Car U-shaped plate manufacturing mold

A U-shaped, automotive technology, applied in the direction of forming tools, manufacturing tools, feeding devices, etc., can solve the problem of easy scratches when the U-shaped plate is removed, and achieve the effect of easy removal and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

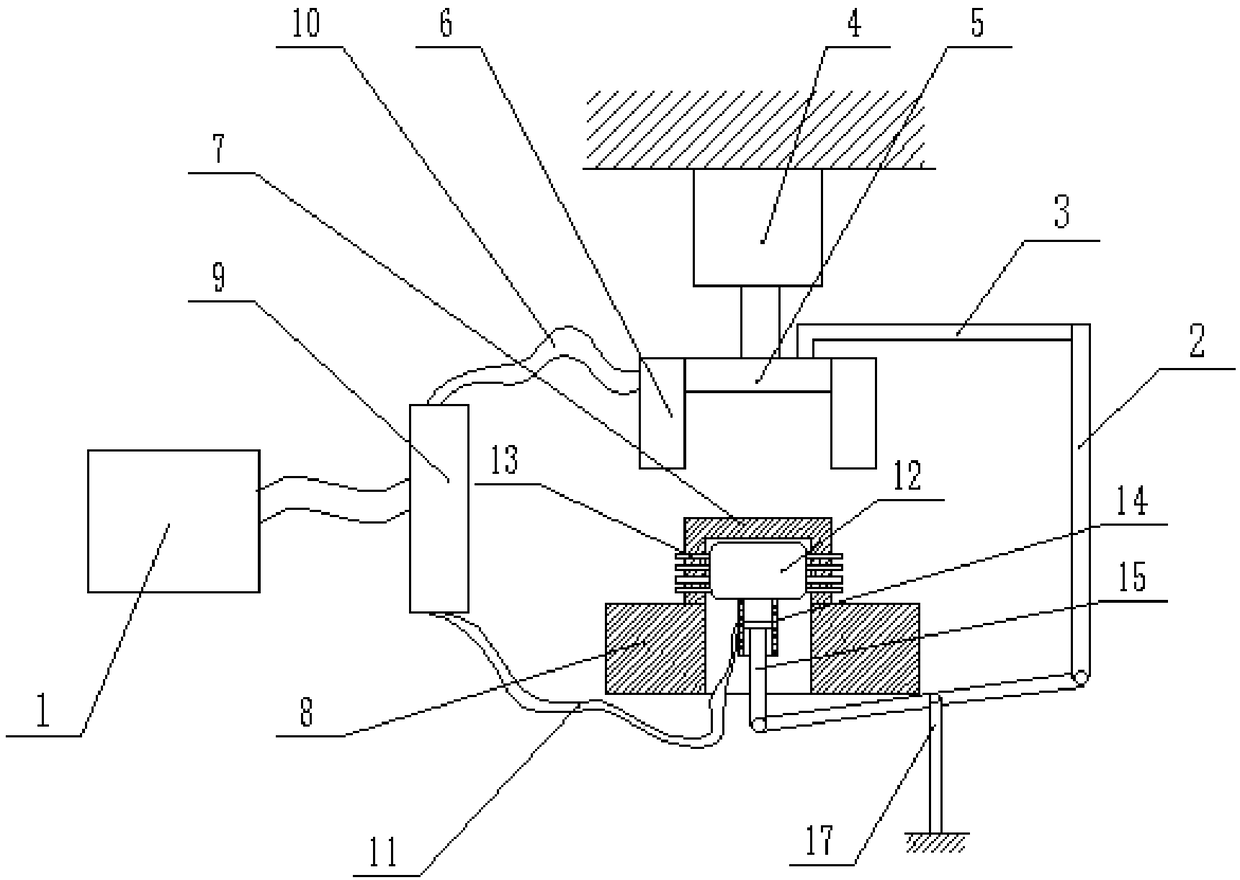

[0019] The reference signs in the drawings of the description include: compressed air supply chamber 1, third connecting rod 2, fourth connecting rod 3, hydraulic cylinder 4, pressing plate 5, bending punch 6, positioning seat 7, base 8, vortex tube 9. The first air intake pipe 10 , the second air intake pipe 11 , the air bag 12 , the raised portion 13 , the sleeve 14 , the first connecting rod 15 , the second connecting rod 16 , and the support rod 17 .

[0020] Such as figure 1 As shown, the automobile U-shaped plate production mold includes a frame 1, a movable mold 2 and a fixed mold 3 are fixed on the frame 1, the movable mold 2 includes a pressure plate 5, a hydraulic cylinder 4 is also fixed on the frame 1, and the pressure plate 5 is connected At the lower end of the hydraulic cylinder 4 piston rod, the left and right sides of the pressing plate 5 are connected with bending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com