Patents

Literature

30results about How to "Guarantee metallurgical quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead-free solder for micro alloyed eutectic alloy of stannum and zinc

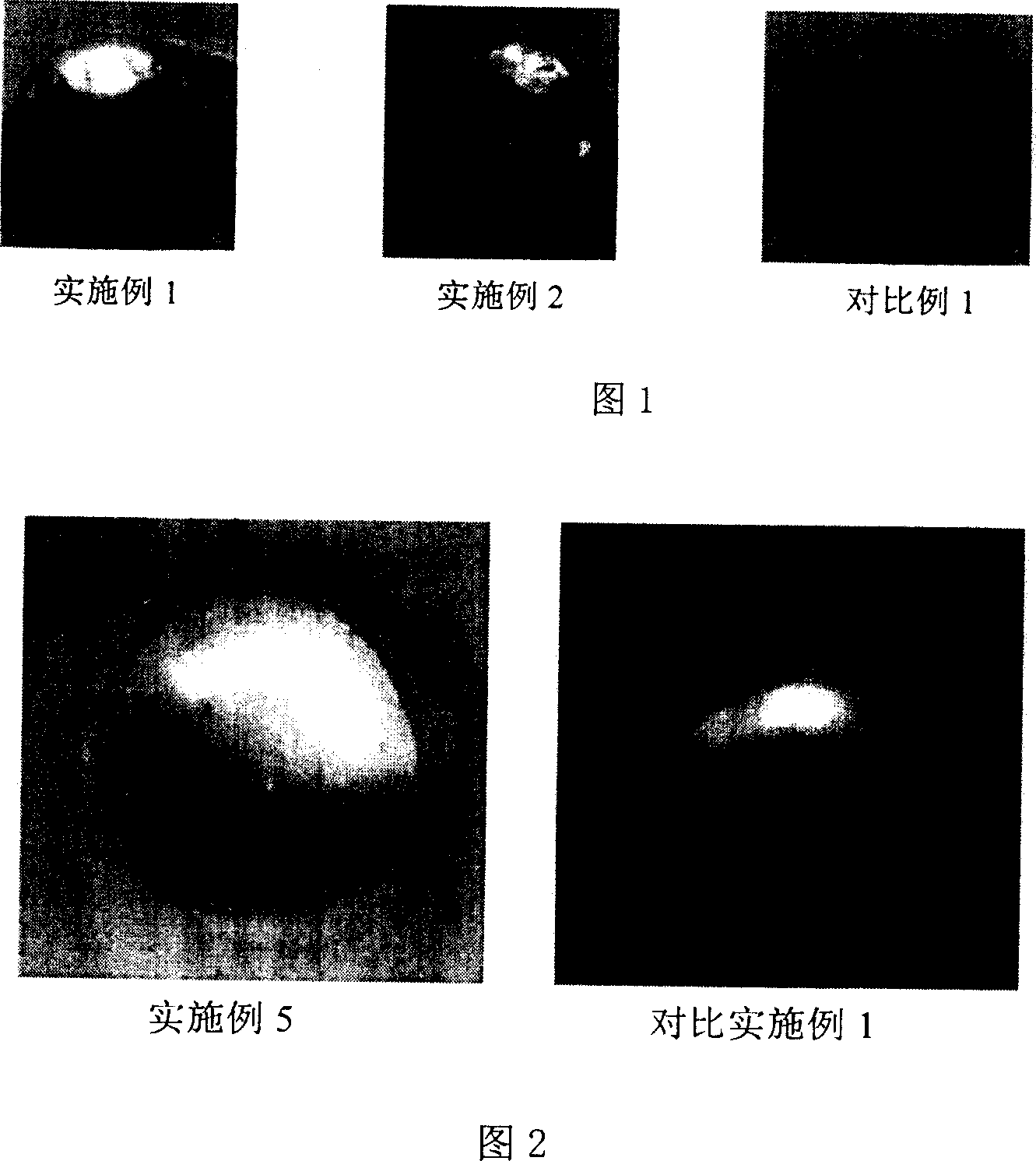

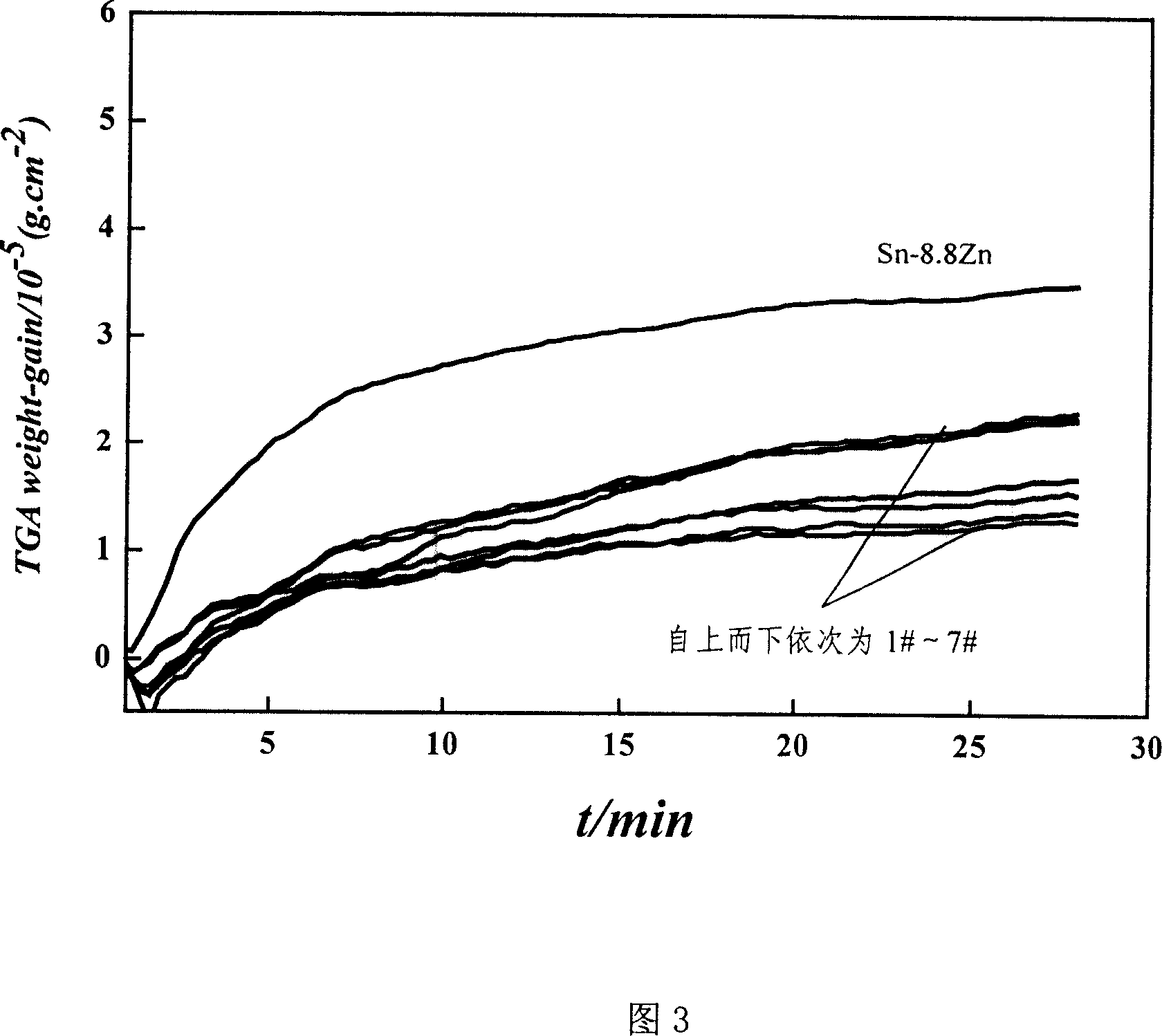

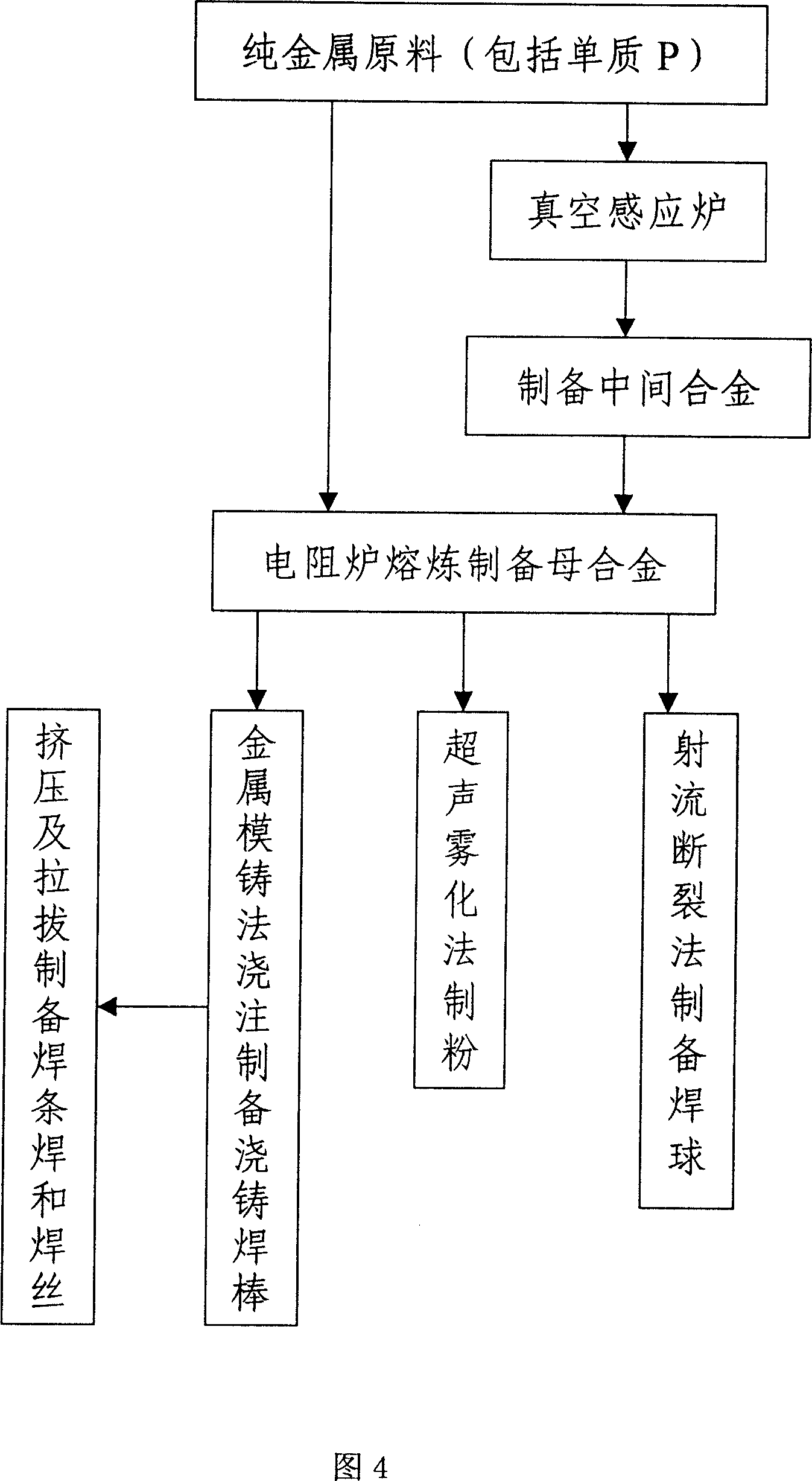

InactiveCN101092006AImprove antioxidant capacityExcellent brazing performanceWelding/cutting media/materialsSoldering mediaAlloy elementZinc

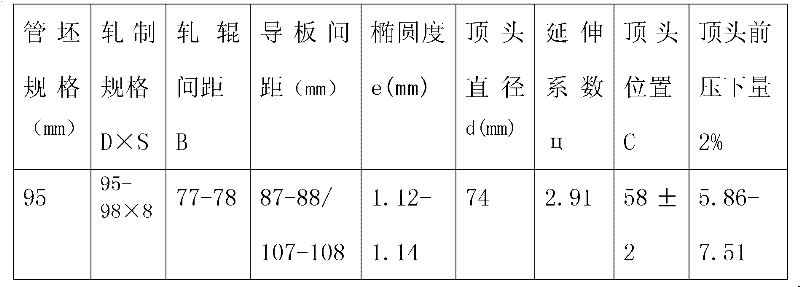

The invention discloses a micro-alloying tin-zinc eutectic alloy tinless solder that the main constituent is Sn-Zn eutectic alloy, Zn is 8-10wt% and the rest is Sn, adding one or the complex from Ga, P, Al, Ge, and Mg, the content of single alloy element is below 0.1%. The invention extremely maintains the feature of Sn-Zn eutectic alloy, and has the advantages of strong oxidation resistance, simple constituents, easy to recycle, etc.

Owner:有研科技集团有限公司

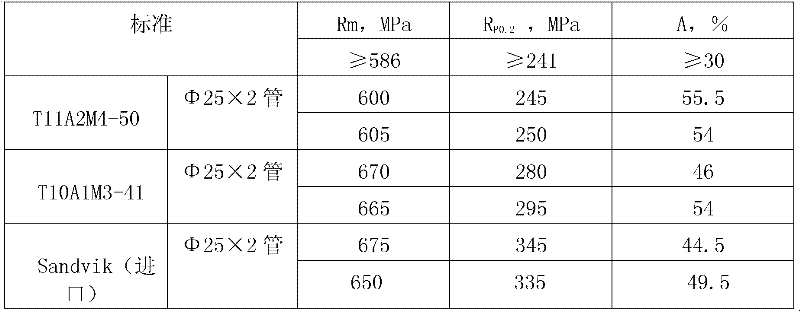

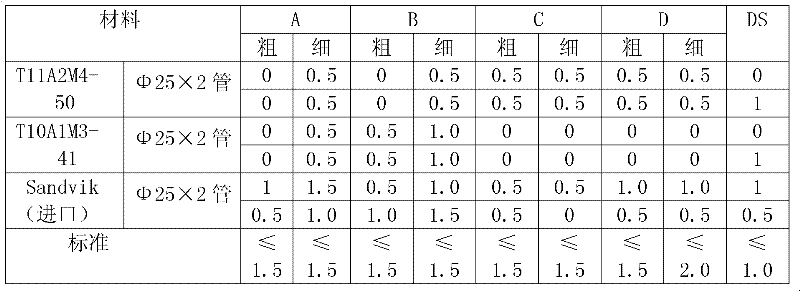

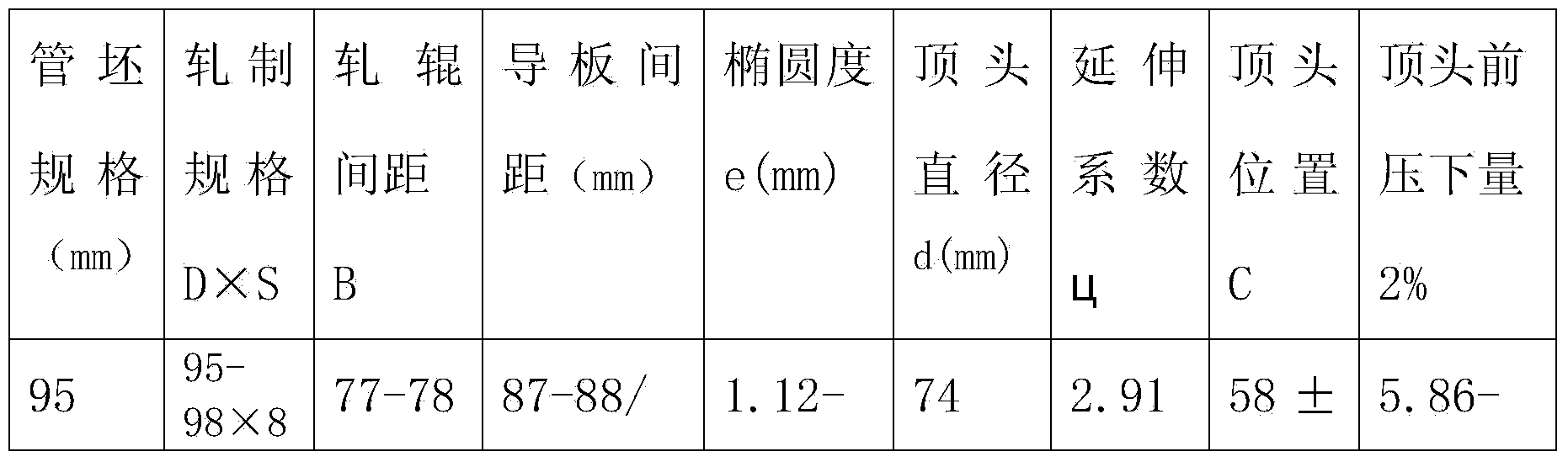

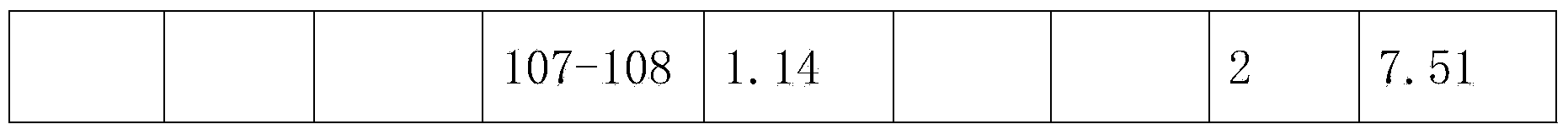

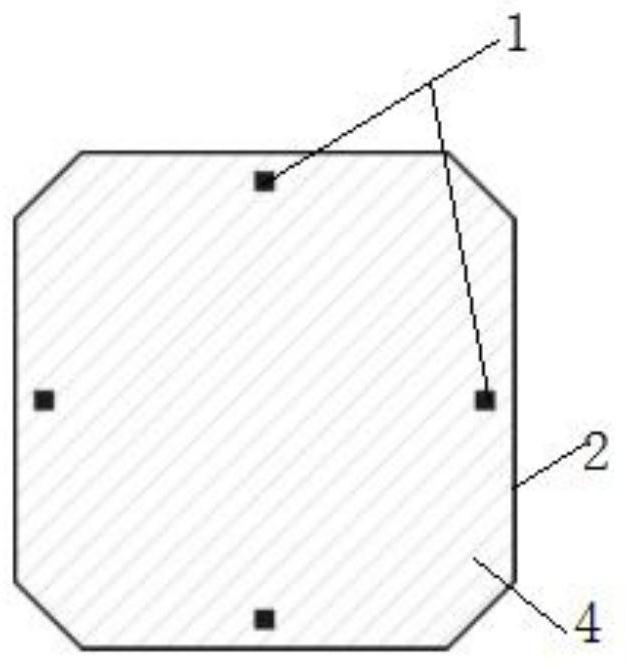

Manufacturing method of alloy tubular product

ActiveCN102527724AC, low content of NGuaranteed corrosion resistanceFurnace typesMetal rolling arrangementsChemical industrySolution treatment

The invention discloses a manufacturing method of an alloy tubular product. The manufacturing method is characterized in that the method comprises the the steps of melting NS1402 alloy steel to be made into rods; sawing the rods into short cut materials, centering the short cut materials, and manufacturing the short cut materials into centering materials; heating the centering materials to the temperature being 950 DEG C, keeping the temperature for 20-30min, then heating the centering materials to the temperature being 1100 DEG C-1120 DEG C, and keeping the temperature for 15-20min, and subsequently, conducting hot punching on the centering materials to be manufactured into a tube blank; rolling the tube blank by 1 to 5 passes so as to manufacture the tube blank into a cold rolled tube; and conducting protective atmosphere solution treatment on the cold rolled tube to manufacture the alloy tubular product. Due to the adoption of the method, the production process is relatively simple, the yield is high, the production cost is low, the performance of the tubular product is good, and the produced alloy tubular product can be widely applied to the fields such as oil, chemical industry and the like.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

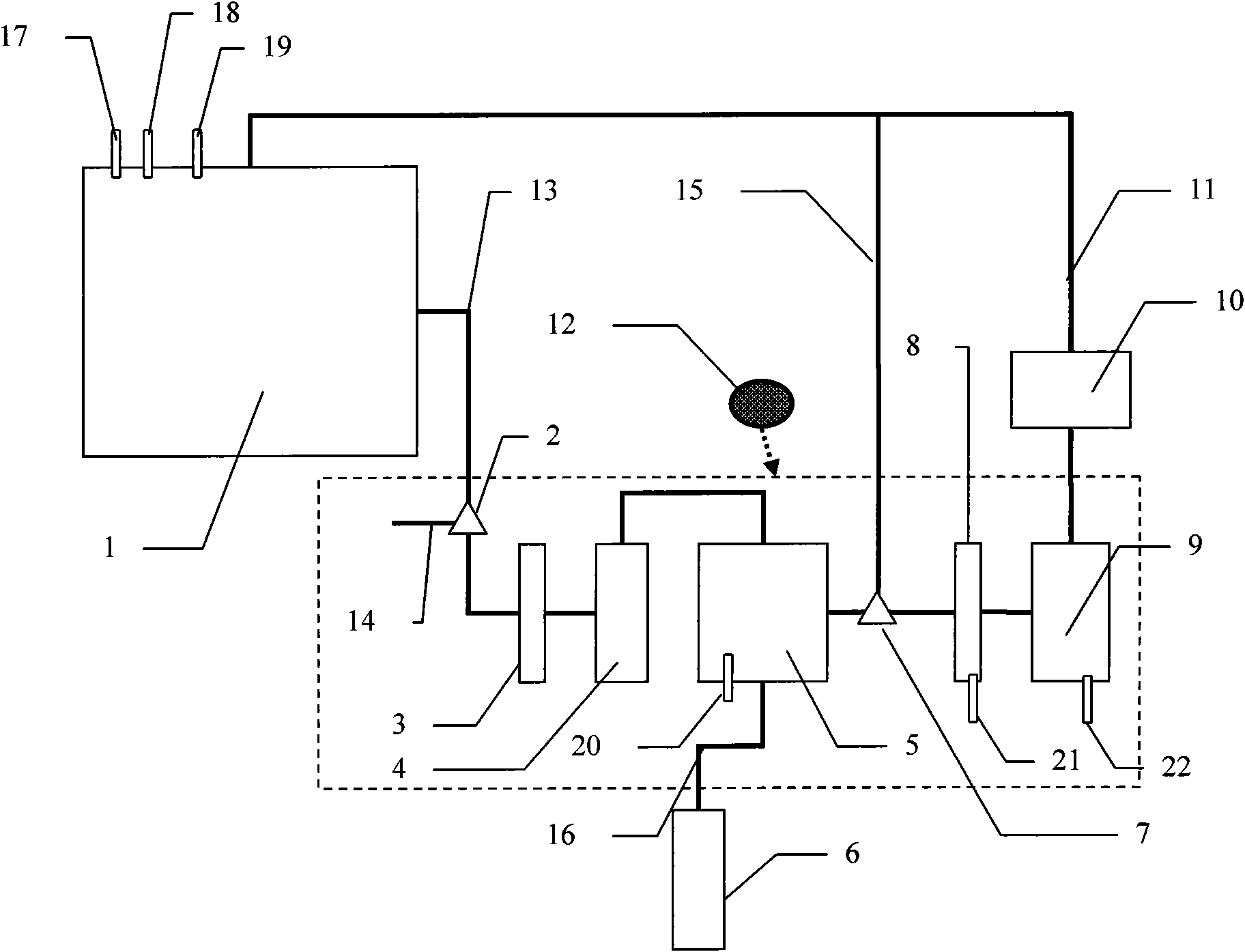

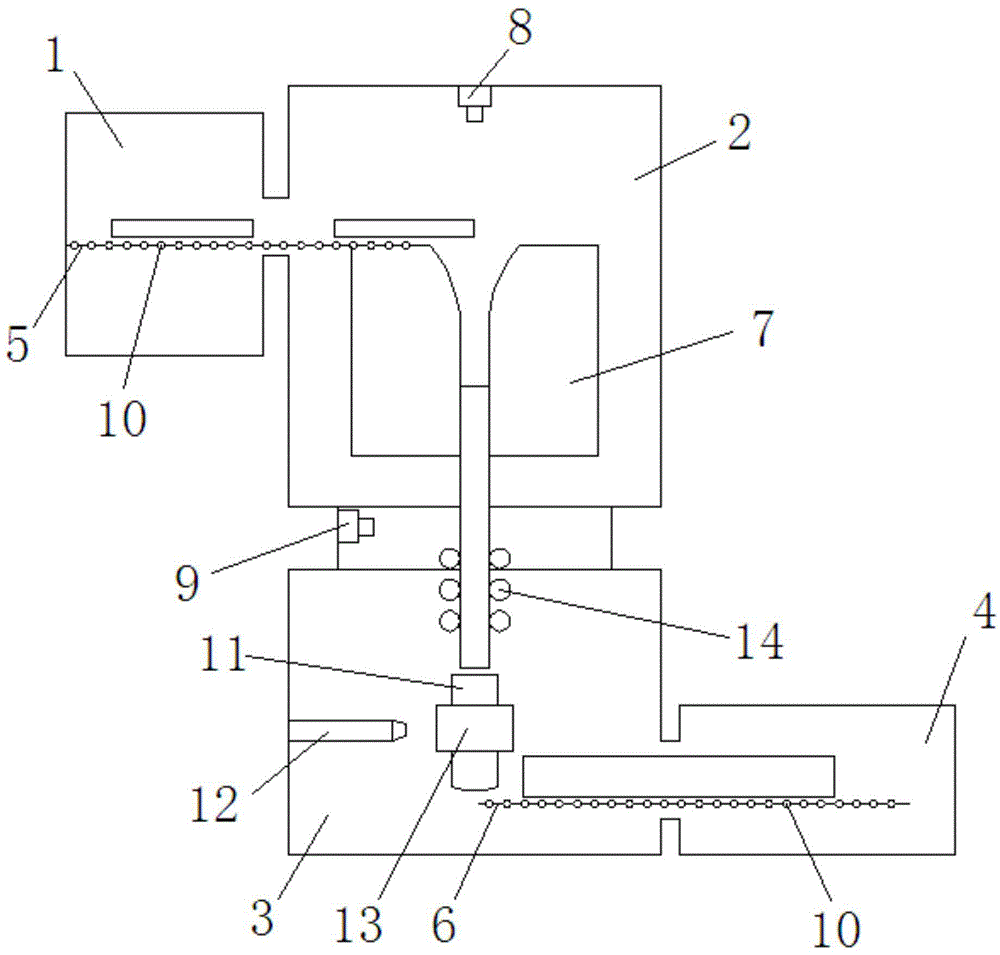

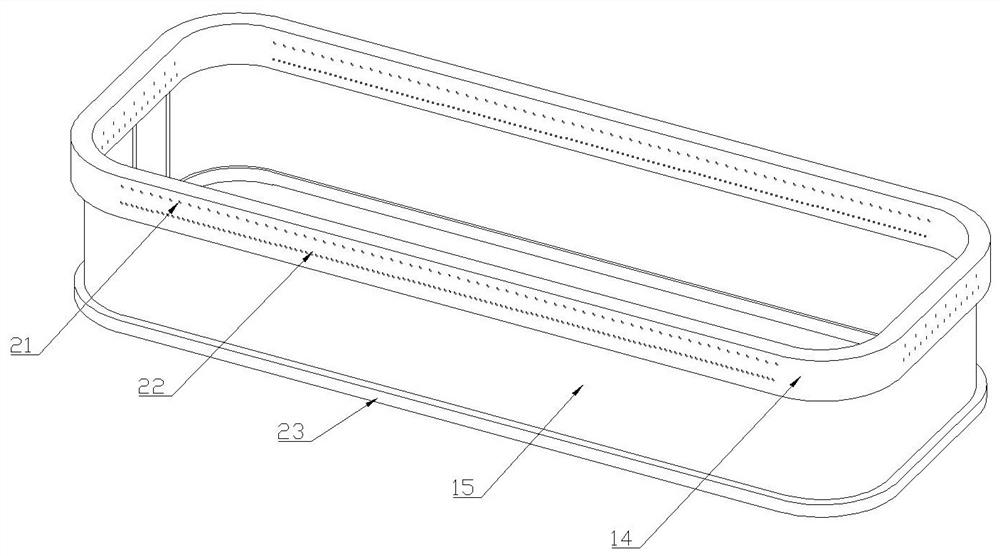

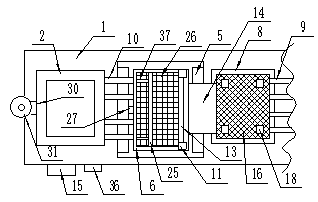

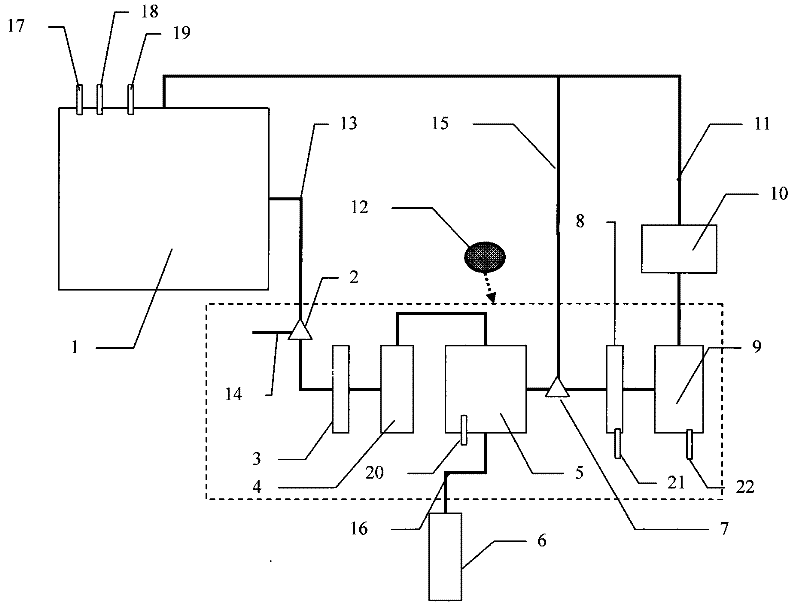

Inert atmosphere control device for laser forming and repair

ActiveCN101607348AReduce the use effectEmission reductionLaser beam welding apparatusGas cylinderBottle

The invention discloses an inert atmosphere control device for laser forming and repair. A return air duct (13) is sequentially connected in series with a three-way valve (2) of an exhaust pipe, a dust filter (3), a diaphragm booster pump (4), a pressure gasholder (5), a three-way valve (7) of an air inlet pipe, a dehydrator (8), an argon purifier (9) and a water cooling jacket (10); an air intake pipeline (11) of the water cooling jacket is connected with a water cooling unit (10) and an atmosphere protective cover (1); an exhaust air duct (14) is connected with the three-way valve (2) of the exhaust pipe; both ends of an air intake duct (15) of the air storage tank are respectively connected with the three-way valve (7) of the air inlet pipe and the air intake pipeline (11) in a sealing way; and both ends of an air supplement pipeline (16) are respectively connected with a gas bottle (6) and the pressure gasholder (5). The invention causes work air in a laser forming and repairing process to be cyclically utilized, reduces use and exhaust of argon, saves the running cost, controls contents of oxygen and nitrogen up to 10 ppm in a working process, and ensures the quality of the laser forming and repair.

Owner:西北工业大学资产经营管理有限公司

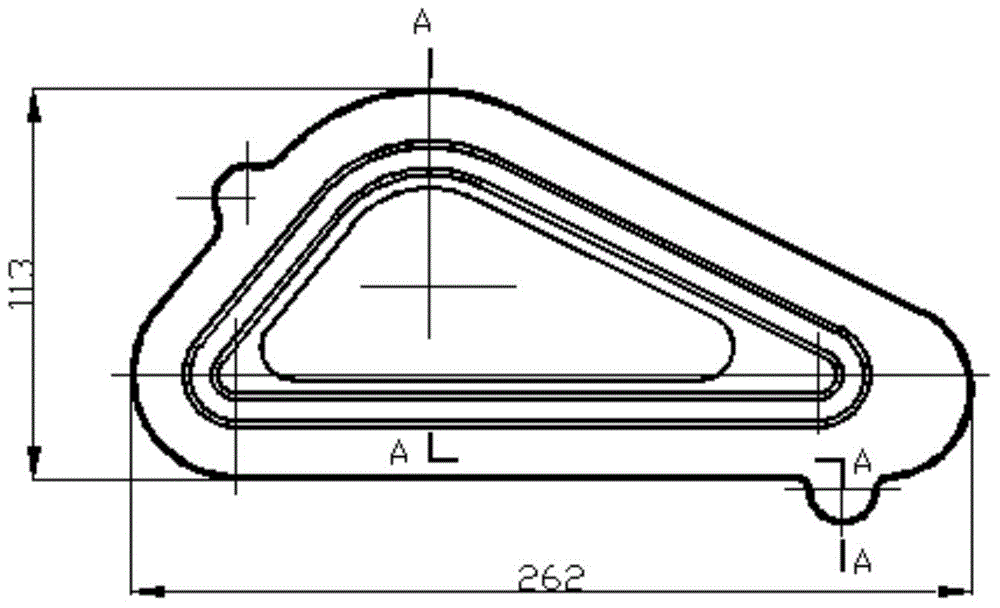

Forging method for complex thin-rib stainless steel die forging with center hole

InactiveCN105215629AEnsure fair distributionSave raw materialsMetal-working apparatusPunch pressStress relieving

The invention relates to the field of structural member die forging and provides a forging method for a complex thin-rib stainless steel die forging with a center hole. The method includes the steps that a bar is blanked into a billet; burrs on the two end faces of the billet are ground and removed; the ground billet is heated and then forged to form a free-forging blank; the free-forging blank is heated and then pre-forged to form a pre-forged piece, a hole is punched in the center of the pre-forged piece through waste heat, and the size of the punched hole is smaller than the required size of an inner hole of the forging; surface defects of the pre-forged piece are ground; the pre-forged piece is heated and then is finish-forged and formed at a time to form the forging, and after forging is stopped, edge cutting is conducted on the forging through a punch press by means of waste heat; the forging is heated, the punch press and a final punching die are used for punching a triangular hole in the center of the forging; stress relieving, quenching, tempering and forging hardness detecting are conducted on the well-machined forging; and shot blasting de-scaling is conducted on the forging.

Owner:AECC AVIATION POWER CO LTD

Titanium and titanium alloy low-cost continuous casting technology and equipment

The invention relates to a titanium and titanium alloy low-cost continuous casting technology and equipment. Under argon protecting or inert gas atmosphere, a plasma gun of at least 65 KW is used as a heat source. Through a crystallizer, a plasma gun and a down-pulling mechanism, continuous casting of titanium and titanium alloy circular and flat cast ingots is achieved. The machining cost of titanium alloy is lowered by about at least 15%. The produced titanium and titanium alloy are even in components, segregation is avoided, and metallurgical quality problems are avoided.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

Forging method for maraging steel disc-shaft integrated forged piece

InactiveCN105728631AAvoid local empty burningAvoid heatingEngine componentsMaterials scienceMaraging steel

The invention discloses a forging method for a maraging steel disc-shaft integrated forged piece. According to the technical scheme for achieving formation of the disc-shaft integrated forged piece through one heating number, avoiding local idle burning of the forged piece and lowering the production difficulty of the forged piece, the traditional final forging temperature of the maraging steel forged piece is adjusted to 750 DEG C from 820-870 DEG C, the traditional technique that disc upsetting is conducted after rod pulling is changed into the technique that rod pulling is conducted after disc upsetting, then effective protective measures are taken in the deformation process of the forged piece, and the effect that formation of the forged piece is completed through one heating number on the premise that the requirement for the final forging temperature is met is guaranteed. According to the technical scheme, the operability is high, the forging method is suitable for popularization, and the preparation technique for the disc-shaft integrated forged piece and particularly for a large disc-shaft integrated forged piece with the length exceeding 2000 mm is remarkably improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

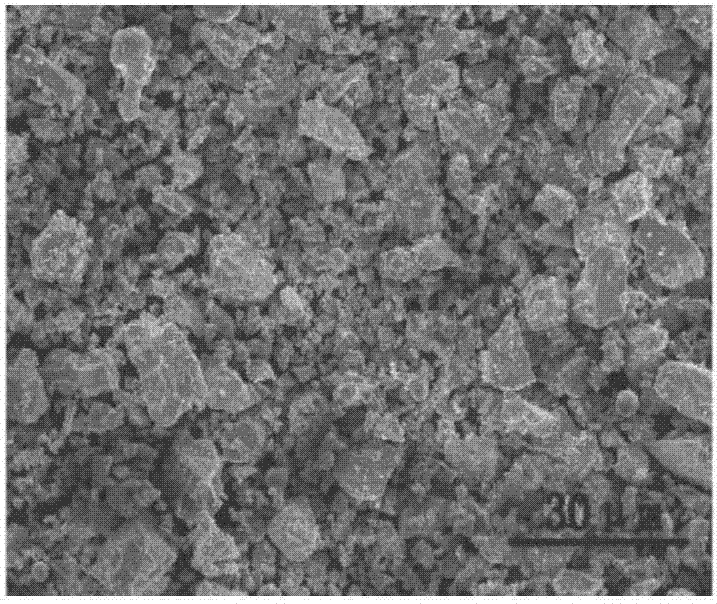

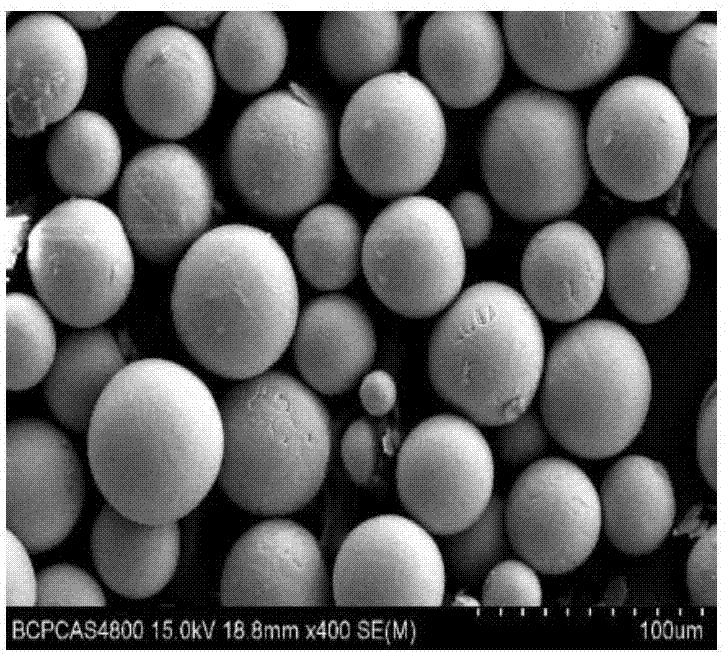

Fine-grain titanium aluminum powder forming method

The invention relates to the field of materials, belongs to the field of titanium aluminum intermetallic compounds, and in particular, relates to a fine-grain titanium aluminum powder forming method. The invention provides a design method of a cold isostatic pressing formed ladle and a titanium aluminum powder forming method under different powder production processes; and compact sintering is performed on a pressed blank with excellent forming performances. The method comprises the following steps: original spherical prealloying titanium aluminum powder and element powder are respectively mixed on a planet ball mill and a polishing machine; titanium aluminum powder prepared by the method is filled in a rubber ladle for continuous compaction; then, the rubber ladle and a corresponding device are put in a cold isostatic pressing machine for near net shaping; and the formed pressed blank is sintered in a vacuum sintering furnace to form a needed round rod sample or a small component. The method can realize the near net shaping technology of a titanium aluminum powder component, and is fine in structure grain and excellent in internal metallurgy quality and size deviation control.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

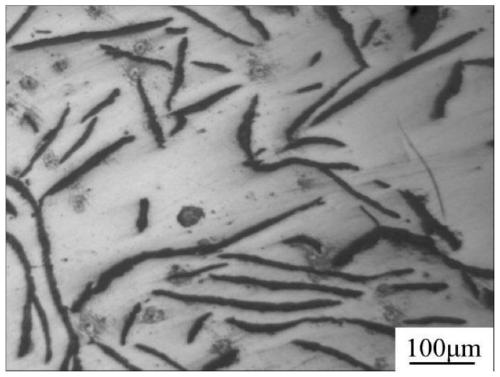

Casting method of complex-structure ductile iron thin-wall casting of ship turbocharger

ActiveCN102784889ABottom shrinkage improvementImprove pass rateFoundry mouldsFoundry coresTurbochargerDuctile iron

The invention relates to the casting technology of complex-structure ductile iron thin-wall castings, such as a fuel feed case, which are important parts of a ship turbocharger, and in particular relates to a casting method of a complex-structure ductile iron thin-wall casting of the ship turbocharger. The casting method includes the steps of, in sequence, fabricating moulds, modeling, making a core, assembling the moulds, pouring and clearing the sand shakeout. The method is characterized in that a pouring system used in the pouring process consists of a riser runner, a chilling block, a live riser arranged on a bottom flange of the fuel feed case and a feeding head arranged at the lateral side of the bottom flange. A filter screen is arranged on the pouring system. With the casting method disclosed by the invention, the defect of shrinkage porosity of the bottom flange of the fuel feed case is solved, the conventional idea of changing the entire cast solidification sequence by increasing the number the chilling blocks is thoroughly changed, the problem of shrinkage porosity at the bottoms of the castings is completely improved by adopting the new feeding scheme, the percent of pass of the castings is improved, and regular batch production of the castings is ensured.

Owner:KOCEL EQUIP

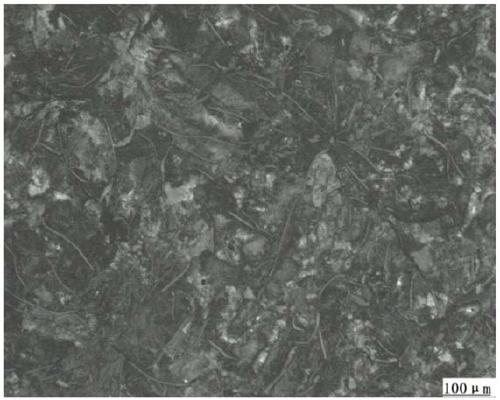

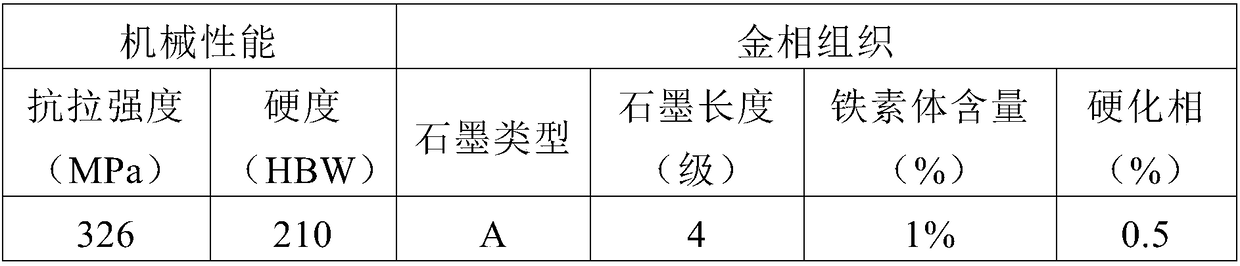

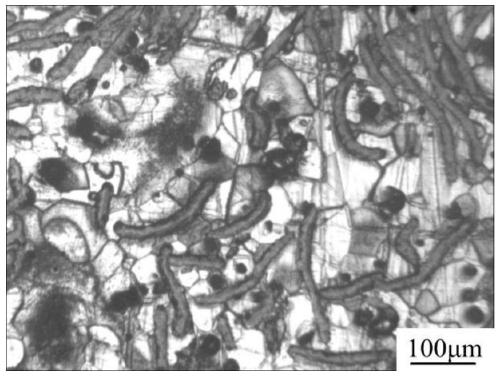

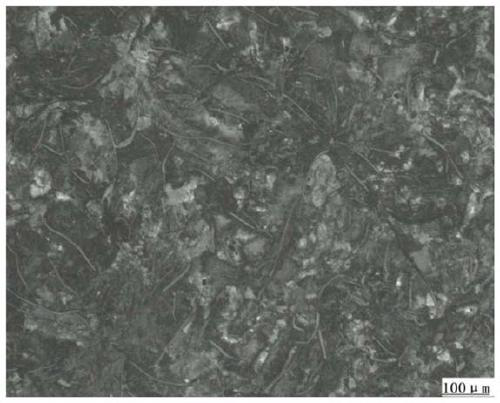

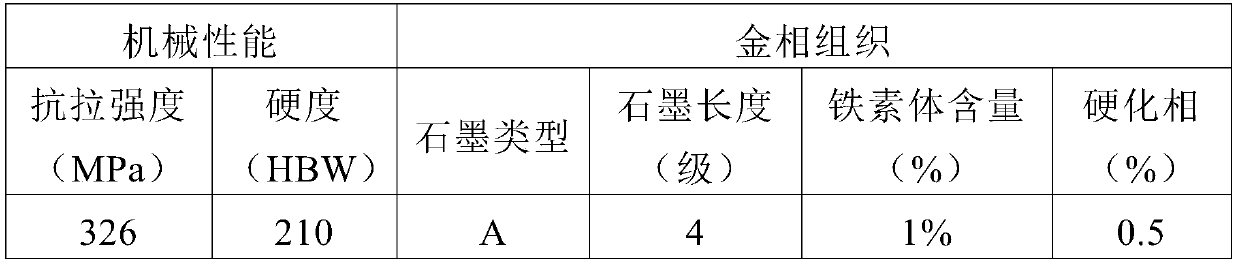

Gray cast iron and smelting method thereof

The invention provides gray cast iron and a smelting method of the gray cast iron, and relates to the technical field of metallurgical materials. The gray cast iron is prepared from nonmetallic alloyelements, metal alloy elements and the balance iron and inevitable impurities, wherein the nonmetallic alloy elements comprise, by mass, 2.8-3.2% of C, 2.2-2.4% of Si, 0.2% or less of P, 0.15% or lessof S, the metal alloy elements comprise, by mass, 0.25-0.35% of Cr and at least one of Mn, Cu, Mo, Li, Sn and Sb, and the total content of the metal alloy elements except for Cr is 1.5-1.6%. According to the gray cast iron, by reasonably designing the chemical ingredients, the gray cast iron can meet performance requirements of machine tool basic parts, waste iron and waste steel can be adopted as main furnace materials, therefore, raw material selection and matching flexibility are improved, and the raw material cost and the production cost are reduced.

Owner:CRRC DALIAN CO LTD

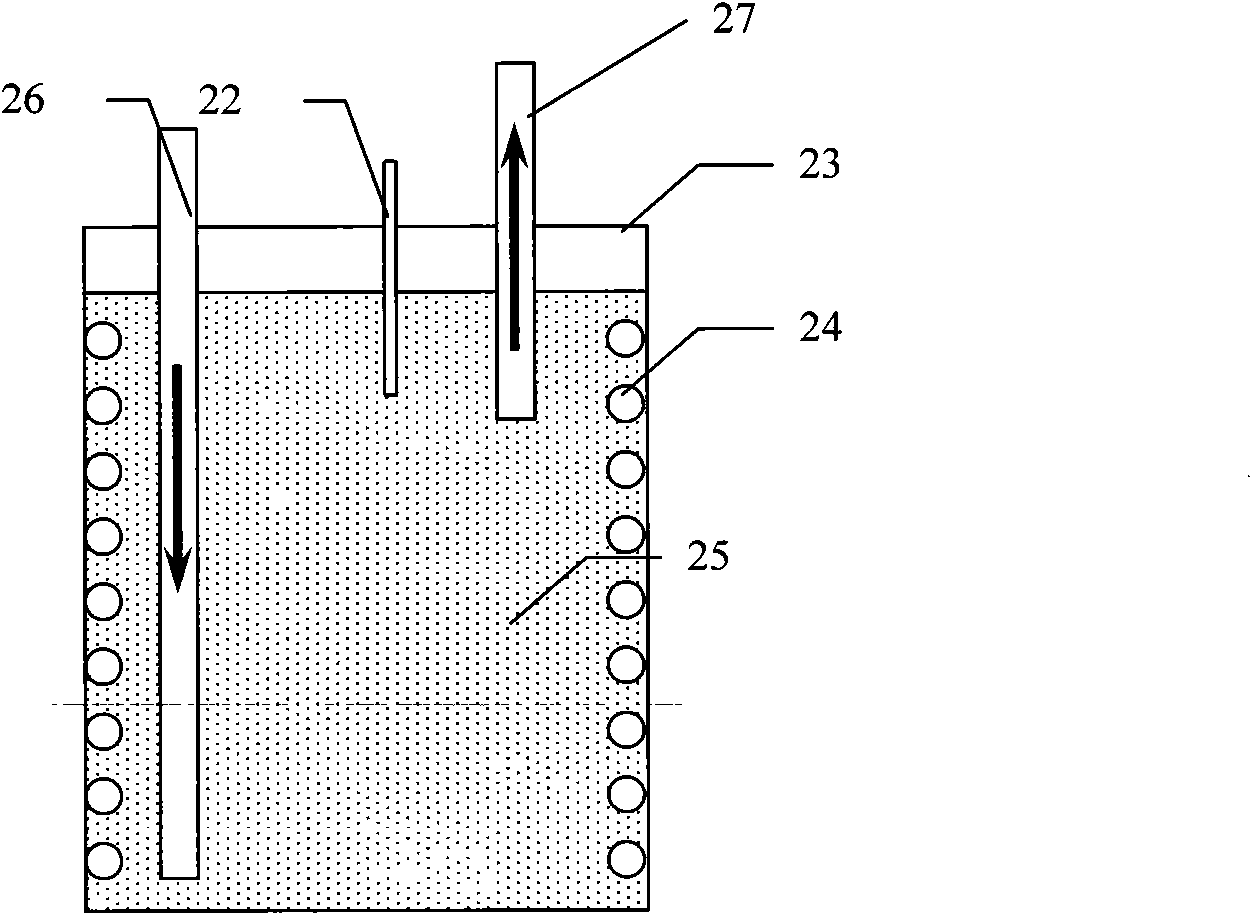

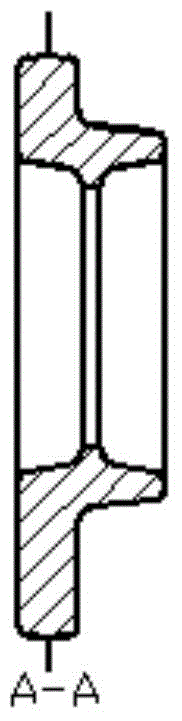

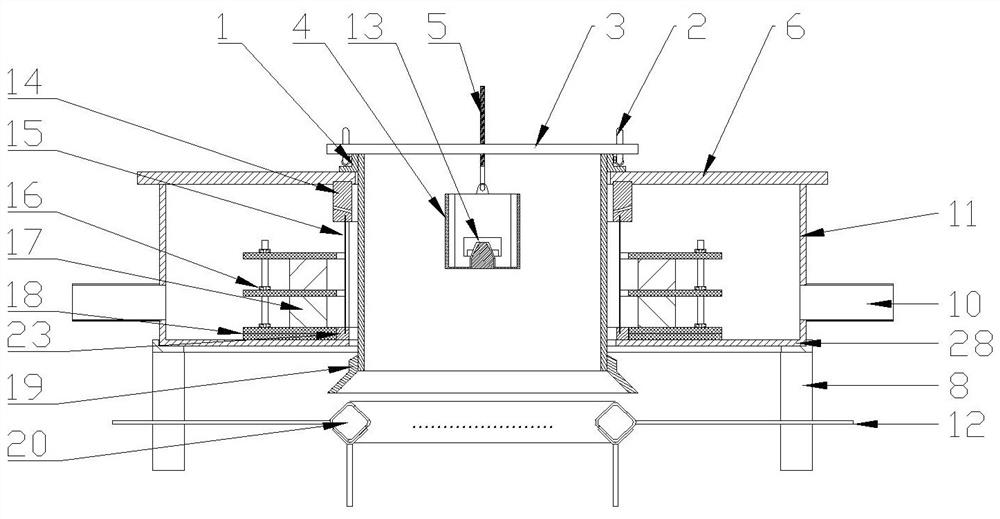

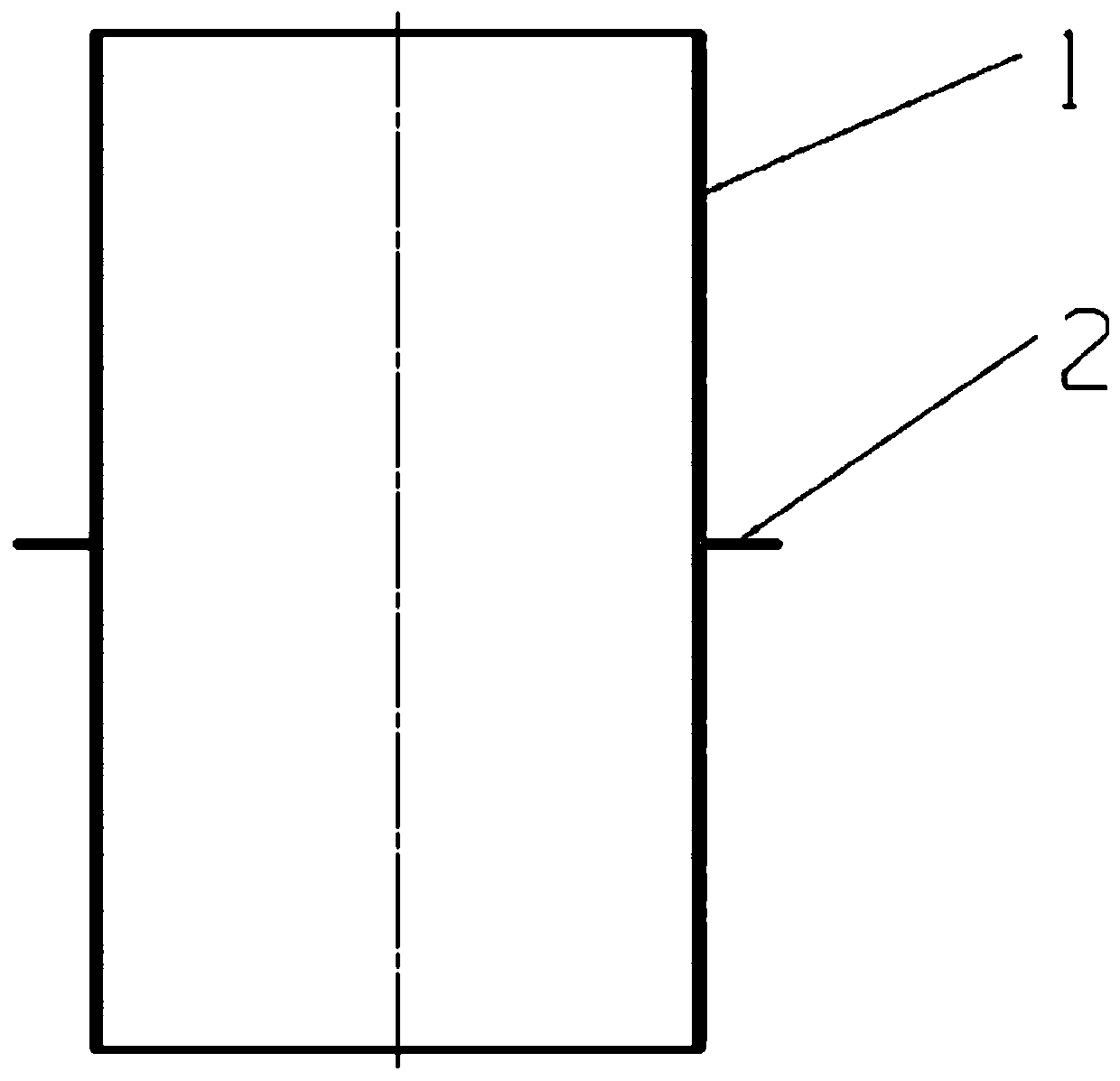

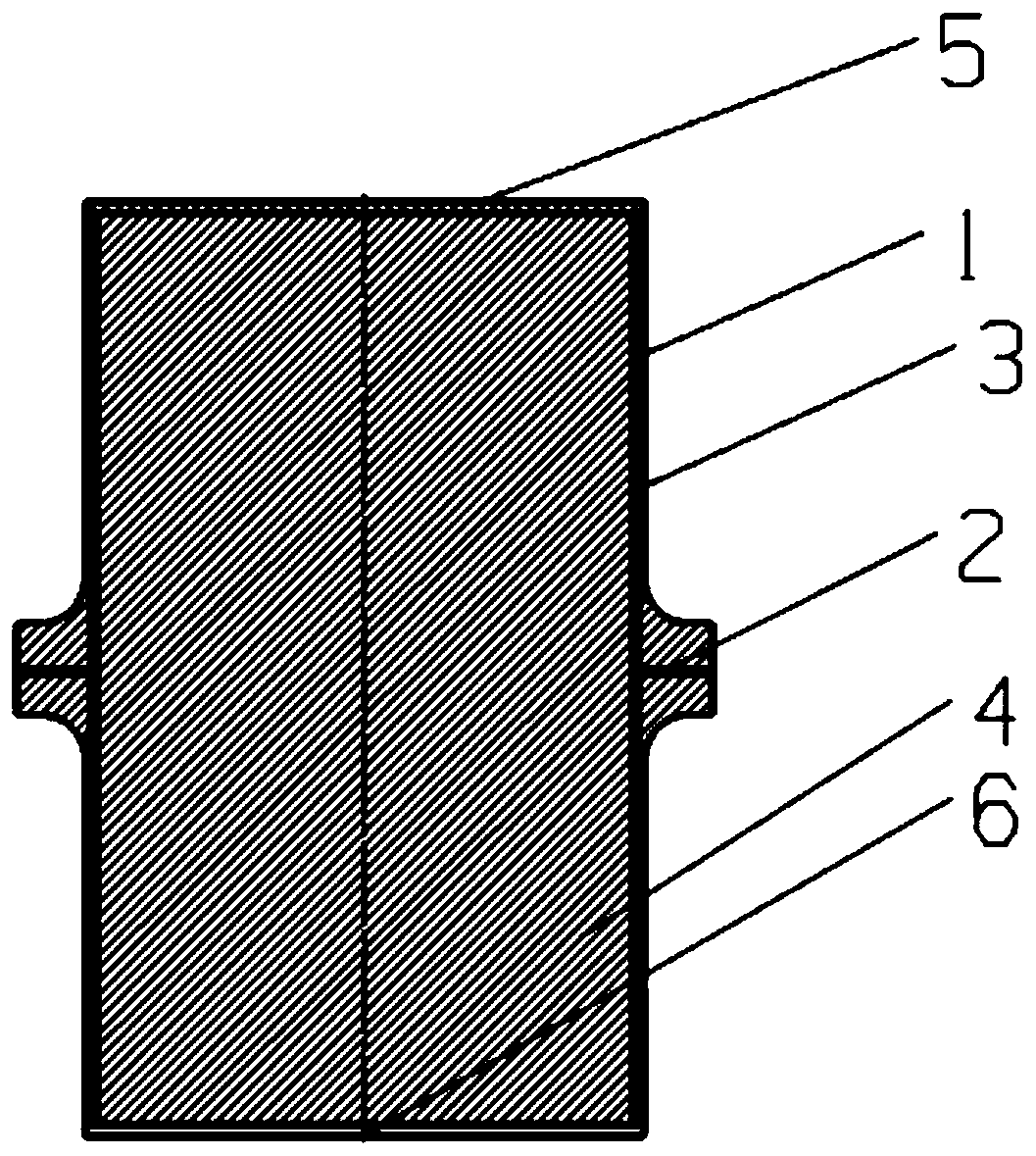

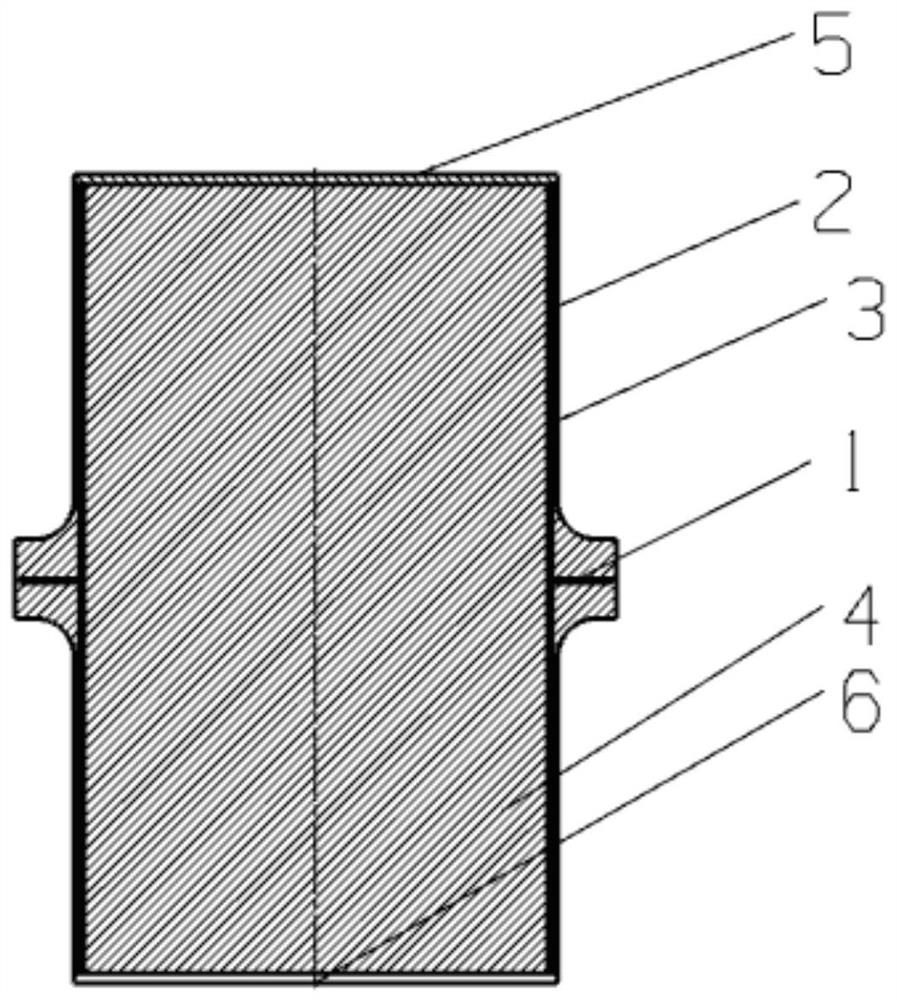

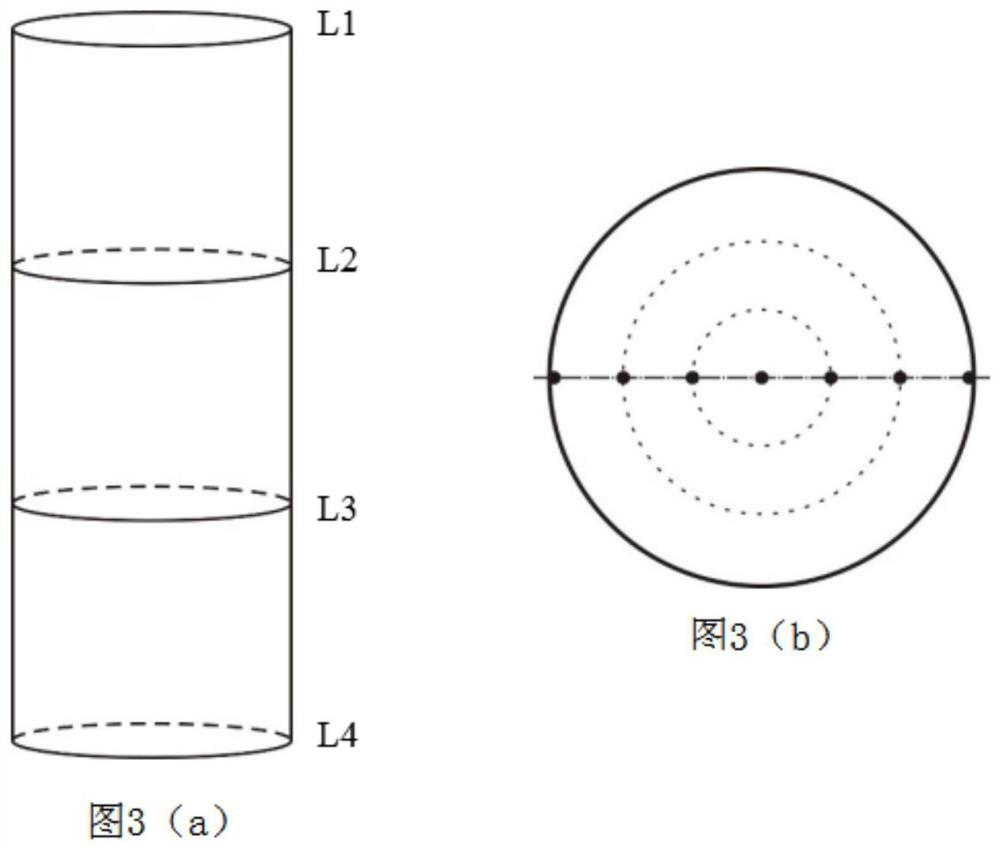

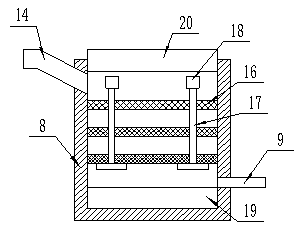

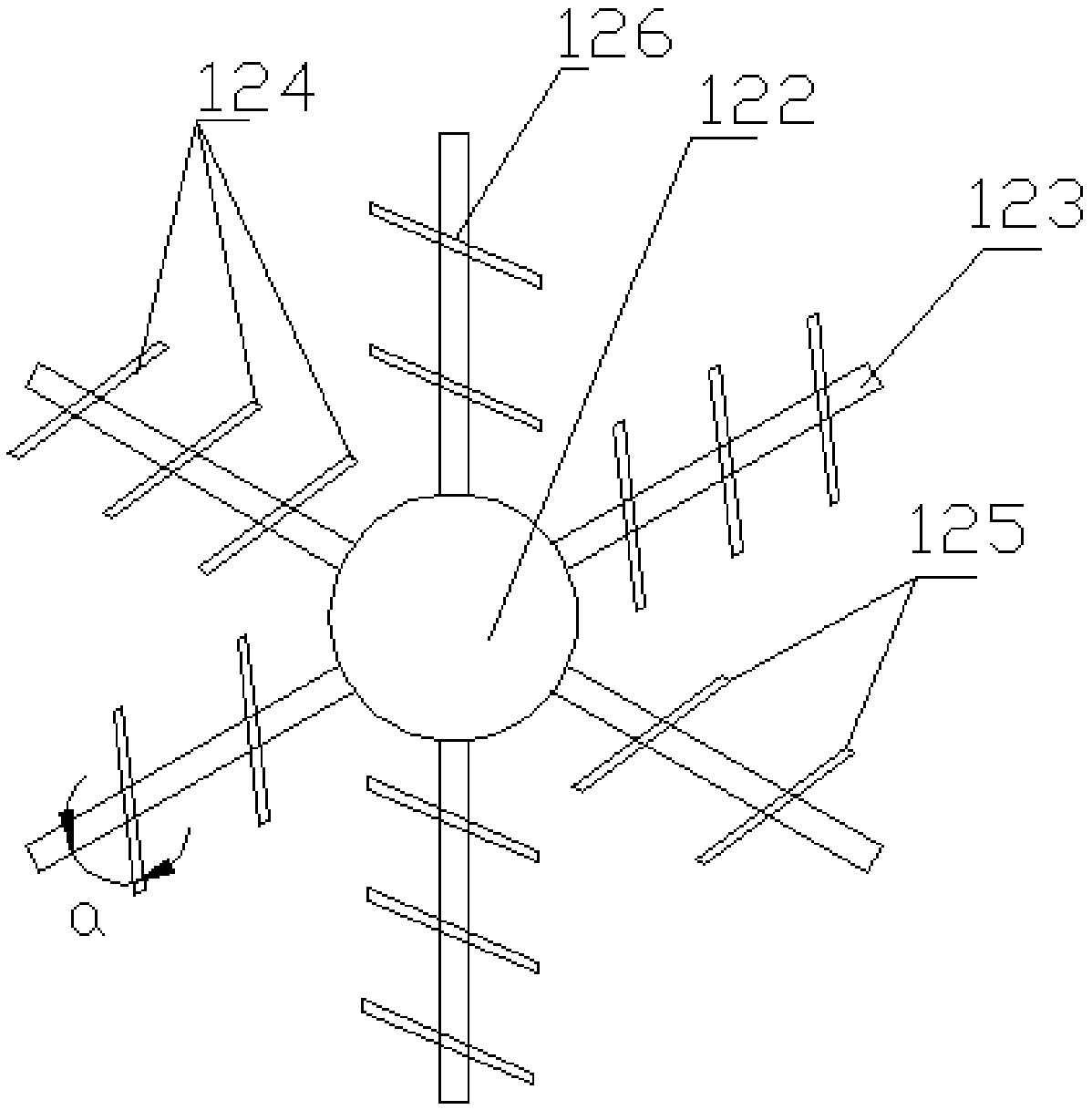

Crystallizer for continuous casting of titanium alloy pipes

The invention relates to a crystallizer for continuous casting of titanium and titanium alloy pipes. Titanium alloy pipe blank with different size requirements can be continuously cast under the protection of argon or the atmosphere of inert gases. An outer mold of the crystallizer controls the cooling speeds and temperatures of different areas through a three-section water cooling system, and thus the metallurgical quality of pure titanium and titanium alloy pipe blank is guaranteed. Meanwhile, an ingot pull rod rotates at a certain speed while the blank is pulled downwards, and hence the metallurgical quality and surface quality of the pipe blank are effectively improved. The produced titanium and titanium alloy pipes are even in ingredients and free of segregation and metallurgical quality defects. The machining cost of the titanium alloy pipes is lowered by about 30%.

Owner:NANJING UNIV OF TECH

High-strength and heat-resistant cast aluminum alloy material

The invention provides a high-strength and heat-resistant cast aluminum alloy material and further provides a preparation method of the high-strength and heat-resistant cast aluminum alloy material. The high-strength and heat-resistant cast aluminum alloy material is composed of the following components of, by mass, 7.2-7.8% of Si, no more than 0.45% of Fe, 3.1-3.6% of Cu, 0.2-0.5% of Mn, 0.25-0.4% of Mg, 0.2-0.3% of Zn, no more than 0.04% of Cr, 0.1-0.25% of Ni, 0.12-0.2% of Ti, 0.004-0.01% of Sr, no more than 0.1% of Pb and the balance Al and inevitable impurities. The high-strength and heat-resistant cast aluminum alloy material is high in strength, good in heat-resistance performance, scientific and economic in formula, good in casting performance and especially suitable for being usedas an engine air cylinder cover cast aluminum alloy material.

Owner:铜陵康达铝合金制品有限责任公司

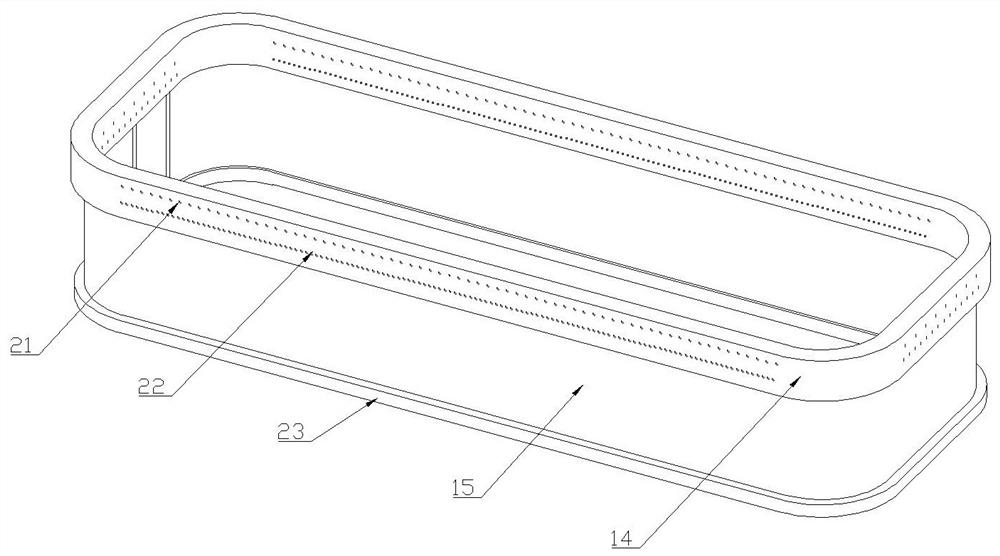

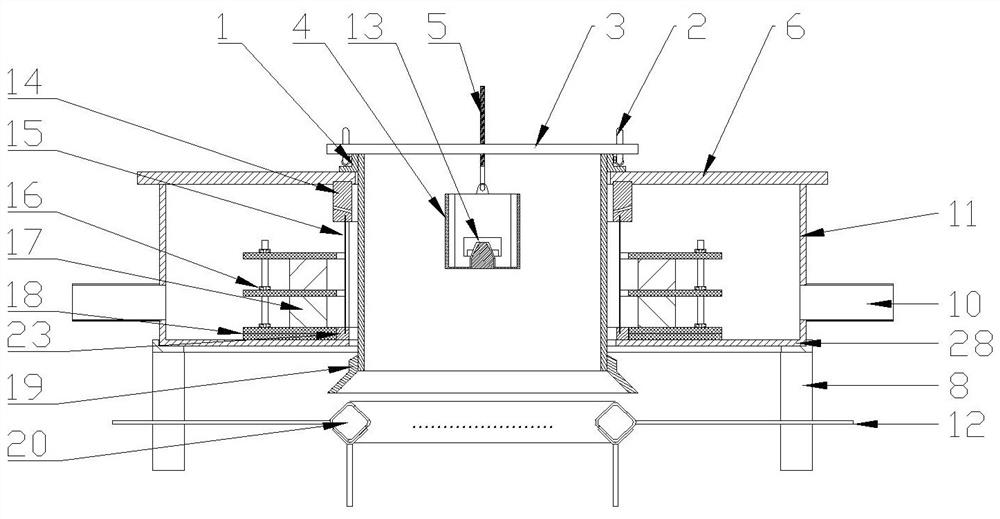

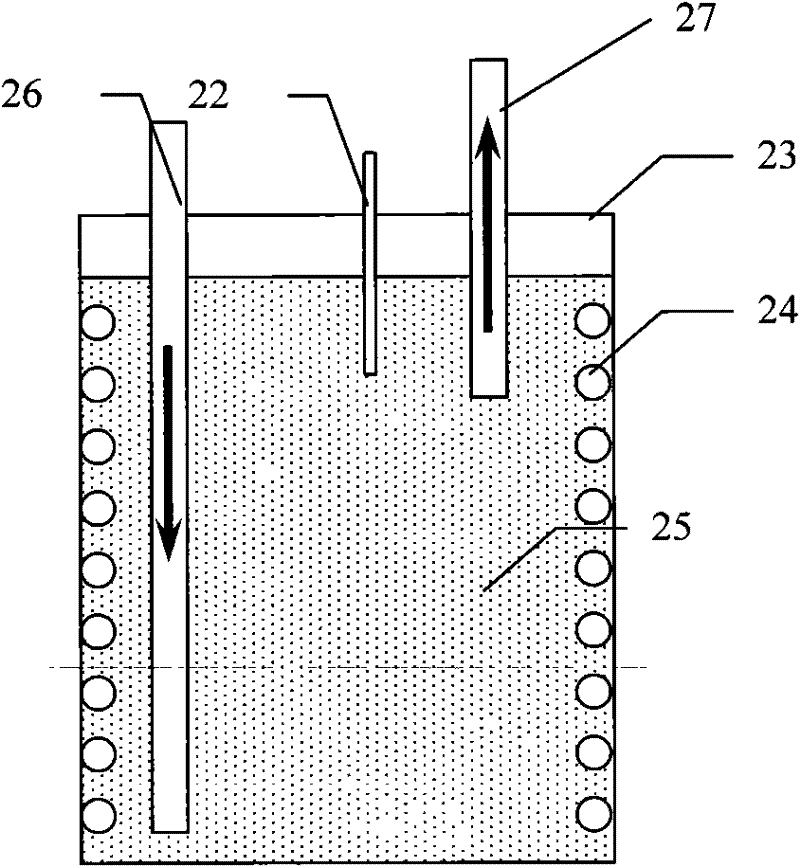

Electromagnetic semi-continuous casting device for high-casting-stress alloy cast ingot and method

The invention belongs to the technical field of casting, and particularly relates to an electromagnetic semi-continuous casting device for a high-casting-stress alloy cast ingot and a method for casting the cast ingot by applying the electromagnetic semi-continuous casting device. The electromagnetic semi-continuous casting device mainly comprises a diversion trench, a crystallizer and a dummy barhead, wherein the crystallizer comprises a crystallizer inner sleeve, a cold water tank, a coil and a bottom bracket. Under the condition that the amount of cold water is not changed, the cold watertank with double rows of different-diameter crossed water holes is adopted, so that double water flow beams appear in cold water, the cooling rate of alloy melt at the contact position of the cold water and the crystallizer inner sleeve is reduced, and the crack generation probability is reduced; through the arrangement of the distance between the two rows water holes, control over the cooling strength during casting can be achieved, and the surface quality of the cast ingot can be improved; the temperature gradient and the casting stress of the center and the edge of a slab ingot can be effectively reduced by using the diversion trench in the electromagnetic semi-continuous casting device, so that the cracking possibility of the cast ingot is reduced; and according to the electromagneticsemi-continuous casting device, production of products within a certain specification range can be achieved by replacing the specification of the crystallizer inner sleeve.

Owner:NORTHEASTERN UNIV

Near-net forming method for thin-wall complex component

ActiveCN110947970ARealize high temperature diffusion connectionReduce manufacturing costThin walledHot isostatic pressing

The invention relates to a near-net forming method for a thin-wall complex component. According to the method, a metal sheath designed through a special structure is utilized, a local thin-wall structure is placed in an insert plate, powder is adopted for the rest of the thin-wall structure, and densification of the powder and diffusion connection of the powder and the insert plate are achieved through hot isostatic pressing. By means of the method, the problem that in the hot isostatic pressing near-net forming process of powder of a large complex sheet metal structural component, the local thin-wall part is prone to being short of meat due to the fact that powder filling is difficult is solved, net forming is achieved, and the problems that the local thin-wall part is poor in rigidity and cannot be machined are solved. The near-net forming method can be used for forming complex components such as an air inlet channel and a cabin, the forming precision can be improved, and the structural integrity can be improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High-strength creep-resistant high-temperature alloy and preparation method thereof

InactiveCN114737084AHigh strengthImprove creep resistanceMetal-working apparatusEfficient propulsion technologiesPhase formationSuperalloy

The invention provides a high-strength creep-resistant high-temperature alloy and a preparation method thereof, and belongs to the technical field of metallurgy. The alloy comprises the following components in percentage by mass: 10.00%-12.00% of Cr, 12.00%-18.00% of Co, 5.50%-7.50% of W, 1.50%-3.50% of Mo, 3.00%-4.20% of Al, 3.00%-4.20% of Ti, 1.00%-2.20% of Nb, 0.40%-1.50% of Ta, 0.01%-0.04% of C, 0.01%-0.04% of B, 0.09%-1.20% of Zr, less than 0.10% of Hf and the balance of Ni, and the total mass percentage of gamma'phase forming elements Al, Ti, Nb and Ta in the high-temperature alloy is as follows: 9.5% < = (Al + Ti + Nb + Ta) < = 10.3%; the mass percentage content of a gamma'phase in the high-temperature alloy is 50%-55%, and the mass ratio of Al to Ti in the high-temperature alloy is that (Al / Ti) is larger than or equal to 0.9 and smaller than or equal to 1.0. The alloy and the disc piece of the alloy can be manufactured through the method, and the disc piece of the alloy can meet the requirements of future aviation turboshaft engines for high temperature resistance, high strength and creep resistance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

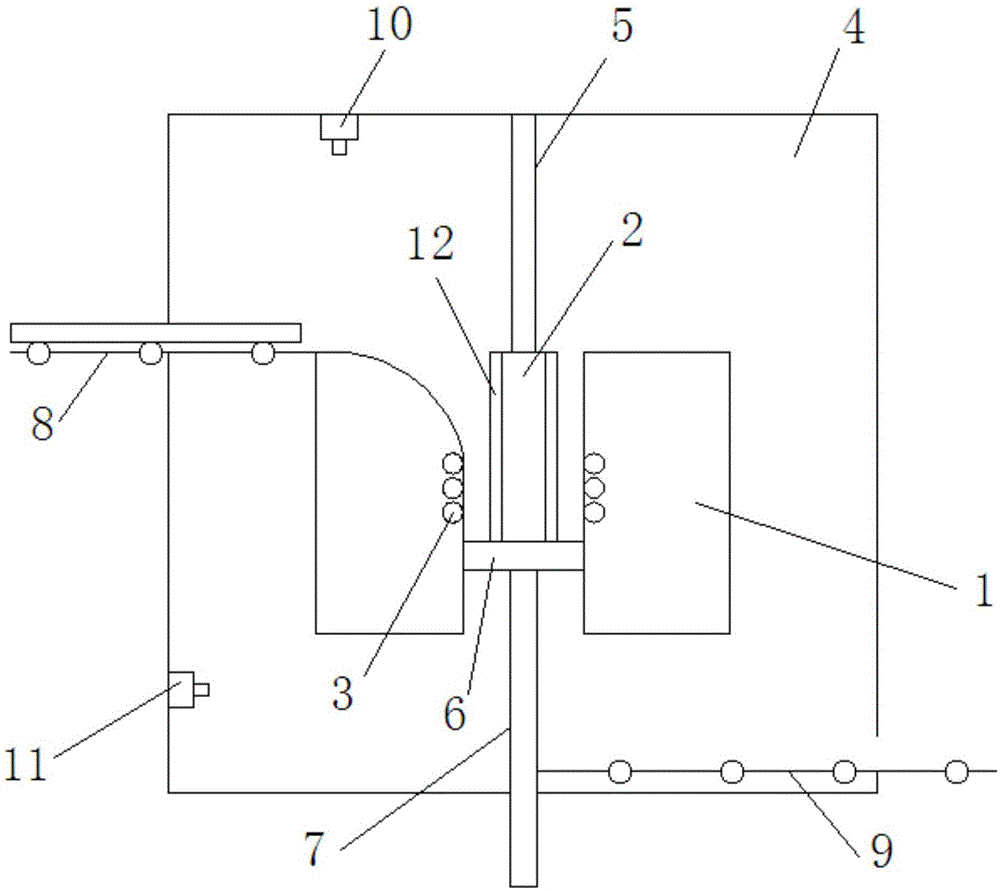

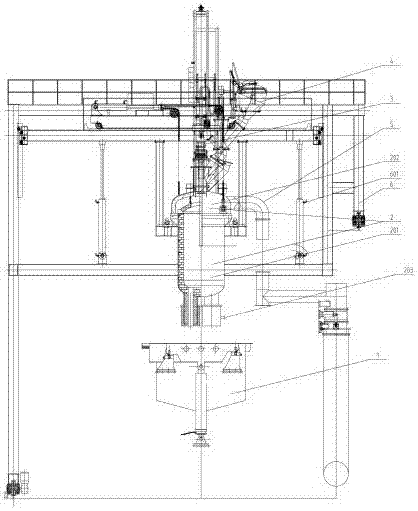

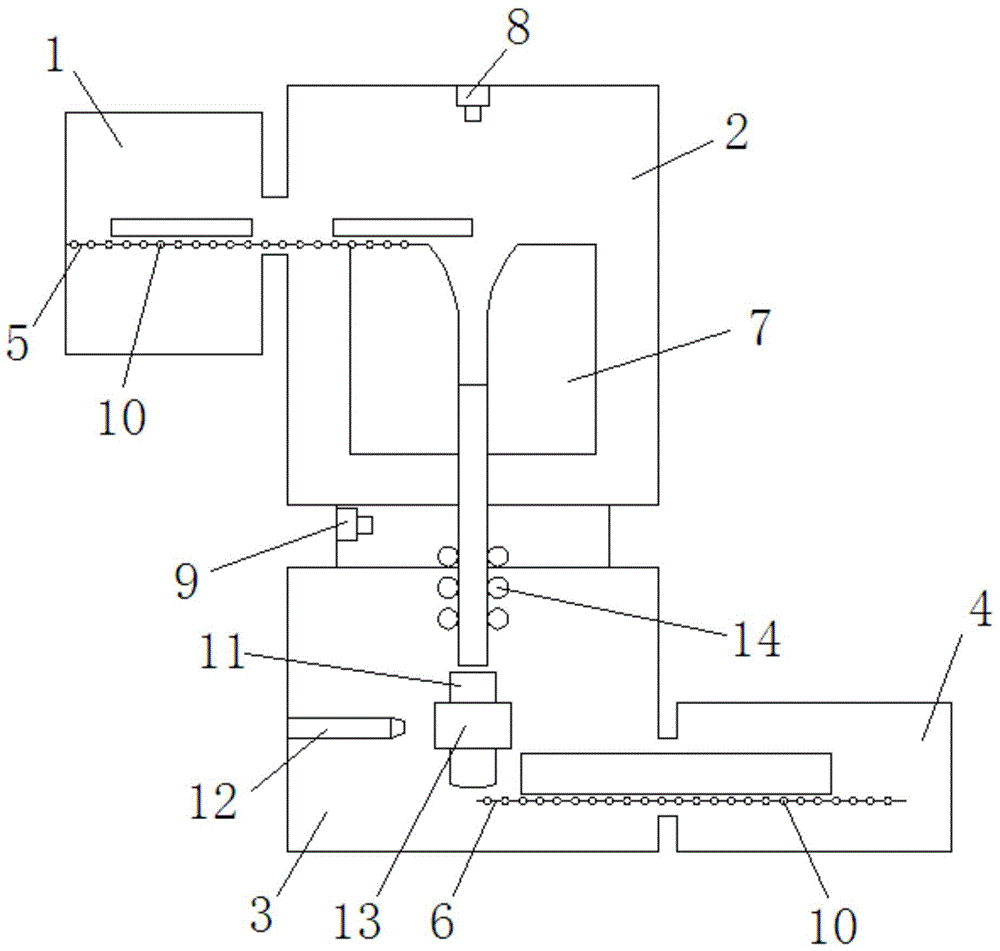

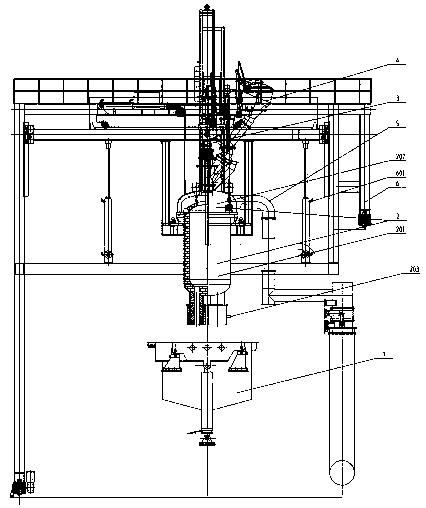

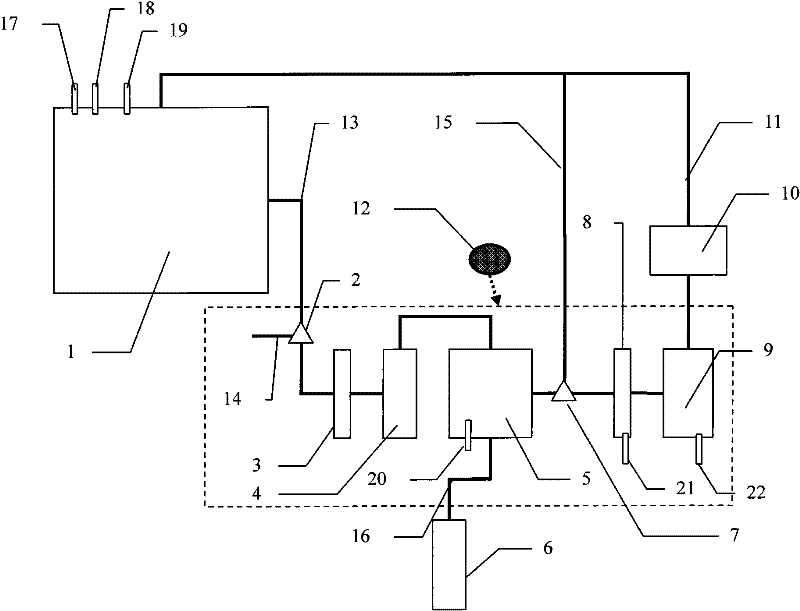

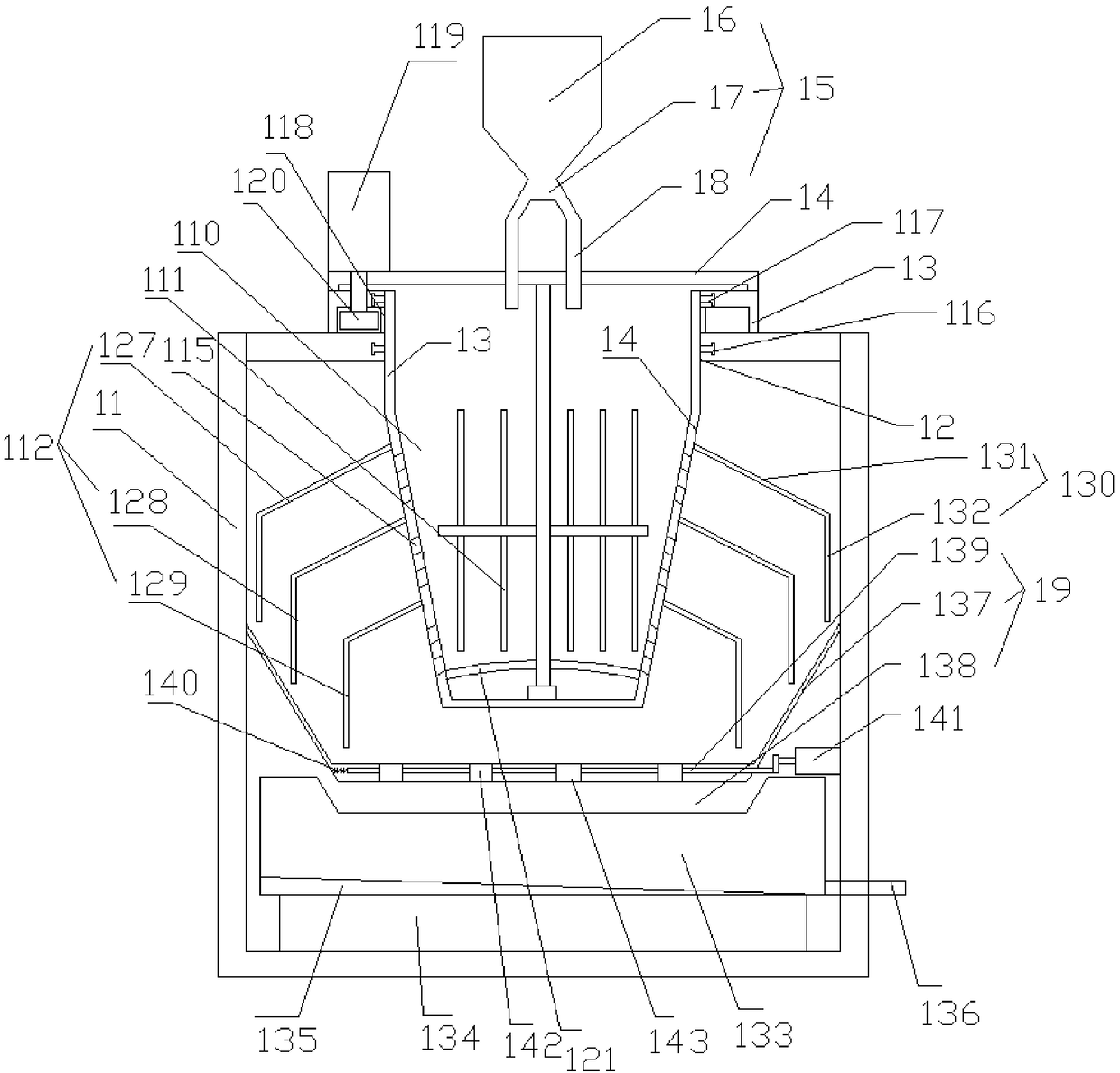

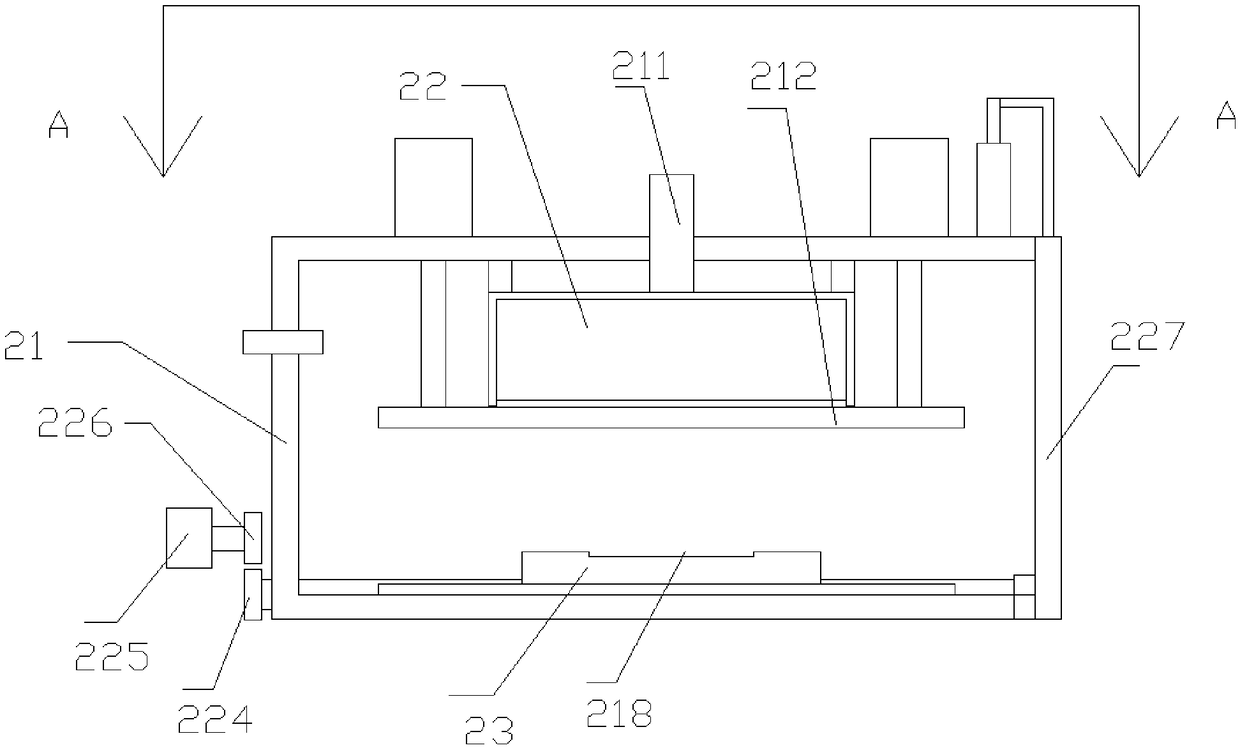

Vacuum circular smelting device, medium-frequency induction smelting furnace system and method

The invention relates to a medium-frequency induction smelting steel production system. The system comprises a medium-frequency induction smelting furnace, a vacuum circular smelting device, an oxygen gun and spraying gun lifting system, a vacuum charging device and a rail car; the vacuum circular smelting device is arranged above the medium-frequency induction smelting furnace; the rail car drives the vacuum circular smelting device to perform a lifting motion, so that a vacuum groove and a vacuum cover perform a lifting motion in the vertical direction; the oxygen gun and spraying gun lifting system and the vacuum charging device are respectively mounted on the vacuum cover; the oxygen gun and spraying gun lifting system is used for driving an oxygen gun and a spraying gun to freely access the vacuum cover; and the vacuum charging device is used for feeding alloy materials into the vacuum groove in a vacuum state. The system has the advantages of low smelting energy consumption, no environmental pollution, high metal recovery rate and high refining efficiency.

Owner:XIAN UNIV OF SCI & TECH

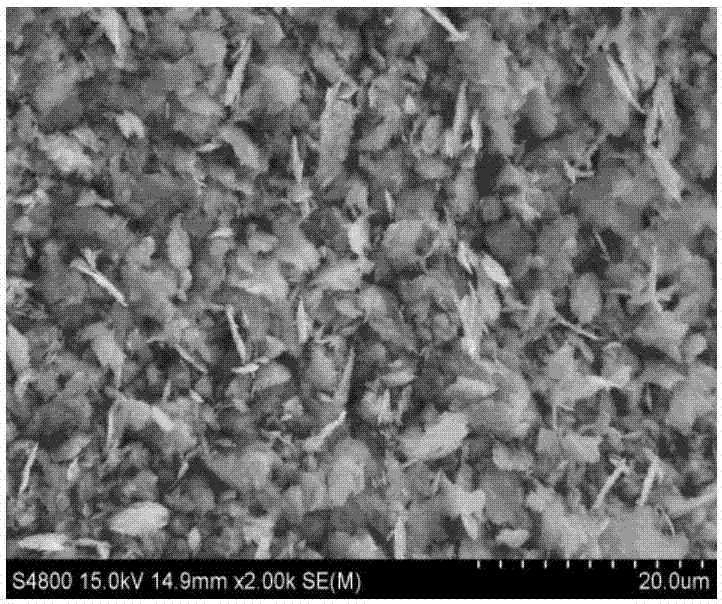

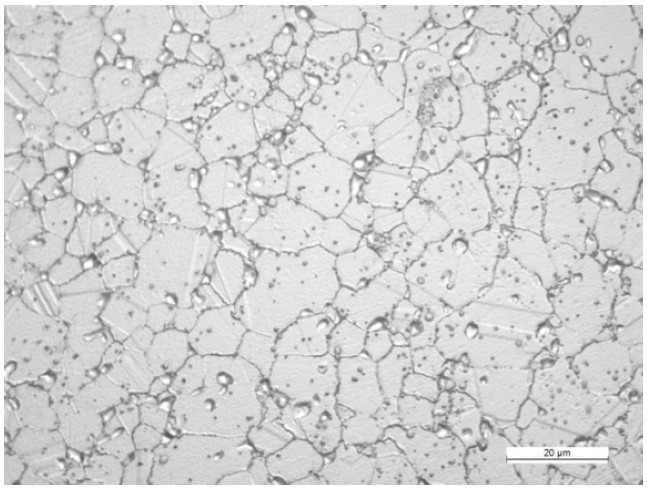

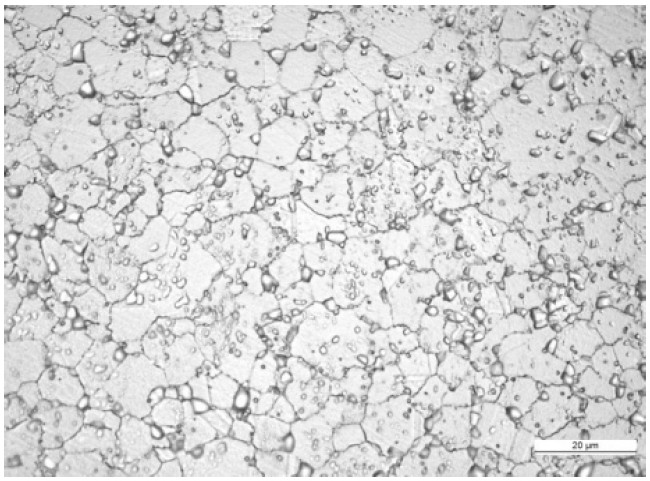

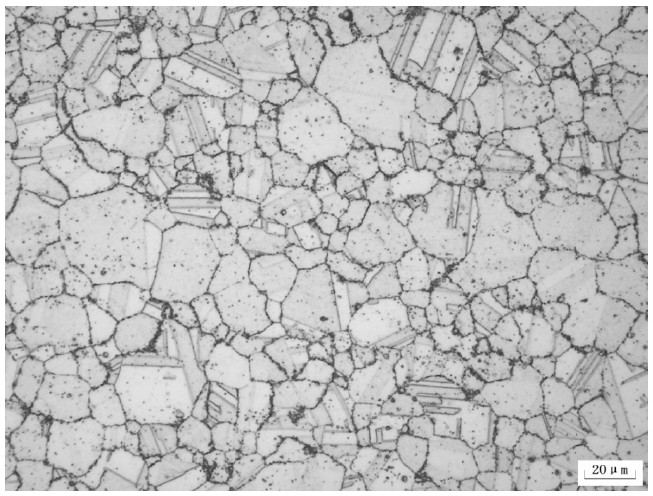

Alloyed gray cast iron resistant to high-temperature aluminum and zinc liquid corrosion and its smelting process

The invention belongs to the technical field of metallurgy, and particularly relates to high-temperature aluminum and zinc liquid corrosion resisting alloyed gray pig iron and a smelting technology thereof. The high-temperature aluminum and zinc liquid corrosion resisting alloyed gray pig iron specifically comprises following elements including, by weight percent, 3.1%-3.3% of C, 1.9%-2.2% of Si,0.8%-1.0% of Mn, smaller than or equal to 0.06% of P, smaller than or equal to 0.03% of S, 0.15%-0.3% of Cr, 0.05%-0.15% of Ni, 0.05%-0.2% of Cu, 0.15%-0.25% of Mo, 0.02%-0.04% of light rare earth andthe balance Fe. Through the synergistic effect of electrolytic copper, chromium, nickel, ferromolybdenum, the light rare earth and other alloy elements, the content of pearlite in a base body is increased, the pearlite layer sheet thickness and sheet distance are obviously reduced, base body structure grains are fine, a graphite sheet formed through one-time crystallization is fine and disperse,a small number of ferrite base body structures are easily obtained, hardness can be better reduced, material toughness is improved, the metallurgical quality is good, and strength is high.

Owner:武汉机械工艺研究所有限责任公司

A kind of gray cast iron and its smelting method

The invention provides gray cast iron and a smelting method of the gray cast iron, and relates to the technical field of metallurgical materials. The gray cast iron is prepared from nonmetallic alloyelements, metal alloy elements and the balance iron and inevitable impurities, wherein the nonmetallic alloy elements comprise, by mass, 2.8-3.2% of C, 2.2-2.4% of Si, 0.2% or less of P, 0.15% or lessof S, the metal alloy elements comprise, by mass, 0.25-0.35% of Cr and at least one of Mn, Cu, Mo, Li, Sn and Sb, and the total content of the metal alloy elements except for Cr is 1.5-1.6%. According to the gray cast iron, by reasonably designing the chemical ingredients, the gray cast iron can meet performance requirements of machine tool basic parts, waste iron and waste steel can be adopted as main furnace materials, therefore, raw material selection and matching flexibility are improved, and the raw material cost and the production cost are reduced.

Owner:CRRC DALIAN CO LTD

A method for near-net shaping of thin-walled complex components

ActiveCN110947970BRealize high temperature diffusion connectionReduce manufacturing costForming processesStructural integrity

The present invention is a method for near-net molding of thin-walled complex components. The method utilizes a metal sheath designed with a special structure, a part of the thin-walled structure is placed in a mosaic plate, and the rest of the parts are made of powder, and the powder is compacted by hot isostatic pressing. This method solves the problem that the local thin-walled parts are prone to lack of meat due to the difficulty of powder filling in the near-net powder hot isostatic pressing process of large-scale and complex sheet metal structures, and realizes net Forming solves the problem of poor rigidity of local thin-walled parts and cannot be processed. It can be used to form complex components such as air inlets and cabins, which can improve forming accuracy and structural integrity.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Continuous casting technology and equipment for titanium or titanium alloy

The invention relates to a titanium and titanium alloy low-cost continuous casting technology and equipment. Under argon protecting or inert gas atmosphere, a plasma gun of at least 65 KW is used as a heat source. Through a crystallizer, a plasma gun and a down-pulling mechanism, continuous casting of titanium and titanium alloy circular and flat cast ingots is achieved. The machining cost of titanium alloy is lowered by about at least 15%. The produced titanium and titanium alloy are even in components, segregation is avoided, and metallurgical quality problems are avoided.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

Electromagnetic semi-continuous casting device and method for alloy ingot with high casting stress

Owner:NORTHEASTERN UNIV LIAONING

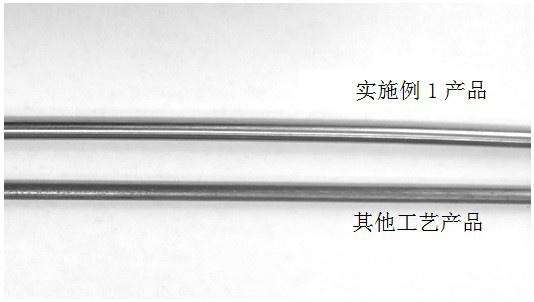

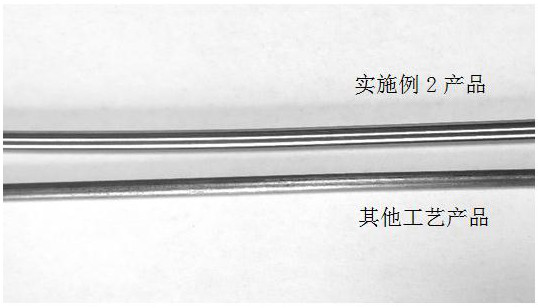

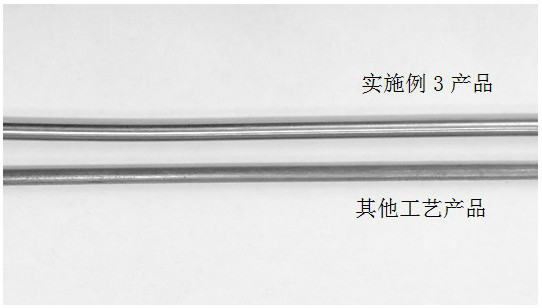

Production method of invar steel wire with high surface quality

PendingCN114130849AGuarantee metallurgical qualityAvoid heavy scaleTemperature control deviceBelt grinding machinesWater coolingMill scale

The invention discloses a production method of a high-surface-quality invar steel wire. The production method comprises the working procedures of vacuum melting, electroslag remelting, forging blank forming, rolling, cold drawing and aging heat treatment. The rolling procedure comprises the steps of high-temperature blooming, high-temperature temperature compensation and spinning water cooling; in the high-temperature temperature compensation step, the temperature is compensated to 1100-1200 DEG C, and the temperature compensation time is 0.5-2 hours; a cold-drawing process: performing peeling and double-abrasive-belt polishing treatment before drawing to the last but one pass or when drawing to D > d + 0.8 mm, and then continuing drawing; wherein D is the diameter of mm of the wire in the drawing process, and d is the diameter of mm of the finished wire; and in the aging heat treatment process, a protective atmosphere is adopted for annealing treatment. The method is suitable for producing invar steel wires with the diameter of 3.0-6.5 mm, the produced wires are bright in surface, free of oxide skin, scratches and drawing powder residues and good in mechanical property, the tensile strength of the wires is larger than or equal to 1100 MPa, and the percentage elongation after fracture at the gauge length of 250 mm is larger than or equal to 5%.

Owner:HEBEI IRON AND STEEL +3

Manufacturing method of alloy tubular product

ActiveCN102527724BGuaranteed corrosion resistanceGuarantee metallurgical qualityFurnace typesMetal rolling arrangementsChemical industrySolution treatment

The invention discloses a manufacturing method of an alloy tubular product. The manufacturing method is characterized in that the method comprises the the steps of melting NS1402 alloy steel to be made into rods; sawing the rods into short cut materials, centering the short cut materials, and manufacturing the short cut materials into centering materials; heating the centering materials to the temperature being 950 DEG C, keeping the temperature for 20-30min, then heating the centering materials to the temperature being 1100 DEG C-1120 DEG C, and keeping the temperature for 15-20min, and subsequently, conducting hot punching on the centering materials to be manufactured into a tube blank; rolling the tube blank by 1 to 5 passes so as to manufacture the tube blank into a cold rolled tube; and conducting protective atmosphere solution treatment on the cold rolled tube to manufacture the alloy tubular product. Due to the adoption of the method, the production process is relatively simple, the yield is high, the production cost is low, the performance of the tubular product is good, and the produced alloy tubular product can be widely applied to the fields such as oil, chemical industry and the like.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

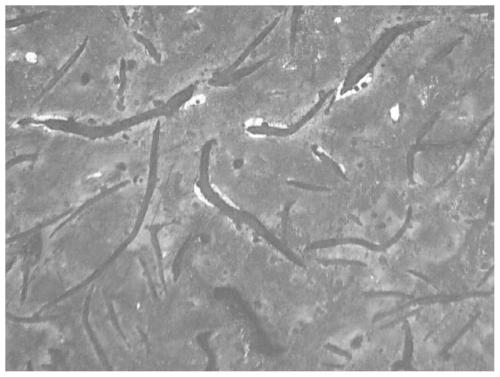

A method for reducing segregation of titanium alloy ingot with high iron content

The invention discloses a method for reducing segregation of a high-iron composition titanium alloy casting ingot. The method comprises the following steps that 1, 0-grade sponge titanium, Al-V-Fe, Ti-Fe, aluminum shots and TiO2 are used as raw materials, and the weights of the required raw materials are weighed according to the component proportion of a titanium alloy; 2, the 0-grade sponge titanium, the Al-V-Fe, the aluminum shots and the TiO2 are mixed uniformly to obtain a preliminary mixture, and the Ti-Fe component is wrapped into an alloy wrapping strip through an aluminum foil; and then an edge inverse segregation distribution method is adopted for distribution; 3, an oil press is used for pressing to obtain a single electrode block; 4, the single electrode block is welded to obtain an overall consumable electrode; and 5, the overall consumable electrode is dried, and the casting ingot is melted. According to the method for reducing segregation of the high-iron composition titanium alloy casting ingot, an edge inverse segregation distribution manner is adopted to an easy-segregation alloy, the problems that the titanium alloy containing easy-segregation elements is uneven in smelting constituent, easy to segregate and the like are solved; and during melting, the manners of the large magnetic field and the small current are adopted to ensure the metallurgical quality ofthe casting ingot.

Owner:XIANYANG TIANCHENG TITANIUM IND

An intermediate frequency induction melting furnace system and method

The invention relates to a medium-frequency induction smelting steel production system. The system comprises a medium-frequency induction smelting furnace, a vacuum circular smelting device, an oxygen gun and spraying gun lifting system, a vacuum charging device and a rail car; the vacuum circular smelting device is arranged above the medium-frequency induction smelting furnace; the rail car drives the vacuum circular smelting device to perform a lifting motion, so that a vacuum groove and a vacuum cover perform a lifting motion in the vertical direction; the oxygen gun and spraying gun lifting system and the vacuum charging device are respectively mounted on the vacuum cover; the oxygen gun and spraying gun lifting system is used for driving an oxygen gun and a spraying gun to freely access the vacuum cover; and the vacuum charging device is used for feeding alloy materials into the vacuum groove in a vacuum state. The system has the advantages of low smelting energy consumption, no environmental pollution, high metal recovery rate and high refining efficiency.

Owner:XIAN UNIV OF SCI & TECH

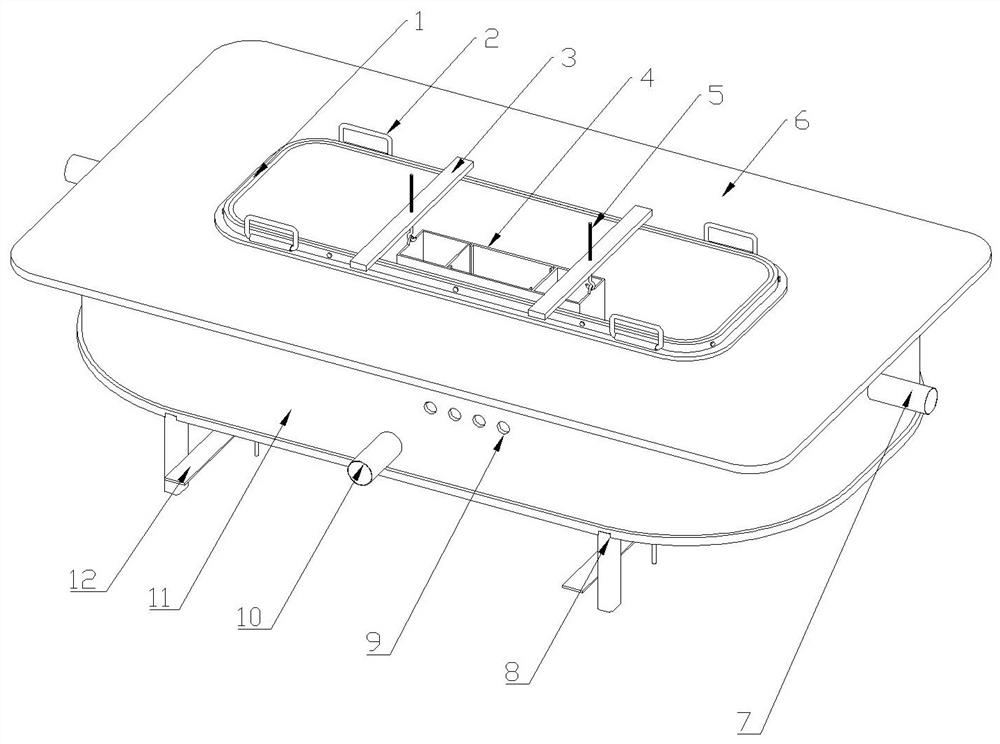

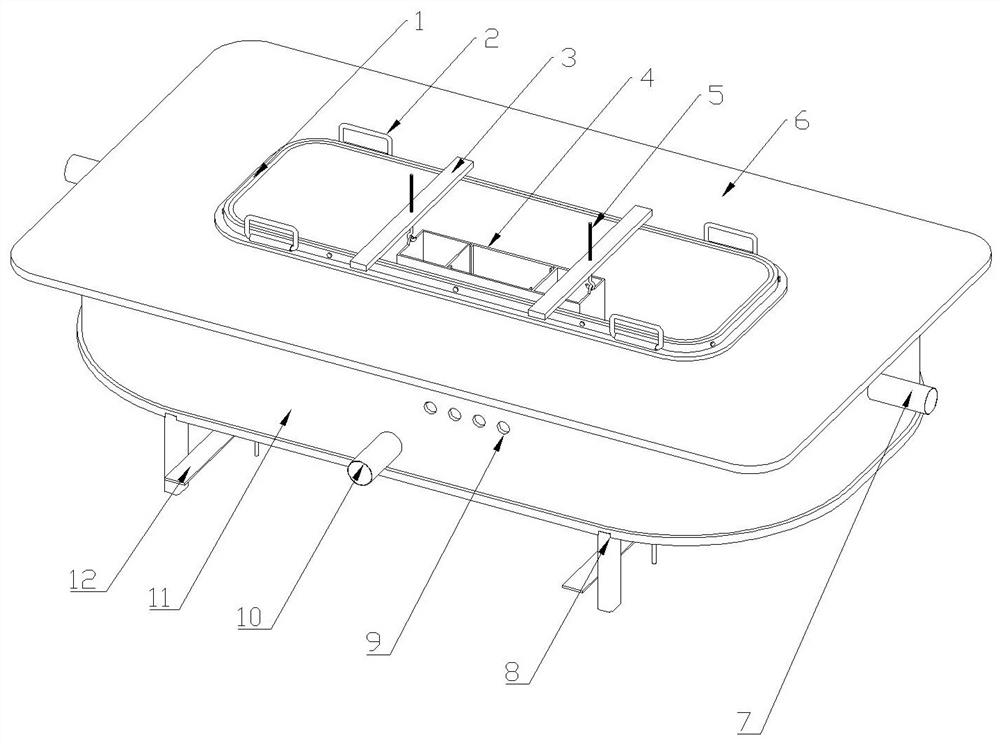

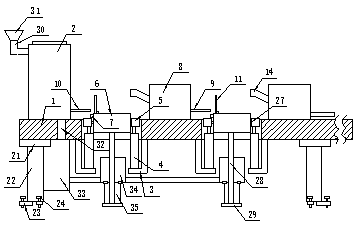

Metallurgy dust mud leaching device

InactiveCN108624750AImprove filtering effectGuaranteed liquiditySludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processFiltrationContinuous operation

The invention discloses a metallurgy dust mud leaching device. The metallurgy dust mud leaching device comprises a strip bearing base; a dust mud leaching mechanism is arranged on the upper surface ofthe strip bearing base; and a support fixing mechanism is arranged on the lower surface of the strip bearing base. The metallurgy dust mud leaching device has the following beneficial effects: the device is more convenient to use and convenient to perform multiple times of precipitation, filtration and leaching on dust mud in metallurgy, so that the dust mud is precipitated at the bottom of the bearing place, and the dust mud collecting effect is excellent; and through proper heating, the fluidity of mixtures is guaranteed, the continuous operation is convenient, and the metallurgy quality isguaranteed.

Owner:赵鹏

An inert atmosphere control device for laser forming and repairing

ActiveCN101607348BReduce the use effectEmission reductionLaser beam welding apparatusGas cylinderEngineering

Owner:西北工业大学资产经营管理有限公司

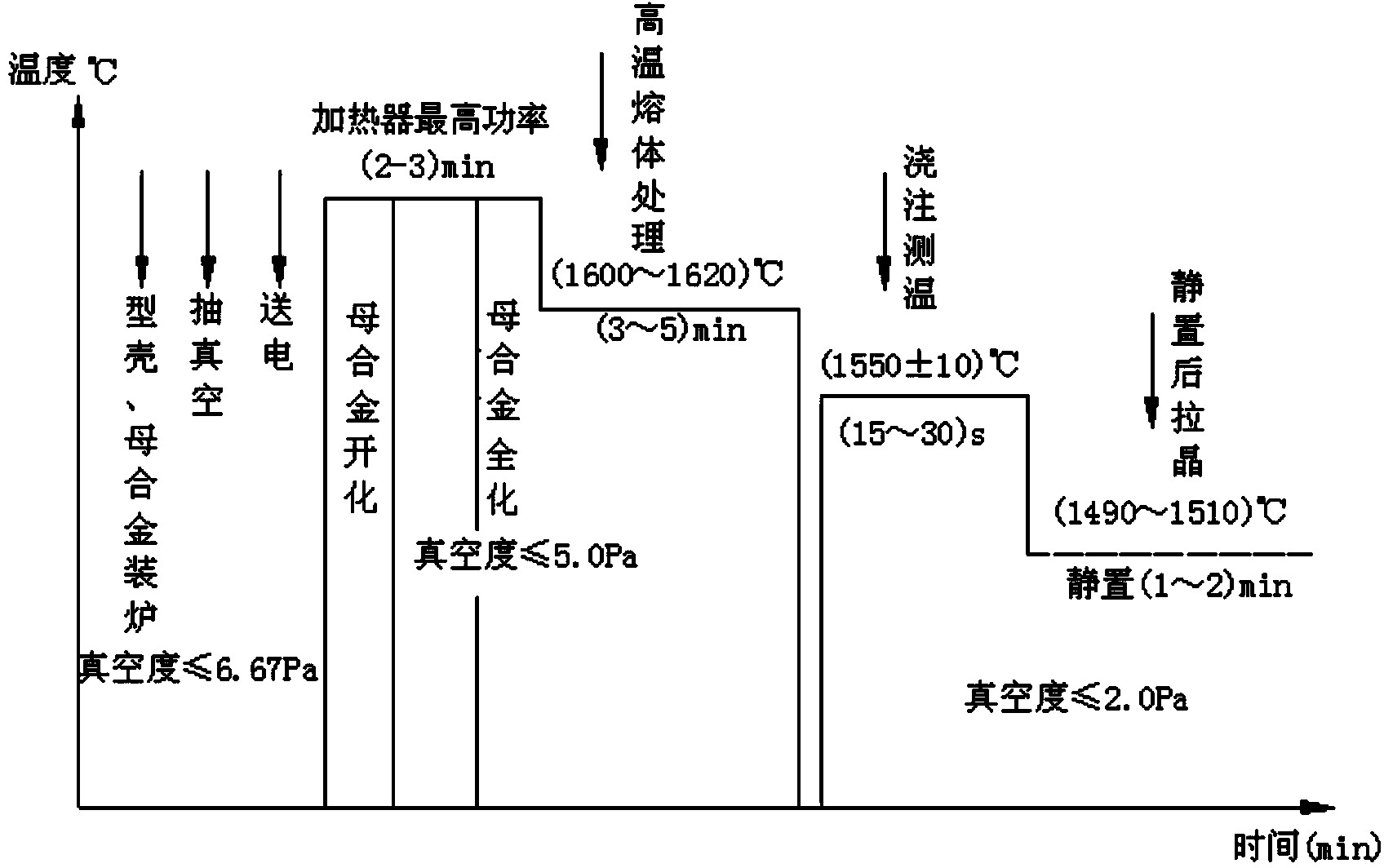

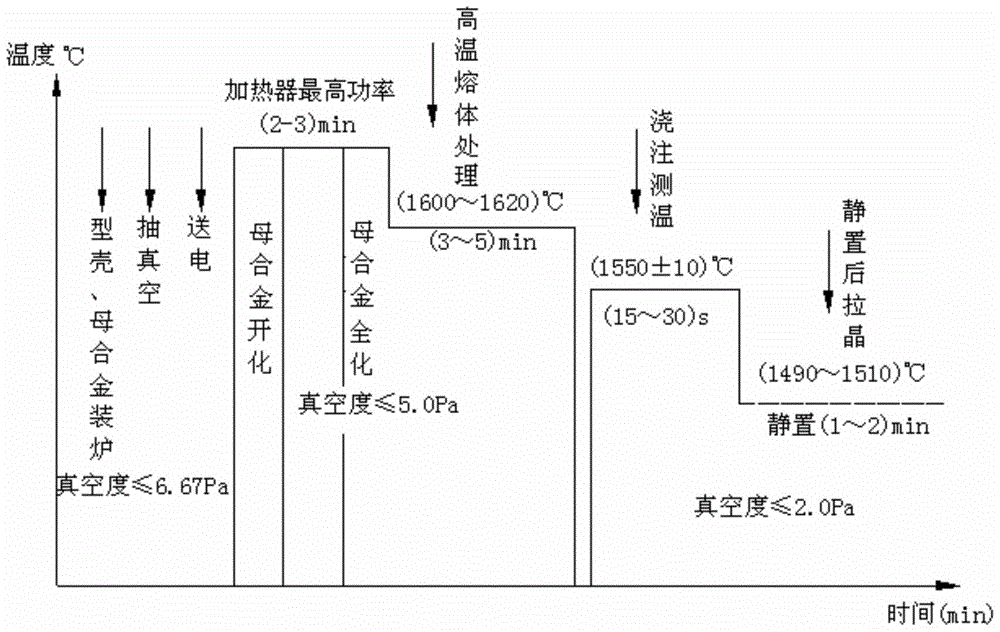

Pouring technique of directional turbine blade with block cast cover board structure

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A casting method of complex structure thin-wall ductile iron ship turbocharger casting

ActiveCN102784889BBottom shrinkage improvementImprove pass rateFoundry mouldsFoundry coresTurbochargerDuctile iron

The invention relates to the casting technology of complex-structure ductile iron thin-wall castings, such as a fuel feed case, which are important parts of a ship turbocharger, and in particular relates to a casting method of a complex-structure ductile iron thin-wall casting of the ship turbocharger. The casting method includes the steps of, in sequence, fabricating moulds, modeling, making a core, assembling the moulds, pouring and clearing the sand shakeout. The method is characterized in that a pouring system used in the pouring process consists of a riser runner, a chilling block, a live riser arranged on a bottom flange of the fuel feed case and a feeding head arranged at the lateral side of the bottom flange. A filter screen is arranged on the pouring system. With the casting method disclosed by the invention, the defect of shrinkage porosity of the bottom flange of the fuel feed case is solved, the conventional idea of changing the entire cast solidification sequence by increasing the number the chilling blocks is thoroughly changed, the problem of shrinkage porosity at the bottoms of the castings is completely improved by adopting the new feeding scheme, the percent of pass of the castings is improved, and regular batch production of the castings is ensured.

Owner:KOCEL EQUIP

A pouring process method for directional turbine blades with integral cast cover plate structure

The invention relates to a blade pouring technique, and particularly relates to a pouring technique of a directional turbine blade with a block cast cover board structure. According to the technical scheme disclosed by the invention, the pouring technique of the directional turbine blade with the block cast cover board structure is as follows: alloy liquid is poured in a high-temperature state, and crystal is pulled in a low-temperature state. The invention provides a pouring technique of a directional turbine blade with a block cast cover board structure, the impact force on a ceramic core and a glass tube caused by the alloy liquid is reduced, the problems of deviation, leakage and breakage of the ceramic core and the glass tube in the pouring process are avoided, the metallurgical quality of the blade is ensured, and the qualified rate of precision casting is increased.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

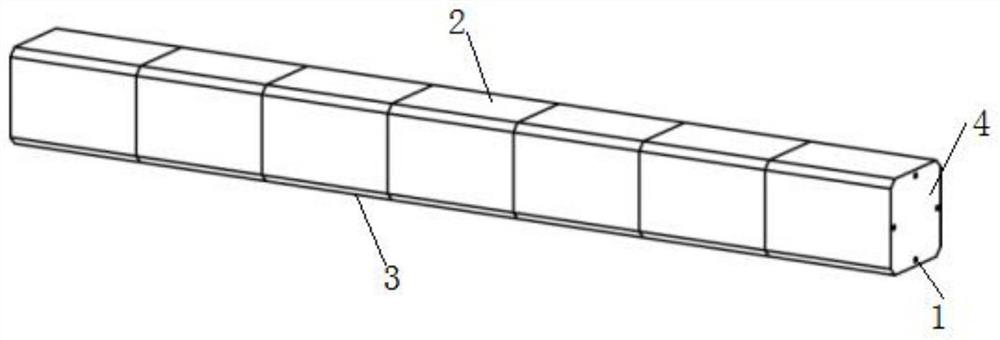

A kind of preparation method of neutron absorbing composite material with high neutron absorption rate

ActiveCN107008894BAvoid harmFully mixed powderTransportation and packagingMixersRare earthBoron carbide

The invention relates to a preparation method of a neutron-absorbing composite material with a high neutron absorption rate, the steps of which are as follows: (1) weighing 8-40 parts of boron carbide powder, 32-96 parts of aluminum alloy powder and light rare earth in parts by weight 0.1-10 parts of powder; (2) Add boron carbide powder, aluminum alloy powder and light rare earth powder to the powder mixing equipment for mixing; (3) Put the materials evenly mixed by the powder mixing equipment into the vacuum sintering furnace for sintering Obtain the slab; (4) cast a layer of aluminum alloy layer with a thickness of 0.05-1cm on the four side walls of the slab and then mold it; (5) carry out 3-8 passes of hot rolling after the molding. After annealing at 450-500°C, the neutron-absorbing composite material with high neutron absorption rate can be obtained, which ensures the metallurgical quality of the material and ensures that the composite material has excellent mechanical properties, thermal conductivity and neutron absorption capacity.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com