Patents

Literature

204results about How to "Change rotation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

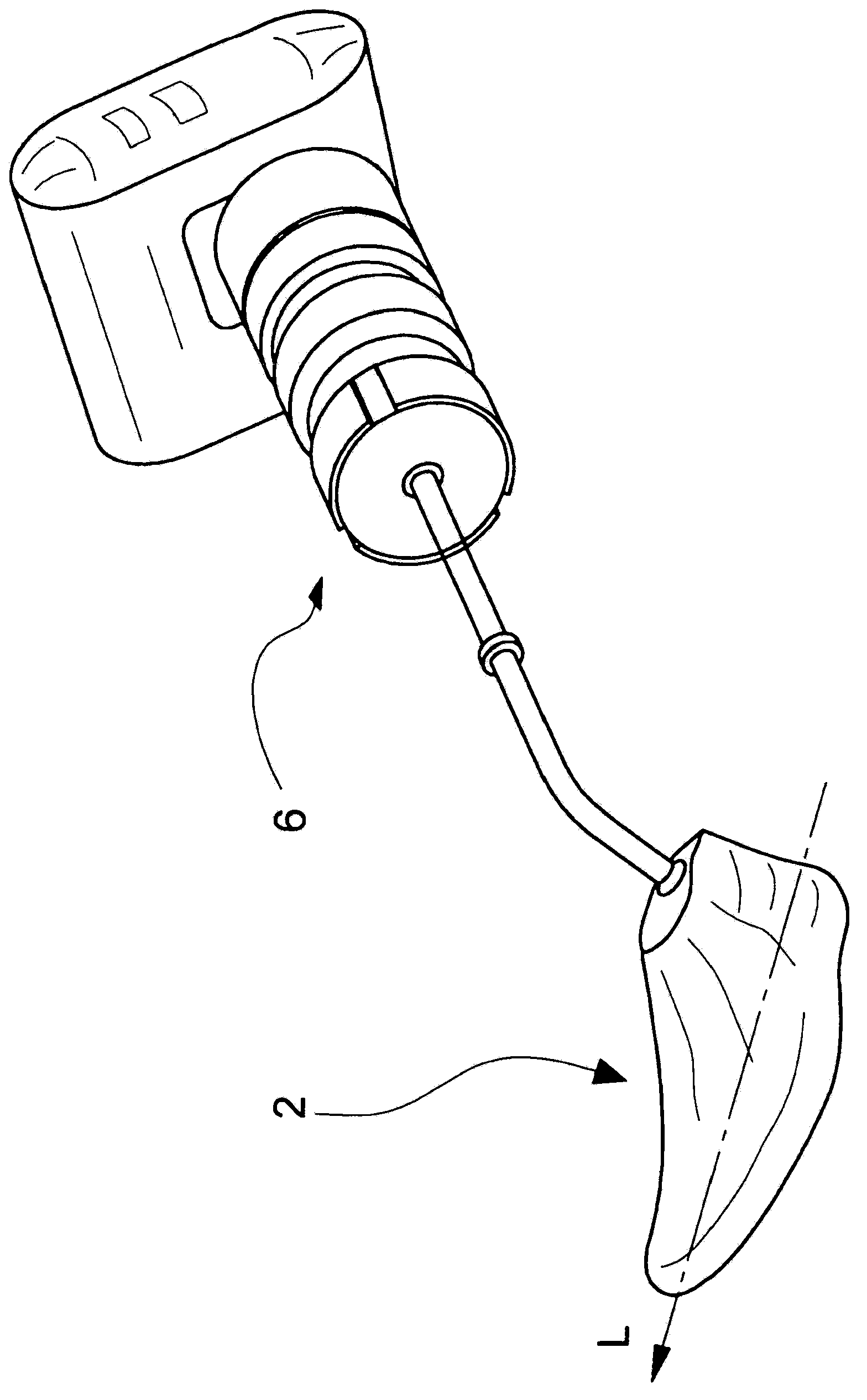

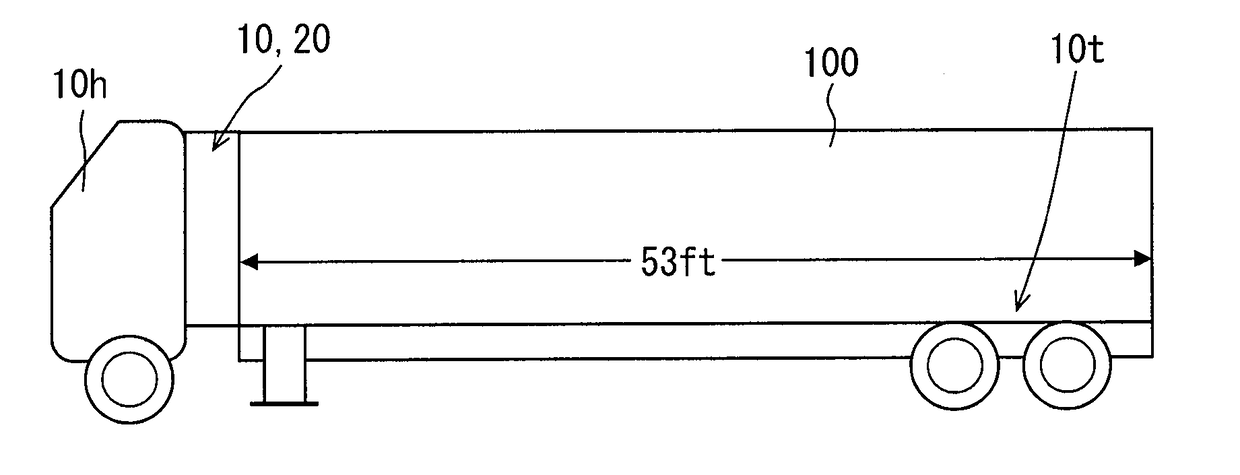

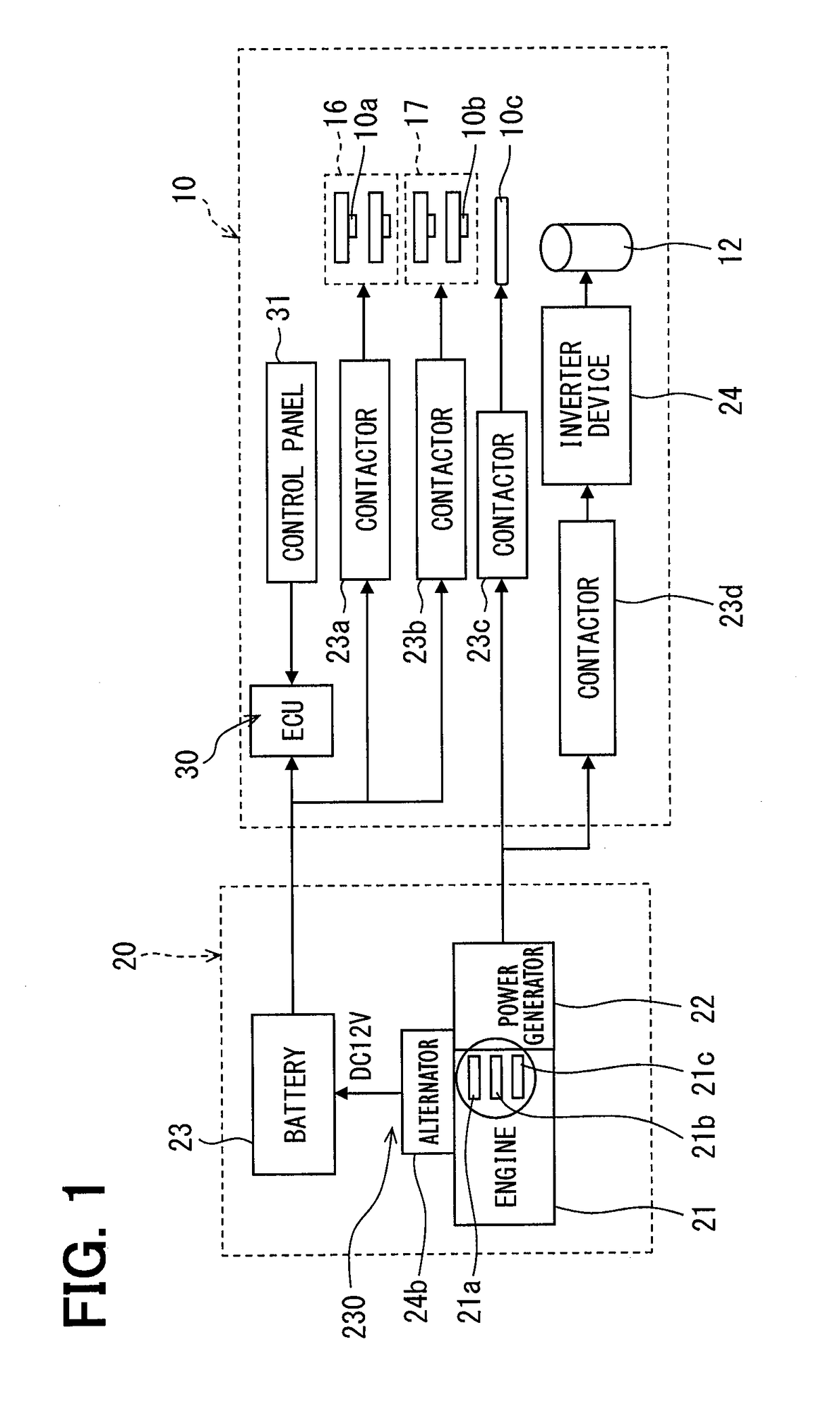

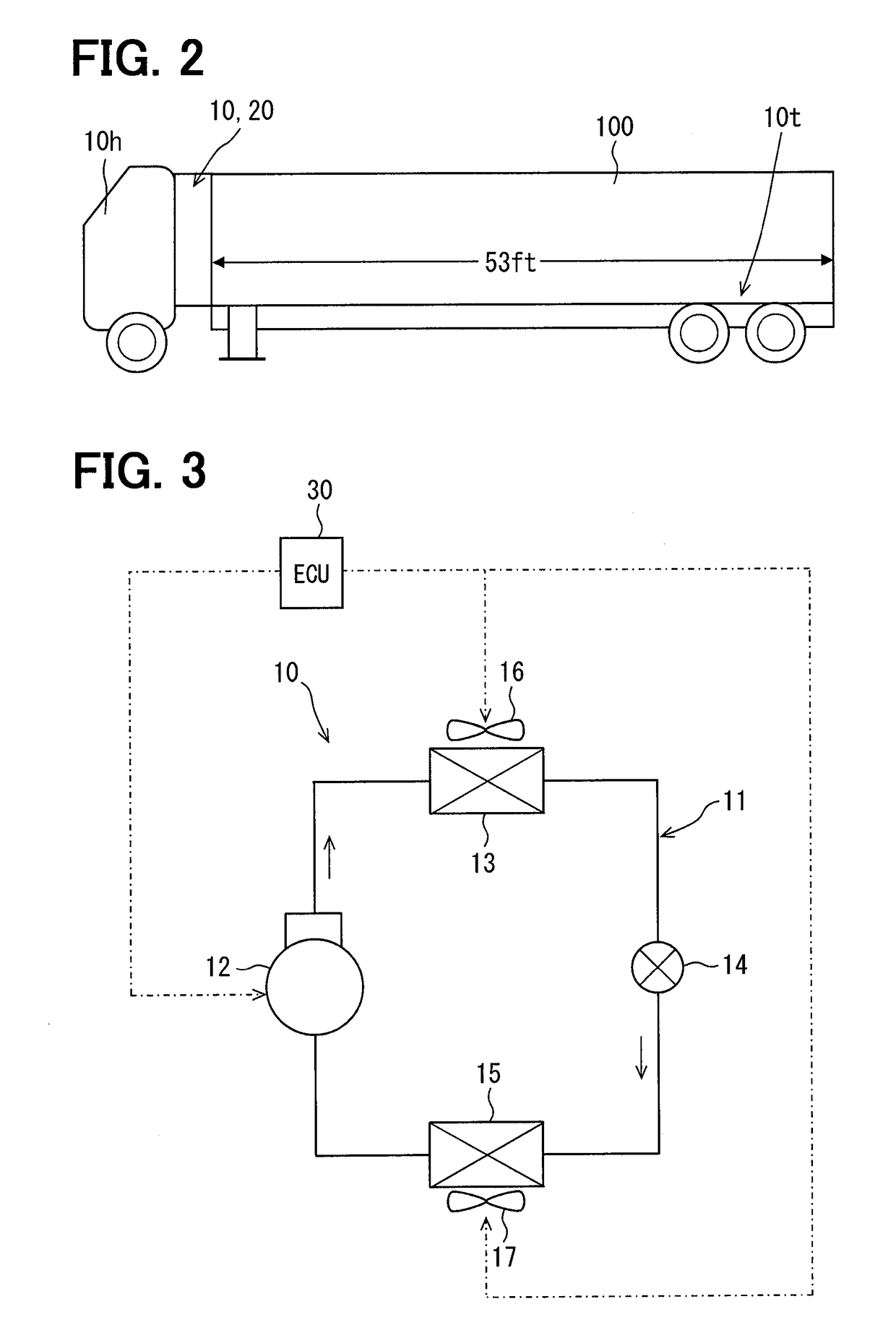

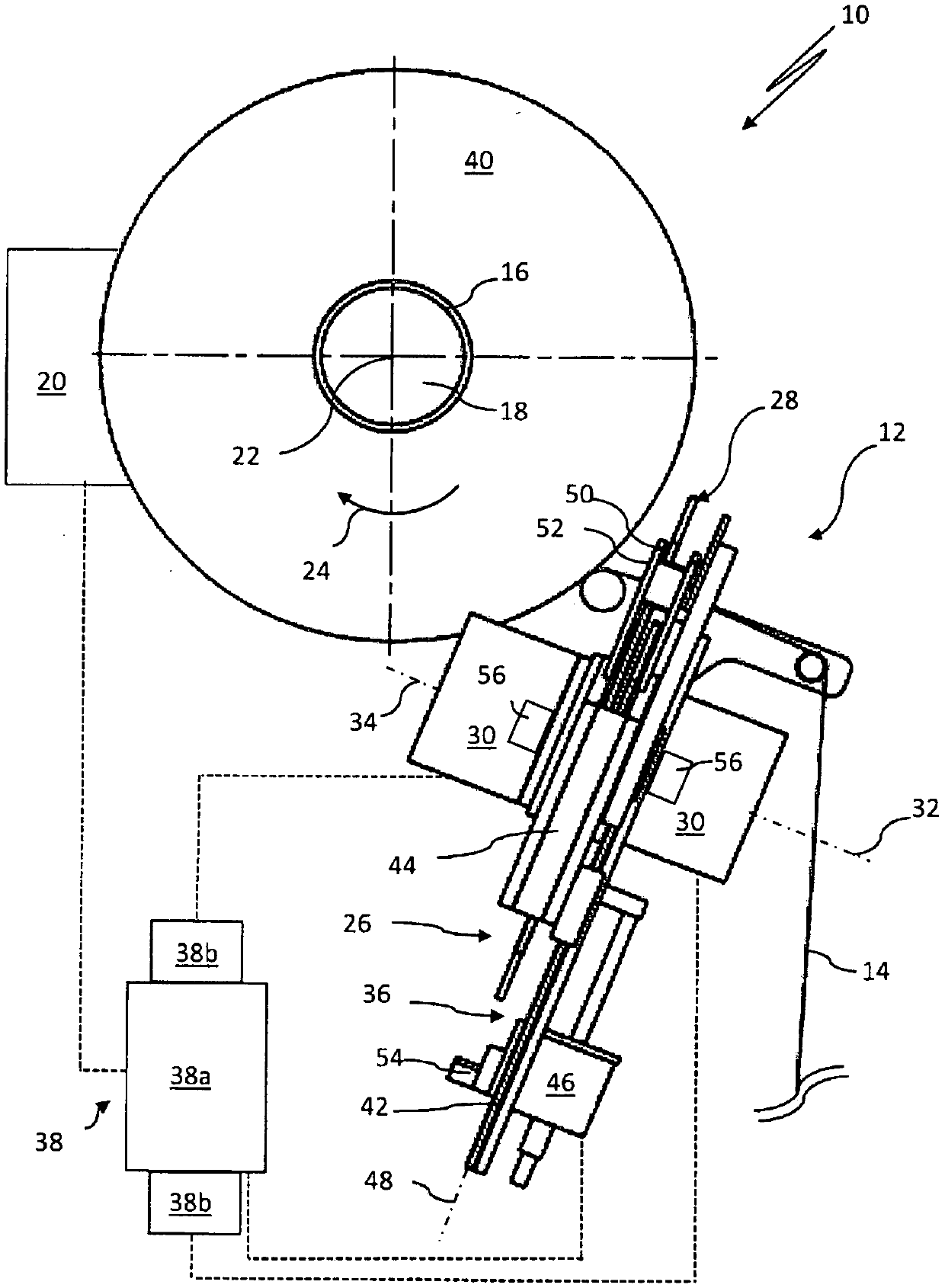

Refrigeration device and container refrigeration system

InactiveUS20180222278A1Reduce rotation speedChange rotation speedAir-treating devicesAC motor controlRefrigerantEvaporator

The refrigeration device has an inverter device, an electric compressor, a condenser, an evaporator, a condenser fan, an evaporator fan, and a controller. An AC output from a power generator is supplied to the inverter device. A refrigerant discharge amount of the electric compressor is controlled by the inverter device. The refrigerant from the electric compressor flows in the condenser, and the condenser causes the refrigerant to radiate heat to outside air outside a container. The refrigerant from the condenser flows in the evaporator, and the evaporator cools an interior of the container. The condenser fan is driven by a DC output from a DC power supply device and blows air to the condenser. The evaporator fan is driven by the DC output from the DC power supply device and blows air to the evaporator. The controller controls at least the electric compressor, the inverter device, and the engine.

Owner:DENSO CORP

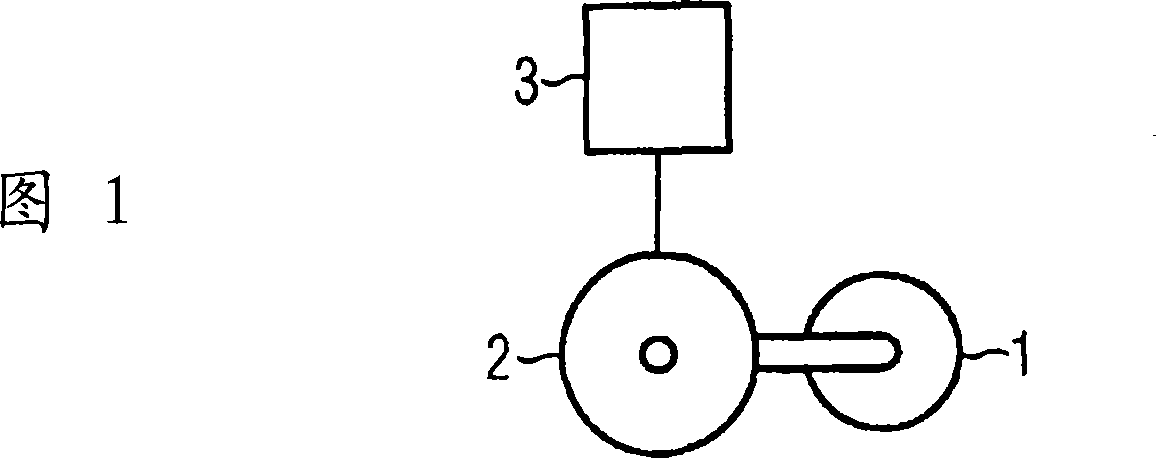

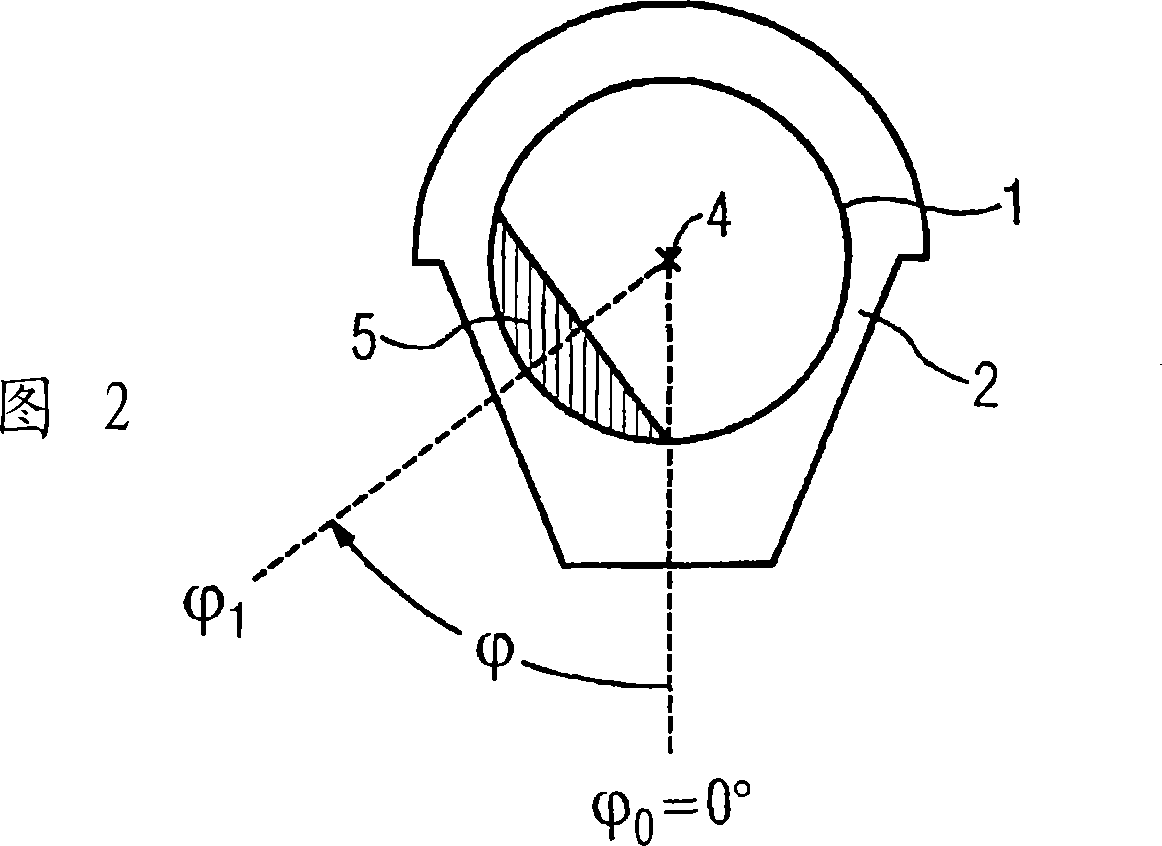

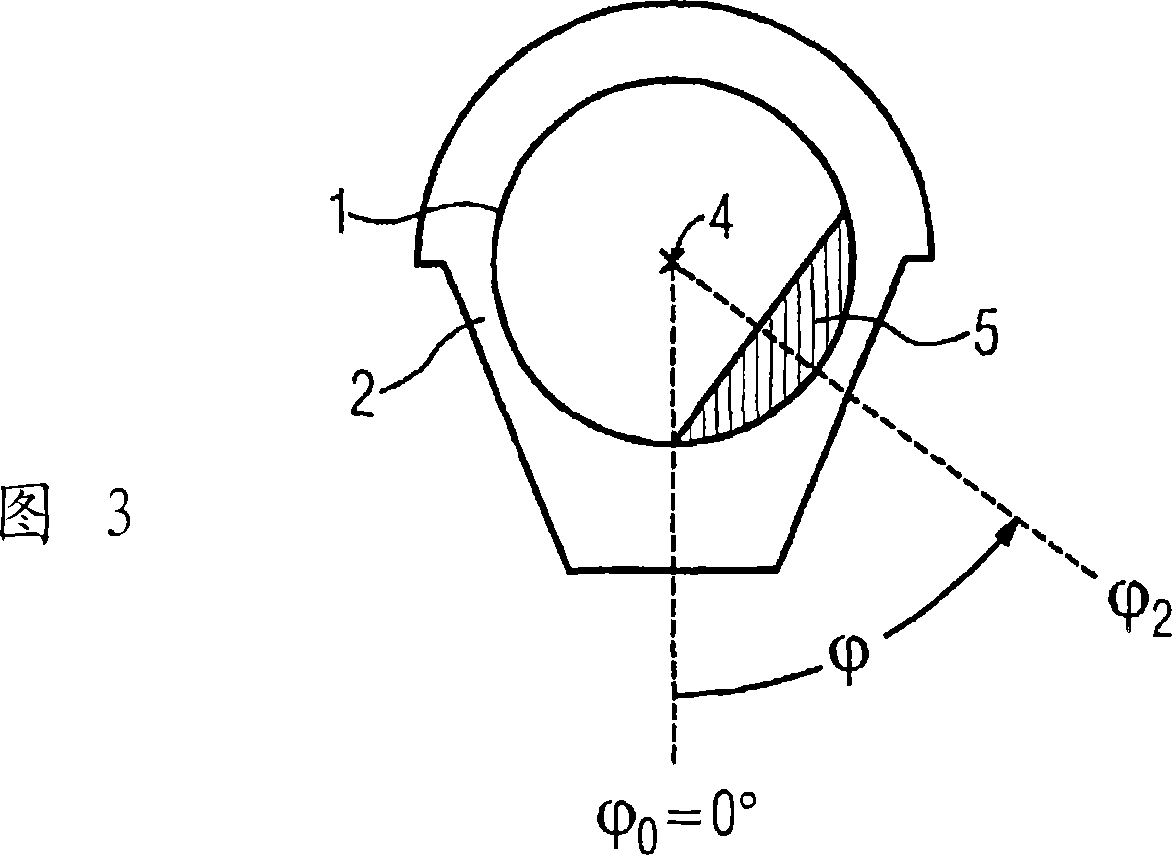

Method, control device and drive device for detaching a charge stuck to the inner wall of a grinding pipe

InactiveCN1993182AChange rotation speedChange direction of rotationGrain treatmentsEngineeringAngle of rotation

The invention relates to a method for detaching a charge (5) which is stuck to the inner wall of a grinding pipe (1), wherein the drive device (2) of the grinding pipe (1) is controlled by a control device (3) for targeted removal of the charge (5) that is stuck. The grinding pipe (1) is rotated in a targeted manner such that the charge (5) that is stuck is removed from the inner wall of the grinding pipe (1) as a result of multiple modification of the rotational speed of the grinding pipe (1) and, optionally, as a result of abrupt braking of the grinding pipe (1). Generally speaking, the material-dependent maximum angle of rotation F of the grinding pipe is not exceeded in order to avoid the charge that is stuck from falling in an uncontrolled manner. The invention supercedes labour-intensive and protracted methods for detaching such charges (5) since the tasks can be carried out by the same motor of the drive device (2) which is used to drive the grinding pipe (1) during the grinding process.

Owner:SIEMENS AG

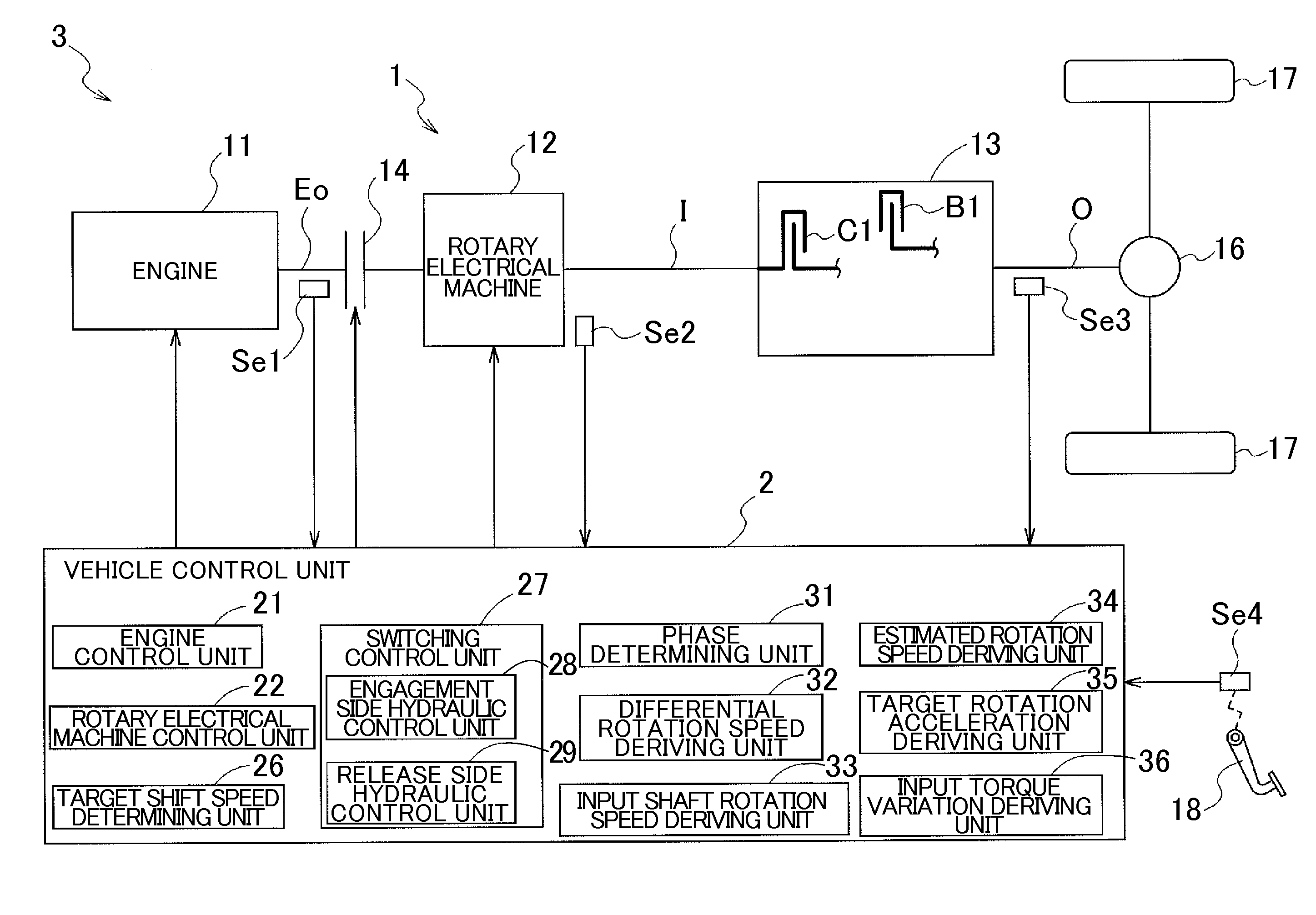

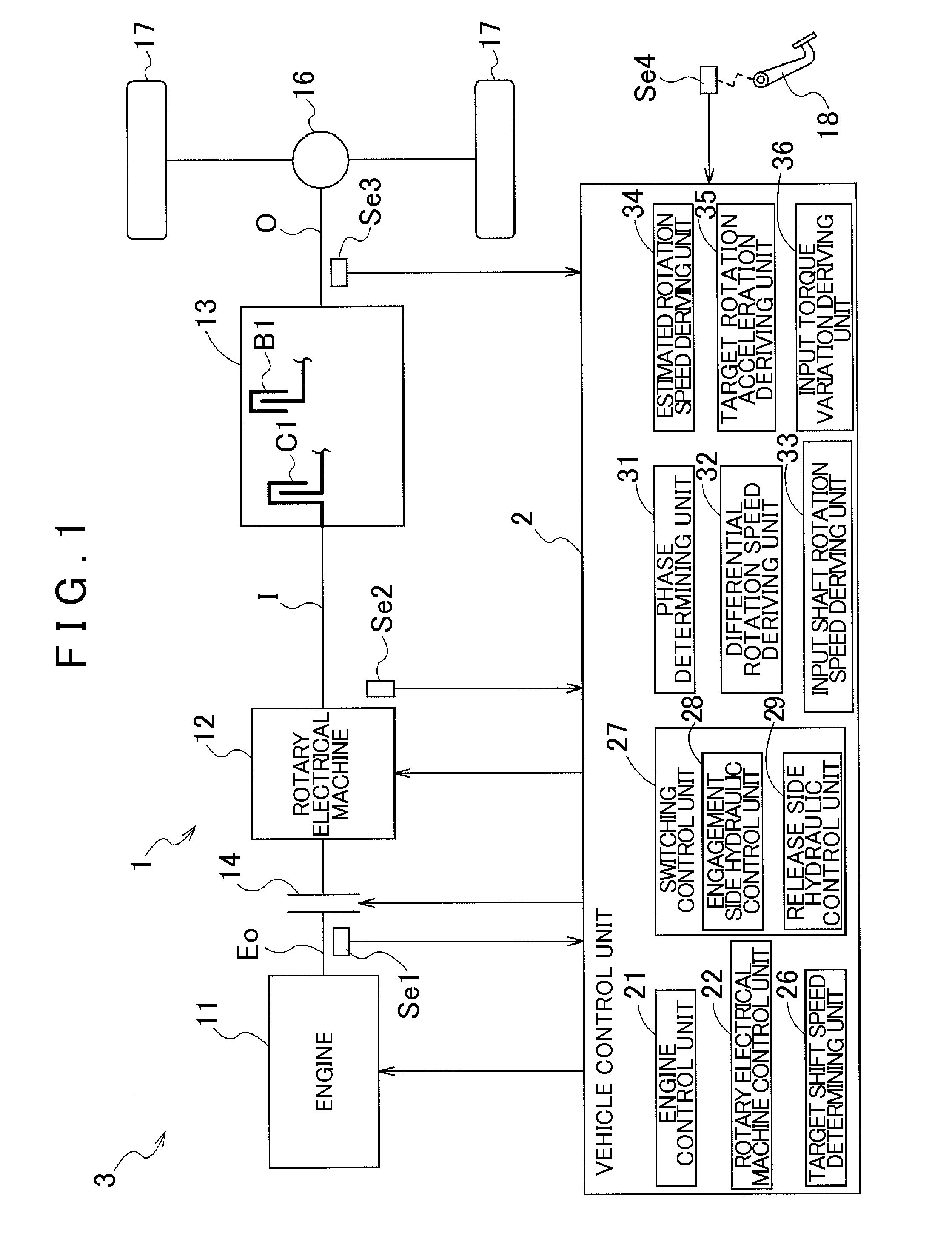

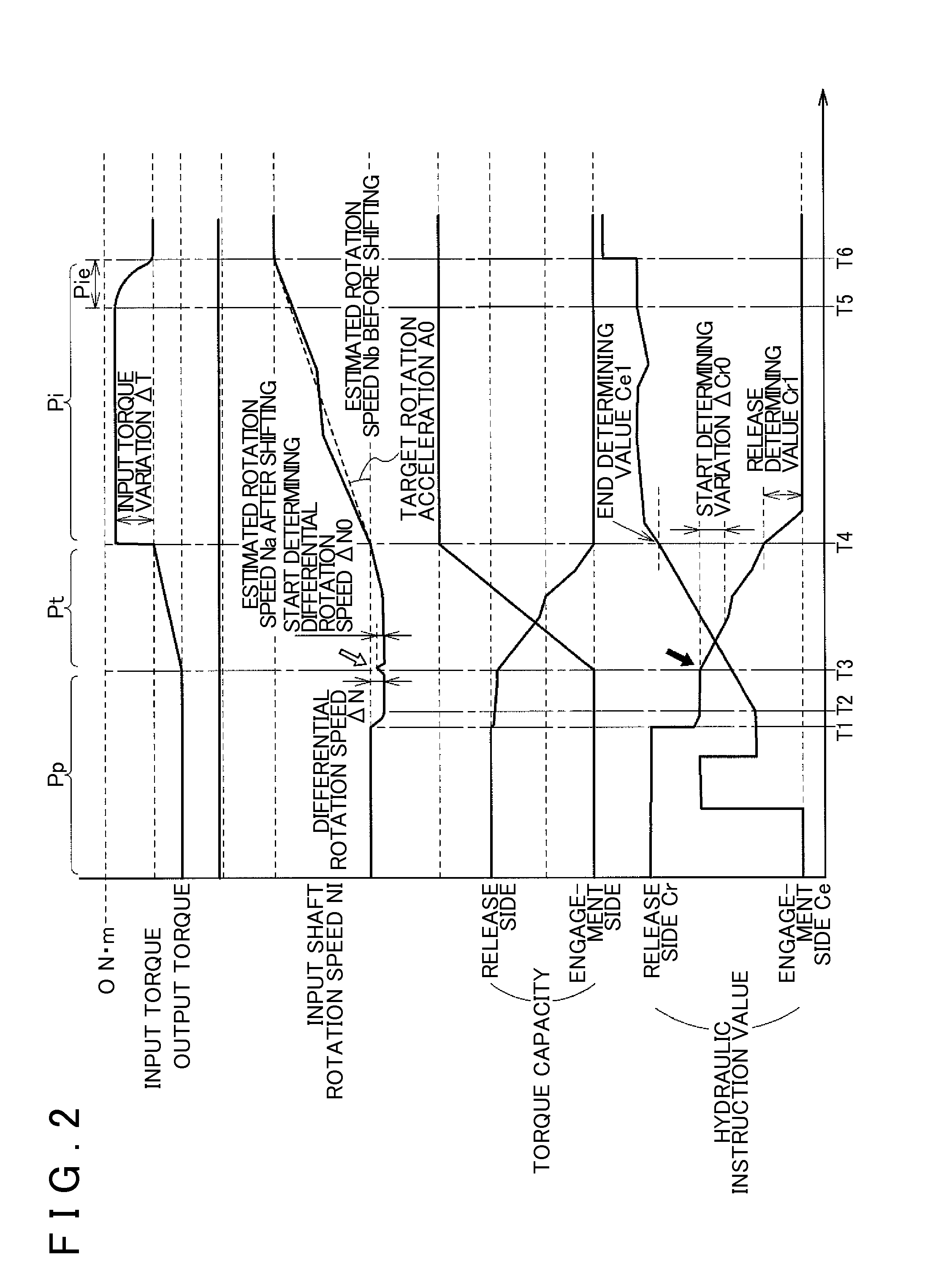

Vehicle control device

InactiveUS20110106356A1Determined accurately and reliablyReduce speedHybrid vehiclesDigital data processing detailsMachine controlElectric machine

Owner:AISIN AW CO LTD

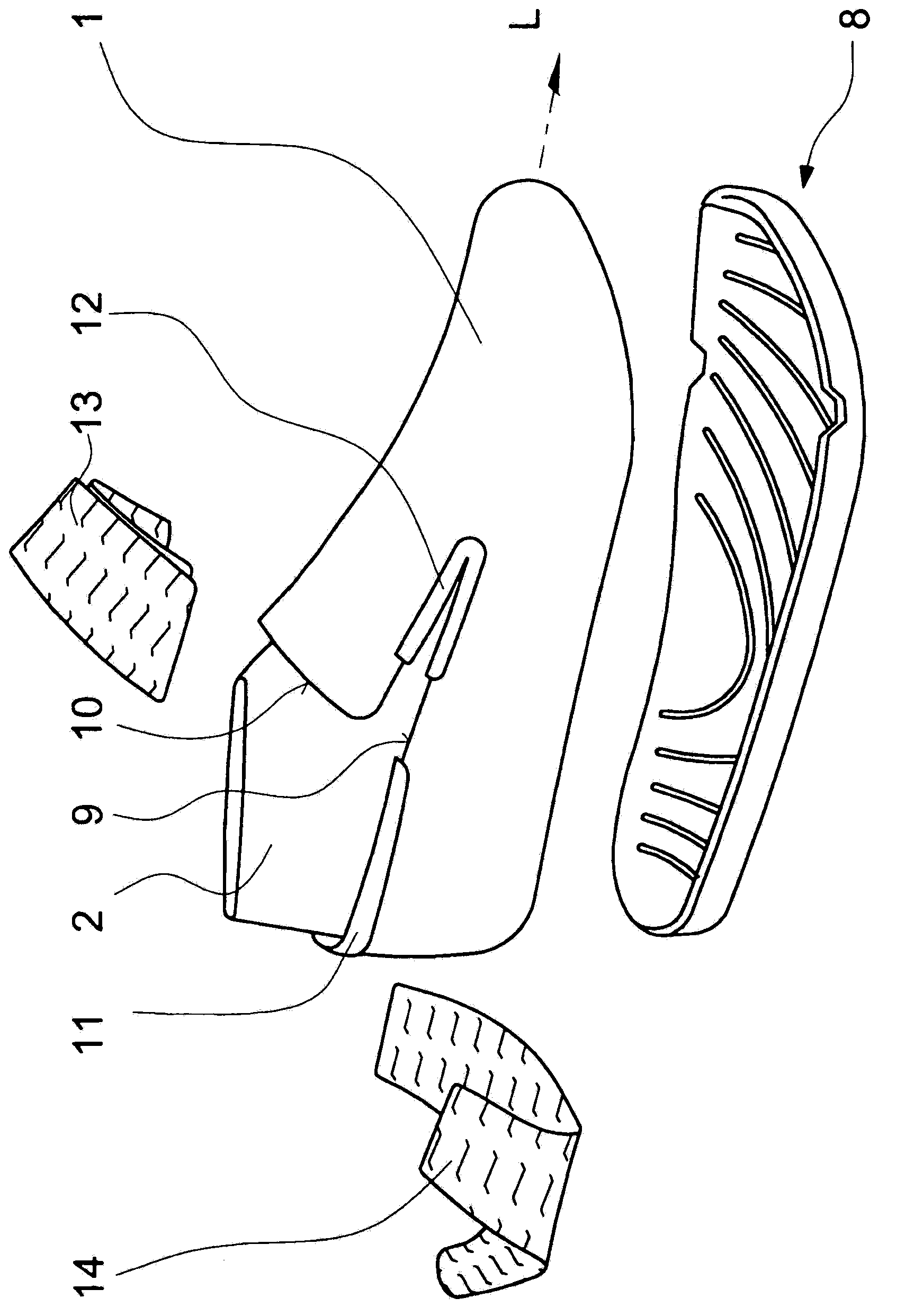

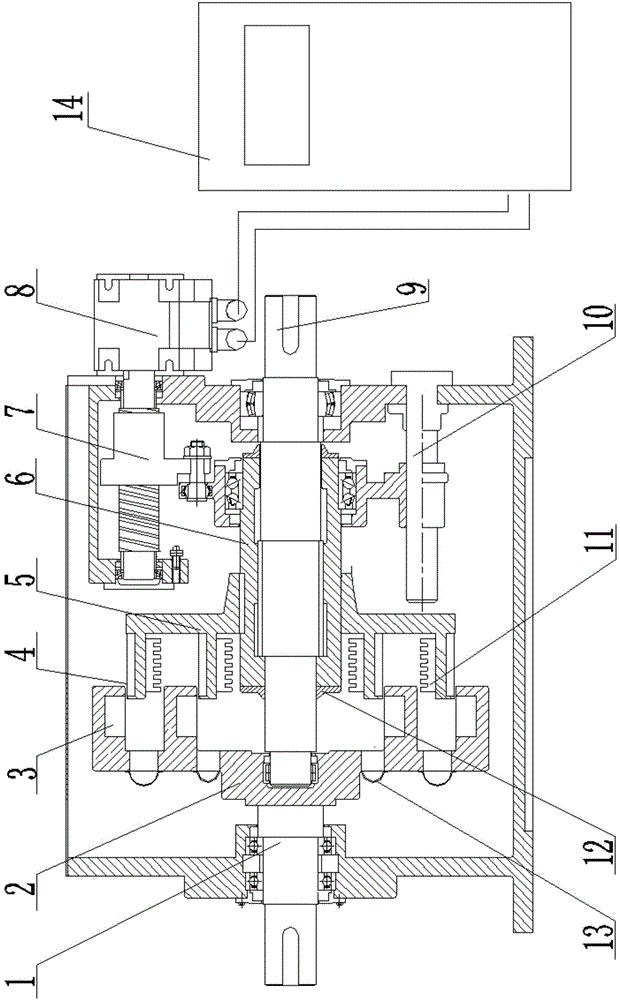

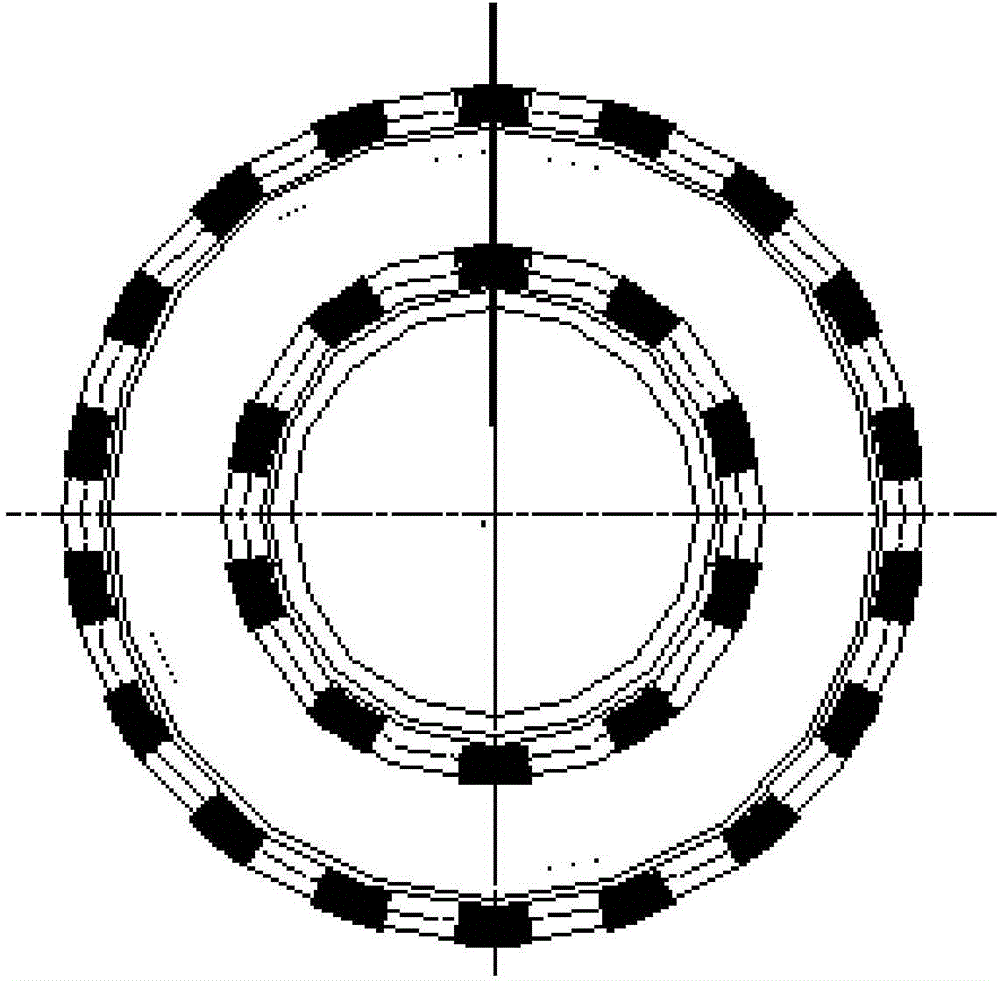

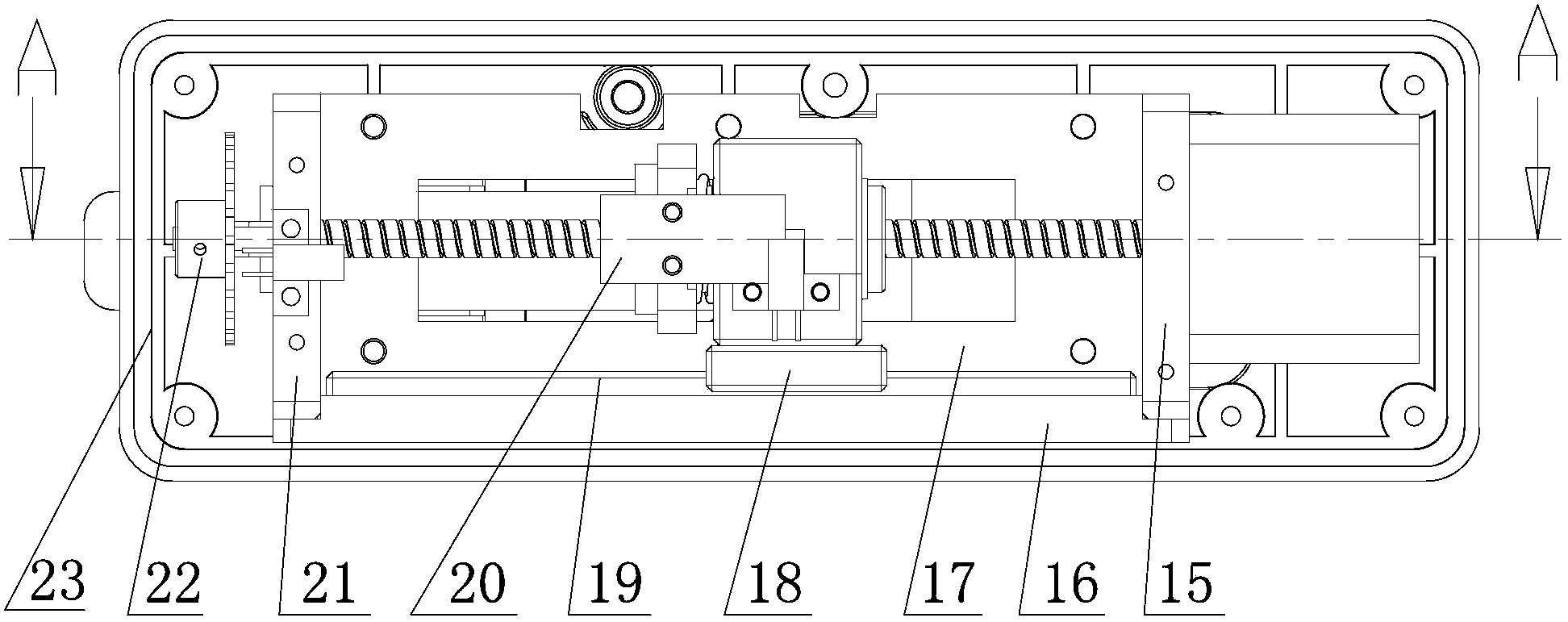

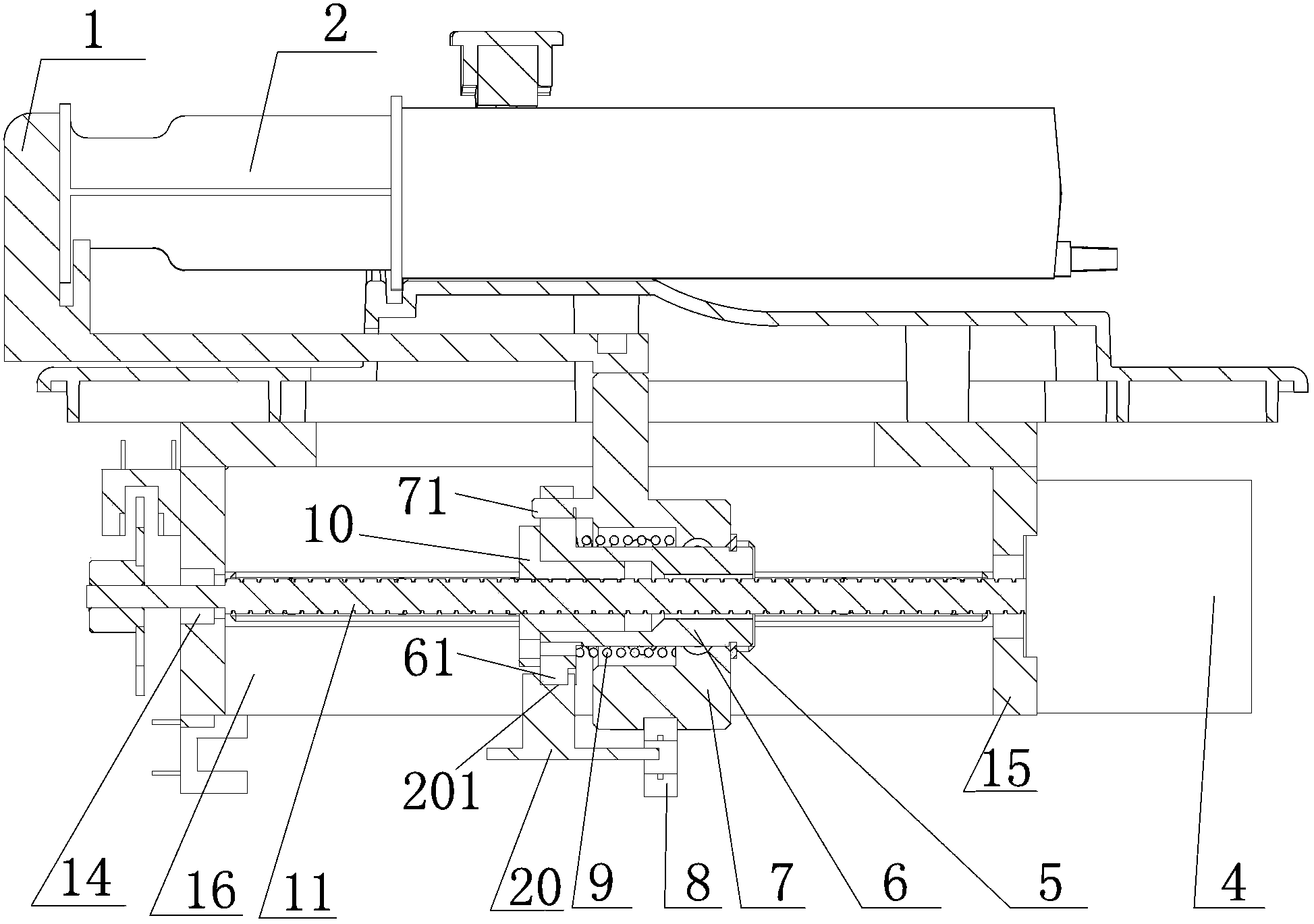

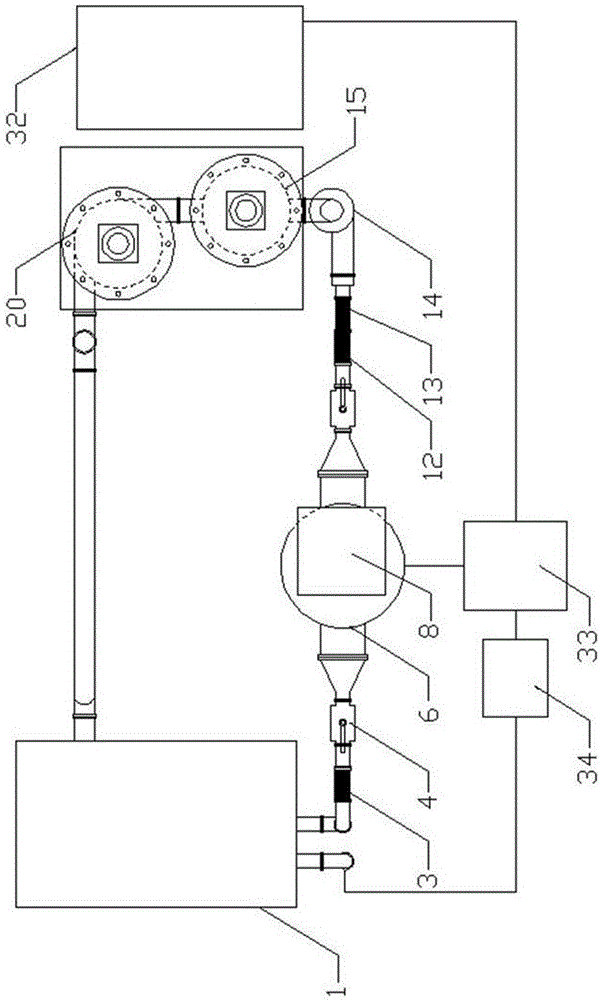

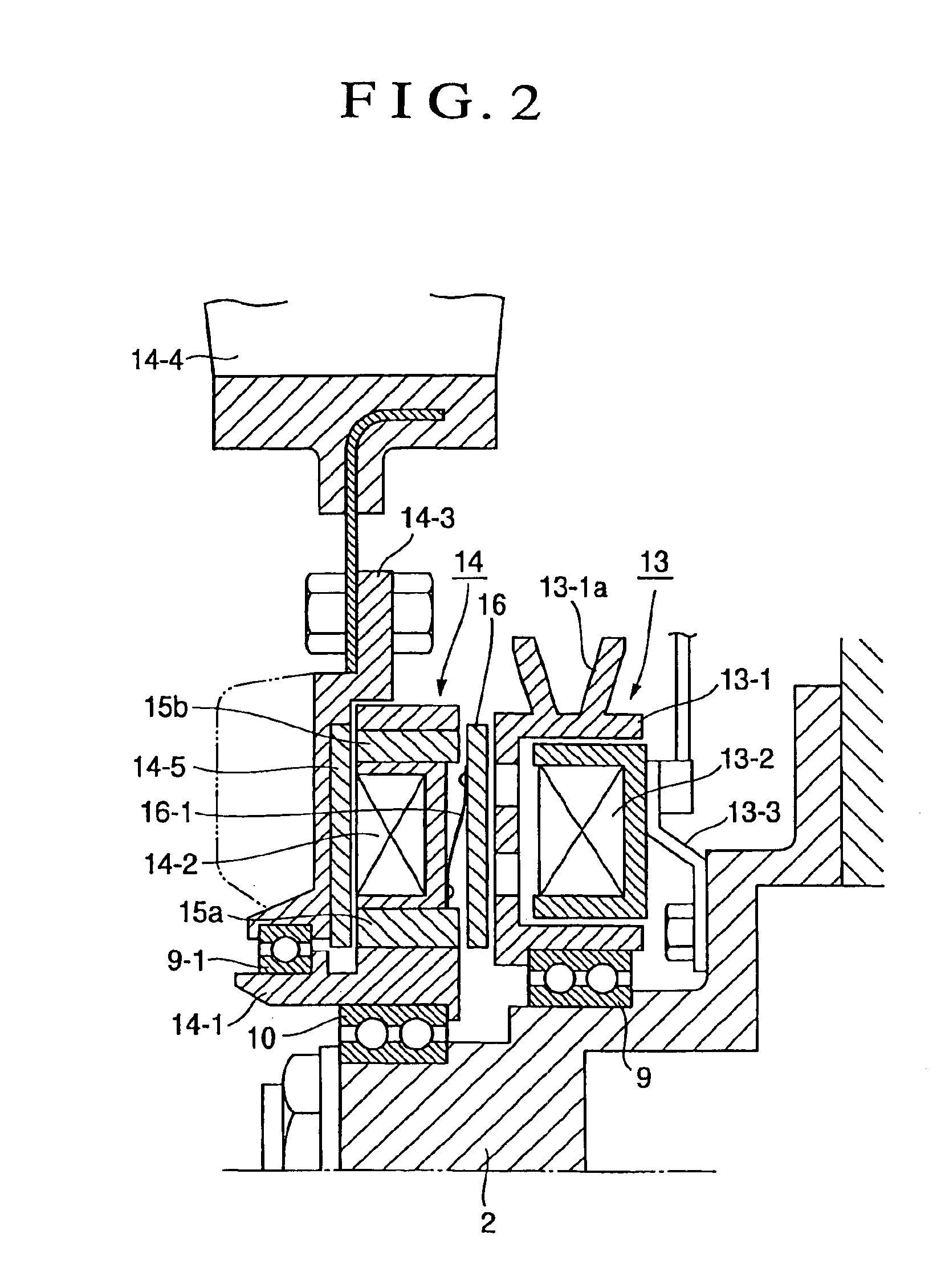

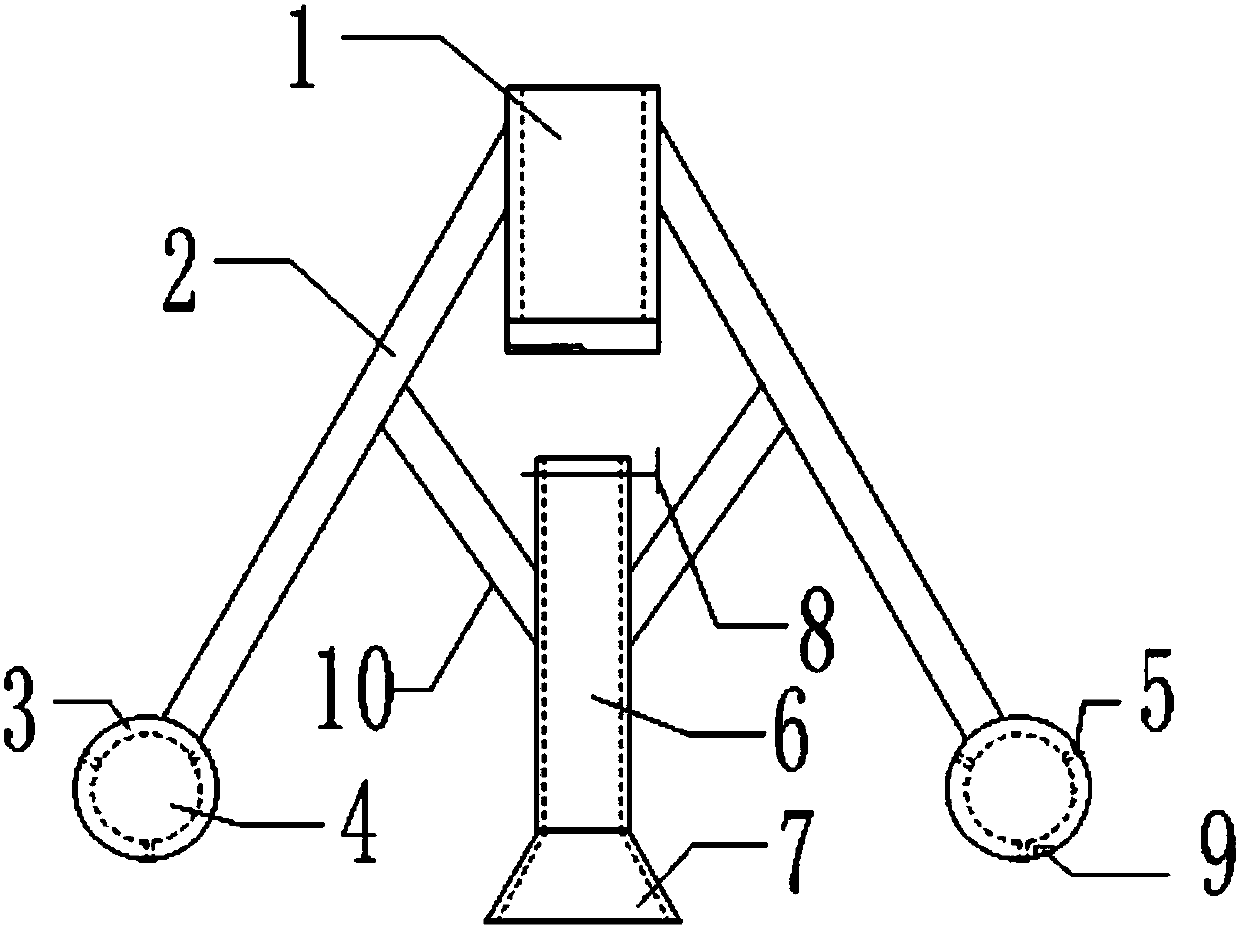

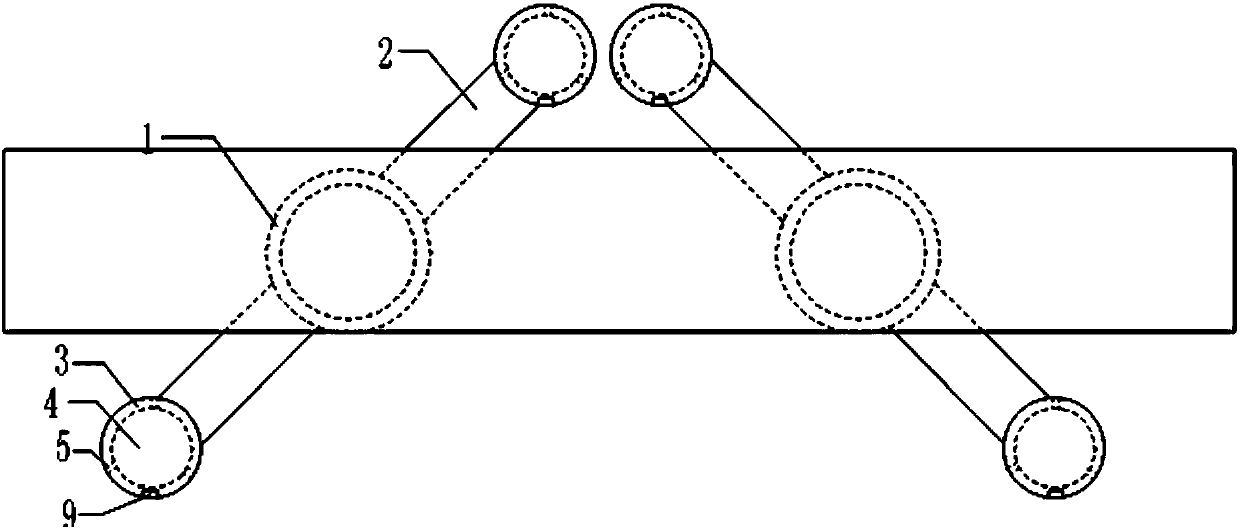

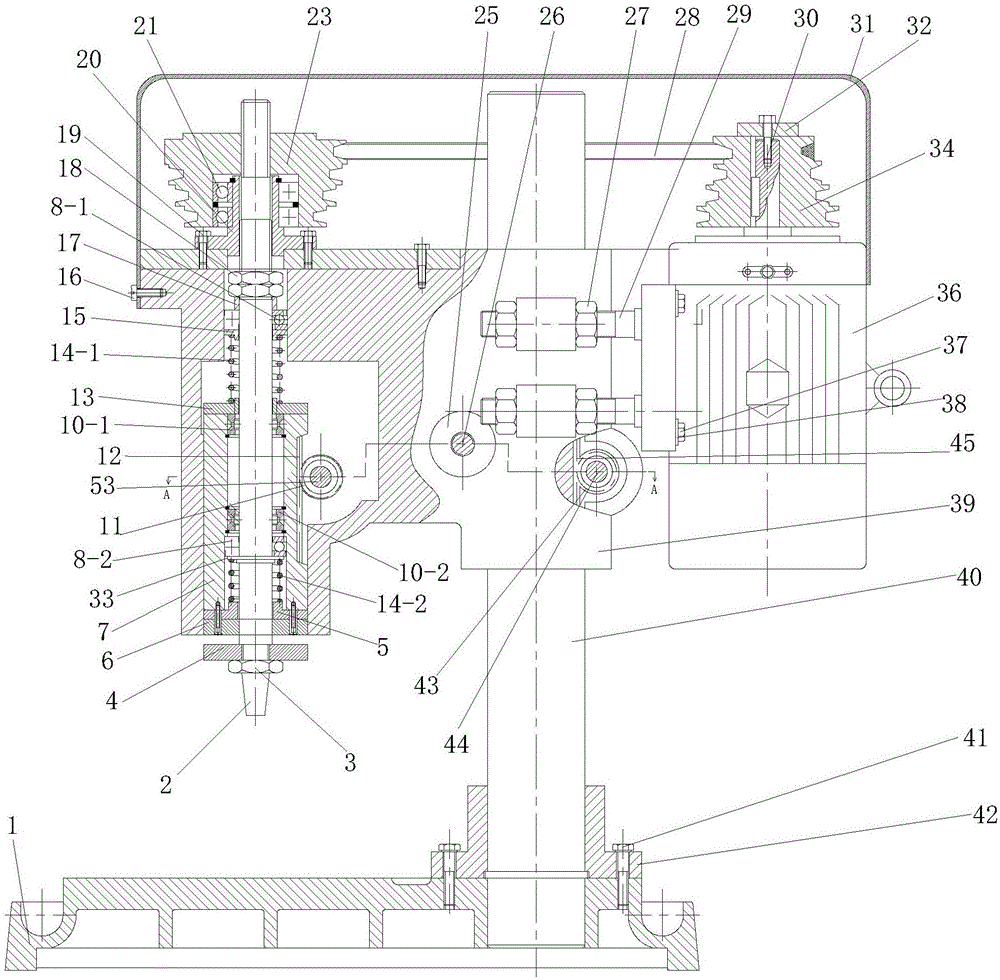

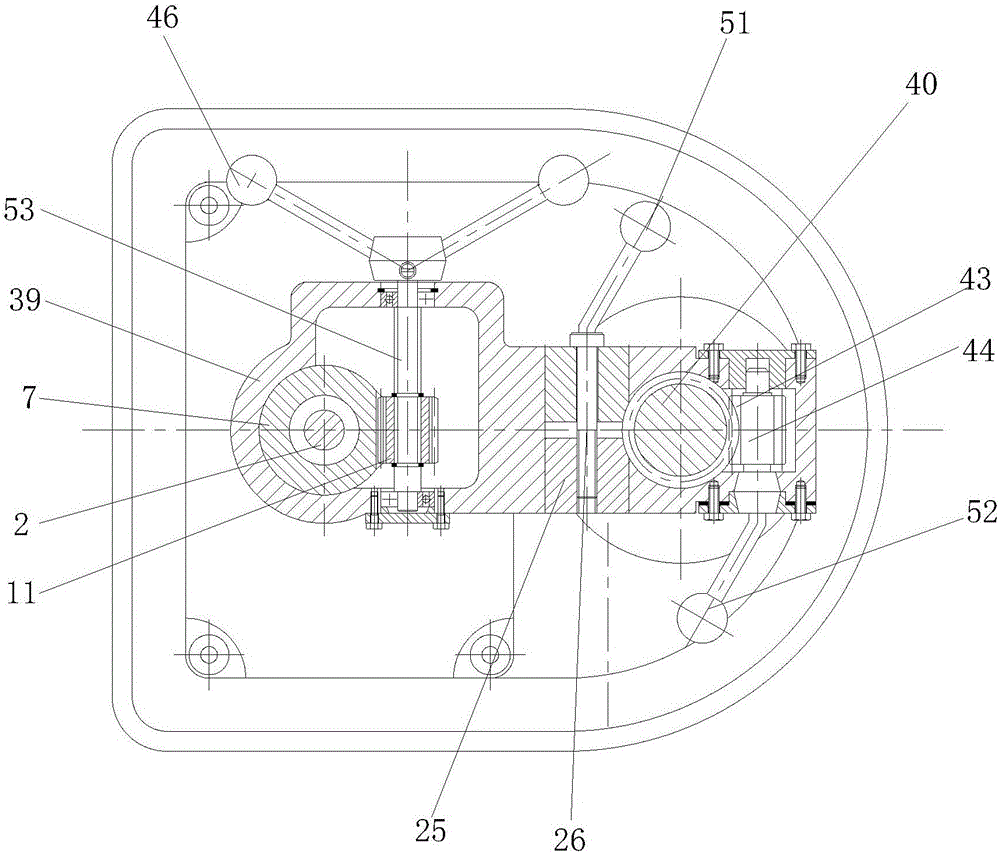

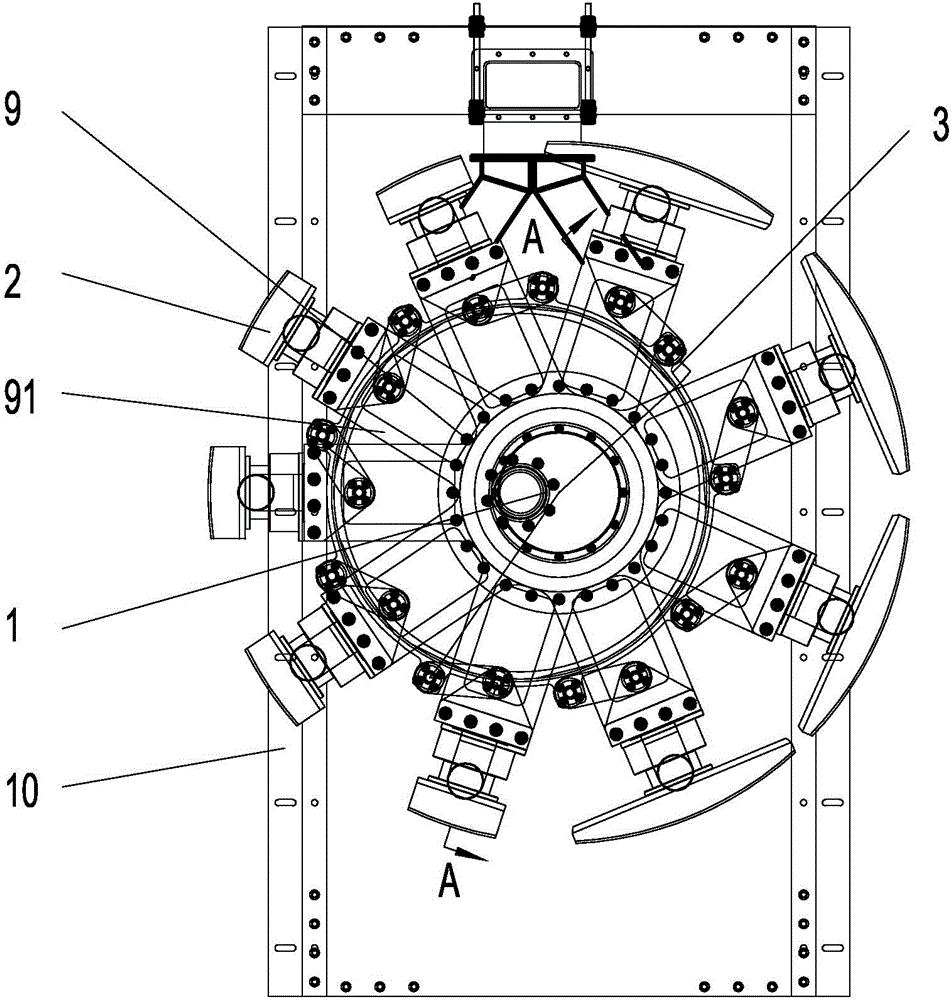

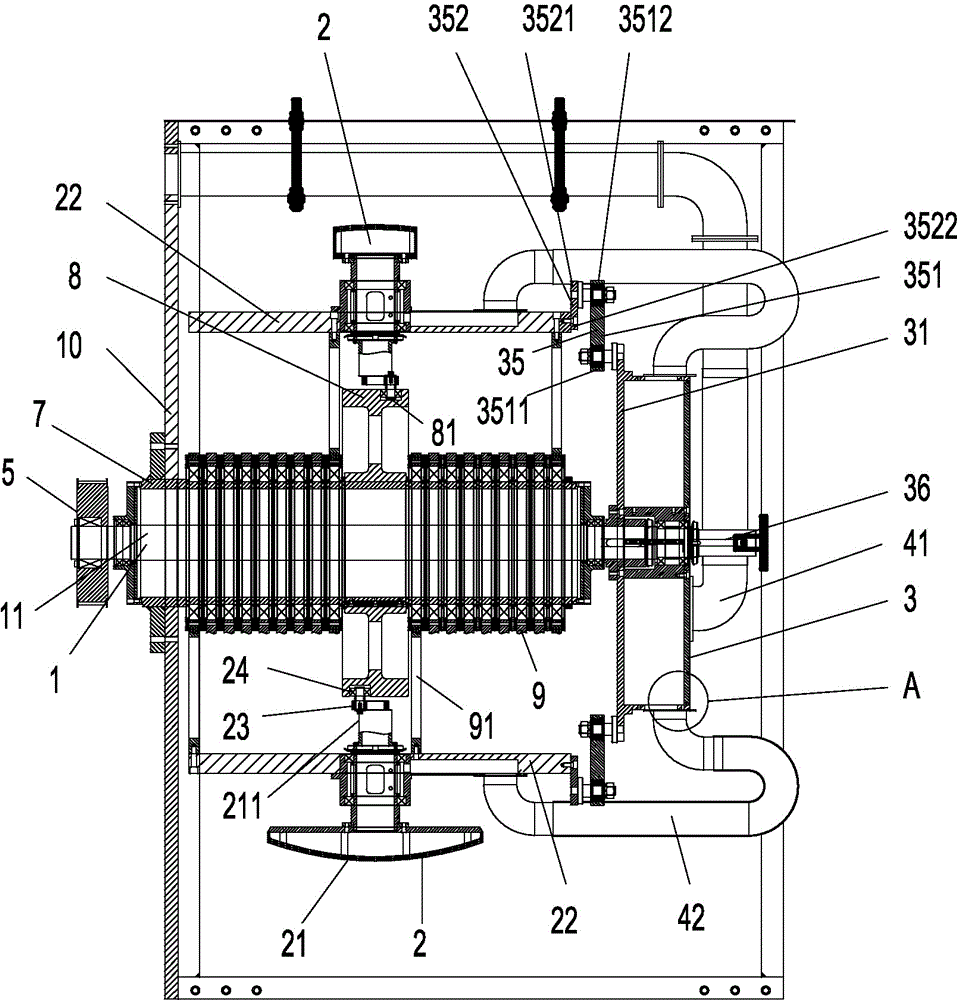

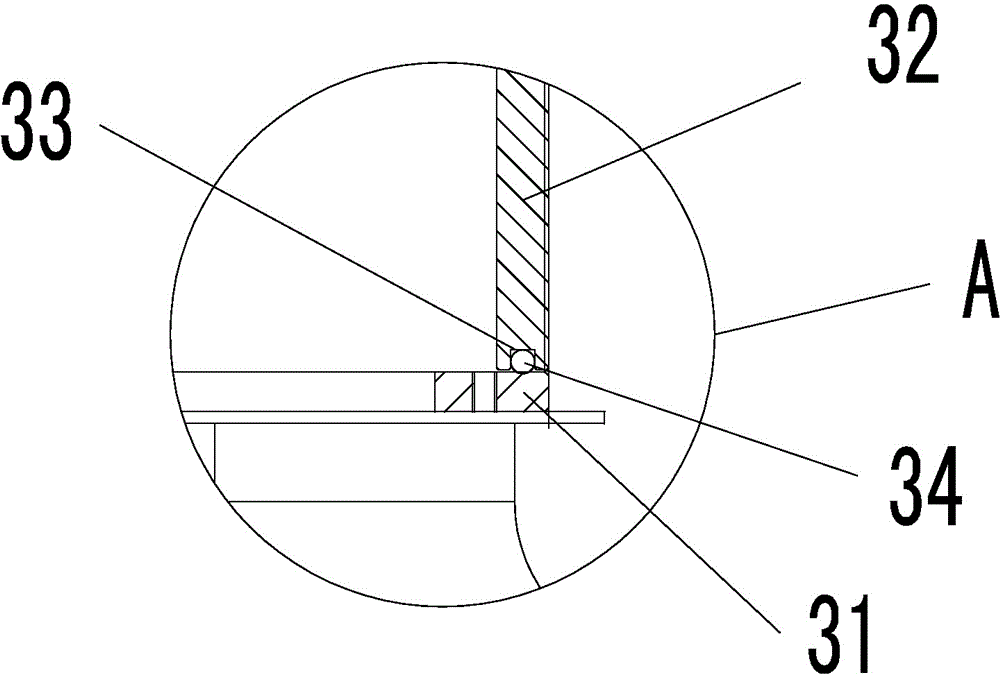

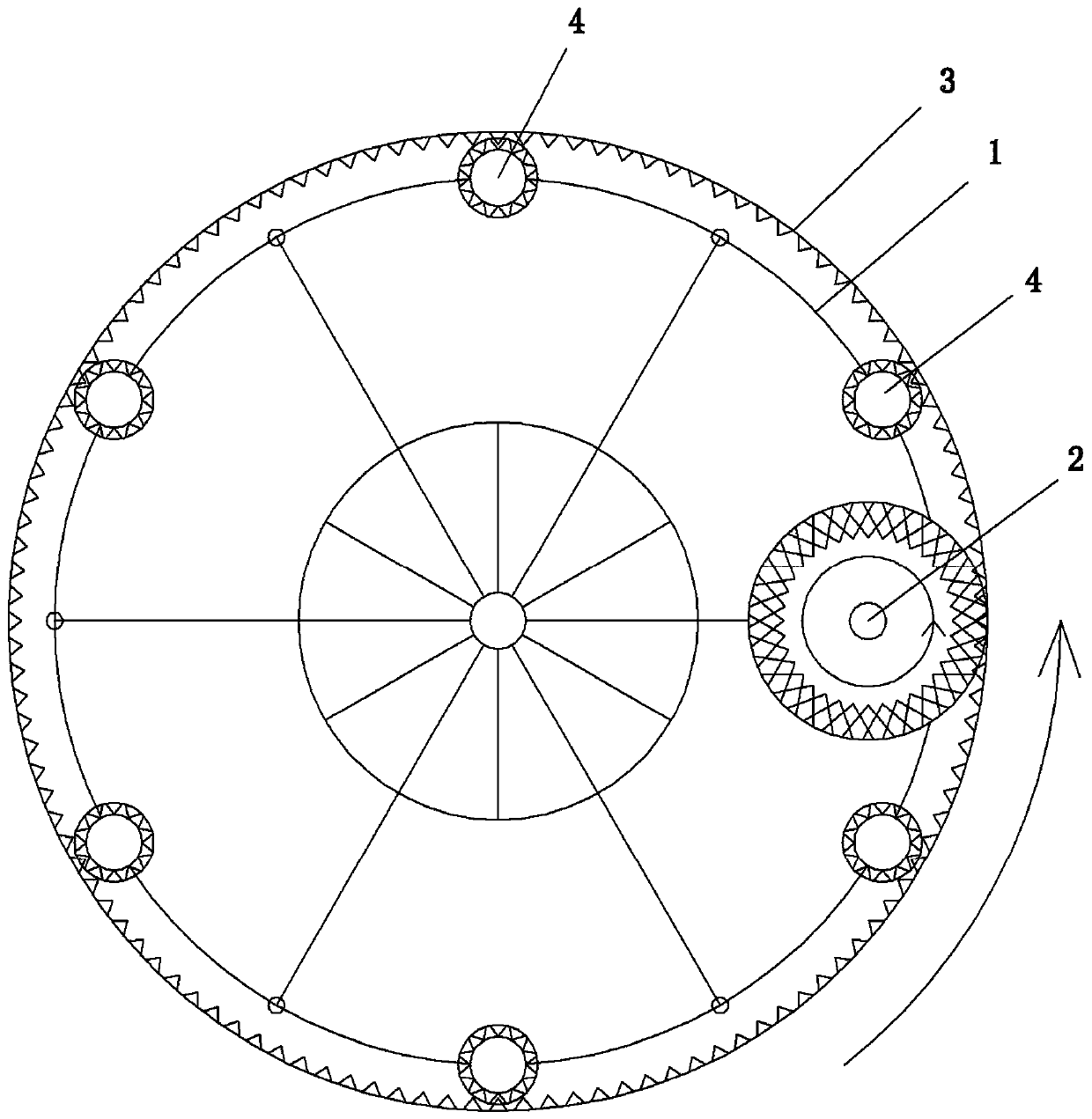

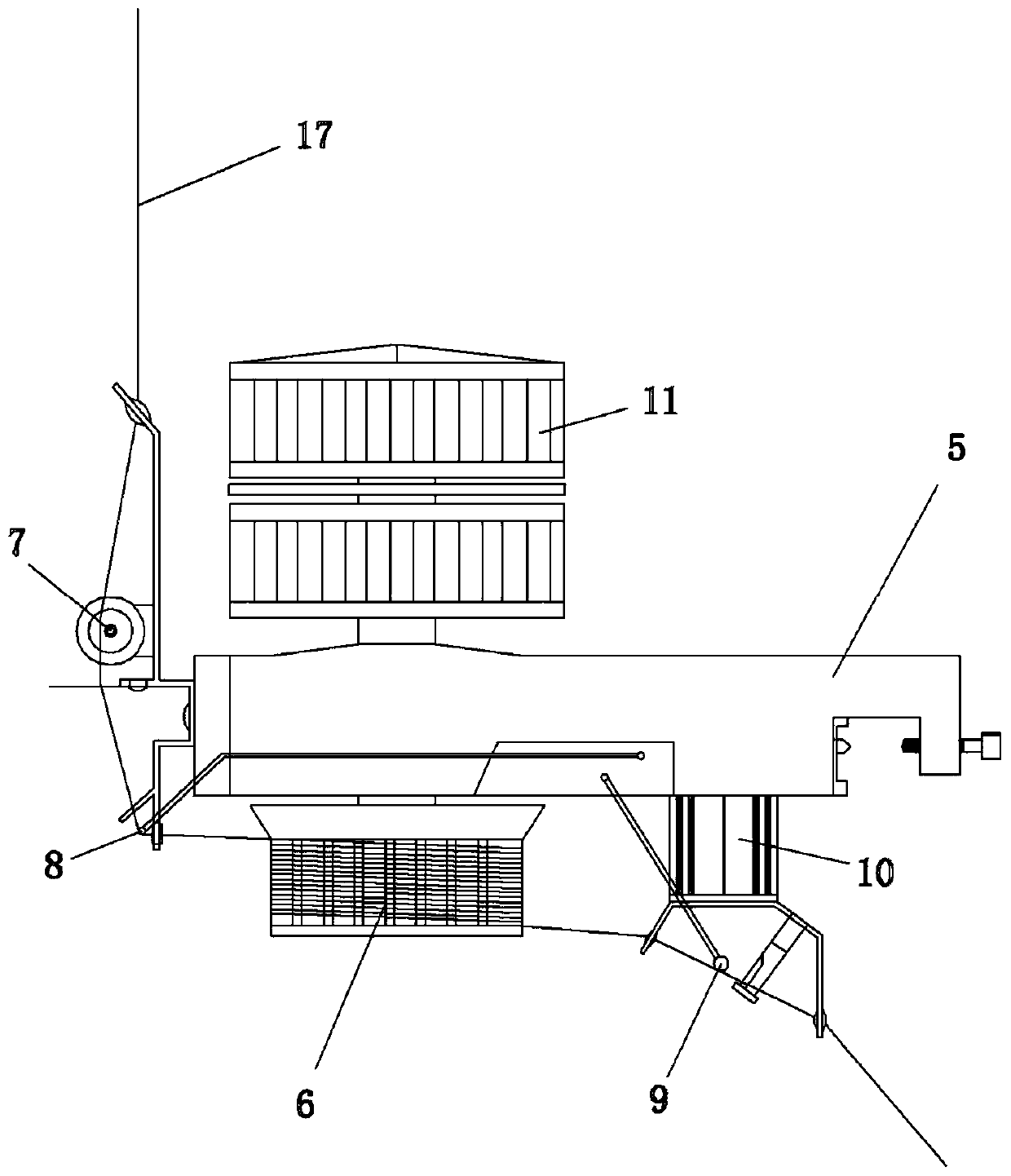

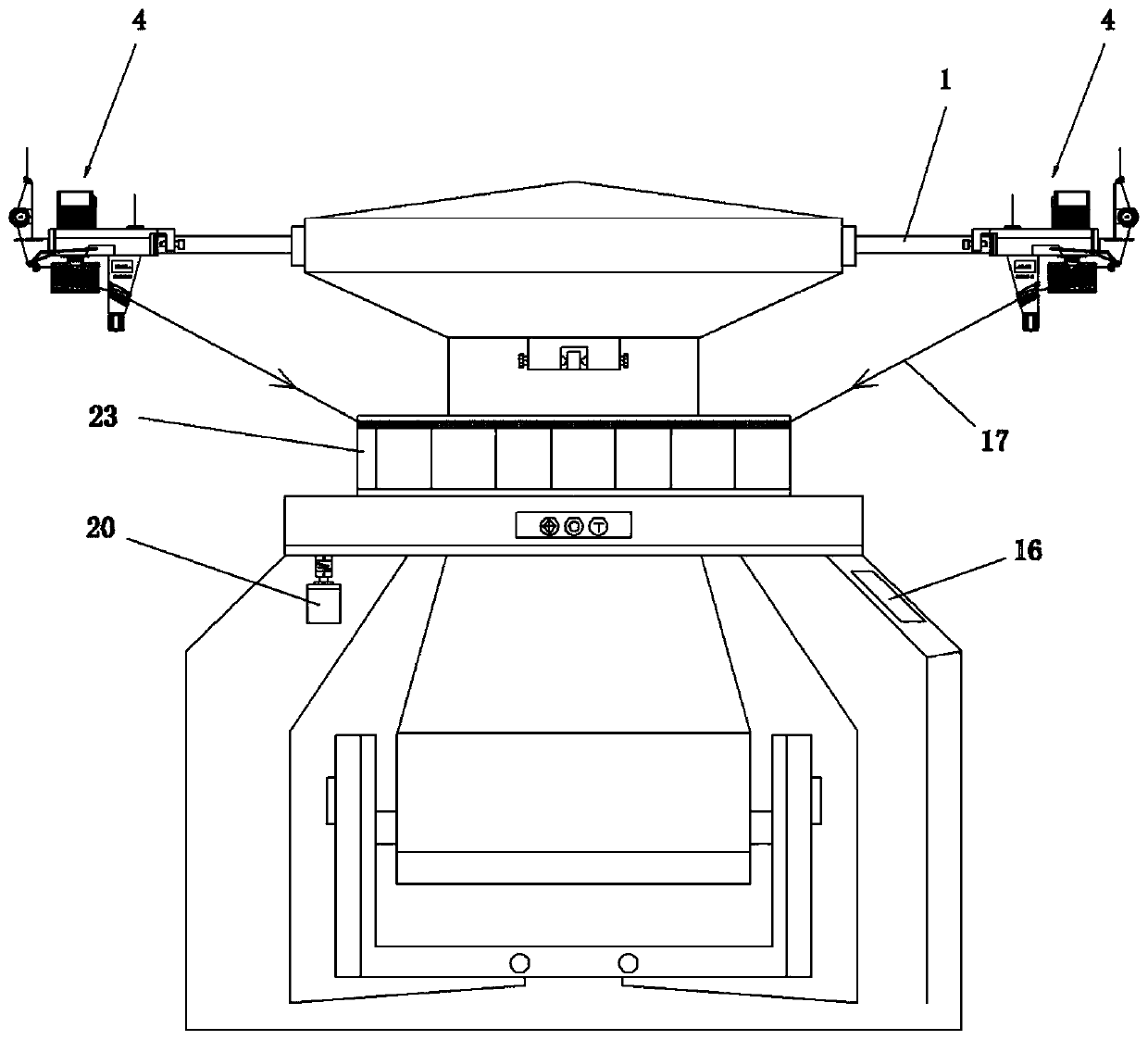

Intelligent adjustable permanent magnet flexible coupling speed regulator

ActiveCN103986306AImprove cooling effectChange rotation speedDynamo-electric gearsControl principleMagnet

An intelligent adjustable permanent magnet flexible coupling speed regulator is characterized by being mainly composed of a driving shaft (1), a driving disc (2), permanent magnets (3), copper rings (4), a driven disc (5), a speed regulation sleeve (6), a ball screw (7), a servo motor (8), a driven shaft (9), a guide rod guide sleeve (10), cooling fins (11), a dust removing shovel (12), an air guide cover (13) and a central control system (14). A flexible start closed-loop control algorithm is set in the central control system of the intelligent adjustable permanent magnet flexible coupling speed regulator. According to the control principle of the central control system, each sensor parameter of the permanent magnet flexible coupling speed regulator is collected by the central control system, and the optimal coupling proportion or target set start time is obtained through calculation according to the algorithm of the central control system.

Owner:南京迪瓦机械制造有限公司

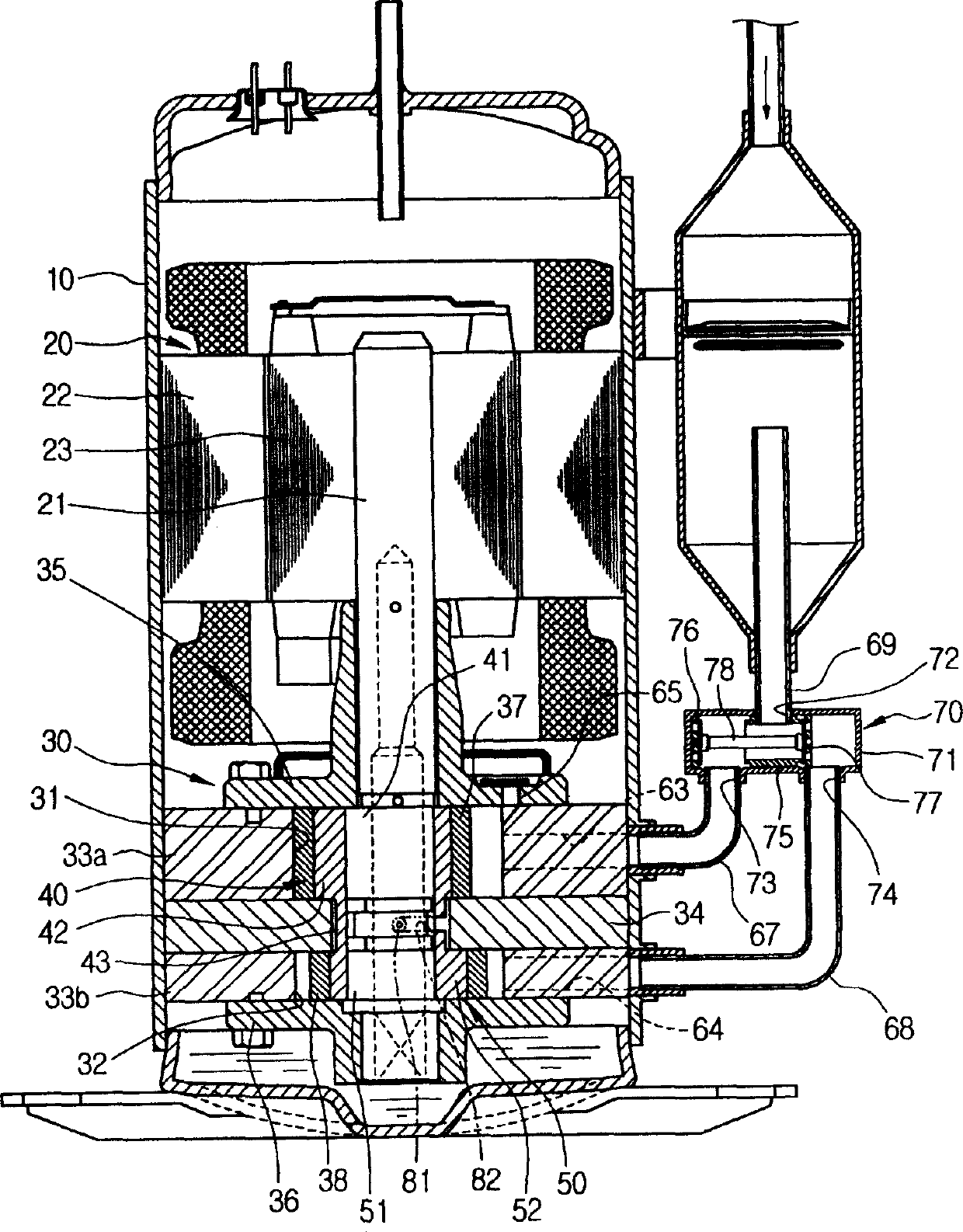

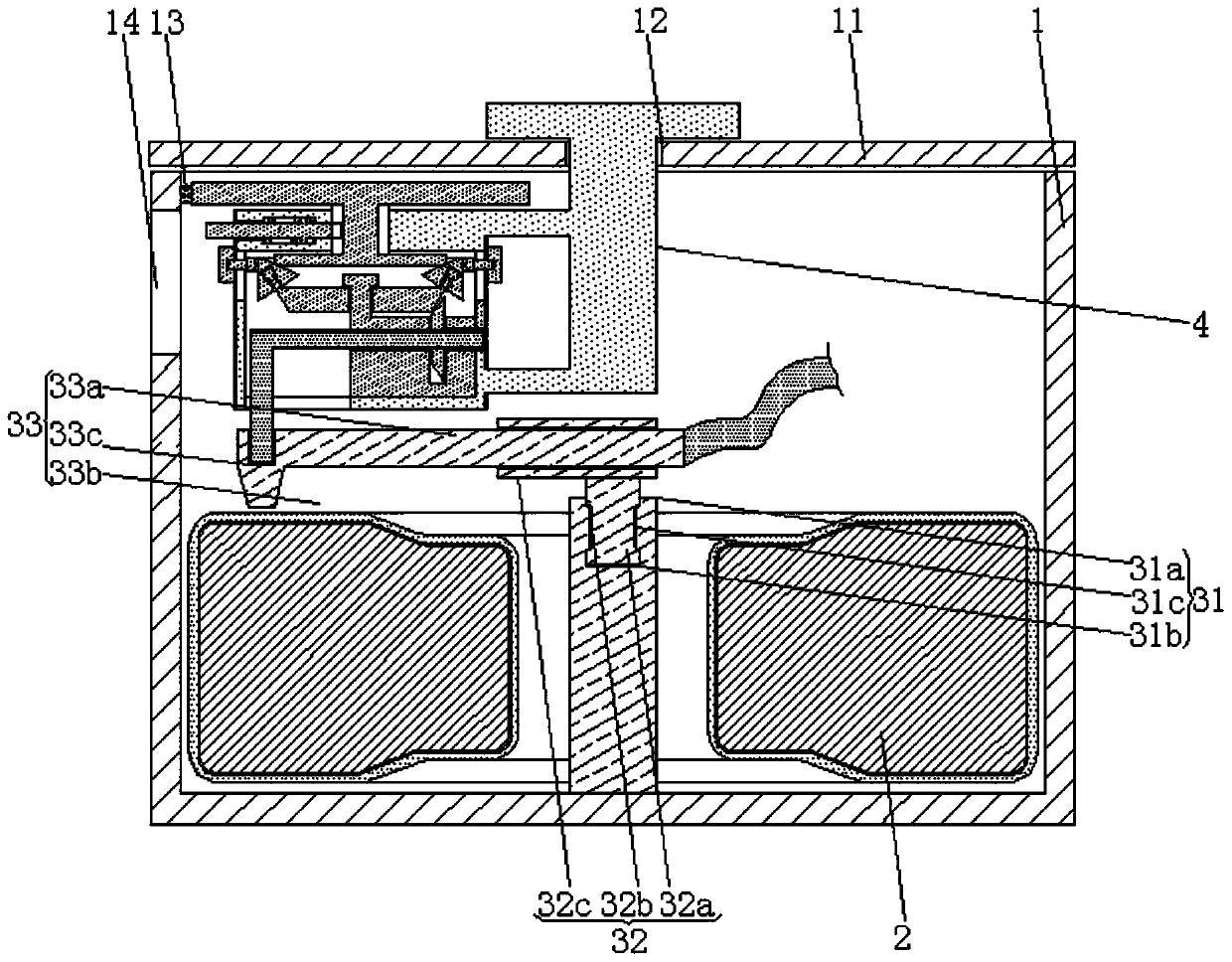

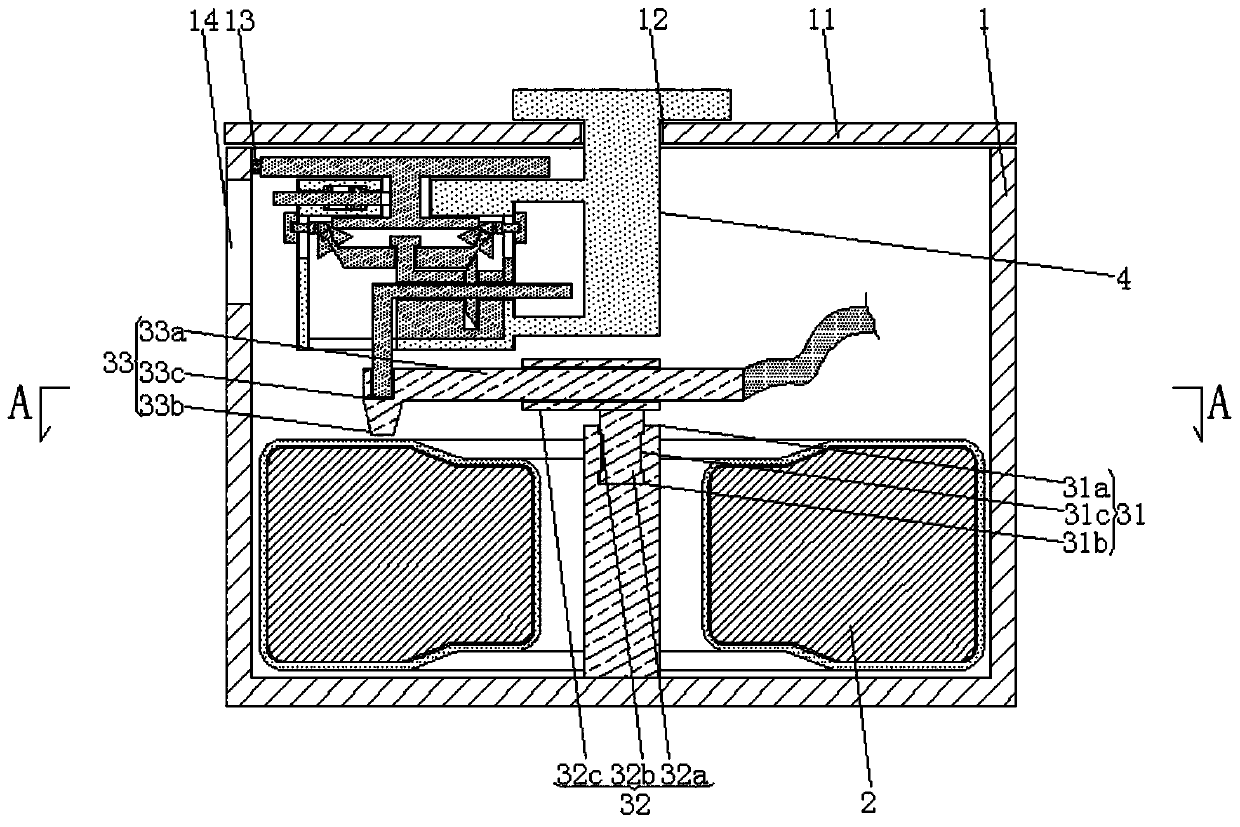

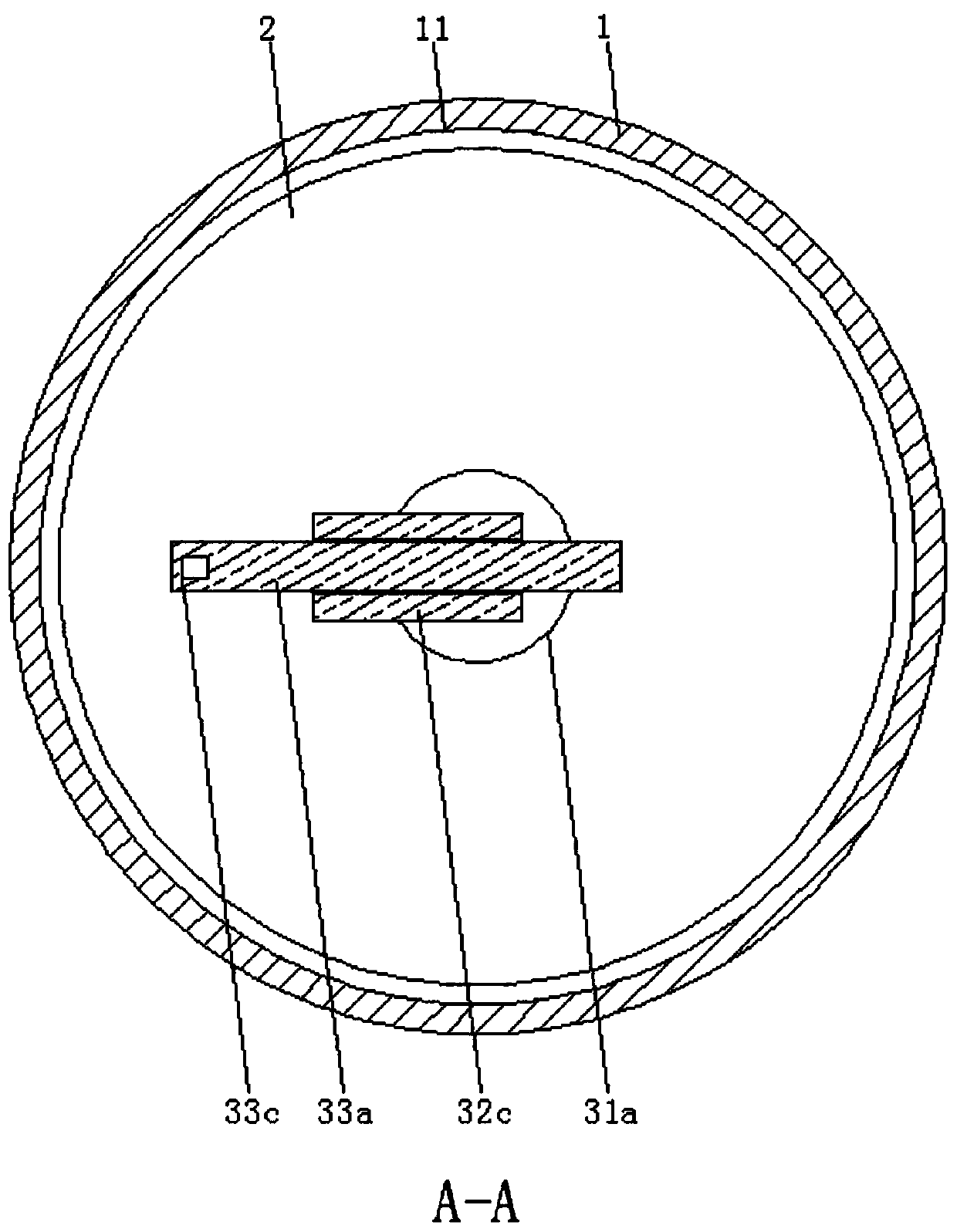

Variable capacity rotary compressor

InactiveCN1534196AChange rotation speedRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsElectric machineElectrical control

A variable capacity rotary compressor capable of varying a compression capacity thereof. The variable capacity rotary compressor includes a housing defined therein with first and second compressing chambers having different volumes, a rotating shaft adapted to rotate in the first and second compressing chambers, a compressing unit arranged in the first and second compressing chambers, and adapted to perform a compression operation in a selected one of the first and second compressing chambers in accordance with a change of a rotating direction of the rotating shaft, and a drive motor adapted to rotate the rotating shaft in a first direction or in a second direction, the drive motor being variable in rotating speed in accordance with an electrical control operation. The variable capacity rotary compressor can achieve a multi-stage variation in capacity thereof within a wide range while reducing a variation range of rotating speed, as compared to conventional cases, because it is possible not only to mechanically vary the capacity of the compressing device in accordance with a change of the rotating direction of the drive motor, but also to control the rotating speed of the drive motor in accordance with an electrical control method.

Owner:SAMSUNG ELECTRONICS CO LTD

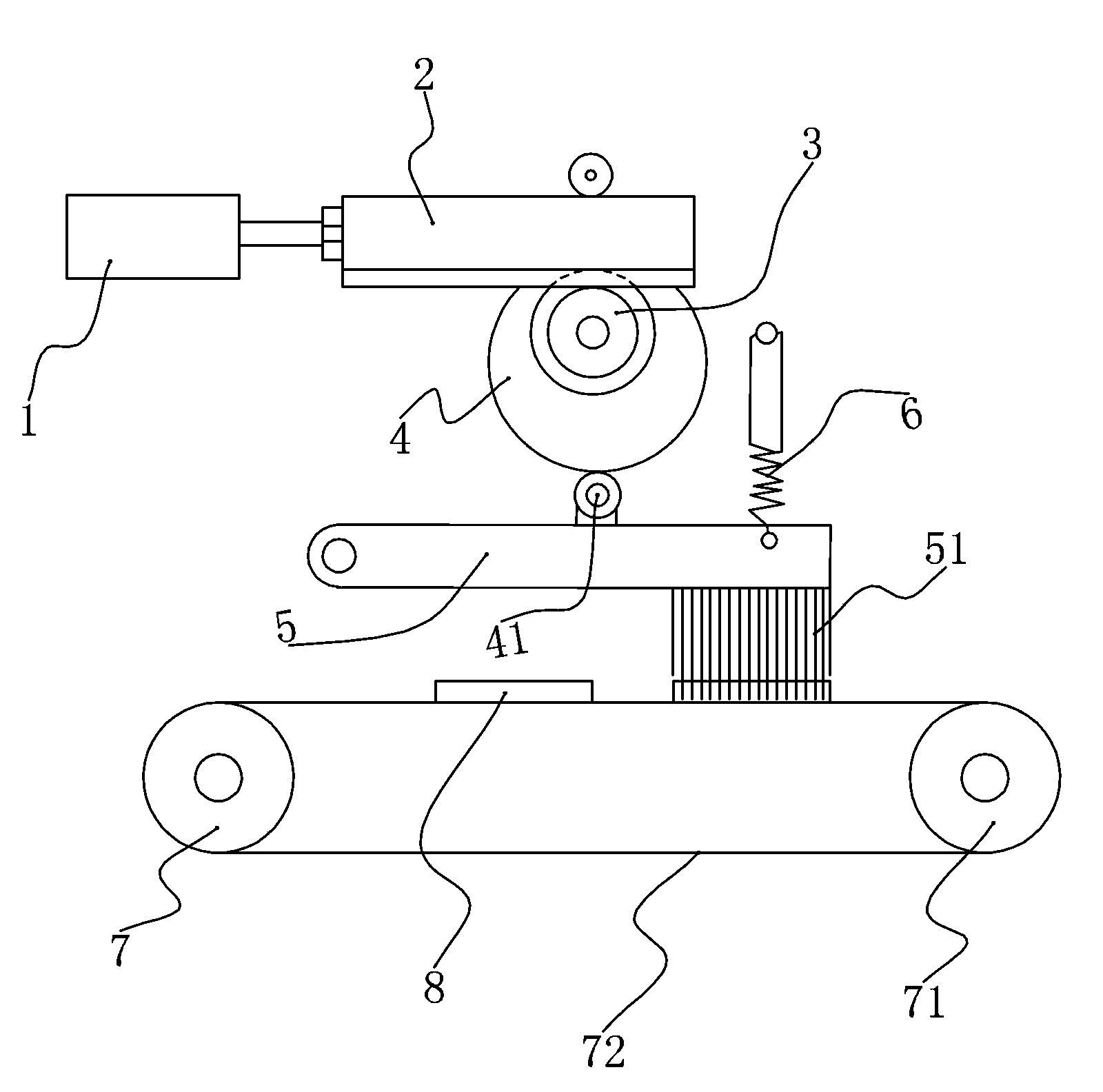

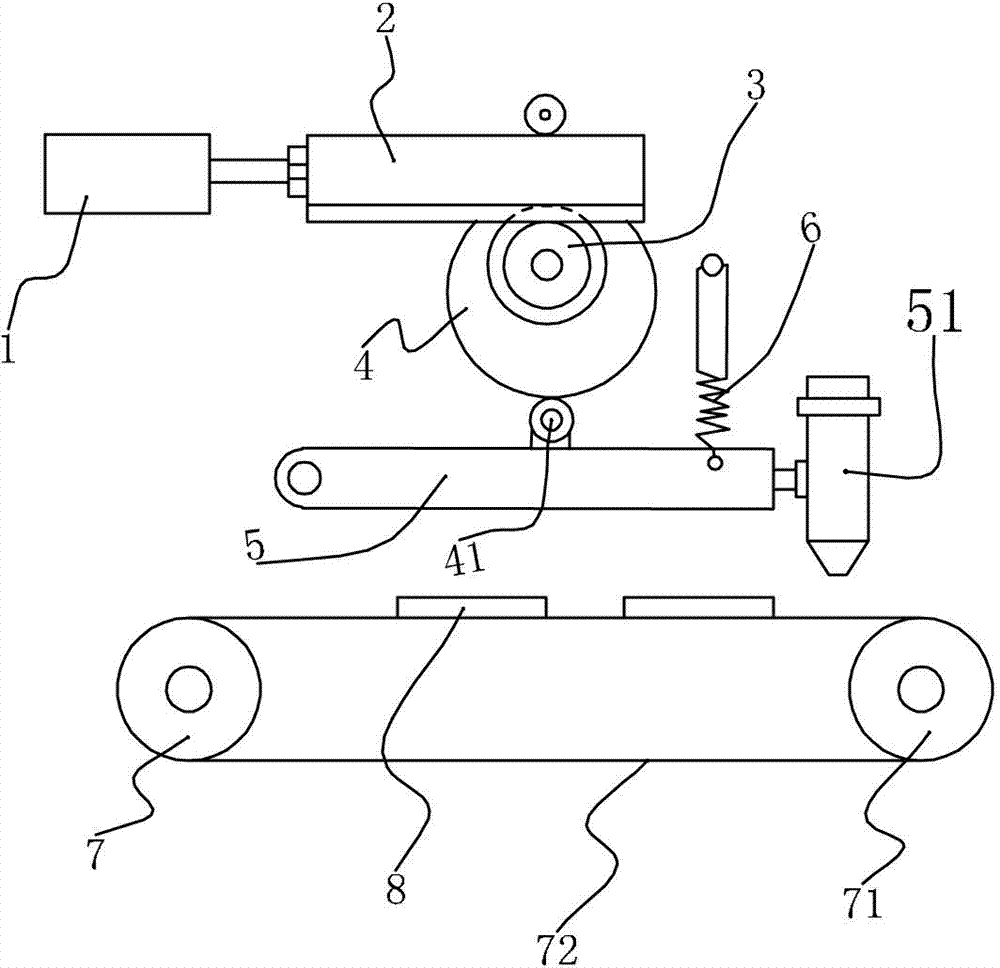

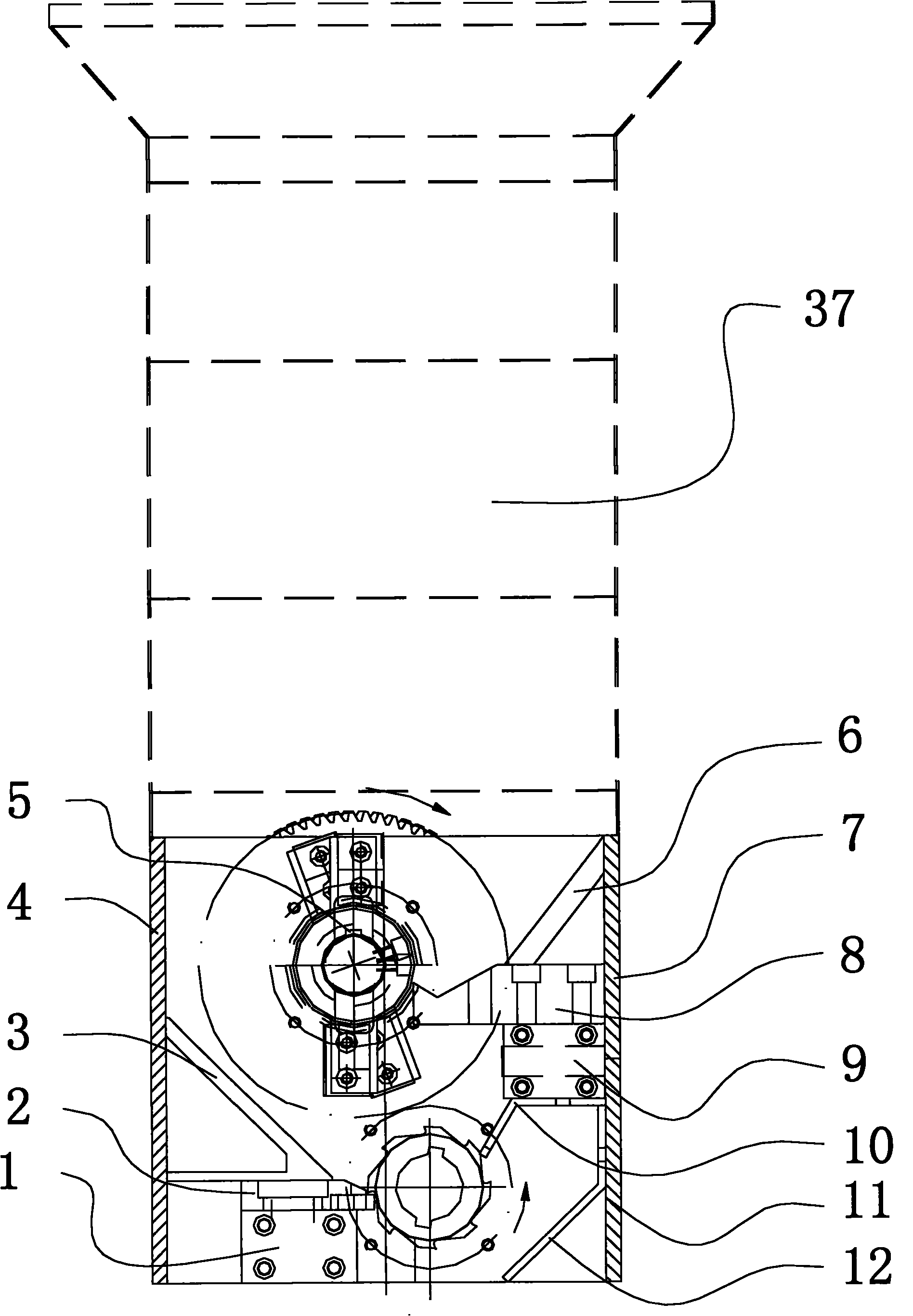

Swing type slicing and feeding device at variable speeds

InactiveCN103707346AReturn quicklyChange rotation speedMetal working apparatusReciprocating motionCam

The invention discloses a swing type slicing and feeding device at variable speeds. A rack is driven to move in a reciprocating mode through movements of a piston rod of an air cylinder, the rack drives a gear and a cam to rotate together, wherein the cam and the gear are coaxially arranged. Because the distances from the outer edges of the cam to a rotating shaft of the cam are different, a cam driven piece is driven by the cam to drive a toolbar to rotate with the rotating shaft as a base point, and straight reciprocating motion of the air cylinder can be converted into reciprocating swing motion through the effect of the cam. In addition, protruding edges on the cam are irregular, movement speeds of tool bits arranged on the toolbar are different in the swinging process of the toolbar, and the speeds can be changed in the process of cutting materials. Because a driving belt wheel is hinged to a support, as long as placement positions of the materials are computed, slicing on the materials can be completed when a conveyor belt conveys the materials, and higher processing efficiency and processing accuracy can be achieved.

Owner:CHONGQING JIDING FOOD

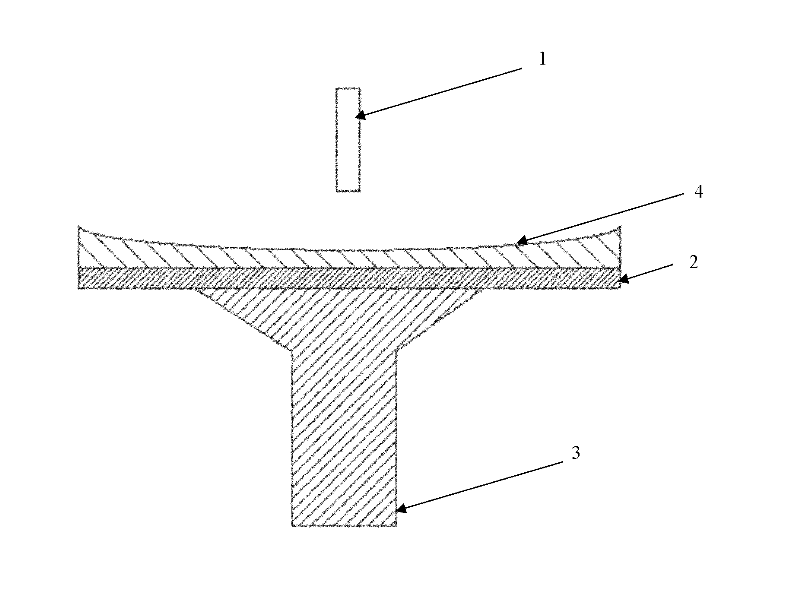

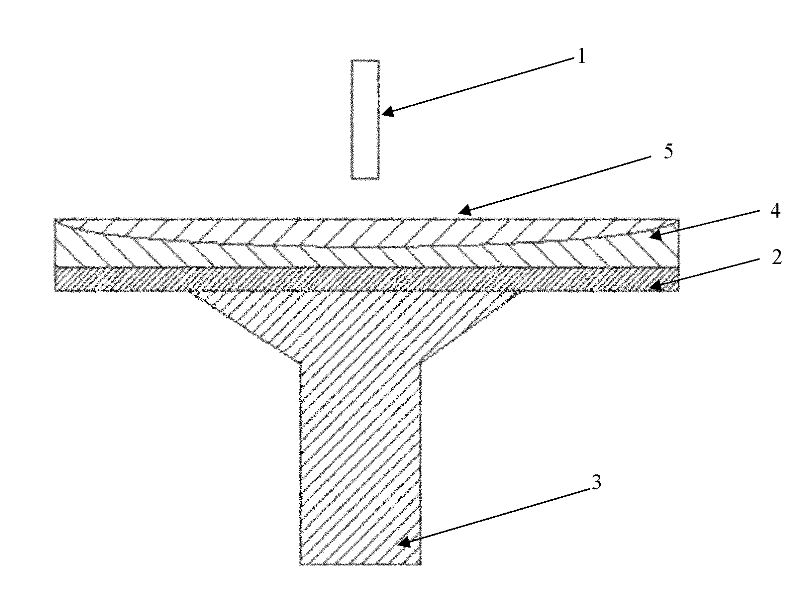

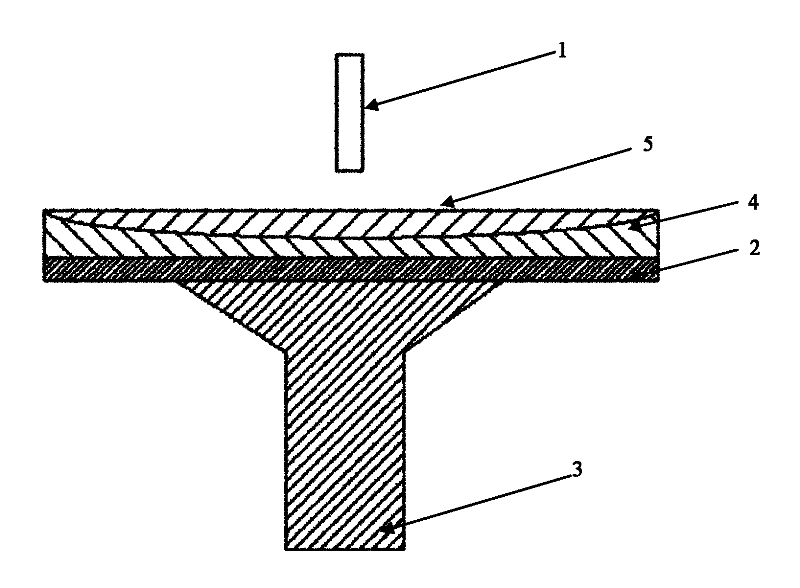

Thick Film Spin Coating Method for Semiconductor Packaging

ActiveCN102259083ALow retrofit costChange rotation speedLiquid surface applicatorsSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The invention relates to the field of semiconductors, and specifically relates to a spin-coating method for forming a thick film for packaging a semiconductor through two stages of special spin-coating on a semiconductor wafer. Specifically, a special two-stage coating method is adopted for packaging the semiconductor. Through complementation of different film thicknesses and forms of the films coated in the two stages, homogeneity of the thick film for packaging is achieved. In the first coating stage, the cement is coated in a manner that the film turns thicker from the center to the edge, that is to say, the cement is coated in a manner that a cross section through the central point is in an inferior pattern. In the second coating stage, the cement is coated in a manner that the film turns thinner from the center to the edge, that is to say, the cement is coated in a manner that a cross section through the central point is in a convex pattern. With the two-stage special coating method provided by the invention, a film coating requirement of thick high-viscosity film packaging technology is satisfied, and a defect of prior two-stage coating technologies is solved.

Owner:SHENYANG KINGSEMI CO LTD

Heparin pump

InactiveCN103830785AImprove reliabilitySimple structureDialysis systemsMedical devicesHeparin InjectionDrive shaft

The invention discloses a heparin pump. The heparin pump comprises a casing, a machine frame, a stepping motor, a control circuit board, a lead screw, a lead screw nut, a guide rail and a sliding block connection block, wherein the machine frame is fixed in the casing, the stepping motor and the control circuit board of the stepping motor are arranged on a motor installation plate of the machine frame, one tail end of the lead screw is directly connected with a driving shaft of the stepping motor, the other tail end of the lead screw is in supporting connection with a supporting sleeve, the lead screw nut is in threaded connection with the lead screw, the lead screw nut is fixed to the nut connection block, the guide rail is fixed to the side plate of the machine frame, and the sliding block connection block is arranged on the guide rail. A spring with preset pressure is compressed in an inner hole of the sliding block connection block by the nut connection block through an axial retainer ring, and one tail end of the sliding block connection block is fixedly connected with a push rod for directly pushing an injector matched with the heparin pump in use. The heparin pump is simple and reliable in structure and has the functions of blockage, empty liquid warning, fast heparin injection and slow heparin injection.

Owner:GUANGZHOU JIHUA MEDICAL APP & INSTR

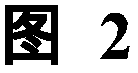

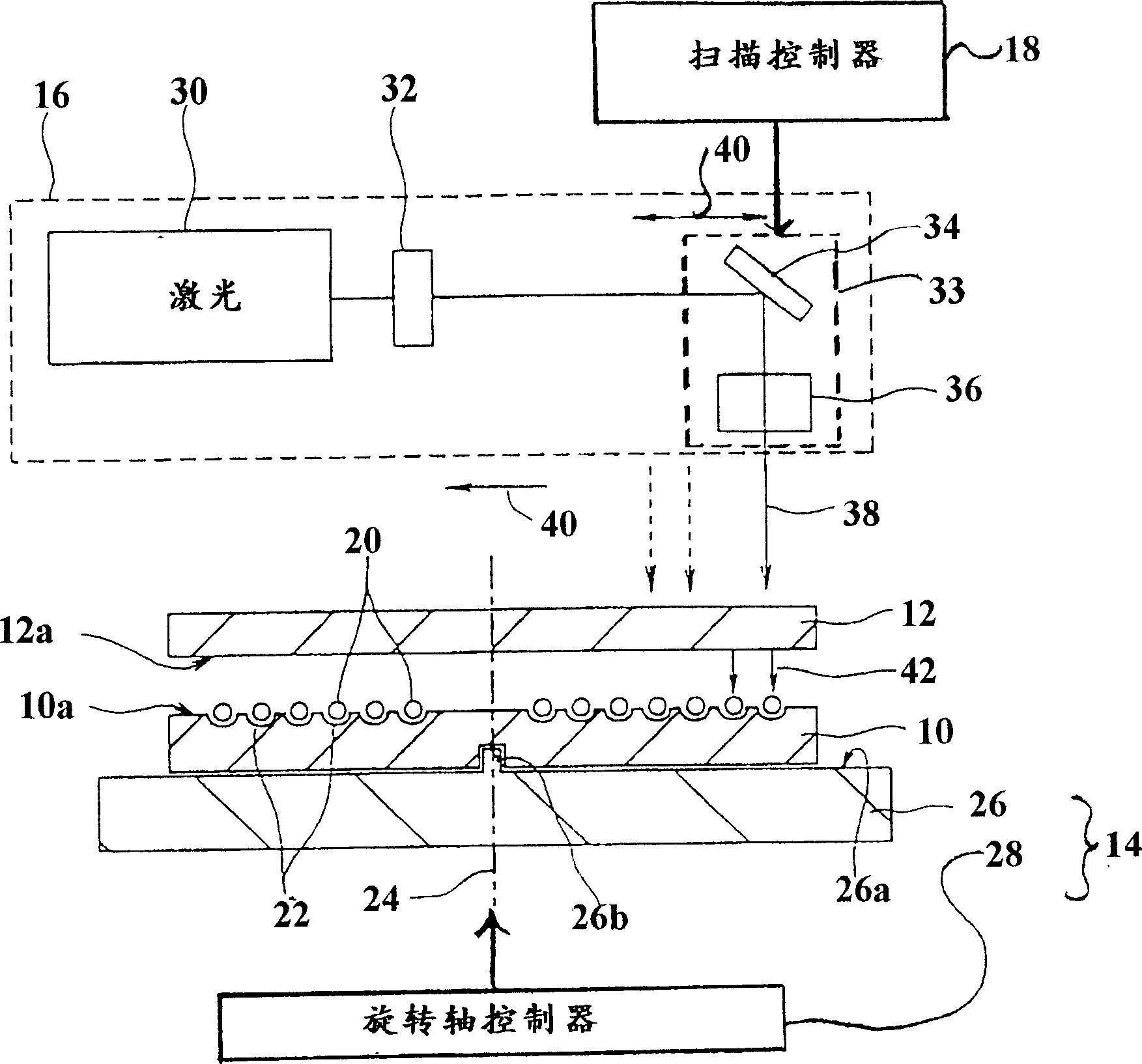

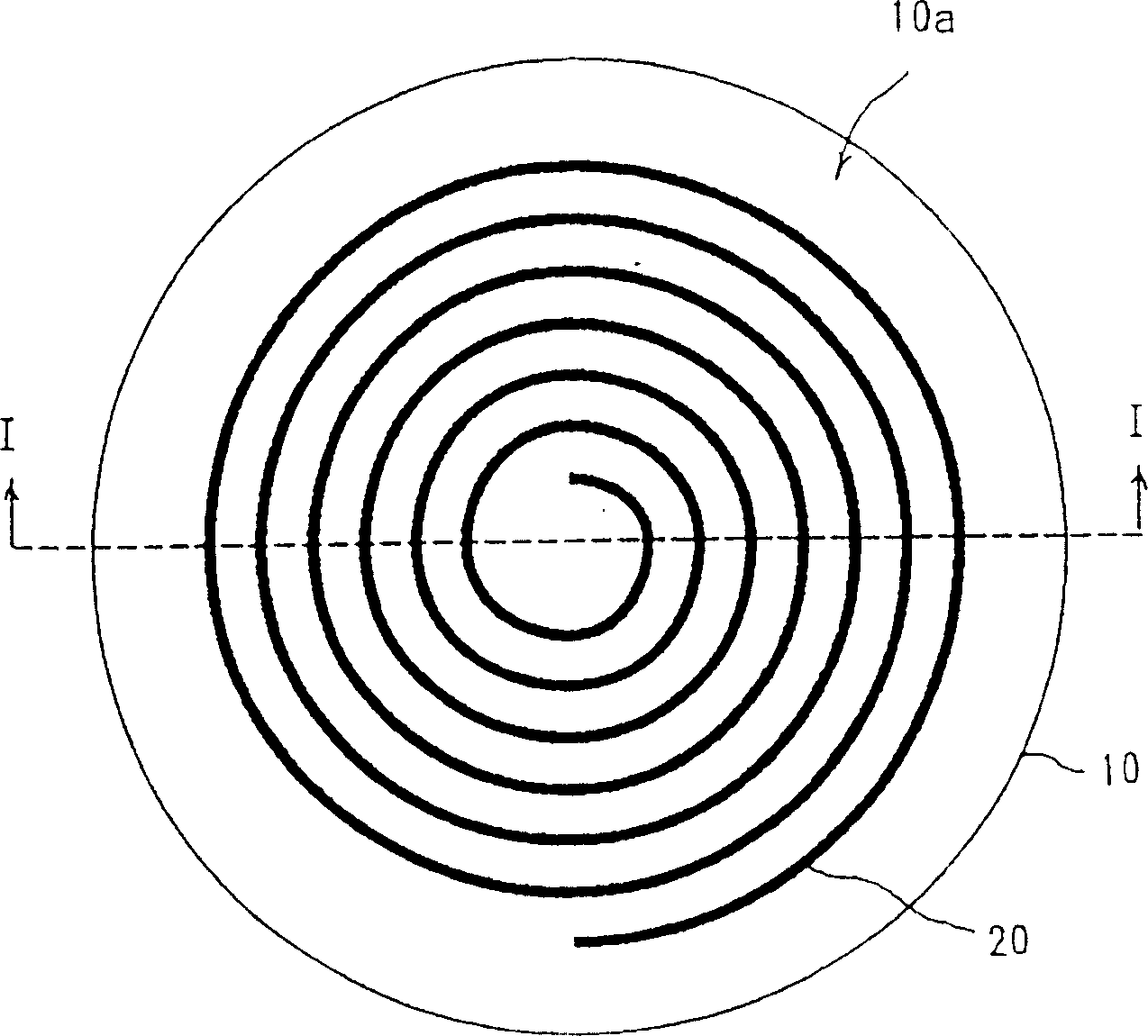

Optical filter

InactiveCN1515917AChange rotation speedFinal product manufacturePhotomechanical apparatusFiberRefractive index

An optical filter comprises a fiber holder (10) having plane surface, on which a spiral groove (22) is; and a optical fiber (20) fixed in said spiral groove (22) and having refractive index modulated periodically.

Owner:OKI ELECTRIC IND CO LTD

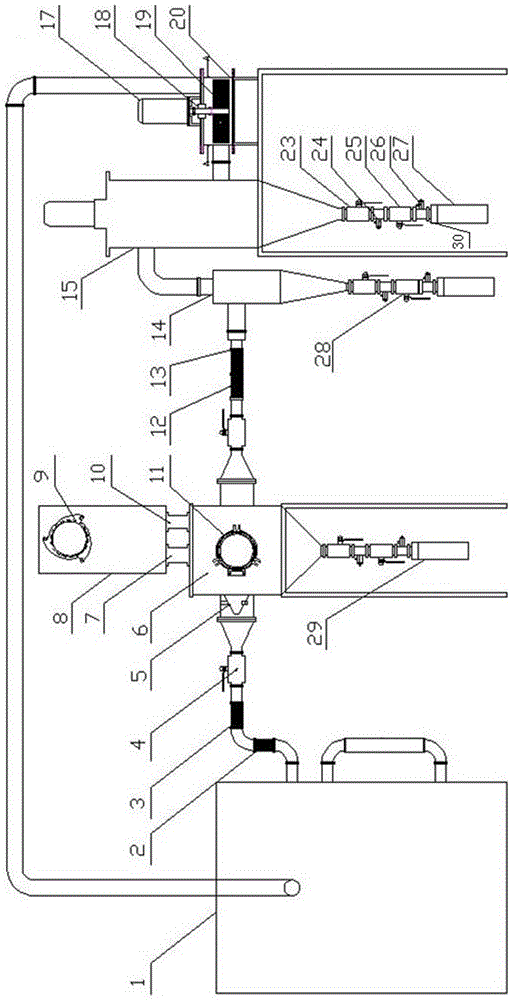

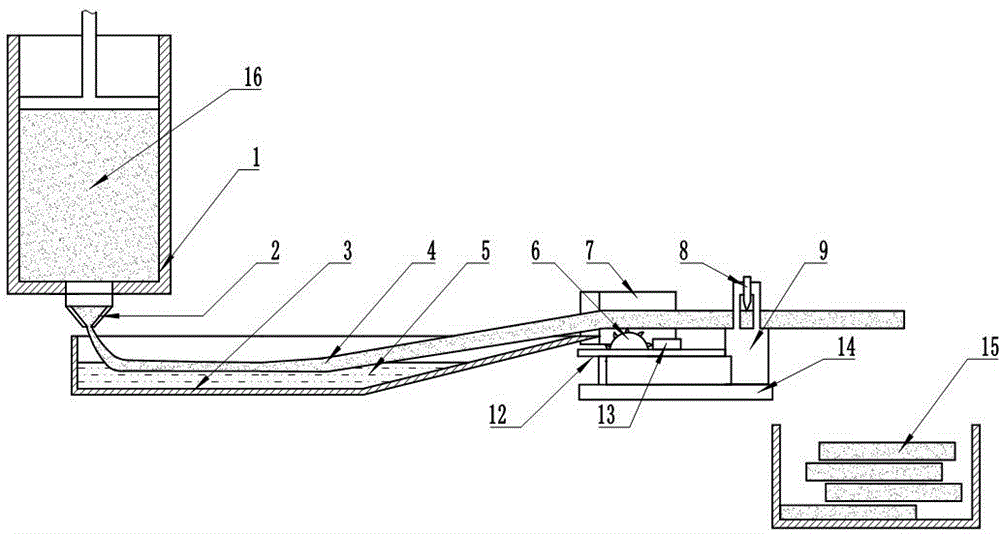

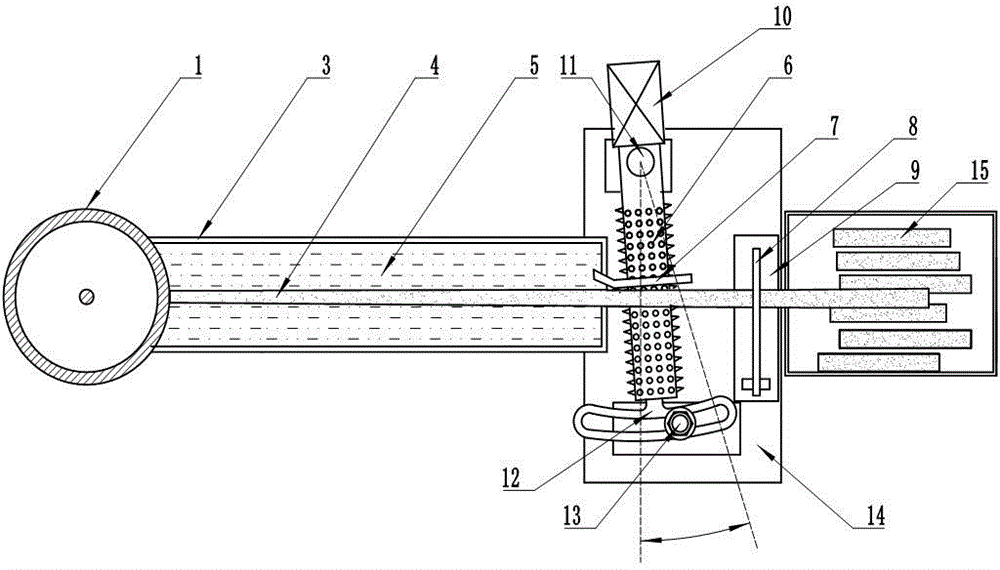

Equipment for preparing nano powder by electrical explosion method

ActiveCN106807310AChange rotation speedAchieve straightening and conveyingEnergy based chemical/physical/physico-chemical processesMicroballoon preparationElectricityNanoparticle

The invention discloses equipment for preparing nano powder by an electrical explosion method, and belongs to the field of nanomaterial preparation. The equipment aims at solving the problem that the conventional nano powder production equipment has a strict requirement for an insulating structure and an insulating material of a high-voltage part. The equipment comprises a nano powder reaction mechanism, an electrical explosion generation mechanism, a wire feeding mechanism matched with the nano powder reaction mechanism, an air cooler, a first connecting tube, a first insulating tube, a second connecting tube, a second insulating tube and a third connecting tube. According to the equipment, instant high voltage is generated by electrodes, so that materials in an explosion reaction cavity react to generate corresponding nano particles. Due to an improvement of a structure, the working voltage of the equipment is equal to or lower than 25KV, and a high-voltage part has a very low requirement for a high-voltage structure and a withstand voltage material. In addition, raw materials of the equipment are filamentary materials and non-insulators, so that the equipment has the characteristics of wide raw material source and high adaptability, and has good universality for various filamentary non-insulator materials.

Owner:四川弘博新材科技股份有限公司

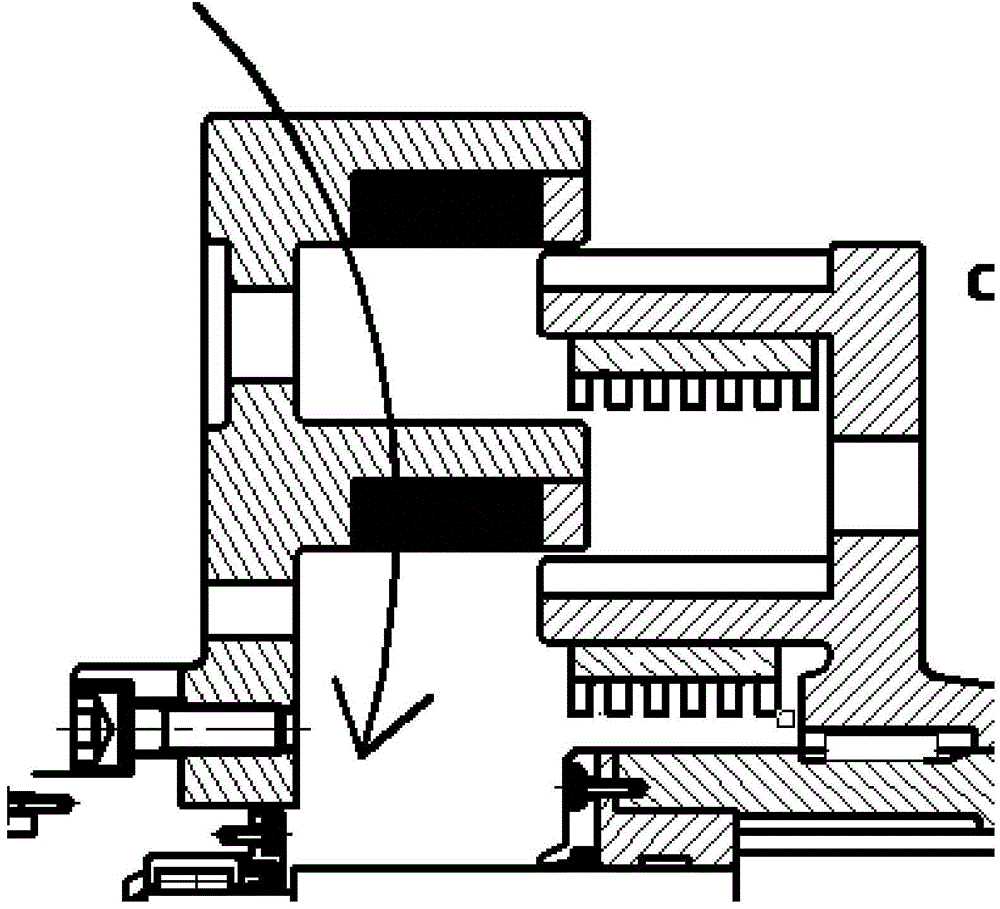

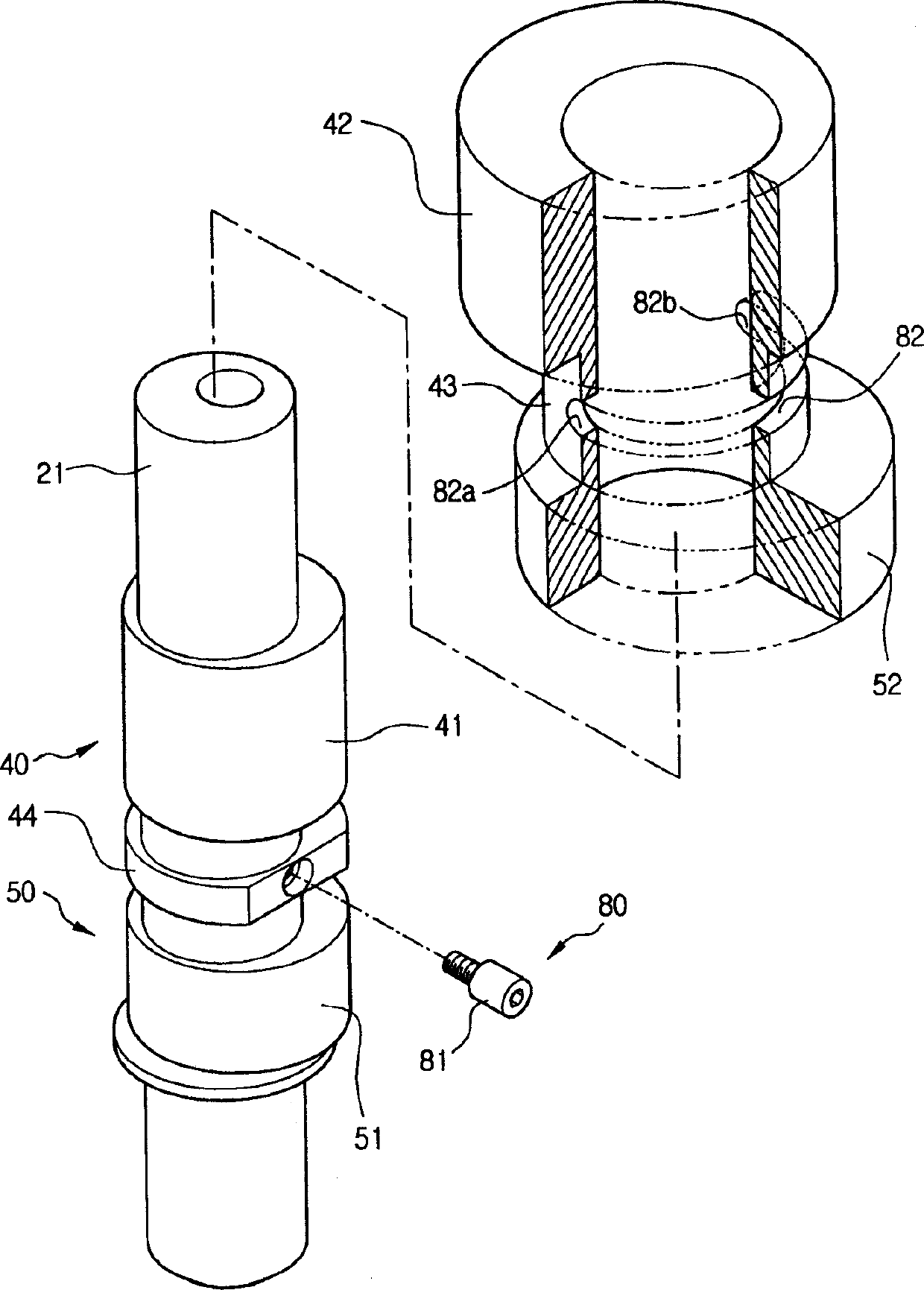

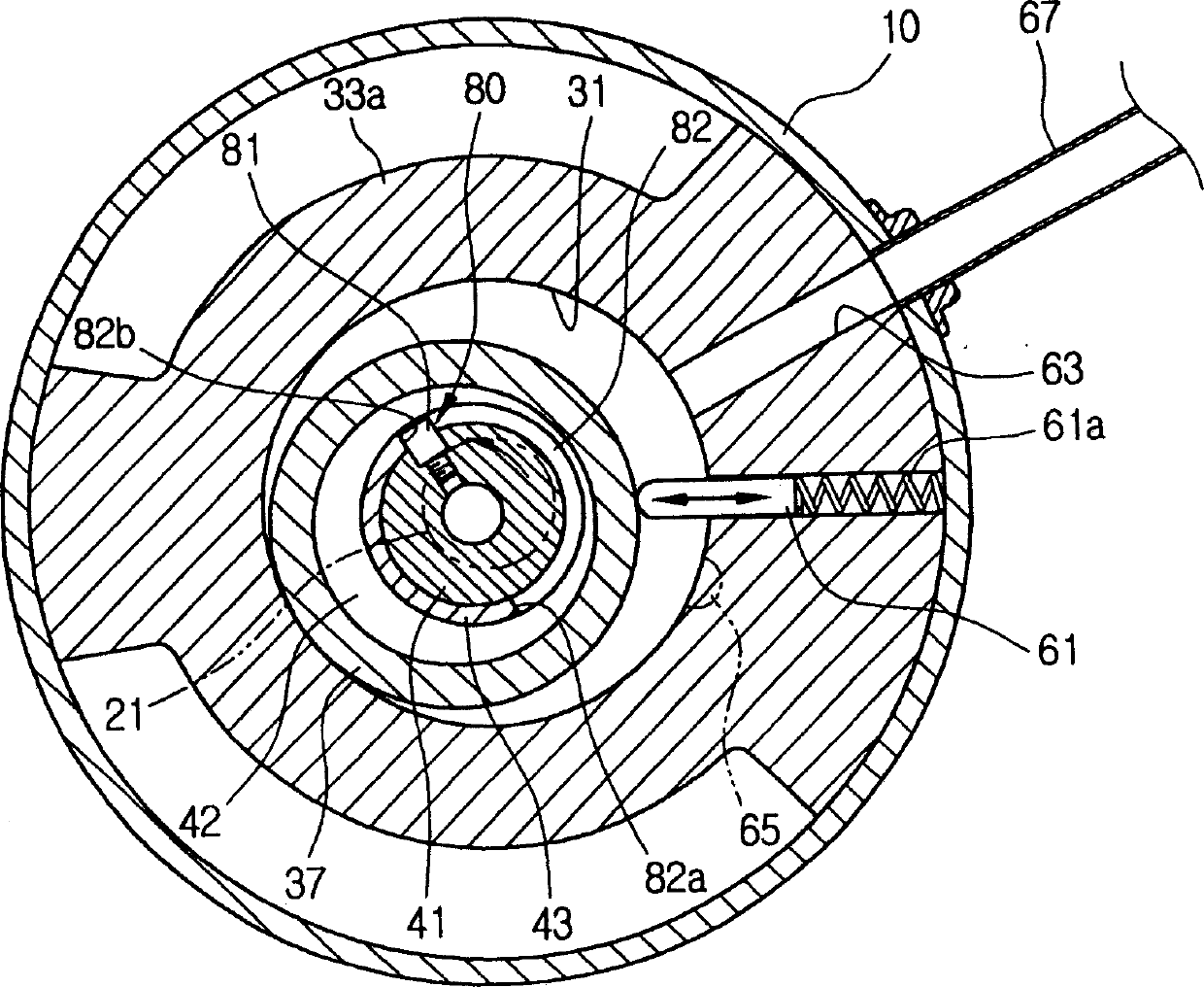

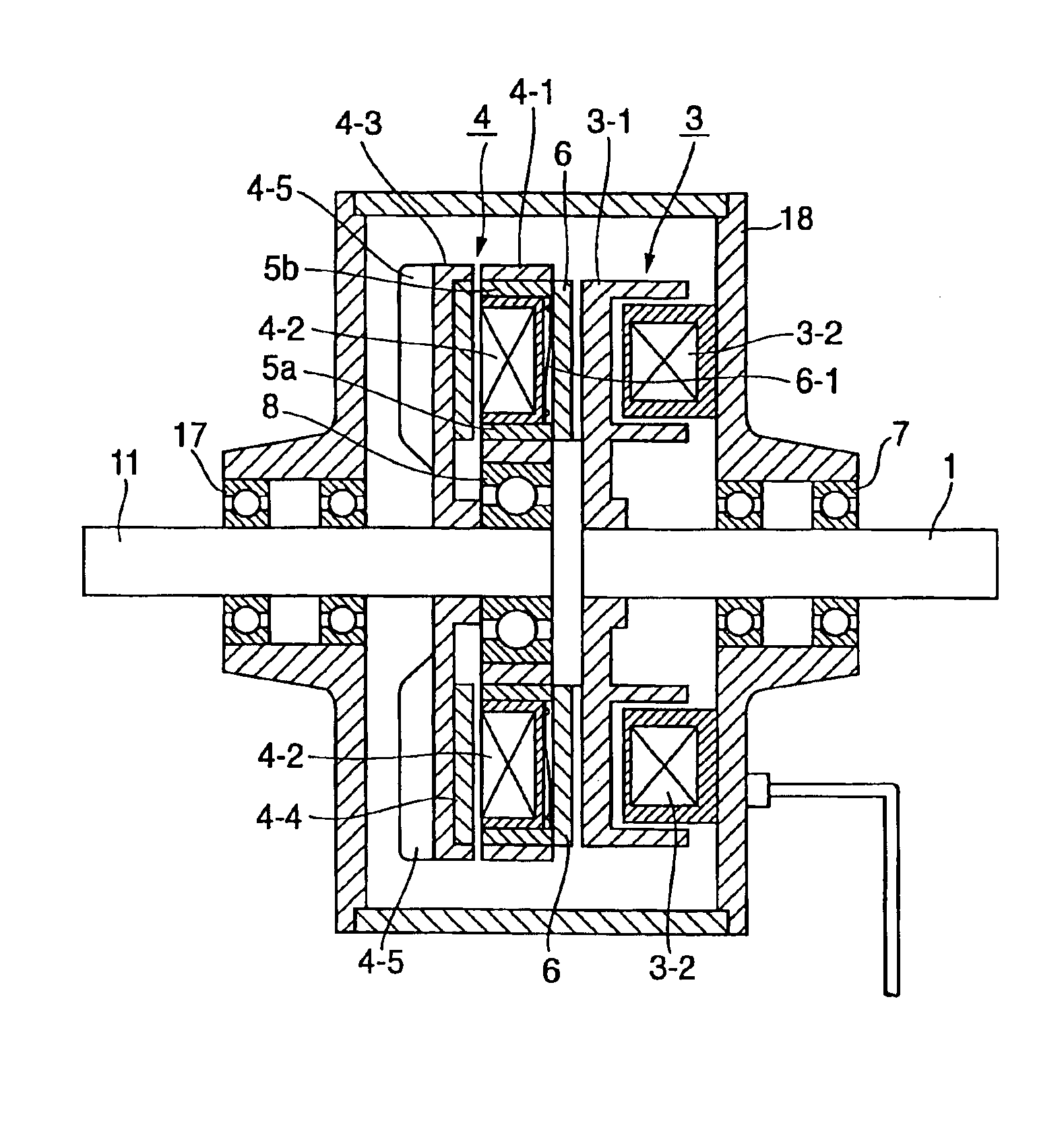

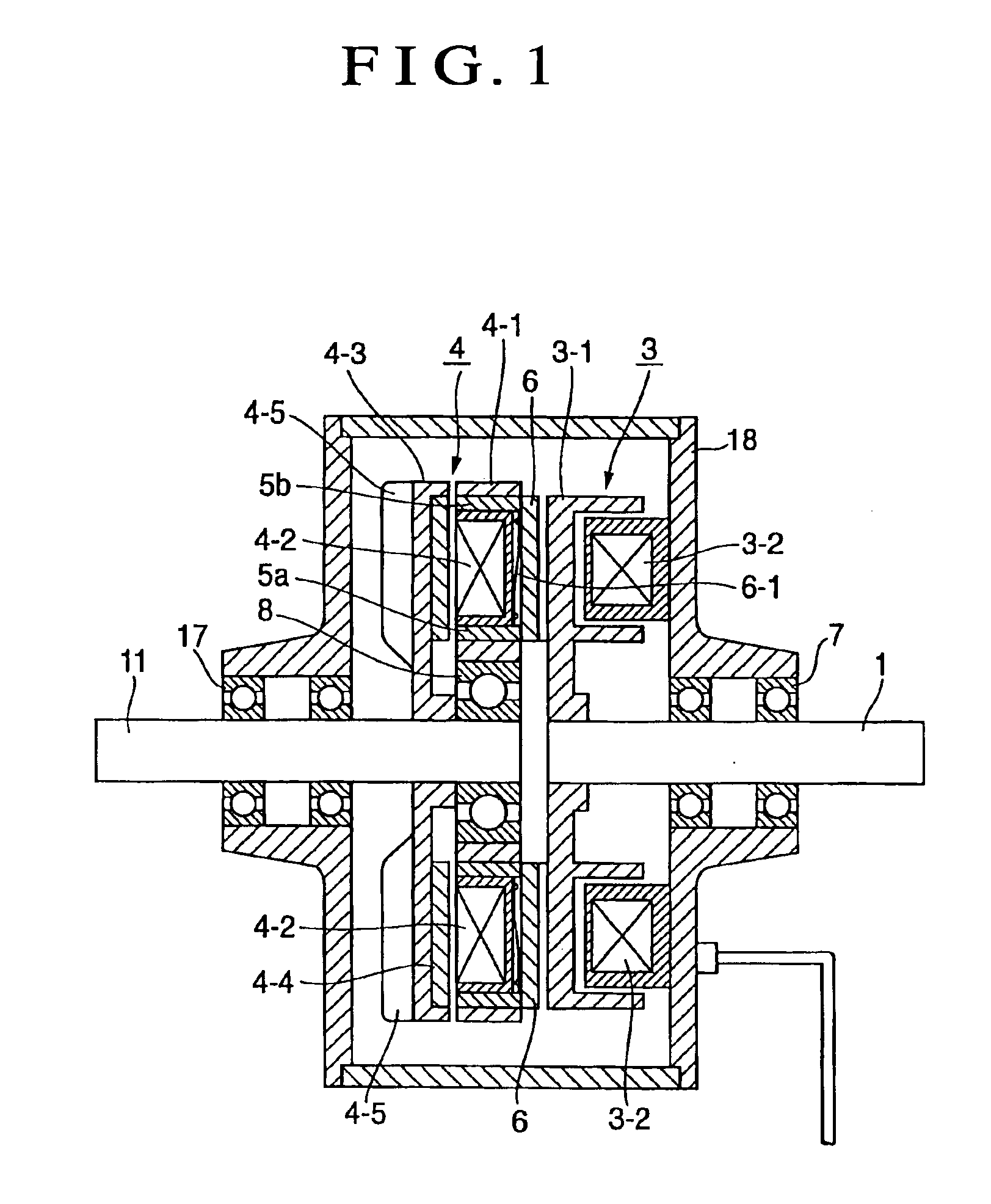

Magnet type clutch device or magnet type fan clutch device

InactiveUS6935477B2Reduce fan noiseIncreased fuel costMechanical actuated clutchesMagnetically actuated clutchesElectromagnetic clutchCoupling

The invention provides a magnet type clutch device or a magnet type fan clutch device able to arbitrarily change the rotation speed of a fan by switching and controlling the directions of magnetic fluxes of a permanent magnet and an electromagnetic clutch. The magnet type clutch device or the magnet type fan clutch device constructed by integrating the electromagnetic clutch and a magnet coupling using the permanent magnet is characterized in that a magnetic loop element is assembled into a permanent magnet rotating body and the rotation speed of the fan, etc. can be changed by switching and controlling the magnetic flux direction of the electromagnetic clutch.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

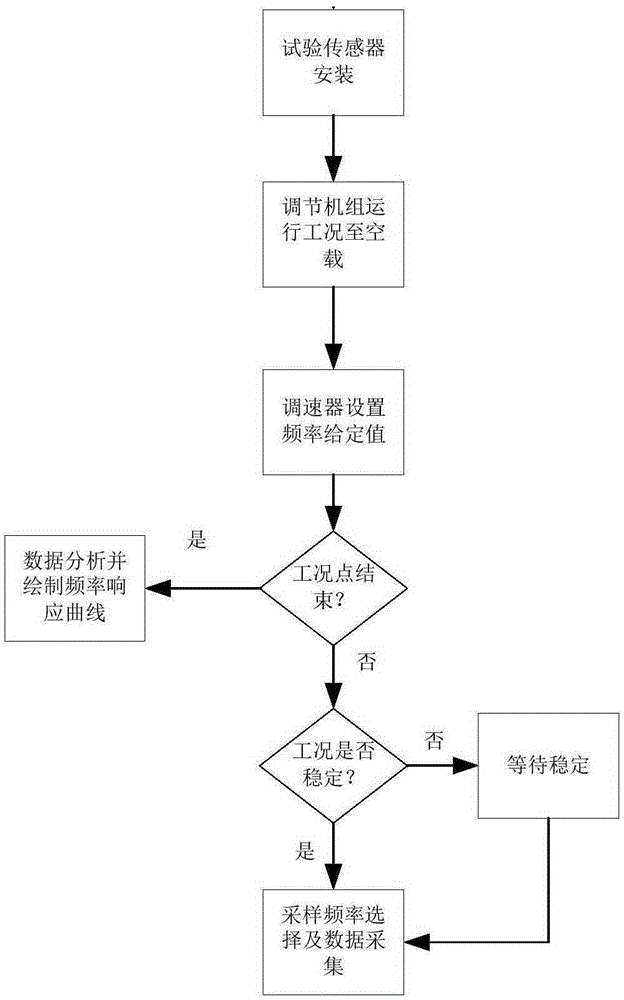

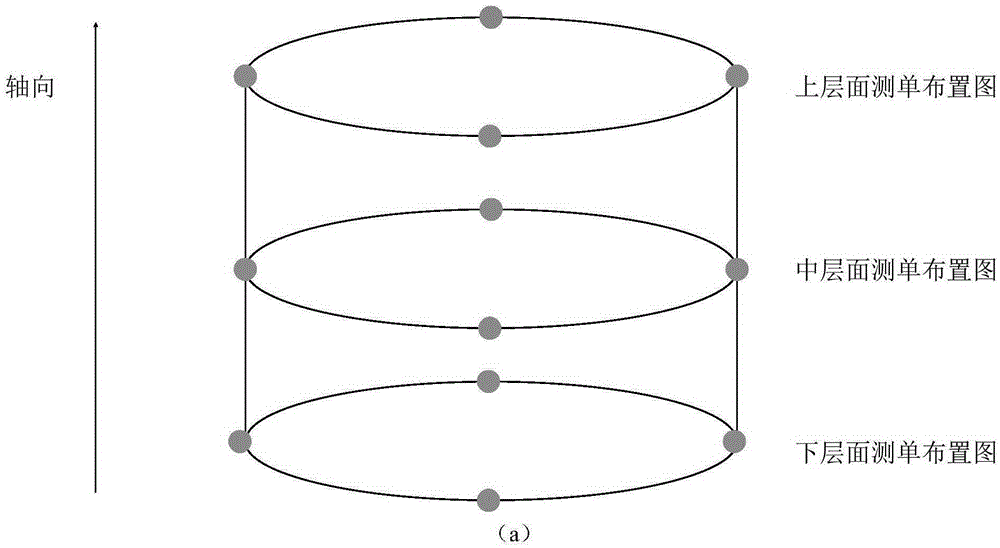

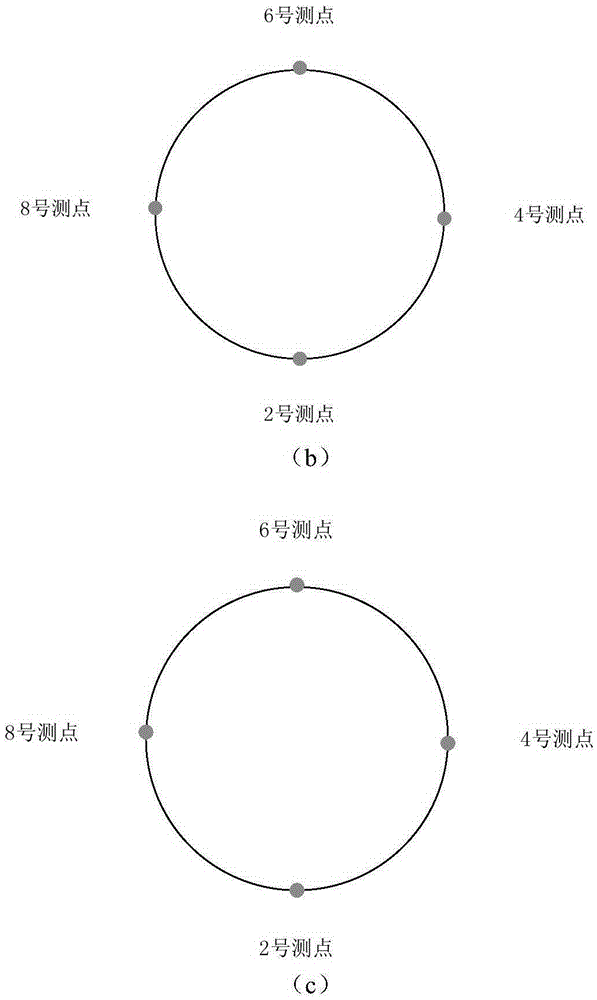

Method for measuring inherent frequency of stator core/support system of water turbine generator prototype

ActiveCN105277348AFlexible measuring point arrangementEasy to measureMachine part testingSubsonic/sonic/ultrasonic wave measurementStatorDynamo

The invention discloses a method for measuring the inherent frequency of a stator core / support system of a water turbine generator prototype. Through arrangement of an automatic excitation regulator, the terminal voltage of a hydropower unit is kept at a rated value. By setting a given value of the zero load frequency, the method changes the rotational speed of a generator rotor. Thereby the method changes an excitation input of the stator core / support system, i.e. the generator rotor rotation magnetic field force wave rotational speed, and measures a frequency response function of the stator core / support system of the water turbine generator prototype under electromagnetic force excitation of different frequency. According to the frequency response function, a frequency value corresponding to the maximum amplitude can be found, and the frequency value is the inherent frequency of the stator core / support system of the water turbine generator prototype. The method only needs to stop the generator and install a sensor, does not need to apply for heavy maintenance, is simple and convenient in measurement, and thus has a wide application prospect in the field of inherent frequency measurement of stator core / support systems of water turbine generator sets.

Owner:STATE GRID CORP OF CHINA +2

Belly massage belt

The invention provides a belly massage belt, belongs to the technical field of physical therapy device, aims at solving the problems of bad massage effect, irreconcilable massage strength and blood circulation influenced by a massage device of the prior art, and provides the following scheme: the belt comprises a belt body, the belt body comprises a plurality of massage components, the massage components comprise rotary motors, a rotary shaft, massage rods and massage balls. The rotary motors drive the rotary shaft, the base ends of the massage rods are connected with the rotary shaft in a hinge mode, the free ends of the massage rods are connected with the massage balls in a fixation mode, a fixing bar and location-limited rods are placed under the rotary shaft, one ends of the location-limited rods are connected with the fixing bar in a hinge mode, and the other ends of the location-limited rods are connected with the massage rods. A sucking disc is connected with the lower end of the fixing bar in a fixation mode. Both the rotary speed and direction are same when the rotary motors in the belt body work, and the initial phase difference of the rotation of the massage rods drivenby two adjacent rotary motors is 90 degree. The belt is applicable to belly massage.

Owner:ZUNYI NORMAL COLLEGE

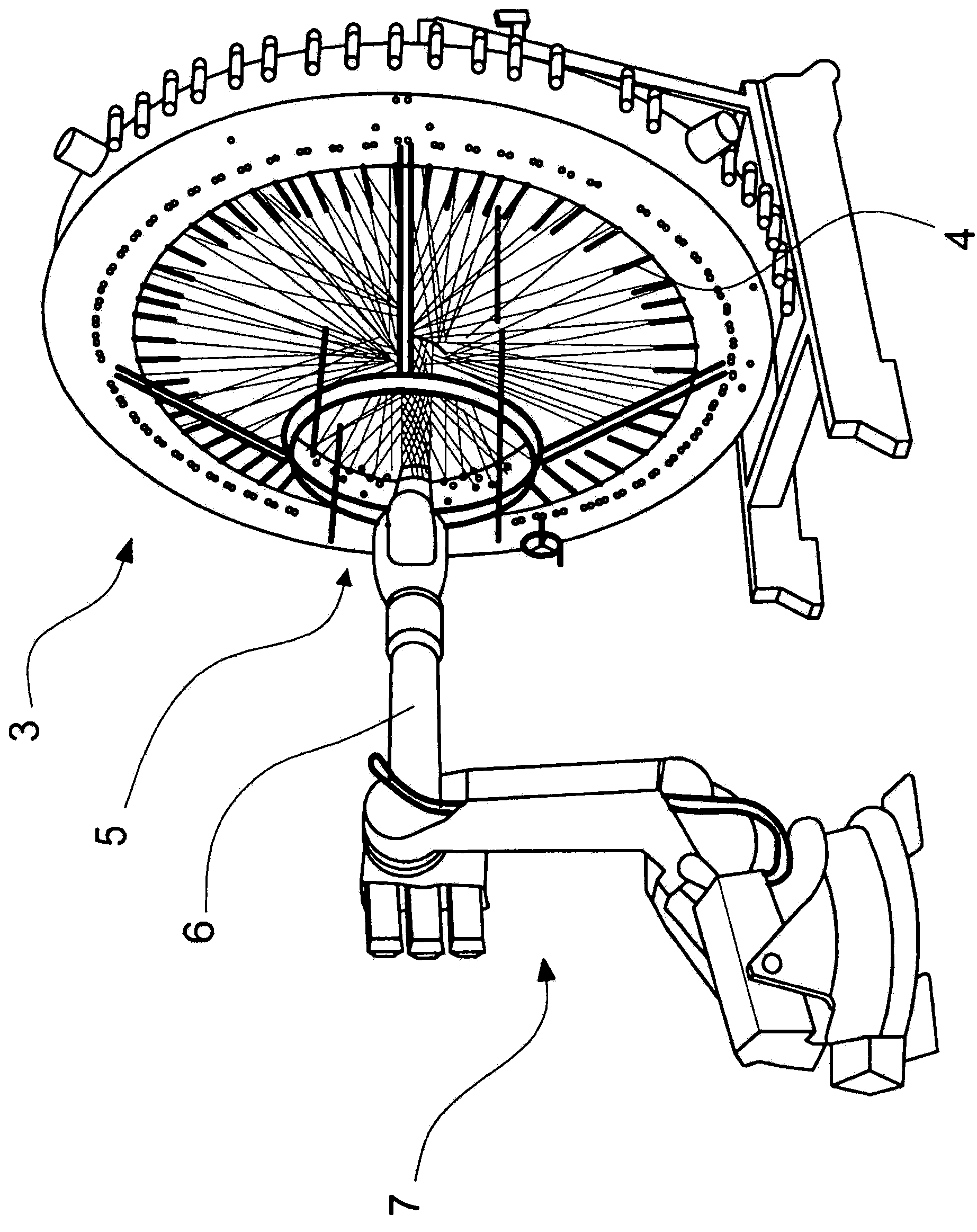

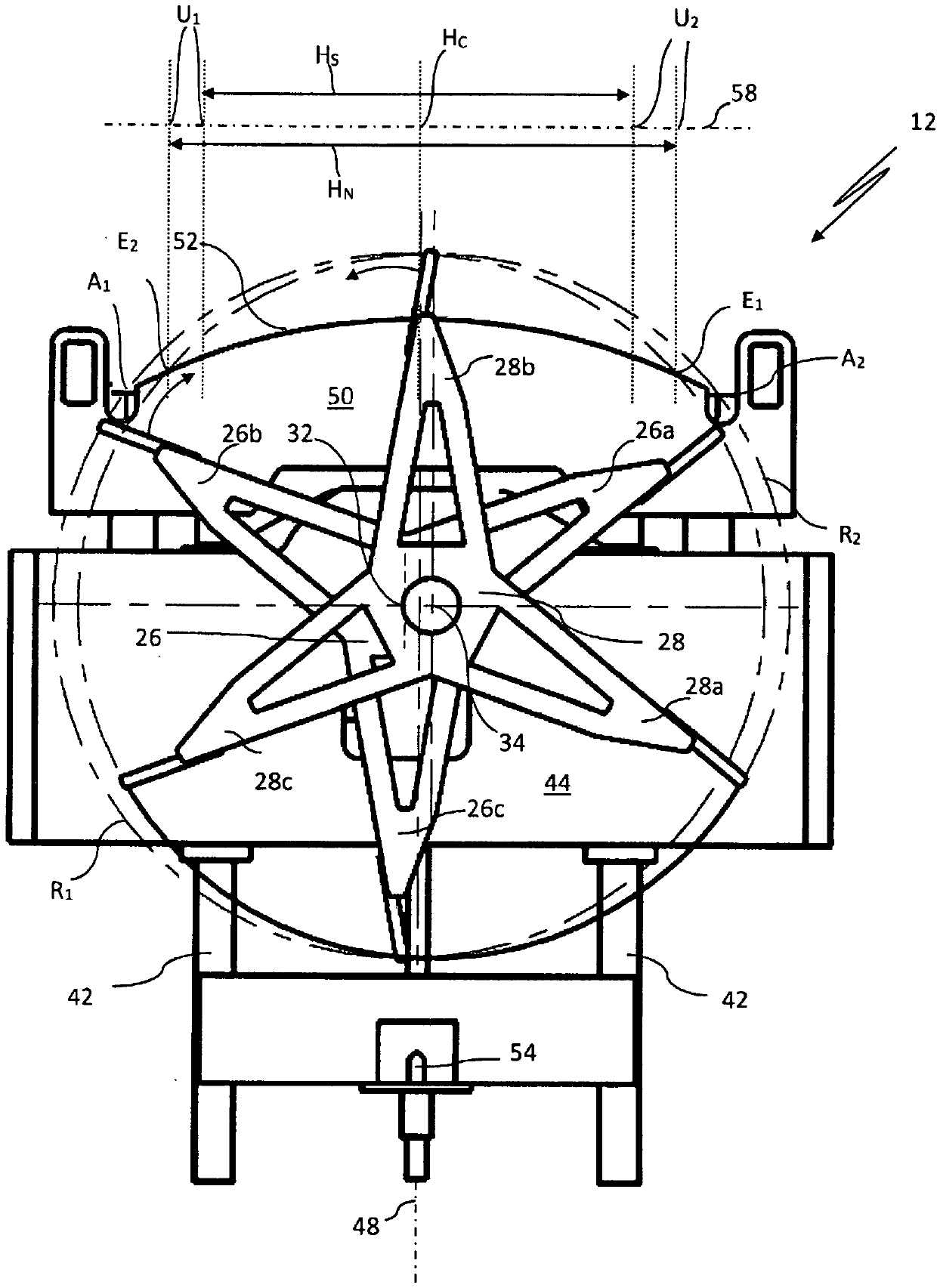

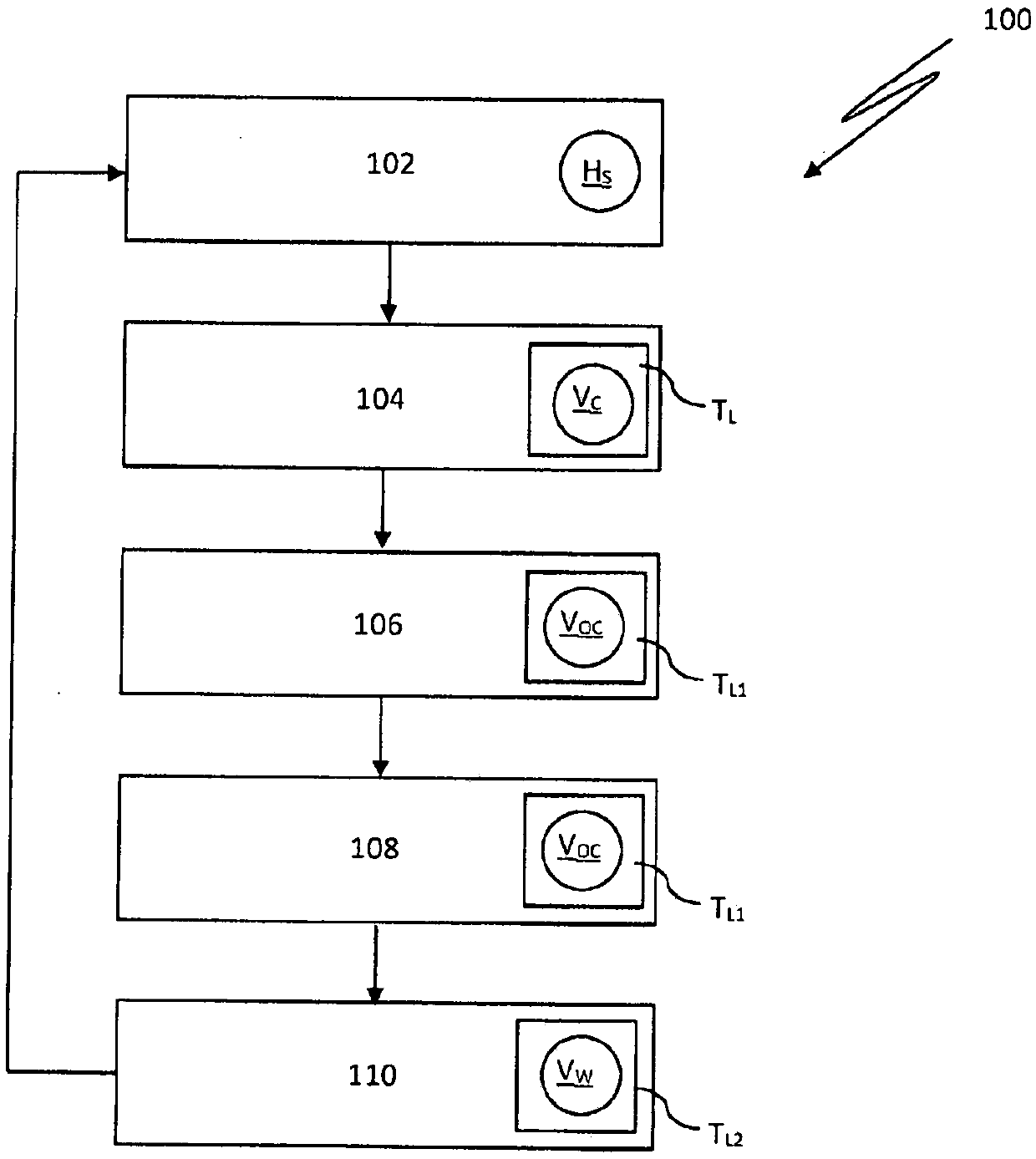

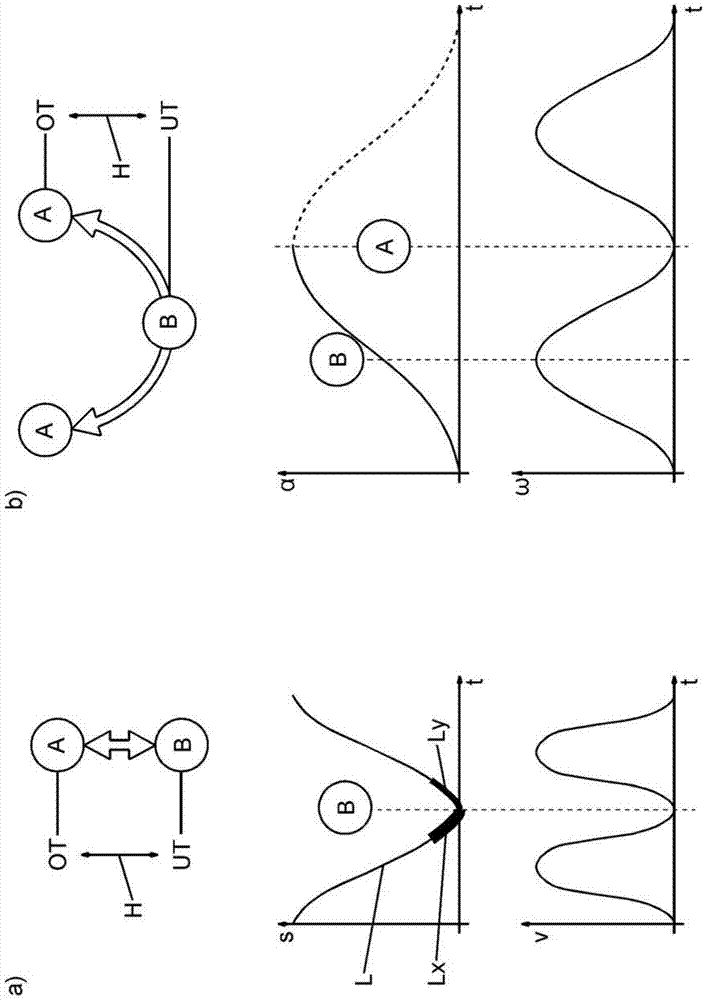

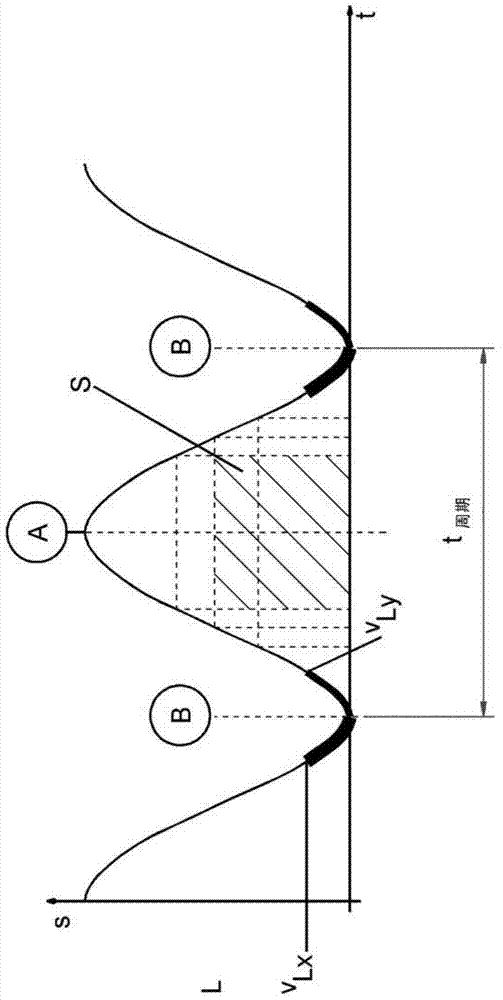

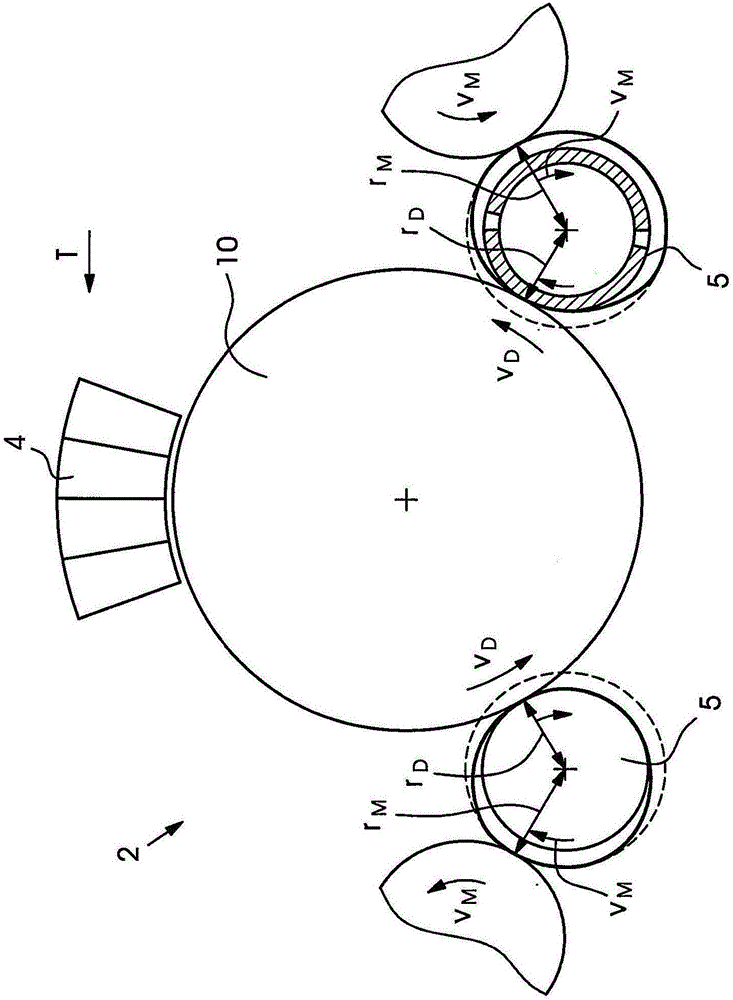

Method for controlling an impeller-type thread laying device, impeller-type thread laying device, and winding machine

The invention relates to a method (100) for controlling a thread laying device comprising two impellers (26, 28) which can be driven in opposite directions in order to move a thread to be wound on a rotating spool back and forth between two turning points (U1, U2) along the spool longitudinal axis by means of a traversing movement with a target traversing stroke width (Hs) of the thread laying device, said target traversing stroke width differing from a base traversing stroke width (HN). According to the invention, each impeller (26, 28) being moved in the idle traversing stroke, i.e. each idle traversing stroke impeller (26, 28), is first accelerated or braked to an overcompensation angular speed (Voc) in the idle traversing stroke interval (TL) of the impeller, said overcompensation angular speed being determined on the basis of a theoretical constant compensation angular speed (Vc) required to transfer the thread in the next turning point (U1, U2) of the traversing movement of the thread. The impeller is then moved at its specified operating angular speed (Vw) in order to receive the thread from the other impeller (26, 28) guiding the thread at the operating angular speed (Vw) in the next turning point (U1, U2) of the traversing movement of the thread. The invention further relates to a thread laying device and to a winding machine comprising such a thread laying device.

Owner:SSM萨罗瑞士麦特雷有限公司

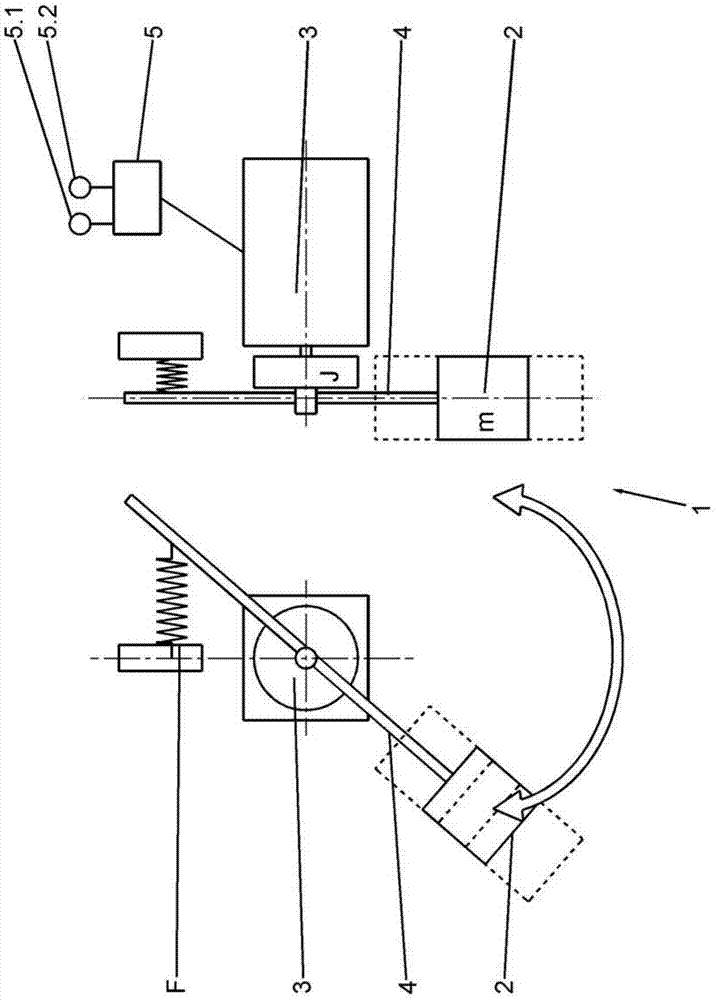

Method and device for operating a machine tool such as a press

A method for operating a machine tool such as a press includes determining and providing / storing energy for machining a work piece as available energy by considering a first value of the energy to be applied of at least one element of the machine tool to store energy. Available energy provided in a section or in a partial section of a motion sequence of a stroke element determined for machining the work piece is gathered. Part of the available energy of the energy to be applied for machining the work piece from an energy potential provided / stored in the machine tool is used. A second value for an effective required energy is formed via at least one energy-storing element. A control / regulation of different energy transfers or contents of individual drive components is influenced in an accelerating or decelerating manner during a sequence of the stroke element or during a path of a stroke to compensate for asymmetric loads.

Owner:舒乐绞扭机有限责任公司

Insulin pen storage box mounted on patient bedhead

PendingCN109893368AEasy to useConvenient treatmentShaking/oscillating/vibrating mixersInfusion syringesTherapeutic effectPediatrics

The invention discloses an insulin pen storage box mounted on a patient bedhead. The storage box comprises an insulin pen storage box main body, a storage mechanism, a quick shaking mechanism and an insulin pen, wherein the storage mechanism is embedded into and connected to the middle part of the insulin pen storage box main body; an installation fixing plate is embedded into and connected to oneside of the storage mechanism; a fixing screw penetrates through is and connected to the bottom of the installation fixing plate; the quick shaking mechanism is embedded into and connected to the inner part of the storage mechanism; the quick shaking mechanism can achieve the effect of shaking the insulin uniformly; through the arrangement of the quick shaking mechanism, the medical staff can conveniently shake the insulin in an inner container of the insulin pen uniformly, thereby improving the treatment effect of the insulin pen and realizing the effect that the storage mechanism can preserve the insulin pen; through the arrangement of the storage mechanism, the medical staff can conveniently store the insulin pen and the insulin pen is protected from being damaged, so that the safety of the insulin pen is improved and the insulin pen storage box has wide development prospects in the future.

Owner:QINGDAO CENT HOSPITAL

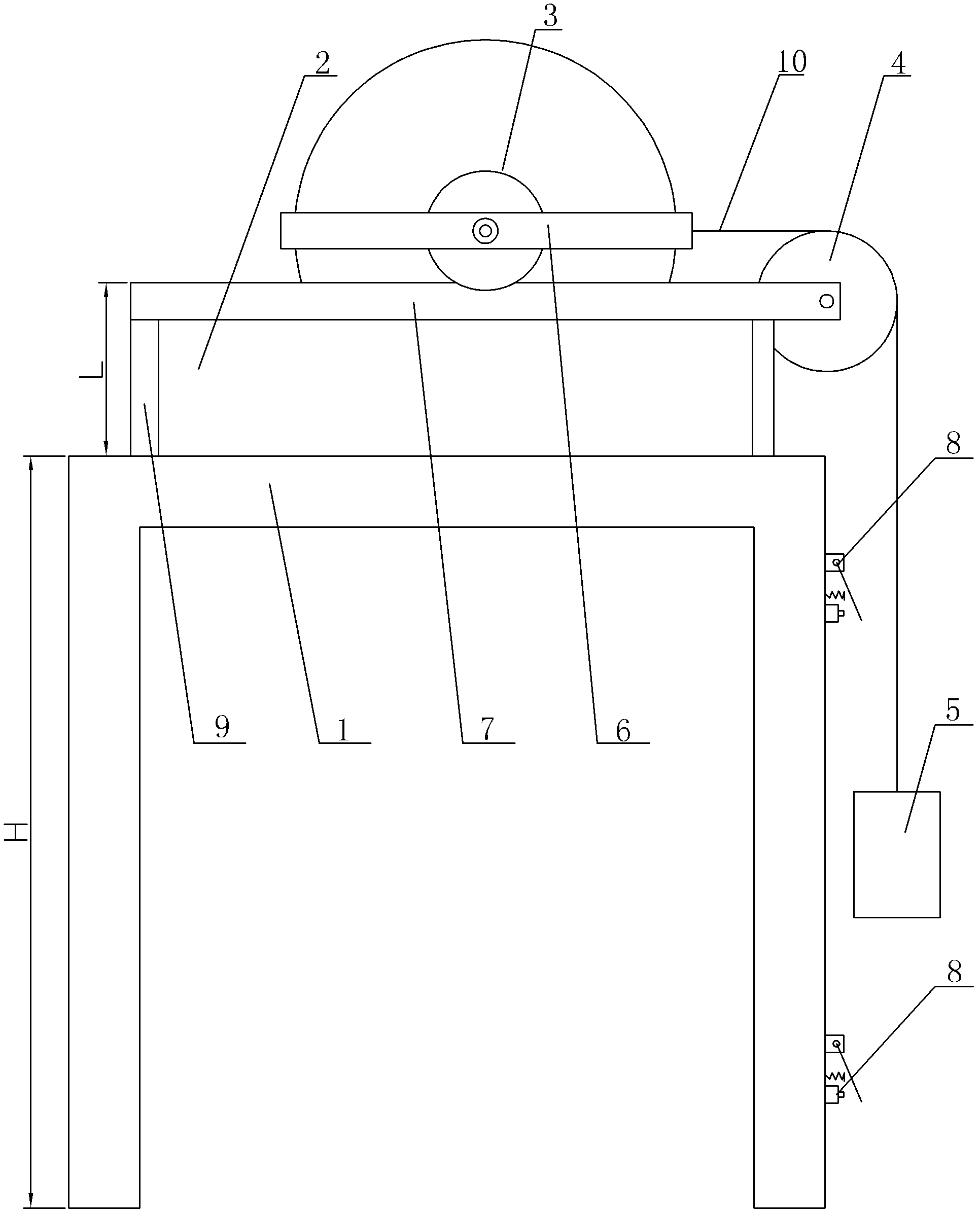

Method for testing and predicating wearing of excavating device cutter in soft soil environment

InactiveCN108387473ATest for wearReduce workloadUsing optical meansInvestigating abrasion/wear resistanceOptimal testWorkload

The invention a method for testing and predicating the wearing of an excavating device cutter in a soft soil environment. The method simulates the actual working condition of engineering through a test technique, and predicts the wearing of the cutter in the actual engineering. The method can be used to scientifically and effectively test the wearing condition of the excavating device cutter in the soft soil environment, the onsite inspection and maintenance of the cutter are guided through the test of the wearing of the cutter, and the actual wearing amount of the cutter is calculated to determine the replacing cycle of the cutter, so inspection and maintenance personnel has no need to frequently enter a pressure chamber in the engineering and detect, the workload is reduced, and the excavating engineering process is improved; and the method fully considers the characteristics of the influences of the soft soil on the wearing of the cutter, and the optimal test running time is determined through preliminary test to make the test result scientific and close to the actual working condition, so the error of the test is reduced to well guide the engineering practice.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

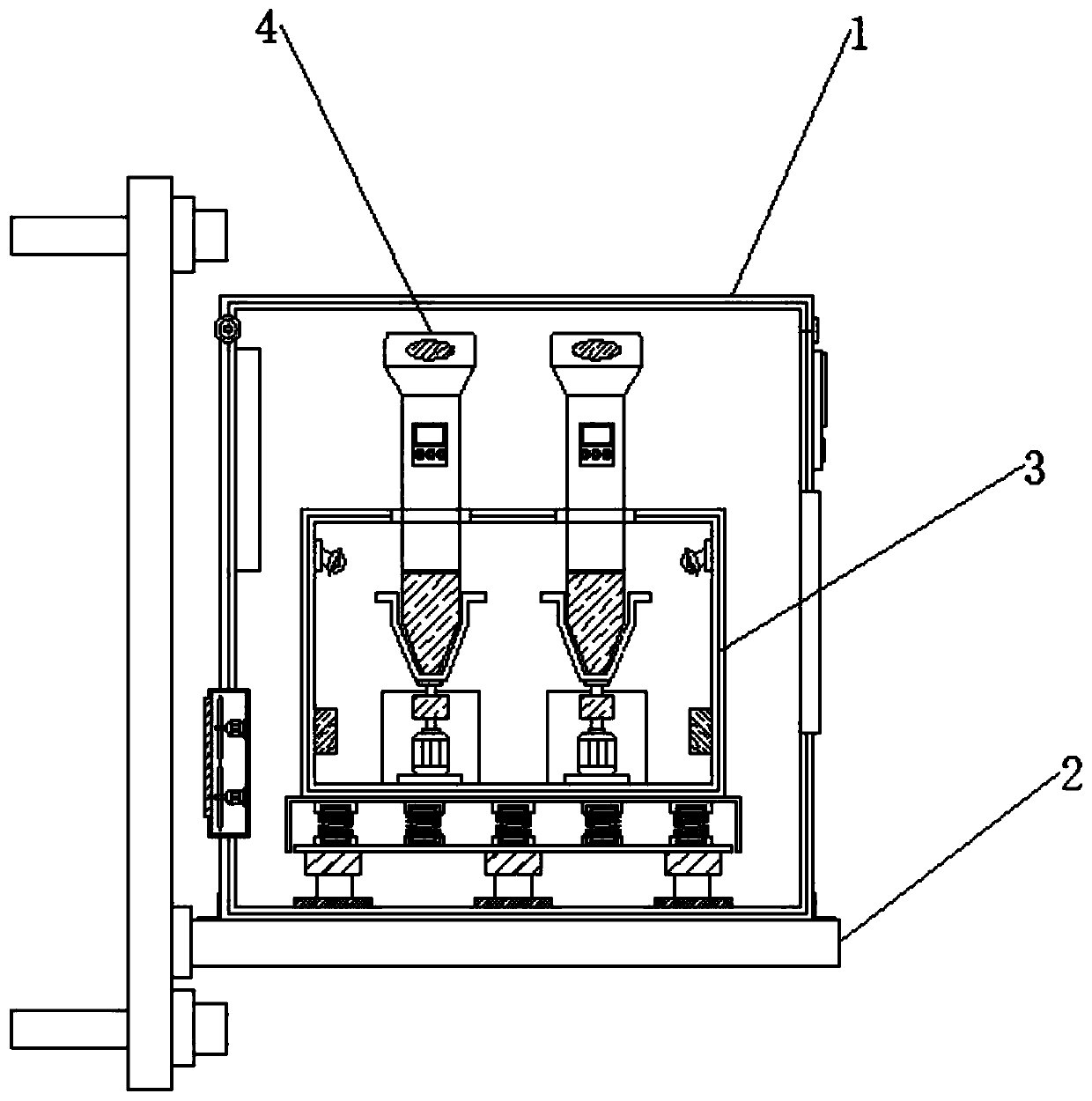

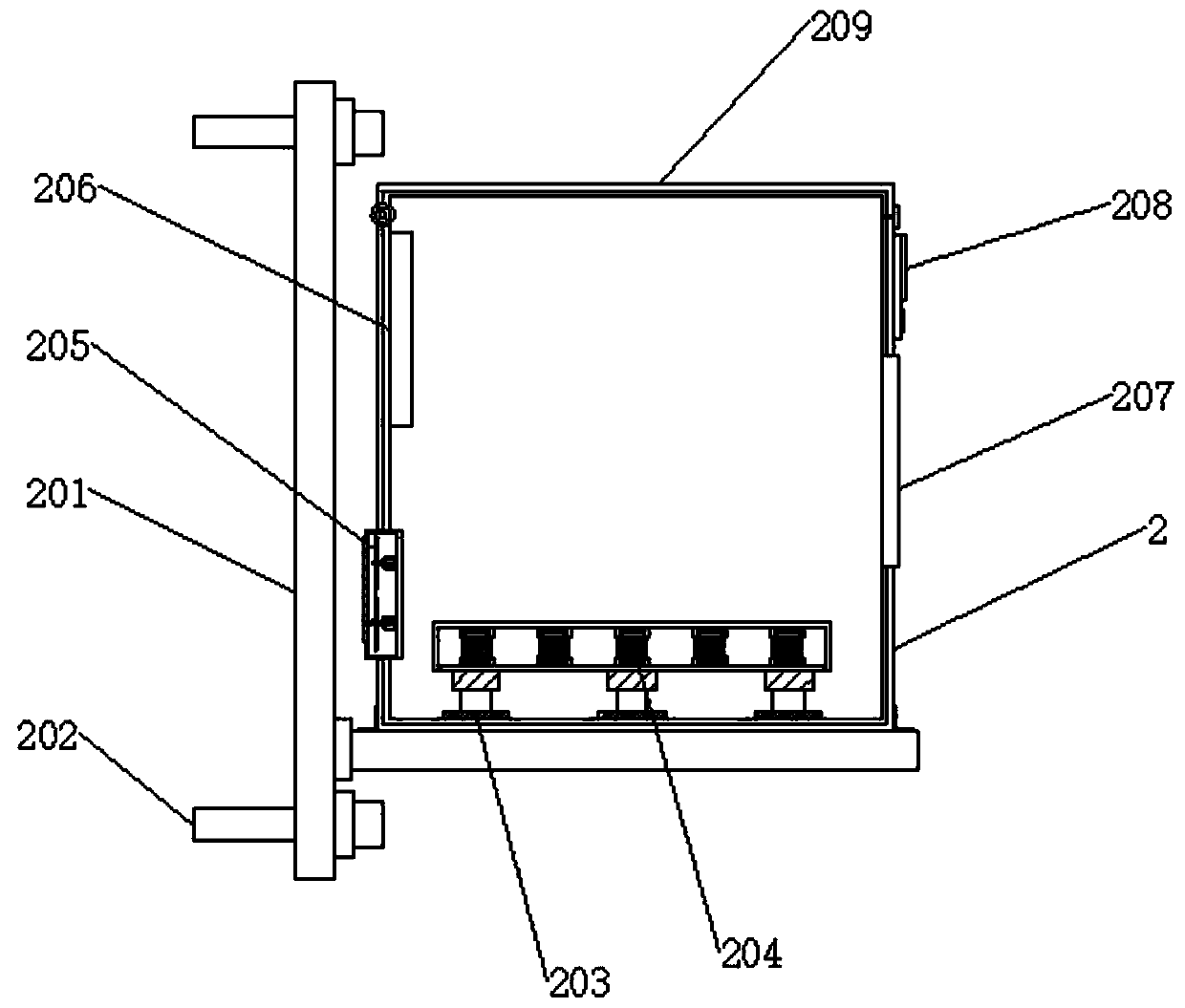

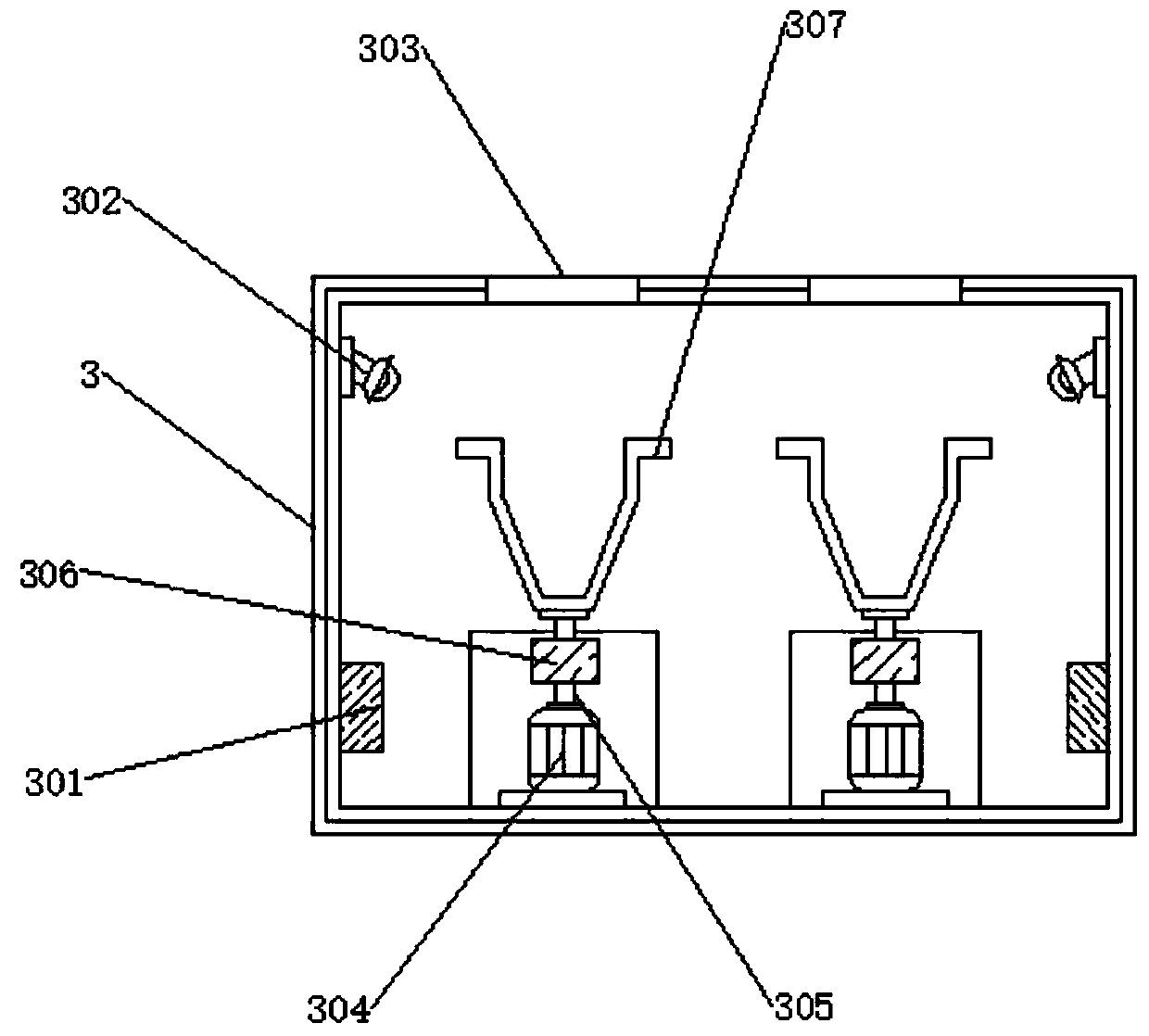

Charging and feeding device capable of swinging food at variable speed

The invention discloses a charging and feeding device capable of swinging food at a variable speed. A moving belt of a piston rod of a cylinder drives a rack to do reciprocating motion; the rack drives a gear to rotate; a cam arranged coaxially with the gear rotates at the same time. As the distances from the outer edges of the cam to the rotating shaft of the cam are different, a cam driven piece under the driving of the cam drives a material rod to rotate by regarding the rotating shaft as a basic point, and the linear reciprocating motion of the cylinder is changed into reciprocating swing under the action of the cam. In addition, as the flange of the cam is irregular, moving speeds of joints arranged on the material rod in a swinging process are inconsistent, and the speed can be changed when mixing materials are added. As the bracket is provided with a driving belt wheel in a hinged manner, materials while being conveyed can be mixed only by calculating the placing position of the materials while the materials are conveyed by a conveyor belt. Therefore, relatively high processing efficiency and relatively high processing precision are achieved.

Owner:CHONGQING JIDING FOOD

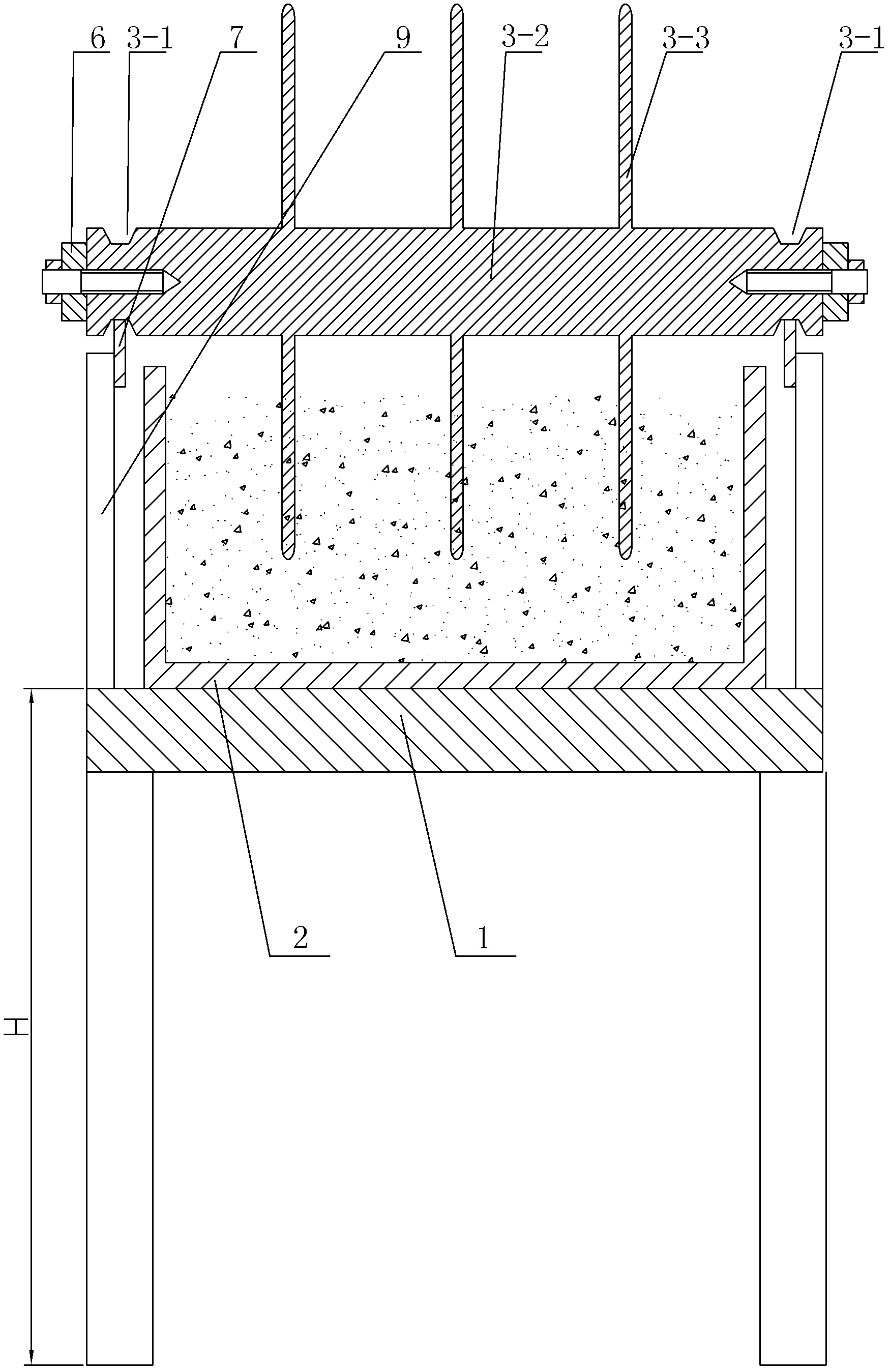

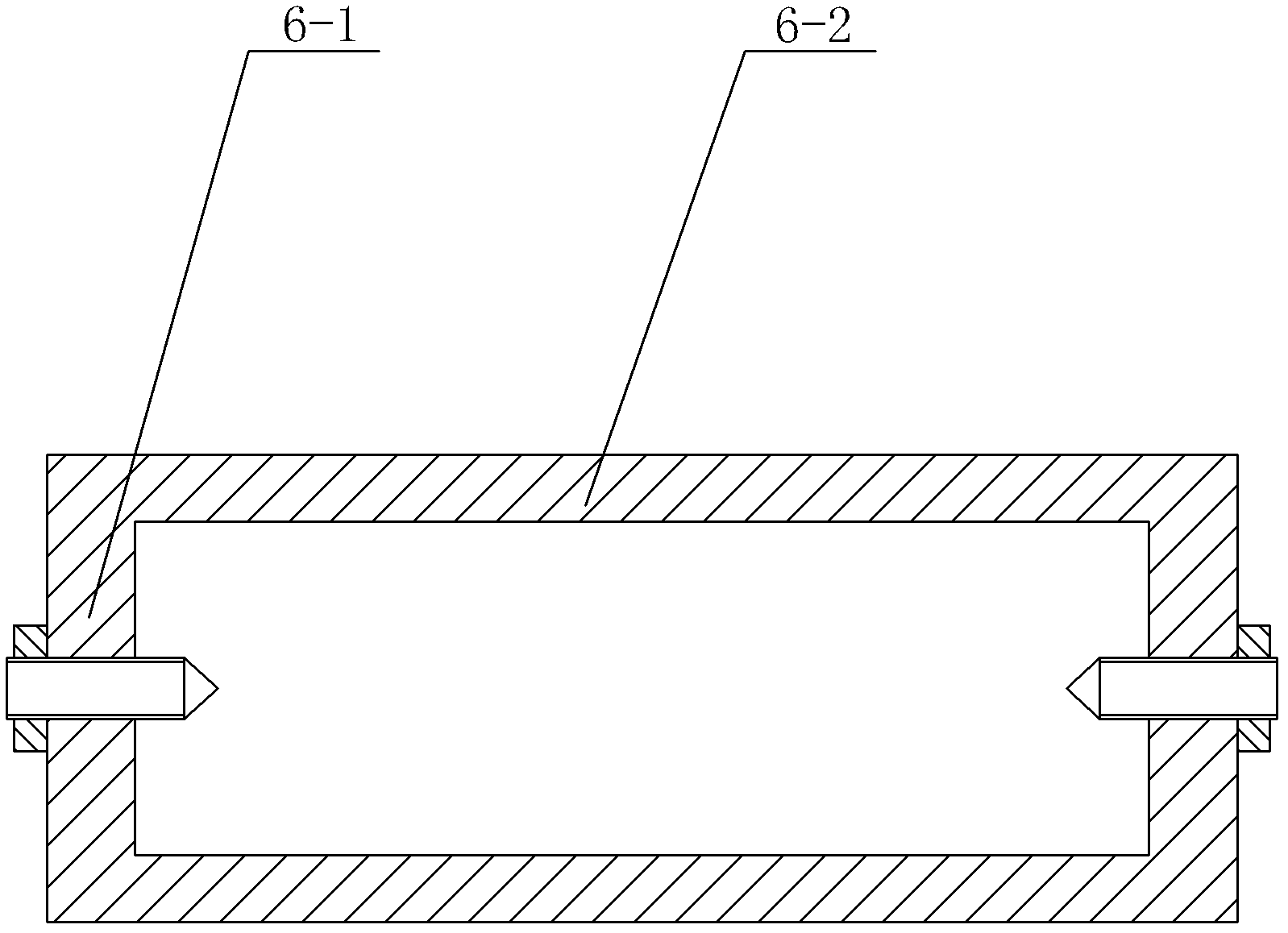

Concrete viscometer

The invention discloses a concrete viscometer, which relates to a viscometer, in particular to a concrete viscometer. The concrete viscometer aims at solving the problem that a concrete viscometer in prior arts cannot accurately measure the rheological parameter of concrete. According to the invention, all slide rails are laid on the surface of a test bench through two slide rail brackets; a longslot is laid on the surface of the test bench; a framework is sleeved on a roller; two slide rail grooves are respectively arranged at two ends of the roller; a pulley is installed between two slide rails; one end of a string is connected with the middle of a long side of the framework; the other end of the string is connected with a weight via the surface of the pulley; the weight can pull the roller to move on a horizontal plane along the two slide rails through gravity; two weight travel switches are arranged on a vertical plane at one end of the test bench from the upper part to the lowerpart; when the weight longitudinally moves along the vertical plane and passes the weight travel switches, the weight can contact the weight travel switches; and each weight travel switch is connected with a timer. The concrete viscometer is used for measuring the viscosity of concrete.

Owner:江苏省金陵建工集团有限公司 +1

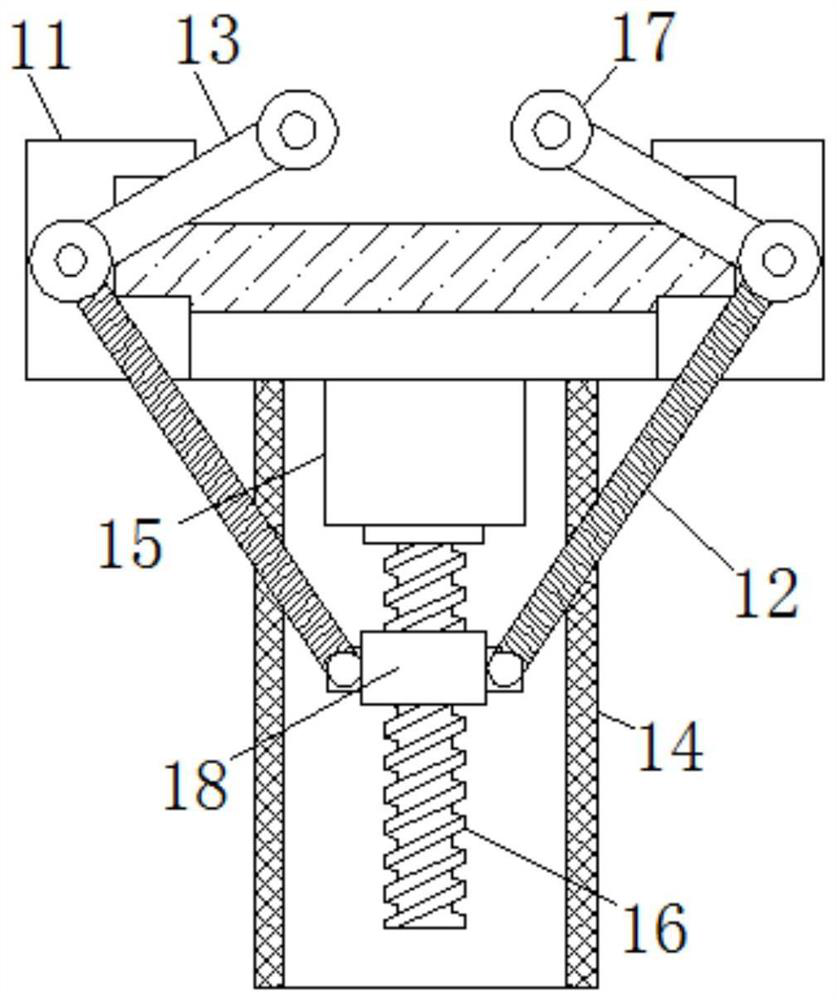

Permanent magnetic drilling machine

InactiveCN106270616ASimple structureReasonable designBoring/drilling componentsMaintainance and safety accessoriesSurface finishVibration amplitude

The invention discloses a permanent magnetic drilling machine which comprises a horizontally arranged base, a rack mechanism and a permanent magnetic drilling rig device, wherein the rack mechanism comprises a column, a tank body and a tank sliding mechanism; the permanent magnetic drilling rig device comprises a rotation driving mechanism and a permanent magnetic vibration mechanism; the rotation driving mechanism is connected with the permanent magnetic vibration mechanism in a transmission manner; the permanent magnetic vibration mechanism comprises a main shaft used for mounting a cutter and connected with the rotation driving mechanism in a transmission manner, a permanent magnetic mechanism mounted on the main shaft and used for driving the main shaft to vibrate up and down, and a telescopic movement mechanism sleeving the main shaft; a vibration amplitude adjusting mechanism for adjusting a vibration amplitude of the main shaft is arranged on the tank body. The permanent magnetic drilling machine provided by the invention is simple in structure, reasonable in design and high in reliability, enables the cutter to be in periodical contact with a workpiece to be drilled, increases instantaneous drilling force, reduces drilling temperature, shortens drilling time, and improves surface finish and processing precision of the workpiece to be drilled.

Owner:XIAN UNIV OF SCI & TECH

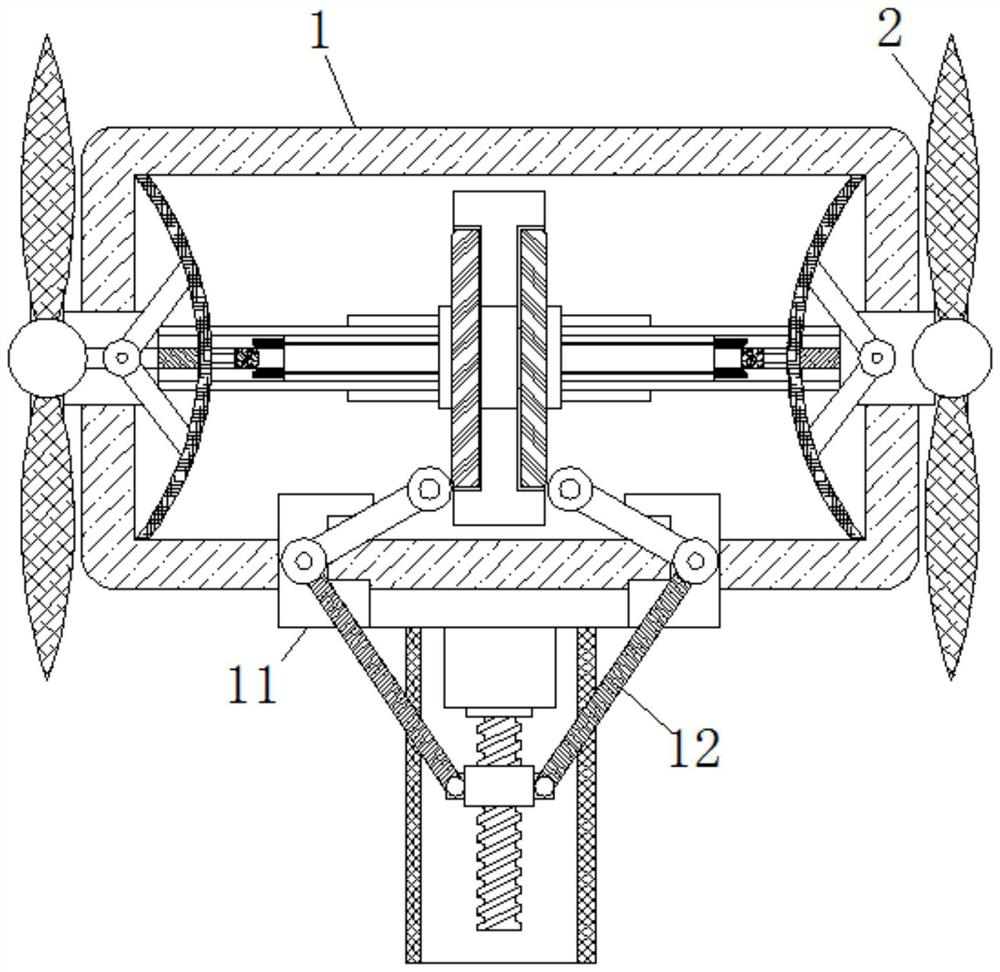

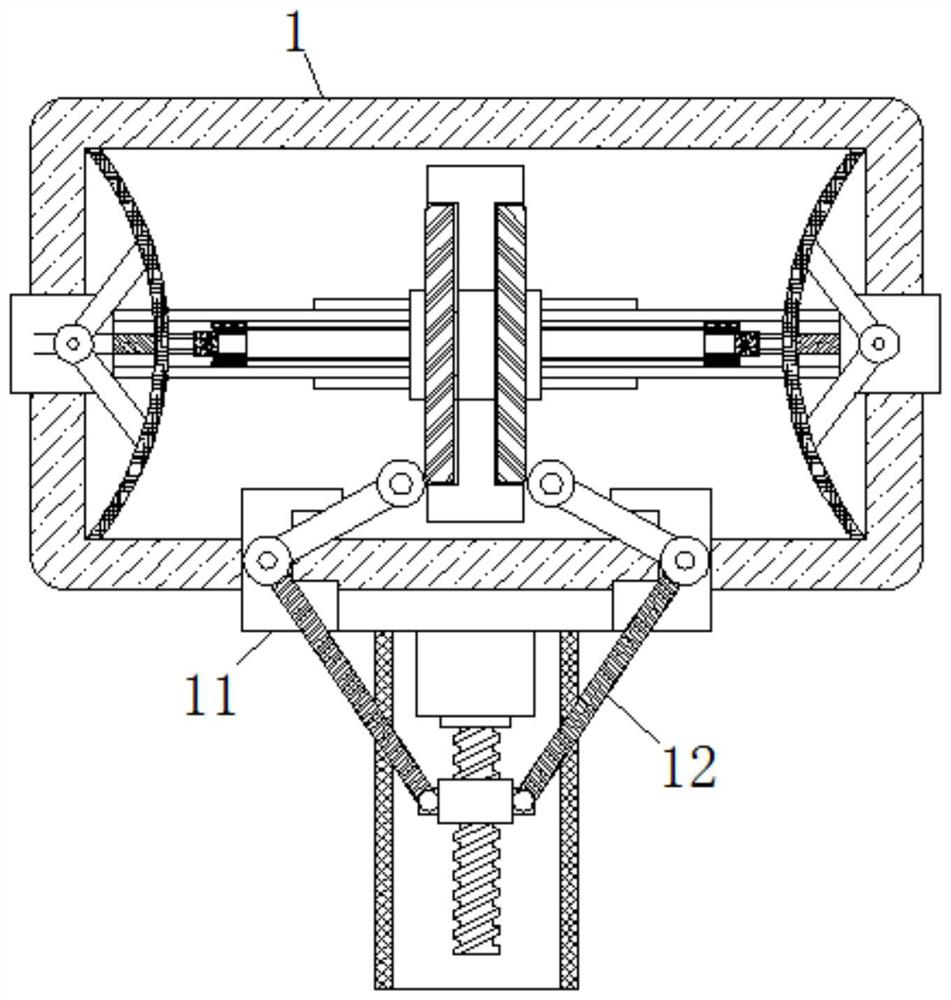

Wind power generation wind speed data detection device based on friction braking

InactiveCN112032004AChange rotation speedRealize the deceleration effectWind motor controlMachines/enginesCapacitanceAir velocity

The invention relates to the technical field of data collection, and discloses a wind power generation wind speed data detection device based on friction braking. The wind power generation wind speeddata detection device based on friction braking comprises a main frame, wherein driving fans are rotatably connected to the left and right ends of the main frame; and rotating shafts are rotatably connected to the left and right ends of the interior of the main frame. According to the device, when the rotating speed of the driving fan is increased, the wind speed on the outer surface of the main frame and near the driving fan is increased, and according to the Bernoulli's principle, the air pressure in the place with the large air flow speed is small, so that the air pressure in the main frameis larger than the air pressure at the driving fan, and air in the main frame extrudes an arc-shaped plate to the main frame; and under the action of a capacitor plate and an electrode plate, the driving rod electrically connected with the capacitor plate and the electrode plate starts to work and drives a screw rod to rotate, the screw rod drives a moving block to move downwards, an extrusion rod gets close to an extrusion wheel, and the rotating speed of the extrusion wheel is changed by increasing a friction force between the extrusion wheel and a speed reduction wheel, so that a speed reduction effect is achieved.

Owner:史春梅

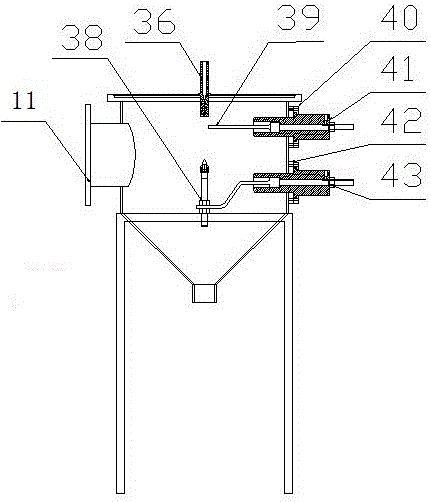

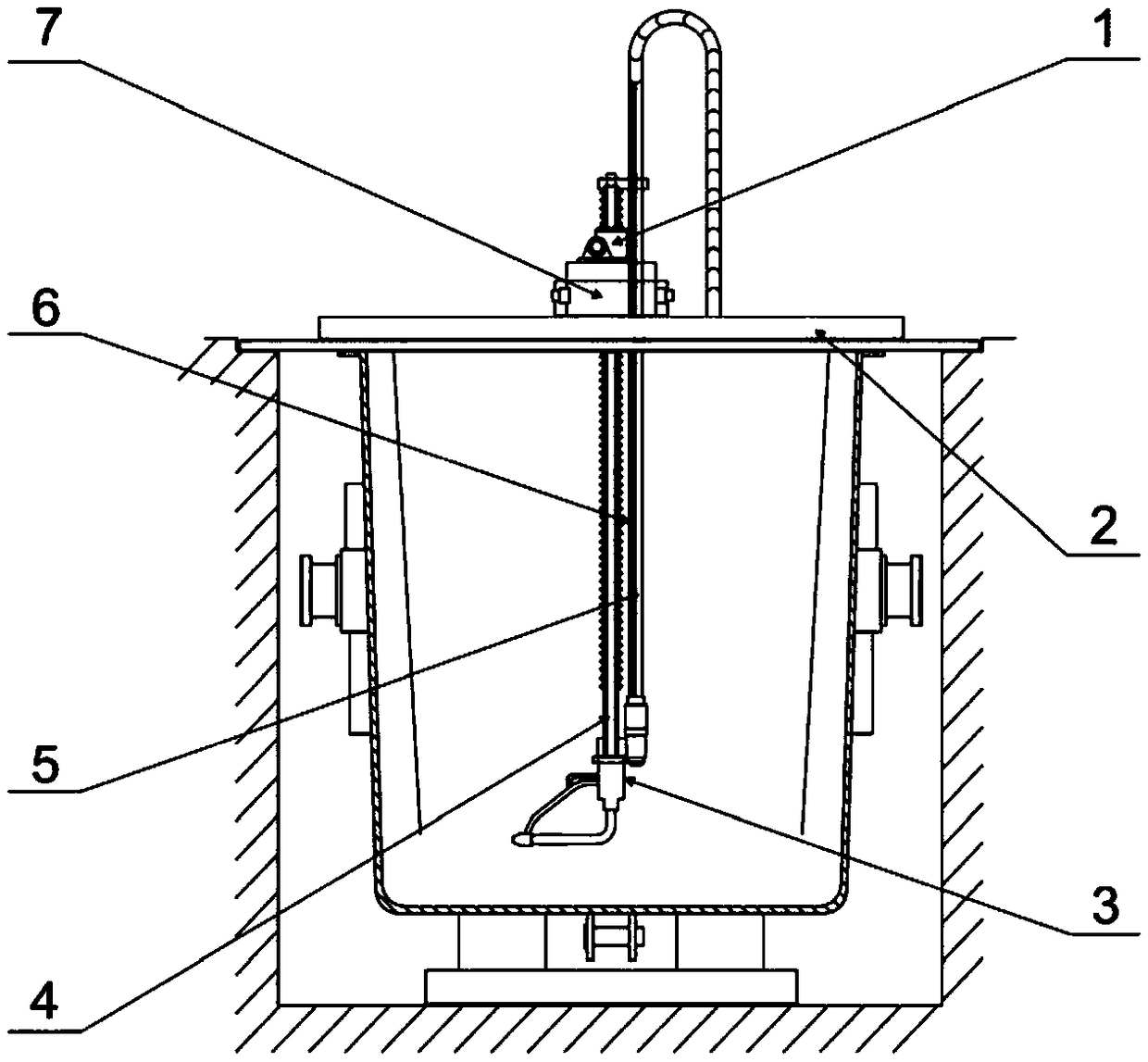

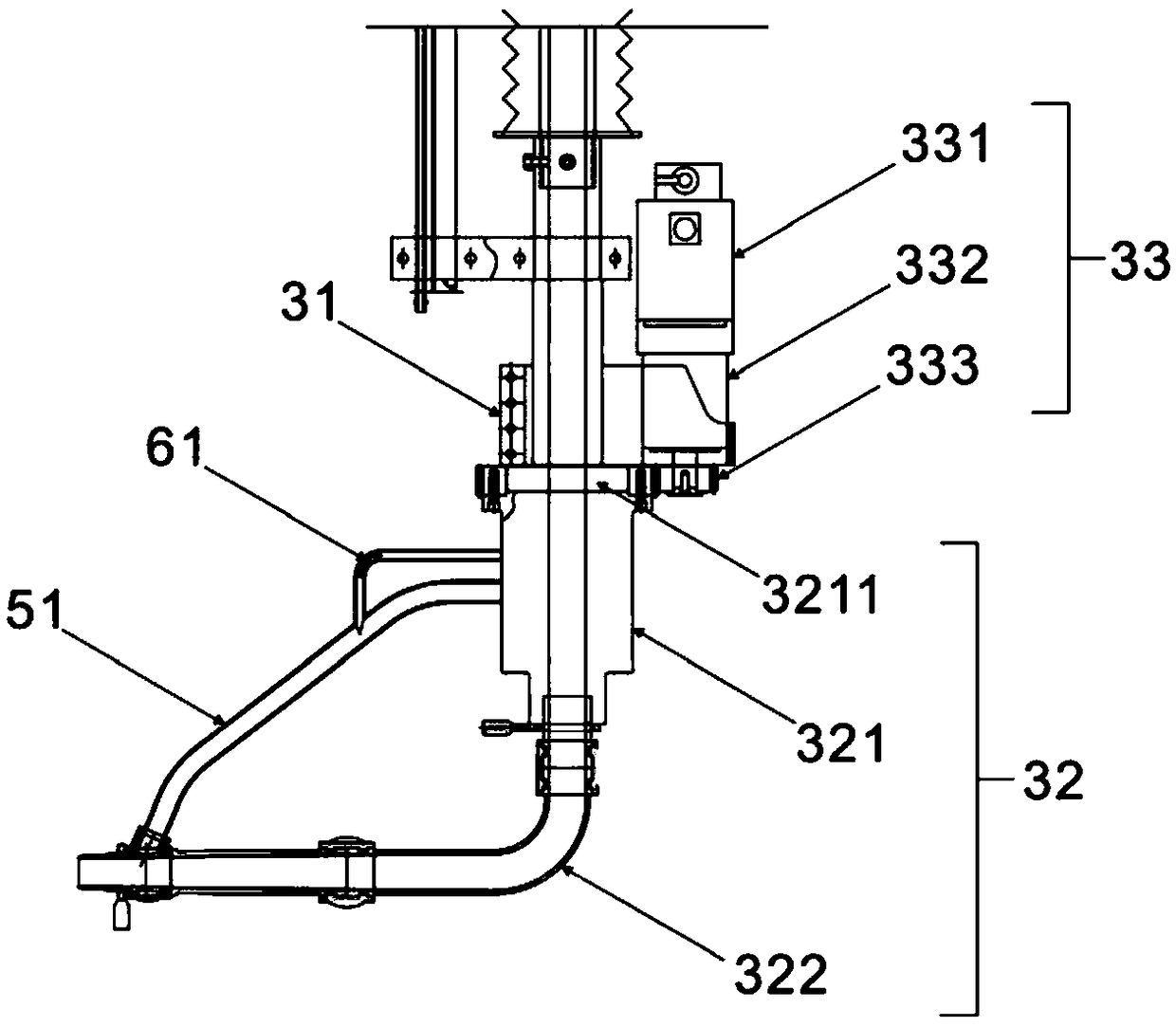

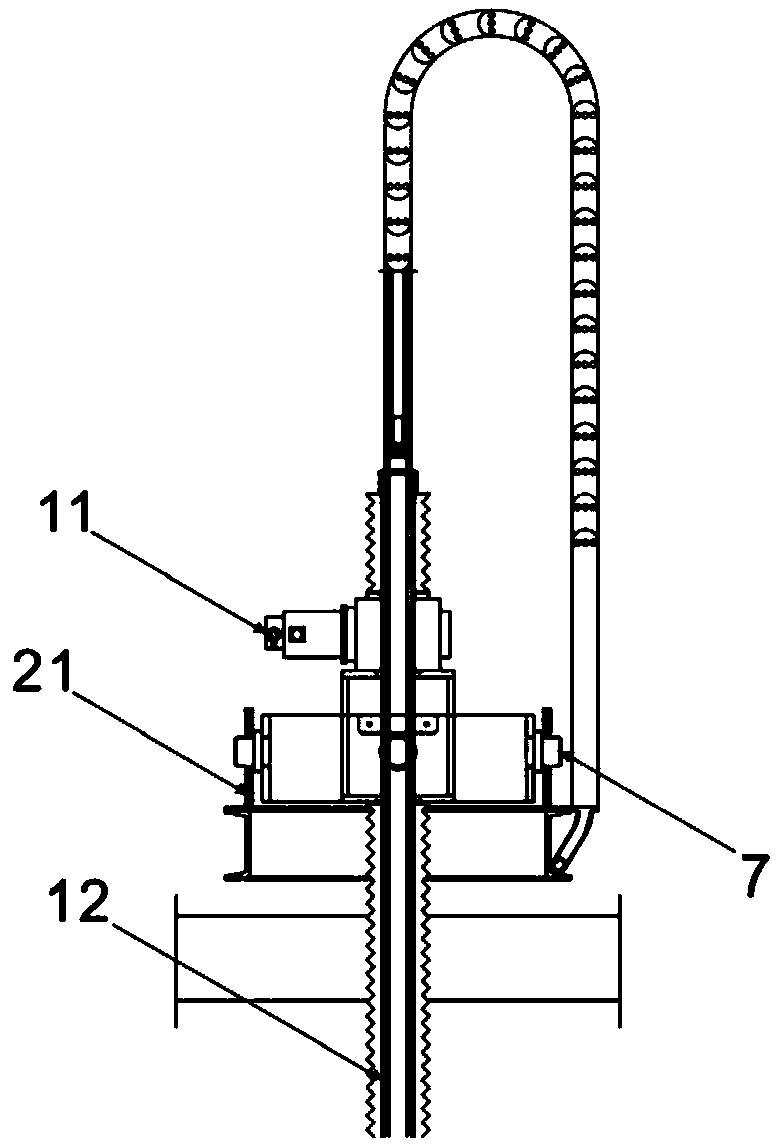

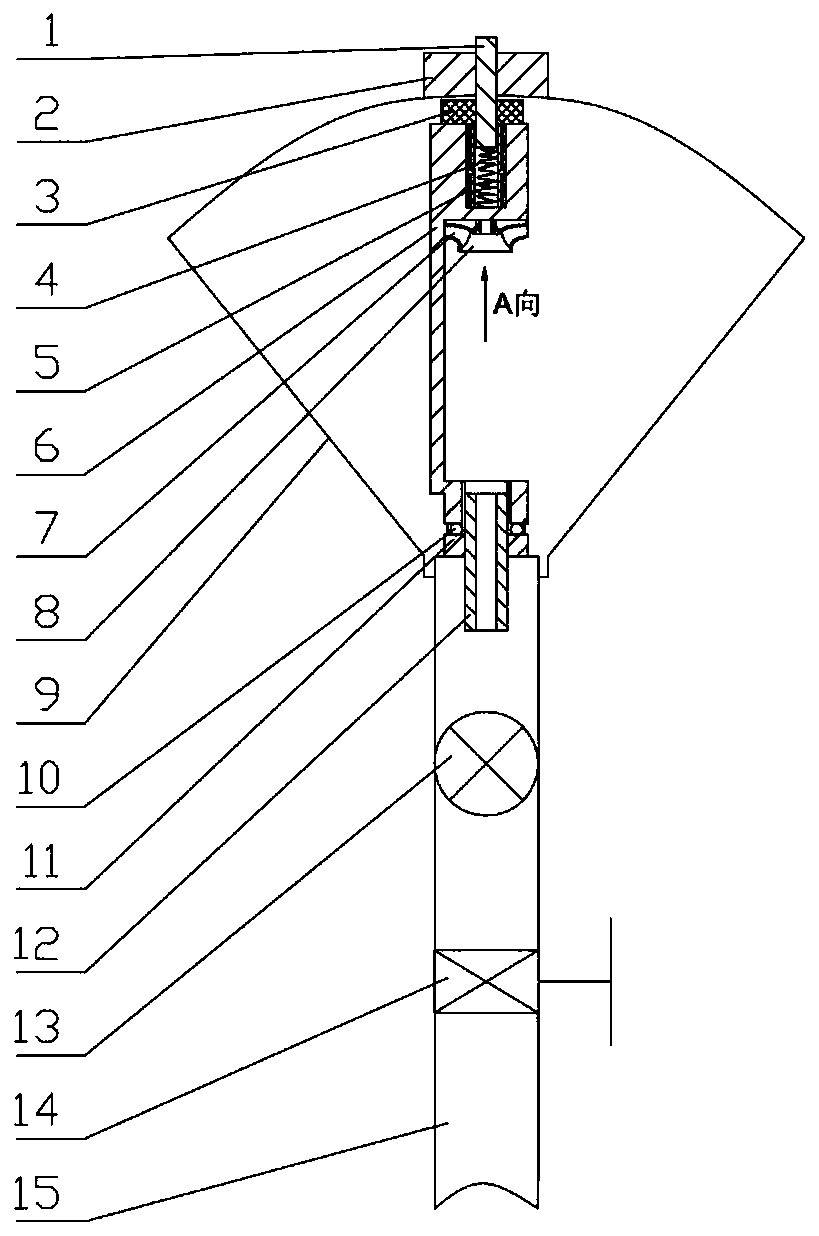

Spray lance device and ladle lining refractory jet device

PendingCN109108262AReduce labor intensityImprove injection efficiencyMelt-holding vesselsBlast furnace componentsMultiple injectionSpray nozzle

The invention provides a spray lance device and a ladle lining refractory jet device, relates to the technical field of refractory jet equipment, and solves the technical problems of high labor intensity and low construction efficiency existing in the prior art. The spray lance device comprises a support box, a spray gun drive device and a rotary spray gun, the rotary spray gun comprises a gas-liquid rotary joint and a nozzle, the nozzle is connected to a refractory pipeline through the gas-liquid rotary joint, and the gas-liquid rotary joint and the nozzle can rotate relative to the refractory pipe. The ladle lining refractory jet device comprises the refractory pipeline, a compressed air pipeline, a quick-setting agent pipeline, the spray gun device, a lifting device and a control device. The jet direction of the spray gun device can be freely adjusted, the labor intensity is reduced, and the jet efficiency is improved; a lifting body and the spray gun device are controlled by the control device, and multiple injection modes of point jet, area jet and automatic circulation jet are realized.

Owner:PUYANG PUNAI FUNCTIONAL MATERIALS CO LTD +1

Eccentric turning wheel device

ActiveCN104891150ACompact structureStable structurePackagingConveyor partsEngineeringRotational rate

The invention discloses an eccentric turning wheel device. The eccentric turning wheel device comprises a frame, a main shaft, adsorption mechanisms, a steering mechanism enabling the adsorption mechanism to rotate at 90 degrees and a negative pressure mechanism providing the adsorption mechanism with negative pressure. An input end of the main shaft is in transmission connection with a synchronizing wheel. An output shaft of the main shaft is provided with a rotary disc in a sleeving ode. A support sleeve is eccentrically in sleeve joint with outside of the main shaft between the synchronizing wheel and the rotary disc and fixed onto the frame. Multiple main bearing seats are fixedly arranged on the support sleeve. The adsorption mechanisms are fixedly mounted onto the main bearing seats. An inside disc body of the rotary disc is in transmission connection with the adsorption mechanisms by means of rocking arm mechanisms. The main shaft and the rotary disc of the turning wheel device are arranged coaxially. The adsorption mechanisms and the main shaft are designed to be eccentric. In the way that the rotary disc drives adsorption boxes to rotate by means of the rocking arm mechanisms for changing rotation speed of the same absorption box, linear velocity of the adsorption boxes is thus changed; and finally speed of the adsorption boxes on a turning wheel is matched with speed of a production line at the front and back portions of the adsorption boxes.

Owner:JINJIANG SHUNCHANG MACHINE MFG

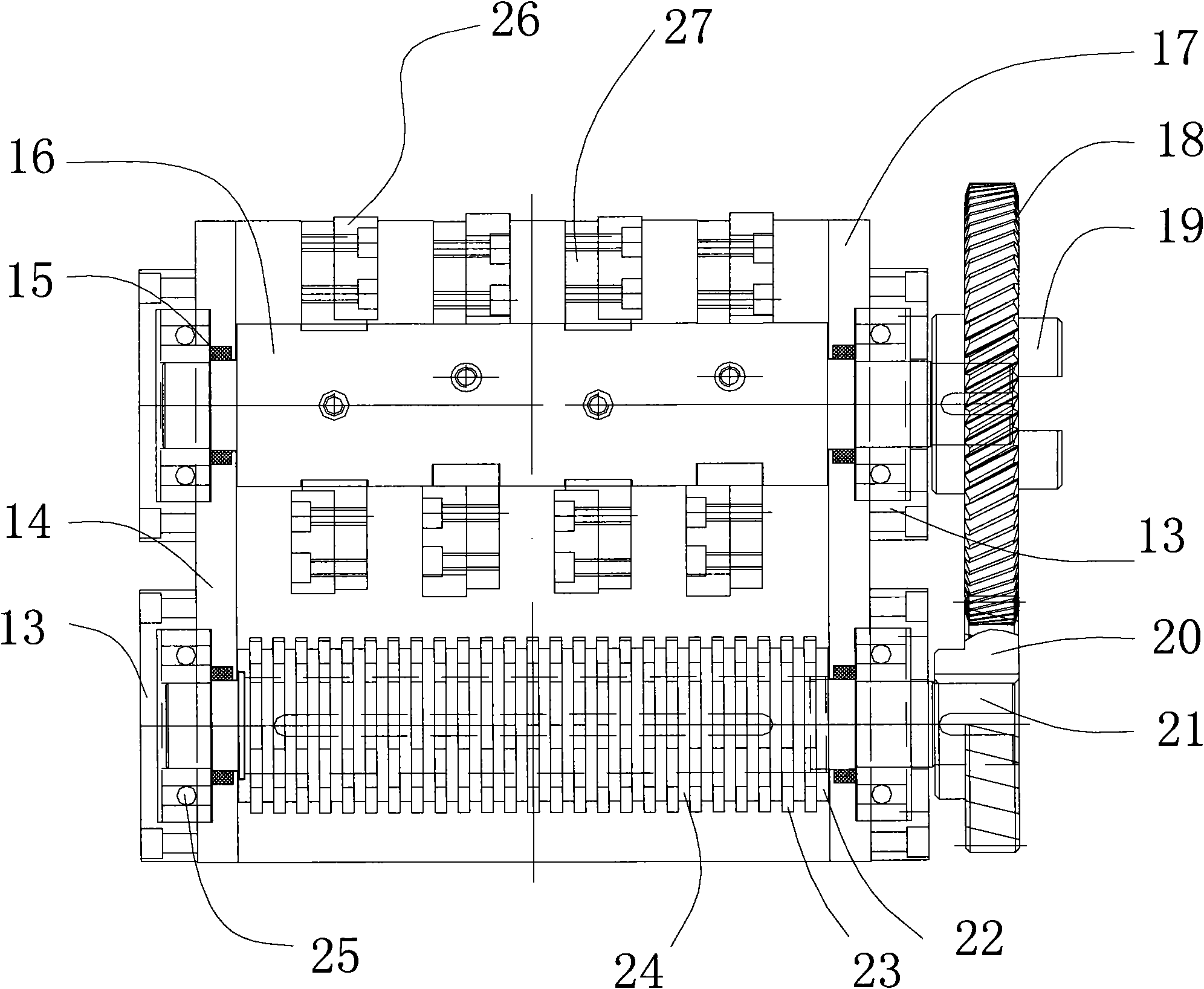

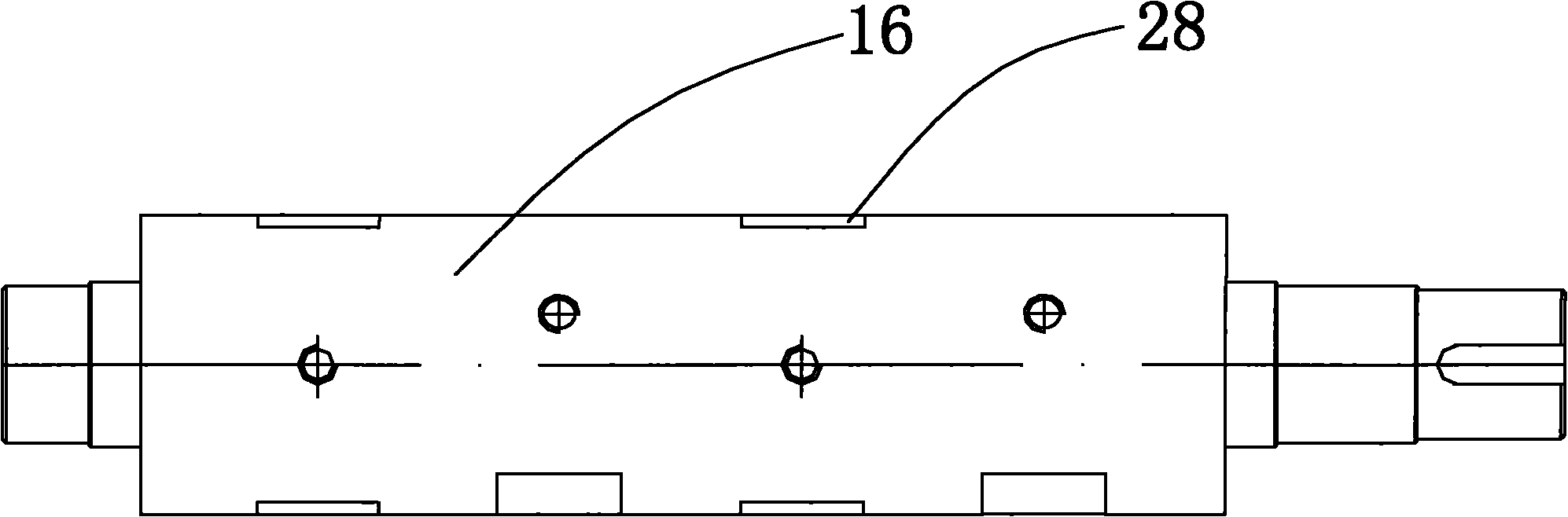

Double-layer grinder

The invention relates to a double-layer grinder grinding twice, overcoming the disadvantages that an upper-layer grinder structure and a lower-layer grinder structure are connected by a main shaft and mainly bear abrasion and extrusion forces, and the equipment has larger pressure in the prior art. The double-layer grinder comprises a cylinder body in which a grinding chamber and a rotating shaft are arranged, a grinding cutter is fixed on the rotating shaft, the positions of the inner wall of the cylinder body corresponding to a cutter frame shaft and a teeth-cutter shaft are respectively fixed with a claw cutter and a teeth cutter, the claw cutter is provided with a cutter claw extruding into the gap between the grinding cutters on the cutter frame shaft, and the teeth cutter is provided with cutter teeth extruding into the gap between the cutters on the teeth-cutter shaft. Firstly, the grinding cutter on the cutter frame shaft performs crude grinding, and then the grinding cutter on the teeth-cuter shaft performs fine grinding, thus lightening action force borne by parts during grinding every time and slowing abrasion of the parts so as to prolong the service life.

Owner:宁波斯曼尔电器有限公司

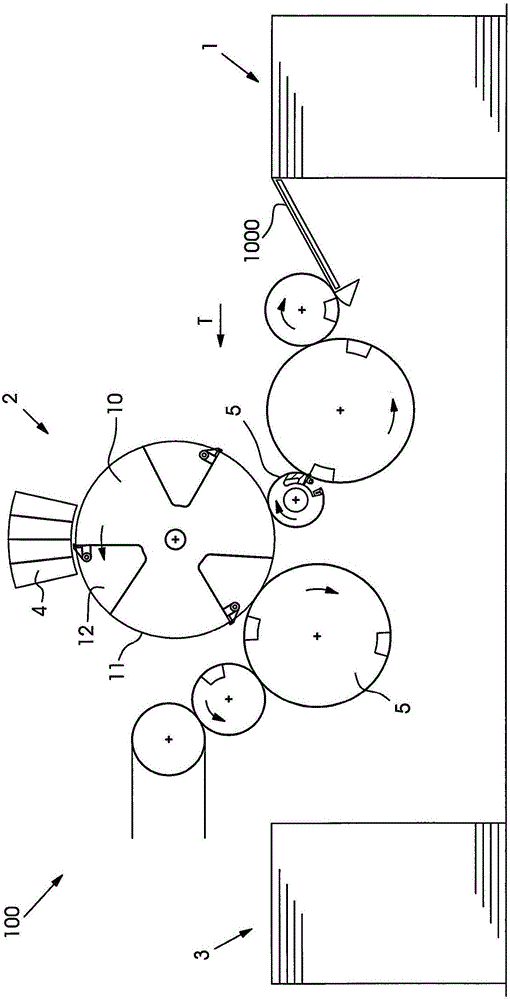

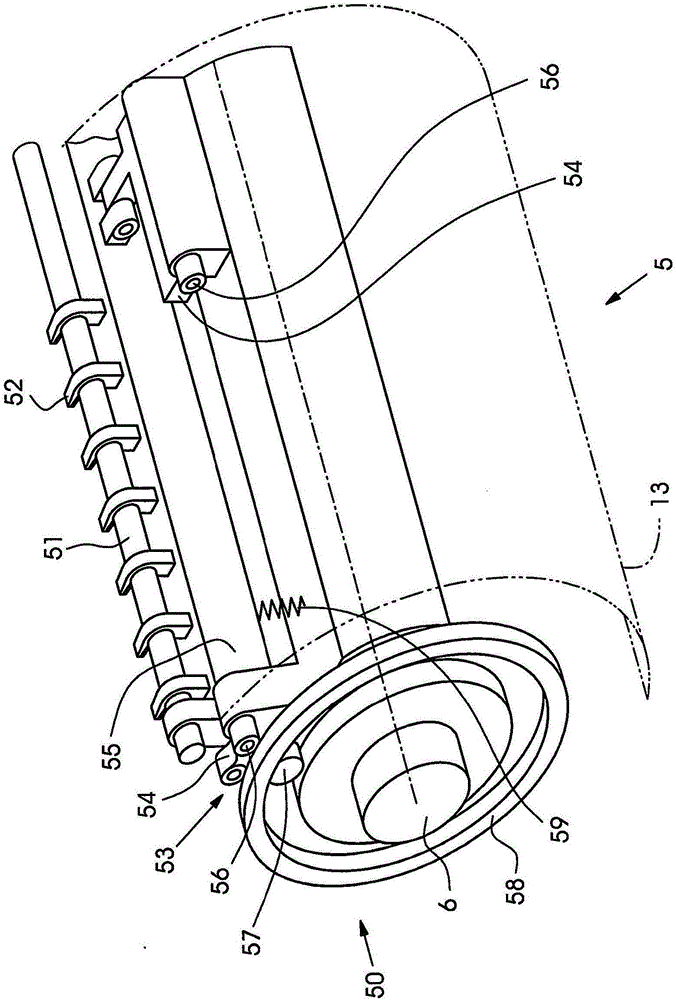

Printing mechanism of page printing machine

InactiveCN106064526AReduce spacingSmall vacancyOther printing apparatusPrinting press partsLow speedEngineering

The present invention relates to a printing mechanism (2) for a page printing machine (100). The printing mechanism (2) has a printing drum (10), a front transfer roller (5) and a rear transfer drum (5). According to the invention, the transfer drum (5) has a device (50) for stopping or accelerating the page. The device (50) has at least one substantially radially movable gripper bridge (51), so that the tangential velocity of the gripper bridge (51) can be varied and thus the tangential direction of pages (1000) speed can also be changed. The pages (1000) can be conveyed at a relatively low speed and at a relatively small distance from each other during the printing process by means of such a printing mechanism, thereby ensuring high printing quality and high printing efficiency. The invention also relates to the page printing machine (100) having such a printing mechanism.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Automatic deep-fried twisted dough stick machine

InactiveCN103999889AEvenly heatedWell-proportionedOil/fat bakingBaking plantsMarket potentialFrying-pans

Disclosed is an automatic deep-fried twisted dough stick machine. The automatic deep-fried twisted dough stick machine is mainly composed of a dough conveying device, a forming mouth, a frying pan, a rotating pulling device, a cutter and the like. Dough is conveyed by the dough conveying device to the forming mouth to be extruded to form a continuous deep-fried twisted dough stick blank which then enters the frying pan, the deep-fried twisted dough stick blank is fried in the frying pan to be well cooked through traction and rotation of the rotating pulling device, and then the cooked deep-fried twisted dough stick is conveyed to a cutting-off mechanism to form a finished deep-fried twisted dough stick with proper length. By means of the automatic deep-fried twisted dough stick machine, automatic mechanical production of the deep-fried twisted dough stick can be achieved, the producing efficiency is greatly increased, labor intensity is reduced, the deep-fried twisted dough stick is fully shaped, uniform in colors, crispy on the outside and tender on the inside, and great market potential can be achieved.

Owner:李冉

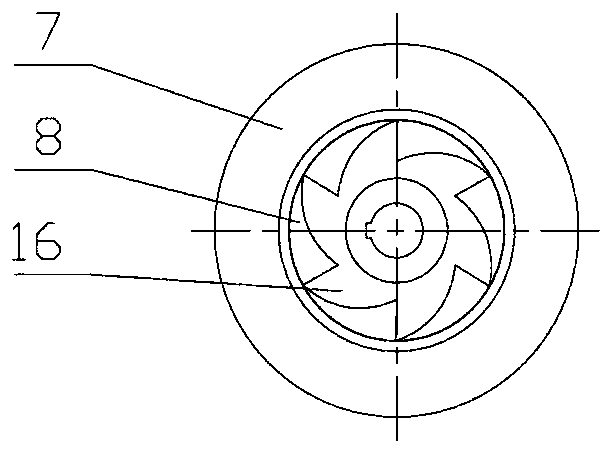

Impeller-driven rotary nozzle and rotation speed adjusting method thereof

ActiveCN111330753AStable and reliable rotation workIncrease spray rangeWatering devicesMovable spraying apparatusPhysicsImpeller

The invention provides an impeller-driven rotary nozzle and a rotation speed adjusting method thereof. The impeller-driven rotary nozzle comprises a damping device, a rotating body, a nozzle and an impeller, wherein the nozzle is mounted on a support frame; one end of the rotating body is rotatably mounted on the nozzle; the impeller is arranged on the rotating body and drives the rotating body torotate through the nozzle; the other end of the rotating body is rotatably mounted on the support frame; and the damping device is arranged between the rotating body and the support frame and used for adjusting the resistance of the rotating body in the rotation process. The impeller-driven rotary nozzle can solve the key technical problems that a rotary spraying element is complex in structure,hydraulic performance parameters are not easy to adjust, energy consumption is high, and work is not stable enough, and has the advantages of simple product structure, low energy consumption, reliableoperation and the like.

Owner:JIANGSU UNIV

Positive yarn feeding system of circular knitting machine and control method thereof

PendingCN110983602AChange rotation speedReal-time control of running speedWeft knittingYarnElectrical and Electronics engineering

The invention discloses a positive yarn feeding system of a circular knitting machine and a control method thereof. The yarn feeding system comprises a yarn feeding device, an upper computer and a coder, wherein the coder is used for measuring a rotating speed of a dial of the circular knitting machine and converting the rotating speed into a synchronous pulse signal to send to the upper computer;the yarn feeding device comprises a fixed ring and a plurality of yarn feeders uniformly arranged on the fixed ring, each yarn feeder comprises a bracket, and a yarn feeding wheel, a servo motor andan MCU controller which are arranged on the bracket; the servo motor is used for driving the yarn feeding wheel to rotate and feed yarns, the MCU controller is respectively in signal connection with the servo motor and the upper computer, and the MCU controller controls the servo motor to operate according to a yarn feeding quantity signal and the synchronous pulse signal sent by the upper computer. Each yarn feeder in the invention can dynamically adjust the yarn feeding amount in real time and can be used for weaving jacquard fabrics.

Owner:肇庆市立泰电子产品有限公司

Adjustable transformer

InactiveCN110098038AAvoid damageAvoid reciprocating frictionTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerConductor Coil

The invention relates to an adjustable transformer, which comprises a housing and an annular core and further comprises a carbon brush and an adjusting device. According to the adjustable transformerof the invention, the adjusting device drives the carbon brush to rotate in the circumferential direction and adjusts the position of the brush head in the radial direction; the reciprocating frictionbetween the brush head and a winding of the annular core on the same circular trajectory is avoided so as to prevent the damage of the winding of the annular core; the moving direction of a sliding brush rod can also be switched so as to enable the brush head to have two moving modes such as expansion and relaxation in the radial direction, and the brush head is enabled to be continuously used; the moving speed of the brush head is very slow, so that it is unnecessary to manually change the moving direction of the sliding brush rod for many times; and the moving speed of the sliding brush rodcan also be adjusted.

Owner:吕娜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com