Manufacturing method of alloy tubular product

A manufacturing method and pipe technology, applied in the field of manufacturing, can solve the problems of narrow processing temperature range, large thermal deformation resistance, low yield, etc., and achieve the effects of low production cost, good performance and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of manufacturing method of NS1402 alloy pipe, is to adopt the processing technology of cross-rolling piercing+cold rolling to produce many batches of NS1402 pipe, now choose 2 heat batch numbers as embodiment, concrete steps are as follows:

[0025] a. Cut the Φ95 bar of NS1402 alloy into 750mm short material, and center the center of the short material by drilling;

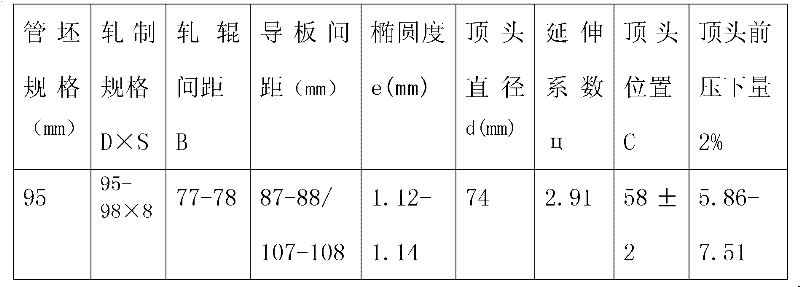

[0026] b. Heat the centering material to 950°C for 30 minutes, then heat it up to 1120°C for 20 minutes, and then hot-pierce it into a cold-rolled Φ98*8.0mm tube blank; the specific piercing parameters are shown in Table 1:

[0027] Table 1:

[0028]

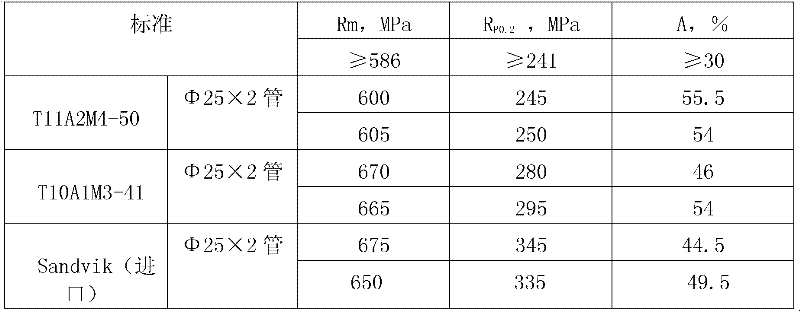

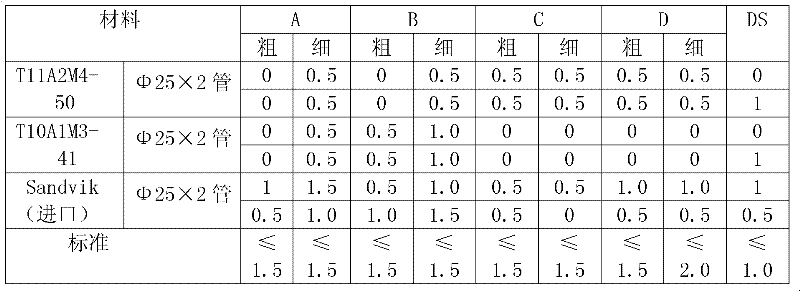

[0029] c. Roll the Φ98*8.0mm tube billet for 3 passes to produce a Φ25*2.0 cold-rolled tube;

[0030] d. The above-mentioned cold-rolled pipe is subjected to solution treatment in a protective atmosphere:

[0031] Solid solution temperature of semi-finished products: 1060°C, holding time: 0.5 hours, using hydrogen protection heating;

[0032] So...

Embodiment 2

[0049] A method for manufacturing an alloy pipe, comprising the following steps:

[0050] a. Smelting: Using pure iron and other metals as raw materials, the composition and weight percentage are mainly carbon (C)≤0.05%, silicon (Si)≤0.5%, chromium (Cr) through vacuum induction furnace + electroslag remelting process ) 19.5-23.5%, nickel (Ni) 38.0-46.0%, molybdenum (Mo) 2.5-3.5%, manganese (Mo) ≤ 1.0%, copper (Cu) 1.5-3.0%, titanium (Ti) 0.6-1.2%, Sulfur (S) ≤ 0.015%, phosphorus (P) ≤ 0.03%, aluminum (Al) ≤ 0.2%, the balance is iron (Fe) alloy steel; and made into bars;

[0051] b. Centering: Saw the bar into short cuts, and center the short cuts to make centering materials;

[0052] c. Tube billet making: heat the centering material to 950°C and keep it warm for 20-30 minutes, then heat it up to 1100°C-1120°C and keep it warm for 15-20 minutes, and then make a tube blank (required for cold rolling) by hot piercing ;

[0053] d. Cold rolling: the tube billet is rolled for 1...

Embodiment 3

[0058] A manufacturing method of NS1402 alloy pipe, comprising the following steps:

[0059] a. Smelting: Using pure iron and other metals as raw materials, the composition and weight percentage are mainly carbon (C)≤0.05%, silicon (Si)≤0.5%, chromium (Cr) through vacuum induction furnace + electroslag remelting process ) 19.5-23.5%, nickel (Ni) 38.0-46.0%, molybdenum (Mo) 2.5-3.5%, manganese (Mo) ≤ 1.0%, copper (Cu) 1.5-3.0%, titanium (Ti) 0.6-1.2%, Sulfur (S) ≤ 0.015%, phosphorus (P) ≤ 0.03%, aluminum (Al) ≤ 0.2%, the balance is iron (Fe) alloy steel; and made into bars;

[0060] b. Centering: Saw the bar into short cuts, and center the short cuts to make centering materials;

[0061] c. Tube billet making: heat the centering material to 950°C and keep it warm for 25 minutes, then heat it up to 1100°C to 1120°C and keep it warm for 18 minutes, and then make a tube blank (required for cold rolling) by hot piercing;

[0062] d. Cold rolling: the tube billet is rolled for 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com