A pouring process method for directional turbine blades with integral cast cover plate structure

A technology of turbine blades and process methods, applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve the problem of reducing blade core wrapping rate and precision casting pass rate, ceramic core and glass tube fracture, ceramic core and glass. Pipe impact force and other problems, to achieve the effect of good fluidity, improved metallurgical quality, and improved precision casting qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

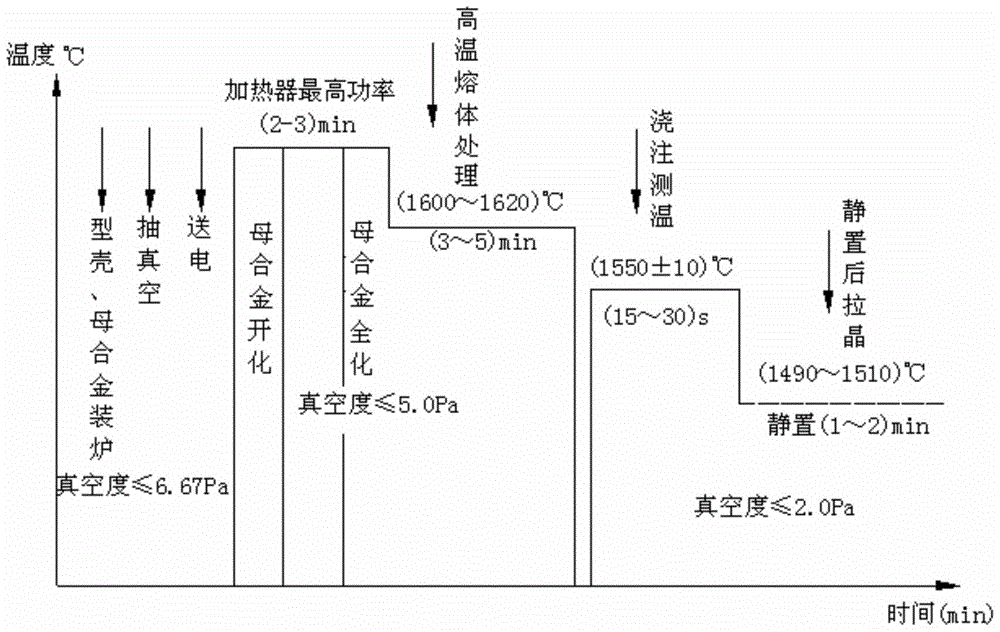

[0020] Such as figure 1 As shown, a casting process method for directional turbine blades with integral cast cover plate structure includes the following steps:

[0021] Step 1: Put the prepared ceramic core and glass tube shell into the shell chamber, add the master alloy into the melting chamber, vacuum the shell chamber and the melting chamber, and when the vacuum degree of the shell chamber and the melting chamber reaches less than When it is greater than 6.67Pa, the heaters in the shell chamber and the melting chamber start to transmit power to heat the shell and melt the master alloy;

[0022] Step 2: Adjust the heater power of the melting chamber to the highest level. After the master alloy is melted into alloy liquid, control the temperature of the melting chamber at 1610°C for high-temperature melt treatment for 5 minutes, and control the vacuum degree of the melting chamber to not more than 5.00Pa;

[0023] Step 3: Control the temperature of the shell at 1490°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com