Patents

Literature

180results about How to "Save foreign exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of alloy tubular product

ActiveCN102527724AC, low content of NGuaranteed corrosion resistanceFurnace typesMetal rolling arrangementsChemical industrySolution treatment

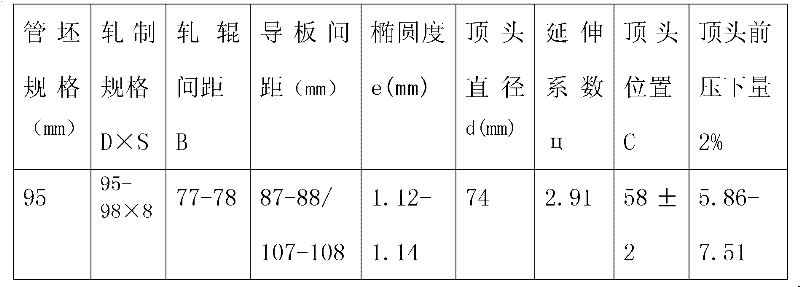

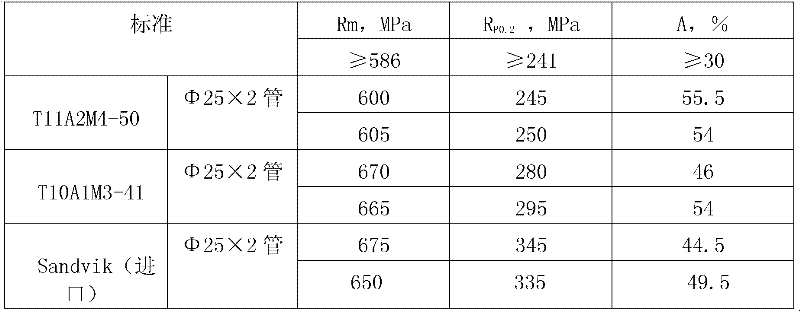

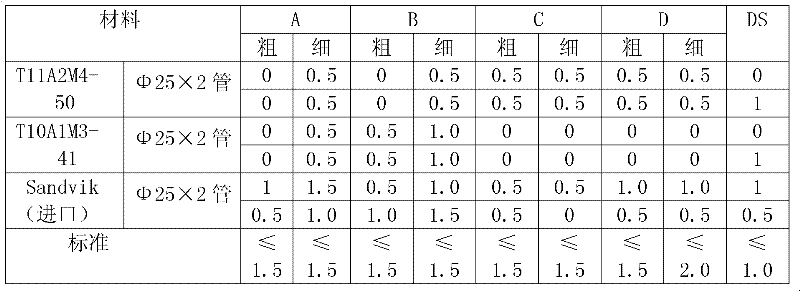

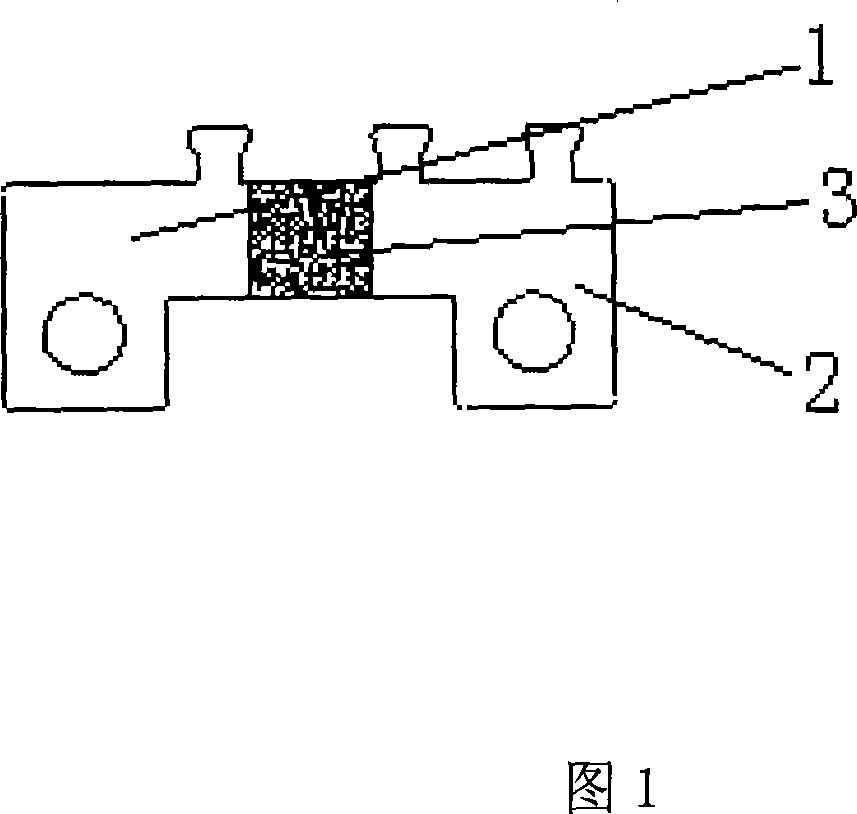

The invention discloses a manufacturing method of an alloy tubular product. The manufacturing method is characterized in that the method comprises the the steps of melting NS1402 alloy steel to be made into rods; sawing the rods into short cut materials, centering the short cut materials, and manufacturing the short cut materials into centering materials; heating the centering materials to the temperature being 950 DEG C, keeping the temperature for 20-30min, then heating the centering materials to the temperature being 1100 DEG C-1120 DEG C, and keeping the temperature for 15-20min, and subsequently, conducting hot punching on the centering materials to be manufactured into a tube blank; rolling the tube blank by 1 to 5 passes so as to manufacture the tube blank into a cold rolled tube; and conducting protective atmosphere solution treatment on the cold rolled tube to manufacture the alloy tubular product. Due to the adoption of the method, the production process is relatively simple, the yield is high, the production cost is low, the performance of the tubular product is good, and the produced alloy tubular product can be widely applied to the fields such as oil, chemical industry and the like.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Electric wire and cable for flexible composite drag links and manufacturing process thereof

InactiveCN101140815ACompact structureSmall footprintFlexible cablesCable/conductor manufactureBatch productionUnevaluable

The invention belongs to the technical field of wire and cable, especially relating to wire and cable for a flexible composite towline and its manufacturing process, which comprises a conductor, cable materials and stuffing. The cable materials are set outside of the conductor and stuffing. The conductor is a copper conductor while the stuffing is polypropylene reticular tearing fiber. The said cable materials is the insulating compound and covering materials which is composed of polyvinyl chloride soft packing, butyronitrile compound and elastomer. The cable provided in the invention has the advantages of compact structure in reason with less space occupation, outstanding flexibility in continuous bending and low price. The successful development of the wire and cable for flexible composite towline supplies a gap in domestic production. Batch production of the cable not only creates a business opportunity for enterprises, but also drives the same trades to make batch production of the wire and cable for the flexible composite towline, which brings invaluable economic efficiency of enterprises and inestimable social benefit.

Owner:SHENYANG SHIELDING CABLE

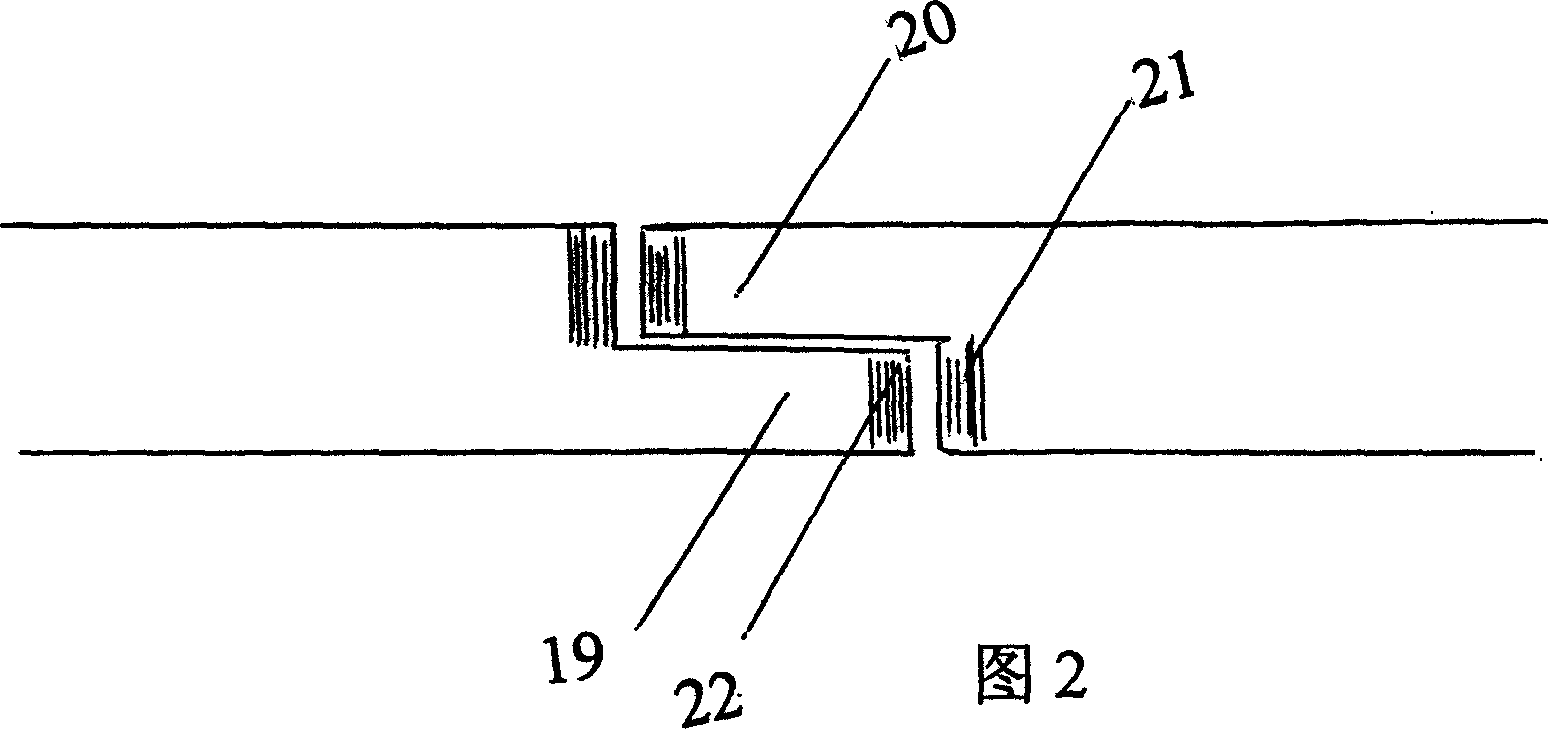

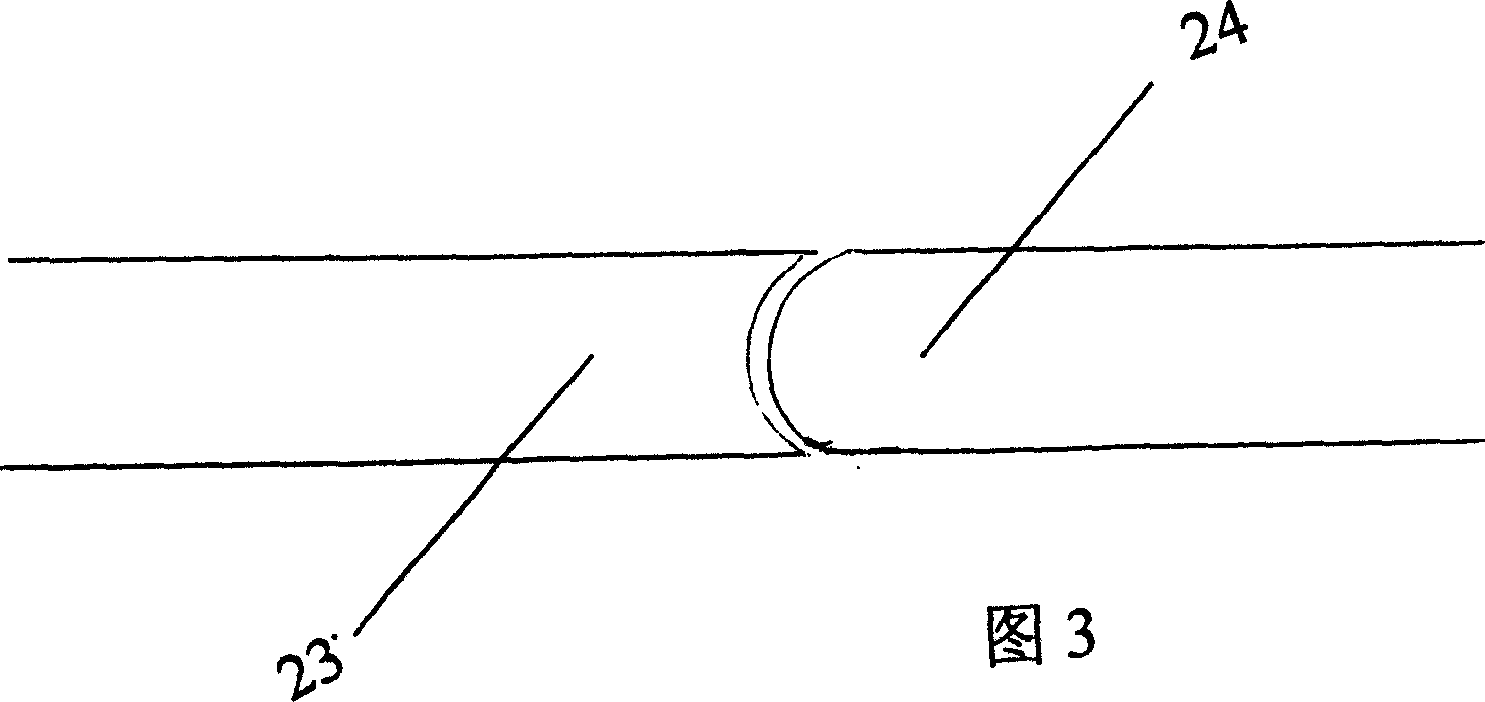

Forming method of current divider

InactiveCN101097232AReduce feverSmall temperature coefficientTime integral measurementElectrical resistance and conductanceShunt Device

The invention discloses a forming method of diverter used in electric energy meter, specially a forming method of diverter made by resistance metal material and conducting metal material. The purpose of the invention is providing a forming method of diverter whose operation is easy, performance is stable, and efficiency is high. The method includes three steps of selecting material, welding and punching figuration. The forming method of diverter possesses characters that course of production is unpolluted, precision is high.

Owner:TONGXIANG WEIDA ELECTRONICS

Chromium-free waterborne corrosion resistant coating used for surface of metal and preparation method thereof

ActiveCN101693811AImprove compactnessLower electrode potentialAnti-corrosive paintsChromium freeSolvent

The invention relates to a chromium-free waterborne corrosion resistant coating for the surface of metal and a preparation method thereof. The chromium-free waterborne corrosion resistant coating comprises the following components in percentage by mass: 15-33 flaked zinc powder, 2.5-8 flaked aluminium powder, 13.5-24 solvent, 0.2-2.5 assistant, 14-22 first silane coupling agent, 2-6 second silane coupling agent, 0.05-1.5 nano SiO2,0.03-1.2 nano TiO2, 0.02-1.5 nano ZrO2, 0.3-1 silver salt, 0.1-0.3 polyaniline, 0-0.6 tackifier and the balance of H2O, wherein the first silane coupling agent is a bi-[Gamma-(triethoxysilane) propyl] tetrasulfide; and the second silane coupling agent is a Gamma-aminopropyltriethoxysilane or Gamma-methacryloxypropyl trimethoxysilane. The coating contains no chromium and has corrosion resistance according with an international newest metal surface corrosion prevention technology.

Owner:CHANGZHOU JMT SURFACE ENG TECH

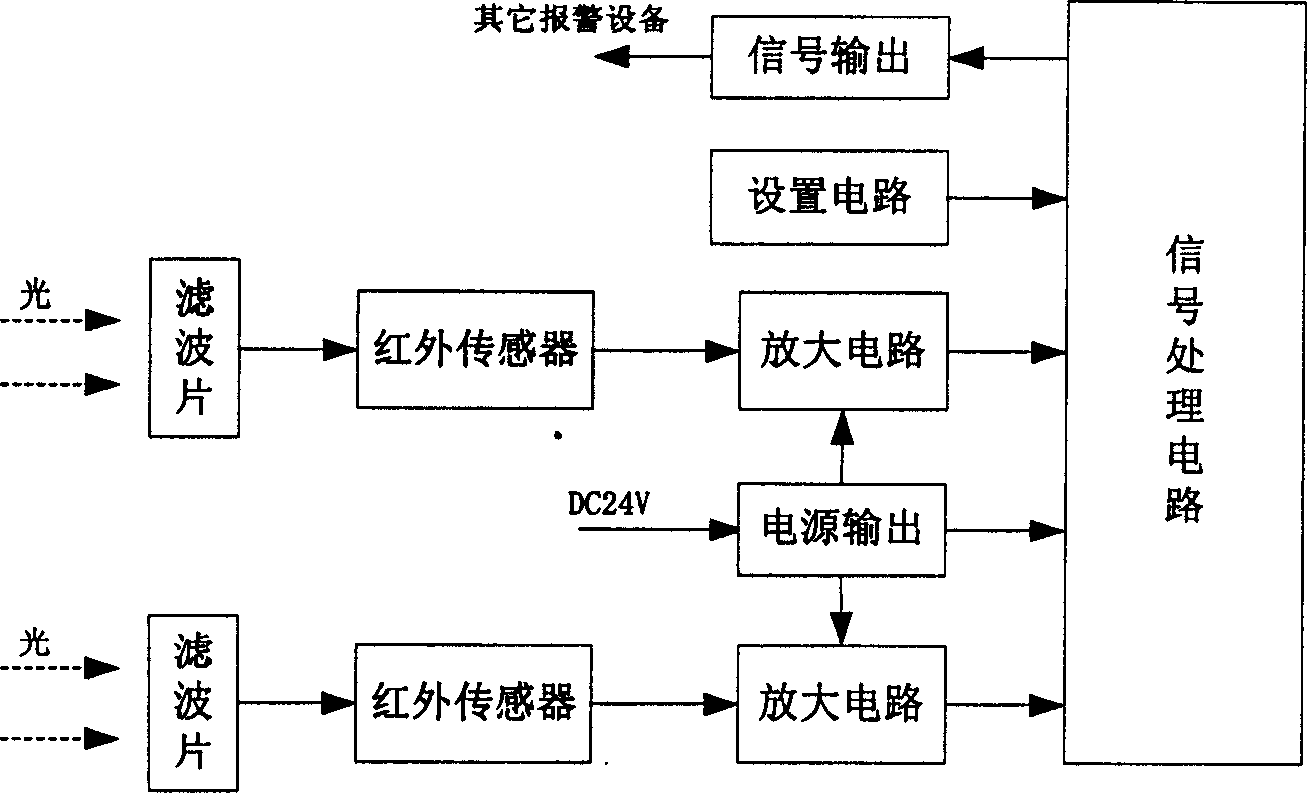

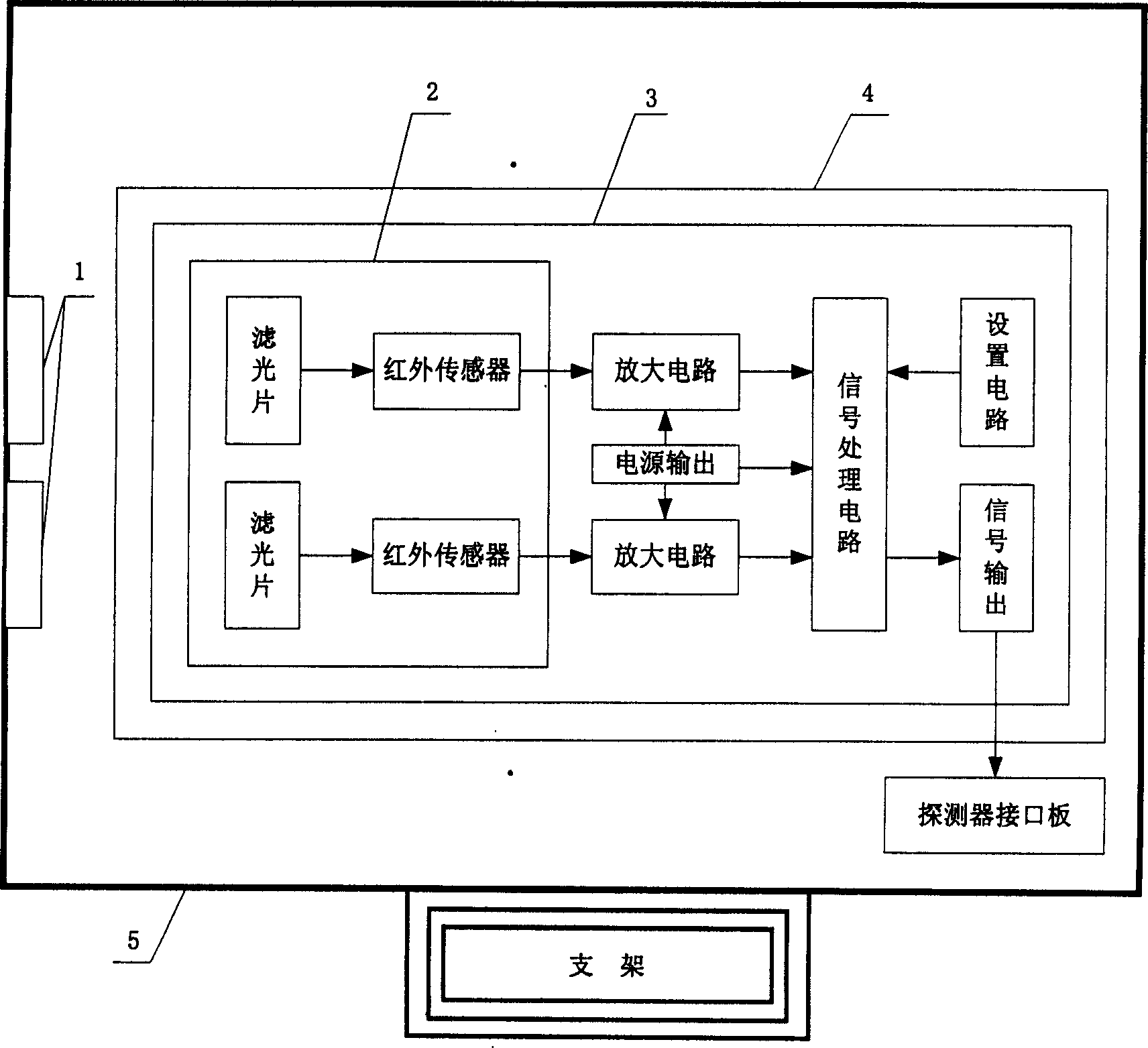

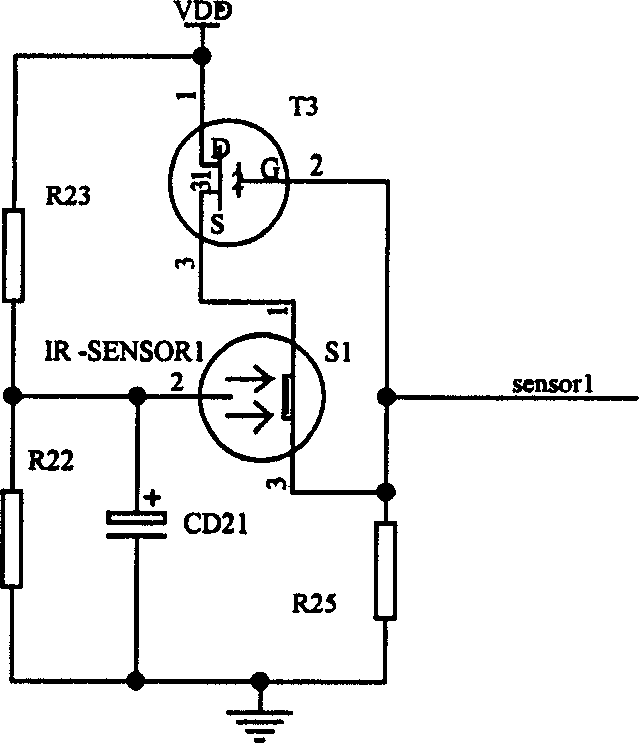

Bi wave band infra red flame detector and its detecting method

InactiveCN1719481ALow costReduce lossesFire alarm radiation actuationSignal processing circuitsFilter (signal processing)

The present invention relates to a double-waveband infrared flame detector and its detection method. Said detector includes supporting frame, external shell, protective lens, filter, infrared sensor, amplification circuit, signal processing circuit, power supply conversion circuit, signal output circuit, internal and external shielding covers,detector interface plate and setting circuit. Said invention also provides its working principle and concrete steps of its detection method.

Owner:SHENYANG FIRE RES INST OF THE MIN OF PUBLIC SECURITY

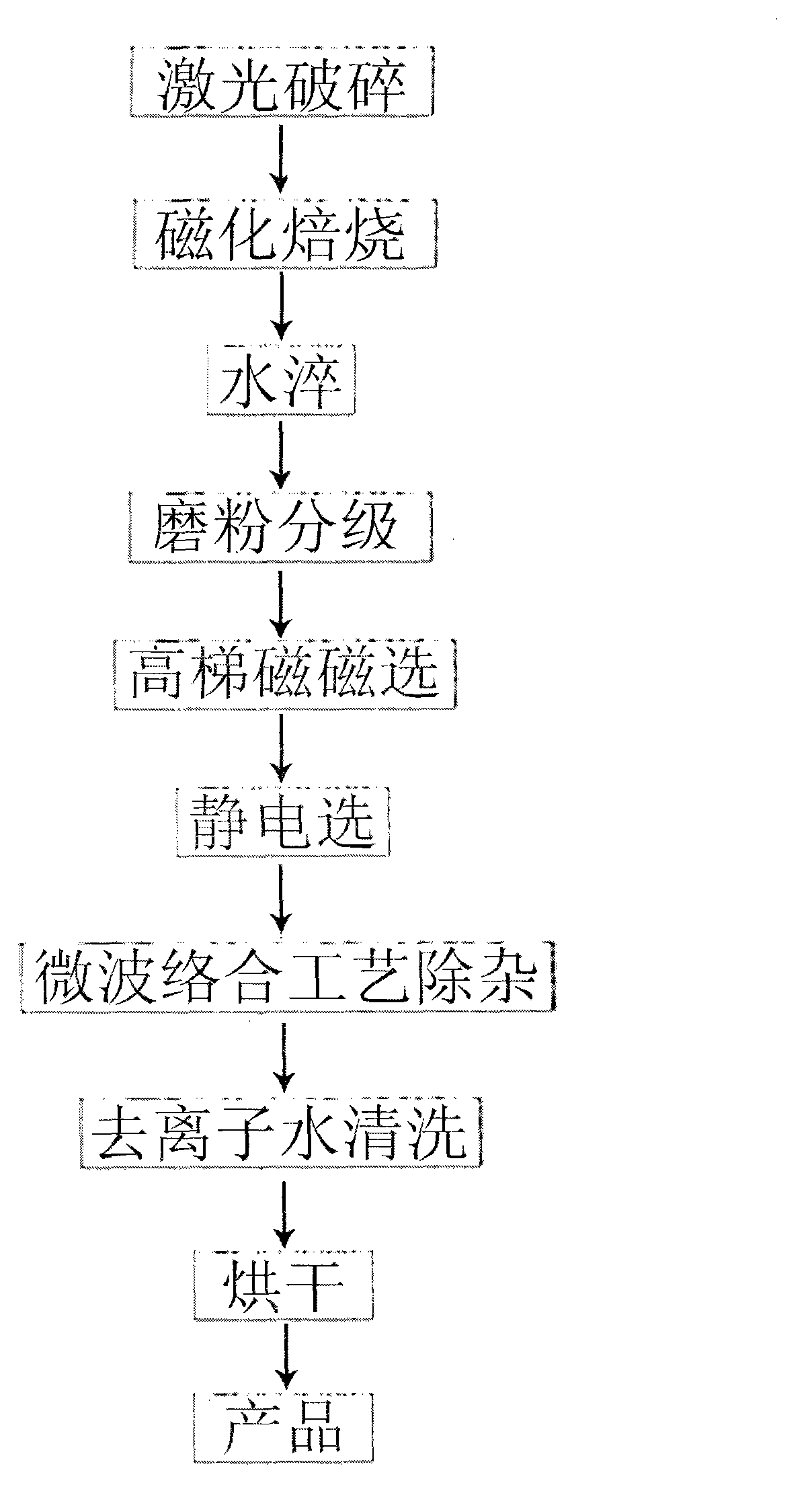

Process for preparing high-purity quartz from vein quartz

The invention discloses a process for preparing high-purity quartz from vein quartz, which comprises the steps of raw vein quartz ore selection, laser fracturing, electromagnetic roasting, water quenching, pulverization and grading, high-gradient magnetic separation, electrostatic separation, impurity removal based on a microwave complexing method, deionized water cleaning and drying. According to the invention, the process flow and structure are reasonable, the technology is advanced, efficient and easy to control, the impurity removal is targeted, high in quality index and favorable in stability; and the high-purity ultrafine quartz material can be used in such high and new technical fields as novel electric light sources, high-insulation sealing, aerospace instruments, war industry technical products, micro electronics, high-grade optical glass, quartz crucible main materials, quartz tubes and quartz rods.

Owner:刘少云

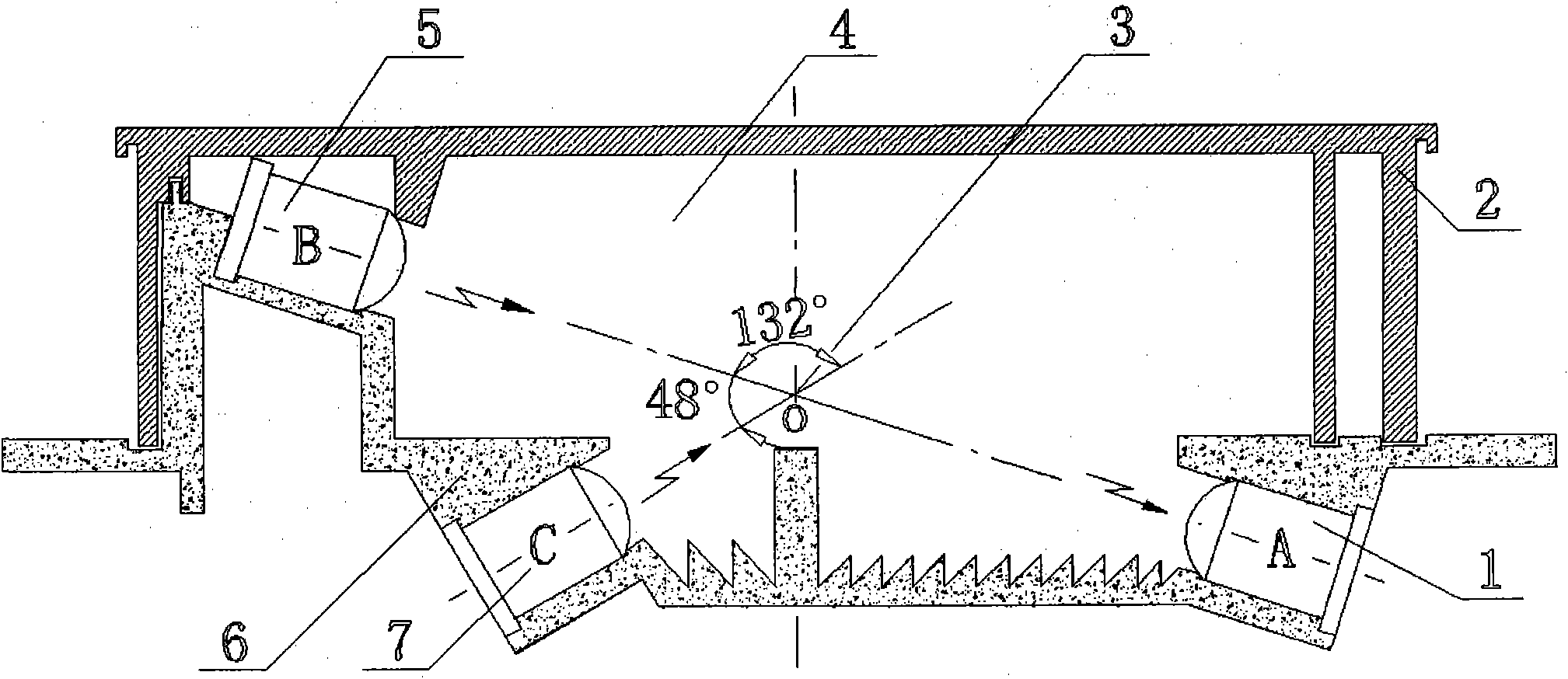

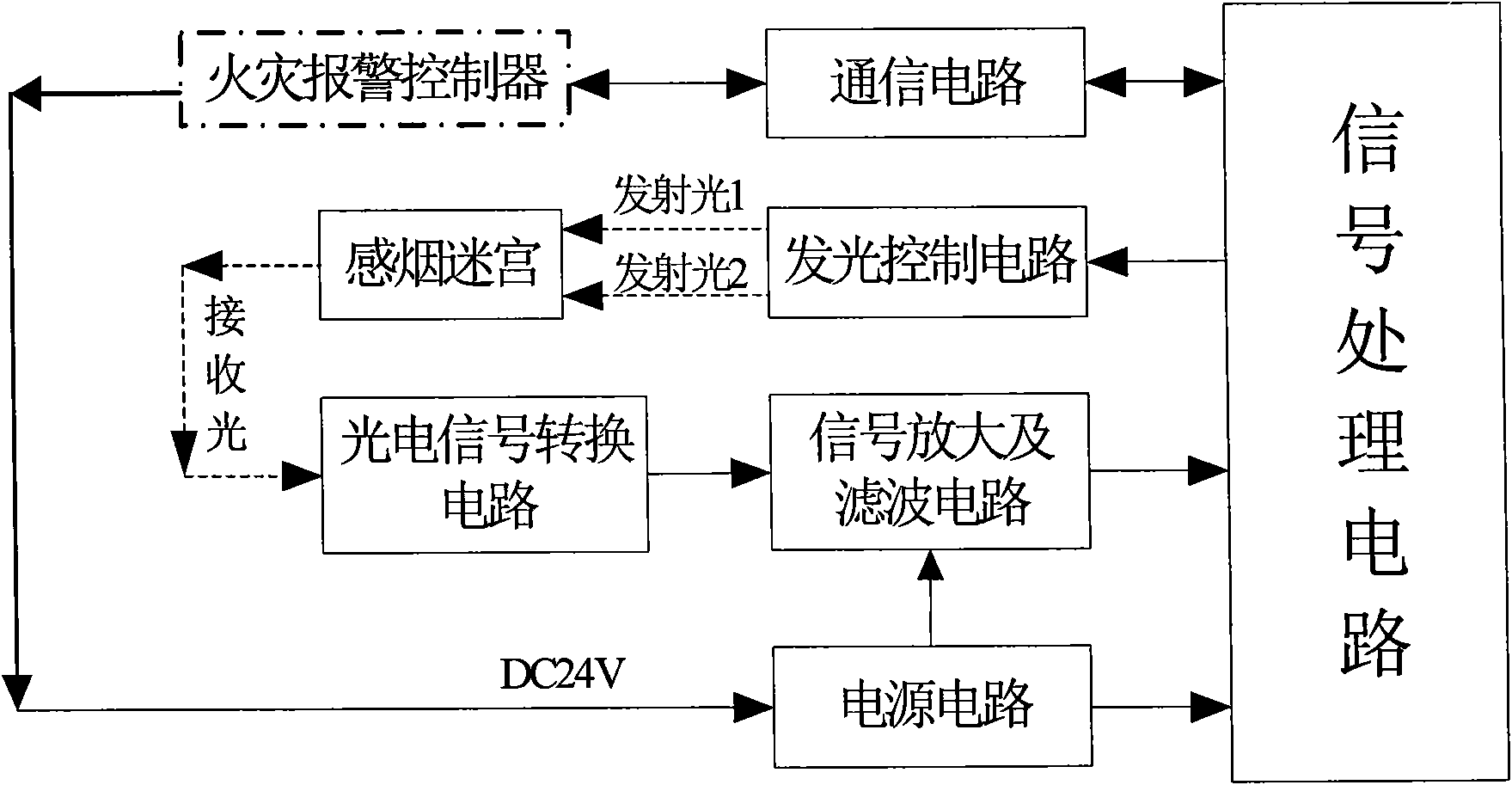

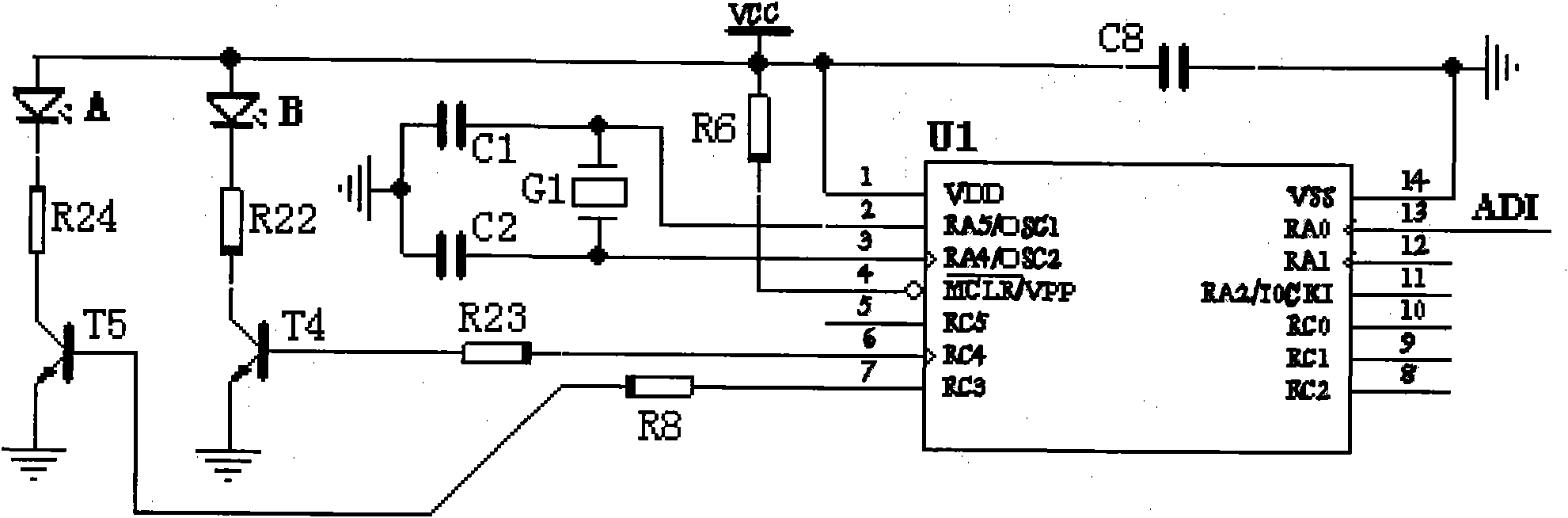

Obscuration-forward scatter composite spot-type photoelectric smoke fire detector and detection method thereof

InactiveCN101859469AWell-balanced sensitive response performanceImproving the ability of early fire detection and alarmFire alarmsForward scatterFire detector

The invention relates to an obscuration-forward scatter composite spot-type photoelectric smoke fire detector and a detection method thereof, belonging to the technical field of fire detection. The detector of the invention comprises a smoke-sensing maze. The device is characterized in that the inside of the smoke-sensing maze is provided with a first infrared LED, a second infrared LED and an infrared receiving tube, wherein the angle COA using the center of the smoke-sensing maze as angular point between the second infrared LED and the infrared receiving tube is 123-139 degrees, the angle BOA using the center of the smoke-sensing maze as angular point between the first infrared LED and the infrared receiving tube is 180 degrees, and the first infrared LED, the second infrared LED and the infrared receiving tube are separately connected with a control circuit. The detection method comprises the following steps: ensuring an infrared LED C to light for 100mu S while sampling the forward scatter smoke current value; and ensuring an infrared LED B to light for 100mu S while sampling the obscuration smoke current value; and perform forward scatter smoke-sensing and obscuration smoke-sensing multisensor / multiple-criteria fire determination, and performing initial value compensation every four hours.

Owner:SHENYANG FIRE RES INST OF THE MIN OF PUBLIC SECURITY

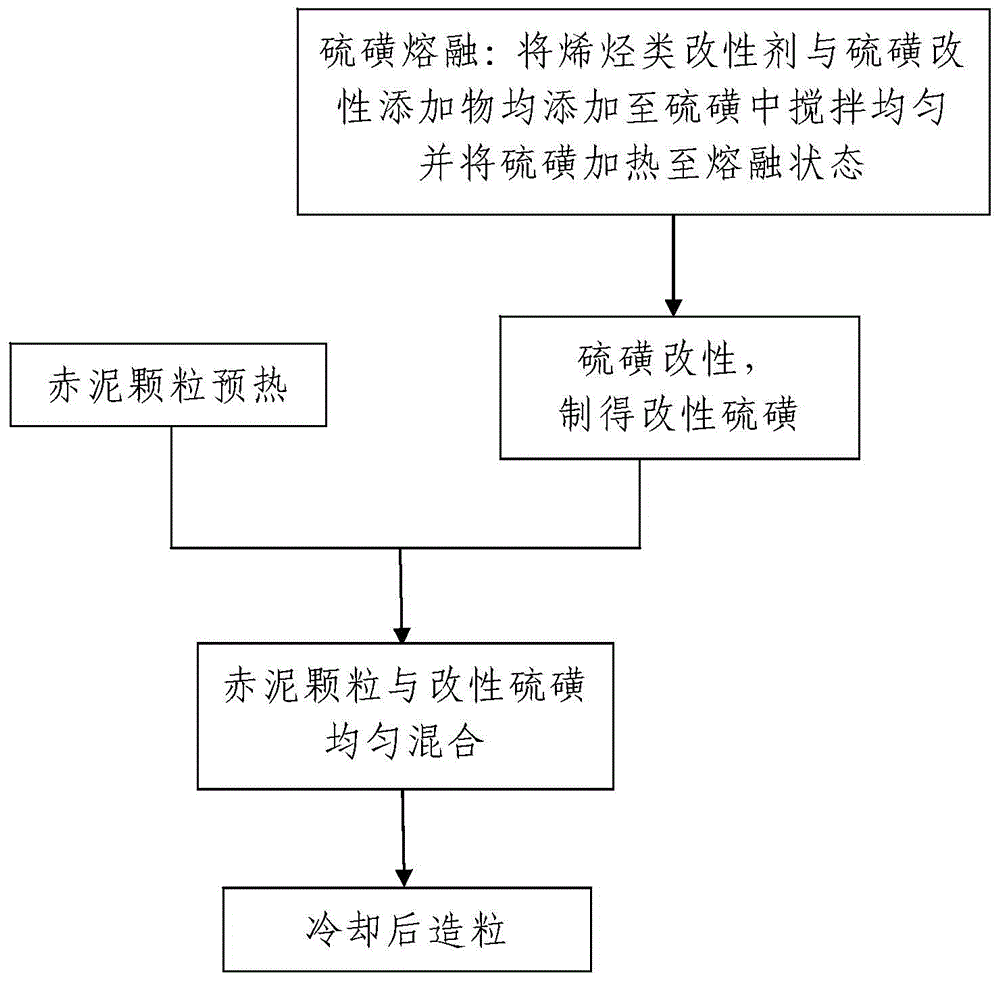

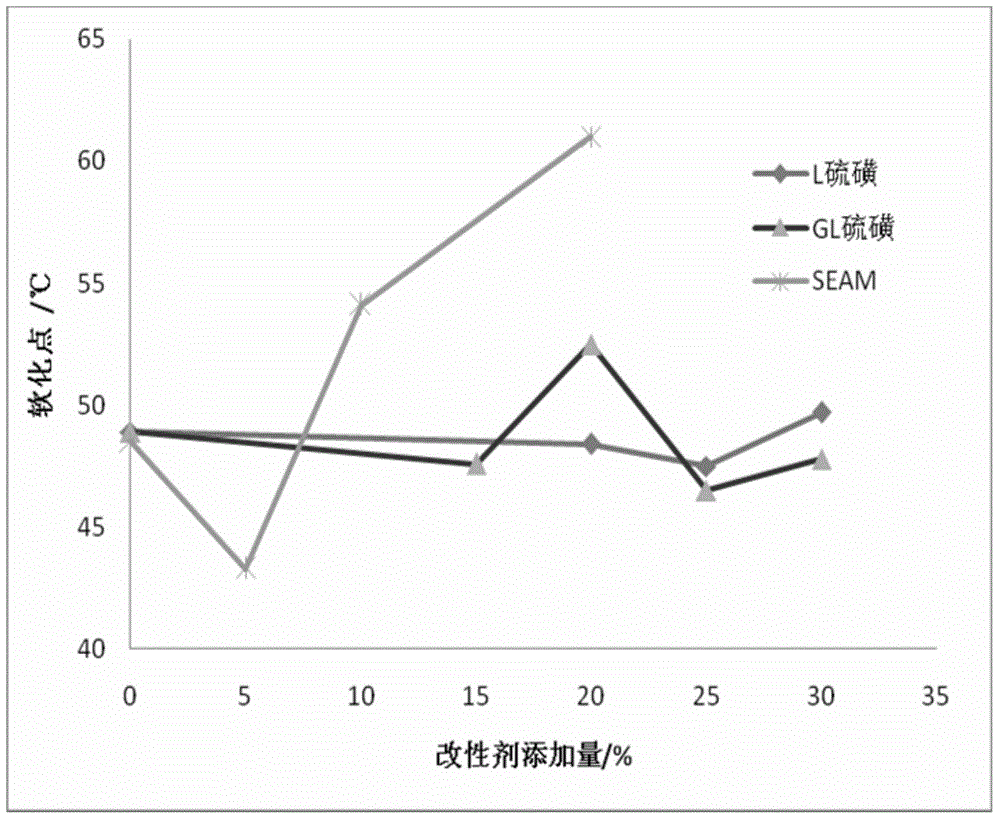

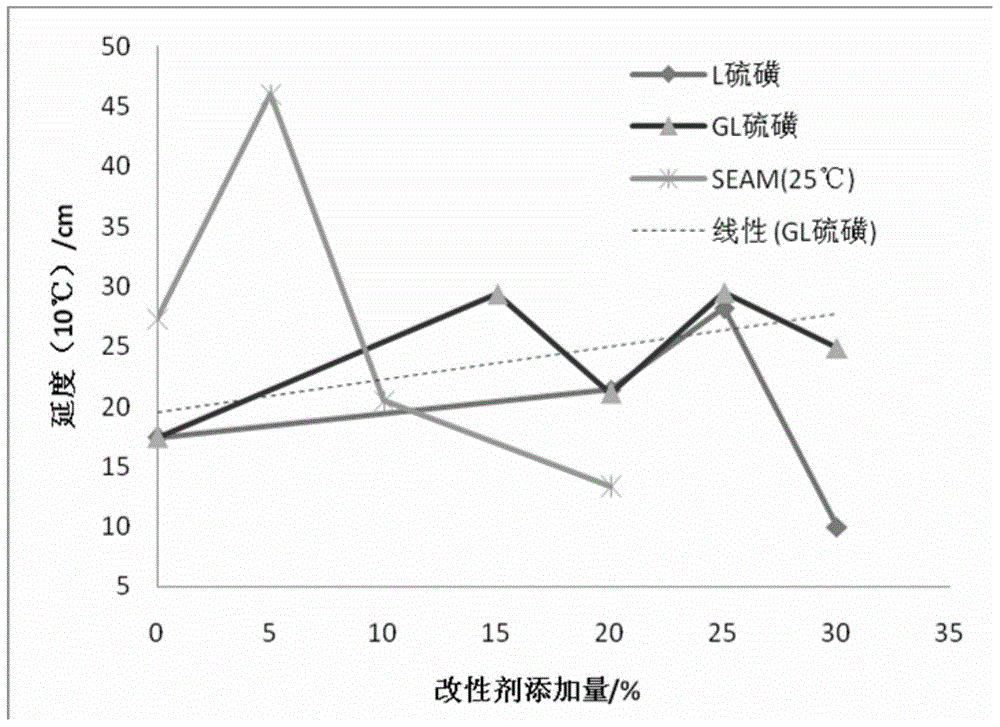

Asphalt modifier and industrial production method and application thereof

The invention discloses an asphalt modifier and an industrial production method and application thereof. The asphalt modifier is prepared by uniformly mixing modified sulfur and red mud particles. The industrial production method comprises the following steps: 1, preparing the modified sulfur, namely performing sulfur fusion and sulfur modification; and 2, adding the red mud particles. In the industrial production method, the modified sulfur is prepared in a way that an olefin modifier and a sulfur modification additive are added into sulfur for modifying sulfur; a weight ratio of the olefin modifier to sulfur is 2-6:100, and a weight ratio of the red mud particles to the sulfur is 10-30:100. The application process of the asphalt modifier comprises the following steps: I, preheating raw materials; and II, mixing, namely mixing the preheated asphalt modifier, mineral aggregate and matrix asphalt. The asphalt modifier adopted in the production method is simple in production process, low in construction cost, incombustible, safe to use and excellent in performance, the amount of discharged atmospheric pollutants in the production and application process is small, comprehensive performance of the modified asphalt concrete is excellent, and industrial waste red mud can be effectively utilized.

Owner:XIAN UNIV OF SCI & TECH

Monoester process of synthesizing trichlorosucrose

InactiveCN1526716AReduce manufacturing costSave foreign exchangeDisaccharidesFood preparationPickled vegetablesToxicity

The present invention relates to the synthesis of sweet food material. Sucrose is esterified to produce sucrose-6-acetate; sucrose-6-acetate is then chlorinated to produce trichlorosucrose-6-acetate; and trichlorosucrose-6-acetate is reduced to produce trichlorosucrose. The produced trichlorosucrose has the features of high sweetness, low heat value, no toxicity and dental caries resistance. With low production cost, the present invention may be used in beverage, pickled vegetable, composite seasoning, wine, ice cream and other food products.

Owner:李宝才

Method for producing large thickness and high intensity steel plate for boiler drum

InactiveCN101451213AImprove mechanical propertiesImprove performance qualityMolten metal pouring equipmentsRoll mill control devicesSteam drumAustenite

The invention discloses a production method for a high tensile steel plate used for a high thickness boiler drum. The production method comprises the following steps: (1) smelting: smelting molten steel in an electric furnace, the refining the molten steel in an LF finer, adding 300 to 500 meters of Al thread, and carrying out vacuum treatment in a bale VD furnace when the temperature of the bale is more than or equal to 1600 DEG C; (2) casting: keeping the temperature between 1,545 and 1,555 DEG C after damaging the vacuum; (3) heating: realizing the sending, clearing and filling of a steel ingot at a moderate temperature, cooling down the furnace for over 30 minutes before steel filling, and stewing the steel for one hour; (4) rolling: adopting II type rolling control technology, and setting a first stage as an austenite recrystallization stage and a second stage as an austenite non-recrystallization stage; (5) water cooling: cooling down the rolled steel plate on line, and keeping the red temperature between 700 and 750 DEG C; (6) heat treatment: carrying out the normalizing plus tempering treatment of the steel plate; and (7) shot blasting: carrying out shot blasting before storing the steel plate in a warehouse so as to completely remove the iron sheet produced during heating. The method shortens the steel rolling and heating time, reduces the consumption of production energy, and meets the requirements of a plurality of heat cycles during the boiler manufacturing process. The steel plate has good welding performance.

Owner:WUYANG IRON & STEEL

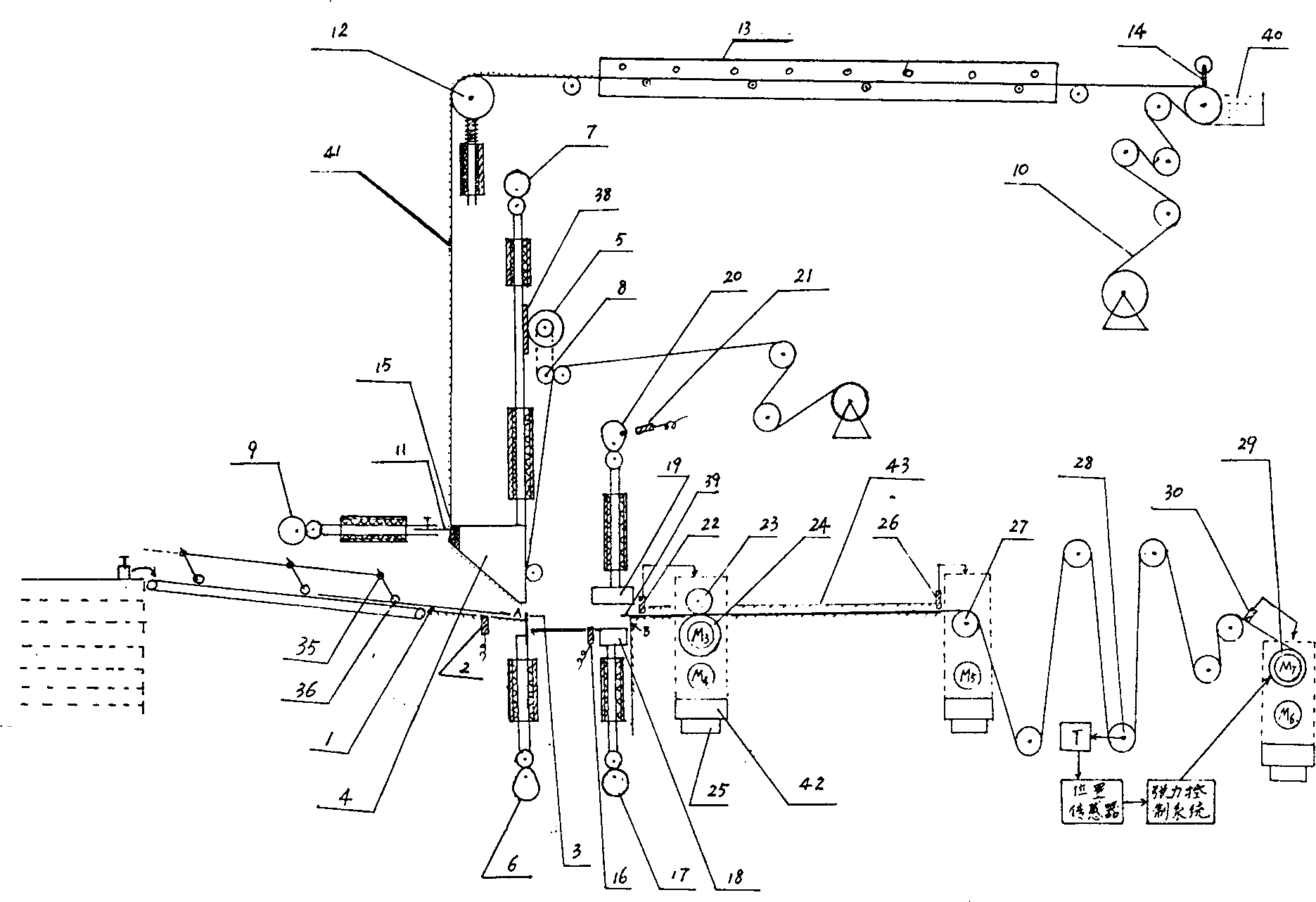

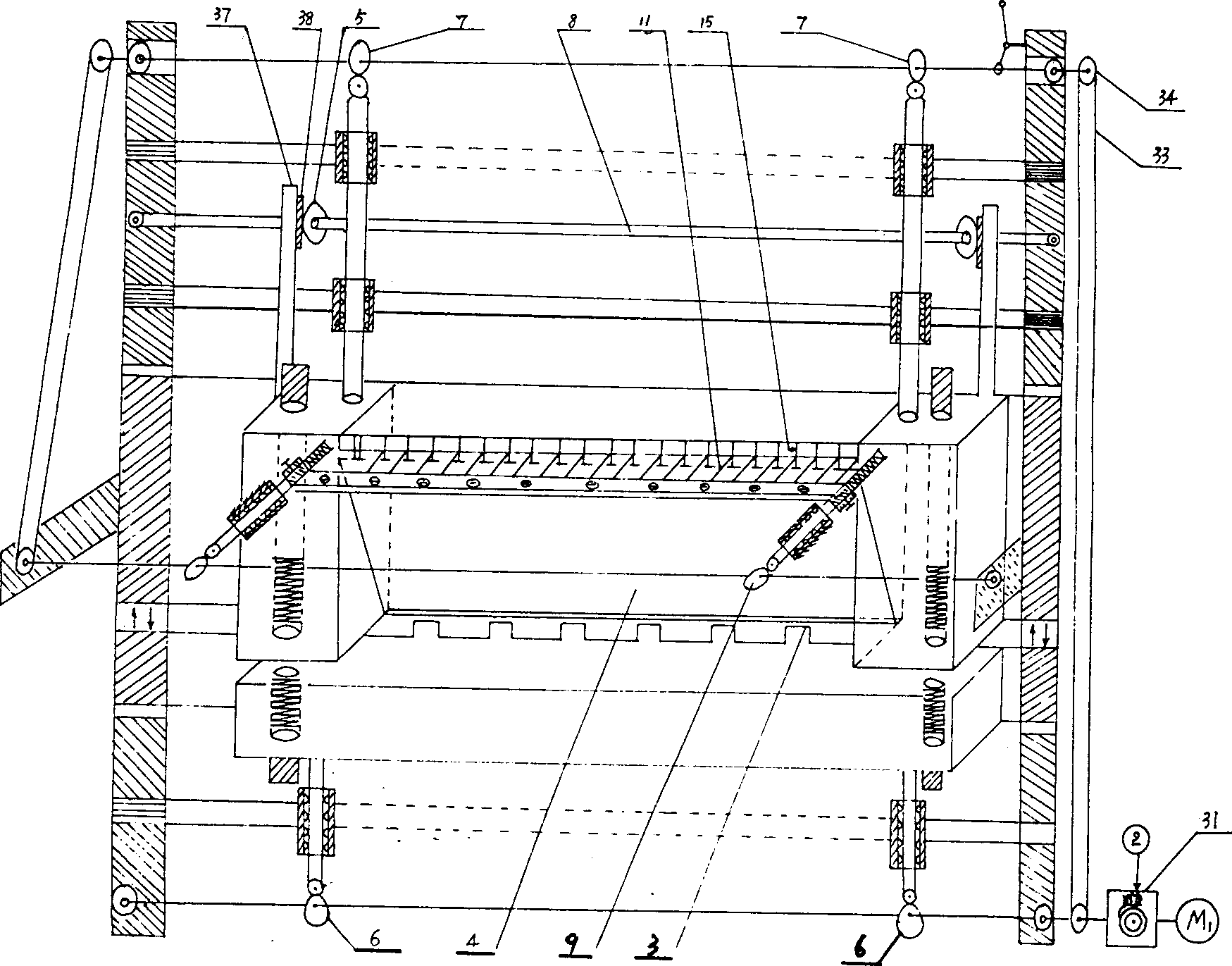

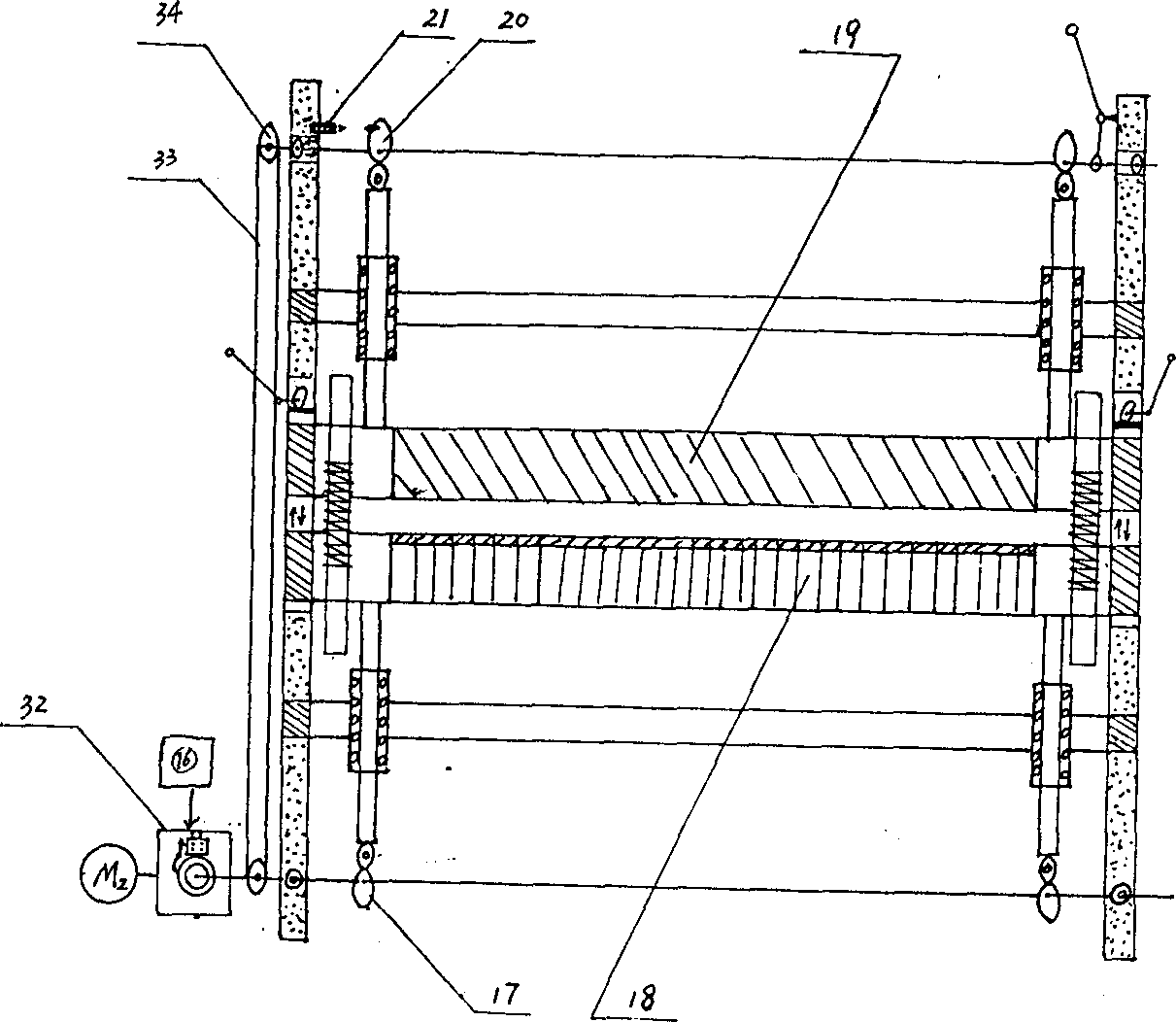

Production process of flat offset printing roll color-printing pressure-sensitive adhesive trade mark

The production process of plane sheet offset rolled colour-printed pressure-sensitive adhesive label includes the following steps: 1. face paper plane sheet PS plate printing; 2. edging; 3. automatically-adhering single-sheet printed face paper and coiling; 4. finely-coating pressure-sensitive adhesive and lamination; 5. cutting roll and die-cutting. The single-sheet printed face paper automatically adhering and coiling process includes the following steps: positioning face paper to the glue-applying place, at the same time transferring and pressing pressure-sensitive adhesive onto the face paper form parting paper; adhering head and tail of face paper, digital-control taking up by servo-motor, rectifying deviation, using position sensor and tension control system to regulate and control brake and constant tension rolling up.

Owner:高国明

Production process of high purity aluminium foil for electrolytic capacity

InactiveCN1887513AGood market demandCurbing rising pricesElectrolytic capacitorsOther manufacturing equipments/toolsElectrolysisElectrolytic capacitor

The present invention provides the high effect production process of high purity aluminum foil for electrolytic capacitor, and the production process includes the main steps of asynchronous cold rolling and heat treatment of high purity aluminum foil. The present invention features the asynchronous cold rolling at speed ratio of 1.05-1.30 and controlled aluminum foil rolling deformation state and rolling texture configuration to obtain great deformation high purity aluminum foil in less rolling turns; and continuous annealing in protecting atmosphere to produce high purity aluminum foil with very strong cube texture ultimately. Thus produced high purity aluminum foil for electrolytic capacitor has the advantages of one level raised asynchronous rolling precision compared with conventional rolling and {100} plane cube texture over 95%.

Owner:黄涛 +1

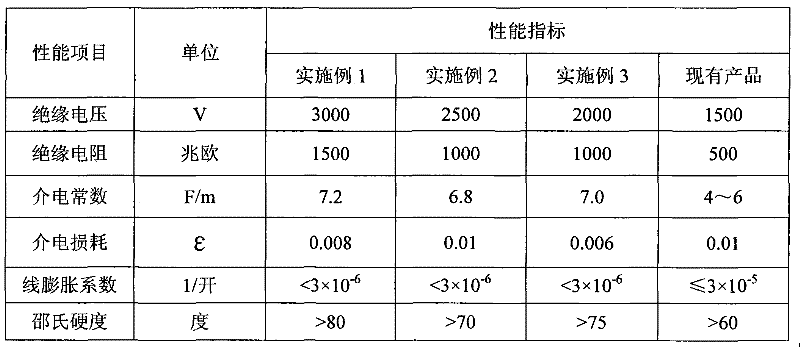

Organic silicon modified phenolic resin encapsulating material and preparation method and usage thereof

InactiveCN102337002ASimple processLess investmentFixed capacitor housing/encapsulationNegative temperature coefficient thermistorsHigh pressureThermistor

The invention discloses an organic silicone modified phenolic resin encapsulating material and a preparation method and usage thereof. The encapsulating material comprises the following components in parts by weight: 15-19 parts of modified phenolic resin, 3-5 parts of titanium white, 1-2 parts of organic silicon, 50-64 parts of silicon micro powder, 5 parts of pigment, 3 parts of thixotropic agent, 5 parts of drying agent and 4-7 parts of curing agent. The preparation method of the encapsulating material comprises the following steps: spraying, extrusion, crushing and ball milling. The encapsulating material has the advantages of high pressure resistance, temperature difference resistance, good insulating property, good moisture proof performance, high mechanical strength, quick natural drying, stable electric property, good adhesion, no cracking before and after curing, no color variation and the like, the production efficiency is increased by 20%, the output rate is improved by 10%, the manufacturing cost is reduced, the encapsulated product has a bright and attractive surface, is green and environment-friendly, and can replace an imported encapsulating material. The organic silicone modified phenolic resin encapsulating material is mainly used for the dipping encapsulation of porcelain medium capacitors, ceramic filters, thermistors and other electronic components.

Owner:LAIZHOU SHUNLIDA ELECTRONICS MATERIAL

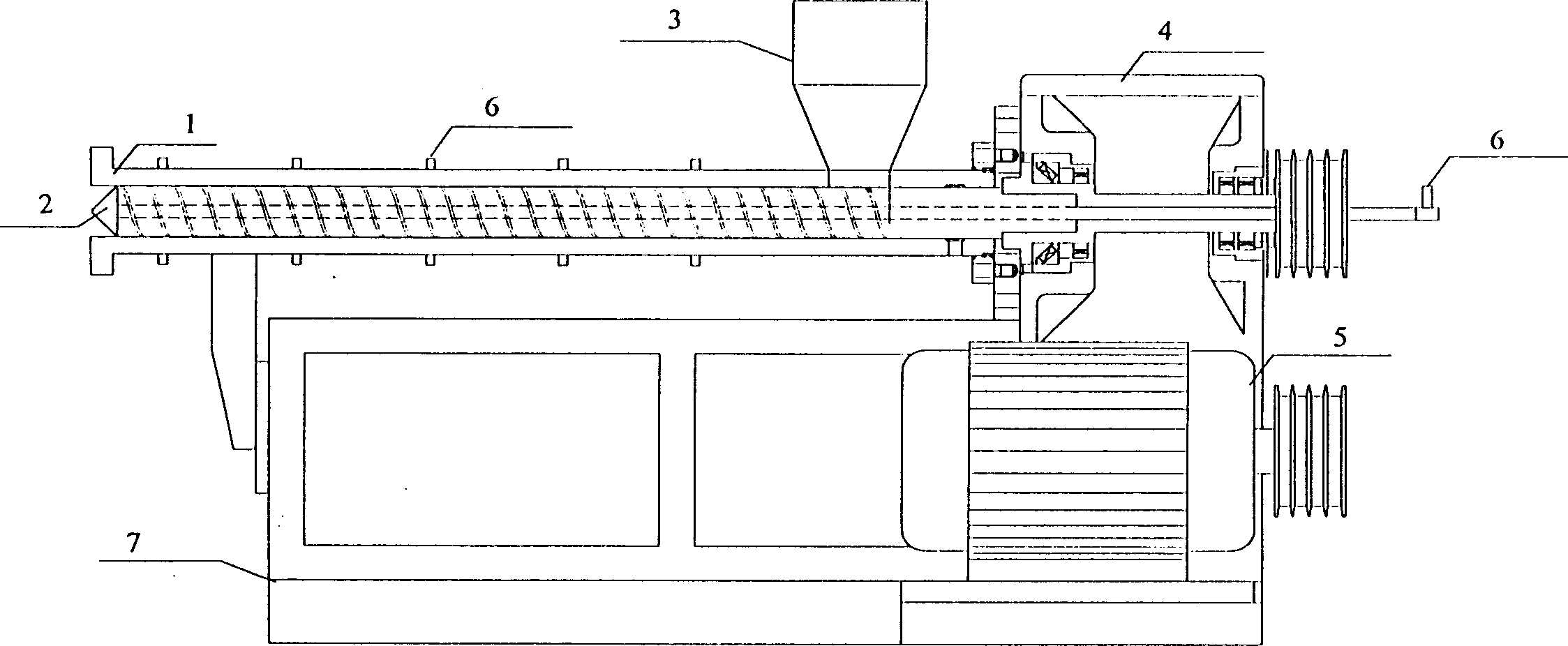

Super high-pressure single screw extruder

The invention relates to a hyper-pressure single-worm extrusion machine, comprising: a machine barrel, a screw bolt, a charging hopper, a driver, a motor, a cooling device, and an engine base. The invention is characterized in that: the cooling device is arranged on the machine barrel and the screw bolt; the geometric compression ratio of screw bolt is designed as high as 10-120; and the rotational speed of screw bolt is 30-1500 r / min. The invention has following advantages that: the cooling devices are arranged on the machine barrel and the screw bolt to eliminate the temperature over normal ones caused by the high-speed friction between chemical material and the machine barrel and screw bolt; the compression ratio of screw bolt is designed as high as 10-120 (according to the property of chemical material) to form a hyper-pressure solid transfer piston formed by extruded chemical material between the machine barrel and screw bolt; then the chemical material and the screw bolt, the chemical material and the machine barrel, the chemical material and the chemical material has friction in the hyper-pressure condition to generate heat, with which the chemical material can be melt and molded in short time, to be incised and mixed smelt; according to the friction temperature, the rotational speed of screw bolt is set at 30-1500 r / min, for controlling the amount of feeding material, the cooled amount and the friction temperature in stable balance condition.

Owner:包赟元

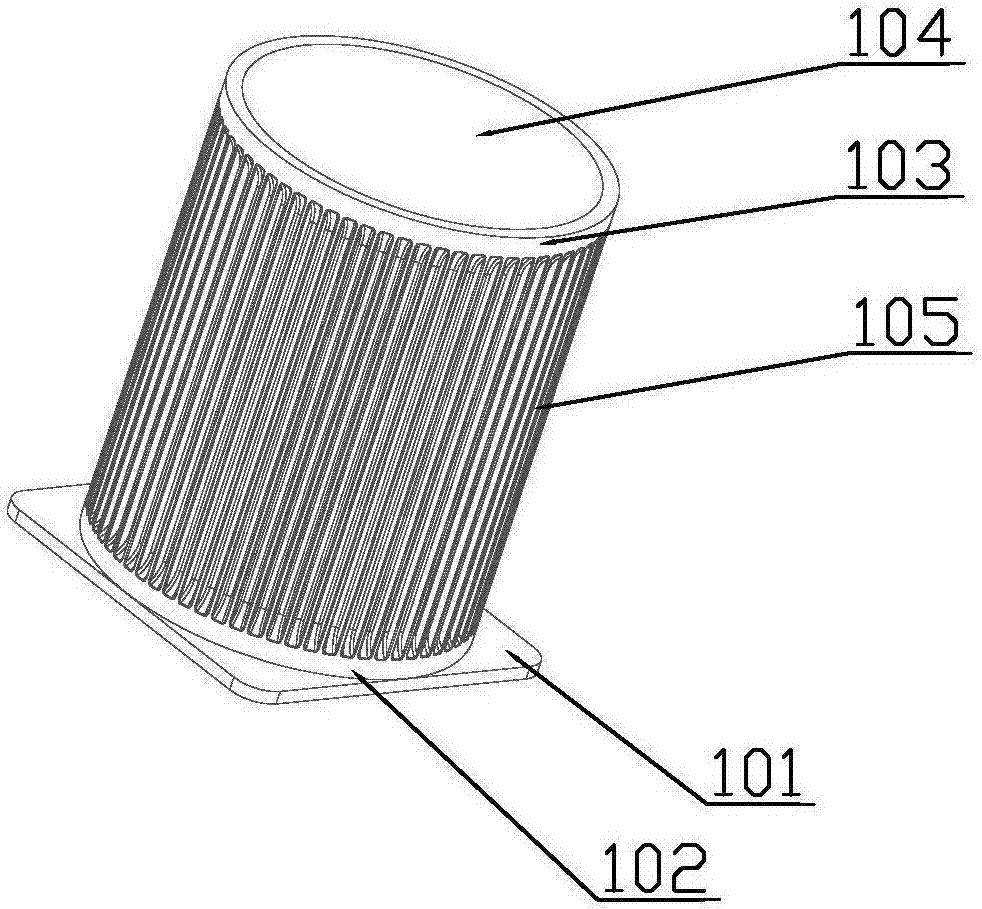

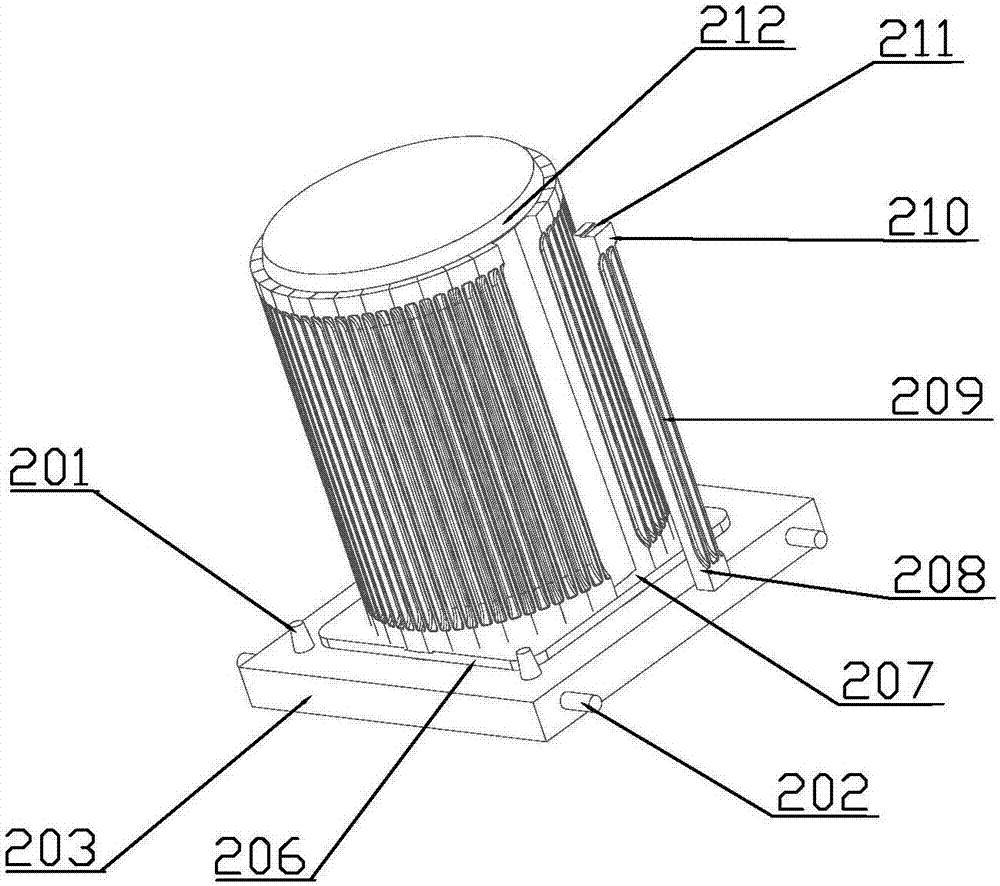

High-accuracy composite type grinding crankshaft grinding wheel

InactiveCN101733710AFulfil requirementsSave shopping timeOther chemical processesAbrasion apparatusGrinding wheelCrankshaft

The invention relates to a high-accuracy composite type grinding crankshaft grinding wheel which has three layers of an upper layer, a middle layer and a lower layer. The high-accuracy composite type grinding crankshaft grinding wheel is characterized in that an abrasive at the upper layer of the grinding wheel is rubing grain (PA), an abrasive at the middle layer of the grinding wheel is white alundum (WA), and an abrasive at the lower layer of the grinding wheel is rubing grain (PA); the grinding wheel also comprises a special ceramic bond, wherein the ceramic bond comprises the following chemical components: 17-23% of Al2O3, 50-55% of SiO2, 4-8% of K2O, 4-8% of Na2O, less than 1% of MgO, less than 1% of CaO, less than 1% of Fe2O3, less than 1% of TiO2 and 8-13% of B2O3. The invention meets the requirements of users, can replace the imported grinding wheels with the similar type, saves the merchandise purchase time of users, also lowers the cost and saves the foreign exchange for China.

Owner:沈阳科锐特砂轮有限责任公司

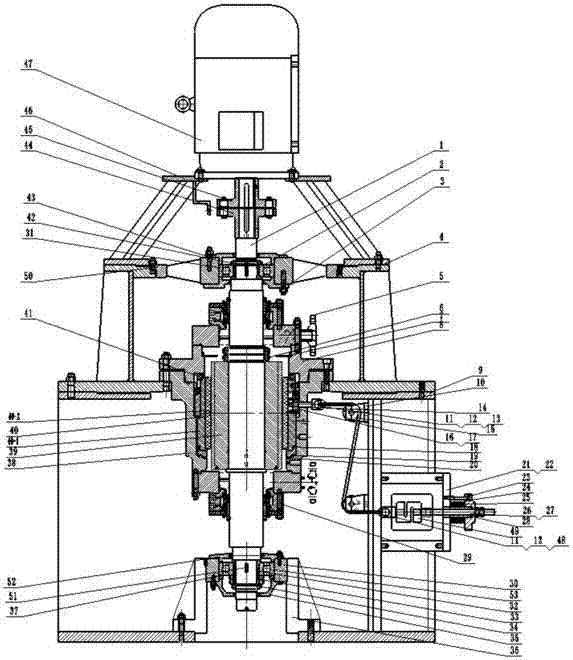

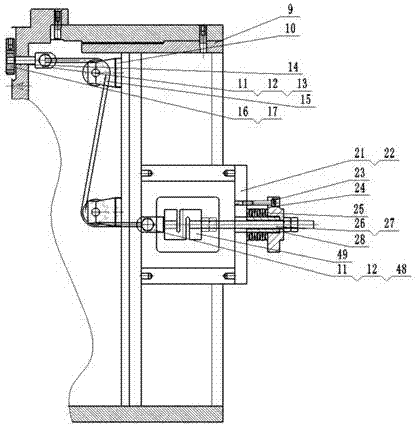

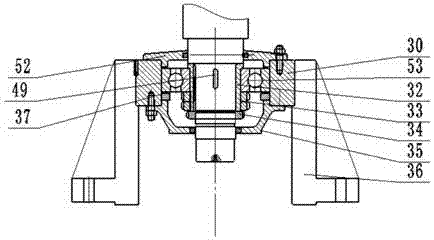

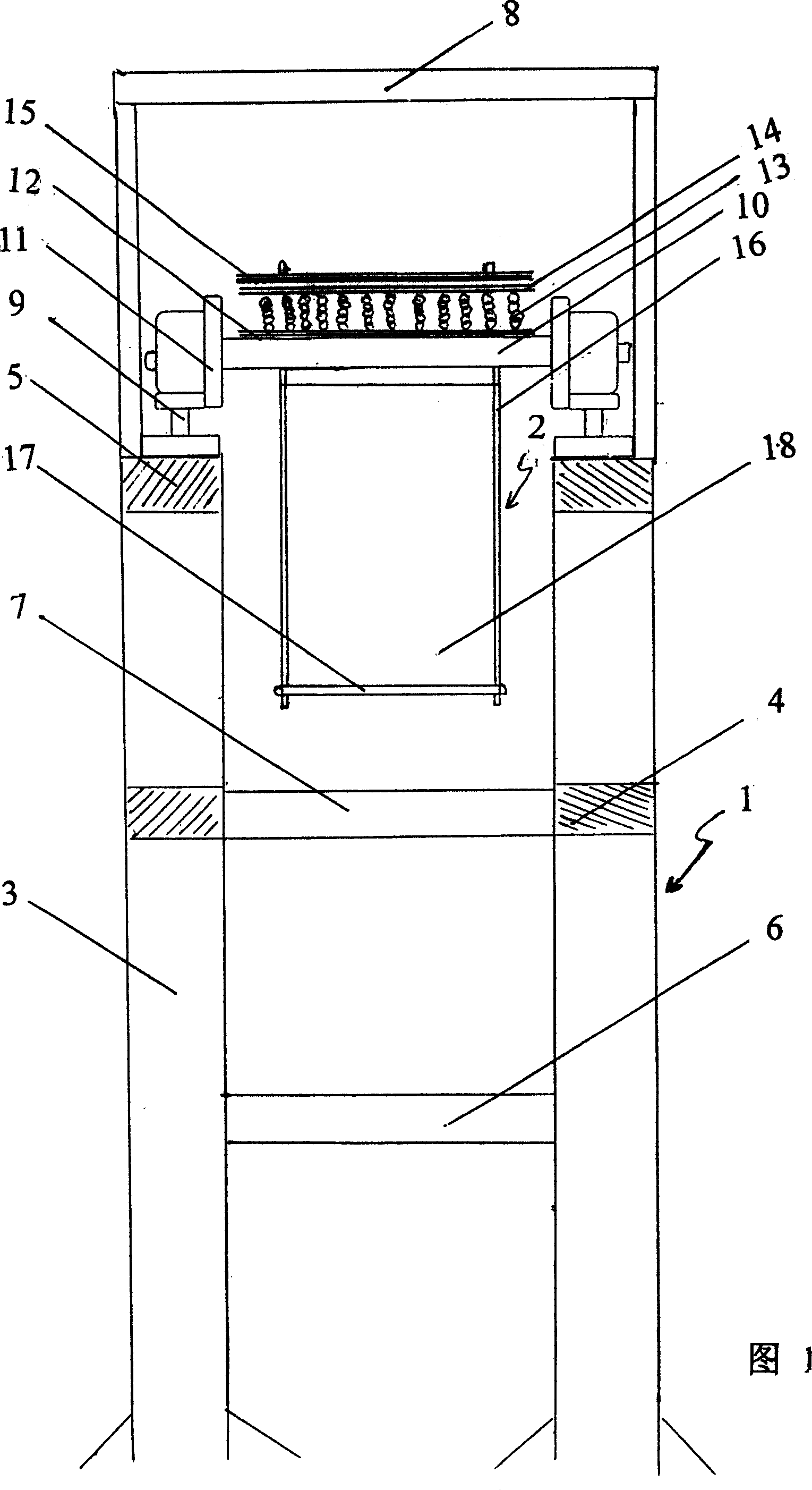

Vertical water lubrication transverse bearing test device and test simulation method thereof

ActiveCN107121286AImprove compatibilityEasy to operateMachine bearings testingElectric machineryDrive motor

The invention provides a vertical water lubrication transverse bearing test device. The vertical water lubrication transverse bearing test device comprises a bracket formed by a motor bracket, a middle bracket and a lower bracket, an upper rotor support assembly arranged at a joint part of the motor bracket and the middle bracket, a test bearing fixing assembly arranged at a joint part of the middle bracket and the lower bracket, a lower rotor support assembly arranged at the bottom of the lower bracket, a load applying device arranged at the side part of the lower bracket and a driving motor arranged on the motor bracket. The invention further provides a test simulation method of the vertical water lubrication transverse bearing test device. The vertical water lubrication transverse bearing test device and the test simulation method thereof have the advantages that the structure is simple, the applicability is high, the application range is wide, and the device and the method are applicable to different levels of performance tests of water lubrication transverse bearings of reactor coolant pumps.

Owner:SHENYANG BLOWER WORKS GRP NUCLEAR PUMP +1

A-60 rock wool for ship

InactiveCN1663931AImprove high temperature resistanceSmall rate of changeChemical compositionMaceral

Disclosed is an A-60 rock wool for ships, wherein the principal raw materials include basalt or diabase, a predetermined proportion of aluminum oxide powder and other inorganic raw mineral materials. Its preparation consists of melting in induction furnaces or electrical resistance furnaces, and centrifuging to obtain the rock wool fiber whose chemical constituents (by weight percentage) include SiO2 38-45%, Al2O3 30-38%, Fe2O3 (containing FeO) 6.5-8%, CaO+MgO 5-8%, other constituents and 9.5-12%.

Owner:宁波环宇耐火材料有限公司

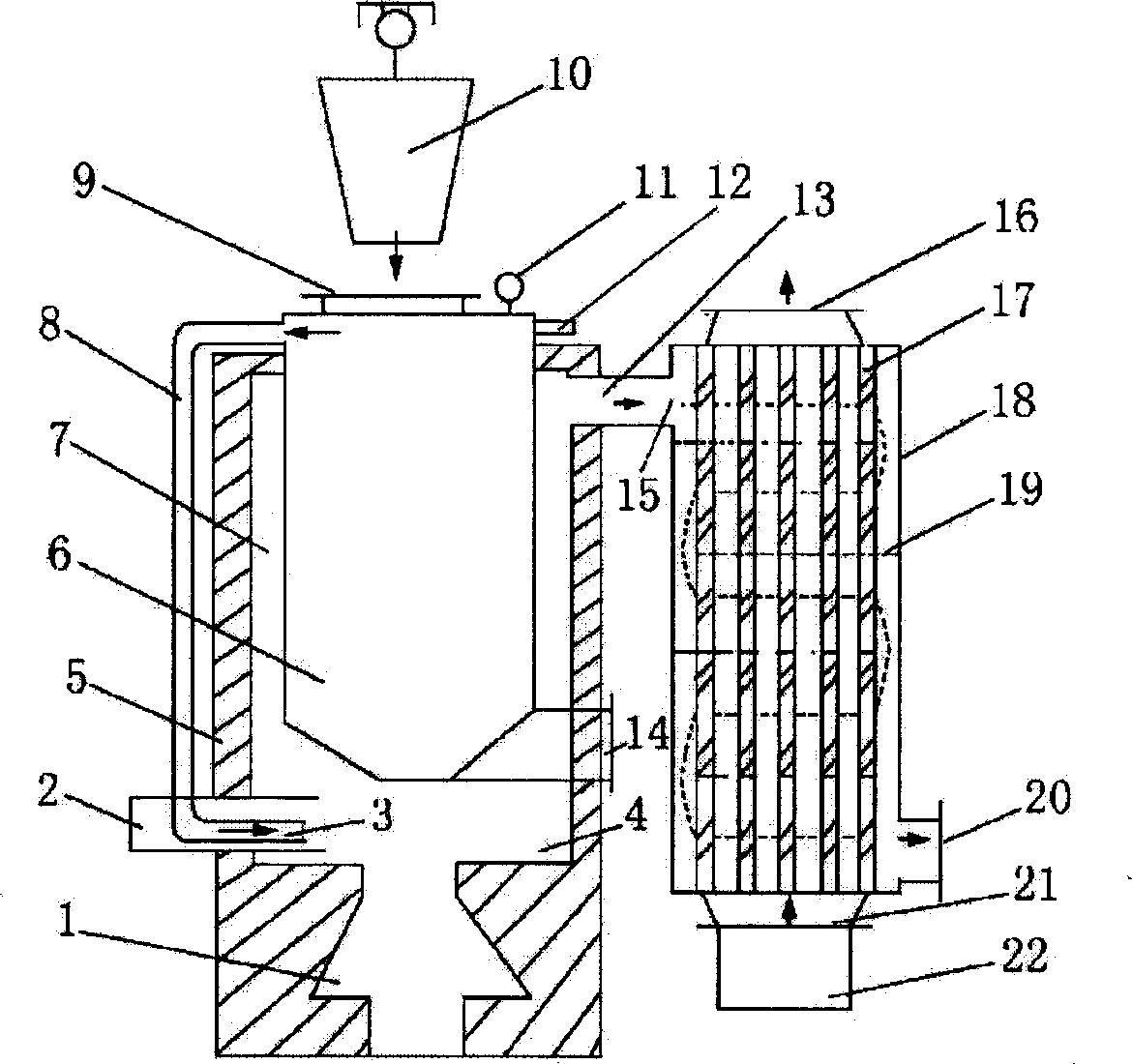

Anaerobic carbonization dangerous solid wastes disposing apparatus

ActiveCN1888535APrevent regenerationAvoid it happening againIncinerator apparatusCombustion chamberMedical waste

In the invention, a refractory insulated casing is disposed in the anacrobic pyrolyzation zone. A heating furnace is set in the tower part of the casing, a combustible gas combustion chamber is set in the middle part of the casing and in the upper part of the casing there is a hearth fire passage. In the hearth fire passage is suspended a pyrolyzation tank, on top of which a sealed charge door is corresponding to a above feeder and the top is in communication with the outlet pipe of the combustion gas and the bottom of the pyrolyzation tank is connected with a slagging means. On top of the refractory insulated casing is opened a flue outlet insulated casing is opened a flue outlet in communication with a pneumatic quench region, at the bottom of whose casing is set a fan and on its top is set an air-vent.

Owner:山东盛乙环保科技有限公司

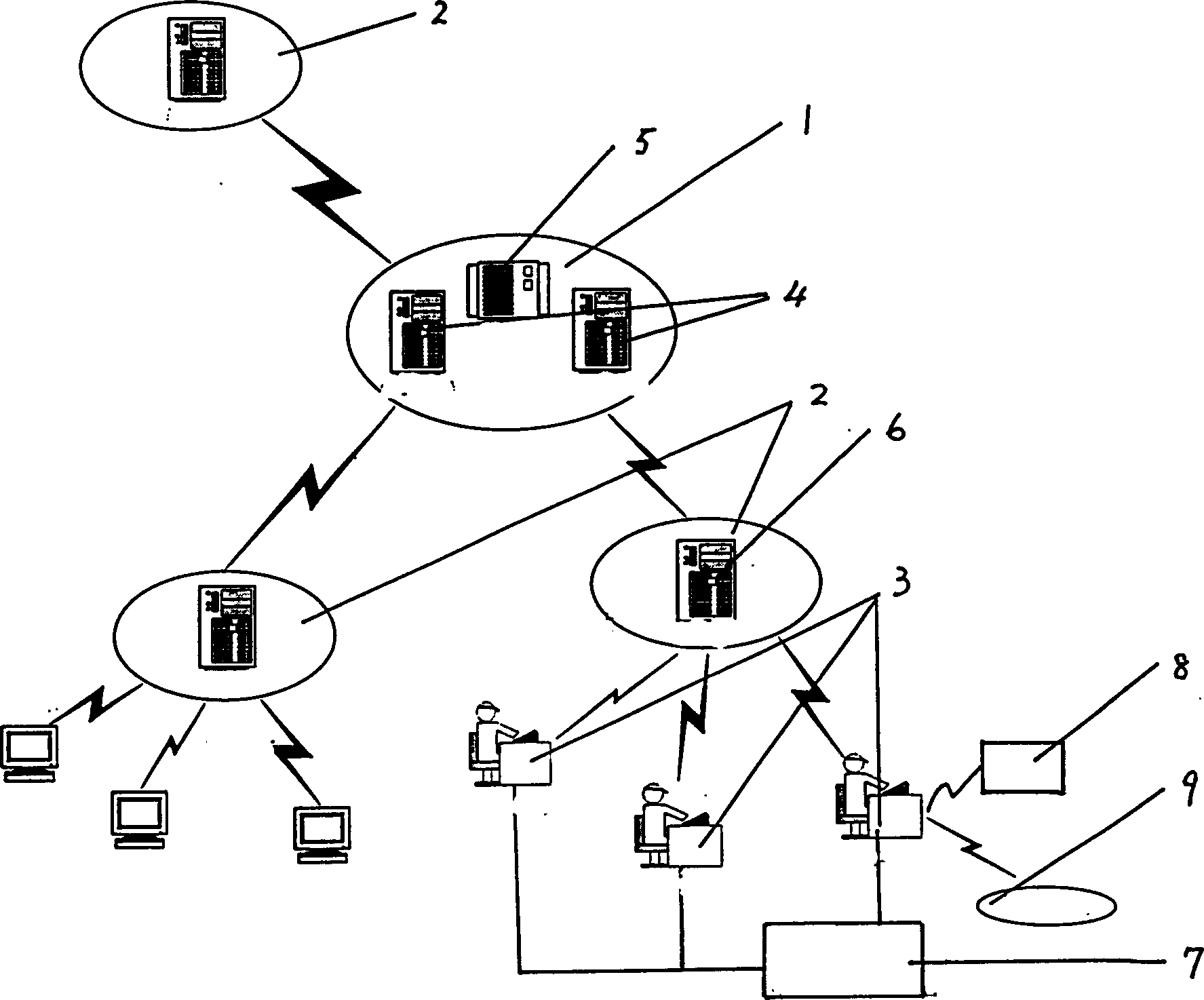

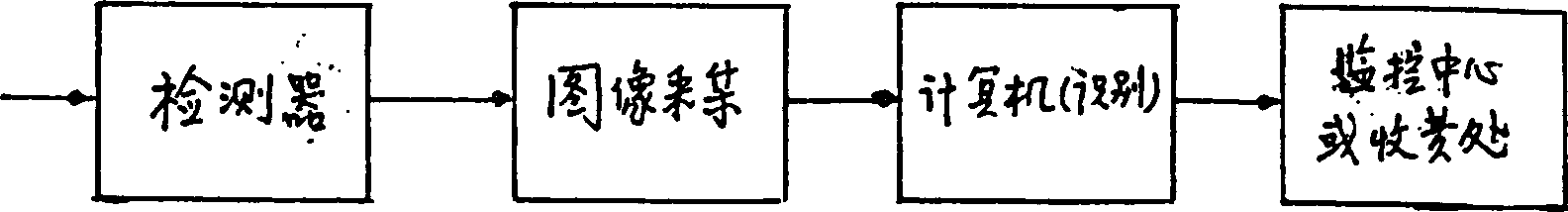

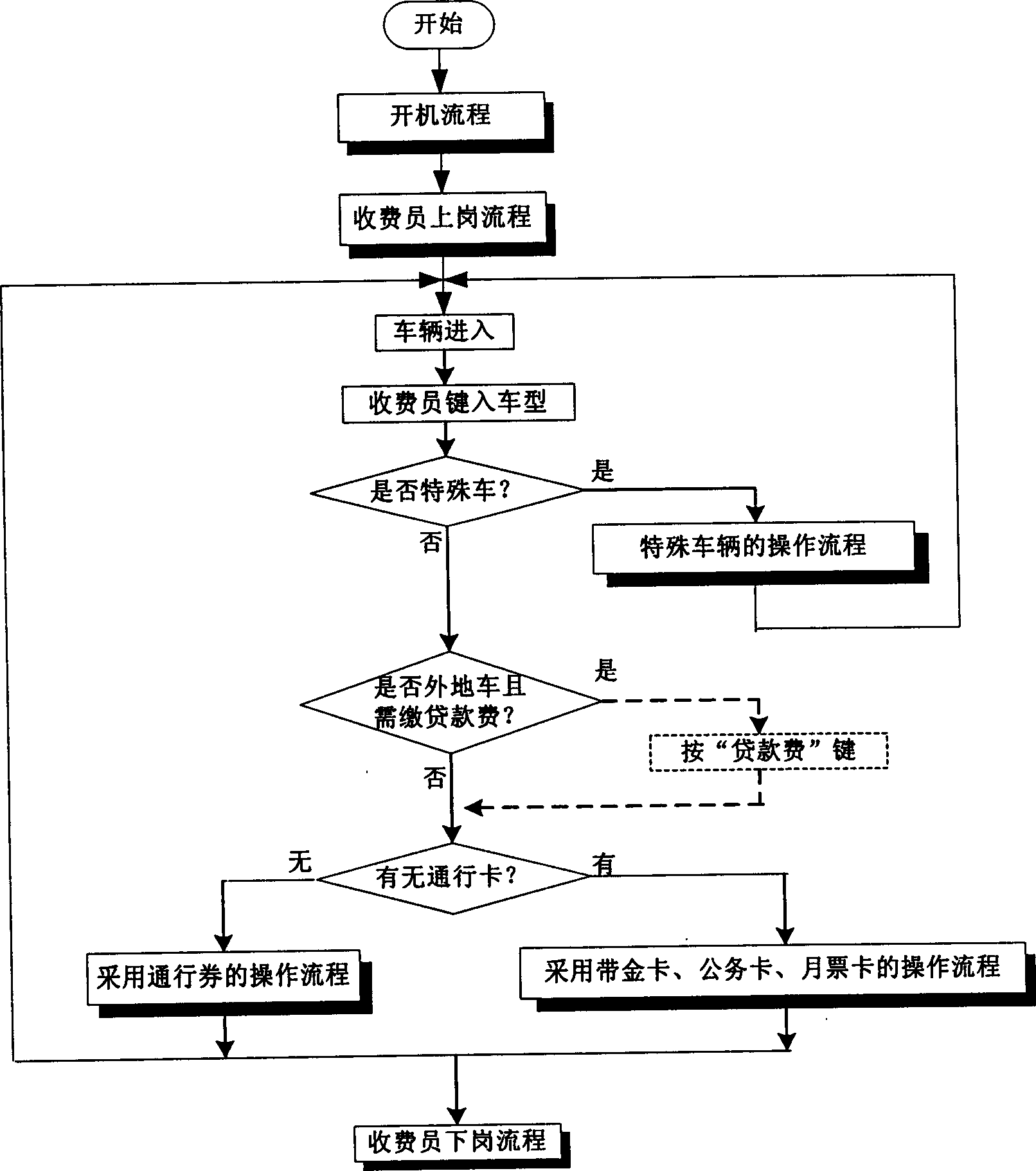

Computer on-line toll system for high-way roads

InactiveCN1779720AIncrease capacitySave foreign exchangeTicket-issuing apparatusCash registersCommunications softwareDisk array

A network computer toll system of highway comprises toll center computer including center server, disc array, software and communication software, toll station computer including server, software and communication software, lane toll computer including lane controller. It is featured as connecting toll center computer to toll station computer first then to toll lane computer, setting key technique of vanity plate identification on said system.

Owner:SHANGHAI SEARI INTELLIGENT SYST CO LTD

Inorganic coating for high temperature steel member label

The invention provides a steel part high temperature labeled inorganic coating. A binder, white pigment and a dispersant according to the weight ratio of 100: (10 to 30):( 0.1 to 5) are mixed with water and are ball-milled into the coating which is white slurry has the average particle size less than 10 mu m, the solid content 20 to 60 weight percent, and the pH value 5 to 9. The white pigment of the coating can be one or more of titanium dioxide, zinc sulfide, lithopone, barium sulfate and talc; the dispersant of the coating can be one or two of sodium cellulose glycolate and sodium alginate; and the binder of the coating can be low temperature crown glass powder or the mixture of the low temperature crown glass powder and water glass, wherein the low temperature crown glass is prepared from raw materials which are less than 180 meshes, are intensively mixed and sintered for 1 to 3 hours at 600 DEG C and ground into less than or equal to 300 meshes; and the raw materials comprise the following components: 60 to 80 percent of P2O5, 1 to 10 percent of B2O5, 15 to 30 percent of ZnO, and 0 to 5 percent of Na2O.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Dielectric material with low dielectric constant and low loss for microwave functional module and its prepn process

InactiveCN1609025ASpeed up the development processDielectric properties comparable toGlass shaping apparatusInorganic insulatorsMicrowaveLow-pass filter

The present invention relates to the dielectric material with low dielectric constant and low loss for microwave functional module and its preparation process. The preparation process includes mixing material including MgO, Al2O3, SiO2, ZnO and B2O3 and founding glass; quenching glass to obtain transparent vitreous body without recrystallization; wet ball grinding, adding TiO2 as temperature coefficient regulating agent, mixing, ball milling, drying, pressing into disc and sintering to obtain the material of the present invention. The MgO-Al2O3-SiO2-ZnO-B2O3 system with TiO2 temperature coefficient regulating agent has low dielectric constant, low loss, low temperature coefficient of frequency, low thermal expansion coefficient and other advantages, and may be used in producing various microwave modules.

Owner:ZHEJIANG UNIV +1

Preparation method of mullite ceramic glazed composite large brick for chlorination furnace

The invention discloses a preparation method for producing a mullite ceramic glazed composite refractory material for a lining of a medium-and-high-temperature chlorination furnace from titanium white through a chlorination method. The preparation method comprises the following steps: in a production unit, manufacturing a refractory brick; in a refractory production enterprise, proportioning and mixing to obtain glaze fine powder; and in a titanium white production enterprise, laying the refractory brick on a chlorination furnace by a furnace building construction unit, coating the glaze mixed solution onto the surface of the brick through a manual spreading manner or an equipment spraying manner to form a low-temperature-glazed high-temperature glaze of 2-5 mm, and forming a high-temperature-glazed layer which has a thickness of 1-3 mm and can resist the corrosion of chlorine gas, titanium tetrachloride and strong acid on the surface of the brick in the subsequent furnace drying process, thus avoiding the leakage and corrosion of high-temperature chlorine gas, high-temperature titanium tetrachloride, strong acid and chlorinated impurities.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Method for expressing thymopolypeptides šŒ1 by use of escherichia coli and its application

InactiveCN1431311APowerful immune mediatorHigh purityPeptide/protein ingredientsAntiviralsEscherichia coliDisease

A process for expressing thymopeptide alpha 1 by colibacillus includes PCR amplification to obtain the full-length gene of thymopeptide alpha 1, endonuclease severing at both ends, and cloning to colibacillus for stable expression. After purified, it can be used as injection to treat immunodeficiency diseases.

Owner:ZHEJIANG UNIV PHARM CO LTD

Casting mold of motor housing of new energy large energy storage fly wheel and process method thereof

The invention discloses a casting mold of a motor housing of a new energy large energy storage fly wheel and a process method thereof. The casting mold comprises an integrated fly wheel housing casting mold and a split flywheel housing casting mold; the mold is a resin sand mold which is core-pulled and formed by an aluminum mold; an outer mold adopts at least 30 fan-shaped modules which are tightly spliced to form the round barrel-shaped outer mold; the angles of central angles corresponding to the fan-shaped modules are equally divided angles of the central angles, the resin sand core mold and a base are positioned and assembled in an inner hole of the barrel by means of hoisting equipment; the split flywheel housing comprises a barrel and a bottom plate, and the barrel and the bottom plate are perpendicularly formed mutually by means of robot welding, and the motor housing is manufactured by means of an integrated casting mold process method and a split casting mold process method.The flywheel housing disclosed by the invention adopts an aluminum-silicon alloy and American standard A356, and is produced by means of a resin sand molding low-pressure pouring process, so that thecasting mold is high in production efficiency, low in cost, stable and reliable in product quality and high in rate of finished products.

Owner:昆山久帜金属有限公司

Heat resistant ceramic material of jolite and mullite

A refractory ceramic is proportionally prepared from magnesite, magnesium clay, kaolinite, bauxite, black clay and aluminium mica. Its advantages are high strength and thermal stability and low cost.

Owner:江西永华瓷业有限公司

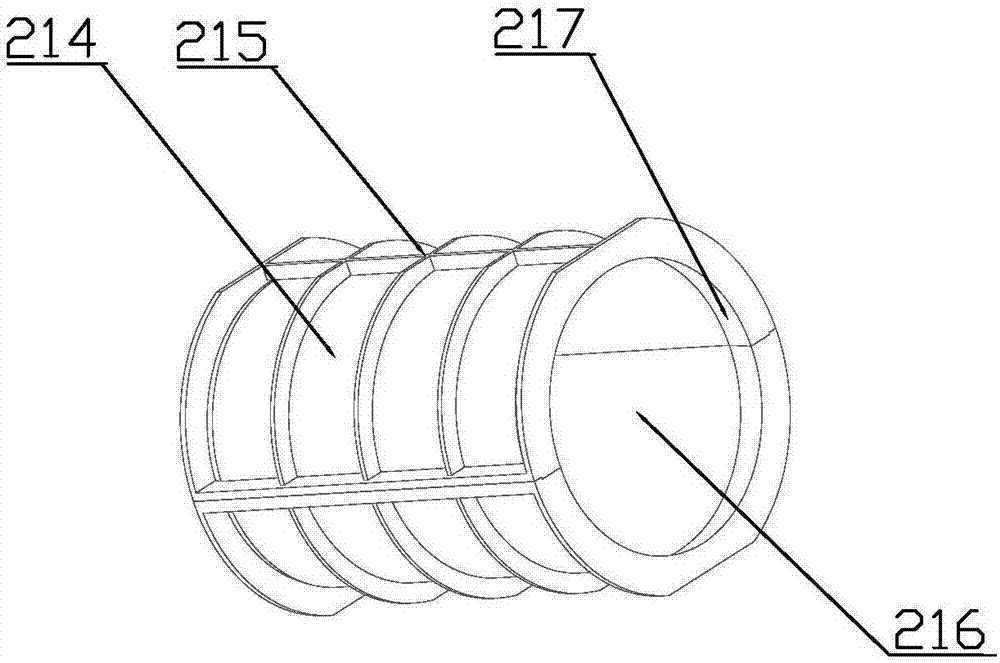

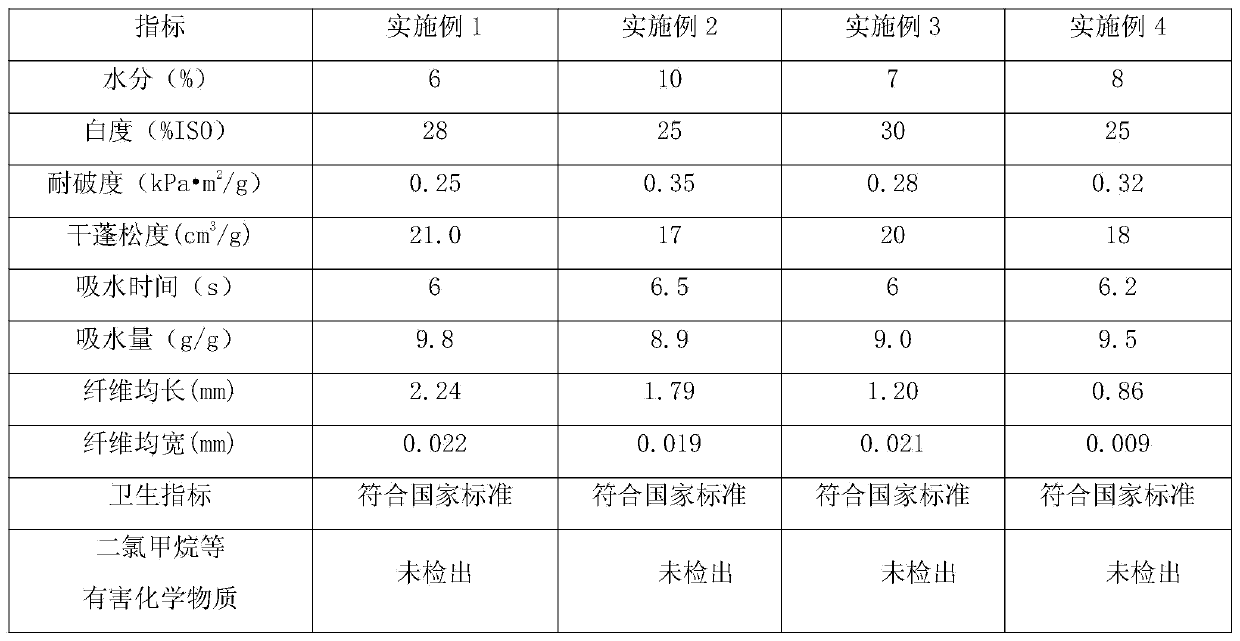

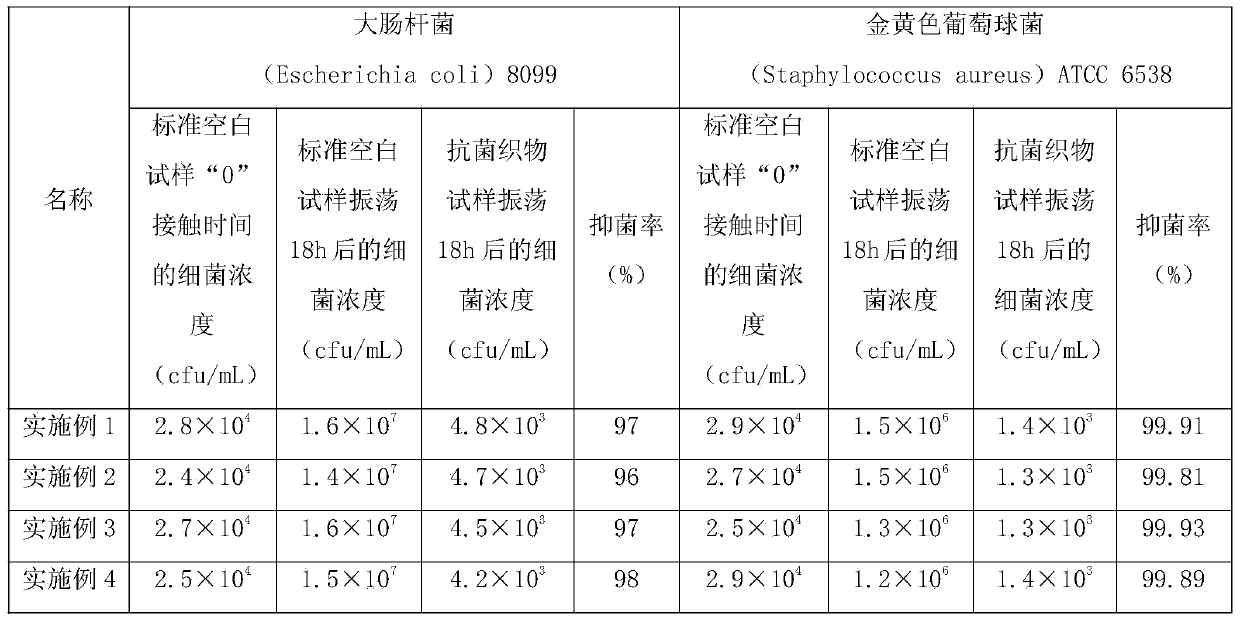

Natural-color fuzzy bamboo pulp with high bacteriostatic activity and preparation method thereof

ActiveCN104195868AReduce usageAvoid residual contaminationPaper/cardboardPulping with inorganic basesBursting strengthFiber

The invention discloses natural-color fuzzy bamboo pulp with high bacteriostatic activity. The natural-color fuzzy bamboo pulp is 25-30%ISO (International Standardization Organization) in whiteness degree, is 0.25-0.35kPa m<2> / g in bursting strength, is 17-21cm<3> / g in dry filling power, is 6-6.5s in water absorption time, is 8.9-9.8g / g in water absorption capacity, is 0.86-3.79mm in average fiber length and is 0.009-0.022mm in average fiber width. A preparation method of the natural-color fuzzy bamboo pulp comprises the steps of pulping raw materials, cooking, washing, modifying and drying, wherein the washing step comprises coarse selection by a vibrating screen, black liquid extraction by a vacuum pulp washer, fine selection by a pressure screen, dedusting by a residue removal and pulp washing by a vacuum pulp washing machine. The natural-color fuzzy bamboo pulp has long fiber length, high flexibility and good water-absorbing ability and water-retaining property, has soft and fluffy texture and strong antibacterial property, can keep the 100% natural color of the bamboo fiber and can remarkably improve the quality of the down-stream products; and the preparation method has the characteristics of simplicity in operation, convenience in production, low cost and environment protection.

Owner:SICHUAN HUANLONG NEW MATERIAL

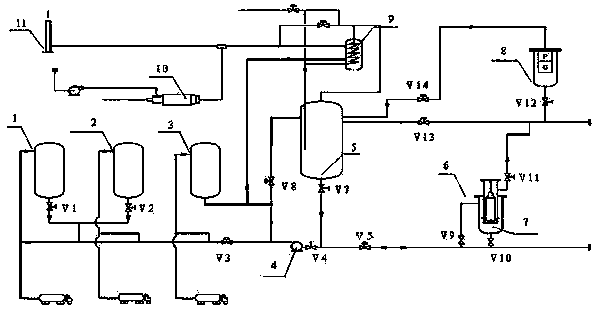

Novel cryogenic pump test stand

ActiveCN103758744AGuaranteed safety and reliabilityImprove recycling ratesMachine part testingPump testingGas phaseWorking environment

The invention relates to a cryogenic pump and low-temperature immersed turbine test device. A novel cryogenic pump and low-temperature immersed turbine test stand comprises a storage area, a circulation area, a testing area and a tail gas treatment area. The circulation area is arranged between the testing area and the storage area, a storage tank is arranged in the storage area, a circulation tank is arranged in the circulation area, a gas outlet of the circulation tank is communicated with a condenser, and after processing by the condenser, a liquid phase condensation outlet is communicated with the circulation tank. A gas phase outlet is connected to a torch or a hot blast heater. A tested pump or a tested turbine is arranged in the testing area. The interior of the storage tank is communicated with the circulation tank through a pipeline, the circulation tank is communicated with the tested pump or the tested turbine through a pipeline, the tested pump or the tested turbine is communicated with the circulation tank through a pipeline, and then a testing loop is formed. The novel cryogenic pump and low-temperature immersed turbine test stand has the advantages of being simple in operation process and easy to operate, and can be reliably operated in the low temperature working environment.

Owner:DALIAN DEEP BLUE PUMP CO LTD +2

Tissue culture quick-breeding method for polygonum multiflorum

InactiveCN1934933ASave foreign exchangeSave seedling areaPlant tissue cultureHorticulture methodsLolium multiflorumMurashige and Skoog medium

The present invention provides a tissue culture fast-propagation method of Chinese medicinal plant polygonum multiflorum. Said method mainly includes the following several steps: preparing explant, induction culture, differentiation culture and rhizogenetic culture. Besides, said invention also provides the concrete requirements of the above-mentioned every step and its concrete operation method.

Owner:NANJING FORESTRY UNIV

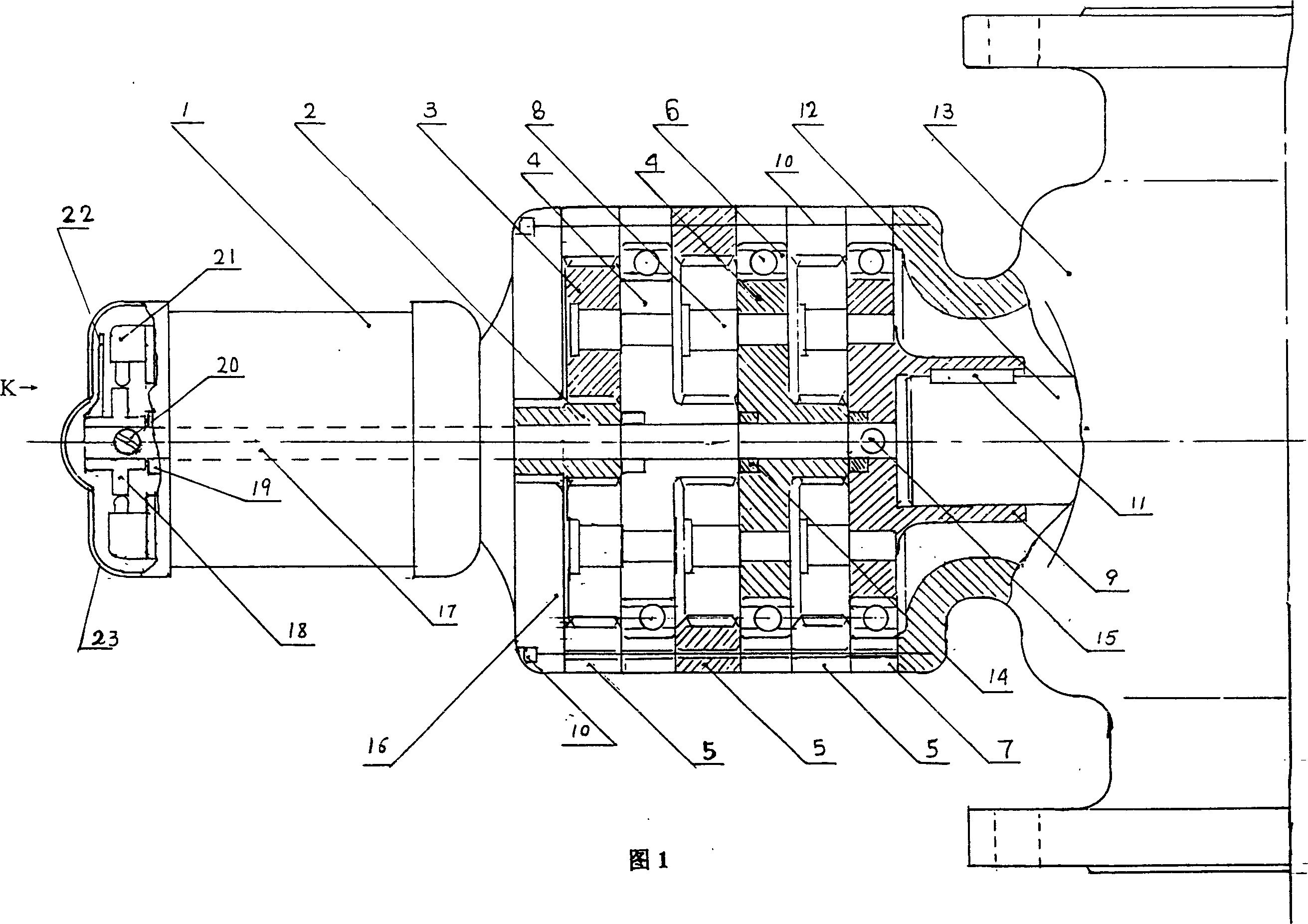

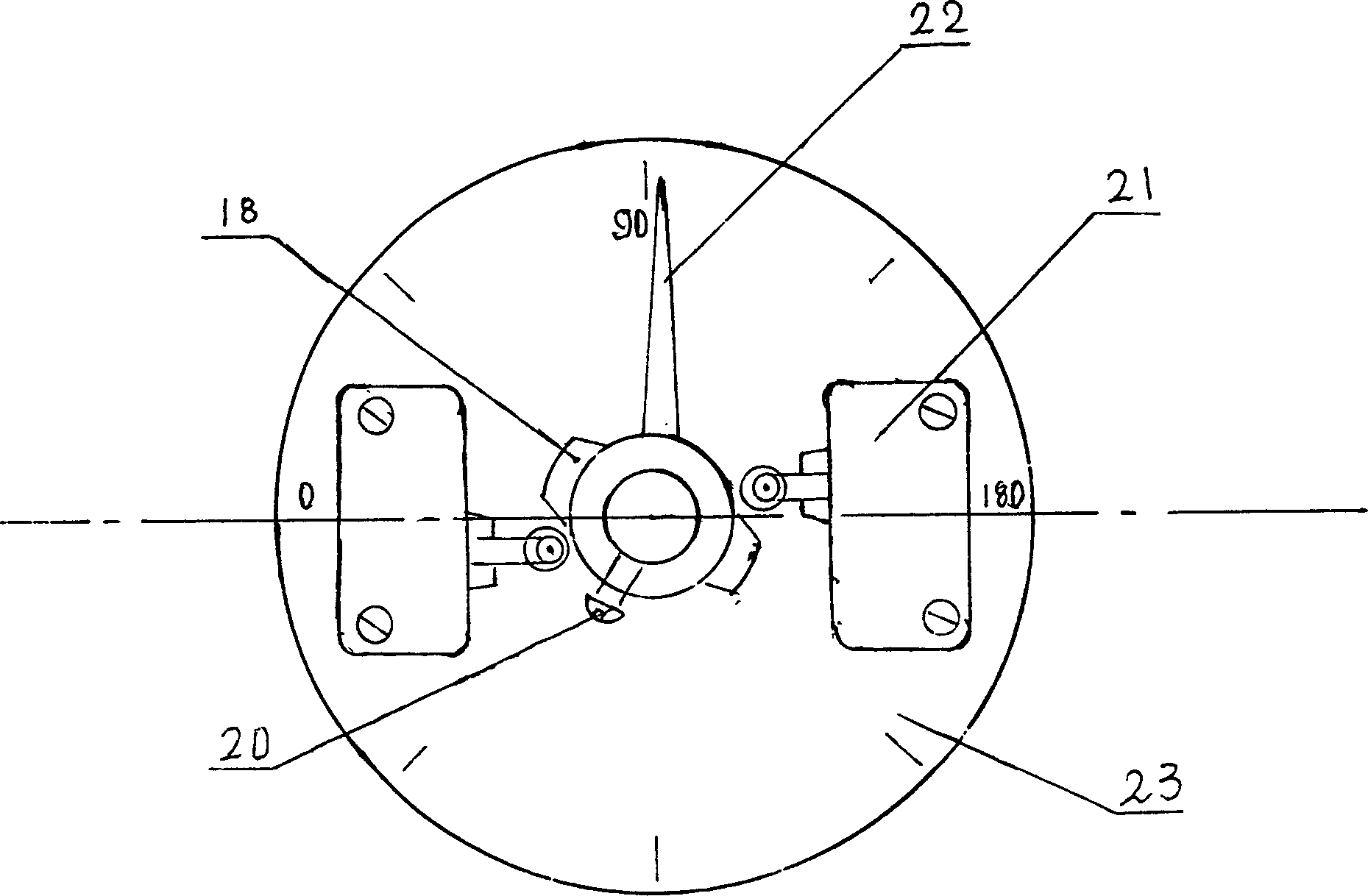

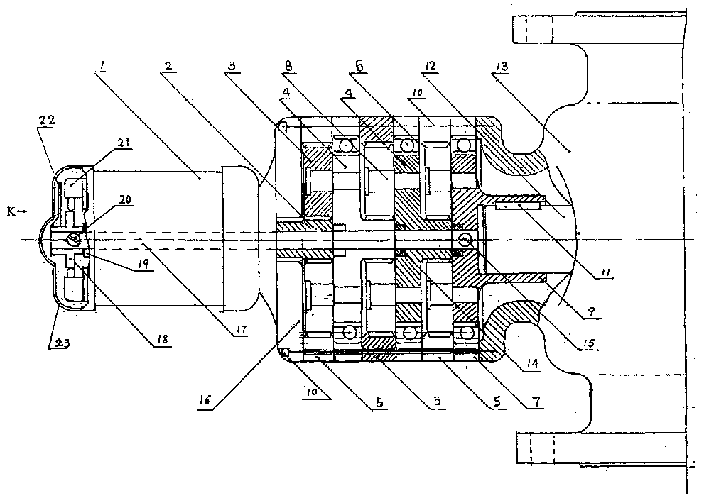

Composite planetary actuating mechanism

InactiveCN1515815AGuaranteed uptimeReliable strengthOperating means/releasing devices for valvesToothed gearingsGear wheelCoupling

The present invention relates to a valve speed-regulating technique, in the concrete, it is a composite planetary actuating mechanism. It includes motor, central gear, planetary gear group, coupler, bearing and inner toothed ring. It also includes feed-through shaft, cam, control switch and relay, etc. It also provides their connection relationship and assembly structure.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Suspension high speed railway, city suspension railway and train frame changeover device

InactiveCN1532103ALow costReduce land occupationRailway system combinationsRailway componentsVehicle frameTransit bus

The suspension high speed railway and the city suspension railway are overhead railway for suspending train, and the overhead railway is laid on the railway frame supported by the railway piles erected on the ground. Suspending train can lower the gravitational center of the train and this makes it possible to raise train speed to reach the speed level of magnetically suspension train. The present invention has simple structure, low cost and saving in earth.

Owner:刘毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com