Technological method for purifying and preparing high pure germanium tetrachloride and removing organic impurities

A technology of high-purity germanium tetrachloride and a process method, applied in the field of hydrometallurgy, can solve the problem that the infrared transmittance of the product cannot meet the standard requirements, and achieve the effects of saving production cost input, improving quality and quality, and efficiently purifying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

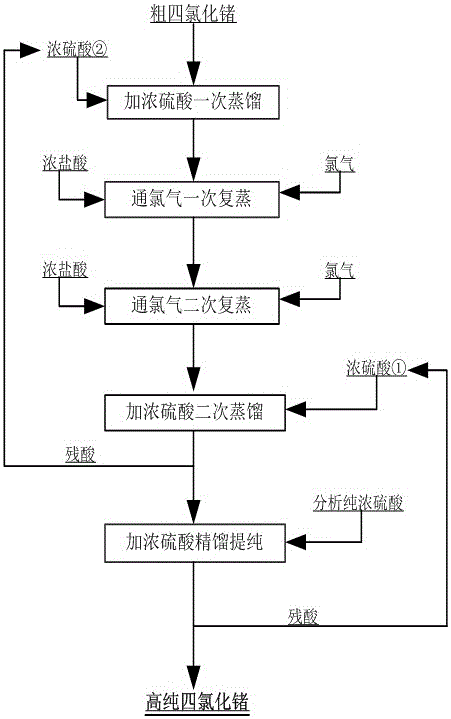

[0020] Embodiment 1: this method is the processing method of producing high-purity germanium tetrachloride for the first time, and implements according to the following steps:

[0021] (1) Initial steaming of crude germanium tetrachloride and concentrated sulfuric acid: take a certain amount of crude germanium tetrachloride produced by chlorination and distillation of germanium concentrate, transfer it to a still, and add analytically pure concentrated sulfuric acid for heating digestion and initial steaming, The dosage of concentrated sulfuric acid is 0.4 times the volume of crude germanium tetrachloride, the distillation temperature is 80-90 °C, and the distillation time is 2.2 h;

[0022] (2) Chlorine gas is passed for 2 times of re-steaming: the germanium tetrachloride produced by the initial steaming is transferred to the double-steam distillation still, and analytically pure hydrochloric acid is added and chlorine gas is introduced for one-time heating and re-steaming, an...

Embodiment 2

[0026] Embodiment 2: this method is a continuous production high-purity germanium tetrachloride process method, and is implemented according to the following steps:

[0027] (1) Initial steaming of crude germanium tetrachloride and concentrated sulfuric acid: take a certain amount of crude germanium tetrachloride produced by chlorination and distillation of germanium concentrate, transfer it to a still, and add concentrated sulfuric acid (concentrated sulfuric acid ②) for heating and digestion Initial steaming, distillation temperature 80-90 ℃, distillation time 2.5 h;

[0028] (2) Chlorine gas is passed for 2 times of re-steaming: the germanium tetrachloride produced by the initial steaming is transferred to the double-steam distillation still, and analytically pure hydrochloric acid is added and chlorine gas is introduced for one-time heating and re-steaming, and the amount of analytically pure hydrochloric acid added is: The volume of germanium tetrachloride is 1.2 times, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com