Patents

Literature

130results about How to "Reduce production cost input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

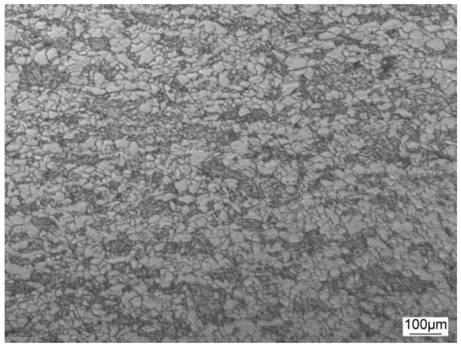

Tensile strength 800-MPa-class hot rolling complex phase steel and production method thereof

InactiveCN110343961AHigh expansion rateQuality improvementProcess efficiency improvementMetallurgyMartensite

The invention discloses tensile strength 800-MPa-class hot rolling complex phase steel and a production method thereof and belongs to the field of metal material and preparation thereof. The tensile strength 800-MPa-class hot rolling complex phase steel comprises the main components of 0.05%-0.09% of C, 0.10%-0.30% of Si, 1.40%-2.00% of Mn, 0.010%-0.050% of Al, 0-0.020% of P, 0-0.008% of S, 0.010%-0.070% of Nb, 0.08%-0.14% of Ti, 0.10%-0.25% of Mo, and the balance Fe and inevitable impurities. Through treatment of casting blank hot charging, hot continuous rolling and related process steps, yield strength is 700 MPa or above, tensile strength is 800 MPa or above, the hole expansion rate is larger than 60%, the microstructural type is a mixed structure composed of ferrite, granular bainiteand a small amount of island-shaped martensite, after the product is subjected to continuous pickling, product surface quality and performance are excellent, and the product is widely used for manufacturing automobile chassis structural parts, safety belt supports, bumpers and other parts.

Owner:MAANSHAN IRON & STEEL CO LTD

Micropore ceramic filter element and preparation method thereof

InactiveCN101780353AReduce manufacturing costReduce production cost inputOther chemical processesFiltration separationWater basedPunching

The invention relates to a micropore ceramic filter element, in particular to a micropore ceramic filter element and a preparation method thereof. In the process of preparing the micropore ceramic filter element, raw materials are weighed according to the percentage in the formula, are added, mixed and uniformly stirred according to specified steps, and then are extruded or punched by an extruder or a punching machine into a blank, then the blank is dried at certain temperature to be shaped, and then the polyporous micropore ceramic filter element is formed. The micropore ceramic filter element is made of kaolin and diatomaceous earth which are bonded by a water-based adhesive, and has the advantages of low manufacturing cost, safety and environment protection. Simultaneously, the blank is molded by extrusion or punching, so cumbersome technology in the grouting process is eliminated, only moisture in the blank needs to be removed in the molding process, the existing energy-consuming process of long-time high-temperature calcination is avoided, and the production cost is greatly reduced.

Owner:张顺 +1

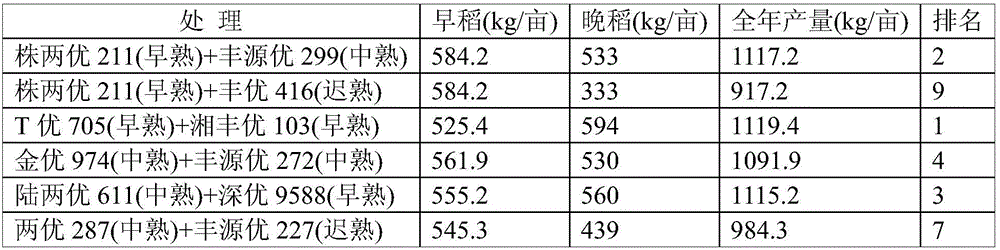

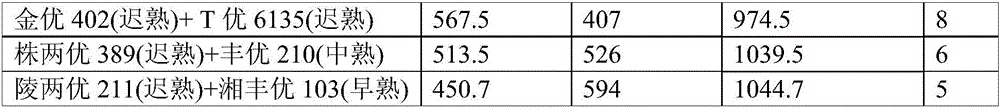

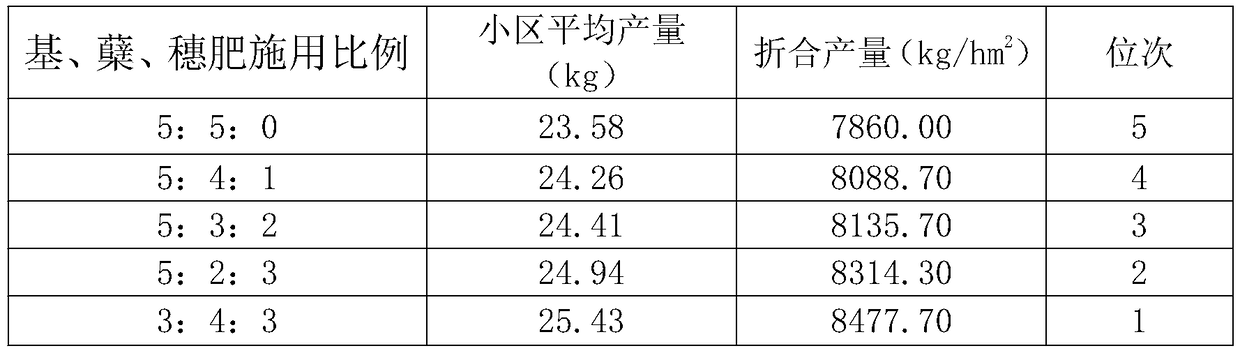

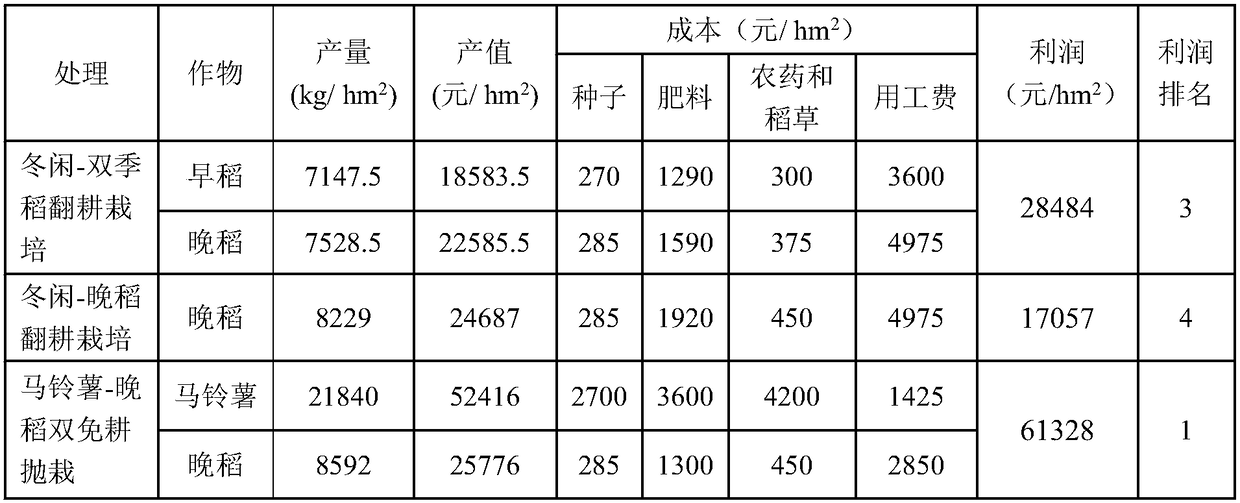

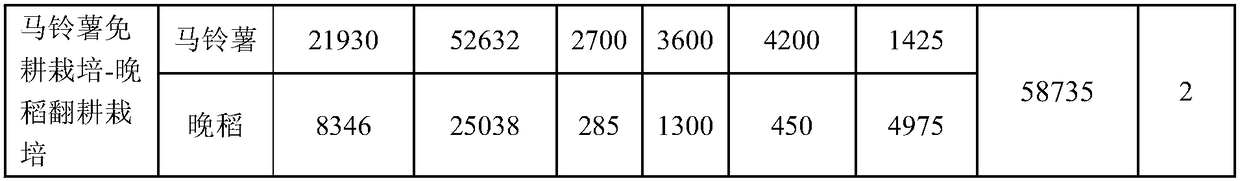

Solanum tuberosum and double cropping rice rotation crop rotation culture method for improving south double cropping rice paddy soil micro-aggregate structure

InactiveCN106069031AIncrease resourcesReduce non-point source pollutionCultivating equipmentsRice cultivationInsect diseaseEconomic benefits

The invention provides a solanum tuberosum and double cropping rice rotation crop rotation culture method for improving a south double cropping rice paddy soil micro-aggregate structure, and belongs to the field of agricultural production. The method mainly comprises the first step of solanum tuberosum high-yield cultivation and the second step of early rice and late rice high-yield cultivation, wherein the first step comprises the substeps of preparation before seeding, variety selection, cutting of seed solanum tuberosum, seeding at suitable time and coverage of straw and a mulching film, field management comprising timely film breaking, topdressing, drainage and insect disease prevention, timely harvesting, and field returning of solanum tuberosum stem leaves and straw for coverage, and the second step comprises the substeps of variety selection, seedling transplanting, filed management comprising scientific fertilization, weeding, irrigation and insect disease prevention, timely harvesting and field returning of straw. By means of the method, south double cropping rice paddy winter agriculture can be reasonably developed, the rice paddy soil micro-aggregate structure is effectively improved, soil is fertilized, economic benefits of solanum tuberosum in one season are increased on the basis of ensuring the double cropping rice yield, the purposes of improving the rice paddy soil structure and obtaining high-yield year-round crops are achieved, and the popularization value is high.

Owner:HUNAN SOIL & FERTILIZER INST

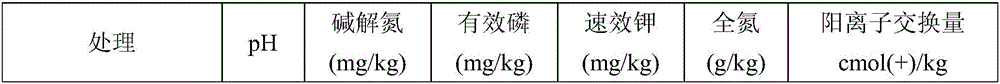

Tobacco culturing method applying large holes for concentrated fertilization

InactiveCN103141256AImprove qualityImprove efficiencyHorticultureFertilizer mixturesFertilizerRoot system

The invention relates to a tobacco culturing method applying large holes for concentrated fertilization. The method is applicable to plain areas of Henan province, and mainly comprises the steps that a base fertilizer is not applied in a culturing process; according to the planting density (16500-18000 plants / hm<2>), the large holes are dug at central positions of tobacco plants planted on a tobacco ridge in a tobacco seedling transplanting process; and various fertilizers are mixed uniformly, applied in the holes according to the calculated fertilization amount of each plant, and sealed after being mixed with soil in the holes sufficiently and uniformly. According to the method, soil water and fertilizer nutrition absorption of the tobacco plants and coordination of water, the fertilizers, air and heat are facilitated; a supply of mineral elements such as N, P,K and Cl is optimized; root development and thickening of the tobacco plants can be facilitated; the disease-resistant ability of tobaccos is improved; the growth advantage of a whole growth period is obvious; resource waste and environmental pollution due to blind fertilization are avoided; the production cost is lowered; effects of oil increasing, aroma enhancing, potassium increasing, alkali reducing, chlorine reducing and starch reducing are exerted in an aspect of improving the quality of tobacco leaves; the internal quality of the tobacco leaves is improved; and economic indicators of the tobacco leaves are increased remarkably.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

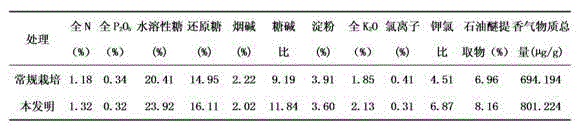

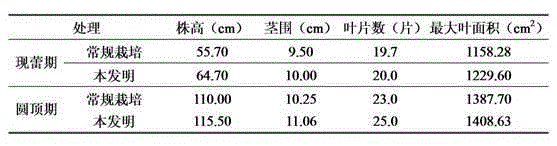

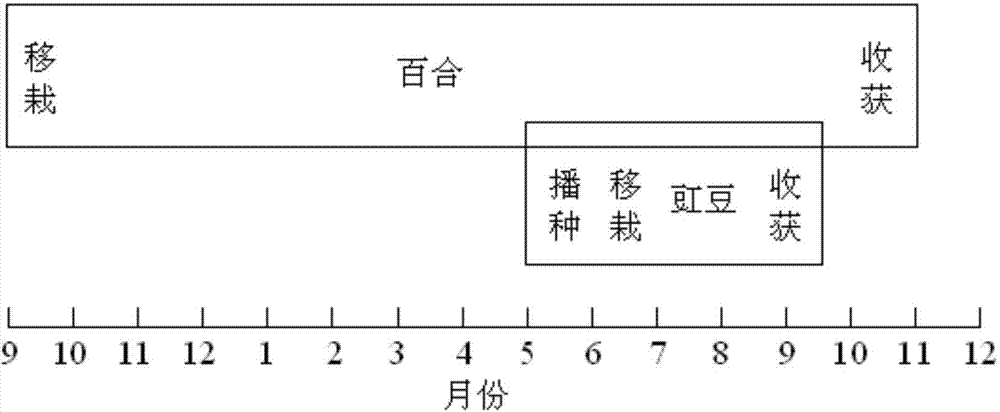

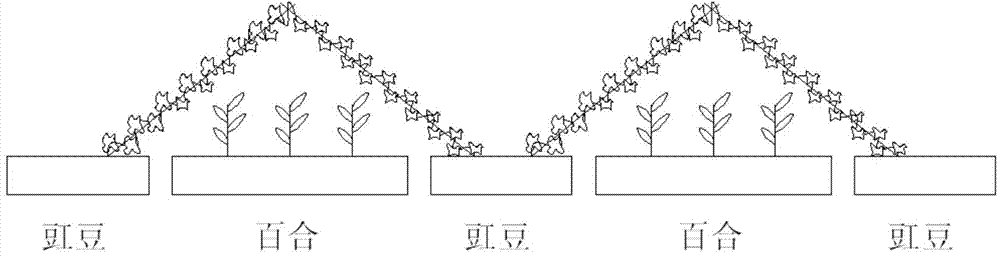

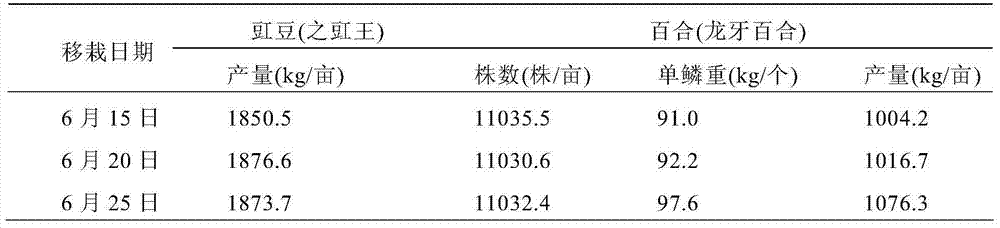

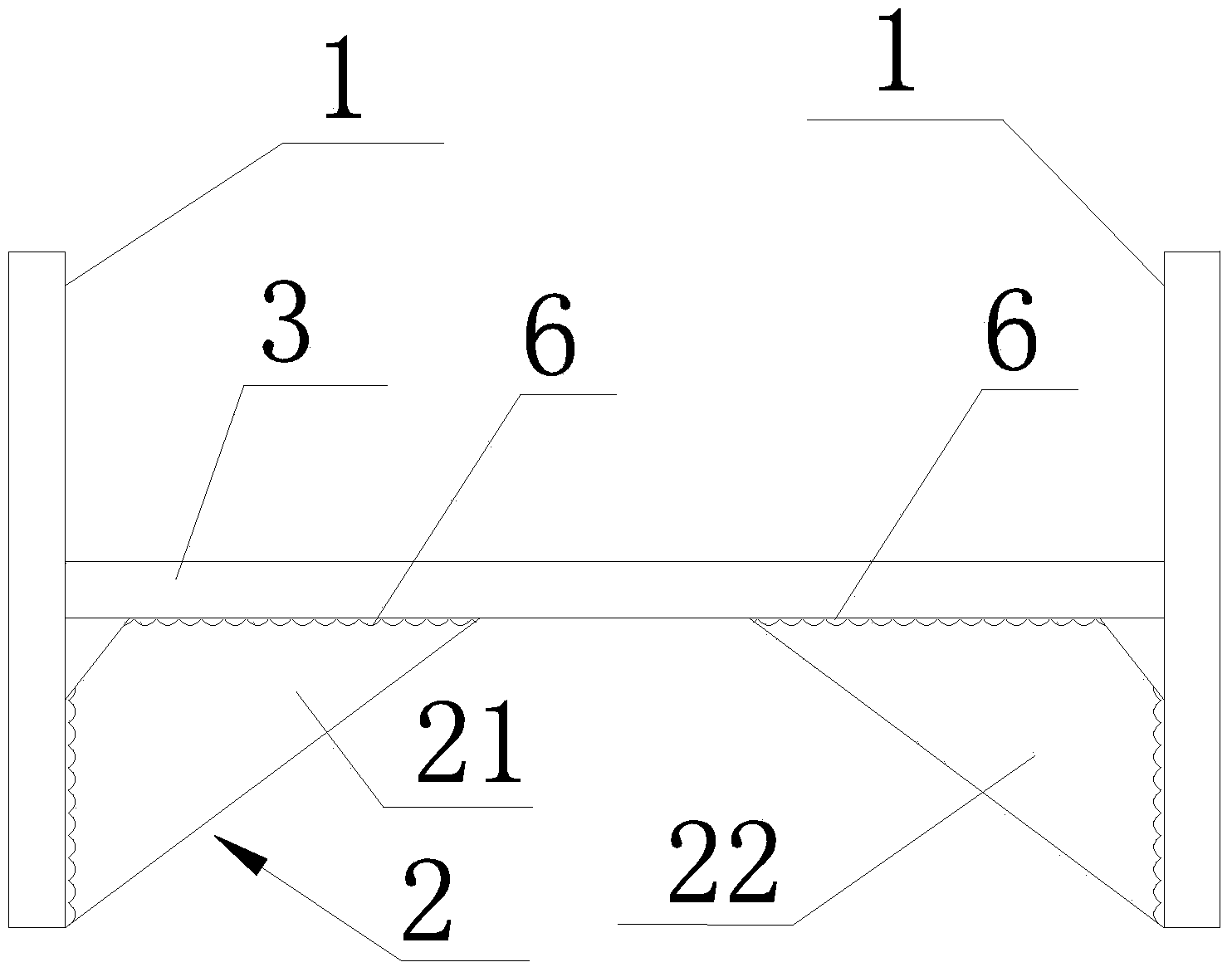

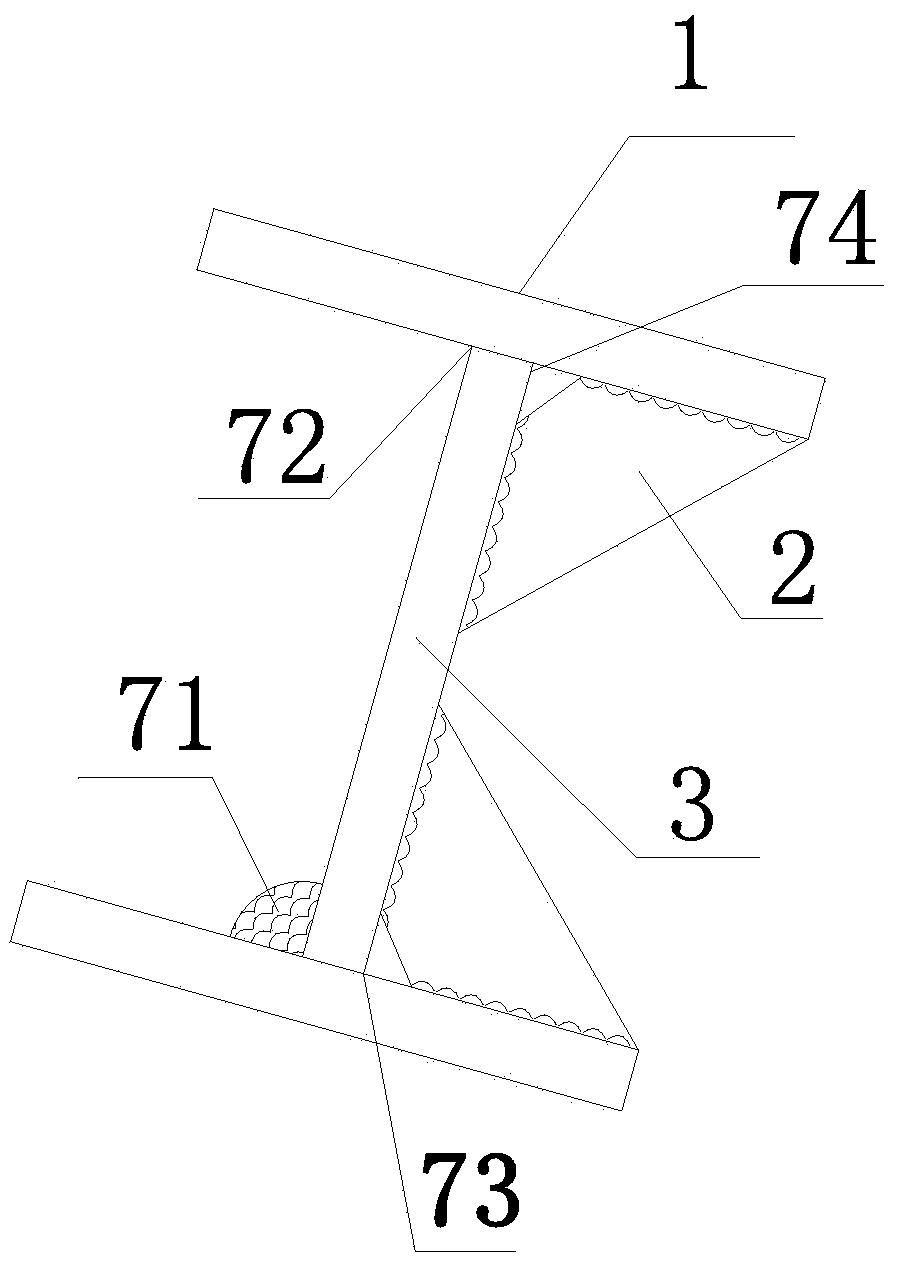

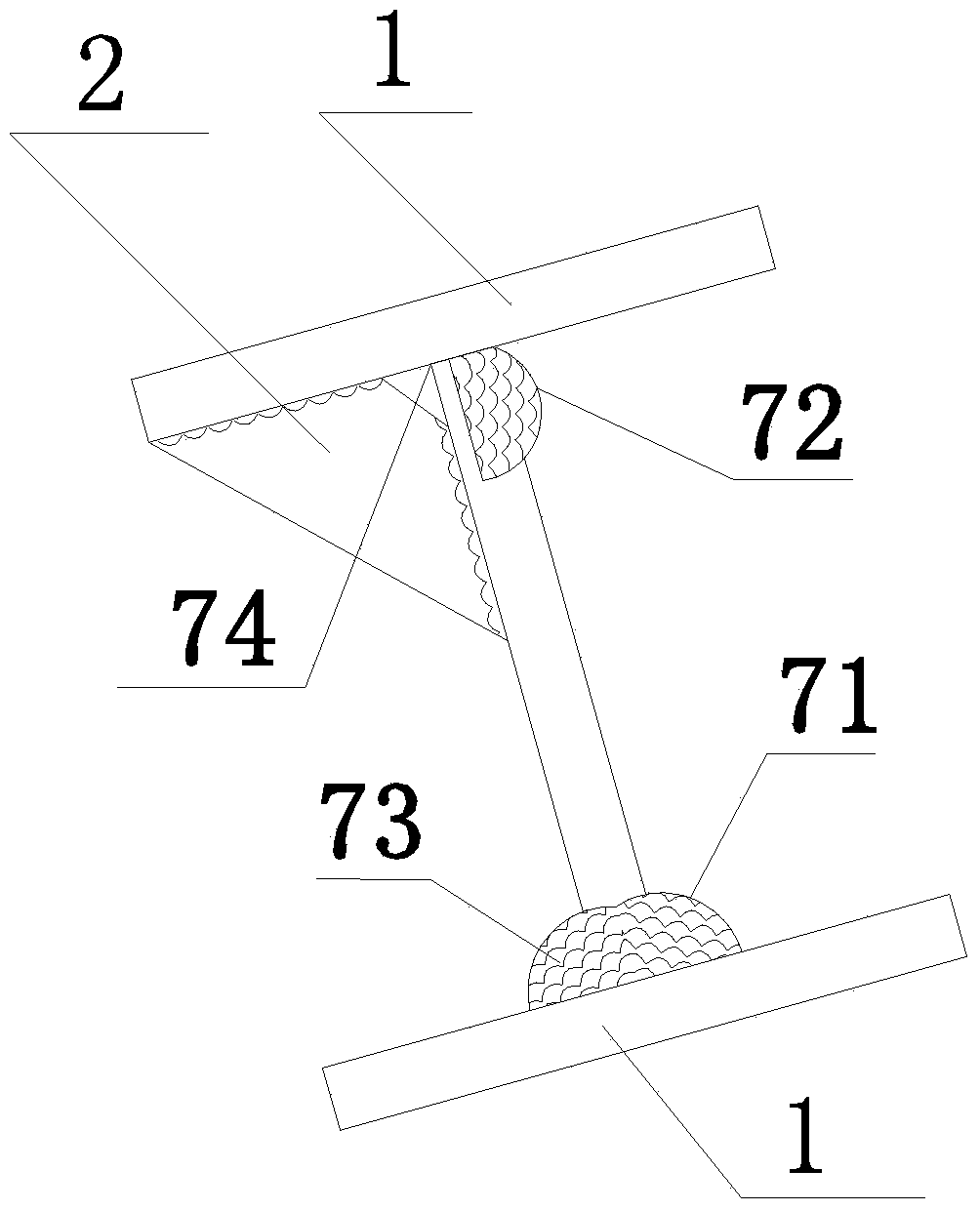

Cultural method for interplanting lily with cowpea

InactiveCN104756723APlay the role of shading and coolingReduce production cost inputHorticultureLiliumEconomic benefits

The invention discloses a cultural method for interplanting lily with cowpea, and relates to the technical field of crop planting. The method comprises the steps that site preparation and fertilization is performed, ridging and bedding are performed, the lily is transplanted on the bed faces, deep trenches are excavated on the two sides of each bed face, and high ridges used for planting the cowpea are formed beside the deep trenches; the lily is transplanted in September to October and harvested in the end of October to the middle ten-day of November next year; the cowpea is sowed and seeded in the last ten-day of May to the first ten-day of June and interplanted and transplanted in the last ten-day of June to the first ten-day of July, hill spacing is 25-30 cm, and tendrils are guided to canopy frames when the cowpea sprouts the tendrils. According to the cultural method for interplanting the lily with the cowpea, one-season cowpea can be additionally planted while the lily is planted, the land area can be effectively utilized, not only is the space of subsoil utilized, but also the upper space formed by the canopy frames can be effectively utilized for the growth of the cowpea, and meanwhile a partial shading effect is played for the lily. Ridging and bedding and the design of the canopy frames are in accordance with the growth characteristics of the lily and the cowpea, the planting method is easy to operate and manage, the lily production and quality can be guaranteed, one-season cowpea production can be added, the obvious economic benefit can be achieved, the interannual planting belt interchange crop rotation can be achieved, and the insect attack of the lily and the cowpea can be reduced.

Owner:HUNAN SOIL & FERTILIZER INST

Process for molding I-steel main welding seam non-back chipping full-penetration I-level component

InactiveCN104227182AGuaranteed quality levelReduce production cost inputWelding/cutting auxillary devicesAuxillary welding devicesEngineeringEnergy conservation

The invention discloses a process for molding an I-steel main welding seam non-back chipping full-penetration I-level component and relates to a molding process of light thin-walled I-steel. The process comprises the following steps of preparing a plate, testing welding processing property on the plate, blanking and cutting a flange plate to form a technical beveled edge, cutting or shearing and leveling a technical triangular stiffening plate, positioning and performing full-length welding (single side and singe surface) on the technical triangular stiffening plate, performing submerged-arc door welding on the I-steel, performing ultrasonic (UT) flaw inspection on a main welding seam of an I-steel web, transferring the qualified I-steel component after inspection to the next procedure. When the I-steel is welded, the quality grade of the welding seam can be guaranteed to meet the requirement of full-penetration welding I grade, the deformation of the I-steel is small, back chipping on the opposite surface of a weld bead is not required, backing, filling and surface covering operations which are sequentially performed on the opposite surface of the weld bead are not required, the production cost is relatively low, the production efficiency is relatively high, and the requirements of advanced technology, energy conservation and environment friendliness on construction are met.

Owner:湖北源盛钢构有限公司

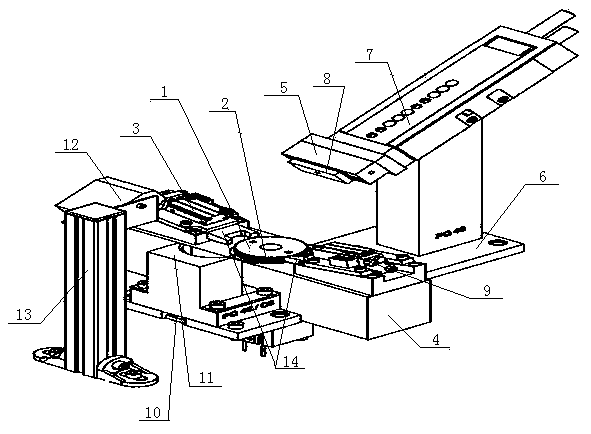

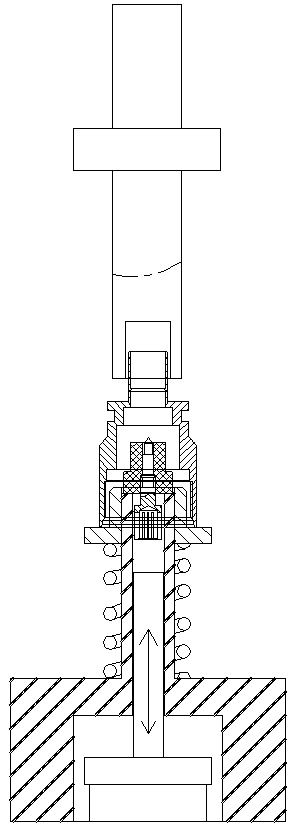

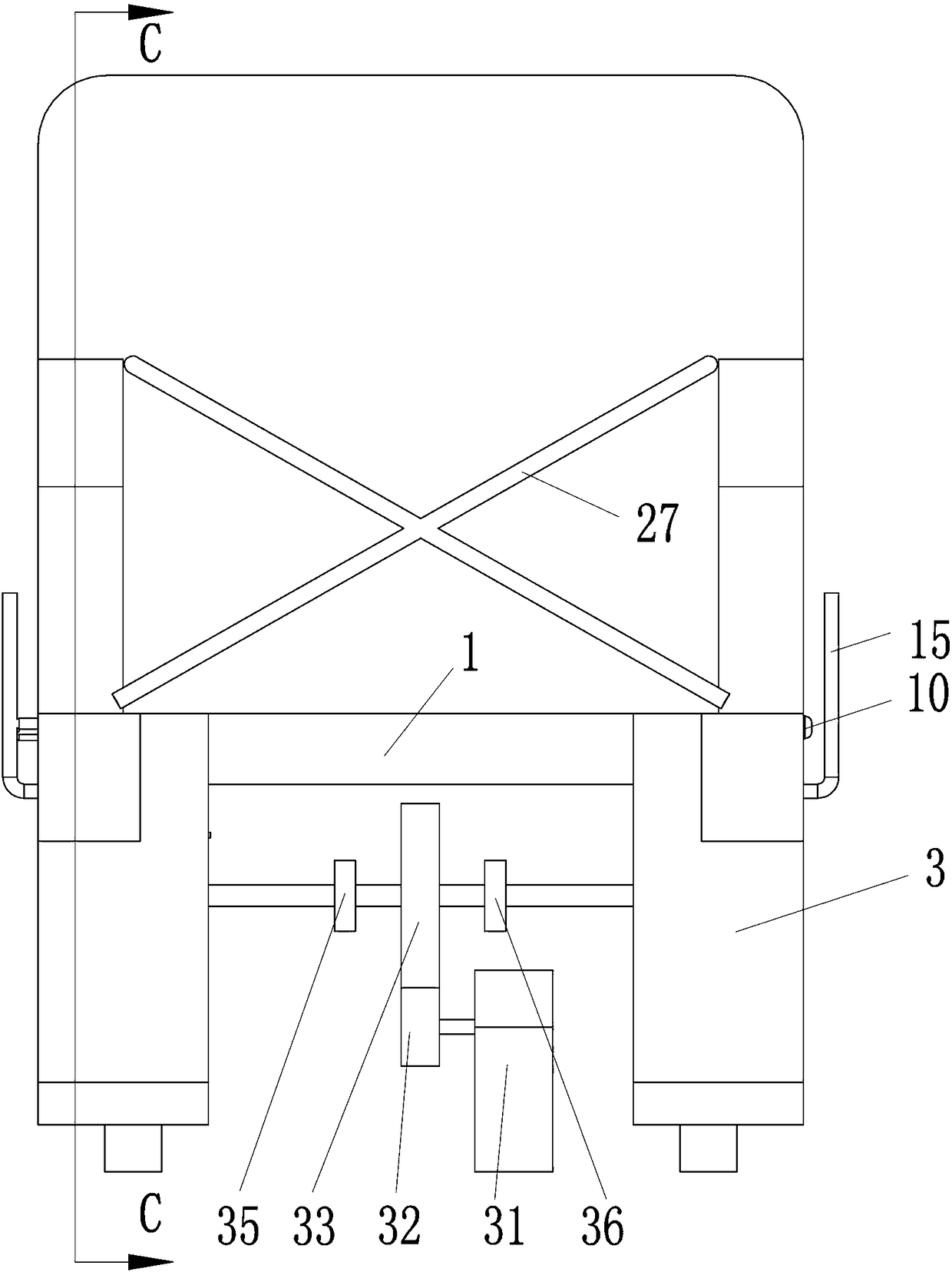

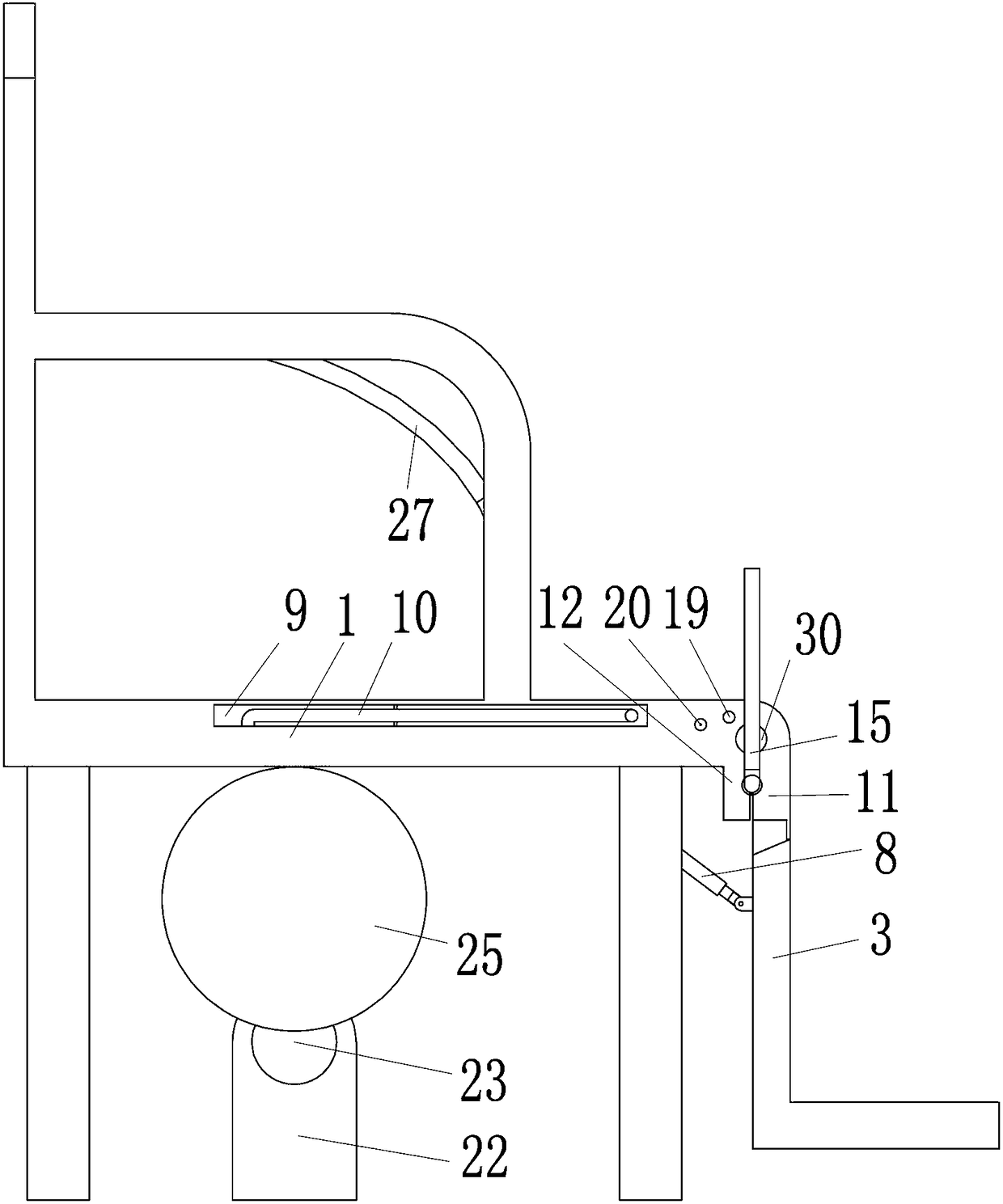

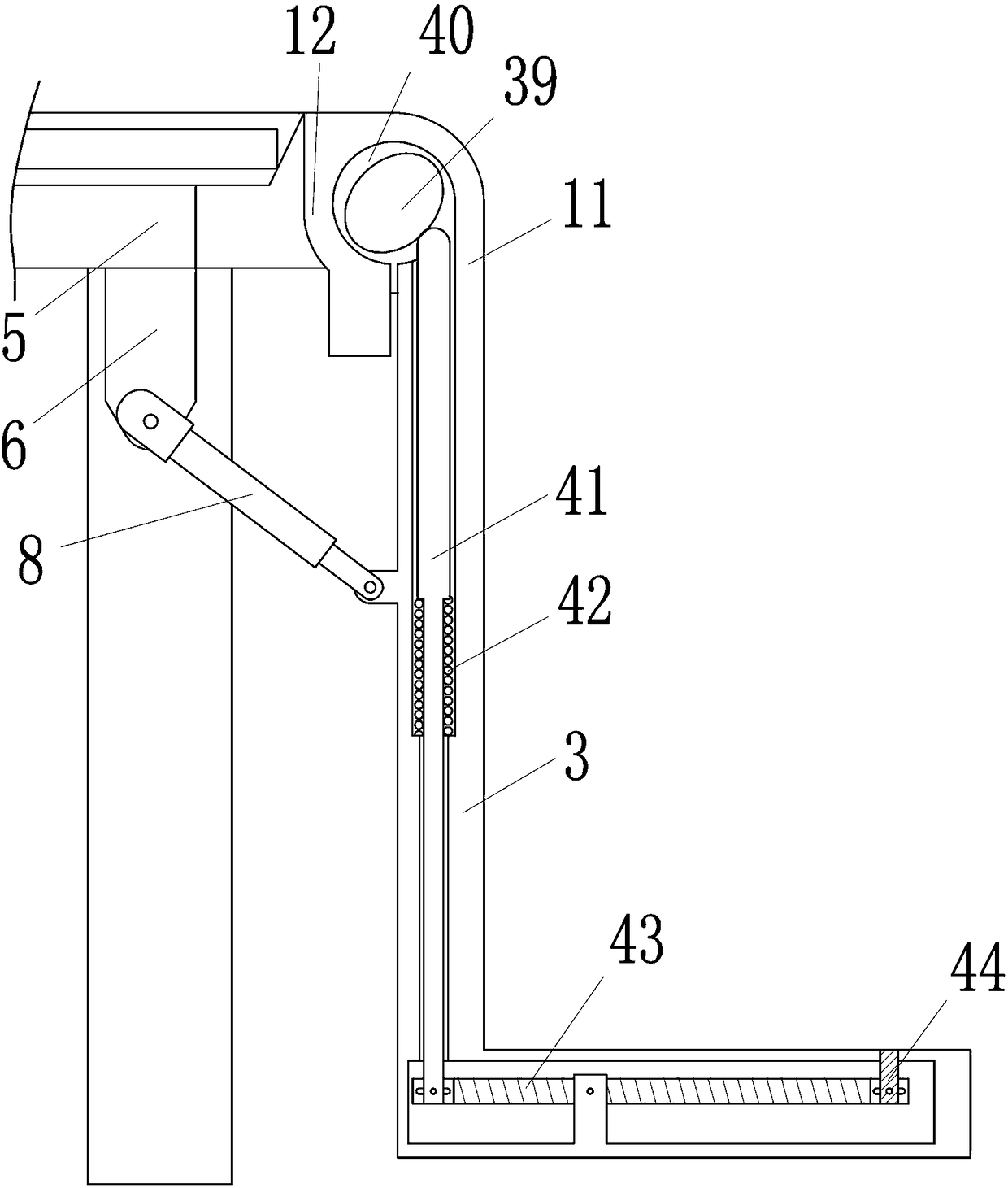

Air tightness detection device

ActiveCN103398827AReduce production cost inputQuality improvementMeasurement of fluid loss/gain rateProduct testingAssembly line

The invention belongs to the technical field of detection of assembling air tightness of a plastic electronic product and discloses an air tightness detection device. The air tightness detection device comprises a sealing device, a product clamping fixing and testing device and a product testing and identifying device. The air tightness detection device has the following advantages that 1, the sealing device, the product clamping fixing and testing device and the product testing and identifying device are reasonably integrated and can be widely embedded into various types of assembling testing equipment and are seamlessly joined with all assembling measuring procedures, so that the field area of the equipment is reduced, and the field cost is effectively reduced; 2, continuous and batch product detection can be rapidly carried out, and the detection period is shortened; the labor cost is reduced, and the product detection efficiency is effectively improved; 3, the production detection can be accurately carried out and the quality of outgoing products is improved, so as to guarantee the market competitiveness of enterprise products. To sum up, the difficulty in a detection aspect of assembly line products of existing enterprises is solved, the requirements on rapid and accurate detection of the products are realized, and the investment of enterprise production cost is reduced.

Owner:OECHSLER PLASTIC PROD TAICANG

Plant pulling and under-membrane transplanting method for floating tobacco seedling raising

InactiveCN107409670AImprove survival rateImprove seedling growth ratePlant cultivationCultivating equipmentsDiseaseEconomic benefits

The invention discloses a plant pulling and under-membrane transplanting method for floating tobacco seedling raising, and relates to the technical field of tobacco planting. The method comprises the following steps: performing field building, preparing seedling raising plates and seedling raising substrates, loading the substrates to the plates and performing sowing, and performing management in a seedling stage to obtain strong seedlings; transplanting the strong seedlings in the seedling raising plates to tobacco ridges in time and in batches through an under-membrane transplanting method; and continuing to cultivate remained weak seedlings for 3-5 days, wherein the strong seedlings are tobacco seedlings which have a stem height of 6-10cm and a stem girth of 1-2cm, have 4-5 functional leaves, are subjected to leaf shearing for 1-2 times, are hardened for not less than 10 days, and have a seedling age of 60-70 days. According to the invention, the method for flue-cured tobacco seedling raising has the advantages of intensification, management normalization, tobacco seedling growth accordance, less diseases and insect pests, a short tobacco seedling restitution stage, robust tobacco seedlings, simple and convenient transplanting and the like; and tobacco seedling utilization rate through the under-membrane transplanting method is improved, the seedling restitution stage is effectively shortened, tobacco plant survival is facilitated, and flue-cured tobacco economic benefits are increased.

Owner:HENGYANG COUNTY BRANCH HENGYANG COMPANY OF HUNANTOBACCO

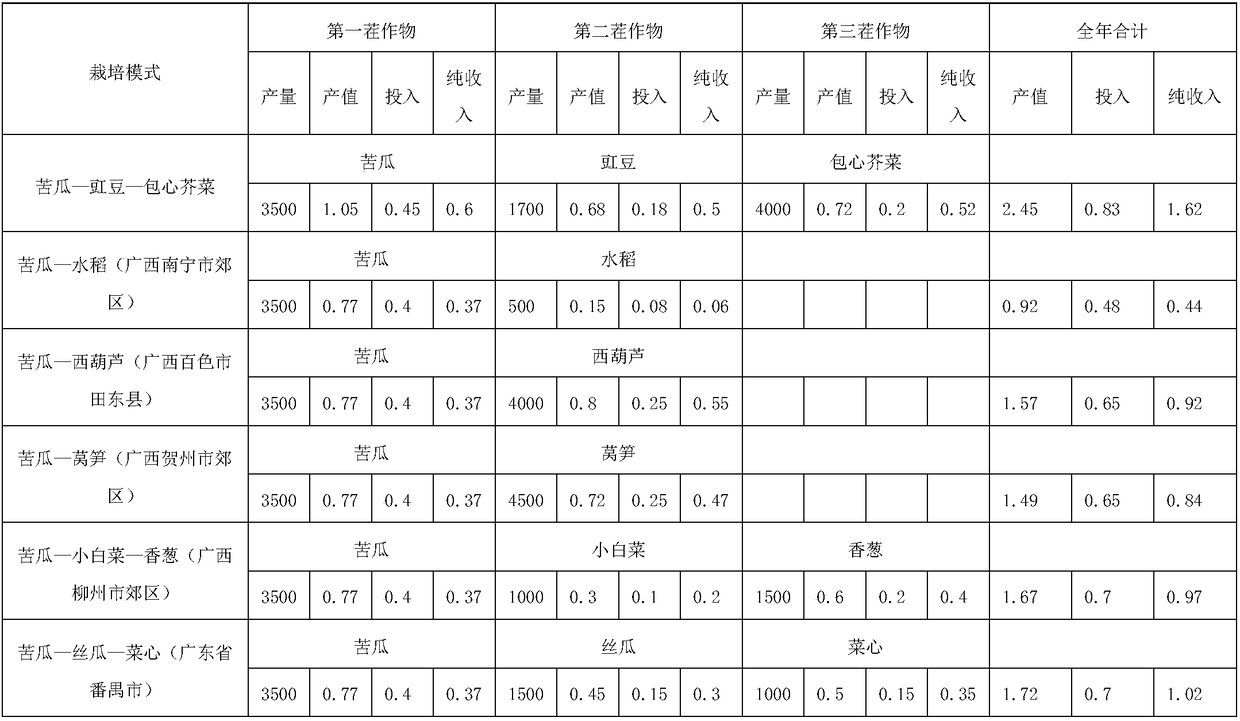

Three-crop-in-one-year cultivation method for crop rotation of bitter gourd, cowpea and leaf mustard in open field in south China

InactiveCN108633639AIncrease productionIncome increase guaranteeFabaceae cultivationLeaf crop cultivationEconomic benefitsSouth china

The invention belongs to the technical field of vegetable crop rotation cultivation and specifically relates to a three-crop-in-one-year cultivation method for crop rotation of bitter gourd, cowpea and leaf mustard in the open field in south China. The three-crop-in-one-year cultivation method for crop rotation of bitter gourd, cowpea and leaf mustard in the open field in south China comprises thefollowing steps: (1) crop rotation period arrangement; (2) appropriate good variety selection; and (3) cultivation method. According to the cultivation method disclosed by the invention, two crops including the cowpea and the leaf mustard suitable for seasons are planted after the bitter gourd is harvested, and therefore, the total production value of the three vegetables per 667m<2> is 24500 yuan, the total input is 8300 yuan, and the annual net income is 16200 yuan. Compared with a traditional local two-crop-in-one-year cultivation mode for bitter gourd and rice, the three-crop-in-one-yearcultivation method has the advantages that the annual total revenue per 667m<2> is 9200 yuan, the production cost of two crops is about 4800 yuan, and the average annual net income is only 4400 yuan.The production value per 667m<2> can be increased by 15300 yuan, the net income is increased by 11800 yuan, and the economic benefit is remarkable.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Moisturizing, whitening and relaxing essence liquid and preparation method of same

InactiveCN107496319ASoothing and calmingPlay a role in whiteningCosmetic preparationsToilet preparationsPunicaSkin color

The invention discloses moisturizing, whitening and relaxing essence liquid which is mainly prepared from: extract of chamomile, extract of astragalus membranaceus, essence liquid of volcanic mud, hyaluronic acid, ginseng extract, punica granatum extract, arbutin, nicotinamide, pearl powder, lycium ruthenicum extract and camellia seed oil. The moisturizing, whitening and relaxing essence liquid can adsorb excessive grease on skin and condition water-oil balance on skin. By adding the active components, such as the extract of chamomile, to the essence liquid, the essence liquid has relaxing and calming effect on skin; in addition, due to the active components including the ginseng extract, punica granatum extract, nicotinamide, lycium ruthenicum extract and the like, the essence liquid has the effect of deeply moisturizing skin, fading spots and brightening skin, thus whitening skin; through the synergistic effect among the components, deep moisturizing to skin is achieved. The essence liquid has effects of calming and relaxing skin, moisturizing skin, fading spots and brightening skin. The preparation method is simple, is fairly low in requirement on equipment, and is low in production cost.

Owner:兰新全

Tissue culture quick-breeding method for polygonum multiflorum

InactiveCN1934933ASave foreign exchangeSave seedling areaPlant tissue cultureHorticulture methodsLolium multiflorumMurashige and Skoog medium

The present invention provides a tissue culture fast-propagation method of Chinese medicinal plant polygonum multiflorum. Said method mainly includes the following several steps: preparing explant, induction culture, differentiation culture and rhizogenetic culture. Besides, said invention also provides the concrete requirements of the above-mentioned every step and its concrete operation method.

Owner:NANJING FORESTRY UNIV

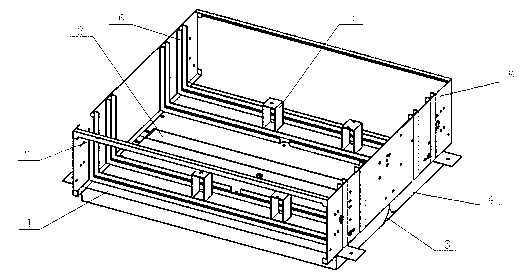

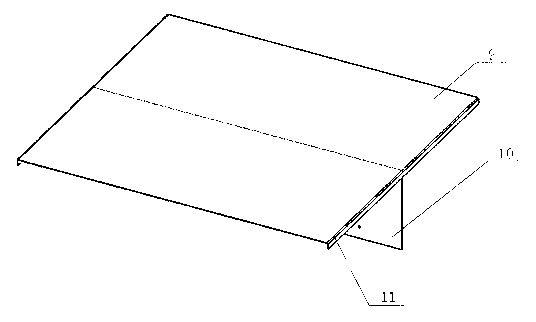

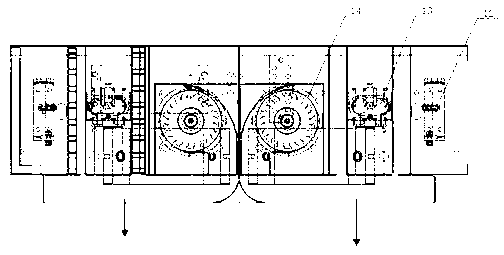

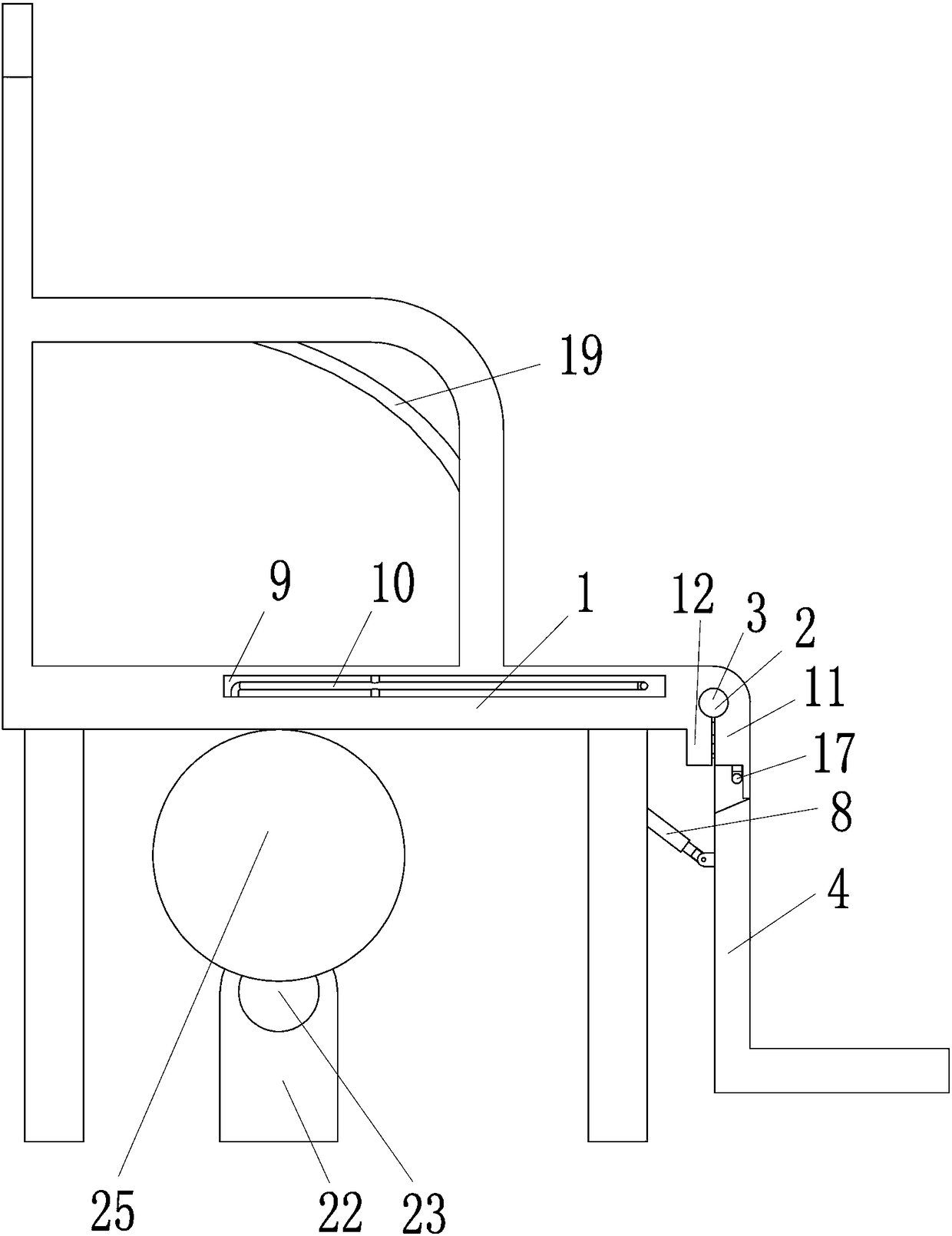

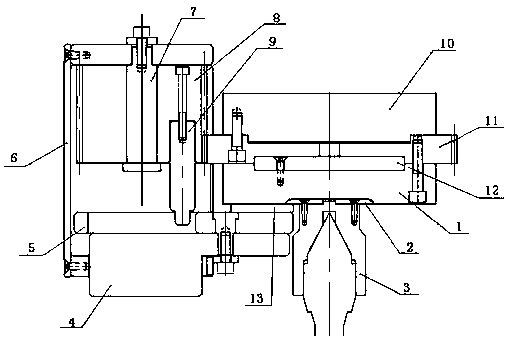

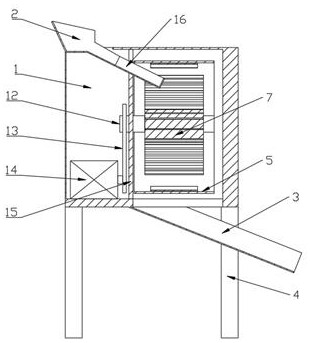

Moon roof type air purifier device for passenger car and working method thereof

The invention particularly discloses a moon roof type air purifier device for a passenger car and a working method of the moon roof type air purifier device. The device comprises a flow guide air flue base, a ventilation opening, a flow guide plate, air walls, fixing plates, filtering net inserting grooves, L-shaped filtering net fixing grooves, fixed supporting bases, a cover plate, a partition board, fixing pieces, plasma assemblies, ultraviolet lamps and fans. The device has the following advantages that the size of a purification bin is increased, and the moon roof type air purifier device is short in purifying time when being used for purifying a passenger car with the same carriage area; one-time assembly of the plasma assemblies, the fans, the ultraviolet lamps and filtering nets can be achieved, and production efficiency is improved by 300%; the purification bin is reasonable in design, the utilization rate of materials is improved, and cost and investment are reduced; by means of the fans which are independently arranged in different spaces, the situation that air power is reduced due to parallel connection of the fans during normal work of the device does not exist; according to test detection, processing efficiency of the device for formaldehyde, toluene, dimethylbenzene and TVOC reaches 95% per hour, the processing efficiency for PM2.5 reaches 98% per hour.

Owner:太仓绿奇空气净化器科技有限公司

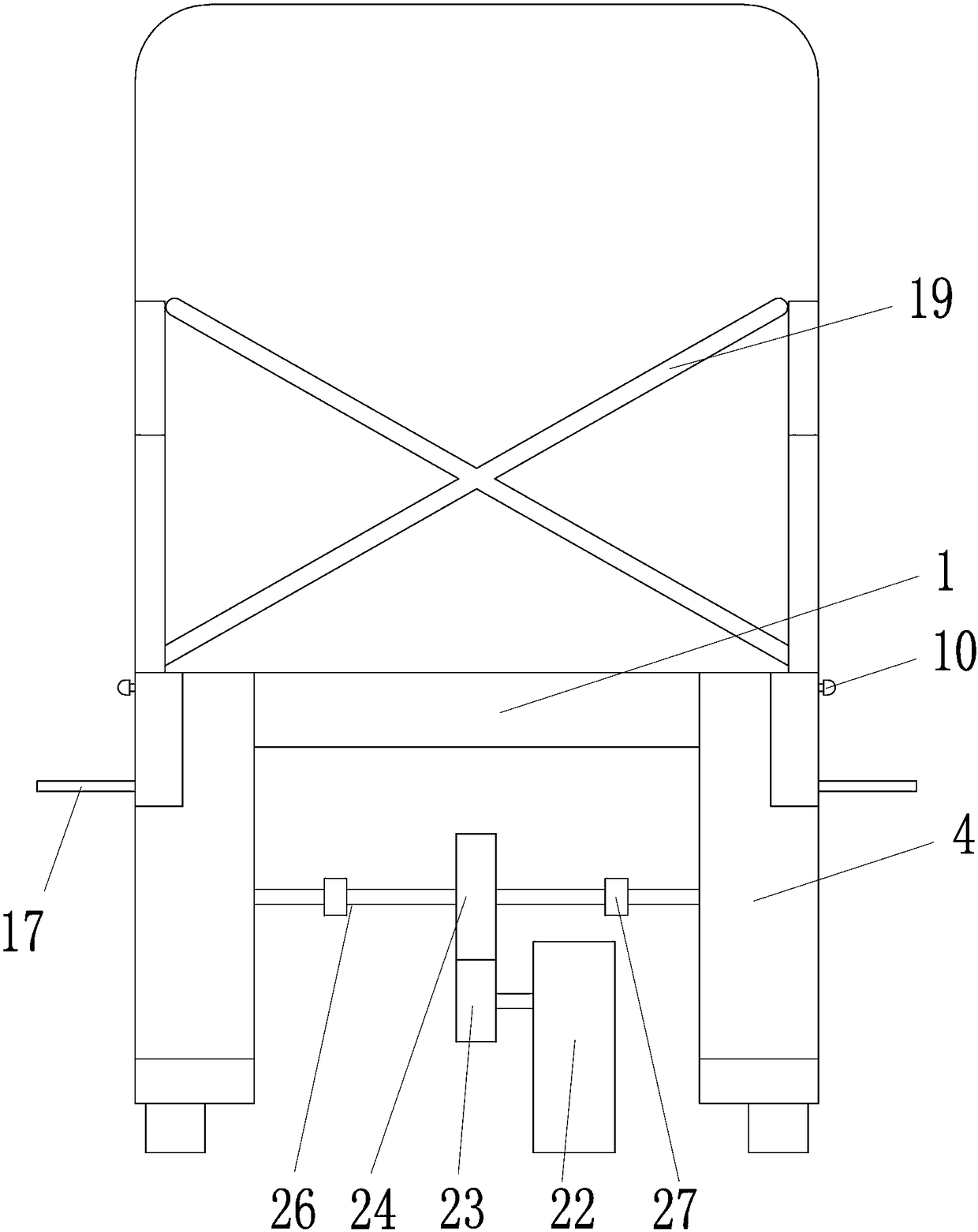

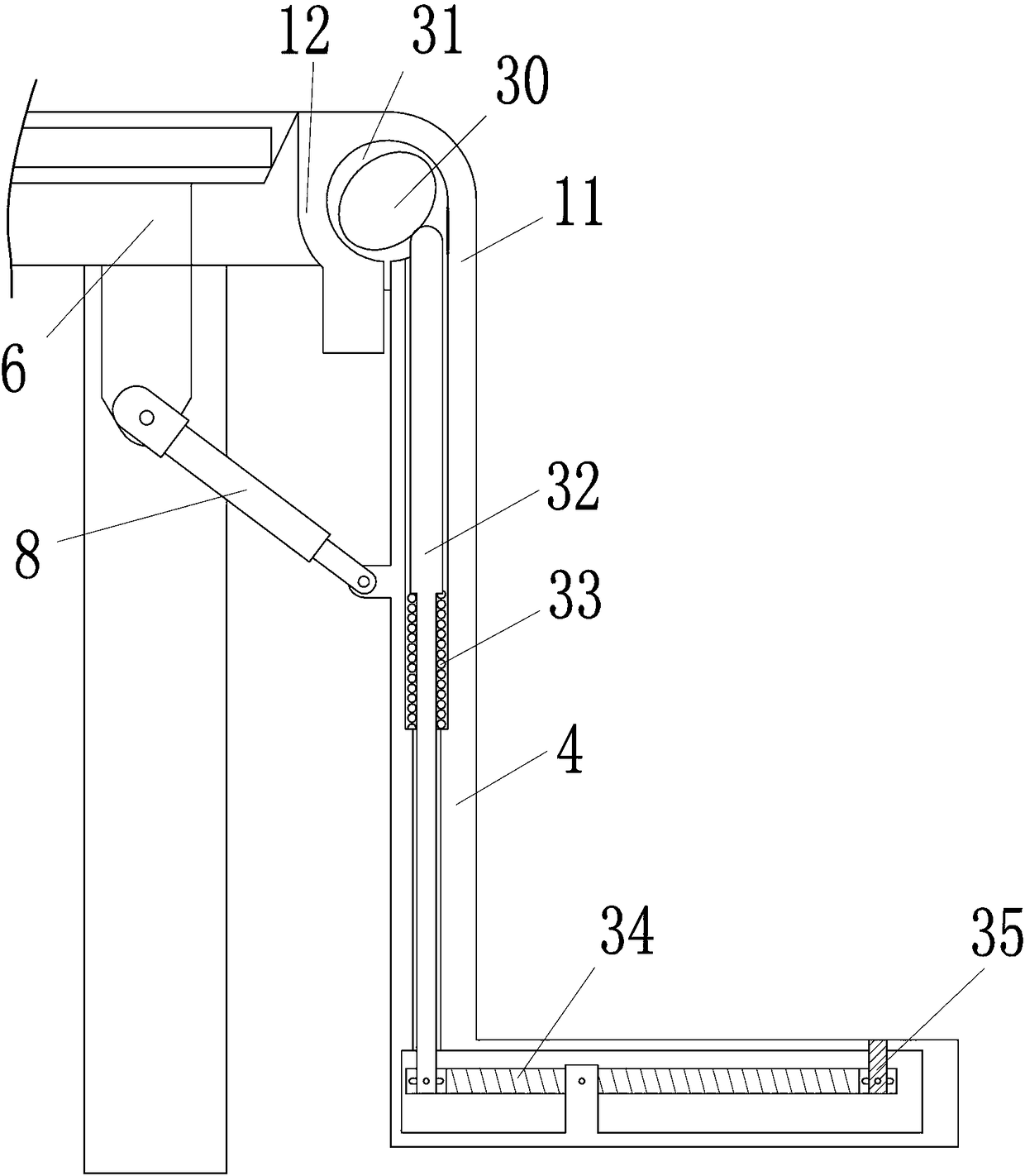

Rehabilitation instrument for neurosurgery department

InactiveCN108578169AIngenious structureEasy to useGymnastic exercisingChiropractic devicesMechanotherapyEngineering

The invention discloses a rehabilitation instrument for a neurosurgery department. The rehabilitation instrument effectively solves the problem that when a patient is under mechanotherapy, the nervoussystem and the limb movement can not be simultaneously treated. The rehabilitation instrument comprises a sitting plate; rotating holes are formed in the front end of the sitting plate; the rotatingholes are rotatably connected with a rotating shaft; the rotating shaft is fixedly connected with caliper splints; a switching mechanism is arranged in the caliper splints; sliding grooves are formedin the lower end face of the sitting plate; each sliding groove is connected with a rack in a sliding mode; one rack is fixedly connected with a supporting seat; the supporting seat is rotatably connected with an air support rod, and the other end of the air support rod is rotatably connected with one caliper splint; a power mechanism is arranged under the sitting plate; the sitting plate is internally provided with cavities positioned on the sliding grooves; a special-shaped rod is rotatably connected in each cavity; and a handle is arranged in each rotating hole. The rehabilitation instrument is ingenious in structure, convenient to use, and has more obvious and effective rehabilitation efficacy; through training, the speed of recovery of a user is accelerated; manufacturing is easy andproduction cost is lowered; andthe rehabilitation instrument is suitable for wide application, and is of great benefit to medical institutions and the patients.

Owner:THE FIRST AFFILIATED HOSPITAL OF BENGBU MEDICAL COLLEGE

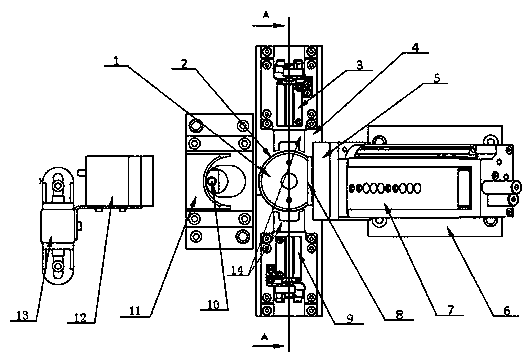

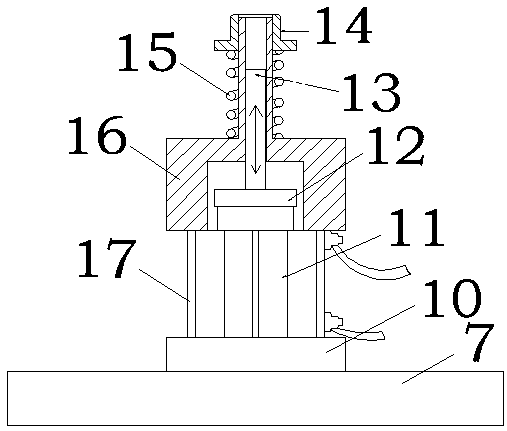

Automatic fitting fixture of connector

ActiveCN108110592AImprove work efficiencyImprove pass rateContact member assembly/disassemblyElectrical conductorEngineering

The invention discloses an automatic fitting fixture of a connector, wherein after being arranged in an insulator in a sleeving manner, an inner conductor is placed into a lower mold hole in the top of a lower mold pillar on a lower mold plate, the bottom end of the insulator is limited by the top end of the lower mold pillar, an outer shell is placed on a product carrier on the top of the lower mold pillar on the lower mold plate, after passing through an upper mold base, an expansion link of a fitting cylinder drives an upper mold pressing rod to move downwards, the upper mold pressing rod presses the outer shell to push the product carrier to move downwards along the lower mold pillar, the insulator is limited by the top end of the lower mold pillar to keep still, and thus the insulatoris embedded into the outer shell; a time relay controls the upper mold pressing rod to be retreated back after staying for a while, and controls a lower mold core cylinder via a sensing switch to drive a lower mold core to move upwards, and the top end of the lower mold core to prop up an inner conductor so as to be upwards inserted into the insulator; therefore, the automatic fitting can be completed, the production cost and investment can be reduced, and the production efficiency can be improved.

Owner:江苏华兴通讯科技有限公司

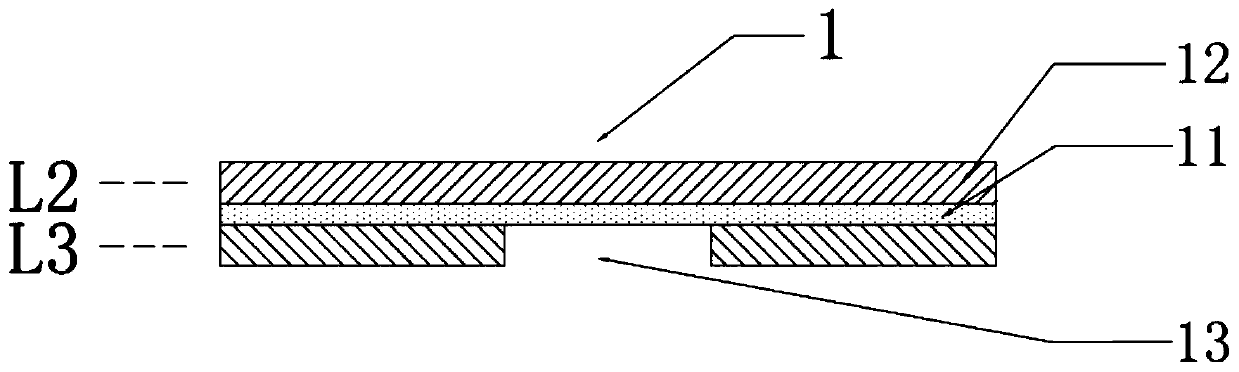

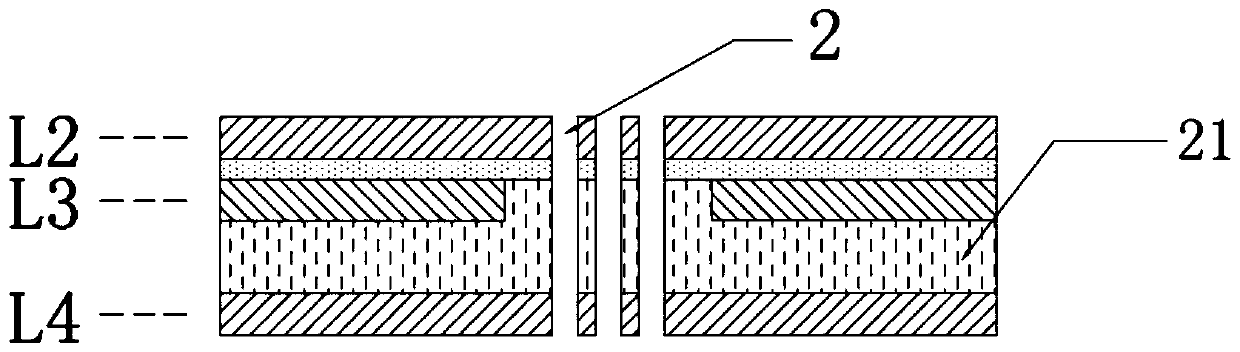

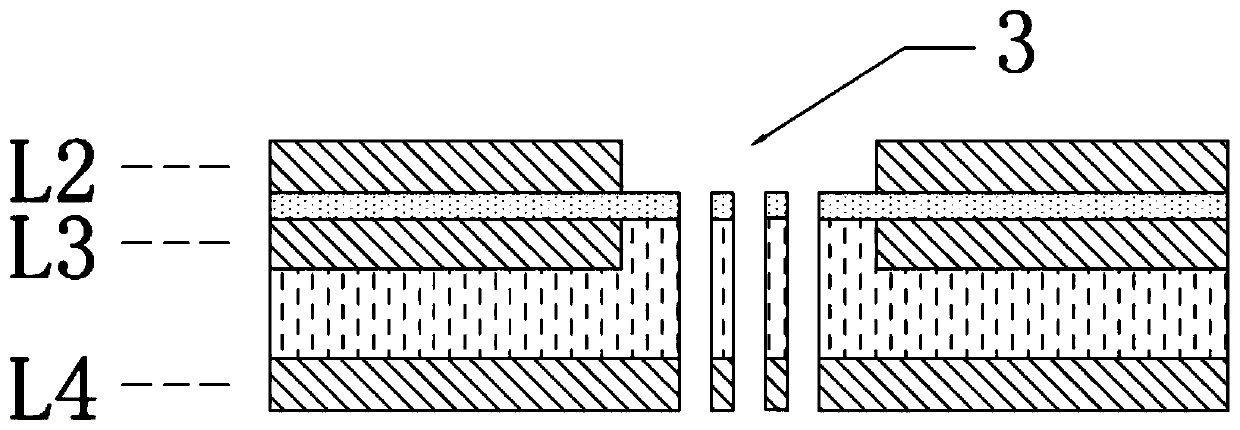

A method for manufacturing an MEMS microphone support plate with porous sound inlet and single-hole sound transmission

ActiveCN109862500AEliminate the placement processSimplify the placement processElectrostatic transducer microphonesSingle processMems microphone

The invention discloses a method for manufacturing an MEMS microphone support plate with porous sound inlet and single-hole sound transmission, and the method can omit a traditional microphone mounting process for realizing the cavity expansion of a sound transmission path through the chip mounting through a hole steel sheet through the design of embedding a sound cavity in the support plate, thereby simplifying the chip mounting process, and reducing the cost investment. Through the design of embedding the sound cavity in the support plate, the sound transmission sound cavity with high variability is formed in the sound path of the microphone, which is conducive to improving the frequency response and improving the performance of the microphone. Through the miniature porous design of thesound inlet sound hole, the sound inlet volume can be ensured, the dustproof effect is achieved, the butt joint with the chip through the single sound transmission hole in the embedded sound cavity isachieved, and the sound transmission performance of the microphone can be greatly improved; And the single-process production process is mature, the production cost investment is low, the improvementeffect is remarkable, and the performance of terminal products is improved.

Owner:JIANGSU PROVISION ELECTRONICS CO LTD

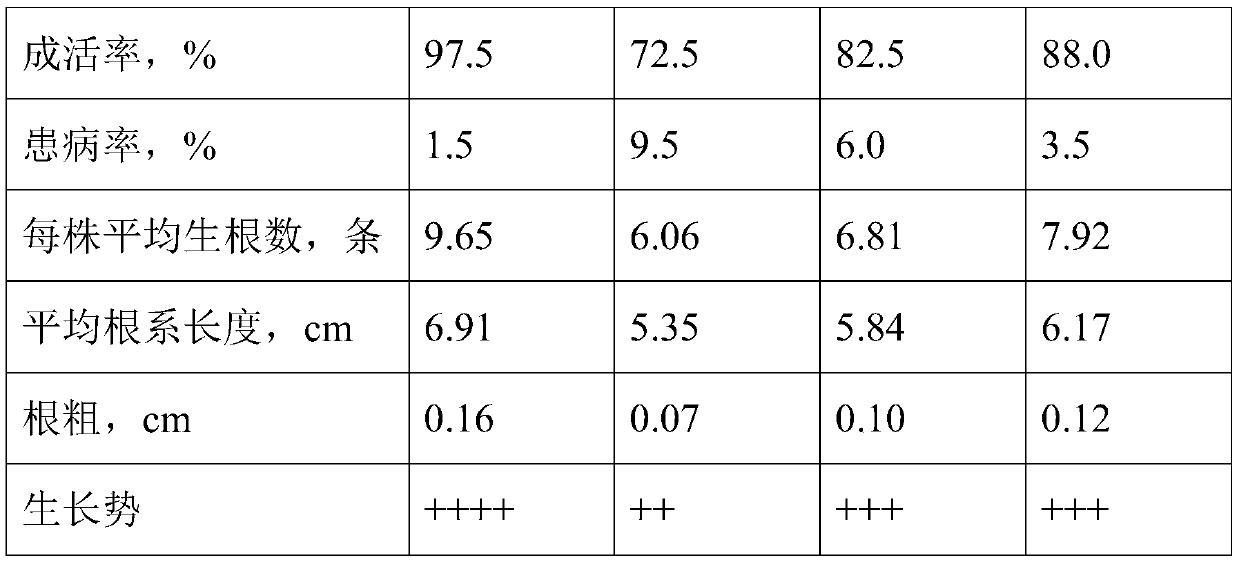

Cutting breeding method for Acer buergerianum Jinling Hong

InactiveCN106718751AIncrease production capacitySolve the technical problems of large-scale multiplicationGrowth substratesCulture mediaAnimal scienceGrafting

The invention discloses a cutting breeding method for Acer buergerianum Jinling Hong. According to the method, traditional grafting and tissue culture breeding modes are replaced by cutting breeding method; therefore, during the process of breeding Acer buergerianum Jinling Hong, workers can conveniently and quickly realize breeding with low cost; and the Acer buergerianum Jinling Hong can be bred on a large scale.

Owner:NANJING DENGBO BIOTECH

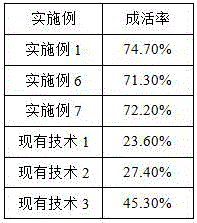

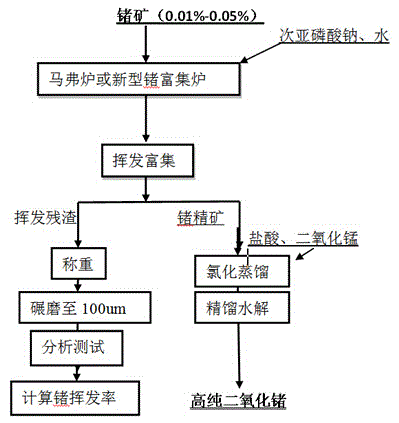

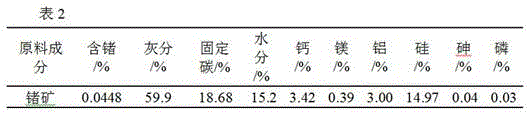

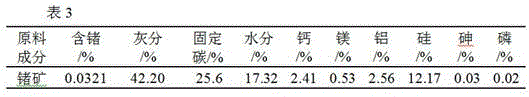

Method for extracting germanium by thermally reducing and volatilizing germanium ores

The invention discloses a method for extracting germanium by thermally reducing and volatilizing germanium ores, belongs to a germanium extracting method in the technical field of non-ferrous metallurgy, and in particular relates to a method for extracting the germanium by thermally reducing and volatilizing the germanium ores by taking sodium hypophosphite as a reducing agent. The method comprises the following steps: adding the sodium hypophosphite into the germanium ores, isolating air, increasing the temperature, roasting, volatilizing and gathering to obtain germanium concentrate, wherein the recovery rate of the germanium is higher than 96% during adding 2.5% of the sodium hypophosphite, roasting at 1000 DEG C, volatilizing and gathering. By virtue of the method, the main problems that in the prior art, the recovery rate difficultly exceeds 75% in the production process of enriching and extracting germanium from germanium ores through a pyrogenic process, the production cost for recycling germanium furnace slag through a secondary pyrogenic process is high, the recovery rate is low, and the wet-process treatment cost is high because of low quality of germanium concentrate can be solved.

Owner:YUNNAN LINCANG XINYUAN GERMANIUM IND +1

Rotational collecting method for vietnamese sophora root

ActiveCN103299788AQuality is not affectedGuaranteed reproductive capacityHarvestersSophora RootPlant roots

The invention relates to a rotational collecting method for a vietnamese sophora root, which comprises the following steps: (1) collecting half of the vietnamese sophora plant root in the harvest time; (2) applying the wound of the root and covering the root with soil; (3) collecting the other half of the root and processing the wound timely in the next year; and (4) repeating the collecting steps in the fifth year. According to the method provided by the invention, under the condition of not affecting the quality of vietnamese sophora root, the fertility of the vietnamese sophora root is guaranteed, and the yield of the vietnamese sophora root is greatly improved, and the method provides a development approach for the vietnamese sophora root.

Owner:安顺市宝林科技中药饮片有限公司

Production process of power-frequency encapsulated transformer

InactiveCN110164675AImprove qualityExtended service lifeEncapsulation/impregnationCoils manufactureCooking & bakingDoubling test

The invention belongs to the technical field of transformer application, and particularly discloses a production process of a power-frequency encapsulated transformer. The process comprises the following steps: 1, material taking; 2, primary winding; 3, secondary winding; 4, tin soldering; 5, appearance inspection; 6, turn-to-turn voltage withstand test; 7, silicon steel sheet assembling; 8, argonarc welding; 9, voltage withstanding test on a semi-finished product; 10, testing of the electrical performance of the semi-finished product; 11, assembling of a shell; 12, baking and drying; 13, automatic vacuum filling and sealing; 14, glue surface inspection; 15, inspecting of the appearance of a finished product; 16, frequency doubling and voltage doubling test of the finished product; 17, voltage withstanding test on the finished product; 18, testing of the electrical performance of the finished product; 19, packaging. The invention has the beneficial effects that the preparation processis reasonable in design; the prepared product is excellent in quality, long in service life and high in production efficiency; meanwhile, the rejection rate of the product is low, and the productioncost input of raw materials is saved.

Owner:NANJING ANSEN ELECTRONICS CO LTD

Preparation process for xylylene diisocyanate

InactiveCN103351313AHigh purityMeet the needs of processing and synthesisIsocyanic acid derivatives preparationOrganic compound preparationXylyleneFiltration

The invention specifically discloses a preparation process for xylylene diisocyanate, which belongs to the technical field of synthetic materials. The preparation process comprises the following steps: 1, with bis(trichloromethyl)carbonate and hydrochloride in a mass ratio of 1: 1.5-3 as reaction raw materials, controlling temperature to be -10 to 40 DEG C, introducing carbon dioxide, carrying out stirring for 15 to 30 m, then carrying out cooling and adding an inertial organic solution; 2, heating a reaction solution for a reaction, wherein air pressure is 0.1 to 1 Mpa and heating temperature is 60 to 100 DEG C; and 3, subjecting a prepared reaction solution to pressure reduction, filtration and distillation so as to obtain xylylene diisocyanate. The preparation process for xylylene diisocyanate provided by the invention overcomes the problems of low processing and synthesis efficiency, low purity and a complex method in the prior art and can rapidly and easily process and synthesize xylylene diisocyanate with high purity; meanwhile, the price of equipment used in processing and synthesis is moderate, so needs for processing and synthesis of middle and small-sized enterprises are met, and production cost investment of the enterprises is reduced.

Owner:TAICANG HENGYI MEDICINE CHEM MATERIAL FACTORY

Production process of high-frequency and high-voltage encapsulation vacuum transformer

InactiveCN110111989AImprove qualityExtended service lifeEncapsulation/impregnationTransformerHigh pressure

The invention belongs to the technical field of transformer application, and particularly discloses a production process of a high-frequency high-voltage encapsulation vacuum transformer. The method comprises the following steps of: the step 1, material receiving; the step 2, laser marking of a shell; the step 3, primary winding; the step 4, secondary winding; the step 5, foot winding; the step 6,peeling of skin by a laser; the step 7, appearance inspection; the step 8, tin soldering; the step 9, appearance inspection; the step 10, assembling of a magnetic core; the step 11, electrical performance test of a semi-finished product; the step 12, assembling of a housing; the step 13, baking and drying; the step 14, automatic vacuum encapsulation; the step 15, inspection of glue surface; the step 16, appearance inspection of a finished product; the step 17, test of pressure resistance of the finished product; the step 18, electrical performance test of the finished product; and the step 19, package. The preparation process is reasonable in design, the prepared finished product is good in quality, long in service life and high in production efficiency of the product, the production process is reasonable in design, the product rejection rate is low, and the product cost input of raw materials is saved.

Owner:NANJING ANSEN ELECTRONICS CO LTD

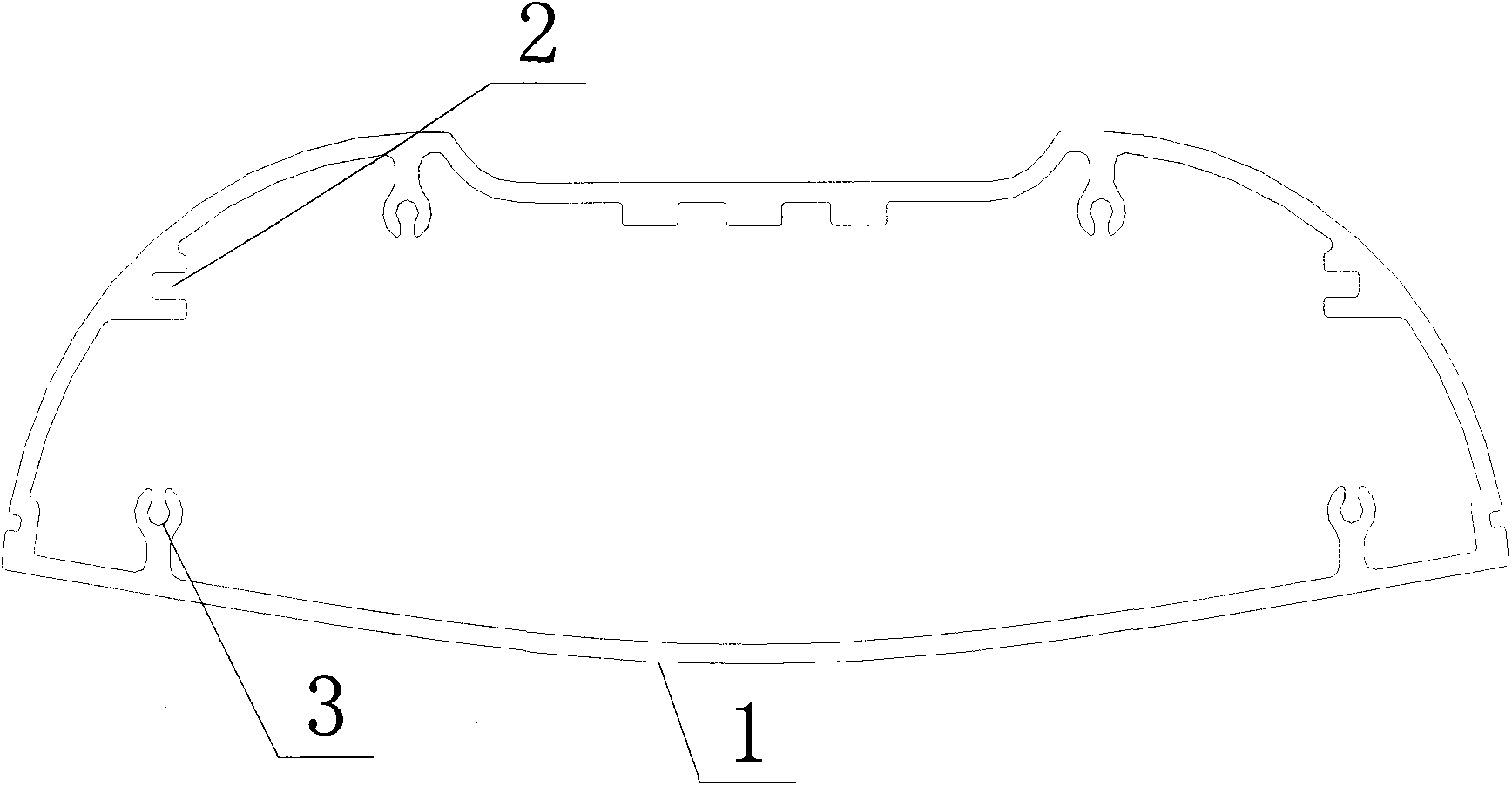

Method for manufacturing detection equipment shell and universal detection equipment shell

InactiveCN103934345AImprove versatilityReduce manufacturing costMeasurement apparatus housingsHollow articlesEngineeringAir channel

Provided is a method for manufacturing a detection equipment shell. Aluminum is adopted as a manufacturing raw material, and drawing and shaping are carried out through a drawing die; the cross section of the drawing die does not deform, the outer side of the drawing die is provided with air channel groove forming blocks used for forming of an air channel groove, and the air channel groove forming blocks are symmetrically disposed on the drawing die. According to the method for manufacturing the detection equipment shell, aluminum is adopted as the manufacturing raw material, drawing and shaping are carried out through the drawing die, the cross section of the drawing die does not deform, the outer side of the drawing die is provided with the air channel groove forming blocks used for forming of an air channel groove, and the air channel groove forming blocks are symmetrically disposed on the drawing die. The method has the advantages that universality of the equipment shell is improved, a shell die does not need to be redeveloped during updating of the equipment shell, and manufacturing cost of the equipment shell is greatly lowered. A universal detection equipment shell is manufactured in the method. By means of the method, production cost is reduced, universality is enhanced, and appearance uniformity is strong.

Owner:河北中康韦尔环境科技有限公司

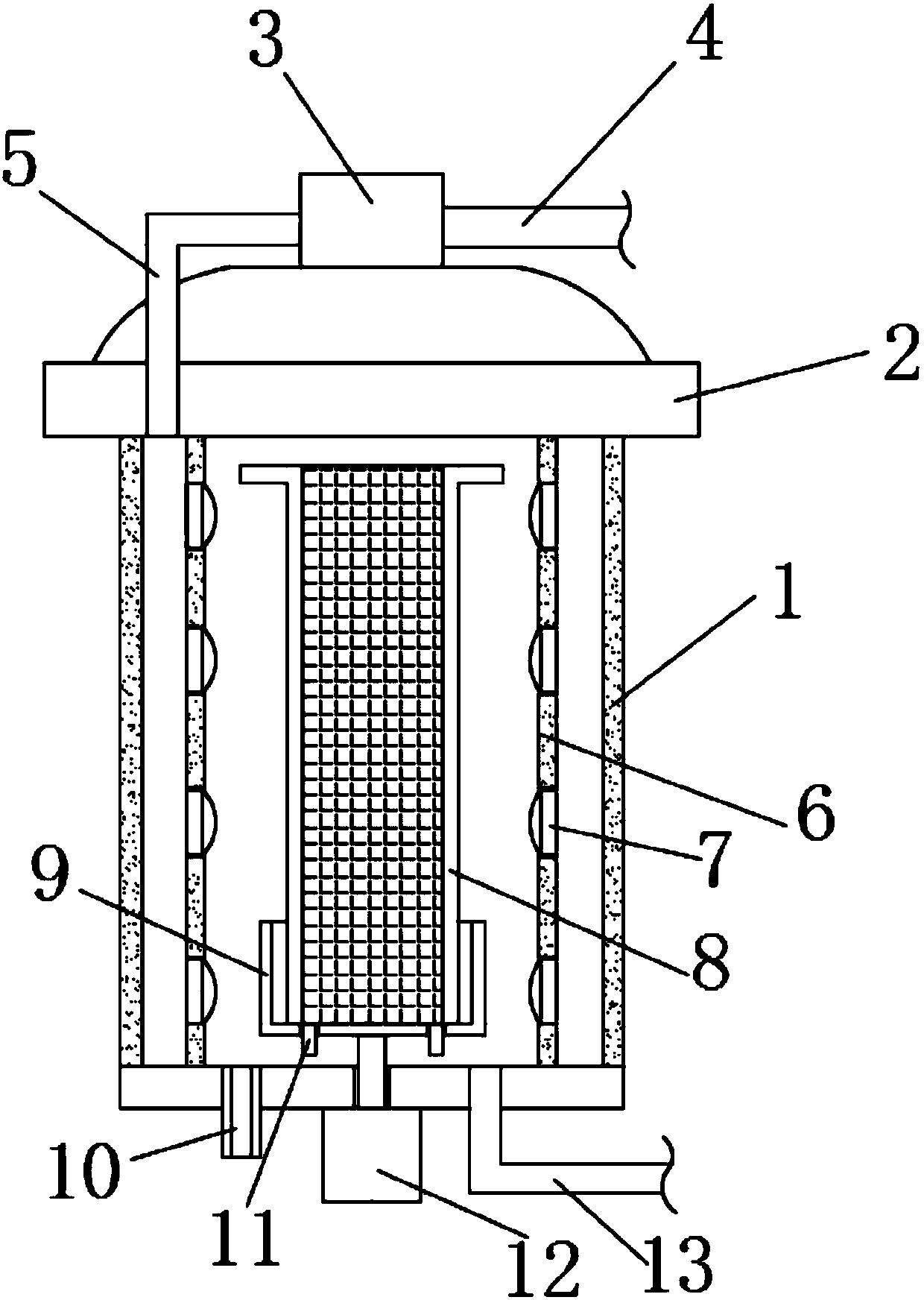

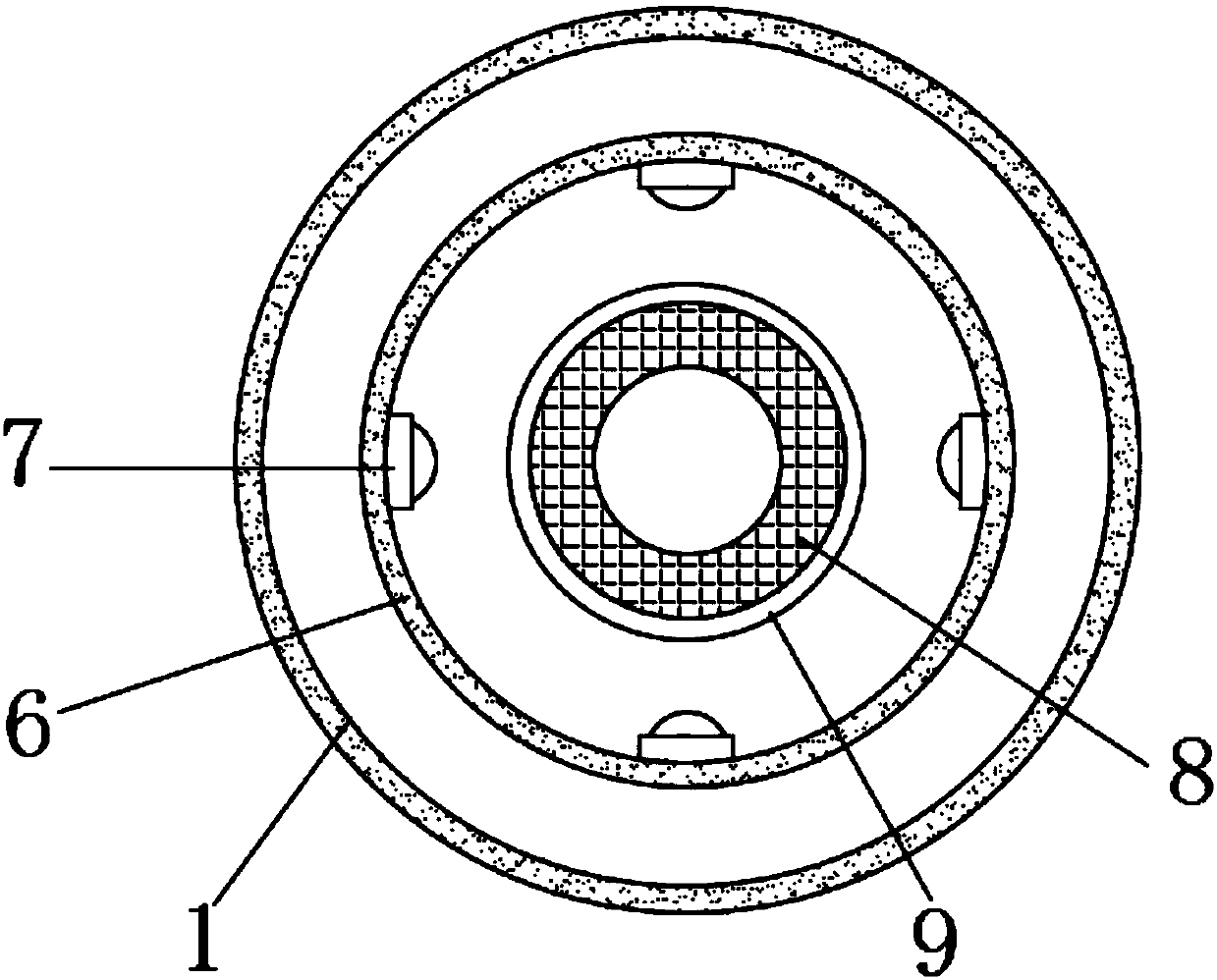

Full-automatic cleaning device for cloth printing and dyeing filter screen

InactiveCN110013707AReduce production cost inputImprove efficiencyFilter regenerationWater sourcePulp and paper industry

The invention discloses a full-automatic cleaning device for a cloth printing and dyeing filter screen. The full-automatic cleaning device comprises an outer cylinder; a cylinder cover is rotationallyconnected to the outer cylinder; an inner cylinder is arranged in the outer cylinder and the bottom end of the inner cylinder is fixed on the inner cylinder wall of the outer cylinder; an annular cavity is formed between the inner cylinder and the outer cylinder; a high-pressure pump is fixedly connected on the cylinder cover; the input end of the high-pressure pump communicates with a water inlet pipe; the output end of the high-pressure pump is fixedly connected with a connecting water pipe; and one end, far away from the high-pressure pump, of the connecting water pipe extends into the annular cavity. According to the device, the filter screen is placed into the cleaning cylinder which can rotated by 360 degrees, the filter screen is effectively cleaned through high-pressure spray heads vertically spraying water on the inner cylinder wall, and impurities on the filter screens are collected onto a filter plate of the cleaning cylinder, so that the collection treatment is facilitated. The cleaning water source is recycled water, so that the water source is conveniently saved. The cleaning degree is ensured by the device, and a large amount of manpower is not needed, so that manpower resources are not wasted, production cost investment of enterprises is reduced, and efficiency is high.

Owner:唐海元

Novel horizontal side cutting die

ActiveCN103394579AImprove pass rateReduce production cost inputMetal working apparatusGear systemKnife holder

The invention discloses a novel horizontal side cutting die which is composed of a die core module, a cutter holder system and a gear system. The die core module comprises a female dire core and a male dire core. The cutter holder system comprises a fixed cutter holder and a swinging cutter holder. The gear system comprises a gear box, a small gear and a large gear. The novel horizontal slide cutting die can reduce instant shear force on products in laterally cutting or punching the products. In punching, the shear force is even and stable so as to enable side cutting to be more accurate. Thus, the requirements of production enterprises are met, the yield of the products is improved, and production cost is reduced. Meanwhile, the novel horizontal side cutting die is simple to operate, reasonable in structure and easy to popularize.

Owner:OECHSLER PLASTIC PROD TAICANG

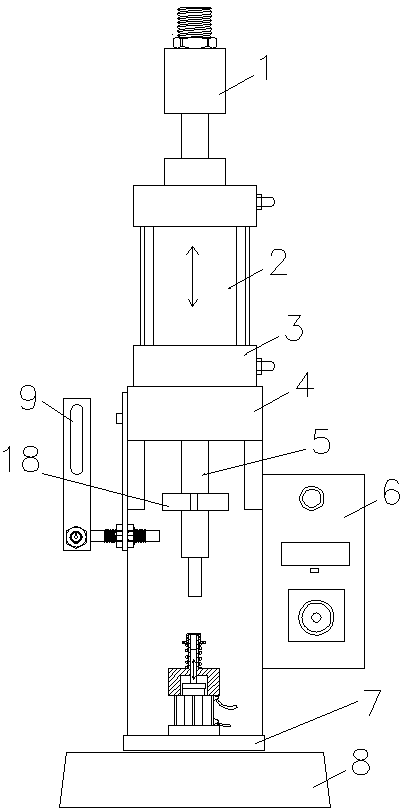

Limb rehabilitation instrument for surgery department

InactiveCN108403385AIngenious structureEasy to useChiropractic devicesPhysical medicine and rehabilitationSurgical department

A limb rehabilitation instrument for the surgery department effectively solves the problems that limb functions of patients cannot be recovered through medicine treatment and people need to cooperatively use an existing rehabilitation instrument. The rehabilitation instrument comprises a sitting plate, a leg support is rotationally connected to the front end hole of the sitting plate, and a switchmechanism for controlling the leg support to rotate is arranged in the leg support; a power mechanism for providing power for movement of the leg support is arranged on the lower surface of the sitting plate; handles for controlling the leg support to rotate are arranged on the left side and the right side of the sitting plate. The limb rehabilitation instrument is ingenious in structure and convenient to use, and a user can increase the recovery speed through training; other personnel are not needed for assistance in the using process; production and manufacturing are easy, the production cost and investment can be reduced, and the limb rehabilitation instrument is suitable for being used and popularized in a wide range and is beneficial for medical institutions and the patients.

Owner:QINGDAO MUNICIPAL HOSPITAL

Production process of low-frequency common mode choke

InactiveCN110136944AImprove qualityExtended service lifeInductances/transformers/magnets manufactureCooking & bakingElectricity

The invention belongs to the technical field of application of a low-frequency common mode choke and discloses a production process of the low-frequency common mode choke. The production process comprises the following steps: 1) material collection, preparation before production and preparation of all raw materials required for production of claimed products; 2) primary side winding; 3) secondaryside winding; 4) foot winding; 5) soldering; 6) appearance inspection; 7) magnetic core assembly; 8) magnetic core fixation; 9) electrical performance inspection of semi-finished products; 10) insulating varnish dipping; 11) baking and drying; 12) appearance inspection of finished products; 13) withstand voltage test of the finished products; 14) electrical performance inspection of the finished products; and 15) packaging. The beneficial effects are that the preparation process is reasonable in design; the prepared low-frequency common mode choke is excellent in quality and long in service life, and product production efficiency is high; and meanwhile, through the reasonably designed production process, product rejection rate is low, and raw material production cost is saved.

Owner:NANJING ANSEN ELECTRONICS CO LTD

Seedling growing method capable of improving disease resistance

InactiveCN111108926AWater retentionImprove disease resistanceGrowth substratesCulture mediaAxillary budVegetable oil

The invention discloses a seedling growing method capable of improving disease resistance. The seedling growing method comprises the following steps that rice straw, corn straw and pine branches are burned to obtain ash, then sand and clay are added, even mixing is carried out, and granulating is carried out to obtain pre-made seedling soil; sodium carboxymethylcellulose, microcrystalline cellulose, vegetable oil and water are stirred evenly, anhydrous ethanol and sepiolite are added, and even stirring is carried out to obtain a binder; the pre-made seedling soil is rolled and preheated to 50-60 DEG C, then the binder is sprayed onto the surfaces of particles of the pre-prepared seedling soil, even stirring is carried out, drying is carried out at 100-110 DEG C until the water content is 4-10wt%, and composite seedling soil is obtained; the robust branches are cut into cuttings with 2-3 axillary buds, the upper ends of the cuttings are cut flat, the lower ends of the cuttings are cut to 45 degrees, then lower end cuts are soaked with clear water, and then the lower end cuts are soaked in a rooting agent after disinfected; and the treated cuttings are vertically stuck in the composite seedling soil for planting cultivation, the environment temperature is 20-24 DEG C, the environmental humidity is 65-70%, and the seedlings are taken out of a nursery.

Owner:范书豪

Potato and late rice double-no-tillage cast transplanting planting method

PendingCN108967100AAlleviate the tension in the connectionEfficient use ofRoot crop cultivationPlant protective coveringsEconomic benefitsSolanum tuberosum

The invention discloses a potato and late rice double-no-tillage cast transplanting planting method, belonging to the field of agricultural production. The method mainly comprises the following stepsof (1) potato no-tillage cultivation including (a) fine breed selection, (b) ditching and raking, (c) potato seed processing, (d) reasonable close planting and the application of enough base fertilizer, (e) covering with straws, (f) field management, and (g) timely harvest, and (2) late rice no-tillage cast transplanting including (a) breed selection, (b) seedling cast transplanting, (c) field management including scientific fertilization, reasonable irrigation, timely weeding and the prevention and control of pests and diseases, and (d) timely harvest. The method provided by the invention hasan obvious influence on the economy, yield and economic benefit of rice, the yield of late rice can be obviously increased, and the method has the characteristics of reducing labor intensity, savingcost and increasing efficiency, increasing production and income, and being simple and easy.

Owner:INST OF SOIL FERTILIZER & RESOURCE ENVIRONMENT JIANGXI ACAD OF AGRI SCI

Environment-friendly bundling agent

InactiveCN106283639ASimple preparation processReduce production cost inputFibre treatmentSodium bicarbonatePhosphate

The invention discloses an environment-friendly bundling agent. The environment-friendly bundling agent is prepared from, by weight, 4-12 parts of mono-dodecyl phosphate triethanolamine, 2-10 parts of an anionic surfactant, 16-24 parts of a nonionic surfactant, 0.2-0.6 part of sodium bicarbonate, 0.2-0.6 part of an environment-friendly lubricating agent and 60-80 parts of water. By using the biodegradable environment-friendly surfactants, the environment-friendly bundling agent is nontoxic, harmless, green, environmentally friendly, simple in preparation technology and low in production cost input.

Owner:SUZHOU LEO BIOTECH

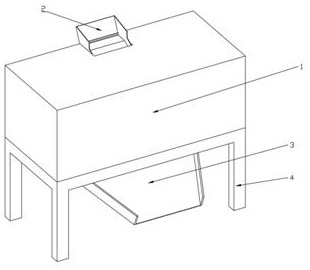

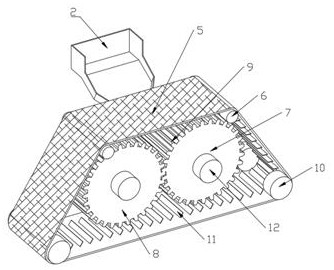

Casting molding sand recycling, crushing and screening device

InactiveCN112264130AEasy for secondary crushingImprove crushing effectGrain treatmentsElectric machineryStructural engineering

The invention discloses a casting molding sand recycling, crushing and screening device. The casting molding sand recycling, crushing and screening device comprises a crushing box body, wherein a feeding hopper is arranged at the upper end of the crushing box body, a discharging hopper is arranged in the middle of the lower end of the crushing box body, and the four corners of the lower end of thecrushing box body are fixedly connected with the same rack. According to the casting molding sand recycling, crushing and screening device, driving crushing teeth and driven crushing teeth in a crushing cavity are meshed with each other, so that molding sand is crushed in time; meanwhile, a plurality of material returning guide plates on the inner wall of a conveying screen net are used for conveniently conveying the molding sand which is not completely crushed to a crushing position for secondary crushing, so that the molding sand is prevented from being not completely crushed at a time, andthe crushing effect is improved; and meanwhile, a single driving motor runs, a driving roller and a driven roller in the crushing cavity are driven to run through belt transmission, so that the driving crushing teeth and the driven crushing teeth carry out crushing operation, meanwhile, the belt drives the conveying screen net to work, and the production cost investment is reduced.

Owner:含山县永帮再生资源利用有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com