Reactor, plant and industrial process for the continuous preparation of high-purity silicon tetrachloride or high-purity germanium tetrachloride

a technology of high-purity germanium tetrachloride and reactor, which is applied in the direction of chemical/physical/physical/physical-chemical processes, silicon compounds, energy-based chemical/physical/physical-chemical processes, etc., can solve the problems of high operating costs of the plant, frequent shutdown of the plant, and considerable disadvantage of hydrogen-containing compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

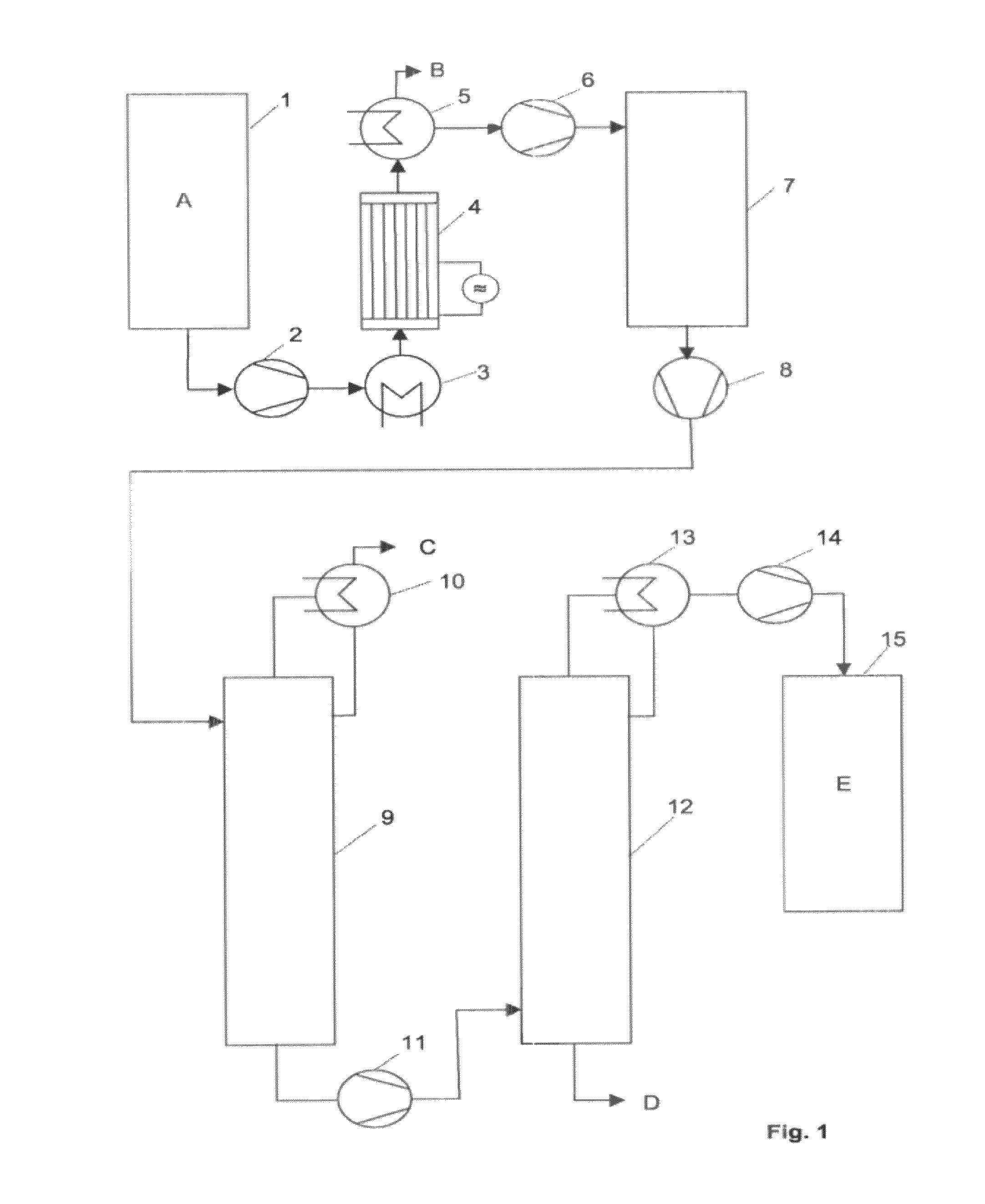

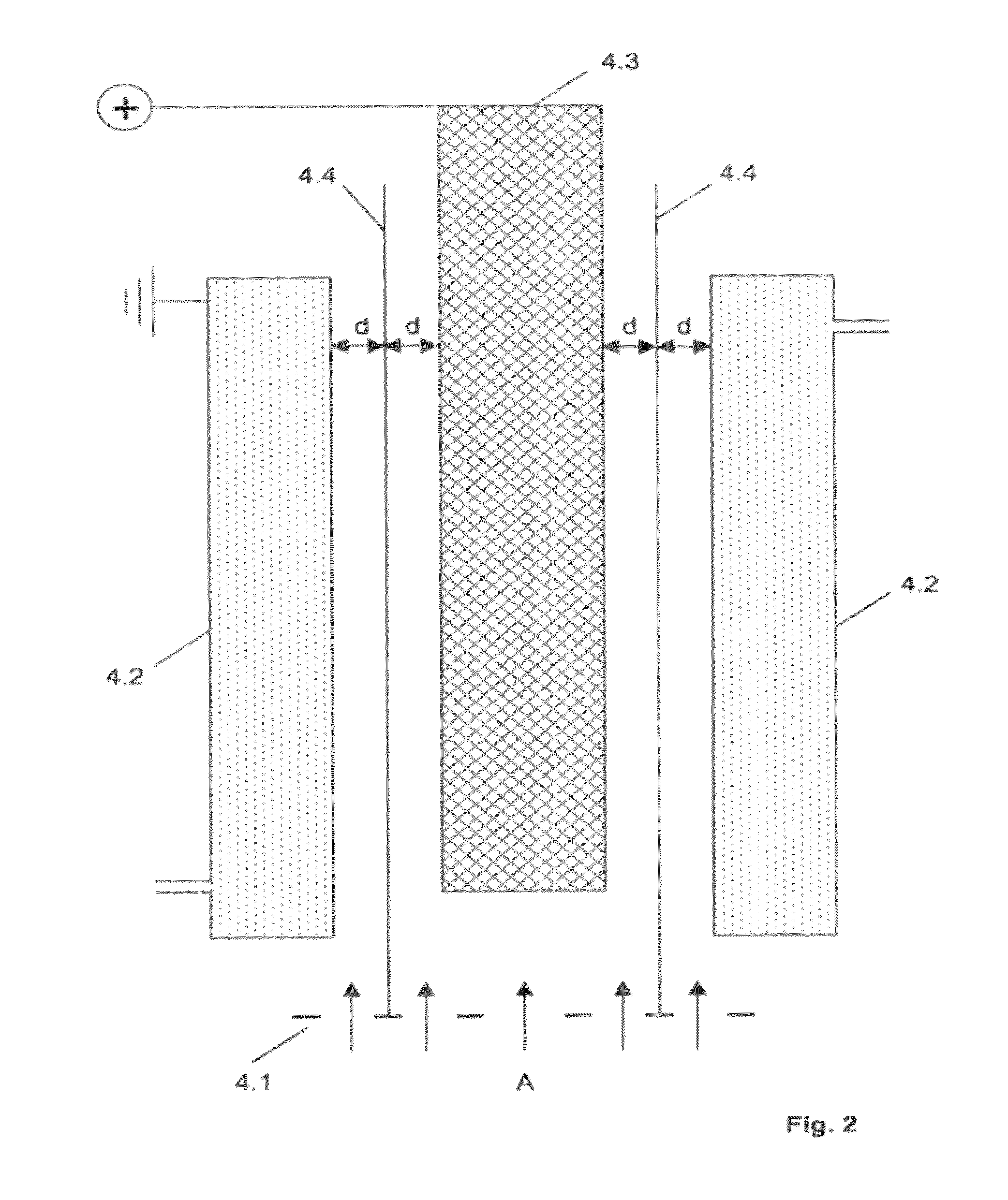

[0101]In a plant as shown in FIG. 1, the PRG was supplied with 400 kg / h of SiCl4 (contaminated by 10 ppm by weight of methyltrichlorosilane) and the gas phase was treated by means of a cold plasma. The PRG was equipped with 1 200 micro units, cf. FIG. 2, with the tube length of the dielectrics being 1.5 m and the respective internal diameter being 10 mm. The gap was 0.5 mm. The PRG was operated at about 30° C. This resulted in a mean residence time of the gas of 1 s in the reactor at a pressure of about 300 mbar abs. This corresponded to a residence time at STP of about 3 s. The treated gas phase was subsequently fractionally condensed. No methyltrichlorosilane could be detected in the purified SiCl4 product phase obtained in this way.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com