Patents

Literature

2876results about How to "Won't fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

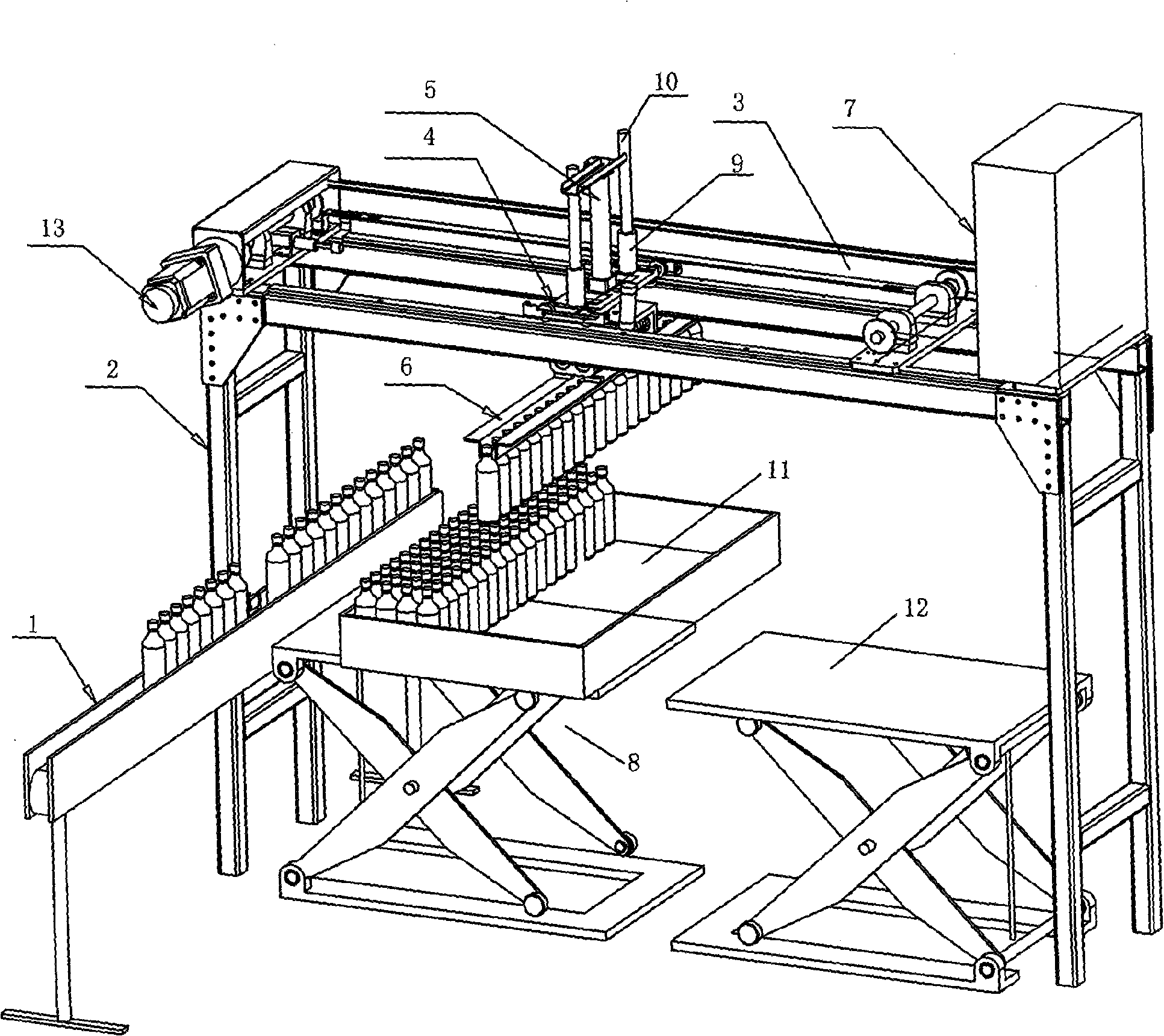

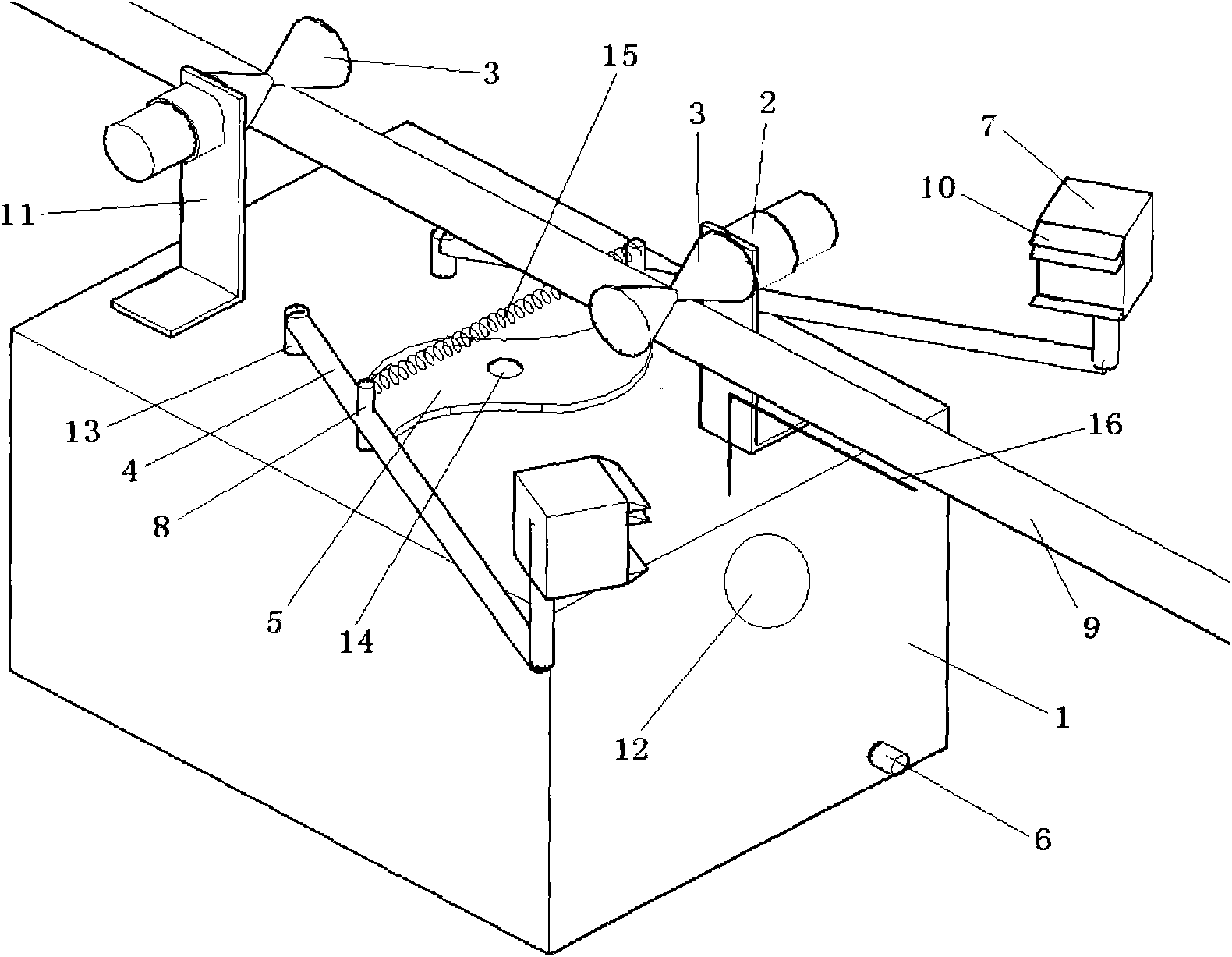

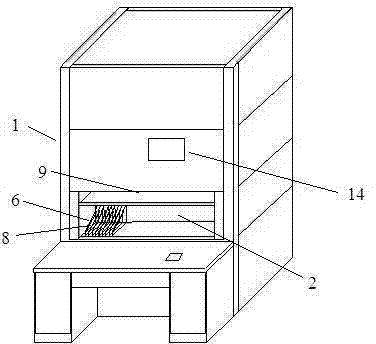

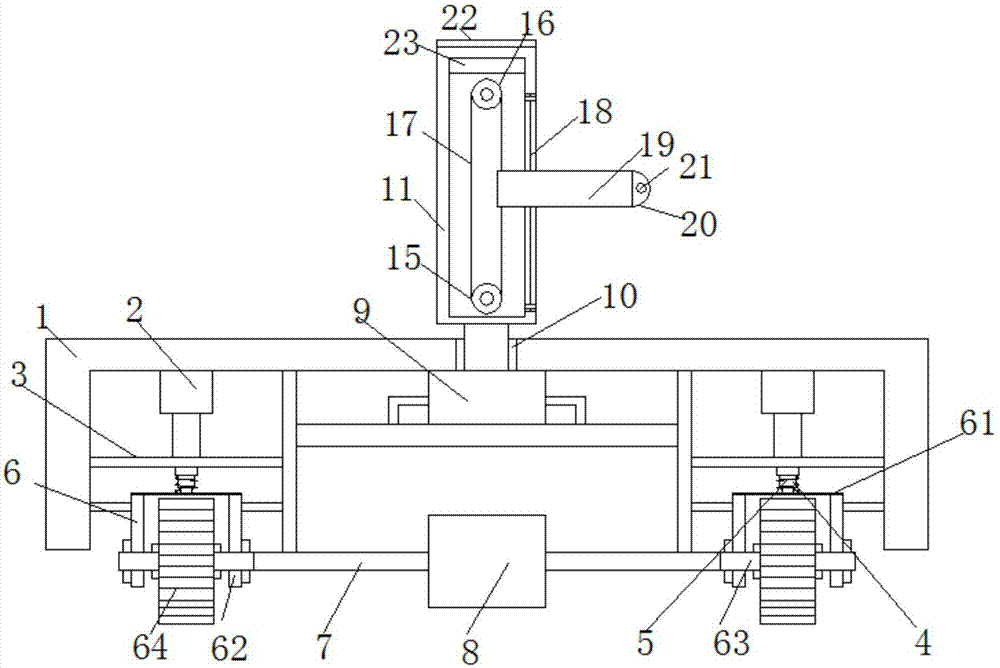

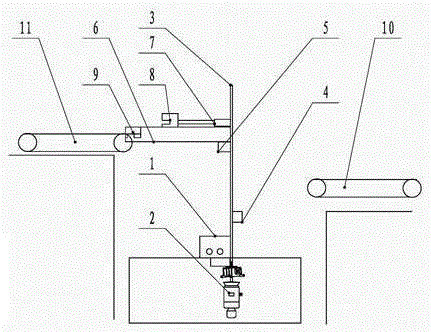

Automatic collecting and arranging machine for plastic soft bottle

ActiveCN101327851AImprove processing progressRealize the collectionProgramme-controlled manipulatorGripping headsAutomatic controlEngineering

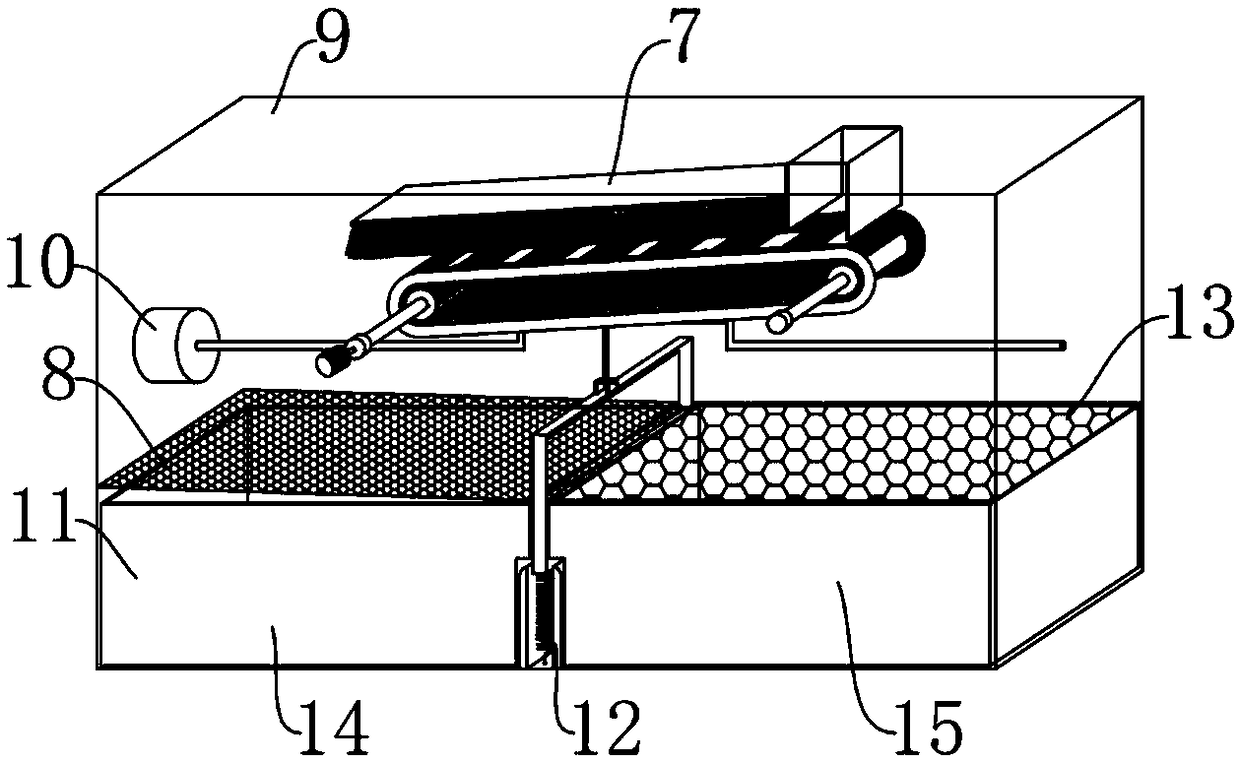

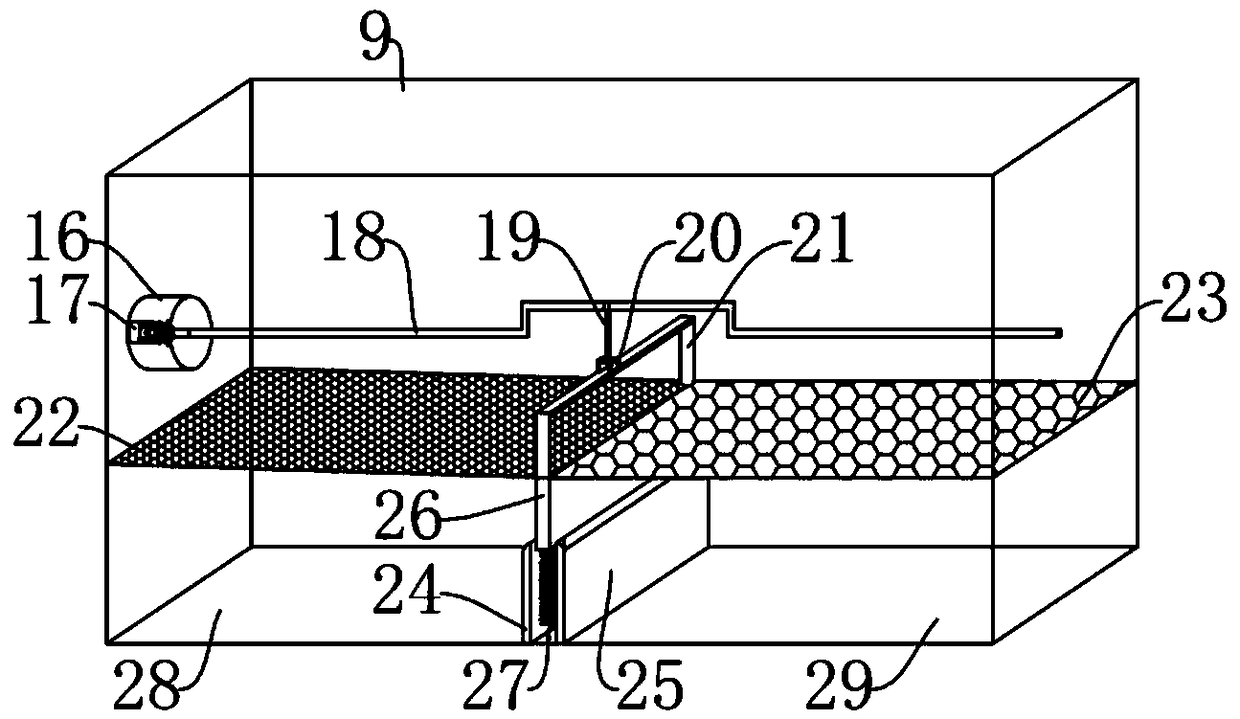

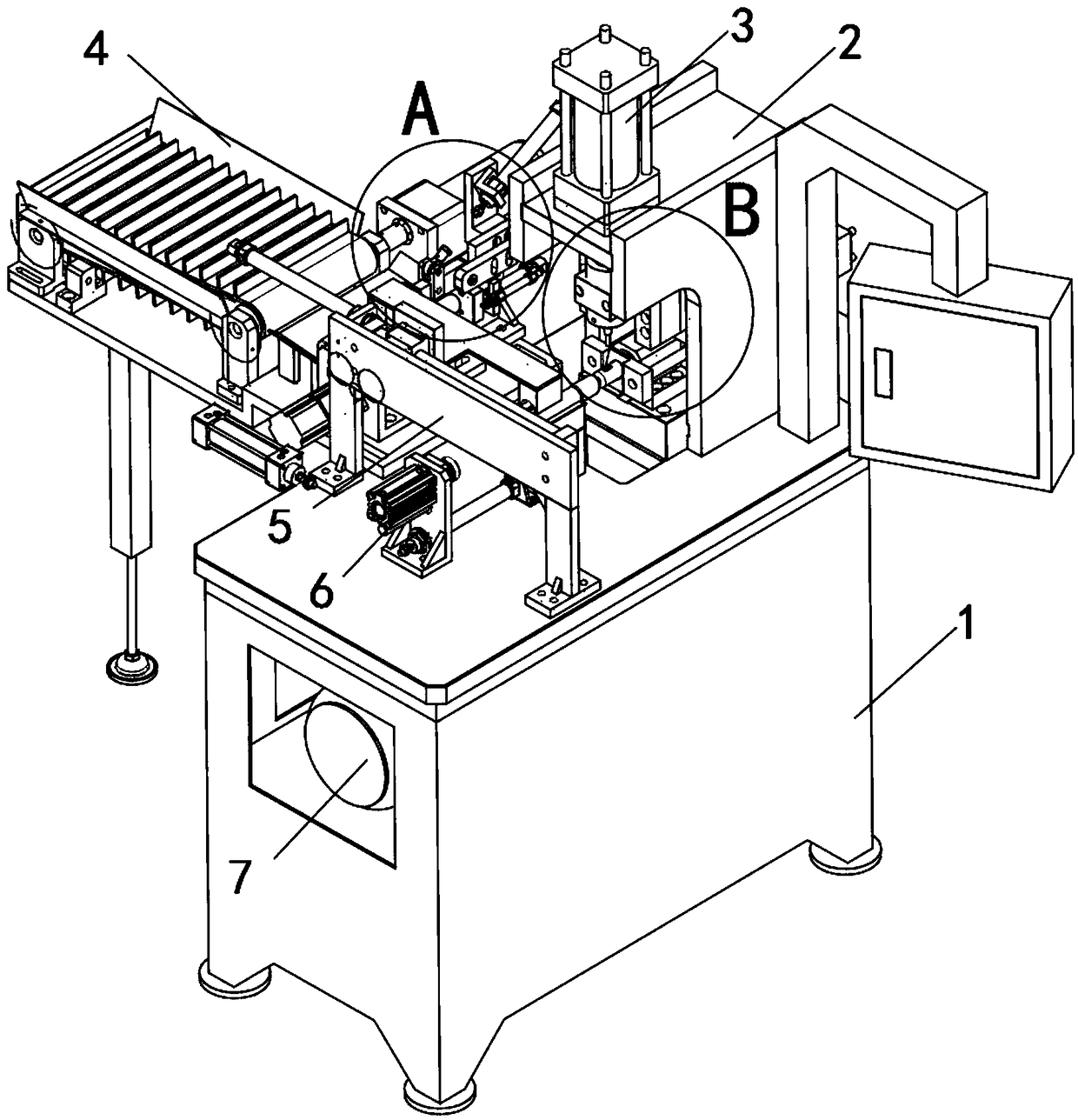

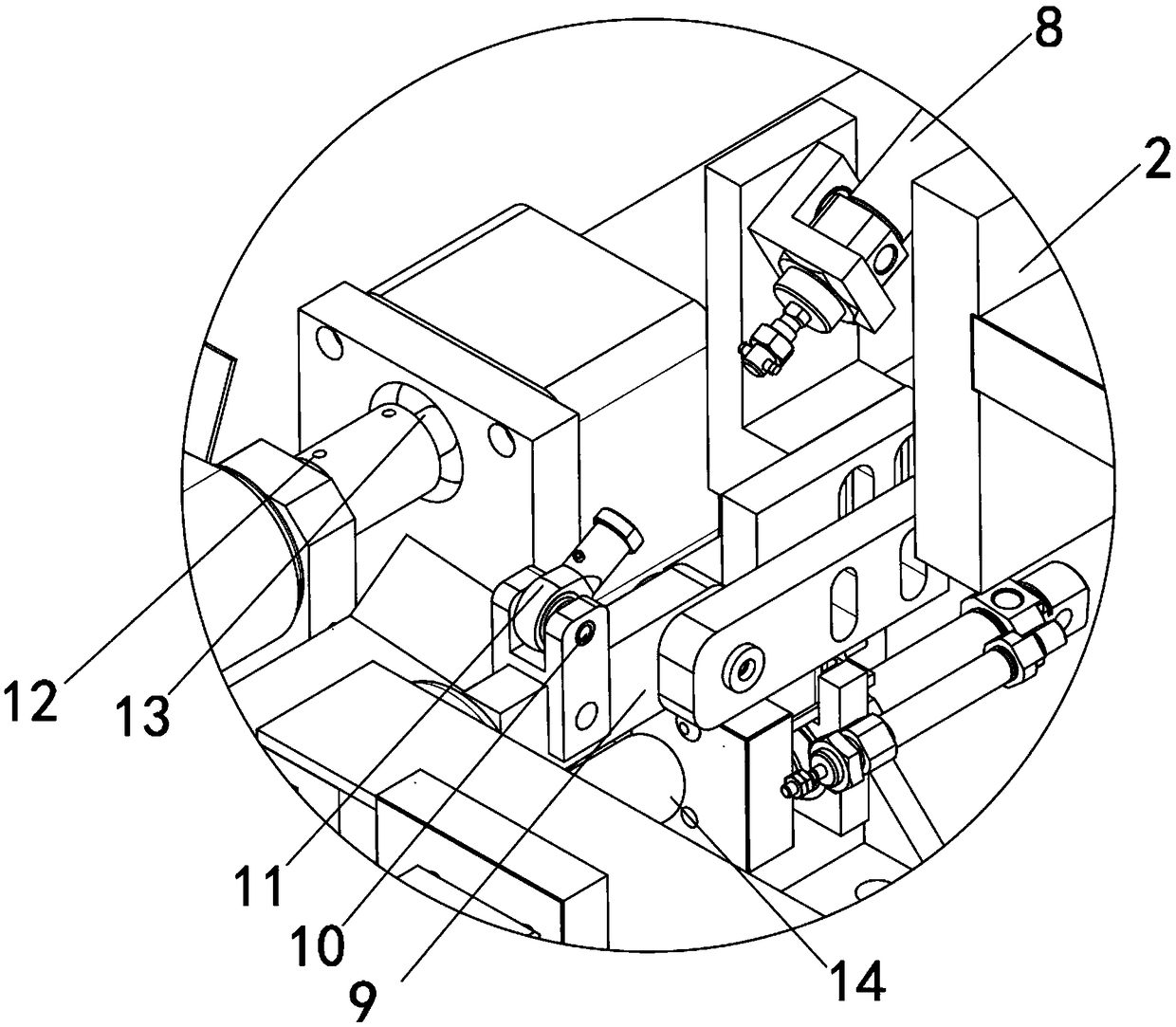

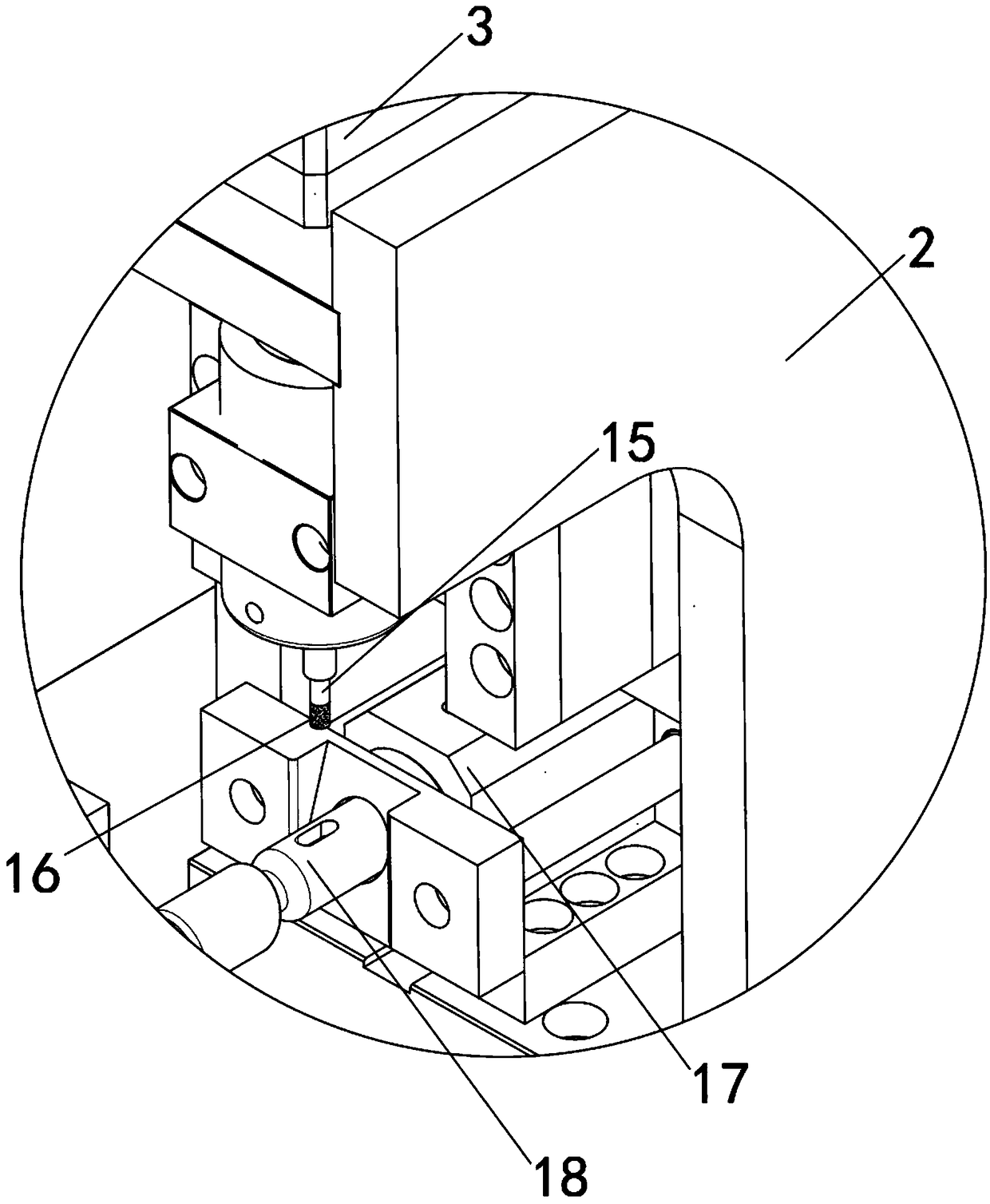

The invention discloses an automatic machine for collecting and sorting plastic soft bottles. The device comprises a conveyor for plastic bottles, soft bottles or soft bags, as well as a machine frame, wherein a traction device moving horizontally is arranged above the machine frame; a bottle clamping device connected via a lifting cylinder is arranged on a moving trolley of the traction device; the traction device, the lifting cylinder and the bottle clamping device are connected with an electric control device with electrical automatic control; a product collecting device is arranged below the machine frame beside the conveyor; and the electric control device controls the bottle clamping device to make vertical up-down lifting movement under the drive of the lifting cylinder and to make horizontal translating movement under the drive of the traction device, and controls the bottle clamping device to clamp a product input by the conveyor, to transfer the product to the product collecting device through the lifting cylinder and the traction device and then to unclamp the product. The machine can clamp, lift and translate plastic bottles, soft bottles or soft bags input by the conveyor to a preset distance, drop and put the bottles or bags into the product collecting device.

Owner:SICHUAN KELUN PHARMA CO LTD

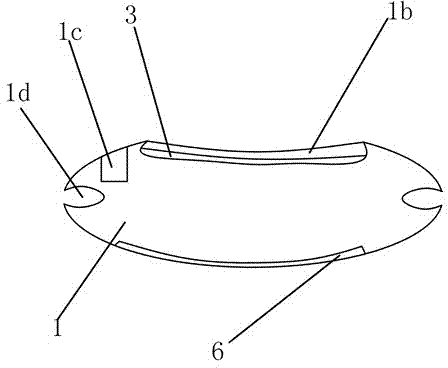

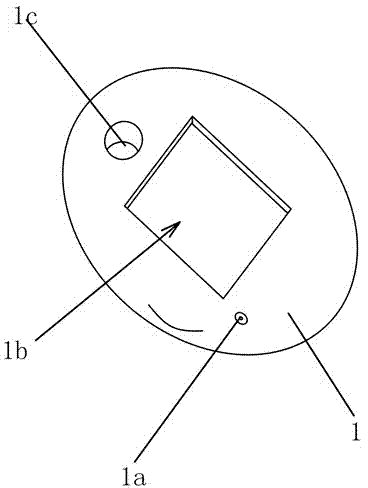

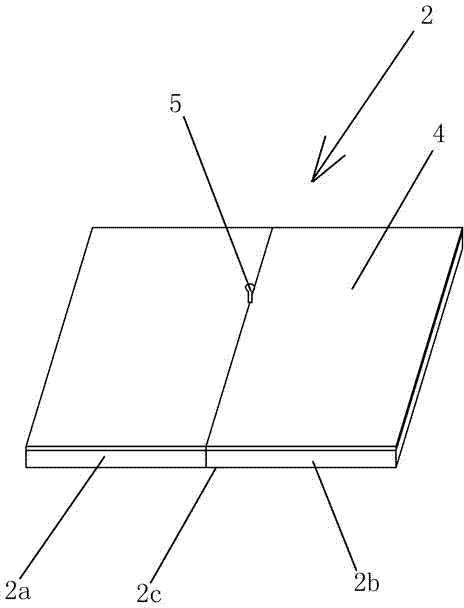

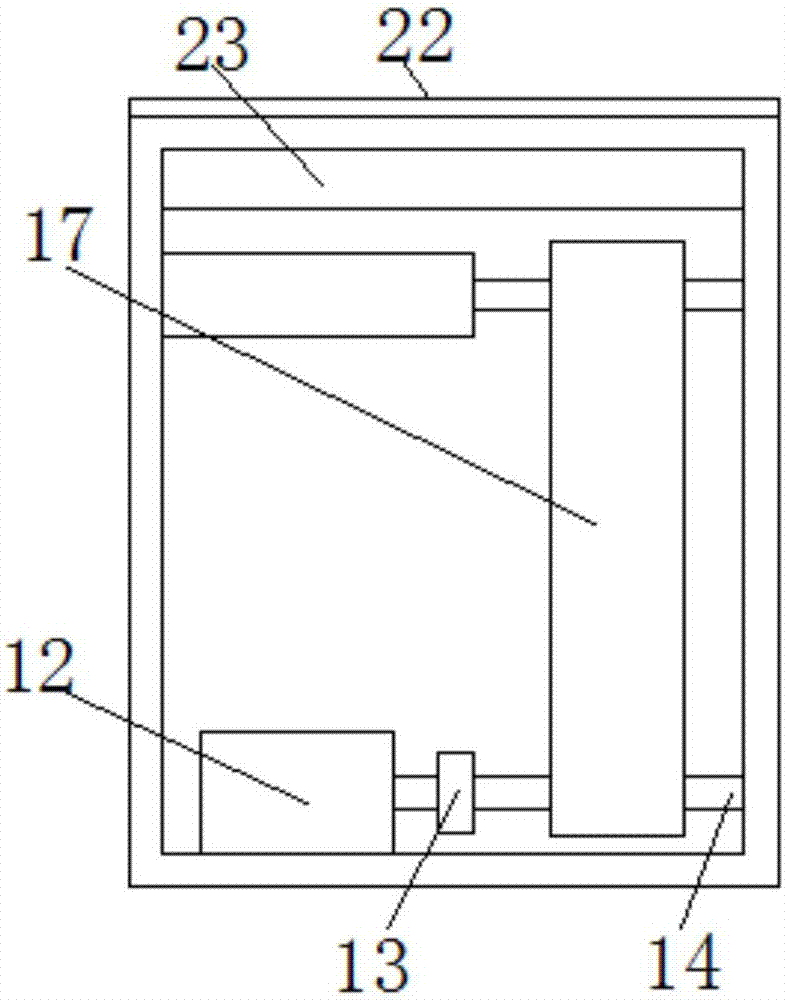

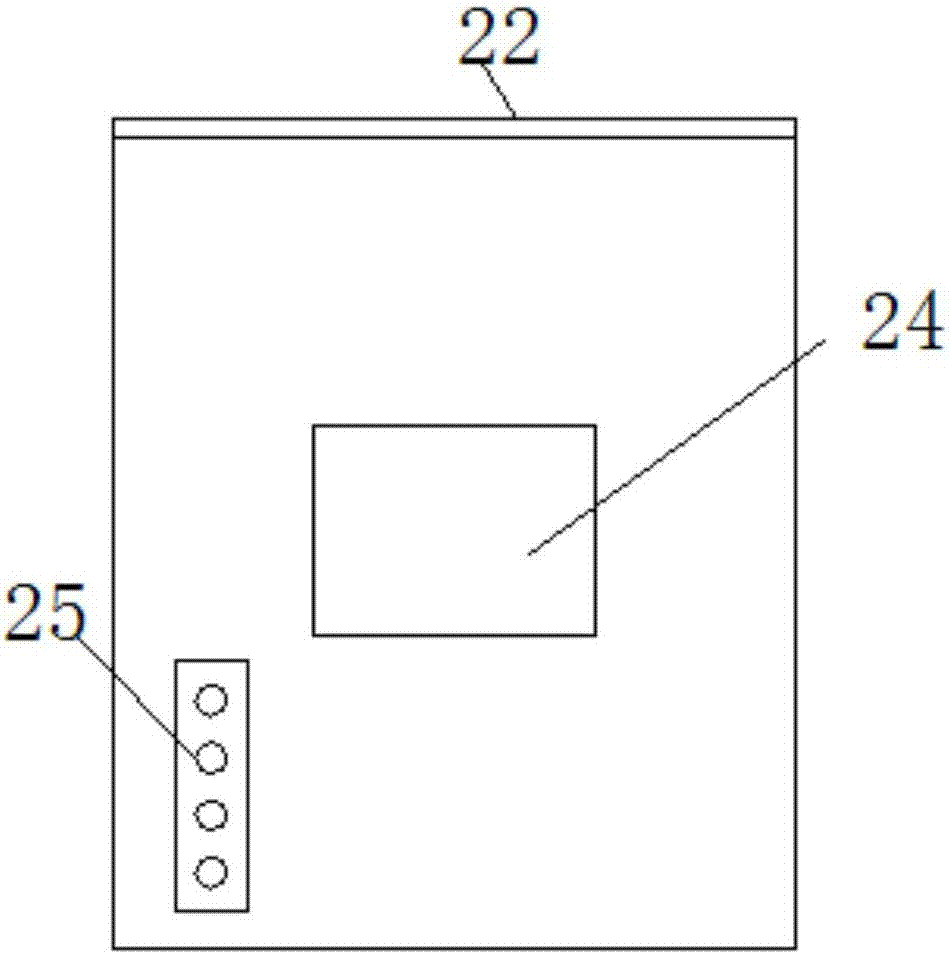

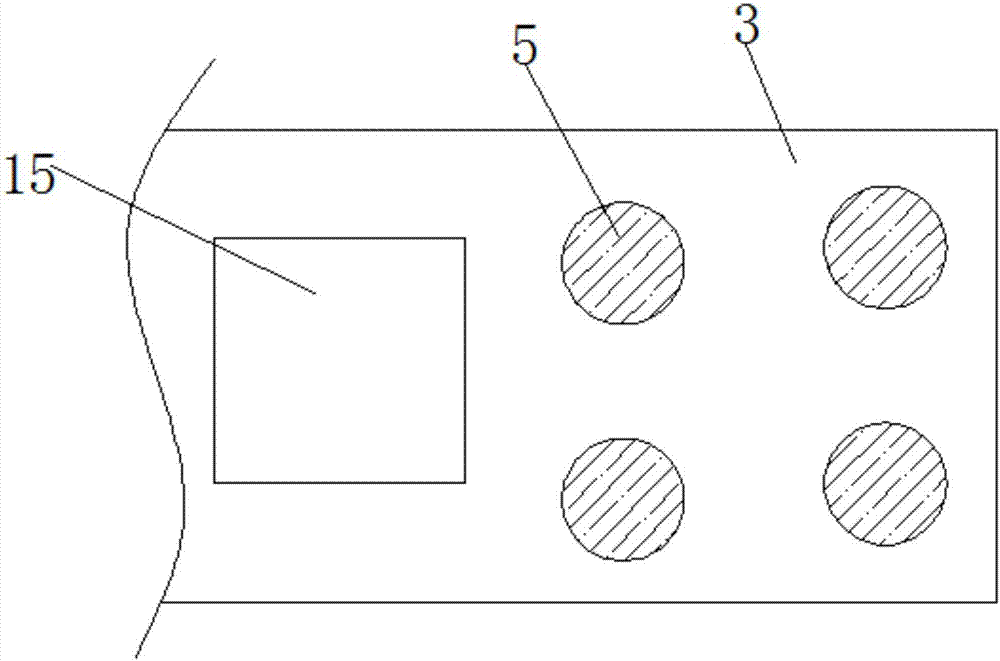

Waterproof computer bag for bathing

ActiveCN104490057AIngenious designEasy to installOther accessoriesMetallic materialsPersonal computer

The invention provides a waterproof computer bag for bathing and belongs to the field of daily necessities. The waterproof computer bag comprises an ellipsoidal air bag, wherein a unidirectional inflation hole is formed in the air bag, a square placing groove is formed in the upper end of the air bag, a square independent bag is arranged in the placing groove and consists of a bag body I and a bag body II, the independent bag is less than the placing groove, the bag body I is communicated with the bag body II, the bottom of the placing groove is fixedly connected with a metal plate made of a metal material, one sides of the bag body I and the bag body II are both fixedly connected with a soft magnetic sheet and are respectively provided with a zipper mechanism, the bag body I and the bag body II are connected to each other by virtue of the zipper mechanisms, the other sides of the bag body I and the bag body II are used as operation surfaces, each operation surface is made from PET and a silica gel material, and a stable board is arranged at and fixedly connected to the bottom in the air bag. The waterproof computer bag for the bathing is capable of sealing a panel personal computer in a bathroom and has diversified functions.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

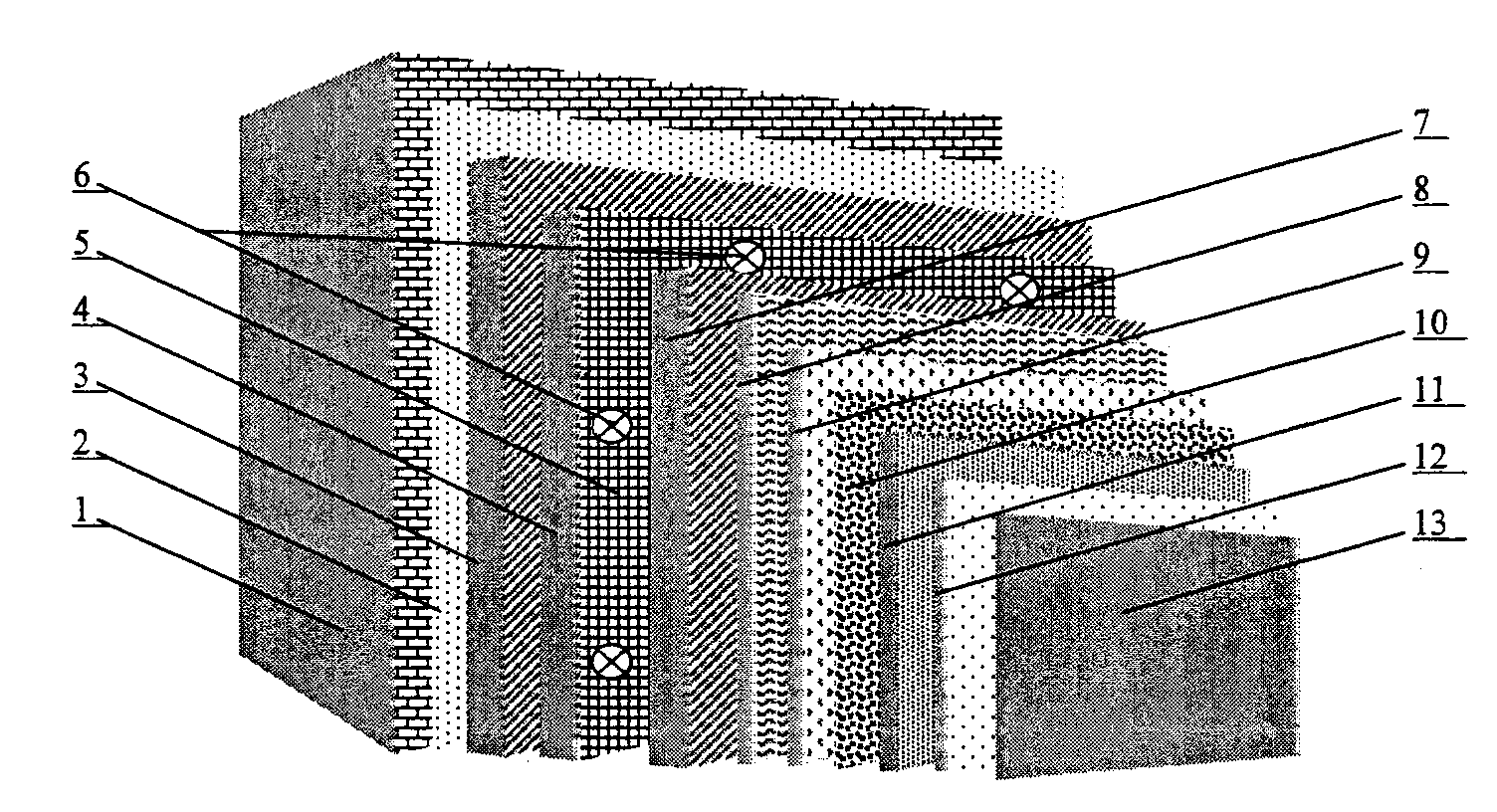

Method for retreading old porcelain brick wall by paint

InactiveCN101586401AAvoid crackingImprove water resistanceCovering/liningsBuilding repairsGlass fiberBrick

The invention relates to a method for retreading the old porcelain brick wall by the paint, a retreading decorative layer composed of a interface binder layer (2), a first polymer cracking-resistant putty layer (3), a second polymer cracking-resistant putty layer (4), a glass fiber girding cloth (5), a third polymer cracking-resistant putty layer (7), a double-component flexible putty layer (9), a smooth surface putty layer (9), a seal coat layer (10), a middle coating layer (11), a flexible silicone-acrylate latex paint layer (12) and a fluoric-carbon coating varnish layer (13) is formed on the old wall surface porcelain brick of the old wall (1), an anchor nail (6) passes through the glass fiber gridding cloth (5), the second polymer cracking-resistant putty layer (4) and the first polymer cracking-resistant putty layer (3) and is embedded in the old wall (1) for the mechanical reinforcement, all layers above are dried and solidified and are integrated with the old wall (1) firmly to complete the retread of the old wall surface. The construction cost and the labor strength are low, the old porcelain brick on the wall surface can not fall off, the decorative is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

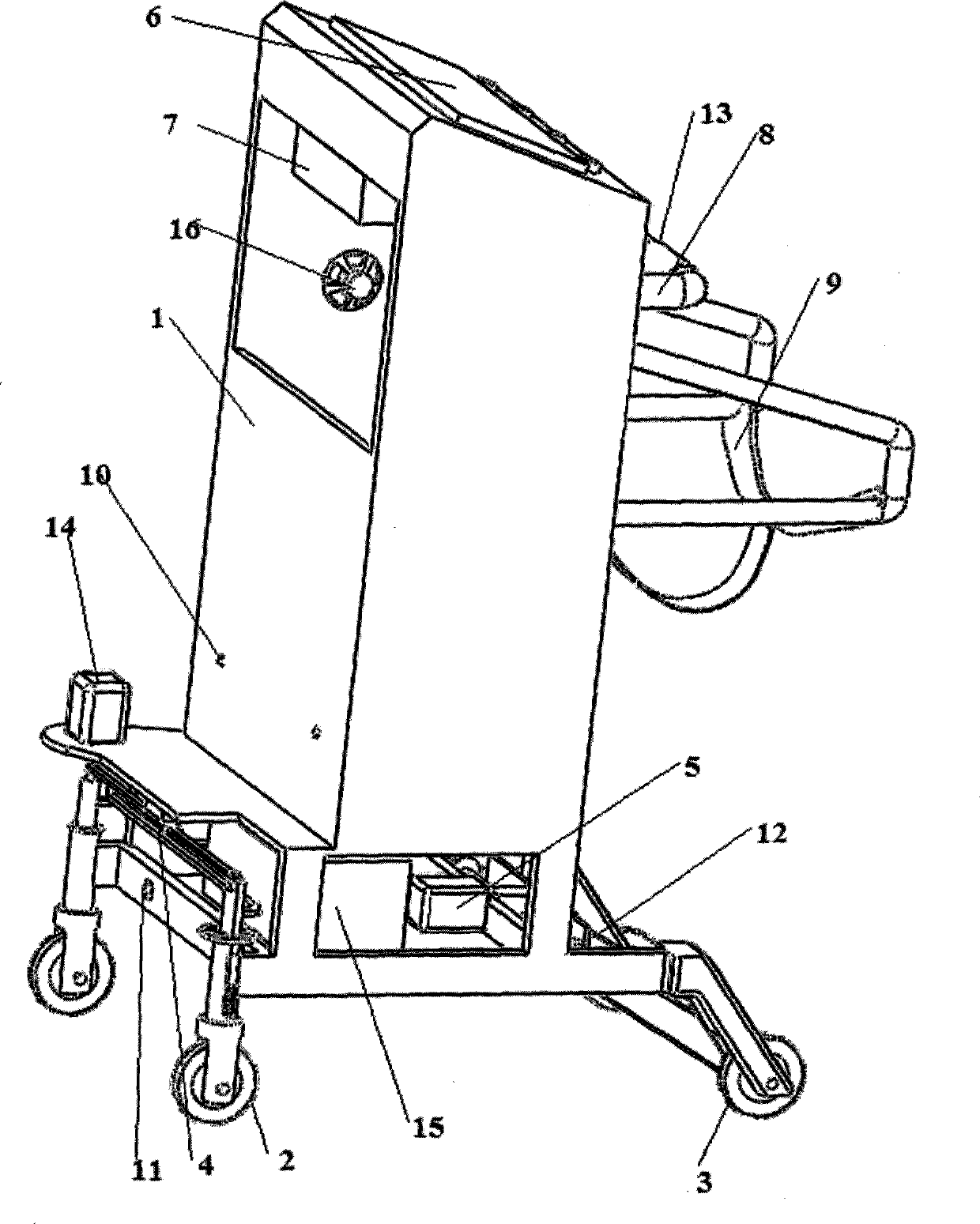

Intelligent walk-assisting robot

The invention relates to an intelligent walk-assisting robot. A controller controls a guiding control device to control motion of the robot according to input signals. A control and display panel can be used for determining whether the robot is controlled by a nurse or a patient through a key switch. The nurse can input motion time, motion speed, path parameters in advance and pull a key out, and the robot can move according to the set parameters. When the robot is controlled by the patient, the patient can control speed of the robot through a button on the panel, and enables the robot to veer through rotating of a handrail to enable the left pressure and the right pressure of a pressure sensor on the handrail to be different. The wheel-type robot can drive the patient to move according to a set program, and also can move along with steps of people. The various motion modes can ensure that leg motion training of different types of patients is met.

Owner:HARBIN INST OF TECH

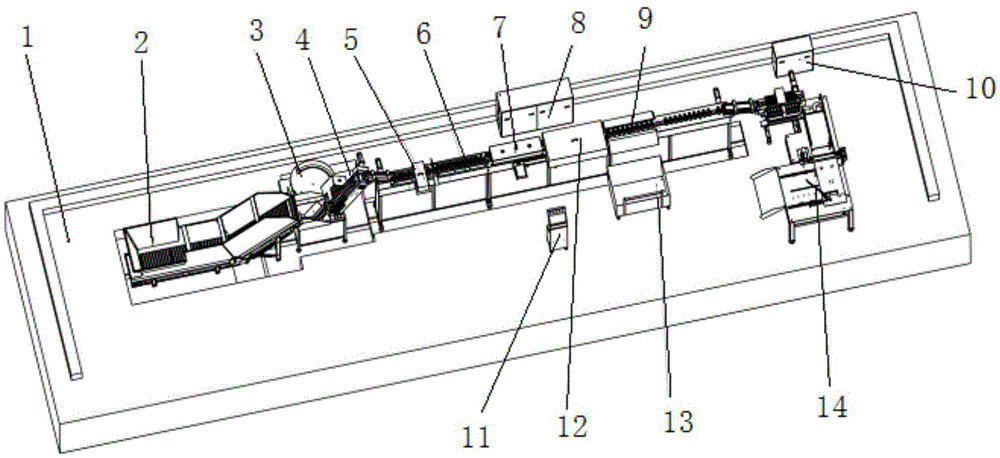

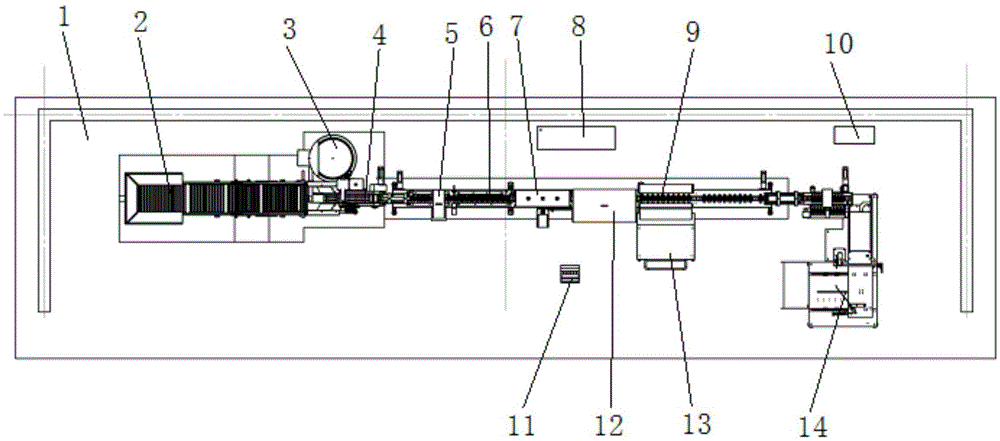

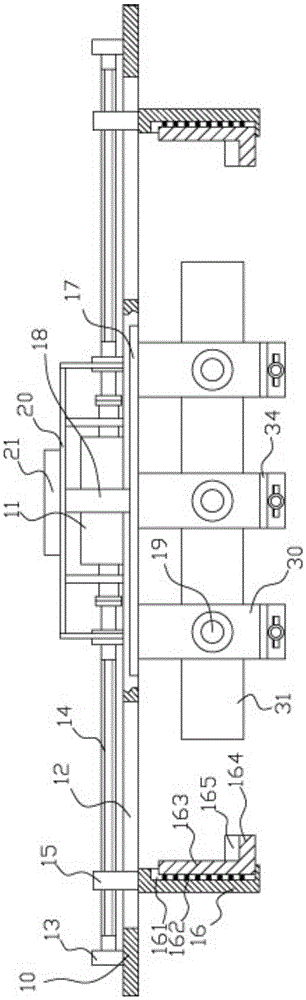

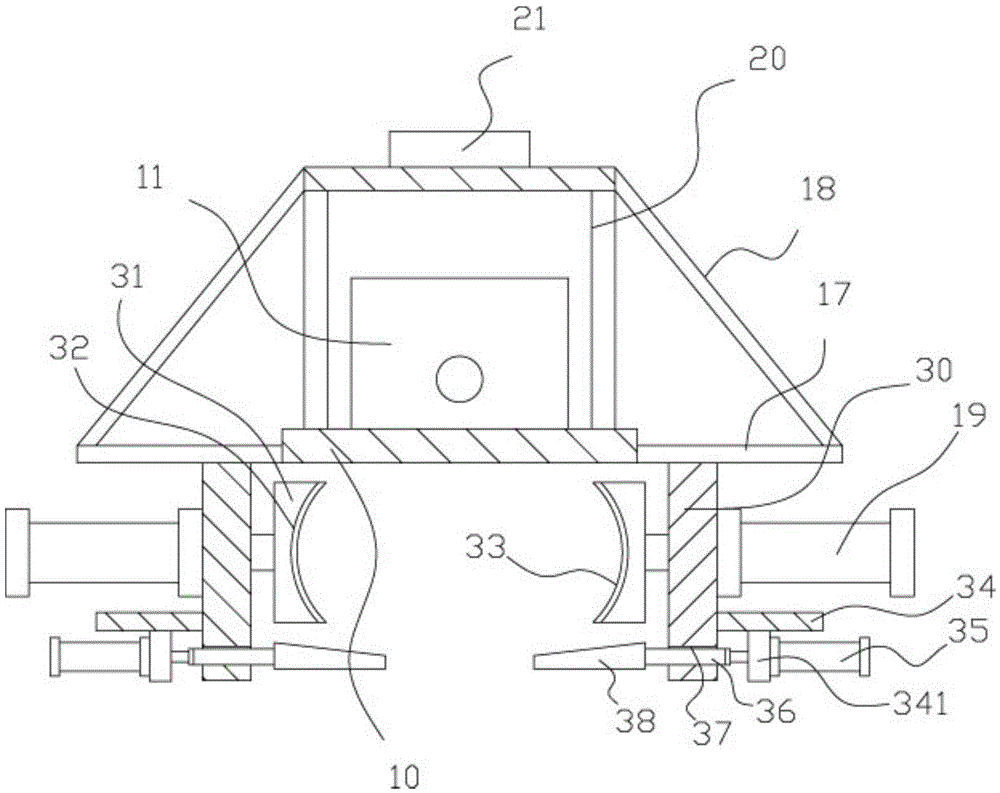

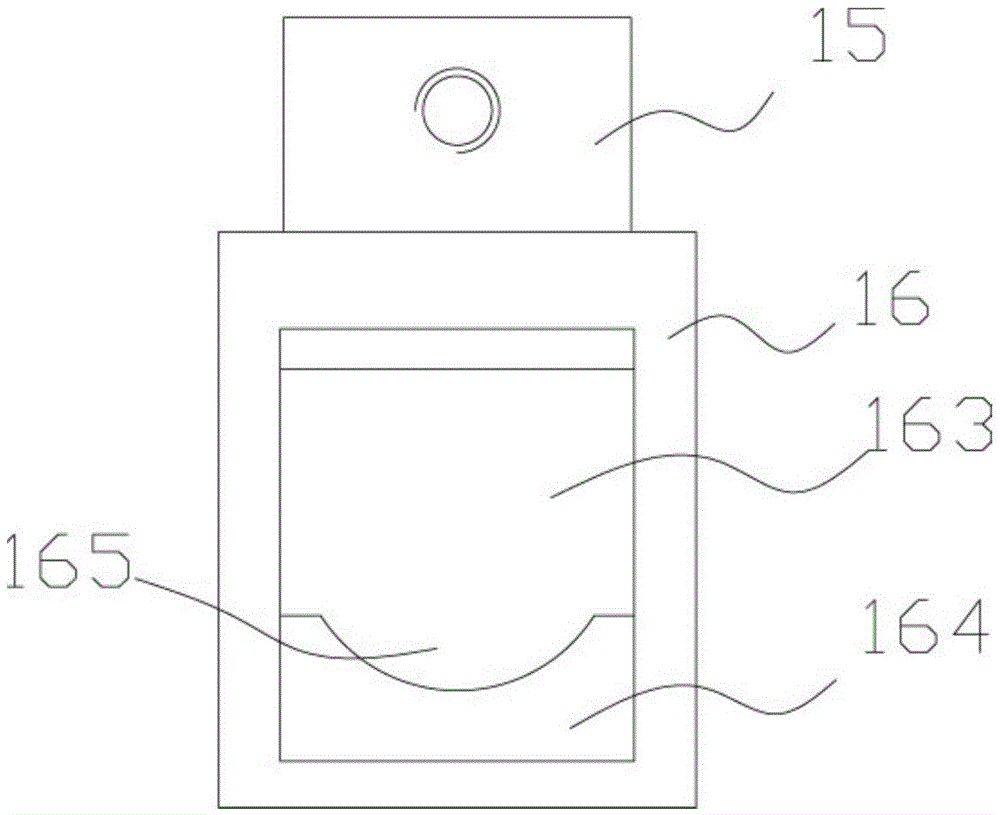

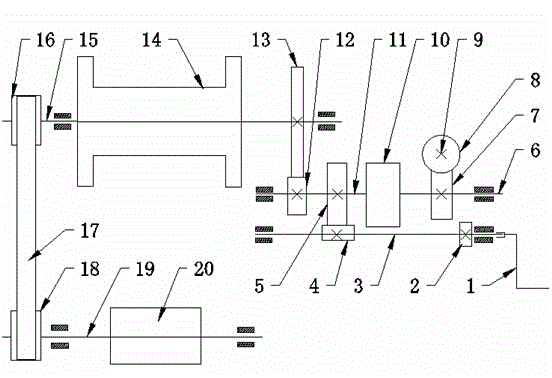

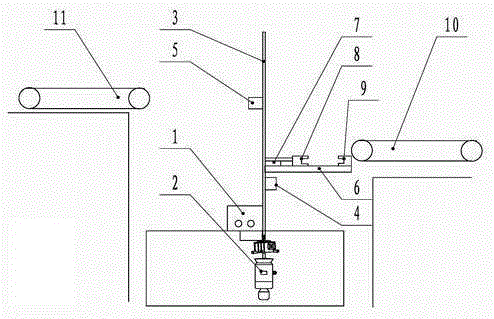

Casing pipe detection equipment and detection method thereof

InactiveCN105523369ASolve online detection problemsFully automatedConveyorsOptically investigating flaws/contaminationPetroleum engineeringVisual detection

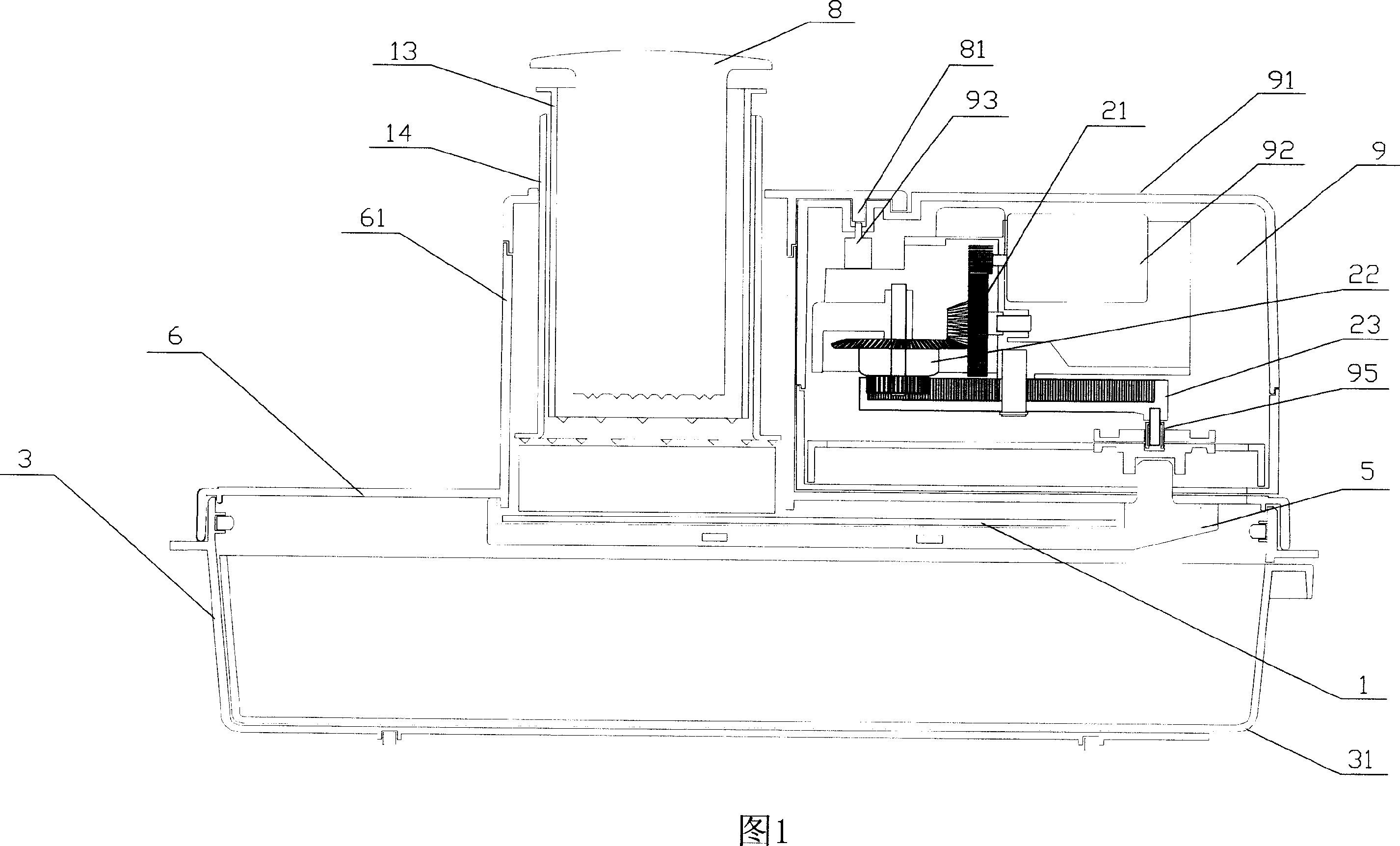

The invention discloses casing pipe detection equipment and a detection method thereof. The casing pipe detection equipment comprises a storing and loading device, a conveying device, a pre-judging and removing device, a blow-drying device, a visual detection system, a pneumatic removing system, a material arranging device and a lifting and reversing device, wherein the conveying device is connected to the lifting and reversing device, and the pre-judging and removing device, the blow-drying device, the visual detection system and the pneumatic removing system are sequentially installed on the conveying device in the conveying direction. Casing pipes are arranged to be conveyed forwards firstly, then openings of the casing pipes are arranged towards the same side, the visual detection system detects the casing pipes, the unqualified casing pipes are removed, and the qualified casing pipes are output. According to the invention, internal shortcomings of the casing pipes can be recognized, the unqualified casing pipes can be effectively detected, the shortcomings of detecting and packaging the casing pipes manually in the prior art are overcome, the work efficiency is greatly improved, the labor intensity is lowered, the product quality is guaranteed, and the railway safety is guaranteed.

Owner:HUNAN JINGNING TECH +1

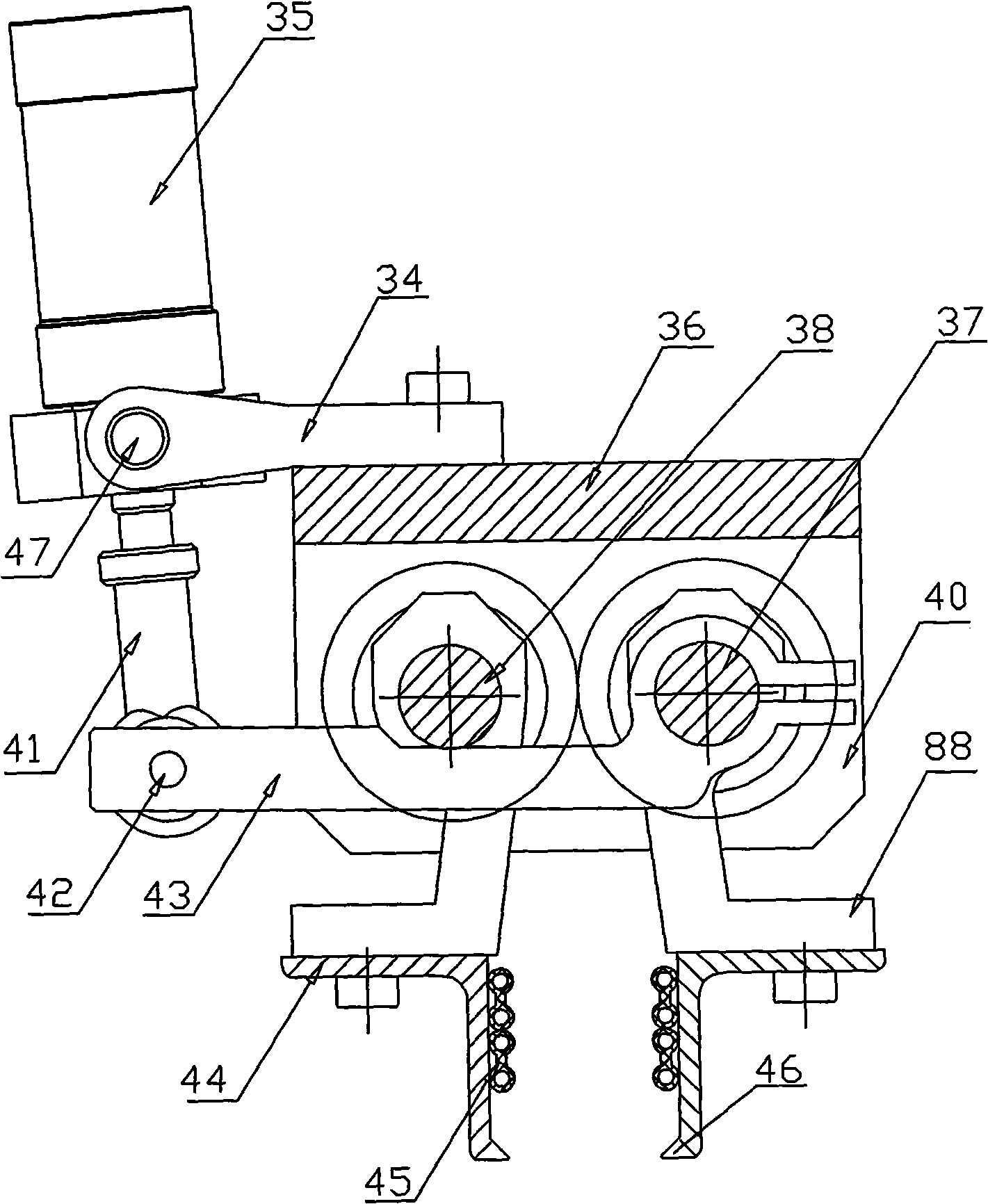

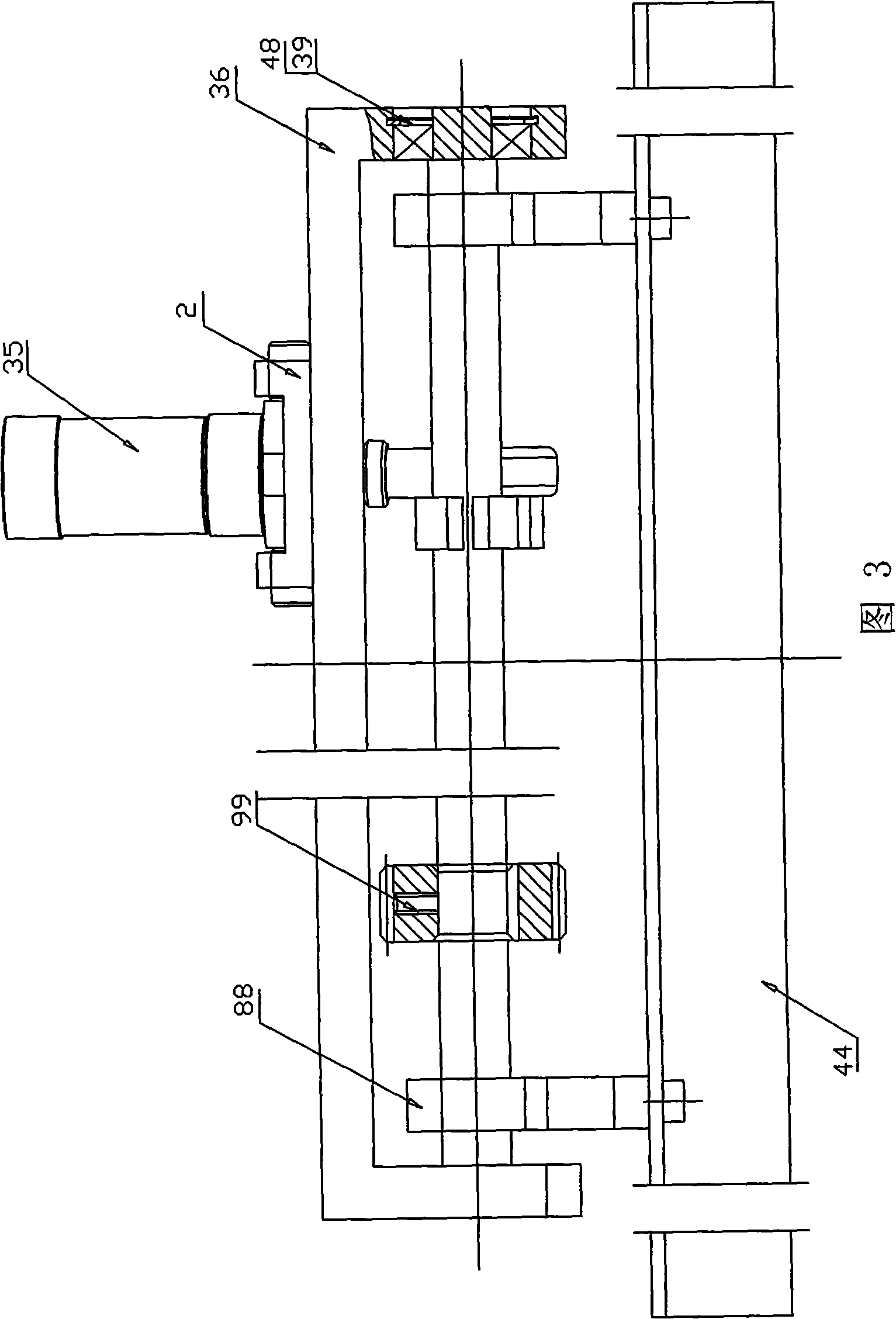

Reinforced clamping mechanism for conveying round steel

The invention discloses a reinforced clamping mechanism for conveying round steel. The reinforced clamping mechanism comprises a conveying plate; a double-extension-shaft drive motor is fixed to the top face of the middle portion of the conveying plate; long through grooves are formed in the two sides of the conveying plate; supporting plates are fixed to the positions, on the left side and the right side of the long through grooves, of the top face of the conveying plate; the two ends of a transmission screw rod are hinged to the two corresponding supporting plates; moving blocks are connected into the transmission screw rod in a screwing mode, and are inserted into the corresponding long through grooves; clamping blocks are arranged on the lower portions of the moving blocks and located below the conveying plate; the opposite walls of the two clamping blocks are provided with placing grooves; a plurality of buffer springs are fixed to the walls of the placing grooves; the buffer springs are fixed to main clamping end plates which are inserted into the placing grooves; the lower portions of the opposite walls of the two main clamping end plates are provided with bottom convex blocks; and arc-shaped placing grooves are formed in the top faces of the bottom convex blocks. The reinforced clamping mechanism can clamp the round steel firmly, facilitate conveying, prevent the round steel from falling off and has high safety.

Owner:陈玲婷

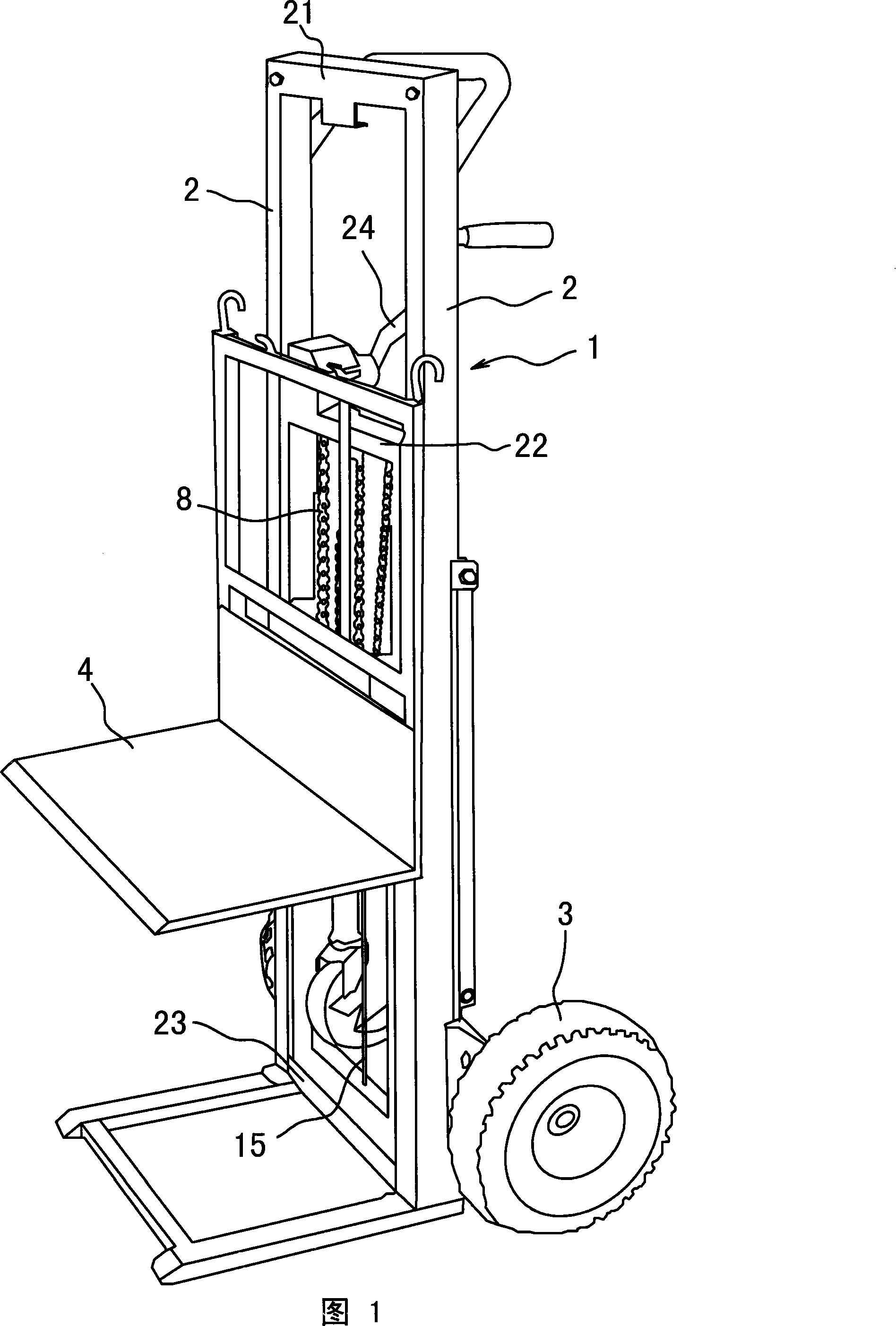

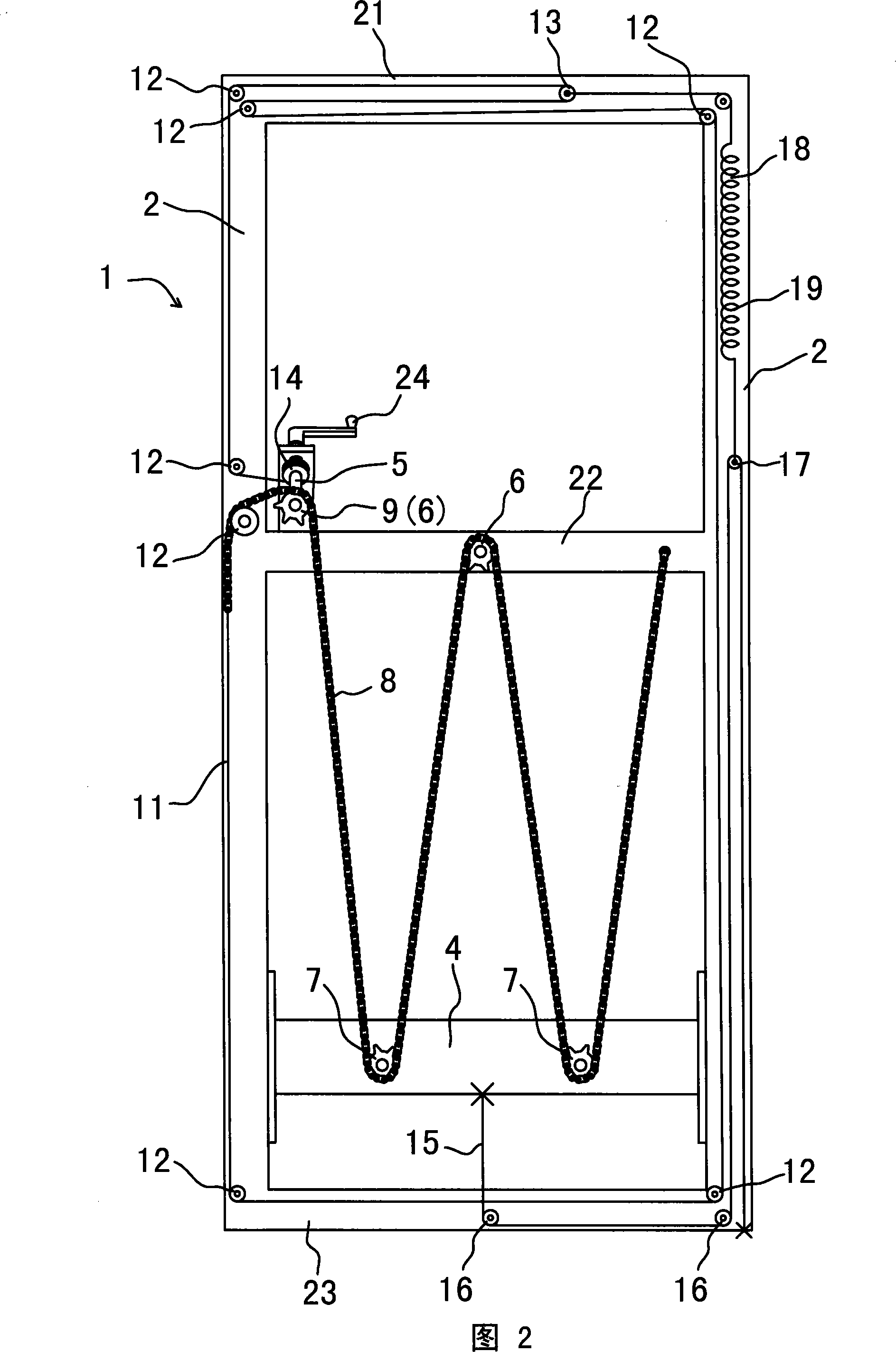

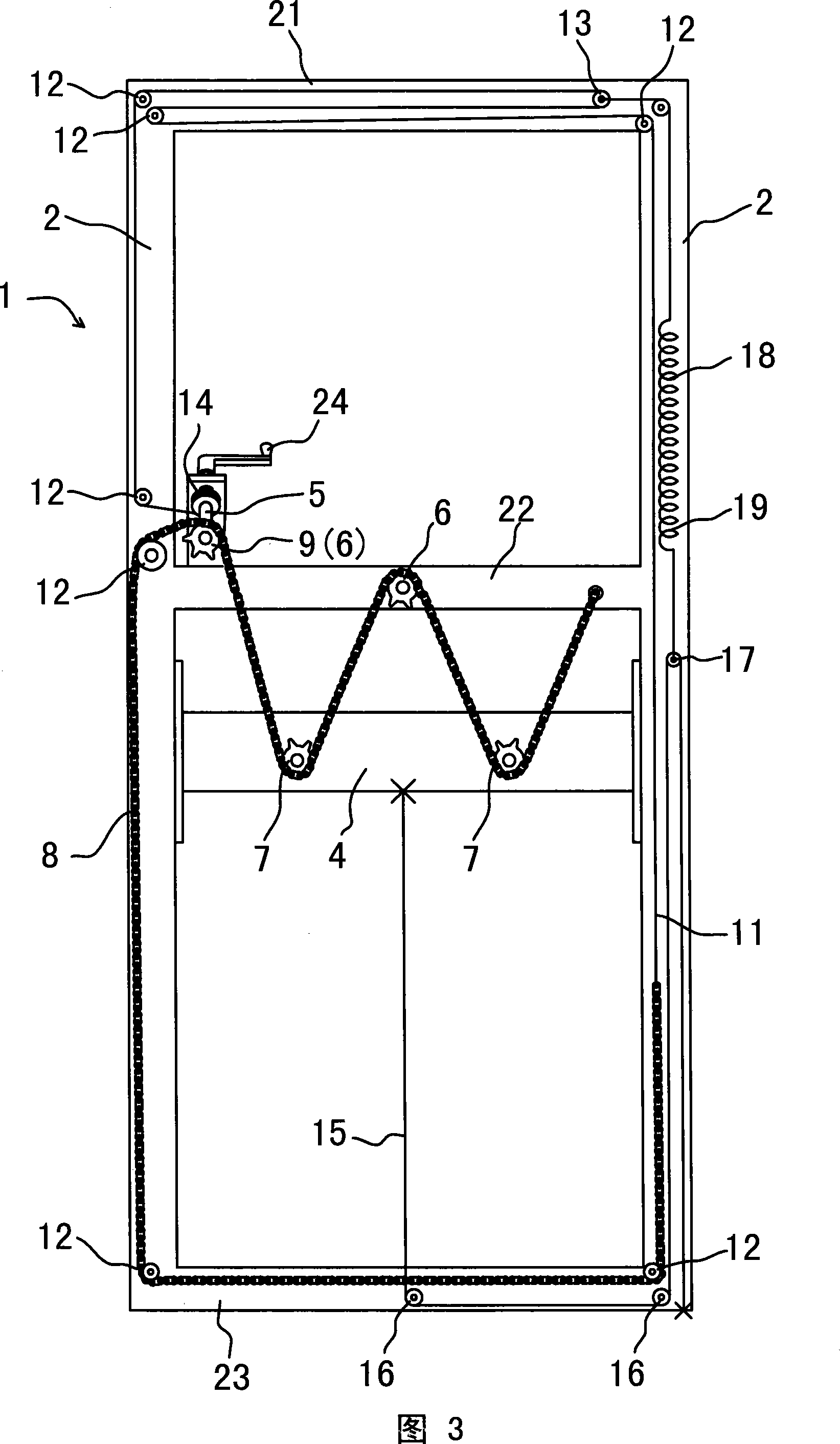

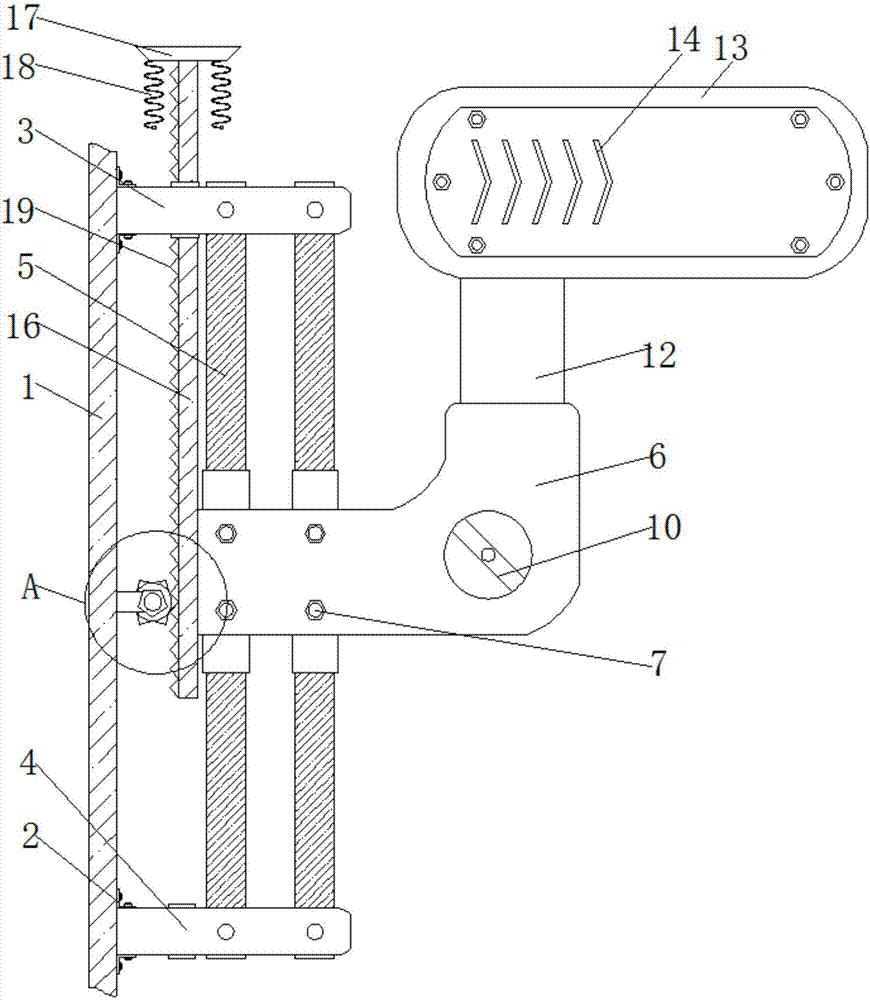

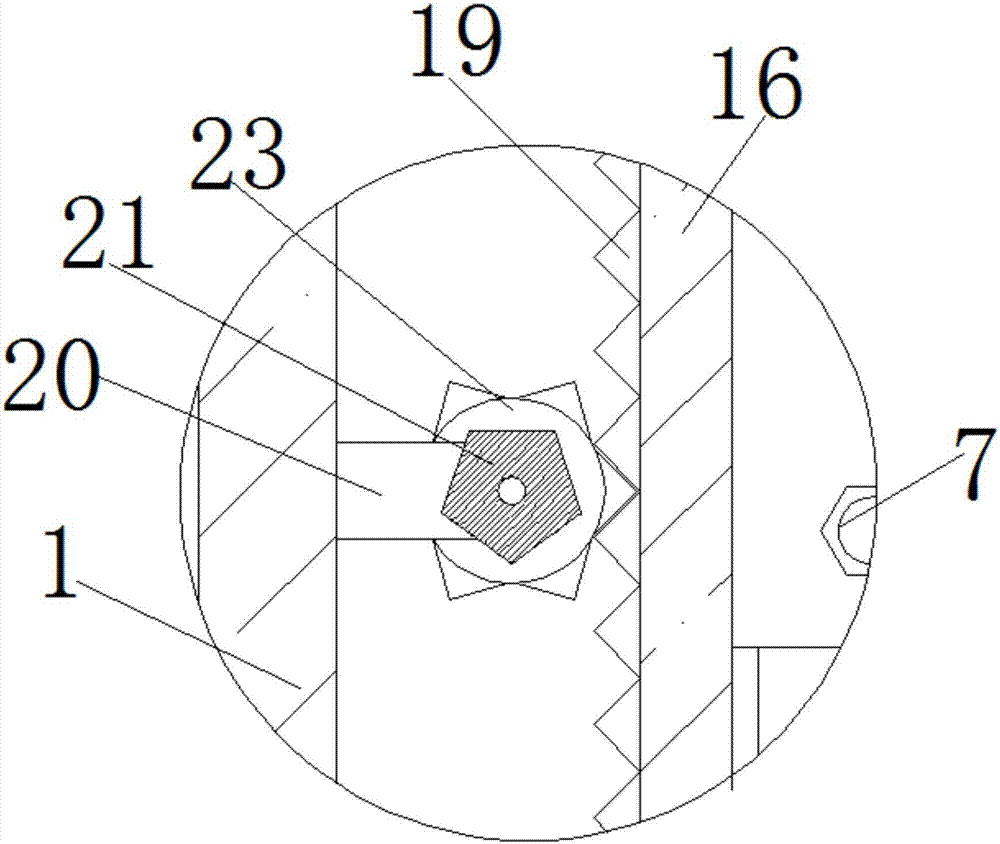

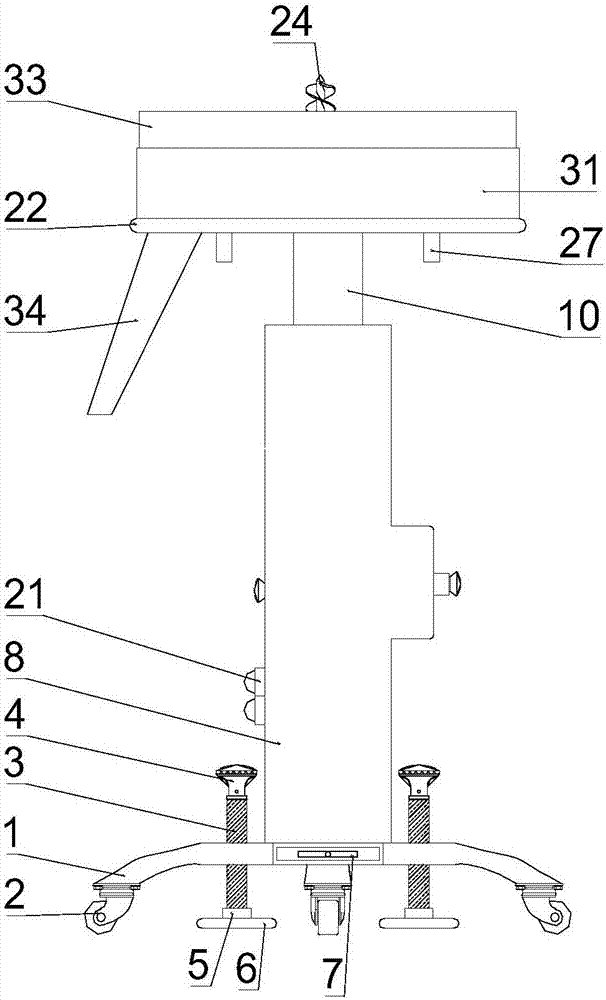

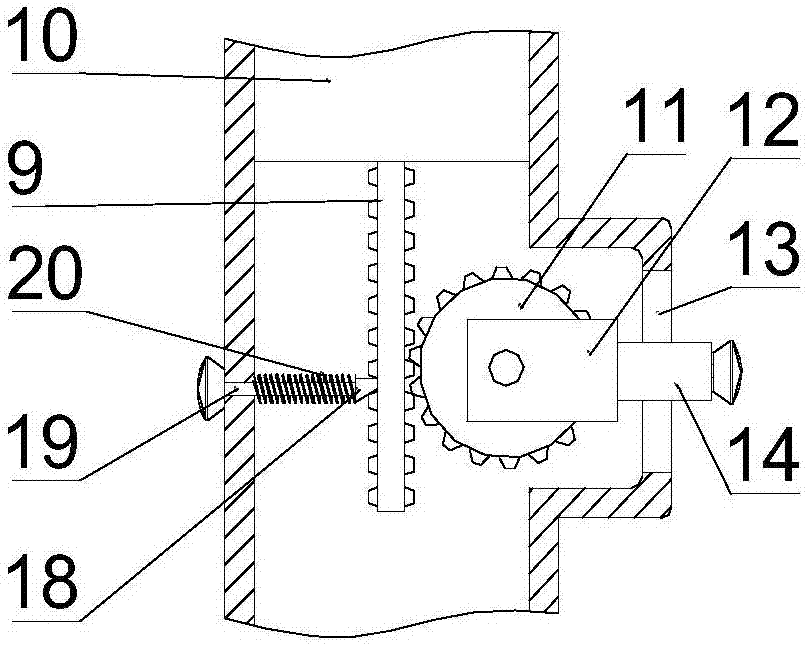

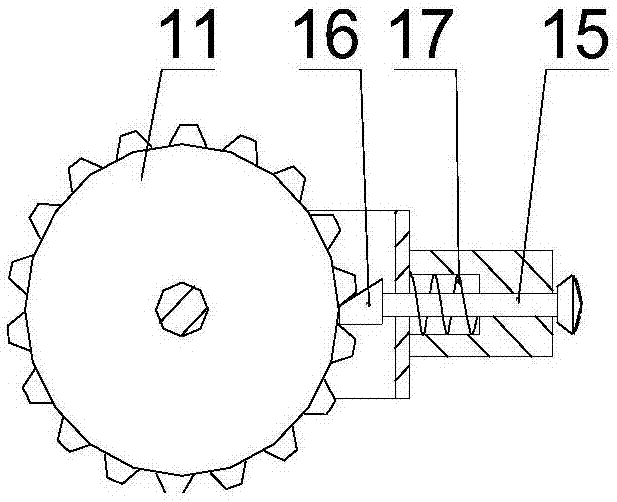

Liftable hand propelled carrying vehicle

The invention provides a lifting hand-pushing van, comprising a vertical frame which includes an enclosed frame formed by hollow pipes; the bottom of the frame is provided with a walking wheel; the vertical frame is connected with an object arranging frame in a sliding way; a lifting hoisting mechanism is arranged between the upper part of the vertical frame and the object arranging frame; the lifting hoisting mechanism consists of a pulley block, a traction rope, a mainshaft and a reverse rotary self-locking device. The invention is characterized in that the traction rope is a chain; the last crown block of the pulley block is a drive chain wheel which is fixedly connected with the mainshaft which is connected with a power source by the reverse rotary self-locking device; the invention also comprises a chain tensioning and intake mechanism consisting of a first cable wire, a first guide wheel, a first movable wheel and a first pulling spring section, and a backing tensile stabilizing mechanism consisting of a second cable wire, a second guide wheel, a second movable wheel and a second pulling spring section; the invention has the advantages of good strength of chain, being not easy to be broken or be disconnected from the wheel, reliable operation, and high safety.

Owner:刘清华

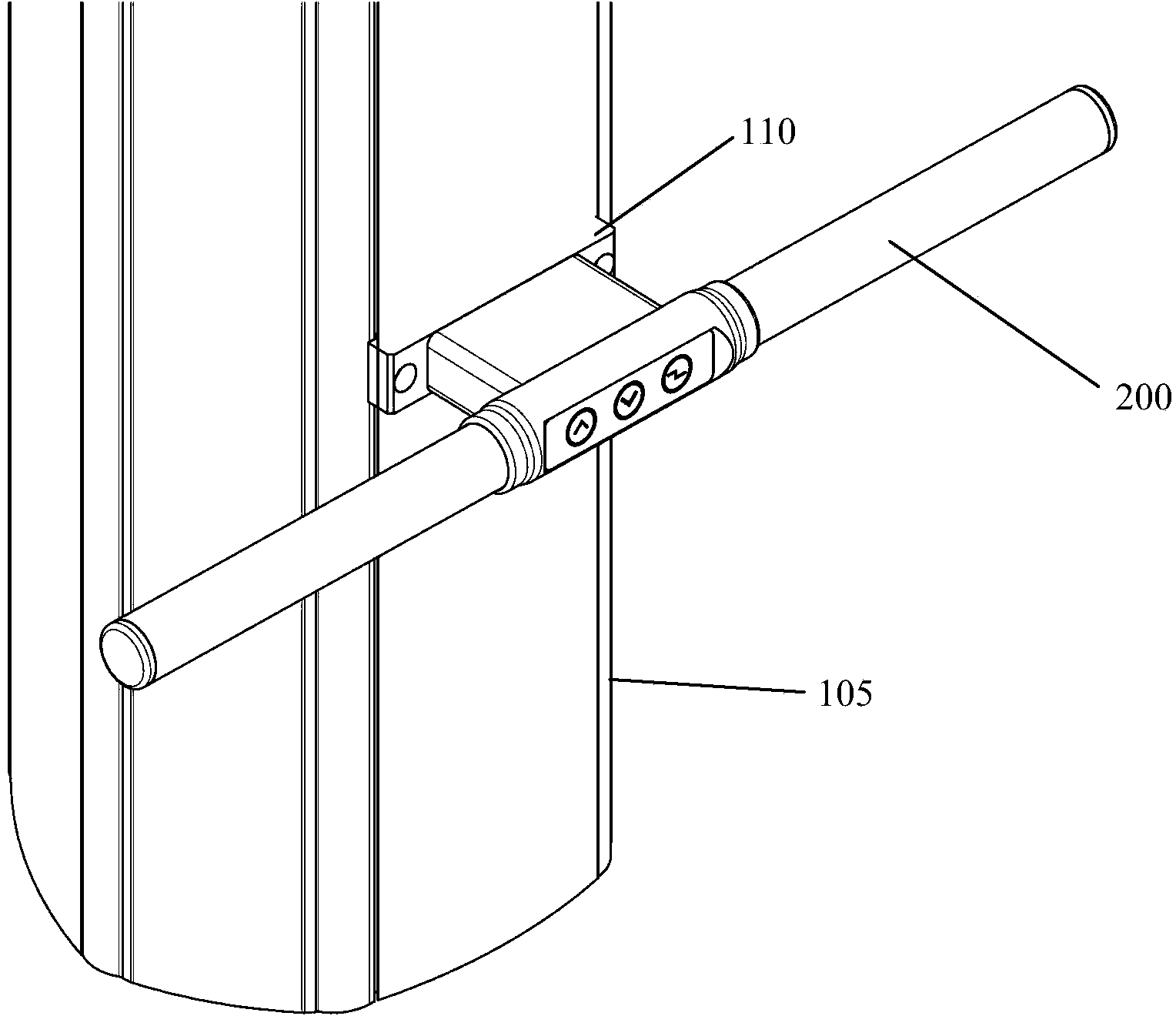

Movable type accessory fixing device applied to medical crane

The invention relates to a movable type accessory fixing device applied to a medical crane. The movable type accessory fixing device applied to the medical crane comprises a body, a left clamping piece, a right clamping piece and a clamping piece fastening piece. The body is provided with an accessory mounting part used for mounting accessories, clamping piece containing troughs used for containing the left clamping piece and the right clamping pieces respectively are arranged on the left side and the right side of the body, and the left clamping piece and the right clamping piece move towards each other to clamp the medical crane tightly through the fastening function of the clamping piece fastening piece. The movable type accessory fixing device applied to the medical crane has the following advantages that the device can be lifted to adjust the height of mounted accessories freely, the device is convenient to disassemble and assemble fast, consumed time is quite short, communication cables and electric cables are needless of being connected complexly, and the device is large in bearing capacity and not prone to loosing.

Owner:MAQUET SUZHOU

Comprehensive cleaning device for sports ball equipment of different sizes

InactiveCN107469308APrevent slippingMeet cleaning requirementsBall sportsTransverse axisSports equipment

The invention discloses a comprehensive cleaning device for sports ball equipment of different sizes, and relates to the field of sports equipment. The comprehensive cleaning device comprises a bearing table, a supporting frame, a bearing support arranged at the upper portion of the supporting frame, and annular clamping plates symmetrically arranged in the middle of the bearing table. A balancing plate is arranged at the lower end of the bearing support and fixed to the top wall of the bearing support through a plurality of supporting connecting rods. Clamping groove sliding openings are symmetrically formed in the surface of the balancing plate in the direction of the transverse axis. Two connecting rods are symmetrically arranged in the clamping groove sliding openings. The bottom ends of the two connecting rods are connected with two first electric push rods. The ends of the two first electric push rods are connected with the annular clamping plates respectively. The lower ends of the two first electric push rods are provided with two second electric push rods respectively. The ends of the two second electric push rods are each connected with an annular cleaning brush plate. The comprehensive cleaning device is simple in structure, meets the requirement of cleaning balls with different diameters, more comprehensively cleans the surfaces of the ball equipment, is better in cleaning effect and reduces the environment pollution.

Owner:弘毅天承知识产权股份有限公司

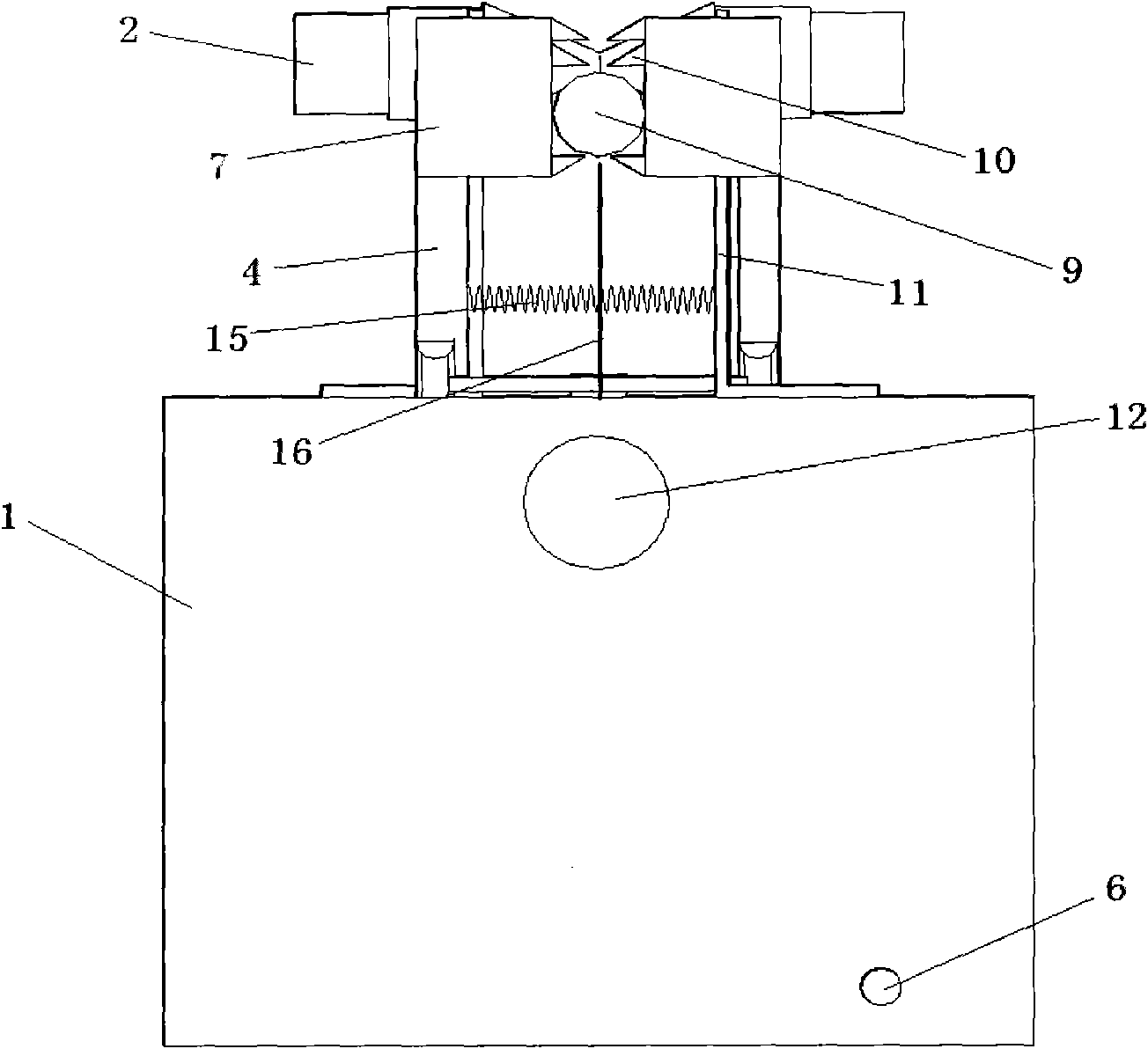

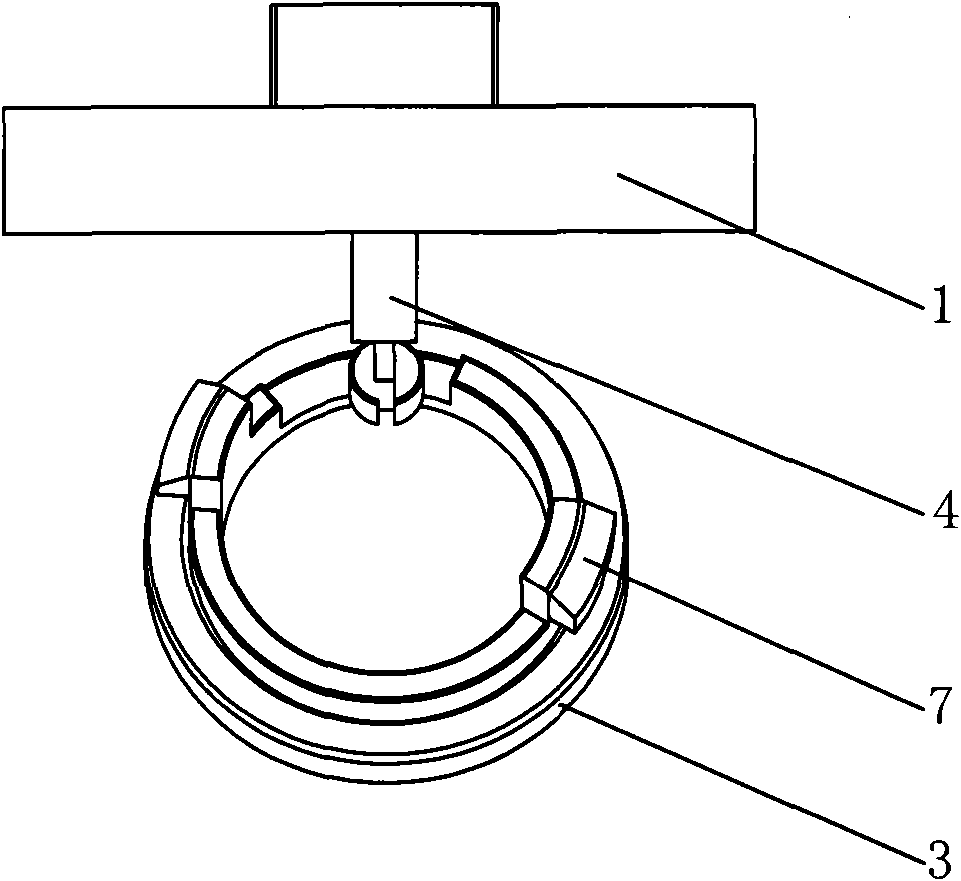

Deicing device for high-voltage power transmission cable

InactiveCN101567540AMobile stable and reliableEasy to driveOverhead installationMotor driveEngineering

The invention provides a deicing device for a high-voltage power transmission cable, and belongs to a high-voltage power transmission auxiliary device. The device consists of a host, a striking device and a traveling device, wherein a wireless receiving module, a limit switch, a motor driving module, an alarm module and an illuminator, which are arranged on the host, are connected with a micro processor respectively; an L-shaped probe is arranged at the front end of a shell of the host; a power supply is connected with and supplies power for all circuit modules in the host; the striking device is provided with two striking rods, one end of each striking rod is provided with a striking hammer and the other end of the striking rod is fixed on the shell of the host through a bearing, and the striking rods can rotate around the bearings; a friction rod is arranged between the striking rods, and the two striking rods are fixedly provided with springs; the shell of the host is fixedly provided with a motor, and a rotary shaft of the motor is fixedly provided with a cam; two support racks of the traveling device are fixed on the shell of the host respectively, and the two support racks are fixedly provided with two driving motors of which rotary shafts are fixedly provided with traveling wheels; control switches of the motor of the striking device and the two driving motors are connected with the motor driving module respectively. The device is practical and can be conveniently and safely used.

Owner:SHANDONG UNIV

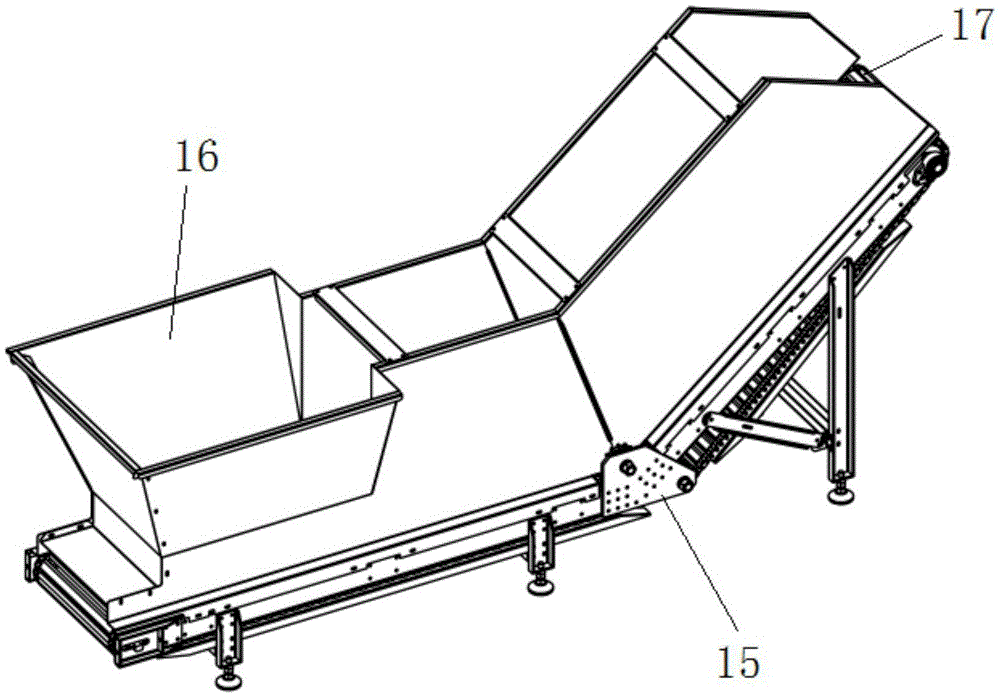

Picking cart for prickly pear

ActiveCN109287270ASimple structureImprove picking safetySievingScreeningPEARAgricultural engineering

The invention discloses a picking cart for prickly pear. The cart comprises a mobile mechanism, a cutting mechanism, a tightening mechanism, a conveying mechanism, a thorn removal mechanism, a screening mechanism, a supporting mechanism and a key module. The supporting mechanism is arranged on the mobile mechanism, the screening mechanism is arranged on the mobile mechanism, and the thorn removalmechanism is arranged on the screening mechanism; the cutting mechanism is arranged on the supporting mechanism, the conveying mechanism is arranged on the cutting mechanism and the mobile mechanism,the tightening mechanism is arranged on the cutting mechanism, and the key module is arranged on the supporting mechanism and the tightening mechanism. The invention belongs to the technical field ofagricultural machinery and particularly provides the picking cart for the prickly pear. The picking cart for the prickly pear is easy to operate, convenient to move, high in safety and picking efficiency and capable of cutting the prickly pear without damage, guaranteeing that the prickly pear without damage is conveyed to a loading box and achieving real-time thorn removal and screening.

Owner:济宁理工思源物业服务有限公司

Solid wood composite antique floor and manufacturing method thereof

ActiveCN102134903AGood dimensional stabilityWith antique effectNatural patternsDecorative surface effectsSolid woodWood fibre

The invention relates to a solid wood composite antique floor and a manufacturing method thereof, and belongs to the technical field of floor manufacturing. The solid wood composite antique floor comprises a solid wood composite plate, wherein a sunken wood grain imitation texture with the depth of 0.1 to 0.5mm in a direction vertical to the direction of wood fibers is carved on a surface layer on the front side of the solid wood composite plate; the wood grain imitation texture is provided with a surface carbonization structure; and a paint coating is covered on the surface layer on the front side of the solid wood composite plate. The method comprises the following steps of: processing the front side of the solid wood composite plate by using a carving roller to ensure that the front side of the solid wood composite plate is provided with the sunken wood grain imitation texture; performing surface hot pressing carbonization on the front side of the solid wood composite plate by using a hot pressing roller with a protruding texture; and performing surface sanding and coating on the front side of the solid wood composite plate, wherein the protruding texture on the hot pressing roller is matched with the sunken wood grain imitation texture. Compared with the conventional solid wood antique floor, the solid wood composite antique floor has the advantage of high dimensional stability.

Owner:ZHEJIANG SHIYOU TIMBER

Management method for positioning archival data to books and device for realizing method

The invention discloses a management method for positioning archival data to books. The management method comprises the steps as follows: (1), a plurality of rotatable hanging hoppers are mounted in an archive cabinet, and after information of archival data books is input into a terminal control system of the archive cabinet for storage, the archival data books are placed in the hanging hoppers in sequence; (2) the information of one archival data book is input into the terminal control system, one hopper stored with information of the archival data book is operated to an access window, a laser indicator light is switched on, and laser irradiates on the archival data book or the position where the archival data book is placed; (3), after the archival data book is stored, the single operation is completed; and (4), the step (2) and the step (3) are repeated, and the next archival data book can be positioned and stored. With the adoption of the management method for positioning the archival data to the books, the work efficiency of archive management staff can be improved, and the archival data can be searched accurately and positioned to books. The invention further relates to a device for realizing the management method for positioning archival data to the books.

Owner:JIANGSU XUNJIE HARNESS TECH

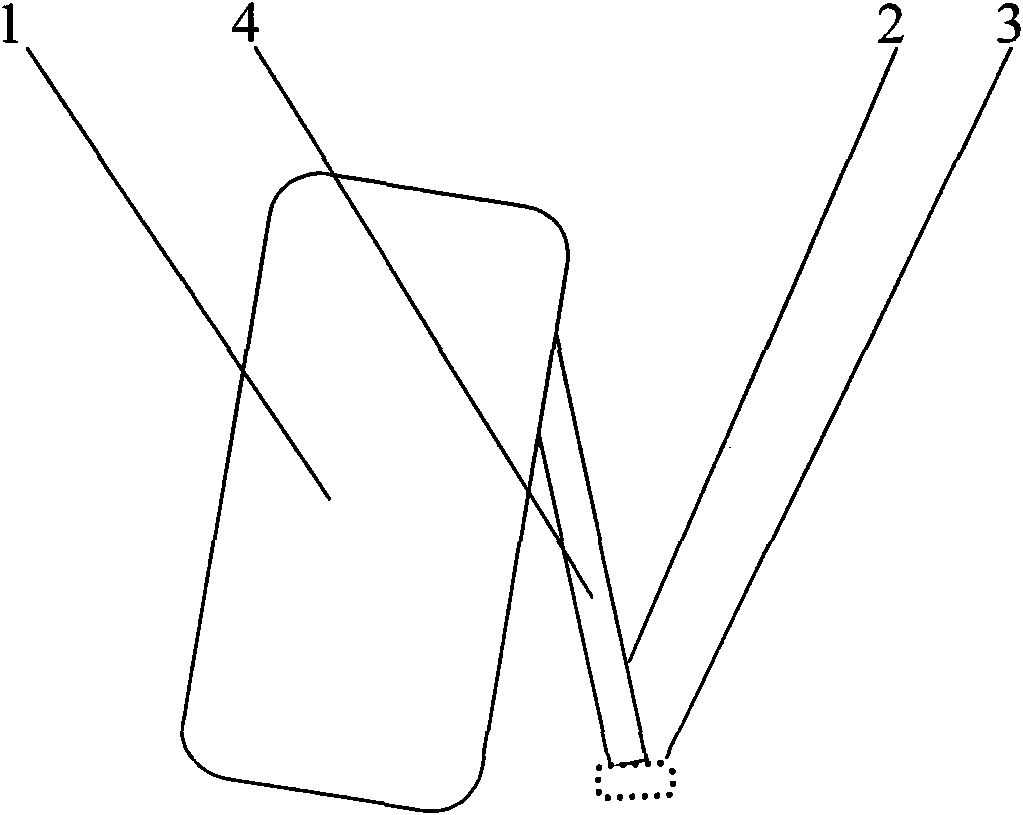

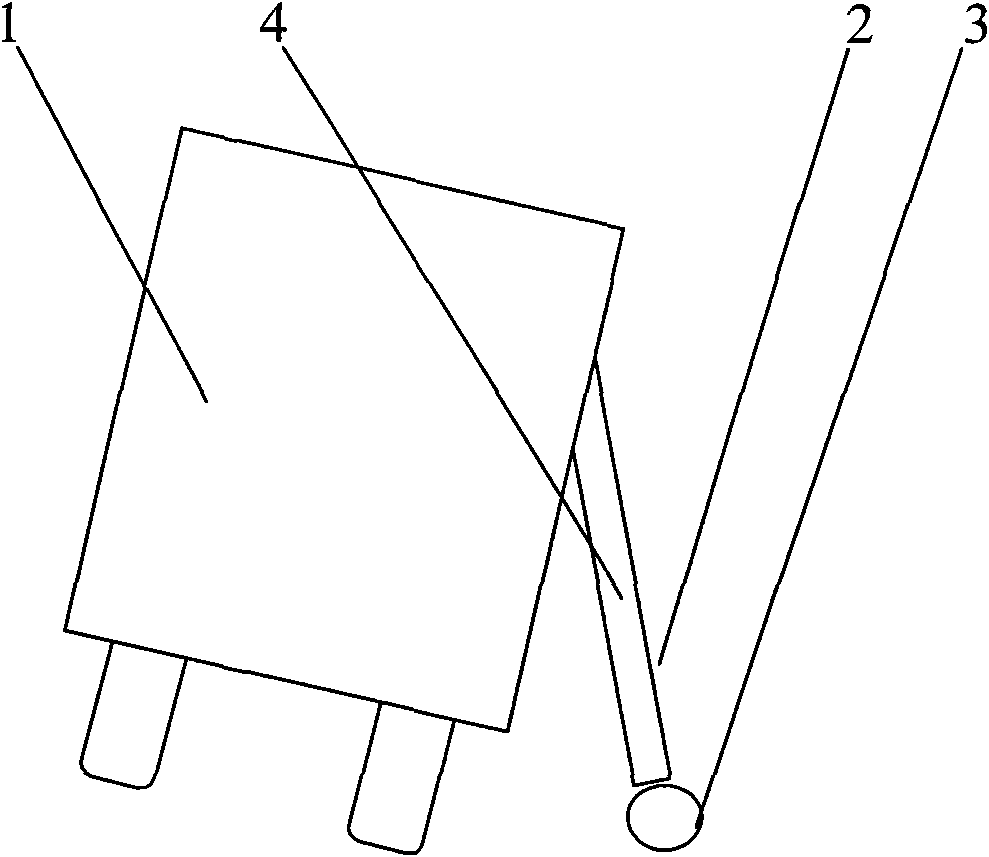

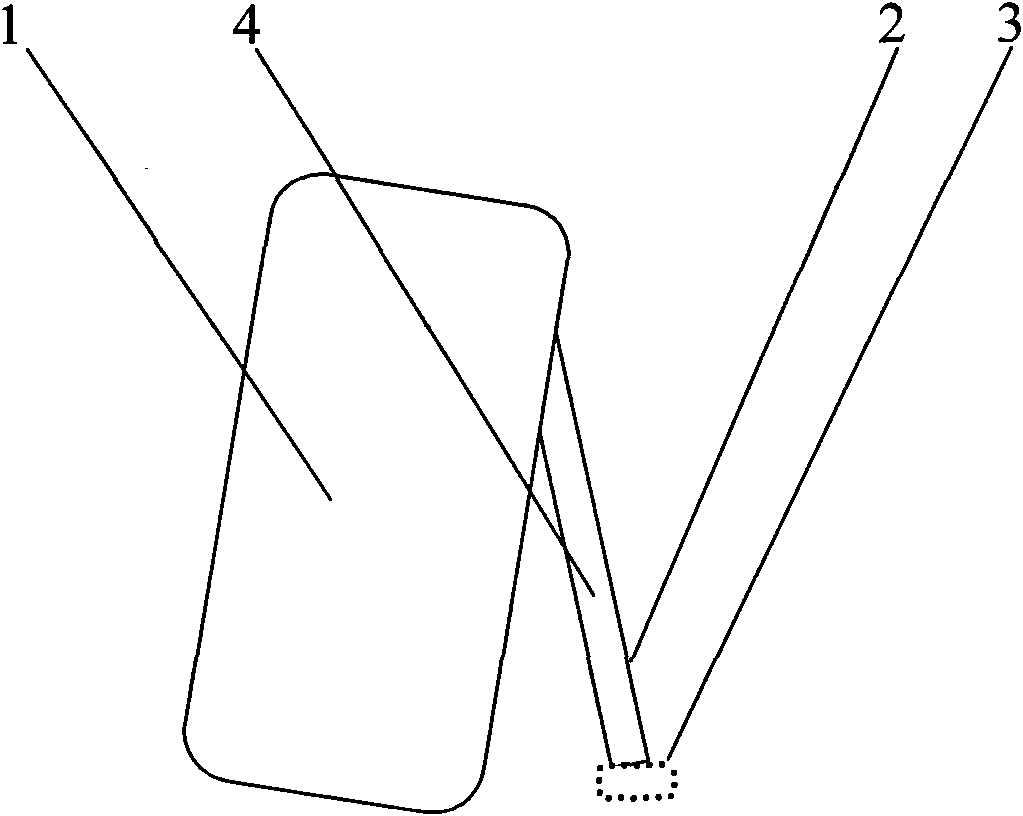

Anti-toppling device

InactiveCN101885320ASolve the problem of easy to fallWon't fallPedestrian/occupant safety arrangementSocial benefitsState of art

The invention discloses an anti-toppling device, which comprises an article body. The proper position of the article body is provided with the anti-toppling device capable of unfolding, folding and stretching, wherein the anti-toppling device is static in a steady state, is started during inclining and consists of at least one adjustable column (or plate) of which the end is provided with a cushion, a wheel, a floating ball or a floating plate. The anti-toppling device overcomes the defects of the prior art; when an article is oblique, the anti-toppling device can automatically unfold and extend to the ground (or water surface) to support the article so that the article does not topple and is difficult to damage and a moving object can continuously move. The anti-toppling device reduces property loss and casualties, has the advantages of simple technique, convenient manufacture and low cost, can be applied to valuable apparatuses, also can be applied to traffic and transport tools such as bicycles, motorcycles, tricycles, automobiles, trains, steamships, naval vessels, airplanes, armored vehicles, tanks and the like, and has broad economic benefit, social benefit and military value.

Owner:张虹玥

Movable adjustable method of intelligent monitoring device

ActiveCN107339576AAdjust the monitoring rangeAdjust the monitoring directionClosed circuit television systemsStands/trestlesDrive shaftElectrical and Electronics engineering

The invention discloses a movable adjustable method of an intelligent monitoring device. The intelligent monitoring device comprises a base. The two ends of the top surface on the inner side of the base are both fixedly connected with electric push rods. The tail ends of the two electric push rods are both fixedly connected to the middle portions of connecting plates. The middle portions of the bottom faces of the two connecting plates are fixedly connected with limiting telescopic rods. The ends, away from the connecting plates, of the two limiting telescopic rods are both fixedly connected with movable devices. The limiting telescopic rods are inserted into buffer springs. One ends of the two buffer springs are fixedly connected to the bottom faces of the connecting plates. The other ends of the two buffer springs are both fixedly connected to the top faces of the movable devices. A driving shaft is fixedly connected between the two movable devices. According to the movable adjustable method of the intelligent monitoring device provided by the invention, a rotation motor and an adjusting motor are matched with each other, the purpose of adjusting the monitoring device is achieved, the method has the advantage that the monitoring device can be moved and adjusted, and the problem that the monitoring range of an existing movable intelligent monitoring device cannot be adjusted is solved.

Owner:金税信息技术服务股份有限公司

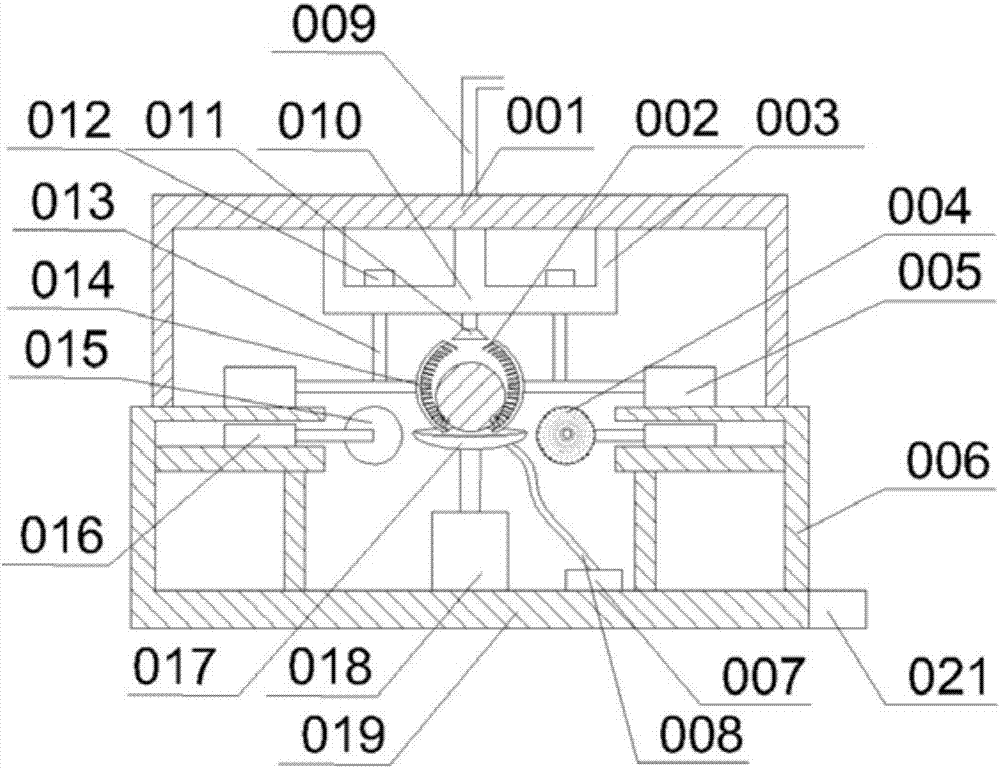

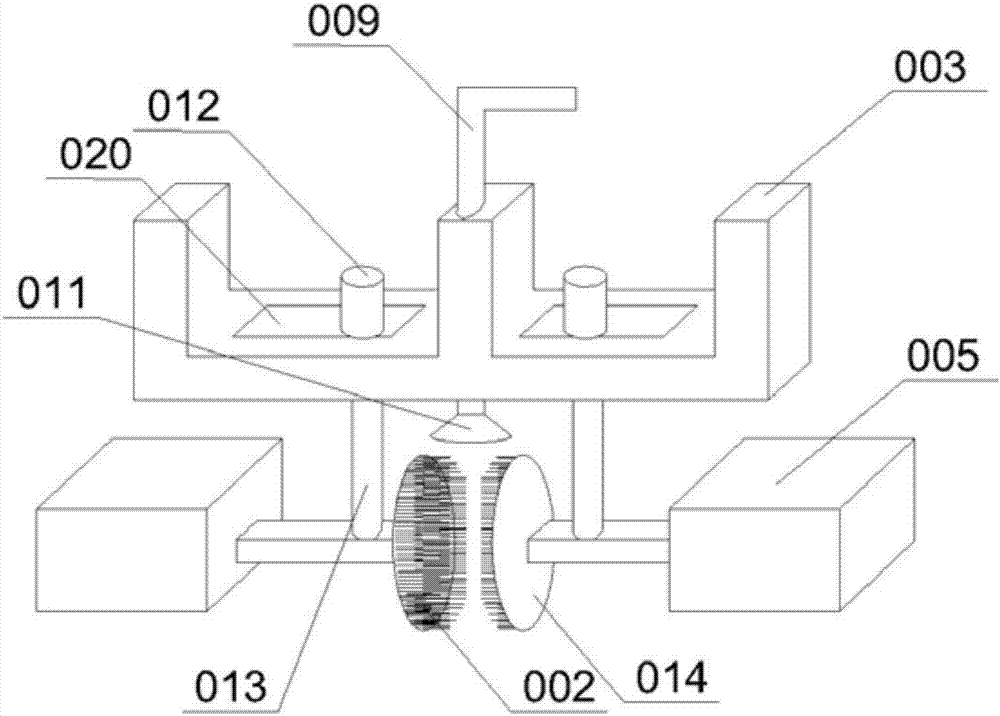

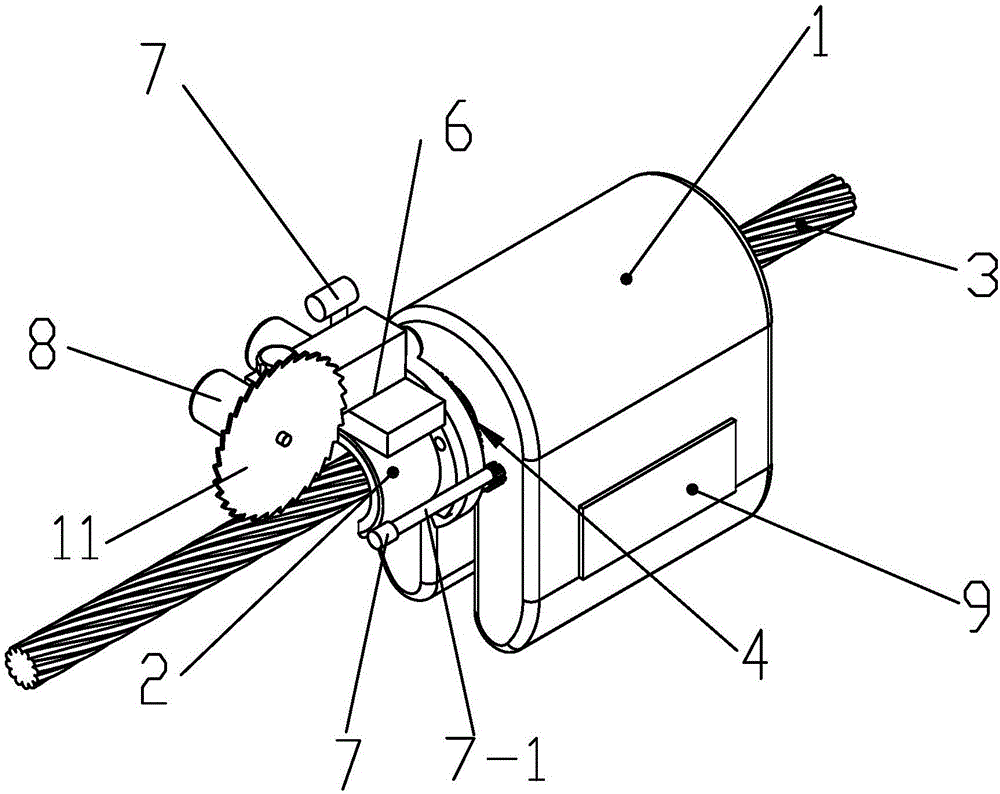

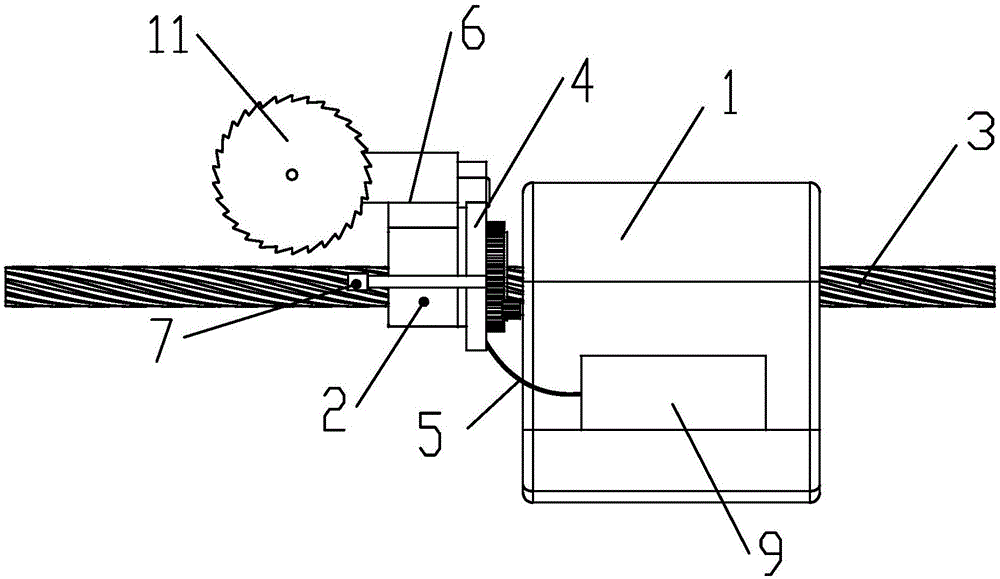

Multidimensional removal device for fittings of overhead transmission line

ActiveCN106655004AGood working angleWon't fallProgramme-controlled manipulatorApparatus for overhead lines/cablesEngineeringControl circuit

The invention provides a multidimensional removal device for fittings of an overhead transmission line. The removal device comprises a main machine and a machine head, wherein a travelling mechanism is arranged on the main machine; a power supply, a controller and a control circuit are arranged in the main machine; a safety mechanism is arranged at the lower part of the travelling mechanism; the machine head comprises a wire fixing sleeve, a multidimensional work bench capable of controlling multidirectional movement of a cutting tool bit, and the cutting tool bit; the wire fixing sleeve is connected with the main machine through a rotating mechanism; the multidimensional work bench is fixed on the wire fixing sleeve; the cutting tool bit is arranged on the multidimensional work bench and comprises a cutting motor and a cutter head; the power supply and the controller are connected with the rotating mechanism and the travelling mechanism through signal wires; and the multidimensional work bench is connected with a signal control end of the cutting motor through a control motor. According to the multidimensional removal device, manpower can be replaced for travel and operation on the wires, and the multidimensional angle of the tool bit can be adjusted, so that the operation of cutting and removing the fittings at optimal position and angle is achieved and the wires are not injured.

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +2

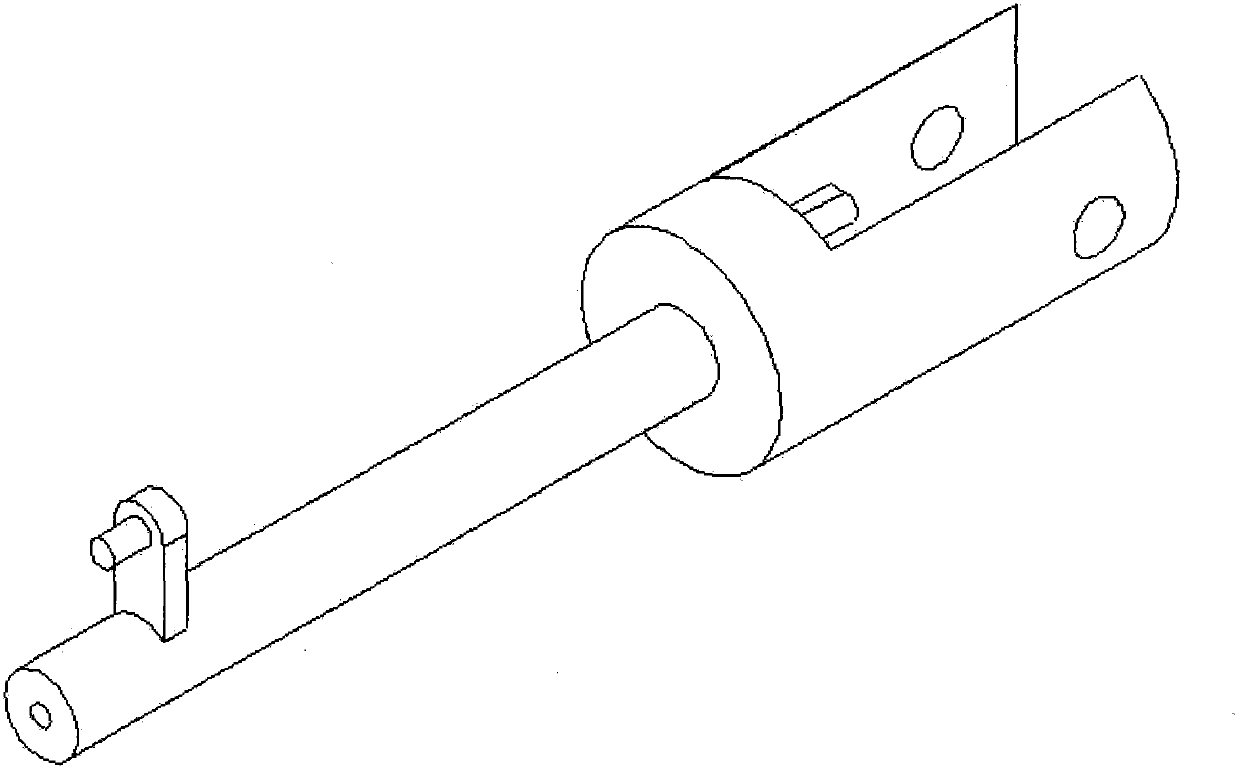

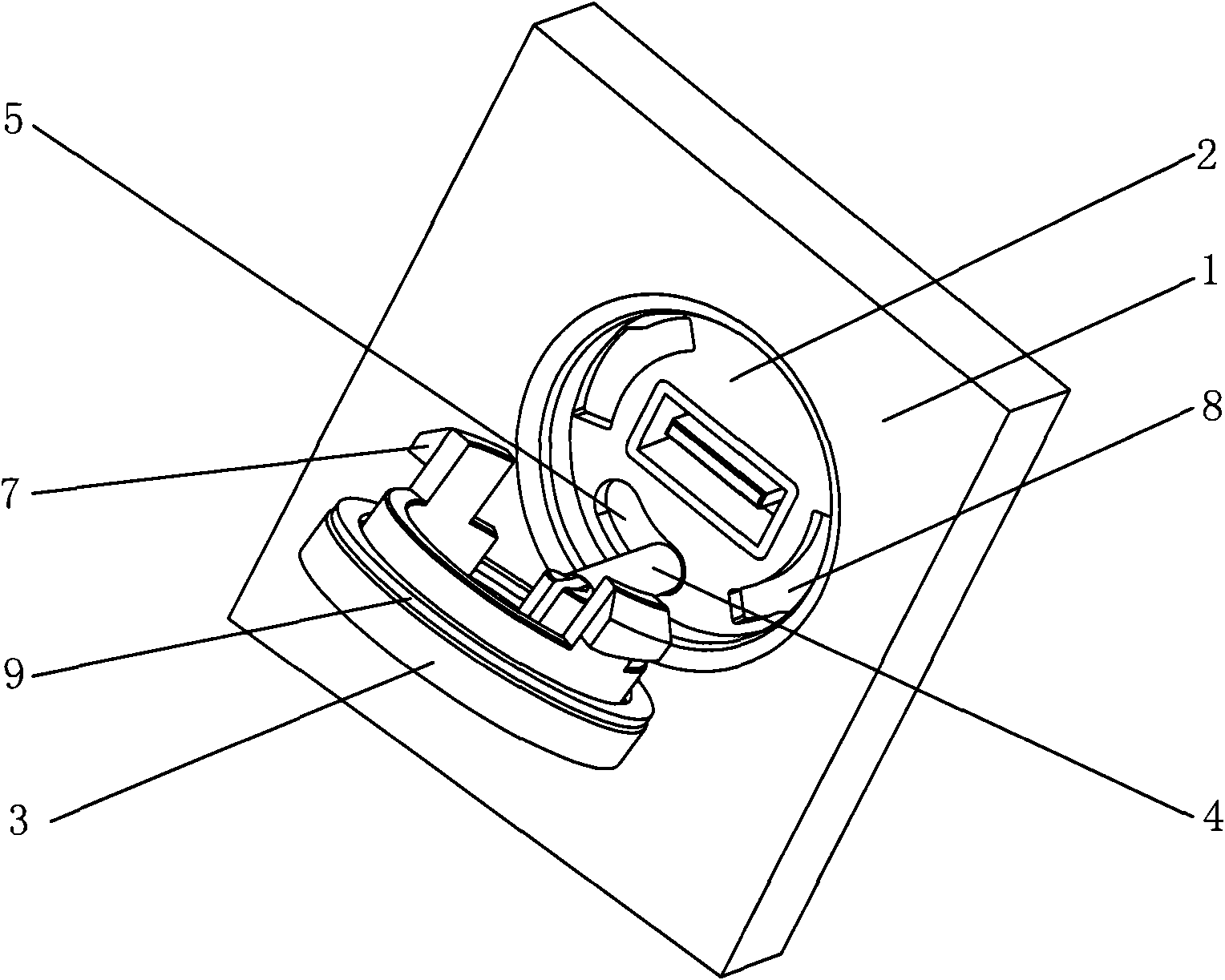

USB port protection cover

InactiveCN101895025AWon't fallImprove protectionCasings/cabinets/drawers detailsCouplings bases/casesEngineeringUSB

The invention relates to a USB port protection cover. The protection cover covers a USB port of a chassis. The chassis is provided with a port slot to be connected with the USB port. The USB port protection cover comprises an aluminium cover body and a rotation shaft, wherein the aluminium cover body is matched with the port slot, and one end of the rotation shaft is connected with the cover body; a limiting hole is disposed in the port slot, the rotation shaft penetrates through the limiting hole, and the other end of the rotation shaft is screwed with a nut, thus the rotation shaft is always in the limiting hole. The protective cover utilizes the rotation shaft to be connected with the chassis and the cover body, thus the cover cannot fall off when in use. The USB port protection cover has the advantages of good protection effect, convenient manufacture and high production efficiency.

Owner:ADVANTECH CHINA

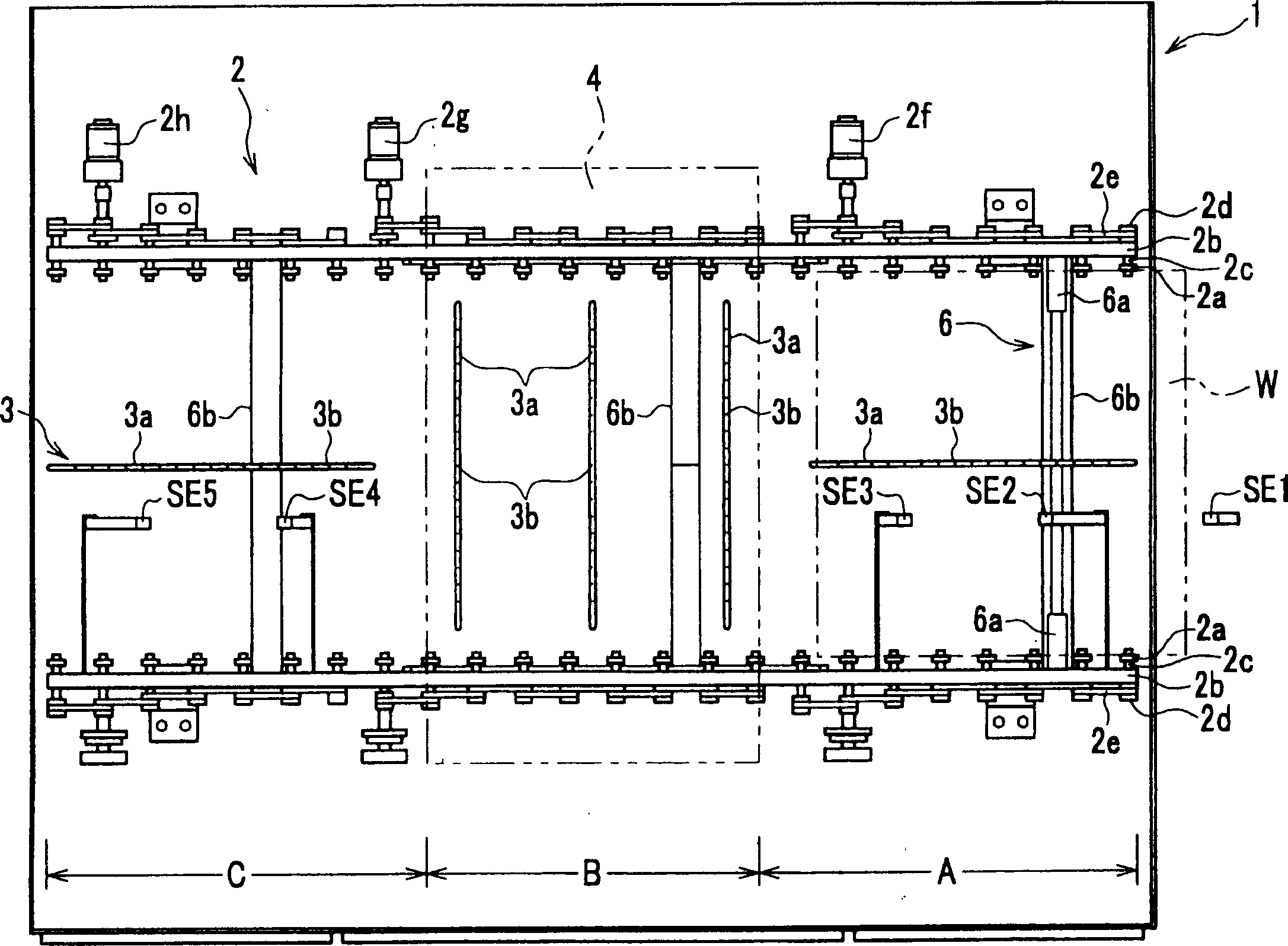

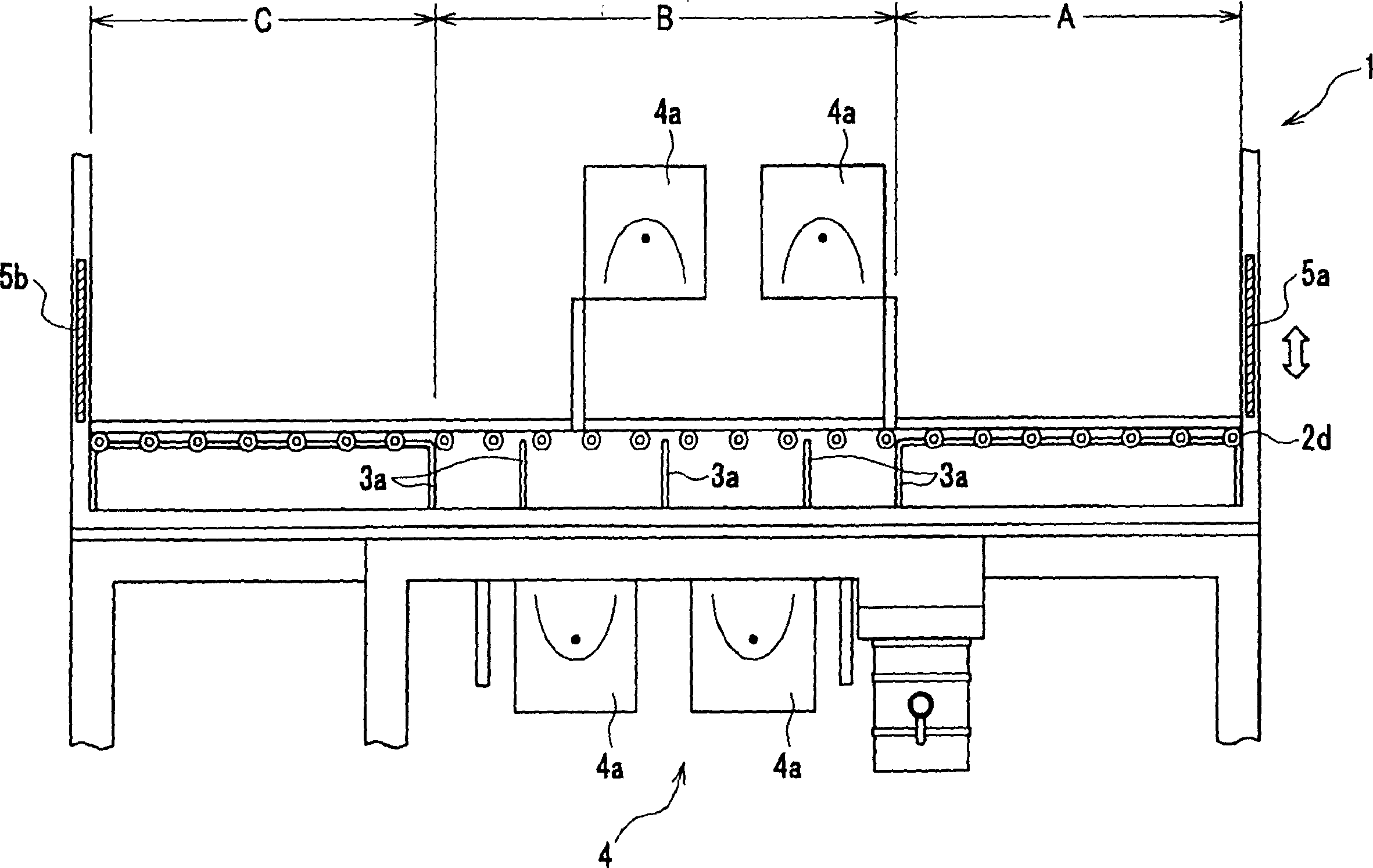

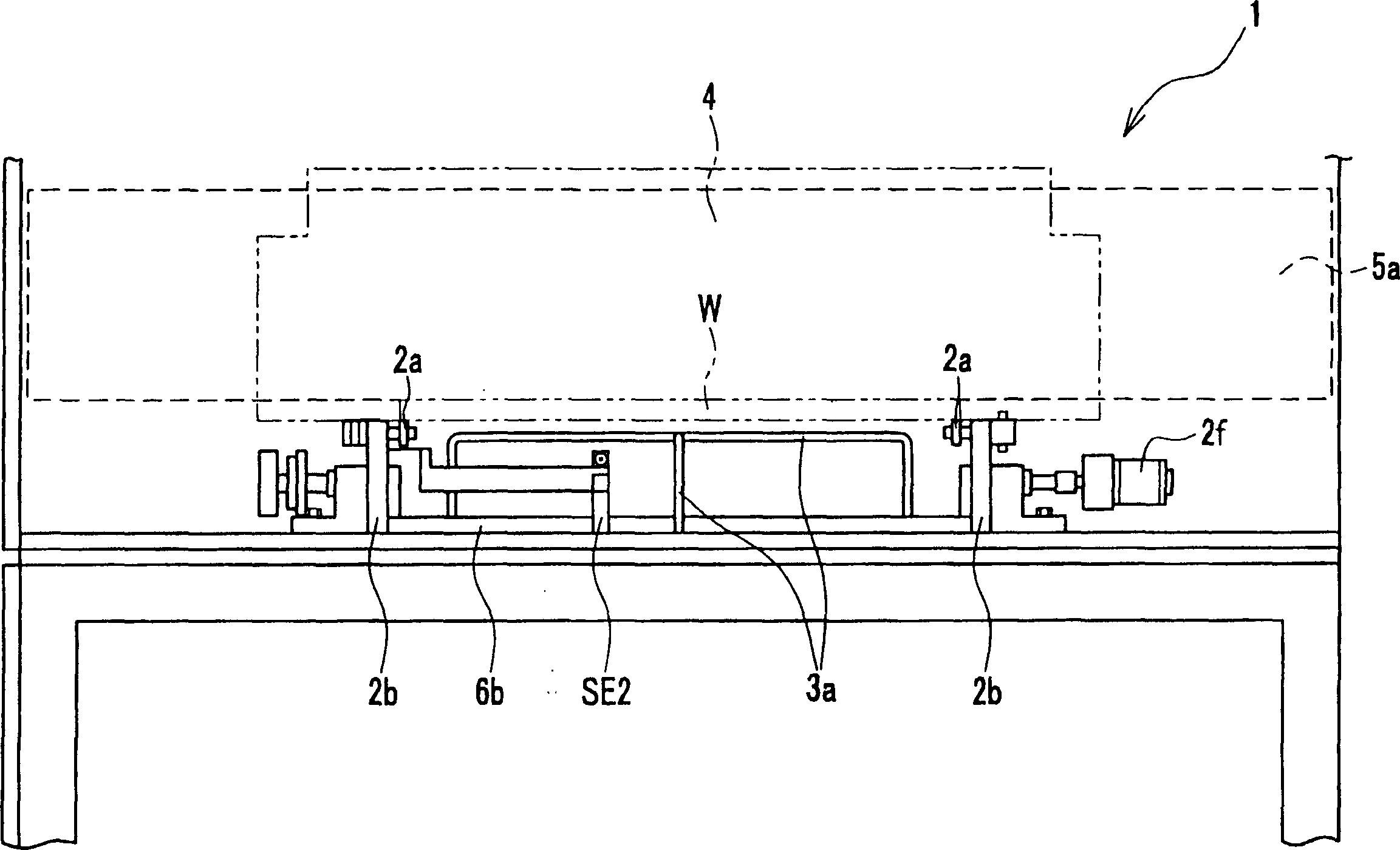

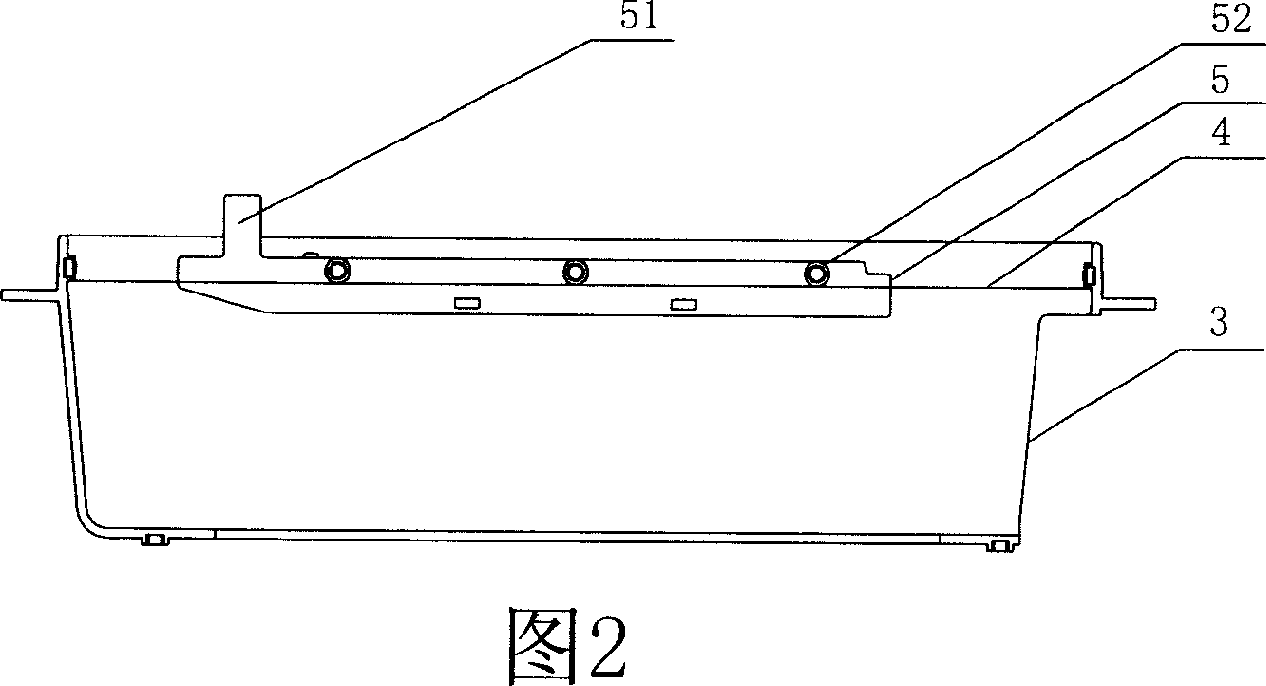

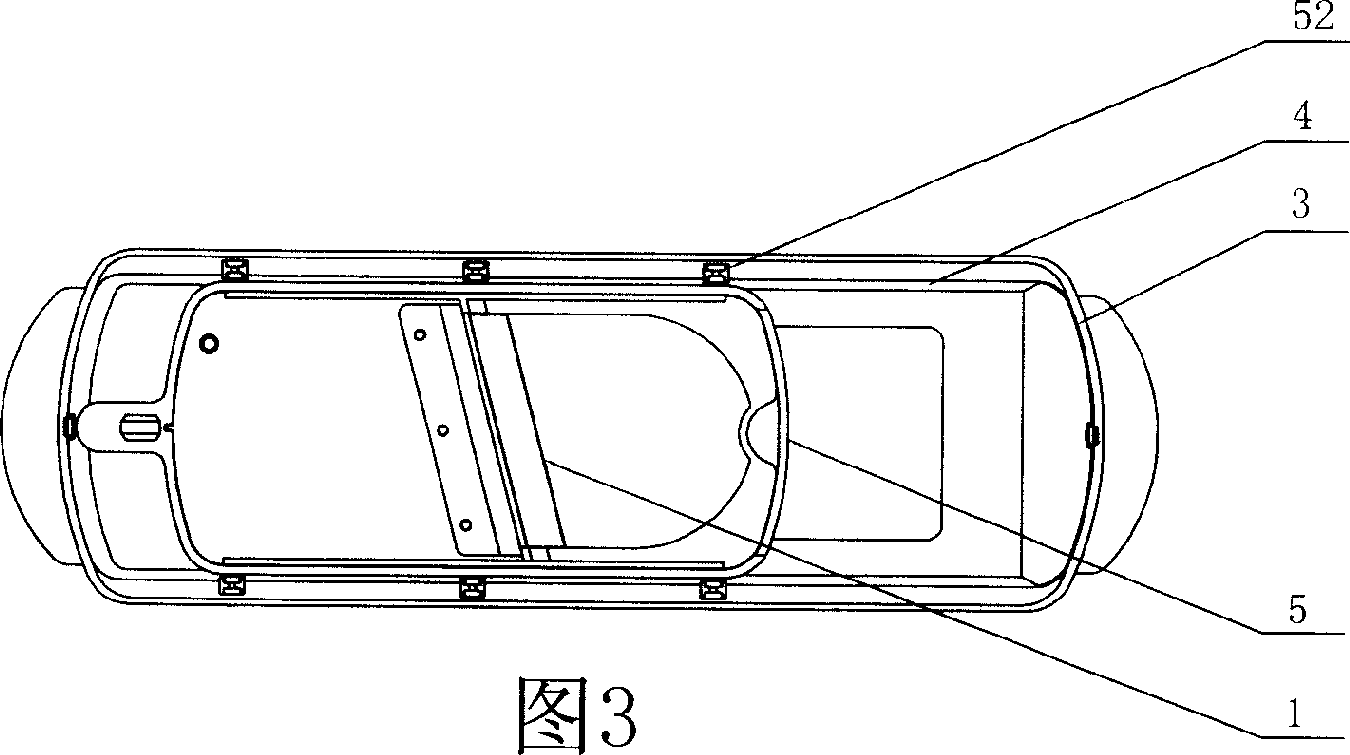

Sustrate olelivery mechanism

InactiveCN1449980ASmooth transmissionWon't fallSemiconductor/solid-state device manufacturingCharge manipulationProduct gasEngineering

The present invention provided a base transporting mechanism capable of stably transporting a base without dropping in curing work of the base, preventing the attachment of dust to the transported base, or the scratching of or damage to the base, and easily and simultaneously curing both faces of the base with ultraviolet ray of the same light intensity. This base transporting mechanism 2 comprises a feeding roller 2a for supporting both ends of the base W and transporting the same, and a transport auxiliary mechanism 3 for supporting the base W by the air in a non-contact state at a lower part of the base W supported by the feeding roller 2a, and the transport auxiliary mechanism 3 comprises air piping 3a having a predetermined length and mounted along the base W, and an air blowing-up hole 3b formed on the air piping 3a, and the air piping 3a is made out of a translucent material transmitting the ultraviolet ray.

Owner:ORC MFG

Sun-cure shed for sun-cured tobaccos, sun-cure devices and tobacco clips

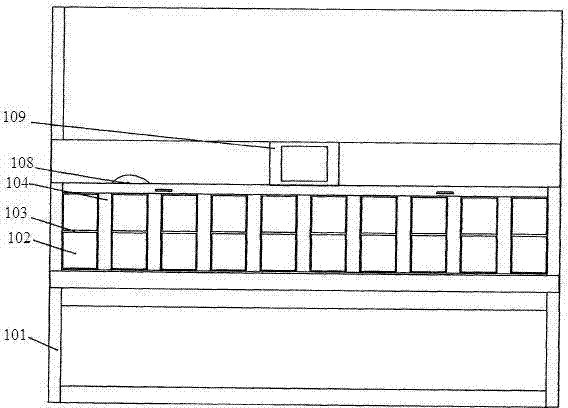

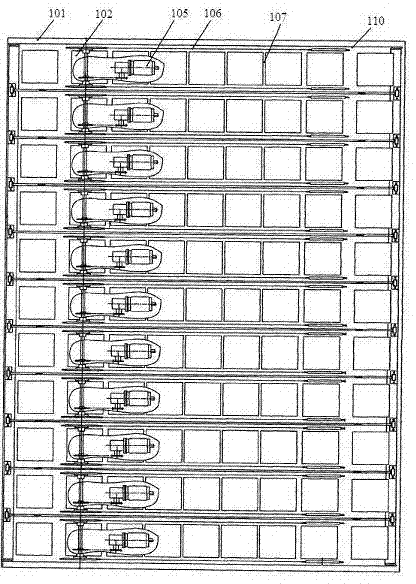

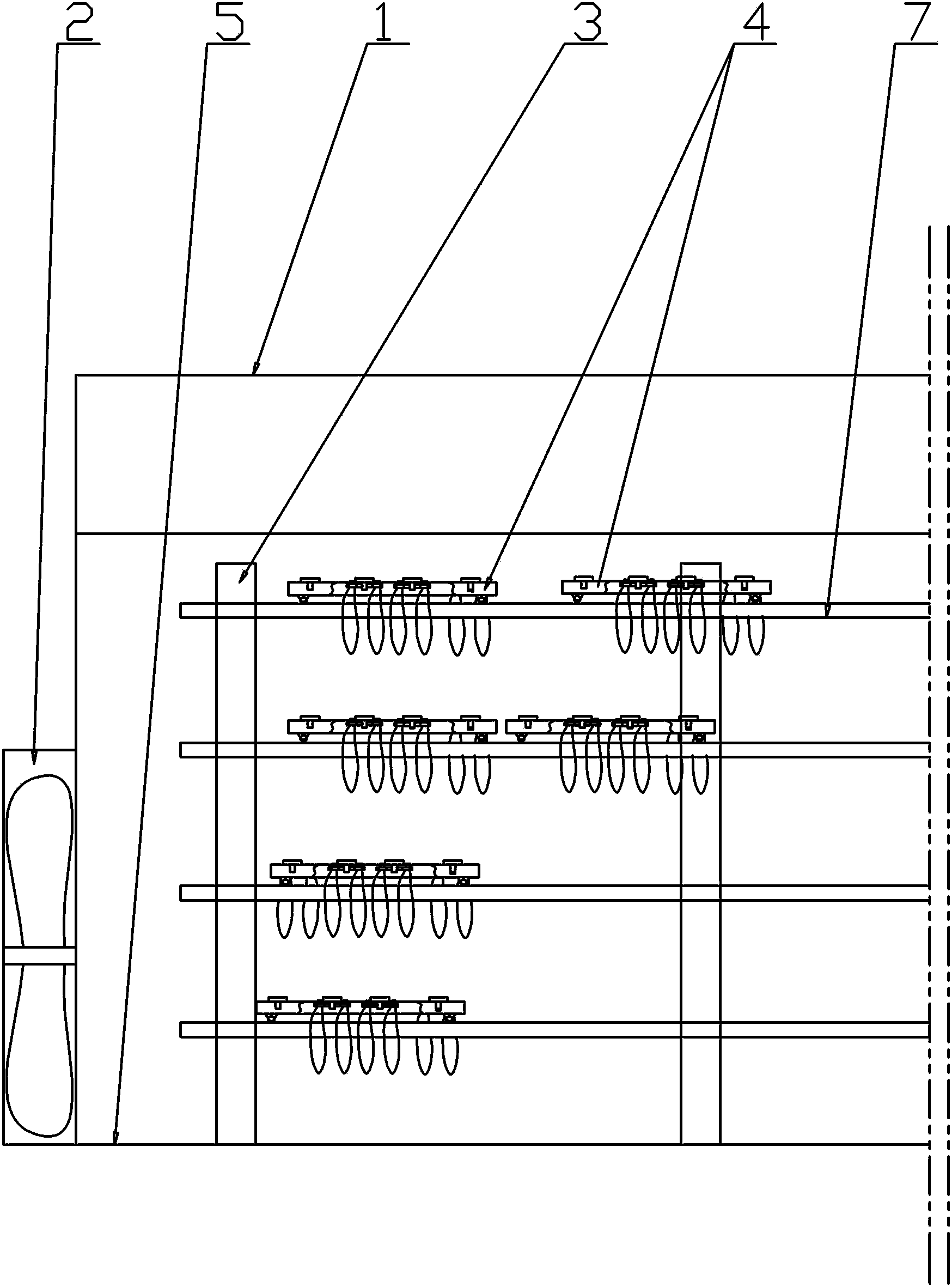

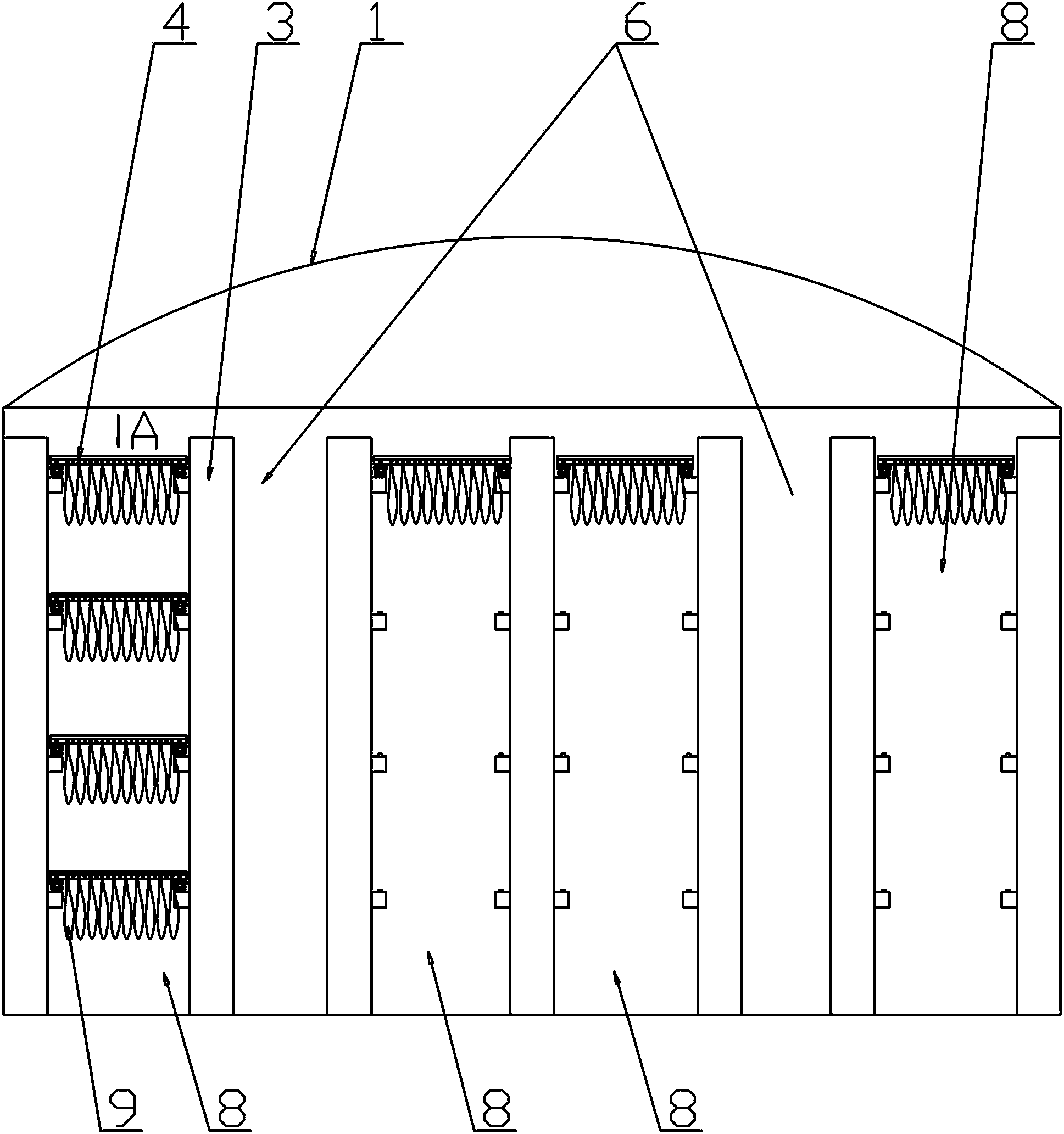

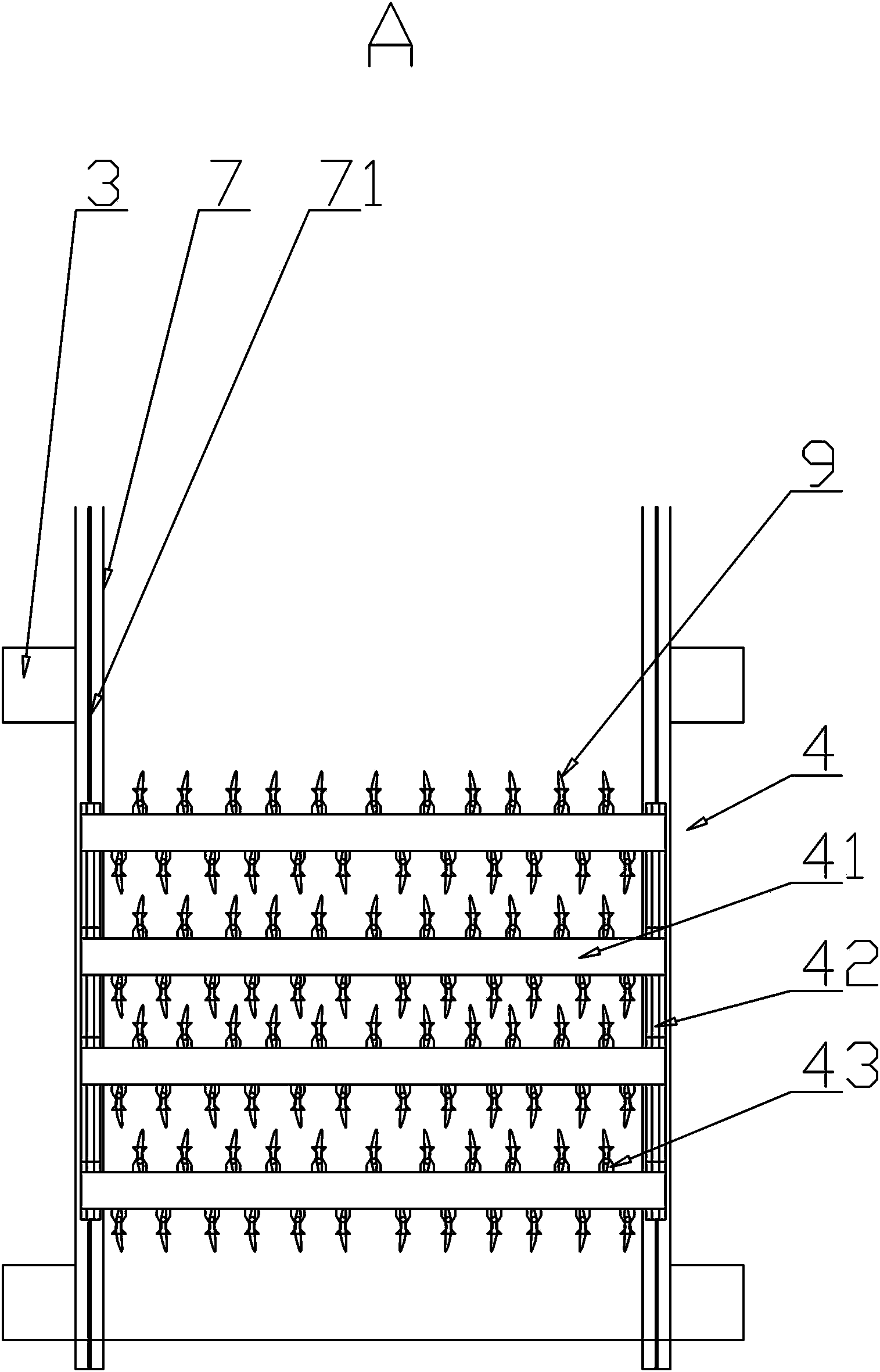

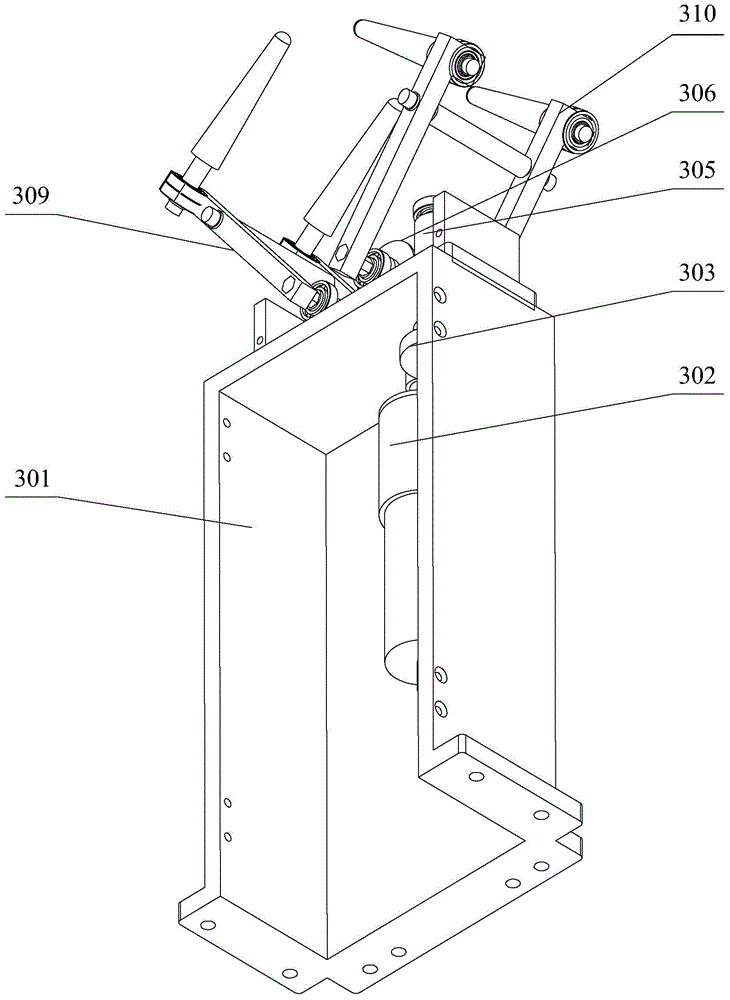

The invention discloses a sun-cure shed for sun-cured tobaccos, sun-cure devices and tobacco clips. The sun-cure shed comprises a shed. The shed is provided with a plurality of rows of sun-cure units, and transverse channels are arrange at the ends of the sun-cure units; a plurality of upright columns are arranged on two sides of each sun-cure unit, a plurality of slide rails are arranged on opposite sides of the upright columns, and the corresponding sun-cure devices are arranged on the slide rails on each same layer and can slide along the slide rails; the multiple tobacco clips used for clamping the tobaccos are arranged on the sun-cure devices. The sun-cure shed, the sun-cure devices and the tobacco clips have the advantages that the sun-cure shed is provided with the sun-cure devices and the tobacco clips used for clamping the multiple tobaccos, and the tobaccos can be subjected to sun-cure in a clustered manner by the aid of the sun-cure devices; the sun-cure devices can slide along the slide rails, so that the tobaccos can be fed mechanically and can be cured in an industrialized manner; the shortcoming of draping of tobacco braiding ropes is overcome, accordingly, the tobacco sun-cure density is increased as compared with a tobacco sun-cure mode implemented by the aid of the tobacco braiding ropes, and tobaccos of 82 tobacco plants can be cured in each square meter of the steel-structured shed while only tobaccos of 33 tobacco plants can be cured in each square meter of an existing standard cure shed; the production efficiency is improved, the integral cost is lowered, and the labor intensity is reduced.

Owner:湖北省烟草公司宜昌市公司

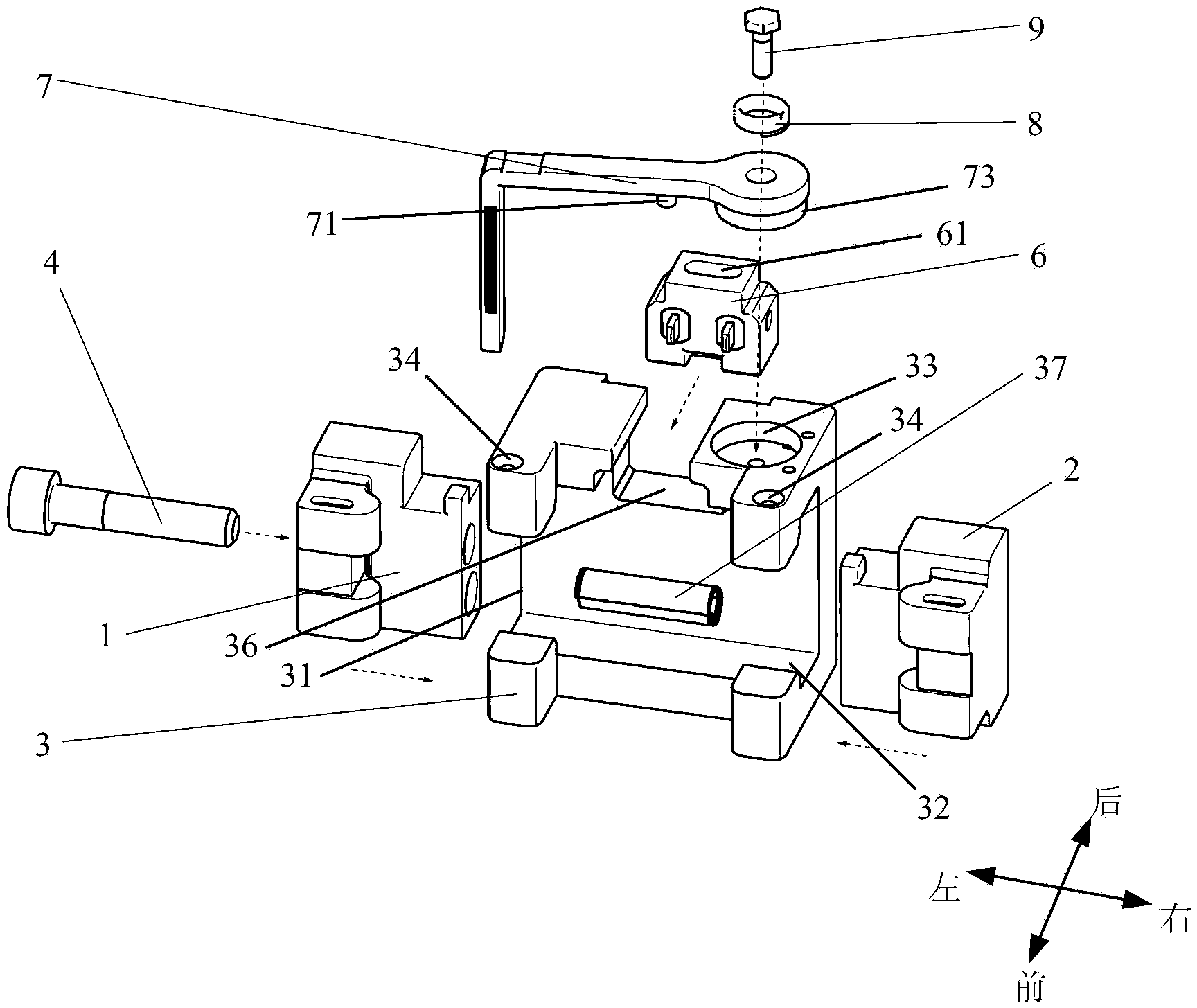

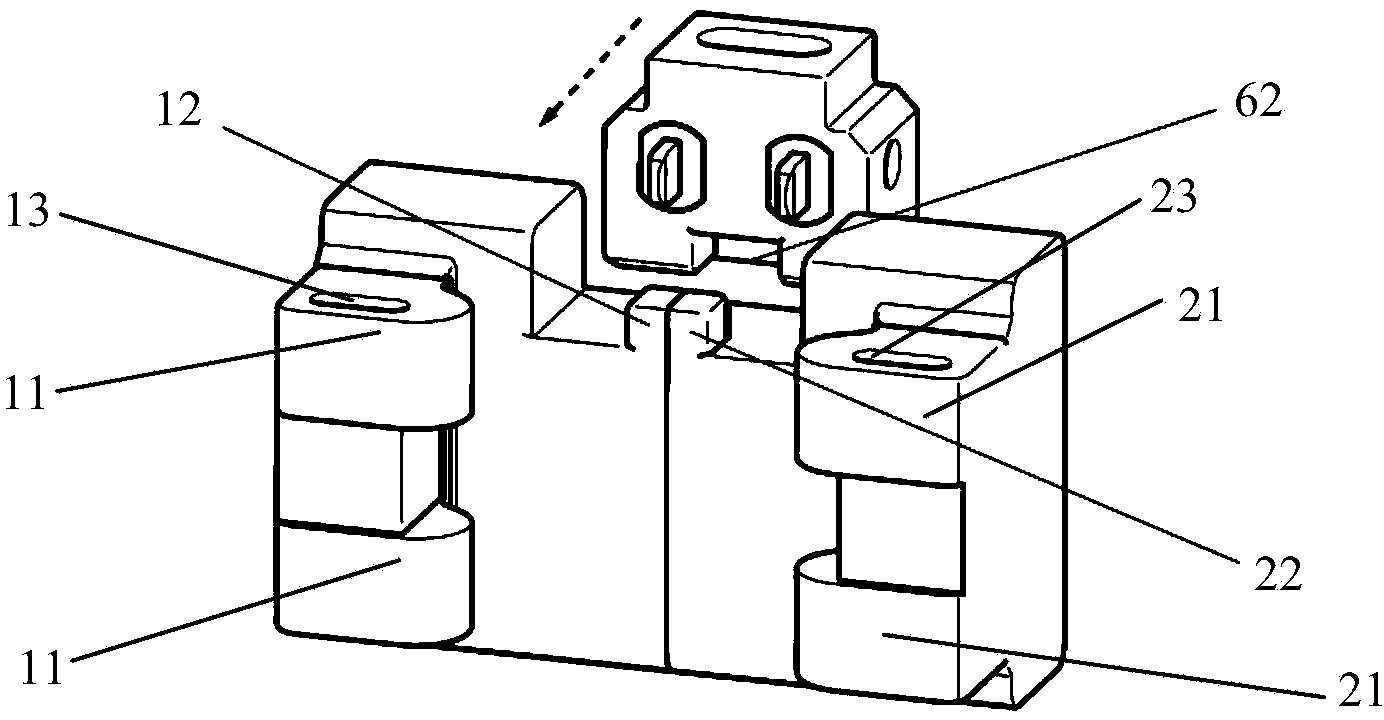

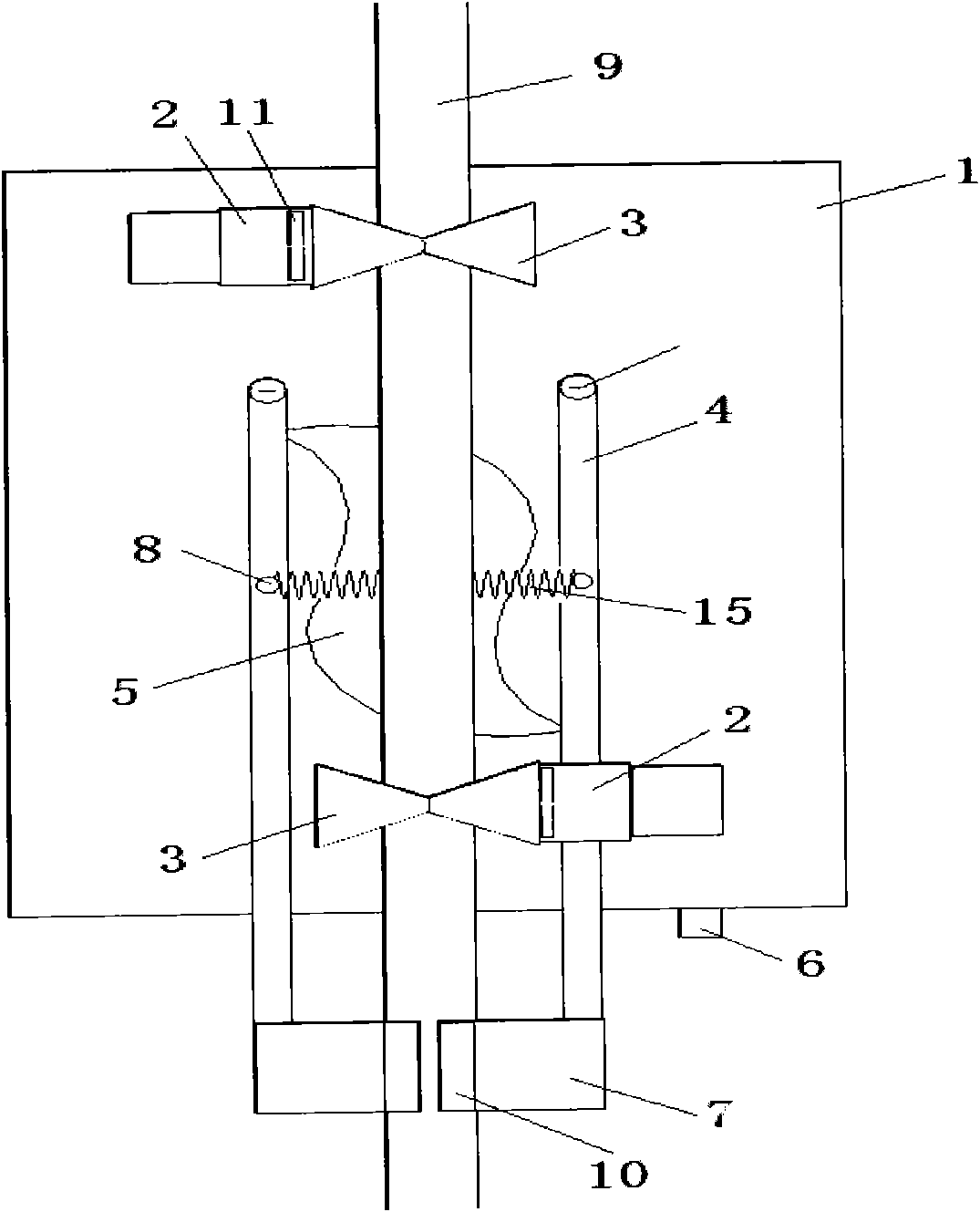

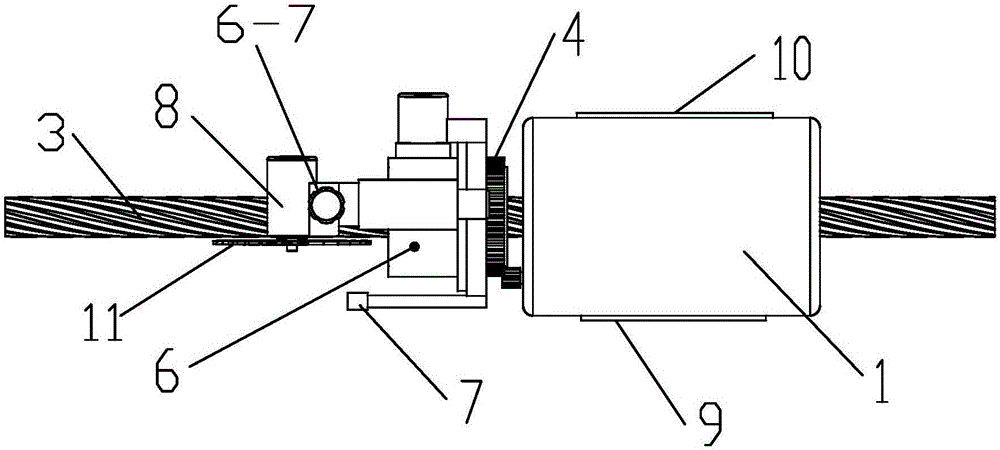

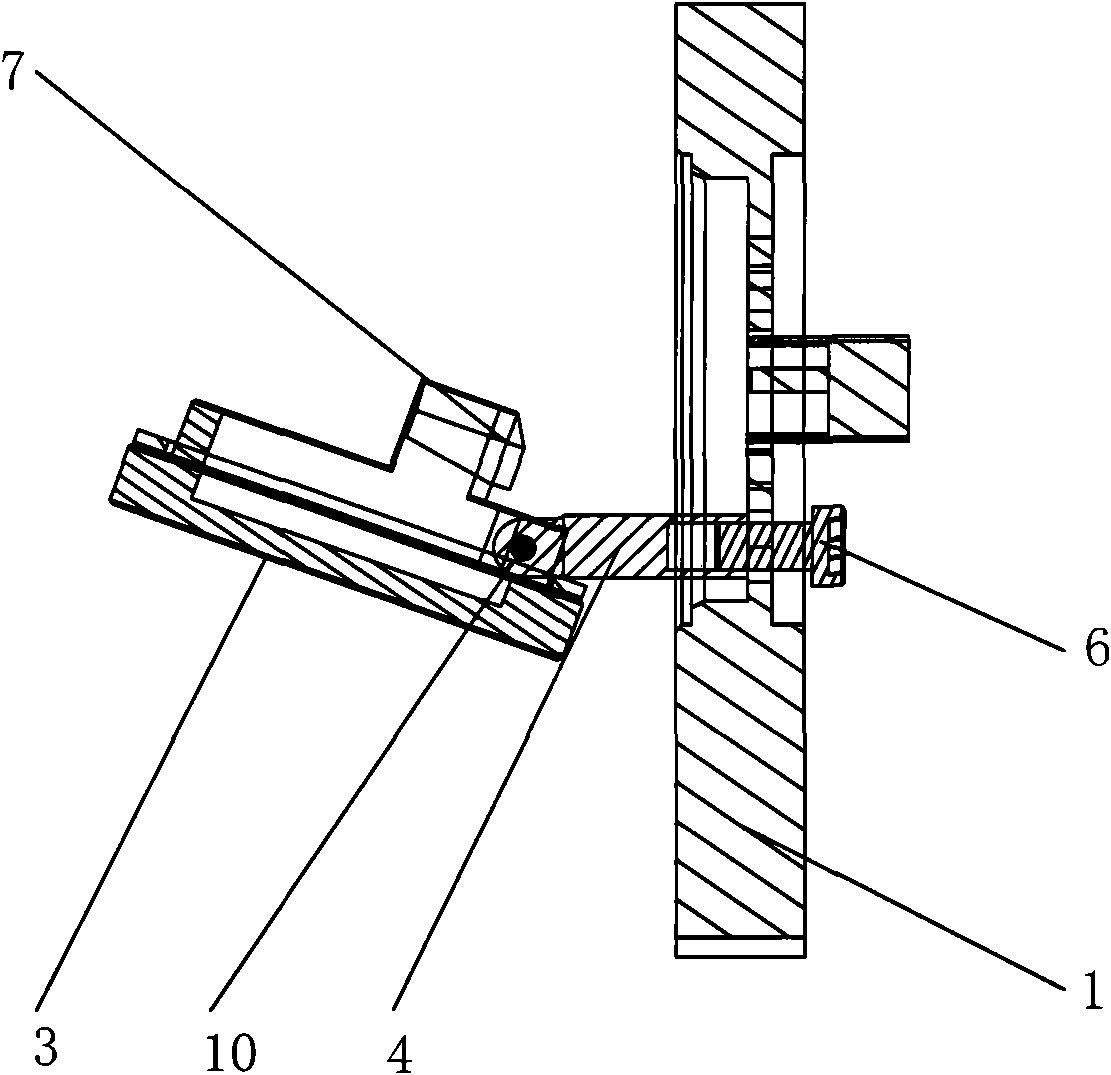

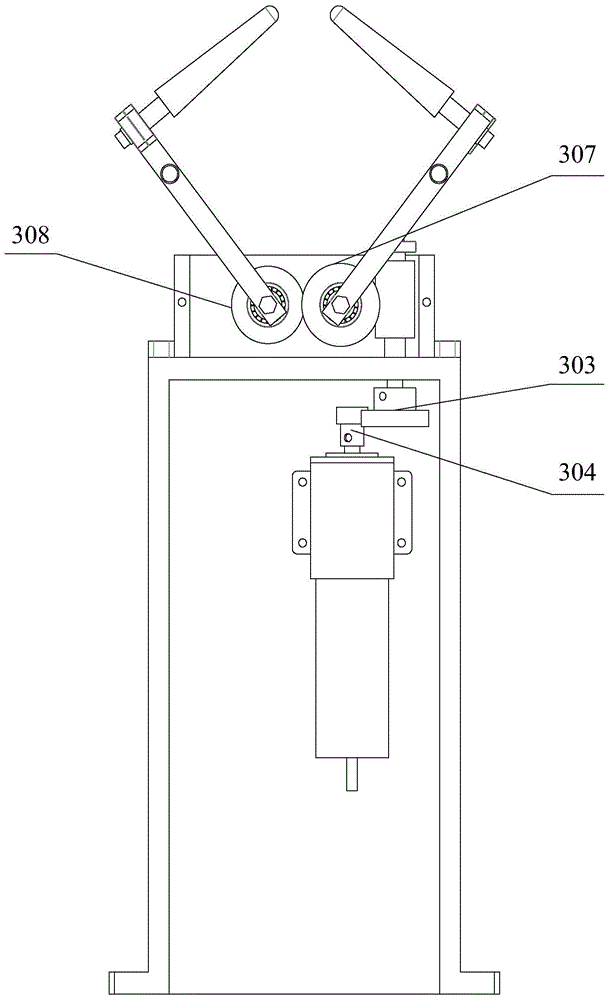

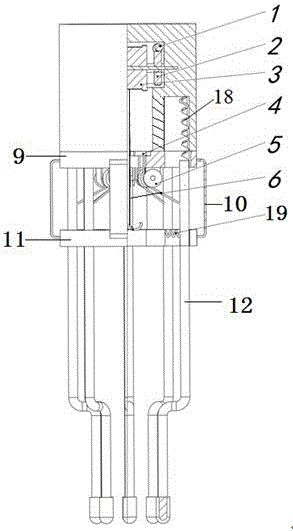

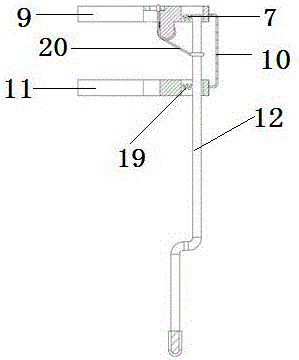

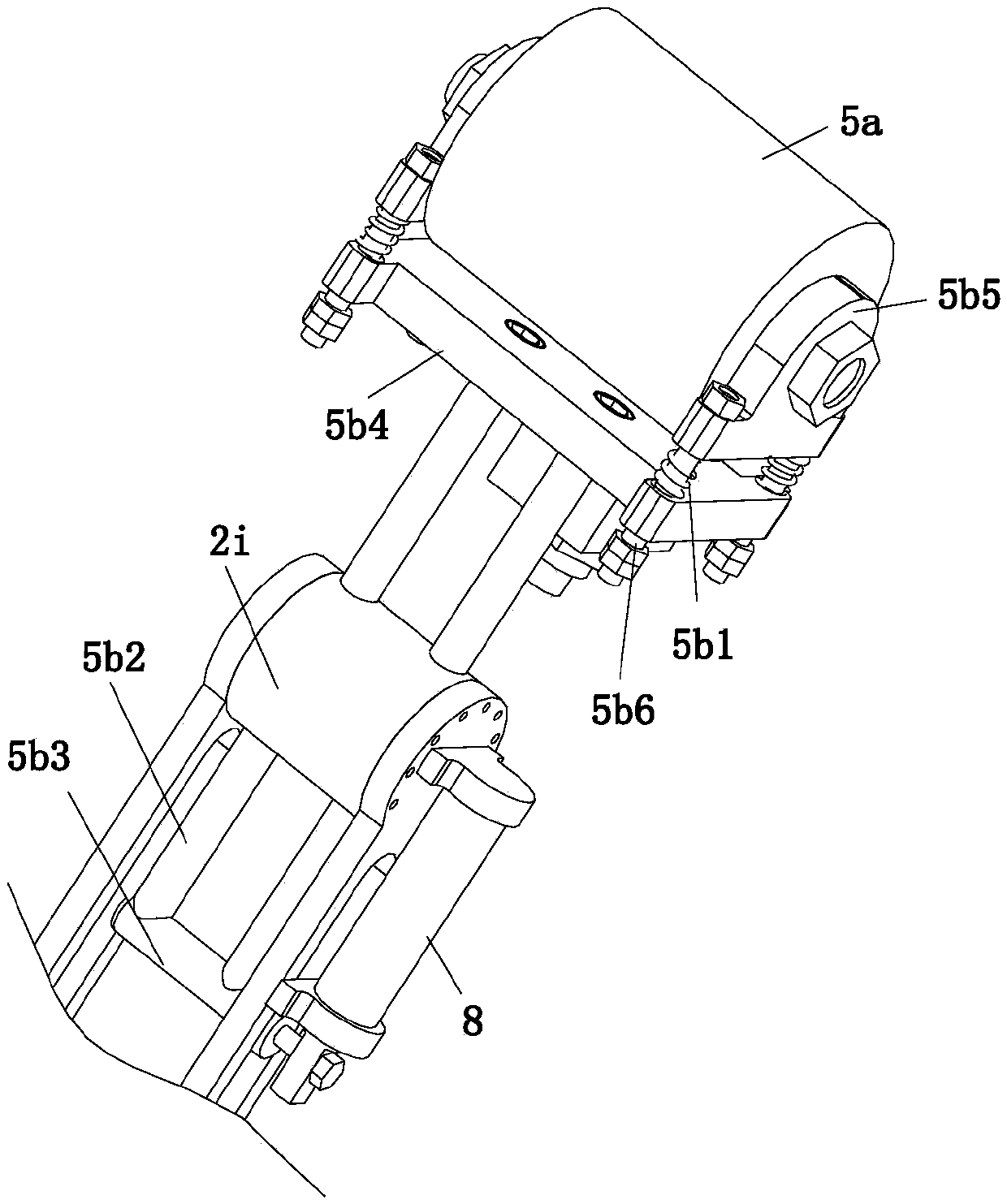

Clamping mechanism and inspection robot walking mechanism

ActiveCN103606851AWon't fallRealize the pressing effectApparatus for overhead lines/cablesDrive wheelEngineering

The invention discloses a clamping mechanism. The clamping mechanism comprises a supporting box, a supporting frame, a first rotating shaft, a second rotating shaft, a clamping drive device, a first clamping claw and a second clamping claw, wherein the supporting frame is arranged on the supporting box; the first rotating shaft and the second rotating shaft are arranged on the supporting frame in a rotating mode and are in transmission connection through a transmission mechanism; the clamping drive device is used for driving the first rotating shaft or the second rotating shaft to rotate; the first clamping claw is fixed to the first rotating shaft; the second clamping claw is fixed to the second rotating shaft. According to the clamping mechanism, the clamping drive device is used for driving the first rotating shaft or the second rotating shaft to rotate and then driving the first clamping claw and the second clamping claw to do opposite movements or separating movements, and therefore the purpose of holding lines or loosening lines can be achieved. When a drive wheel and a clamping wheel cross obstacles, the lines can be clamped through the clamping mechanism, and it can be ensured that an inspection robot will not fall off from the lines. The invention further discloses an inspection robot walking mechanism provided with the clamping mechanism.

Owner:STATE GRID CORP OF CHINA +2

Portable type underwater salvage equipment wire take-up device

The invention relates to a portable type underwater salvage equipment wire take-up device, and belongs to the field of electromechanical device manufacturing. The wire take-up device comprises an emergency device, a self-locking device, a gear II, a shaft I, an electromagnetic clutch, a shaft II, a gear III, a gear IV, a coiling block, a shaft III, a synchronous belt wheel driving wheel, a synchronous belt, a synchronous belt wheel driven wheel, a reciprocating lead screw and a rope arranging device. The emergency device is composed of a handle, a ratchet mechanism, a manual shaft and a gear I; the self-locking device is composed of a worm wheel, a worm and a worm shaft. Combination of automation and manual operation is utilized for effectively solving the problem that due to mechanical faults, the device cannot continue working. Meanwhile, the rope arranging device is adopted to arrange cables in order; and in addition, the portable type underwater salvage equipment wire take-up device is relatively simple in structure and convenient to operate and carry.

Owner:KUNMING UNIV OF SCI & TECH

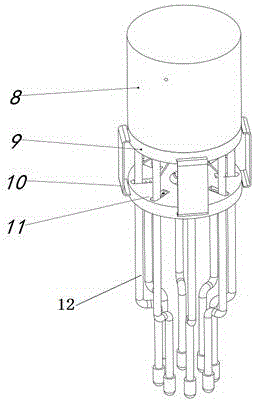

Grabbing and lifting adaptation robot arm

The invention discloses a grabbing and lifting adaptation robot arm and belongs to the technical field of robot arms. The grabbing and lifting adaptation robot arm comprises a worm, a worm wheel, a roller, an end opening cover, fixed pulleys, a steel rope, springs I, a base, a base disc I, a fixing support, a base disc II, clamping rods, a lifting hook, springs II, springs III and a traction rope. The grabbing and lifting adaptation robot arm is used by a robot for grabbing objects, a self-adaptation grabbing function not limited to object shapes is achieved, the multiple grabbing rods are used for obtaining the self-adaptation effect on the object sizes and shapes, the worm wheel and the worm are driven to tightly pull the traction rope through the lifting hook, extrusion force obtained in the manner that the multiple clamping rods are gathered towards the center is achieved, a multidirectional grabbing effect on the objects is achieved, the lifting hook can also be directly used for lifting the objects, the structure is simple, energy consumption is low, grabbing or lifting is fast, reliability is good, the service life is long, and under the assistance of the unidirectional drive of the worm wheel and the worm, grabbing is stable and safety is high.

Owner:KUNMING UNIV OF SCI & TECH

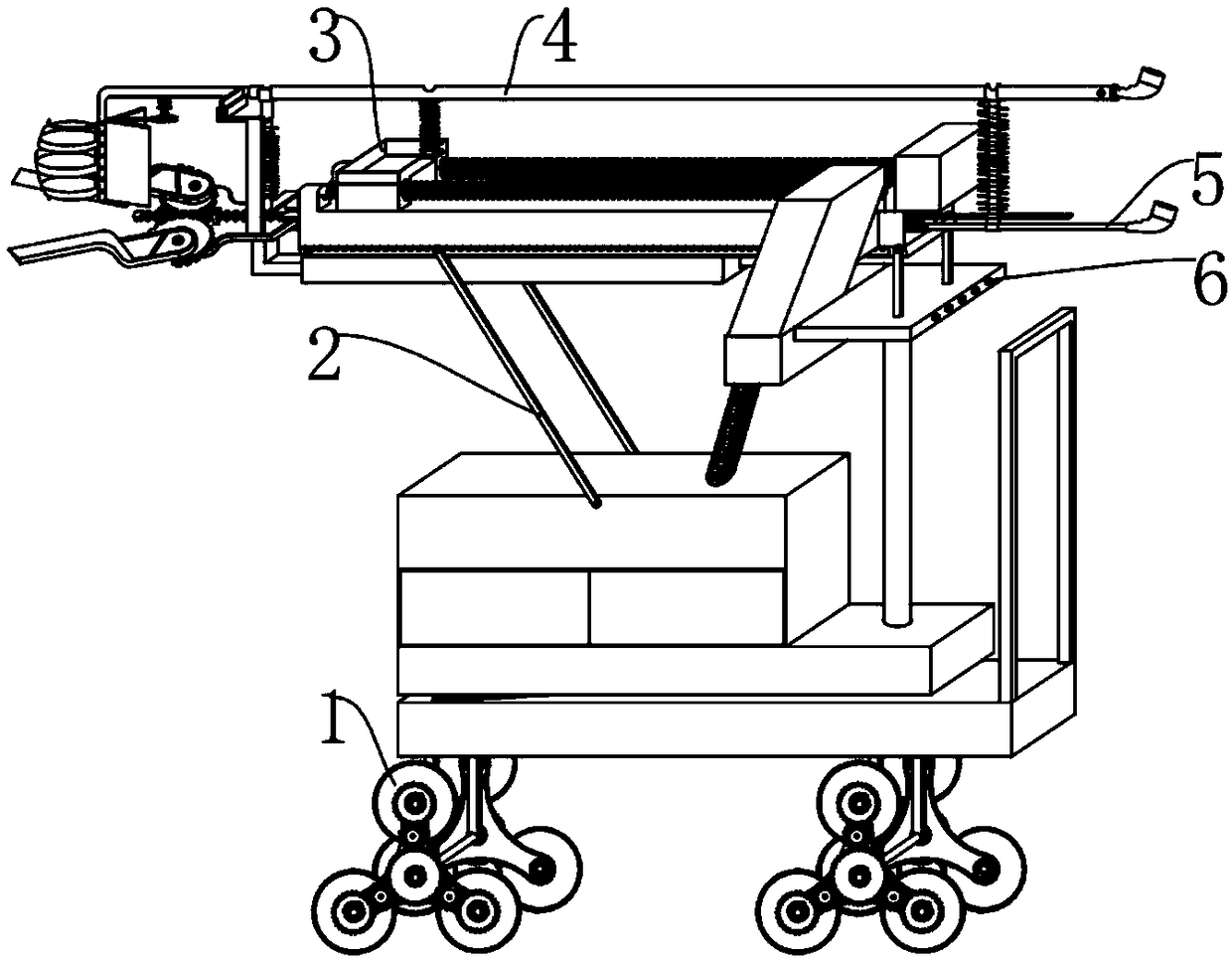

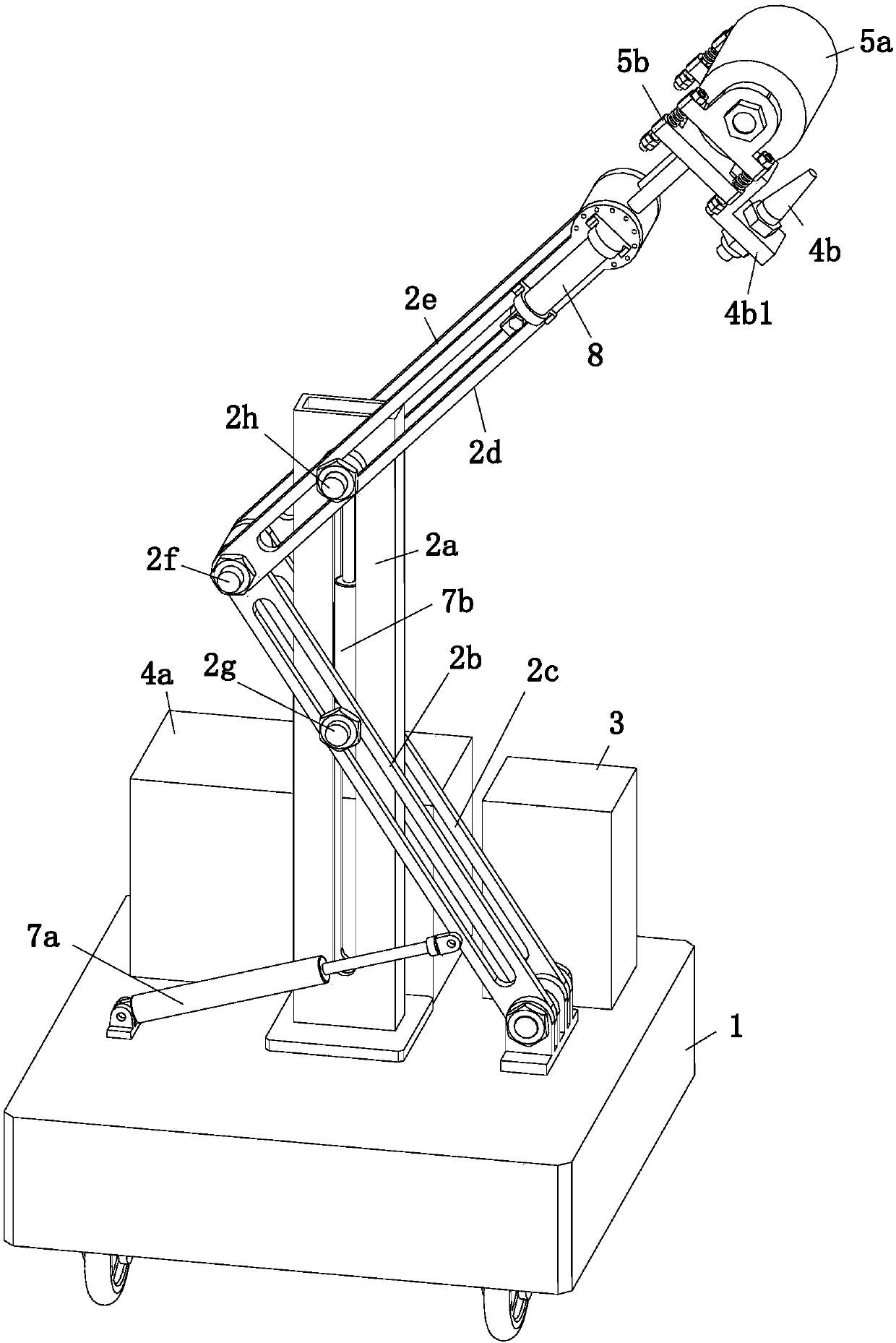

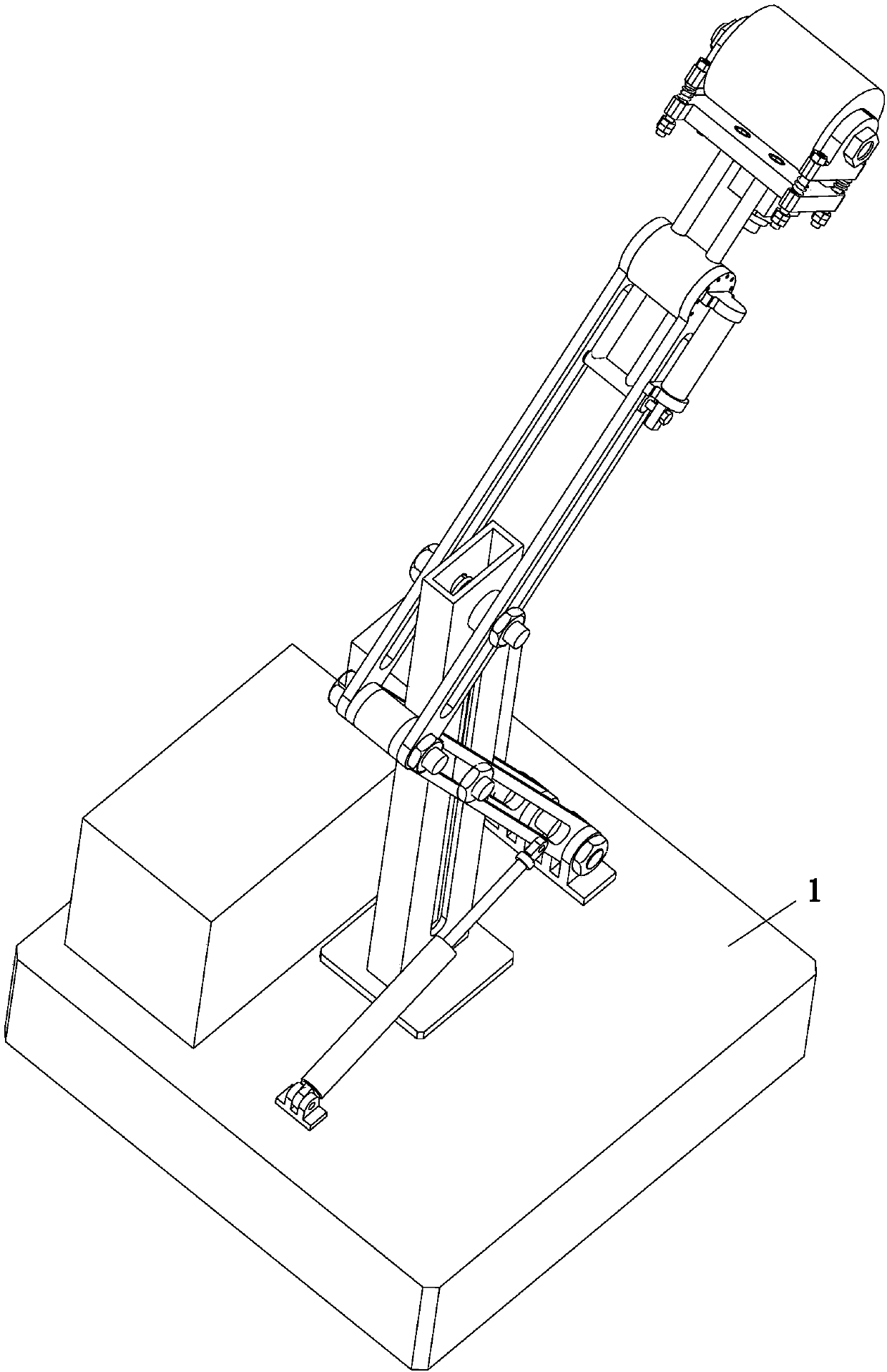

Automatic mortar spraying and roll levelling machine for wall face construction of building

The invention relates to the field of building construction, in particular to an automatic mortar spraying and roll leveling machine for wall face construction of a building. The automatic mortar spraying and roll leveling machine comprises a trolley, a mechanical arm, a mechanical arm driving mechanism, a hydraulic power unit, a spraying mechanism and a roll leveling mechanism. Compared with theprior art, the automatic mortar spraying and roll leveling machine is more stable and does not fall down; roll leveling is conducted on mortar sprayed on the wall face by a roller, the roller is driven by the mechanical arm to achieve going-up and going-down, so that repeated roll leveling is conducted on the spraying face in the vertical direction; and the automatic mortar spraying and roll leveling machine abuts against the wall face all the time through double control of driving devices of the trolley and the roller, the roller is excessively pushed and abuts against the wall face, and theroller can be kept in abutting-against connection with the wall face through springs; and automatic mortar spraying roll leveling operation of the wall face can be achieved by the automatic mortar spraying and roll leveling machine after the functions of the spraying mechanism is synthesized, manual labor intensity is greatly relieved, operation efficiency is improved, and potential safety hazardsof high attitude operation of workers are avoided.

Owner:浙江天源工程管理咨询有限公司

Intelligent camera with adjusting function

Owner:鲲鹏数字技术有限公司

High-precision automatic milling repair device for aviation titanium alloy tube structure

ActiveCN109176182AFlexible grindingComprehensive grindingEdge grinding machinesRevolution surface grinding machinesAviationMotor drive

The invention discloses a high-precision automatic milling repair device for an aviation titanium alloy tube structure. The device comprises a workbench, an upper installation base, a conveying mechanism, a movable sleeve and a swing frame. The upper installation base is arranged at one end above the workbench, the upper installation base is of an inverted-L-shaped structure, the conveying mechanism is perpendicularly arranged on one side of the workbench, and the two ends above the workbench are provided with shield plates correspondingly. The high-precision automatic milling repair device has the beneficial effects that a fourth motor rolls front and back in a rolling groove through a track, the front-back moving range of an installation head is enlarged, therefore, the machining range of the device for the tube structure is enlarged, a third motor drives a sleeve to turn over front and back through a rotating shaft, a fifth motor drives the installation head to adjust and turn overup and down, therefore, the polishing position of a polishing sleeve for the tube structure is flexibly adjusted, and it is ensured that the device is higher in polishing precision for the titanium alloy tube structure. By means of a rubber pad, abrasion produced during matched working of the device and the tube structure is reduced, and the machining quality of the device for the tube structure is improved.

Owner:阜宁德谊精密铸造有限公司

Electric vegetable cutting machine

InactiveCN1944004AImprove stabilityImprove cutting effectMetal working apparatusLinear motionEngineering

The electric vegetable cutting machine includes a vegetable cutter, a driving device to drive the cutter to reciprocating, a container with horizontal rail in the inner wall and a cutter holder on the rail and connected to the cutter. On the container, there are a detachable cover, a hopper in the cover and communicated to the container, and an extruder inside the hopper. The driving device installed detachably on the cover includes a casing, a motor, a switch, a gear set and a crank-slider mechanism with slider connected to the cutter holder. The crank-slider mechanism converts the rotation of the gear set into the horizontal linear motion of the slider to drive the cutter to cut vegetable stably.

Owner:浙江圣光电器有限公司

Controllable color imitation nep yarn manufacture method

The invention discloses a controllable color imitation nep yarn manufacture method. The method comprises a fine yarn color spun color circle manufacture step and a controllable color imitation nep yarn spinning step. The fine yarn color spun color circle manufacture step comprises the color-spun 'three waste' fine yarn classification, cutting and fuzzy processing. The controllable color imitation nep yarn step is different from the conventional method, the woven fabrics have unique color and style. Accordingly, the fabrics manufactured from the yarns spun by the method provided by the invention are extremely significant in the style compared with the fabrics manufactured from the conventional colored point yarns, and are popular to the market. In addition, the controllable color imitation nep yarn can be made into high-grade underwear, T-shirts, casual wears and the like, and is the best material for manufacturing fashion and popular fabrics.

Owner:BROS EASTERN

Building top plate vertical drilling device used for building construction

InactiveCN107498091AGuaranteed verticalityQuickly adjust depthPortable power-driven toolsWork benchesDrive shaftArchitectural engineering

The invention discloses a vertical drilling device for building roofs for building construction, comprising a base plate, a plurality of casters are installed on the lower edge side of the base plate, and a plurality of threaded holes are opened on the base plate, threaded columns are screwed into the threaded holes, threaded The bottom end of the column is fixedly connected in the installation hole of the rotating shaft sleeve; the bottom plate is positioned horizontally by adjusting the rotating handle, which can ensure the verticality of the drilling hole, and the lifting column is moved upward by toggling the toggle block, which is easy to operate , Fast, easy to quickly adjust the height of the drill bit, press the two limit positions inward with your hand at the same time, so that the movable column moves to a certain place, so it is convenient to adjust the depth of the drill bit, the dust from the drill hole falls into the ring sleeve and It is discharged through the discharge pipe. Since the annular plate can shrink into the annular sleeve, the upper part of the annular plate is in contact with the roof of the building during the drilling process, so that the dust will not fall to the outside of the annular plate and improve the construction environment.

Owner:王峰

Process for processing full polyester superfine fiber blanket

InactiveCN1858318AReduce fuzzFeed and feed tension of wool is easy to controlWeft knittingMicrofiberPolyester

The process of producing superfine full polyester fiber blanket includes the following steps: preparing DTY yarn material, weft knitting, dyeing or printing, opening and stoving, fixing color, finishing, heat setting, back pilling and finishing, clipping, and sewing to form the blanket. The production process features the re-networking of DTY yarn before weft knitting to constitute single strand high F superfine denier yarn, and this can reduce broke filament, and result in easy control of feeding tension, homogeneous tension and density. The present invention can produce high quality full polyester fiber blanket with fluff height of 4.5-12 mm, unit area weight of 300-500 g / sq m, plumpy fluff.

Owner:常熟市锦绣经纬编有限公司

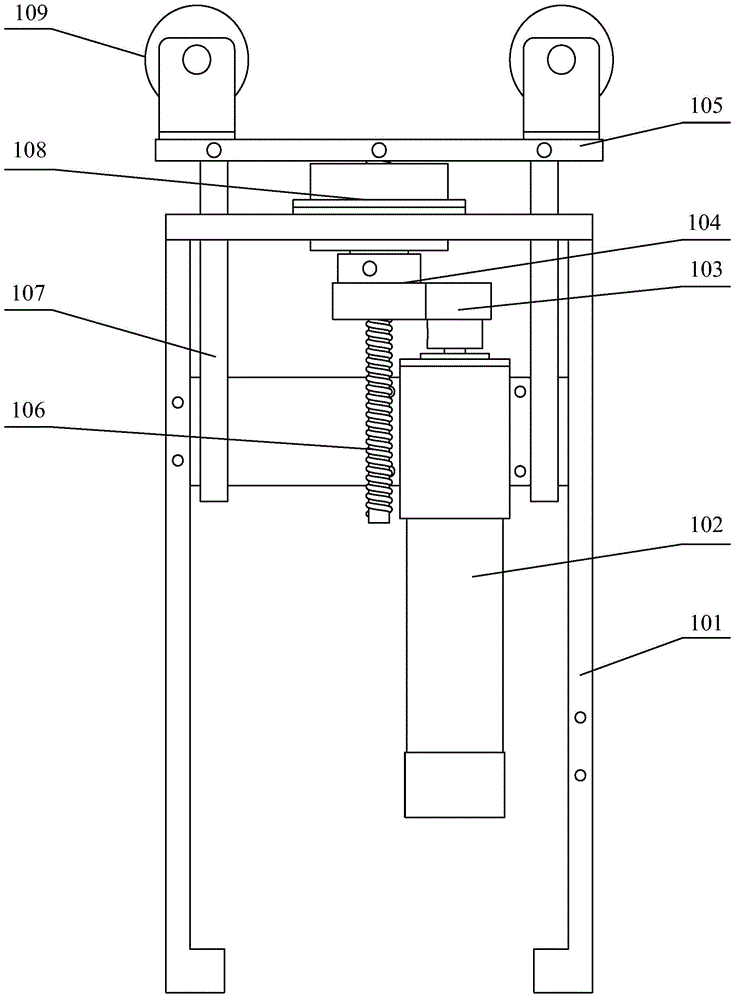

Lifting conveying device

The invention provides a lifting conveying device. The lifting conveying device comprises a controller, a lifting mechanism and a clamping transmission mechanism. The lifting mechanism comprises a driving motor and a screw-nut pair connected with the driving motor, wherein a lead screw is movably connected with a horizontal plate through a nut; a first clamping plate rotationally connected with the front end of the horizontal plate and a groove for containing the first clamping plate are arranged at the front end of the horizontal plate, and a second clamping plate opposite to the first clamping plate is arranged at the rear end of the horizontal plate; the first clamping plate and the second clamping plate are connected with the nut on the lead screw through the clamping transmission mechanism; a first sensor and a second sensor are arranged at the upper and lower ends of the lead screw respectively; the controller is arranged in a control box, and an operation panel is arranged on the surface of the control box. The driving motor, the clamping transmission mechanism and the two sensors are electrically connected with the controller. The requirements of front and back machining equipment for the height of the conveying device are both met through the lifting mechanism and the clamping transmission mechanism, and an electronic element is stably transferred from the front machining equipment to the back machining equipment.

Owner:SUZHOU YUANSHUO PRECISION MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com