Patents

Literature

219results about How to "Guaranteed to be full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

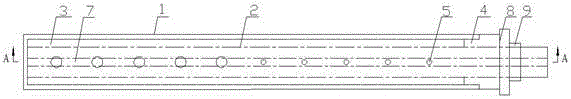

Engineering comprehensive hole measuring system and method based on in-hole camera shooting and single-hole sound waves

ActiveCN106154350AReduce workloadShorten the detection timeGeological measurementsPhysicsSingle hole

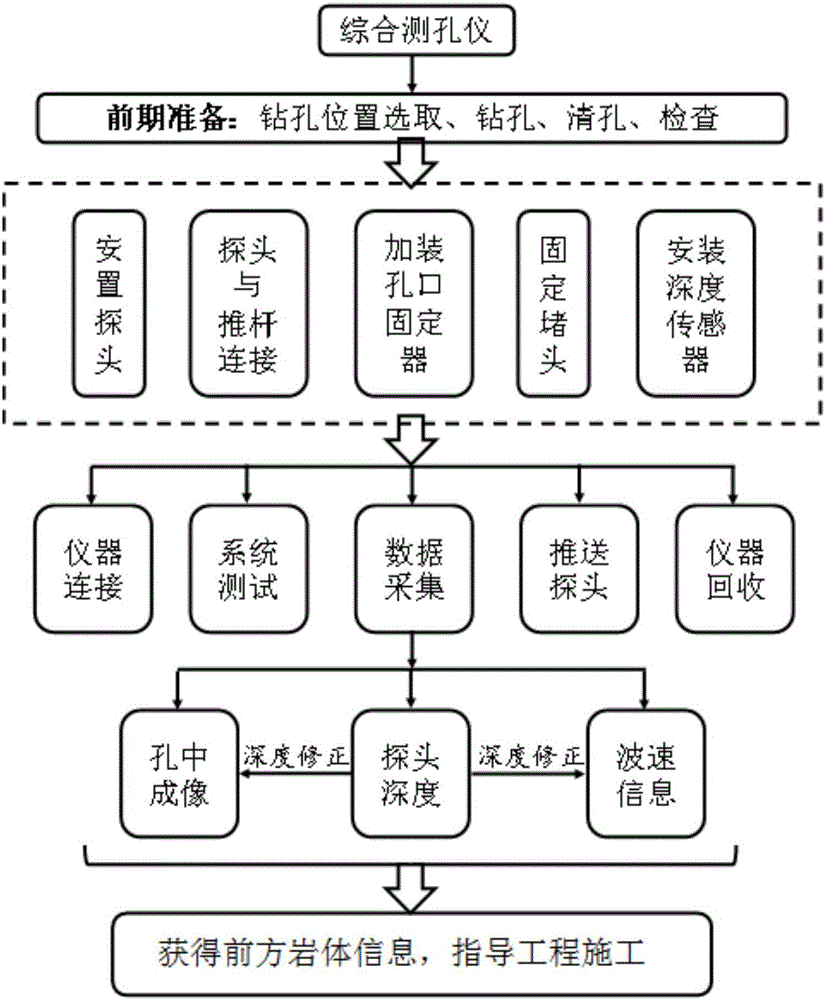

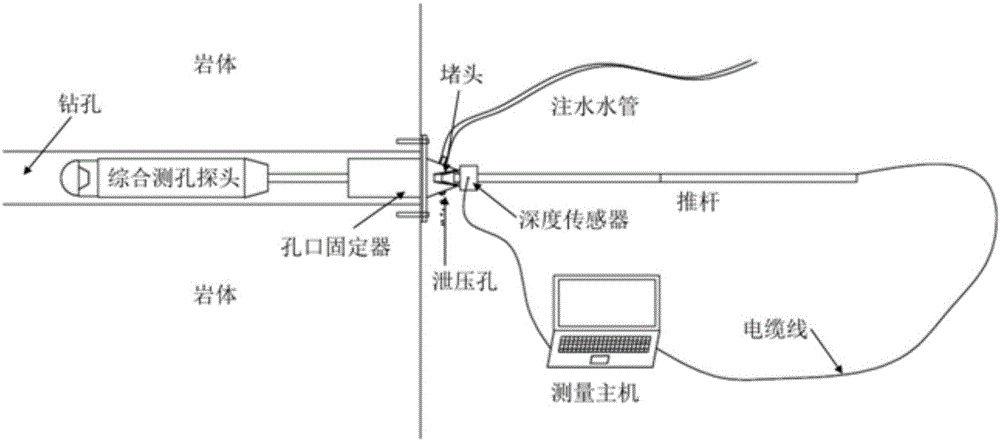

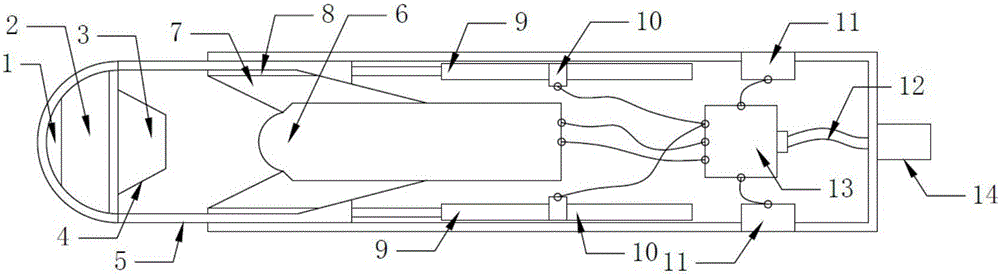

The invention discloses an engineering comprehensive hole measuring system and method based on in-hole camera shooting and single-hole sound waves. The engineering comprehensive hole measuring system comprises a combined measuring probe. The combined measuring probe stretches into a borehole of a rock mass, a push rod is arranged behind the combined measuring probe, the combined measuring probe is connected through a hole opening fixing device, the hole opening fixing device is arranged at the opening of the borehole, a depth sensor is arranged at the front end of the push rod, the depth sensor and the combined measuring probe are connected with a main measuring machine, and the combined measuring probe is pushed to move forwards by controlling the push rod to collect and analyze in-borehole data. The machine learning and data mining method is adopted, the decision tree algorithm, the k-means clustering algorithm and the Apriori association algorithm are utilized to analyze in-hole camera shooting and single-hole sound wave data, and the automation degree and accuracy of exploration forecasting are improved. By means of the engineering comprehensive hole measuring system and method, the workload of in-hole camera shooting and single-hole sound wave detection can be greatly reduced, and meanwhile the detection time can be shortened.

Owner:SHANDONG UNIV

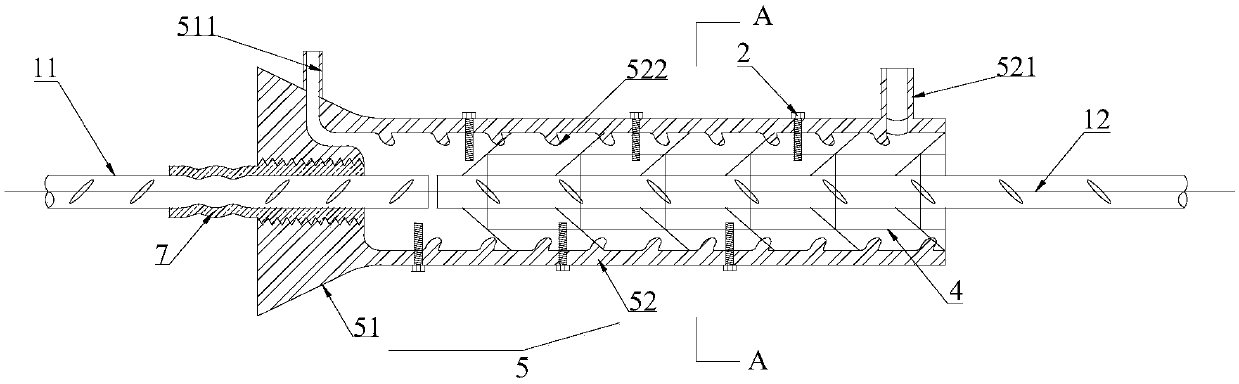

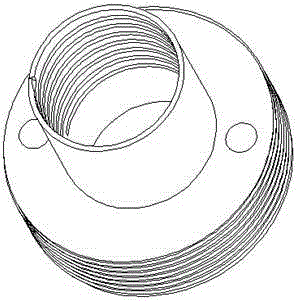

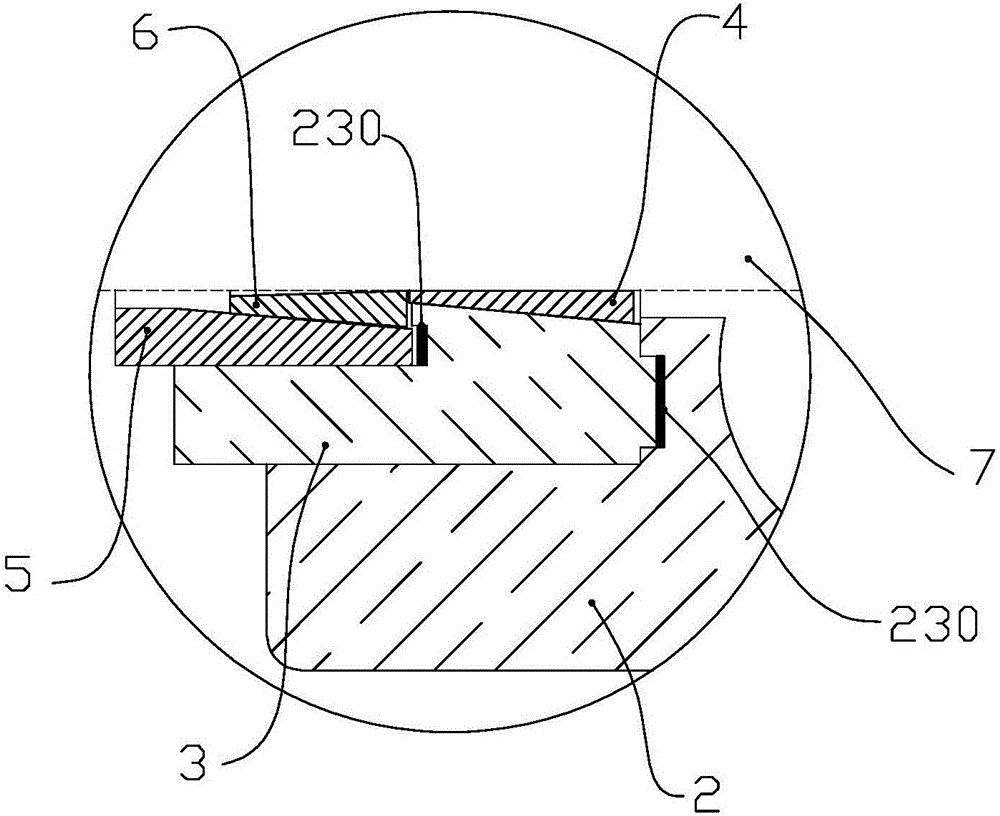

Assembly structure of assembly-type concrete member

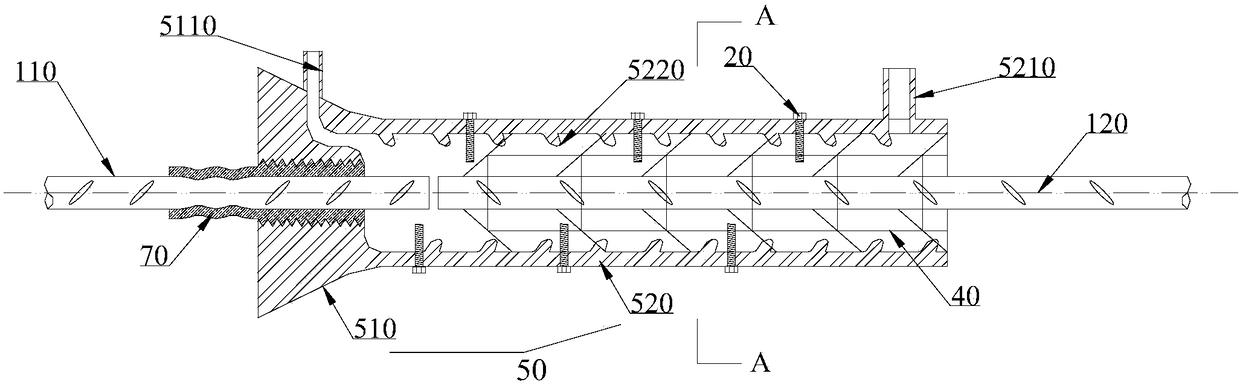

The invention provides an assembly structure of an assembly-type concrete member. A sleeve comprises a non-grouting connection section and a grouting connection section. A steel skeleton comprises inner barbs and outer barbs, the diameter of a passage defined by the multiple inner barbs is smaller than that of a second to-be-connected steel bar, and the outline diameter defined by the outer barbsis larger than the diameter of an inner cavity of the grouting connection section. An alignment device comprises lower supports and upper supports which are both electromagnets, the same magnetic poles of the upper supports and the lower supports are opposite, and the upper supports and the lower supports are connected in the same circuit in series. All parts of the grouting sleeve are machined and manufactured correspondingly and then assembled, mass production is achieved, and the quality of all the parts is easy to control; connection of the grouting sleeve and a steel pipe transition section is operated by machines in a factory, the threaded connection quality is easy to control, the self-locking type steel skeleton is adopted, thus the purpose of pulling preventing is achieved, and shock resistance is improved; through the principle of magnetic levitation, fast and accurate centering of the steel bars of upper and lower concrete member bodies is achieved, so that the time and labor are saved; and through the series-connection circuit, the same magnetic forces of a plurality of supporting mechanisms can be achieved, and stable supporting is guaranteed.

Owner:HEFEI CONSTR ENG GRP

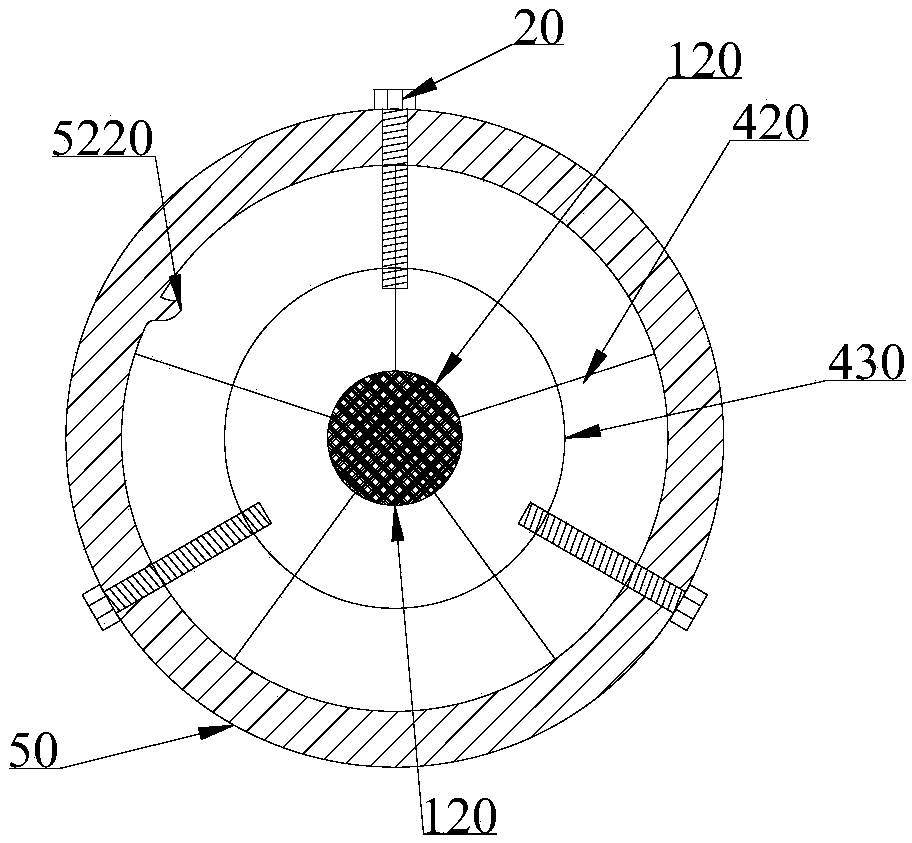

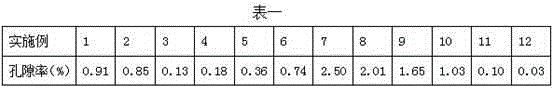

Screw and powder injection molding method thereof

ActiveCN104308163AReduce porosityGuaranteed to be fullTurbinesOther manufacturing equipments/toolsMetallic materialsInjection molding machine

The invention discloses a screw and a powder injection molding method thereof. The method includes the steps of firstly, mixing powder metal materials and binder with the mass ratio being 100:20-200 to form homogeneous feeding materials; secondly, placing the feeding materials into an injection molding machine to perform injection molding so as to obtain injection molding blanks; thirdly, dewaxing; fourthly, pre-sintering at the temperature of 200-800 DEG C to obtain pre-sintered blanks; fifthly, rising the temperature to 1000-2500 DEG C to sinter the pre-sintered blanks for 1-10 hours under a protective atmosphere to obtain screws. The method has the advantages that the binder is added into metal materials for mixing, the metal materials can form the injection molding blanks through injection molding, the binder is completely discharged by dewaxing and pre-sintering, the screws formed by high-temperature sintering, porosity of the screws is reduced greatly, machining procedures are reduced, production efficiency is increased, and the products after injection molding are good in consistency and repeatability.

Owner:HEFEI GENIUS NEW MATERIALS

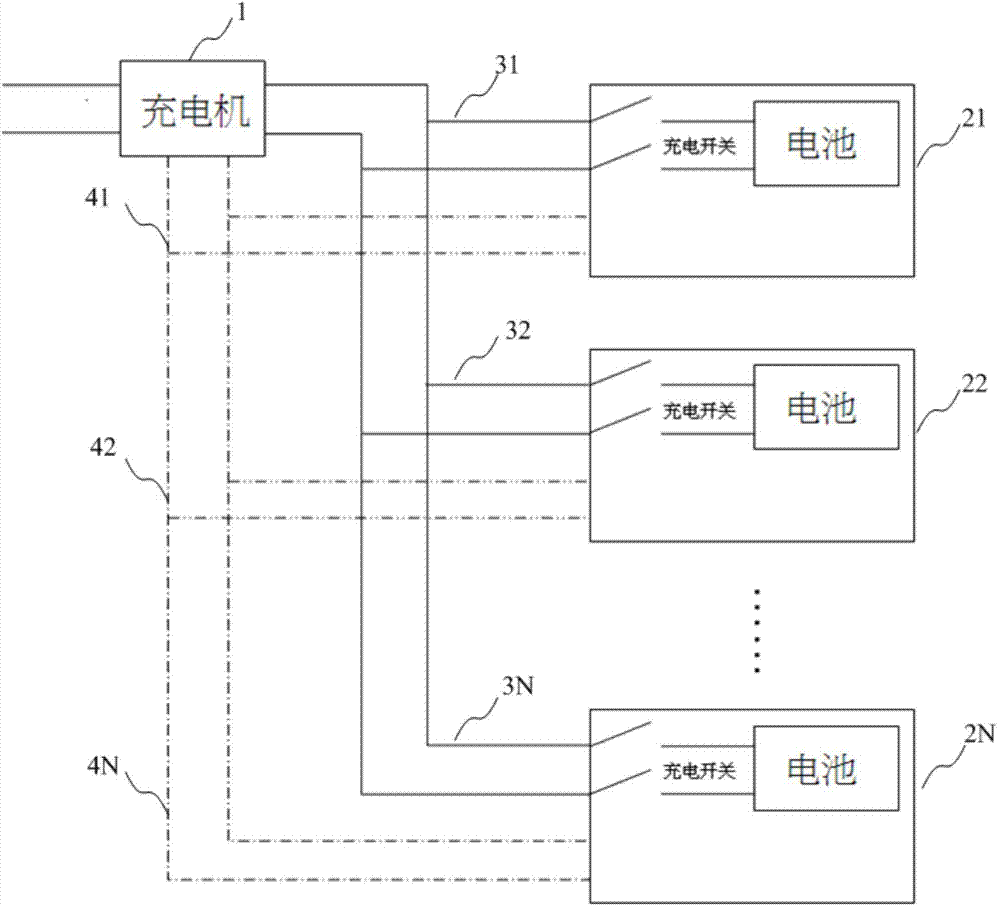

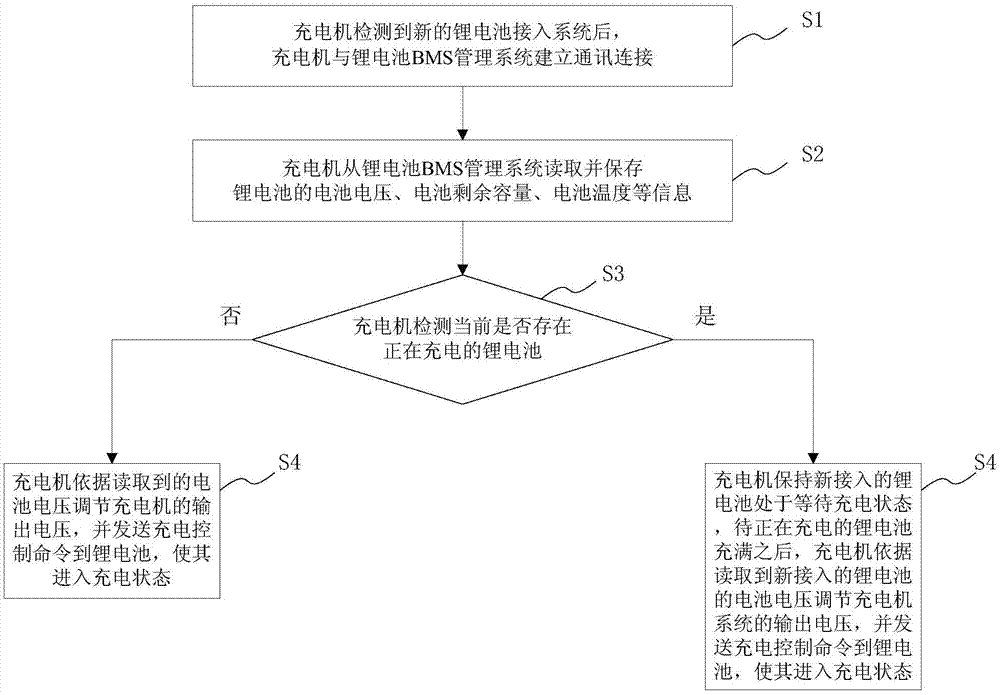

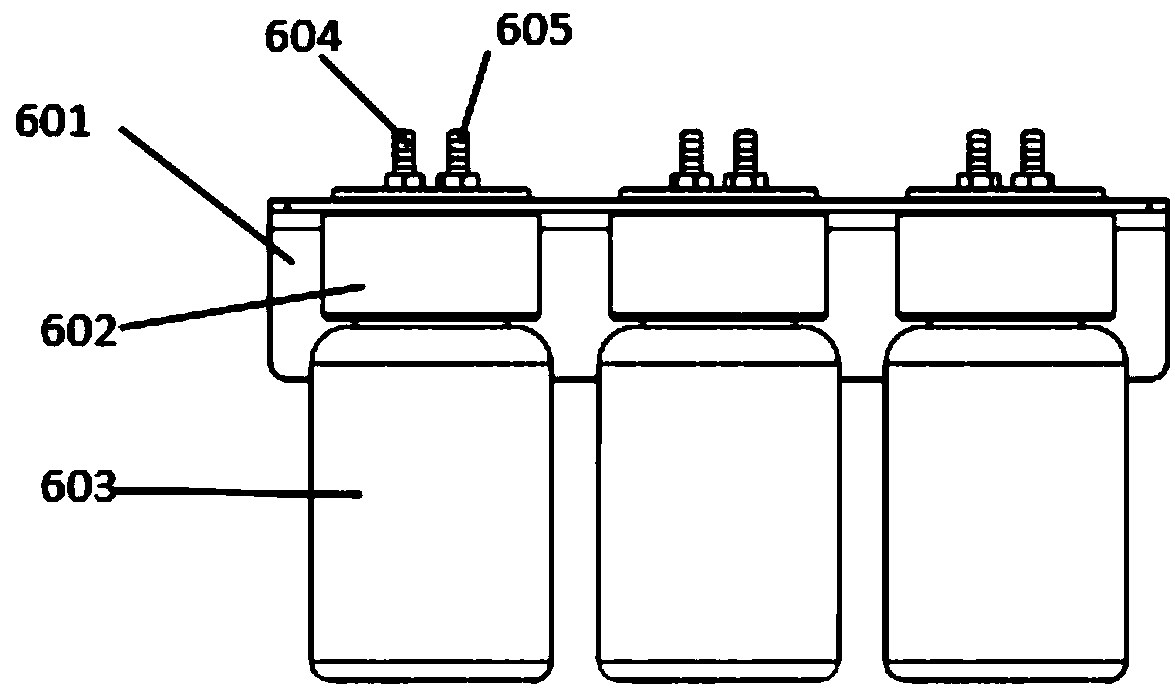

Control system for realizing parallel-connection circulating charging of multiple sets of lithium batteries and method thereof

InactiveCN103795124ARealize parallel cycle chargingGuaranteed to be fullBatteries circuit arrangementsSecondary cells charging/dischargingElectricityControl system

The invention provides a control system for realizing parallel-connection circulating charging of multiple sets of lithium batteries and a method of the control system. The control system at least comprises a charger, the multiple sets of lithium batteries, a charging loop and a communication line set, wherein the multiple sets of lithium batteries and the charger are connected in parallel through the charging loop, and the charger communicates with each lithium battery through the communication line set. The control system for realizing parallel-connection circulating charging of the multiple sets of lithium batteries and the method of the control system can guarantee that each set of lithium batteries is fully charged with electricity under an unattended condition, can obviously reinforce the durability of the lithium batteries, prolong the recycling service life of the battery packs, and meanwhile obviously improve the utilization rate of the charger on the premise of not increasing the control complexity of a charging system and development cost.

Owner:DELTA GREENTECH CHINA CO LTD

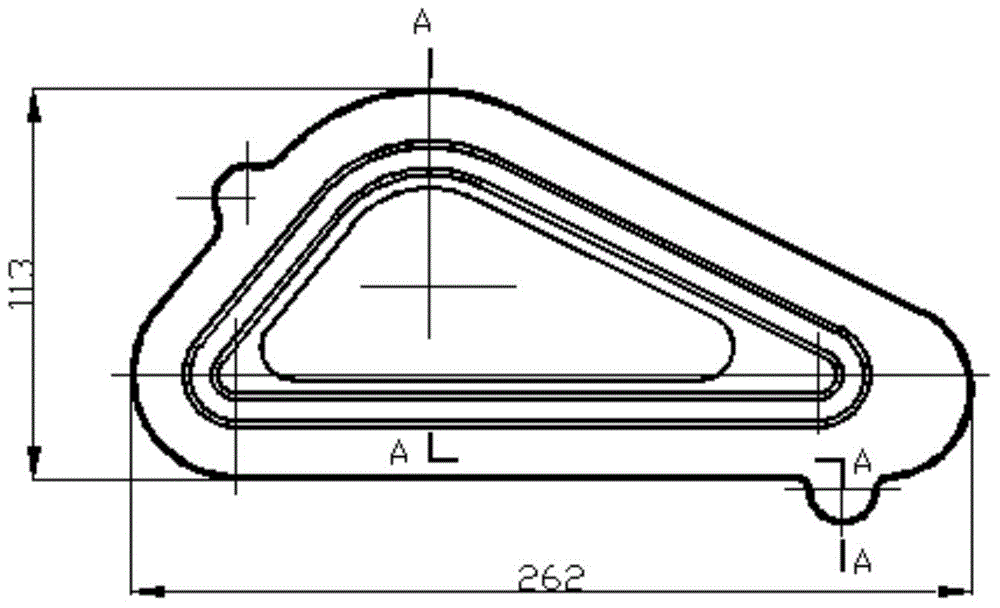

Forging method for complex thin-rib stainless steel die forging with center hole

InactiveCN105215629AEnsure fair distributionSave raw materialsMetal-working apparatusPunch pressStress relieving

The invention relates to the field of structural member die forging and provides a forging method for a complex thin-rib stainless steel die forging with a center hole. The method includes the steps that a bar is blanked into a billet; burrs on the two end faces of the billet are ground and removed; the ground billet is heated and then forged to form a free-forging blank; the free-forging blank is heated and then pre-forged to form a pre-forged piece, a hole is punched in the center of the pre-forged piece through waste heat, and the size of the punched hole is smaller than the required size of an inner hole of the forging; surface defects of the pre-forged piece are ground; the pre-forged piece is heated and then is finish-forged and formed at a time to form the forging, and after forging is stopped, edge cutting is conducted on the forging through a punch press by means of waste heat; the forging is heated, the punch press and a final punching die are used for punching a triangular hole in the center of the forging; stress relieving, quenching, tempering and forging hardness detecting are conducted on the well-machined forging; and shot blasting de-scaling is conducted on the forging.

Owner:AECC AVIATION POWER CO LTD

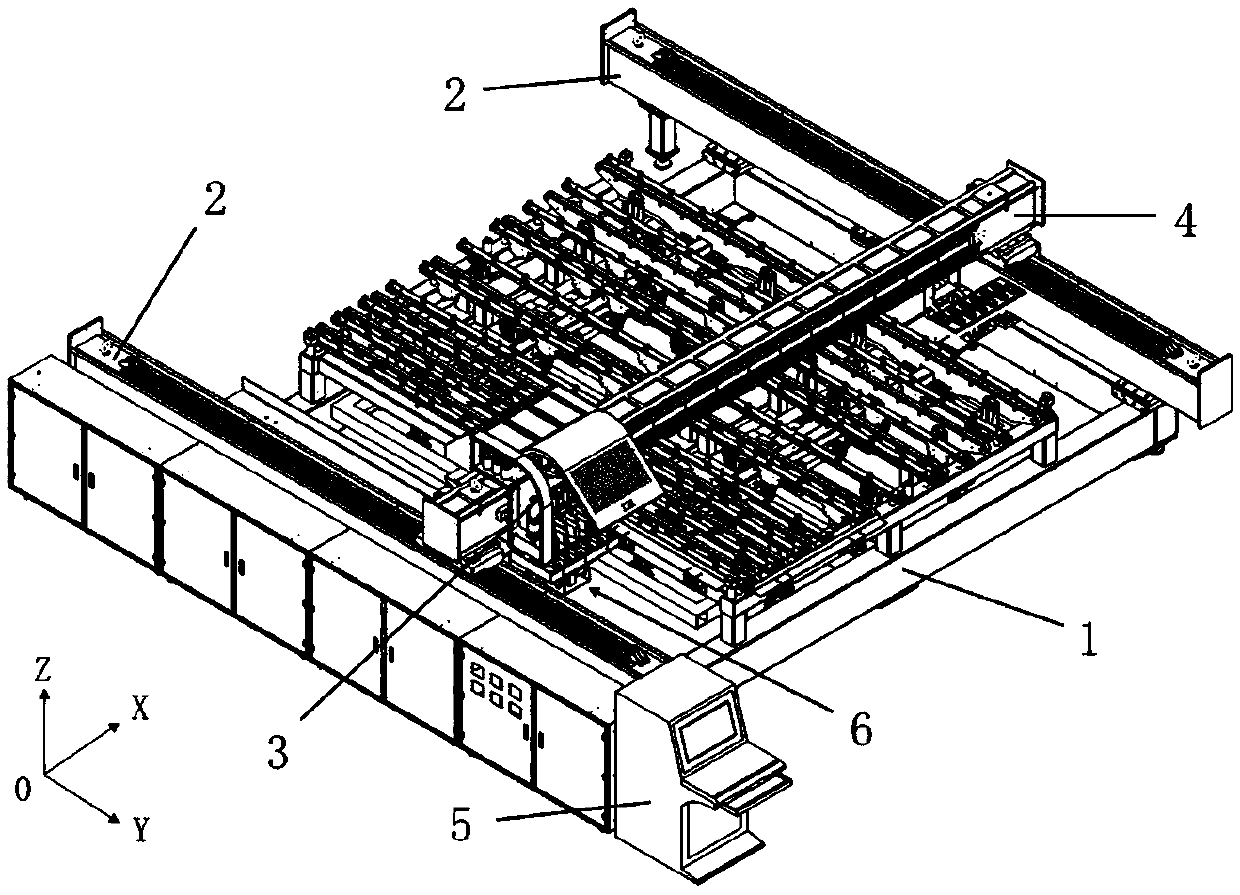

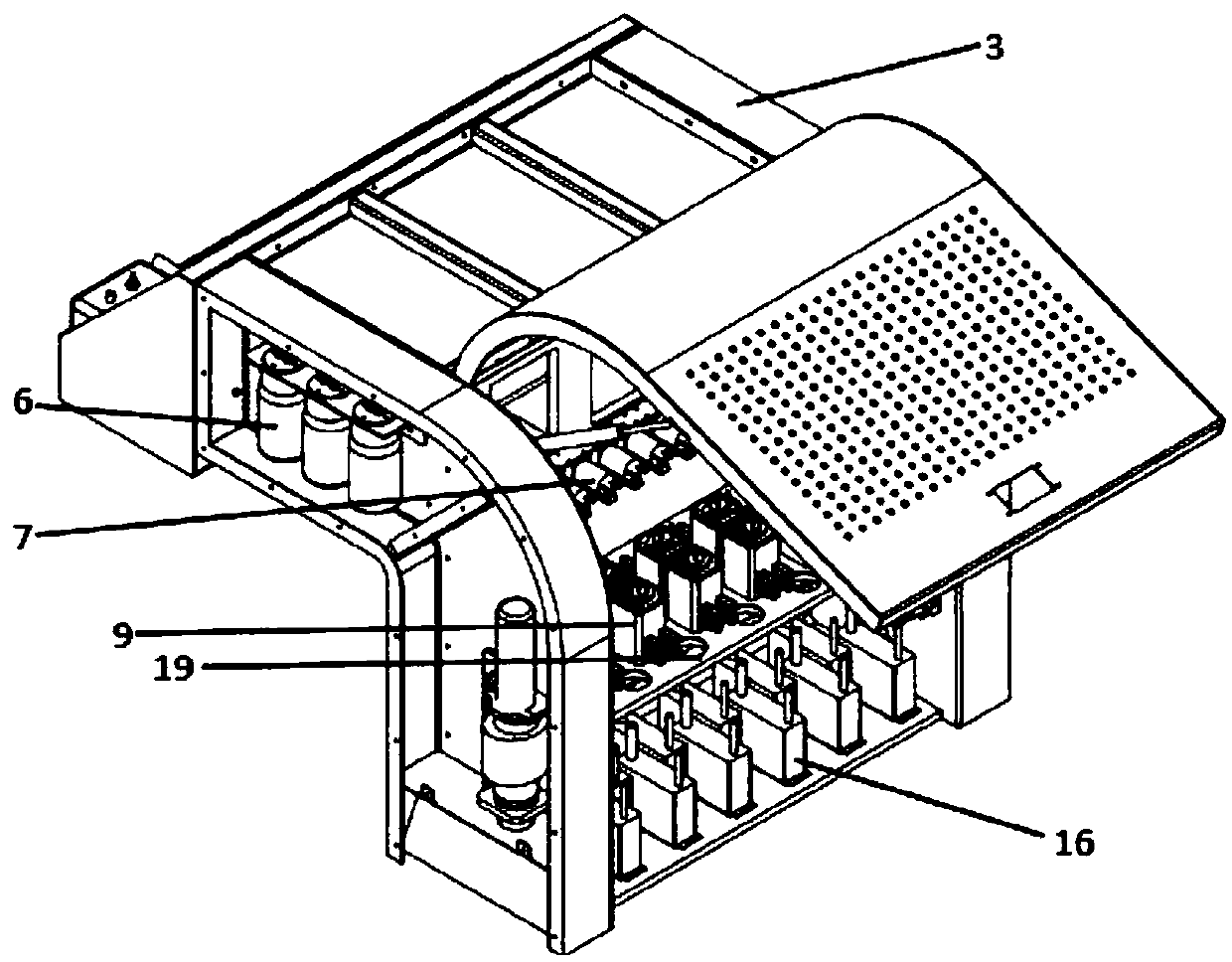

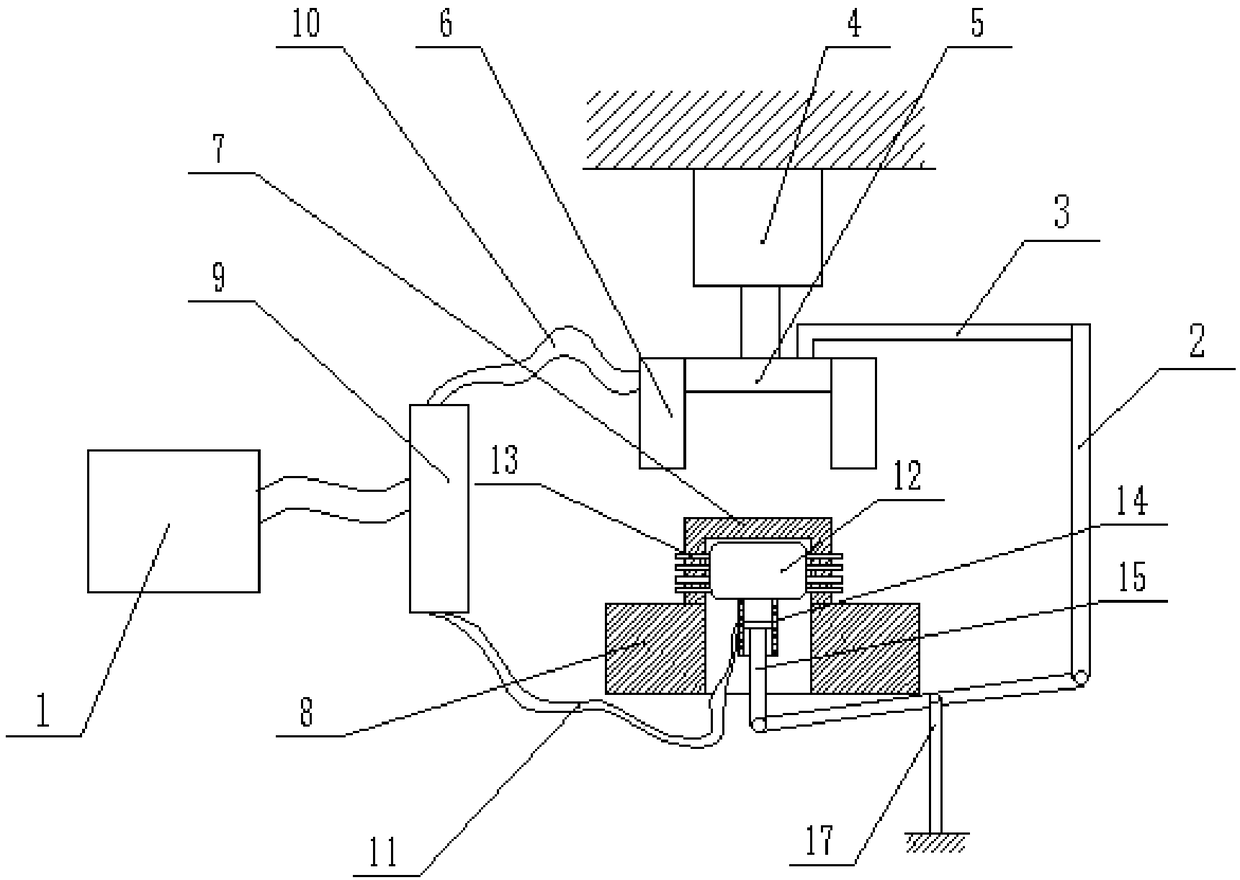

Ink path circulation system and control method of high-temperature glass ink-jet printer

PendingCN109515005AReduces deposit cloggingImprove print quality and efficiencyTypewritersOther printing apparatusPressure controllerEngineering

The invention provides an ink path circulation system and control method of a high-temperature glass ink-jet printer. An ink supply system of the ink-jet printer comprises main ink boxes, wherein themain ink boxes are connected with ink inlet boxes through first ink pumps and filters; the ink inlet boxes are connected with ink pumping boxes through ink nozzles; the ink pumping boxes are connectedwith the main ink boxes through second ink pumps, so that ink can flow back to the main ink boxes; the ink inlet boxes and the ink pumping boxes are correspondingly connected with negative-pressure controllers, so that the ink path circulation can be achieved; and the ink inlet boxes are further connected with ink pressing controllers, so that the ink nozzles can be fully filled with the ink. According to the ink supply system, the ink can continuously flow from beginning to end through the design of an ink supply path and the negative pressure effect; the deposition and clogging reduction effect can be achieved; and meanwhile, basic support can be provided for the good printing operation of the ink nozzles, thereby not only reducing the printing failure, but also prolonging the service life of ink path accessories and reducing the use cost.

Owner:杭州瓦良格智造有限公司

Car U-shaped plate manufacturing mold

ActiveCN108160763AEasy to removeEasy to bendShaping toolsMetal-working feeding devicesCold airHydraulic cylinder

The invention belongs to the field of car part machining molds, and particularly discloses a car U-shaped plate manufacturing mold. The car U-shaped plate manufacturing mold comprises a rack, a movable mold and a fixed mold are arranged on the rack, a hydraulic cylinder is fixed to the rack, the movable mold comprises a pressing plate connected to the bottom end of a piston rod of the hydraulic cylinder, bending punches are connected to the two sides of the pressing plate, a U-shaped mold cavity is formed between the pressing plate and the bending punches, the fixed mold comprises a positioning seat and a base, the positioning seat is matched with the mold cavity in size, a sleeve is arranged in a first through hole, a second air inlet pipe is communicated between the side wall of the sleeve and a cold air outlet end, a second air inlet one-way valve is arranged in the second air inlet pipe, a piston is in sliding connection into the sleeve, the lower side of the piston is fixedly provided with a first connecting rod, a groove communicating with the first through hole is formed in the bottom of the positioning seat, an air bag communicated with the sleeve is arranged in the groove,and a protruding part is arranged on the air bag. According to the scheme, the problem that a machined U-shaped plate is not prone to taking down, and the rejection rate is high is solved.

Owner:CHONGQING YINSHENG MOLD

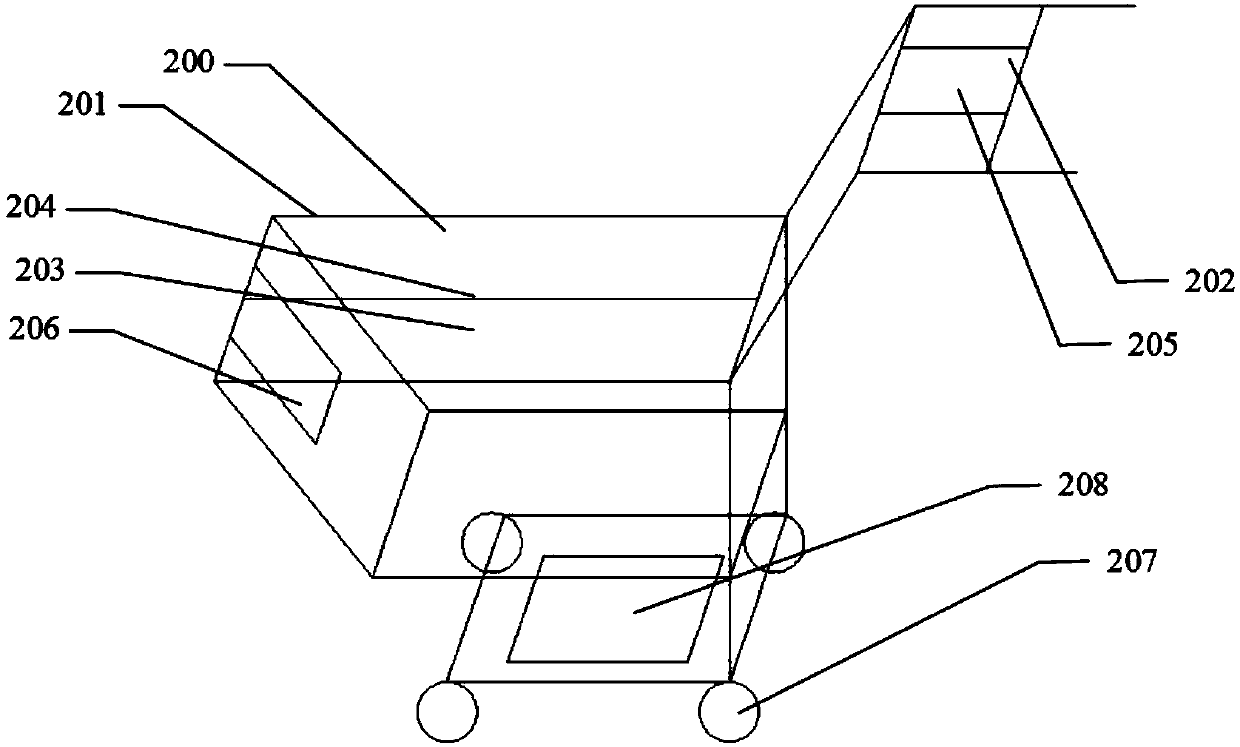

Intelligent shopping system based on identity recognition

ActiveCN107845212AGuaranteed to be fullEasy to buy directlyMarket predictionsRacksIdentity recognitionBarcode

The invention discloses an intelligent shopping system based on identity recognition. The intelligent shopping system based on identity recognition includes an intelligent shelf, an intelligent shopping cart and an identity recognition module, wherein the intelligent shelf includes a shelf body, and a first separator plate which is arranged in the shelf body horizontally; a first movable plate isarranged along the upper end of a second separator plate; a second movable plate which is adapted to the first movable plate sleeves and is arranged along the upper end of the first separator plate vertically; holes adapted to the first movable plate are formed in the second separator plate; the holes include the first hole in the front end and the second hole in the back end; a lifting plate is arranged at the back end of the second movable plate, and a lifting mechanism is arranged at the lower end of the lifting plate; a first push mechanism is arranged at the side end of the lifting plate;the shopping cart includes a shopping cart body and a wireless payment terminal; the wireless payment terminal includes a touch display screen, a bar code identification module, a commodity data storage module, a payment module, a comparison module and a microprocessor; and the bar code identification module, the commodity data storage module, the payment module, the comparison module and the microprocessor are arranged in the wireless payment terminal. The intelligent shopping system based on identity recognition can realize shopping with high efficiency, can provide a humanized shopping mode for purchasers, and has no need for queuing for payment, thus being relatively more convenient and quicker.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production process of ultrathin-wall and leakage-free aviation aluminium alloy castings

The invention relates to a production process of ultrathin-wall and leakage-free aviation aluminium alloy castings. The production process is characterized by comprising the following steps of: manufacturing a pressure-casting mould, machining a double circular ingate, a pressure-casting inlet and a distribution pouring gate on a right mould of the pressure-casting mould; machining a T-shaped exhaust groove on a left mould of the pressure-casting mould, pouring, lightly pressing, strongly pressing and demoulding; and finally carrying out infiltration process treatment. The special pressure-casting mould of the ultrathin-wall and leakage-free aviation aluminium alloy castings adopts a double circular feeding structure and a T-shaped exhaust groove structure, wherein the double circular feeding structure ensures that aluminium liquid fast enters a cavity in the pressure casting process and the thin wall of a part is partially filled; and the T-shaped exhaust groove structure ensures the exhaust of the cavity during the fast filling of the aluminium liquid and prevents the castings from carrying gas. The infiltration process of the invention improves the air impermeability of the product and enables the part to have an inflaming retarding function in addition, and the infiltration is finished through carrying out the work procedures of cleaning with hot water, drying, infiltrating and baking on the castings.

Owner:CHANGZHOU RANTO METALWORK

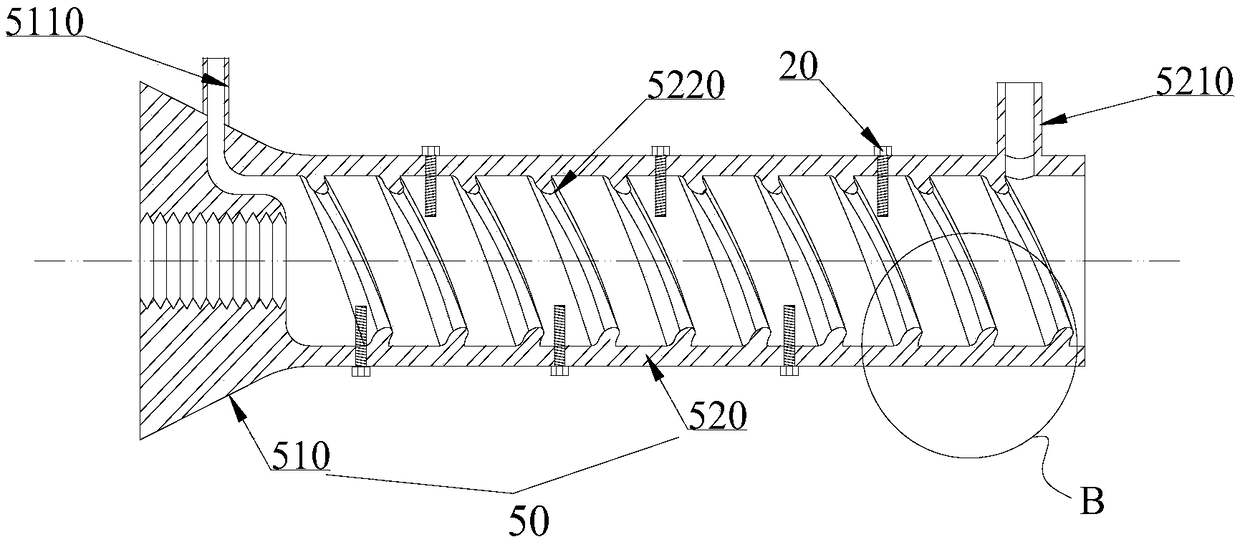

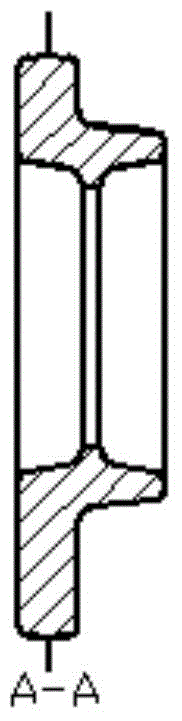

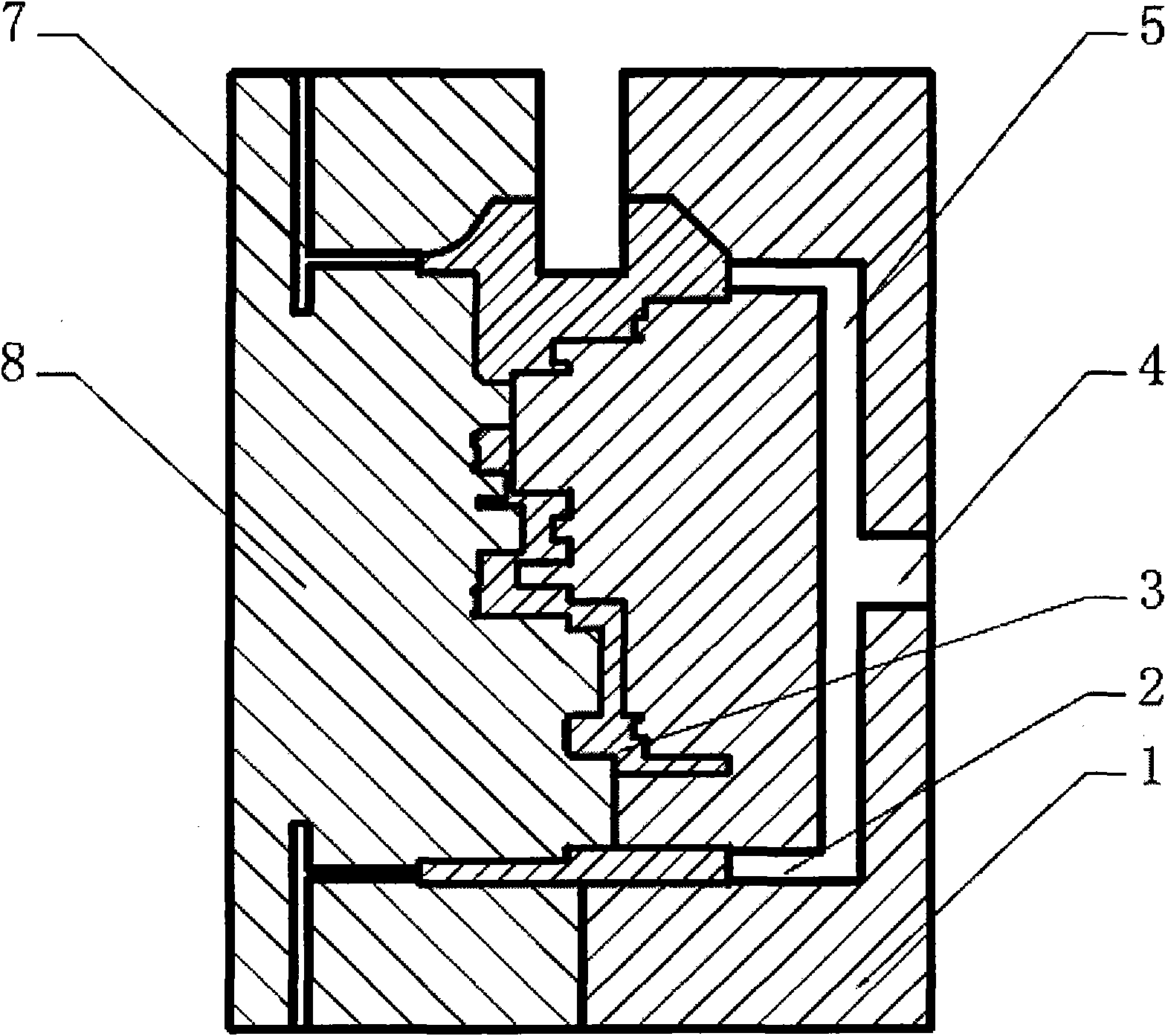

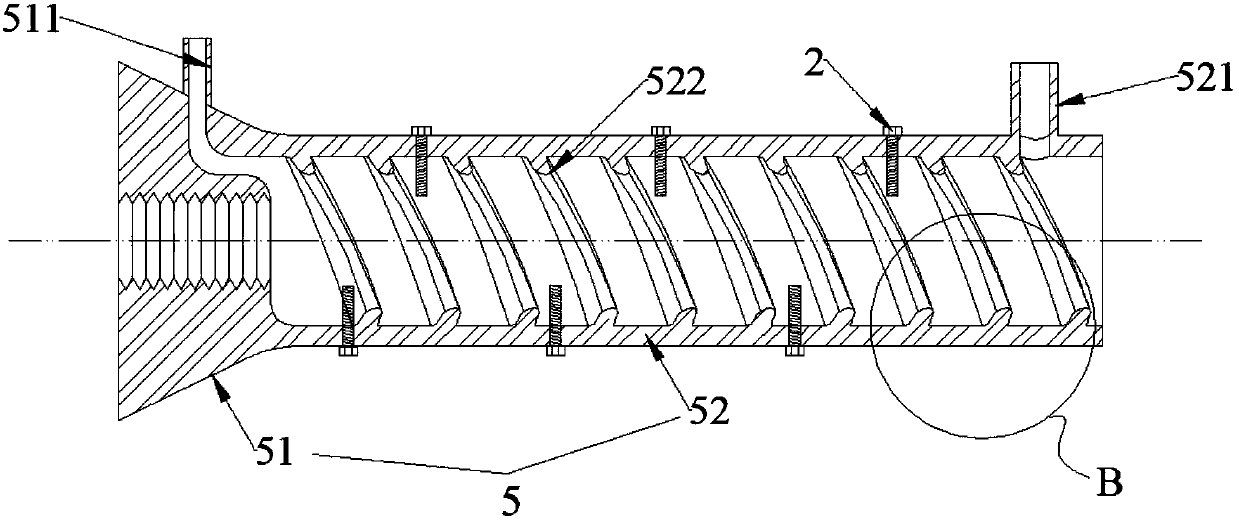

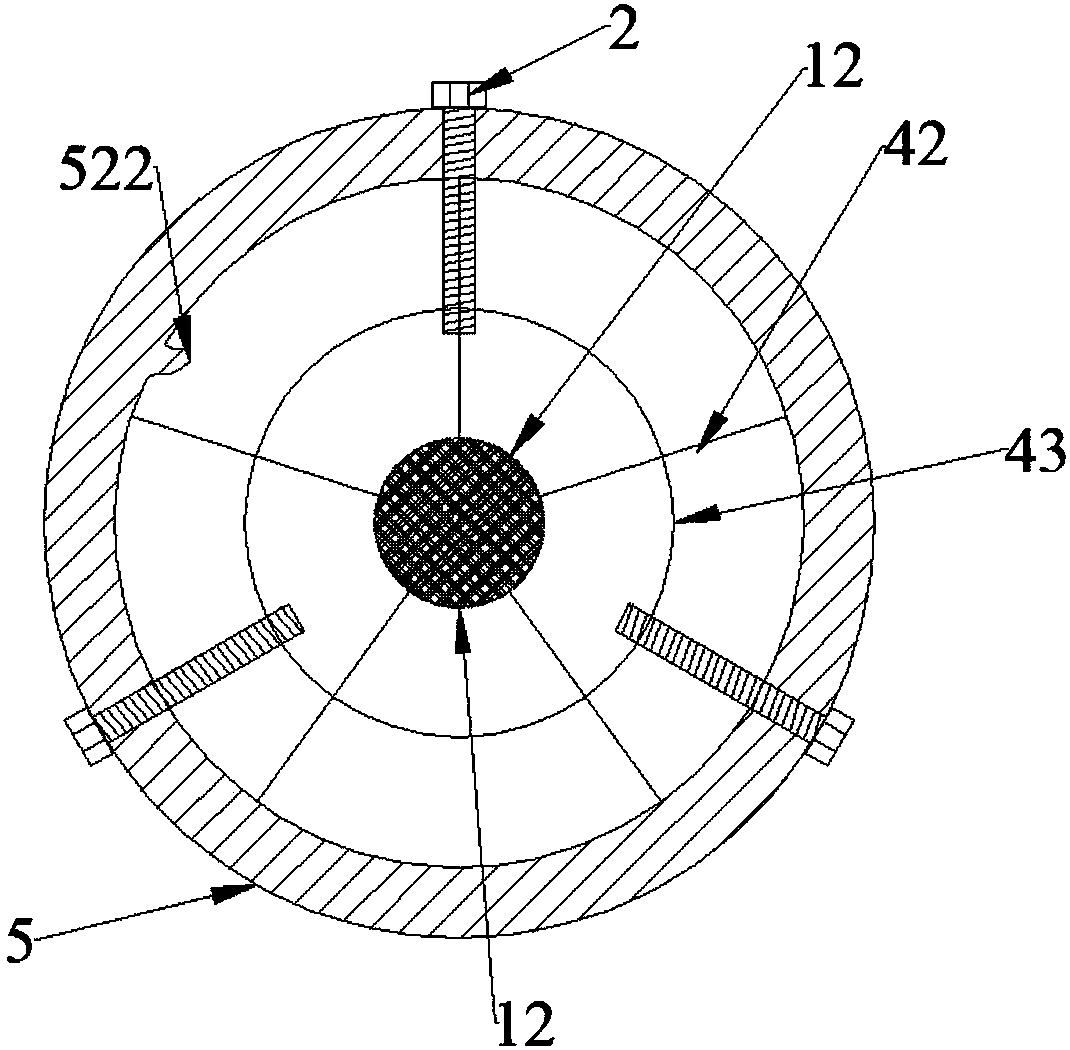

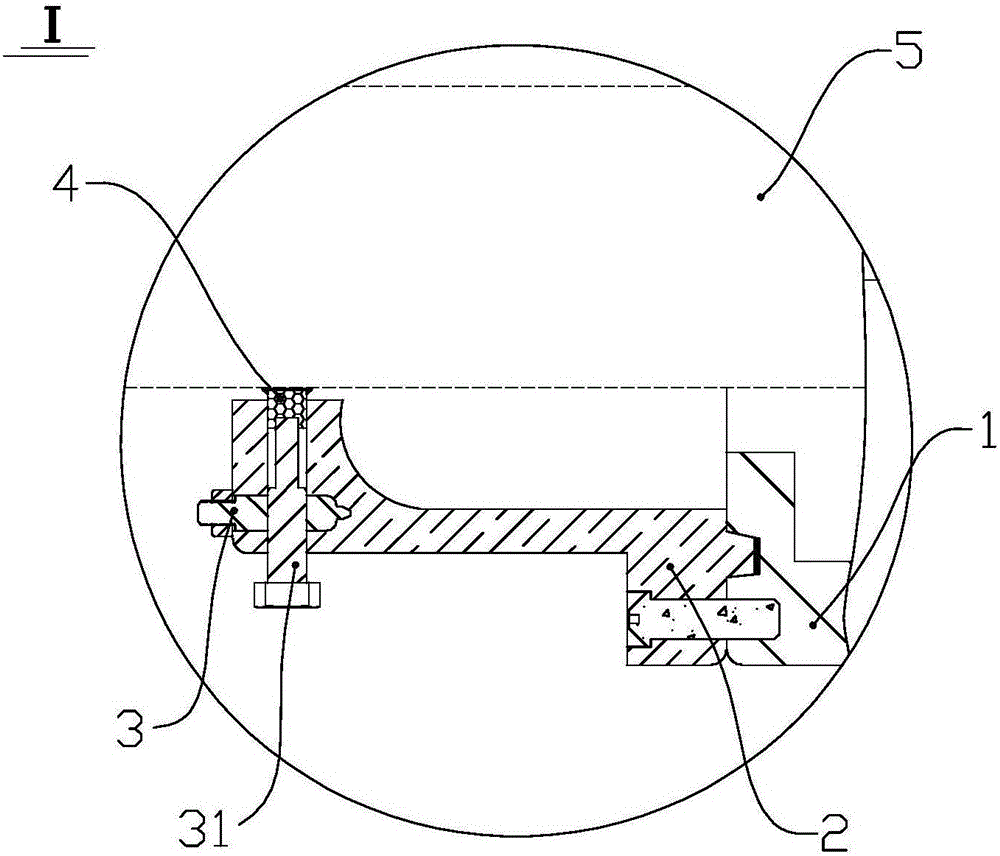

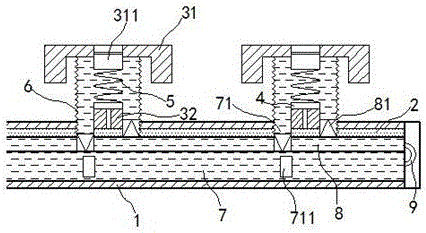

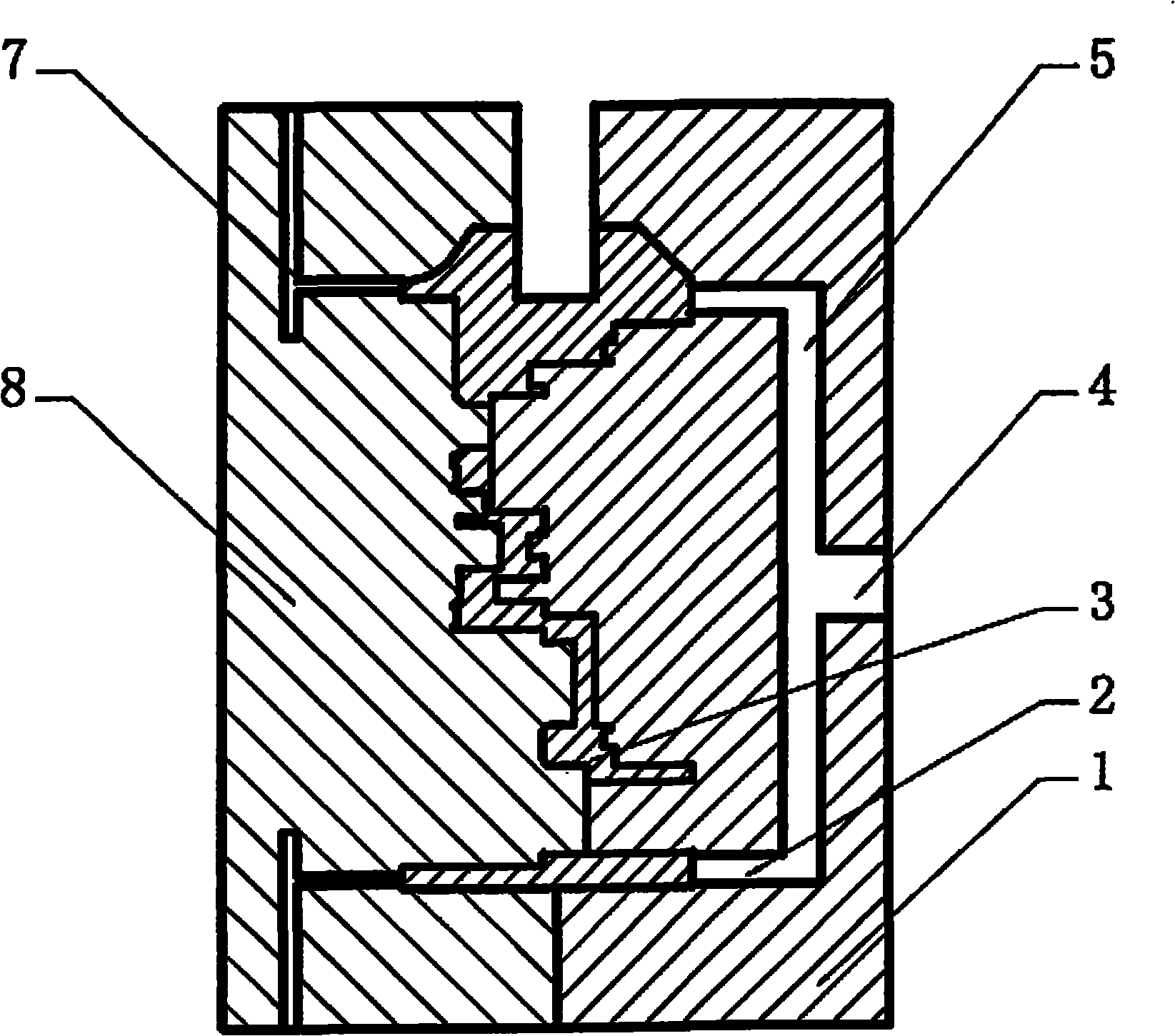

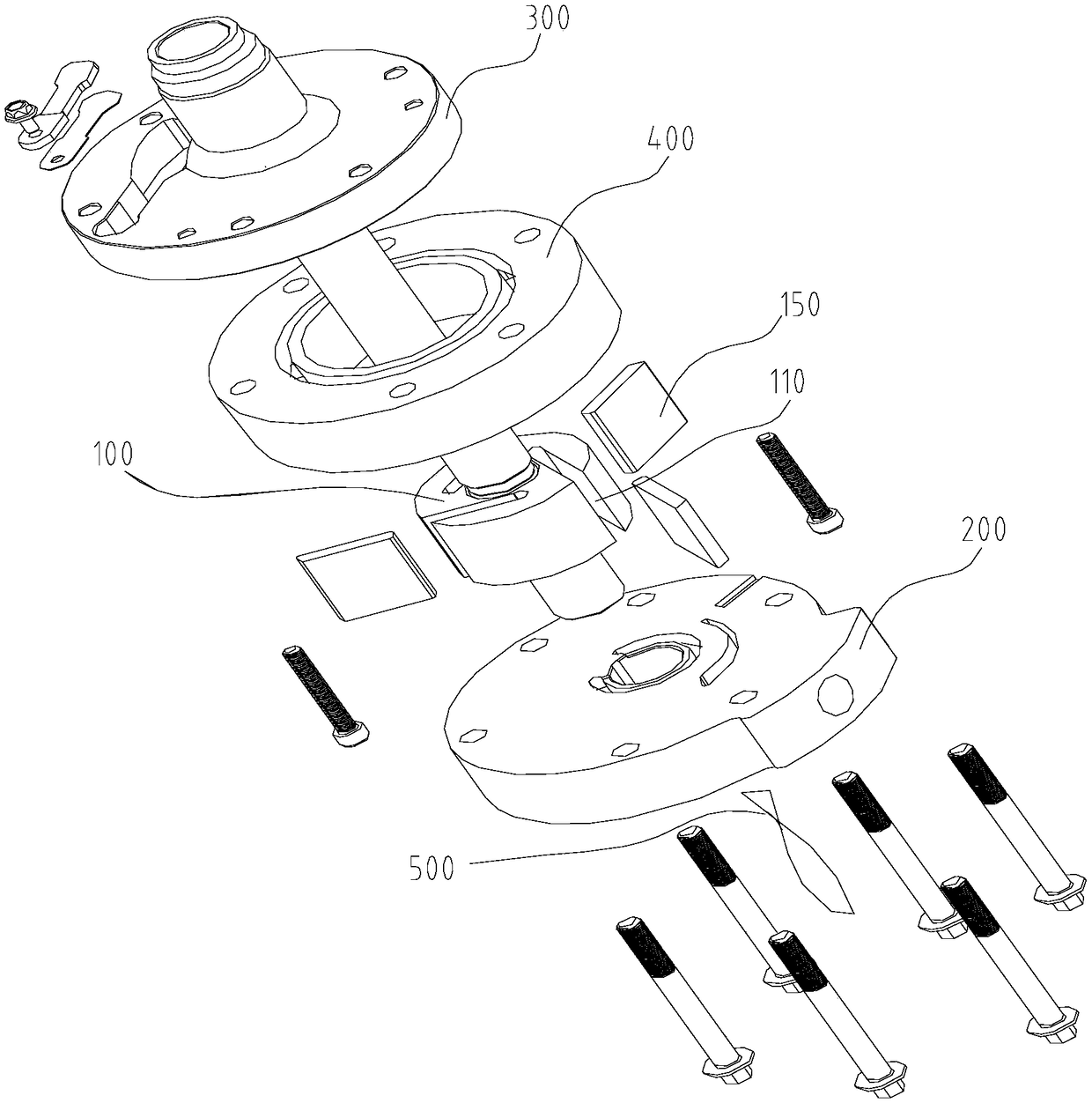

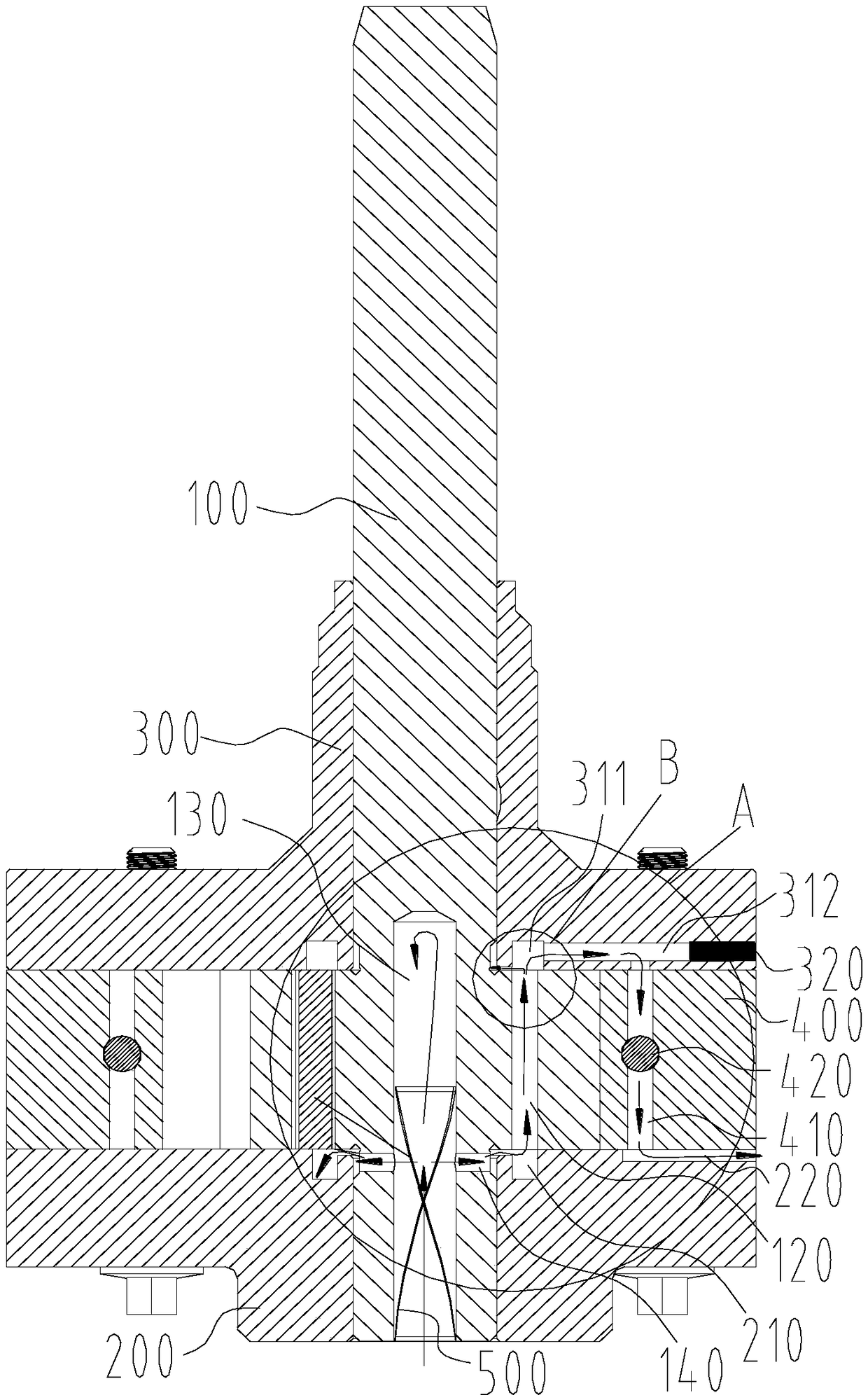

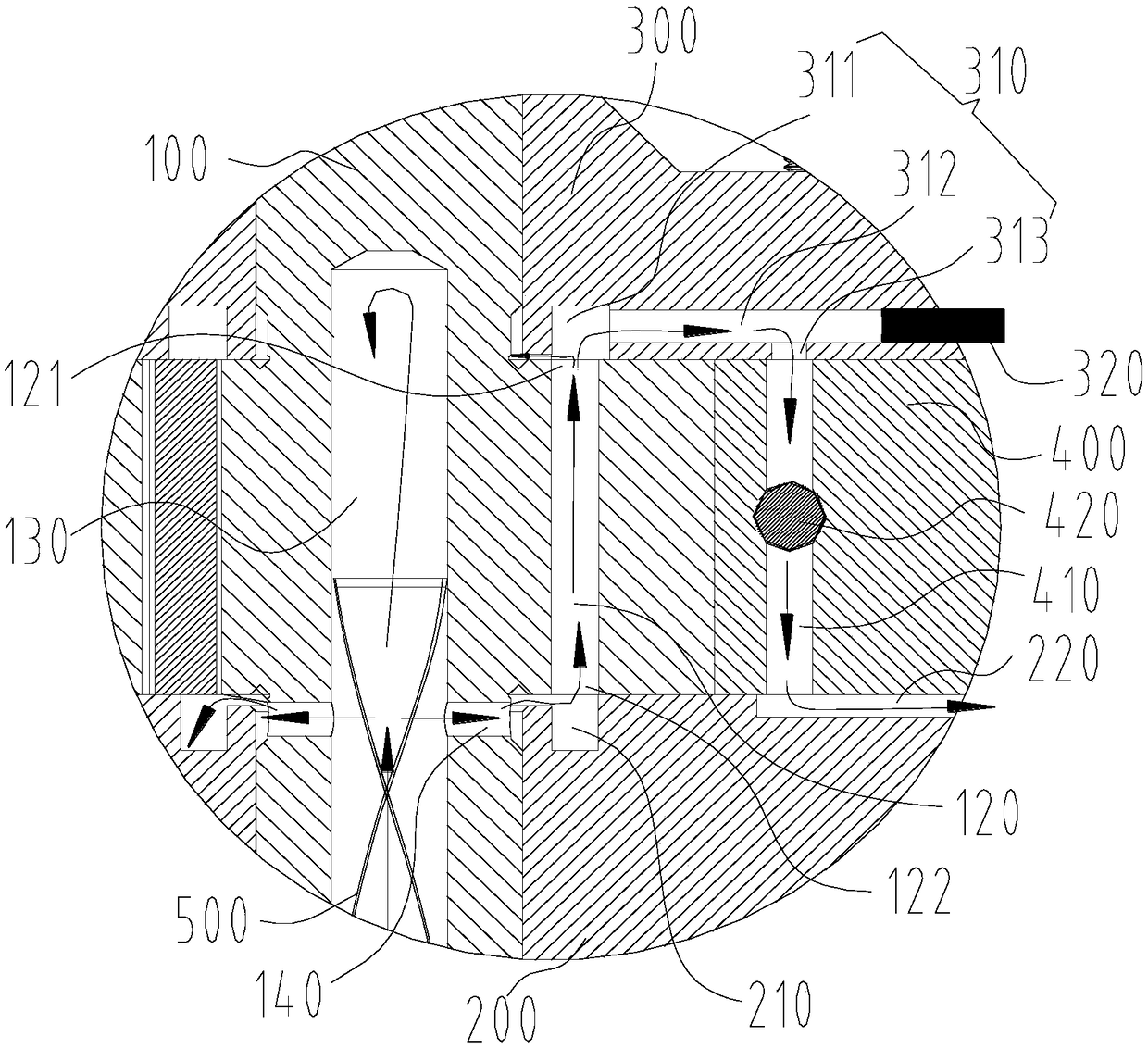

Anti-vibration assembly self-locking type semi-grouting sleeve

The invention provides an anti-vibration assembly self-locking type semi-grouting sleeve. The sleeve comprises a non-grouting connecting section and a grouting connecting section, wherein one tube body section of a steel tube transition section is fixedly arranged in the non-grouting connecting section; another tube body section extends to the outside of the non-grouting connecting section to forma rolling-pressing section which is in rolling-pressing connection with a first to-be-connected reinforcing steel bar; a steel framework comprises inner barbs and outer barbs; the inner barbs are enclosed to form a channel for allowing a second to-be-connected reinforcing steel bar to pass through, and the diameter of the channel is smaller than that of the second to-be-connected reinforcing steel bar; and the outline diameter enclosed by the outer bards is greater than the inner cavity diameter of the grouting connecting section. Each part of the grouting sleeve is separately processed and manufactured, re-assembled, and produced in batch, and easily controlled in quality; connection between the grouting sleeve and the steel tube transition section is operated in a plant through machinery, and threaded connecting quality is easily controlled; the first to-be-connected reinforcing steel bar and the steel tube transition section are directly connected in a rolling-pressing mode, so that processes are simple, and length, inserted into the sleeve, of reinforcing steel bars is easily controlled; and a self-locking type steel framework is adopted, so that the anti-pulling purpose is realized, and antiknock characteristic is improved.

Owner:HEFEI CONSTR ENG GRP

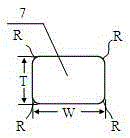

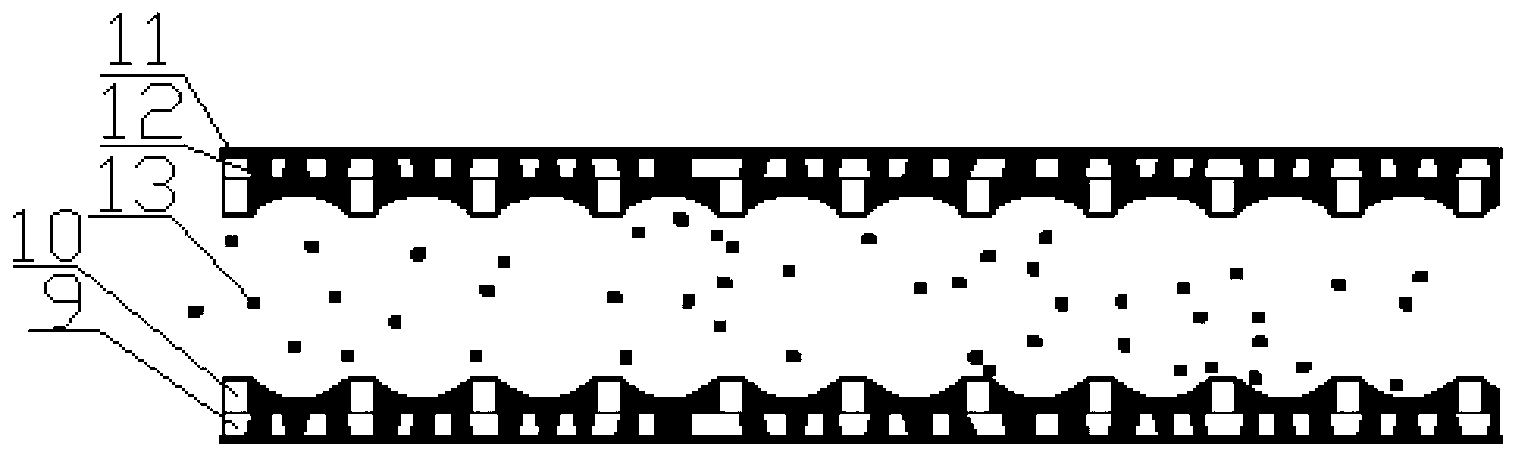

Rectangular cross-section steel wire for radial tire and method for manufacturing steel wire ring thereof

ActiveCN105383227AReduce contact stressImprove section strengthTyre beadsTear resistanceWear resistance

The invention discloses a rectangular cross-section steel wire for a radial tire and a method for manufacturing a steel wire ring thereof. The rectangular cross-section steel wire is manufactured by adopting a round cross-section high-carbon steel wire in a roller-drawing mode and undergoes surface galvanization and tempering treatment, and m rectangular steel wires are twined side by side in n layers and are bundled by straps for forming the steel wire ring. The steel wire ring serves as a tire bead core of the radial tire and is small in cross section area; surface contact is adopted between the steel wires, and therefore the geometrical shape stability is good; the contact stress between the steel wires is small, the cross section strength between the steel wires is high, and therefore the wear resistance and the tearing resistance of a tire bead can be improved, and the manufacturing cost of the tire can be reduced.

Owner:JIANGSU XINGDA STEEL TYPE CORD

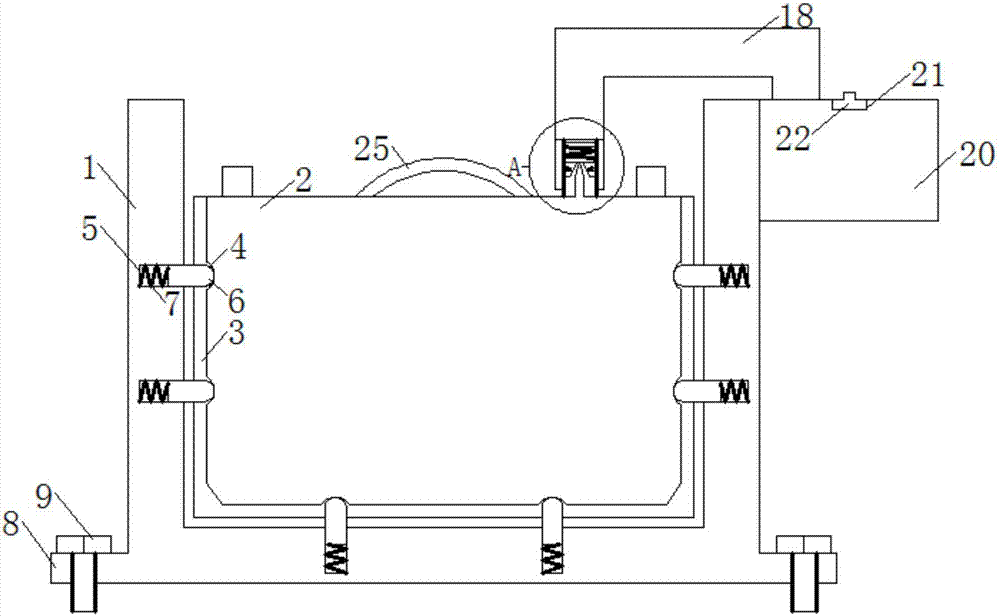

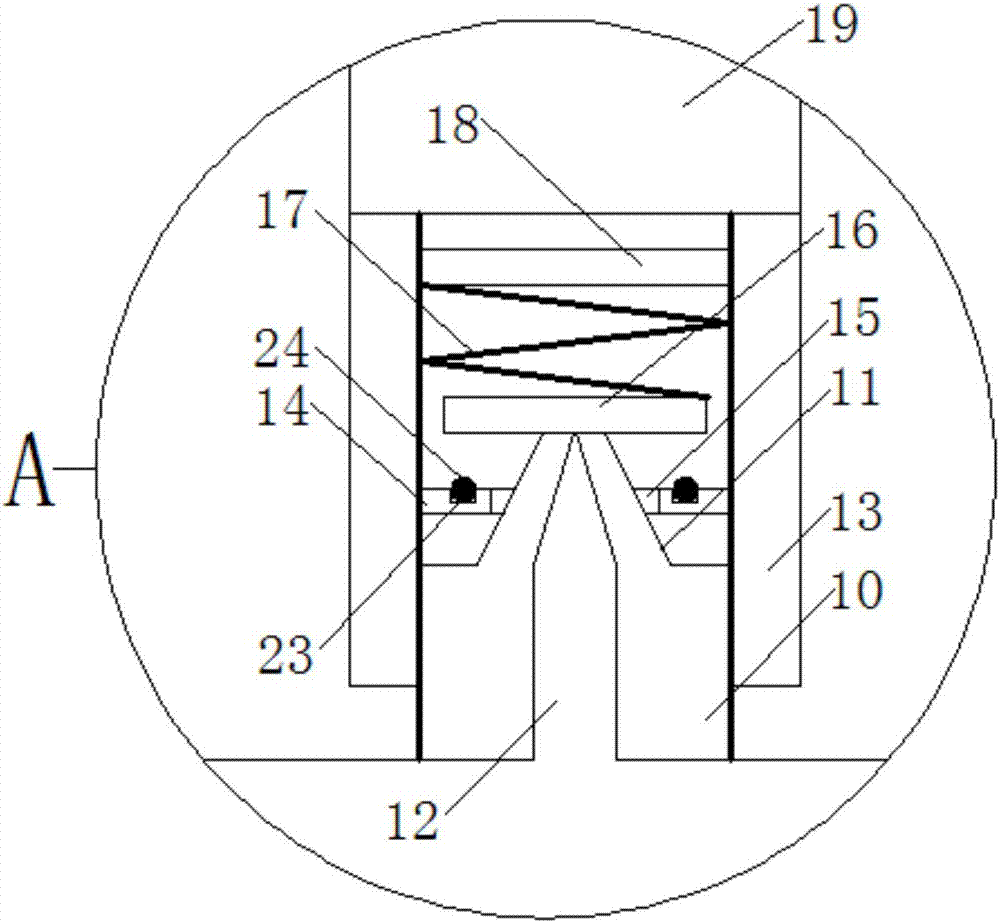

Shockproof automobile battery

PendingCN107958968APlay a buffer rolePlay a shock absorbing roleCell component detailsPropulsion by batteries/cellsAutomotive batteryEngineering

Owner:南京金邦动力科技有限公司

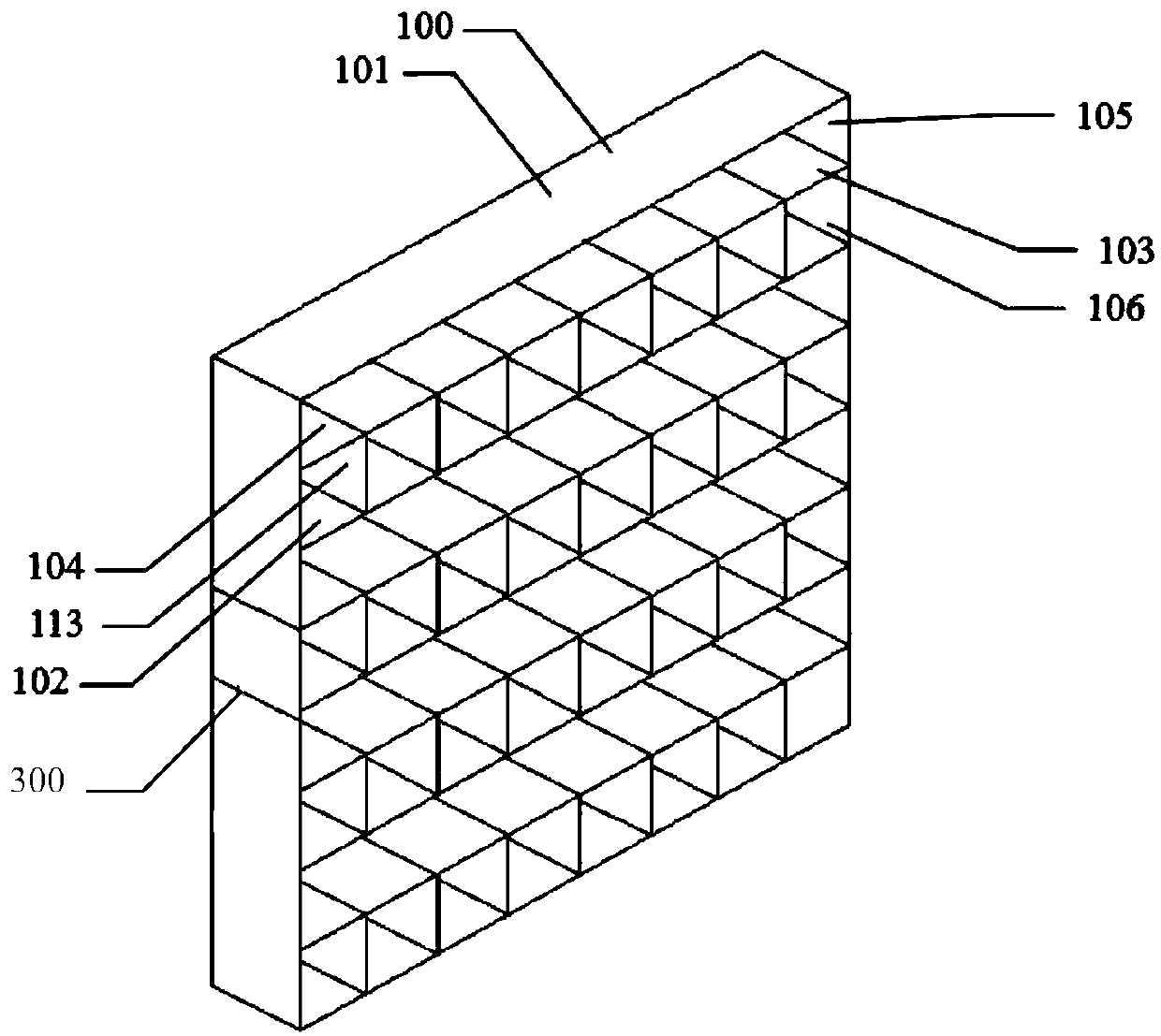

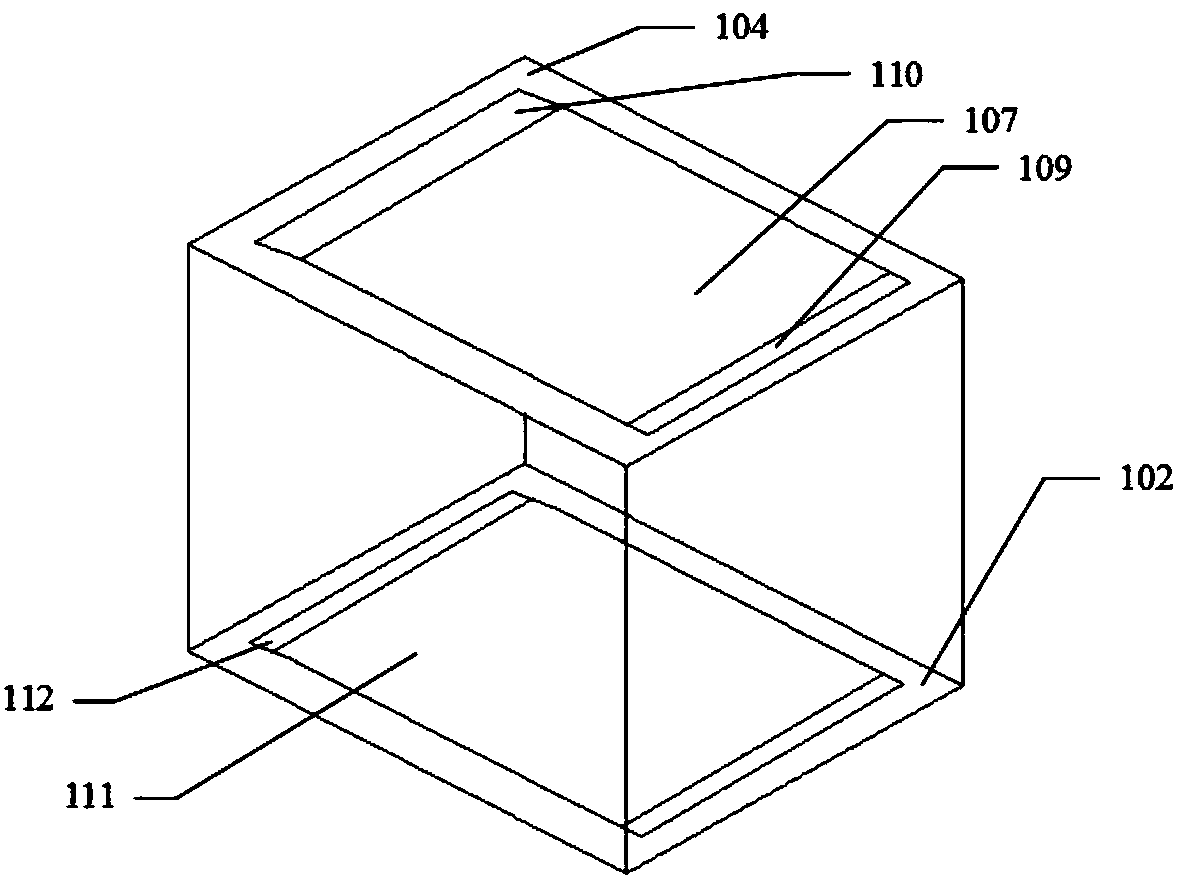

Fireproof explosion-proof combination structure at power cable joint of electric power system and application method

ActiveCN105977898ASolve the problem of airtightnessHigh strengthCable junctionsPower cableElectric power system

The invention discloses a fireproof explosion-proof combination structure at a power cable joint of an electric power system and an application method, belonging to the power cable connector fireproof explosion-proof combination structure. The fireproof explosion-proof combination structure at the power cable joint of the electric power system comprises an outer box body with double sealing structures on a longitudinal assembling surface, an assembling end cap which adopts an embedding sealing structure with the outer box body and a plugging board and a sealing member which seal a gap between related fitting surfaces of a cable annular surface and an assembling end cap, wherein the plugging board and the sealing member are arranged on the assembling end cap; the outer box is provided with a glue injection tube and an exhaust pipe are arranged on the outer box; the cable is fully wrapped by a power cable fireproof pack after connected to a middle connector and is arranged in the outer box; and fireproof sealing glue is injected to the outer box through the glue injection tube. In operation, air in the outer box is discharged through carbon dioxide or nitrogen and the fireproof sealing glue is injected inside the outer box and then high pressure shape forming is performed. The pressure maintaining shape forming is performed on the fireproof sealing glue by virtue of the outer box. The fireproof explosion-proof combination structure at the power cable joint realizes sealing protection on the cable connector, forms a compact filling layer on the periphery of the middle connector, solves a problem that durability and reliability of the fireproof performance are not good, and is low in manufacture cost and easy to promote.

Owner:WUHAN HANYUAN JIJI ELECTRIC POWER EQUIP

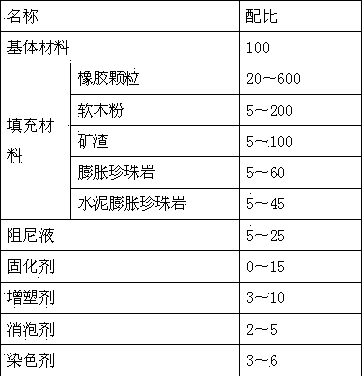

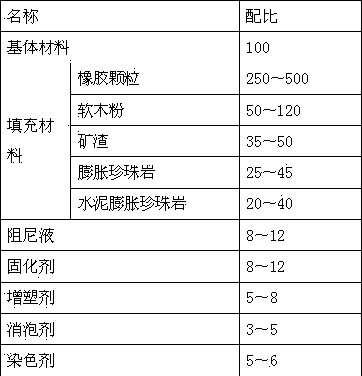

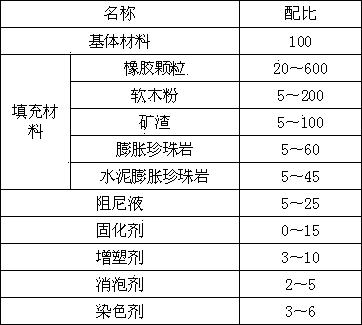

High polymer composite for embedded rail system

The invention discloses a high polymer composite for an embedded rail system, which comprises the following components by weight percentage: 100% of base material, a filling material, 2-25% of damping liquid, 0-15% of curing agent, an appropriate amount of defoaming agent, an appropriate amount of colorant and an appropriate amount of plasticizer, wherein the base material is polyurethane modified epoxy resin; the filling material comprises the following components by weight percentage: 20-100% of rubber particle, 5-200% of cork powder, 5-100% of slag, 5-60% of expanded perlite and 5-45% of cement expanded perlite. The high polymer composite can meet three-way rigidity requirements of the rail system, has good damping capacity and fatigue resistance, does not crack after three million fatigue tests, is excellent in electrical insulation, green and environment-friendly, and can be recycled and smashed as filling for repeated use.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

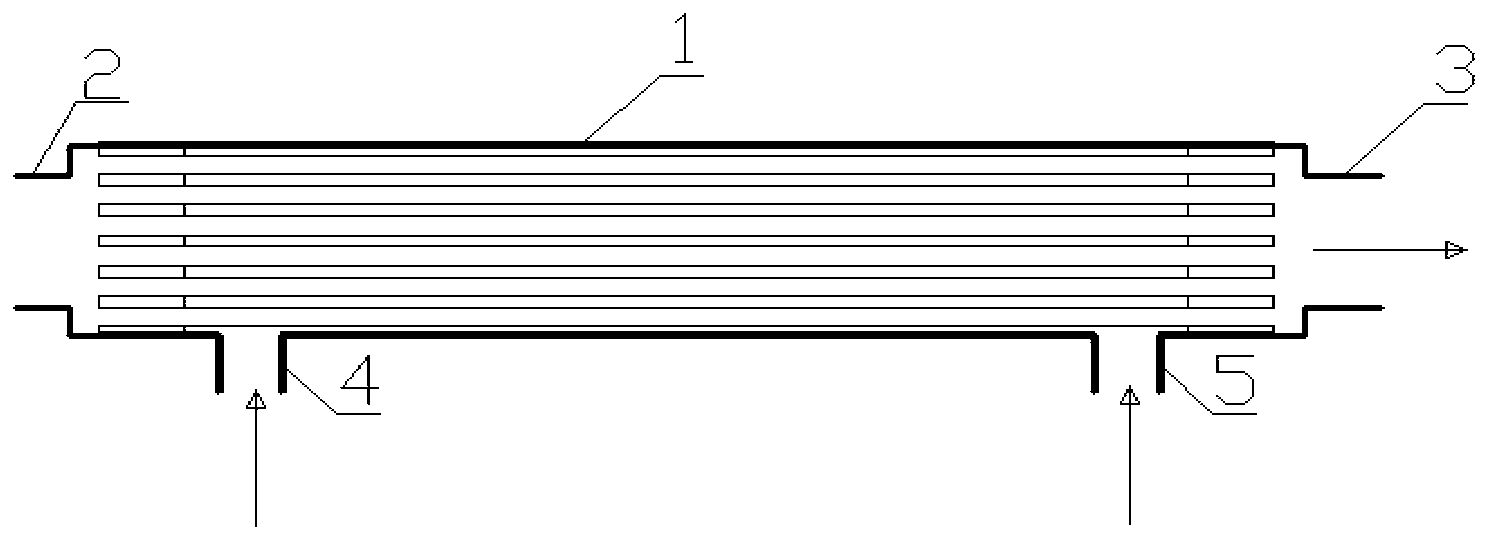

Water cooling keyboard

ActiveCN106200993AImprove experienceSuppress sweatingInput/output for user-computer interactionDigital data processing detailsEngineeringPressure sensitive film

The present invention relates to a water cooling keyboard. The water cooling keyboard comprises a shell, a chip board and keys. The chip board is fixedly installed in the shell, and the keys are regularly arranged on the chip board. The keys comprise key caps and pillars. The bottom of the pillar is fixed on the chip board and a pressure sensitive film is fixed on the top of the pillar. Each pressure sensitive film is electrically connected with the chip board. A pressure spring is fixed on the pressure sensitive film, and the other end of the pressure spring is connected with the key cap. A liquid sealing tube made of elastic material is arranged on the outside of the pillar, the upper end of the liquid sealing tube is tightly fixed on the key cap, and the lower end of the liquid sealing tube is tightly fixed on the chip board. A water supply layer and a heat dissipation layer are laid successively in the lower part of the chip board, a unidirectional water outlet pipe connected with the liquid sealing tube communicates with the heat dissipation layer and a unidirectional water inlet tube connected with the liquid sealing tube communicates with the water supply layer. The structure of the keyboard is novel, which can effectively reduce the temperature of the keyboard to prevent finger from sweating and improve comfort while typing.

Owner:义乌市安航科技有限公司

Intelligent oil pumping system

InactiveCN102359361AGuaranteed to be fullPlay a separate roleFlexible member pumpsFluid removalClutchProgrammable logic controller

The invention discloses an intelligent oil pumping system, which comprises an oil pumping unit, an oil pumping pump and a PLC (Programmable Logic Controller) electronic-control system, wherein the oil pumping unit comprises a rack; the rack is provided with a speed reducer, one input end of the speed reducer is connected with an automatic-operation motor by a coupler, and the side surface of the coupler is provided with a proximity switch; the other input end of the speed reducer is connected with a manual operation motor by a dead-electricity brake clutch and a roller chain; two output ends of the speed reducer are provided with two winding drums with opposite rope race rotation directions; a steel wire rope A and a steel wire rope B respectively pass by pulleys of the beam hanger and a balance weight; then the steel wire rope A and the steel wire rope B are respectively fixed at inner ends and outer ends of the two winding drums by rope clips; and an oil rod and a plunger connected with the beam hanger are arranged in the oil tube and a pump barrel. The intelligent oil pumping system is characterized in that the upper end of the pump barrel is connected with the inner tube; the lower end of the pump barrel is connected with a low-resistance fixing valve; an oil reservoir is arranged outside the inner tube, the pump barrel and the low-resistance fixing valve; an outer tube is connected with the fixing valve in a sealing mode to form an oil pumping path together with the fixing valve; and oil in the oil reservoir opens the low-resistance fixing valve under the action of hydraulic column pressure and enters the pump barrel.

Owner:DALIAN HONGQIAO TECH

Liquid membrane extraction method by taking hollow fiber composite membrane as liquid membrane carrier

ActiveCN103007574AReduce lossesImprove stabilitySemi-permeable membranesLiquid solutions solvent extractionHollow fibreFiber

The invention discloses a liquid membrane extraction method by taking a hollow fiber composite membrane as a liquid membrane carrier. According to the liquid membrane technology, the hollow fiber composite membrane serves as the liquid membrane carrier, an extract phase is filled and attached to the gap and surface of the hollow fiber composite membrane to form the liquid membrane, a feed liquid phase solution and a reverse extraction phase respectively flow through two sides of the carrier, and the separation effect of in-step extraction and reverse extraction is realized through the liquid membrane function. The hollow fiber composite membrane consists of a braided tube layer and a polymer membrane layer; and meanwhile, the extraction phase and the feed liquid phase are fully mixed before entering the membrane by utilizing a mixer, the dispersing effect of the extraction phase liquid drops in the feed liquid phase is improved, the contact probability of the liquid membrane and the feed liquid solution is enhanced, and the mass transfer efficiency is improved. The imbalanced extraction realized by the liquid membrane technology is utilized, the problems that the liquid membrane attachment amount is small, the liquid membrane is instable, the mass transfer efficiency is low and the like in the hollow fiber supported liquid membrane and the liquid membrane updating technology are solved, the mass transfer coefficient and liquid membrane flux are improved, and the magnitude order of the mass transfer coefficient is 10-5.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

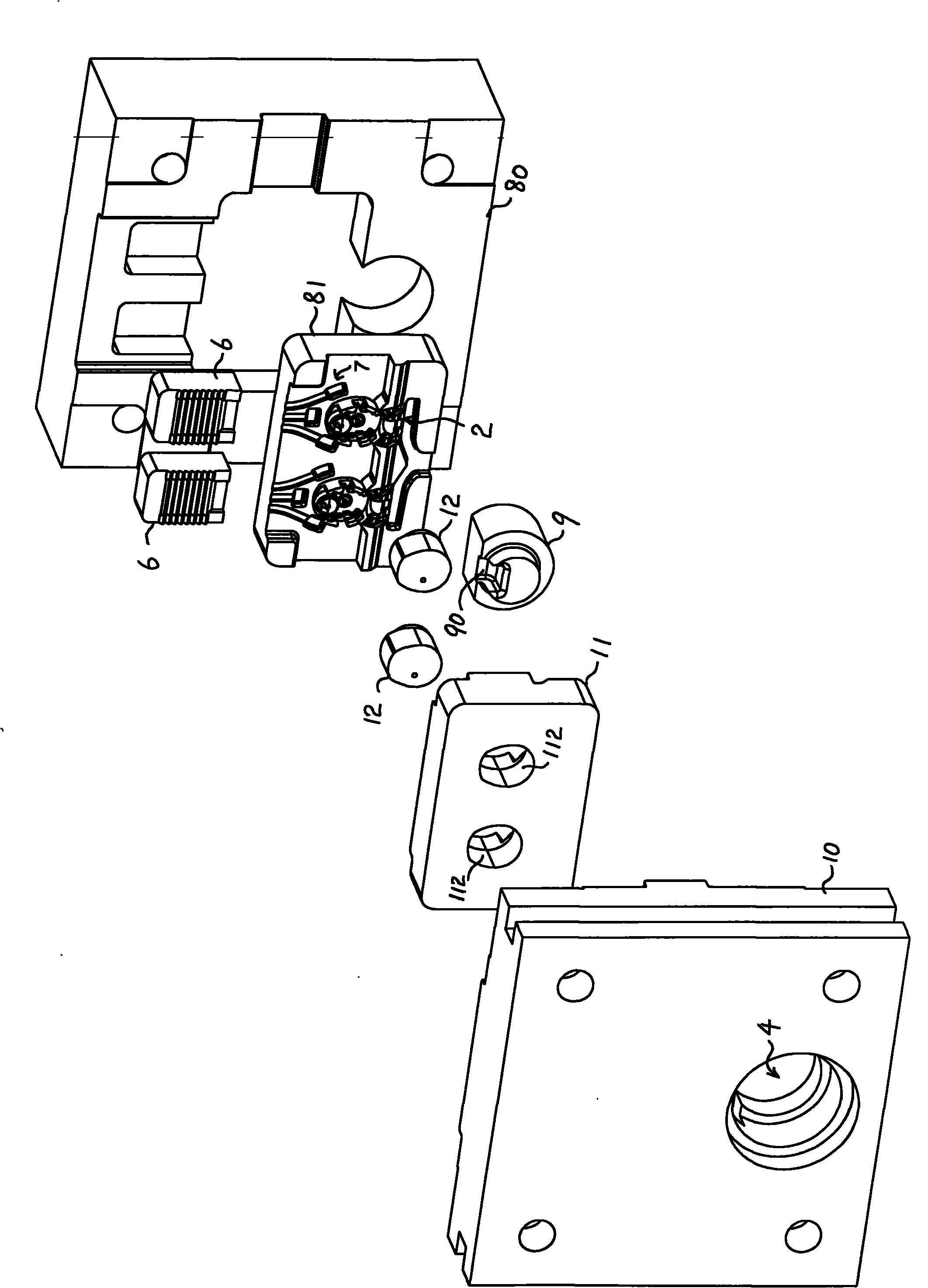

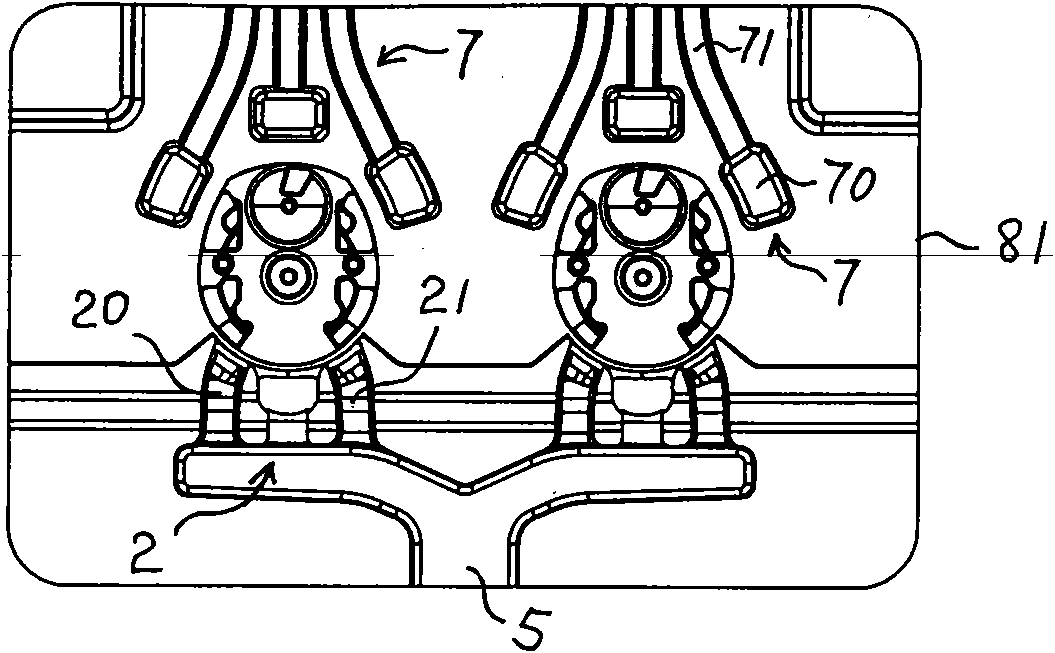

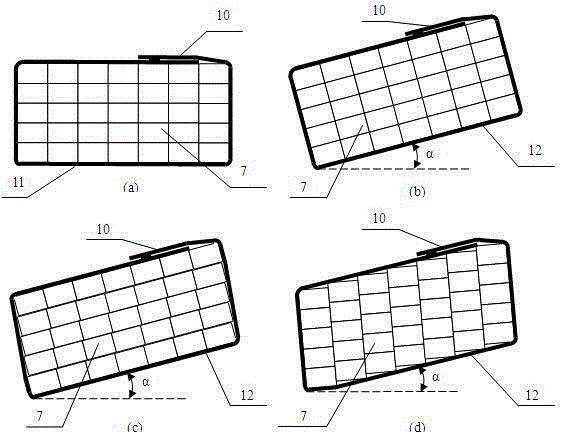

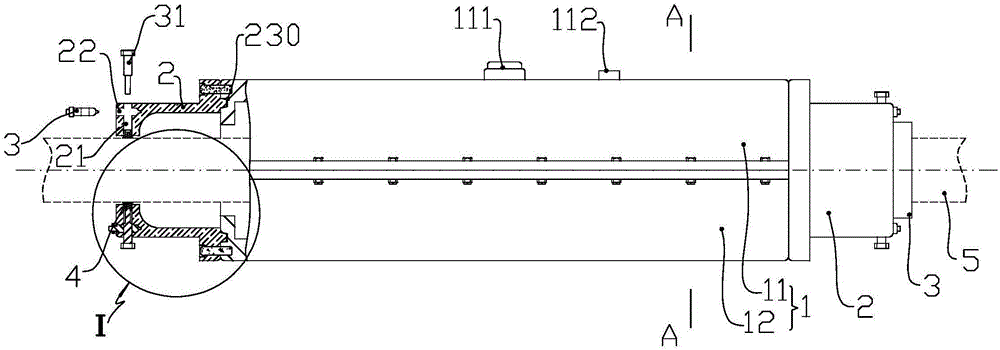

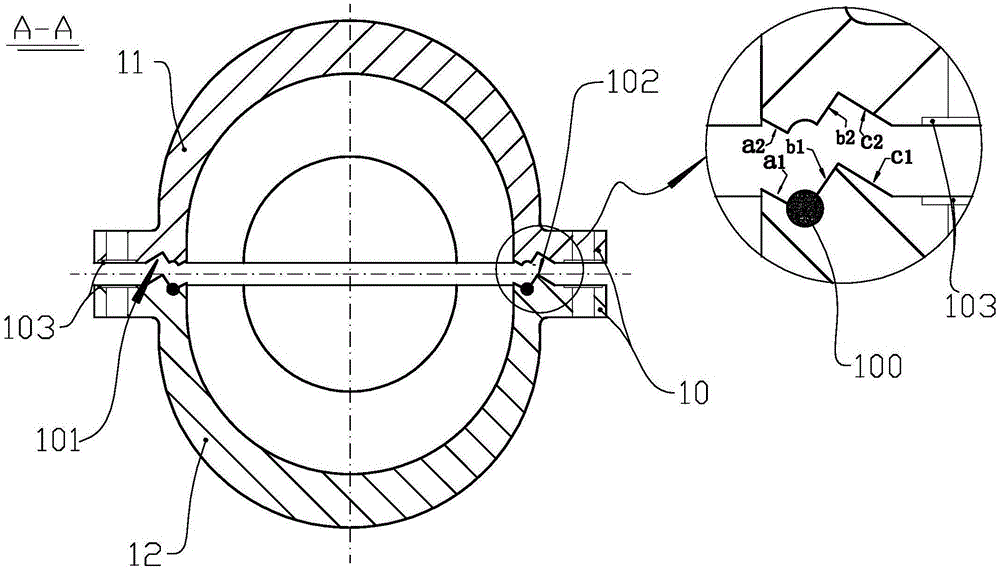

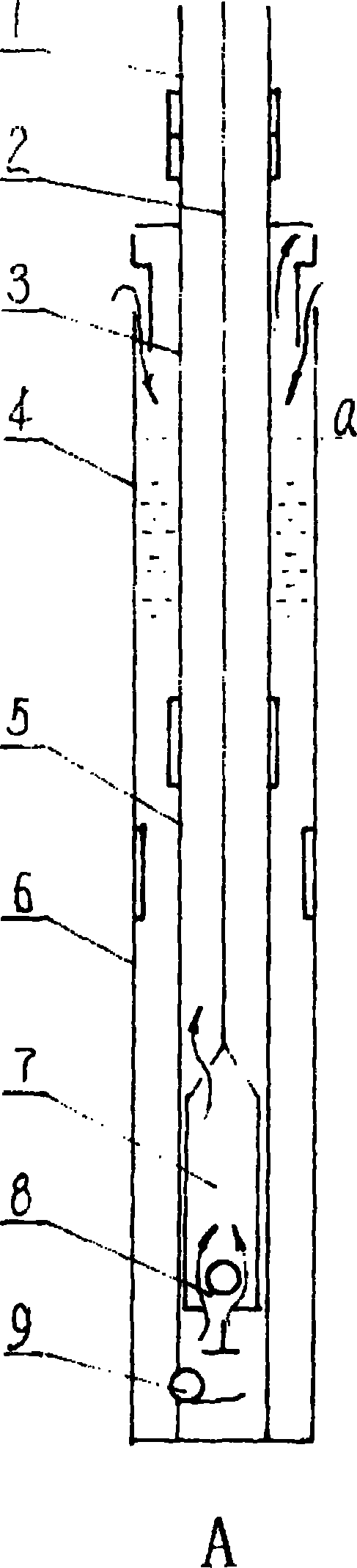

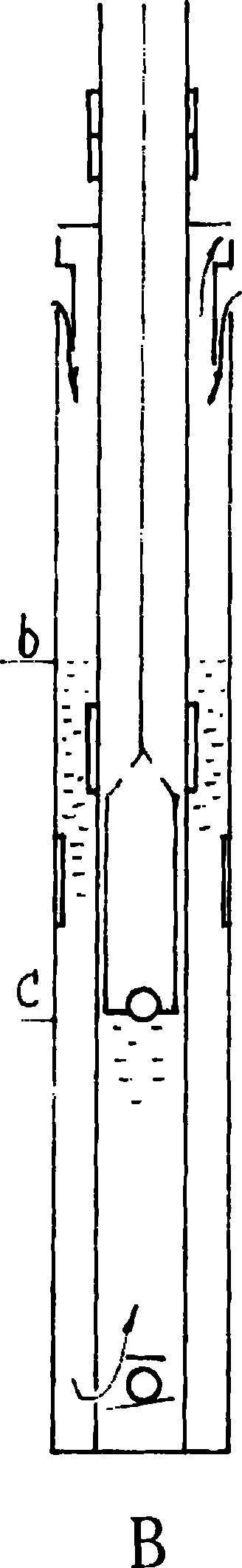

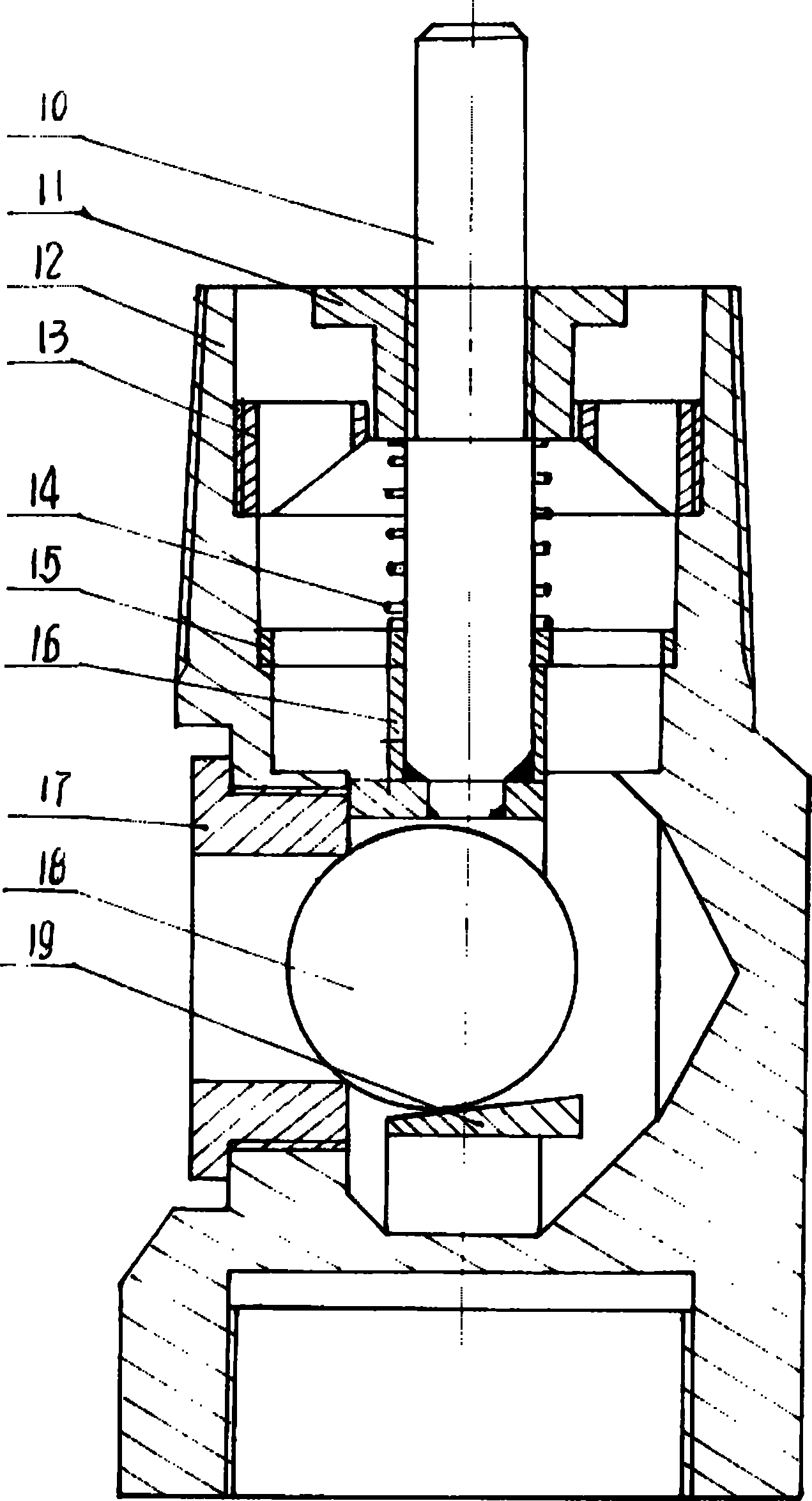

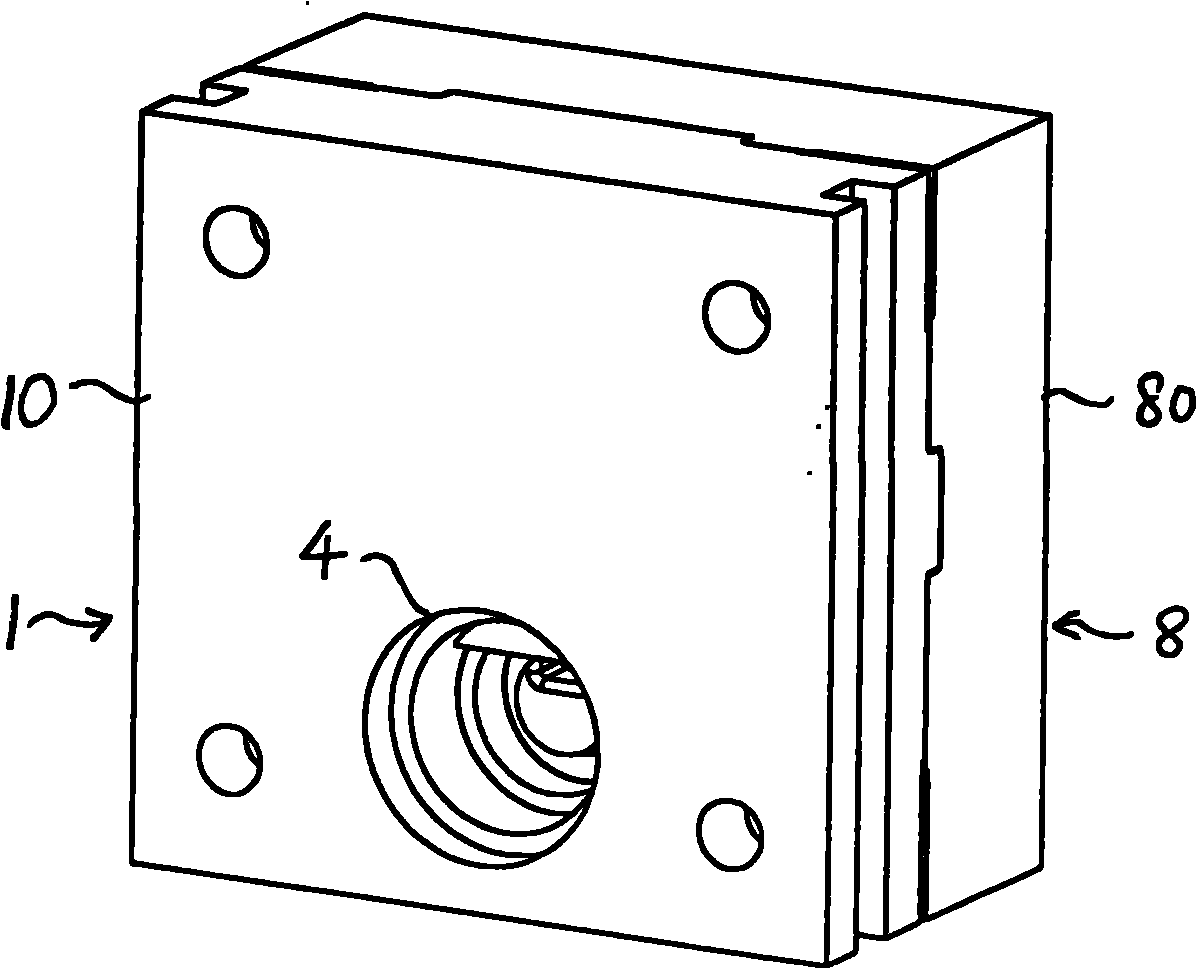

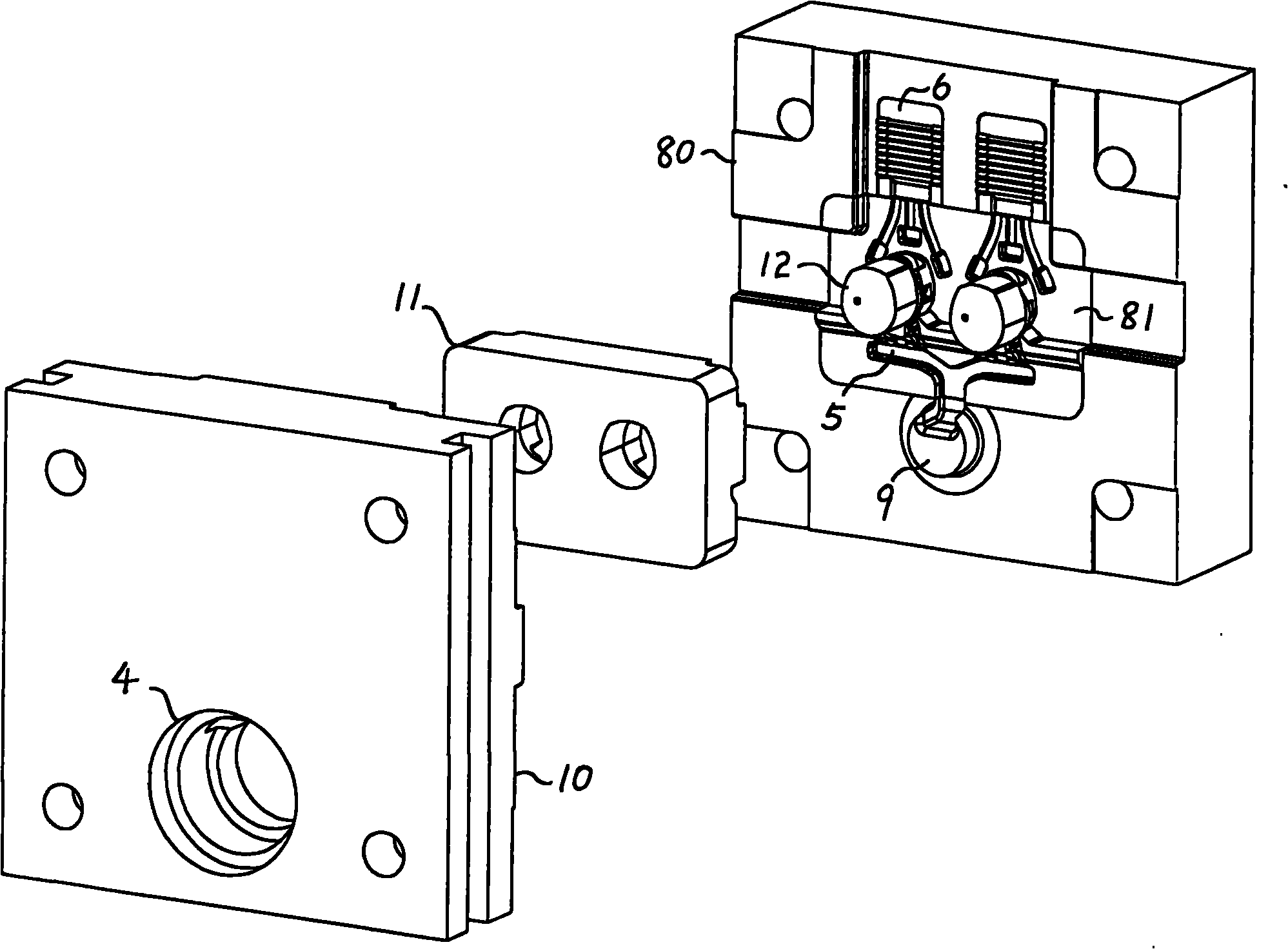

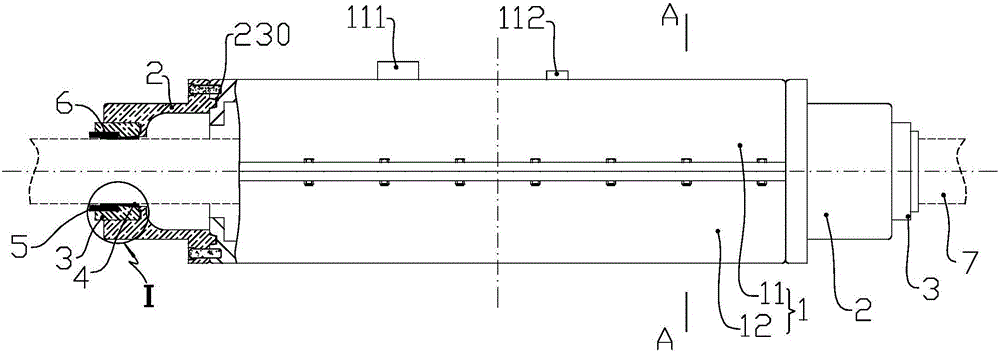

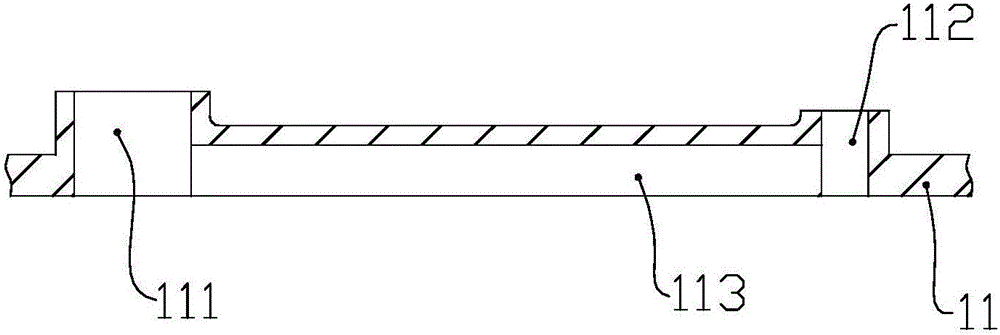

Die casting mould special for ultrathin-wall non-leakage aviation aluminium alloy element

The invention discloses a die casting mould special for an ultrathin-wall non-leakage aviation aluminium alloy element, comprising a right mould (1), a left mould (8) and a die casting inlet (4). The die casting mould is characterized in that the right mould (1) mainly comprises a fixed mould frame (10) and a fixed mould insert (11) embedded in the fixed mould frame (10); the die casting inlet (4) is arranged on the fixed mould frame (10); the fixed mould insert (11) is internally provided with a die cavity (112) in which a fixed mould insert body (12) is arranged; and the left mould (8) mainly comprises a movable mould frame (80) and a movable mould insert (81) embedded in the movable mould frame (80). The die casting mould special for the ultrathin-wall non-leakage aviation aluminium alloy element adopts a dual annular feeding structure and a T-shaped vent channel structure; the dual annular feeding structure ensures that aluminium liquid rapidly enters into the die cavity in the die casting process, thereby ensuring that the thin-wall part of the element is filled fully; and the T-shaped vent channel structure ensures the gas exhaust of the die cavity under the condition that the aluminium liquid is rapidly filled, thereby preventing the gasenclosure of a casting.

Owner:CHANGZHOU RANTO METALWORK

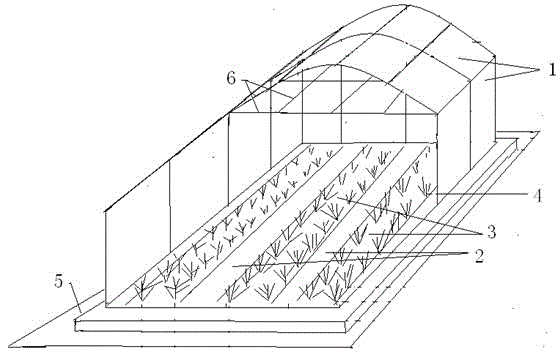

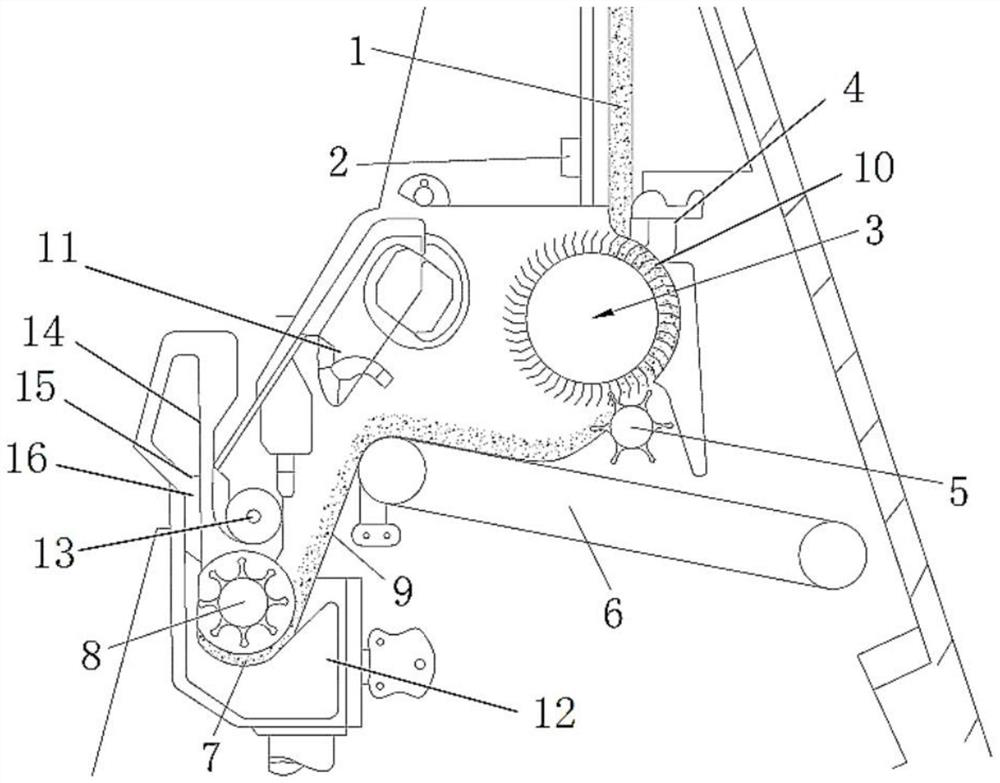

Breeding method and device for young tussah

InactiveCN102715135AReduce lossesSolve the problem that the silkworm reduction rate remains high in the young silkworm stageAnimal husbandryHabitSeedbed

The invention discloses a breeding method and a breeding device for young tussah. A greenhouse is built, hatching tree seedlings are planted in the greenhouse, and a hatching seedling bed is formed; after the fixed planting of the hatching tree seedlings, the hatching tree seedlings are bred into low-trunk tree forms, and 5 to 6 branches are left for each strain; graine is loaded into a kraft paper bag for hastening the hatching of silkworms, after the breakthrough of young silkworms, an opening of the kraft paper bag is opened, after the silkworm head tree climbing completion, the paper bag is removed, and the hatching is completed; the temperature in the greenhouse is maintained at 16 DEG C to 28 DEG C; the young silkworms are fed to 2 to 3 days at the molting of primary sleeping silkworms, and the silkworm heads are moved to a field silkworm plant for breeding outside cages before 9 o'clock in the morning or after 17 o'clock in the afternoon in sunny days. The young tussah is bred through adopting a mode of building three-dimensional breeding environment in rooms, the harm to the young tussah caused by natural environment and natural enemy can be effectively prevented, the labor work for picking and storing oak leaves is also avoided, the ventilation three-dimensional breeding environment is provided, the natural attributives of upward climbing habit, scattering habit and the like of the tussah are met, the disease rate of the silkworm body is reduced, the management requirement is reduced, the disease prevention difficulty and the cost are reduced.

Owner:GUIZHOU SERICULTURE RES INST GUIZHOU PEPPER RES INST

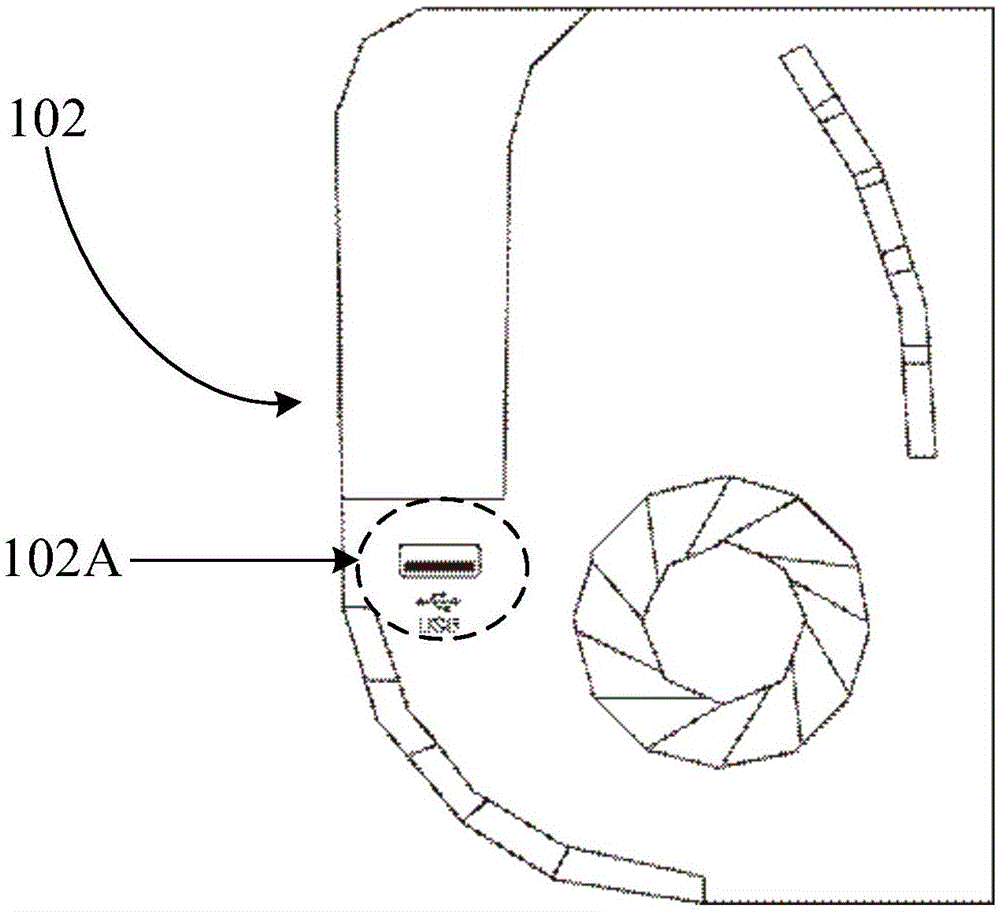

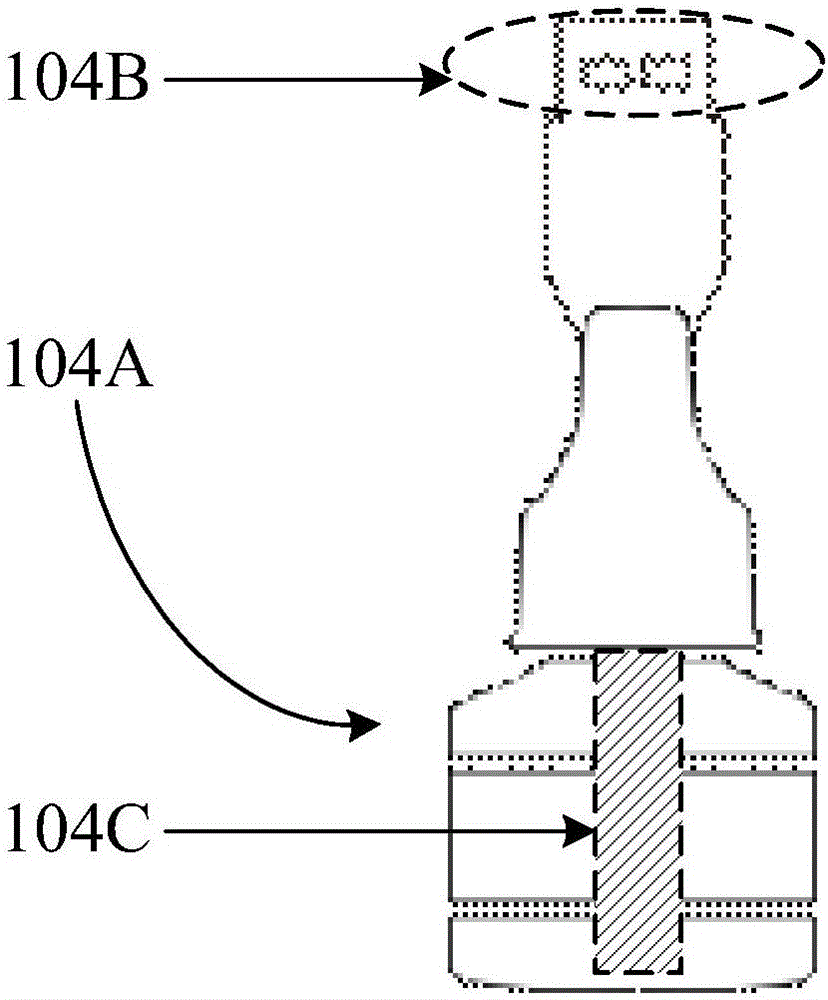

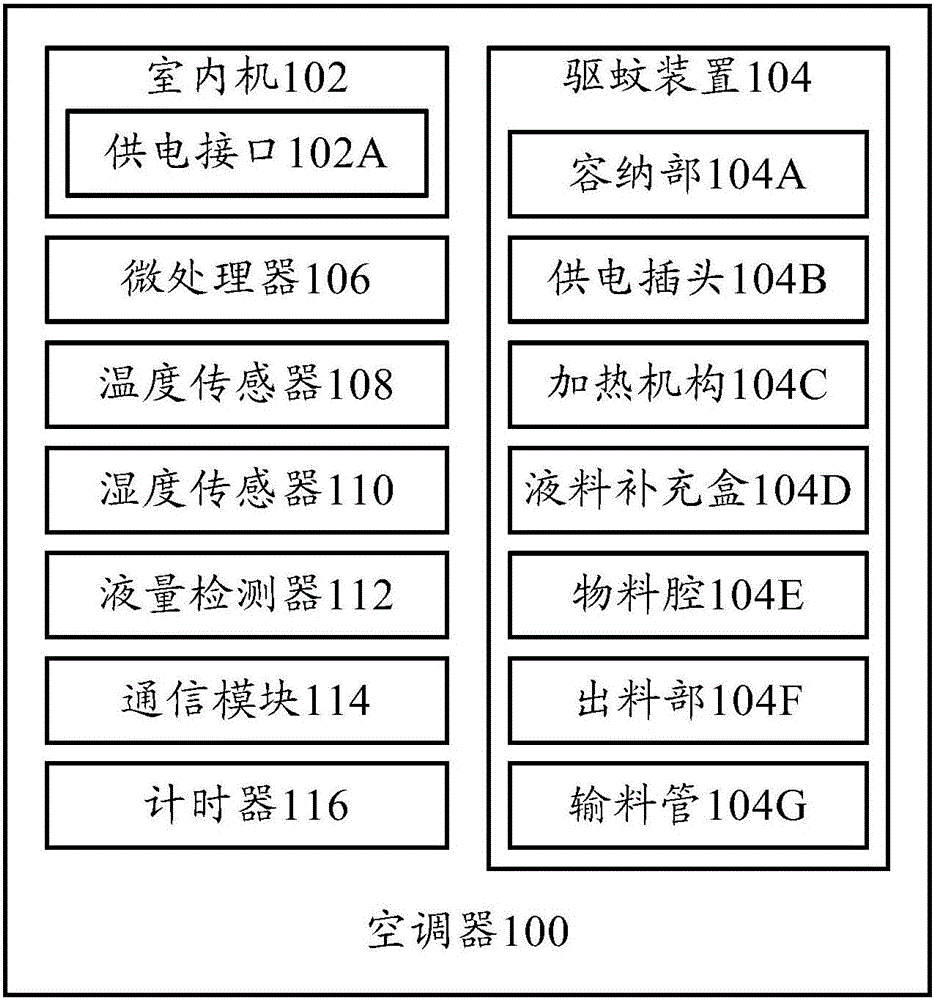

Air conditioner

ActiveCN106322515AImprove mosquito repellent efficiencyImprove user experienceMechanical apparatusSpace heating and ventilation safety systemsEngineering

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Novel composite type groutable anchor rod

The invention discloses a novel composite type groutable anchor rod and belongs to the technical field of mineral engineering anchorage supporting. The anchor rod comprises an outer sleeve, an inner rod body of which the middle is provided with a backflow cavity, a base plate, a nut and a check ring, and grouting holes are formed in the check ring. Grout is poured into a grouting cavity between the outer sleeve and the inner rod body through the grouting holes in the check ring and then is poured into a rock stratum through holes formed in the outer sleeve, after drilling holes are filled with the grout fully, the grout flows back through the backflow cavity, and accordingly grouting is completed. By adopting the anchor rod to conduct supporting, the problems that traditional grouting anchor rods are not high in supporting force and limited in grouting range, and whether drilling holes are filled with grout completely cannot be effectively judged can be solved; grouting is conducted on the deep soft rock stratum, a plastic zone can be decreased, the anchorage force of the anchor rod is increased, and accidents are decreased.

Owner:SHANDONG UNIV OF SCI & TECH

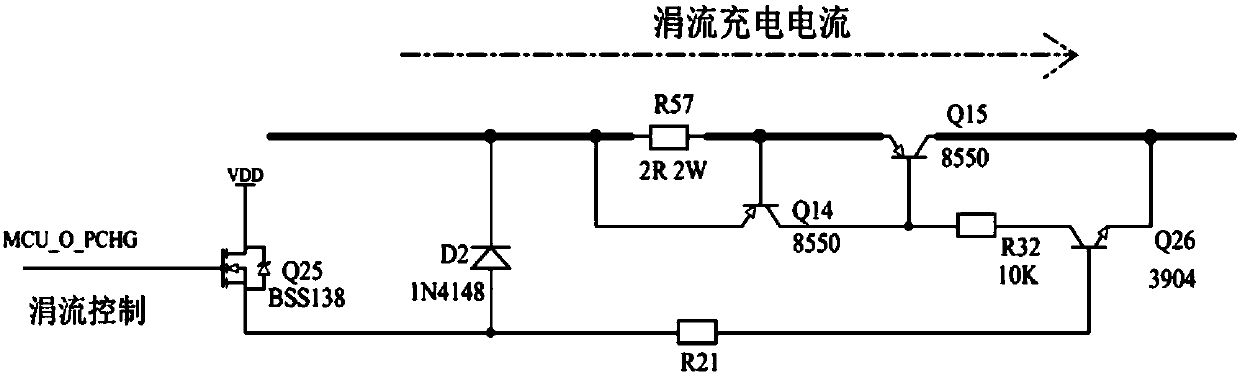

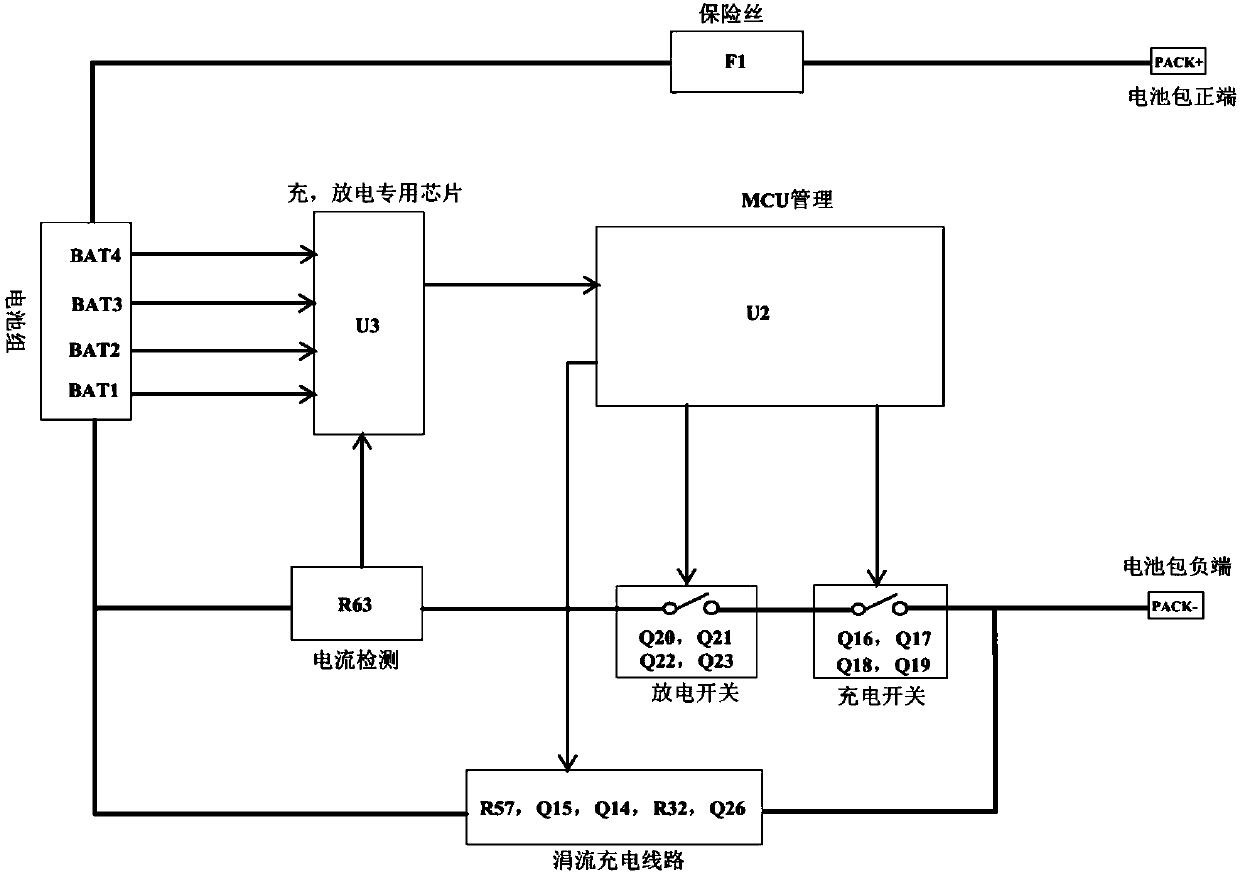

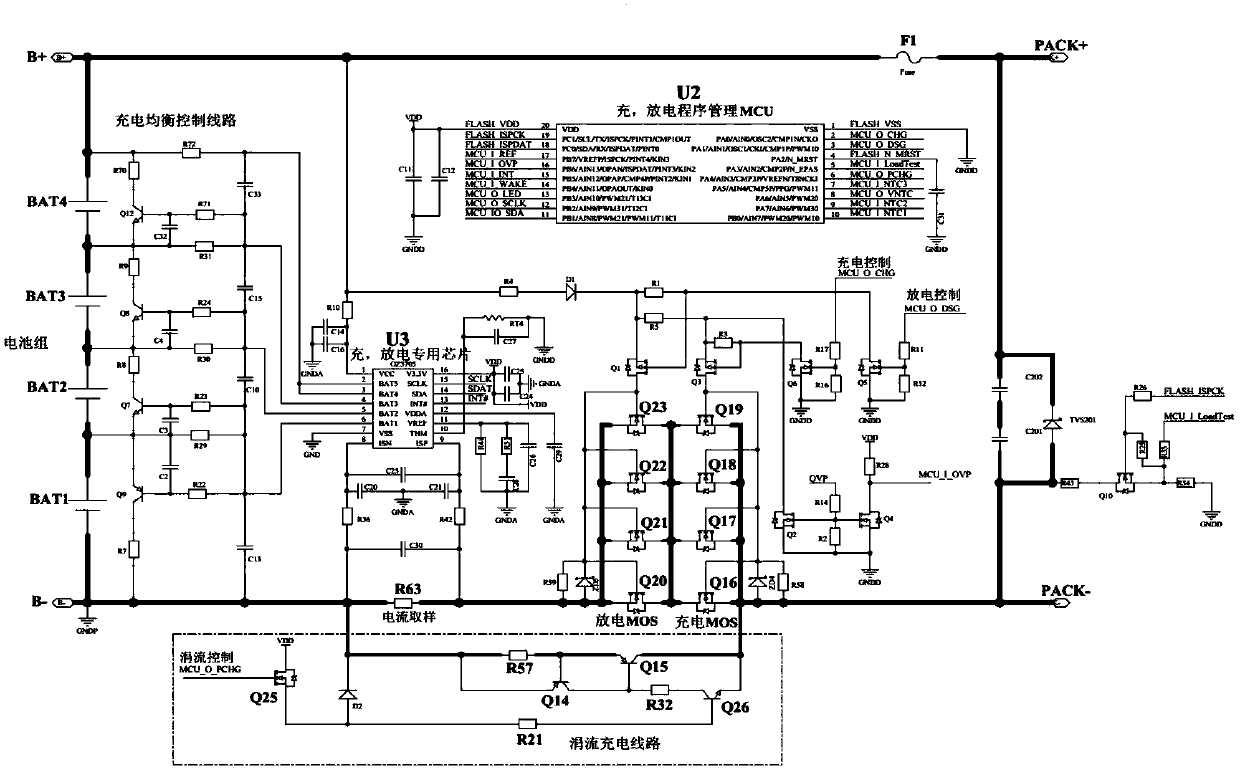

Lithium battery protection board self-adaptive to charging voltage and lithium battery charging method

PendingCN107742907AReduce defective rateReduce the risk of chargingEmergency protective circuit arrangementsSecondary cells charging/dischargingCharge currentPower flow

The invention relates to a lithium battery protection board self-adaptive to charging voltage and a lithium battery charging method. The lithium battery protection board includes a fuse, a program management MCU chip U2, a charging and discharging dedicated chip U3, a resistor for current detection, a discharge switch, a charging switch and a trickle charging circuit, wherein the trickle chargingcircuit is used for simulating a constant voltage trickle charge during the charging of lithium batteries so that the lithium batteries can be fully charged. In the lithium battery charging method, when battery voltage reaches a set value, the charging switch is turned off, an analog trickle charge state is entered, a trickle charge current passes through PACK+, the fuse, each battery, the resistor for current detection, the trickle charge circuit and PACK- to charge the batteries; when the battery voltage is detected to reach full voltage, the batteries are fully charged and the trickle charging circuit is turned off. The lithium battery protection board and the lithium battery charging method can adapt to various charging voltages; this circuit automatically simulates constant voltage trickle charging during post-charging period, is independent of charging voltage and can also ensure that the batteries are fully charged.

Owner:SUZHOU HUAZHIJIE TELECOM +1

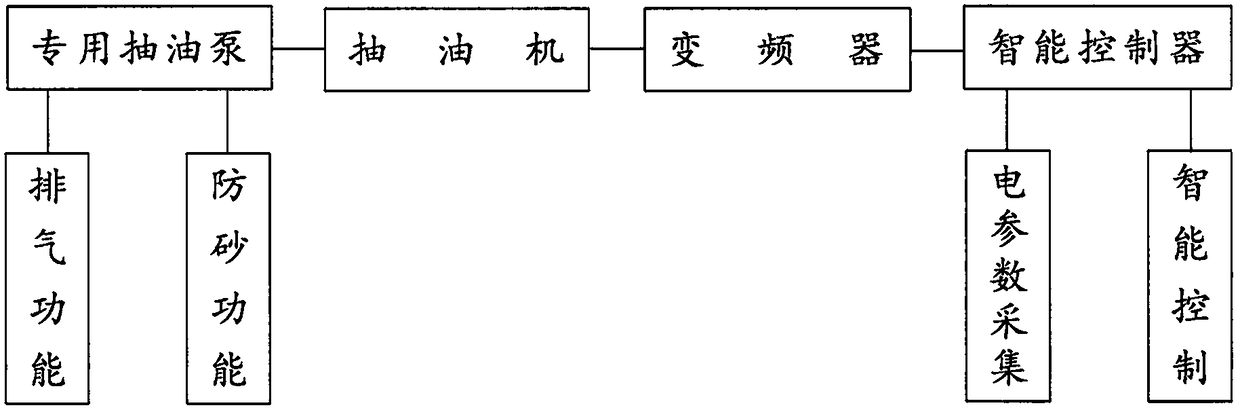

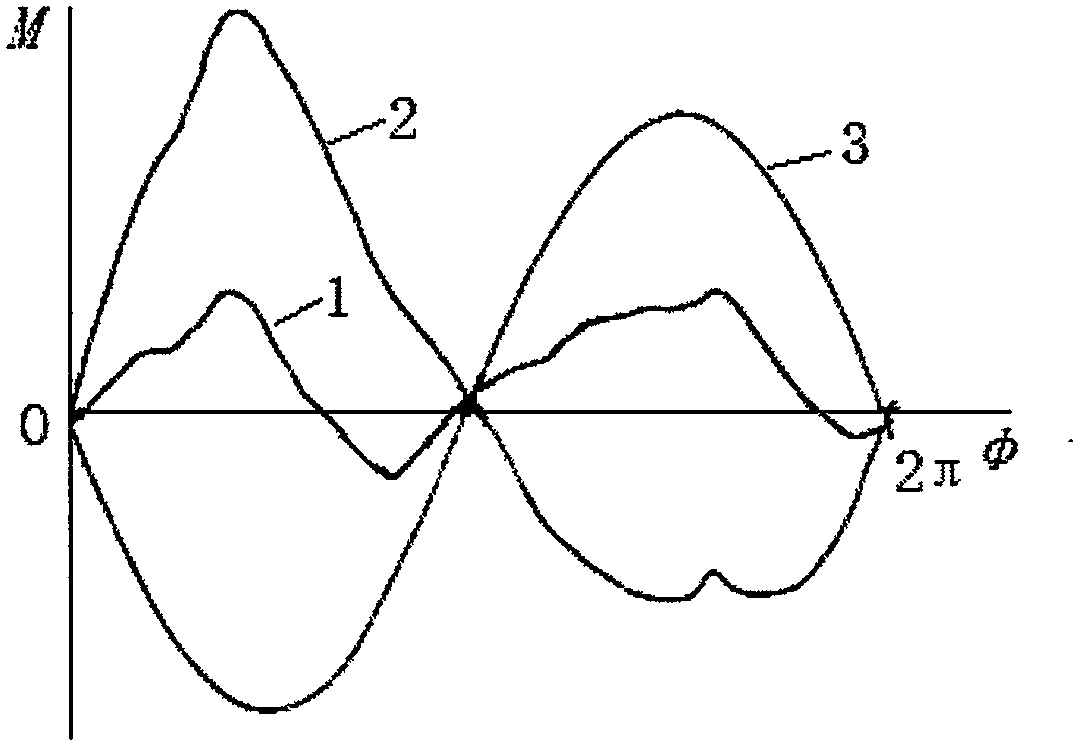

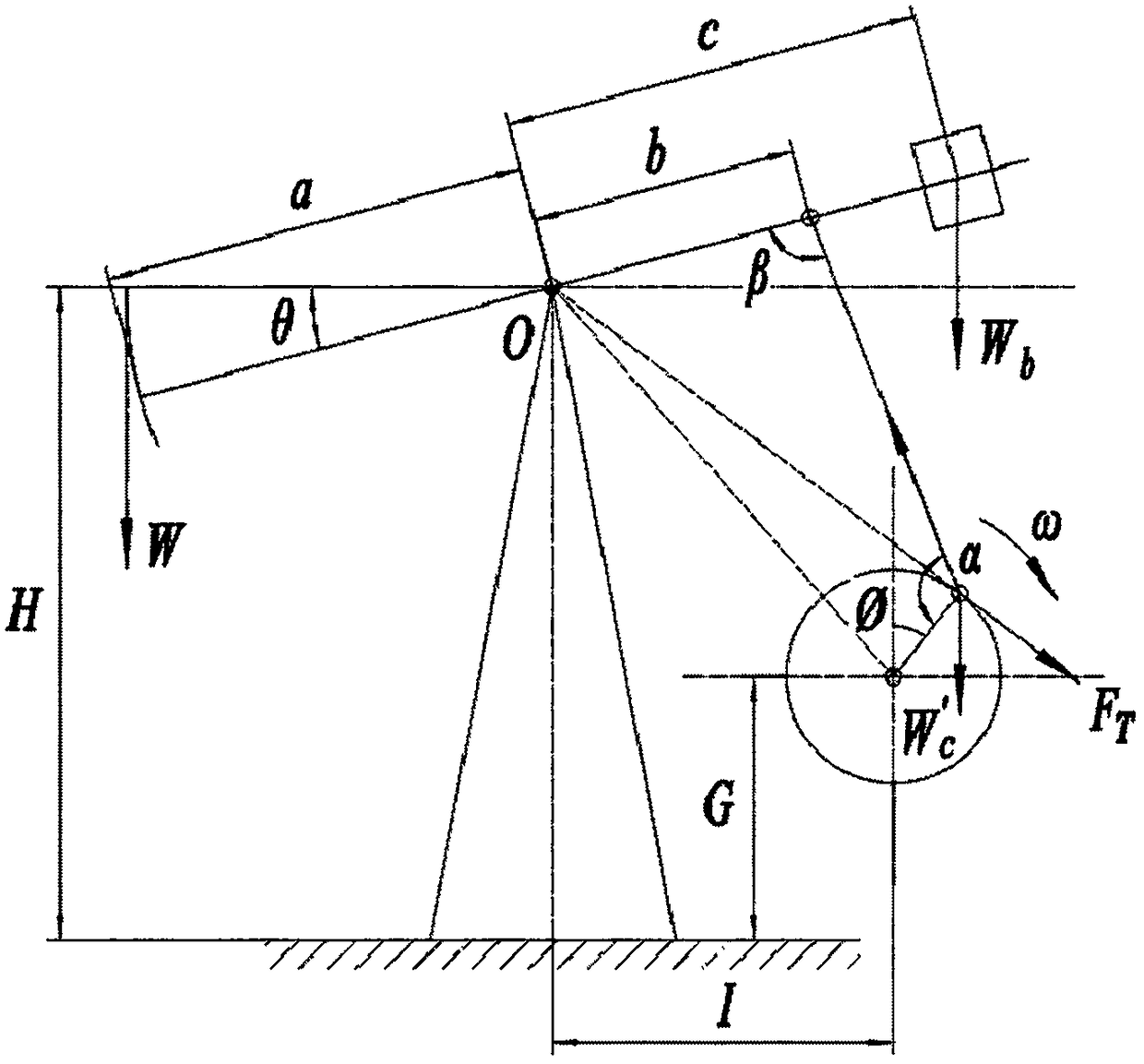

Swabbing parameter matching non-stop intermittent oil pumping and production system

InactiveCN109424337AGuaranteed reliabilityFit clearance is smallConstructionsFluid removalElectricityWorking fluid

The invention relates to a swabbing parameter matching non-stop intermittent oil pumping and production system. The system is characterized by being composed of an intelligent controller, a frequencyconverter and a special oil pump. An electric parameter test acquisition device is installed in the intelligent controller, embedded software is written in the intelligent controller, the active powerof a pumping unit is tested in real time, the working fluid level depth of an oil well is calculated according to the active power and structural parameters of the pumping unit, on this basis, when the working fluid level reaches a certain range, an intelligent program is started automatically, every time after the pumping unit reaches a top dead center, a crank is controlled to swing within a small angle range instead of immediate starting of a lower stroke, the time is provided for filling of the special oil pump, after the crank swings for a set time, an oil production program is started,and the operations are repeated; the oil pump is kept to always work under the optimal submergence condition while the high pumping efficiency is ensured; meanwhile, the pumping diameter of the oil pump is increased, the oil production stroke frequency of the pumping unit is greatly reduced under the condition of the same liquid yield, and the energy consumption of the system is reduced.

Owner:DAQING SENENPU MACHINERY MFG

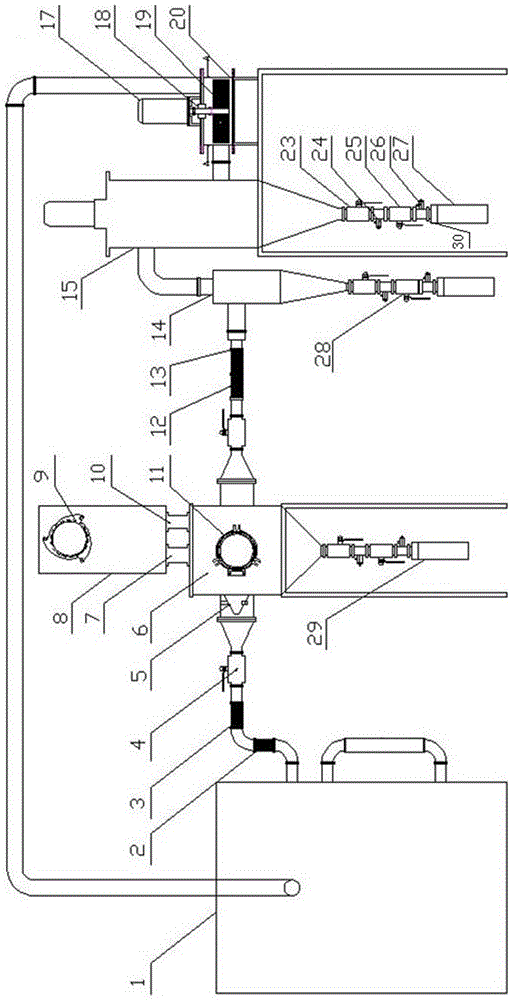

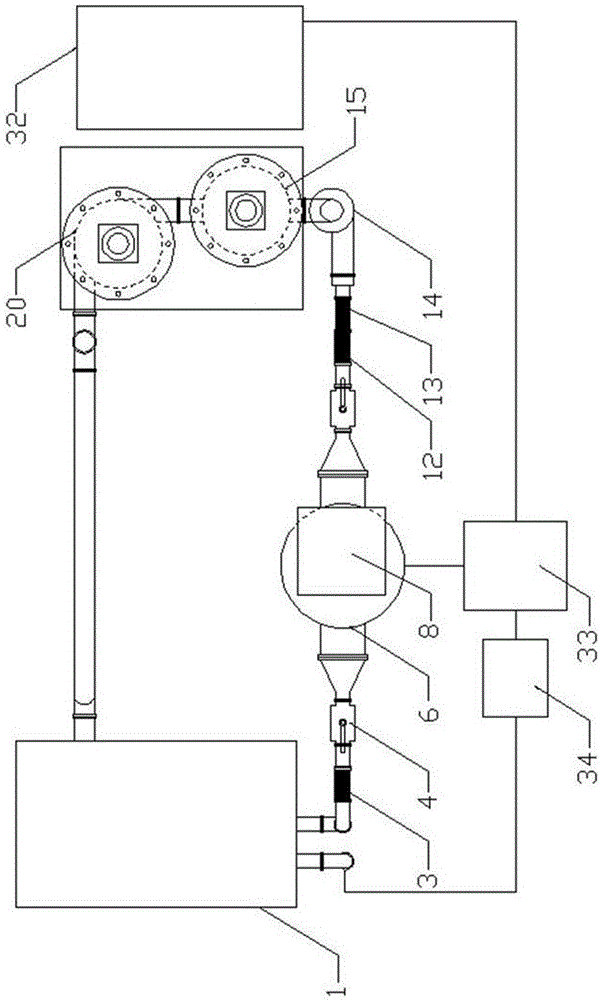

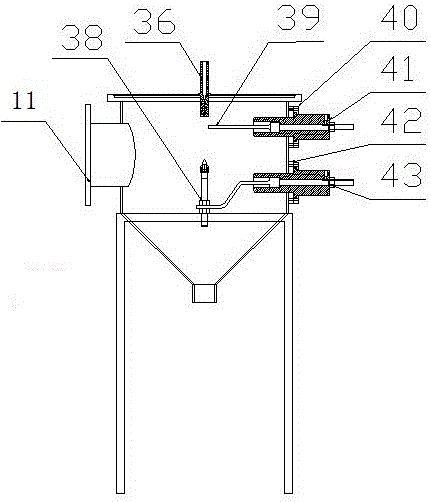

Equipment for preparing nano powder by electrical explosion method

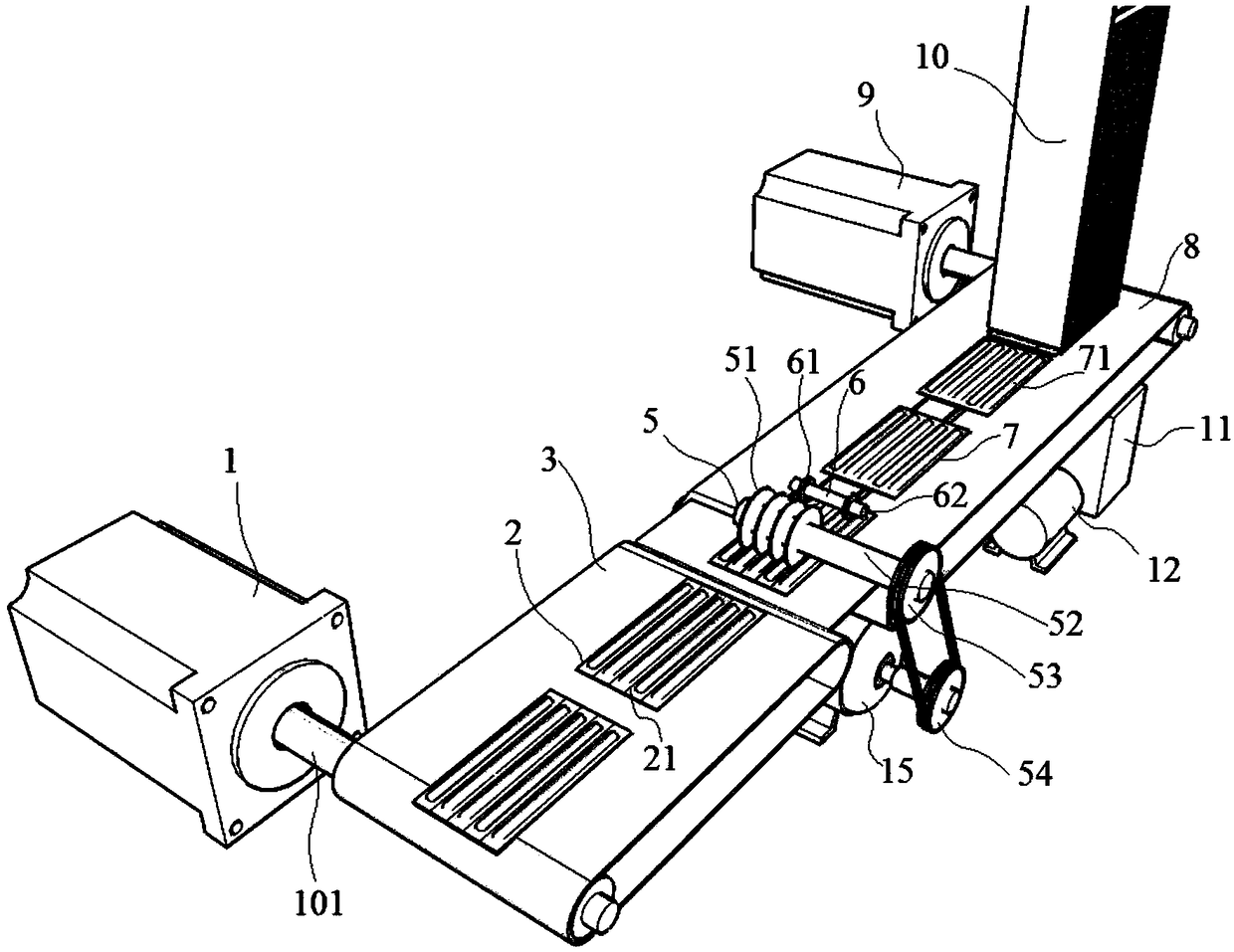

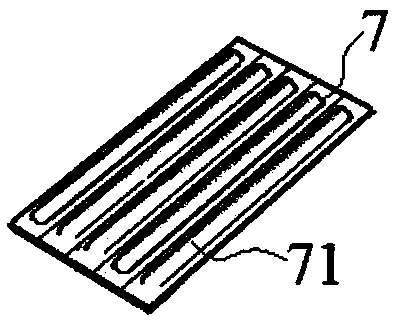

ActiveCN106807310AChange rotation speedAchieve straightening and conveyingEnergy based chemical/physical/physico-chemical processesMicroballoon preparationElectricityNanoparticle

The invention discloses equipment for preparing nano powder by an electrical explosion method, and belongs to the field of nanomaterial preparation. The equipment aims at solving the problem that the conventional nano powder production equipment has a strict requirement for an insulating structure and an insulating material of a high-voltage part. The equipment comprises a nano powder reaction mechanism, an electrical explosion generation mechanism, a wire feeding mechanism matched with the nano powder reaction mechanism, an air cooler, a first connecting tube, a first insulating tube, a second connecting tube, a second insulating tube and a third connecting tube. According to the equipment, instant high voltage is generated by electrodes, so that materials in an explosion reaction cavity react to generate corresponding nano particles. Due to an improvement of a structure, the working voltage of the equipment is equal to or lower than 25KV, and a high-voltage part has a very low requirement for a high-voltage structure and a withstand voltage material. In addition, raw materials of the equipment are filamentary materials and non-insulators, so that the equipment has the characteristics of wide raw material source and high adaptability, and has good universality for various filamentary non-insulator materials.

Owner:四川弘博新材科技股份有限公司

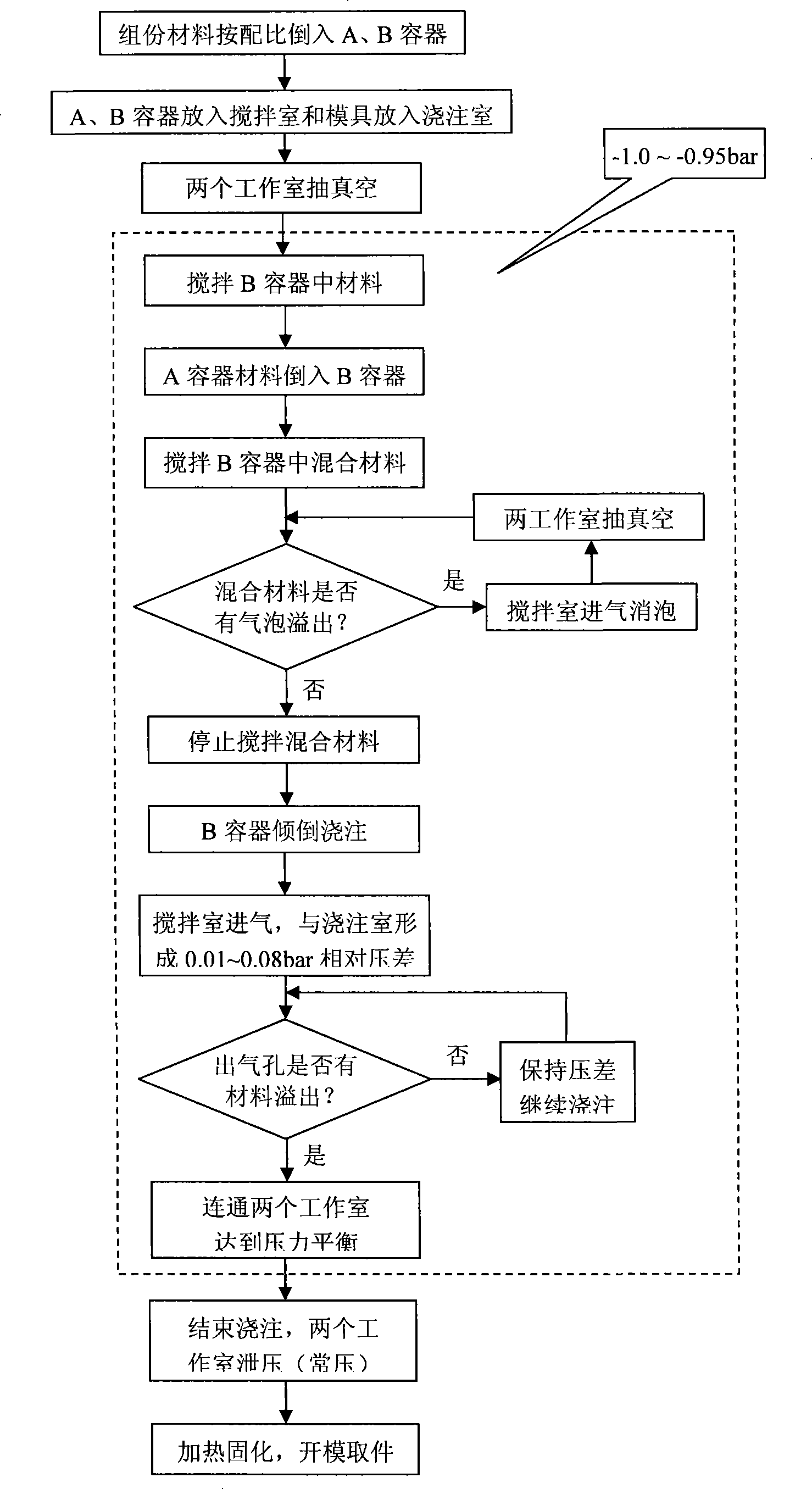

Differential-pressure vacuum injection molding technique

The invention relates to a differential pressure vacuum injection molding process, which includes the steps of preparing two constituent materials, mixing, stirring, injecting, and heating for solidification. During the process of mixing and stirring the two constituent materials, circulating air admission for de-foaming is performed continuously, i.e. the vacuumizing process to eliminate the foams in the mixed constituent materials to avoid producing defective products; when injecting the evenly mixed constituent materials, the filling of the evenly mixed constituent materials is accelerated by the pressure difference between a stirring chamber and an injecting chamber; when the mixed constituent materials overflow all air outlets, the stirring chamber and the injecting chamber quickly reach a pressure balance to prevent too many mixed constituent materials from overflowing. The injection molding process is suitable for producing compact, thin-walled, transparent and meshed plastic parts with few or no air holes and complicated shapes.

Owner:SHANGHAI UNIV

Die-cutting machine and die-cutting method thereof

ActiveCN108247748AReduce security risksIncrease productivityMetal working apparatusMotor driveProduct group

The invention discloses a die-cutting machine and a die-cutting method thereof, and belongs to the technical field of product packaging. The die-cutting machine includes a die-cutting template and a die-cutting tool. A plurality of grooves are formed in the die-cutting template evenly. The die-cutting tool includes die-cutting blades. The die-cutting blades are located in the grooves. The die-cutting method of the die-cutting machine includes the following steps that a feeding conveying belt motor, a vacuum sucker motor, a receiving conveying belt motor and a die-cutting motor are started; product groups before die-cutting are conveyed to a guiding device, receiving pressing wheels on a receiving pressing shaft press on both sides of each product group before the die-cutting, and the receiving pressing shaft rotates to drive the receiving pressing wheels to rotate; and the receiving pressing wheels drive the product groups before the die-cutting to move forwards to the die-cutting template, the die-cutting motor rotates, an output shaft of the die-cutting motor drives a die-cutting motor belt pulley to rotate, a die-cutting tool wheel rotates, a die-cutting tool shaft rotates, thedie-cutting blades drive the product groups before the die-cutting to rotate in the grooves, and die-cutting is achieved. According to the die-cutting machine and the die-cutting method thereof, the fact that dividing dotted lines can be added to product packaging is achieved, and splitting is fast and convenient.

Owner:马鞍山邦德医疗器械有限公司

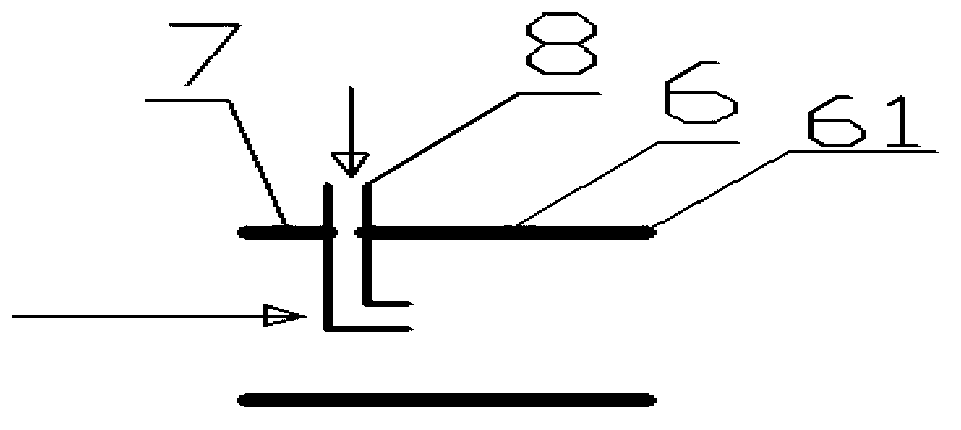

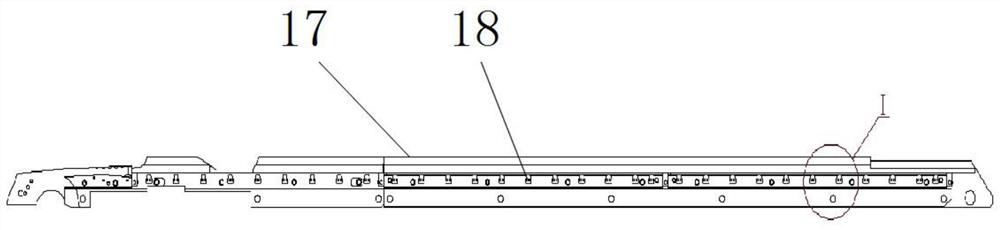

Tobacco feeding and strip forming device

PendingCN112137161AAvoid loweringAvoid breakingCigarette manufactureAgricultural engineeringStructural engineering

The invention discloses a tobacco feeding and strip forming device, and particularly relates to the field of cigarette production. The tobacco feeding and strip forming device comprises a cut tobaccocollecting box, a pre-distributor is arranged below the cut tobacco collecting box, a storage area is arranged below the pre-distributor, a lifting conveying belt is arranged on one side of the storage area, and a bulk material channel is formed in the bottom of one side of the lifting conveying belt; a flat sliding rail is installed on one side of the bottom of the bulk material channel, a needleroller is rotatably installed below the bulk material channel, a plurality of sets of evenly-distributed steel needles are fixedly connected to the peripheral side of the needle roller, the steel needles and the peripheral side of the needle roller are obliquely arranged in a tangent line mode, and a silk flipping windlass is arranged below the needle roller. The angle of the steel needle on theneedle roller is changed, so that tobacco shreds freely fall off when the needle roller rotates, pressing on the tobacco shreds when the tobacco shred flipping roller takes the tobacco shreds can be reduced, the tobacco shreds are prevented from being pressed and broken, the consistency of the lengths of the tobacco shreds is guaranteed, so that the continuity of the filled tobacco shreds and thefullness of cigarette tightening heads are guaranteed.

Owner:湖南叁谐科技发展有限公司

Pump body assembly and compressor

PendingCN108930651AReduce leakage problemsGood lubrication effectRotary piston pumpsRotary piston liquid enginesSlide platePetroleum engineering

The invention provides a pump body assembly and a compressor. The pump body assembly comprises a main shaft, the main shaft is provided with slide plate slots, the tail end of every slide plate slot is a backpressure oil chamber, the backpressure oil chambers are at least a part of an oil channel, the oil outlets of the backpressure oil chambers are located at the tops of the backpressure oil chambers, and the inlets of the backpressure oil chambers are lower than the oil outlets of the backpressure oil chambers, so a lubricating medium enters the backpressure oil chambers through the oil inlets of the backpressure oil chambers, fills up the backpressure the oil chambers, and flows out from the tops of the backpressure oil chambers. The problem of insufficient backpressure of slide platesin the prior art is solved in the invention.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

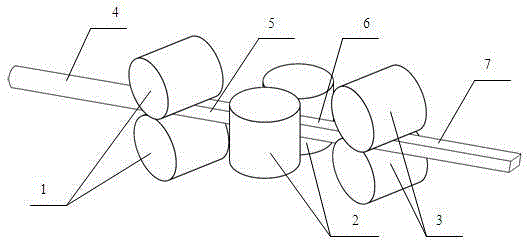

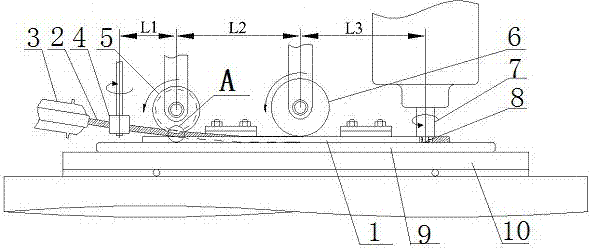

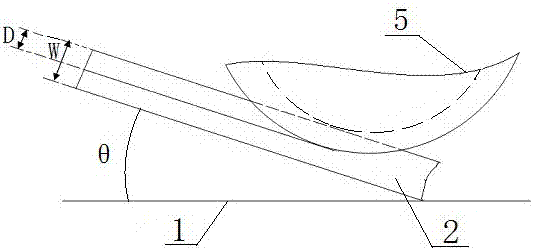

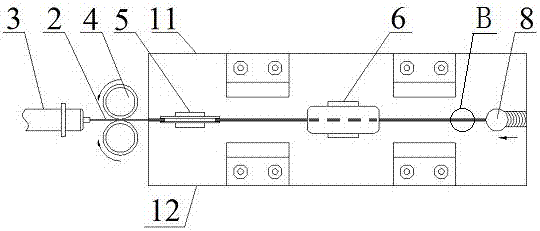

Automatic wire-feeding friction stir welding method for butt joint of dissimilar metal materials

ActiveCN107414283AReduce frictional heatReduce thicknessWelding/soldering/cutting articlesNon-electric welding apparatusButt jointChemical compound

The invention discloses an automatic wire-feeding friction stir welding method for butt joint of dissimilar metal materials. The automatic wire-feeding friction stir welding method comprises the following steps that 1, welding pieces are in butt joint with each other and are clamped, an interval is formed between the welding pieces, strip-shaped welding wires are led out from a wire-feeding gun, a straightening wheel set, a pre-buried wheel and a leveling wheel are sequentially placed on the interval, the strip-shaped welding wires are straightened through the straightening wheel set, then obliquely downwards fed into the interval through the pre-buried wheel and later leveled through the leveling wheel, and the ends of the strip-shaped welding wires are arranged under a stirring head; 2, a welding machine is started, the stirring head starts vertical downwards feeding, later a stirring needle is pressed into the interval where the strip-shaped welding wires are stored, welding is started, and in the welding process, the wire-feeding speed keeps consistent with the welding speed; and 3, the stirring head is lifted, then wire feeding is stopped, and the strip-shaped welding wires are cut off. According to the automatic wire-feeding friction stir welding method for butt joint of the dissimilar metal materials, generation of chemical compounds between metal can be reduced, the interface temperature is decreased, the residual stress is reduced, a welding joint is prevented from generating holes, and the mechanical property and the welding efficiency of welding connectors are improved.

Owner:CHONGQING UNIV OF TECH

Fire and explosion protection structure installed on cable intermediate head, and use method thereof

InactiveCN106058788AReduce security risksLow manufacturing costCable junctionsApparatus for joining/termination cablesCarbon dioxideSizing

The invention discloses a fire and explosion protection structure installed on a cable intermediate head, and a use method thereof, and belongs to the technical field of the fire and explosion protection of a cable head. The fire and explosion protection structure comprises an outer box body, an assembling end cover, a disposable sealing end cover and an inner sealing ring, wherein the longitudinal assembling surface of the outer box body is provided with a double-channel sealing structure; the assembling end cover and the outer box body adopt an embedded sealing structure; the disposable sealing end cover and the inner sealing ring are arranged on the assembling end cover and are used for sealing a gap between a cable ring surface and the relevant cooperation surface of the assembling end cover; the outer box body is provided with a sealant injection pipe and a vent pipe; and the cable is completely covered with a cable fire protection wrapping tape after the cable is connected by the intermediate head, and is arranged in the outer box body, and fire protection sealant is injected into the outer box body through a sealant injection pipe. On an aspect of operation, firstly, carbon dioxide or nitrogen is used for discharging air in the outer box body, and then, the fire protection sealant is injected into the outer box body to carry out high-pressure sizing. The fire and explosion protection structure carries out pressure maintaining sizing on the fire protection sealant through the outer box body to realize the sealing protection of the cable head, a compact filling layer can be formed on the periphery of the intermediate head, the defect of poor fire protection performance durability and reliability is eliminated, and the fire and explosion protection structure is low in cost and is favorable for popularization.

Owner:九江电力勘察设计院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com