Sustrate olelivery mechanism

A technology of conveying mechanism and substrate, which is applied to conveyor objects, pile separation, lighting and heating equipment, etc., can solve the problems of insufficient curing, complicated curing work, and the curing of both sides of the substrate cannot be carried out at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

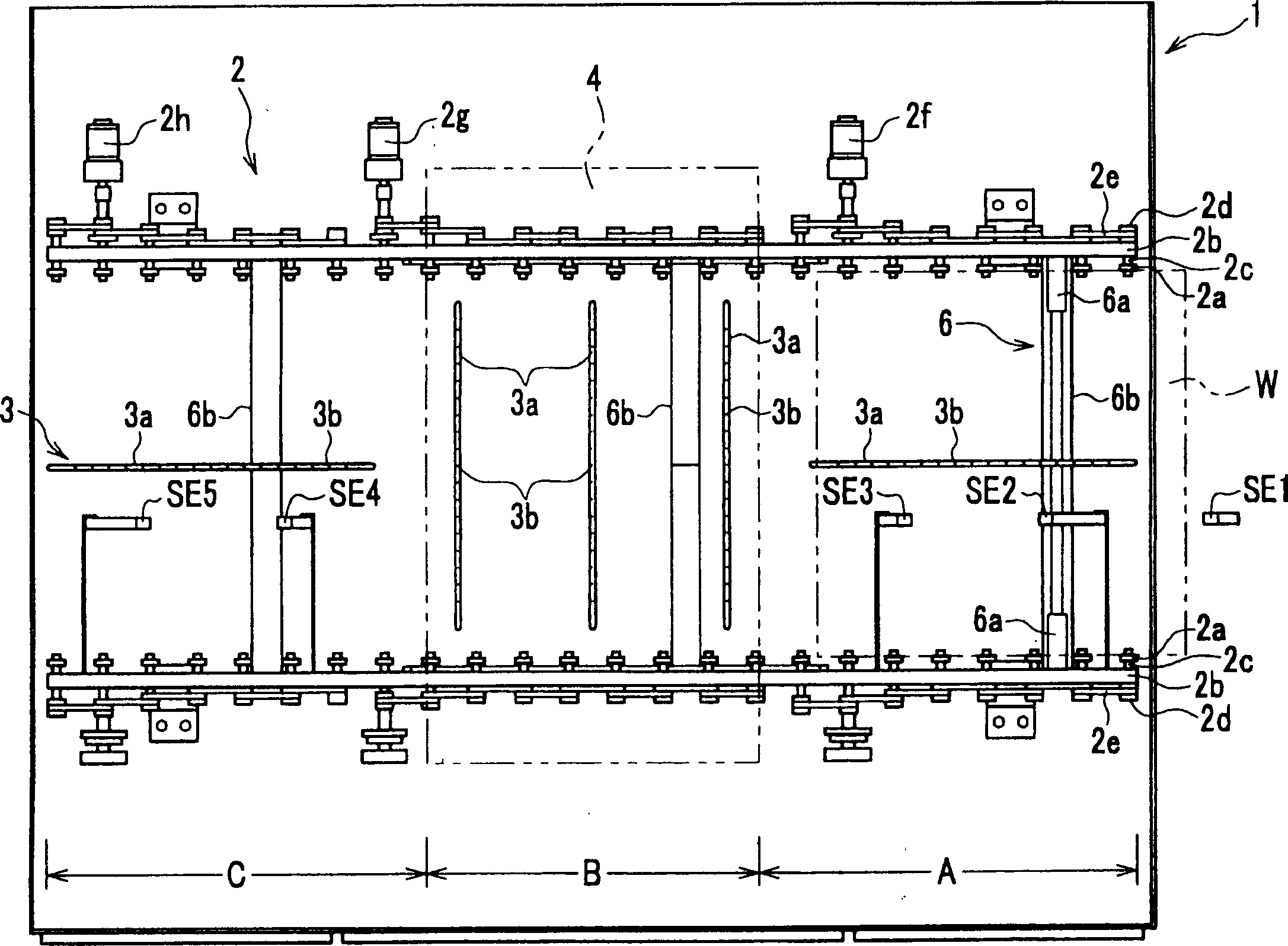

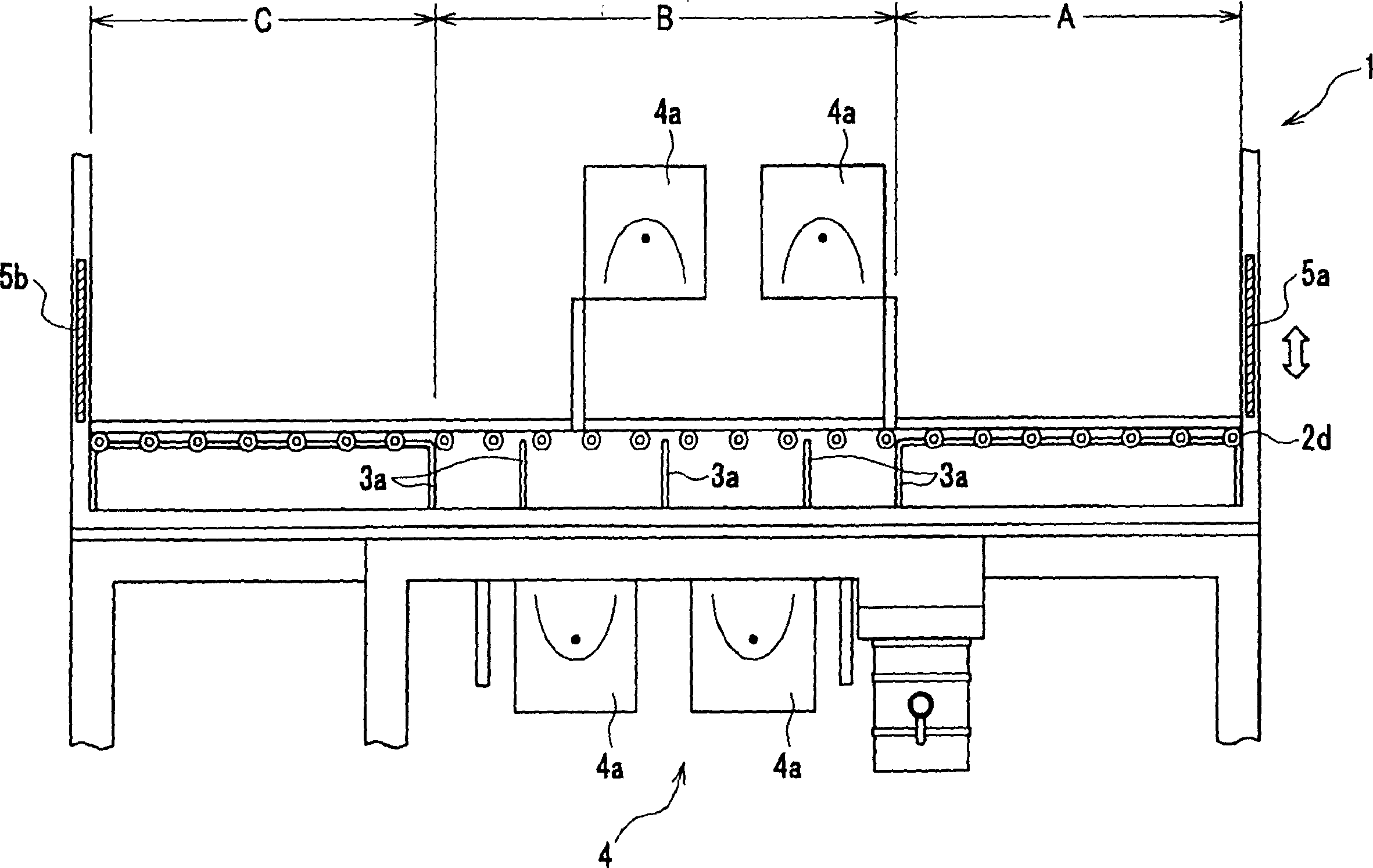

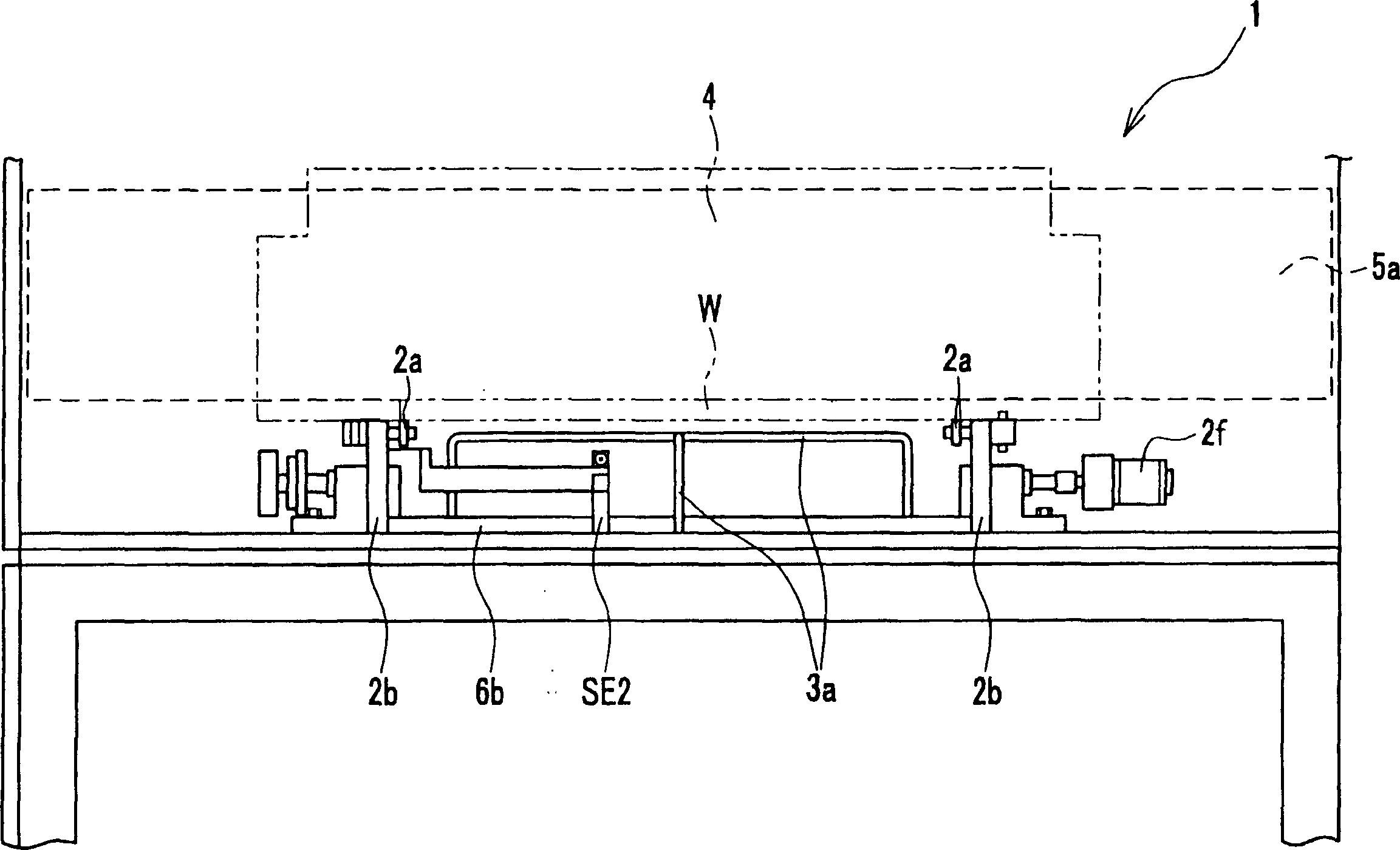

[0043] Embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 is a plan view showing the main part of an ultraviolet radiation apparatus utilizing a substrate transport mechanism. figure 2 yes figure 1 front view. image 3 yes figure 1 A side view of . Figure 4 A is a schematic perspective view of the substrate transfer auxiliary mechanism. Figure 4 B is a partial end view taken along line A-A.

[0044] Such as figure 1 As shown, the substrate conveying mechanism 2 is equipped with: some conveying rollers 2a, which are used to support the two ends of the substrate W to convey the substrate W; The lower portion of the substrate W supports the substrate W in a non-contact state.

[0045] In addition, the substrate transfer mechanism 2 is divided into three parts: a stand-by part A at which ultraviolet rays are not emitted; a send-out part C; and a radiation part B at which ultraviolet rays are emitted . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com