Printing mechanism of page printing machine

A technology of printing mechanism and printing machine, which is applied in the field of printing mechanism of sheet printing machine, can solve the problems such as the reduction of the printing quality of the sheet to be printed and the limitation of the printing speed of the inkjet head, so as to reduce the time not used for printing, improve Printing effect, effect of reducing invalid time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

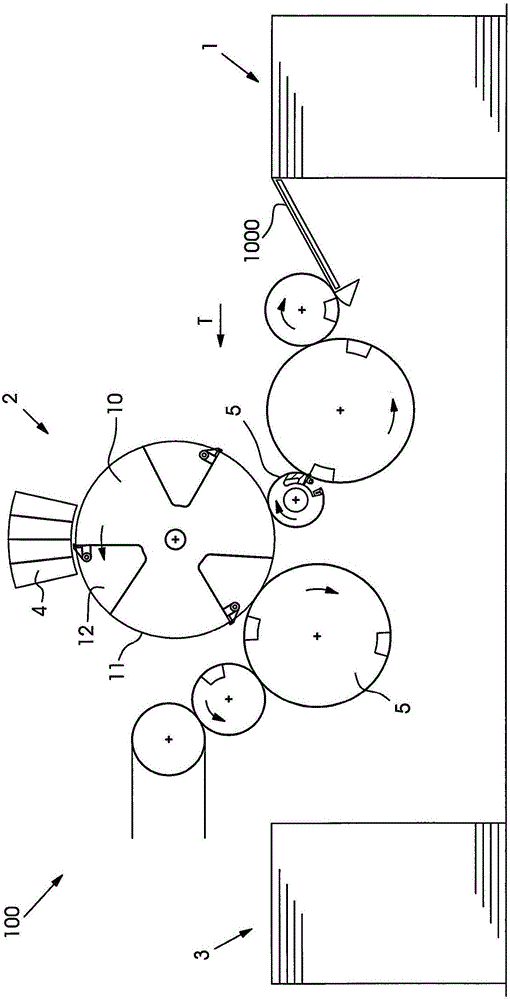

[0024] figure 1 Shown is a sheet printing press 100 , which is designed as a digital printing press. Each sheet 1000 is conveyed from the feeder 1 along the conveying direction T through the printing mechanism 2 to the stacker 3 . Here, the individual sheets 1000 are transported primarily by means of cylinders (ie a plurality of transport cylinders 5 and a printing cylinder 10 ). Arranged above the printing cylinder 10 are inkjet heads 4 which print a sheet 1000 which is moved past the printing cylinder 10 at small intervals. The printing cylinder 10 is therefore also referred to as a jetting cylinder.

[0025] In the embodiment shown, the printing cylinder 10 has three sheet holding areas 11 which are each separated from one another by a channel 12 .

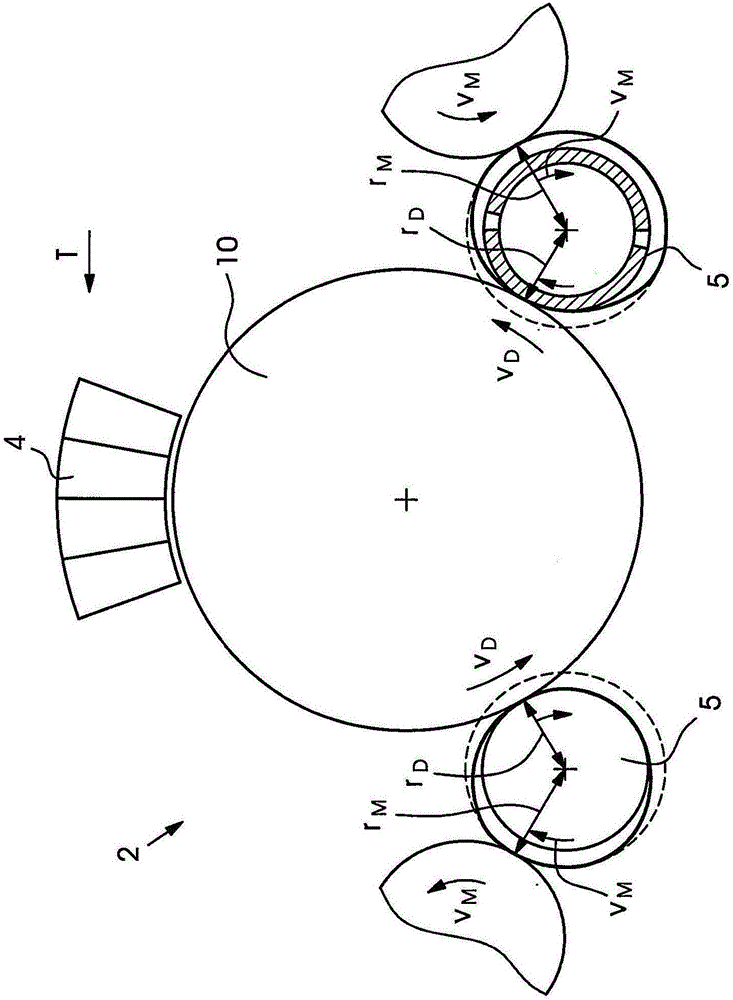

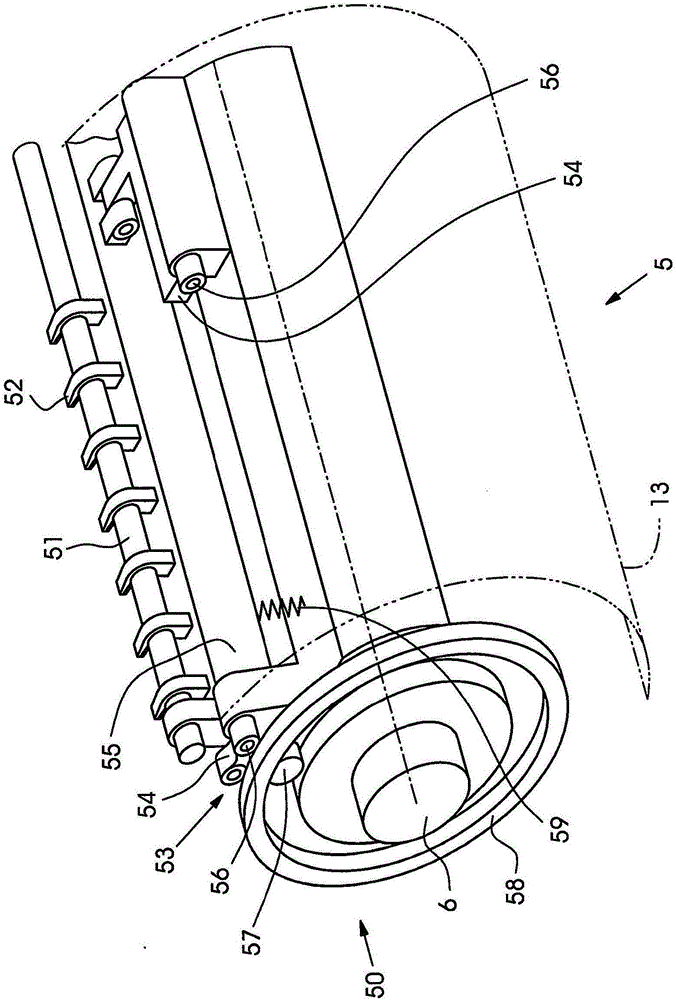

[0026] figure 2 A printing unit 2 according to the invention is shown in . The printing unit 2 has: a forward transfer cylinder 5 , a printing cylinder 10 , and a rear transfer cylinder 5 . The transport rollers 5 each h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com