Forging method for complex thin-rib stainless steel die forging with center hole

A technology for stainless steel dies and forgings, applied in the field of die forging of structural parts, can solve the problems of inability to guarantee the quality of forgings, coarse metal grains, and increased cost, and achieve the effects of eliminating piercing and folding defects, ensuring metallurgical quality, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

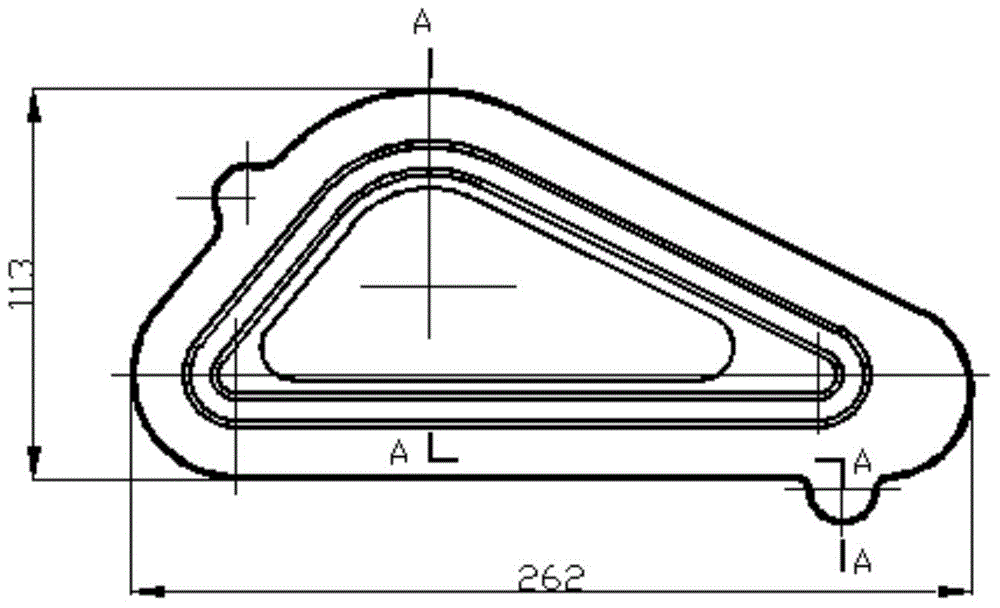

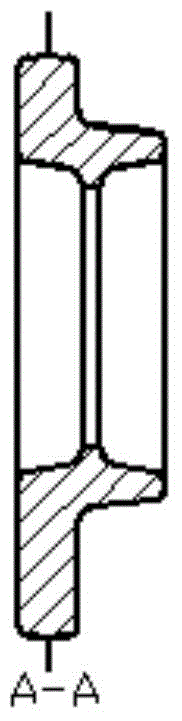

[0046] Attached below Figure 1a , attached Figure 1b The forging process of a typical forging of a 1Cr12Ni3MoVN material mounting seat is shown as an example, and the forging process steps of complex forgings with irregular shapes, thin ribs, and intermediate holes are explained in detail:

[0047] 1. Use a band sawing machine to cut the bar, and use a grinder to grind and remove the burrs on both ends;

[0048] 2. Use a natural gas forging heating furnace to heat the finished billet, the heating temperature is 1160°C, use a 400kg free forging hammer to make the billet, and the forging stop temperature is 950°C. In order to match the subsequent forging process, the shape is as attached figure 2 shown;

[0049] 3. Grinding obvious defects such as hammering after forging;

[0050] 4. Use a natural gas forging heating furnace to heat the blank. The heating temperature is 1150°C. Use a 3-ton electro-hydraulic die forging hammer for pre-forging. The forging stop temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com