A kind of preparation method of neutron absorbing composite material with high neutron absorption rate

A technology of absorbing composite materials and absorbing rate, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve problems such as poor mechanical properties, unstable neutron absorption capacity, low thermal conductivity, etc., and achieve strong adaptability , excellent mechanical properties, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

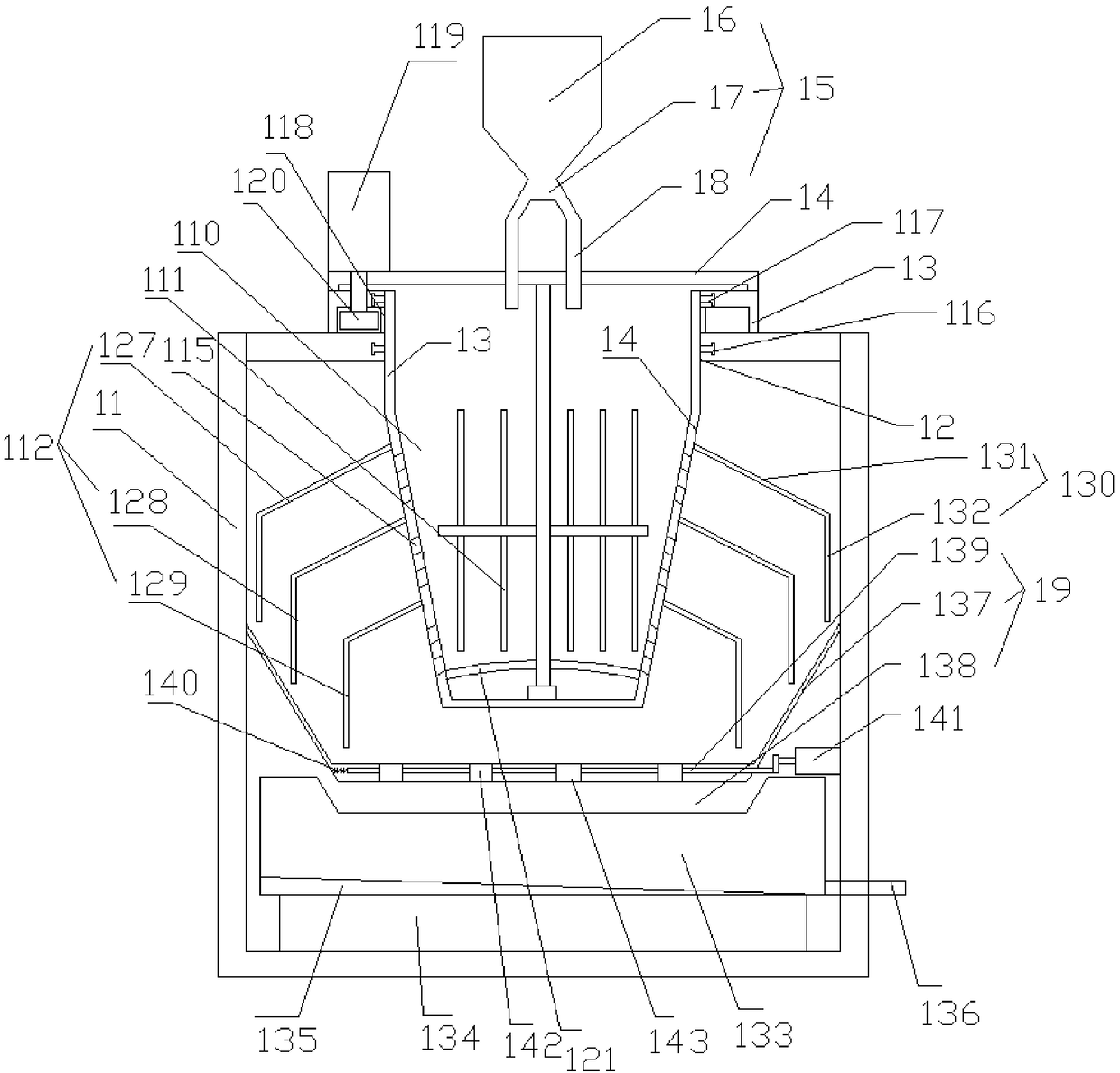

[0032] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

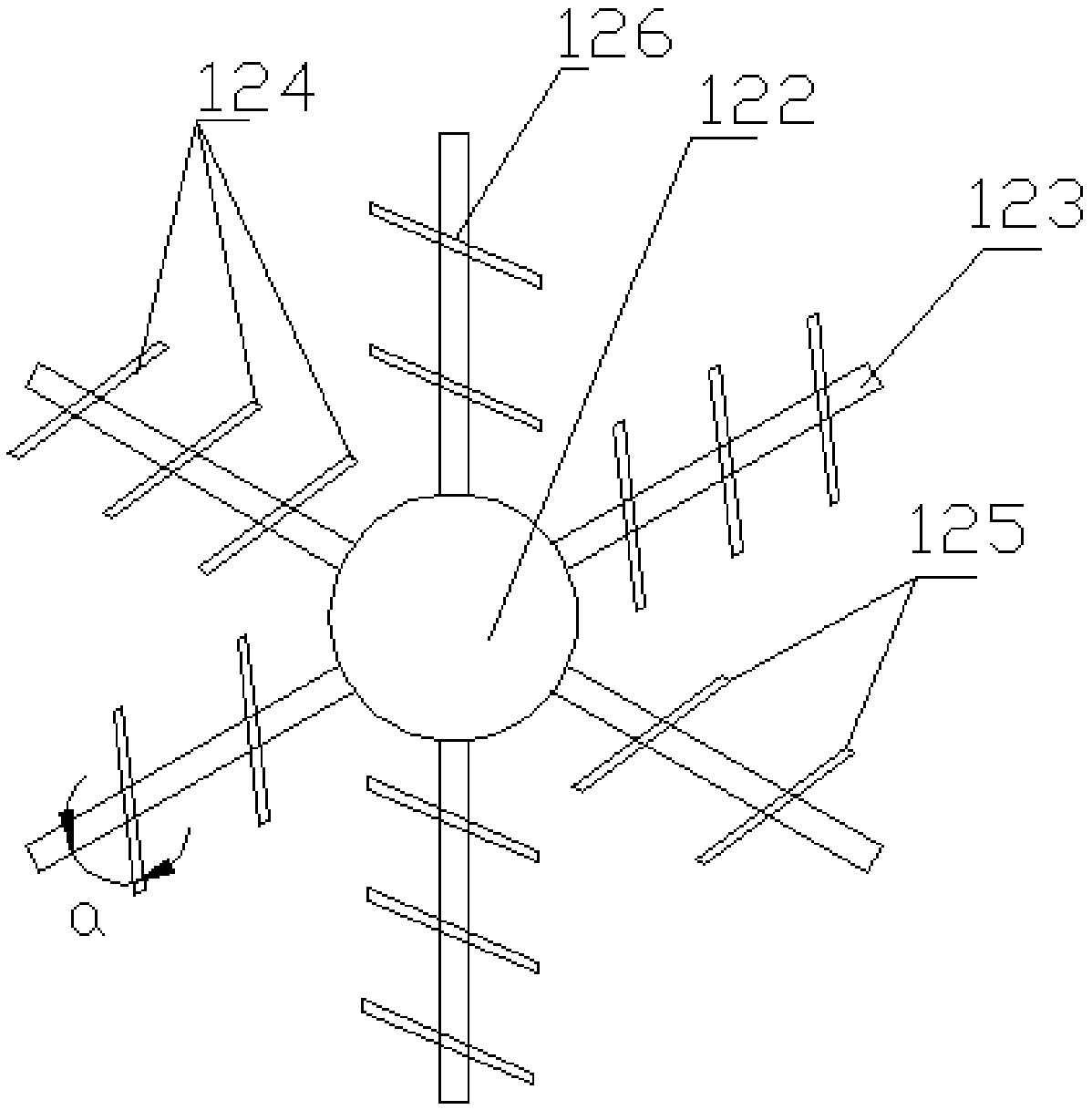

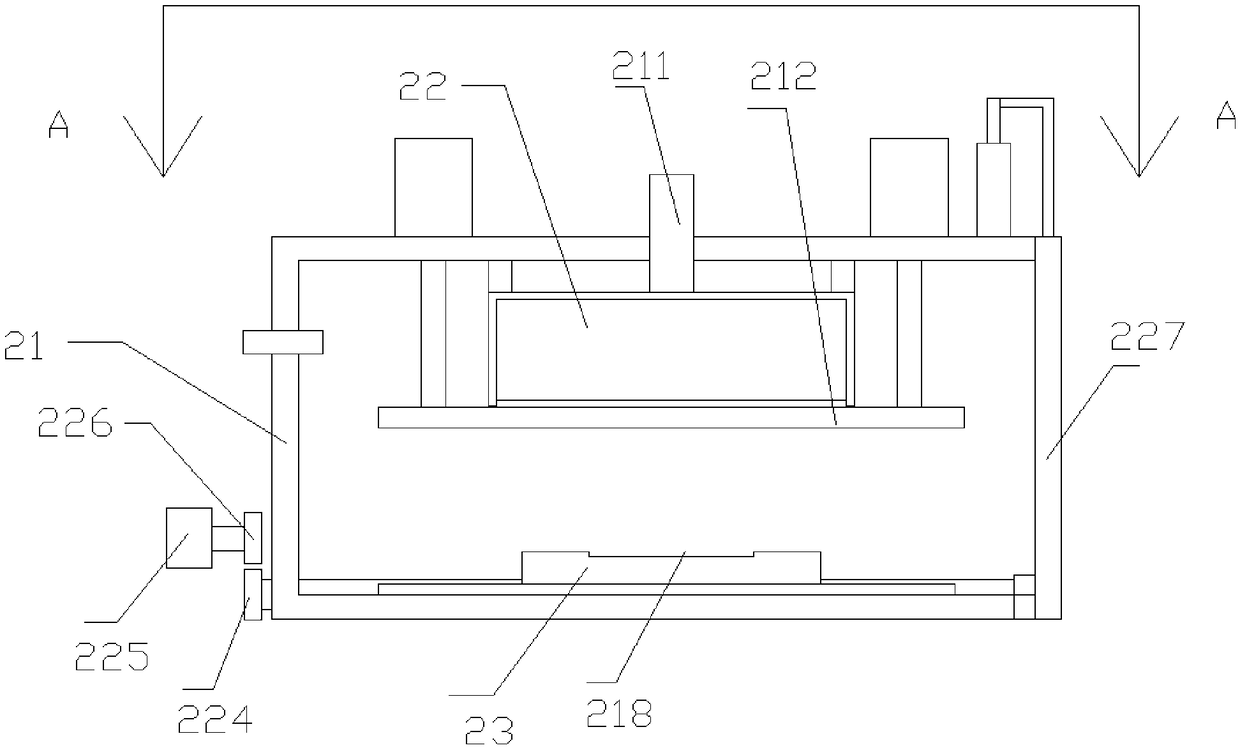

[0033] reference sign

[0034]Housing 11, first opening 12, first support ring 13, second support cover 14, feeding mechanism 15, feeding hopper 16, distribution pipe 17, first feeding pipe 18, separation mechanism 19, mixing bucket 110, the first mixing mechanism 111, the second mixing mechanism 112, the fixed end 113, the mixing end 114, the first discharge hole 115, the first clamping bump 116, the second clamping bump 117, the first Rack 118, first motor 119, first driving gear 120, material guide plate 121, main shaft 122, stirring rod 123, first stirring blade group 124, second stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com