Equipment for preparing nano powder by electrical explosion method

A nano-powder and electric explosion technology is used in the equipment for preparing nano-powder by electric explosion method, the equipment for preparing nano-powder by electric-explosion method, and the field of professional equipment for producing nano-powder, which can solve the problem of uneven particle size distribution of powder, Strict requirements on insulating structure and insulating materials, few types of powder materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

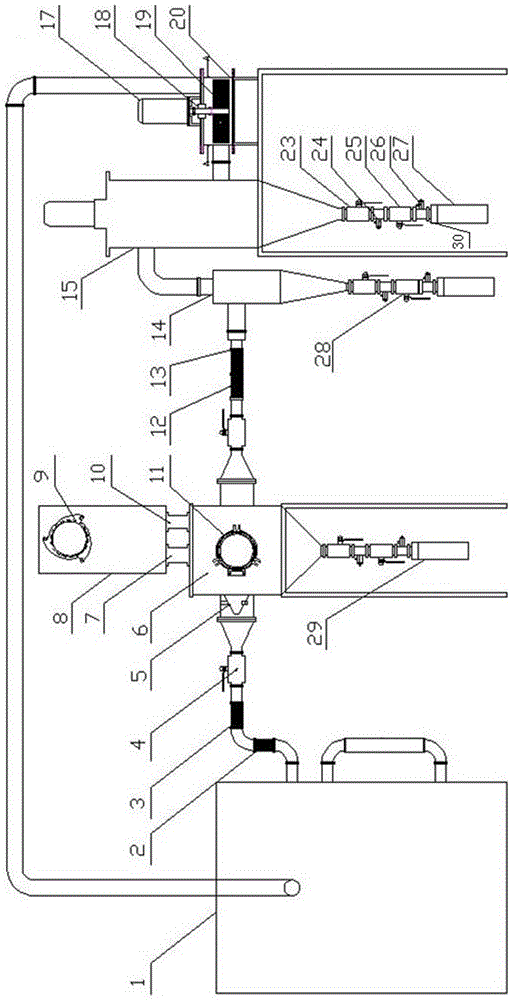

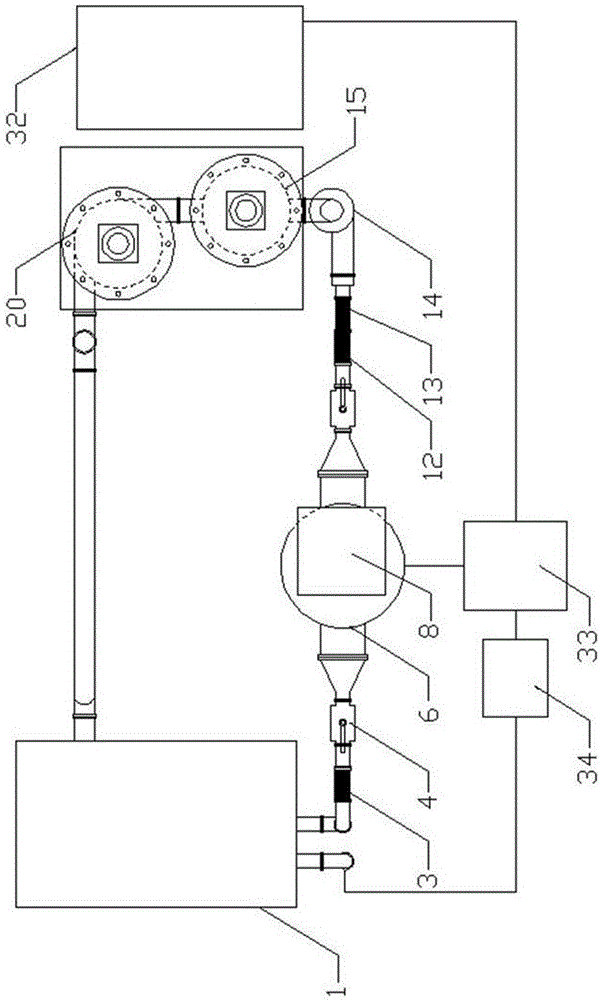

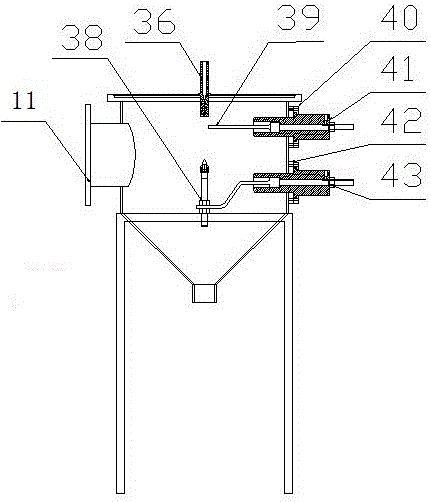

[0111] As shown in the figure, the device for preparing nano-powder by electric explosion method in this embodiment includes a nano-powder reaction mechanism, an electric explosion generation mechanism, a wire feeding mechanism matched with the nano-powder reaction mechanism, a cooling fan, a first connecting pipe, First insulating pipe, second connecting pipe, second insulating pipe, third connecting pipe, primary powder collection device, fourth pipe, third insulating pipe, fifth pipe, fourth insulating pipe, sixth pipe, cyclone separation Device, secondary powder collection device, powder collection bucket, tertiary powder collection device, gas circulation mechanism. Wherein, the wire feeding mechanism is arranged on the nano powder reaction mechanism.

[0112] In this embodiment, the nano-powder reaction mechanism includes an explosion reaction chamber, an explosion air inlet, an explosion air outlet, and a conical splitter. The large mouth end of the tapered flow divide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com