Alloyed gray cast iron resistant to high-temperature aluminum and zinc liquid corrosion and its smelting process

A high temperature resistant and alloying technology, applied in the field of metallurgy, can solve the problems of poor temperature resistance, poor corrosion resistance, unstable mechanical properties, and different metallographic structures, and achieve stable corrosion resistance and small volume expansion coefficient. , the effect of low cementite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

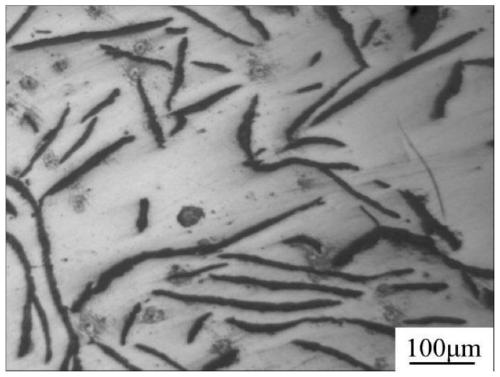

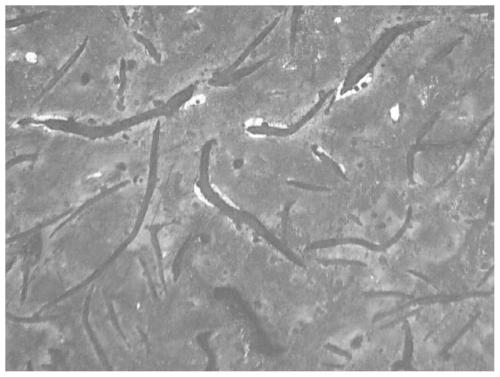

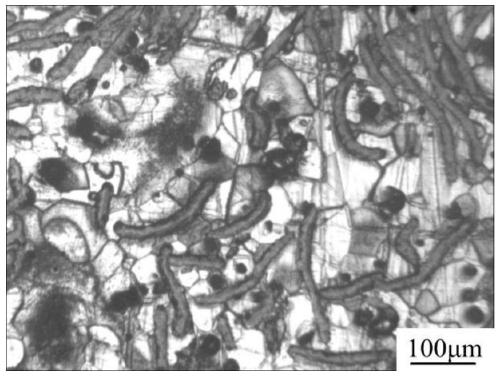

Image

Examples

Embodiment 1

[0035] An alloyed gray cast iron resistant to high-temperature aluminum and zinc liquid corrosion, made of the following raw materials: scrap steel, high-purity pig iron, electrolytic copper, ferrosilicon, ferromanganese, ferrochrome, recarburizer, inoculant, the scrap steel, The components of high-purity pig iron, electrolytic copper, ferrosilicon, ferromanganese and ferrochrome are shown in Table 1. The smelting process includes the following steps:

[0036] S1. Alloy smelting: Put the recarburizer in an intermediate frequency induction furnace, place scrap steel and cast iron on top, and smelt at 1165°C to increase carbon. After a molten pool is formed at the bottom of the furnace, add nickel plate, ferromanganese, ferrochrome and electrolytic copper in sequence , continue smelting, then raise the temperature to 1535°C, add ferromolybdenum and light rare earth to generate molten iron; the recarburizer is petroleum coke graphite, fixed carbon content ≥ 99.29%, particle size 1...

Embodiment 2

[0041] The smelting process of Example 2 is the same as that of Example 1, the difference is that the ratio of raw materials is different, and step S3, tapping molten iron and inoculating treatment: when the temperature of molten iron drops to 1535 ° C, the addition of the inoculant is 0.4% of the mass of molten iron. %, the inoculant is a modified silicon barium inoculant, including the following elements by weight: Si: 68%, Ba: 8%, Ca: 7%, Al: 2%, Zr: 4.5%, Re: 2% , the balance is Fe, and the balance is Fe.

Embodiment 3

[0043] The smelting process of Example 3 is the same as that of Example 1, the difference is that the ratio of raw materials is different, and step S3, molten iron tapping and inoculation treatment: when the temperature of molten iron drops to 1535°C, the addition of the inoculant is 0.6% of the mass of molten iron. %, the inoculant is a modified silicon barium inoculant, including the following elements by weight: Si: 68%, Ba: 8%, Ca: 7%, Al: 2%, Zr: 4.5%, Re: 2% , the balance being Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com