Electric vegetable cutting machine

A vegetable cutting machine, electric technology, applied in metal processing and other directions, can solve the problems of inconvenient cleaning, low safety, poor stability, etc., and achieve the effects of convenient disassembly and assembly, good safety and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

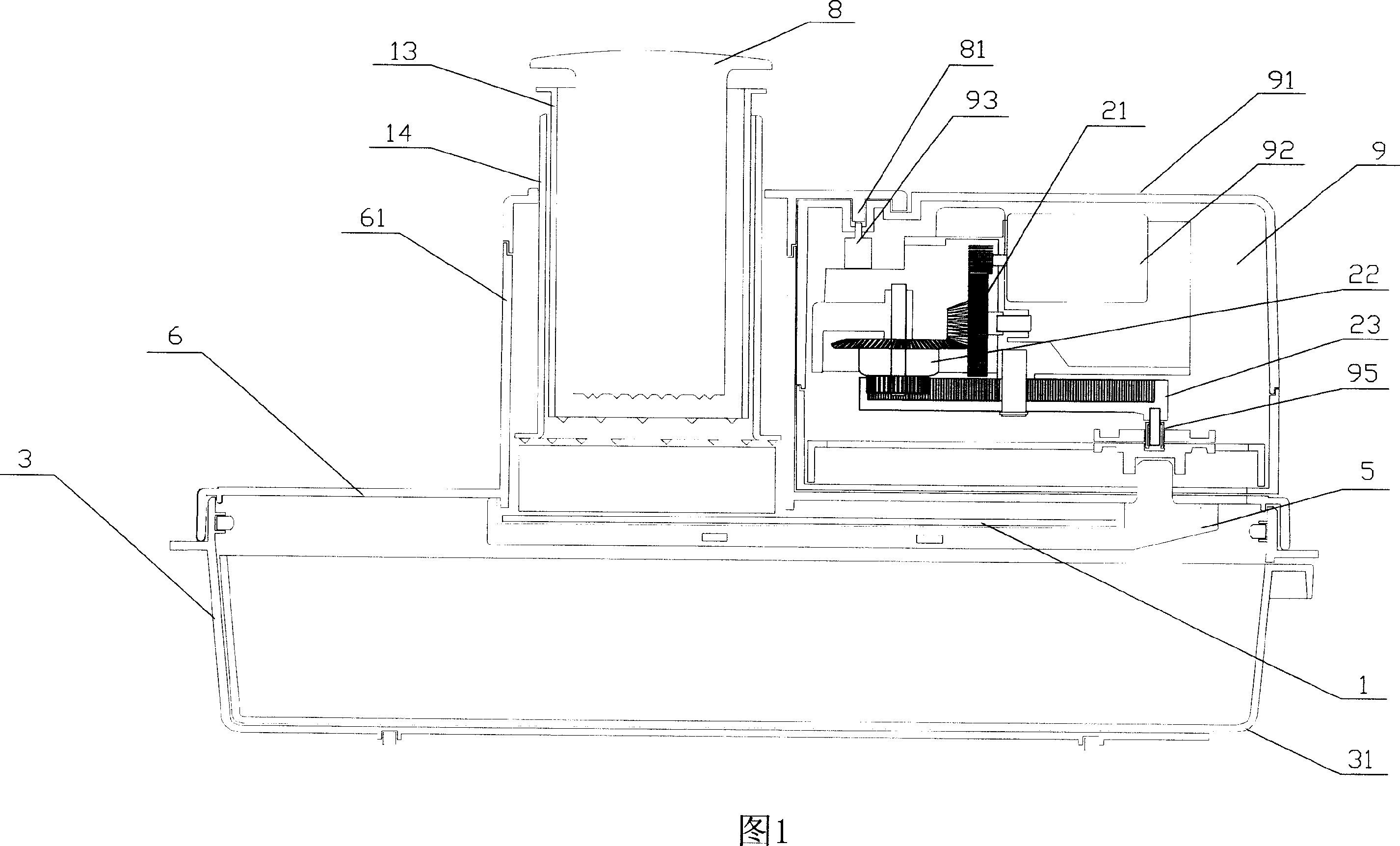

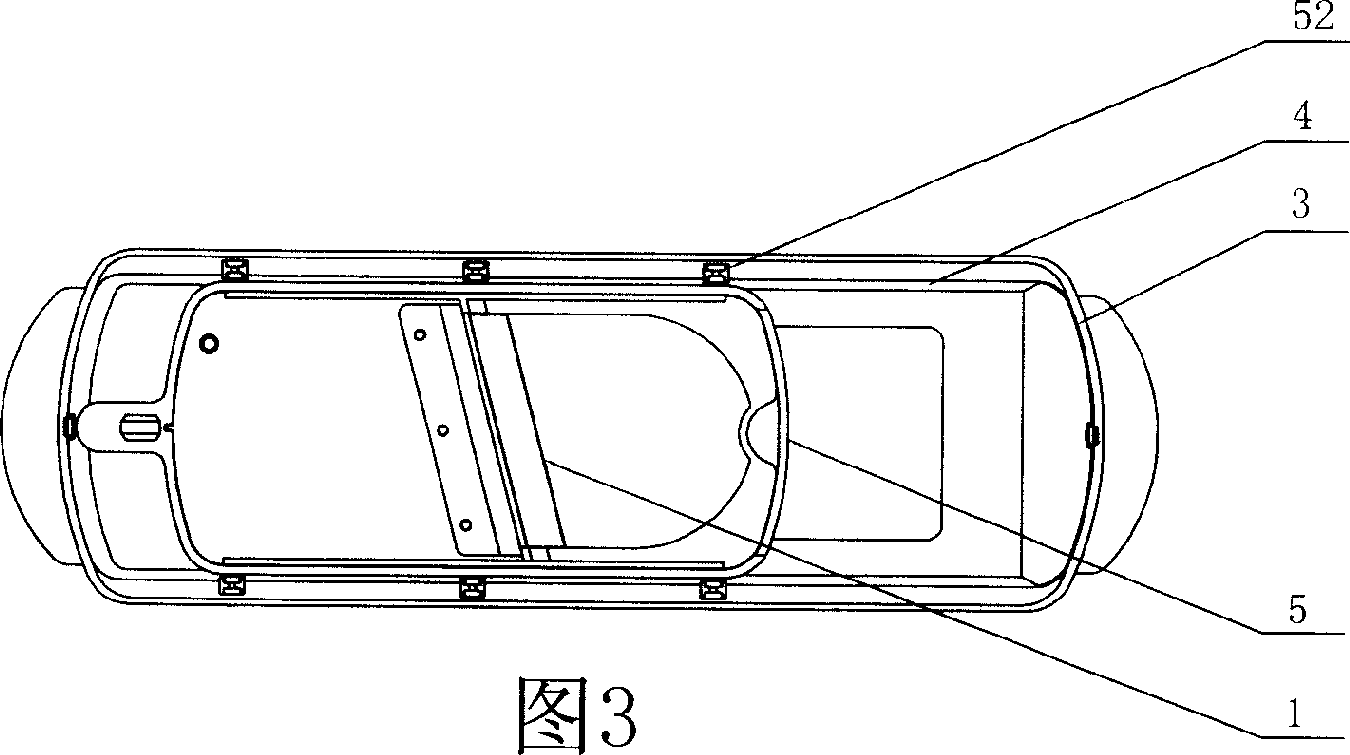

[0024] Referring to accompanying drawings 1, 3, 5, an electric vegetable cutter includes a vegetable cutting blade 1, a transmission device 9 for driving the reciprocating motion of the vegetable cutting blade, a container 3 for holding objects, and the inner wall of the container is provided with a horizontal track 4. The knife rest 5 is slidably installed on the track, and the vegetable cutting blade 1 is connected to the knife rest 5; the container is provided with a detachable container cover 6, and the container cover corresponds to a vegetable cutter The working stroke area of the sheet is provided with a through-type lower hopper 61, the lower hopper communicates with the container, and the lower hopper is provided with an extrusion cover 8; the transmission device 2 is detachably mounted on the container cover , the transmission device includes an organic casing 91, a motor 92, a switch 93, a gear set and a slider crank mechanism, and the slider crank mechanism includ...

Embodiment 2

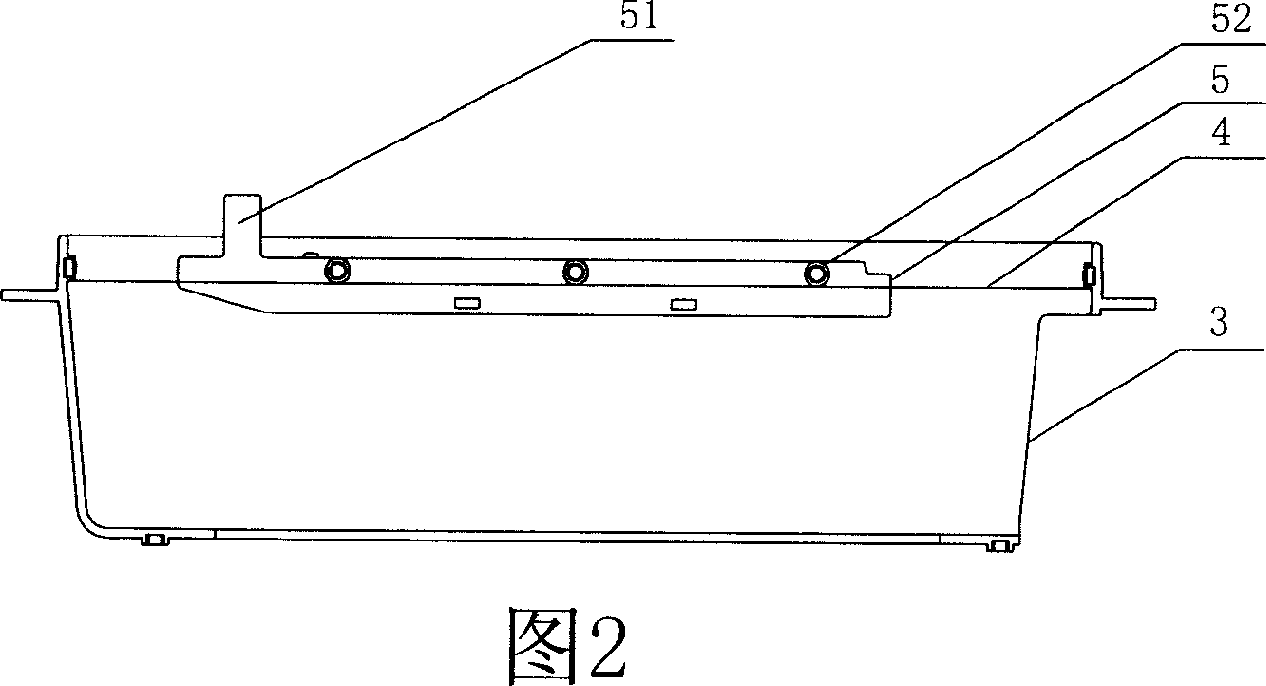

[0026] With reference to accompanying drawing 2,3,4, described knife rest is provided with the projection 51 that is connected with described slide block, and the top end of described projection exposes container cover 6, and described container cover is provided with correspondingly with projection 51. The groove corresponding to the stroke, the slider is provided with a card slot 7 which plays a role in connecting with the protrusion, and the card slot is provided with an elastic block 10, and the outer side of the elastic block is provided with a slot for the protrusion to slide into. The working surface 11 is inclined, and the inner side of the elastic block is provided with a blocking surface 12 that cooperates with the protrusion. In this way, the elastic block and the protrusion form a buckle connection, and the others are the same as in the first embodiment.

Embodiment 3

[0027] Embodiment 3: Referring to accompanying drawings 2 and 3, the tool rest is provided with pulleys 52 that cooperate with the rails along both sides of the rail, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com