Method for measuring inherent frequency of stator core/support system of water turbine generator prototype

A technology for hydroelectric generators and generator stators, which is applied to measuring devices, testing of mechanical components, and testing of machine/structural components. The effect of convenient point layout, significant safety and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

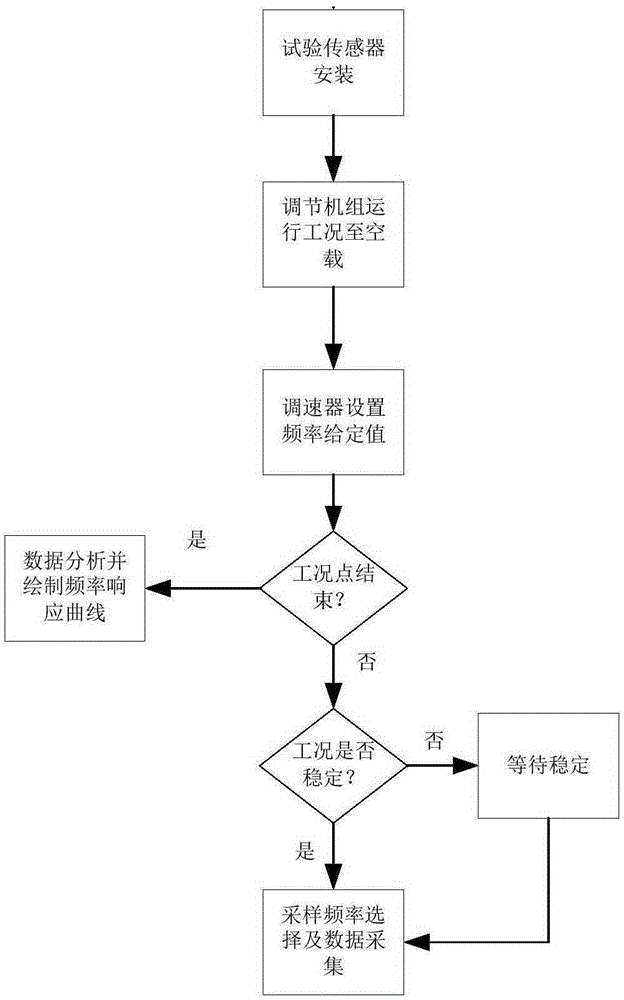

[0029] Such as figure 1 As shown, a method for measuring the natural frequency of the stator core-frame system of a hydroelectric generator prototype includes the following steps:

[0030] Step 1: Install the sensor at the testing point;

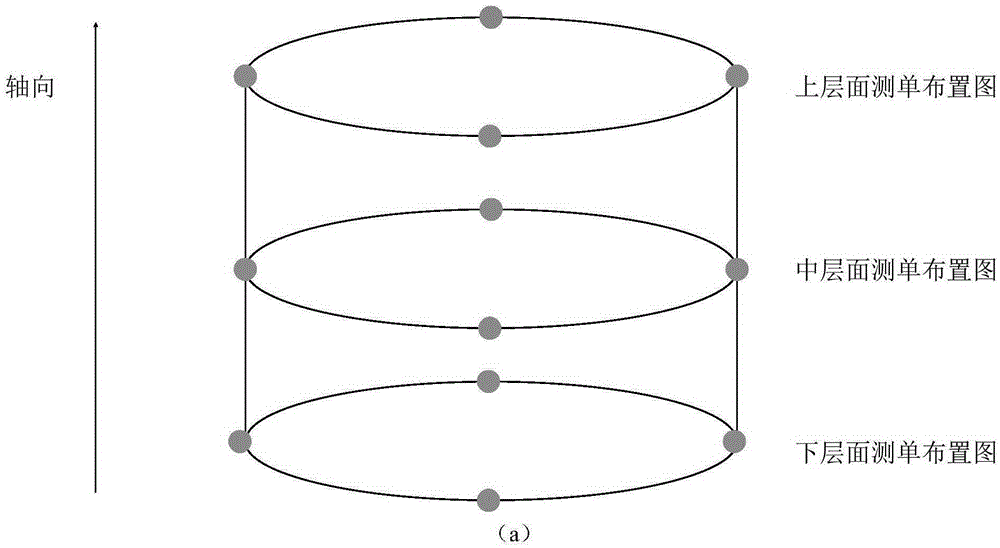

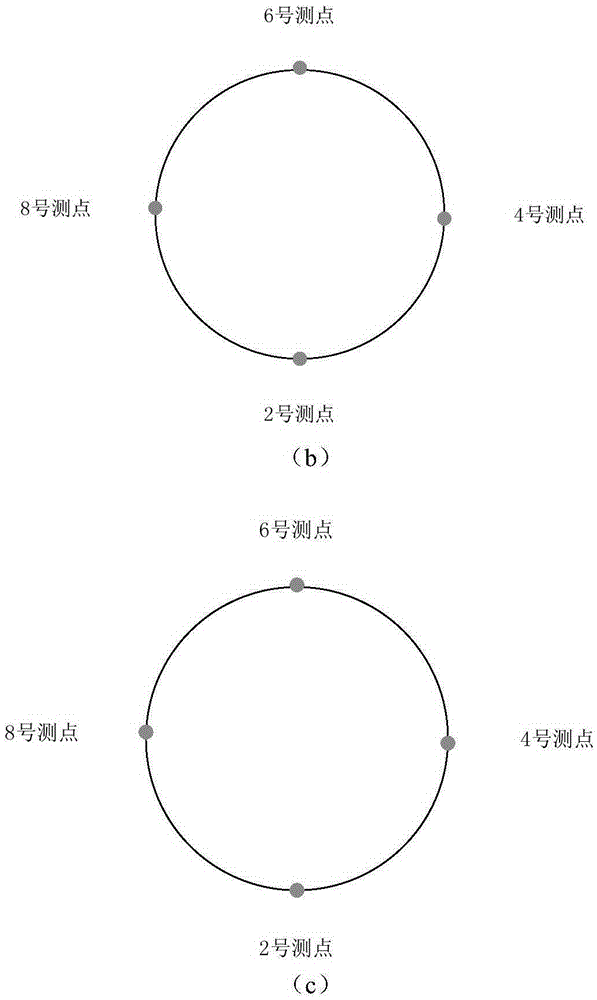

[0031] The sensors installed at the test measuring points include acceleration sensors and vibration displacement sensors, all of which are installed on the vertical ribs of the stator frame;

[0032] Step 2: Adjust the operating condition of the hydro-generator set to no-load;

[0033] Step 3: When the PID control parameter of the governor is the optimal parameter under the no-load condition, set the given value of the governor frequency to change the rotor speed of the generator;

[0034] When the PID control parameters in the no-load condition are the optimal parameters, the unit frequency fluctuation in the no-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com