Permanent magnetic drilling machine

A technology of permanent magnet and drilling machine, which is applied in the direction of boring machine/drilling machine parts, boring/drilling, drilling/drilling equipment, etc. It can solve the problems of increased processing cost, poor heat dissipation, and high drilling temperature, and achieves The effect of increasing the instantaneous drilling force, shortening the drilling time and reducing the drilling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

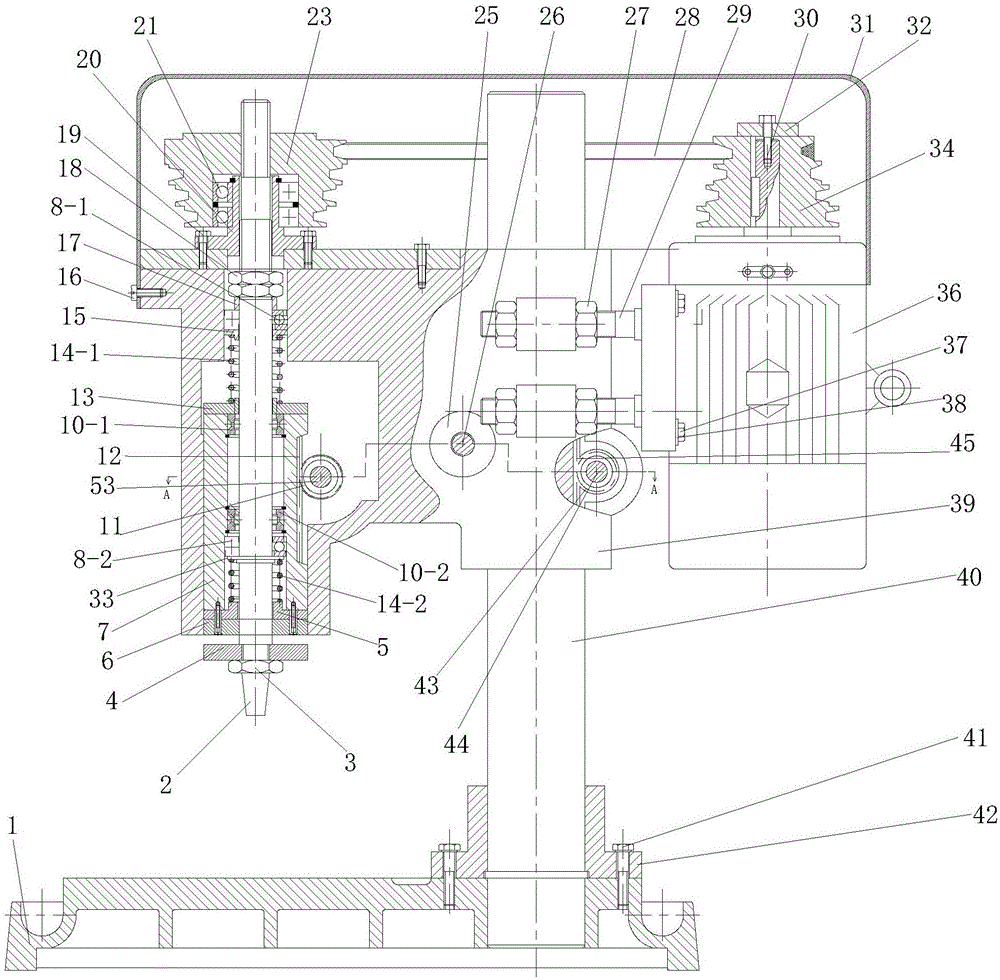

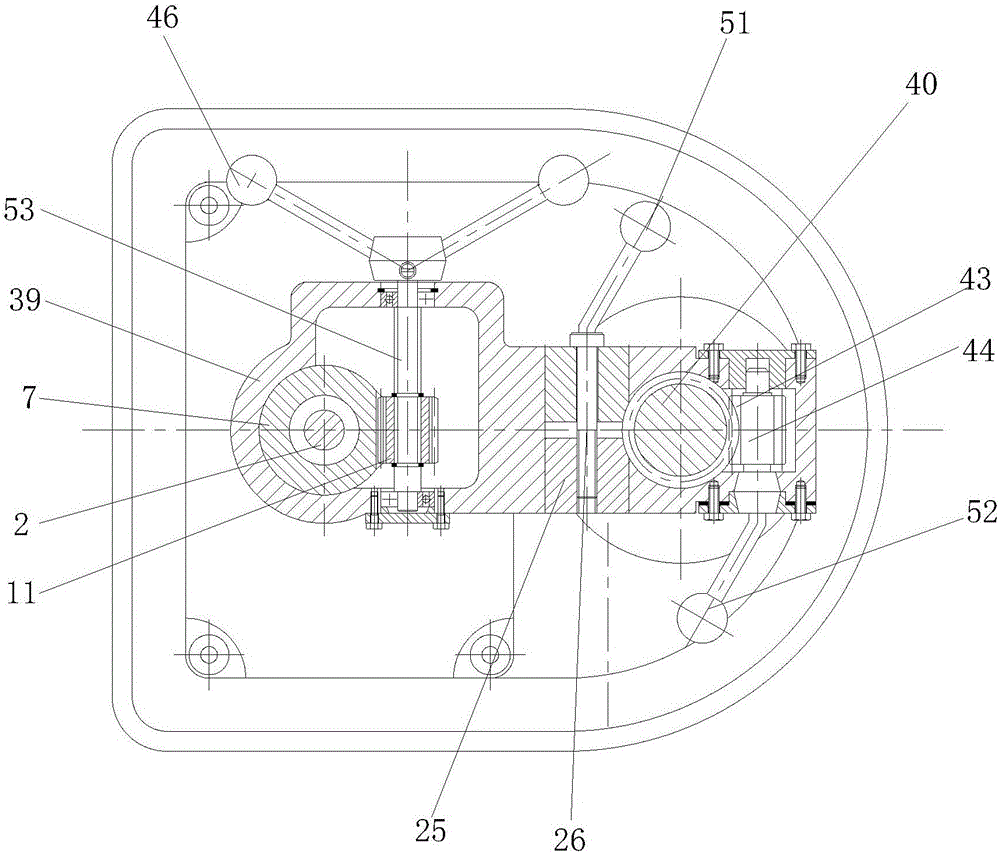

[0050] Such as figure 1 and figure 2 As shown, the present invention comprises a horizontally arranged base 1, a frame mechanism installed on the base 1 and a permanent magnet drilling device installed on the frame mechanism; by setting the permanent magnet drilling device, the tool and the workpiece to be drilled Periodic contact increases the instantaneous drilling force, reduces the drilling temperature, shortens the time required for drilling, and improves the surface finish and processing accuracy of the workpiece to be drilled.

[0051] Described frame mechanism comprises the column 40 that is vertically installed on the base 1, the box body 39 that is installed on column 40 tops and the box body sliding mechanism that moves up and down along column 40 for box body 39; By arranging column 40, be to install The box body 39, and the box body 39 can move up and down along the column 40 to adjust the vertical distance between the box body 39 and the workpiece to be drilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com