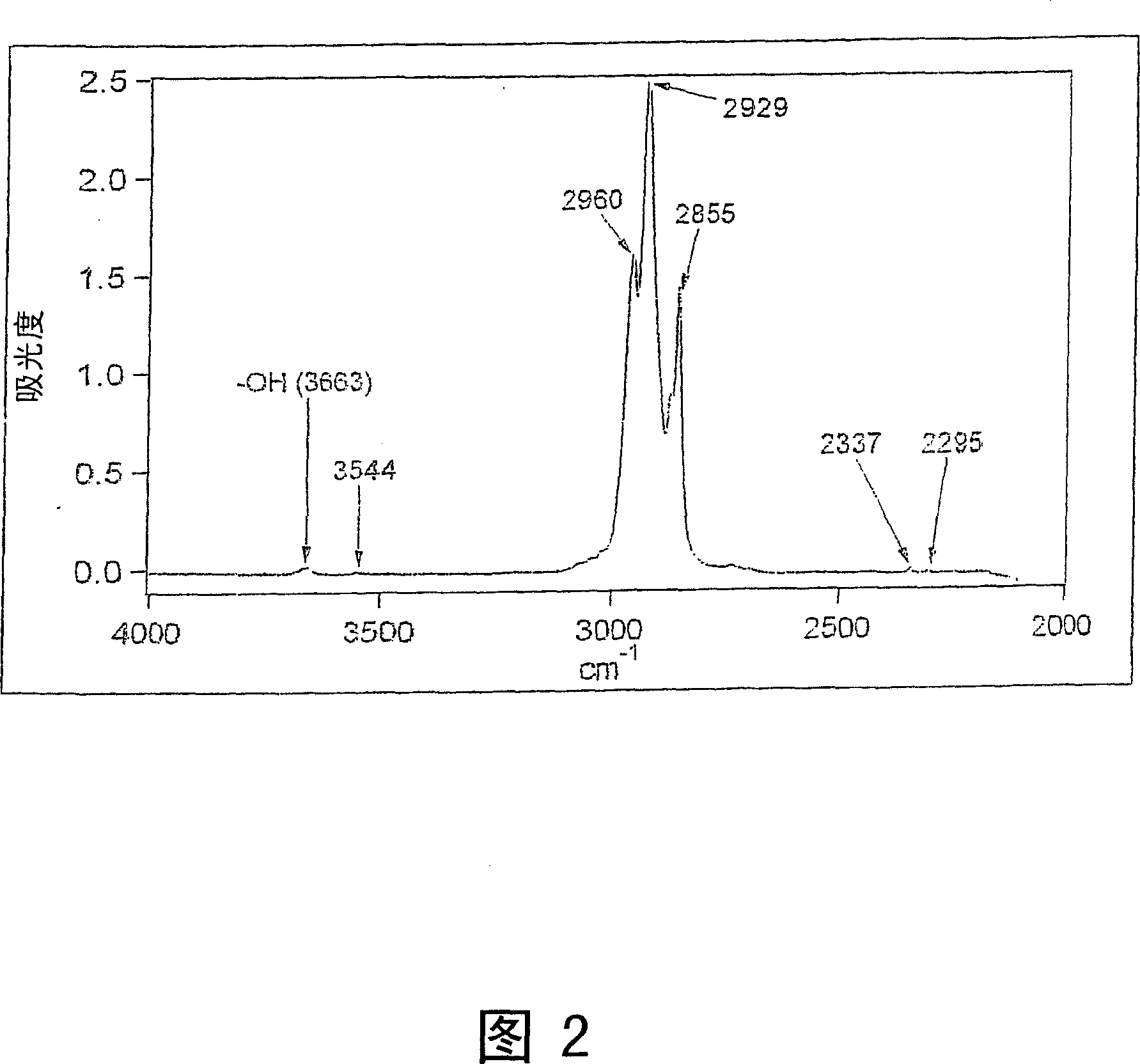

Method and device for removing hydrogen-containing impurities from germanium tetrachloride

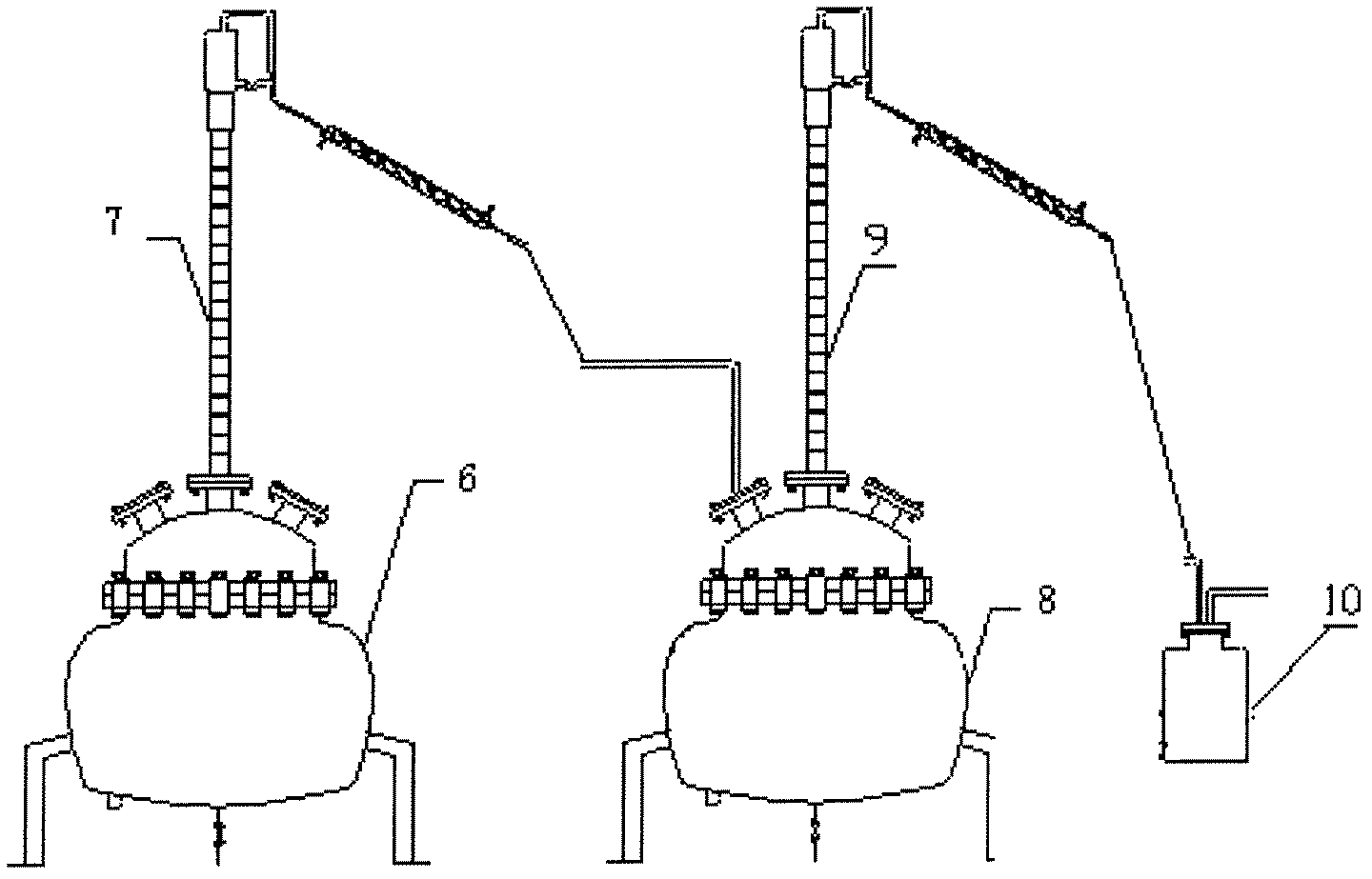

The invention discloses a method and a device for removing hydrogen-containing impurities from germanium tetrachloride. The method comprises the steps of: using rectified germanium tetrachloride as raw materials, adding germanium tetrachloride with the purity being 4N-5N into a rectifying kettle for rectification, increasing the temperature of the kettle to 75-83 DEG C for rectification, keeping the germanium tetrachloride to be in a sub-boiling state and feeding in nitrogen with the flow rate being 30-40L / h to exhaust HCl gas, wherein exhaust time is no less than 6 hours; after the HCl gas is exhausted, continuously increasing the temperature of the kettle, and when all sieve plates of a rectifying column are in a boiling state, starting to calculate total reflux time, wherein the total reflux time is no less than 3 hours; and after total reflux is completed, turning on a switch of an electromagnetic valve to adjust the reflux ratio to be 8:1 to 12:1, taking products at a front section, detecting the distilled germanium tetrachloride, if the detected products satisfy the production requirement of the germanium tetrachloride for optical fibers, putting the electromagnetic valve on the side with the products being taken, and finally shifting to a filling process after the obtained germanium tetrachloride products are detected as acceptable. The method and the device for removing the hydrogen-containing impurities from the germanium tetrachloride have the advantages that the technological process is simple, the operation is simple, the hydrogen-containing impurities can be well removed from the germanium tetrachloride, and the industrial use value is very high.

Owner:云南驰宏国际锗业有限公司 +1

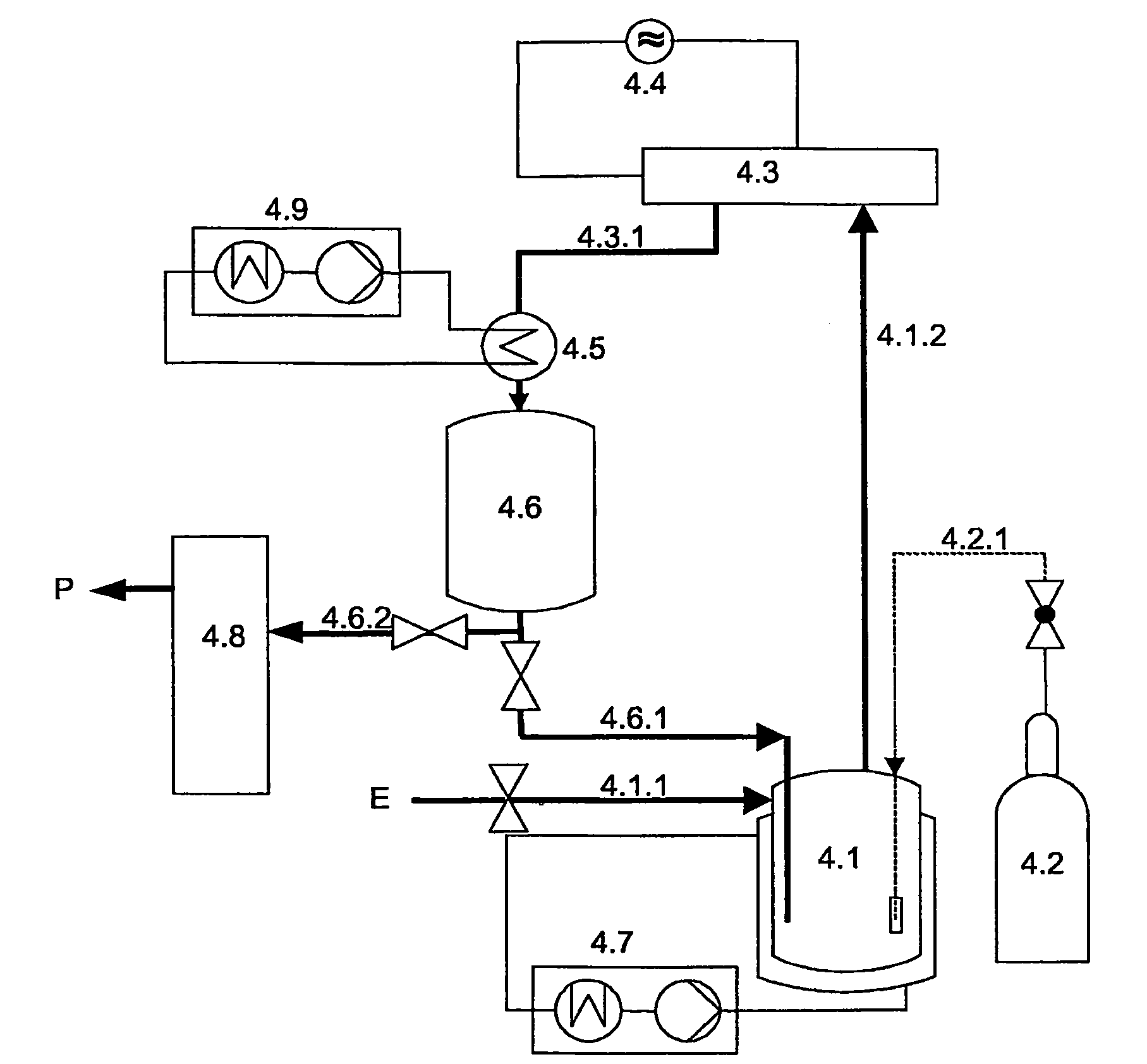

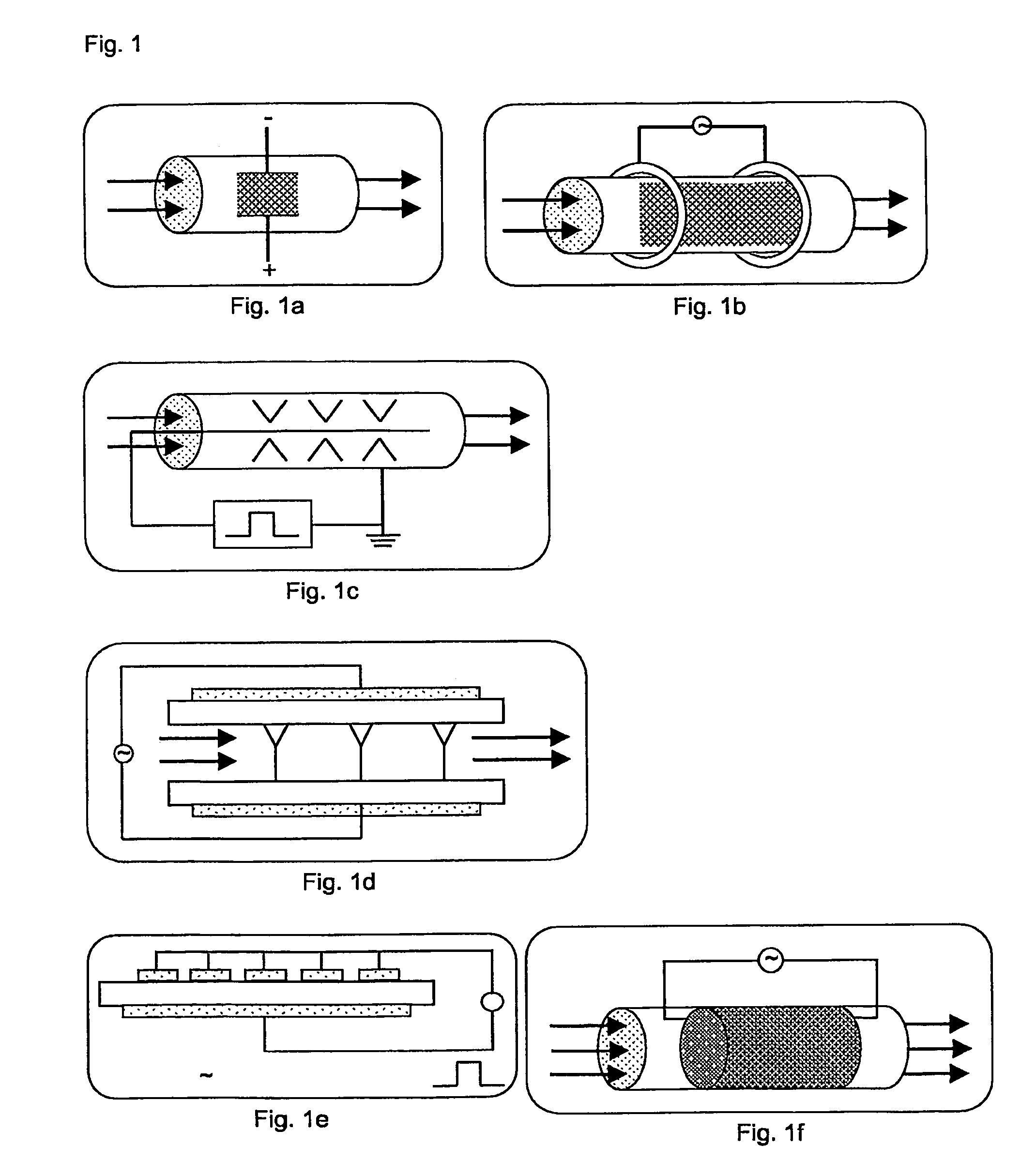

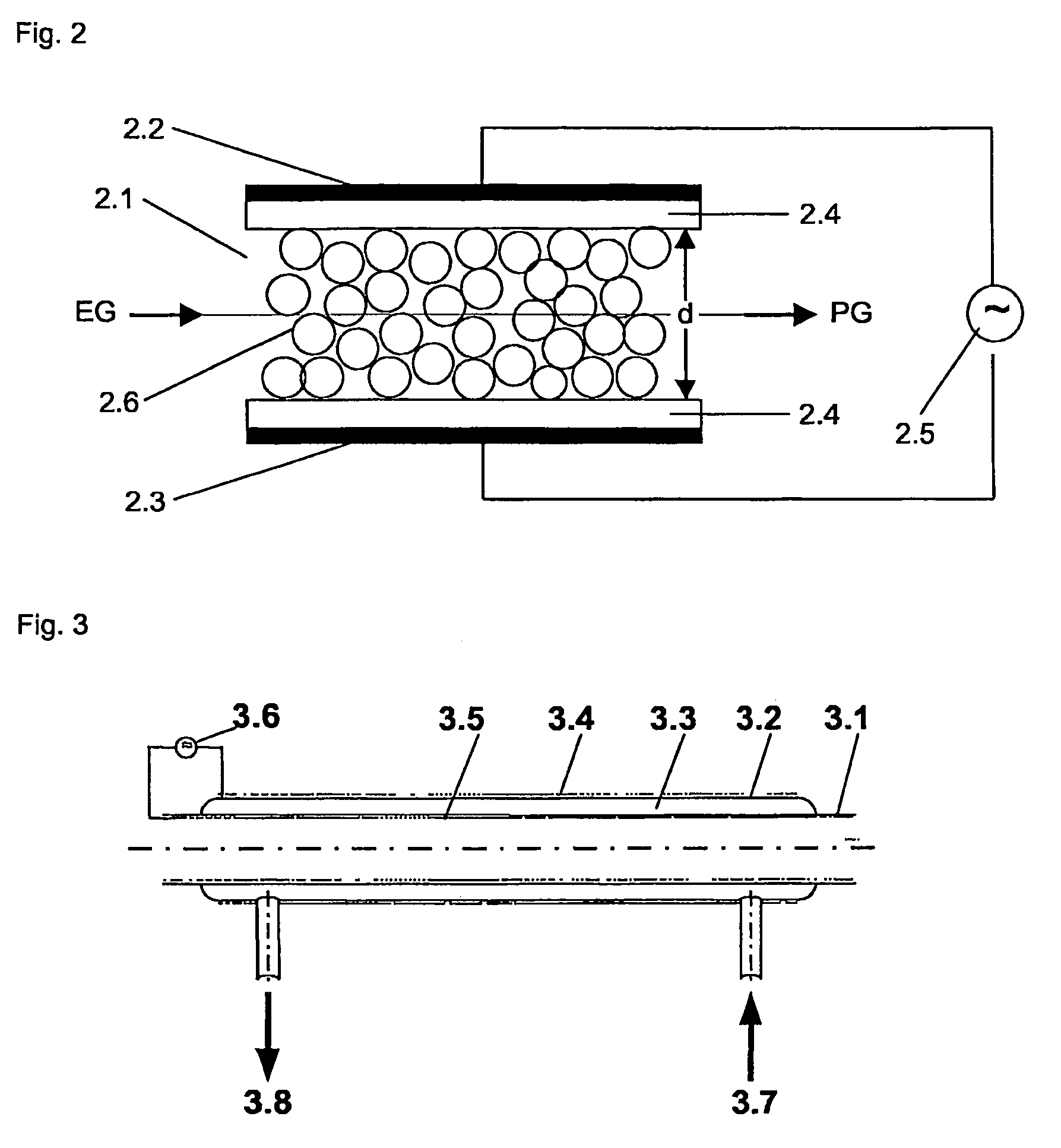

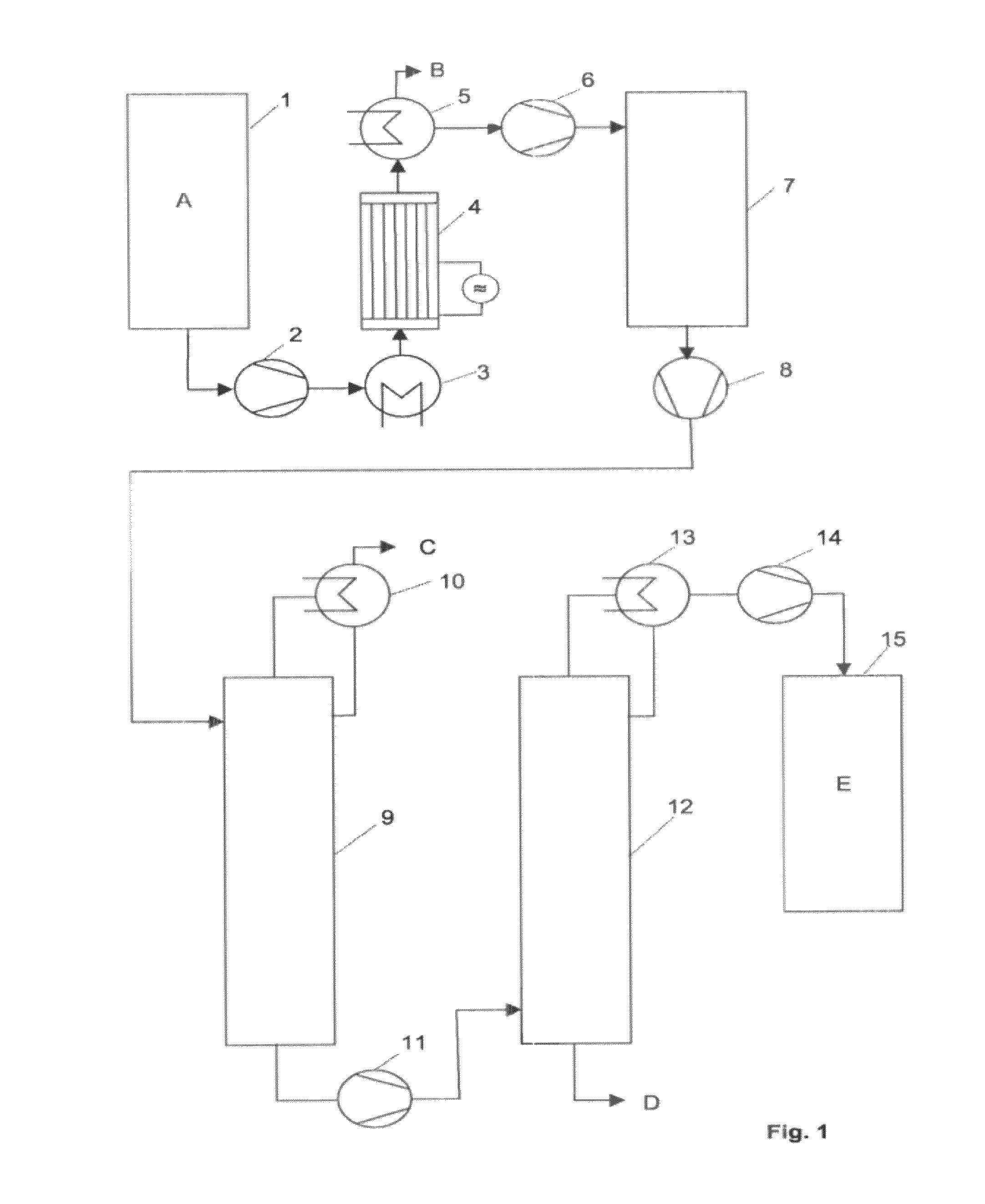

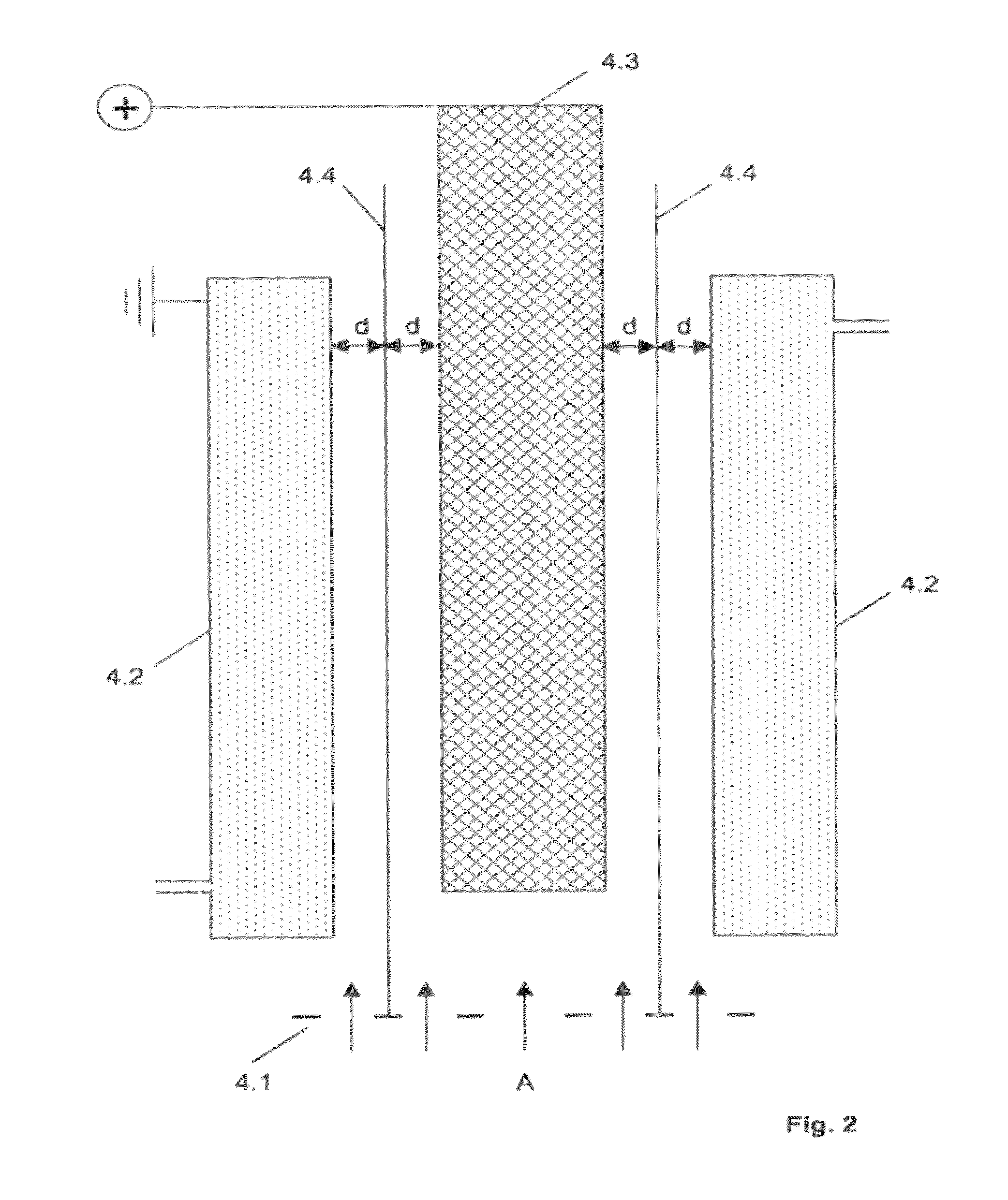

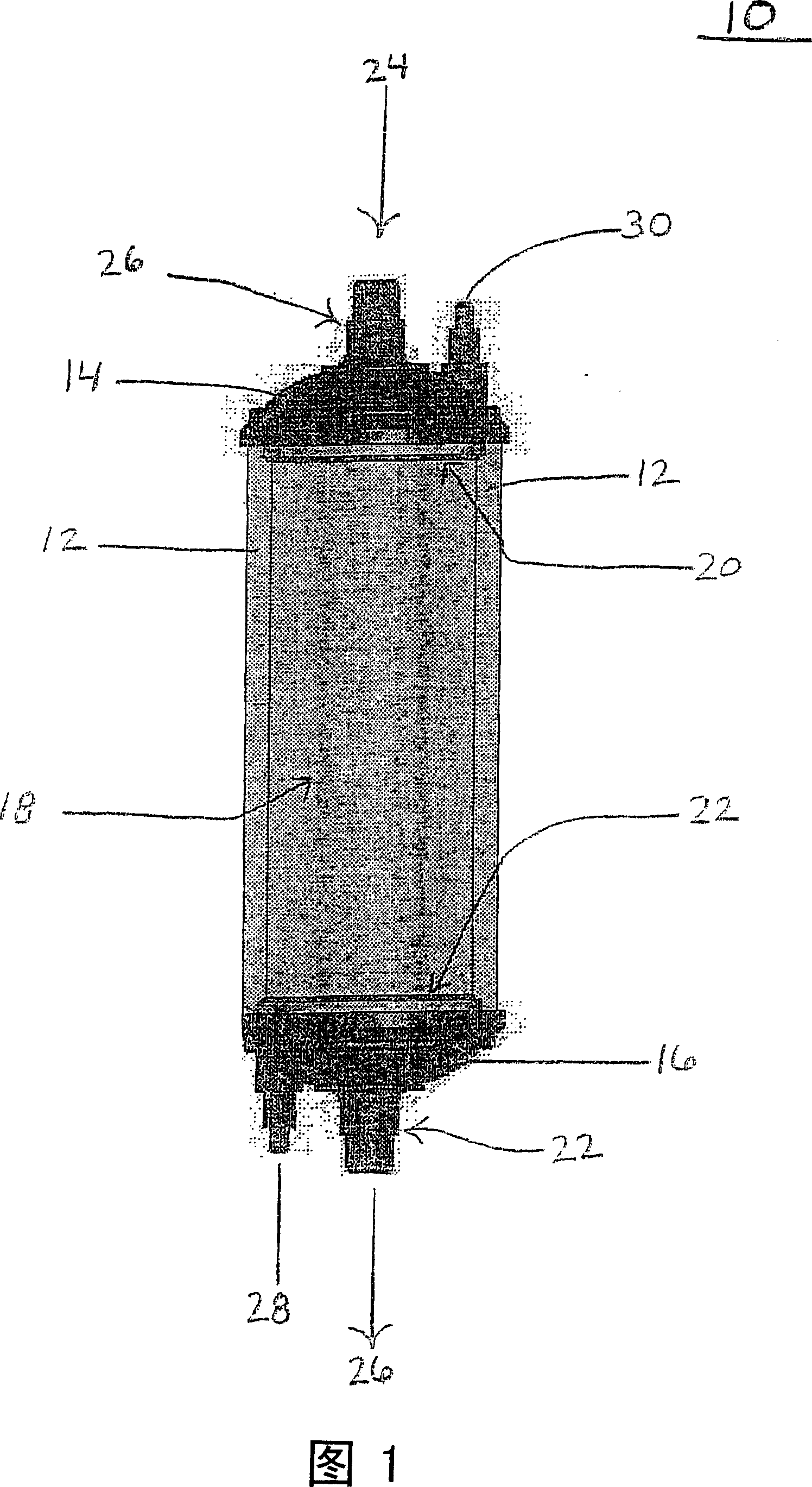

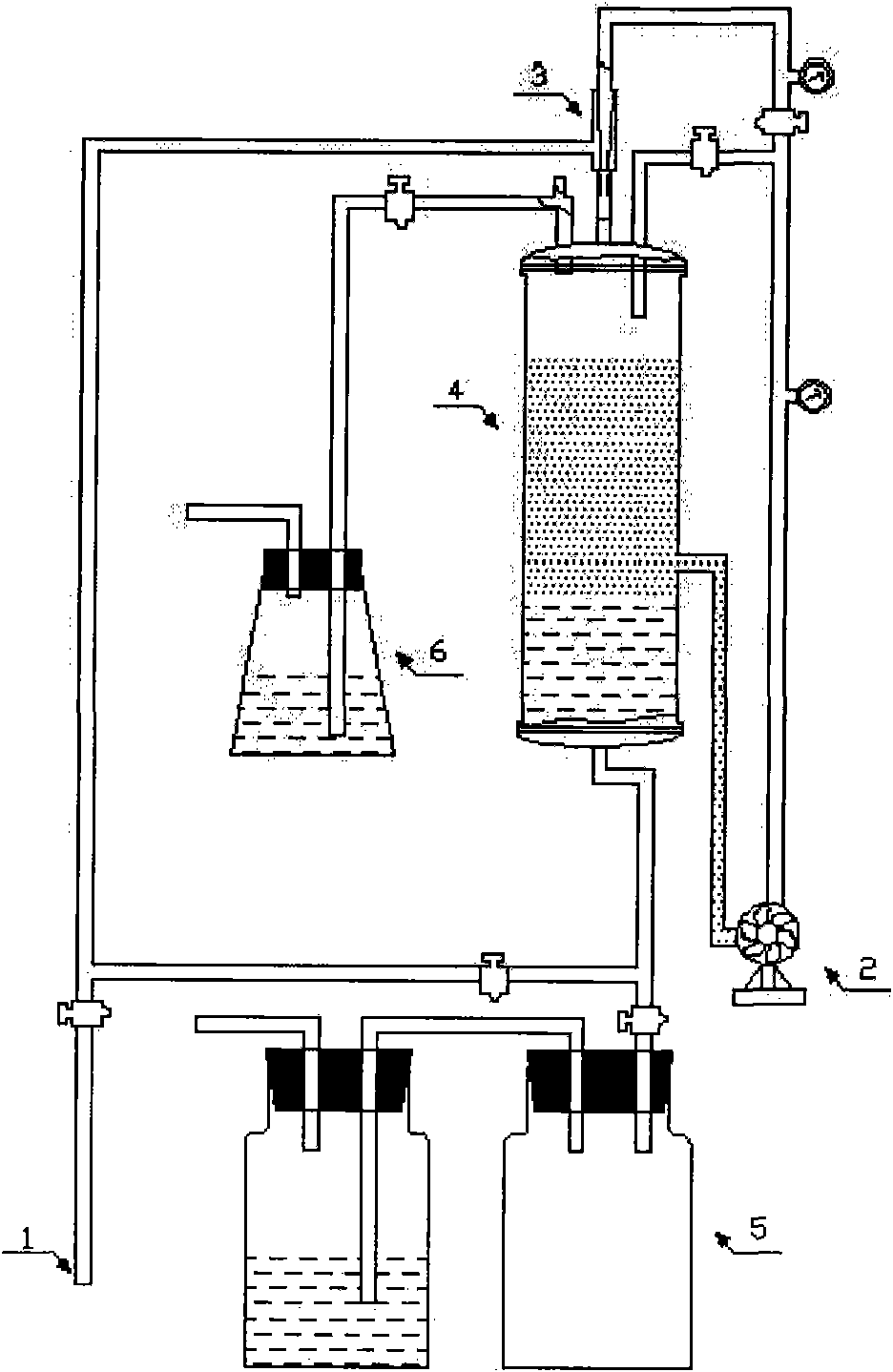

Process and apparatus for purifying silicon tetrachloride or germanium tetrachloride containing hydrogen compounds

ActiveUS8002954B2Germanium halidesEnergy based chemical/physical/physico-chemical processesHydrogenDistillation

The invention relates to a process for the purification's of silicon tetrachloride or germanium tetrachloride contaminated with at least one hydrogen-containing compound, in which the silicon tetrachloride or germanium tetrachloride to be purified is treated in a targeted manner by means of a cold plasma and purified silicon tetrachloride or germanium tetrachloride is isolated from the phase which has been treated in this way. The present invention further relates to an apparatus for carrying out the process of the invention, which comprises a stock and vaporization unit for silicon or germanium tetrachloride (4.1 or 5.1) which is connected via a connecting line with the inlet of the reactor (4.3 or 5.3) with control unit (4.4 or 5.4) for producing the dielectrically hindered discharges whose outlet leads via a pipe either directly or indirectly via at least one further reactor (5.5) to a condensation unit (4.5 or 5.11) with downstream collection vessel (4.6 or 5.12) which is connected via an offtake line (4.6.2 or 5.12.1) to a distillation unit (4.8 or 5.13) and, if appropriate, is equipped with a feed line (4.6.1) to the unit (4.1).

Owner:EVONIK OPERATIONS GMBH

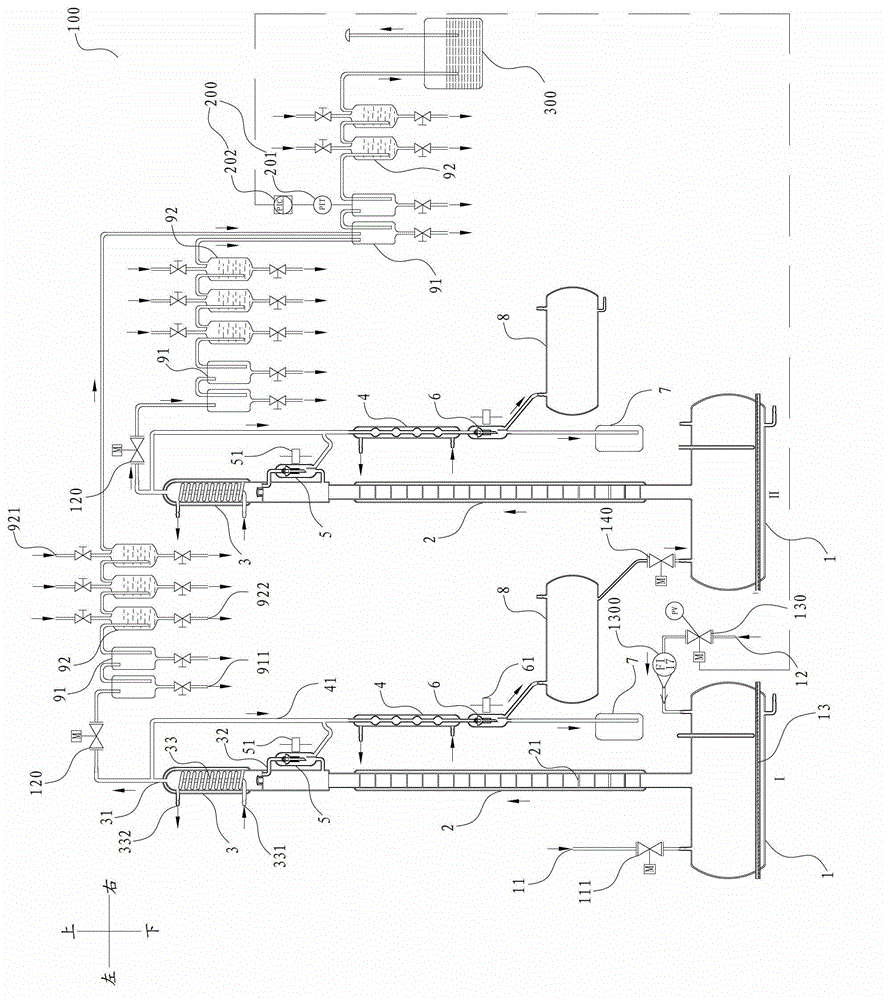

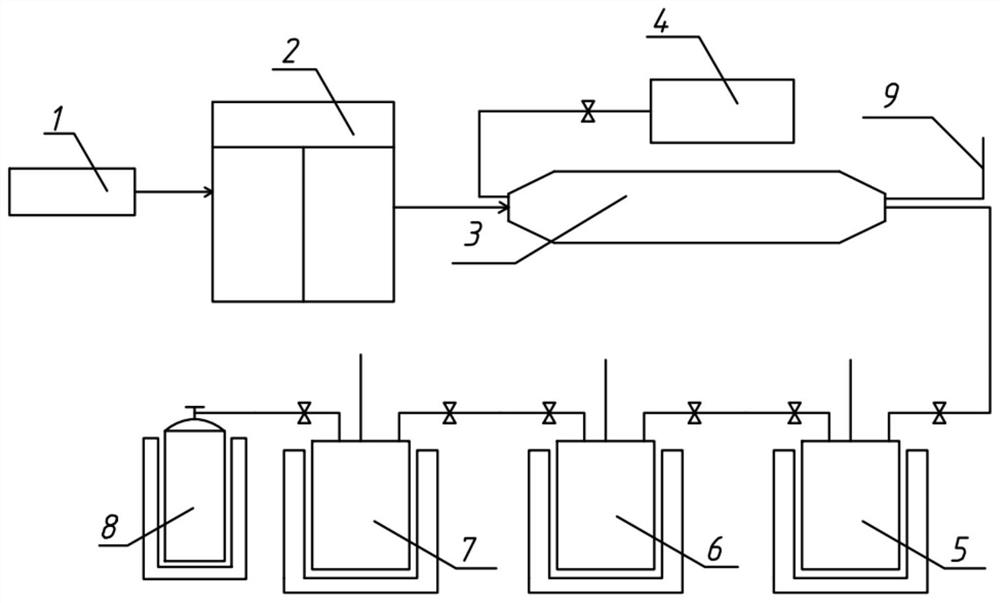

Production system of germanium tetrachloride for optical fiber

ActiveCN102976395AImprove distillation purityIsolated entryGermanium halidesEngineeringProcess engineering

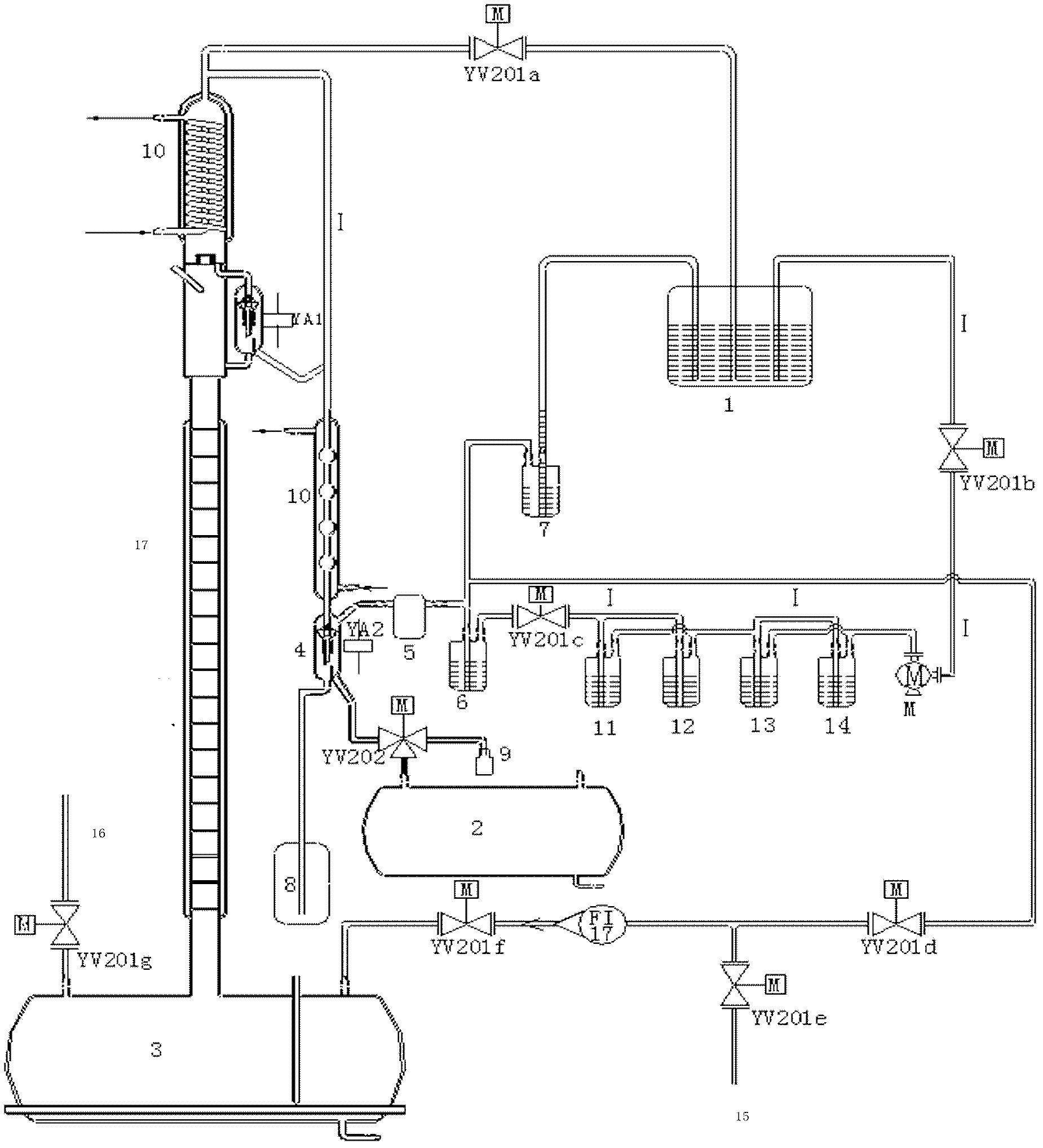

The invention provides a production system of germanium tetrachloride for optical fiber. The production system of germanium tetrachloride for the optical fiber comprises at least two rectification units. The rectification units are connected with each other in series. Each of the rectification units comprises a rectifying still, a rectifying tower, a primary condensing tower, a secondary condensing tower, a discharging head, a primary exhaust gas absorption device, a secondary exhaust gas absorption device and a exhaust gas treatment device. The secondary exhaust gas absorption device is communicated with the primary exhaust gas absorption device. The exhaust gas treatment device is communicated with the secondary exhaust gas absorption device. The production system of germanium tetrachloride for the optical fiber improves the rectifying purity of the germanium tetrachloride for the optical fiber enormously by arranging a plurality of rectification units and improves the reliability of the sealing and maintains the pressure balance in the system by arranging the primary exhaust gas absorption device and the secondary exhaust gas absorption device and can evacuate the exhaust gas finally produced by the production system through the exhaust gas treatment device by arranging the exhaust gas treatment device.

Owner:云南驰宏国际锗业有限公司

Method for producing germanium tetrachloride for optical fibre

InactiveCN101234780AGood removal effectSimple processGermanium halidesPhysical chemistryNitrogen gas

The invention discloses a method for producing germanium tetrachloride for optical fibers, which includes the steps: hydrochloric acid and germanium tetrachloride with a volume ratio of 0.25-2.0: 1 are added into a distiller to be distilled; or while separately distilling the germanium tetrachloride, HCI gas is pumped in until the distilling is finished with the distilling temperature of 76-80 DEG C; after the distilled solution is separated by a hydrochloric separator, the germanium tetrachloride solution is stored in a storage tank to be discharged to an empty tower distiller for 36-72 hours of standing; temperature of the germanium tetrachloride solution is raised to 70-75 DEG C; while continuous pumping nitrogen for 12-36 hours, an ultraviolet lamp is adopted for lighting; finally, distillation operation is carried out at 76-80 DEG C and the product is transferred. The method for producing the germanium tetrachloride for optical fibers has the advantages of simple process course and convenient operation which can remove the impurity containing hydrogen in the germanium tetrachloride with high value for industrial use.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

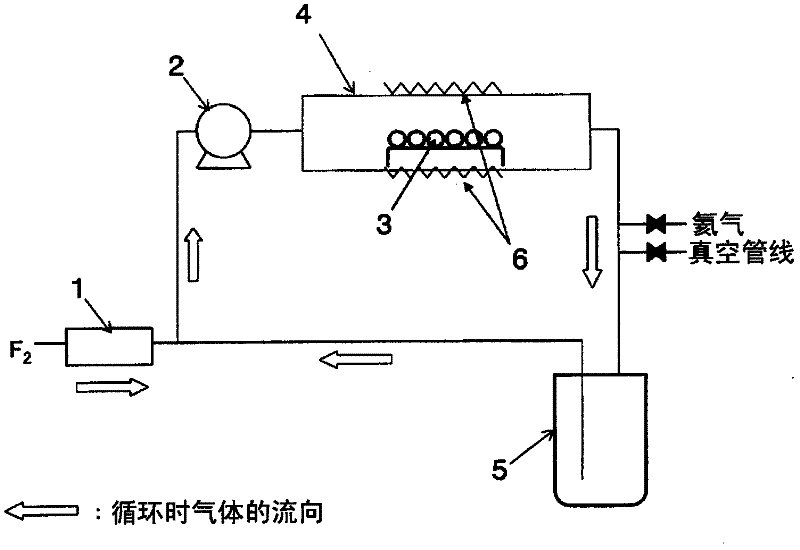

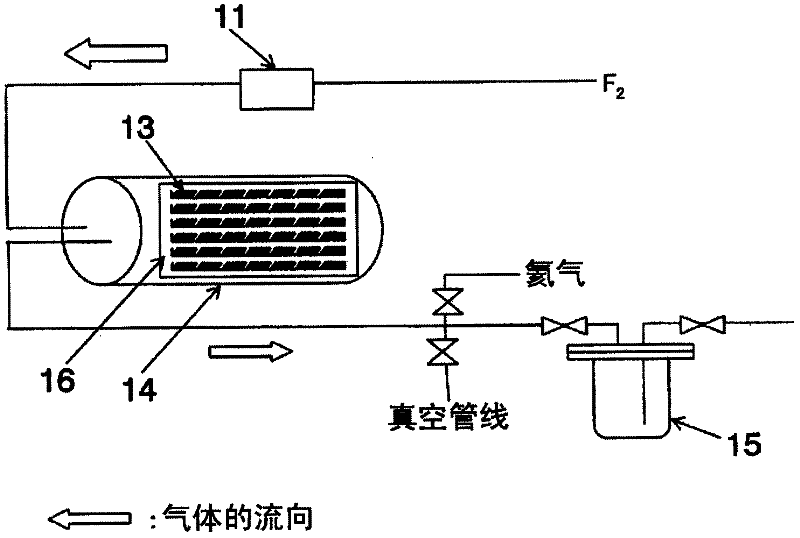

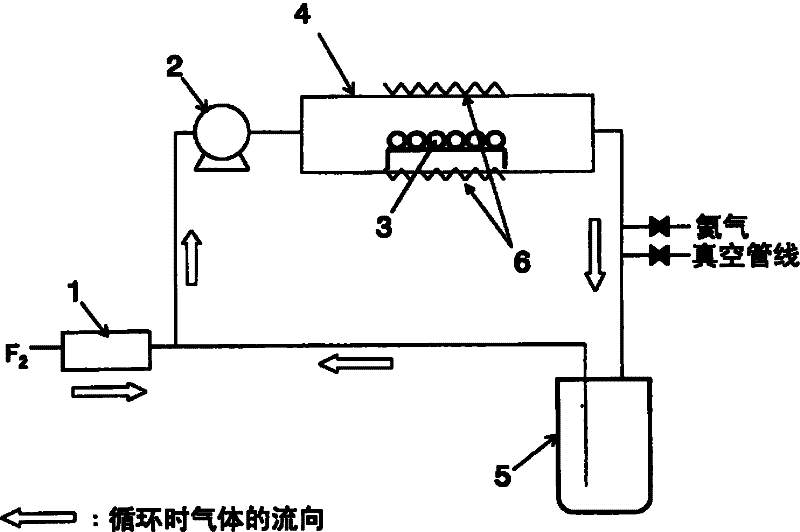

Method for producing germanium tetrafluoride

A method for producing germanium tetrafluoride, which comprises a step of supplying a fluorine gas into a reactor which is filled with germanium metal and a diluent gas; a step of collecting germanium tetrafluoride, which is a reaction product, by passing the gas discharged from the reactor through a cooling collection unit, and a step of circulating the gas passed through the cooling collection unit back to the reactor. By circulating the gas in the closed system as described above, germanium tetrafluoride can be produced safely and efficiently.

Owner:CENT GLASS CO LTD

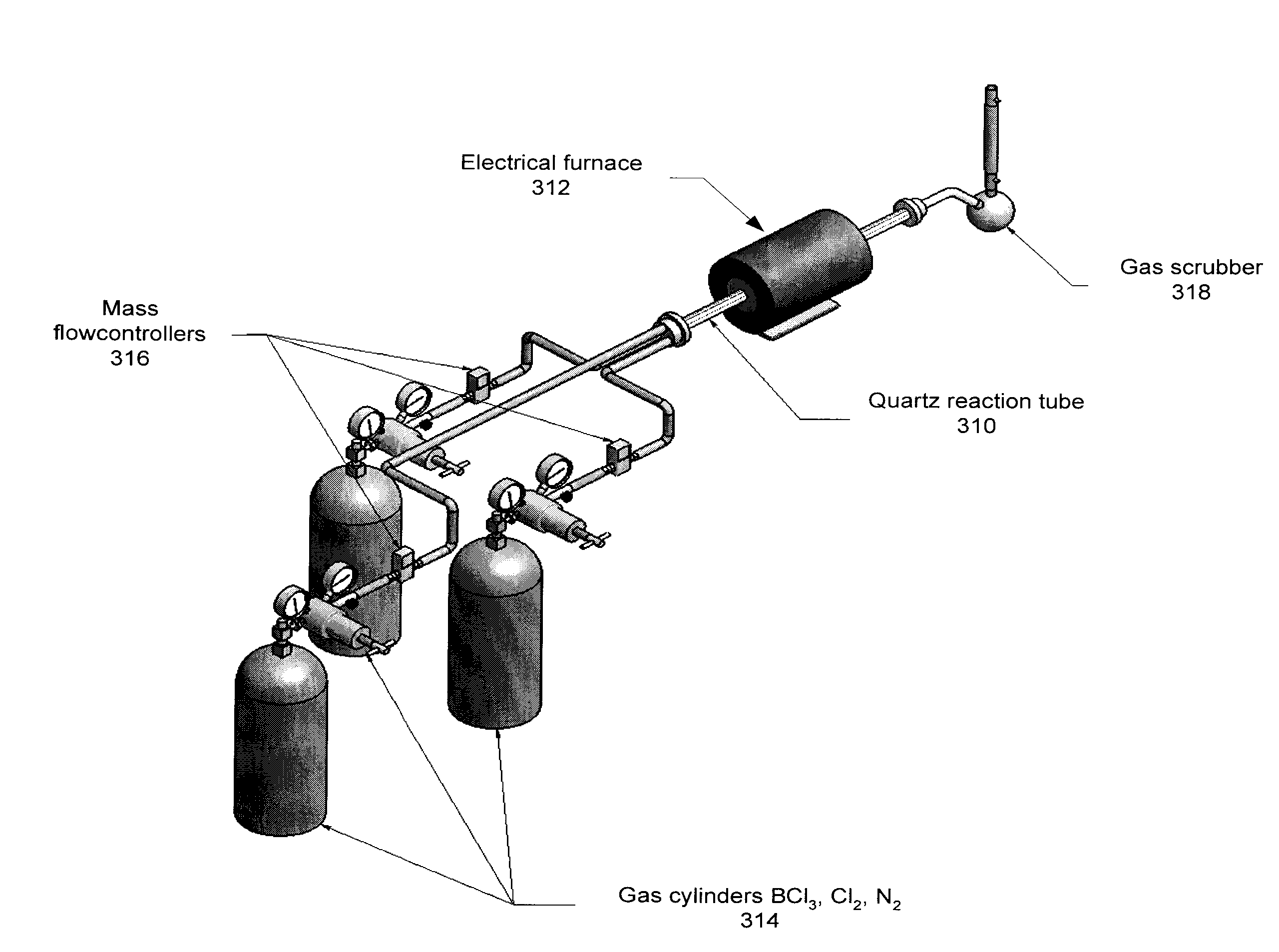

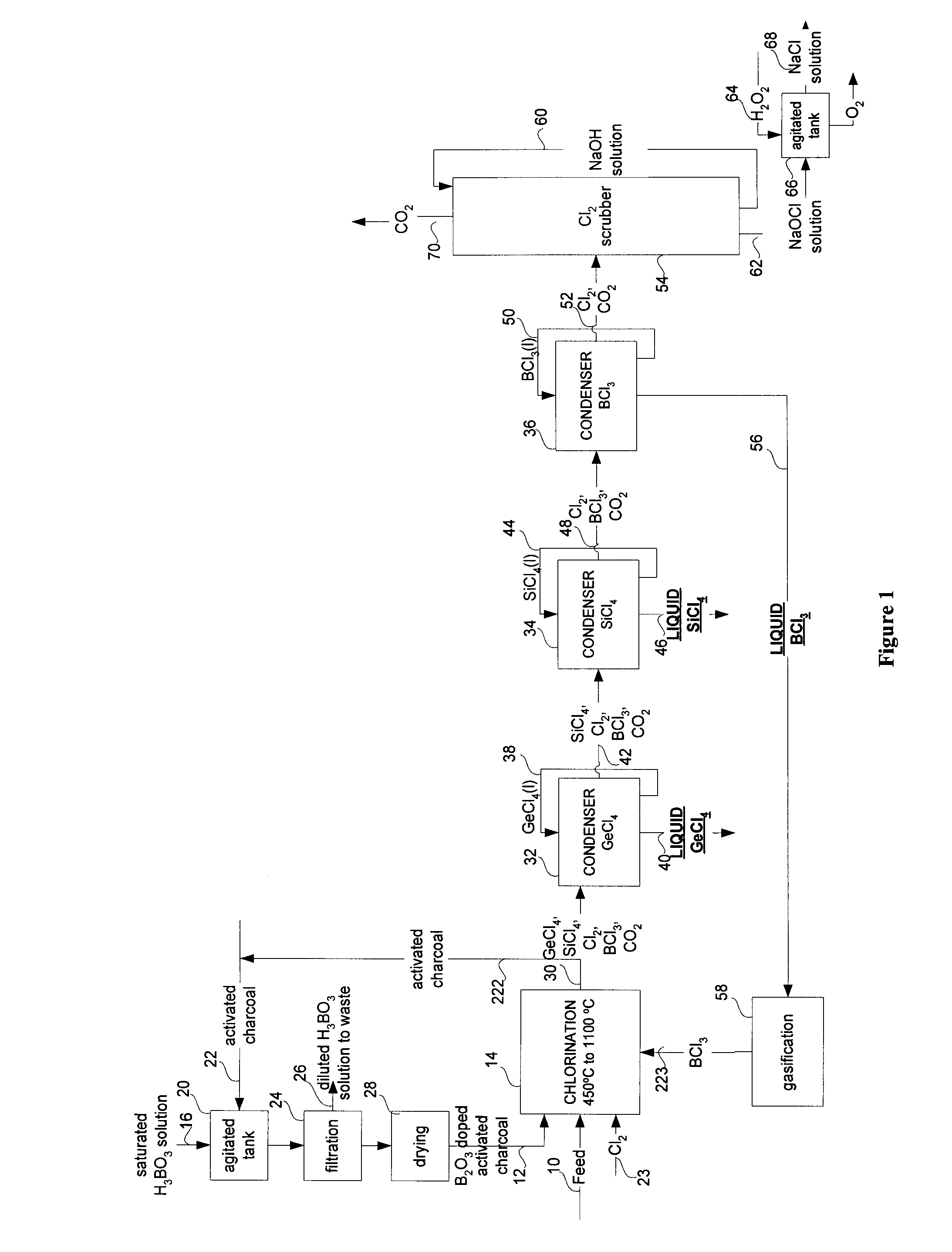

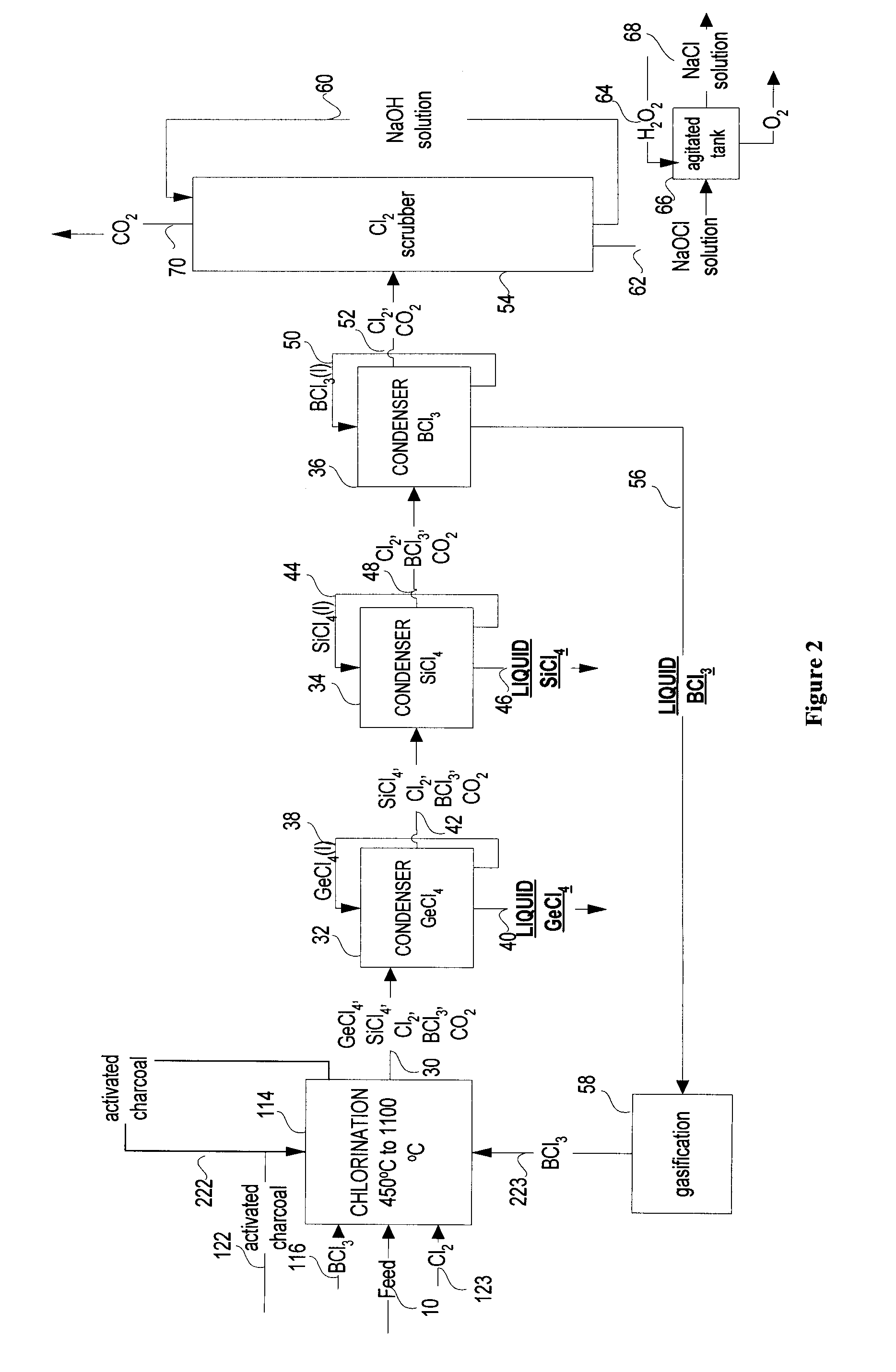

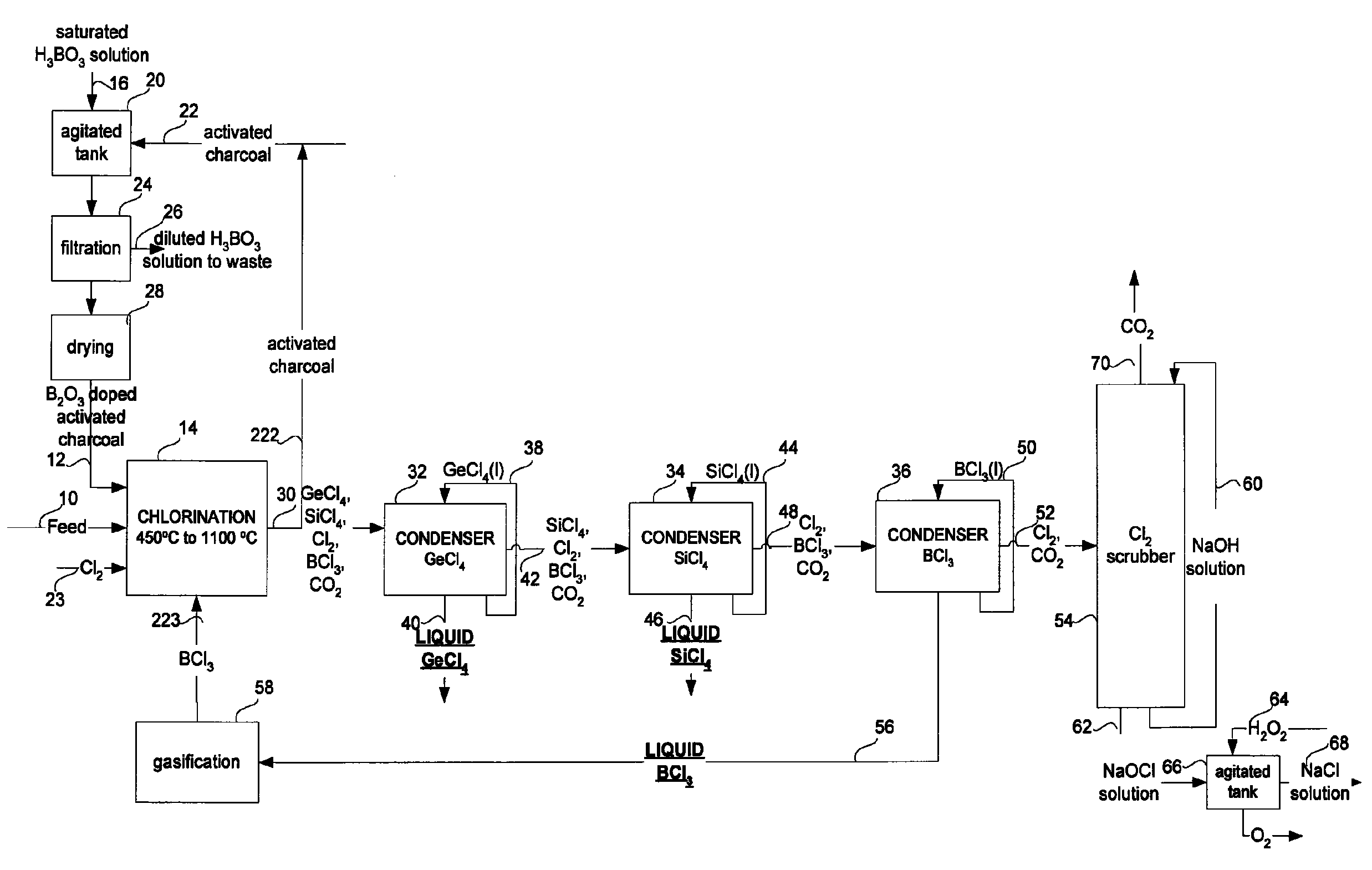

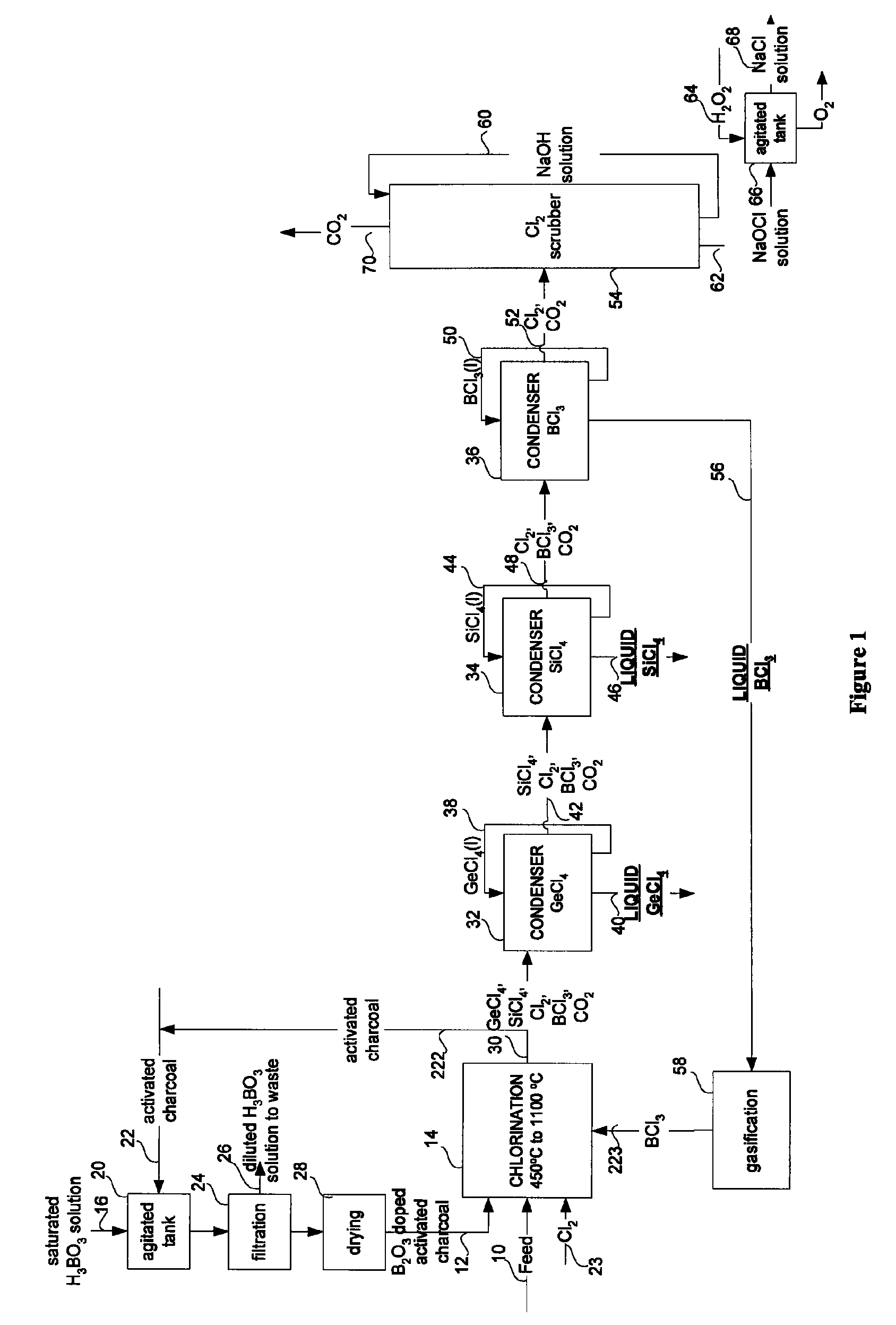

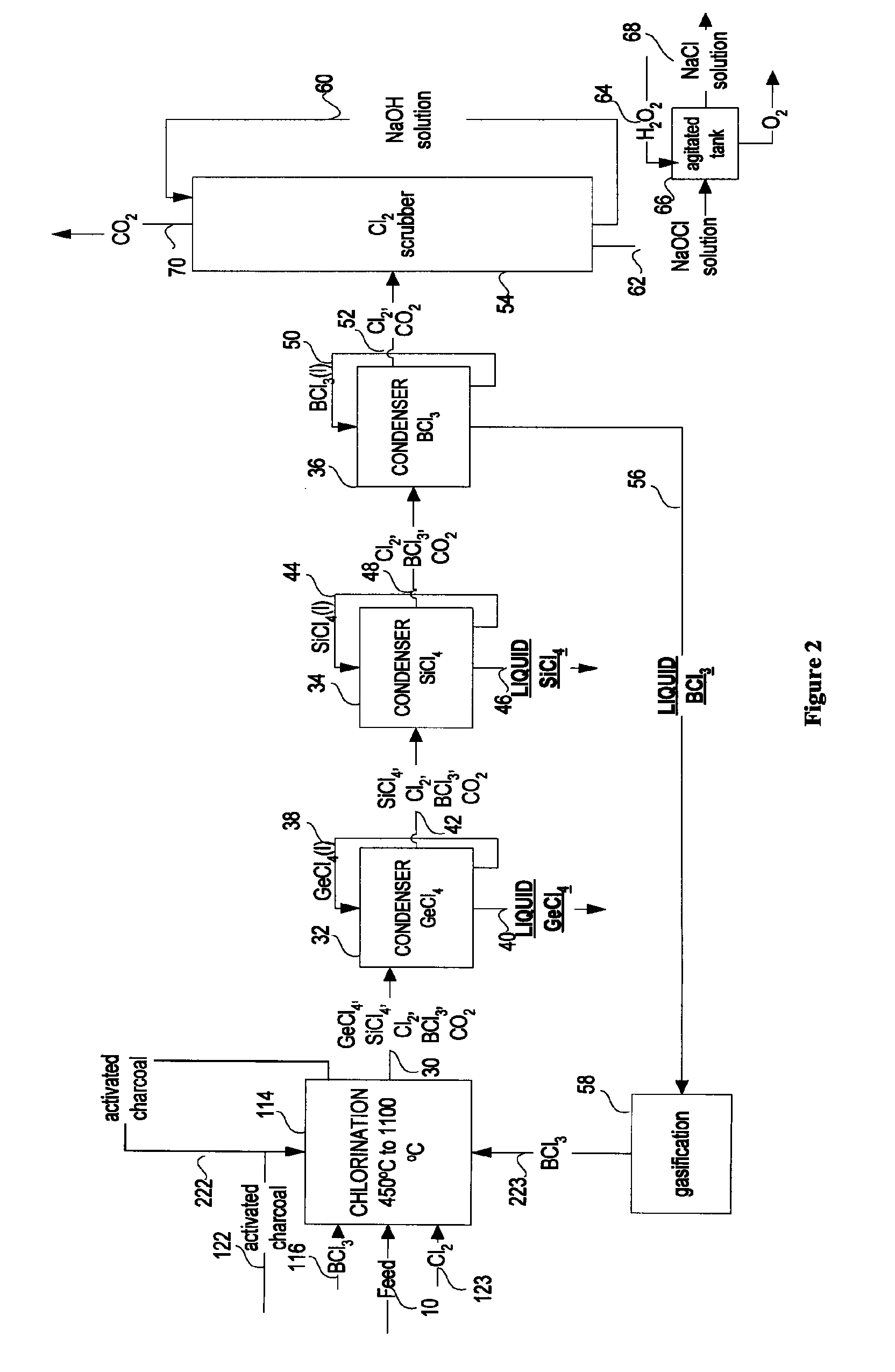

Gecl4 and/or sicl4 recovery process from optical fibers or glassy residues and process for producing sicl4 from sio2 rich materials

InactiveUS20100272625A1Reduce the temperatureSilicon halogen compoundsGermanium halidesBoronReducing agent

A method is provided for producing GeCl4 with or without SiCl4 from optical fibers, the method comprises the steps of: reacting comminuted optical fibers including germanium and optionally silicon oxides with a reagent including a solid carbonaceous reducing agent, chlorine and a boron compound to obtain a gaseous product including gaseous GeCl4, gaseous SiCl4, and gaseous BCl3 in accordance with the reactions: 2BCl3(g)+1.5GeO2=1.5GeCl4(g)+B2O3; 2BCl3(g)+1.5 SiO2=1.5 SiCl4(g)+B2O; B2O3+1.5C+3Cl2=2BCl3(g)+1.5CO2; and then condensing the gaseous GeCl4, BCl3 and optionally SiCl4 into liquid GeCl4, BCl3 and optionally SiCl4. The invention further provides a method for producing SiCl4 (and optionally GeCl4) from glass residues obtained from optical fiber manufacturing and wasted optical cables. The method includes the steps of: reacting comminuted glassy residues with a reagent including a solid carbonaceous reducing agent, a salt, a boron compound to obtain a gaseous product including SiCl4, BCl3, and optionally GeCl4; and then condensing the gaseous SiCl4, BCl3 (with or without GeCl4) into liquid SiCl4, BCl3 and GeCl4. There is also provided a method for producing SiCl4 from a SiO2 containing material.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

Reactor, plant and industrial process for the continuous preparation of high-purity silicon tetrachloride or high-purity germanium tetrachloride

ActiveUS8221593B2Chemical/physical/physico-chemical microreactorsGermanium halidesHydrogenMetallurgy

A reactor, a plant, and a continuous, industrial process carried out therein for preparing high-purity silicon tetrachloride or high-purity germanium tetrachloride by treating the silicon tetrachloride or germanium tetrachloride to be purified, which is contaminated by at least one hydrogen-containing compound, by a cold plasma and isolating purified high-purity silicon tetrachloride or germanium tetrachloride from the resulting treated phase by fractional distillation. The treatment is carried out in a plasma reactor in which longitudinal axes of a dielectric, of a high-voltage electrode, and of a grounded, metallic heat exchanger are oriented parallel to one another and at the same time parallel to the force vector of gravity.

Owner:EVONIK OPERATIONS GMBH

Method for producing germanium dioxide by utilizing germanium-containing wastes

InactiveCN107324376ASave acidSave hydrogen peroxideGermanium dioxideGermanium halidesHydrolysateDistillation

The invention provides a method for producing germanium dioxide by utilizing germanium-containing wastes. The method is characterized by comprising the following steps: directly adding the germanium wastes into a concentrated hydrochloric acid containing ferric trichloride; using chlorine as a shielding gas and adopting a rectifying column for distilling and purifying germanium tetrachloride; preparing germanium dioxide by performing totally closed hydrolysis reaction on the purified germanium tetrachloride; washing the hydrolysate and drying, thereby acquiring dry germanium dioxide; and adding the germanium wastes into a return fluid after completing distillation, thereby continuously producing. The germanium tetrachloride can be continuously produced in the manner of adding the germanium wastes into the concentrated hydrochloric acid containing ferric trichloride, and then adding chlorine for oxidizing, distilling and preparing germanium tetrachloride and adding the germanium wastes after completing the distillation; the usage of acid and hydrogen peroxide can be saved; the distilling return fluid can be repeatedly reused; and no distilling waste acid is generated.

Owner:KUNMING HUIQUAN HIGH PURITY SEMICONUCTING MATERIALS CO LTD

Process method for improving chlorination distillation recovery rate of coarse germanium dioxide

The invention relates to the technical field of hydrometallurgy, in particular to a method for recovering germanium from coarse germanium dioxide by sodium chlorate oxidization arsenic removal and hydrochloric acid chlorination distillation. The process method for improving the chlorination distillation recovery rate of the coarse germanium dioxide recovers the germanium by a hydrochloric acid distillation method. The method is characterized in that: the process steps of sodium hydroxide dissolving and the sodium chlorate arsenic removal are added before the hydrochloric acid distillation; and by the process of the method, the recovery rate of the germanium can reach over 99.0 percent, the content of arsenic in produced germanium tetrachloride is below 10.0 ppm, the recovery rate of the germanium is 9.0 percent higher than that of the conventional hydrochloric acid direct distillation method, the content of the arsenic in the produced germanium tetrachloride is 10 to 15 percent lower than that of the conventional hydrochloric acid direct distillation method, and the distillate efficiency of the arsenic is below 1.0 percent. Processes such as rectification, hydrolyzation, precipitation, drying and the like are performed on the distilled germanium tetrachloride to produce high-purity germanium dioxide. The quality of the high-purity germanium dioxide produced by the process method meets the requirements of over 5N in national standard GB / in T11069.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND

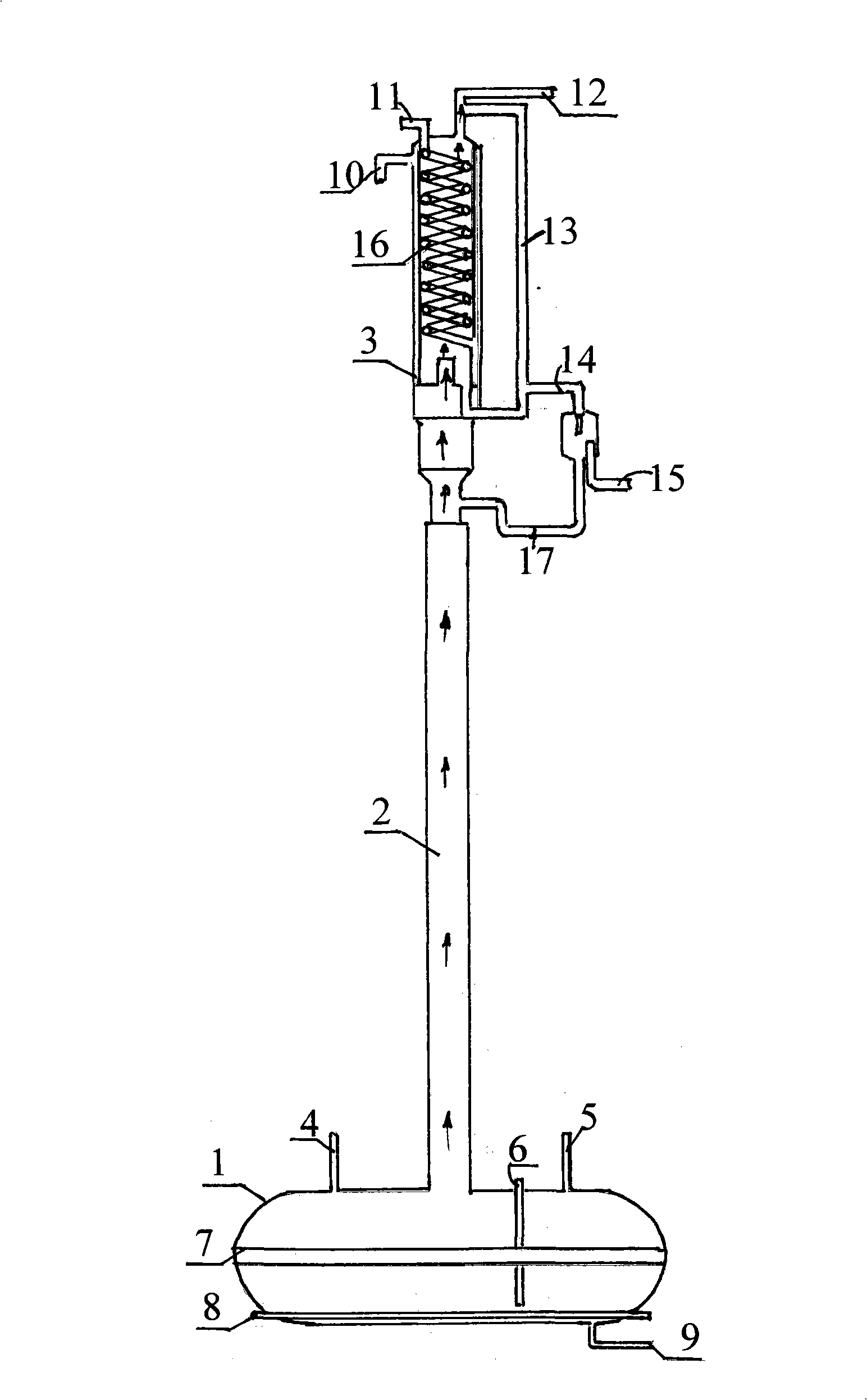

Rectification column for removing hydrogen containing foreign matter in germanic chloride

ActiveCN101269836AObservation is intuitive and convenientImprove removal efficiencyGermanium halidesForeign matterDistillation

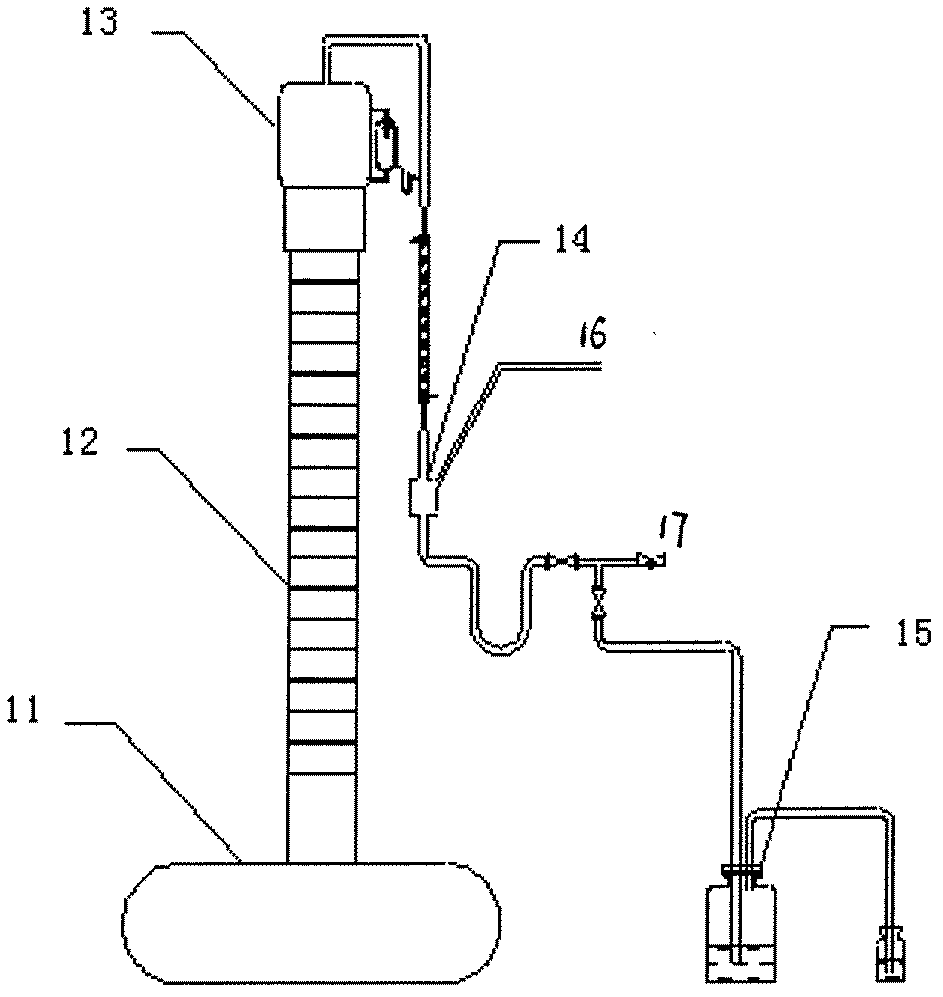

The invention relates to a distillation column eliminating the CH impurity and the HCI impurity in germanium tetrachloride for optical fibers, and the distillation column is mainly used for solving the problem for eliminating the CH impurity and the HCI impurity in the germanium tetrachloride, and the distillation column belongs to the field of special equipment. The distillation column is mainly composed of a column reactor, a column pipe and a column head. The column head is provided with a spiral cooling pipe, a cooling water inlet and a cooling water outlet, and the top of the column head is provided with a gas exit. A pipeline which is linked with a swinging head discharging port is arranged on the gas exit, and the lower part is pumped in the bottom of the column head. The bottom of the swinging head discharging port is provided with the pipeline to be pumped in the upper part of the column pipe, and the column reactor is provided with a feed port, a gas supply port, a temperature monitoring port and a waste discharge port.

Owner:云南驰宏国际锗业有限公司 +1

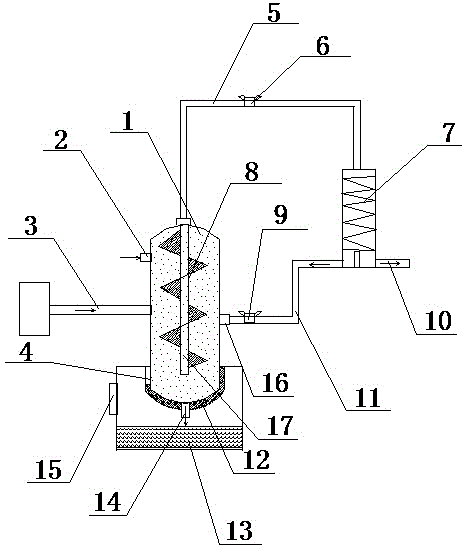

Distillation device for producing high-purity germanium tetrachloride

InactiveCN106730964AFast heatingGood temperature control effectDistillation in boilers/stillsGermanium halidesTemperature controlDistillation

The invention discloses a distillation device for producing high-purity germanium tetrachloride. The distillation device includes a distillation tank and a condensation tank. A material inlet and a first gas inlet are arranged on one side of the distillation tank and a second gas inlet is arranged on the other side of the distillation tank; a gas outlet is arranged on the top of the distillation tank; a spiral shaft is vertically disposed in the axial center in the distillation tank and is provided with a plurality of infrared heating blocks which are uniformly arranged spirally on the external wall of the spiral shaft in the vertical direction; an infrared heating jacket is disposed on the bottom of the distillation tank; a temperature detector is disposed in the infrared heating jacket; the top of the distillation tank is connected to the condensation tank through a first gas outlet pipe; a spiral condensing pipe is arranged in the condensation tank; a second gas outlet pipe and a third gas outlet pipe are arranged on the condensation tank, wherein the second gas outlet pipe is connected to the second gas inlet. The distillation device is high in heating speed and has good temperature control effects.

Owner:衡阳恒荣高纯半导体材料有限公司

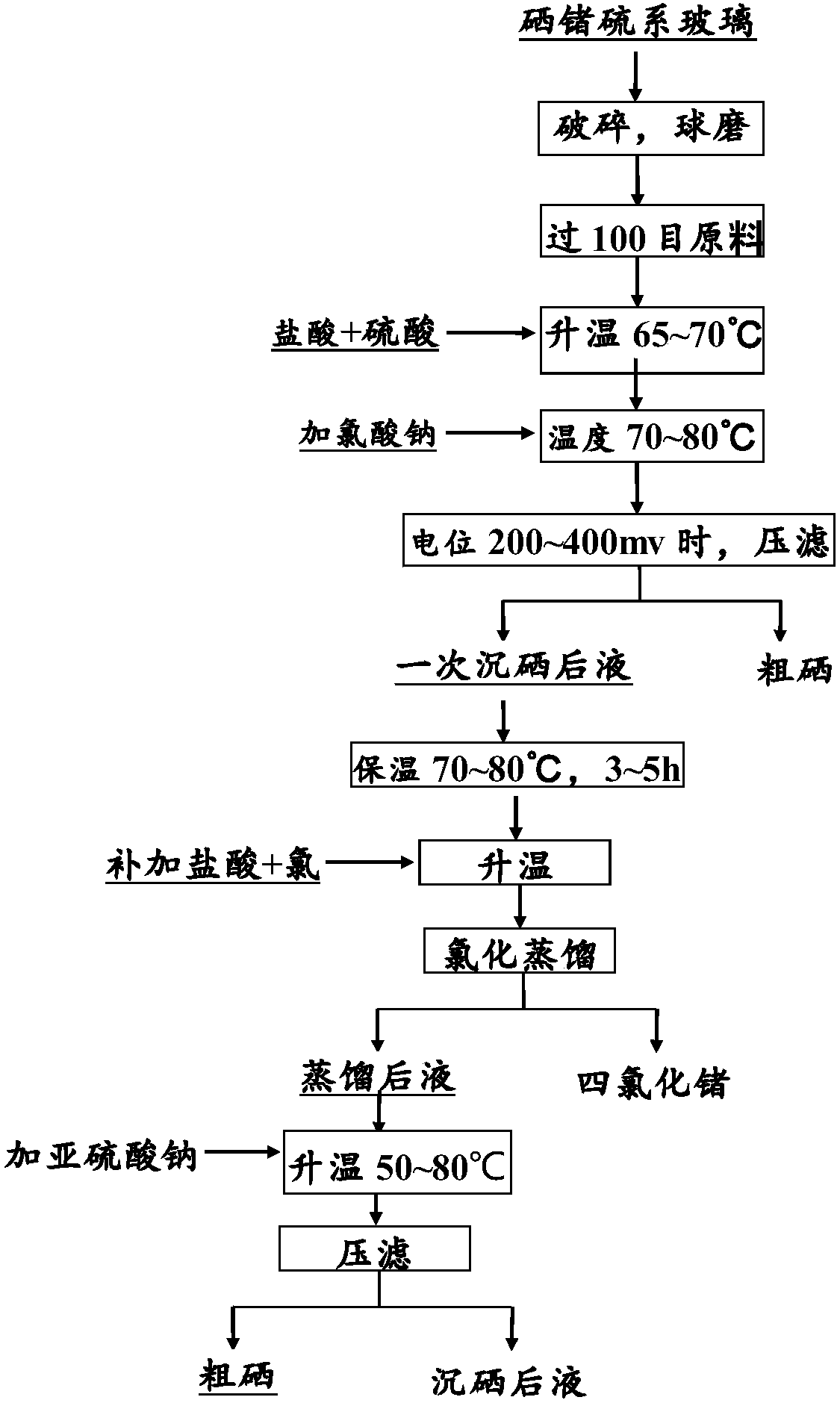

Recovery method of selenium-germanium-sulfur glass

ActiveCN108147375AEfficient separationHigh recovery rateGermanium halidesElemental selenium/telluriumRecovery methodSulfur

The invention provides a recovery method of selenium-germanium-sulfur. The recovery method comprises the following steps: S1) crushing the selenium-germanium-sulfur glass, then performing ball milling, and obtaining glass powder; S2) mixing the glass powder, hydrochloric acid and concentrated sulfuric acid, extracting, adding an oxidant in the extraction process until the potential rises to 200 to400 mV, filtering, and obtaining a solution after the primary selenium deposition and crude selenium; S3) performing the chlorination distillation for the solution after the primary selenium deposition, and obtaining a solution after the distillation and germanium tetrachloride; S4) mixing the solution after the distillation and a reducing agent, reacting, filtering, and obtaining crude selenium.Compared with the prior art, by controlling the potential in the oxidation extraction process, the oxidation process is controlled, so that the selenium in the selenium-germanium-sulfur glass is oxidized from bivalence to zero valence, the element selenium is obtained, the selenium and the germanium are effectively separated, the selenium can be recovered by virtue of various ways, and the recovery rate is higher.

Owner:昆明先导新材料科技有限责任公司

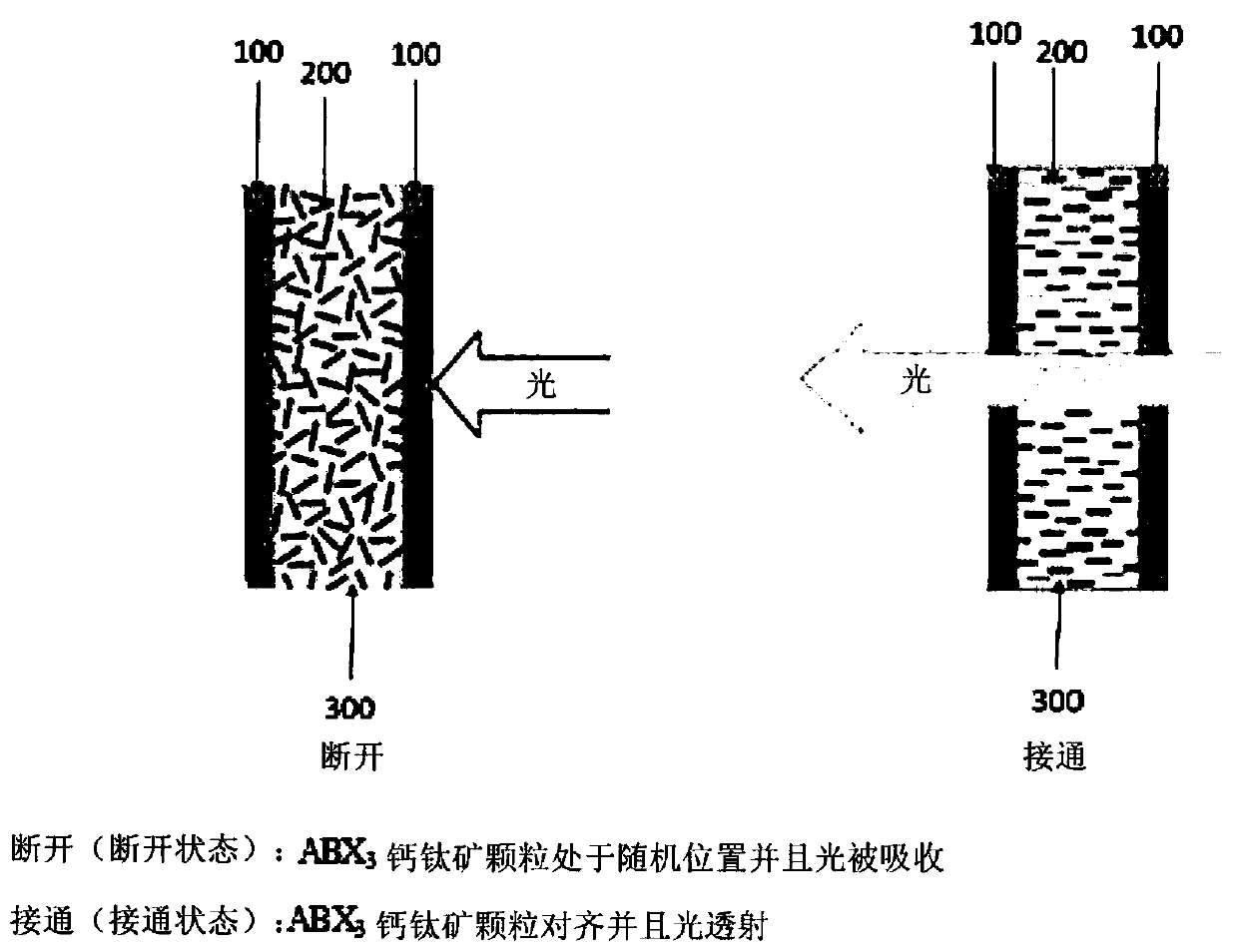

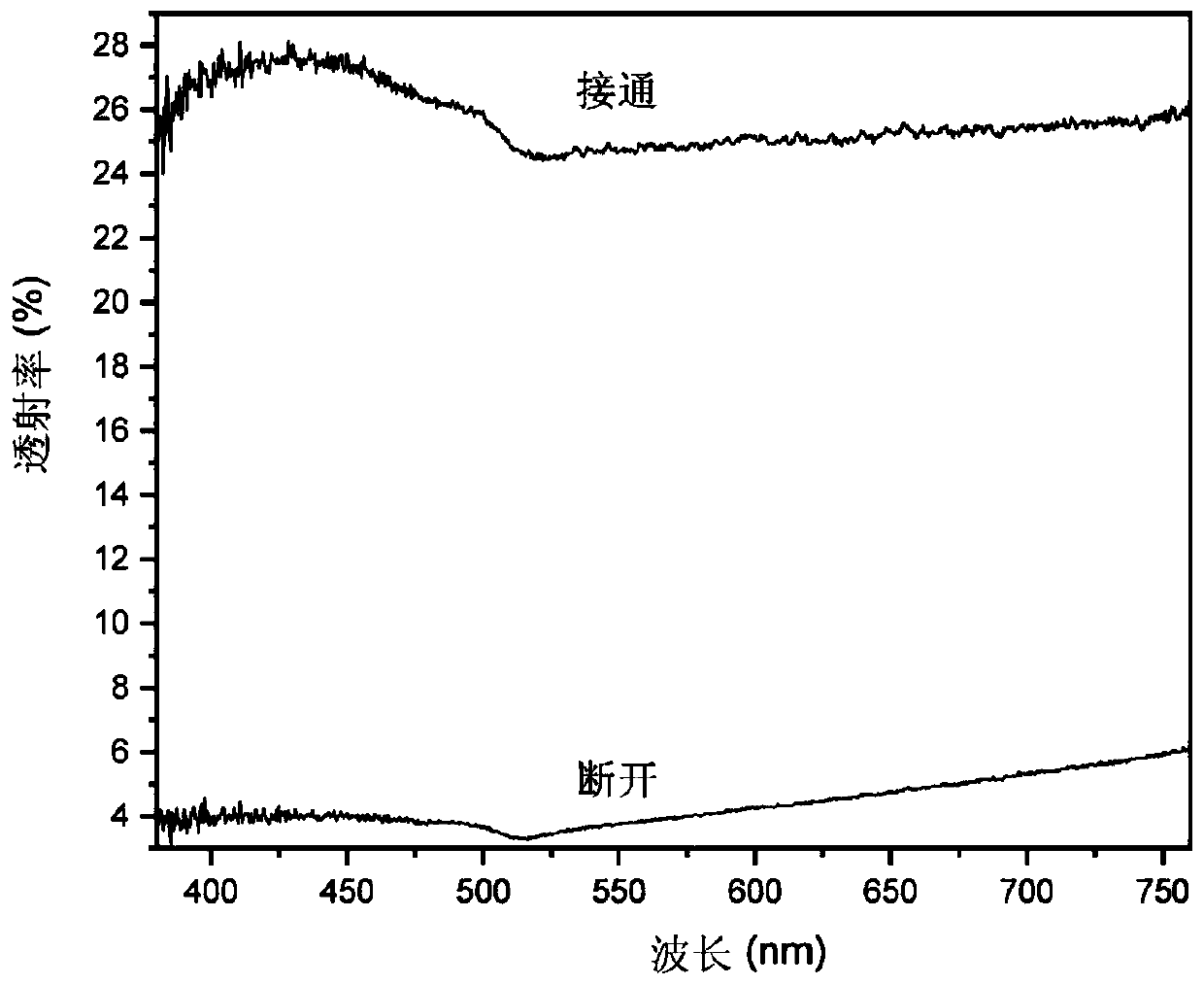

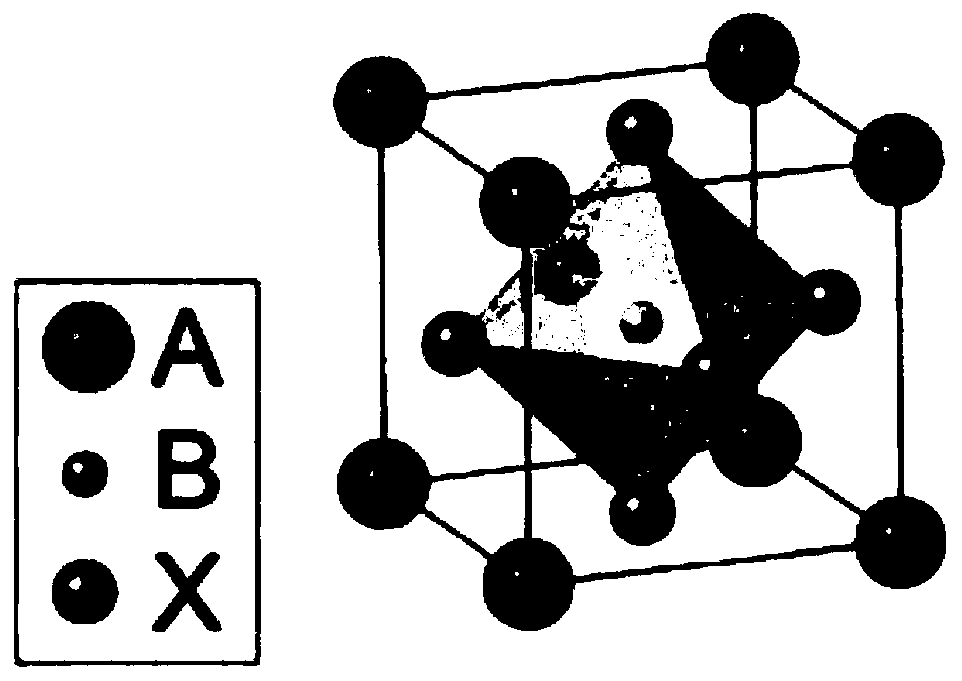

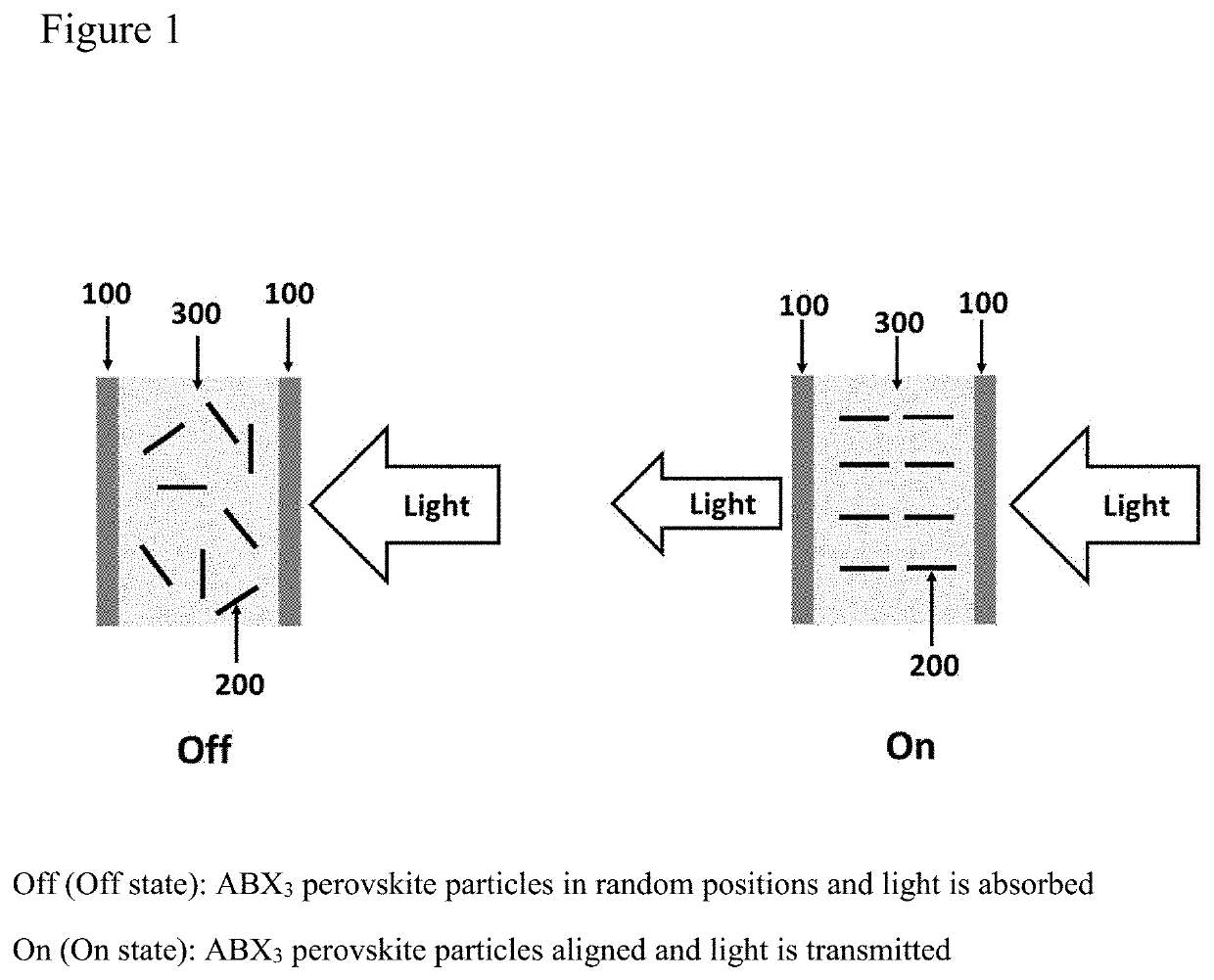

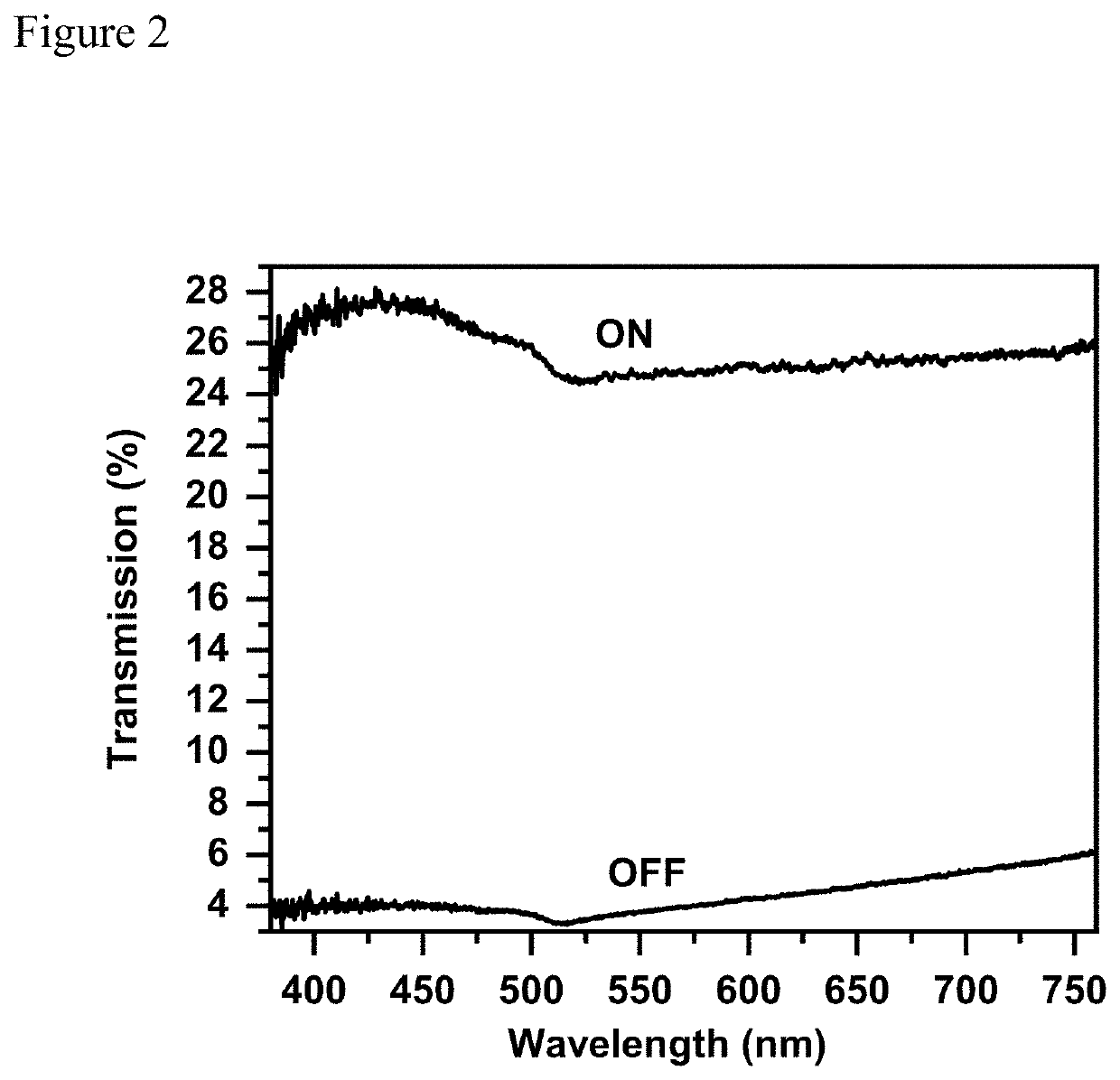

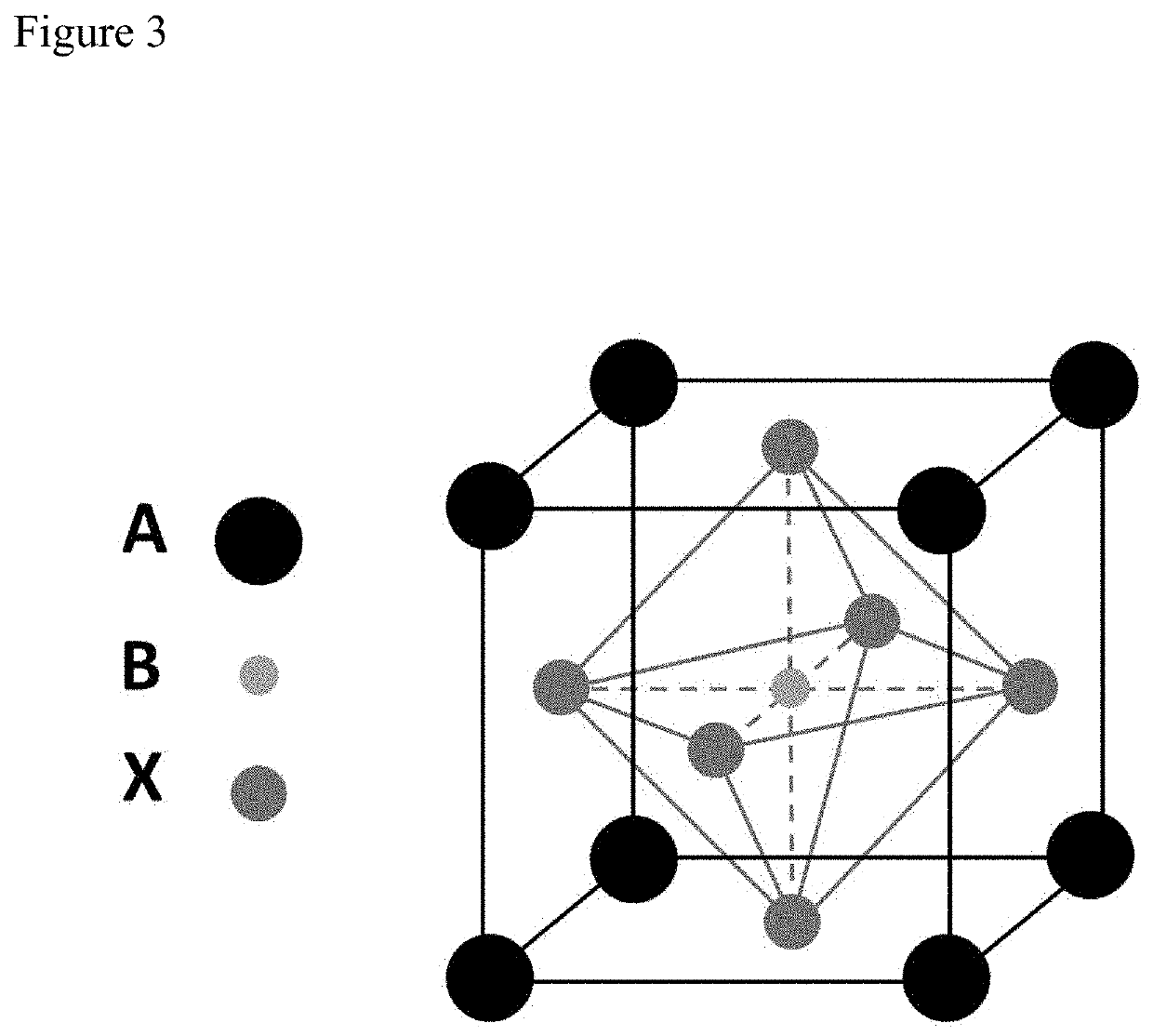

Halide abx3 perovskite particles and their application in controlling photo-flux

A light valve containing ABX 3 perovskite particles (200) suspended in a liquid suspension (300) that can control light transmittance is provided. The preferable ABX 3 perovskite particles (200) are halide ABX 3 perovskite particles wherein A is at least one of Cs +, CH 3NH 3 +, and Rb +, B is at least one of Pb 2+, Ge 2+, and Sn 2+, and X is at least one of Cl-, Br-, and I-. Use of the light valve in the manufacture of a light control device and a method of controlling light transmittance by using the light valve are also provided.

Owner:ZHEJIANG JINGYI NEW MATERIAL TECH CO LTD

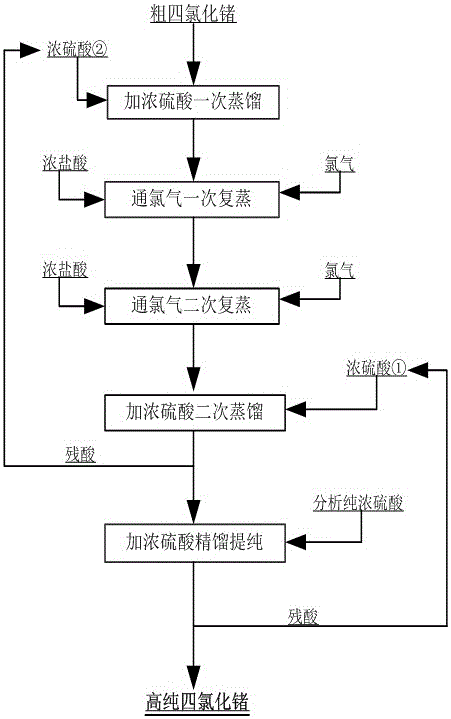

Technological method for purifying and preparing high pure germanium tetrachloride and removing organic impurities

ActiveCN106745201AEfficient purificationRealize reverse recyclingGermanium halidesDistillationHydrometallurgy

The invention relates to the technical field of hydrometallurgy, in particular to a technological method for purifying and preparing high pure germanium tetrachloride and removing organic impurities. The technological method is implemented according to the following steps: adding crude germanium tetrachloride, produced by carrying out chloridizing distillation on germanium concentrate, into concentrated sulfuric acid, and carrying out predistillation while heating; adding analytically pure hydrochloric acid into germanium tetrachloride produced by the predistillation, introducing chlorine, and carrying out primary re-steaming; carrying out secondary re-steaming on the germanium tetrachloride produced by the primary re-steaming by repeating the step (2) ; adding concentrated sulfuric acid into germanium tetrachloride produced by the secondary re-steaming, and then carrying out secondary digestion distillation; transferring germanium tetrachloride produced by the secondary digestion distillation, adding analytically pure concentrated sulfuric acid into the transferred germanium tetrachloride, heating and purifying by rectification. The method is used to realize the aim of further removing organic impurities while efficiently purifying the germanium tetrachloride, and solve the problems that products of a method, which takes germanium-containing lignite as a raw material and adopts the conventional production technology to prepare the high pure germanium tetrachloride, are not qualified, and the like.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND +1

Process for producing germanium tetrachloride by regenerated germanium

InactiveCN108439459AHigh ChlorinationHigh recovery rateGermanium halidesDistillationTitanium tetrachloride

The invention discloses a process for producing germanium tetrachloride by regenerated germanium. According to the process, regenerated germanium raw materials are added into hydrochloric acid solution containing FeCl2 catalysts, chlorine is continuously led in to perform chlorination, and germanium tetrachloride products are recovered by distillation separation after chlorination. The process issimple and low in energy consumption and cost, waste acid closed recycling is effectively realized, environmental problems are solved, the recovery rate of the regenerated germanium raw materials is increased, and higher economic values are generated.

Owner:衡阳恒荣高纯半导体材料有限公司

Halide ABX3 perovskite particles and their application in controlling photo-flux

The present invention provides a light valve containing ABX3 perovskite particles; more specifically is related to a light valve containing halide ABX3 perovskite particles that can control light transmittance. The preferable halide ABX3 perovskite particles in this invention consist of A being at least one of Cs+, CH3NH3+, and Rb+, B being at least one of Pb2+, Ge2+, and Sn2+, and X being at least one of Cl−, Br−, and I−. This kind of halide ABX3 perovskite particles were suspended in a liquid suspension to make a light valve with a light transmittance control, which discloses a completely new application for ABX3 perovskite materials.

Owner:ZHEJIANG JINGYI NEW MATERIAL TECH CO LTD

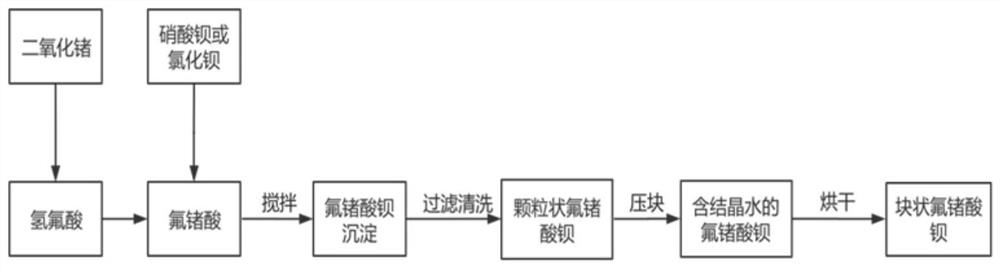

Method for preparing high-purity germanium tetrafluoride through thermal decomposition of barium fluorogermanate

InactiveCN113526544AHigh purityLess impuritiesGermanium halidesGermanium tetrafluorideHydrogen fluoride

The invention belongs to the technical field of germanium tetrafluoride preparation, and particularly discloses a method for preparing high-purity germanium tetrafluoride through thermal decomposition of barium fluorogermanate. The method comprises the following steps: dissolving soluble germanium dioxide in a hydrofluoric acid solution to prepare a fluorogermanic acid solution, wherein the concentration of hydrofluoric acid is 25mol / L, and the molar ratio of the hydrofluoric acid solution to the soluble germanium dioxide is (6-6.25): 1; adding barium salt into the fluorogermanic acid solution to generate barium fluorogermanate precipitate; and making the generated barium fluorogermanate precipitate washed with absolute ethyl alcohol to remove hydrogen fluoride residues, placing the precipitate into a mold to be pressed into blocks and performing drying. Barium fluorogermanate can be rapidly decomposed at the temperature of 600-700 DEG C to generate germanium tetrafluoride, the germanium yield is high, and the solid by-product barium fluoride has very wide application field and scientific application research value. The reaction does not need fluorine gas participation, the requirement for a reaction device is low, configuration is simple, control is easy, and germanium tetrafluoride produced through thermal decomposition is high in purity and few in impurity.

Owner:YUNNAN UNIV +1

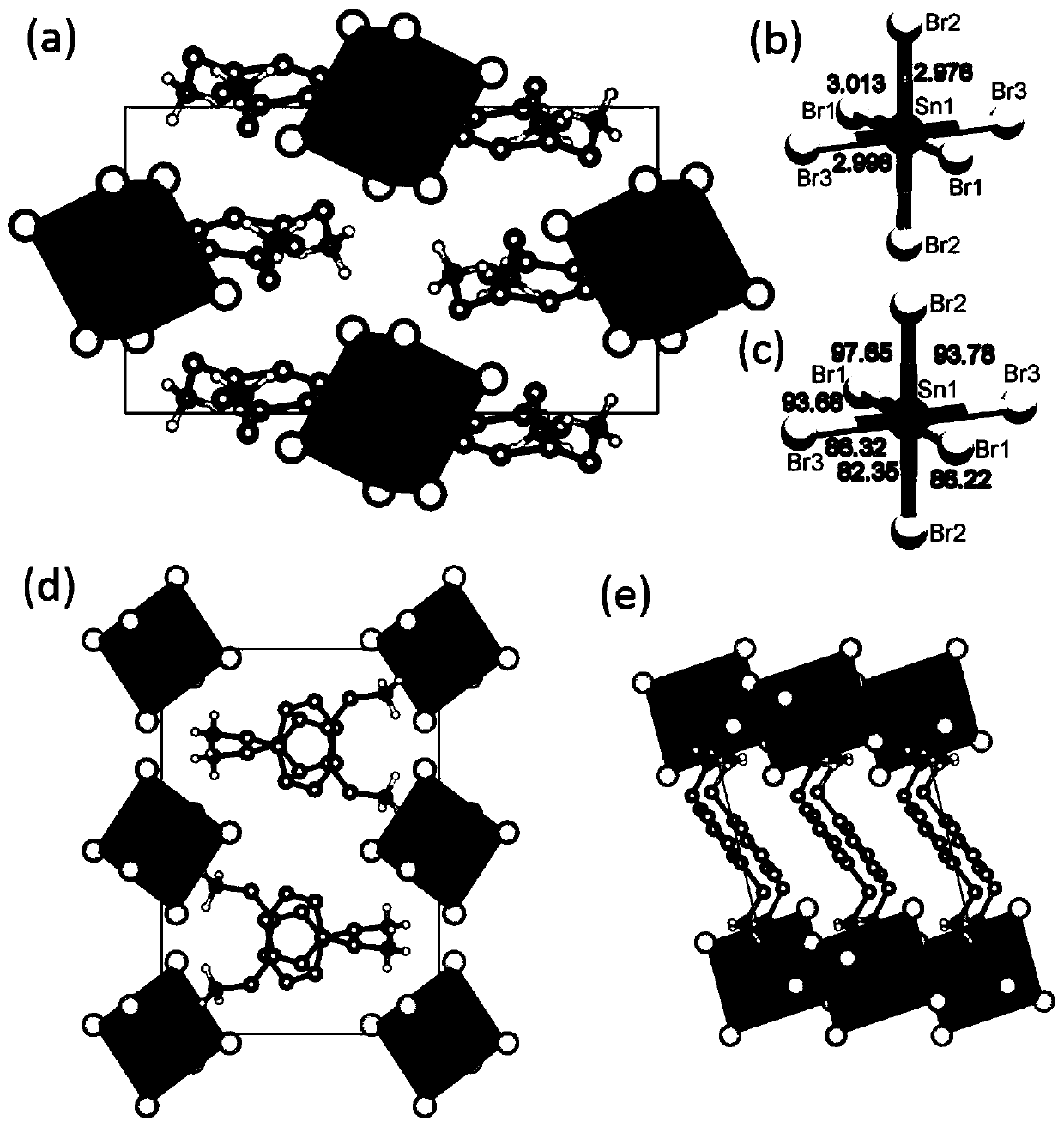

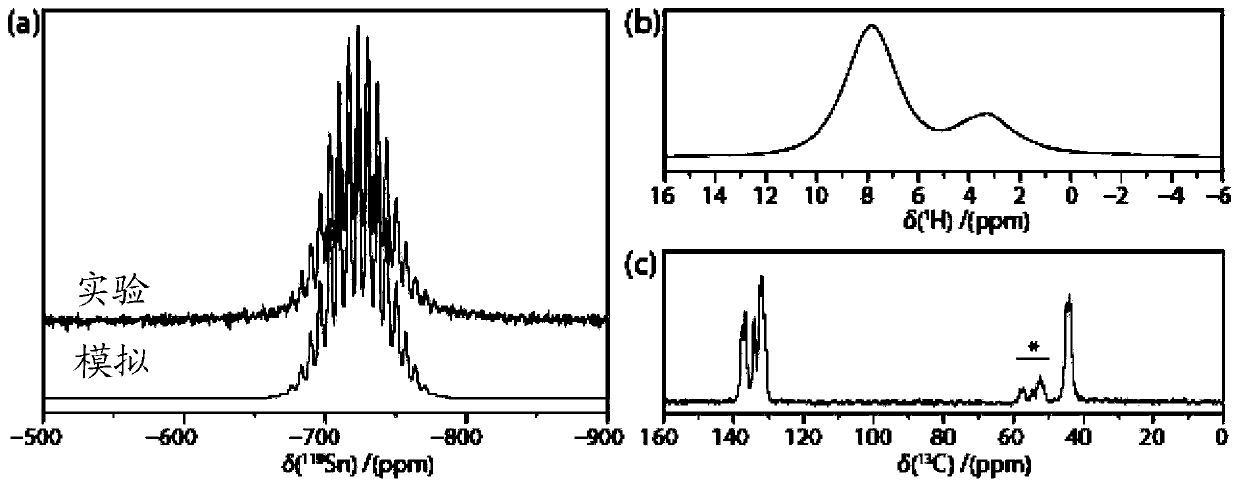

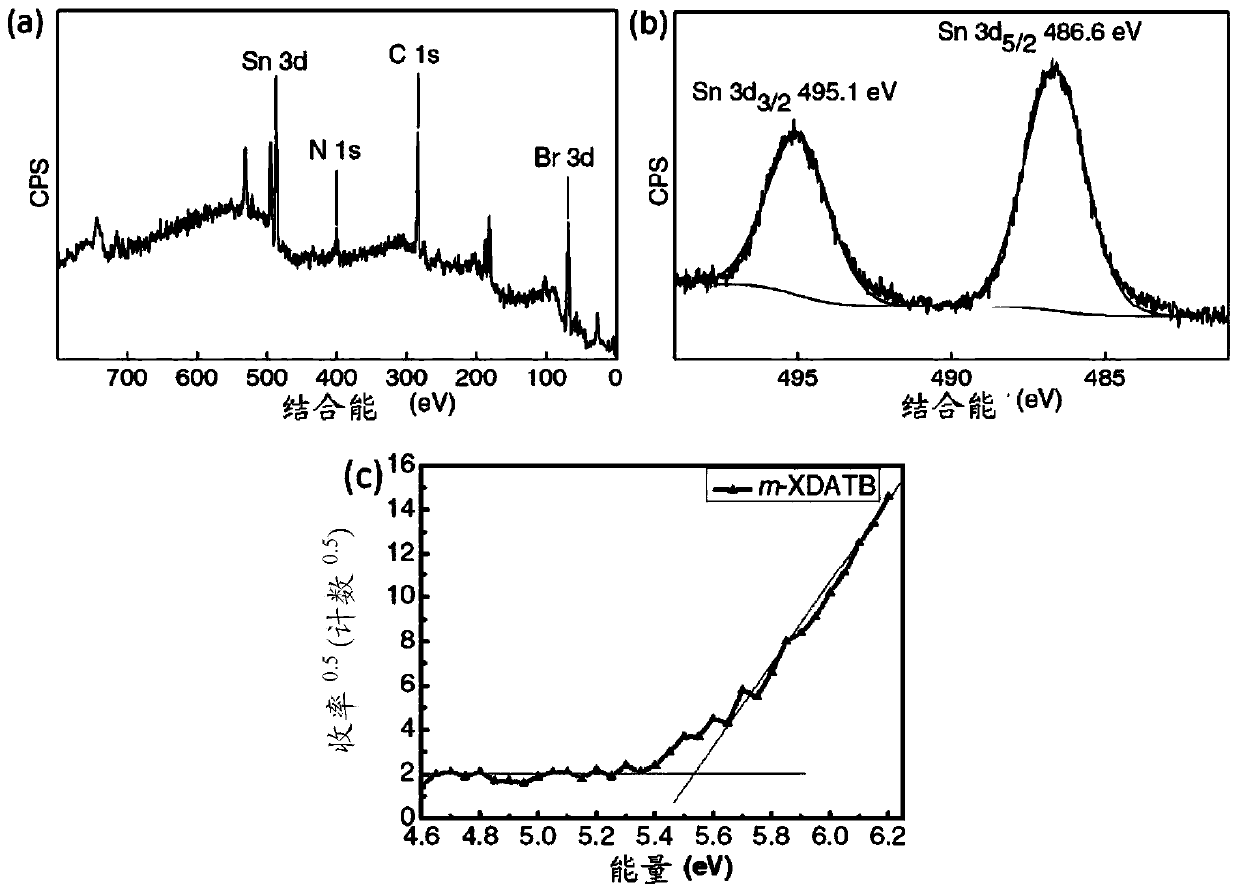

Low-dimensional inorganic-organic hybrid metal halide perovskites

ActiveCN110869466ATin organic compoundsElectroluminescent light sourcesPhysical chemistryMetal halides

Disclosed herein is a zero-dimensional hybrid organic-inorganic perovskite material of Formula (I) wherein A contains at least one aromatic or heteroaromatic ring, M is selected from Ge, Pb, Sn, Mn, Cu, Co, and Eu, and X is a halide or pseudohalide. Preferably, M is Sn, and the organic part is meta-xylenediammonium. Also disclosed herein is a method of preparing said materials and the use of saidmaterials for white light emitting devices.

Owner:NANYANG TECH UNIV

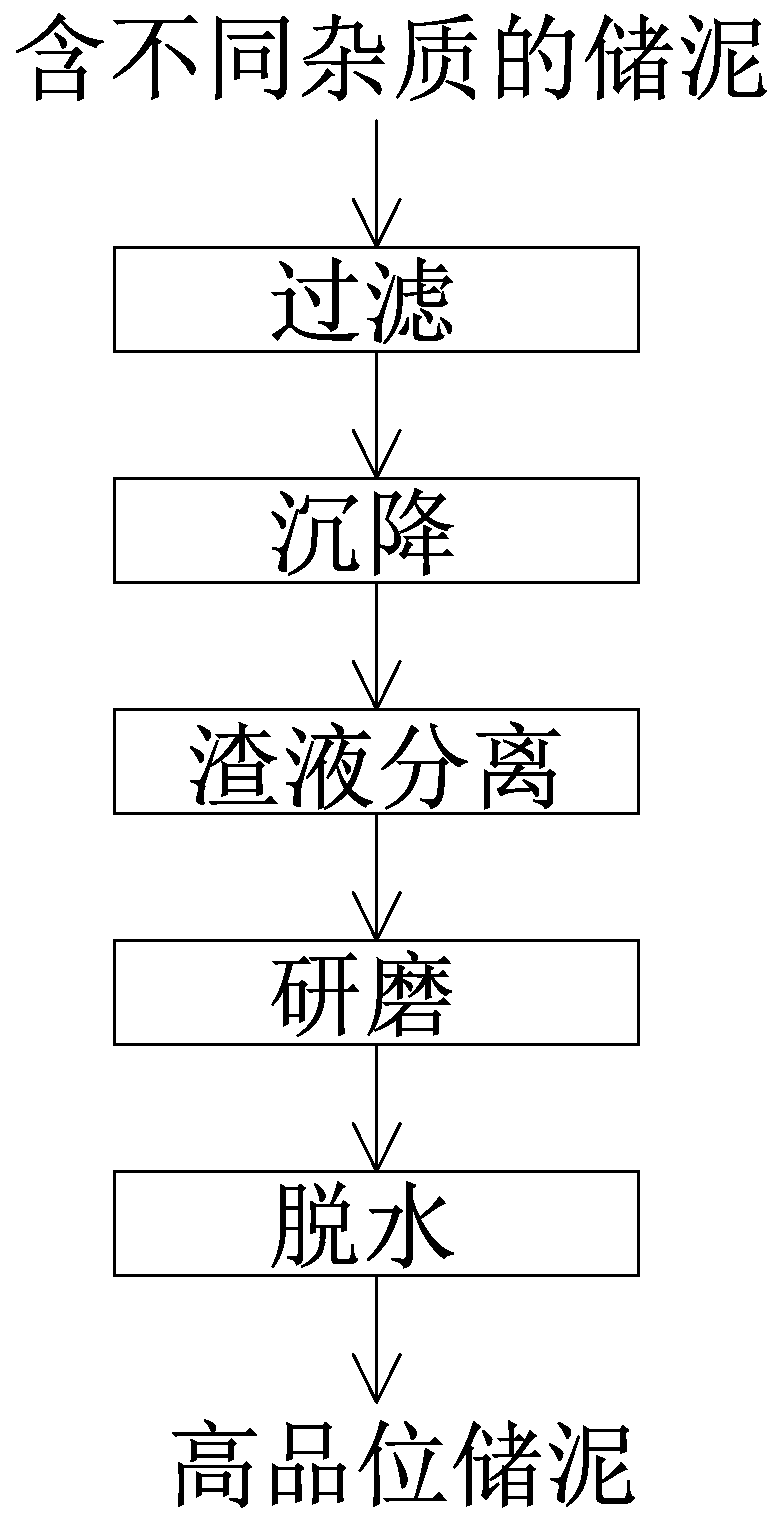

Germanium mud pretreatment method

InactiveCN110922006AWon't cause flyingReduce lossesSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesPretreatment methodDistillation

The invention discloses a germanium mud pretreatment method which comprises the following steps: firstly, filtering to remove glue, oil, sand and other organic matters or inorganic matters with largervolume in equipment cooling liquid and cutting liquid containing germanium mud to obtain germanium mud mixed liquid with fewer impurities, , then carrying out multi-stage sedimentation through a sedimentation tank, uniformly recovering the germanium mud in the sedimentation tank; performing residue-liquid separation on germanium mud mixed liquid collected in the sedimentation tank through a filter press to obtain germanium mud residues with less water content, performing wet grinding on the water-containing germanium mud residues obtained through filter pressing in a grinding machine to obtain germanium mud with finer particle size to reduce flying loss in the process, finally drying and dehydrating the grounded germanium mud to obtain high-grade germanium mud containing trace water and having finer granularity to serve as a raw material for chlorination distillation for extracting germanium tetrachloride. The method solves the problems that in the initial germanium mud pretreatment process of an existing germanium mud treatment technology, germanium flying loss is too serious, harm to the human body is obvious, and the extraction requirement cannot be met.

Owner:云南驰宏国际锗业有限公司

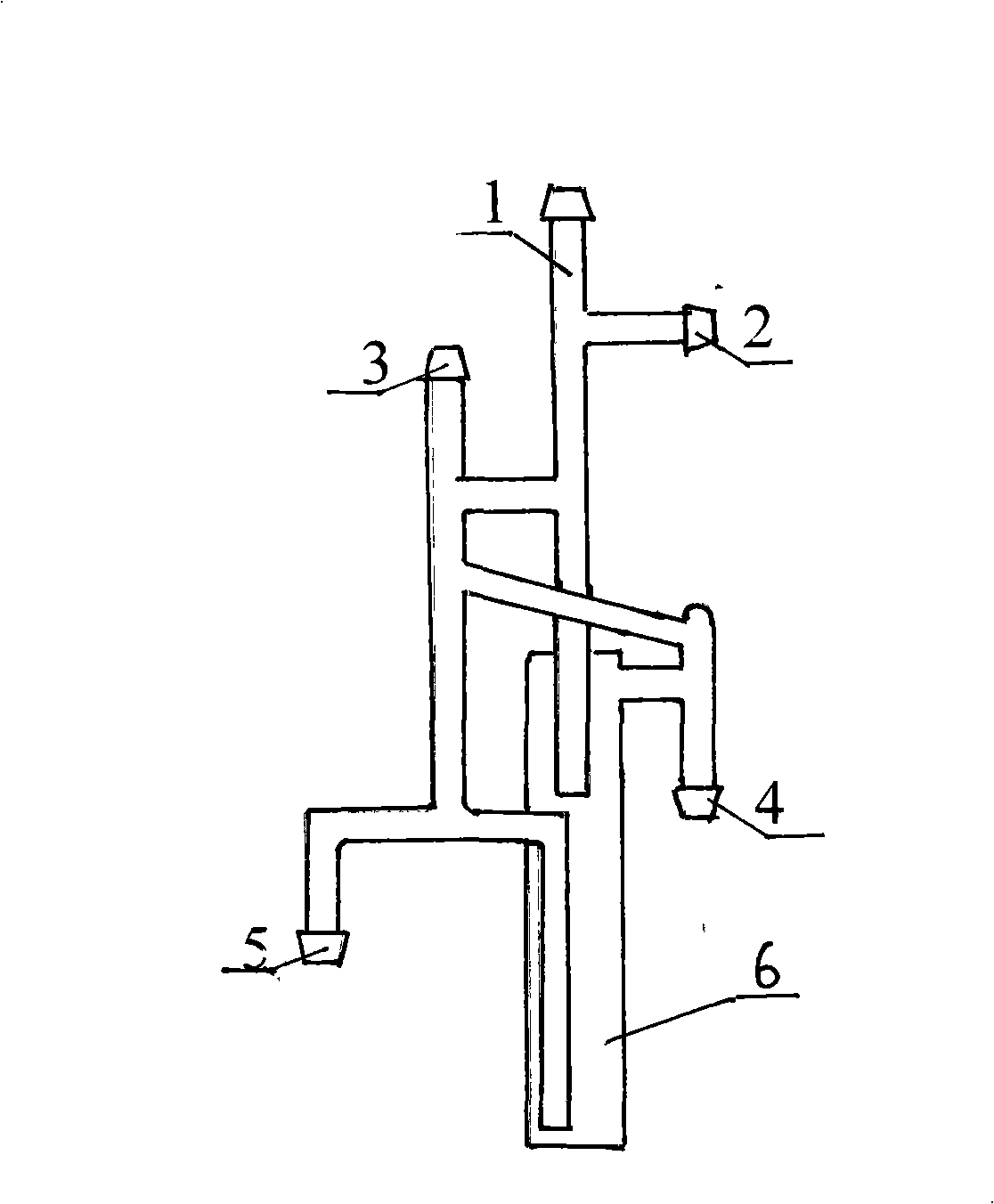

Apparatus for separating hydrochloric acid from germanic chloride for optical fiber

The invention relates to a device separating hydrochloride which is mingled with germanium tetrachloride in the production of germanium tetrachloride for optical fibers, and the device belongs to a production device of the germanium tetrachloride for optical fibers. A separating device is mainly composed of a main separation column, a feed pipe, a tail gas discharge pipe, an atmosphere supply pipe, an acid discharge pipe and a discharging pipe. The top of the main separation column is connected with the feed pipe, the lateral part of which is connected with the tail gas discharge pipe, and the upper side of the main separation column is connected with the acid discharge pipe. The intermediate section of the main separation column is connected with the discharging pipe, a pipe orifice of which extends to the bottom of the main separation column, and the feed pipe is connected with the atmosphere supply pipe, the lateral part of which is communicated with the acid discharge pipe and the feed pipe respectively through two independent pipelines. When the device operates, the real-time separation process can be observed, and the hydrochloride and the germanium tetrachloride can be effectively separated. The whole separation process is isolated from air, thereby avoiding the secondary pollution of the product, and the device has the advantages of simple structure, convenience and practicality and high efficiency.

Owner:云南驰宏国际锗业有限公司

Production technology of optical fiber grade high purity ger manium tetrachloride

InactiveCN1597533ASimple processPromote decompositionGermanium halidesTetrachloridePhysical chemistry

A process for preparing the optical fibre-class high-purity GeCl4 includes such steps as making the rectifying apparatus in non-oxygen and non-water state, proportionally adding catalyst and coarse GeCl4 under protection of inertial gas, introducing halide gas, light triggered reflux and distilling, and transferring product under protection of inertial gas.

Owner:NANJING UNIV

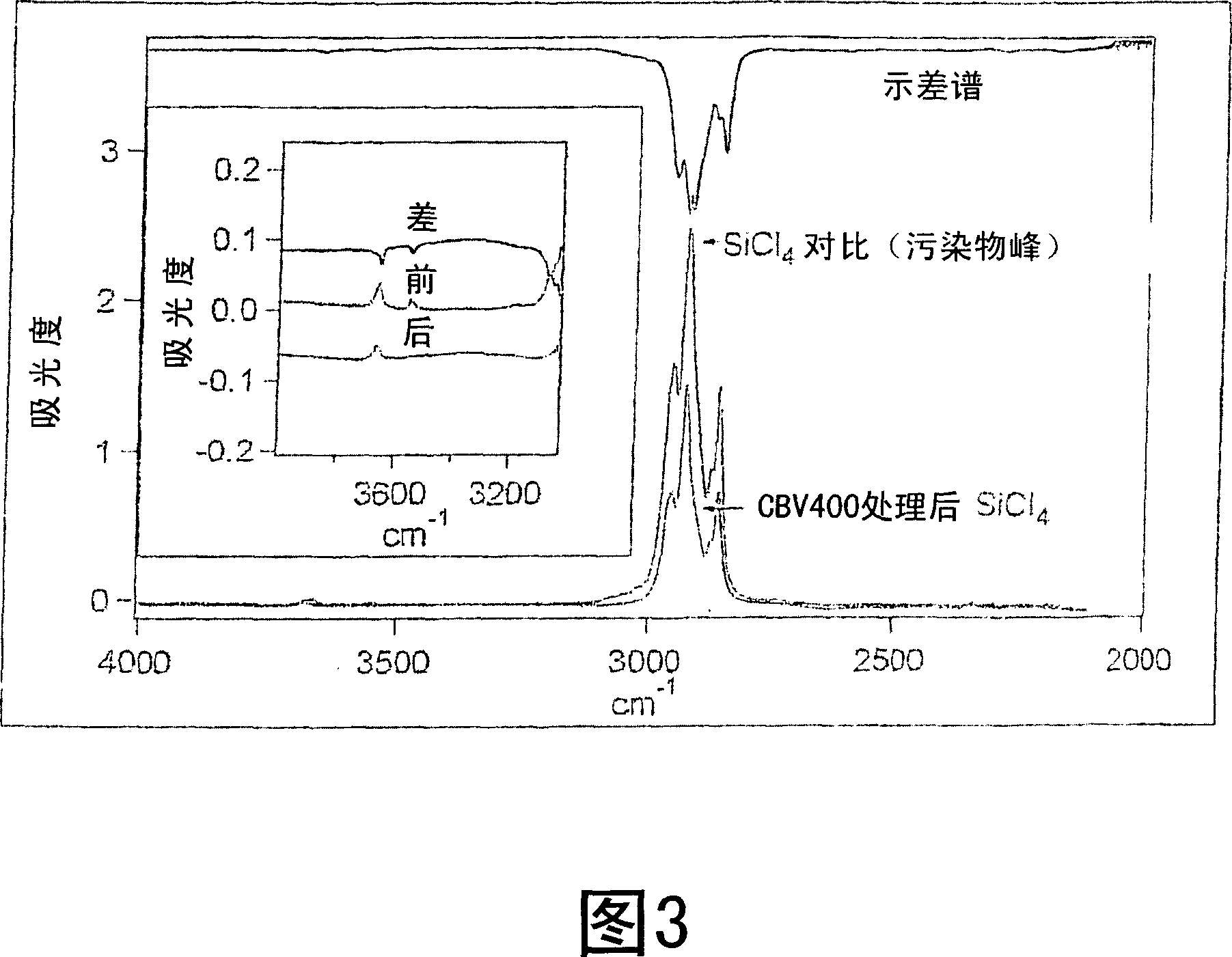

Method and apparatus for purifying inorganic halides and oxyhalides using zeolites

InactiveCN1934031AImprove purification effectKeep the pressurePhosphorus halides/oxyhalidesOther chemical processesHydrogenFiltration

Owner:ENTEGRIS INC

GeCl4 and/or SiCl4 recovery process from optical fibers or glassy residues and process for producing SiCl4 from SiO2 rich materials

A method is provided for producing GeCl4 with or without SiCl4 from optical fibers, the method comprises the steps of: reacting comminuted optical fibers including germanium and optionally silicon oxides with a reagent including a solid carbonaceous reducing agent, chlorine and a boron compound to obtain a gaseous product including gaseous GeCl4, gaseous SiCl4, and gaseous BCl3 in accordance with the reactions: 2BCl3(g)+1.5GeO2=1.5GeCl4(g)+B2O3; 2BCl3(g)+1.5SiO2=1.5SiCl4(g)+B2O; B2O3+1.5C+3Cl2=2BCl3(g)+1.5CO2; and then condensing the gaseous GeCl4, BCl3 and optionally SiCl4 into liquid GeCl4, BCl3 and optionally SiCl4. The invention further provides a method for producing SiCl4 (and optionally GeCl4) from glassy residues obtained from optical fiber manufacturing and wasted optical cables. The method includes the steps of: reacting comminuted glassy residues with a reagent including a solid carbonaceous reducing agent, a salt, a boron compound to obtain a gaseous product including SiCl4, BCl3, and optionally GeCl4; and then condensing the gaseous SiCl4, BCl3 (with or without GeCl4) into liquid SiCl4, BCl3 and GeCl4. There is also provided a method for producing SiCl4 from a SiO2 containing material.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

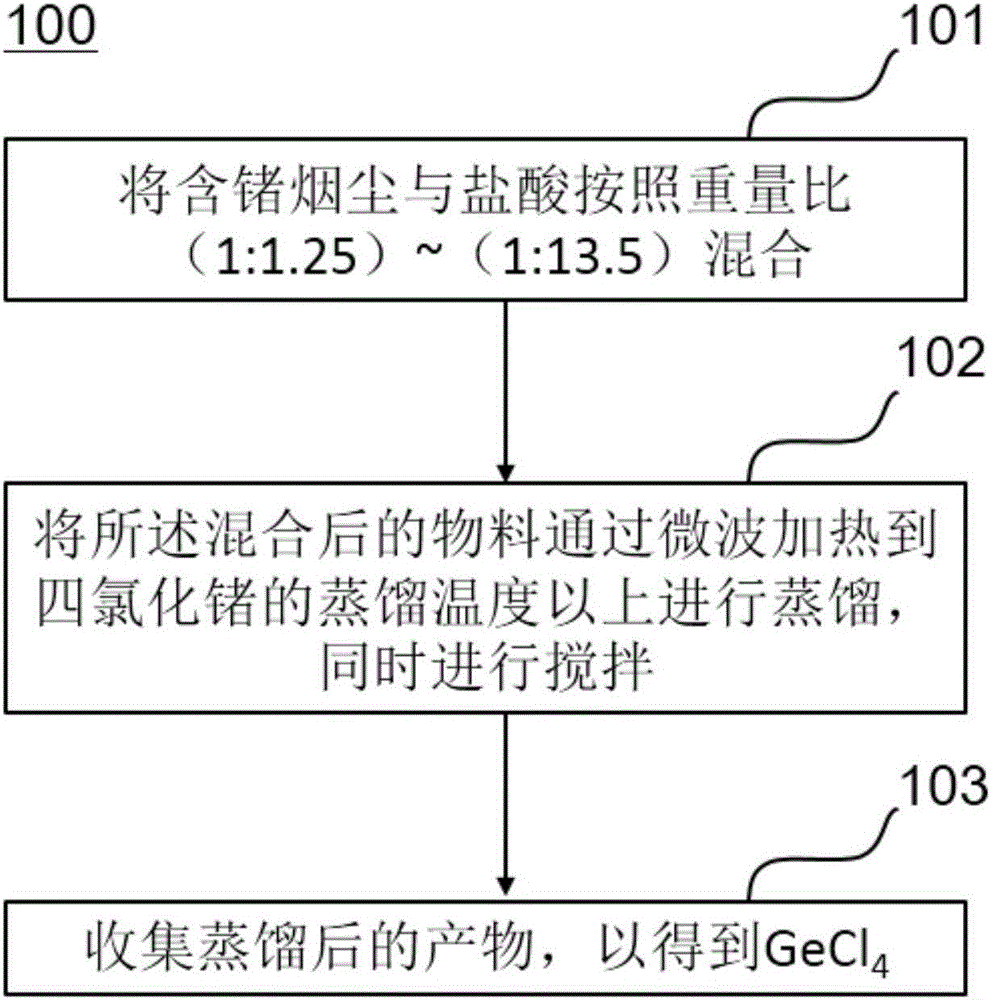

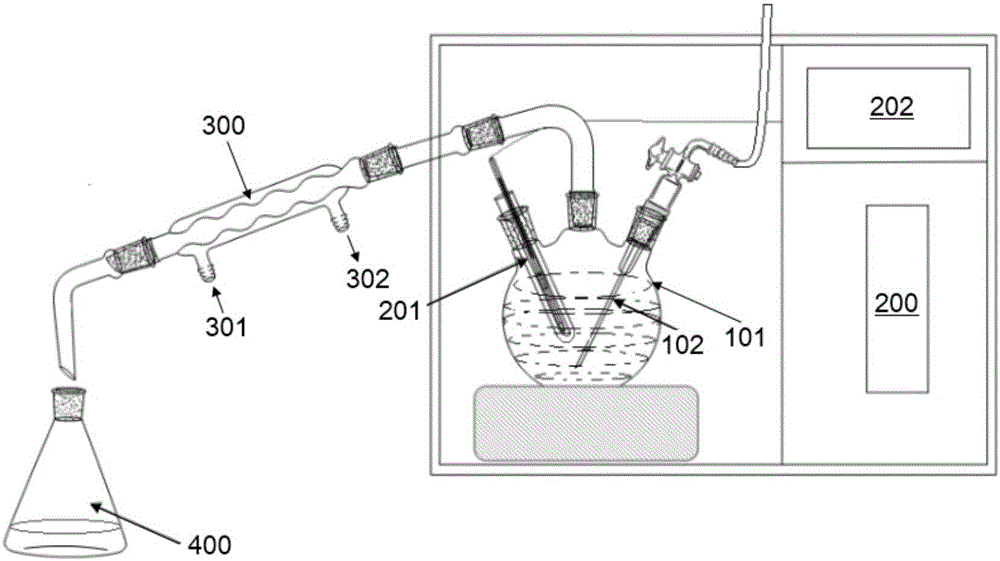

Method for extracting GeCl4 from smoke dust containing Ge

The invention relates to a method for extracting GeCl4 from smoke dust containing Ge. The method comprises following steps: material mixing: the smoke dust containing Ge and HCl are mixed in a weight ratio being (1:1.25)-(1:13.5); microwave heating: the mixed materials are subjected to microwave heating to reach the GeCl4 distillation temperature or higher for distillation, and stirring is performed simultaneously; collecting: products after distillation are collected, and GeCl4 is obtained. The method for extracting GeCl4 from the smoke dust containing Ge is uniform in heating, high in heating speed, good in controllability, energy-saving and efficient and can accelerate the chemical reaction, thereby accelerating the distillation process, reducing the use amount of HCl, reducing energy consumption and emission and increasing the recovery rate of Ge.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

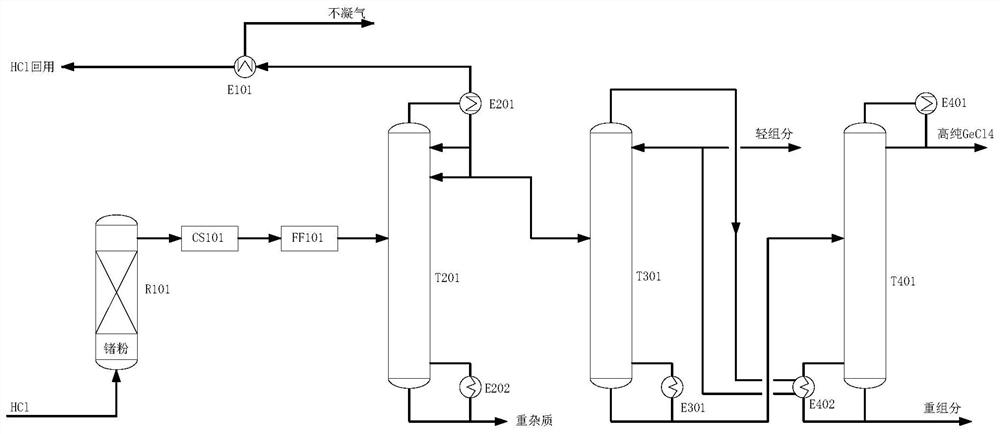

Method and device for synthesizing and refining optical fiber grade germanium tetrachloride

PendingCN111957064AAvoid introducingReduce generationGermanium halidesFractional distillationPhysical chemistryHydrogen chloride

The invention relates to a method and a device for synthesizing and refining optical fiber grade germanium tetrachloride. The method comprises the steps: making hydrogen chloride and germanium powderreact under the conditions where the pressure is 0.1-1 MPa and the temperature is 200-400 DEG C, wherein the effective conversion rate of germanium is 60-90%, and obtaining germanium tetrachloride crude gas through reaction; removing dust from the germanium tetrachloride crude product and then carrying out heavy component removal treatment, wherein the heavy component removal operation pressure is0.1-0.3 MPa, and the operation temperature is 82-123 DEG C; recovering hydrogen chloride from non-condensable gas generated in the heavy component removal process under the operating condition of -130--80 DEG C, and then discharging the gas; and refining the de-heavy material under the conditions where the pressure is 0.2-0.5 MPa and the temperature is 103-143 DEG C to obtain a 8N optical fiber grade germanium tetrachloride product. Germanium powder and hydrogen chloride are adopted for direct reaction, so that introduction of sulfuric acid and hydrochloric acid is avoided, generation of waste acid and waste salt is reduced, and the greenization degree of the production process is improved. The effective conversion rate of germanium is 80-95%, and compared with a traditional process, energy is saved by more than or equal to 40%.

Owner:TIANJIN ZHONGKE TUOXIN TECH CO LTD

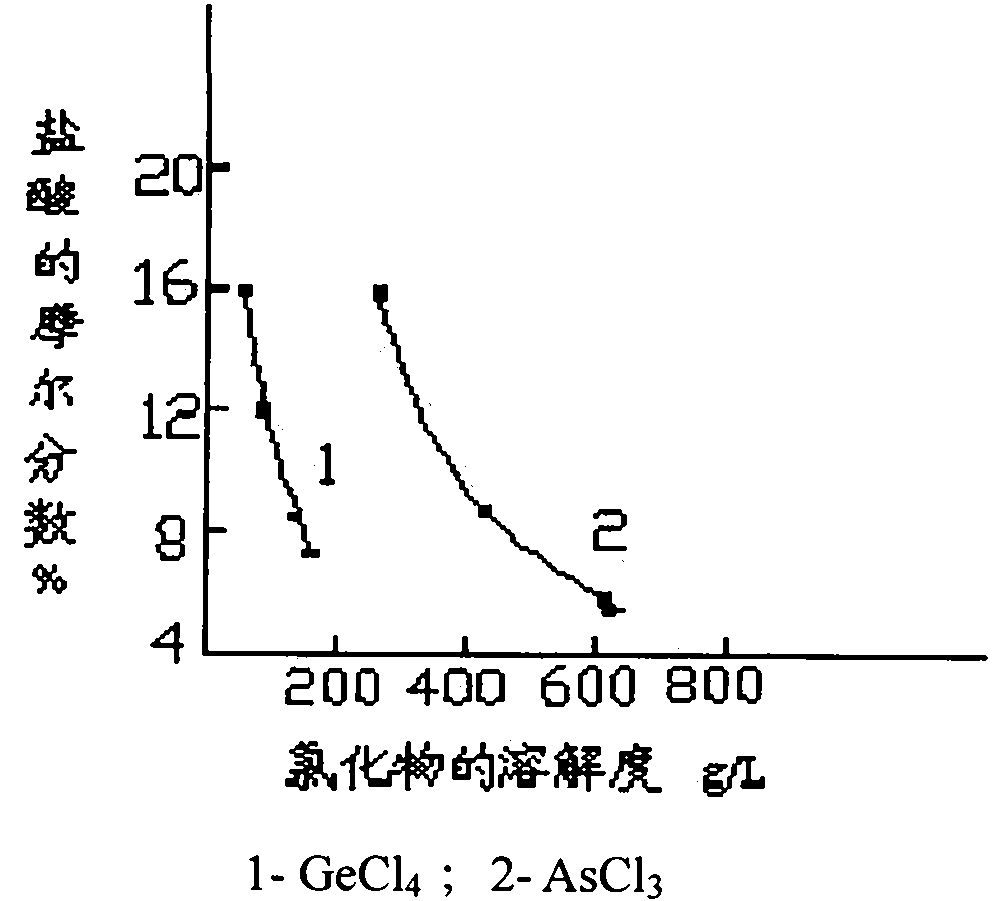

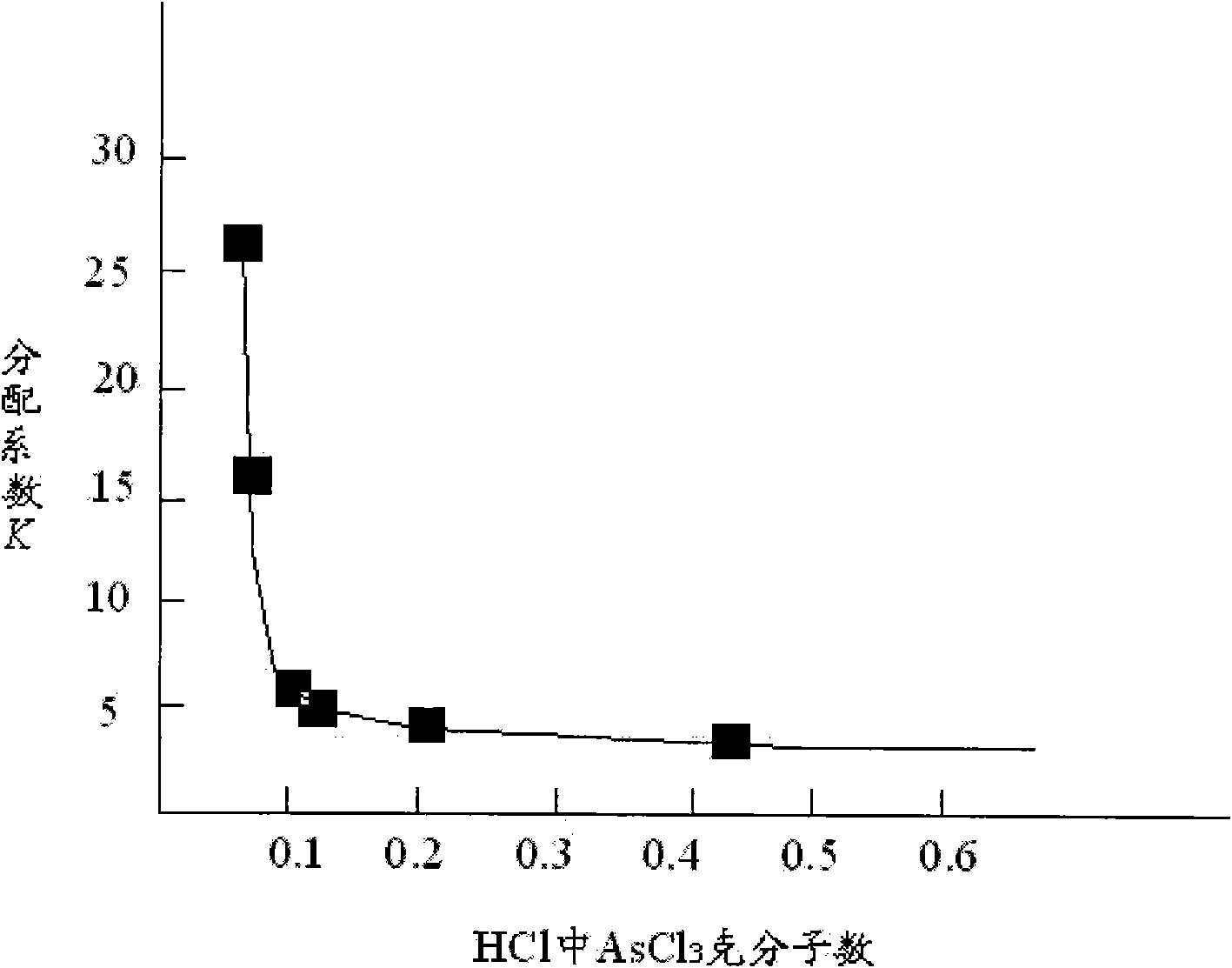

Novel extraction process method for purifying germanium tetrachloride

InactiveCN101891243ALow costMeet environmental protection requirementsGermanium halidesElectrical resistance and conductanceIngot

The invention discloses a novel extraction process method for purifying germanium tetrachloride. Purification is the subject of the germanium metallurgical industry. The method is combined with an extraction theory, and a novel germanium tetrachloride purification process is researched through experiments. The dissolving situations of substances such as AsCl3 and the like in hydrochloric acid and GeCl4 differ greatly, and the aim of purifying GeCl4 can be fulfilled by extracting substances such as AsCl3 and the like in crude GeCl4 by taking the hydrochloric acid as an extracting agent. Conventional extraction is used for extracting active ingredients in a mixture. In recent years, an extraction method is used for purification. Full and effective mixing of the extracting agent and an extracted substance is a relatively key problem. High-speed spray is an effective method which can fully mix the extracting agent and the crude GeCl4. The experiments prove that the quantity of low-resistance germanium ingots can be reduced greatly by adding the process into the conventional technical condition, so that product percent of pass is increased to 90 percent.

Owner:四川高锗再生资源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com