Device for automatic assembly of flexible circuit board

A flexible circuit board, automatic assembly technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of circuit breakage, waste of man-hours, breakage, etc., and achieve the effect of avoiding deviation and reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

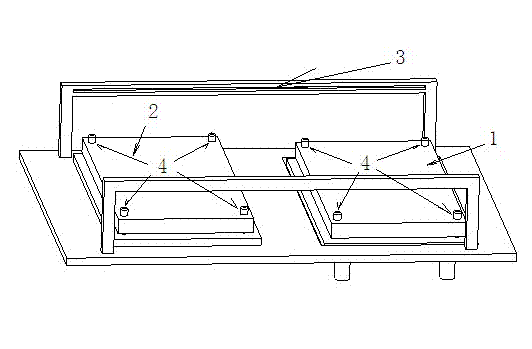

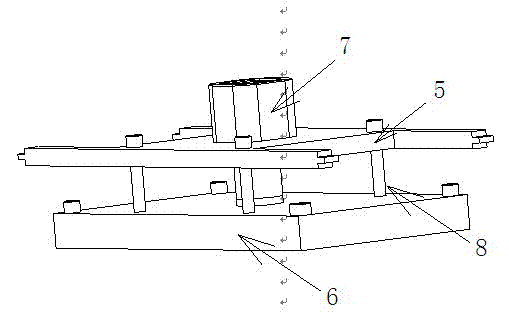

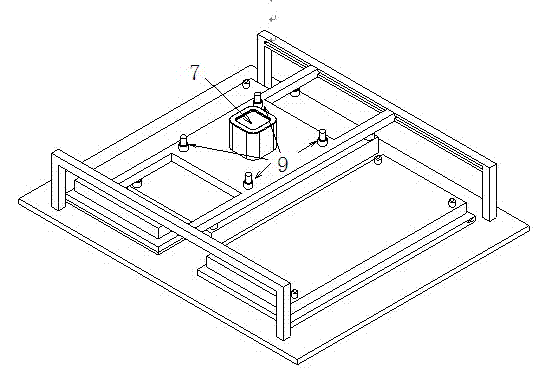

[0013] like figure 1 , 2 , 3: a device for automatic assembly of flexible circuit boards, including a first laminating platform 1, a second laminating platform 2, a moving guide rail 3, a positioning guide post 4, a fixing bracket 5, a material suction cup 6, Cylinder 7, lifting guide post 8, guide post guide sleeve 9 and stepper motor, the two moving guide rails 3 are arranged in parallel, and the first laminating platform 1 and the second laminating platform 2 are arranged between the two moving guide rails 3 , the two lamination platforms have the same size and are arranged along the direction of the motion guide rail 3. Above the first lamination platform 1 and the second lamination platform 2, a fixed bracket 5 that can move along the motion guide rail 3 is arranged. A cylinder 7 is installed on the fixed bracket 5 driven by the motor, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com