A method for near-net shaping of thin-walled complex components

A near-net-shape, thin-walled technology, applied in the near-net-shape field of thin-walled complex components, can solve the problems of material loss, high production cost of parts, poor overall rigidity, uneven deformation during processing, etc., so as to improve overall rigidity and reduce The effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

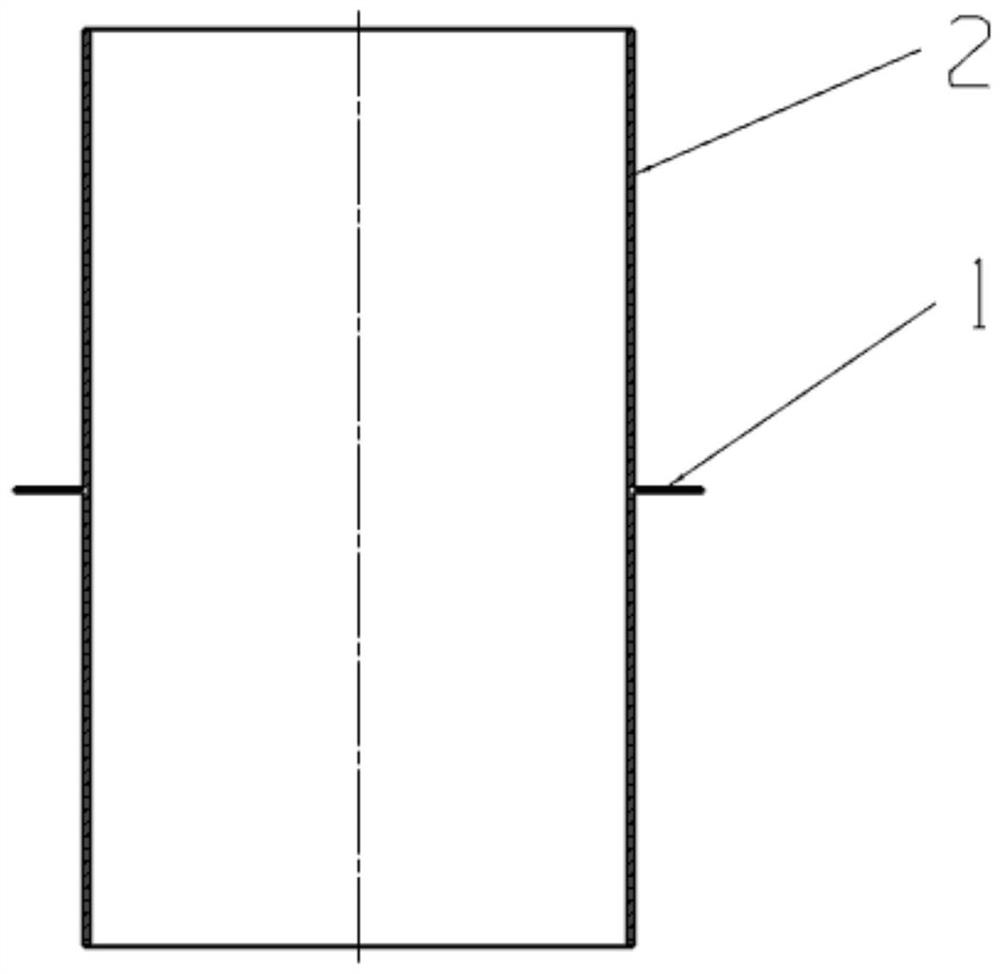

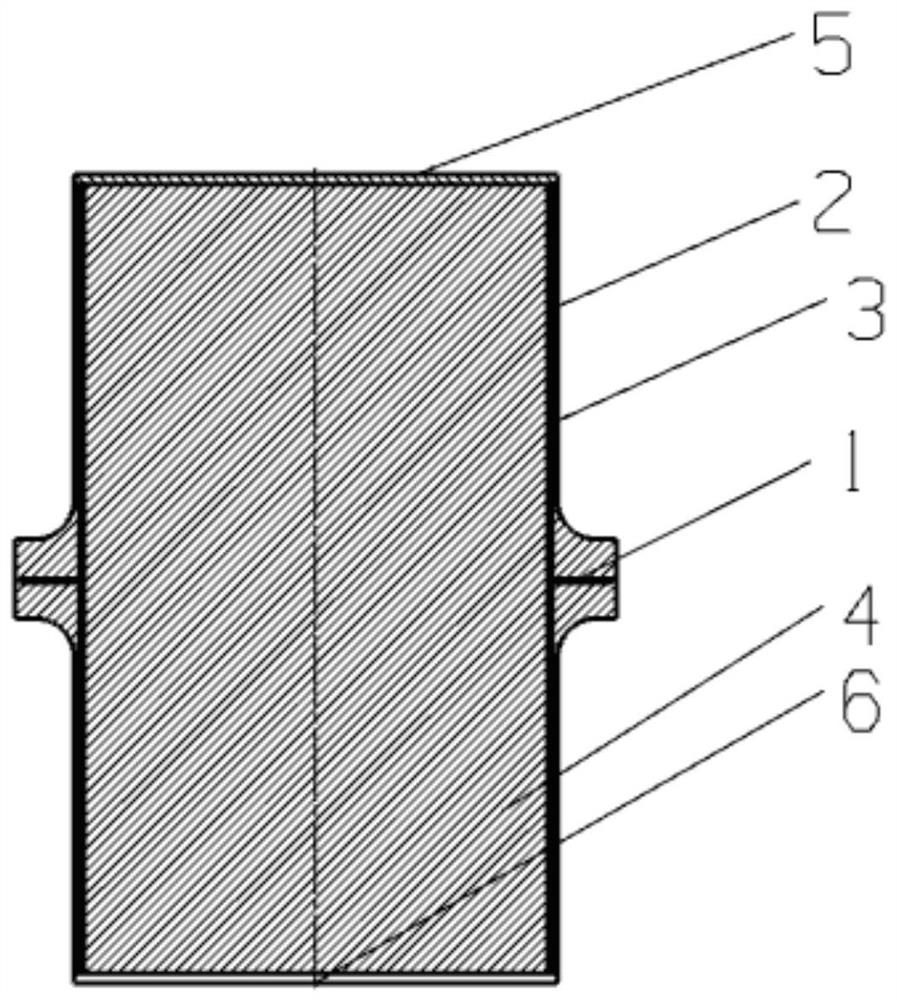

[0017] See attached figure 1 As shown, the processed product of this embodiment is an air inlet, and the material is this TC4 titanium alloy. The maximum size of the plate 2 in the width direction is 300 mm, the wall thickness is 2 mm, and the length is 610 mm. There are 3 thin-wall ribs 1 in total, which are evenly distributed along the length direction outside the wall plate 1. The maximum outer diameter of the annular thin-wall rib 1 is 360 mm, and the thickness is 1.5 mm. mm, thin-walled rib plate 1 and wall plate 2 require integral molding.

[0018] Adopt the method of the present invention to carry out the step of near net shaping to this member as follows:

[0019] 1. Package preparation

[0020] According to the structure of the target part, design and process the carbon steel sheath. The sheath consists of four parts: the cylinder body 3, the mold core 4, the upper end cover 5, and the lower end cover 6. Among them, the cylinder body 3 is a half structure, see the a...

Embodiment 2

[0035] The processed product of this embodiment is an air inlet, which is in a cylindrical state and is composed of irregular cylindrical wall panels and outer ribs. The wall panel material is TiAl alloy, with a maximum dimension of 400 mm in the width direction and a wall thickness of 3 mm. The length is 1500mm, the material of the rib plate is GH4169 high temperature alloy, and it is in the shape of a ring, with a total of 5 lines, which are uniformly distributed along the outer axis of the wall plate. The outer diameter of the ring is 360mm, the thickness is 2mm, and the inner side coincides with the outer side of the wall plate.

[0036] Adopt the method of the present invention to carry out the step of near net shaping to this member as follows:

[0037] 1. Package preparation

[0038] According to the structure of the target part, design and process the carbon steel sheath, which consists of four parts: cylinder body 3, mold core 4, upper end cap 5, and lower end cap 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com