Patents

Literature

50results about How to "Realize the pressing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

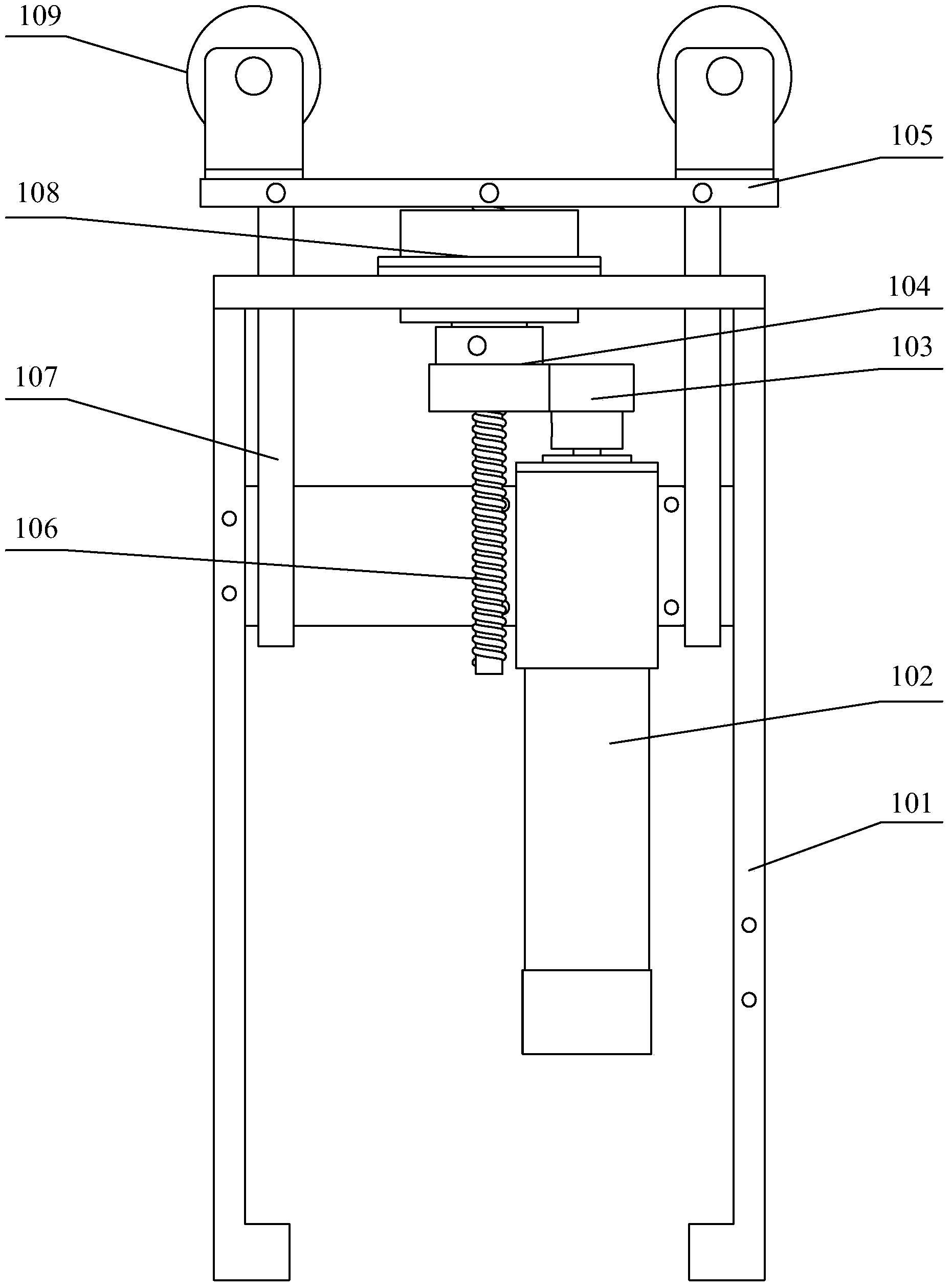

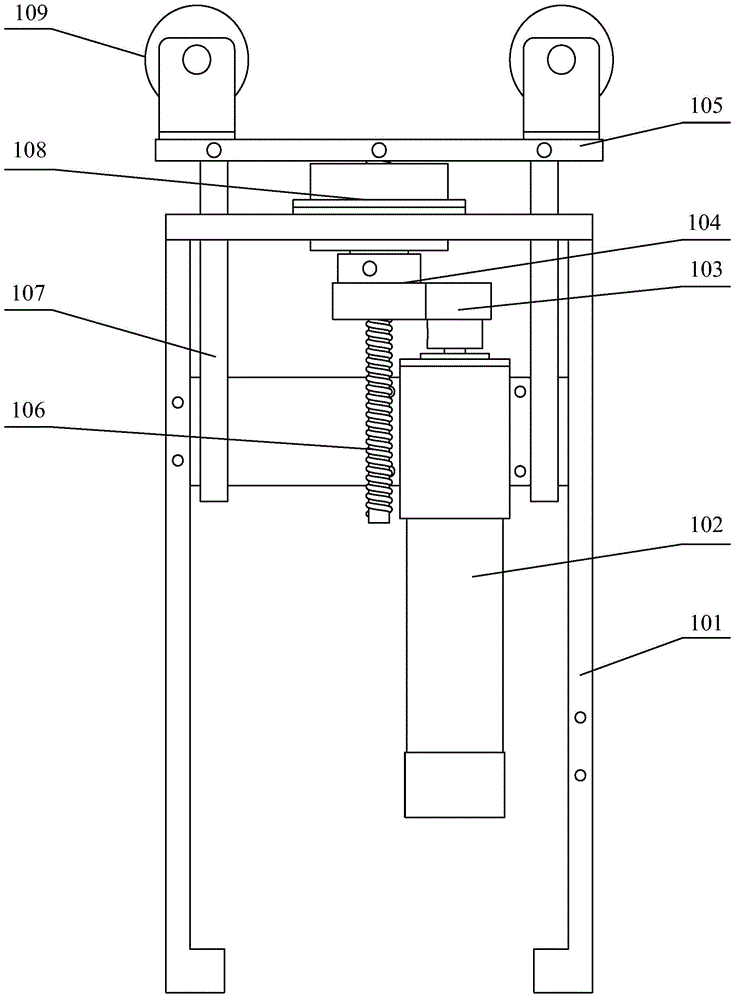

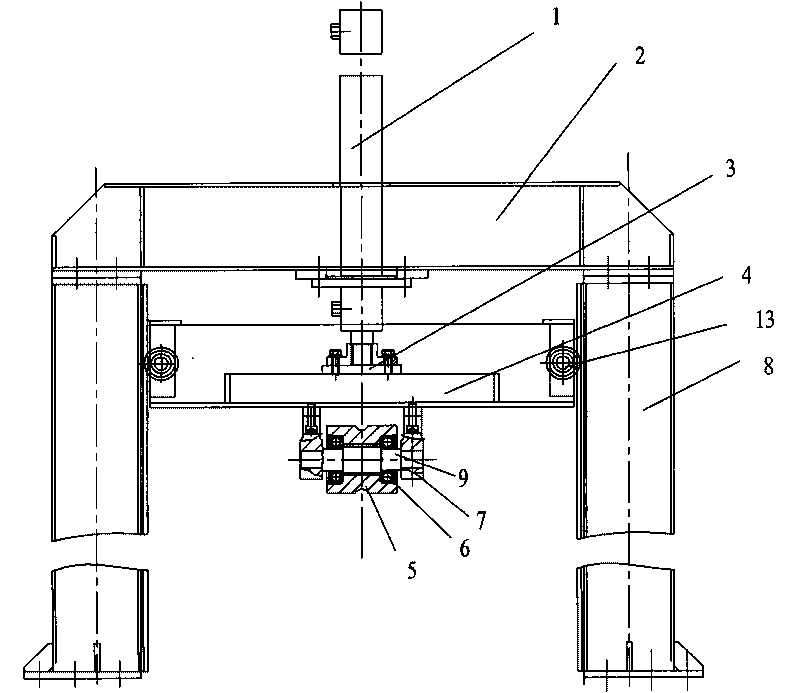

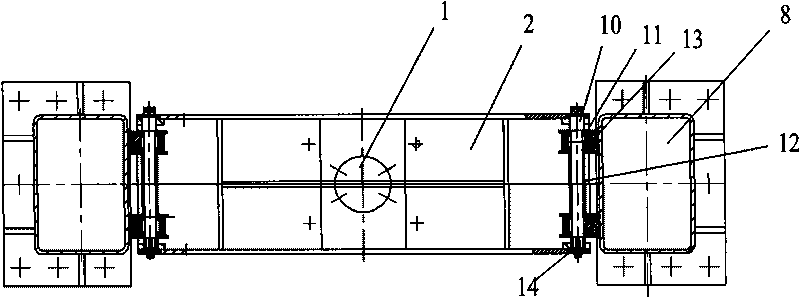

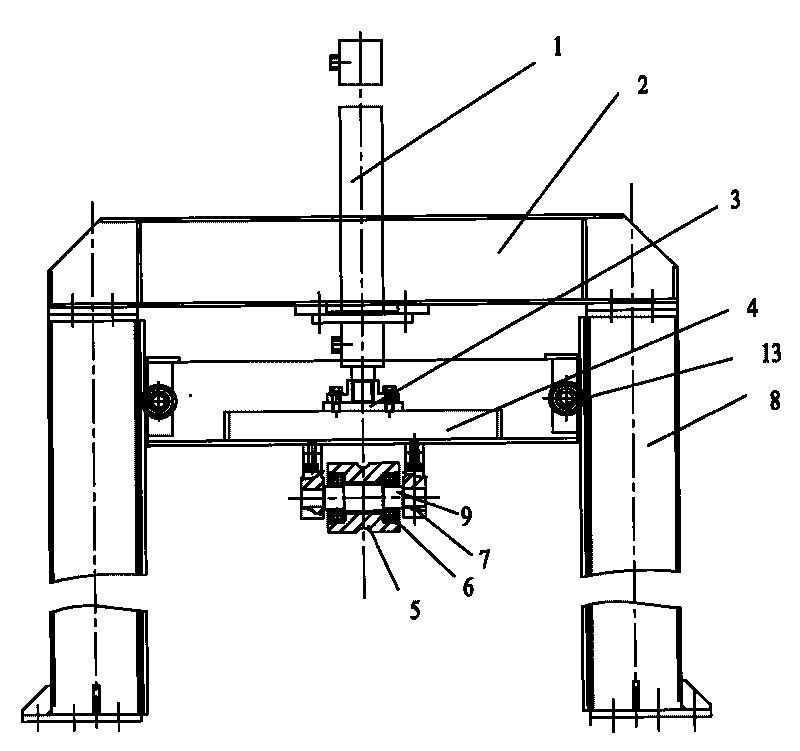

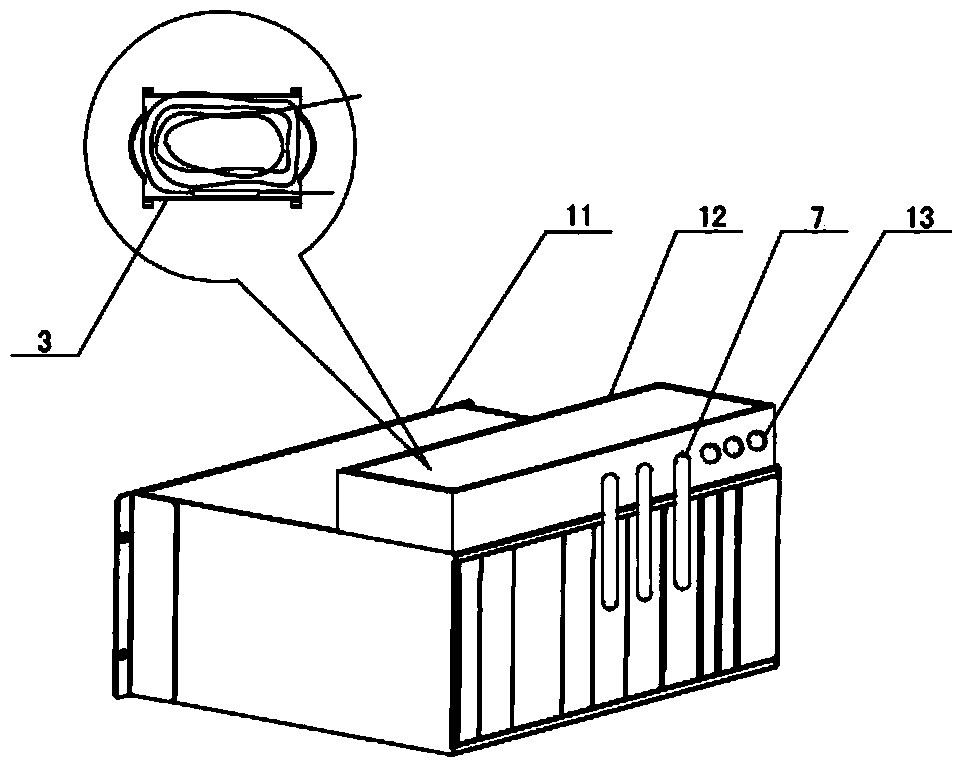

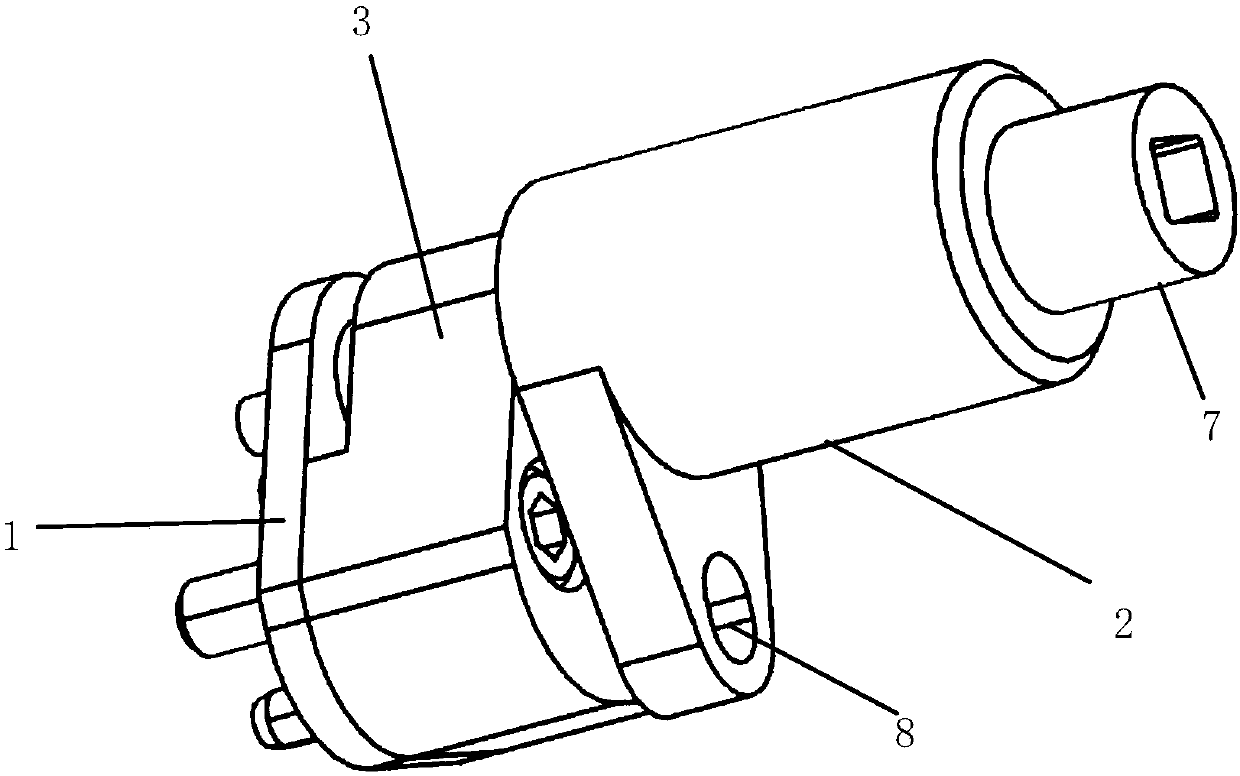

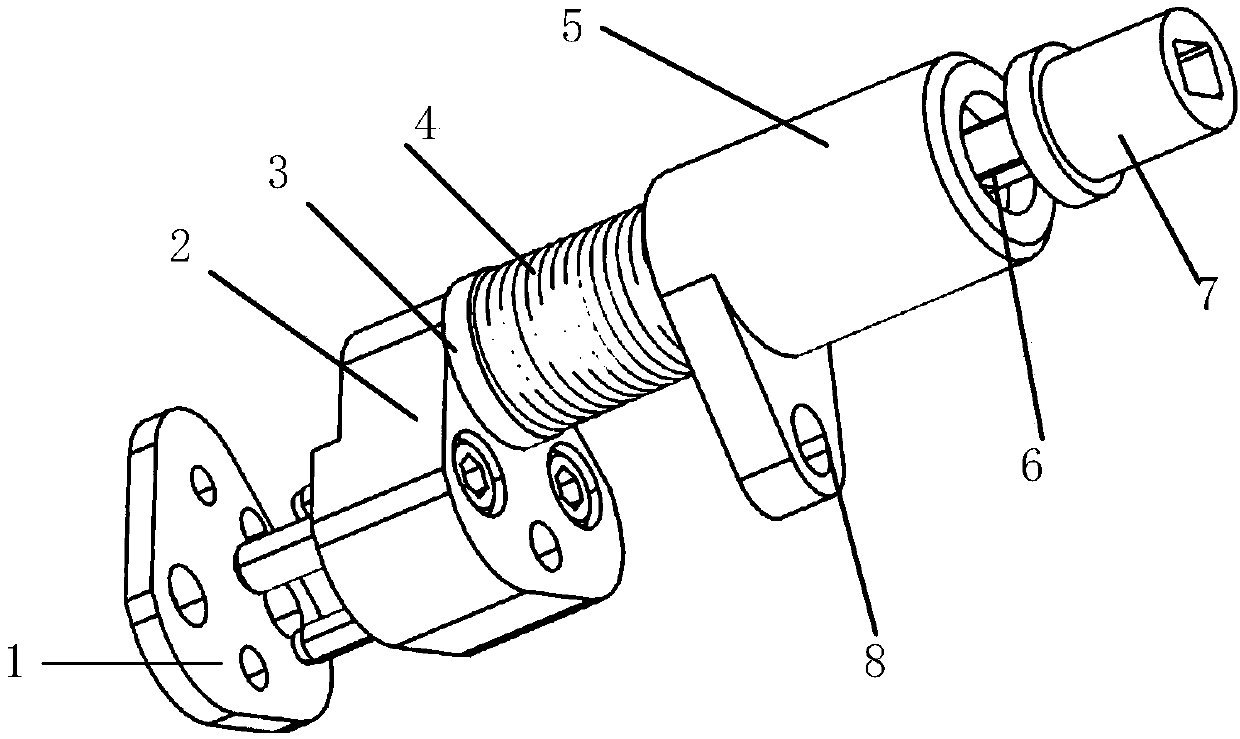

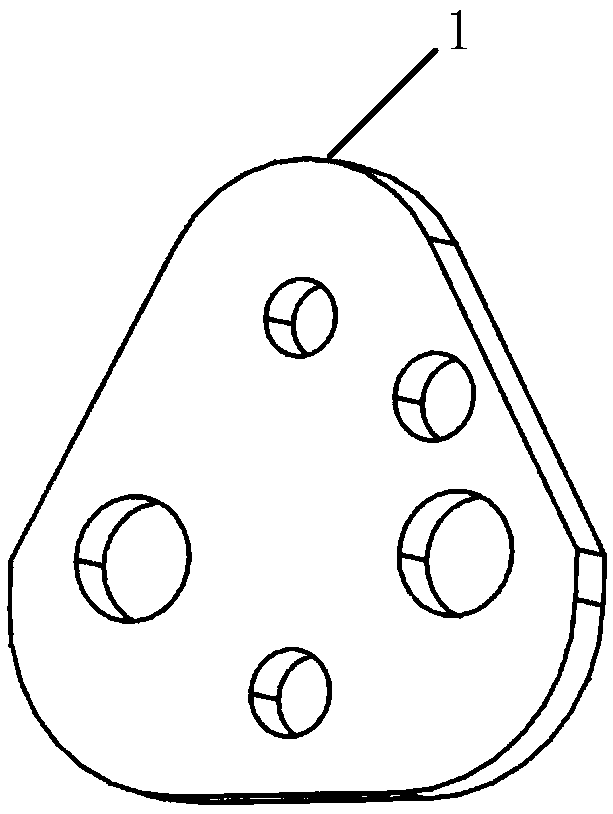

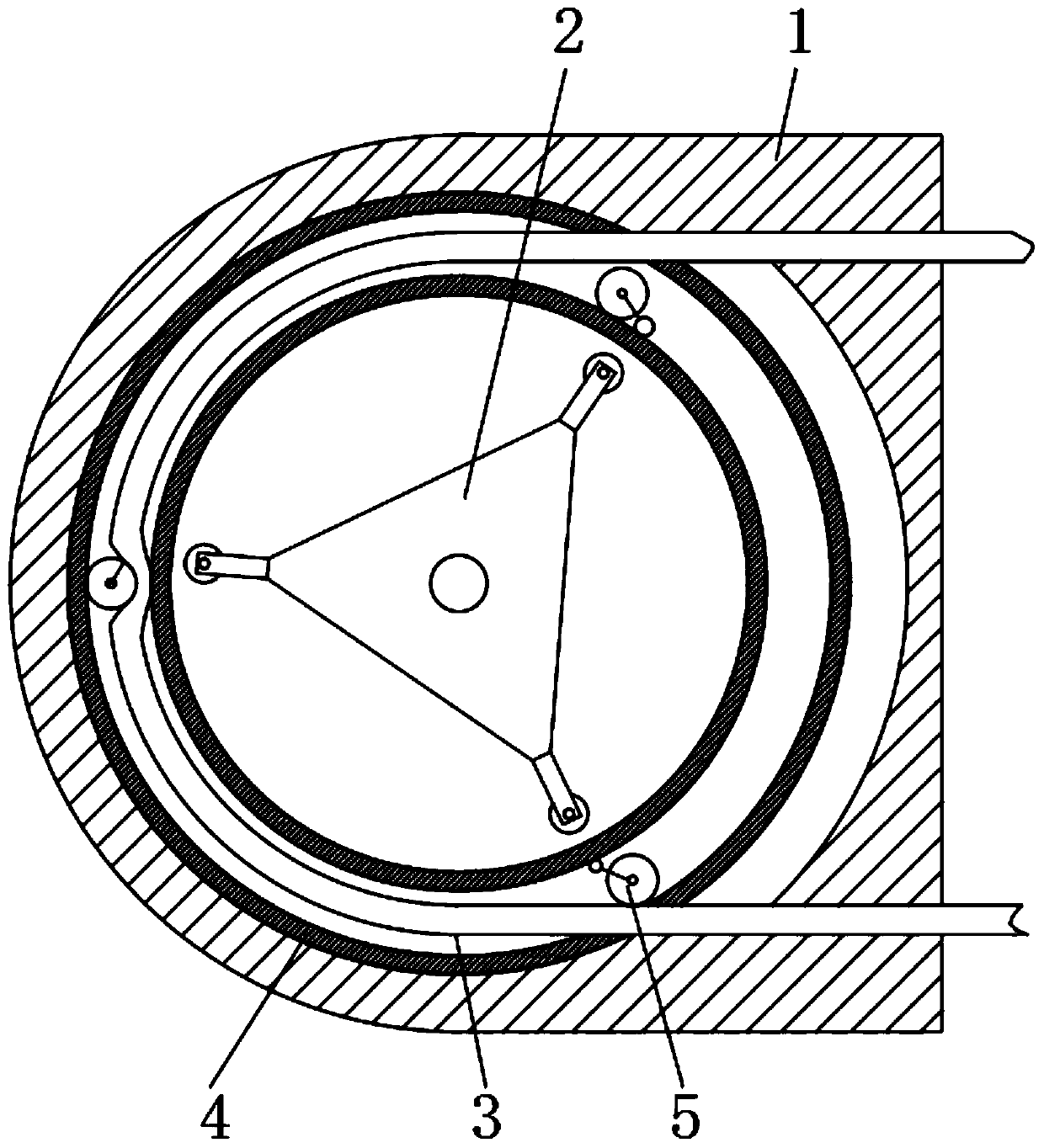

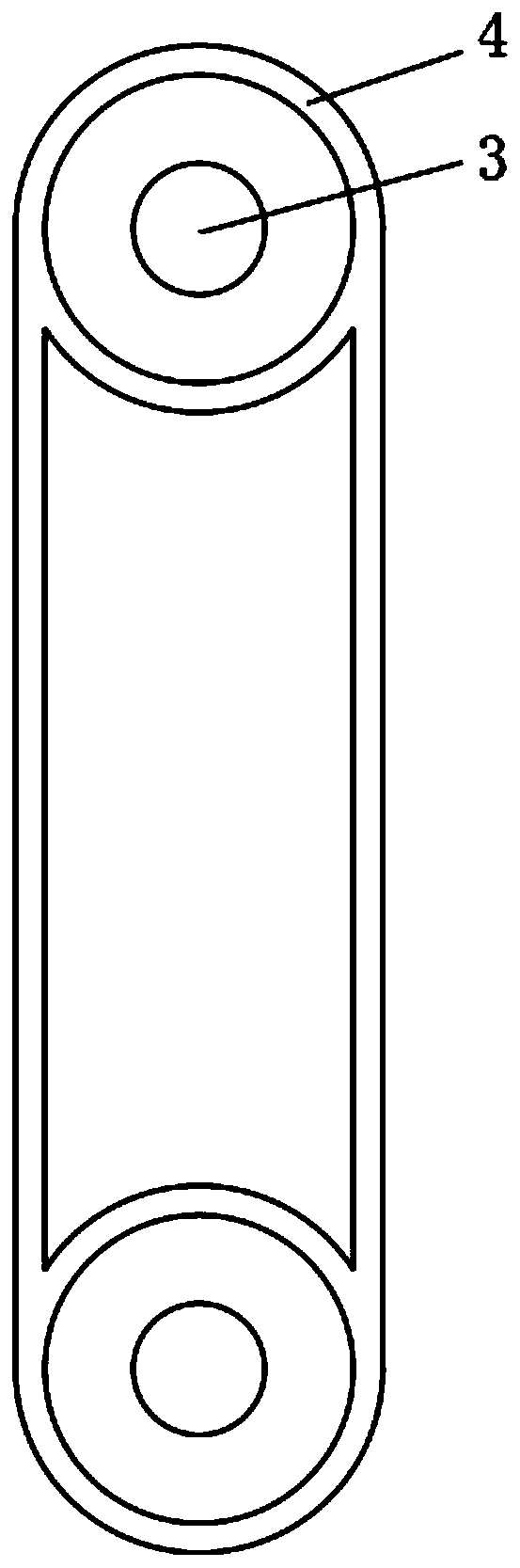

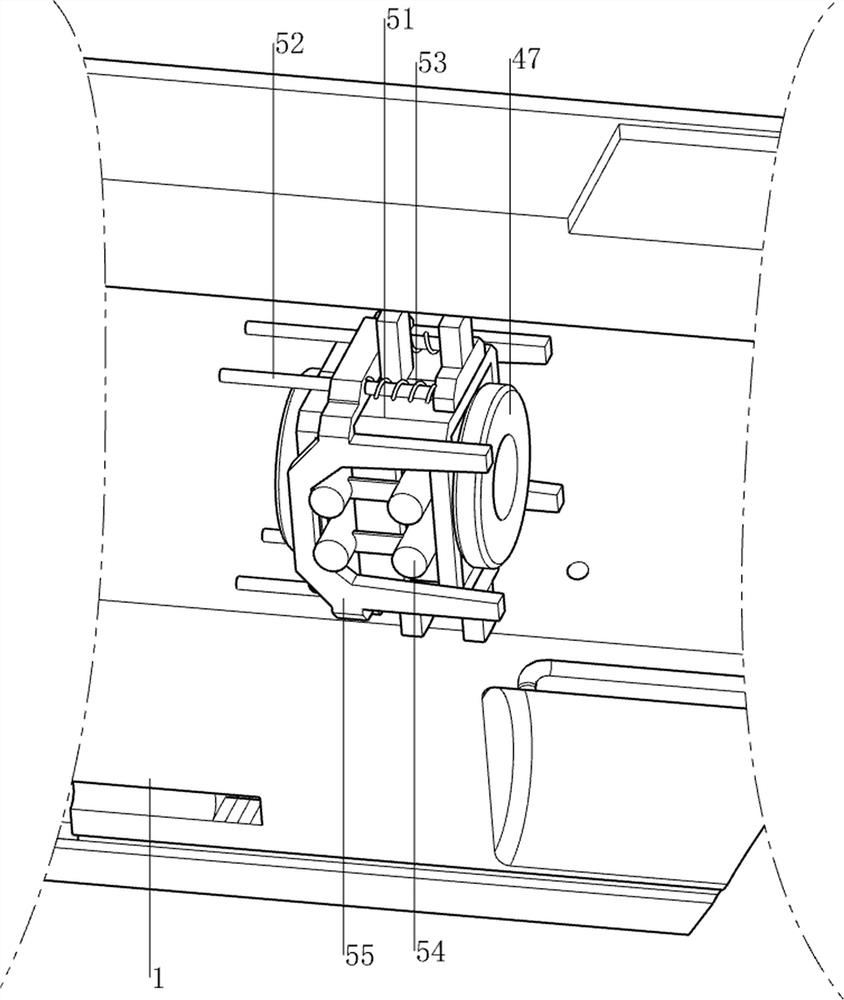

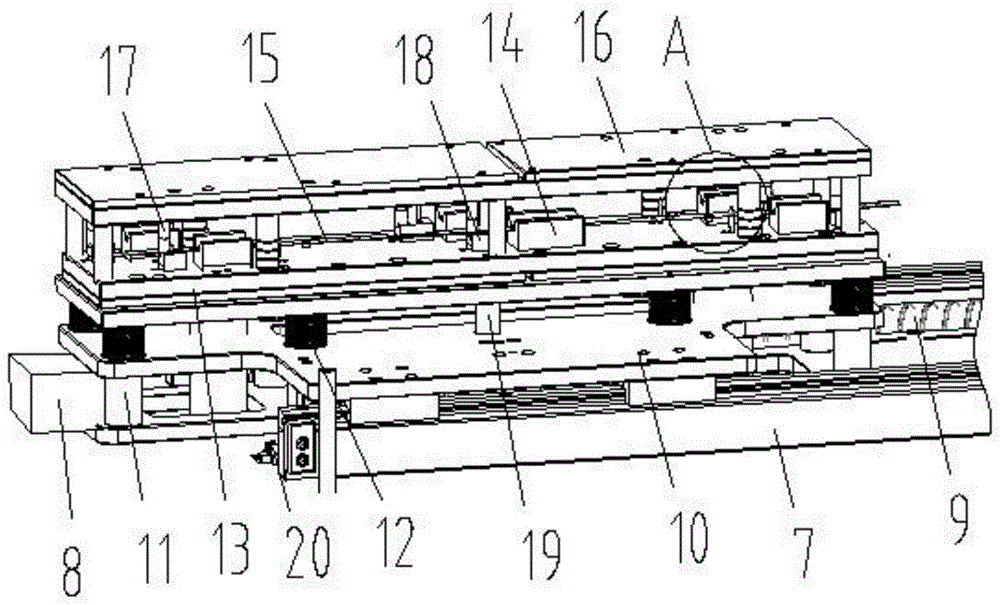

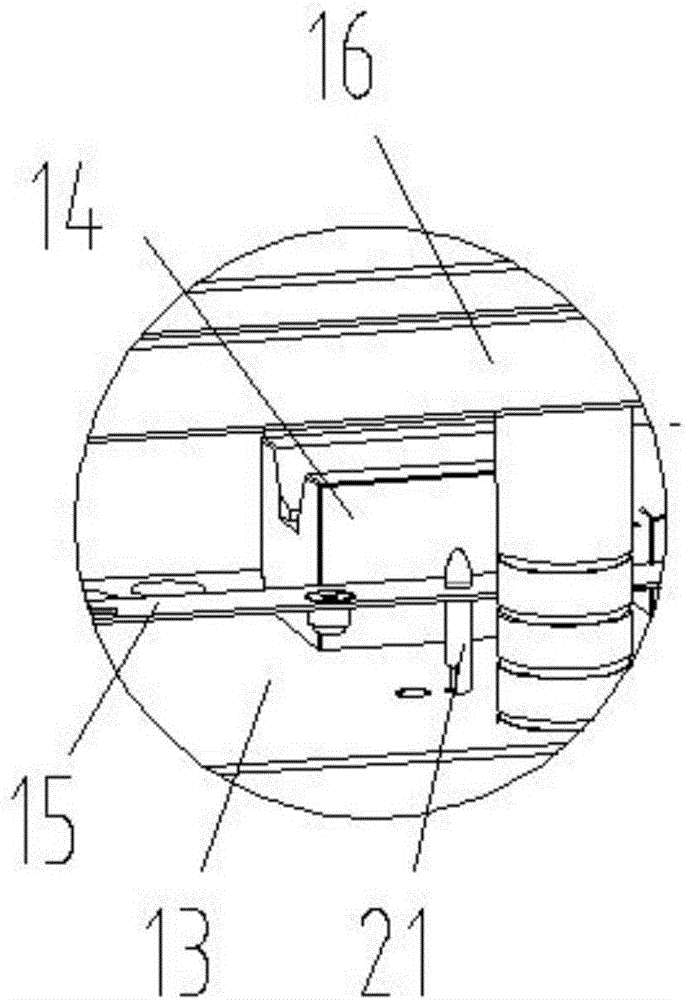

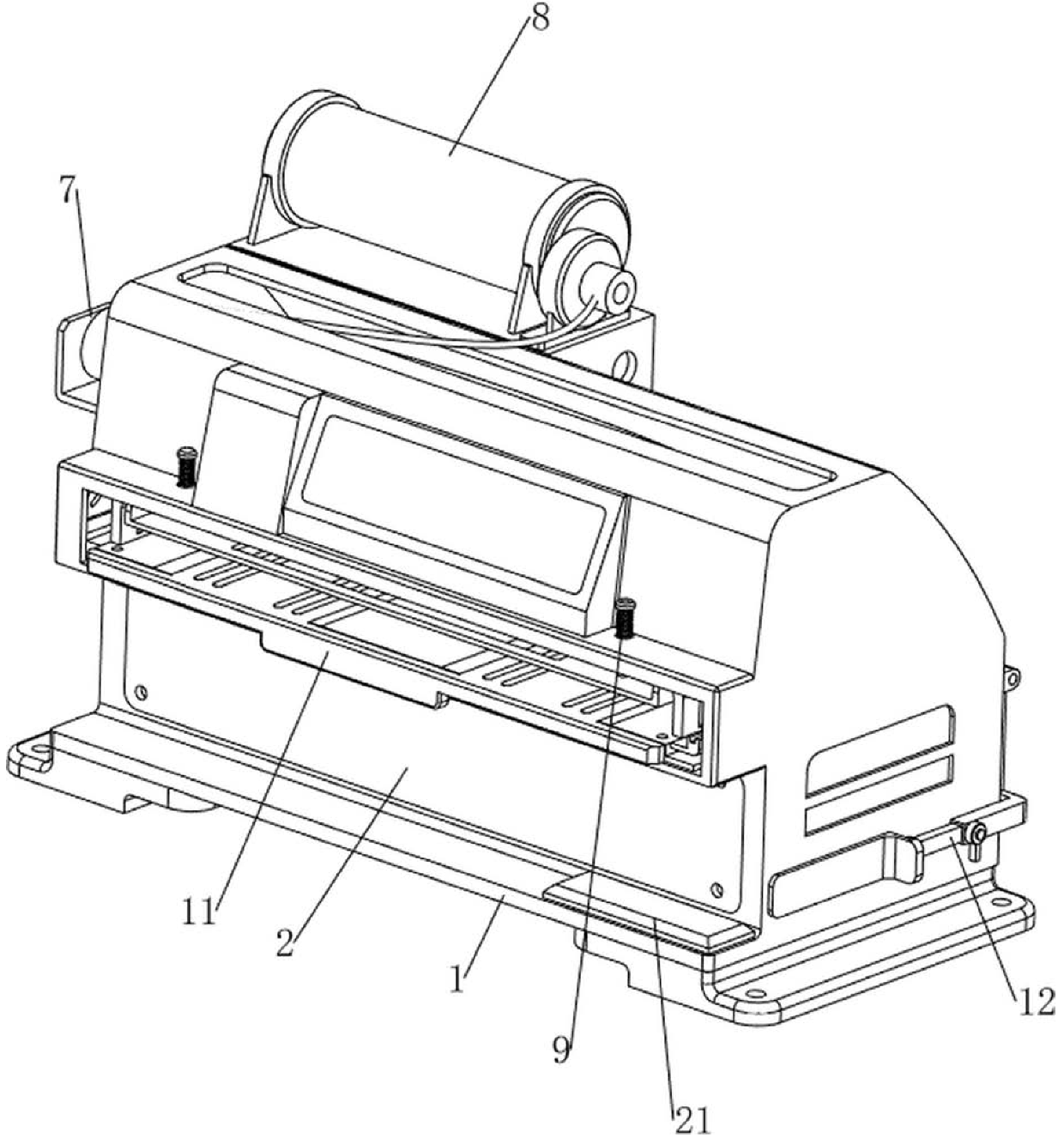

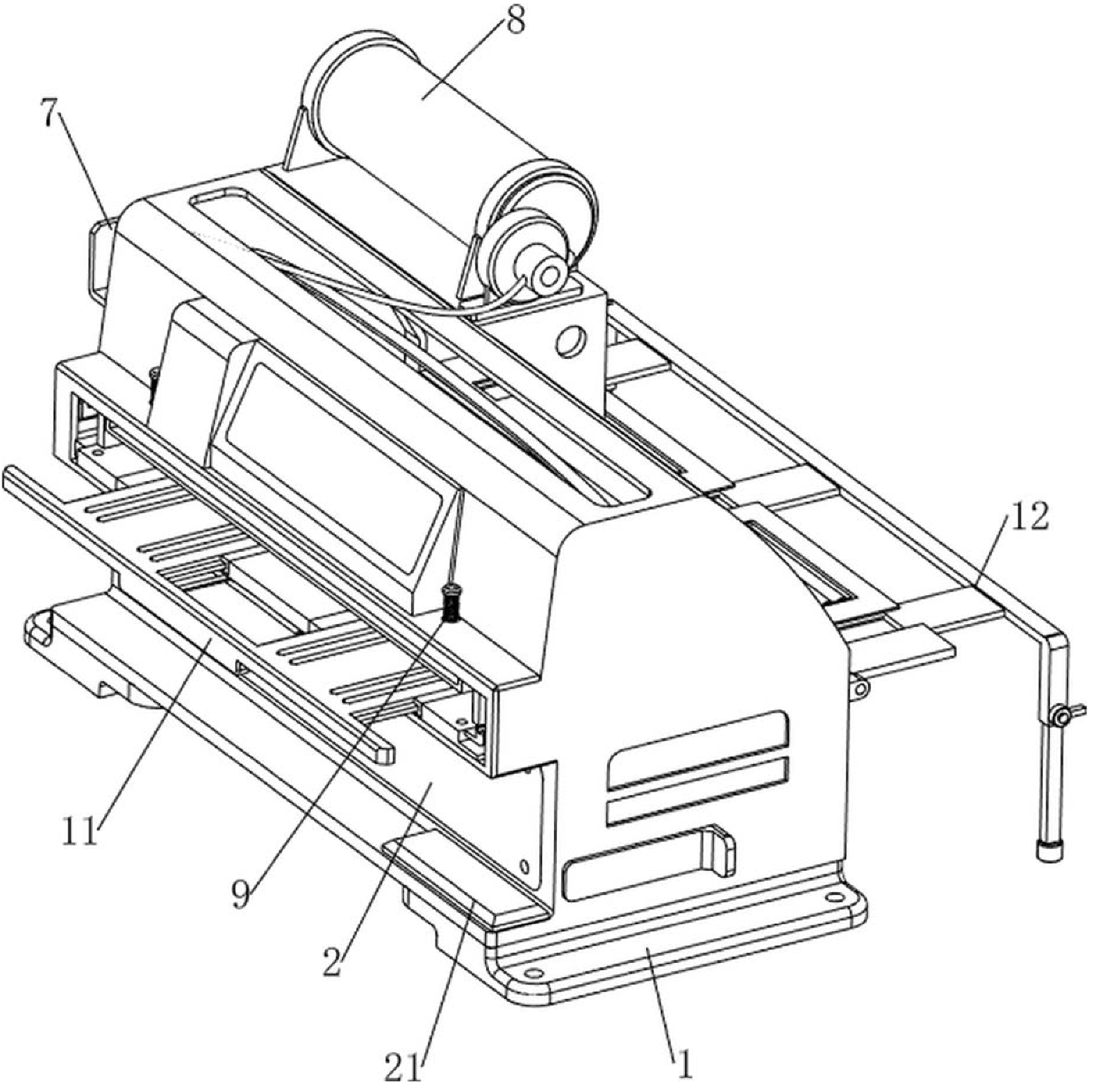

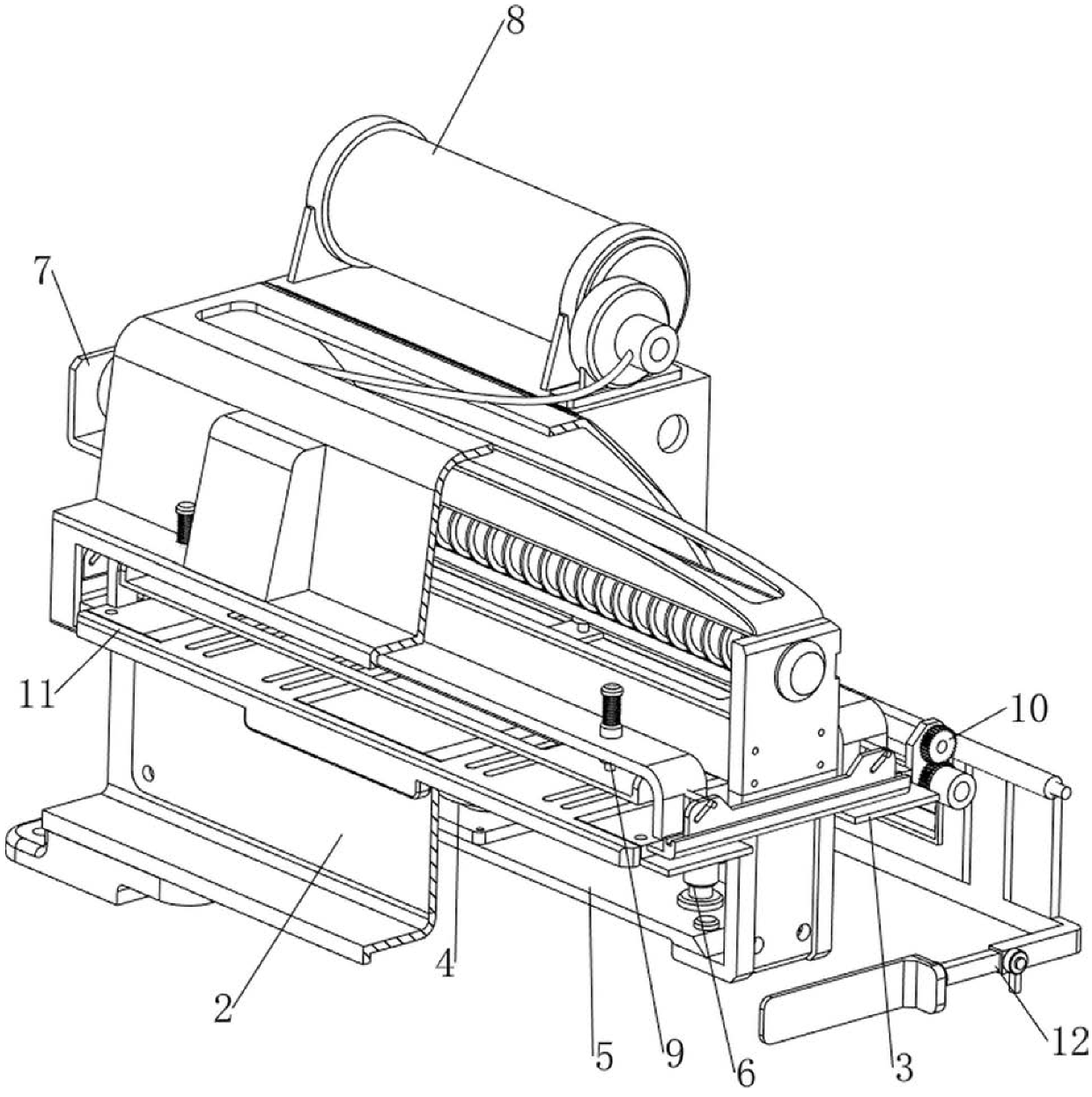

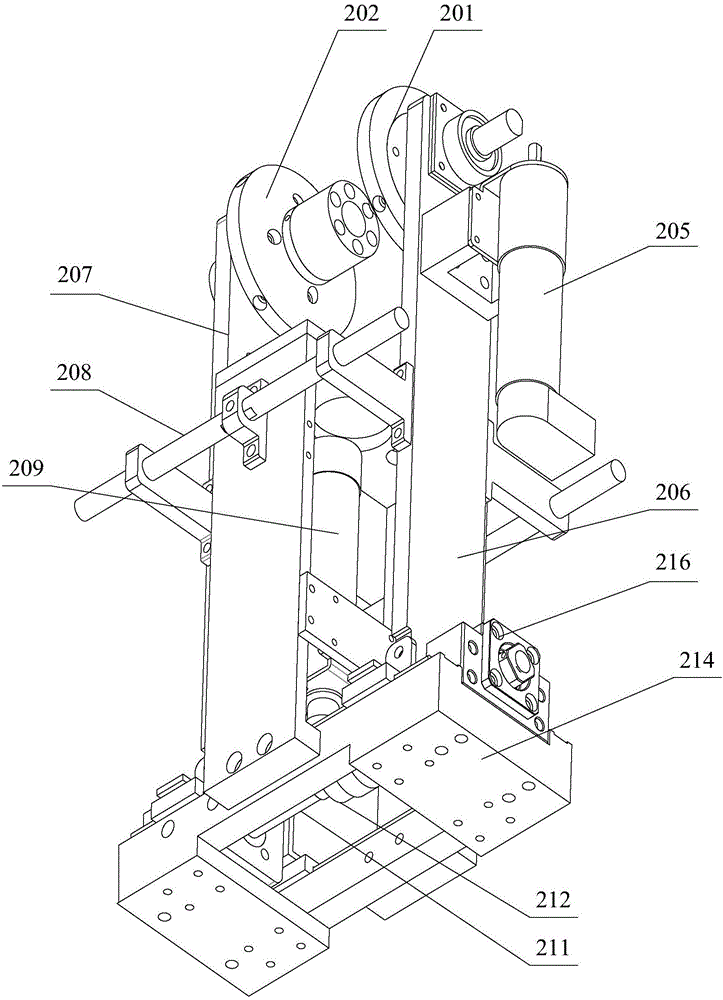

Pinch roller mechanism and traveling wheel set mechanism

ActiveCN103594969ARealize the pressing effectWith barrier functionApparatus for overhead lines/cablesWalking around obstaclesDrive wheel

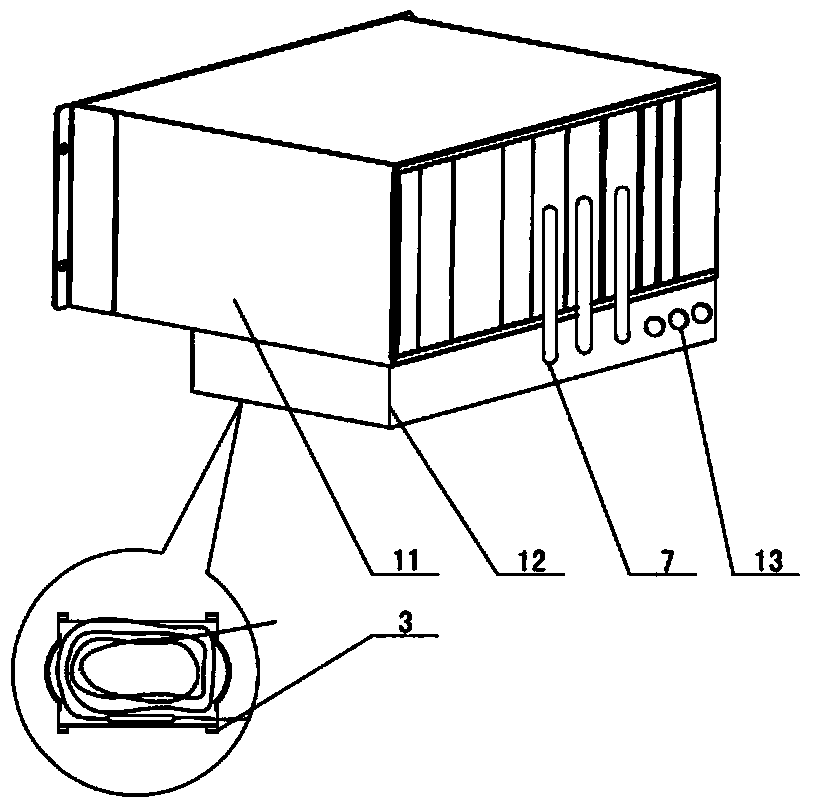

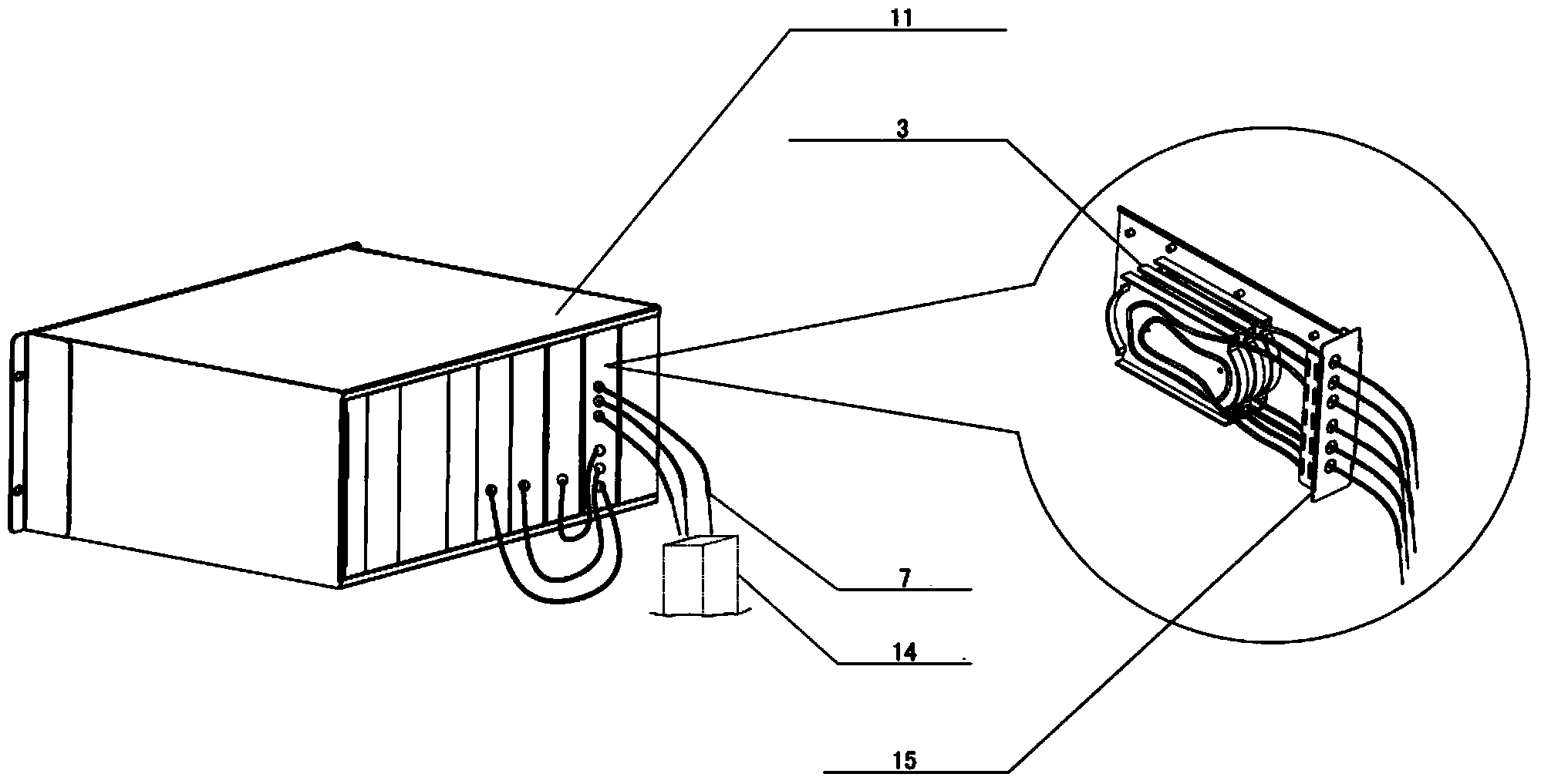

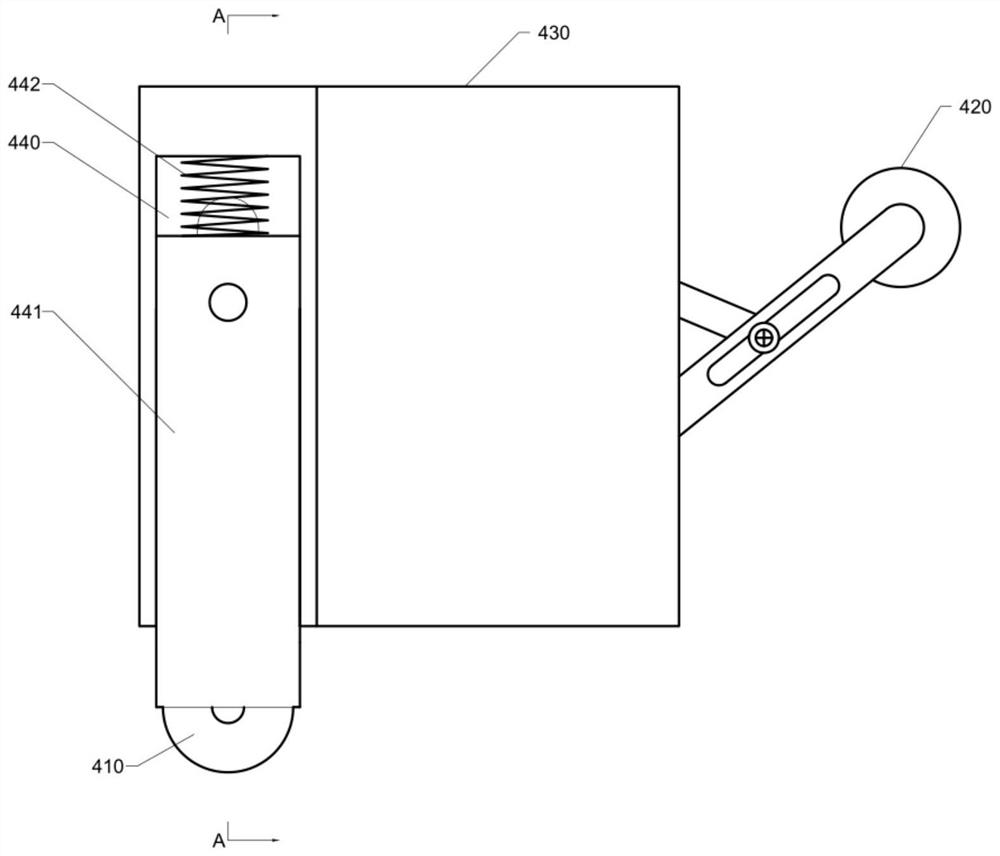

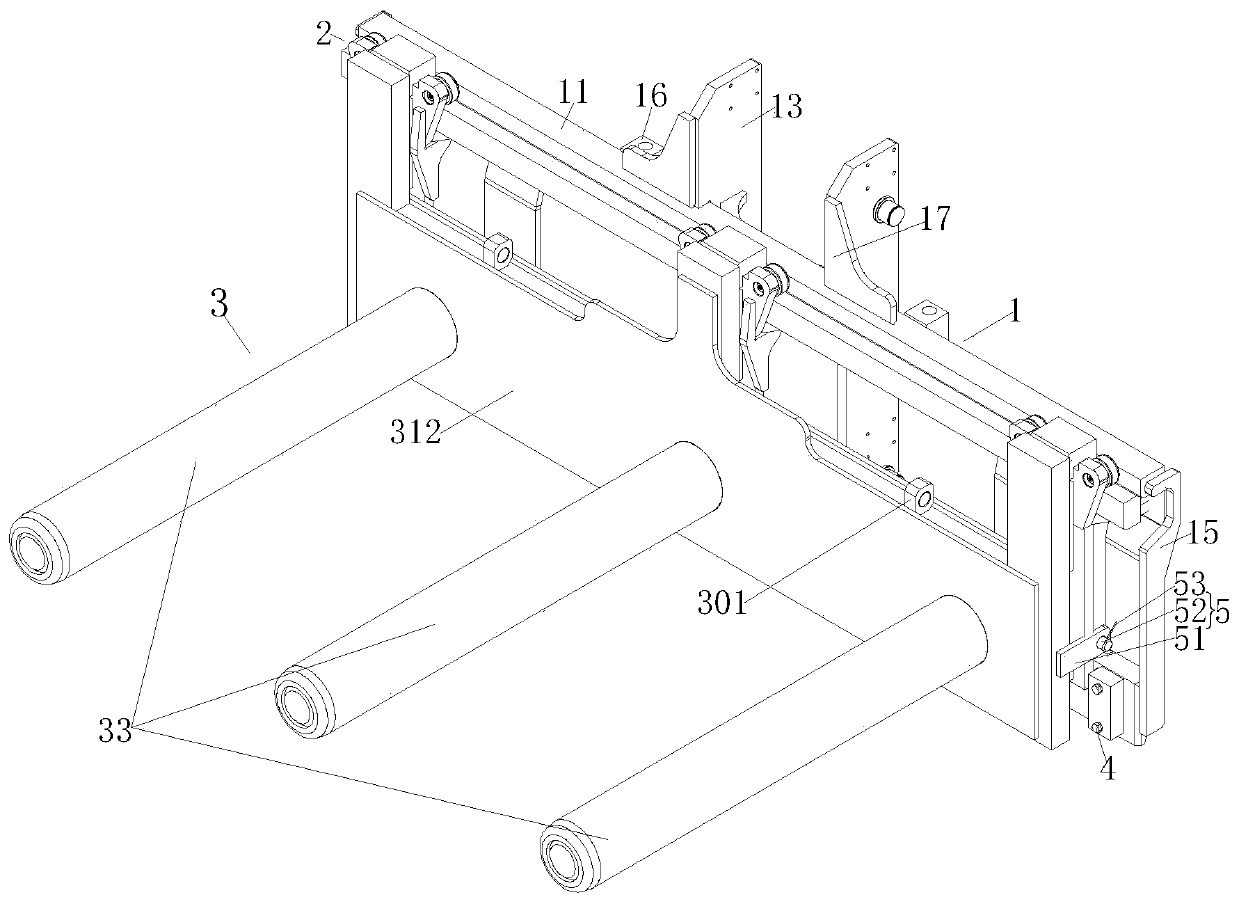

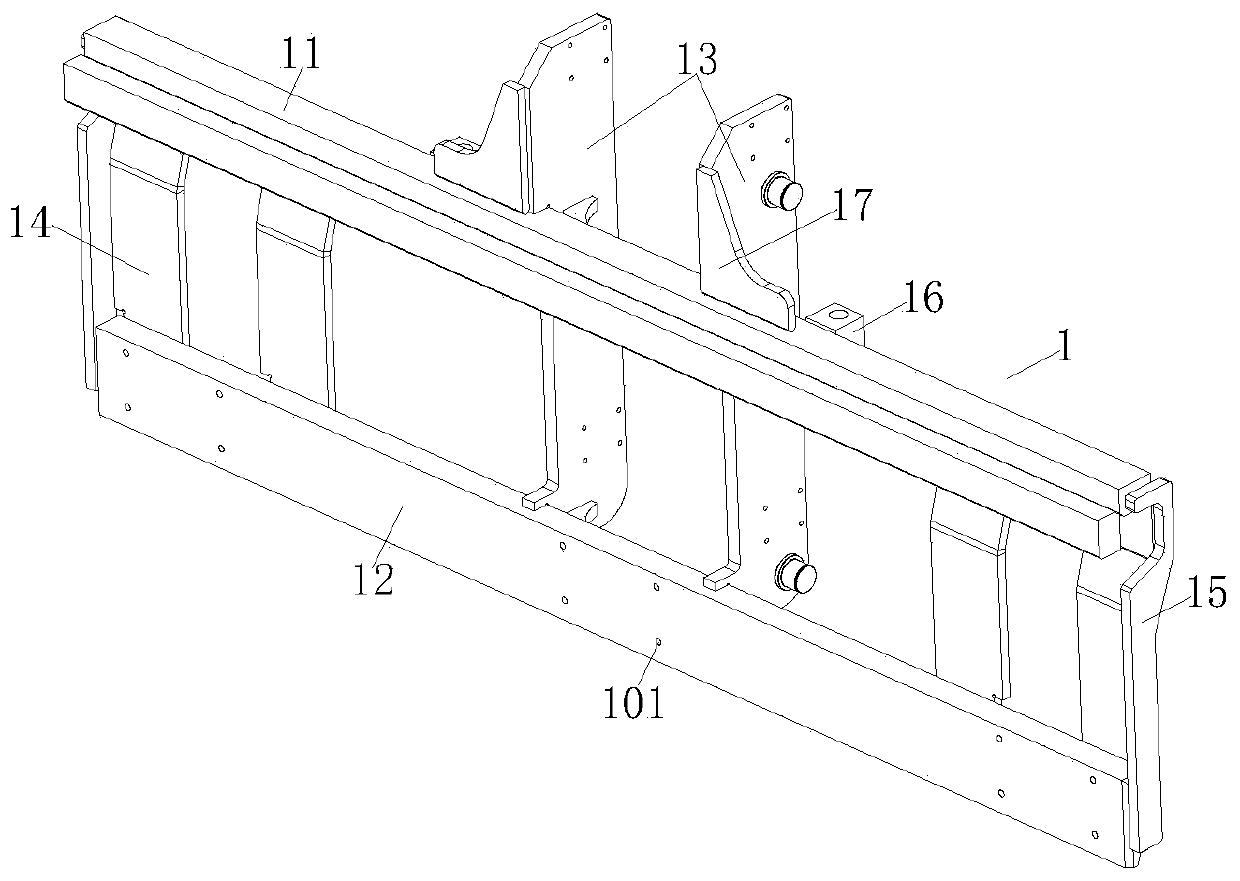

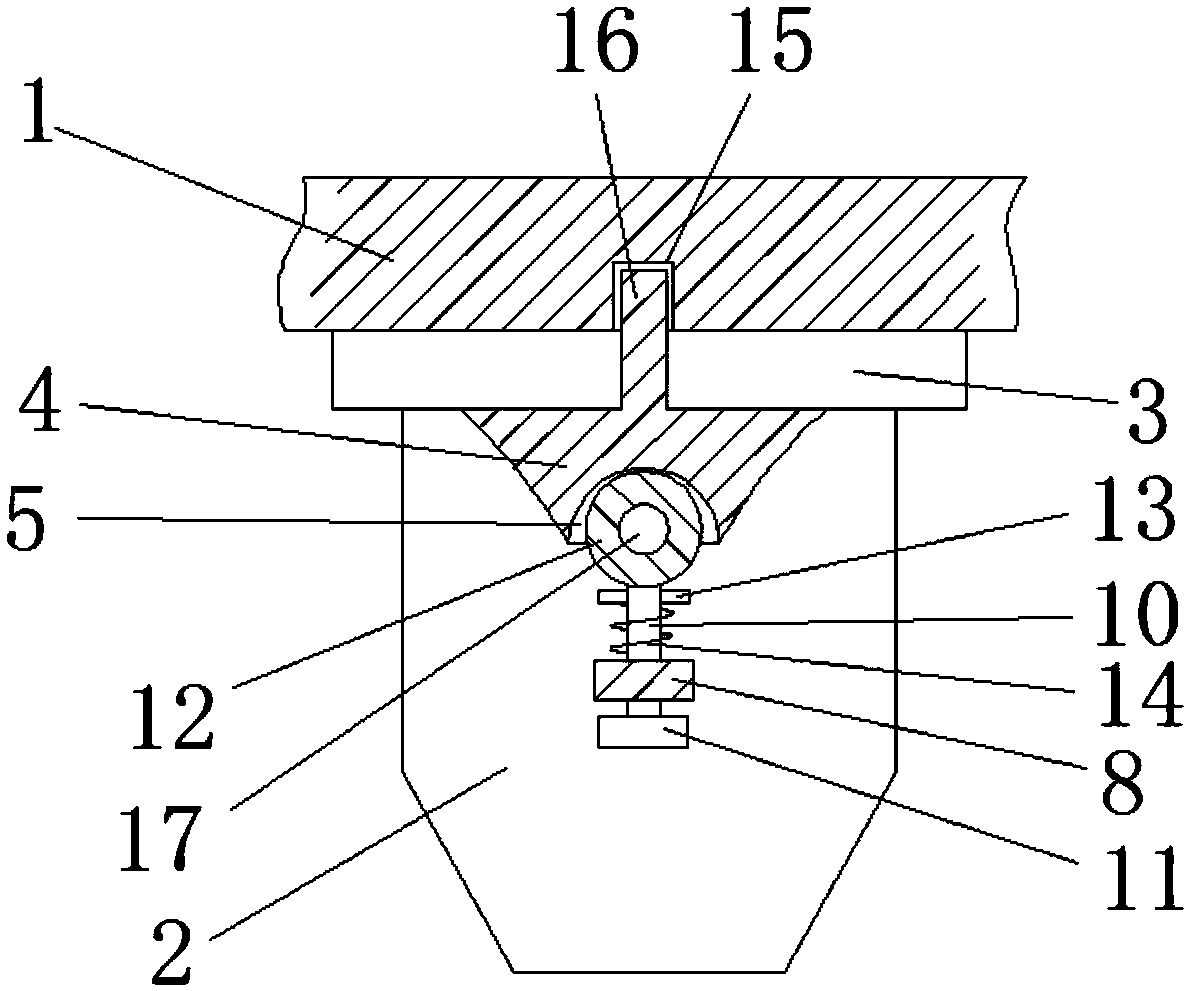

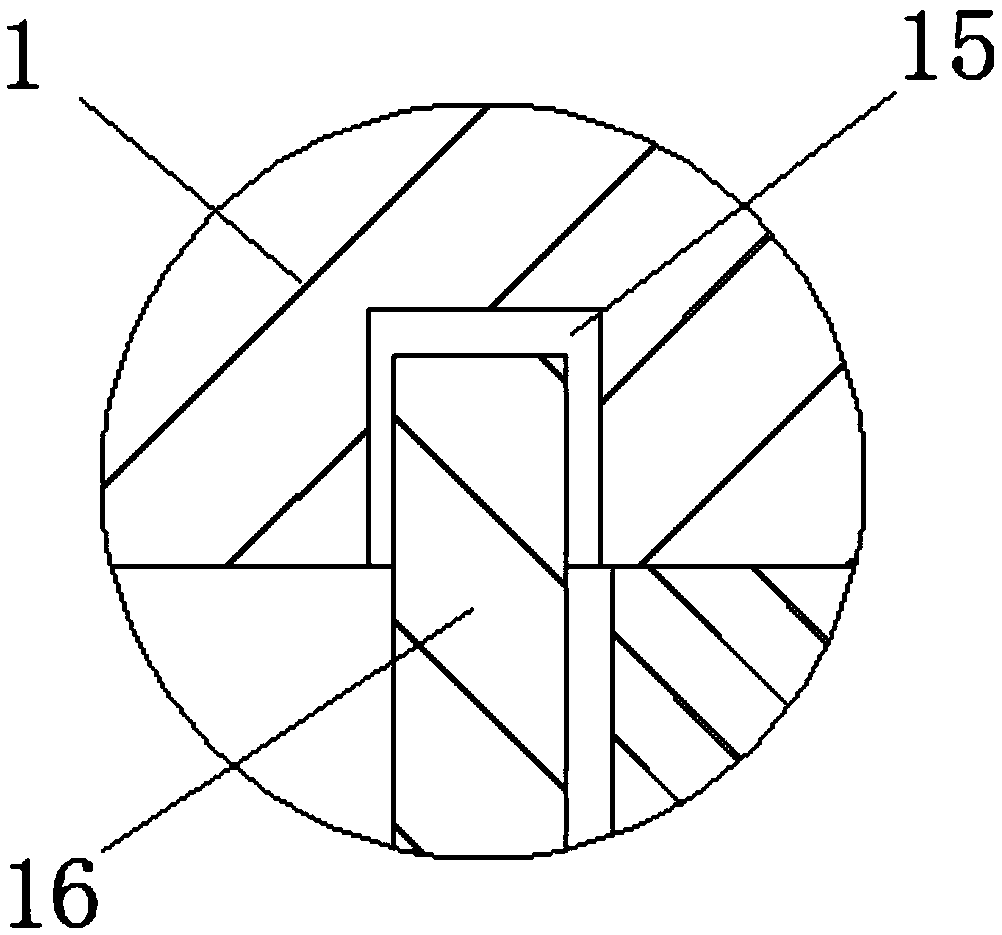

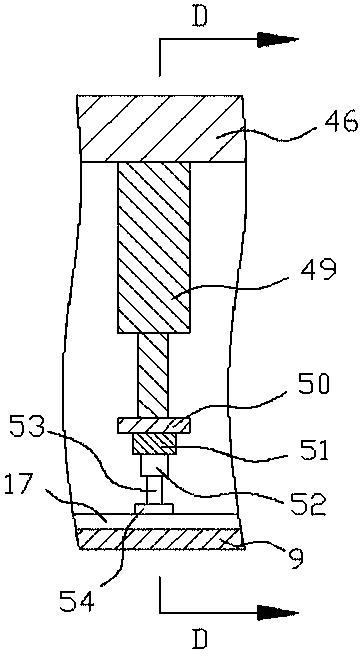

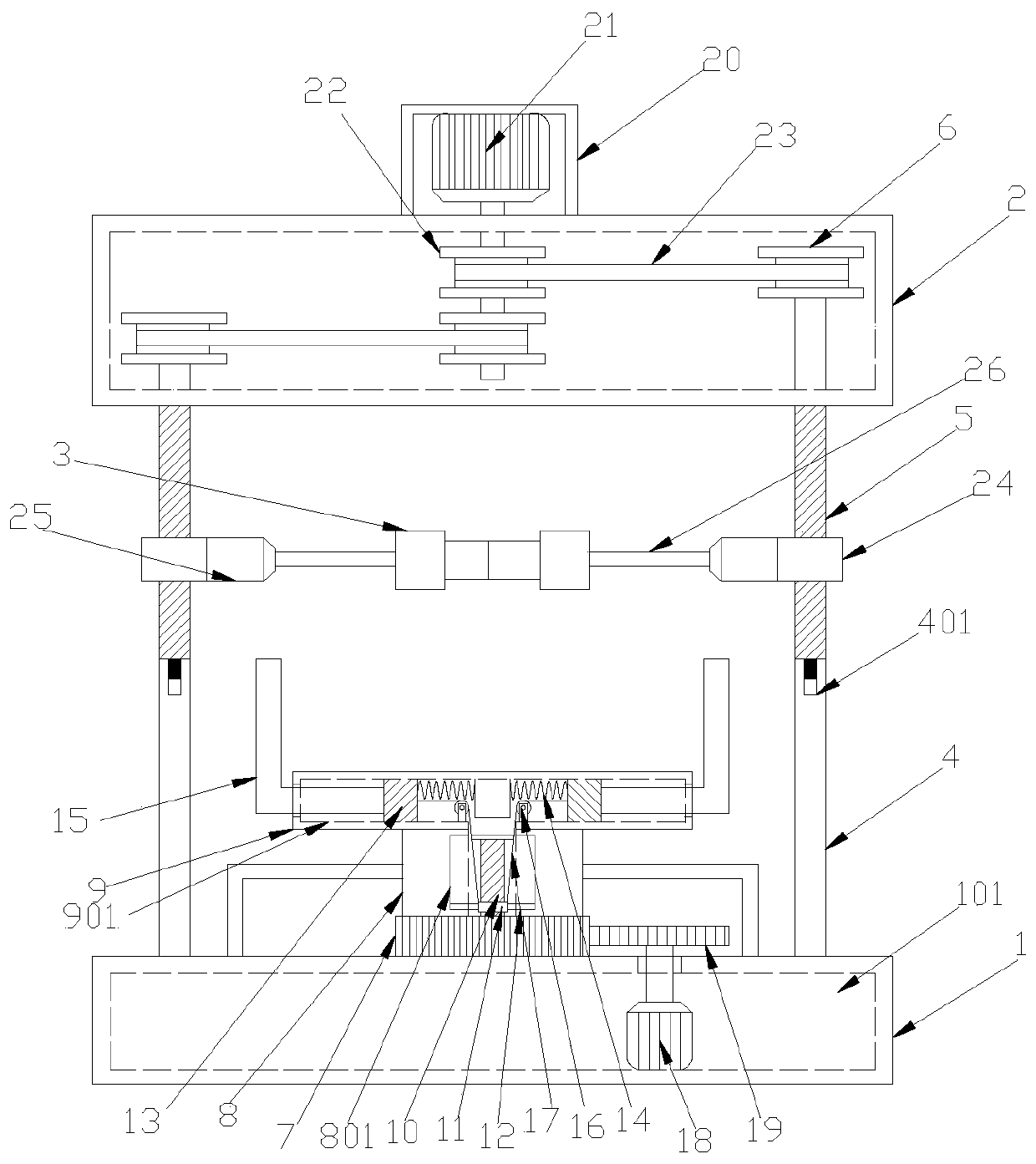

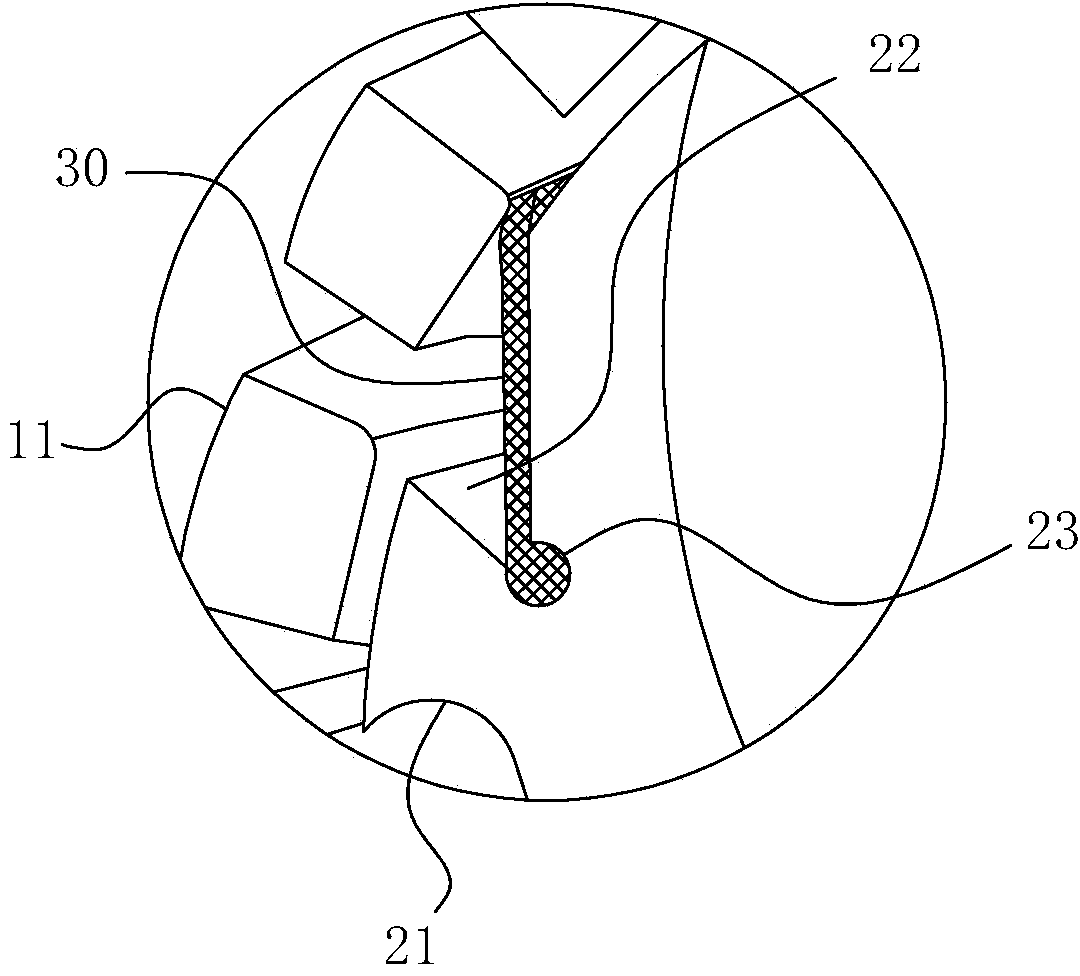

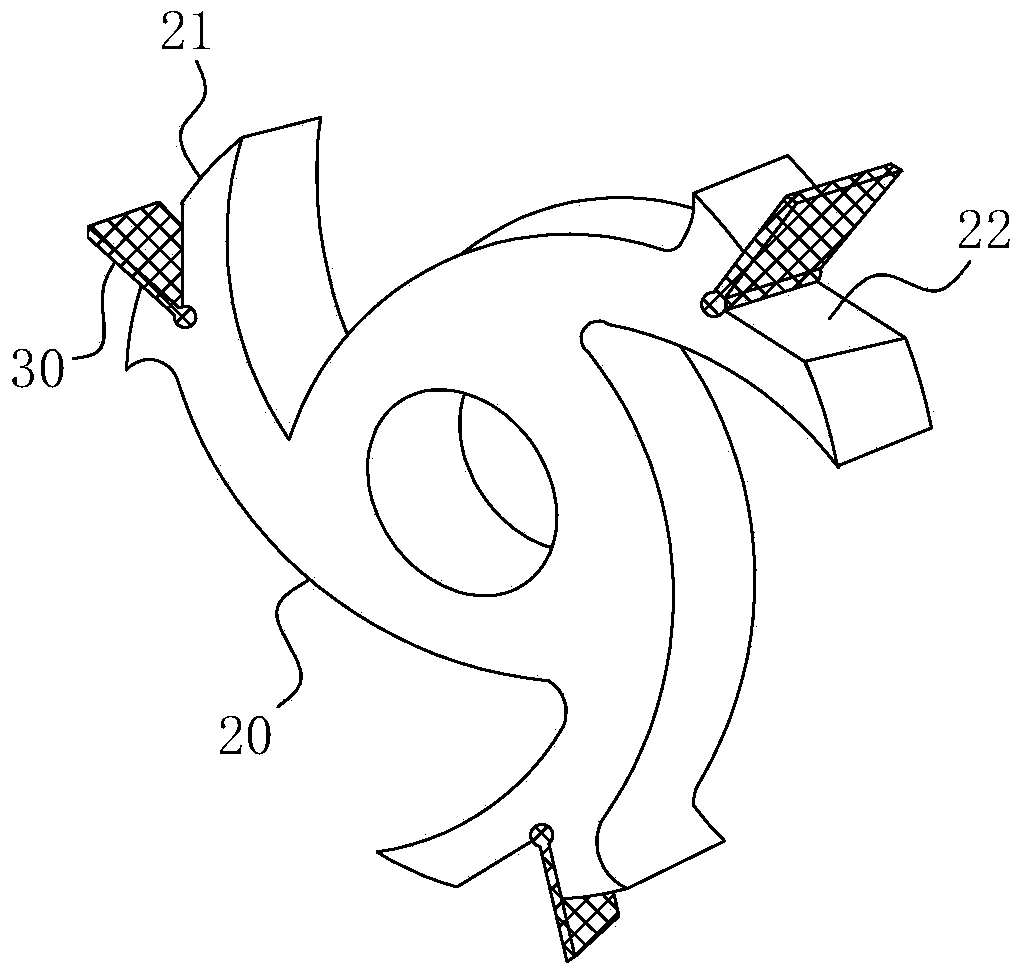

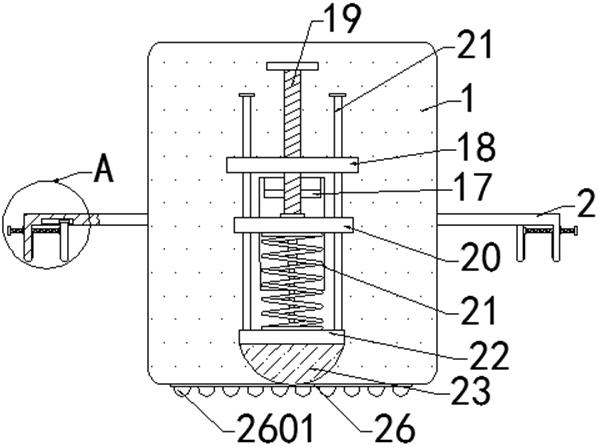

The invention discloses a pinch roller mechanism. The pinch roller mechanism comprises a fixed box, a lifting driving device arranged on the fixed box and a pinch roller set which is connected with the lifting driving device and is driven by the lifting driving device to rise and fall, wherein the pinch roller set at least comprises a pinch roller. When the pinch roller mechanism works, the pinch roller of the pinch roller set is compressed to the lower side of a line, and an inspection robot can walk through cooperation between the pinch roller and a driving wheel mechanism; when one pinch roller mechanism of the inspection robot approaches to a barrier and can not pass through, the pinch roller set is driven by the lifting driving device to move downwards, and then compression of the line is released; the inspection robot walks continuously, the lifting driving device drives the pinch roller set to move upwards when the pinch roller mechanism bypasses the barrier, and then compression of the line is achieved. According to the pinch roller mechanism, an obstacle crossing function is achieved, and the application range of the inspection robot is widened. The invention further discloses a traveling wheel set mechanism provided with the pinch roller mechanism.

Owner:STATE GRID CORP OF CHINA +2

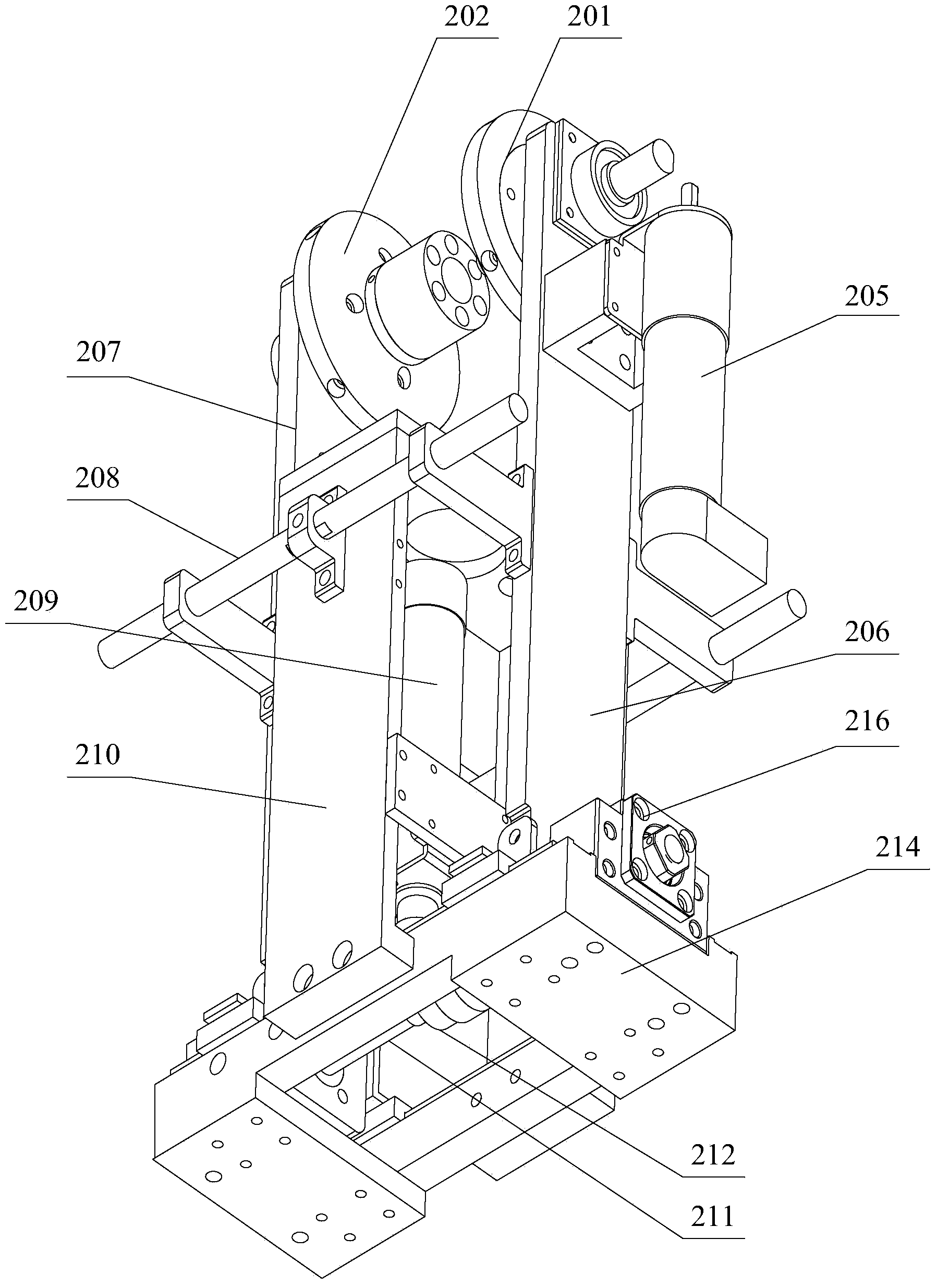

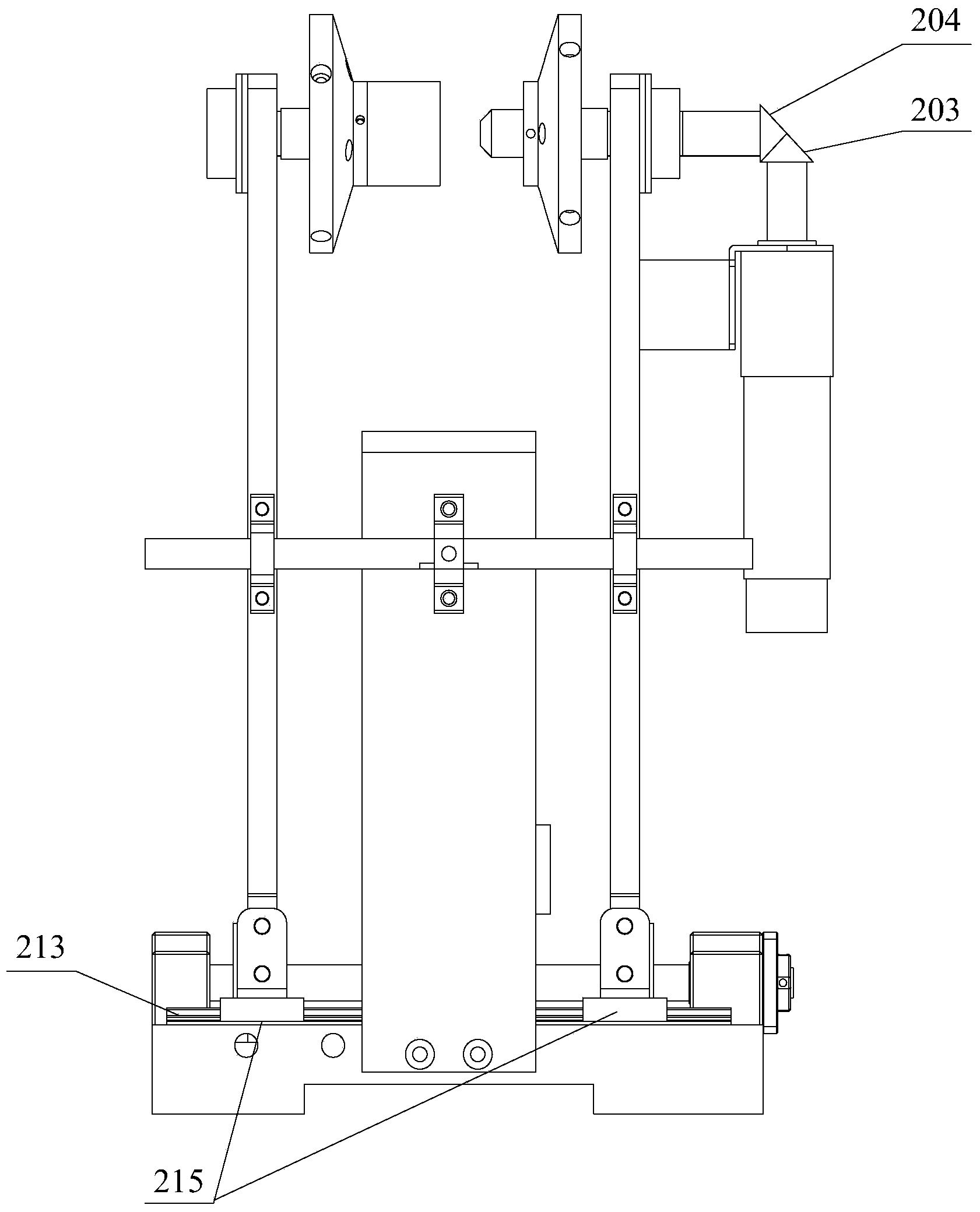

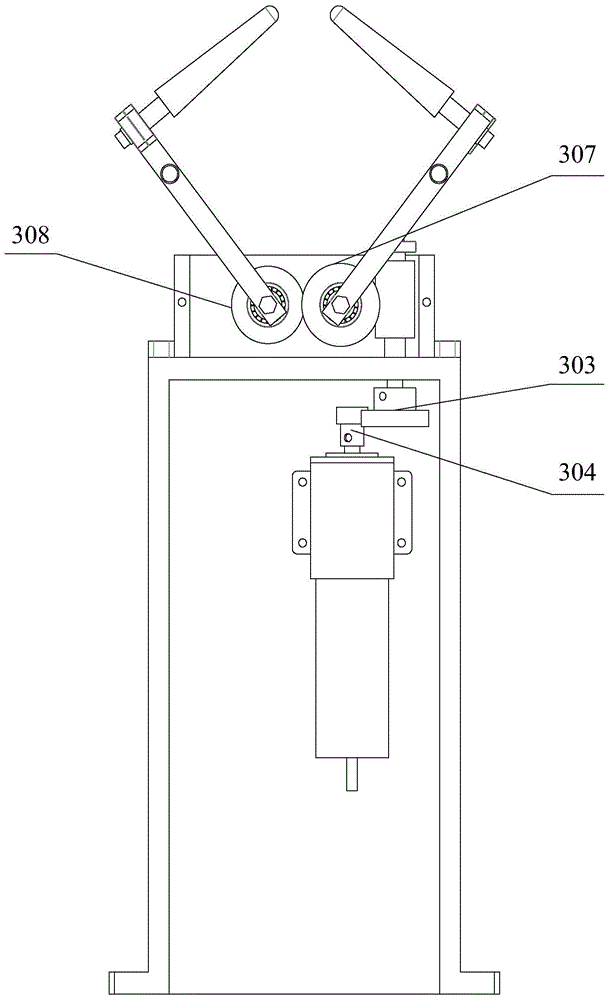

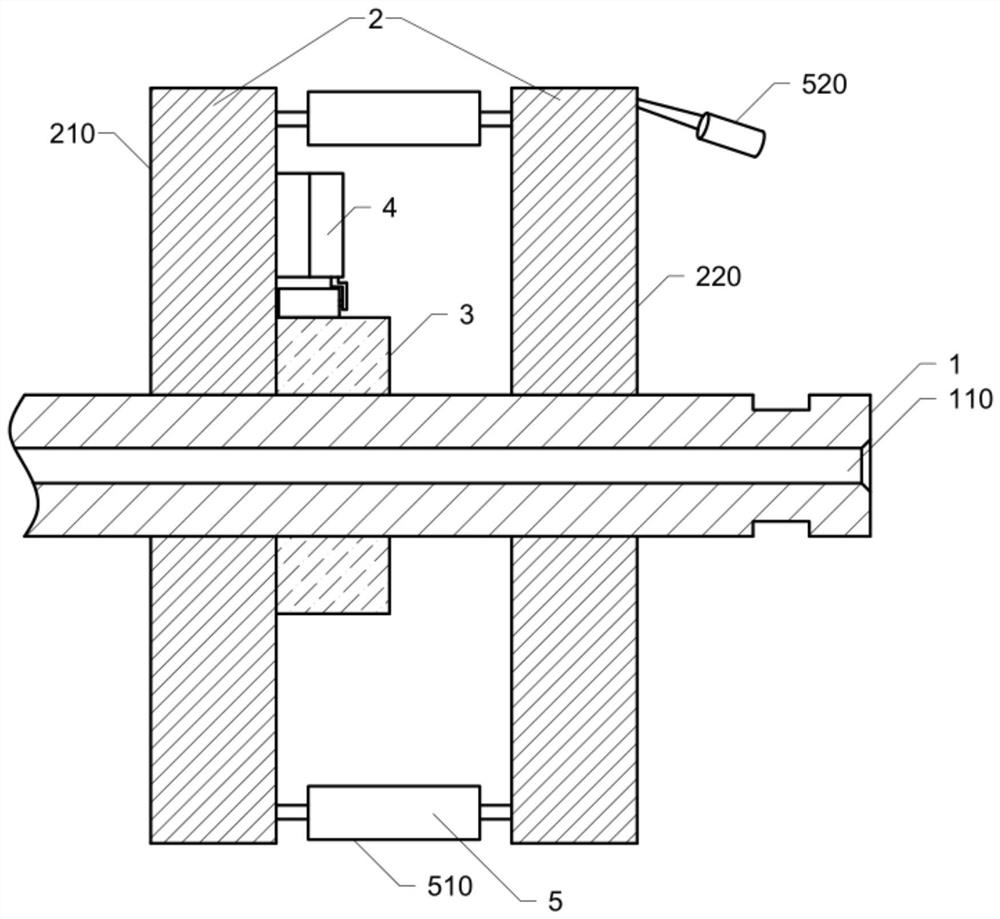

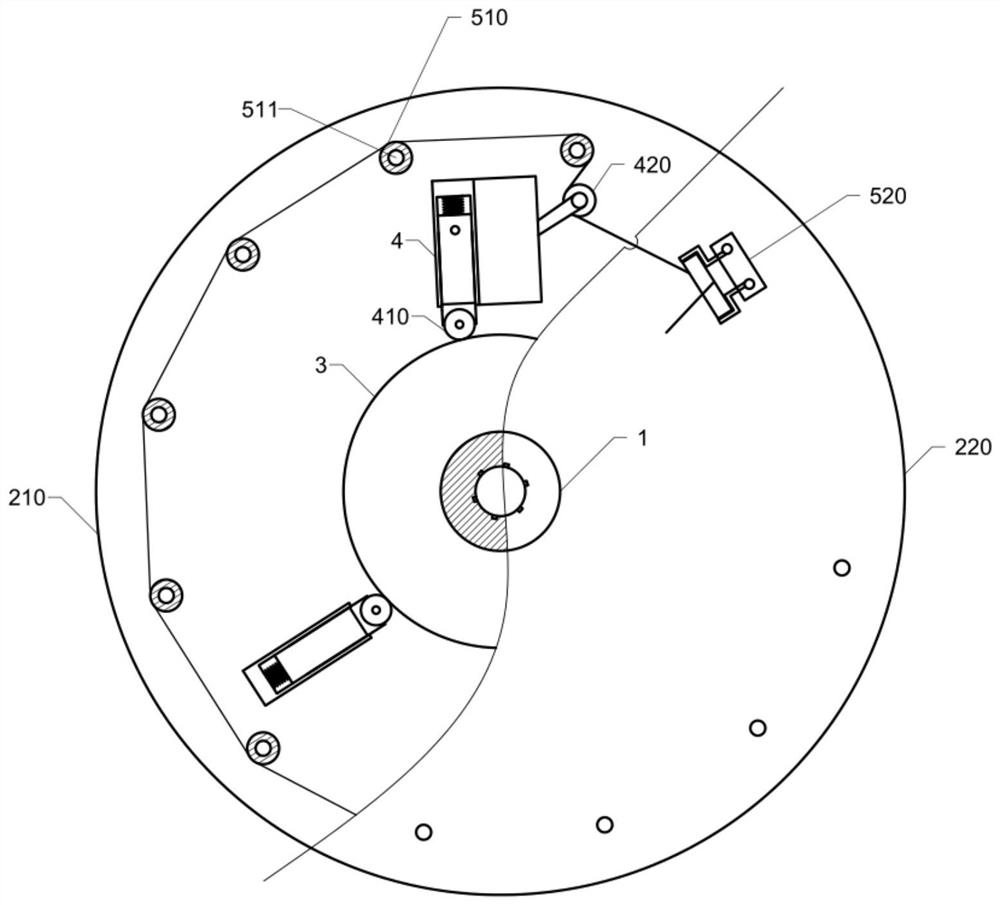

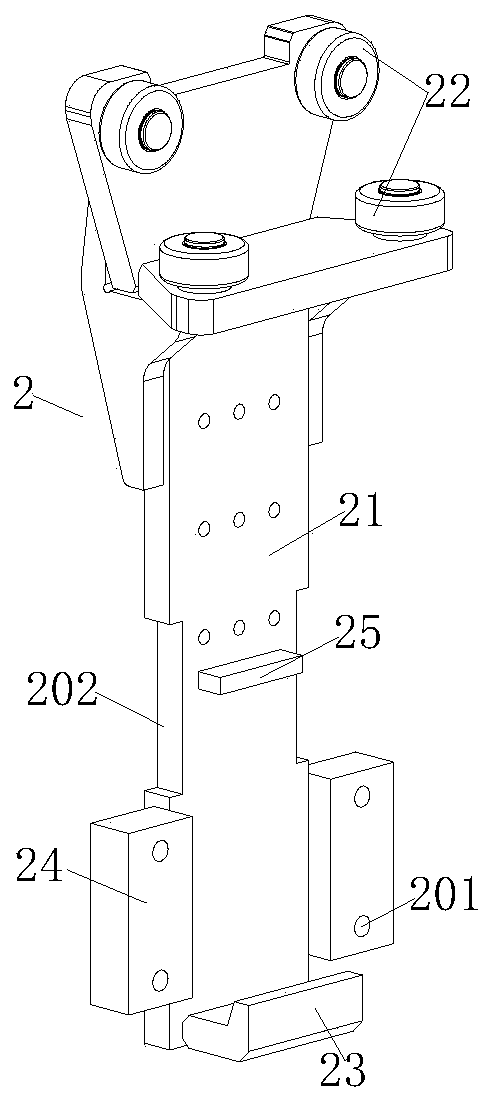

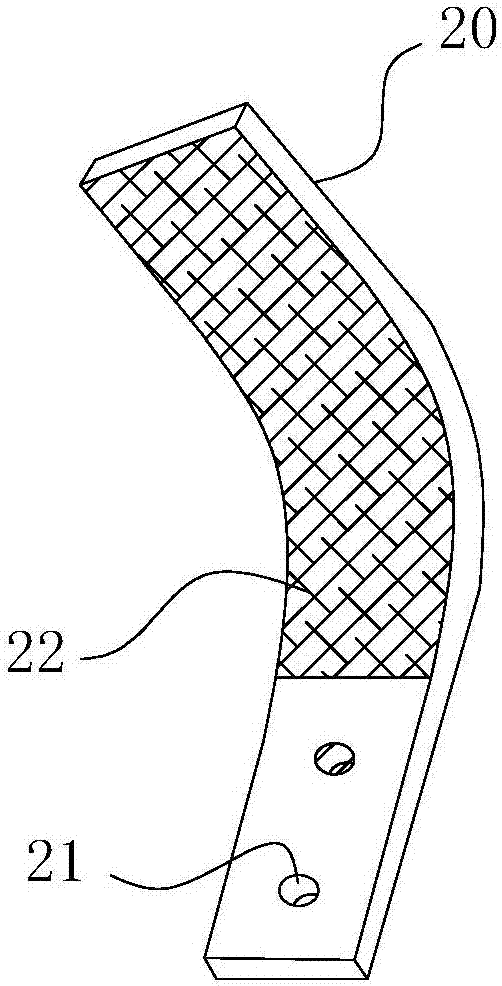

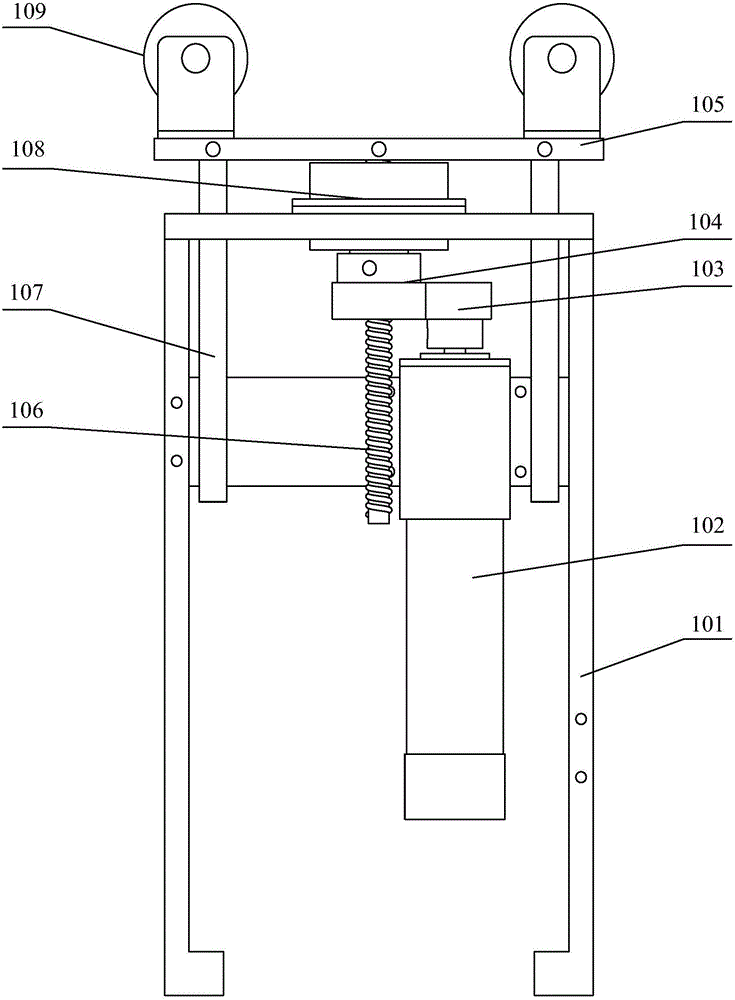

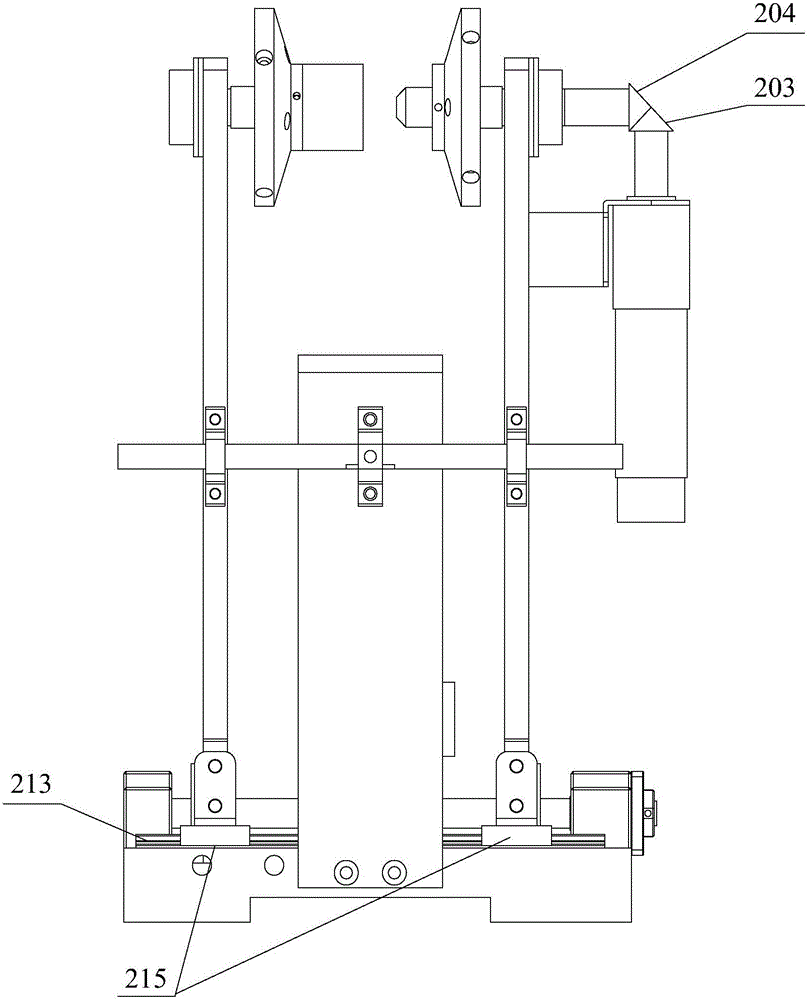

Clamping mechanism and inspection robot walking mechanism

ActiveCN103606851AWon't fallRealize the pressing effectApparatus for overhead lines/cablesDrive wheelEngineering

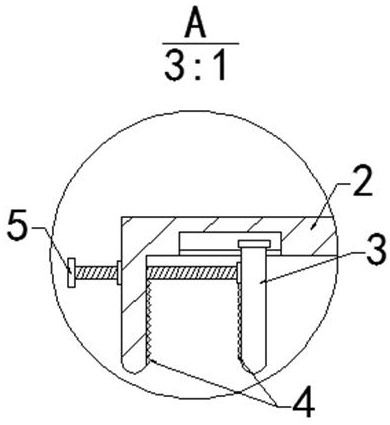

The invention discloses a clamping mechanism. The clamping mechanism comprises a supporting box, a supporting frame, a first rotating shaft, a second rotating shaft, a clamping drive device, a first clamping claw and a second clamping claw, wherein the supporting frame is arranged on the supporting box; the first rotating shaft and the second rotating shaft are arranged on the supporting frame in a rotating mode and are in transmission connection through a transmission mechanism; the clamping drive device is used for driving the first rotating shaft or the second rotating shaft to rotate; the first clamping claw is fixed to the first rotating shaft; the second clamping claw is fixed to the second rotating shaft. According to the clamping mechanism, the clamping drive device is used for driving the first rotating shaft or the second rotating shaft to rotate and then driving the first clamping claw and the second clamping claw to do opposite movements or separating movements, and therefore the purpose of holding lines or loosening lines can be achieved. When a drive wheel and a clamping wheel cross obstacles, the lines can be clamped through the clamping mechanism, and it can be ensured that an inspection robot will not fall off from the lines. The invention further discloses an inspection robot walking mechanism provided with the clamping mechanism.

Owner:STATE GRID CORP OF CHINA +2

Pressing type potato chip packaging and sealing device

PendingCN112498801ARealize the role of sealingRealize the pressing effectWrapper twisting/gatheringPackaging foodstuffsChipped potatoesAgricultural engineering

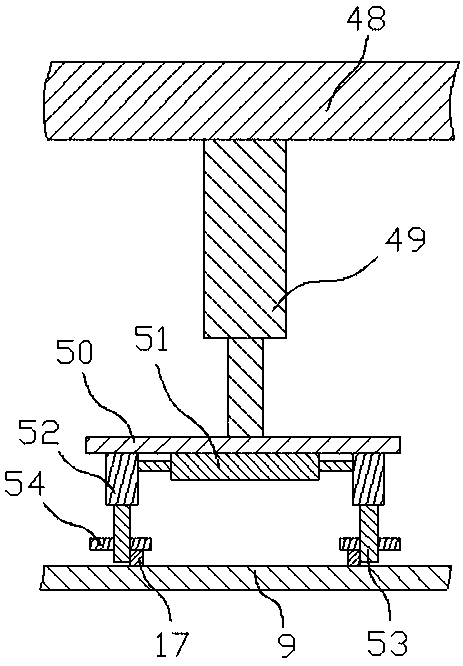

The invention relates to a sealing device, in particular to a pressing type potato chip packaging and sealing device. According to the pressing type potato chip packaging and sealing device, the working efficiency is improved, the production cost is reduced, and food packaging bags are sealed. The pressing type potato chip packaging and sealing device comprises a fixing plate, a supporting rod, acollecting frame, a pressing mechanism, a reciprocating mechanism and the like. The supporting rod is arranged at the top of the left side of the fixing plate, the collecting frame is arranged at thetop of the right side of the fixing plate, the pressing mechanism is arranged in the middle of the top of the fixing plate, and the reciprocating mechanism is arranged at the top of the rear side of the fixing plate. According to the pressing type potato chip packaging and sealing device, the food packaging bags needing to be sealed are placed in the pressing mechanism, the reciprocating mechanismis started, the reciprocating mechanism drives the pressing mechanism to move to seal the food packaging bags, and after sealing is completed, a user pushes the sealed food packaging bags into the collecting frame, so that the sealing effect is achieved.

Owner:吴忠心

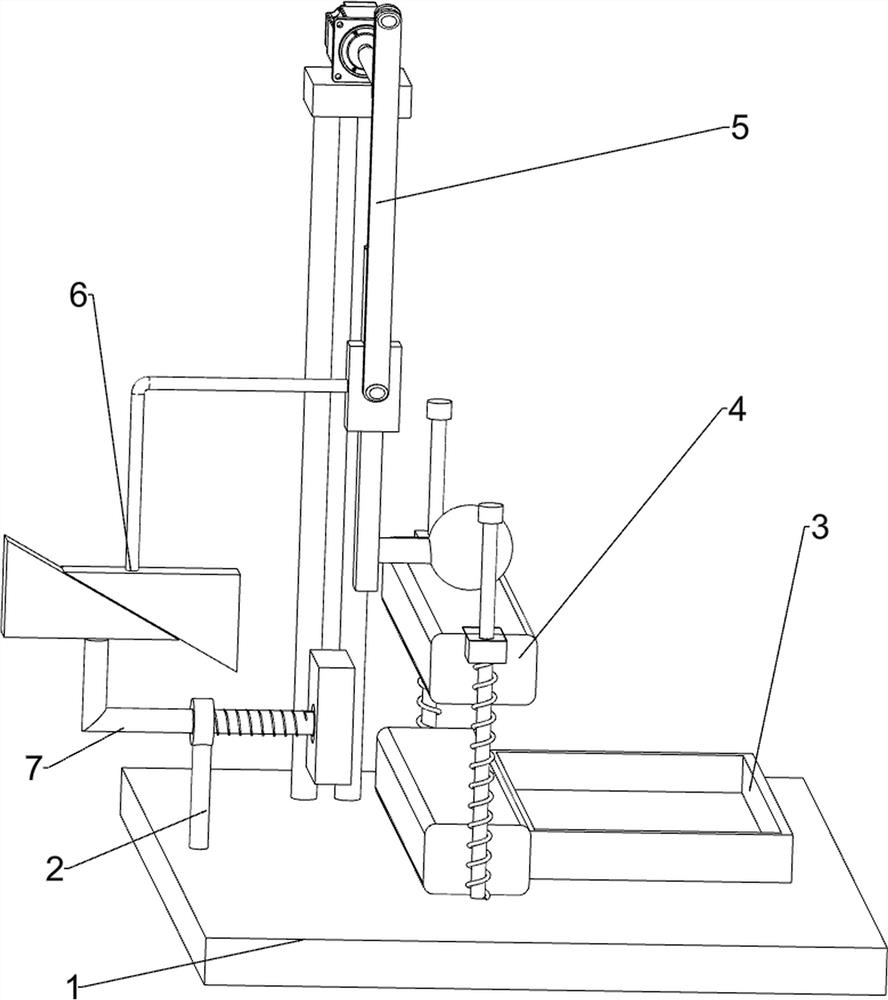

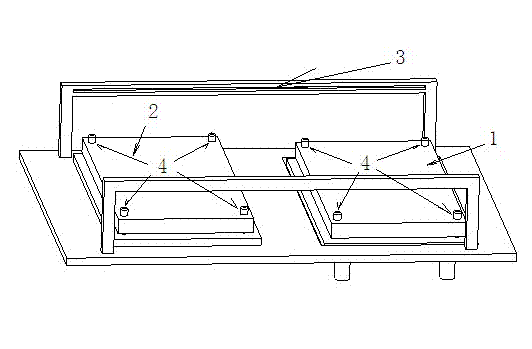

Automatic screen printing equipment for keycaps for keyboard printing

InactiveCN112590364AAchieve printing effectRealize push effectScreen printersScreen printingEngineering

The invention relates to printing equipment, in particular to automatic screen printing equipment for keycaps for keyboard printing. The automatic screen printing equipment for the keycaps for keyboard printing is short in consumed time, high in working efficiency and capable of guaranteeing the printing quality. The automatic screen printing equipment for the keycaps for keyboard printing comprises a bottom plate, an air cylinder, printing mechanisms and a pushing mechanism, wherein a workbench is arranged in the middle of the bottom plate; the air cylinder is mounted in the middle of the lower side of the workbench; the printing mechanisms are arranged on the left side and the right side of the rear wall of the bottom plate; and the pushing mechanism is arranged in the middle of the upper front wall of the bottom plate. An elastic sliding rod is driven to move downwards by stretching a pulling assembly, then a screen printing box is driven to move downwards, a keyboard on the workbench is printed, and the printing effect is achieved.

Owner:唐健常

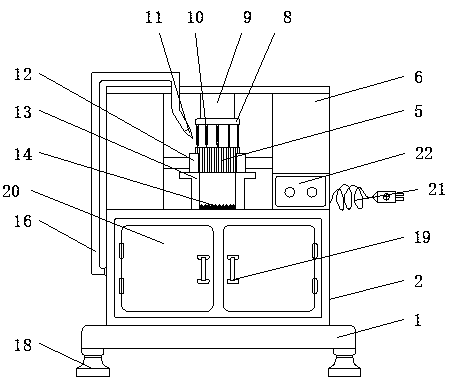

Pressing wheel mechanism of assembling machine

InactiveCN101758357ARealize the pressing effectSmooth seam formationWelding/cutting auxillary devicesAuxillary welding devicesWeld seamFlange

The invention relates to a pressing wheel mechanism of an assembling machine, in particular to a device for tightly pressing H-type steel during assembly. The device comprises a first bearing, a second bearing and a sleeve; a door upper frame is fixed between two upright posts; a pushing oil cylinder passes through a hole of the door upper frame; the shaft end of the pushing oil cylinder is arranged in a flange hole; a flange is fixed on a pushing frame; a guiding assembly is arranged on the pushing frame and is in contact with guide rails on the upright posts; two pressing wheel seats are symmetrical relative to a central axial line of the pushing oil cylinder and are positioned below the pushing frame; two ends of a pressing shaft are respectively fixed in holes of the pressing wheel seats; an inner ring of the first bearing is connected to a pressing shaft; and an outer ring of the first bearing is provided with a pushing wheel. The invention has the advantages of simple and compact structure and convenient installation and maintenance; and the invention can tightly press H-type steel web plates and wing plates and reduce the gap between the wing plates and the web plates, so that the welding seam of the H-type steel is smooth and attractive and the welding quality is ensured.

Owner:WUXI HENGFU TECH

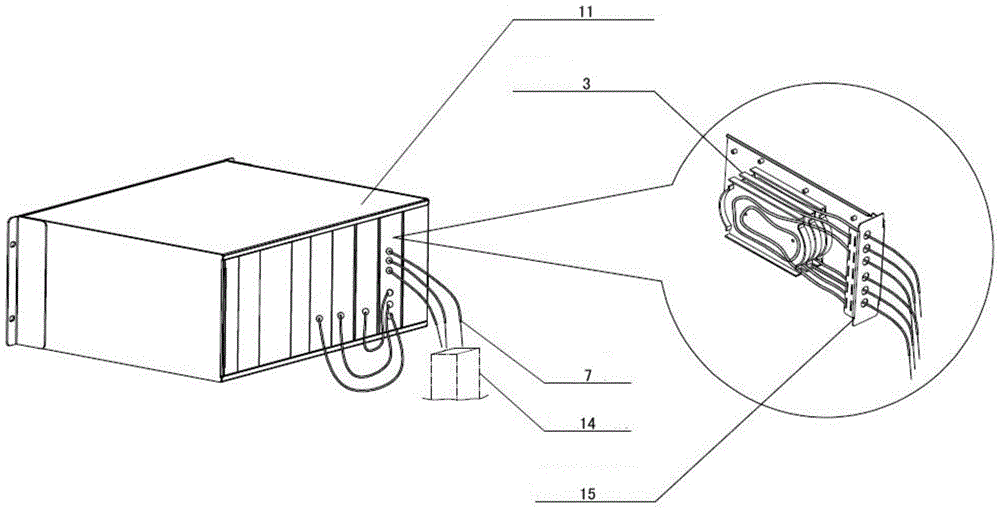

Collecting device with optical fiber protecting function, full-optical-fiber current transformer and mounting method

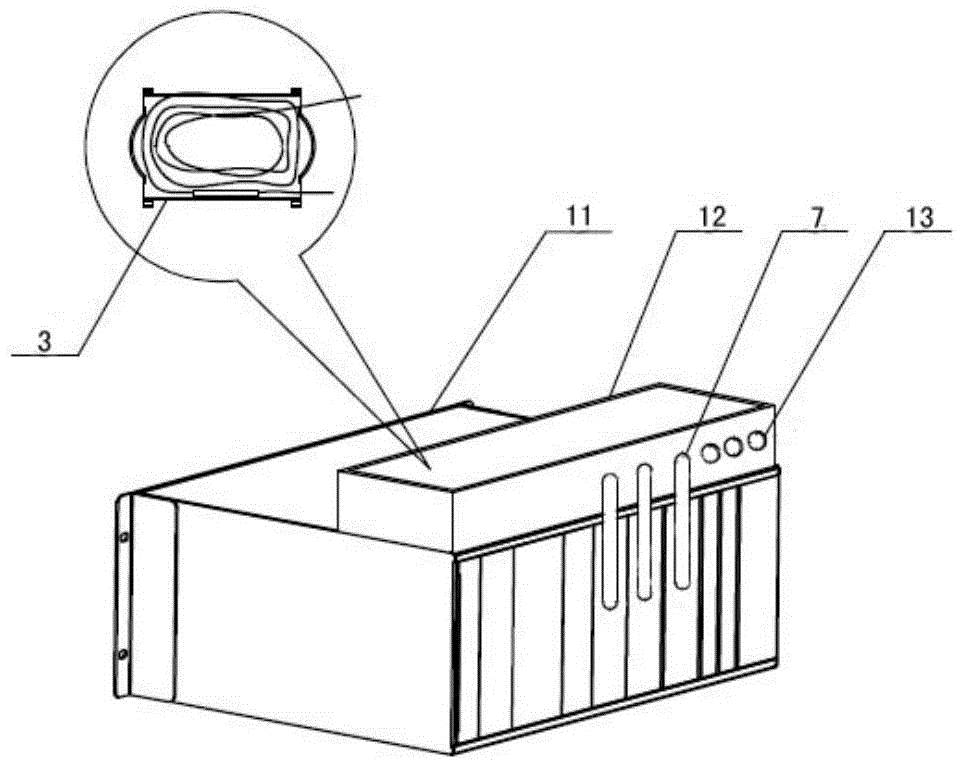

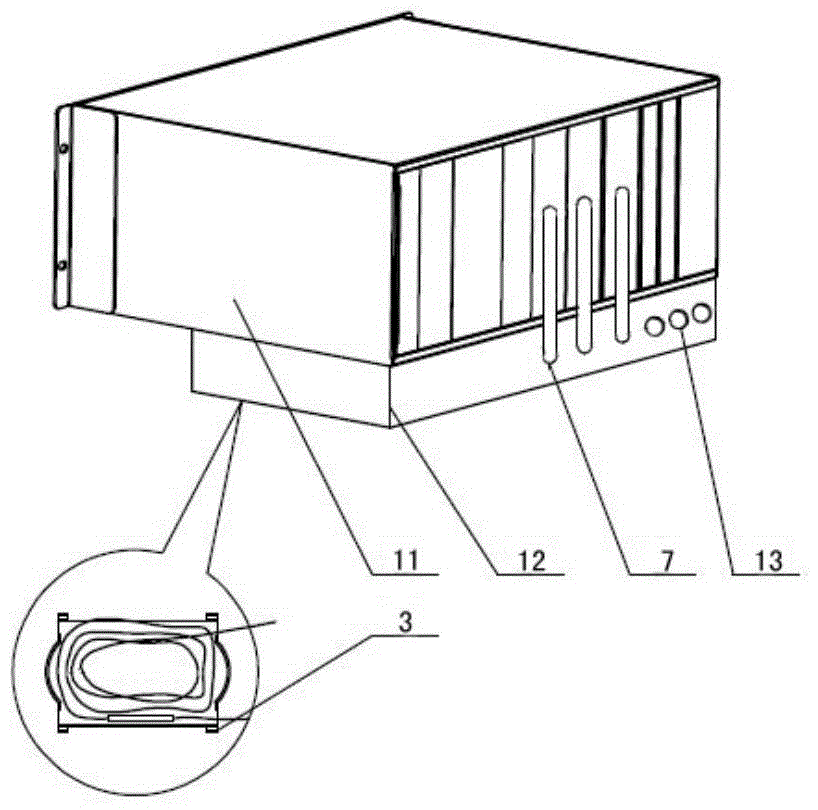

The invention relates to a collecting device with an optical fiber protecting function, a full-optical-fiber current transformer and a mounting method. The collecting device comprises a circuit board, an optical device, a device protecting shell and a fiber coiling box which is fixedly arranged on the outer side face of the device protecting shell and can be opened and closed. The circuit board and the optical device are fixedly arranged in the device protecting shell which is provided with a first optical fiber hole. The device protecting shell is provided with an extending part corresponding to the side where the fiber coiling box is placed. The extending part is provided with a second optical fiber hole which is provided with a pressing connector. Wholly-output optical fibers of the circuit board and the optical device extend out from the first optical fiber hole of the device protecting shell and are coiled in the fiber coiling box. Optical fibers output by the fiber coiling box are guided out from the second optical fiber hole and the pressing connector. The collecting device is simple in structure and can reduce the needed mounting space effectively, and the collecting device has the advantages of being convenient to maintain, high in safety and attractive in appearance.

Owner:江苏彩瑞实业有限公司

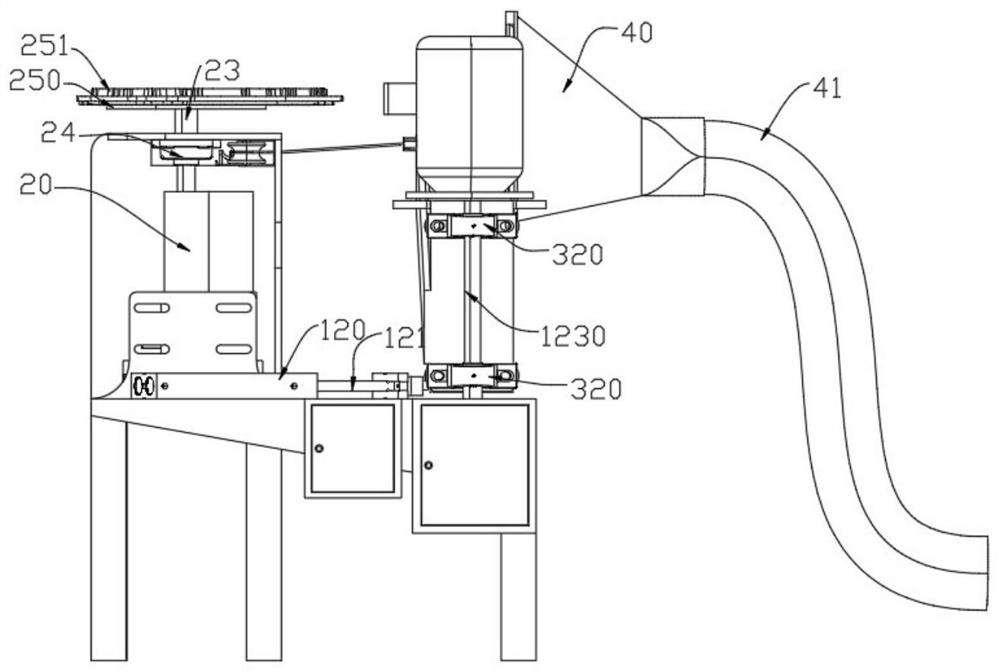

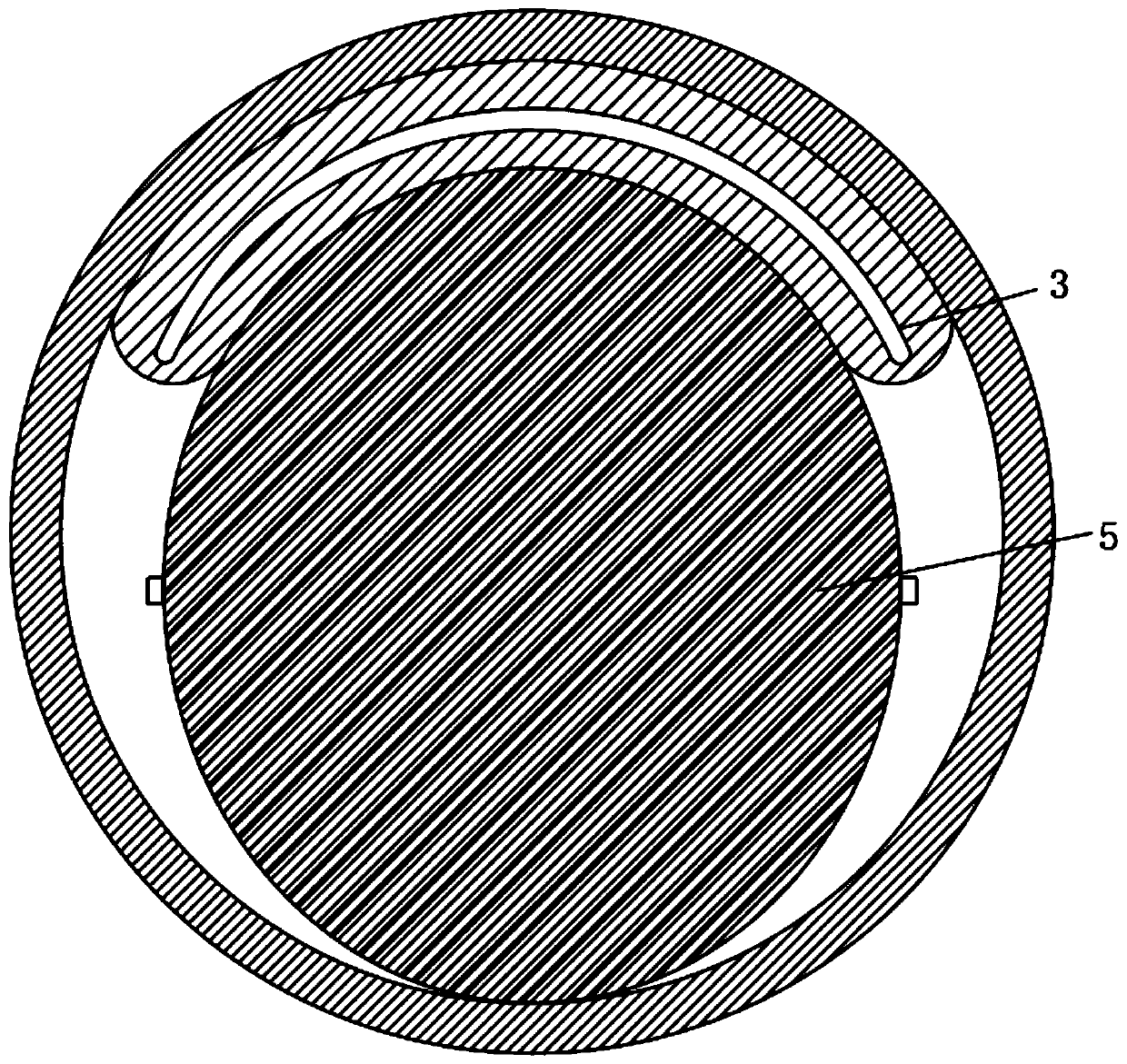

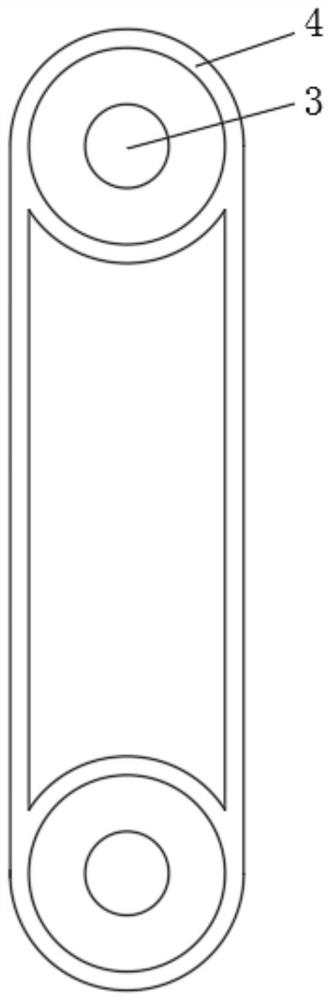

Wrapping device for cable production

InactiveCN111968795ARealize the pressing effectPrevent looseningInsulating conductors/cablesEngineeringStructural engineering

One or more embodiments of the invention provide a wrapping device for cable production. The device comprises a wrapping tape shaft and a guide disc. A first guide disc, a second guide disc and a wrapping tape are included, the wrapping tape is wound on an outer circumferential wall of the wrapping tape shaft in a disc shape, an adjusting module is arranged on the side wall of the first guide discand comprises a pressing wheel arranged in a sliding mode and a dancing wheel arranged in a swinging mode, the pressing wheel abuts against the outermost layer of the disc-shaped wrapping tape, and awrapping tension can be adjusted when the dancing wheel swings; and a conduction band assembly is included. The device is provided with the adjusting module, the wrapping tape can be pressed throughthe pressing wheel, loosening and falling off during high-speed rotation are avoided, meanwhile, the dancing wheel in power connection with the pressing wheel is arranged, the wrapping tension can beautomatically adjusted according to the number of layers of the wrapping tape, wrapping quality is guaranteed, production quality is guaranteed, and meanwhile production efficiency can be improved.

Owner:匠桥智谷科技(涡阳)有限公司

Carrying tool for steel bar coils

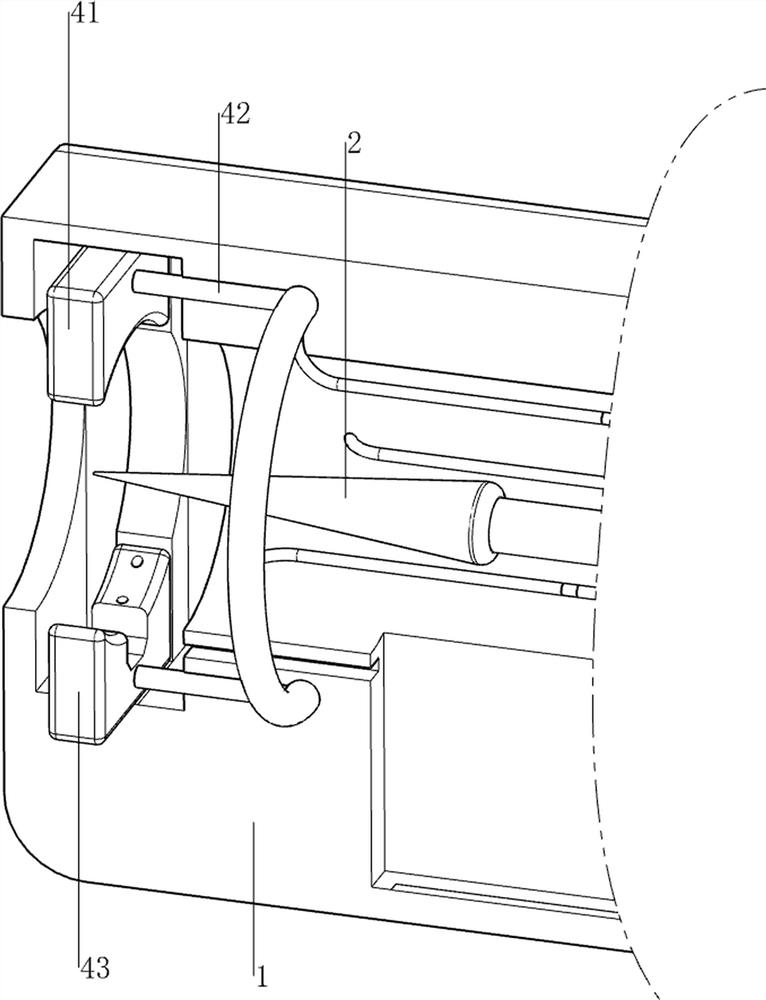

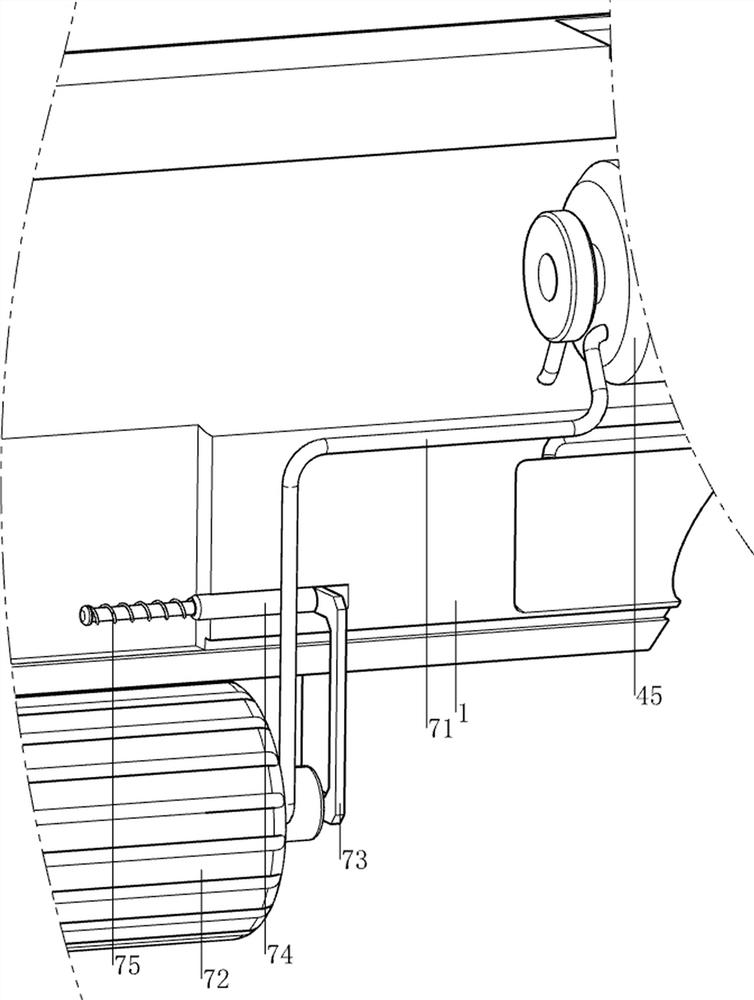

The invention discloses a carrying tool for steel bar coils. The carrying tool comprises a fork arm carrier assembly assembled on a forklift and a stringing rod assembly hung on the front face of thefork arm carrier assembly through a bracket assembly. The stringing rod assembly comprises a baffle assembly arranged in a standing manner, a hook assembly fixedly arranged at the upper portion of thebaffle assembly and a stringing rod assembly arranged on the front face of the baffle assembly, and the stringing rod assembly is used for carrying a steel bar coil. According to the invention, whenthe carrying tool is used for carrying the steel bar coils, each carrying tool only needs to be assembled with one forklift for use, so that the number of the forklifts and the number of the workers are reduced, and the carrying cost of the steel bar coils is greatly reduced. Meanwhile, a plurality of layers of steel bar coils can be carried at one time through the carrying tool, the transferringand stacking number of the steel bar coils is increased as much as possible every time according to the use requirement, the transferring and stacking frequency of the steel bar coils is reduced, andthe carrying efficiency of the steel bar coils is greatly improved.

Owner:ANHUI HELI CO LTD

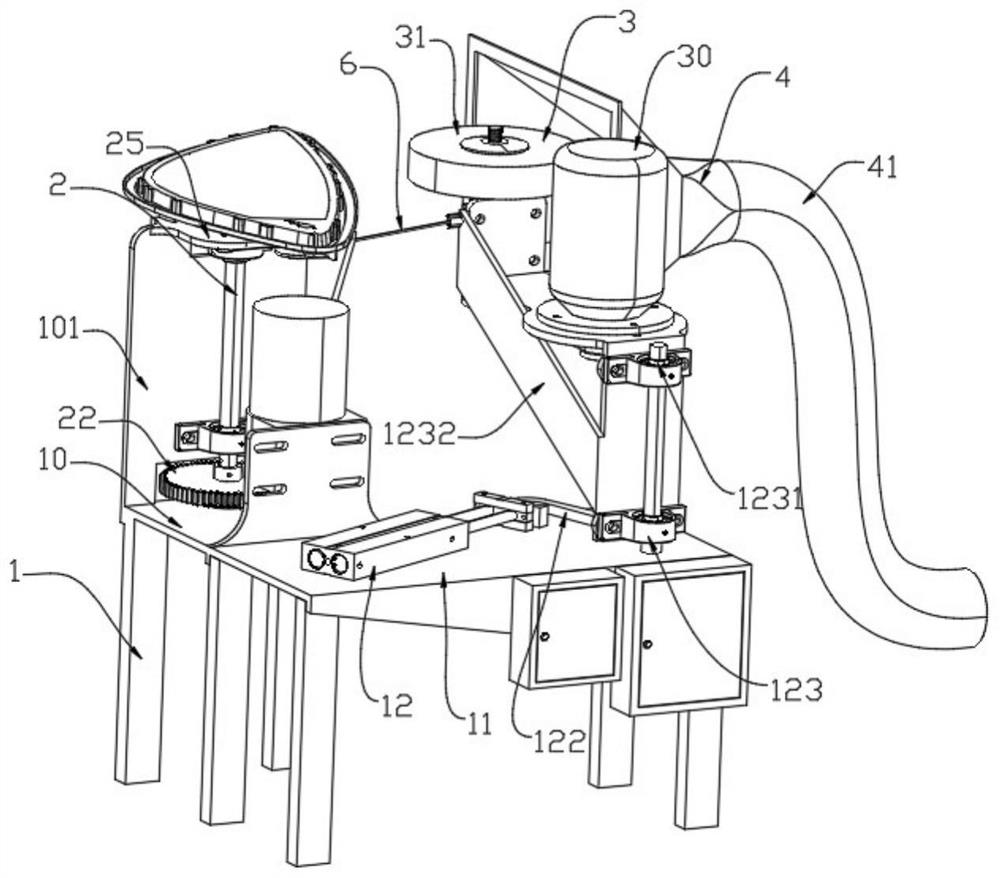

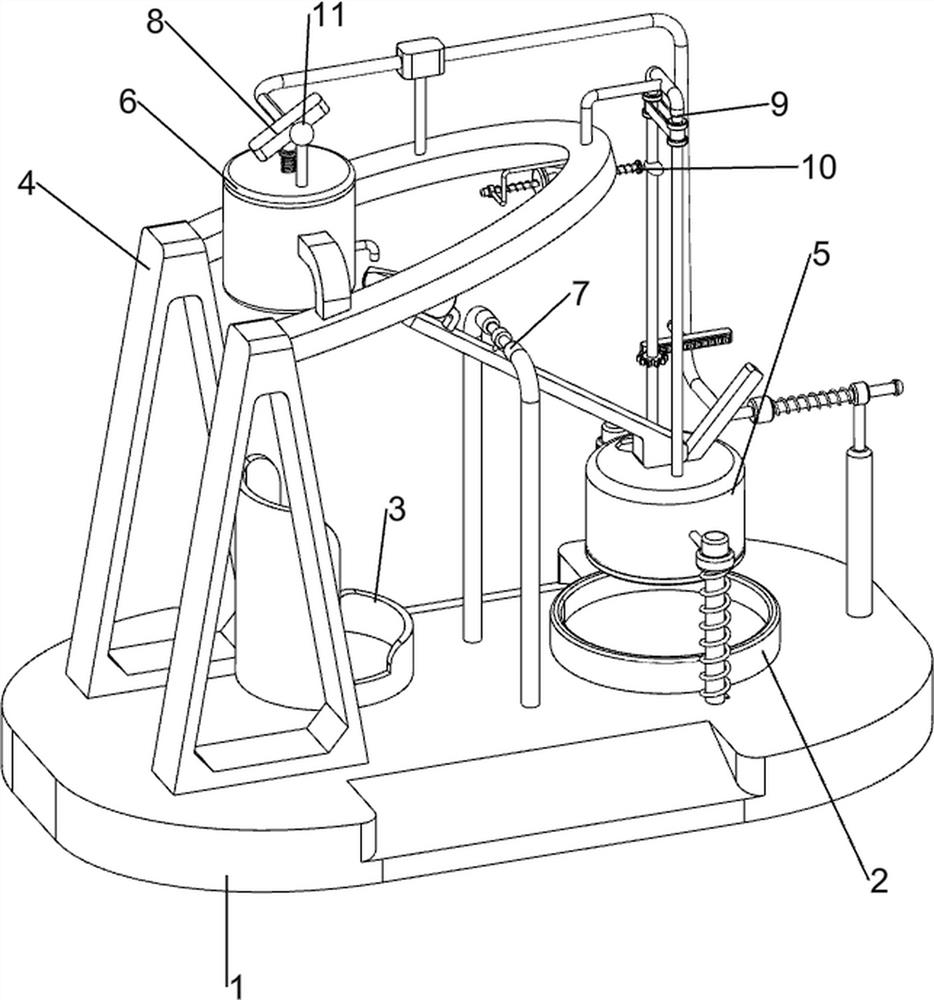

Side edge polishing equipment for special-shaped workpiece and polishing method thereof

ActiveCN112676959ARaise angle adjustmentEffective sandingEdge grinding machinesGrinding carriagesPolishingDust control

The invention discloses side edge polishing equipment for a special-shaped workpiece and a polishing method thereof. The side edge polishing equipment for the special-shaped workpiece comprises a supporting base, a rotating device fixedly mounted on the supporting base and a polishing device fixedly mounted on the supporting base and located on one side of the rotating device, wherein an angle adjusting mechanism is arranged at the top of a polishing worktable, and a dust removal device and a scrap cleaning mechanism are arranged on one side of the polishing device; and a correcting mechanism is arranged between the polishing device and the rotating device. A workpiece is rotated clockwise and a grinding wheel is rotated anticlockwise by adopting a double-shaft rotating mode, so that effective polishing is greatly improved, and different polishing speeds can be achieved for workpieces with different precision requirements, and the polishing precision is controllable; and secondly, the angle adjusting device and the correcting mechanism are additionally arranged, so that the polishing device can adjust the positions of the workpieces with different shapes and sizes in the polishing process, and the special-shaped surfaces and the curved surfaces of the multiple workpieces can be polished.

Owner:NANJING TIANZE AUTO SUBASSEMBLY CO LTD

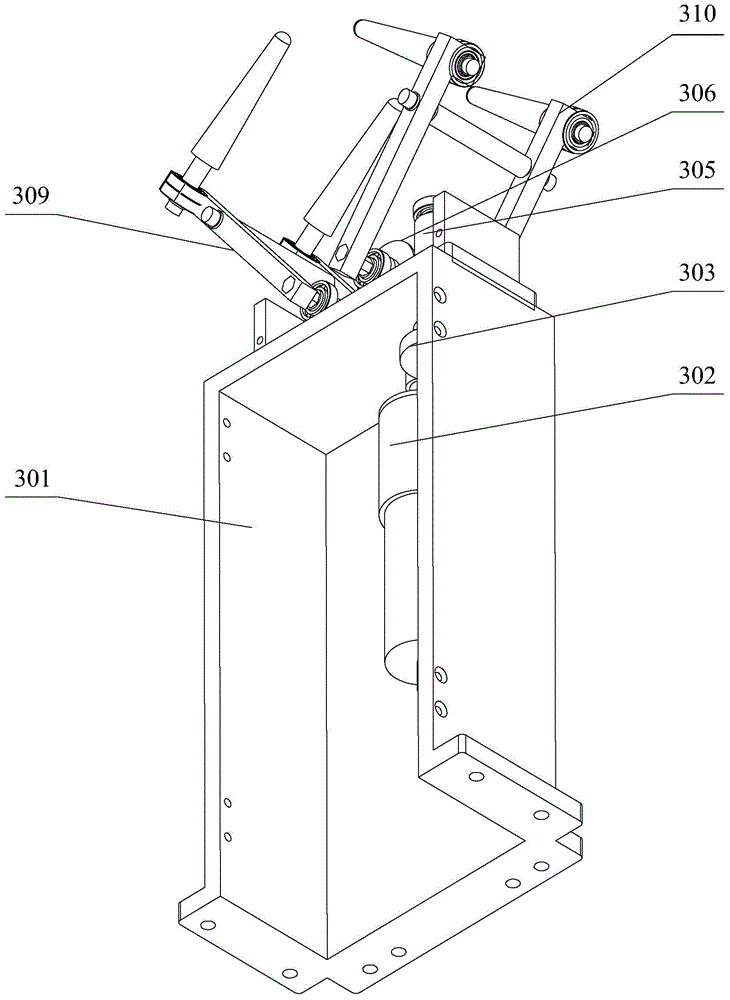

Locking device for rubber extruding die

The invention relates to the technical field of die equipment and particularly relates to a locking device for a rubber extruding die. The locking device comprises a base. An extruding die is arrangedbelow the base; fixed flanges are arranged on two sides of the extruding die; arc-shaped grooves are formed in the fixed flanges; fixed seats are arranged in the bottom of the base and are located ontwo sides of the extruding die; a rotary column is locked in each of the fixed seats; a pressure rod is arranged at one end, far from the fixed seat, of the rotary column; a handle is arranged at oneend of the pressure rod; two locking bars are arranged through one end, far from the handle, of the pressure rod; one ends of the two locking bars are connected to a locking wheel through a rotary shaft; the locking wheel is locked in the corresponding arc-shaped groove; a second limiting block is arranged on each of the locking bars; a spring is arranged between each of the second limiting blocks and the corresponding pressure rod; and each spring sleeves the corresponding locking rod. According to the locking device provided by the invention, the extruding die is conveniently assembled anddisassembled, and is convenient and rapid to replace, so that the replacing efficiency is increased effectively.

Owner:HUANGSHI DINGSHENG MOLD CO LTD

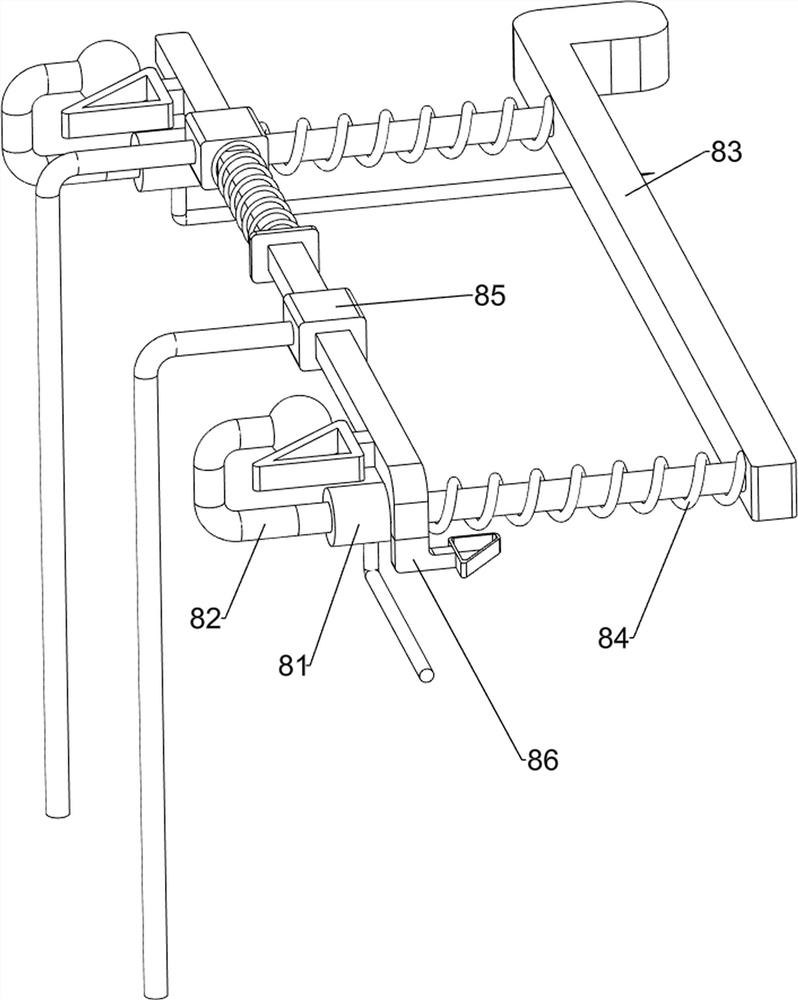

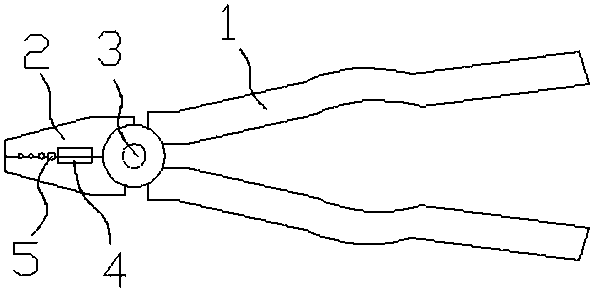

Continuous machining machine for shearing edges of pincers

InactiveCN108527019AImprove processing efficiencyIncrease profitGrinding drivesOther manufacturing equipments/toolsEngineeringMachining

The invention relates to a continuous machining machine for shearing edges of pincers. A feeding shaft in a front-back walking direction is arranged at the left and right ends of a rack, and is sleeved with a feeding chain barrel; the feeding chain barrel is matched with two feeding chains which are arranged side by side in the front-back direction; the feeding chains are uniformly provided with feeding blocks which are matched with machining carriers; the pincers with pincer blocks exceeding the left sides of the machining carriers are arranged in the machining carriers; a machining frame isarranged on the rack, and is provided with a shearing edge machining device matched with the pincer blocks on the machining carriers and a machining material pressing device matched with the machiningcarriers; and the rack is provided with machining supporting plates matched with the lower portions of the machining carriers in the machining state. According to the continuous machining machine forthe shearing edges of the pincers, the machining carriers are used for performing material carrying on the pincers, and in cooperation with the two feeding chains, moving of the machining carriers isachieved; and in cooperation with the shearing edge machining device, continuous machining is performed on the pincers on the machining carriers in continuous feeding and conveying, and the utilizingrate of the shearing edge machining device is increased; and then the overall machining efficiency of the pincers is improved.

Owner:DONGGUAN UNIV OF TECH

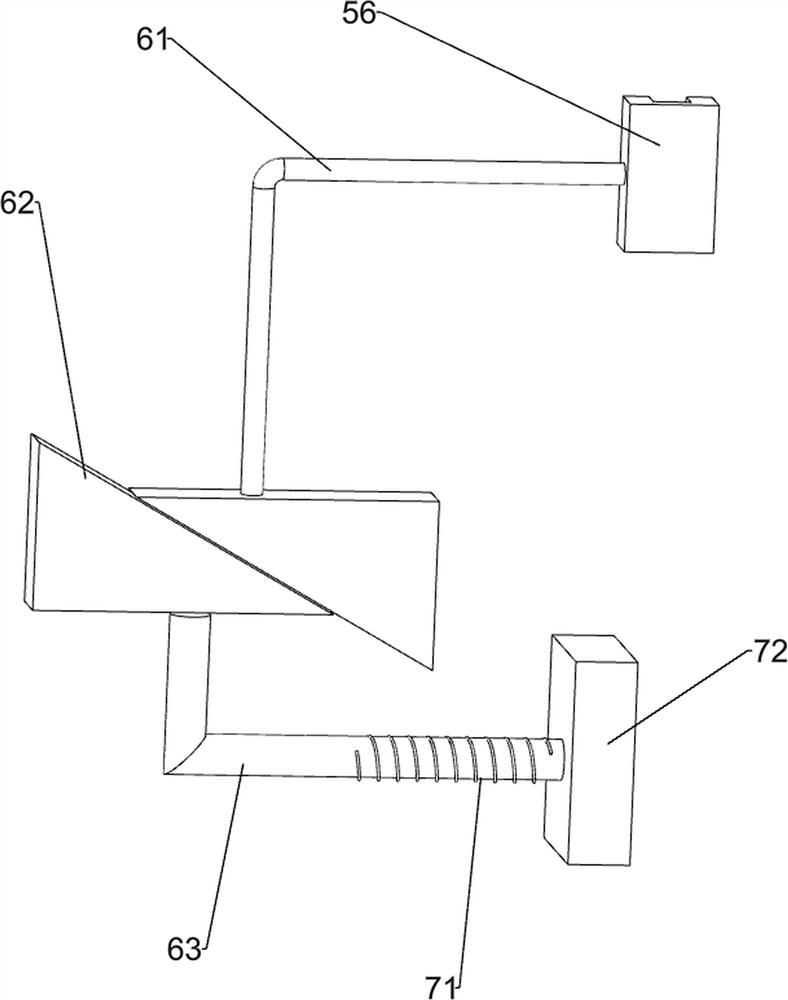

Corner compression device for environmental sanitation brush

The invention discloses a corner compression device for an environmental sanitation brush. The corner compression device for the environmental sanitation brush comprises a base, an adjustment box anda fixing device, wherein vertical columns are fixed to parts close to the edges of the two sides, of the base, a rotary hole is formed in the end surface of the top end of each vertical column, a thread column is rotationally connected into each rotary hole, the adjustment box is rotationally connected to the thread columns, and a first synchronous wheel is fixed to one end extending into the adjustment box, of each thread column; and a gear disc is rotationally arranged at the center of the base, a connection barrel is rotationally connected to the gear disc, a limit groove is formed in the inner wall of the connection barrel, a placement plate is fixed to the connection barrel, an adjustment screw rod is fixed to the gear disc, a thread barrel is arranged on the adjustment screw rod, limit blocks are fixed to the two sides of the thread barrel, the limit blocks are slidably connected with the limit groove, a plurality of guide grooves pointing to a circle center are formed in the placement plate, a moving block is slidably arranged in each guide groove, each moving block is connected with the bottom of the corresponding guide groove through a return spring, and an L-shaped pressdisc is fixed to the side surface of each moving block.

Owner:安徽琼钰刷业有限公司

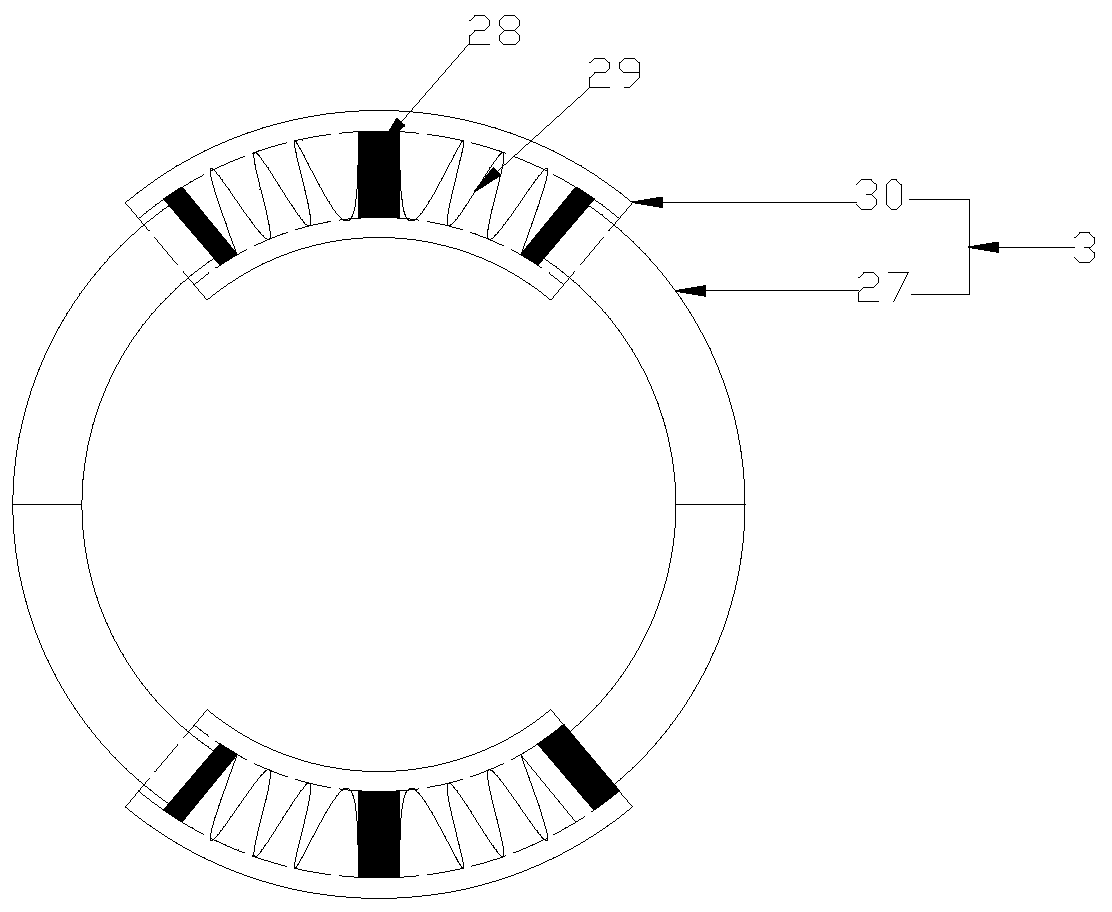

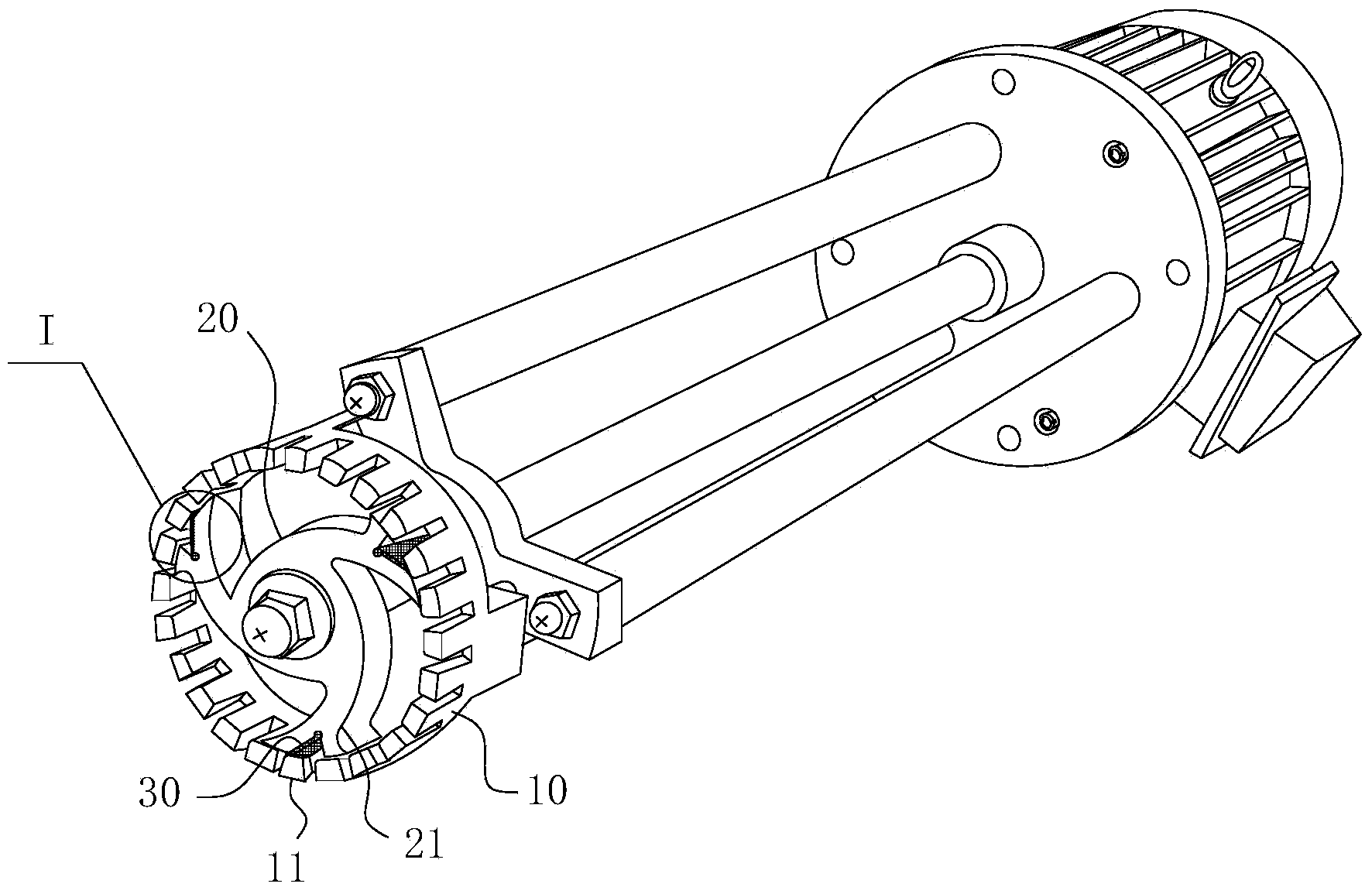

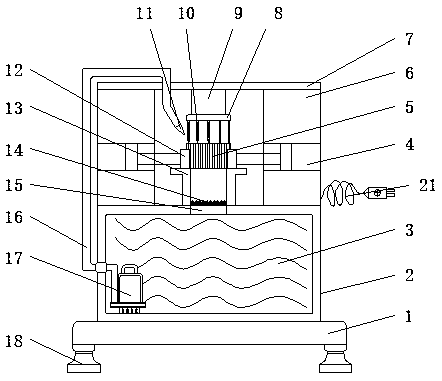

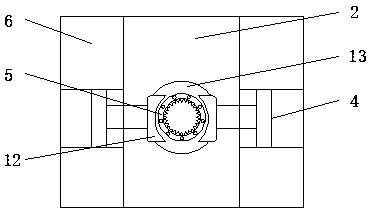

Emulsifying and mixing equipment with grinding, twisting and rolling functions

InactiveCN104174323AImprove stirring efficiencyReliable placement effectMixing methodsMixer accessoriesEngineeringRestoring force

The invention belongs to the field of emulsifying and mixing equipment and in particular relates to emulsifying and mixing equipment with grinding, twisting and rolling functions. The emulsifying and mixing equipment disclosed by the invention at least comprises a stator and a rotor, which are in running fit with each other, and a gap between the running fit surfaces of the stator and the rotor forms a material emulsifying and mixing gap; the emulsifying and mixing equipment also comprises elastic grinding discs; one end of each elastic grinding disc is arranged at the rotor and / or the stator to form a hinged end, and the other end of each elastic grinding disc extends to the running fit surface of the stator and / or the rotor and is pressed against the running fit surface to form a suspension end; in the radial direction of the stator, the length of each elastic grinding disc is larger than the minimum spacing between the hinged end of the grinding disc and the running fit surface which the suspension end is pressed against; a return unit is arranged on each elastic grinding disc; the restoring force provided by each return unit and the rotating of the rotor are in the same direction. The emulsifying and mixing equipment disclosed by the invention is reasonable in structure and high in stirring efficiency, and effects of high-efficiency dispersing, homogenizing and mixing of fine materials, even nanometer level materials, can be effectively improved.

Owner:中慈(青岛)新能源汽车制造有限公司

Acquisition device with optical fiber protection, full optical fiber current transformer and installation method

The invention relates to a collecting device with an optical fiber protecting function, a full-optical-fiber current transformer and a mounting method. The collecting device comprises a circuit board, an optical device, a device protecting shell and a fiber coiling box which is fixedly arranged on the outer side face of the device protecting shell and can be opened and closed. The circuit board and the optical device are fixedly arranged in the device protecting shell which is provided with a first optical fiber hole. The device protecting shell is provided with an extending part corresponding to the side where the fiber coiling box is placed. The extending part is provided with a second optical fiber hole which is provided with a pressing connector. Wholly-output optical fibers of the circuit board and the optical device extend out from the first optical fiber hole of the device protecting shell and are coiled in the fiber coiling box. Optical fibers output by the fiber coiling box are guided out from the second optical fiber hole and the pressing connector. The collecting device is simple in structure and can reduce the needed mounting space effectively, and the collecting device has the advantages of being convenient to maintain, high in safety and attractive in appearance.

Owner:江苏彩瑞实业有限公司

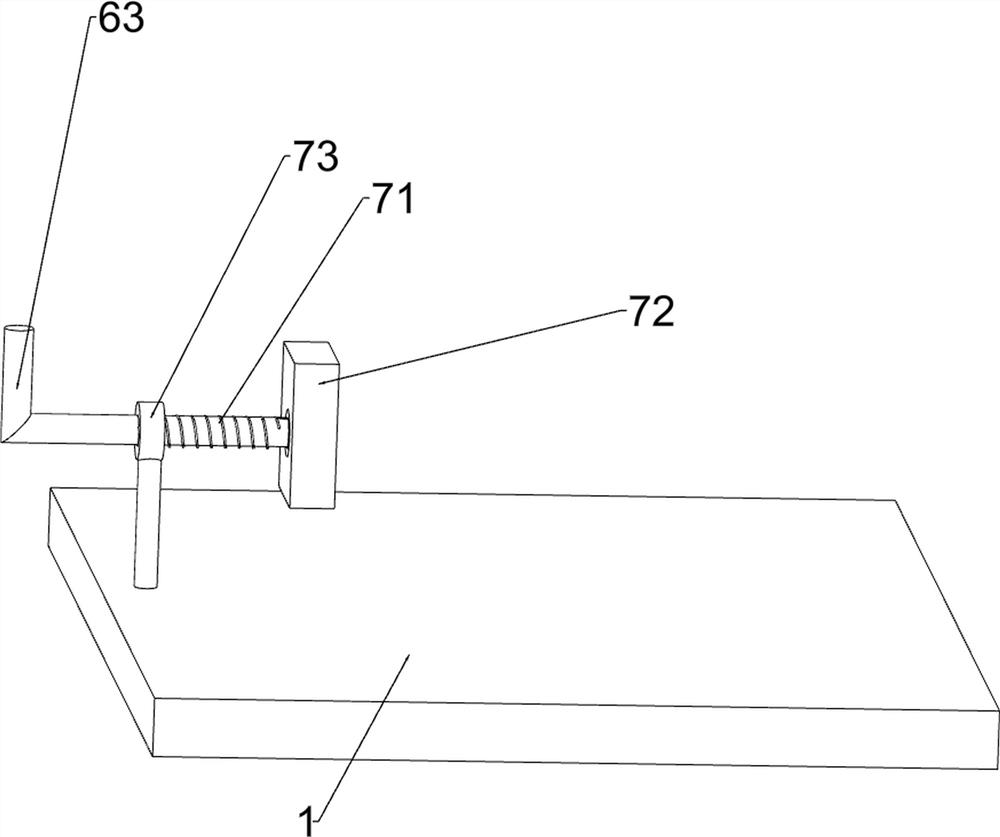

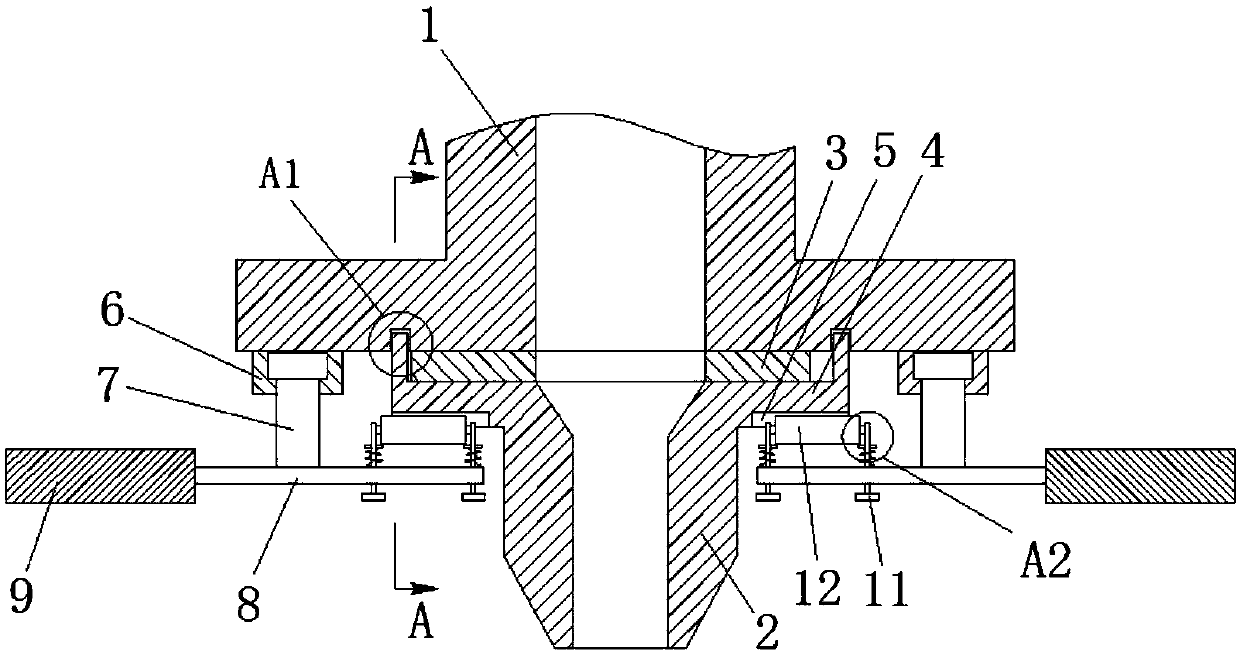

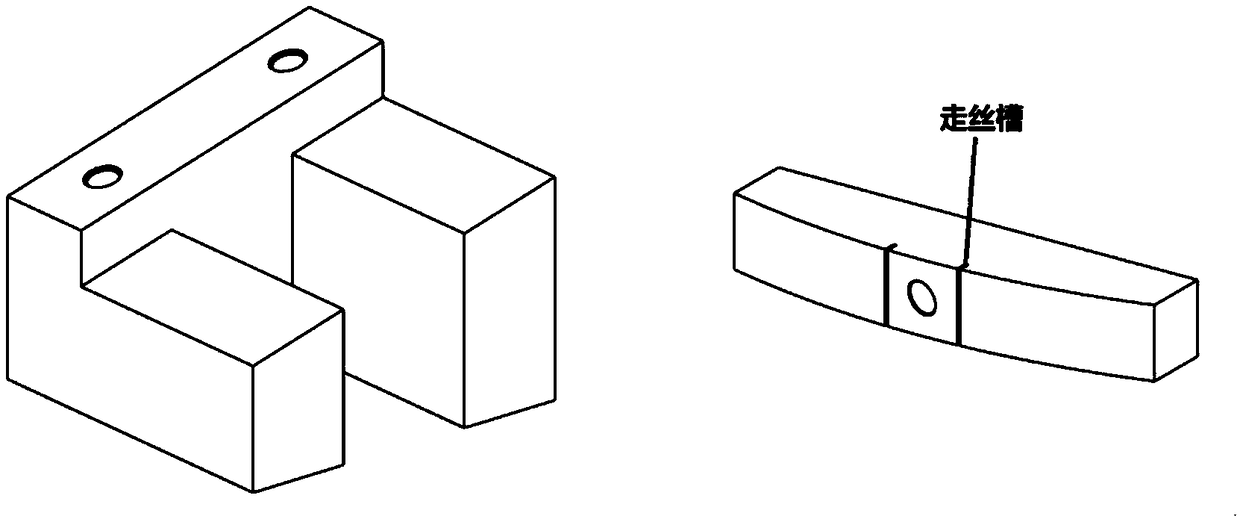

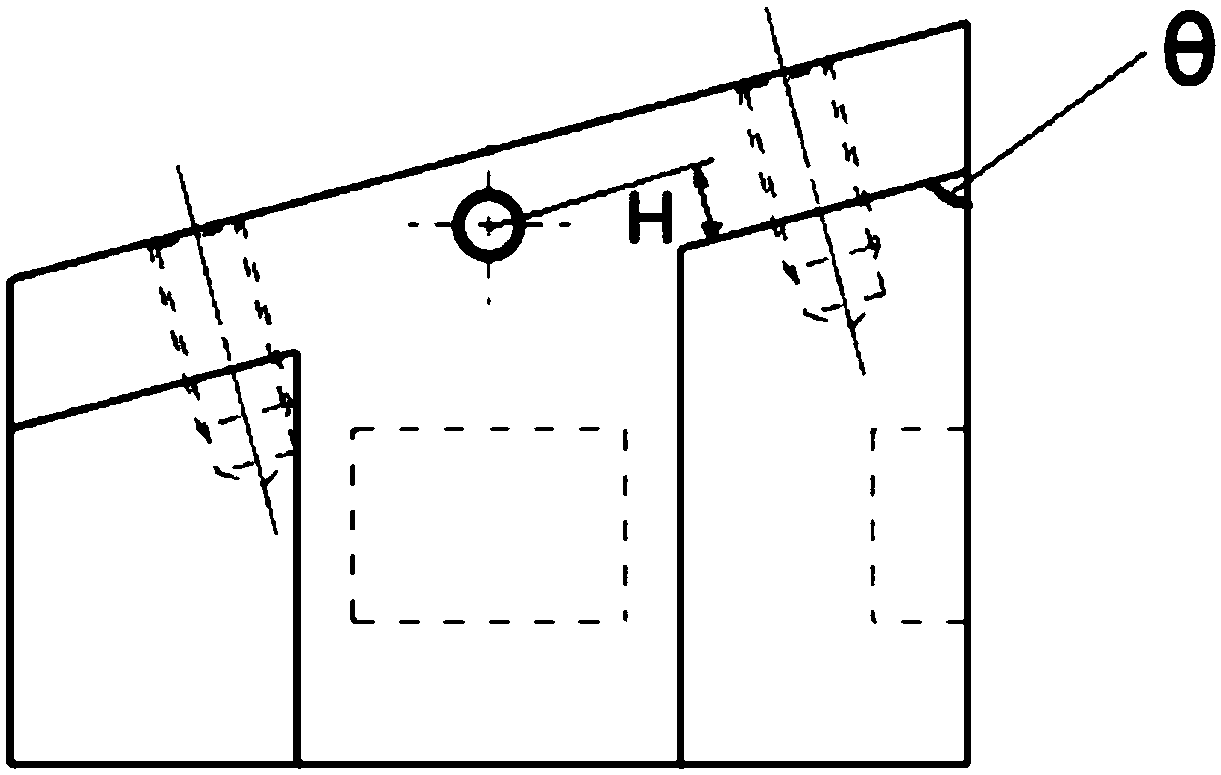

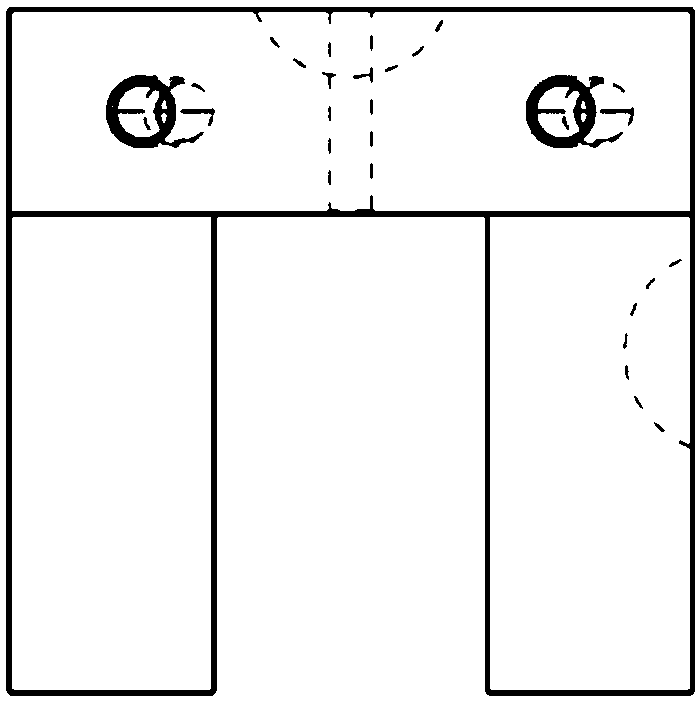

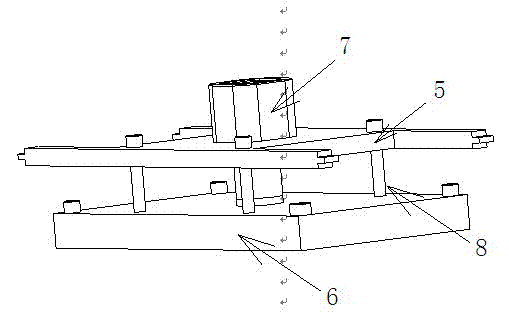

Guide plate type part wire-electrode cutting fixture and method

ActiveCN109352106ASimple structureEasy to operateElectrical-based auxillary apparatusSupport pointMachine tool

The invention discloses a guide plate type part wire-electrode cutting fixture and method. Firstly, a first fixture assembly A (1) is installed on a wire-electrode cutting machine tool and fixed; next, the inner surface of a part (6) to be machined is attached to a first positioning face and a second positioning face of the first fixture assembly A (1) and a front end face of a second fixture assembly B (2); then, a positioning dowel (5) is inserted into the part, a second positioning hole of the second fixture assembly B (2) and a first positioning hole of the first fixture assembly A (1); and two pressing plates (3) are pressed to the part (6), clamping to the part (6) is achieved, meanwhile, a plurality of auxiliary supporting points (7) are added to the lower end position of the part (6), and wire-electrode cutting machining of the part (6) is carried out. According to the guide plate type part wire-electrode cutting fixture and method, the structure is simple, operation is convenient, and rapidness, high efficiency, stability and reliability are achieved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

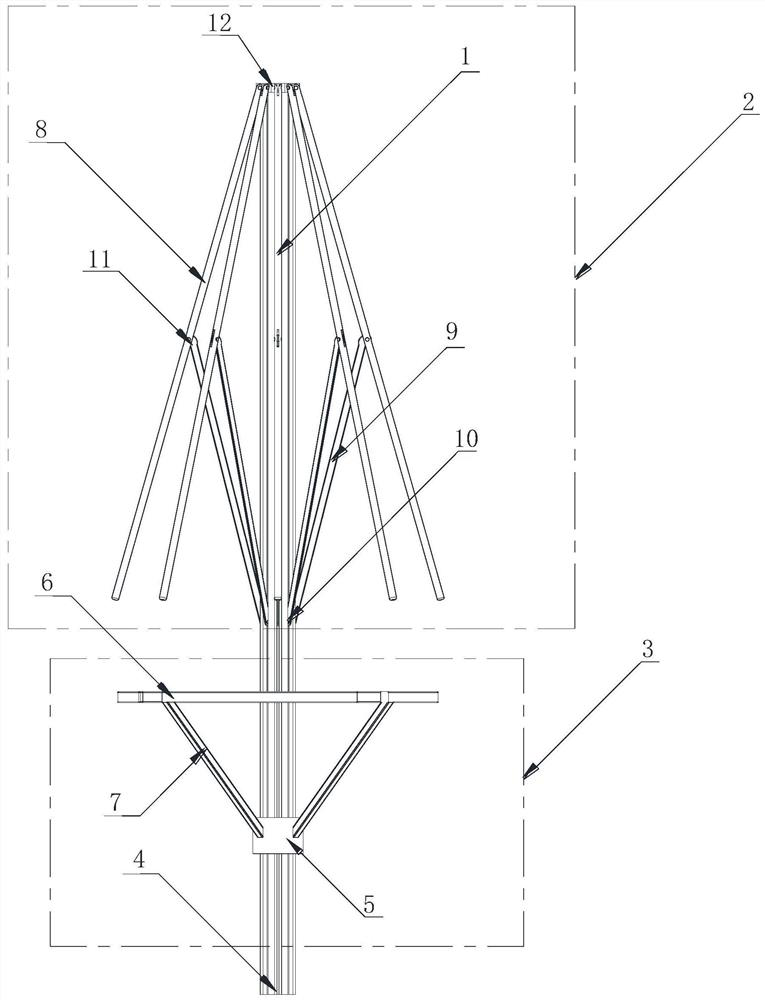

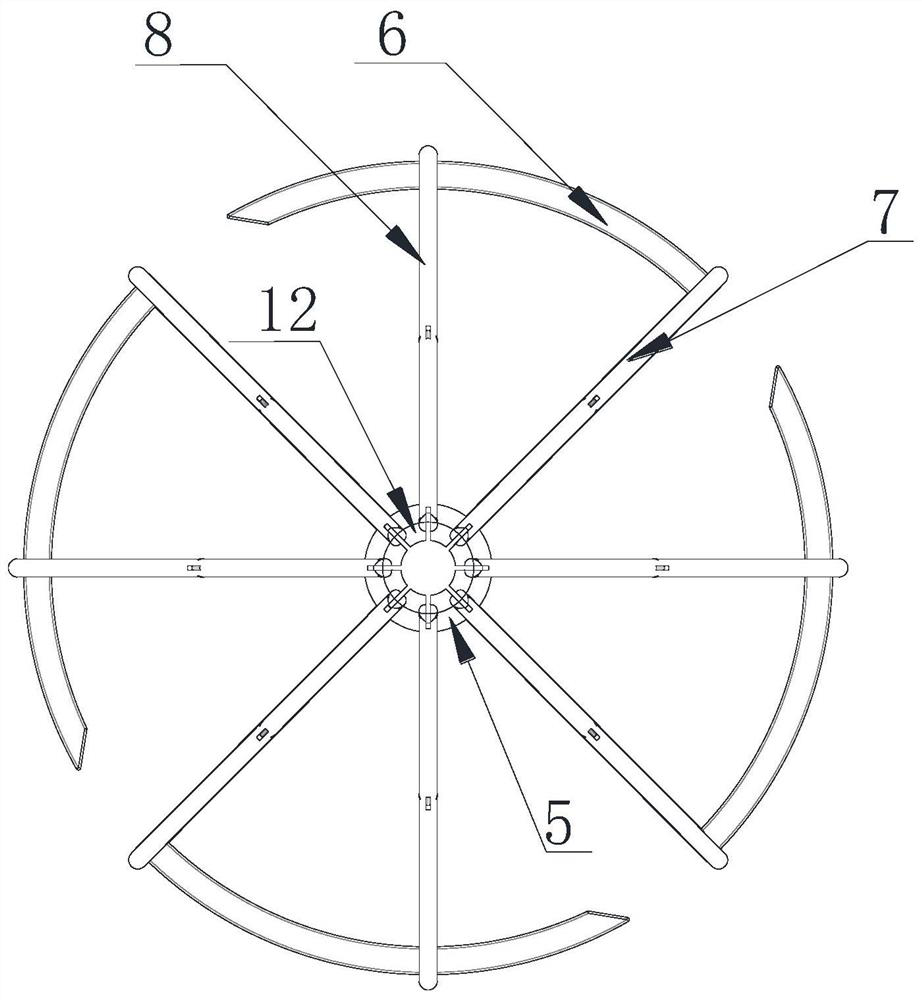

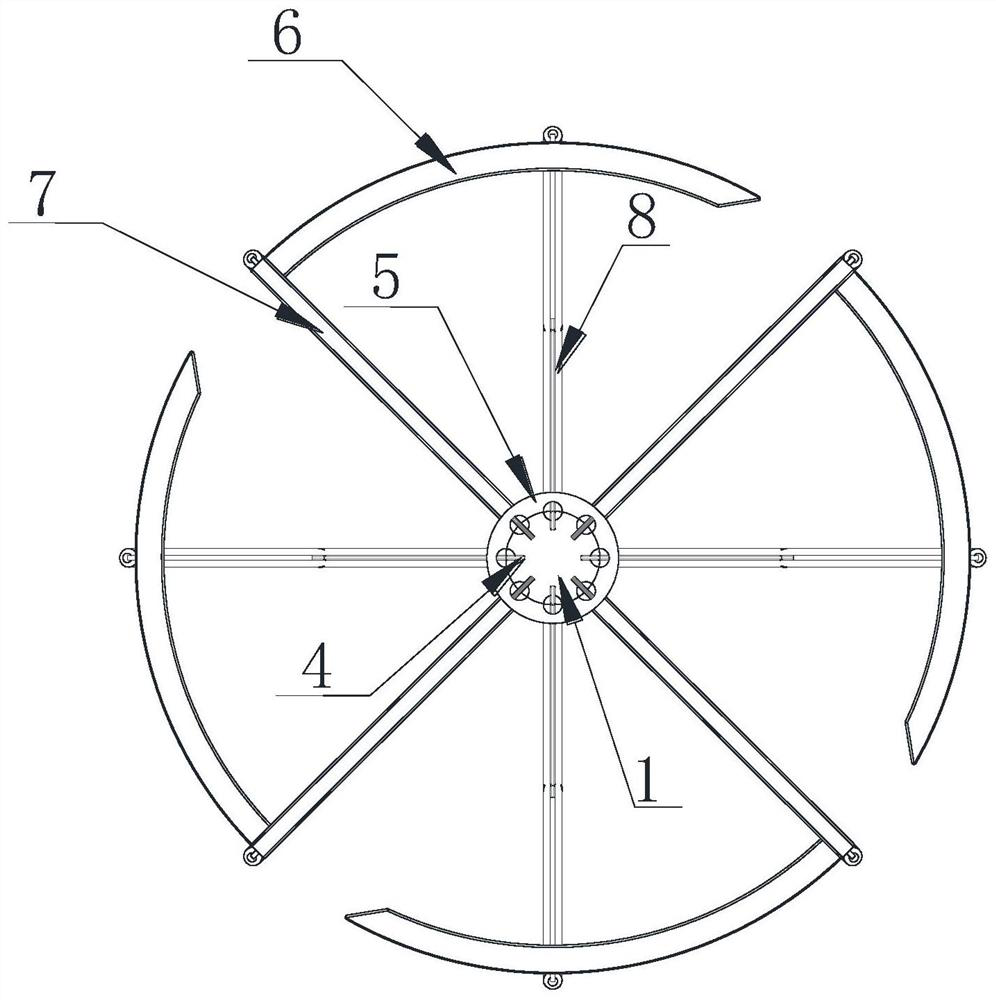

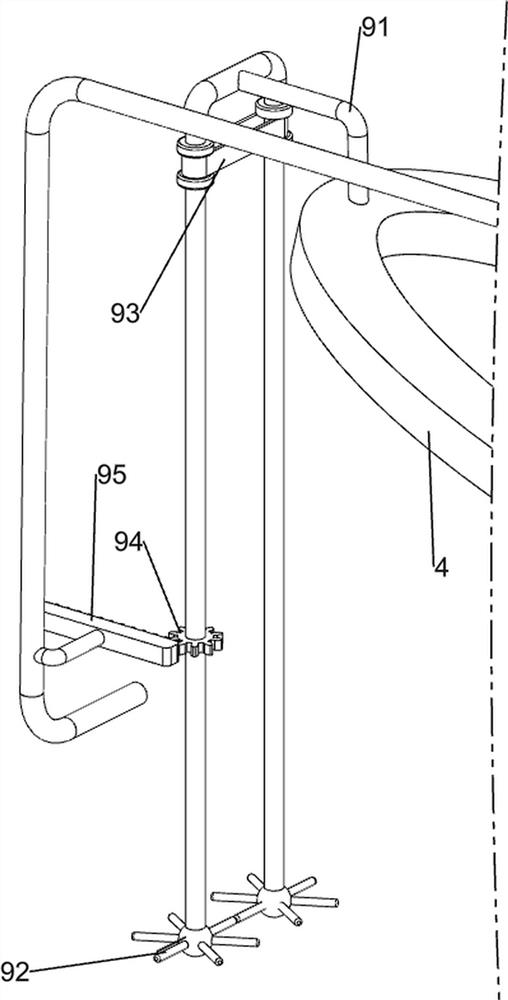

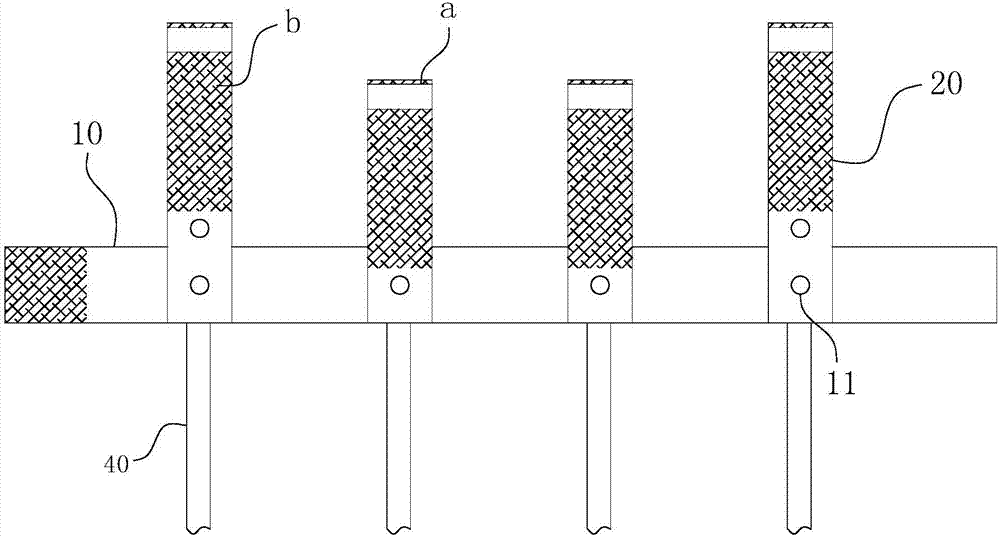

Threading device

The invention provides a threading device. The threading device comprises a supporting column extending in a vertical direction, a warp threading structure arranged on the supporting column and used for pressing warp, and a weft threading structure arranged on the supporting column and used for pressing weft. The threading device is suitable for the complicated three-dimensional distribution of the warp and weft in the three-dimensional textile. As the warp threading structure and the weft threading structure are set in the threading device, both the weft and the warp can be compressed, and the needs of three-dimensional textile can be met.

Owner:CHINESE TEXTILE ACAD

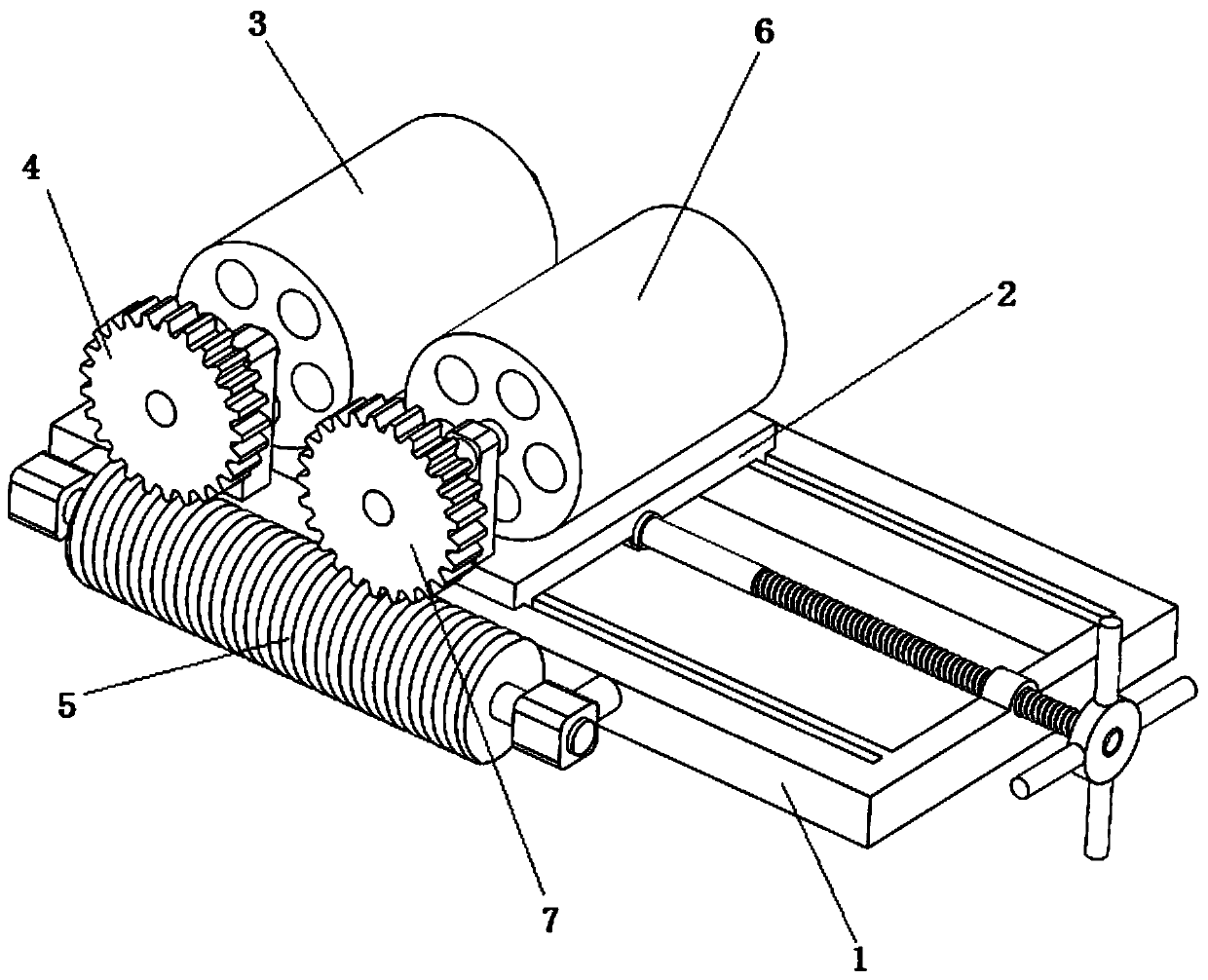

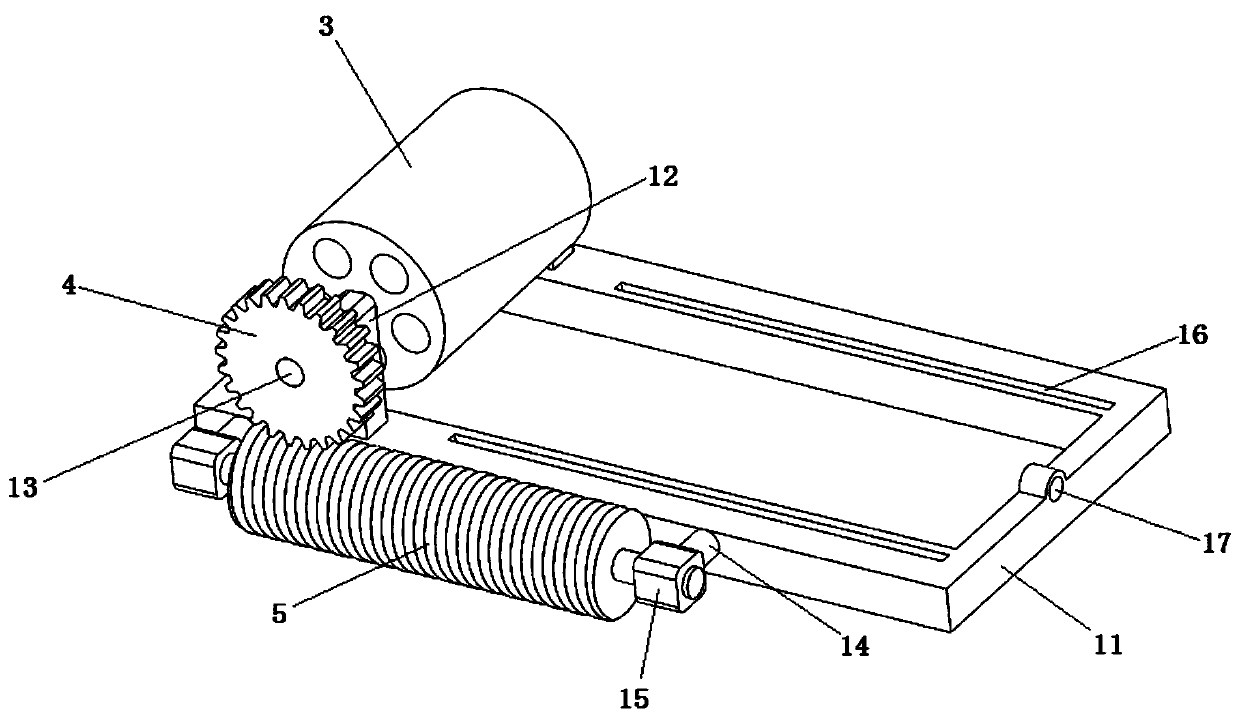

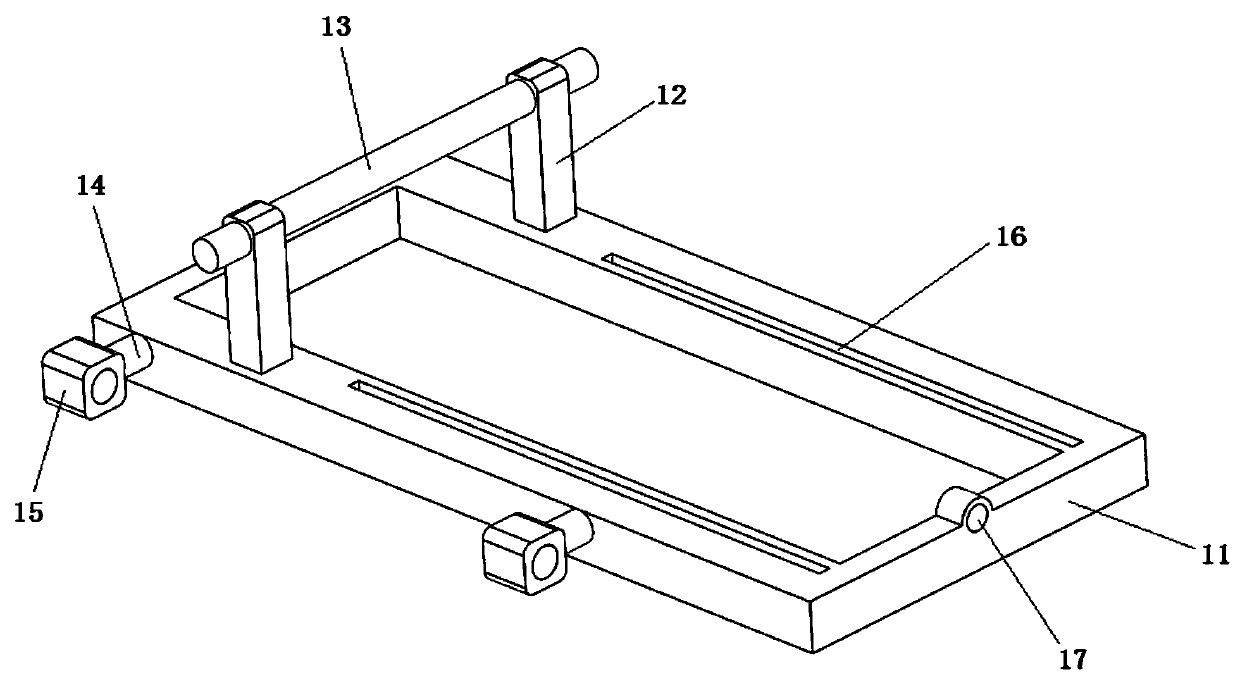

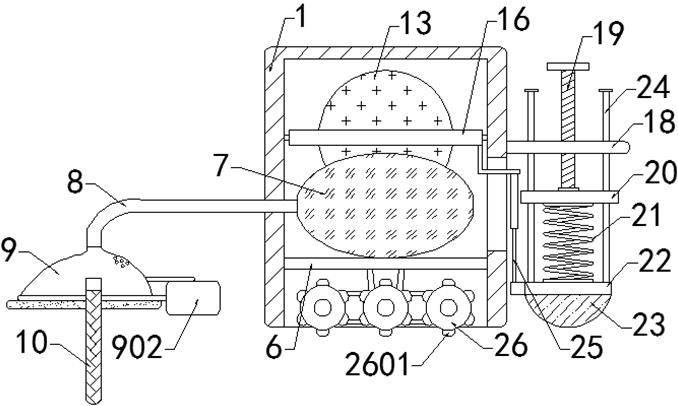

A pressing device for corrugated cardboard single-sided machine

ActiveCN108481876BSimple structureEasy to operateMechanical working/deformationLaminationCardboardGear wheel

The invention discloses a pressing device for a corrugated cardboard single-sided machine, which comprises a supporting mechanism, a sliding mechanism installed on the supporting mechanism, a first roller, a first worm wheel, a worm, a second roller and a second gear; The support mechanism includes a square frame body, the upper surface of the square frame body is fixed with a first roller installation rod, and the surface of the first roller installation rod is fixed with a first shaft; the first shaft rod The surface is fixed with a first roller and a first worm wheel; the sliding mechanism includes a slider and a second roller installation rod installed on the surface of the slider; A convex strip, the elongated convex strip cooperates with the strip-shaped groove. The pressing device of the present invention has a simple structure and is easy to operate. Driven by a motor, driven by a lead screw, and engaged with a worm gear, it can not only realize the pressing effect on corrugated cardboard, but also save a lot of manpower and improve production efficiency.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Material pressing assembly of side punching head

PendingCN111283066AImprove wear resistanceEasy to assemble and disassemblePerforating toolsPunchingStructural engineering

The invention discloses a material pressing assembly of a side punching head. The material pressing assembly comprises a fixing device, a supporting device and an elastically telescopic material pressing device, wherein the supporting device is detachably fixed to the front end of the fixing device, the rear end of the fixing device is detachably fixed to a punching wedge, the material pressing device is elastically connected into the supporting device, the material pressing device is elastically and movably connected into the supporting device in the axial direction, and the front end face ofthe material pressing device abuts against a part in a detachable mode. The material pressing assembly of the side punching head is simple in structure and convenient to disassemble and assemble, daily maintenance of a die can be facilitated, effective material pressing in the punching process is achieved, the punching quality is ensured, and the problem that a material pressing face is difficultto arrange can be effectively solved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

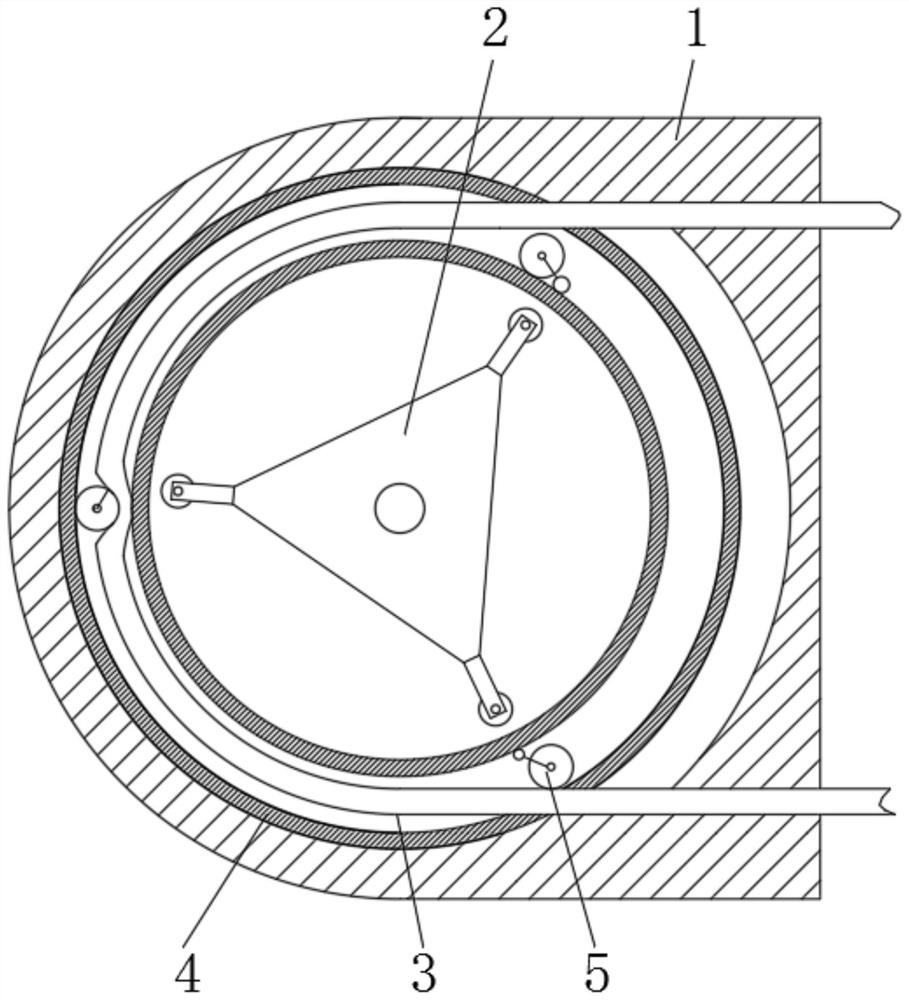

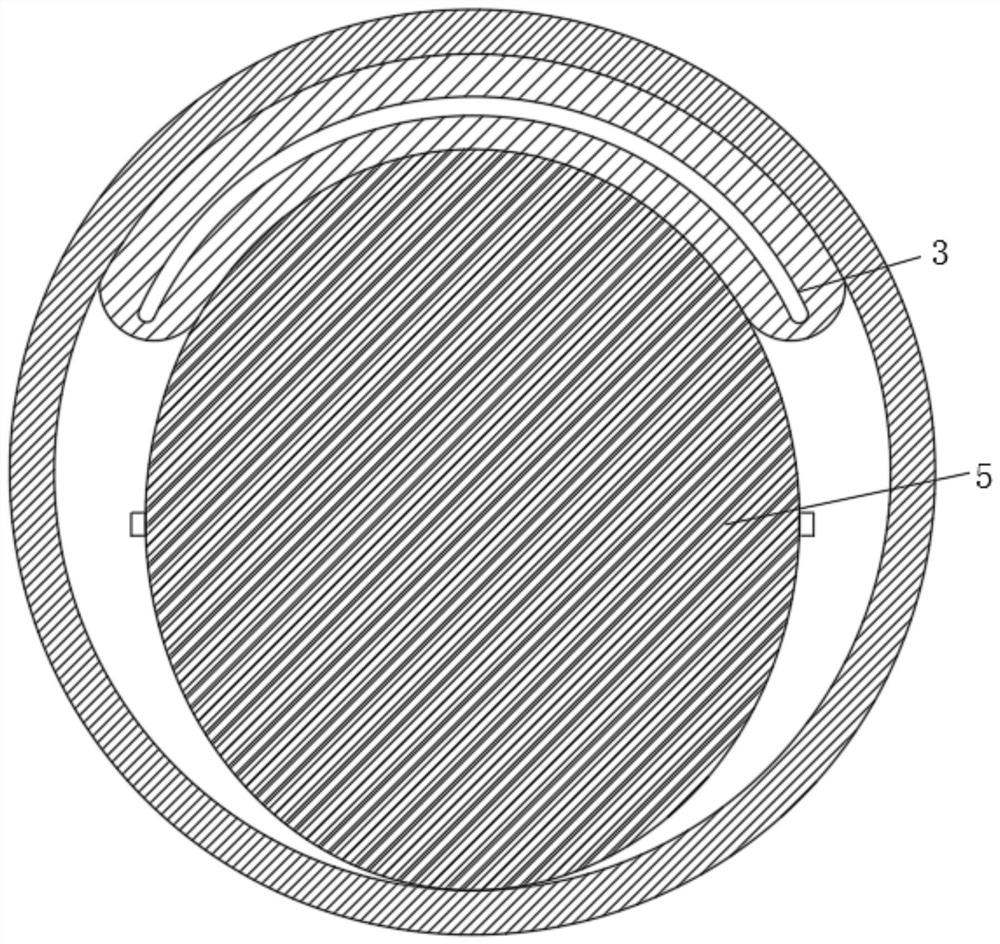

Low-loss peristaltic pump

ActiveCN110905784AGuaranteed accuracyUniform pressureFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

The invention relates to the technical field of fluid pumps, and discloses a low-loss peristaltic pump, which comprises a pump head, a driver and a hose. The driver is installed in the middle of the pump head, an extrusion pipe is fixedly installed on the inner side wall of the pump head, and the hose and an extrusion ball are arranged in an inner cavity of the extrusion pipe in a sleeving mode. According to the low-loss peristaltic pump, since the cut-in angle of the extrusion ball is random, mutual extrusion surfaces between the movable hose and the extrusion ball are random; the extrusion ball bears relatively uniform pressure; material fatigue and loss caused by bending are uniformly distributed on the surface of the hose; service life is greatly prolonged; the elastic property can also be kept unchanged within a longer working time, and operation is kept stable; since the size parameters of the hose, the extrusion pipe and the extrusion ball are fixed, the extrusion force betweenthe hose and the extrusion ball is relatively stable; and meanwhile, since the extrusion ball is deformable and can absorb excessive pressure, the folding bending of the hose is always kept in a reasonable interval.

Owner:济宁市正圆机械制造有限公司

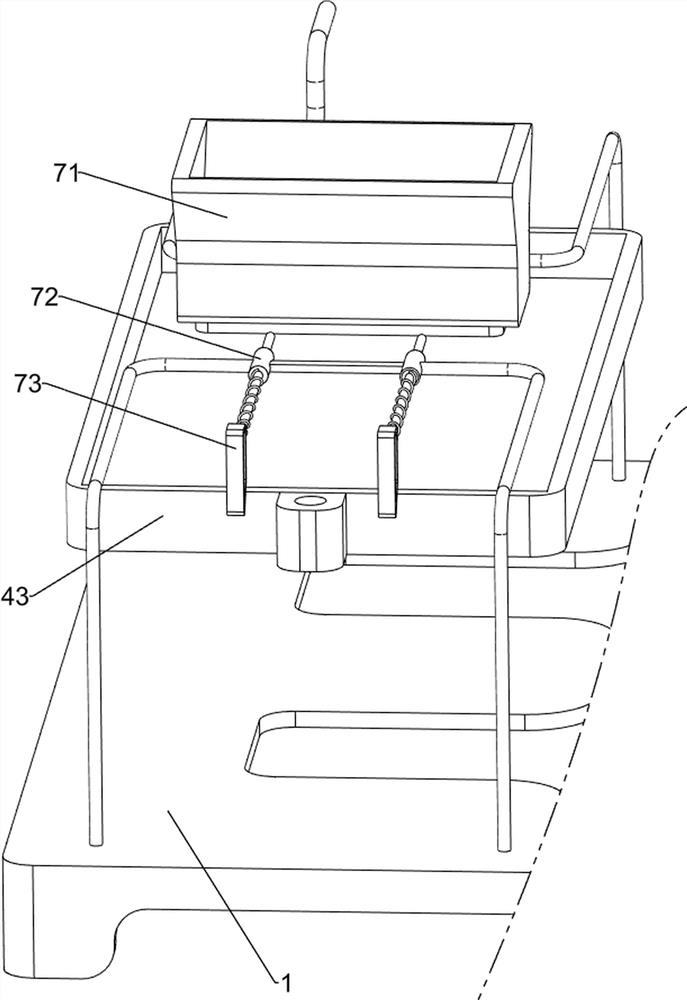

Feeding equipment for poultry farm

PendingCN112970629AReduce labor intensityRealize water quantity detectionAvicultureAlarmsAgricultural scienceWater tanks

Owner:叶建德

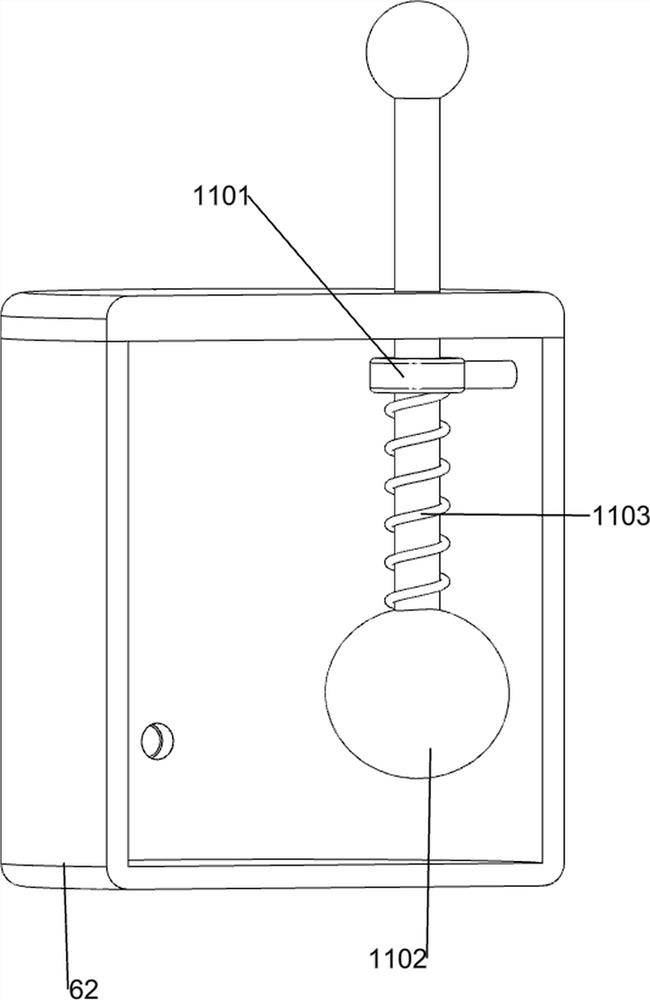

Auxiliary breathing device for pulmonary patient

InactiveCN113952567ARealize the pressing effectMeet the needs of useElectrotherapyRespiratory masksMedicineElectric machinery

The invention discloses an auxiliary breathing device for a pulmonary patient. The auxiliary breathing device comprises a fixing box, wherein side plates are symmetrically fixed to side edges of the fixing box, the side plates are connected with adjusting screw rods through threads, and the adjusting screw rods are connected to clamping plates through bearings. The auxiliary breathing device further comprises a partition plate, wherein the partition plate is fixed in the fixing box, a compressed air bag is arranged on the partition plate, the side edge of the compressed air bag is connected with a connecting pipe, the connecting pipe penetrates through the fixing box, the tail end of the connecting pipe is connected with a mask, an elastic rope is fixed to the mask for wearing, and a soft rubber pad is fixed to the lower end face of the mask for protection; and a motor, wherein the motor is fixed to the fixing box, and a disc is fixed to the tail end of an output shaft of the motor. According to the auxiliary breathing device for the pulmonary patient, an adjustable automatic extrusion mechanism is adopted for replacing manual extrusion to achieve the pressing effect on the compressed air bag, a uniform pressing effect can be guaranteed, gas flow can be adjusted according to actual requirements, and therefore, use requirements of different patients are met.

Owner:史广超

A kind of acne cleaning device for dermatology

ActiveCN113476084BAchieve the protruding effectRealize the effect of the medicineDiagnosticsSurgeryDermatology departmentSurgery

The invention relates to a cleaning device, in particular to an acne cleaning device used in dermatology. The invention provides a dermatological acne cleaning device which is simple to operate, convenient to carry, and can sterilize punctured skin parts in time. A dermatological acne cleaning device comprising: a casing and a protruding mechanism, the casing is provided with a protruding mechanism; a needle, a needle is provided on the protruding mechanism; a drug-applying mechanism, a drug-applying mechanism is provided between the casing and the needle; Mechanism, a closing mechanism is arranged between the drug-feeding mechanism and the shell. The present invention manually pulls the sliding sleeve to move to the left, thereby driving the needle to move to the left, so that the first spring is compressed, and the needle moves to the left to pierce the acne on the skin to achieve the effect of protruding; by manually pushing the first piston The rod moves to the left, so that the medicinal liquid in the first medicinal storage tank can flow into the needle through the flexible pipe and be injected onto the acne, so that the effect of applying medicinal can be realized.

Owner:韦东吉

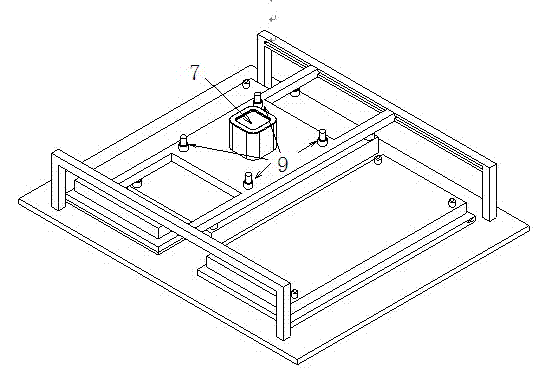

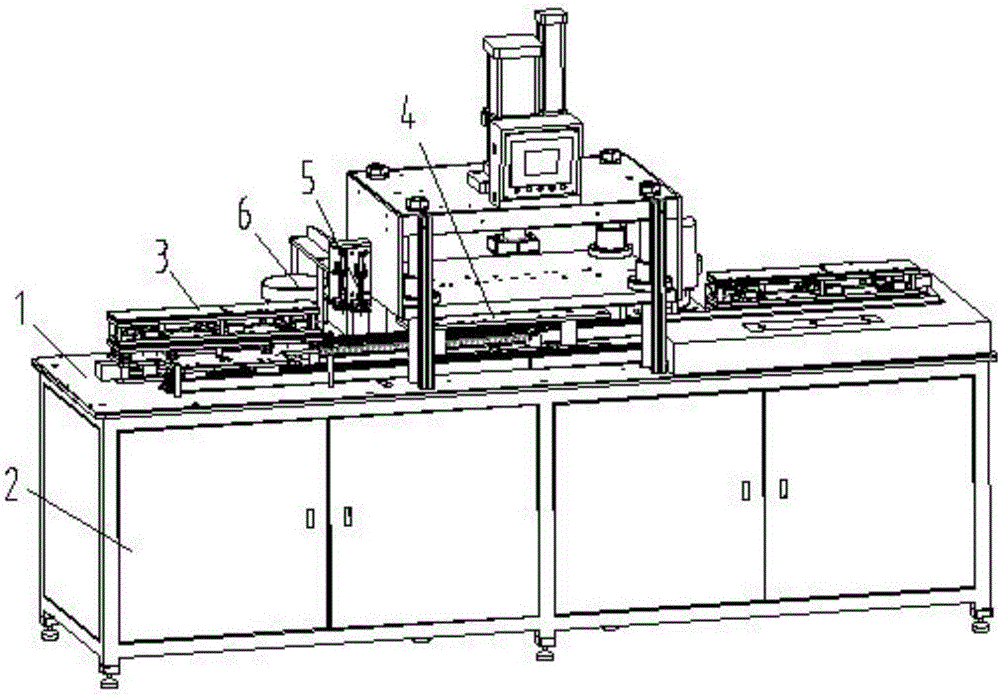

Device for automatic assembly of flexible circuit board

ActiveCN102076172BGuaranteed accuracyRealize the pressing effectPrinted circuit manufactureFlexible circuitsEngineering

The invention discloses a device for automatic assembly of a flexible circuit board. The device comprises a first joint platform, a second joint platform, moving guide rails, positioning guide posts, a fixed bracket, a material sucking disc, a cylinder, a lifting guide post, a guide post sleeve and a step motor, wherein the two moving guide rails are arranged in parallel, the first joint platformand the second joint platform are arranged between the two moving guide rails, the two joint platforms have the same size and are arranged along the directions of the moving guide rails, the fixed bracket capable of moving along the moving guide rails is arranged above the first joint platform and the second joint platform, the cylinder is arranged on the fixed bracket driven by the step motor, the lower end of the cylinder is provided with the material sucking disc, and four corners of the first joint platform and the second joint platform are provided with the positioning guide posts. The device effectively solves high requirement of assembly operation on personnel proficiency, reduces the manpower of the assembly operation, and realizes automatic assembly.

Owner:JIANGSU TRANSIMAGE TECH CO LTD

A non-stop automatic riveting machine for iron sheets

InactiveCN106825379BImprove efficiencyReduce mistakesRivetsHandling devicesDistribution controlProcess equipment

Owner:安徽宁凡模具有限公司

A low loss peristaltic pump

ActiveCN110905784BGuaranteed accuracyUniform pressureFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpPump head

The invention relates to the technical field of fluid pumps, and discloses a low-loss peristaltic pump, which includes a pump head, a driver and a hose. tube, and the inner cavity of the extruded tube is covered with a hose and an extruded ball. The low-loss peristaltic pump, due to the randomness of the extrusion ball cutting angle, the mutual extrusion surface between the moving hose and the extrusion ball is also random, the extrusion ball is relatively uniform in pressure, and the material fatigue caused by bending The wear and tear are evenly distributed on the surface of the hose, its service life is greatly improved, and its elastic properties can also be kept unchanged for a longer working time to maintain stable operation. Secondly, the hose, squeeze tube and squeeze ball The size parameters of the hose are fixed, and the extrusion force between the hose and the extrusion ball is relatively stable. At the same time, because the extrusion ball is deformable, it will also absorb excessive pressure, and the bending degree of the hose is always kept in a reasonable range. Inside.

Owner:济宁市正圆机械制造有限公司

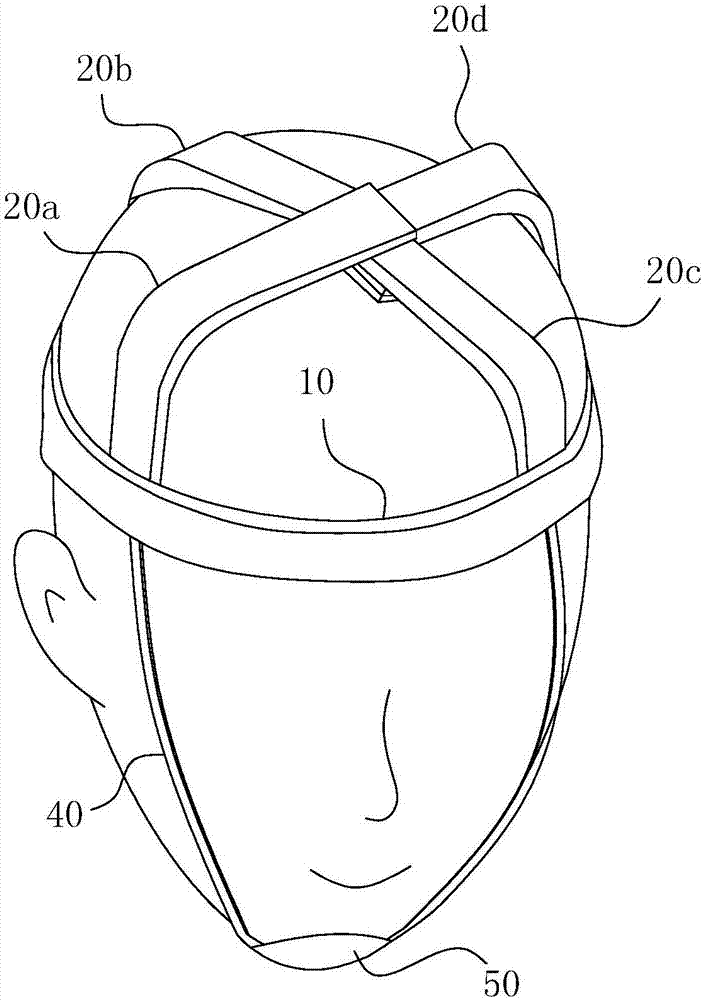

Adjustable headgear

ActiveCN106955194AFirm pressure fixationReduce blood loss and infection rateHead bandagesNeck bandagesEngineeringForehead

The invention belongs to the field of medical auxiliary tools and particularly relates to an adjustable headgear. The adjustable headgear comprises an elastic strap arranged by horizontally surrounding the head by a circle via the forehead of a patient. The e adjustable headgear is characterized in that elastic plates are fixedly connected to strap bodies, located at the front parts and the rear parts of ears of the patient, of the elastic strap, and vertically upward extend along the head outline of the patient; one end; one end, which is fixedly connected to the elastic strap, of each elastic plate, is a fixed end; suspending ends of the four elastic plates are joined at a wound of the head of the patient; in addition, the directions of elastic restoring forces of all the elastic plates point to the wound of the head of the patient. The adjustable headgear disclosed by the invention has the advantages of convenience in use, reliability in fixing, good hemostatic effect and the like; the aims of reliable pressure application and fixation of aseptic dressing can be effectively guaranteed, so that the bleeding amount and the infection rate of the wound of the head can be effectively reduced.

Owner:HEFEI NO 2 PEOPLES HOSPITAL

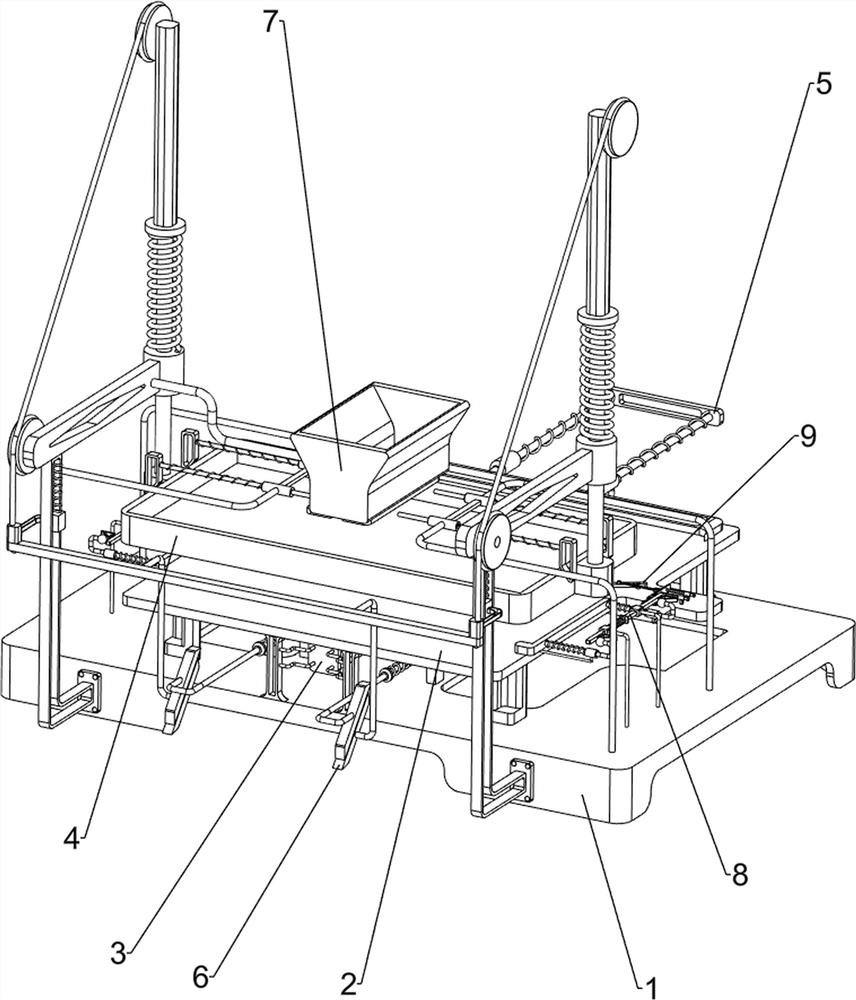

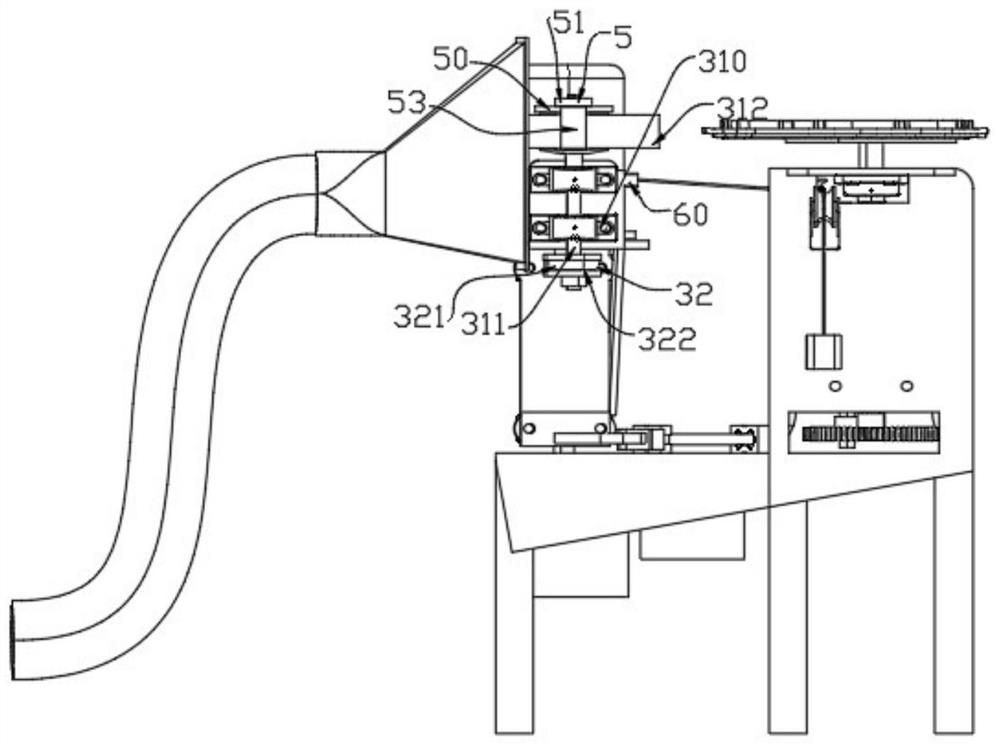

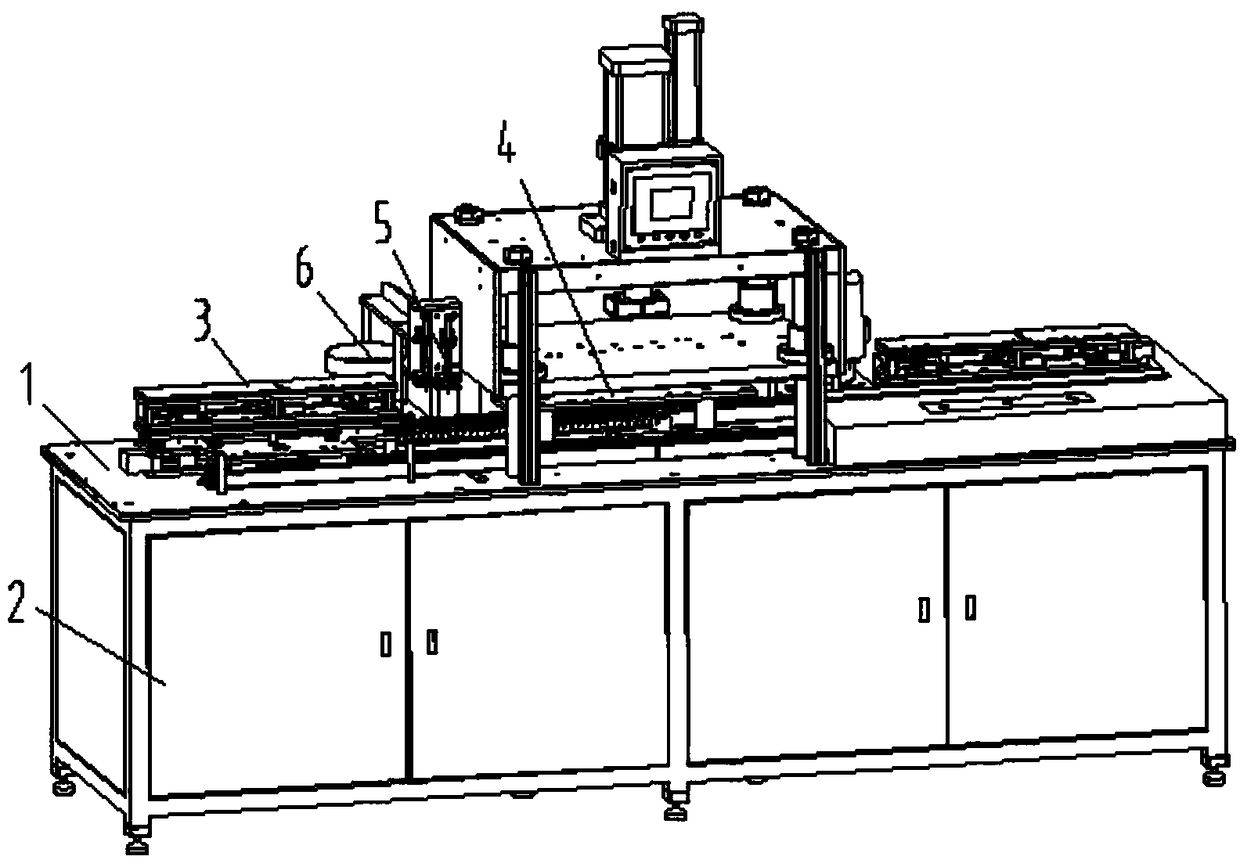

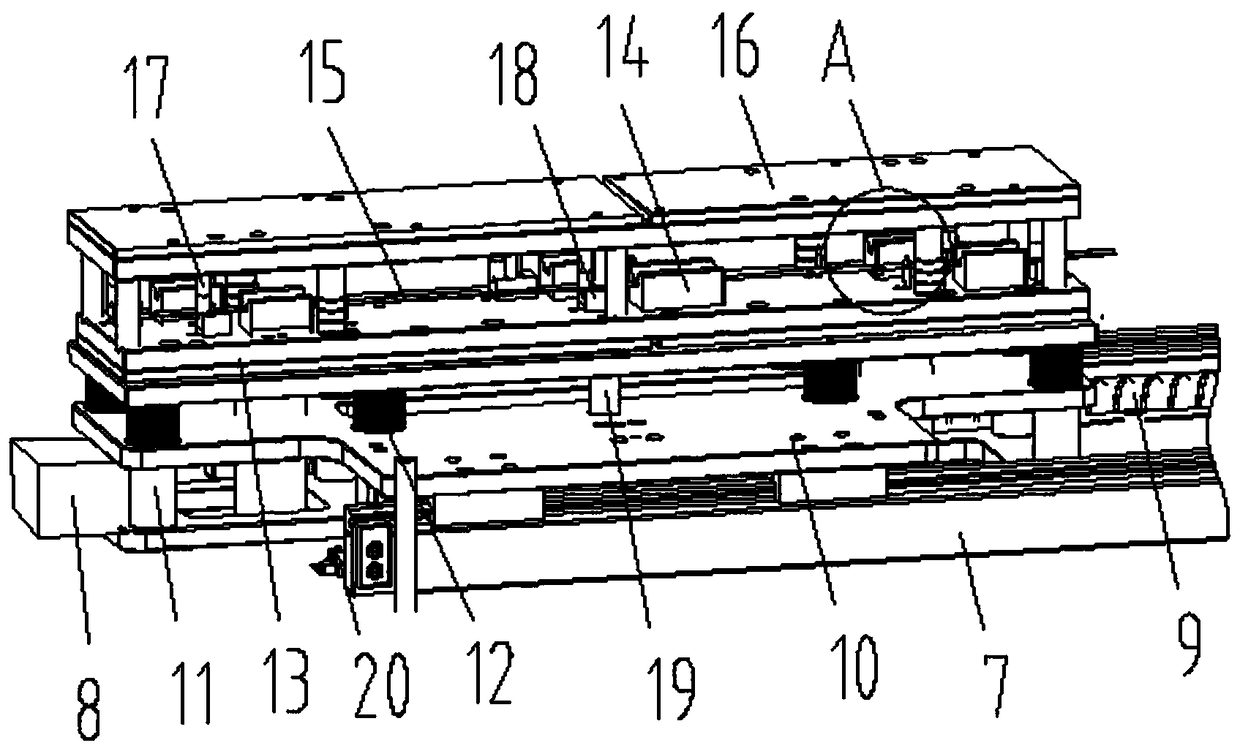

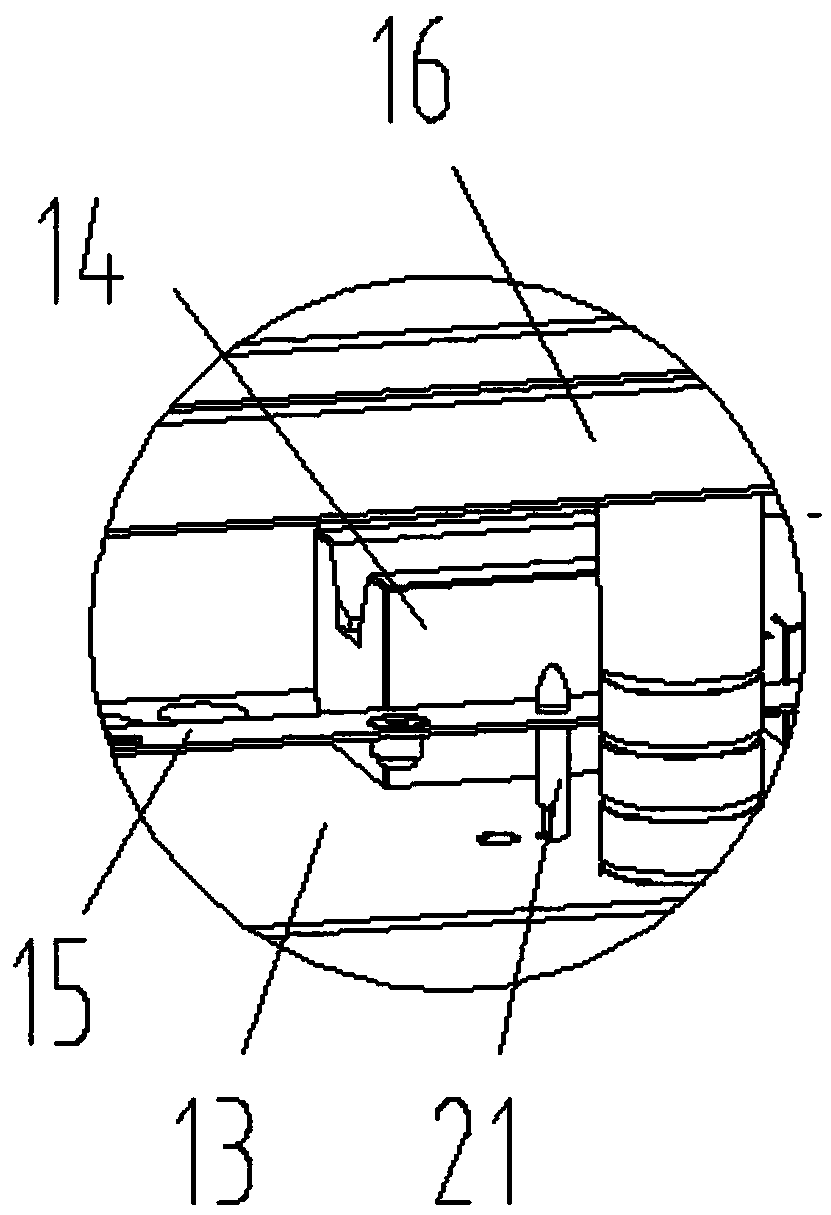

Continuous automatic column riveting machine for iron sheets

InactiveCN106825379AImprove efficiencyReduce mistakesRivetsHandling devicesProcess equipmentDistribution control

The invention relates to the field of processing equipment of iron sheets, in particular to a continuous automatic column riveting machine for the iron sheets. The continuous automatic column riveting machine comprises a machine frame and power distribution control boxes, wherein iron sheet conveying devices matched with the iron sheets are separately arranged on the left side and the right side of the machine frame; a sheet pressing device matched with the iron sheets is arranged in the middle of the two sets of iron sheet conveying devices; a column riveting device matched with holes formed in the iron sheets conveyed by the conveying device is arranged on the side surface of the sheet pressing device; the lower side of the column riveting device is matched with the tail end of a nail delivering groove; and a nail delivering vibrating disk is connected to the nail delivering groove. The invention aims to provide the continuous automatic column riveting machine for the iron sheets, the conveying devices matched with the strip-shaped iron sheets are arranged on the machine frame, besides, the sheet pressing device is arranged in the middle of the two iron sheet conveying devices, and the column riveting device is arranged on the side surface of the sheet pressing device, so that the strip-shaped iron sheets do not need to be separated, continuous and automatic column riveting can be realized, the column riveting efficiency is greatly improved, and the column riveting errors are reduced.

Owner:安徽宁凡模具有限公司

Single-table-board ink jet equipment capable of preventing large panel veneer from warping

ActiveCN114523769ARealize the effect of automatic inkjetRealize the pressing effectTypewritersOther printing apparatusElectric machineryEngineering

The invention relates to single-table-board ink jet equipment, in particular to single-table-board ink jet equipment capable of preventing a large plate from warping. The single-table-board ink jet equipment capable of preventing the large plate from warping is capable of automatically jetting ink, automatically clamping and automatically pushing. A single-table-board ink jet device for preventing a large plate from warping comprises a shell, a first fixing plate, a supporting plate, a first electric push rod, a second fixing plate and a moving mechanism, the first fixing plate is arranged on the shell, the supporting plate is connected between the upper side of the first fixing plate and the shell, and the first electric push rod is installed on the lower portion of the supporting plate; a second fixing plate is connected to a telescopic rod of the first electric push rod, and a moving mechanism is arranged on the second fixing plate. The first distance sensor senses that the distance between the first distance sensor and the shell reaches a preset value, so that the air pump and the first gear motor are started, the sliding block and the spray head move to spray ink to a plate, and the automatic ink spraying effect is achieved.

Owner:胡广辉

A walking wheel mechanism

ActiveCN103594969BRealize the pressing effectWith barrier functionApparatus for overhead lines/cablesDrive wheelWalking around obstacles

The invention discloses a pinch roller mechanism. The pinch roller mechanism comprises a fixed box, a lifting driving device arranged on the fixed box and a pinch roller set which is connected with the lifting driving device and is driven by the lifting driving device to rise and fall, wherein the pinch roller set at least comprises a pinch roller. When the pinch roller mechanism works, the pinch roller of the pinch roller set is compressed to the lower side of a line, and an inspection robot can walk through cooperation between the pinch roller and a driving wheel mechanism; when one pinch roller mechanism of the inspection robot approaches to a barrier and can not pass through, the pinch roller set is driven by the lifting driving device to move downwards, and then compression of the line is released; the inspection robot walks continuously, the lifting driving device drives the pinch roller set to move upwards when the pinch roller mechanism bypasses the barrier, and then compression of the line is achieved. According to the pinch roller mechanism, an obstacle crossing function is achieved, and the application range of the inspection robot is widened. The invention further discloses a traveling wheel set mechanism provided with the pinch roller mechanism.

Owner:STATE GRID CORP OF CHINA +2

Positioning mechanism for machining holes in end surfaces of inner gear rings

InactiveCN108032119ARealize the pressing effectEasy to processPositioning apparatusMaintainance and safety accessoriesHydraulic cylinderSpray nozzle

The invention discloses a positioning mechanism for machining holes in the end surfaces of inner gear rings. The positioning mechanism comprises a base. A tank is mounted on the upper side of the base, a water tank is mounted inside the tank, a high-pressure water pump is mounted inside the water tank, support columns are mounted on the upper side of the tank, hydraulic cylinders are mounted inside the support columns, compression plates are mounted at output ends of the hydraulic cylinders via piston rods, a support frame is mounted above the tank and is positioned on a side of each support column, a filter screen is arranged on the surface of the tank and is positioned at the bottom of the support frame, a first mounting plate is mounted on the tops of the support columns, a drilling structure is mounted in the center of the bottom of the first mounting plate, a second mounting plate is mounted on the lower side of the drilling structure, and drill bits are mounted at the bottom of the second mounting plate. The positioning mechanism has the advantages that the positioning mechanism comprises the hydraulic cylinders, the compression plates, the high-pressure water pump and a high-pressure spray nozzle structure, and accordingly the inner gear rings with optional sizes can be clamped by the positioning mechanism and can be washed by high-pressure water flow.

Owner:TAIZHOU WEIYE MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com