Double-layer grinder

A pulverizer and double-layer technology, applied in the field of double-layer pulverizers, can solve the problems of reducing the overall height of the pulverizer, inconvenient feeding, and large equipment height, and achieve the effects of improving the pulverizing effect, prolonging the service life and reducing the force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

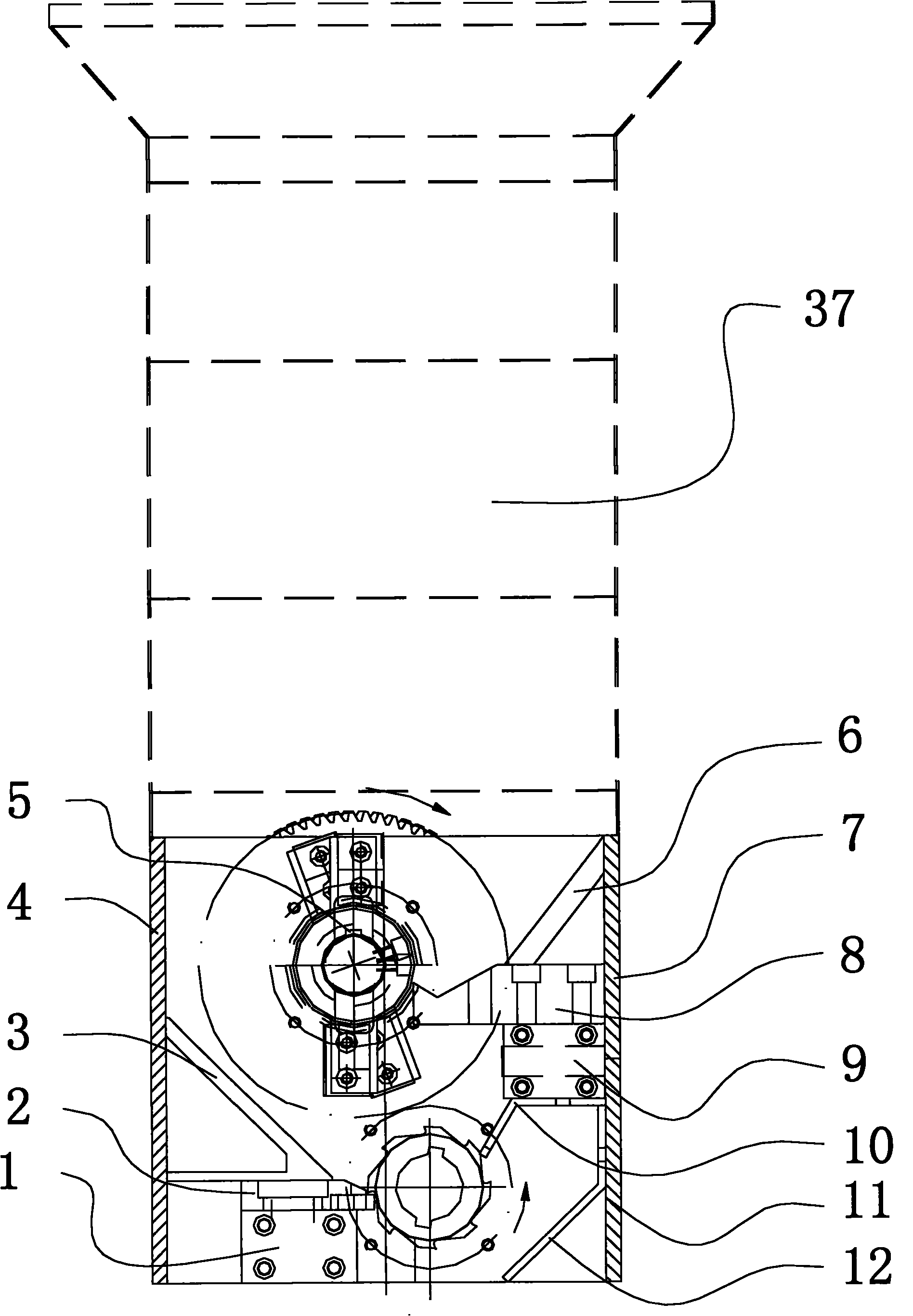

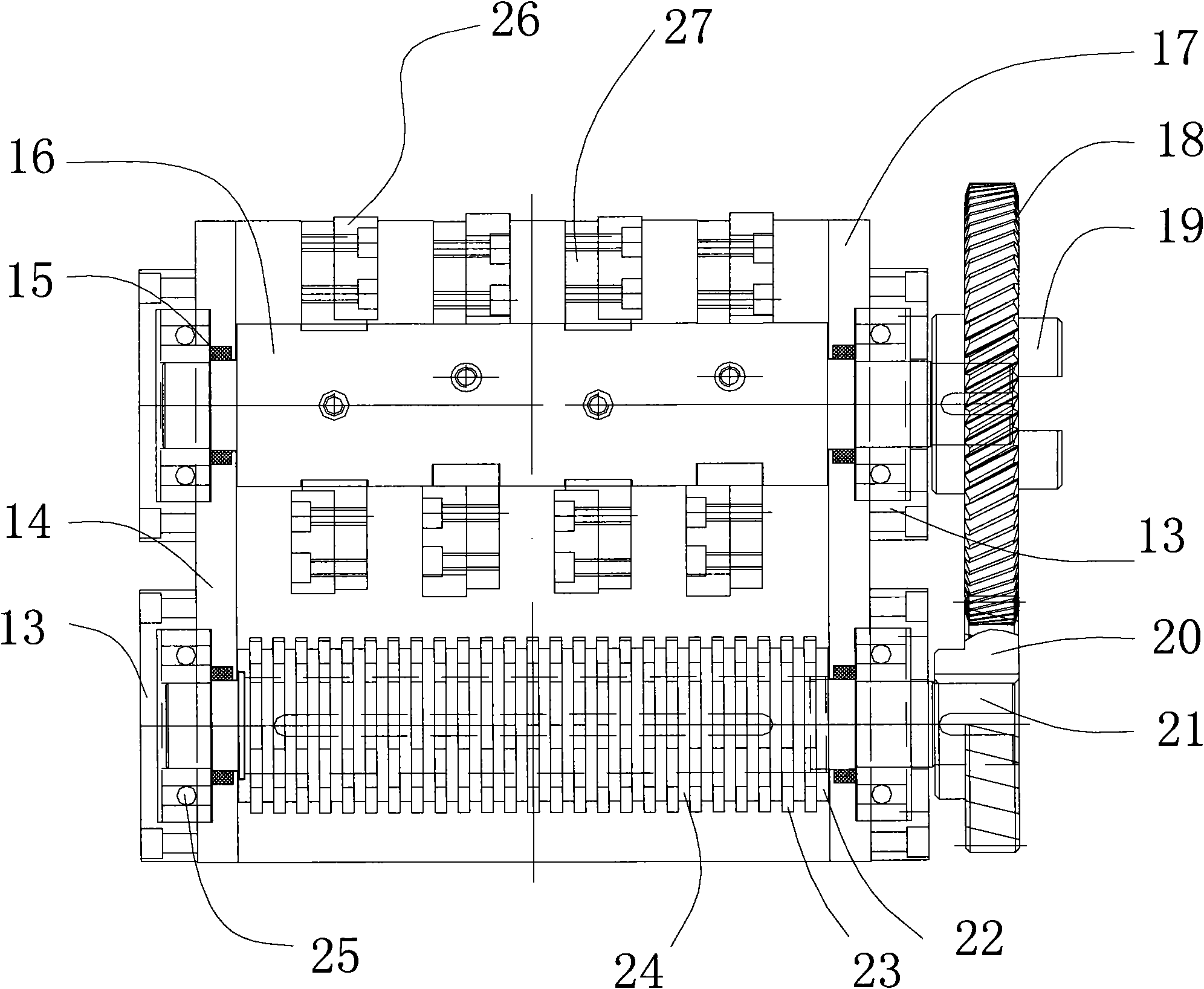

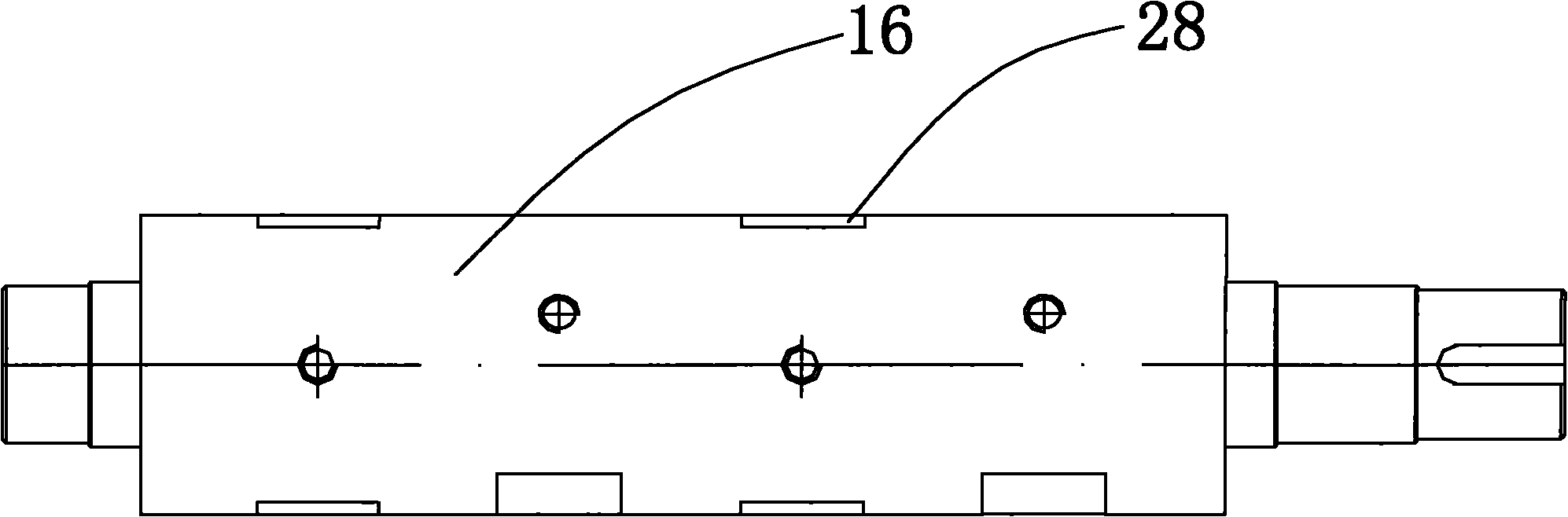

[0037] Embodiment: a kind of double-deck pulverizer (referring to attached figure 1 attached figure 2 ), comprising a vertically placed cuboid cylinder 37, the upper end of the cylinder is a trumpet-shaped feed inlet, the bottom of the cylinder 37 is a crushing chamber, and the crushing chamber is divided into a coarse crushing chamber on the top and a fine crushing chamber on the bottom. The side wall of the cavity is fixed with rear plate 4, left side plate 14, right side plate 17, front upper plate 7, front lower plate 11, and the knife rest shaft 16 is arranged in the coarse crushing chamber (see attached image 3 attached Figure 4 ), the two ends of the tool rest shaft 16 are fixed on the top of the left side plate 14 and the right side plate 17 by the bearing 25 and the bearing cover 13, and a sealing ring 15 is arranged between the tool rest shaft 16 and the bearing 25, and the tool rest shaft 16 The middle part is provided with the square cutter bar hole 28 that ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com