A method for reducing segregation of titanium alloy ingot with high iron content

A titanium alloy and ingot casting technology, which is applied in the field of reducing segregation of titanium alloy ingots with high iron content, can solve problems such as easy formation of β spots, achieve good practical value, solve uneven melting components, and reduce segregation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

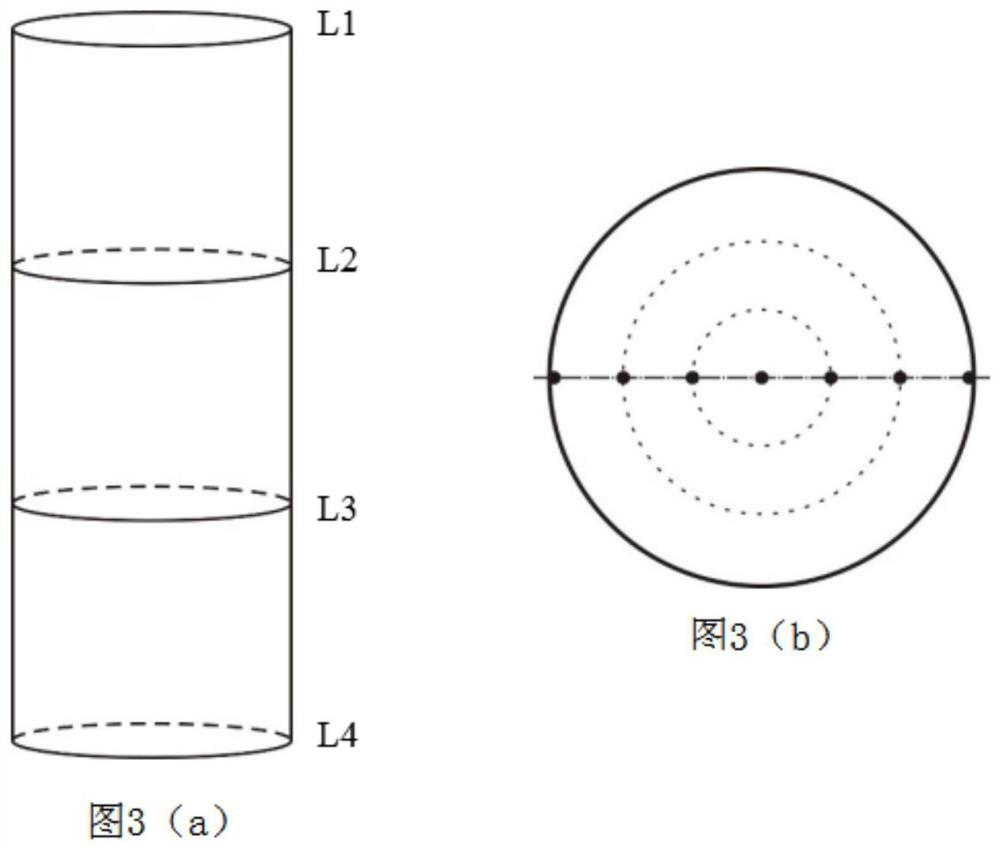

[0066] This example takes the preparation of Φ460TB6-550Kg titanium alloy ingot as an example, and the specific preparation method is as follows.

[0067] Step 1. Use 0-grade sponge titanium, Al-V-Fe, Ti-Fe, aluminum beans, TiO 2 As the raw material, the raw material is selected according to the composition 9.8V-1.8Fe-3.1Al-0.07O, and the sponge titanium is made of 0-grade small particle sponge titanium.

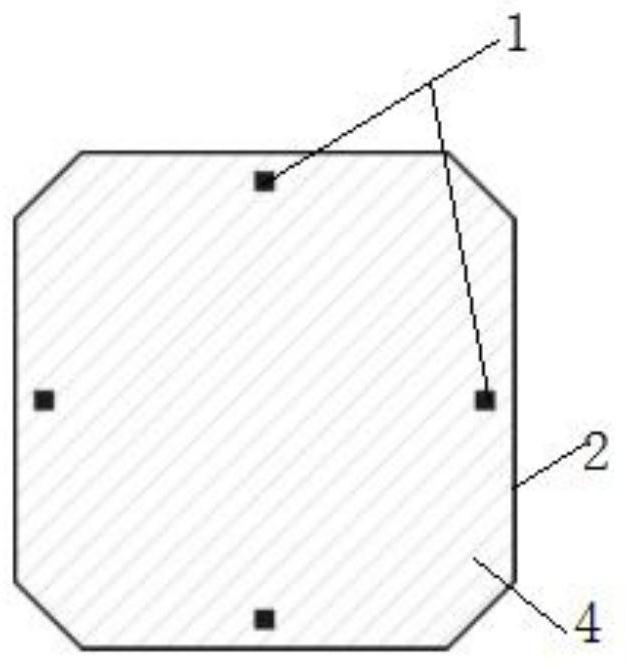

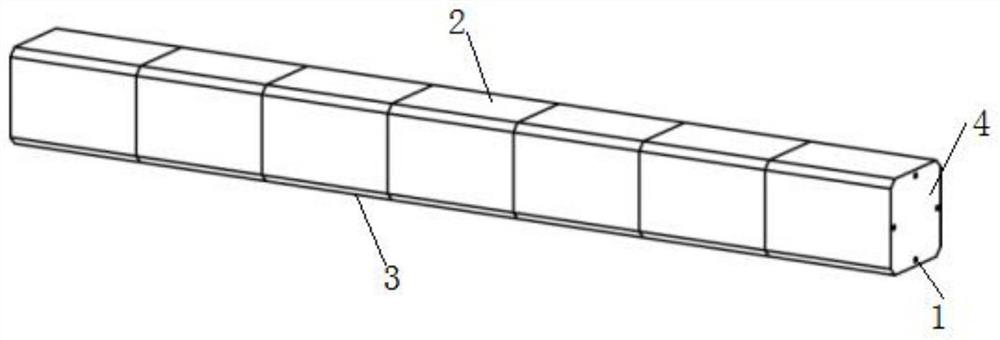

[0068] Step 2, the 0-grade sponge titanium, Al-V-Fe, aluminum beans and TiO 2 Place in an automatic mixer and mix evenly to obtain a preliminary mixture. Divide the Ti-Fe component in step 1 into four equal parts by weight, and wrap it into four alloy strips with aluminum foil; then use the edge reverse segregation cloth method Artificial cloth is carried out, wherein two Ti-Fe alloy clad strips are placed between the second layer paving and the third paving, and the distance between the two Ti-Fe alloy clad strips is 10mm from the mold.

[0069] Step 3. Put the raw materi...

Embodiment 2

[0082] This example takes the preparation of Φ460TB6-1000Kg titanium alloy ingot as an example, and the specific preparation method is as follows.

[0083] Step 1. Use 0-grade sponge titanium, Al-V-Fe, Ti-Fe, aluminum beans, TiO 2 As the raw material, the raw material is selected according to the composition 10V-1.85Fe-3.1Al-0.07O, and the sponge titanium is made of 0-grade small particle sponge titanium.

[0084] Step 2, the 0-grade sponge titanium, Al-V-Fe, aluminum beans and TiO 2 Place in an automatic mixer and mix evenly to obtain a preliminary mixture. Divide the Ti-Fe component in step 1 into four equal parts by weight, and wrap it into four alloy strips with aluminum foil; then use the edge reverse segregation cloth method Artificial cloth is carried out, wherein two Ti-Fe alloy clad strips are placed between the second layer paving and the third paving, and the distance between the two Ti-Fe alloy clad strips is 20mm from the mold.

[0085] Step 3. Put the raw mater...

Embodiment 3

[0097] This example takes the preparation of Φ460TB6-700Kg titanium alloy ingot as an example, and the specific preparation method is as follows.

[0098] Step 1. Use 0-grade sponge titanium, Al-V-Fe, Ti-Fe, aluminum beans, TiO 2 As the raw material, the raw material is selected according to the composition 9.8V-1.8Fe-3.1Al-0.07O, and the sponge titanium is made of 0-grade small particle sponge titanium.

[0099] Step 2, the 0-grade sponge titanium, Al-V-Fe, aluminum beans and TiO 2 Place in an automatic mixer and mix evenly to obtain a preliminary mixture. Divide the Ti-Fe component in step 1 into four equal parts by weight, and wrap it into four alloy strips with aluminum foil; then use the edge reverse segregation cloth method Artificial cloth is carried out, wherein two Ti-Fe alloy clad strips are placed between the second layer paving and the third paving, and the distance between the two Ti-Fe alloy clad strips is 15mm from the mold.

[0100] Step 3. Put the raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com