Patents

Literature

979results about How to "Lower skill requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

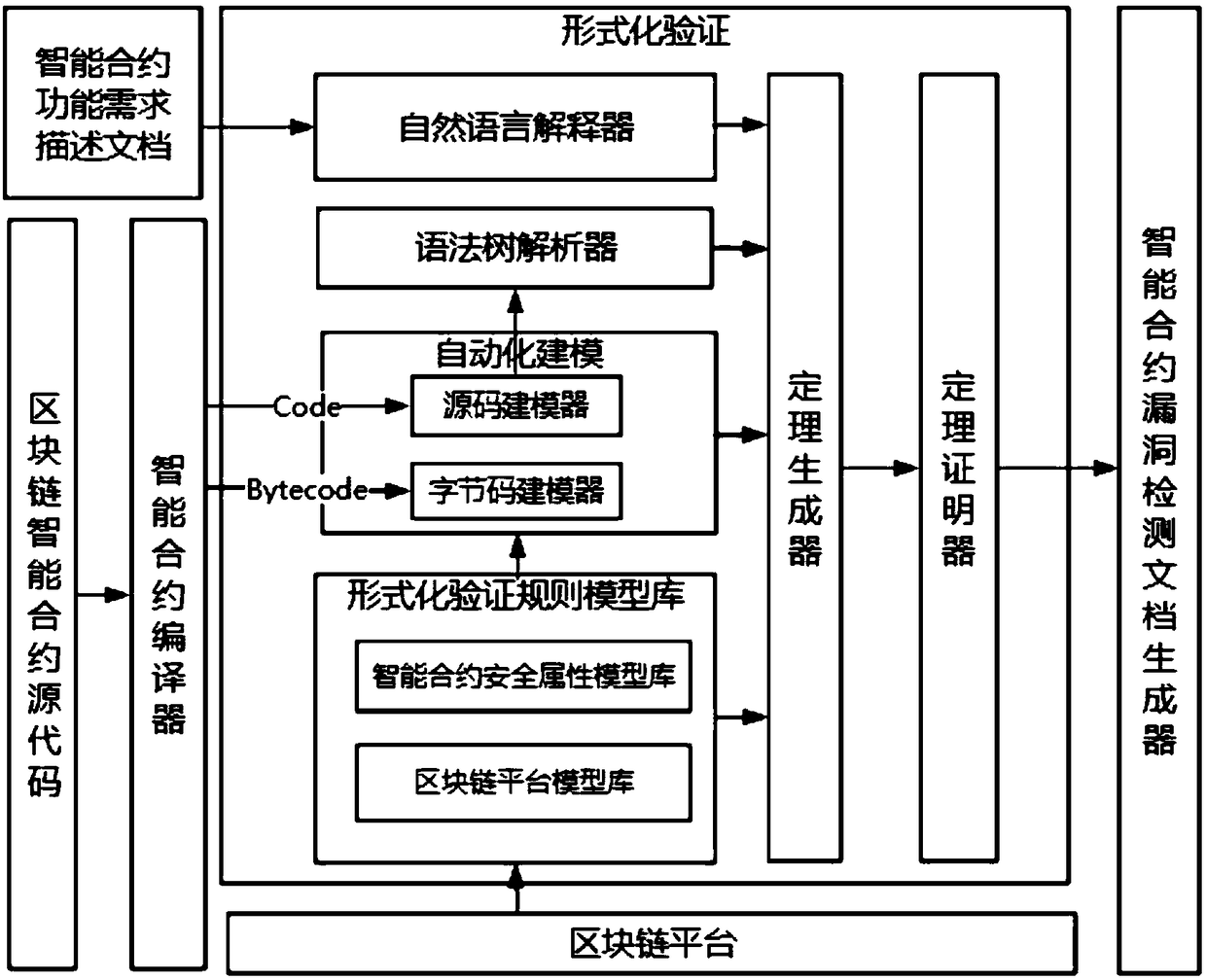

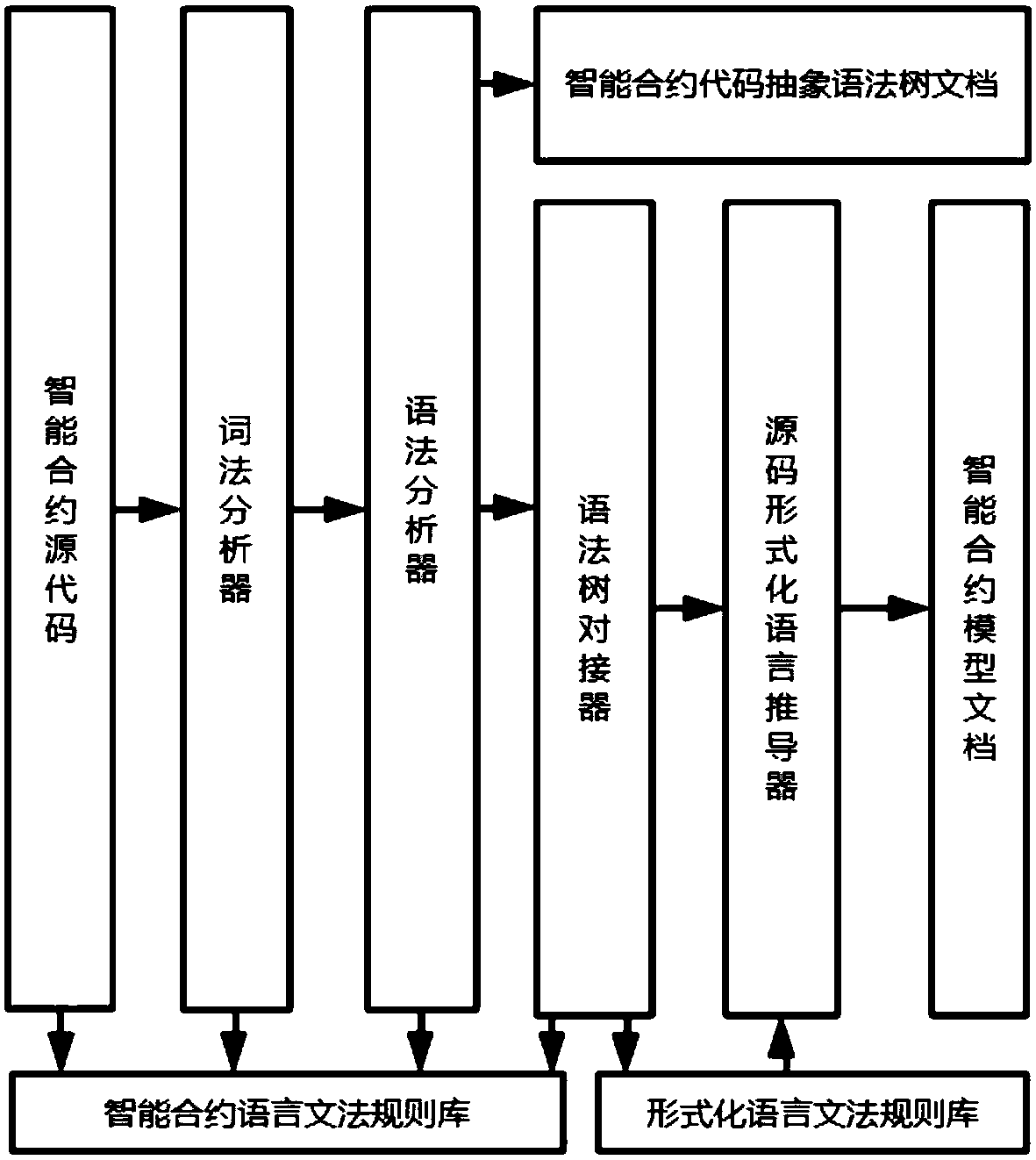

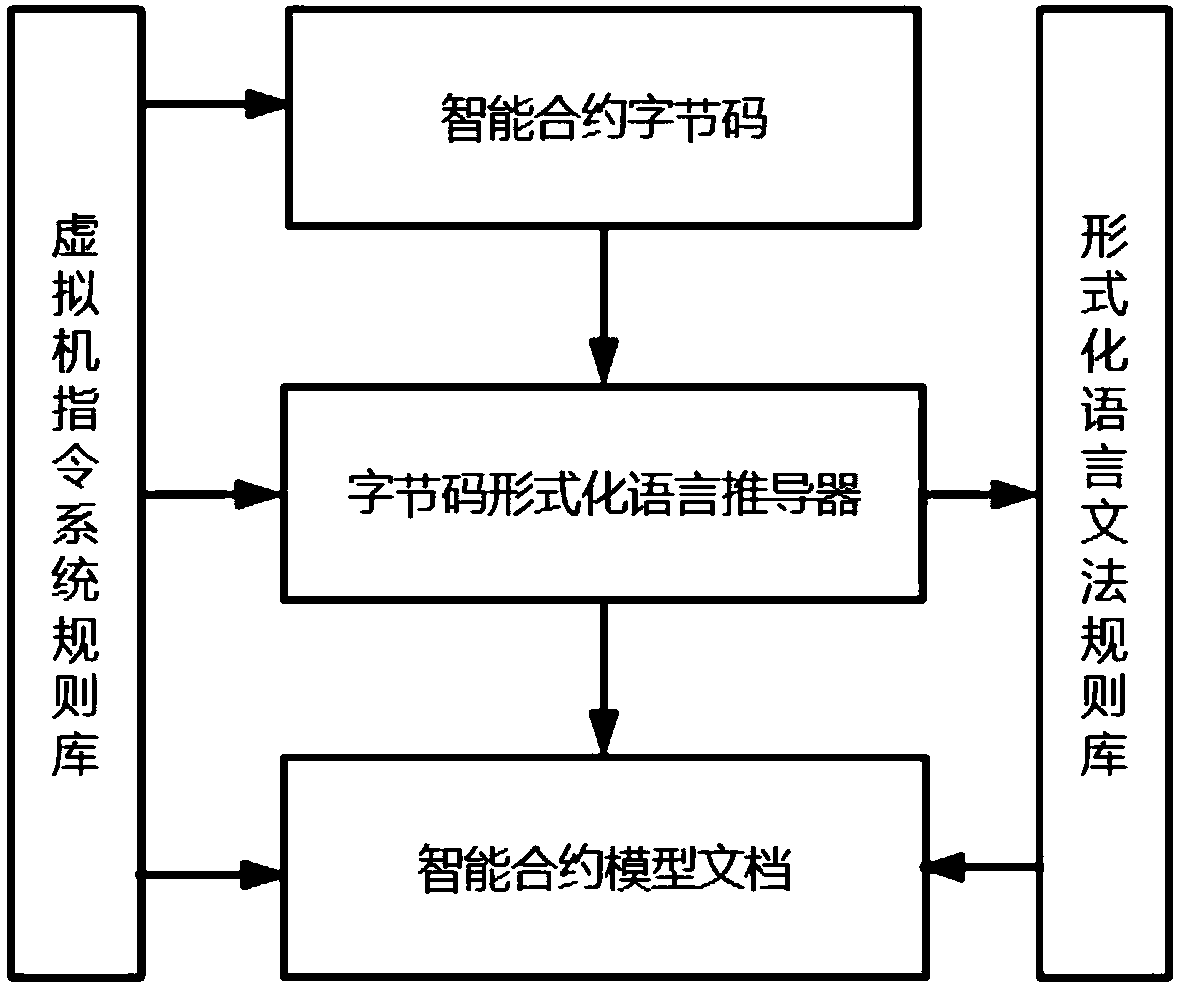

A highly automated intelligent contract formal verification system and method

ActiveCN108985073ASave time and costShorten the verification cycleFinancePlatform integrity maintainanceSpecification documentAutomaticity

The invention discloses a highly automated intelligent contract formal verification system and method. The method includes the following steps: step 001, converting an intelligent contract function requirement description document into an intelligent contract function requirement specification document described in a non-natural language, wherein the content of intelligent contract function requirement specification document includes target contract function specification description and security attribute description; step 002, creating a formal validation rule model library; step 003, automatically modeling the contract source code and / or bytecode by an automated modeling tool; step 004, parsing the abstract syntax tree generated in step 003, and allocating memory addresses for constantsand variables in the code; step 005, performing formal proof. The invention is adapted to program codes written in a plurality of high-level programming languages and also adapted to a plurality of formal languages, and simultaneously provides two automatic modeling modes of source code modeling and bytecode modeling, so that modeling can be carried out according to different modeling requirements of users, and the verification efficiency is further improved.

Owner:成都链安科技有限公司

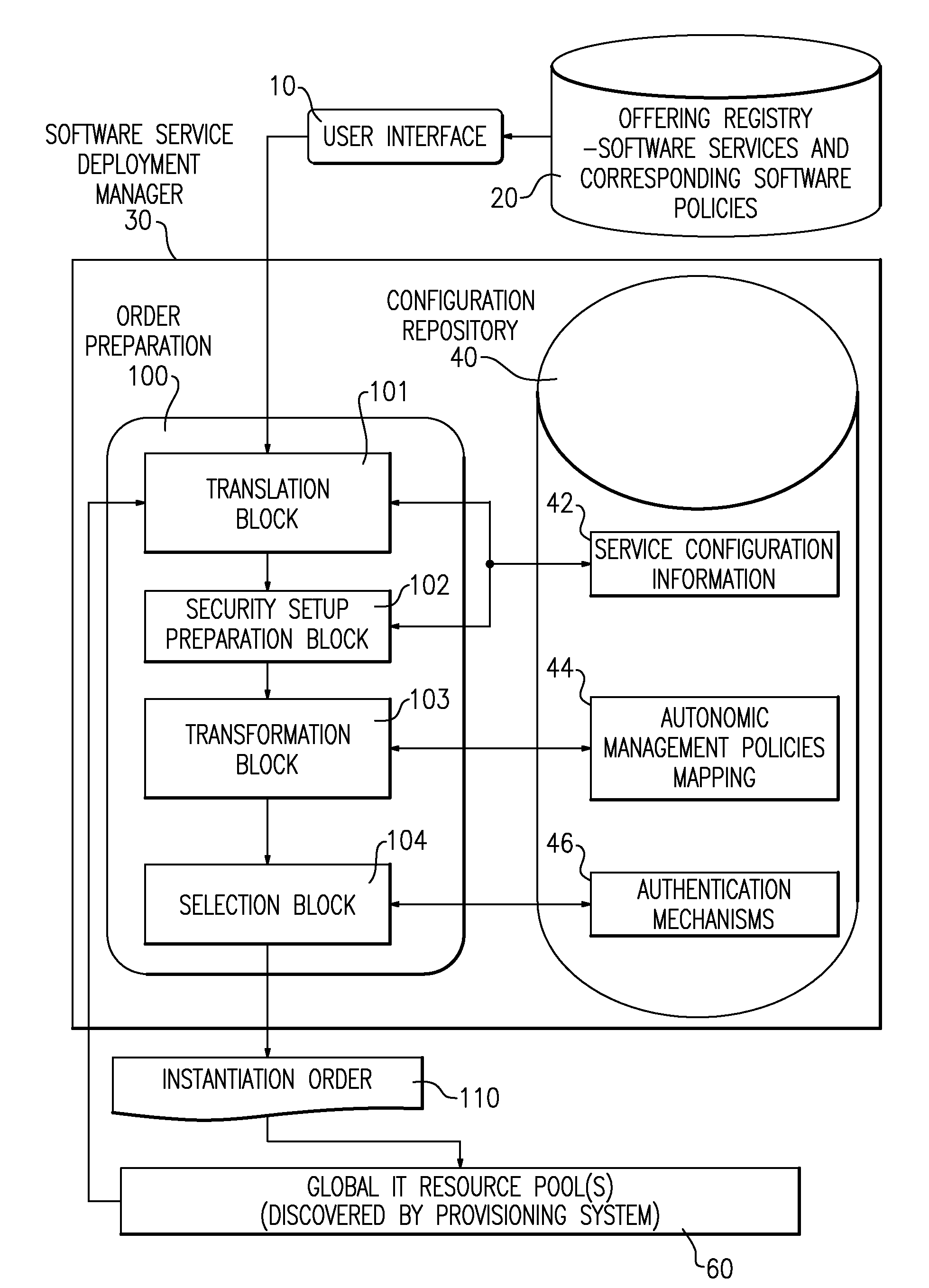

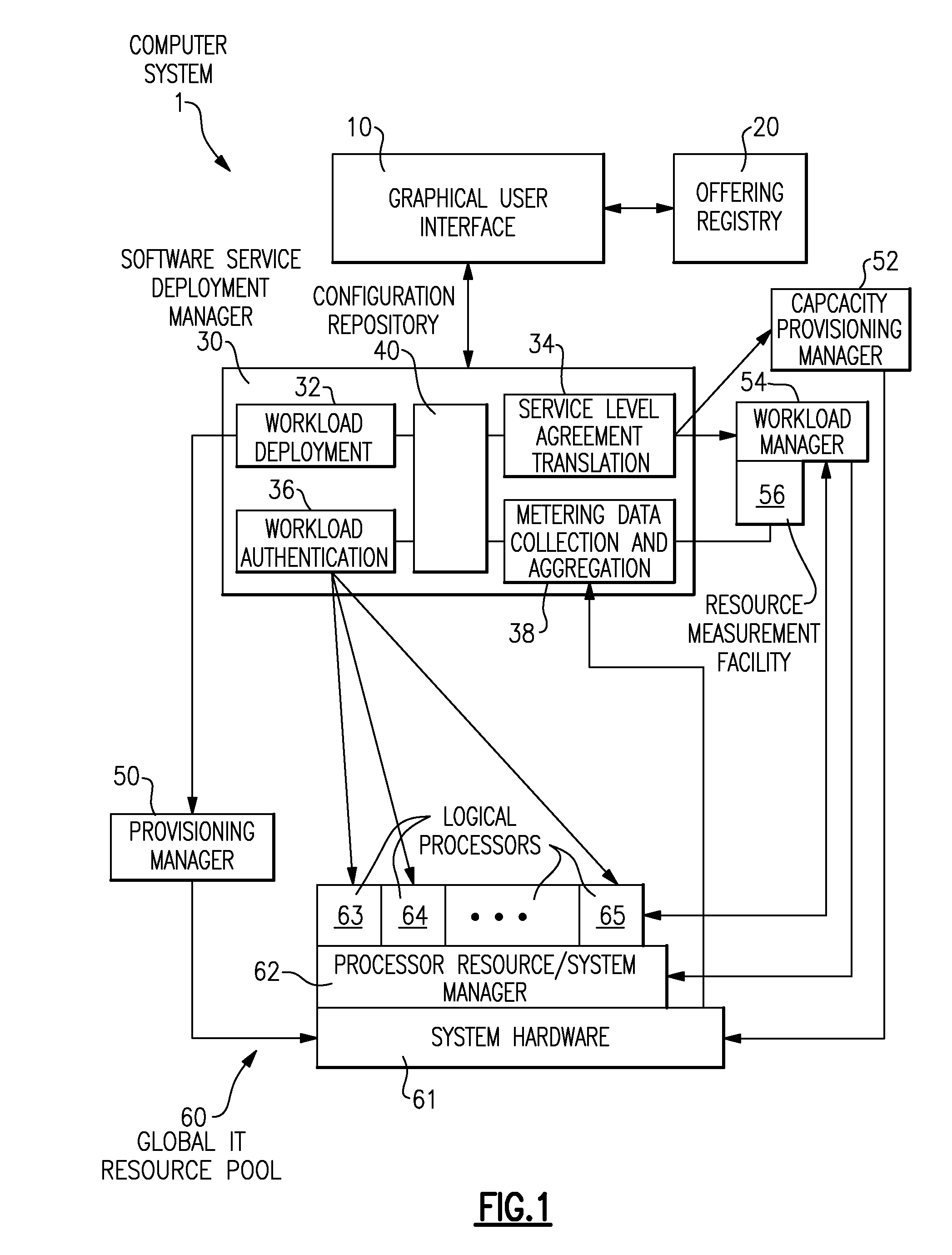

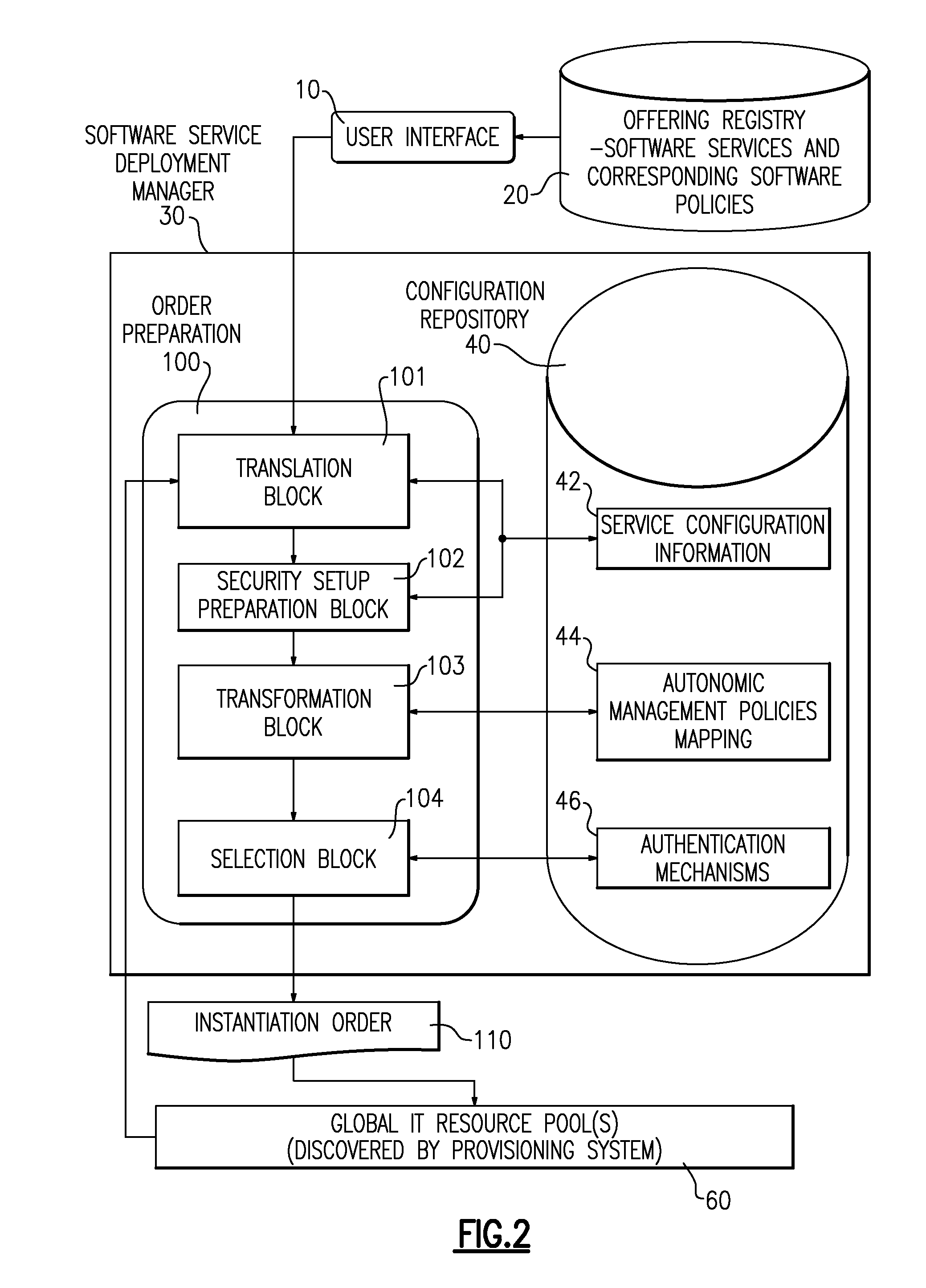

Method, Arrangement, Computer Program Product and Data Processing Program for Deploying a Software Service

ActiveUS20090307685A1Detail informationEasy to useProgram loading/initiatingMemory systemsComputerized systemSoftware as a service

Deploying a software service. A defined software service offering is selected from a plurality of defined software service offerings. An instantiation order for deploying the selected defined software service offering on a corresponding computer system is generated. Each defined software service offering comprises a software service definition and at least one defined software policy. One selected from the group consisting of the software service definition, the software policy, and a combination thereof, provides a hardware configuration for the software service, a software configuration for the software service, and a managing policy for the software service. The instantiation order of the software service for execution on the computer system is created based on the hardware configuration, the software configuration and the managing policy.

Owner:IBM CORP

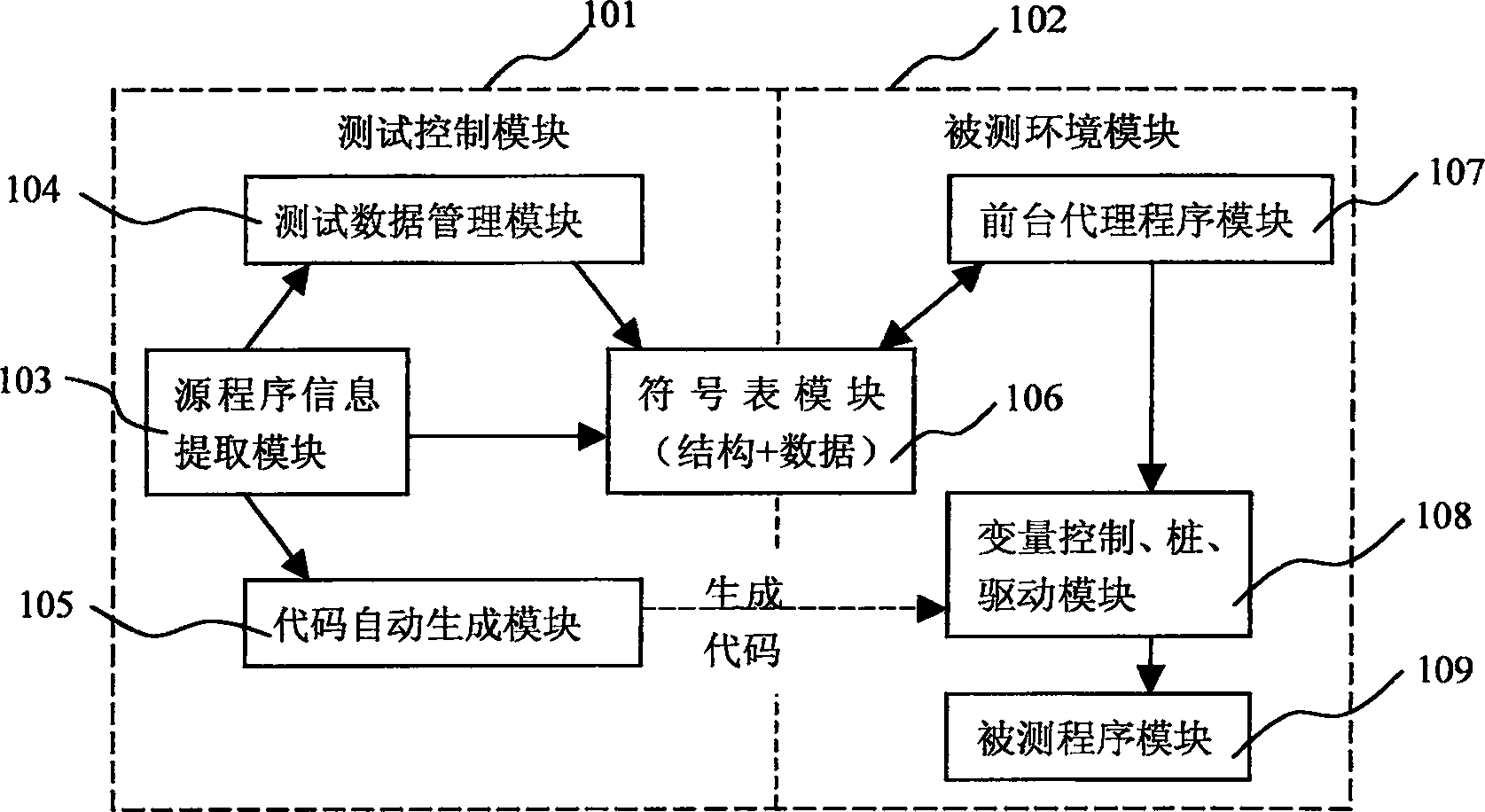

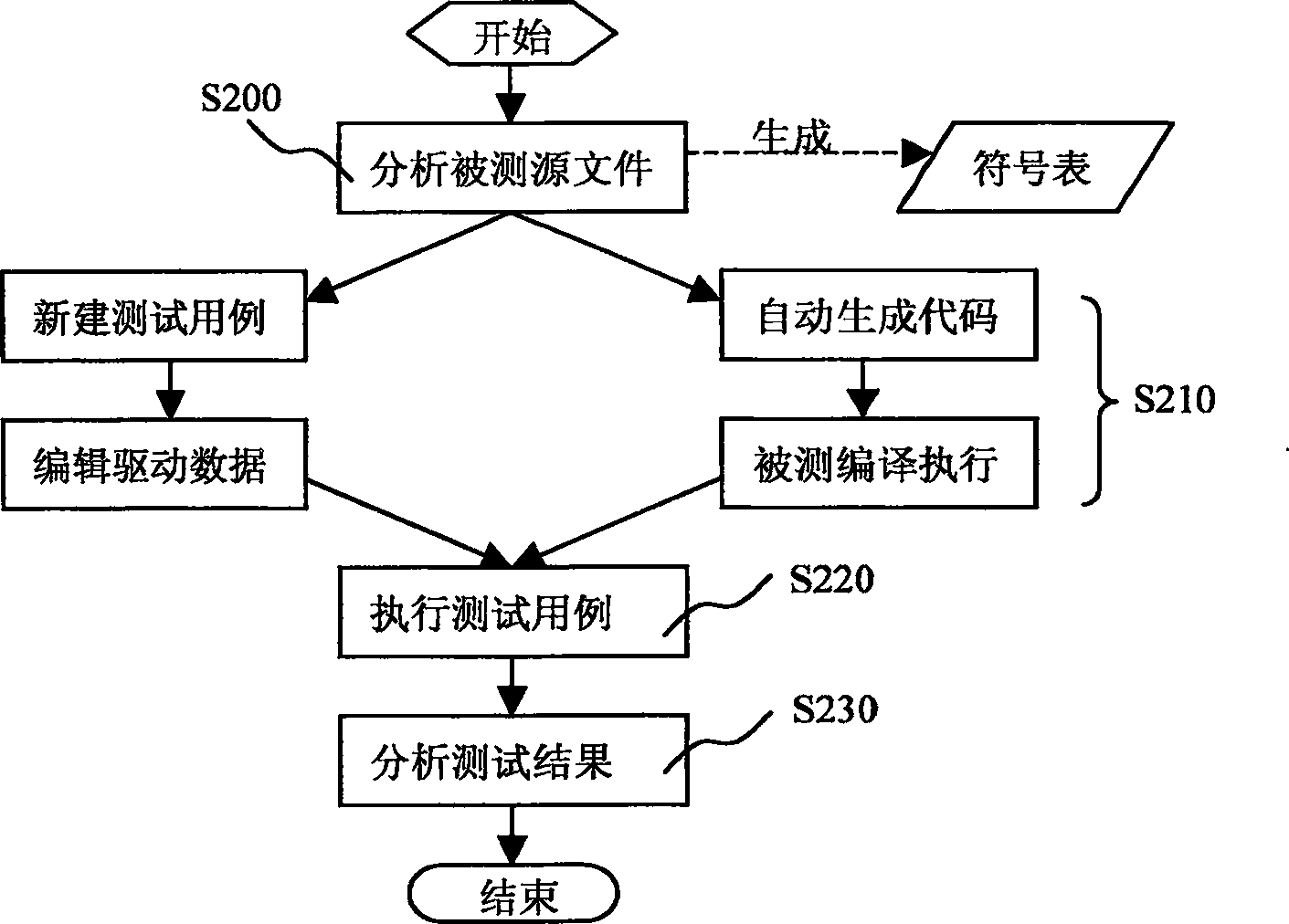

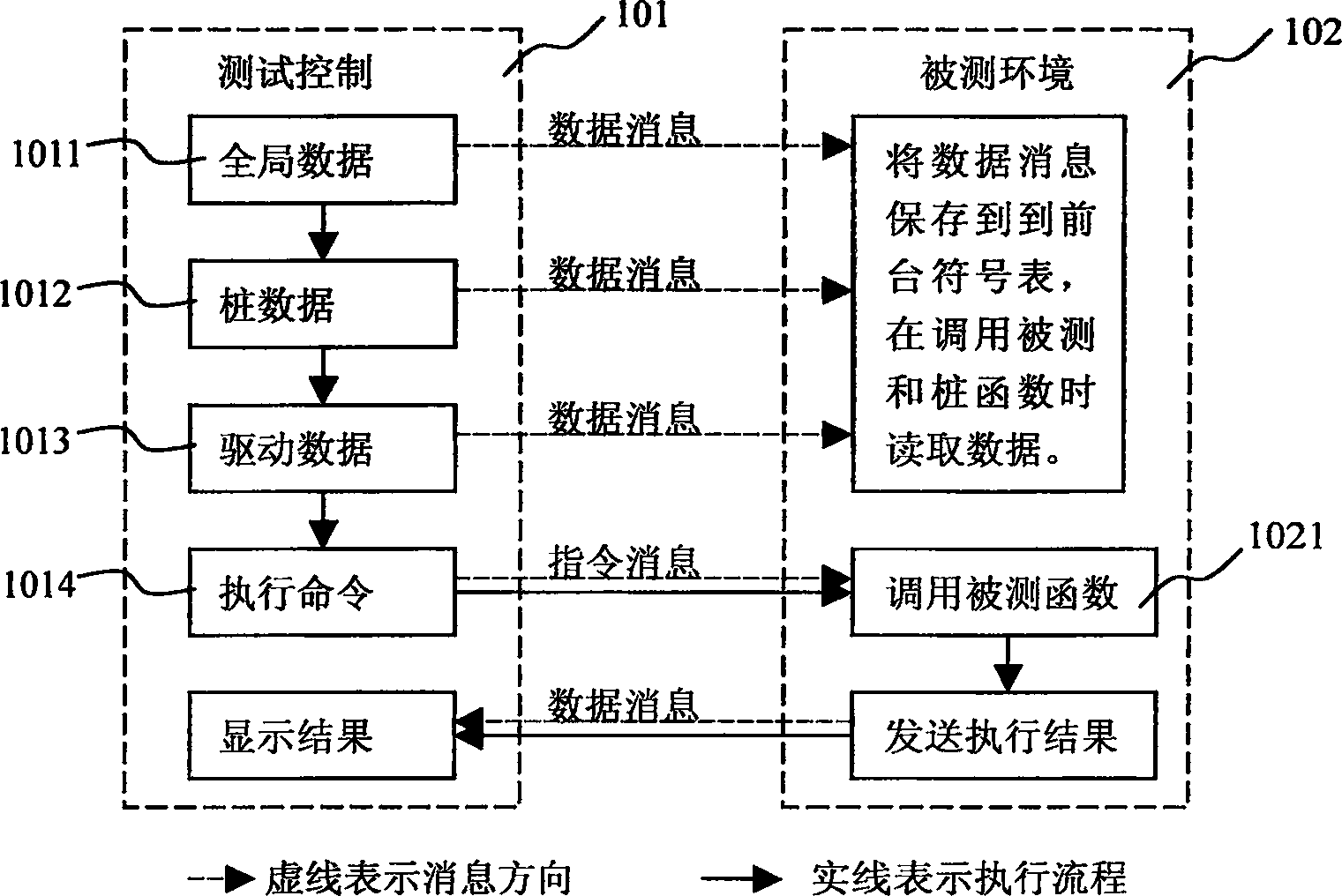

Unit test system and method for automatic generating stub and driving function

InactiveCN1873626AImprove efficiencyQuality improvementSoftware testing/debuggingTest efficiencyUnit testing

The invention discloses a software automatic test system and the method of automatically production variable control function, the pile function, the driving function. This method scans source program on test condition,and obtains this source program the information structure, and saves the information for XML document; as well as, based on the XML document information, automatically produce variable control function, the pile function, the driving function; the test control module controls the test program on test condition. The method can improve the software element testing efficiency.

Owner:BEIJING YUANXIN SCI & TECH

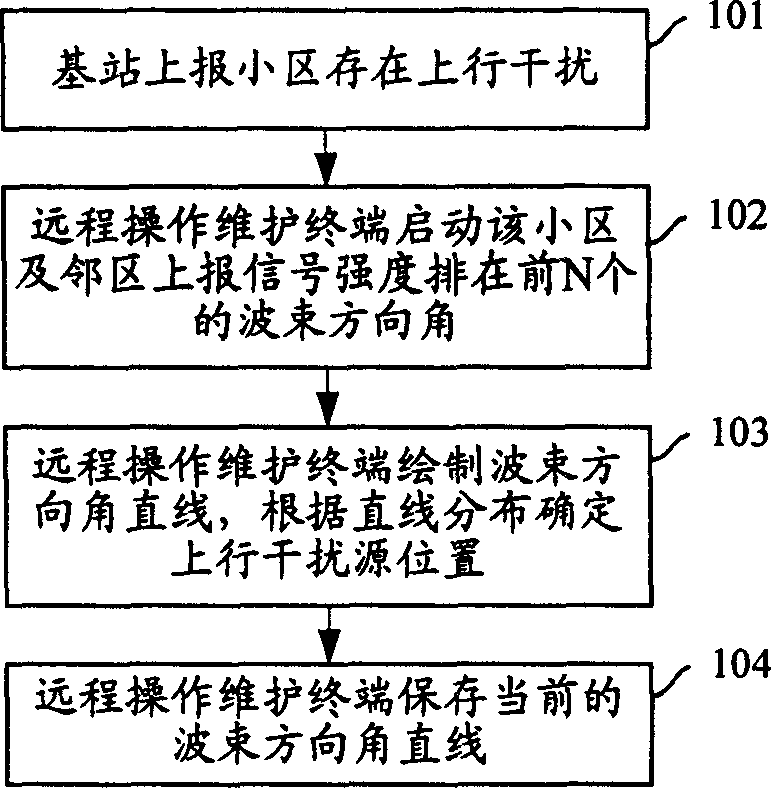

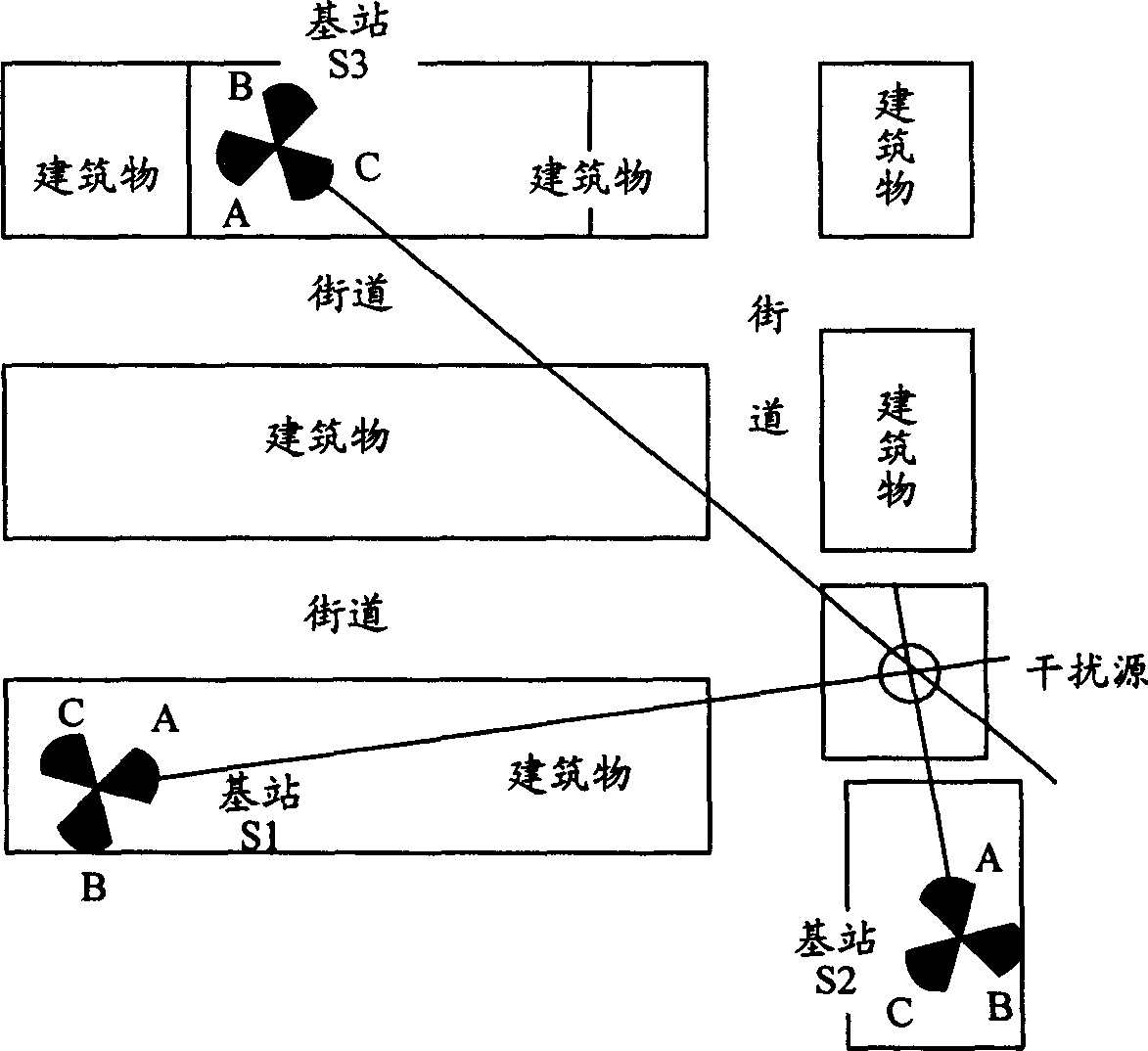

Method for locating interference source in up going route

ActiveCN1798414ALower skill requirementsReduce workloadDiversity/multi-antenna systemsRadio/inductive link selection arrangementsSmart antennaDirection angle

The method includes following steps: when the base station finds there is interference in a cell, and reports it to the remote operation maintaining terminal, the remote operation maintaining terminal locates the upstream interference source base on the direction angle of intelligent antenna beam reported by the cell and its neighboring cells.

Owner:张家港信工企业管理咨询有限公司

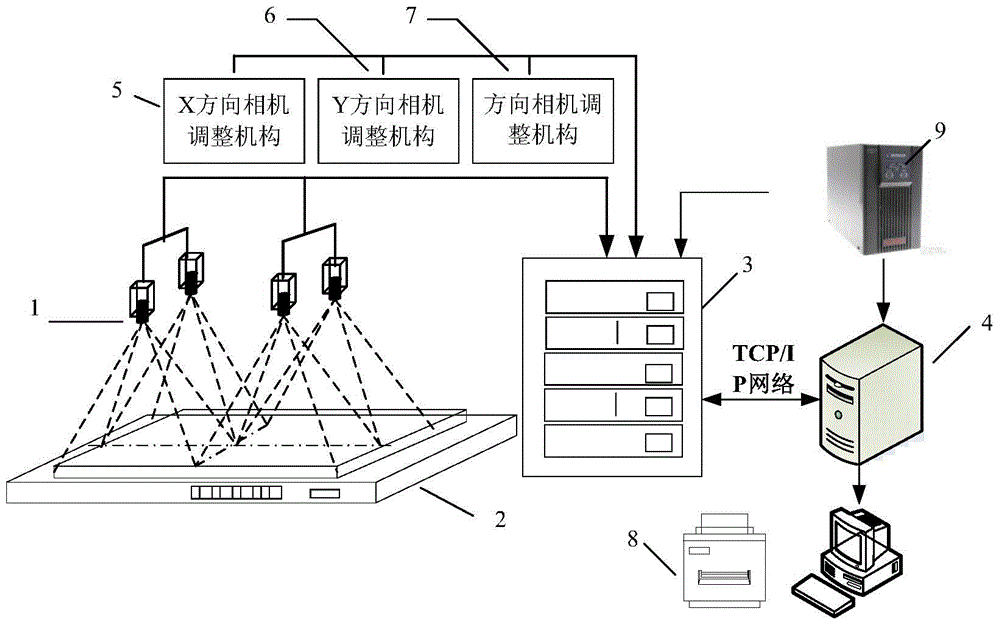

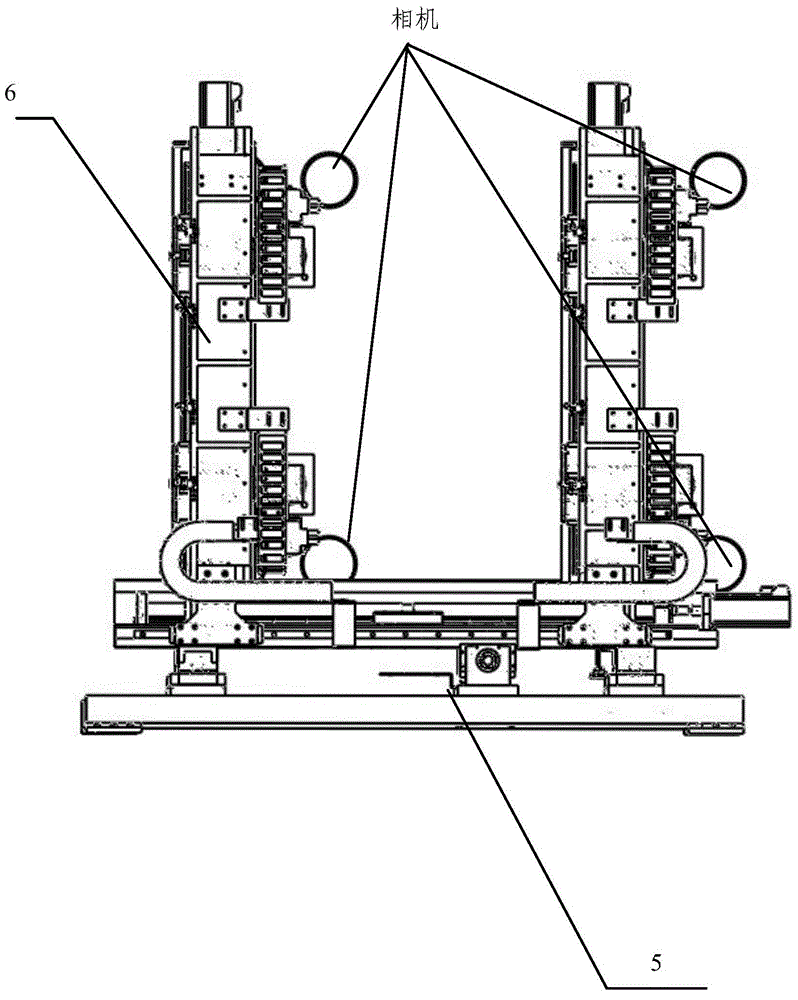

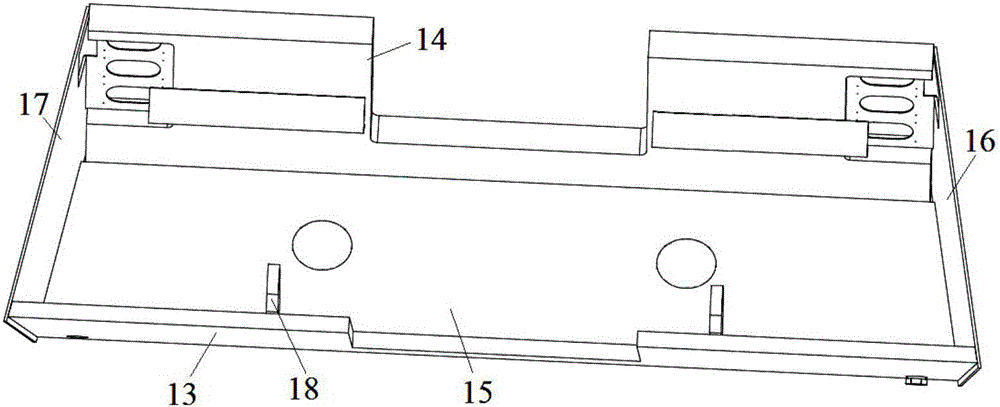

Liquid crystal display detection system

InactiveCN104614878AImprove imaging clarityImproving Imaging AccuracyOptically investigating flaws/contaminationNon-linear opticsImaging processingLiquid-crystal display

The invention relates to a liquid crystal display detection system which comprises an image collecting device, a light-on jig operating table, an image processing device and a management end server. The image collecting device comprises four cameras, and the four cameras cooperate for collecting images, are used for collecting image information of different areas of a liquid crystal display to be detected and send the collected image information to the image processing device. According to the detection system, the four cameras cooperate for collecting the image information of different areas of the liquid crystal display to be detected, the number of collected pixels of the unit area of the liquid crystal display to be detected is guaranteed, and imaging definition and quality detection accuracy of the liquid crystal display to be detected are improved.

Owner:BEIJING C&W ELECTRONICS GRP

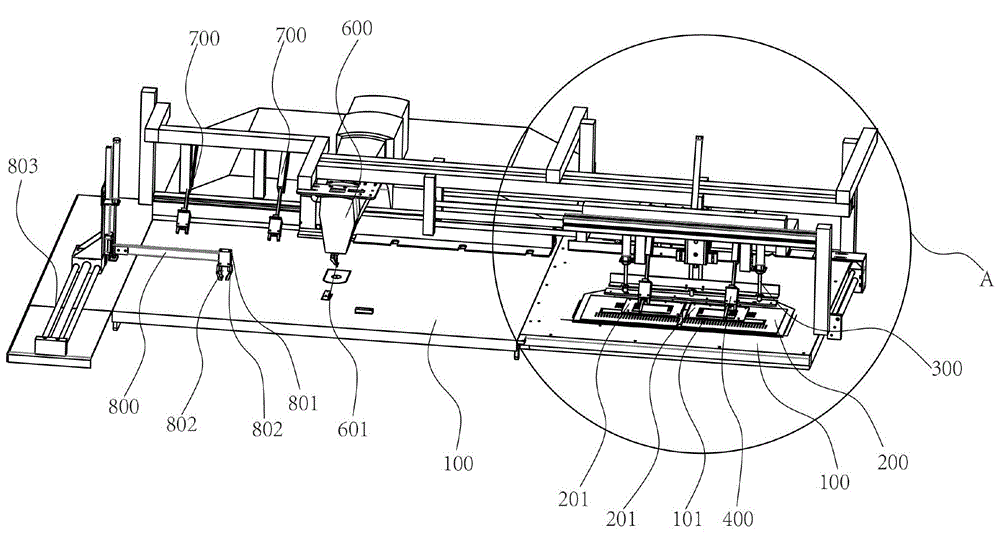

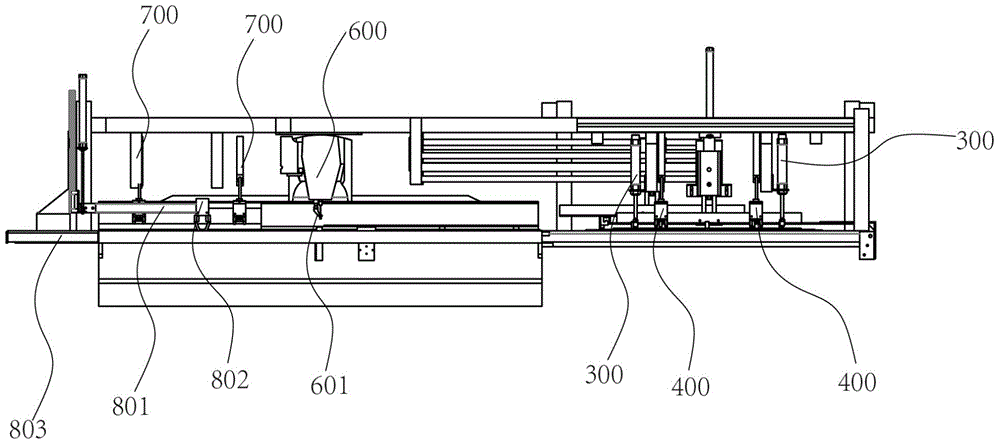

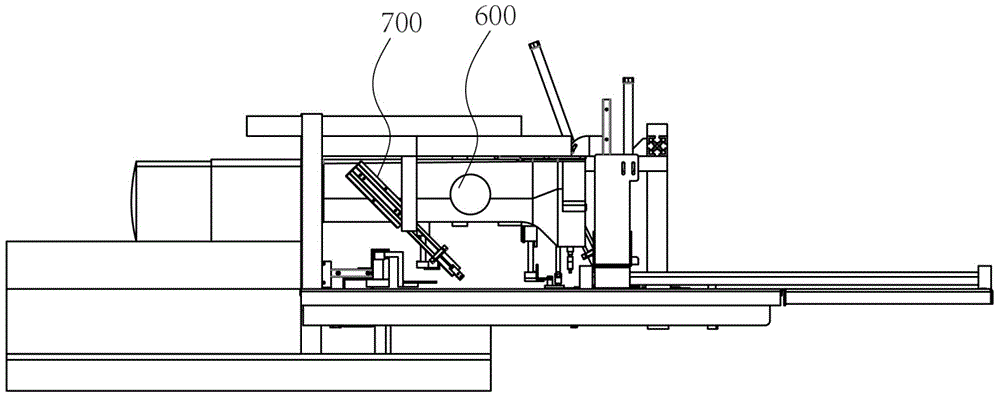

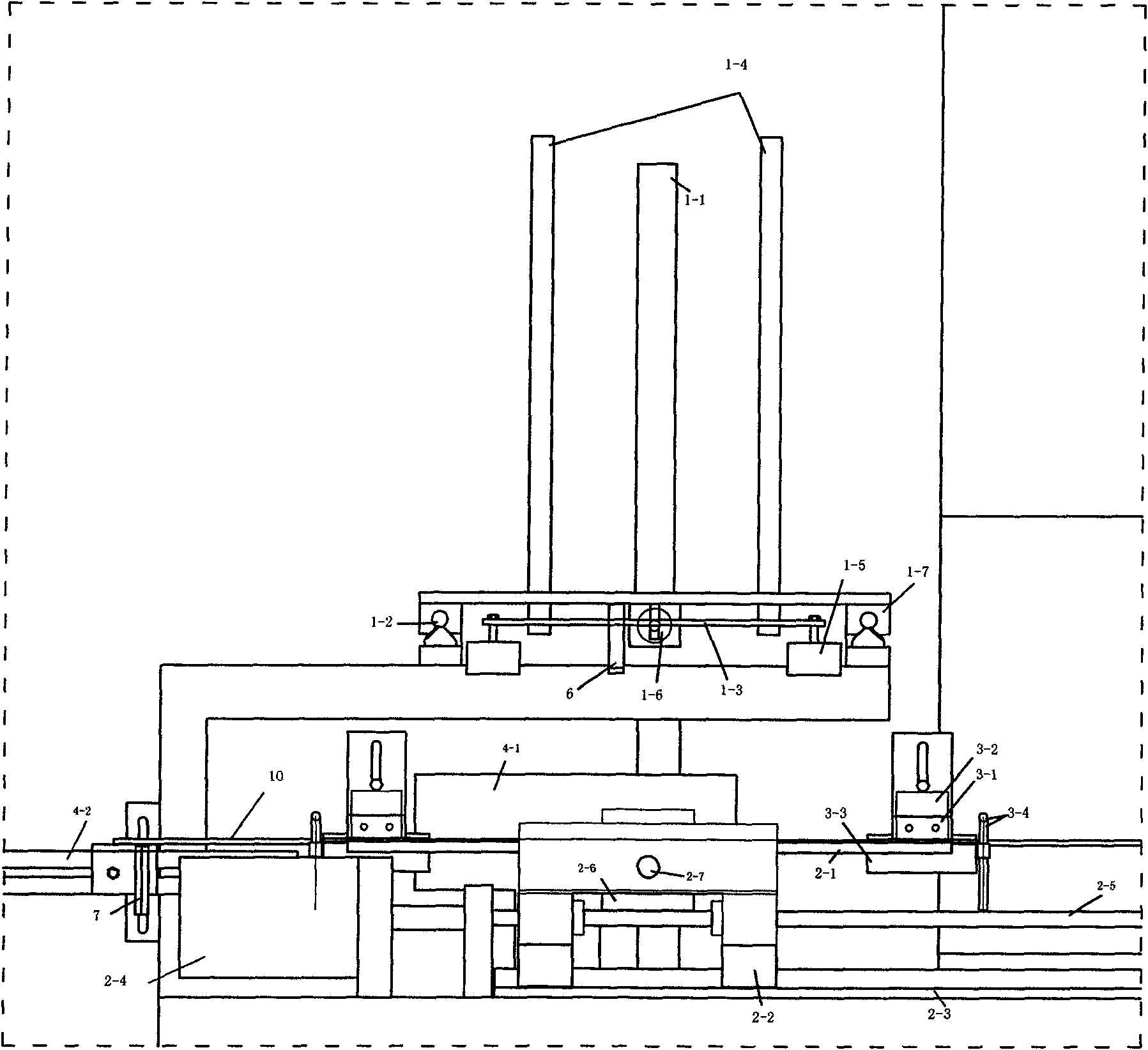

Automatic seam abutting device for cutting pieces and seam abutting method of automatic seam abutting device

ActiveCN104593956AGuaranteed continuous operationLower skill requirementsWork-feeding meansPressersEngineeringMechanical engineering

The invention discloses an automatic seam abutting device for cutting pieces and a seam abutting method of the automatic seam abutting device. The automatic seam abutting device comprises a machine table, a control device, an air sucking device, a stamper device, a positioning device, a feeding device and a sewing device, wherein the air sucking device is provided with a plurality of air sucking holes, and the air sucking holes are formed in a table surface of the machine table; the stamper device is provided with at least one pressing arm and a stamper driving device for driving the pressing arm to move; the positioning device is provided with at least one positioning arm and a positioning driving device for driving the positioning arm to move; the air sucking device, the stamper device, the positioning device, the feeding device and the sewing device are connected to the machine table, and the air sucking device, the stamper driving device, the positioning driving device, the feeding device and the sewing device are electrically connected to the control device. The automatic seam abutting device for the cutting pieces involved by the invention is suitable for the seam abutting technology of most collars, the requirements for the skills of workers are greatly lowered, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

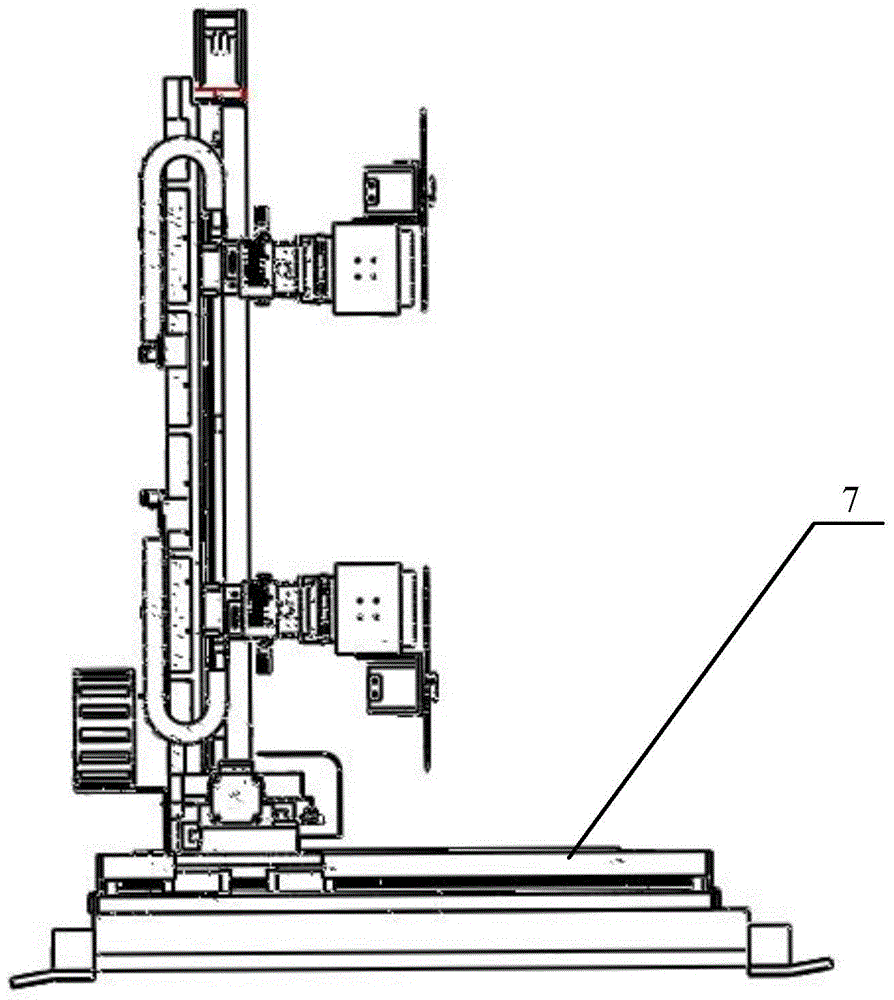

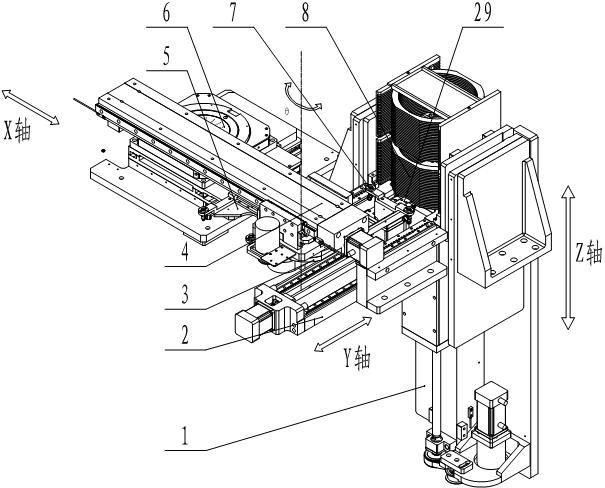

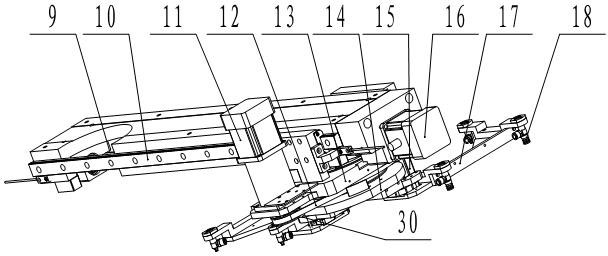

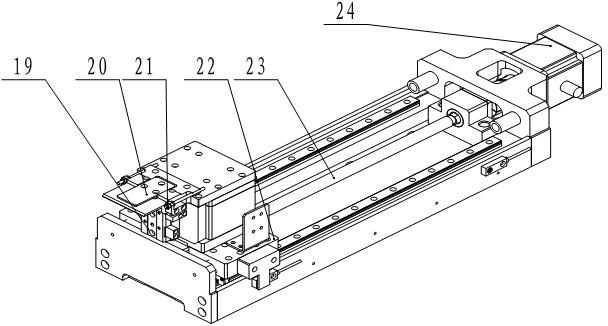

Full-automatic charging-discharging mechanism used for LED (Light Emitting Diode) laser cutting

InactiveCN102350593ALower skill requirementsImprove utilization efficiencyLaser beam welding apparatusInstabilityEngineering

The invention relates to a full-automatic charging-discharging mechanism used for LED (Light Emitting Diode) laser cutting, and the mechanism comprises an X-shaft conveying unit, a Y-shaft conveying unit and a Z-shaft conveying unit, wherein an X-shaft sliding plate of the X-shaft conveying unit is arranged in an X-shaft linear sliding rail; a screw driving pair is composed of the X-shaft sliding plate and an X-shaft ball screw; the X-shaft ball screw is in driving connection with an X-shaft motor; a rotating shaft is mounted on the X-shaft sliding plate; a first sucker and a second sucker are arranged on the rotating shaft; a Y-shaft sliding plate of the Y-shaft conveying unit is arranged in a Y-shaft linear sliding rail; a screw driving pair is composed of the Y-shaft sliding plate and a Y-shaft ball screw; the Y-shaft ball screw is in driving connection with a Y-shaft motor; a clamping mechanism is mounted on the Y-shaft sliding plate; a Z-shaft sliding plate of the Z-shaft conveying unit is arranged in a Z-shaft linear sliding rail; a screw driving pair is composed of the Z-shaft sliding plate and a Z-shaft ball screw; and the Z-shaft ball screw is in driving connection with a Z-shaft motor. The full-automatic charging-discharging mechanism can be applied to the LED laser cutting to realize the full-automatic charging-discharging and solve the problems of low efficiency of traditional LED wafer cutting and instability of manual operation.

Owner:SUZHOU DELPHI LASER

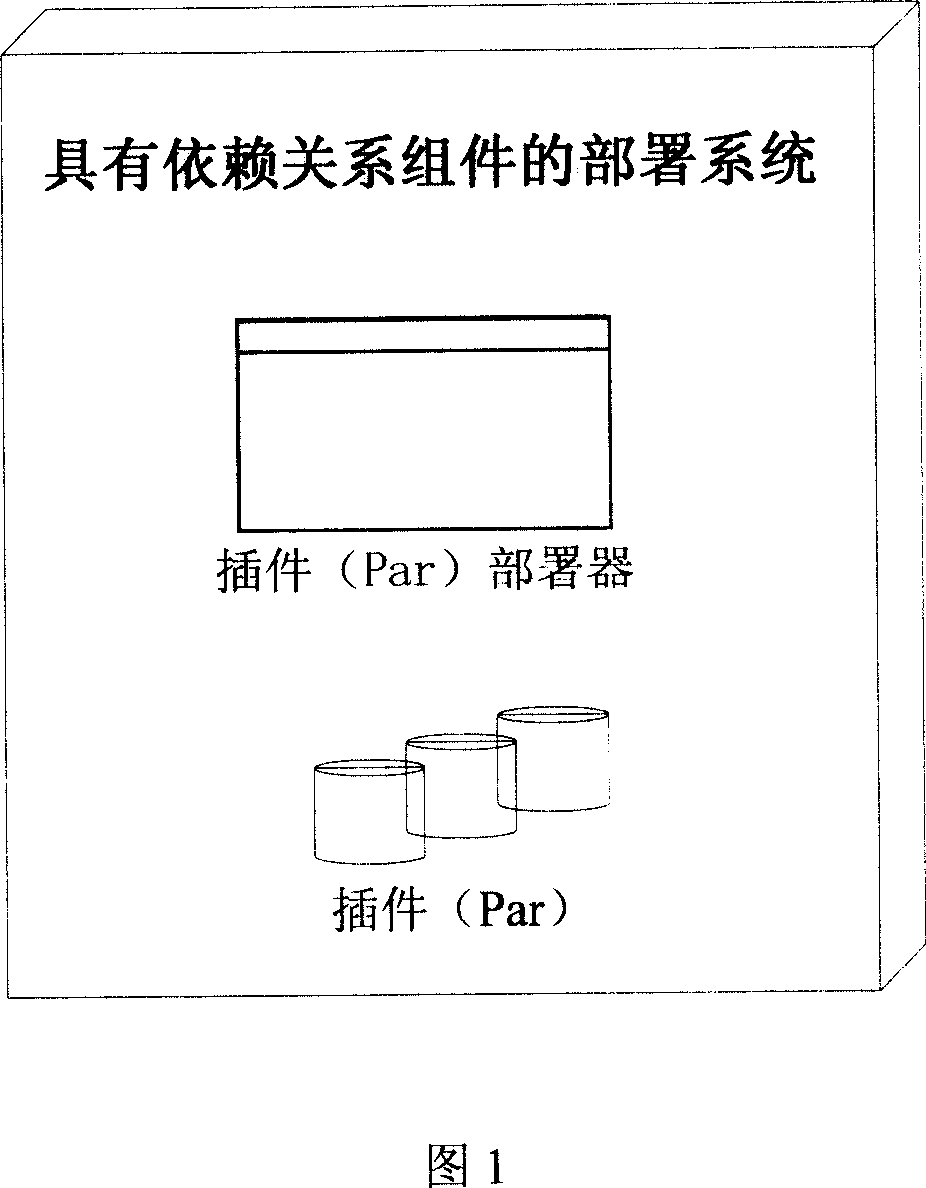

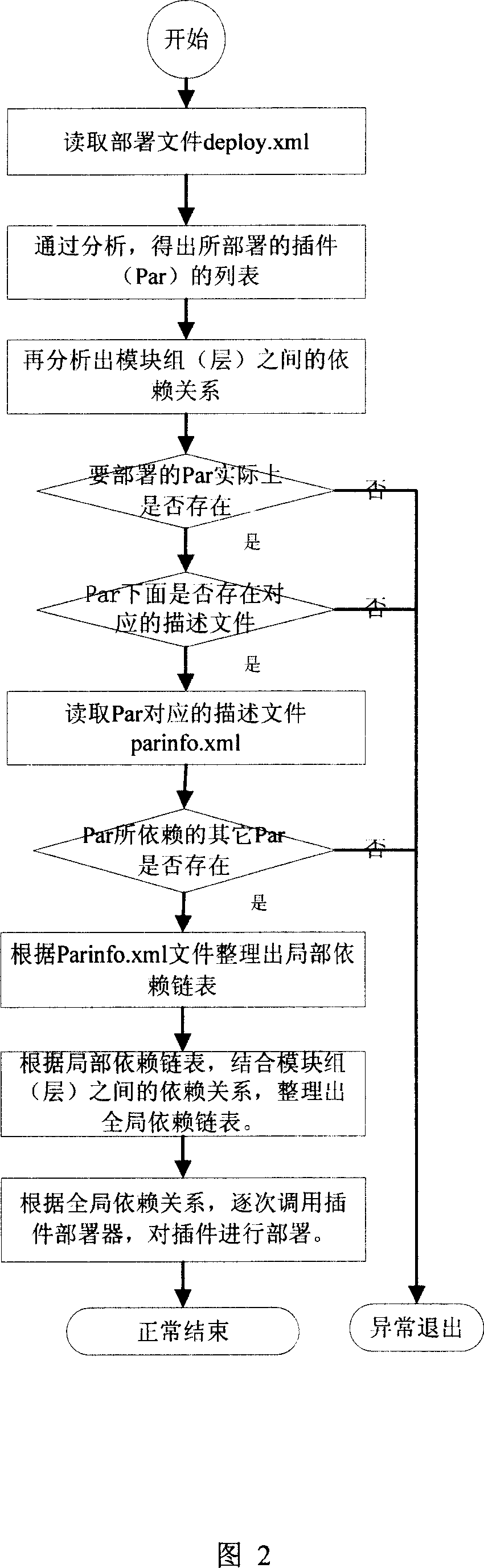

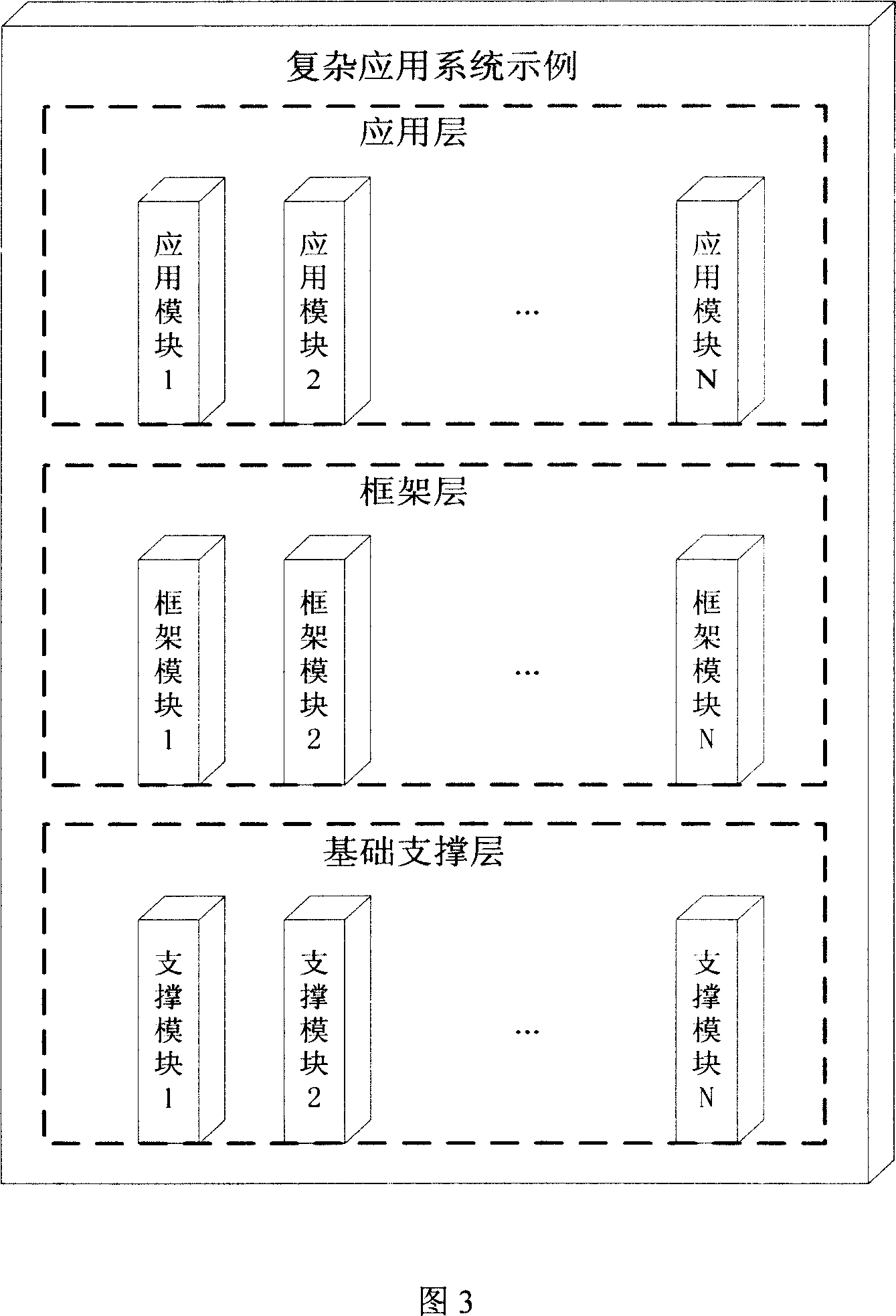

Arranging system and method for module having dependence

InactiveCN1945530ASimple and clear formatStay cohesiveSpecific program execution arrangementsMaintainabilityGranularity

The invention provides the deployment systems and methods which have dependent relation modules to solve the problems, such as unnecessary steps, thin packaging granularity, unrealizable modularization, and bad maintainability. The invention includes plug and plug deployment. The plug is used to encapsulate document concourse of complex application. The plug deployment designates the deployment range and deploy plug. The invention realizes modular deployment and greatly improves the maintainability of the system through plug mechanism.

Owner:ZTE CORP

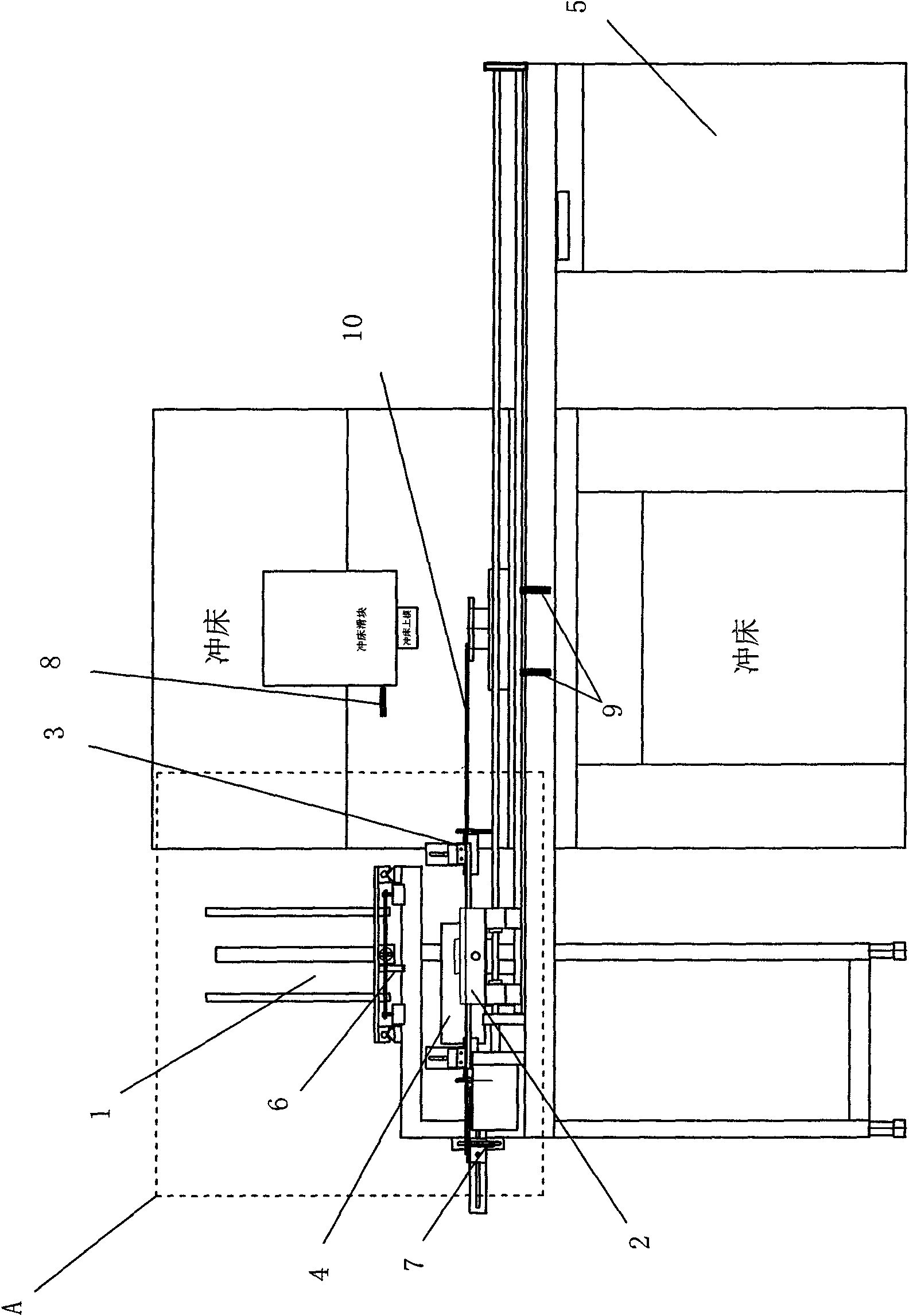

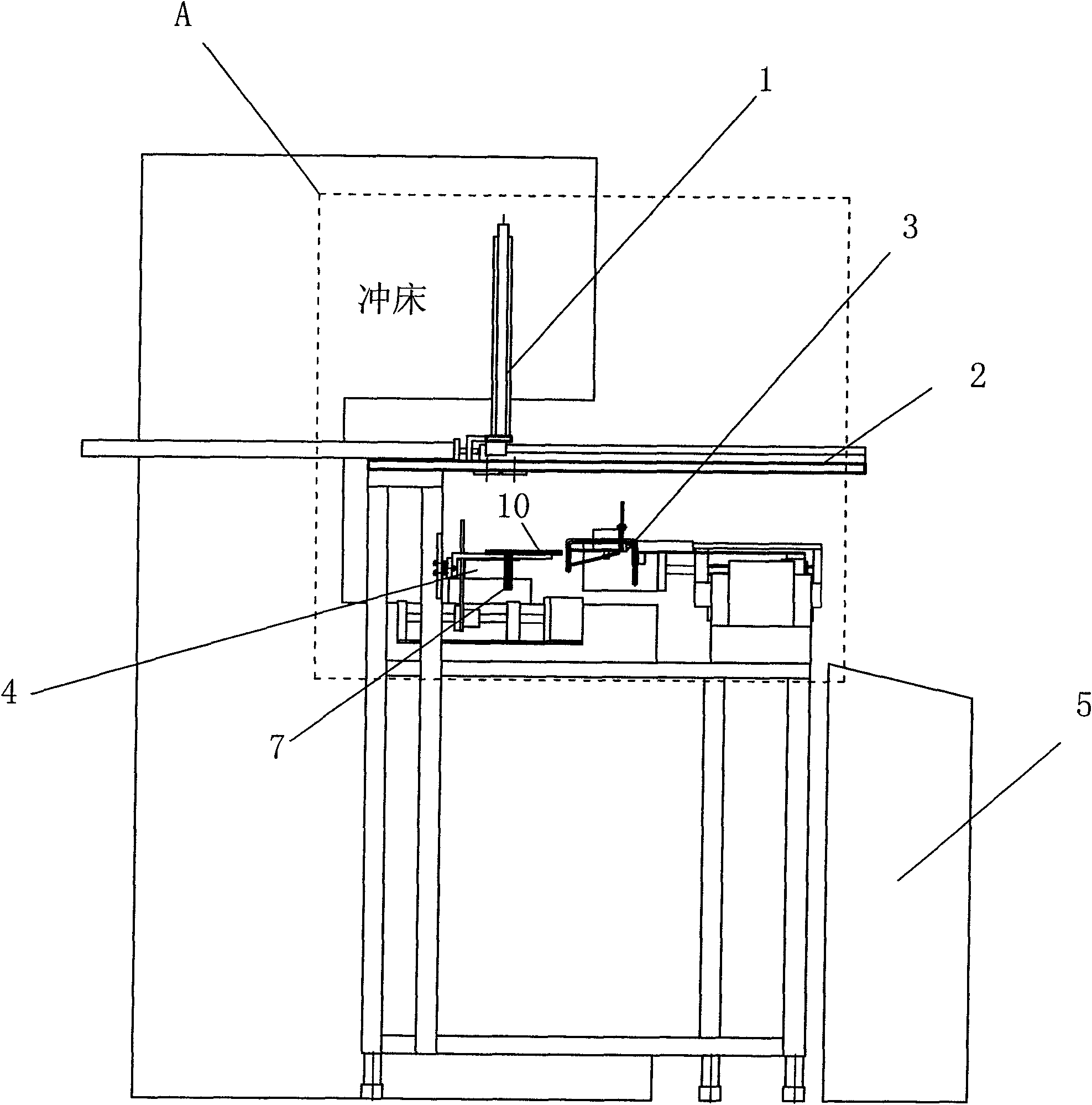

Automatic material loading, feeding and unloading equipment for bar stock blanking and method thereof

InactiveCN102180366AIncrease profitEasy to switchArticle feedersArticle separationPunch pressMulti machine

The invention discloses automatic material loading, feeding and unloading equipment for bar stock blanking and a method thereof. The equipment comprises a material loading mechanism, a feeding mechanism and an electric cabinet, wherein the feeding mechanism is provided with a mechanical arm, and the mechanical arm is connected with a manipulator. The equipment has the following beneficial effects: 1, the equipment can replace workers in the whole process to realize full-automatic operation of material loading, feeding and unloading, thus the purpose that one worker operates multiple machines can be realized; 2, varieties are convenient to switch; 3, in the feeding process, the manipulator has a function of automatically avoiding a punch die so as to realize multi-row reciprocating operation, especially automatic punching operation of narrow bar stock relatively to the die width; 4, although the structure is installed in front of the punch die, the structure barely affects workers to assemble, disassemble and adjust a die in front of a punch; 5, the shutdown rate of the punch is improved; 6, the equipment has the advantages of simple mechanical structure and low cost and is convenient to maintain; and 7, after material is automatically fed, the bar stock can be subjected to multiple-particle blanking because feeding position is accurate.

Owner:吴丽威

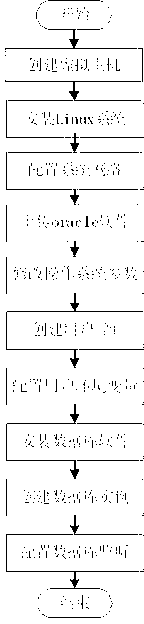

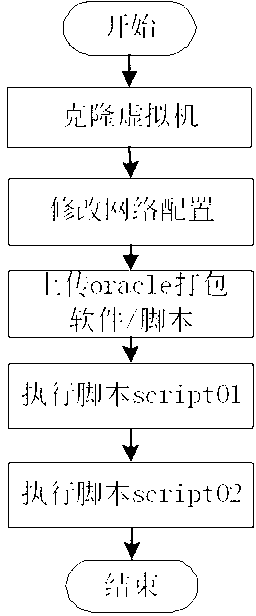

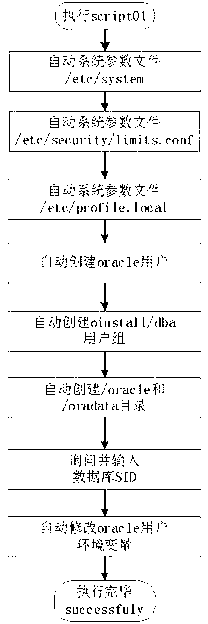

Linux-based rapid deployment method for Oracle database in cloud computing

InactiveCN103235725AAvoid mistakesLower skill requirementsSpecific program execution arrangementsSpecial data processing applicationsOracle databaseVirtual hosting

The invention provides a Linux-based rapid deployment method for an Oracle database in cloud computing. The rapid deployment method comprises the steps of 1.1), firstly, installing oracle database software on a Linux host in a conventional mode, and then packing the software into a compressed file oracle.tar by using a tar compression command; 1.2), using a shell programming language for writing an executable script01 and an executable script02, wherein the script01 completes all setting work before installation of the oracle database, and the script02 completes establishing work of a database example; 1.3), cloning a virtual host which only contains a Linux operating system through a cloning function of a cloud platform, and distributing and modifying an operating system network card internet protocol (IP); 1.4), uploading an oracle installation package and executable scripts to a host on which the database is needed to be installed; 1.5), executing the script01 to finish all setting work before installation of the oracle database, wherein the setting work comprises modification of operating system parameters, establishment of user groups and users, setting of environment variables and establishment of installation directories and example storage directories; and 1.6), executing the script02 to enter an interactive interface, setting characteristics of the oracle database example according to prompts, finishing the oracle database example and monitoring establishment work.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

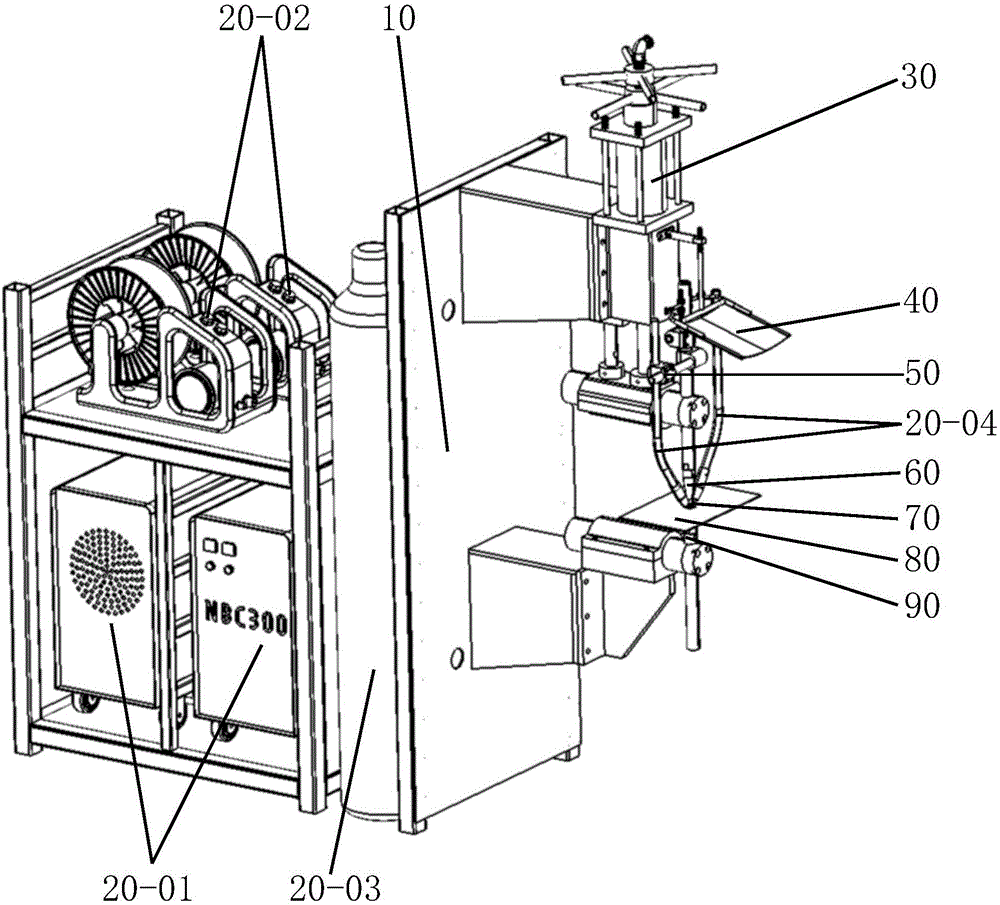

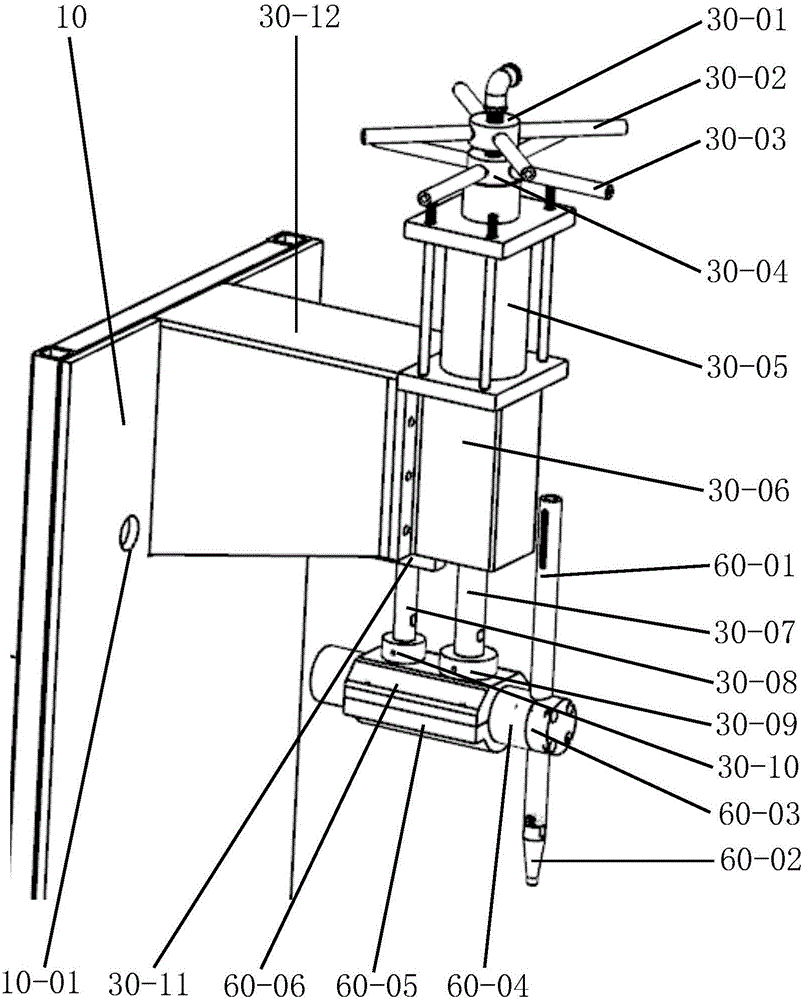

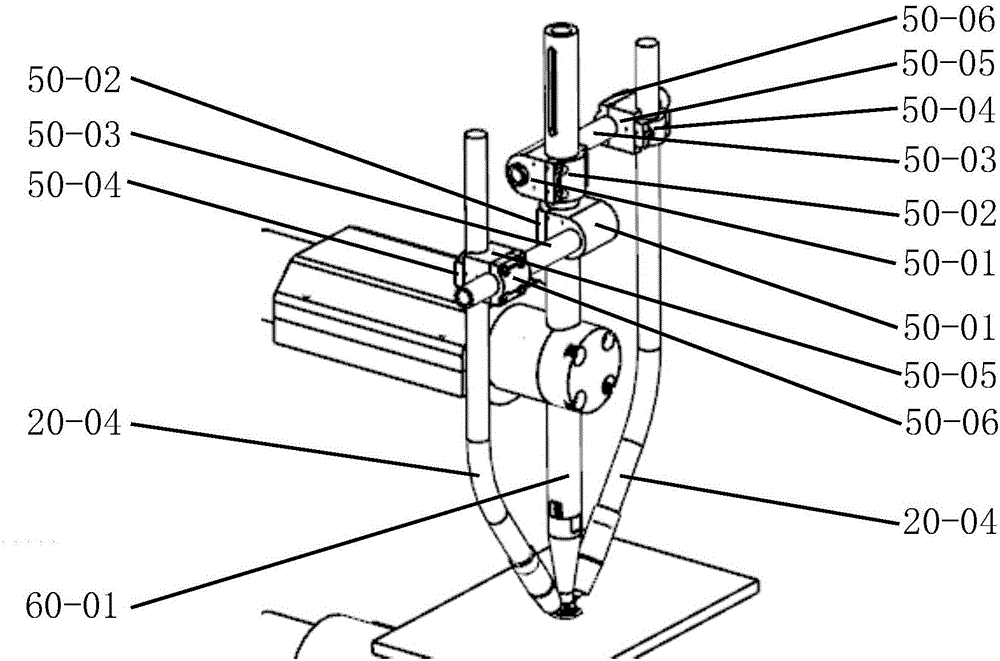

Welding method and equipment for multifunctional threaded fastener

ActiveCN105880895AImprove welding efficiencyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStud welding

The invention discloses a welding method and equipment for a multifunctional threaded fastener. The welding method comprises MAG welding, TIG welding, MIG welding, stud welding and MIG brazing. The threaded fastener and a workpiece are positioned by a positioning mechanism of the equipment, a welding gun is clamped by a clamping mechanism, a pressing force is transmitted to a pressing mechanism by a power component, the threaded fastener and the workpiece are pressed by the pressing mechanism, the welding gun is driven to move downwards at the same time, and the threaded fastener and the workpiece are welded by a welding mechanism. Compared with existing arc welding equipment for welding the threaded fastener, the method and the equipment have the advantages that the efficiency is improved by 2 to 4 times; moreover, the problems of poor stability of conventional resistance projection welding of the threaded fastener, incapability in welding medium- and high-carbon steel, alloy steel, dissimilar metals and dissimilar materials, incapability of welding on the sidewall of a U-shaped sheet metal part, various hollow and solid pipe fittings and thick plates, incapability of abreast welding of the threaded fastener and the workpiece and the like are solved. In addition, the invention further provides MIG-brazed and flame-brazed fastener and a workpiece used for welding a threaded fastener and positioned by a light beam.

Owner:何强

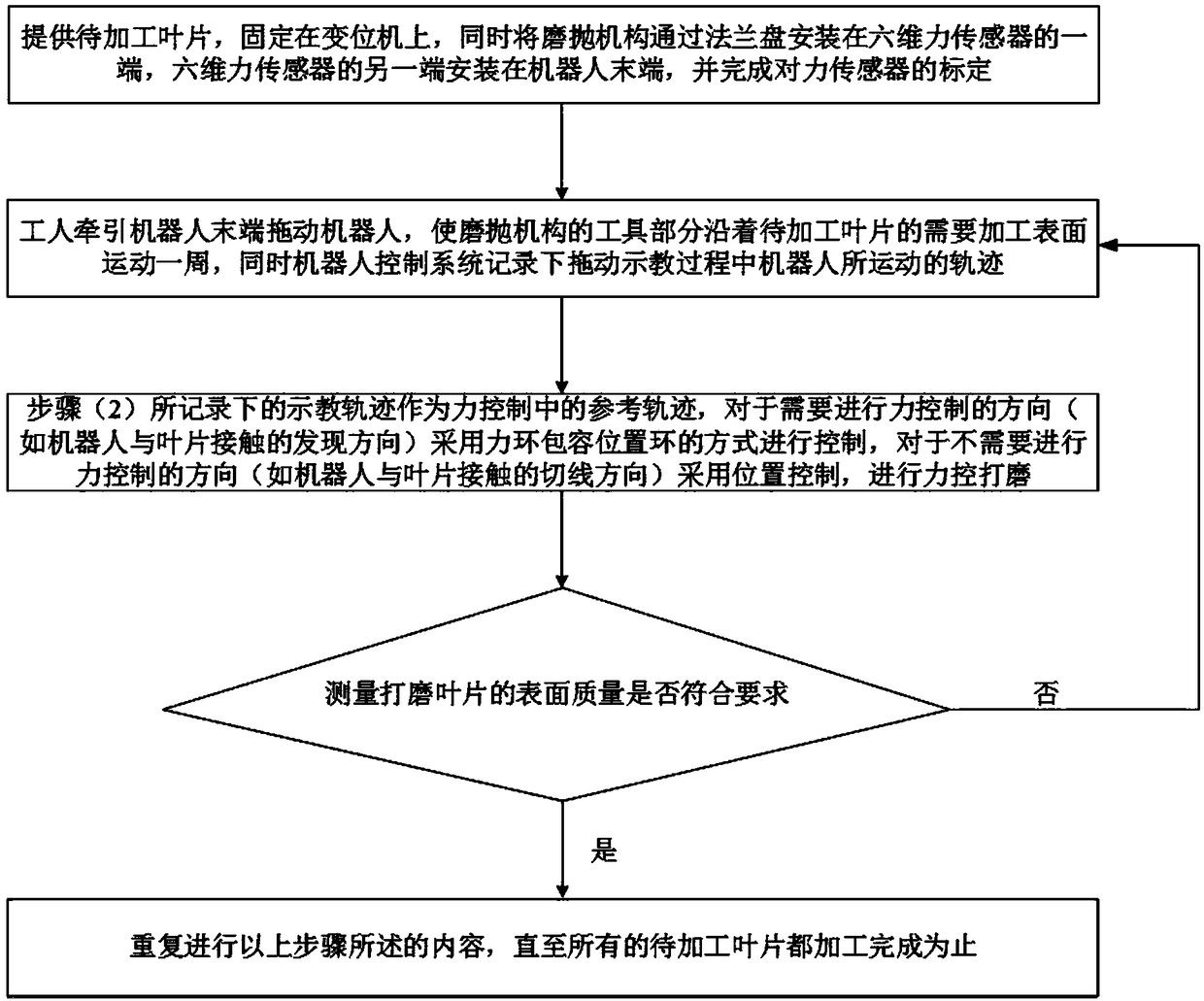

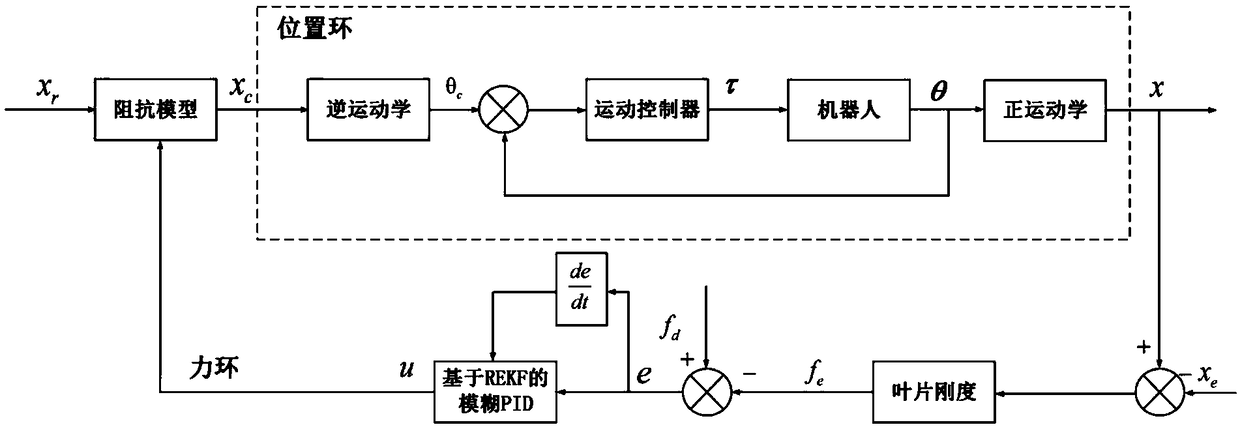

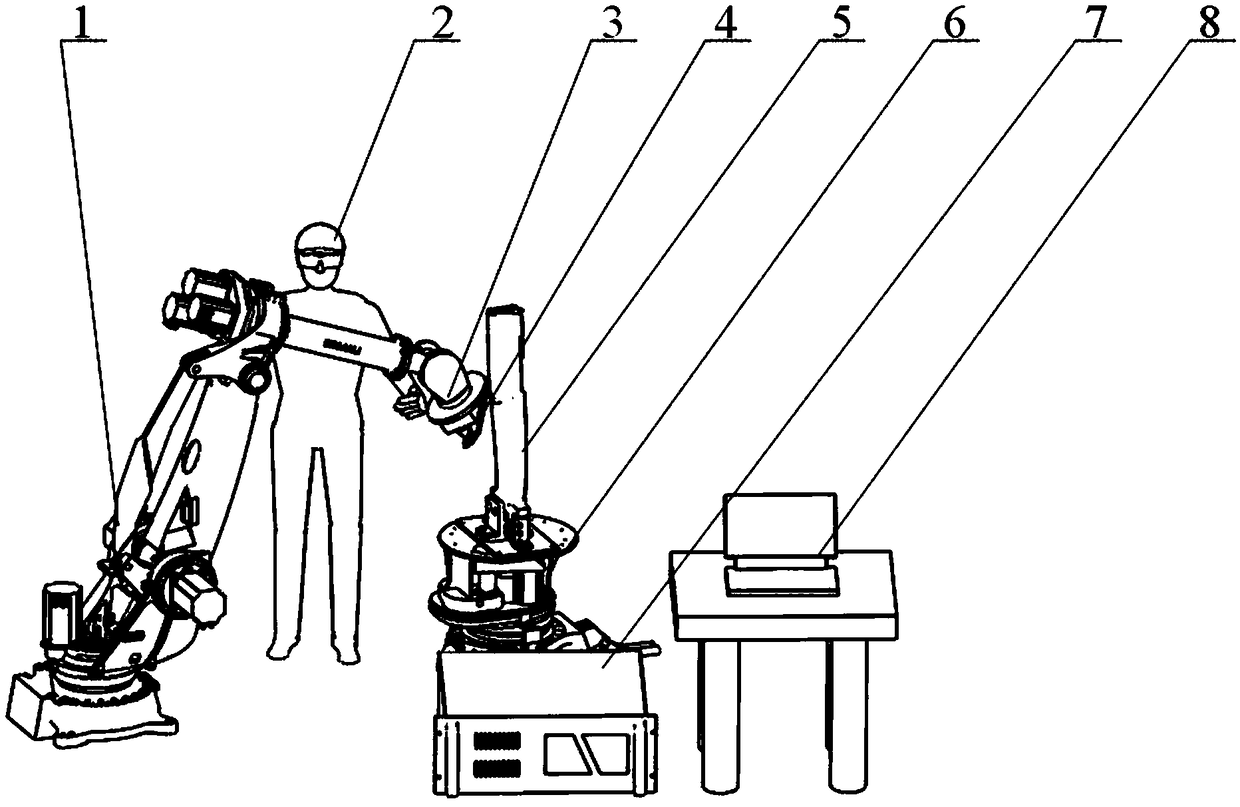

Device and method for force controlling polishing blade through dragging teaching robot

ActiveCN109434843AHigh degree of integrationImprove automationProgramme-controlled manipulatorControl systemContact force

The invention belongs to the related technical field of intelligent machining, and discloses a device and a method for force controlling polishing a blade through dragging a teaching robot. The devicecomprises the robot, a six-dimensional force sensor, a polishing mechanism, a position changing machine, and a robot control system; the six-dimensional force sensor is connected with a tail end executor of the robot and the polishing mechanism; the position changing machine is used for bearing the to-be-machined blade; the robot, the six-dimensional force sensor and the polishing mechanism are connected to the robot control system; the six-dimensional force sensor is used for measuring the contact force between the blade and the polishing mechanism in the blade polishing process, and transmitting the detected data to the robot control system; the robot control system is further used for receiving the tail end position information data of the robot, processing the received data to obtainthe corresponding control quantity, and then controlling the robot to drive the polishing mechanism to carry out corresponding motion. According to the device and the method, the skill requirement foran operator is reduced, and the machining consistency and the machining precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

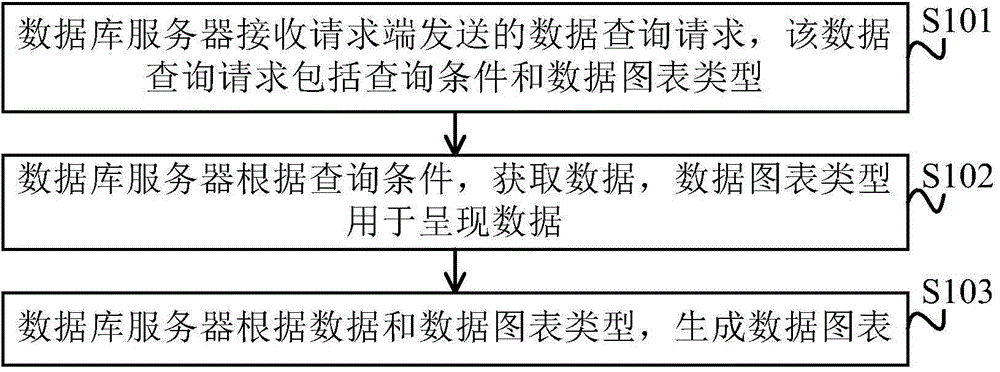

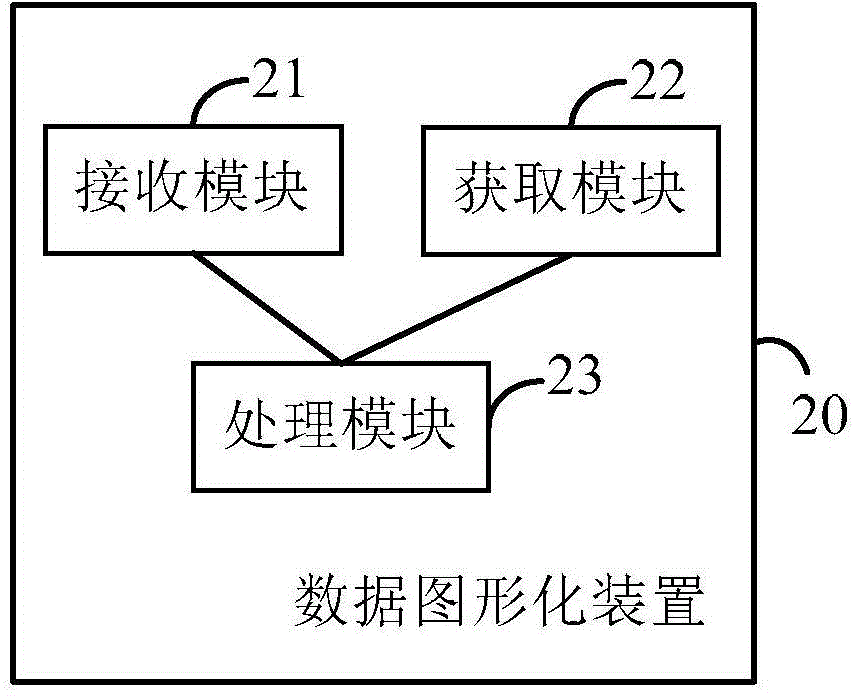

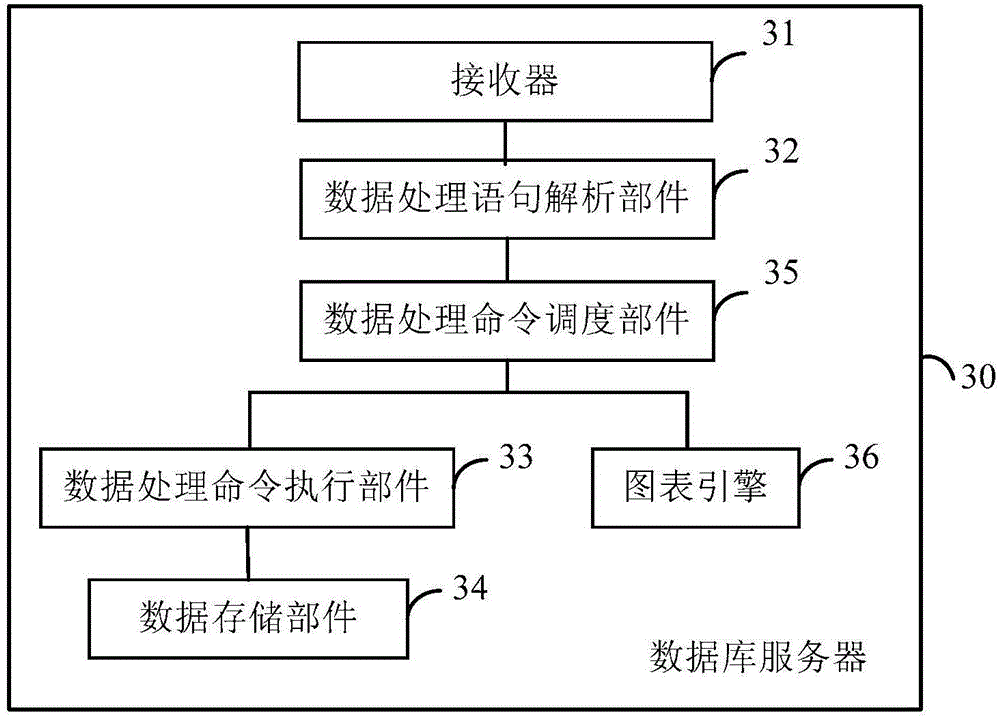

Data imaging method, data imaging device and database server

InactiveCN104484353ALower skill requirementsImprove resource utilizationWeb data indexingSpecial data processing applicationsGraphicsResource utilization

An embodiment of the invention provides a data imaging method, a data imaging device and a database server. The method includes the steps: receiving a data query request comprising a query condition and a data chart type transmitted by a request end by the database server; acquiring data according to the query condition, and using the data chart type for presenting the data; generating a data chart according to the data and the data chart type. The data query request carries the query condition and the data chart type, the data chart is generated in the database server without frequently researching and developing software in different frameworks, resource utilization rate is increased, skill requirements of operators are low, in addition, development processes of applications related to an image and a statement are simplified, and the development efficiency of the applications is improved.

Owner:HUAWEI TECH CO LTD

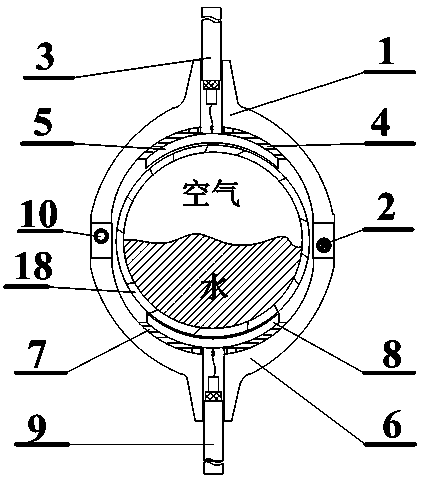

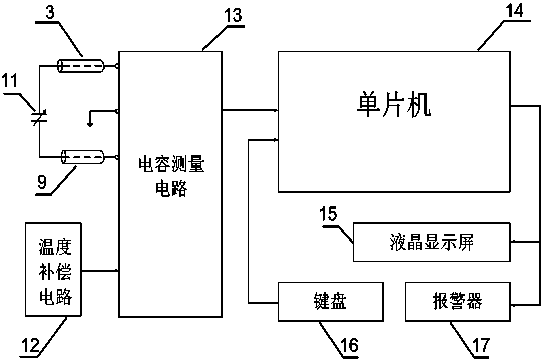

Pipe network blocking detecting device

The invention belongs to the technical field of detection and provides a pipe network blocking detecting device. The pipe network blocking detecting device is characterized in that as an external detecting device used for the pipeline blocking, the detecting device has functions of blocking fault alarming and blocking fault point positioning. A clamping device of a sensor is convenient to detach and mount and composed of an upper clamping handle, a rotary shaft, an upper cable, an upper soft rubber gasket, an upper arc iron plate, a lower clamping handle, a lower soft rubber gasket, a low arc iron plate, a lower cable and a releasable fastener. The pipe network blocking detecting device has the advantages that the clamping device is simple and durable, common running of the pipe network is unaffected during detection of the device, and detection runs smoothly without influence from complicated pipe network. The pipe network blocking detecting device is suitable to blocking identifying and positioning of the industrial feed piping, the urban feed piping and the like and is rapid to respond the fault, easy to mount and operate, high in detecting accuracy and like.

Owner:TAIYUAN UNIV OF TECH

Virtual machine reliability testing method and virtual machine reliability testing device

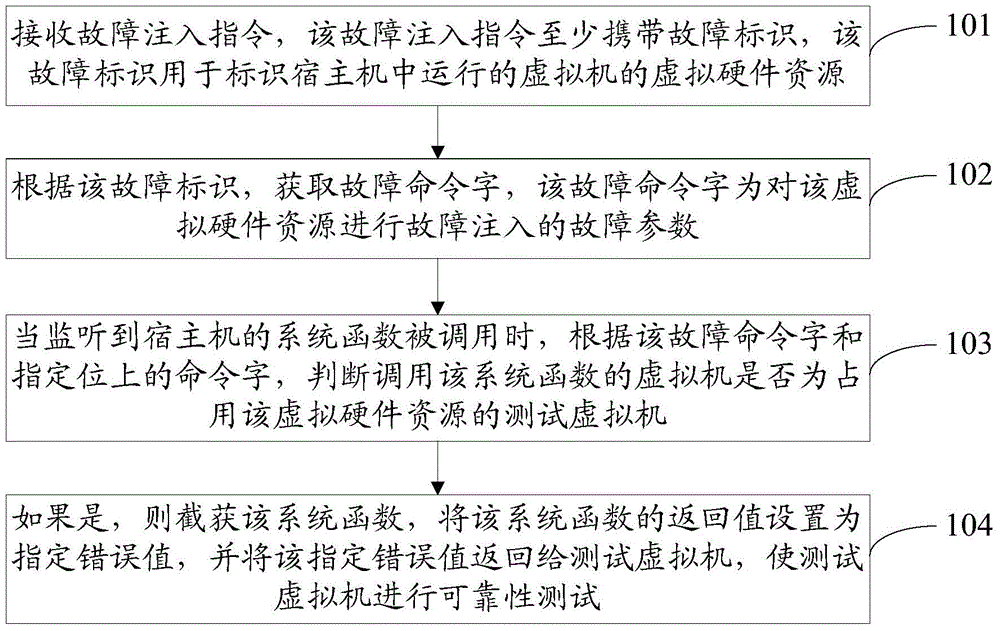

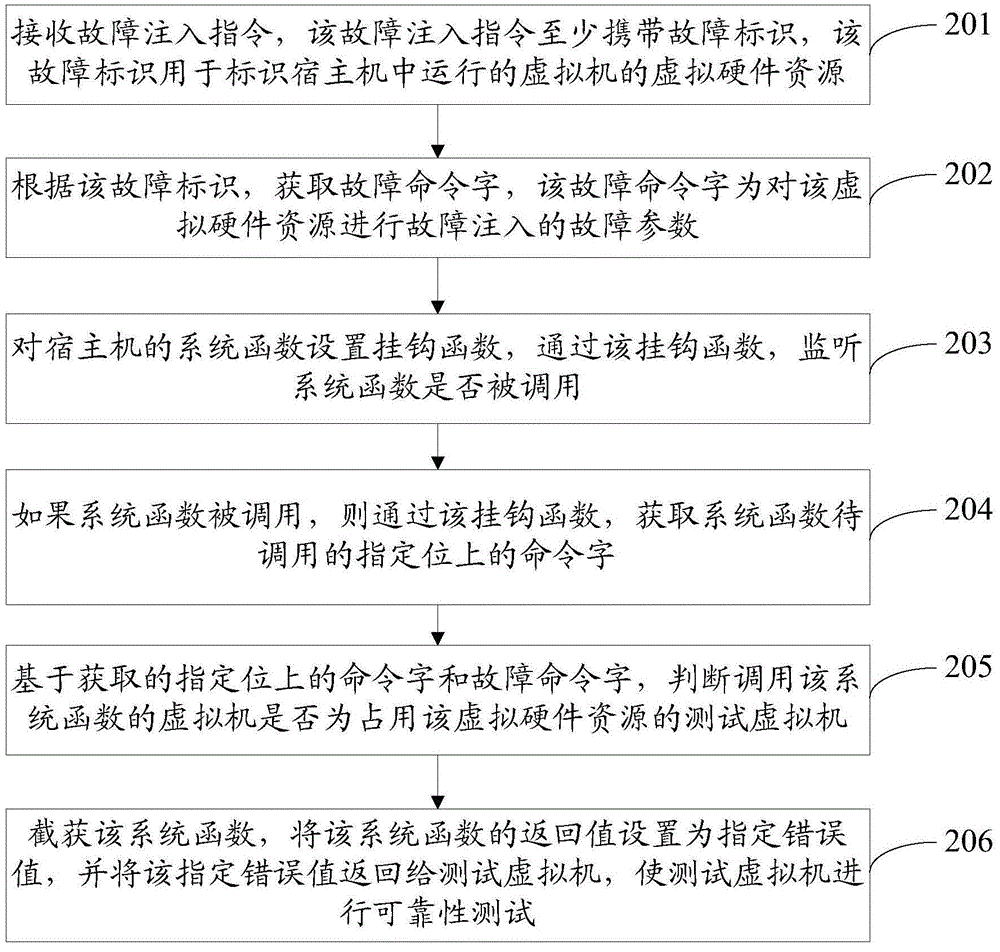

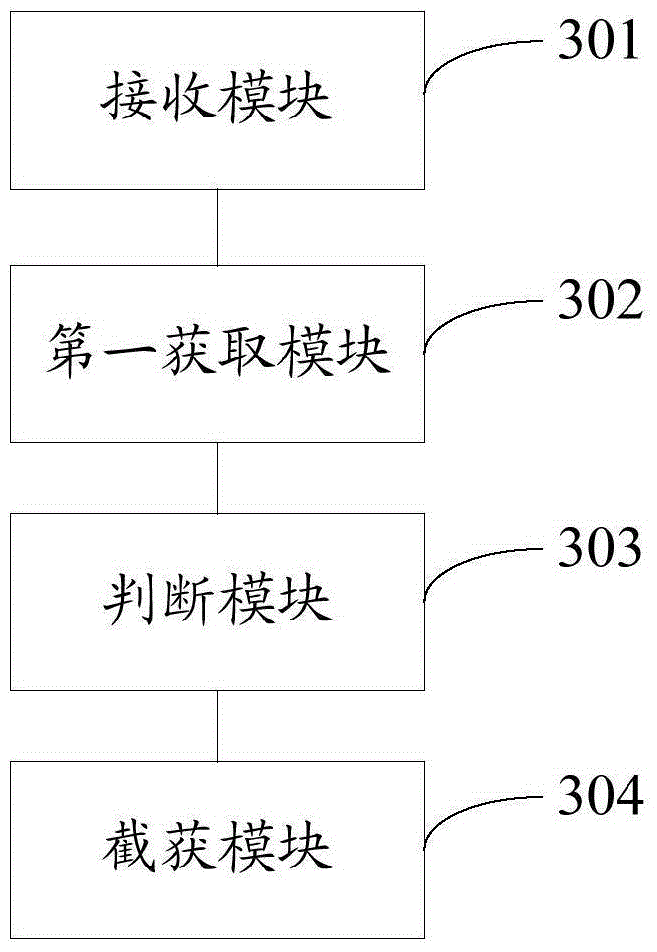

ActiveCN106155883AImplement reliability testingLower skill requirementsSoftware testing/debuggingSoftware simulation/interpretation/emulationDependabilitySource code

The invention discloses a virtual machine reliability testing method and device, belonging to the field of computers. The method includes: receiving a fault injection instruction, the fault injection instruction at least carries a fault identifier, and the fault identifier is used to identify a virtual hardware resource of a virtual machine running in the host computer; according to the fault identifier, obtaining a fault command word, the fault command word is a virtual hardware Fault parameters for resource fault injection; when the system function of the host is monitored, judge whether the virtual machine calling the system function is a test virtual machine that occupies virtual hardware resources according to the fault command word; if so, intercept the system function , setting the return value of the system function to a specified error value, and returning the specified error value to the test virtual machine, so that the test virtual machine performs reliability testing. The invention does not require testers to locate and modify the source code of the host machine on-line, but only needs testers to input fault identifications, which reduces the skill requirements for testers and is relatively simple to operate.

Owner:HUAWEI TECH CO LTD

End face coating fixture for stripe-geometry semiconductor laser and application thereof

InactiveCN105006740ANovel structurePracticalLaser detailsSemiconductor laser structural detailsSemiconductorMechanical engineering

The invention provides an end face coating fixture for a stripe-geometry semiconductor laser and an application thereof. The end face coating fixture comprises a bar strip coating fixture and an auxiliary strip assembly tool. The bar strip coating fixture comprises a sliding part and a combination frame. The combination frame comprises a u-shaped bottom frame and an upper cross frame. Columns at the two sides of the u-shaped bottom frame are internally and respectively provided with slide channels. The two ends of the sliding part are respectively provided with an inverted T-shaped embedded part. The slide channels are matched with the T-shaped embedded parts. The u-shaped bottom frame and the central part of the sliding part are provided with replaceable bar strip clamping ends. The invention also provides an auxiliary strip assembly tool. The auxiliary strip assembly tool is cooperatively used together with the bar strip coating fixture during the bar strip assembling process. The fixture is modular in design, novel in structure, simple to machine, convenient in assembly and high in nimbleness. For bar strips of different types, the fixture is good in adaptability, strong in practicality, easy to clean and maintain, and long in service life.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

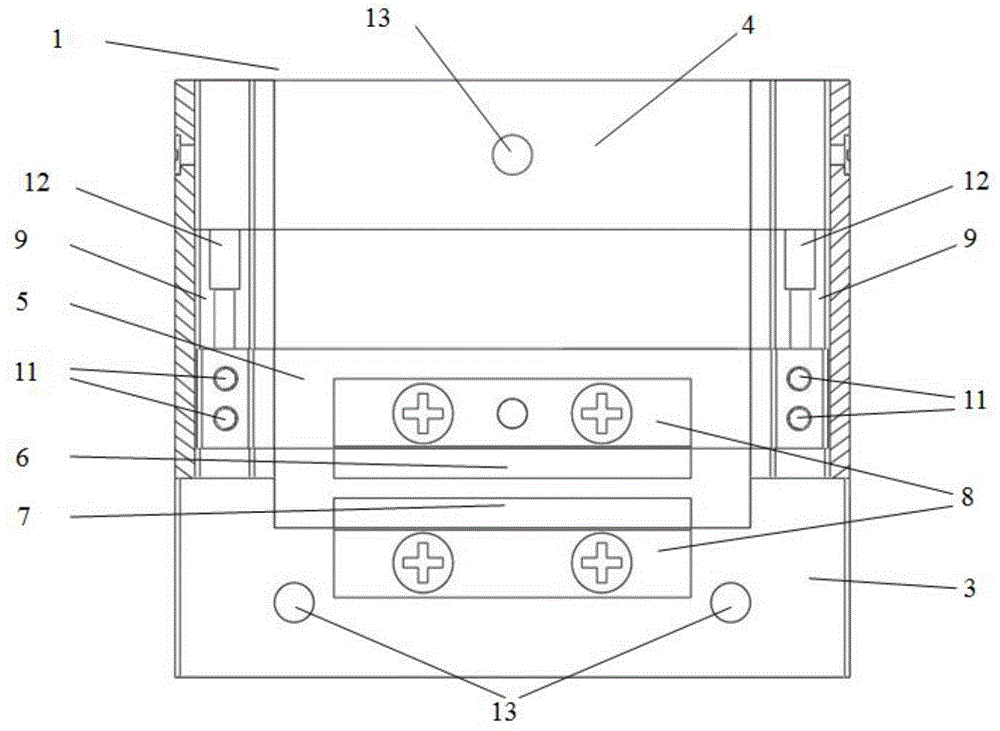

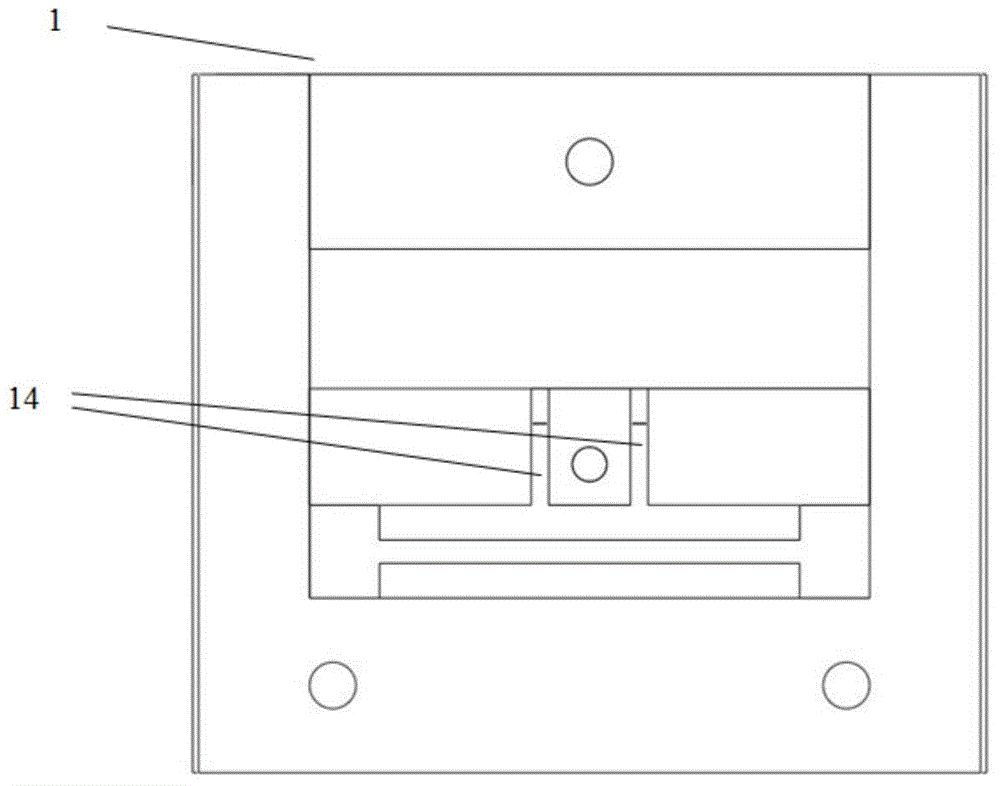

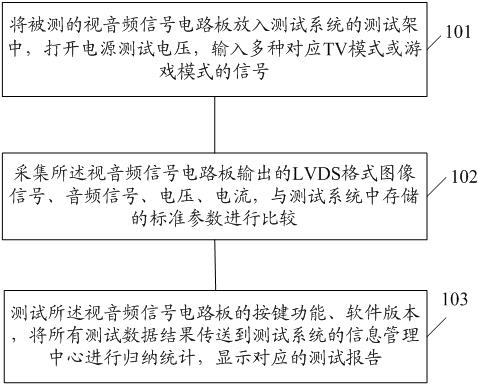

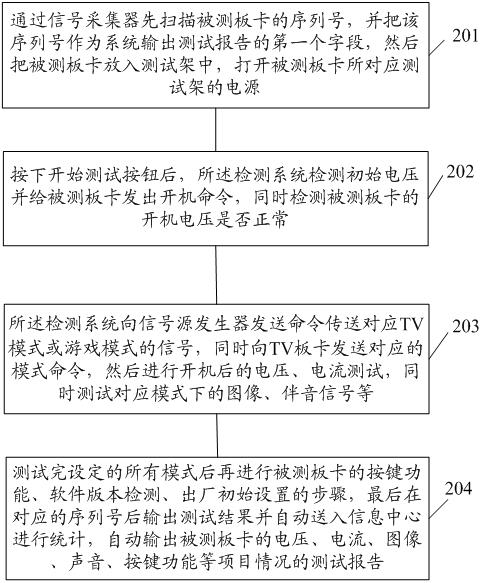

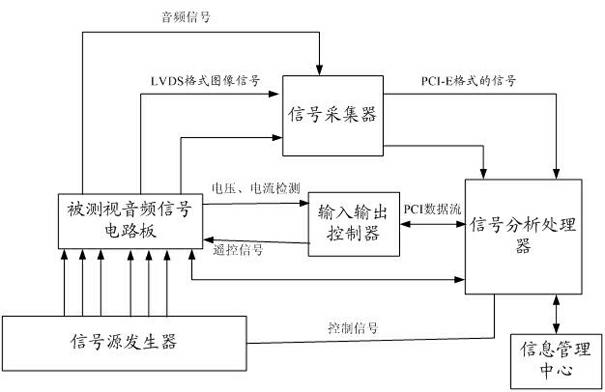

Method and system for detecting video/audio signal circuit board

ActiveCN102087336AFast transmissionLower skill requirementsElectronic circuit testingPower testSignal-to-quantization-noise ratio

The invention discloses a method and system for detecting a video / audio signal circuit board. The method comprises the following steps: A, placing at least two video / audio signal circuit boards in a test frame of a test system, opening a power test voltage, and inputting multiple kinds of signals corresponding to a TV mode or game mode; B, acquiring the image signal of LVDS format (low voltage differential signaling), audio signal, voltage and current output by the video / audio signal circuit board, comparing with the parameters stored in the test system, and comparing the image signal of LVDS format according to pixels of three primary colors to judge whether the image signal is in a preset normal threshold range; and comparing the audio signal according to the frequency characteristic to judge whether the frequency and signal-to-noise ratio are in the preset normal threshold range; and C, testing the key function and software version of the video / audio signal circuit board, and finally displaying a corresponding test report. According to the invention, a plurality of circuit boards with video / audio signal function can be quickly and accurately detected, and the product detection efficiency is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

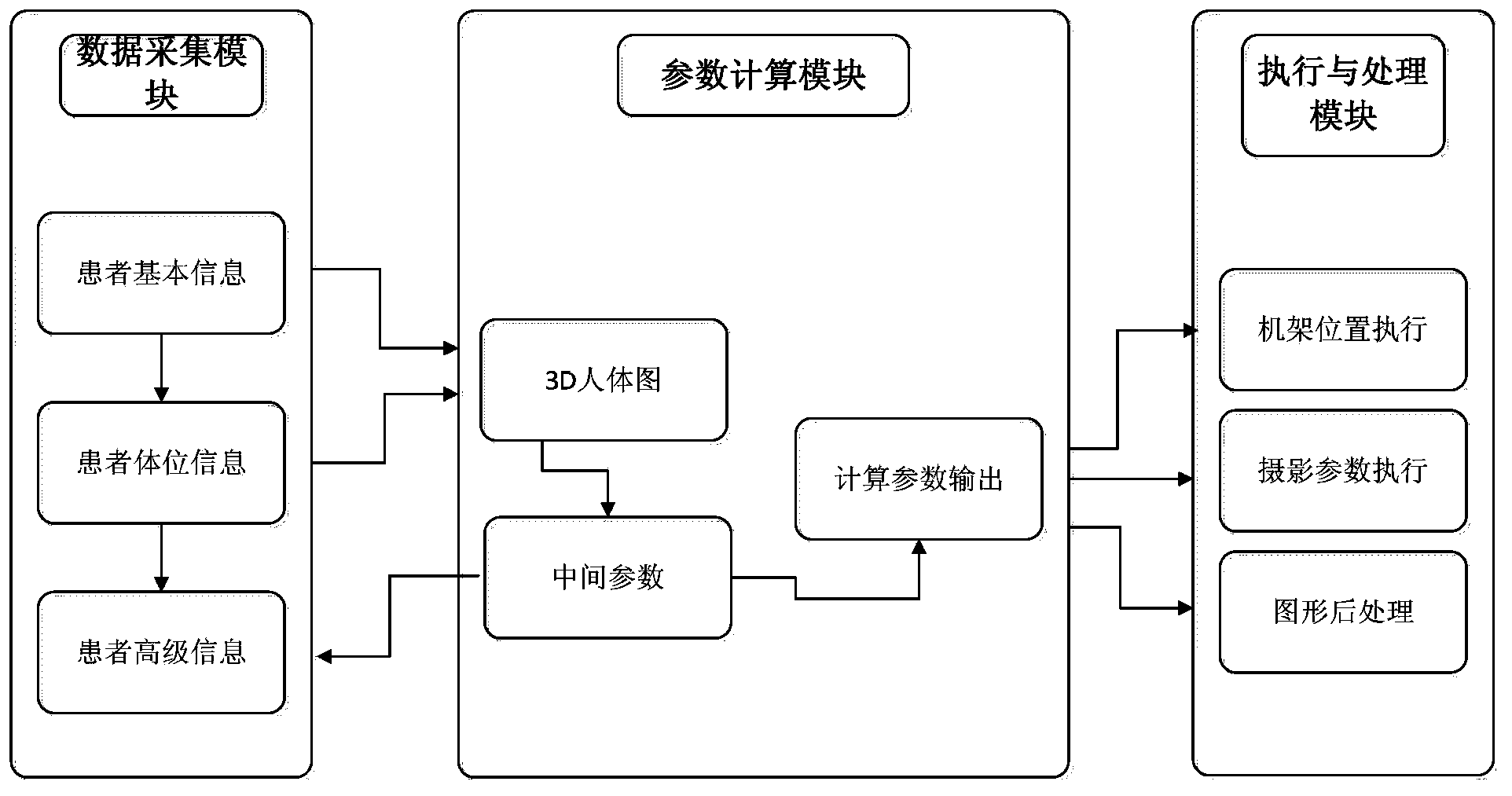

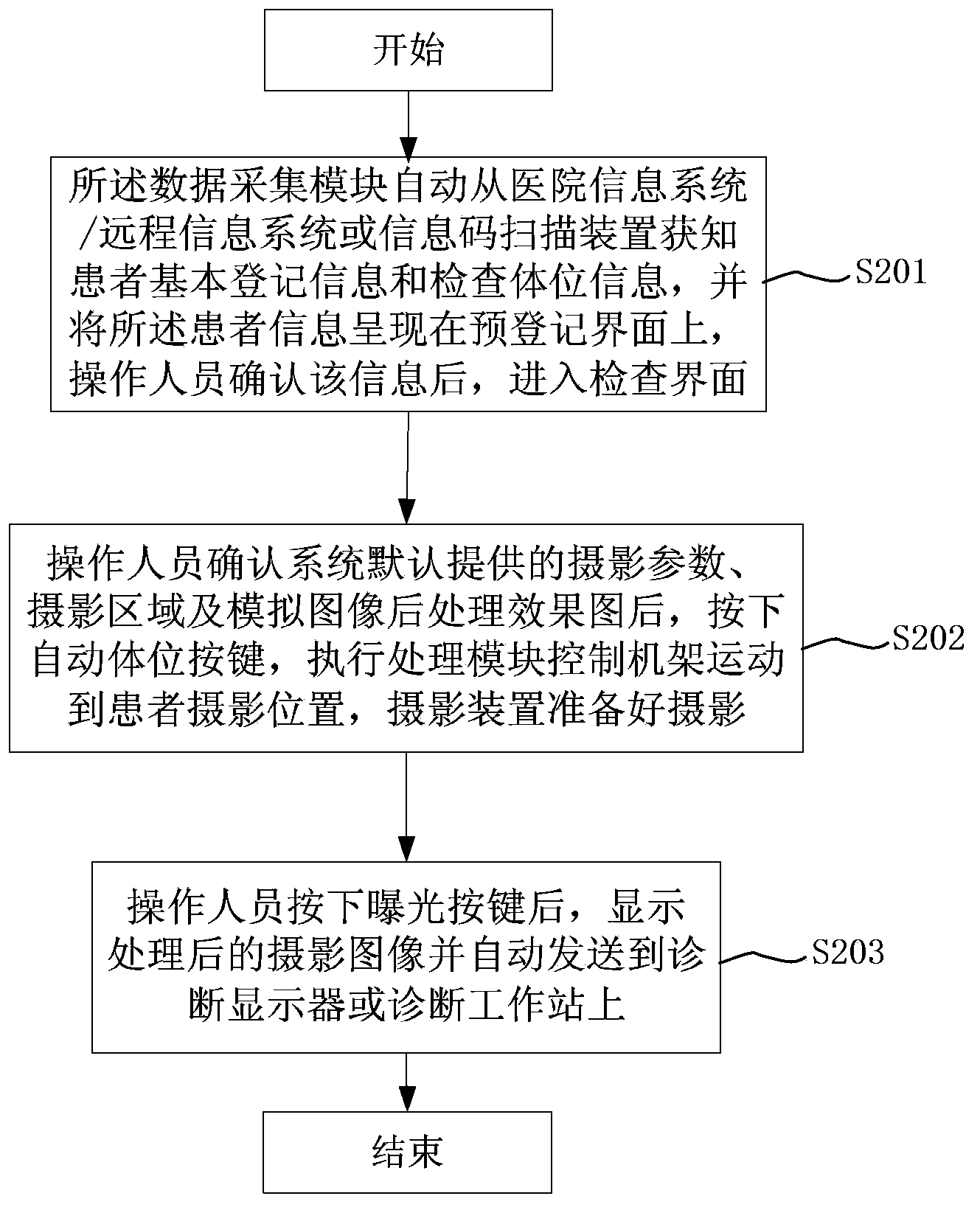

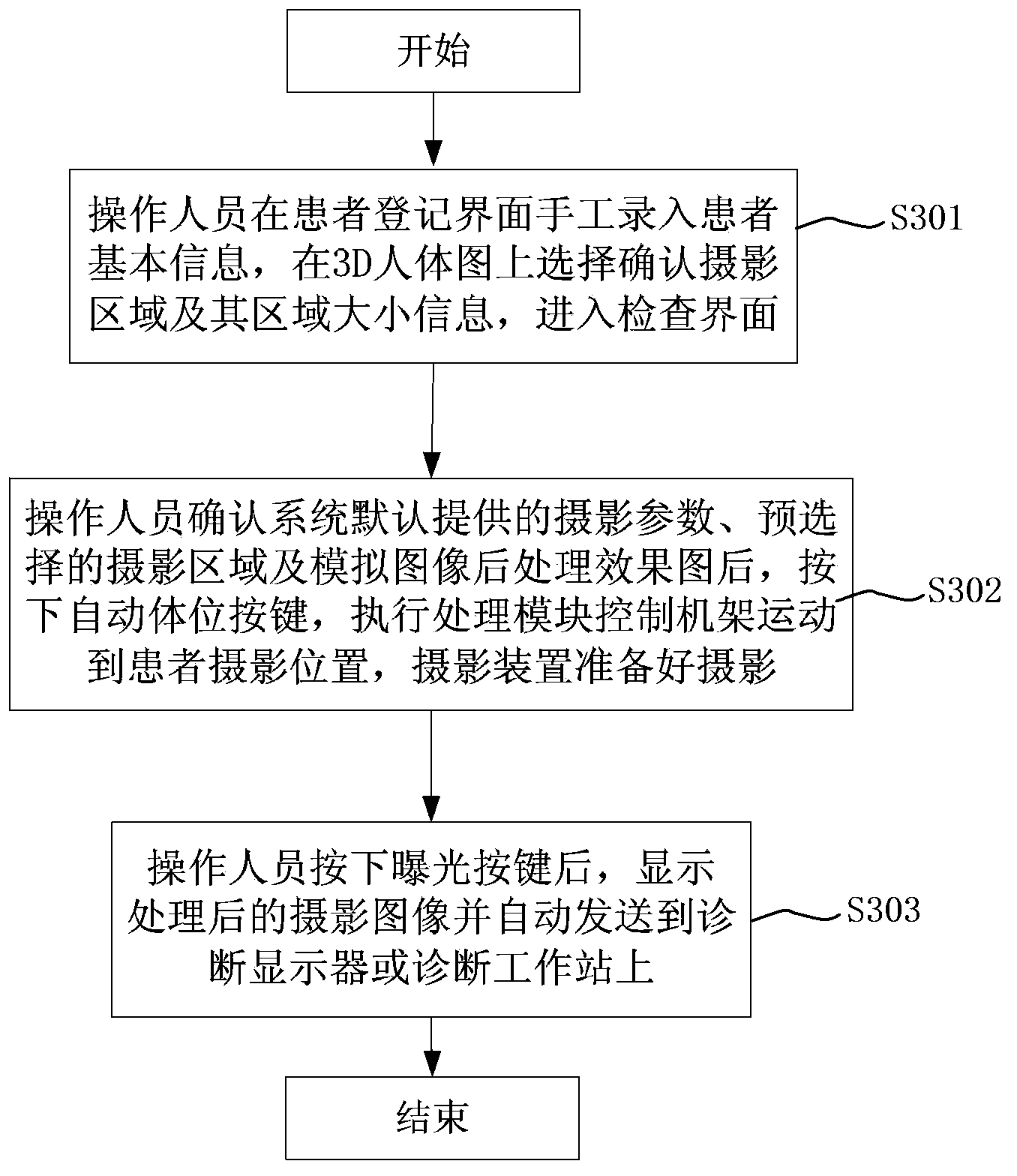

Medical photography system and photography method implemented by same

ActiveCN104068886ALower skill requirementsReduce workloadComputerised tomographsTomographyProcess moduleImage post processing

The invention discloses a medical photography system and a photography method implemented by the same. The medical photography system comprises a data acquiring module, a parameter calculating module and an executing and processing module. The data acquiring module is used for acquiring information of patients; the parameter calculating module determines framework location parameters, photography parameters and image post-processing parameters according to the information of the patients; the executing and processing module controls framework locations according to the framework location parameters, controls photography devices to carry out photography on the positions of the patients according to the photography parameters and processes acquired photography images according to the image post-processing parameters. The medical photography system and the photography method have the advantages that working processes can be simplified, skill requirements on operators can be lowered, the clinical training efficiency can be improved, and the operators can effectively concentrate on medical image diagnosis.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

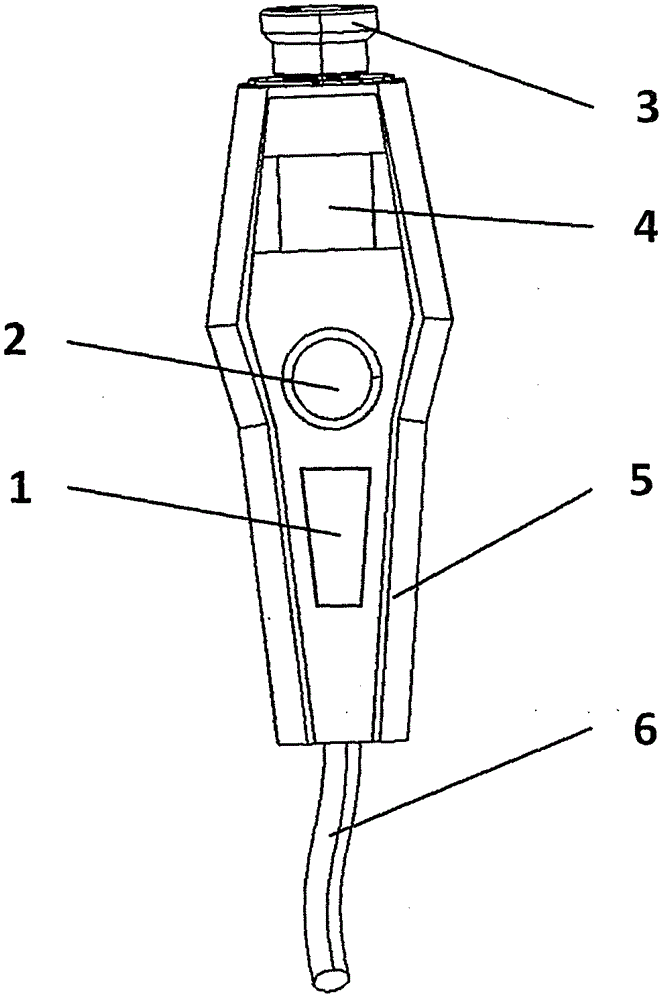

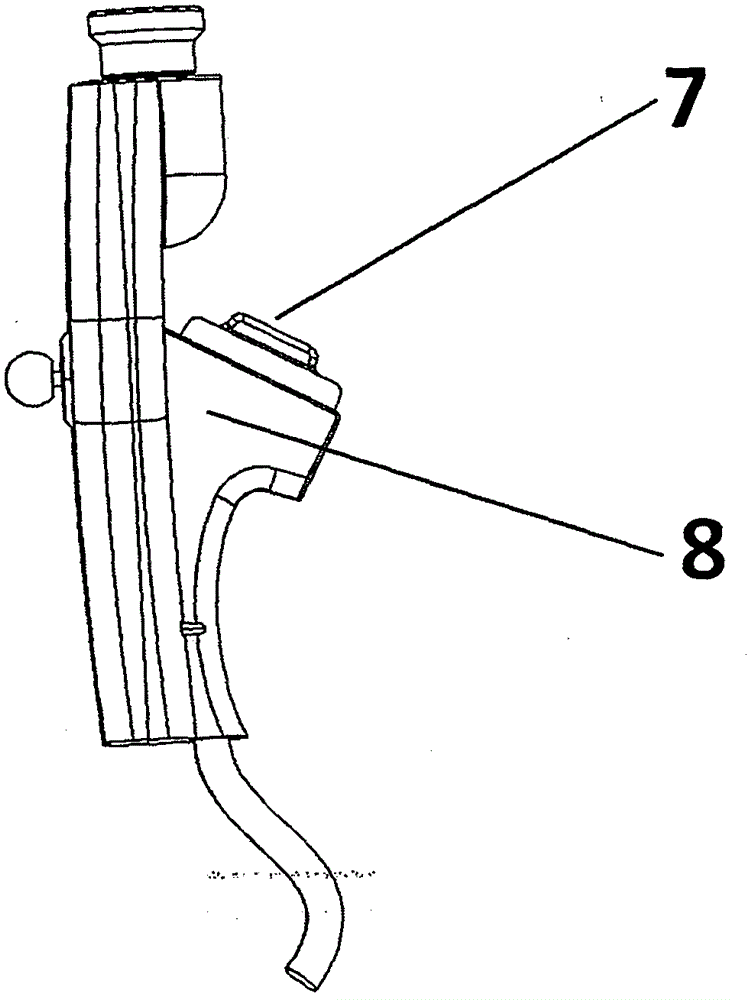

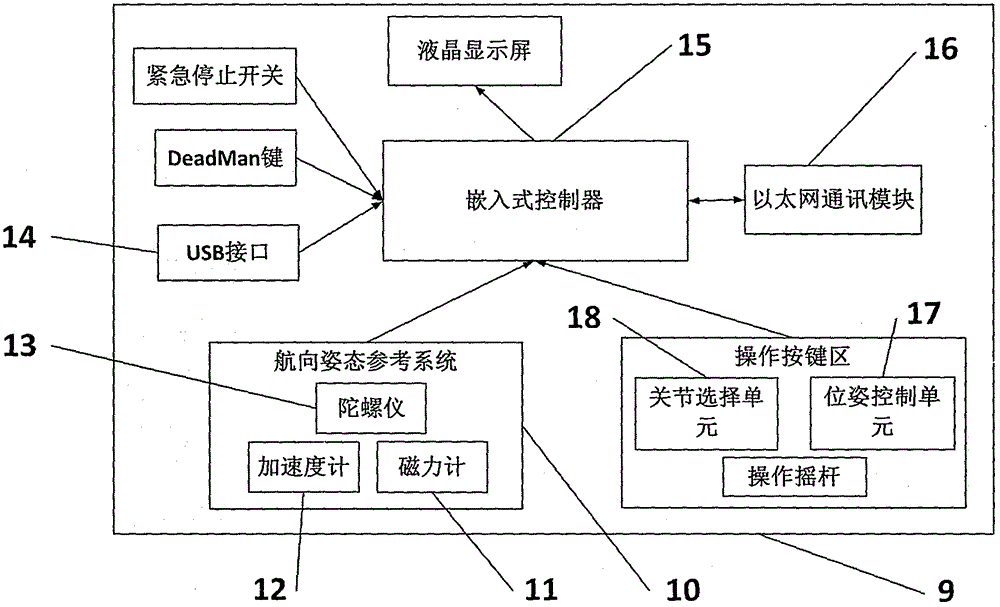

Easy-to-control robot demonstrator

The invention provides an easy-to-control robot demonstrator. The easy-to-control robot demonstrator comprises an embedded controller, a heading attitude reference system, an operation rocker, and the like, wherein the embedded controller is connected with an upper computer robot control system; the heading attitude reference system comprises an accelerometer, a gyroscope and a magnetometer and is used for collecting movement attitude of a demonstrator body and transferring an attitude track to the embedded controller; the embedded controller is used for generating demonstration attitude of a mechanical arm on the basis of attitude transformation of the attitude heading attitude reference system and transferring a demonstration attitude transformation track to the upper computer robot control system; the upper computer robot control system is used for controlling a mechanical arm needing to move to perform corresponding attitude movement on the basis of attitude transformation of the mechanical arm; the operation rocker connected with the embedded controller is used for selecting X,Y and Z axis parameters of the movable mechanical arm, so that the whole demonstration process of the mechanical arm is completed.

Owner:SHANGHAI UNIV

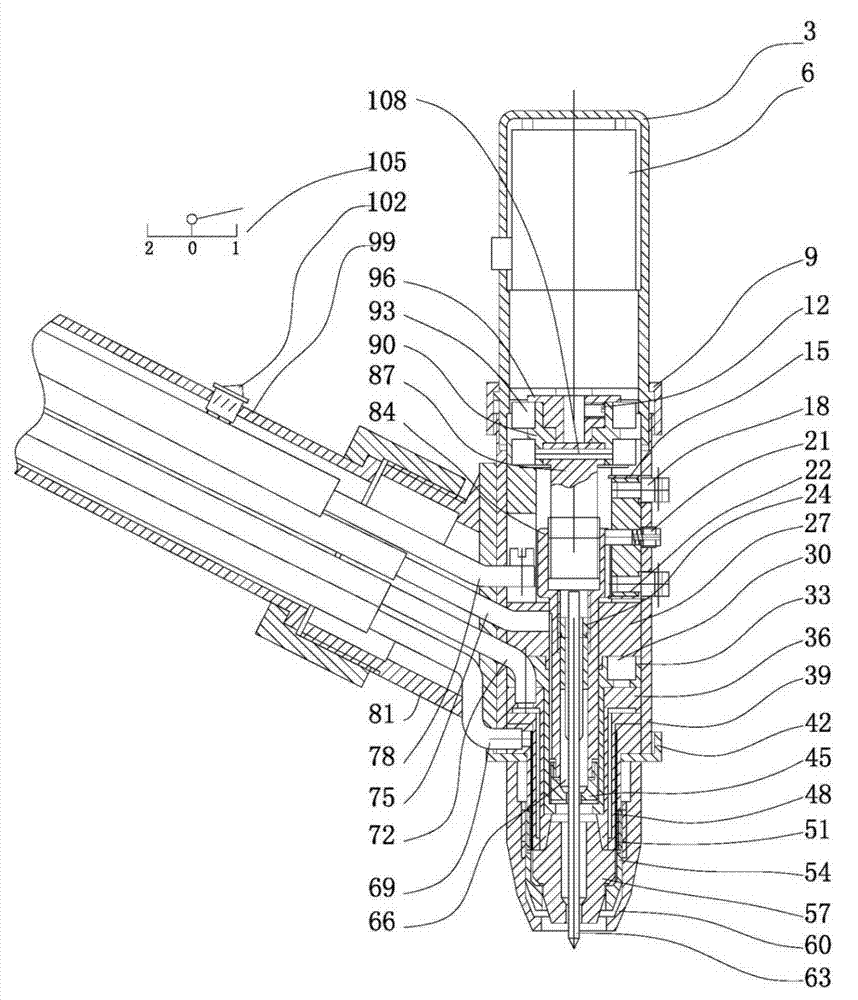

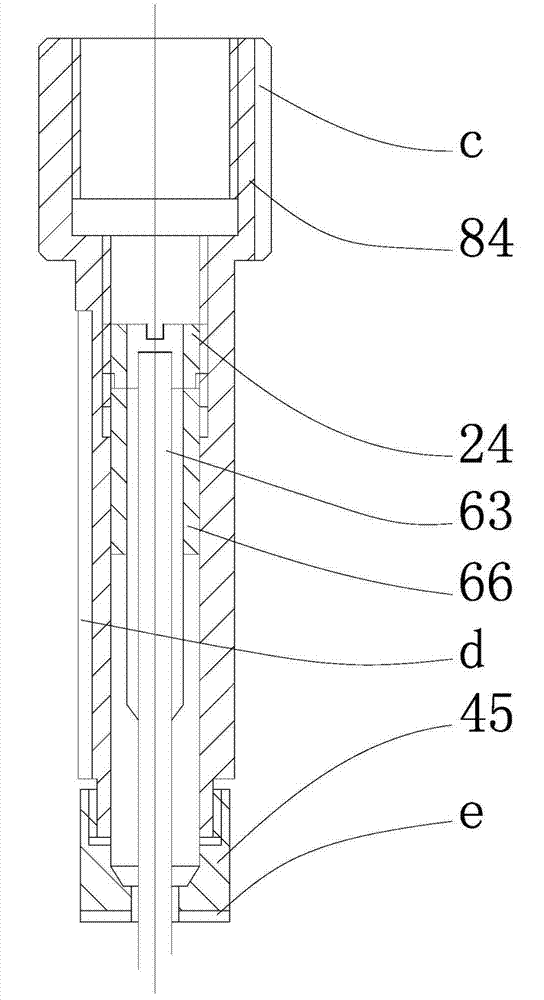

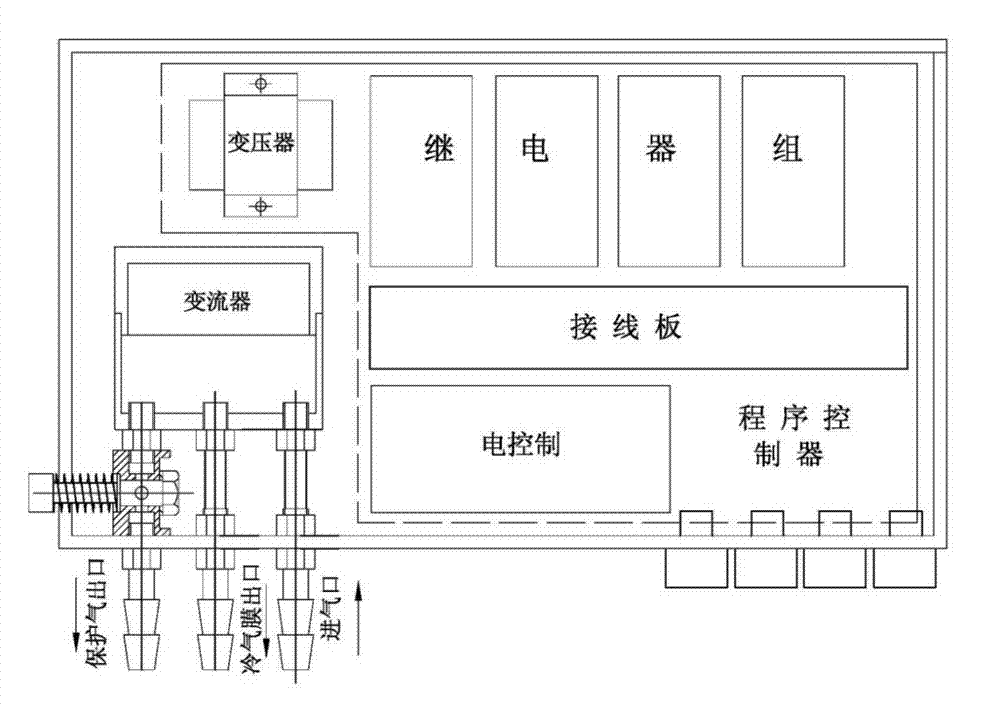

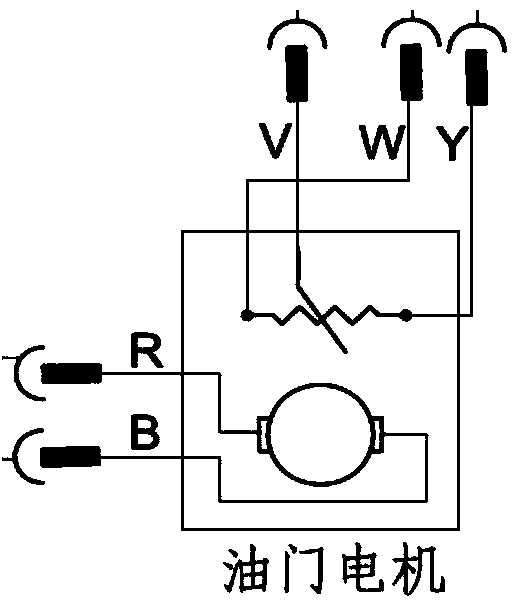

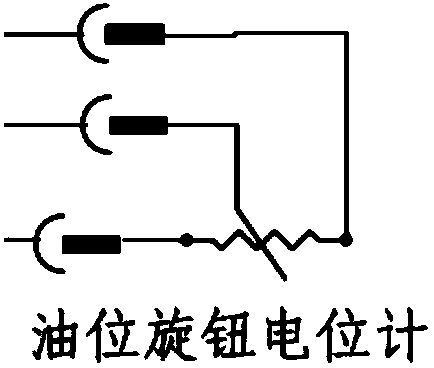

Energy-saving argon tungsten-arc welding assembly with adjustable welding torch

InactiveCN102814581ALower skill requirementsImprove efficiencyElectrode supporting devicesElectrode accessoriesReduction driveShielding gas

An energy-saving argon tungsten-arc welding assembly with adjustable welding torch comprises a welding gun and an electrical control device which is connected with the welding gun, wherein the welding gun comprises a tungsten rod clamping component, a motor reducer (6), a cooling jacket, an electric arc nozzle (57), a nozzle retainer ring and a shielding gas nozzle; the tungsten rod clamping component comprises a tungsten rod (63) and an intermediate rod (84) which drives the tungsten rod (63) to lift and descend; the cooling jacket is used for delivering cool air film and shielding argon flow; and an argon arc welding machine is adopted as a welding source, the motor reducer (6) is taken as a drive source, the tungsten rod (63) is lifted and descended through a limit ring (96), a connecting ring (90), an upper nut and a lower nut (87) and the intermediate rod (84), the electrical control device is used for controlling the rotation direction of the motor reducer (6), furthermore, a top nut contact (21) is controlled to be communicated with an upper piece contact (15) or a lower piece contact (22), so the tungsten rod (63) is freely and continuously adjusted in a stepless manner, and is reset when the arc is quenched.

Owner:上海格瀚斯机械有限公司

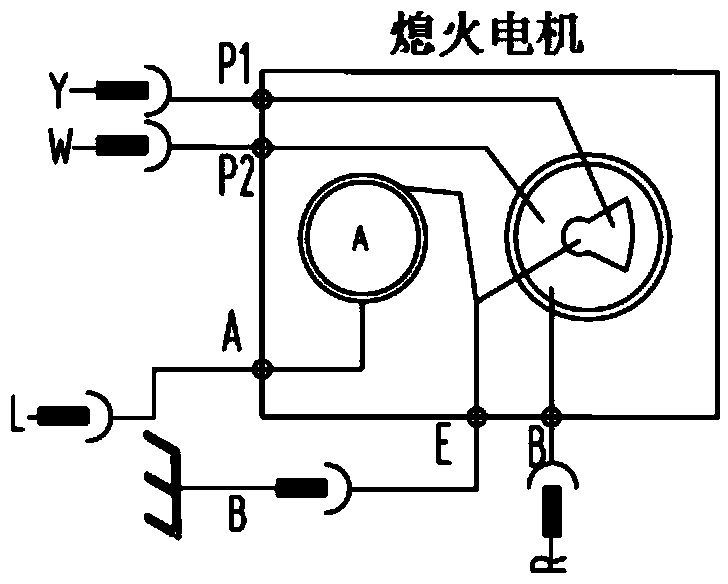

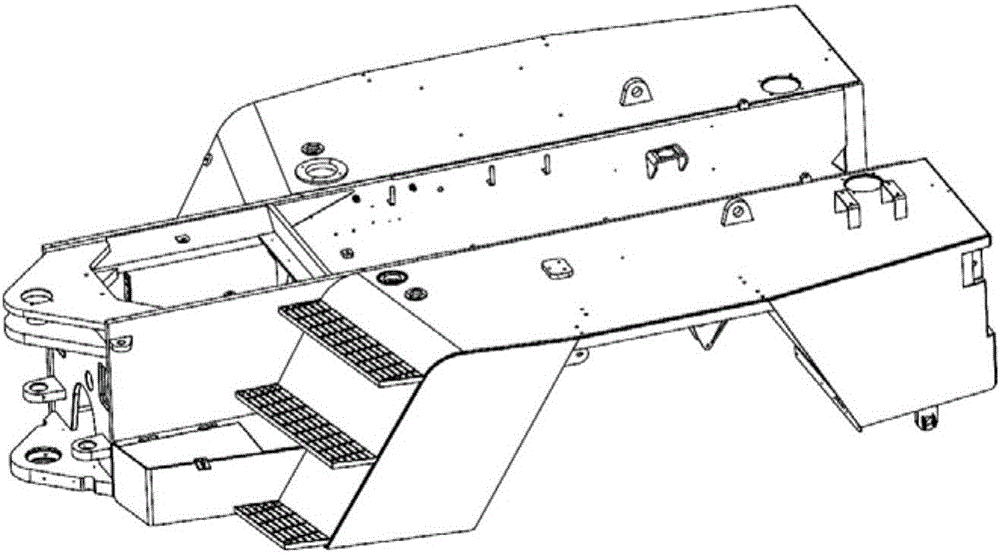

Fault detector of excavator

InactiveCN103954467APrevent return to factoryLower skill requirementsStructural/machines measurementData informationControl system

The invention discloses a fault detector of an excavator. The fault detector of the excavator comprises a detection wiring harness, an electric device drive module, a meter control panel and a power line. The electric device drive module is used for driving to-be-detected electric devices in an air conditioner system, an electronic throttle control system and a flameout system for simulated working state demonstration. The meter control panel comprises an electric device working state demonstration control button, an electric device working state indicator lamp and a display module, wherein the electric device working state demonstration control button is used for controlling the electric device drive module to achieve simulation demonstration of the working state of the to-be-detected electric devices; the electric device working state indicator lamp is used for displaying the working state of the to-be-detected electric devices; the display module is used for displaying related data information and / or related data information change situations of the to-be-detected electric devices in the air conditioner system, the electronic throttle control system and the flameout system under the simulated working state. The fault detector of the excavator can rapidly and accurately detect electric devices which cannot be easily detected or are large in detection difficulty in the maintenance process of the excavator and remove faults, and operation is visual, easy and convenient.

Owner:QINGDAO LOVOL EXCAVATOR

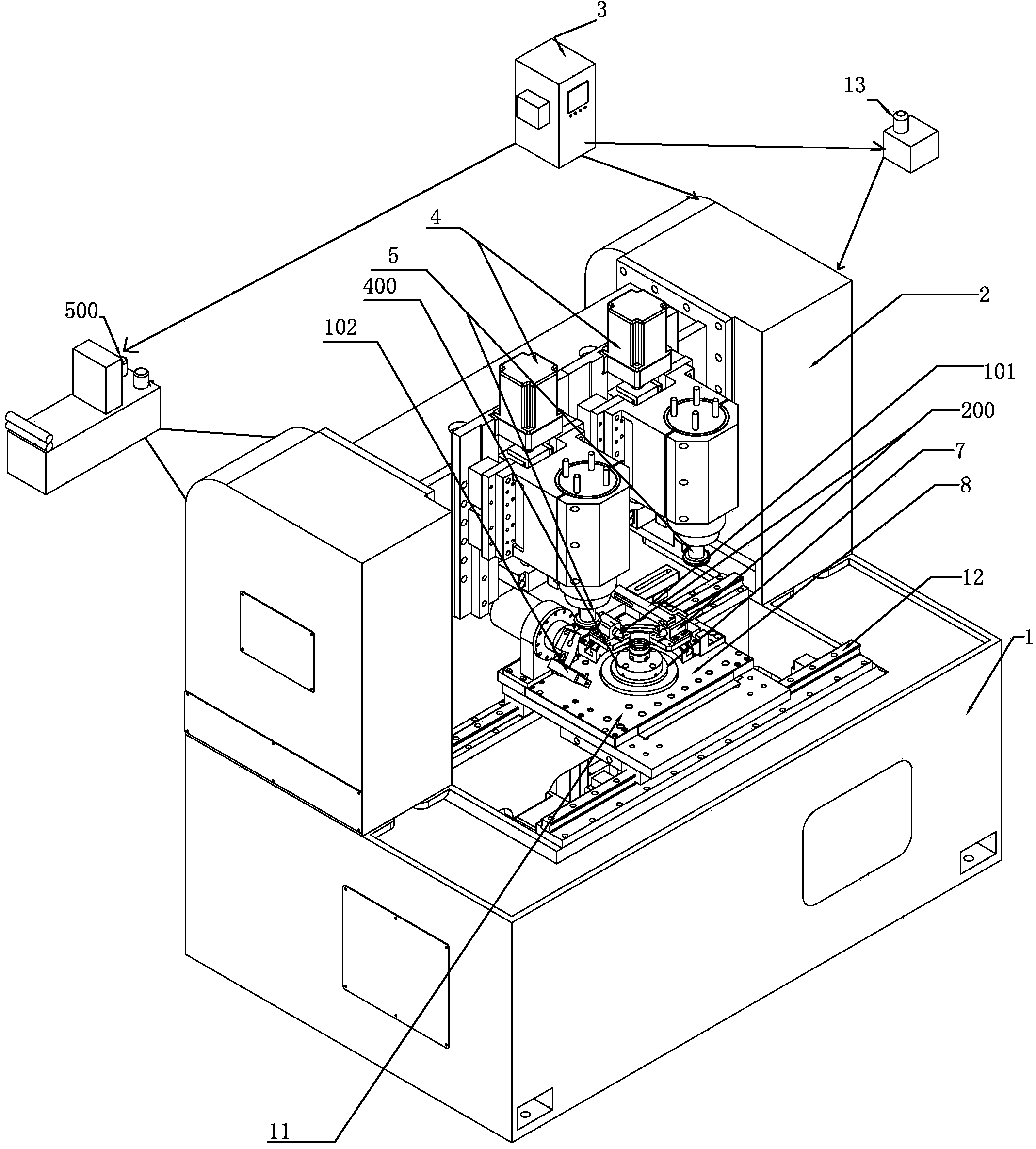

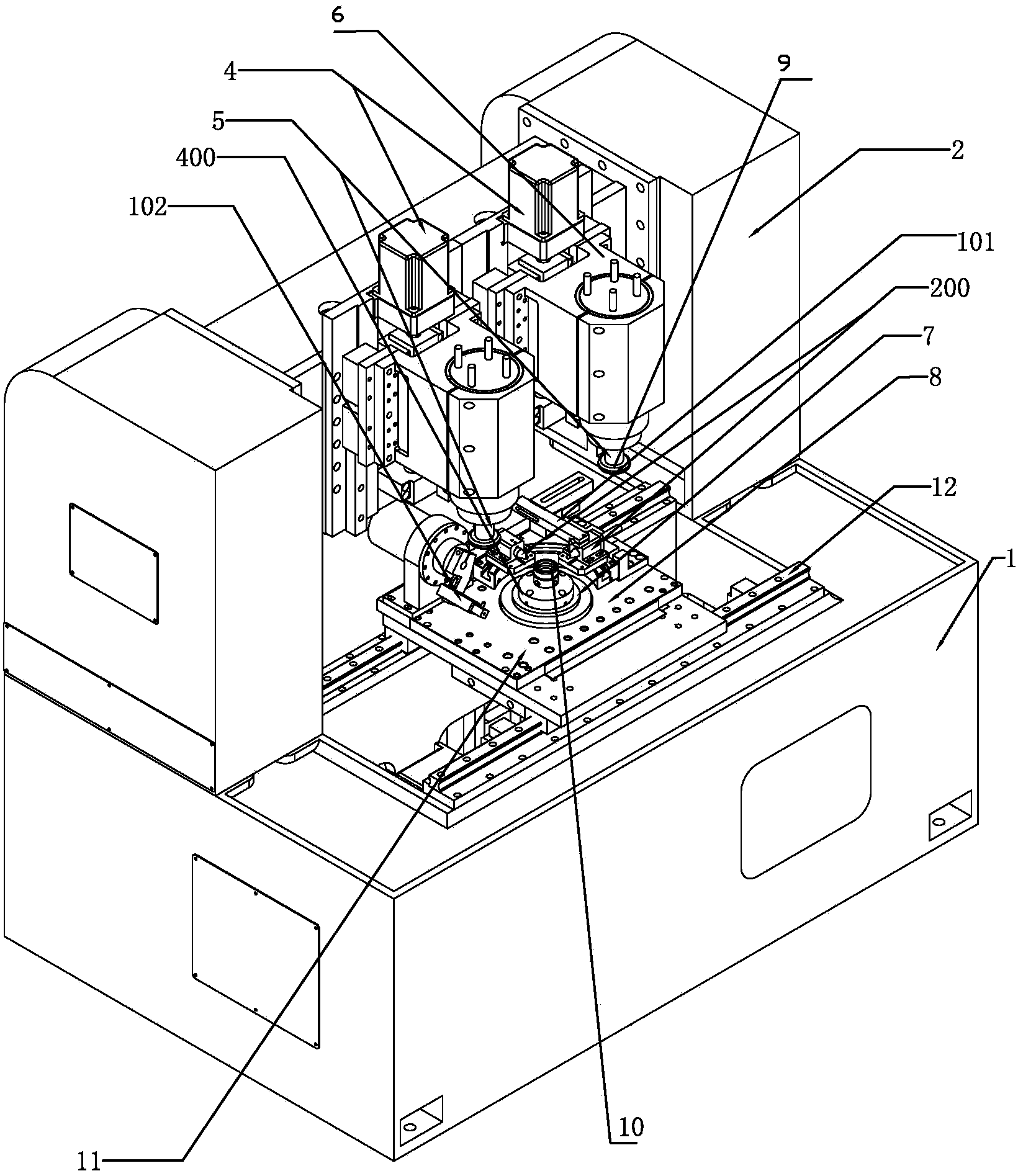

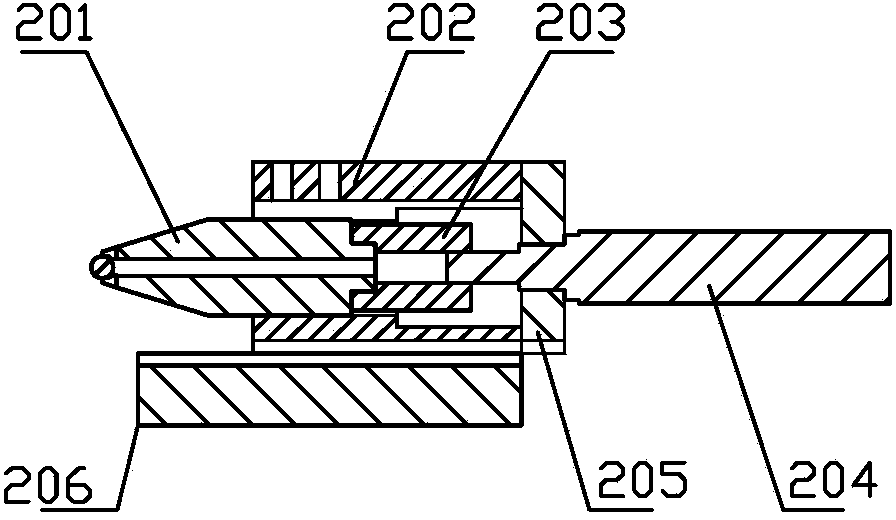

Universal grinding machine special for nuclear power bearing inner race machining

ActiveCN103639872ALower skill requirementsHigh adjustment accuracyAbrasive surface conditioning devicesGrinding machinesMachine toolMachining

A universal grinding machine special for nuclear power bearing inner race machining comprises a machine tool base, a machine tool body, a hydraulic system, an electric control system and a servo system and further comprises electric spindles, spindle lifting mechanisms, a workpiece shaft, a grinding wheel dresser, a workpiece shifting mechanism, a support assembly, a mechanical arm, a magnetic pole, grinding wheels, a cutting liquid circulation system and a nuclear power bearing inner race. Two sets of the electric spindles and the spindle lifting mechanisms are provided and installed on the upper portion of the workpiece shifting mechanism, each electric spindle works independently and moves vertically through the corresponding spindle lifting mechanism, the grinding wheel is installed on the lower end portion of each electric spindle, and the electric spindle drives the grinding wheel to rotate. Under the premise that machining accuracy is ensured, time for replacing mechanical parts and adjusting machining size is saved, machining can be conducted continuously by simply replacing the magnetic pole, and machining efficiency can be effectively improved.

Owner:大连大友高技术陶瓷有限公司

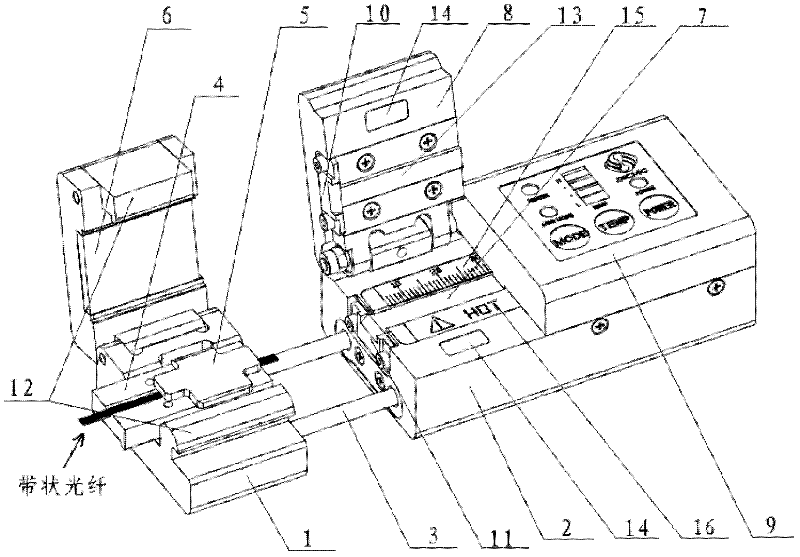

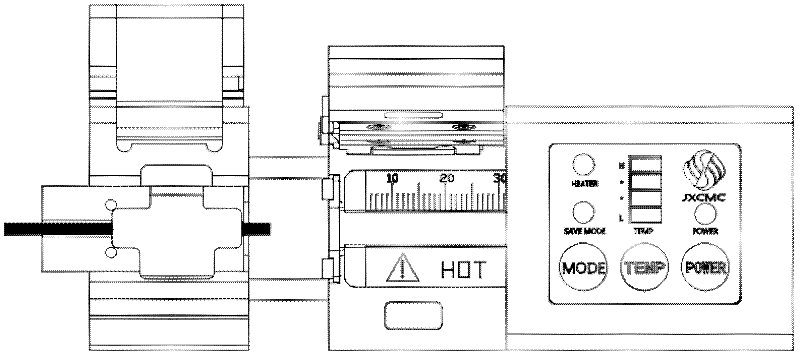

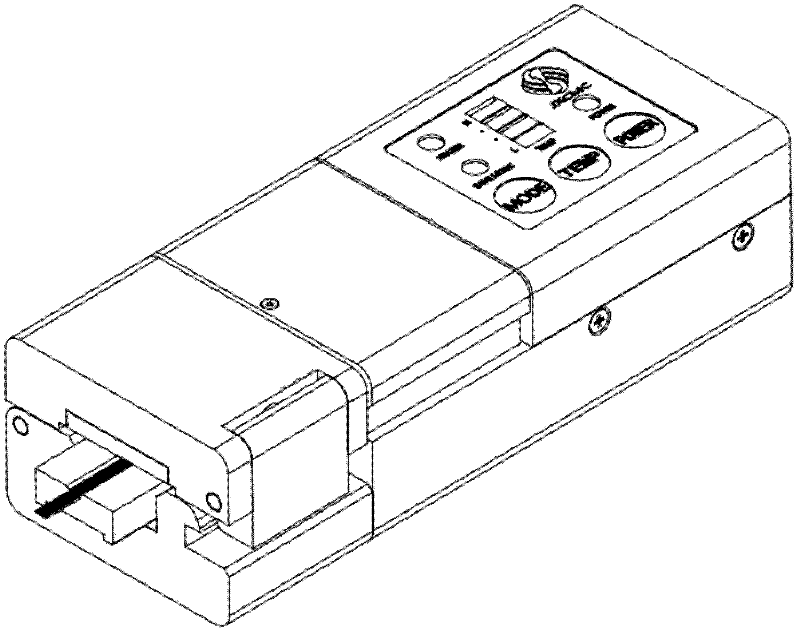

Hot stripping pliers for ribbon fiber

The invention discloses hot stripping pliers for a ribbon fiber. The hot stripping pliers comprise an optical fiber clamp part and a cutting heating part connected through a linear bearing in a sliding manner. The cutting operation adopts a parallel cutting design of an upper blade and a lower blade, and is applicable to fiber stripping operations of a single-core fiber and the ribbon fiber; according to the heating operation, an intelligent heating system is arranged and an optical fiber coating is softened to facilitate the fiber stripping operation of the optical fiber. A design of the linear bearing is adopted, so the release force is small; and the safety and the stability of the operation can be ensured when the optical fiber is drawn to peel off after an optical fiber protecting layer is cut off, and the operation can be finished by one time. The middle heating part adopts a magnet clamping mode so as to facilitate reliable joint of a fiber stripping blade and better strip the coating of the optical fiber. Simultaneously, the skill requirement on an operator is greatly reduced and the popularizing rate of the tool can be greatly improved.

Owner:BENGBU JIXIN COMM MACHINERY

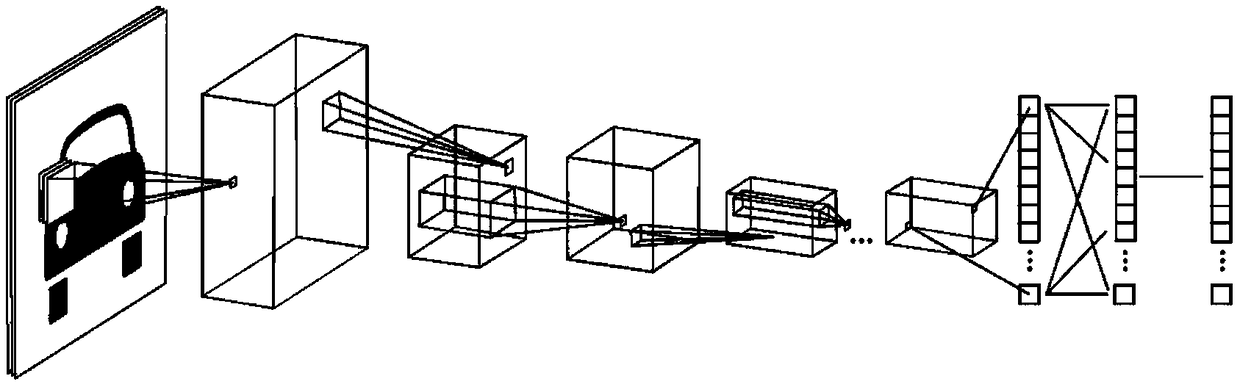

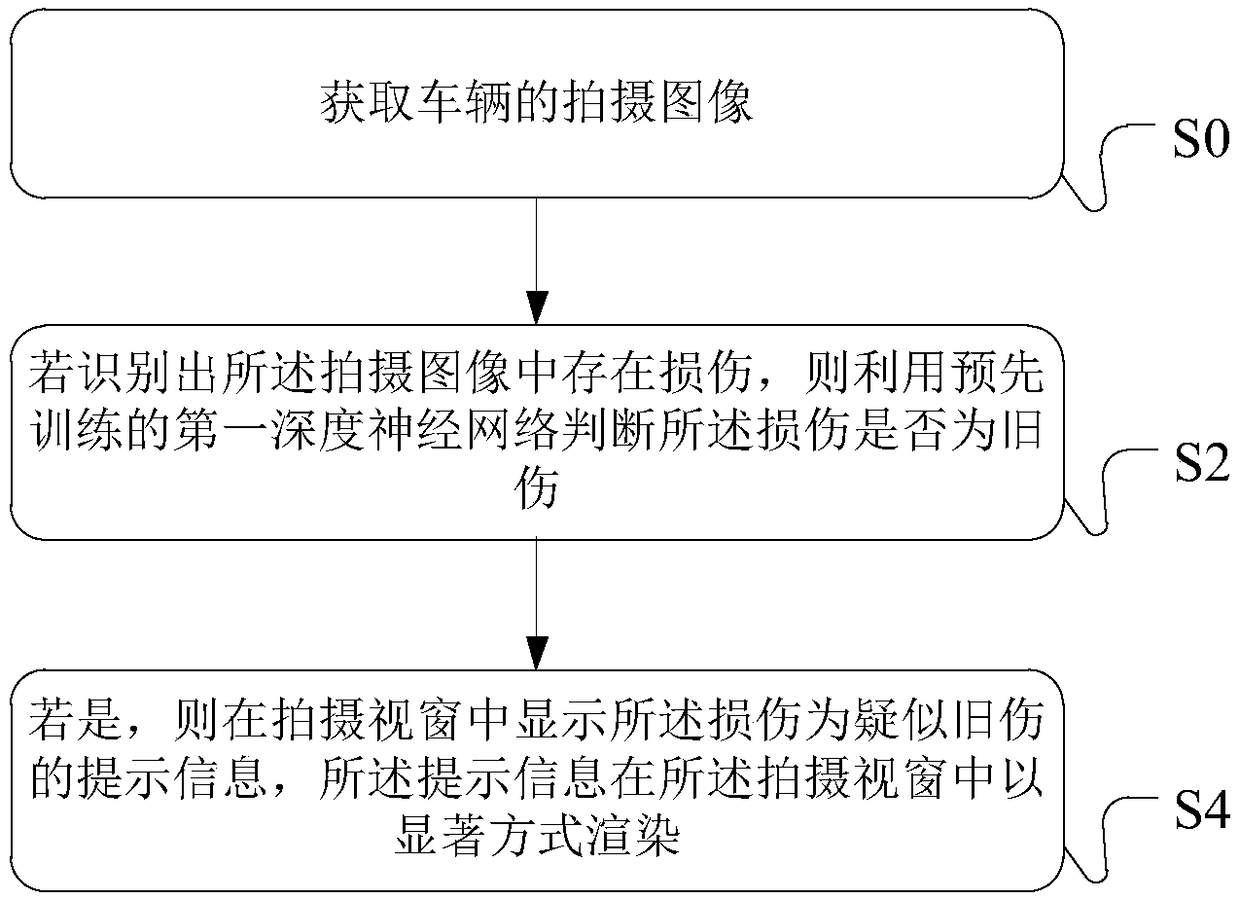

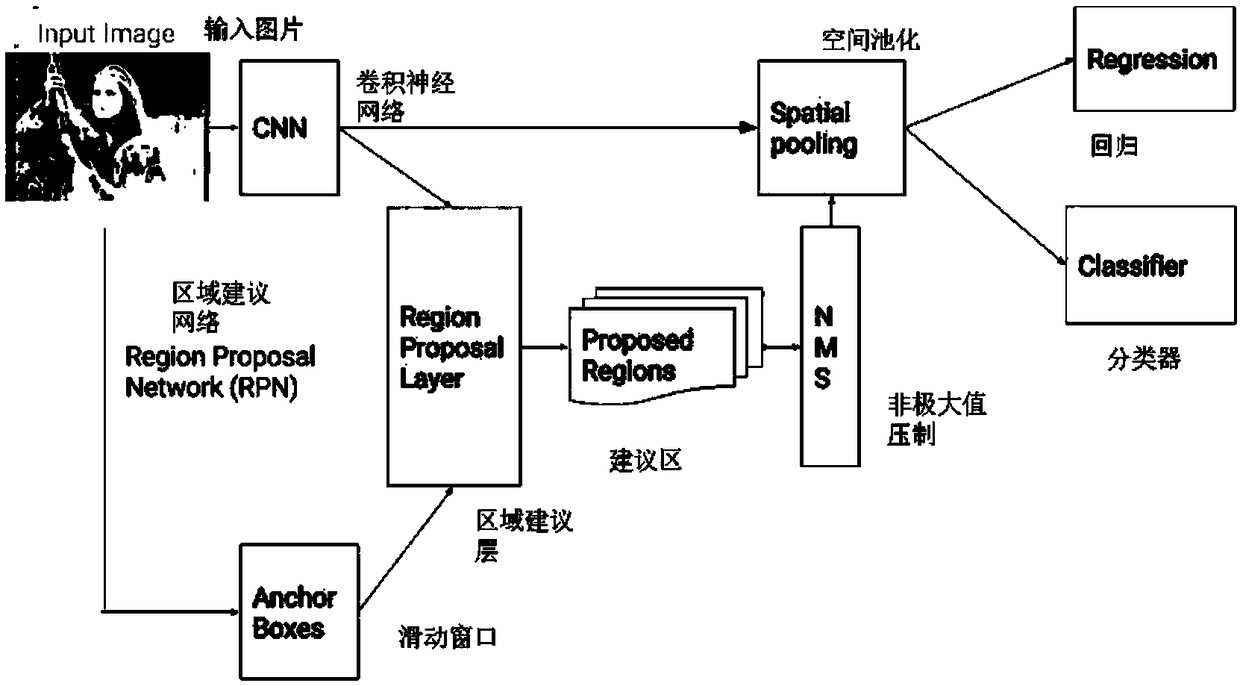

Processing method and processing equipment for vehicle damage identification, client and server

InactiveCN108647712AImprove reliabilityLower skill requirementsFinanceRegistering/indicating working of vehiclesTerminal equipmentComputer science

Embodiments of the invention disclose a processing method and processing equipment for vehicle damage identification, a client and a server. The processing method of the invention is characterized inthat: in one embodiment, whether a vehicle damage is an old damage can be identified automatically on terminal equipment, and whether the damage is the old damage is identified in real time when an image or video is shot without human intervention, thus requirements for skills of survey staff can be effectively reduced; at the same time, information of an identified suspected old damage can be automatically recorded and transmitted to a designated server system, such as an insurance company, in this way, even if the survey staff or malicious users delete images or videos of the old damage, theinformation that the damage has been identified to be an old damage can not be concealed, thus a fraud risk can be effectively reduced, reliability of damage identification can be improved, and reliability of a loss assessment result can be further improved.

Owner:ADVANCED NEW TECH CO LTD

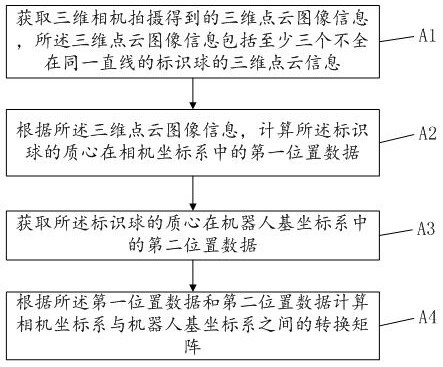

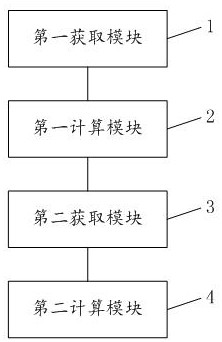

Robot hand-eye calibration method and device, electronic equipment and system

ActiveCN112091971ALower skill requirementsImprove efficiencyProgramme-controlled manipulatorRobot handPoint cloud

The invention provides a robot hand-eye calibration method and device, electronic equipment and a system. The method comprises the steps that three-dimensional point cloud image information obtained through photographing of a three-dimensional camera is obtained, wherein the three-dimensional point cloud image information comprises three-dimensional point cloud information of at least three identification balls which are not completely located on the same straight line; first position data of the mass center of the identification balls in a camera coordinate system are calculated according tothe three-dimensional point cloud image information; second position data of the mass center of the identification balls in a robot base coordinate system are acquired; and a conversion matrix betweenthe camera coordinate system and the robot base coordinate system is calculated according to the first position data and the second position data. Calibration can be completed only by acquiring the image information once, so that hand-eye calibration of a robot can be completed quickly, the efficiency is high, the calibration result is accurate, and the requirement on the industrial skill of an operator is relatively low.

Owner:JIHUA LAB

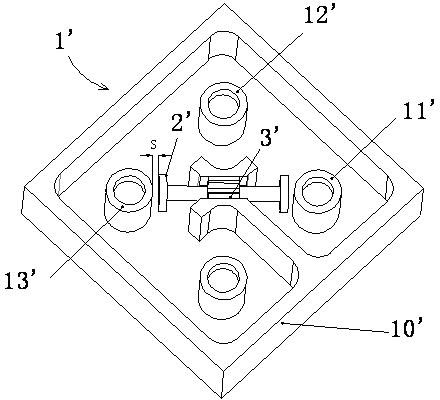

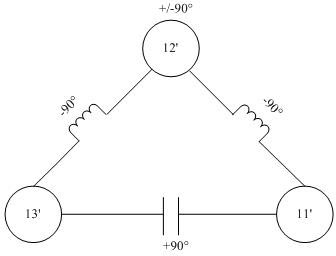

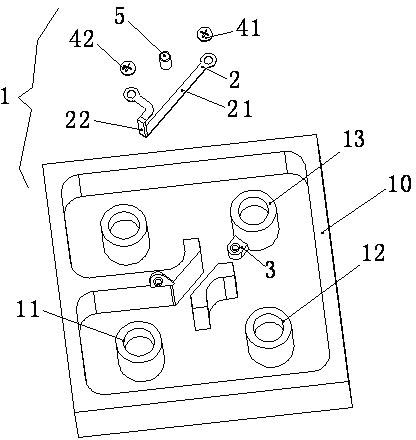

Cavity filter, duplexer, combiner and transmission zero frequency debugging method for cavity filter

The embodiment of the invention provides a cavity filter, which comprises a cavity, a first resonator, a second resonator, a third resonator, a main transmission path, a secondary transmission path and a coupling jumper, wherein the first, second and third resonators are sequentially arranged in the cavity; the main transmission path is led to the third resonator from the first resonator through the second resonator; the secondary transmission path is led to the third resonator from the first resonator; the coupling jumper is arranged between the first and third resonators along the secondary transmission path; and one end of the coupling jumper is assembled on the third resonator, and the other end of the coupling jumper is assembled on the cavity. The cavity filter is easy to assemble, so that work hours for assembly are reduced, requirements for the skills of an assembly operator are greatly lowered, and the error probability of the assembly operator is reduced. Moreover, the coupling jumper is formed by stamping a metal plate, so that the cavity filter is high in consistency and low in cost, the production cost and raw material purchasing cost of the product can be lowered by about 40 percent particularly in batch production compared with those of the conventional transmission zero structure, and the market competitiveness of the product is greatly improved.

Owner:吴芬

Microwave radioradiation crosslinked complete biodegradable material and its processing method

The invention relates the microwave radio-frequency radiation cross-linking biodegradation material, comprising starch, cellulose, A, aminocaprolactam or polyatomic alcohol, B, coupling agent, C, nucleation agent, D, undecylenic acid, calcium carbonate, natrii chloridum, and urea. The method comprises the following steps: mixing the raw material, cross linking with microwave radio-frequency device, foaming, forming, and getting the product. The invention solves the problems of no degradation, complex procedure, high cost and hard technology. The product has the advantages of good draftability, suppleness and obstructing property. The invention has the advantages of wide application area, completely degradation and non pollution. The invention also has the advantages of simple technology, easy operation and low cost.

Owner:杨军现

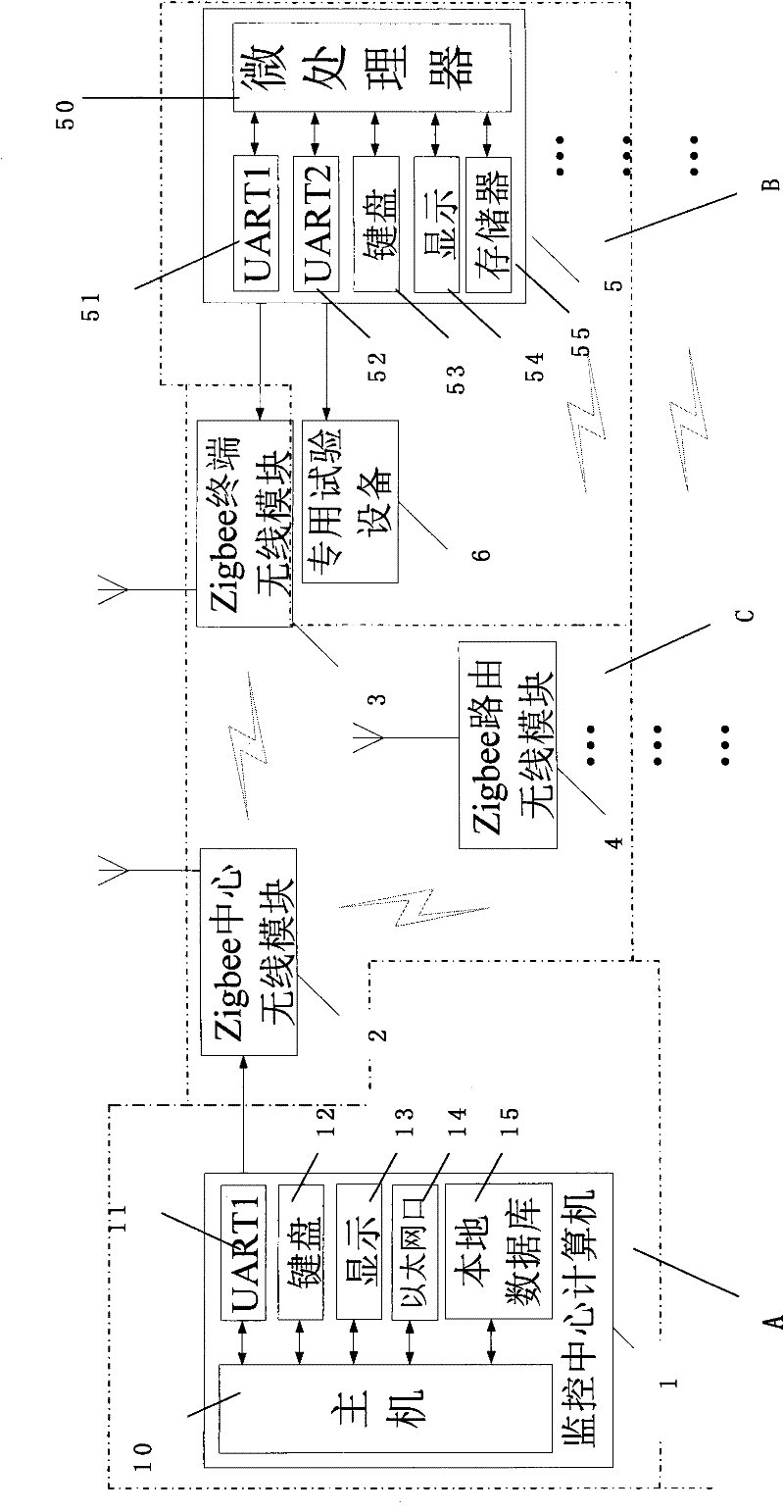

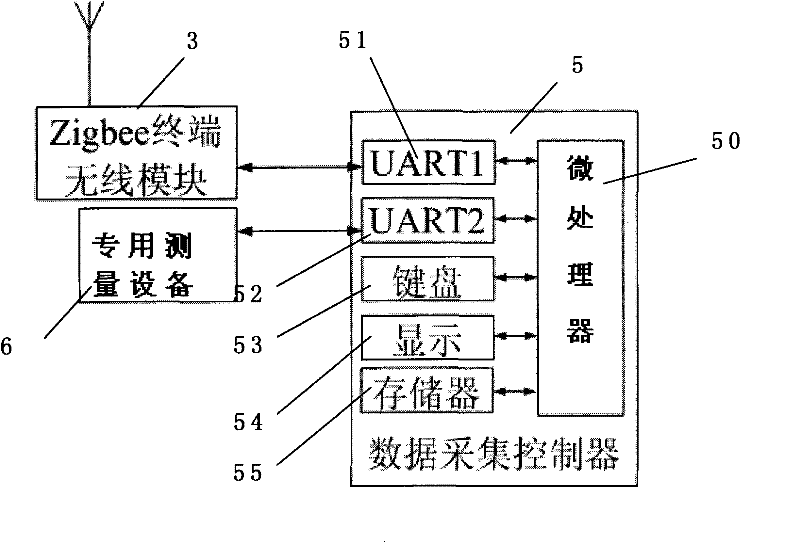

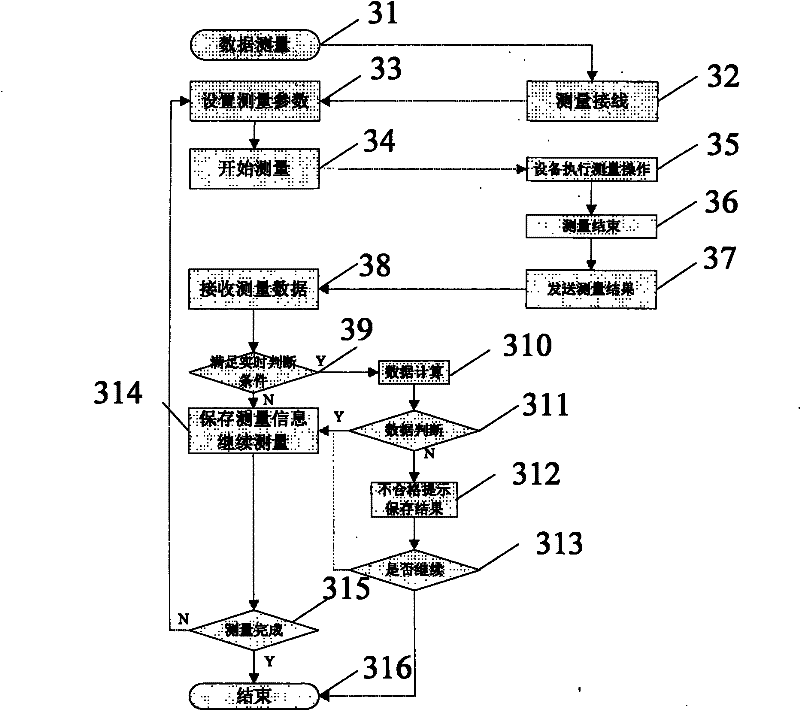

Transformer test data measurement system and its measurement positioning method based on wireless network

ActiveCN102289921APreserve the advantage of flexibilityGet rid of restrictionsTransmission systemsElectrical testingMeasurement deviceTransformer

The invention discloses a transformer test data measurement system and a method thereof based on a wireless network. The system comprises a monitoring center, a data acquisition center and a data transfer center; the monitoring center comprises a monitoring center computer, the data acquisition center comprises a plurality of data acquisition controllers and a plurality of special measurement devices, and the data transfer center comprises a Zigbee center wireless module and a Zigbee terminal wireless module; command and data are transferred between the monitoring center and the data acquisition center through the data transfer center; the special measurement devices are used for marking a corresponding actual position at a measurement position selected by the data acquisition controller so as to measure a target sample, transmitting back data through interfaces of the special measurement devices to the data acquisition controller after obtaining a measurement result, and receiving measurement result data; data is processed by the data acquisition controller after obtaining the data, and position information and the measurement result are stored; and then, selection of a next group of measurement positions and measurement operations are sequentially executed, until all the positions are measured.

Owner:苏州华储电气科技有限公司

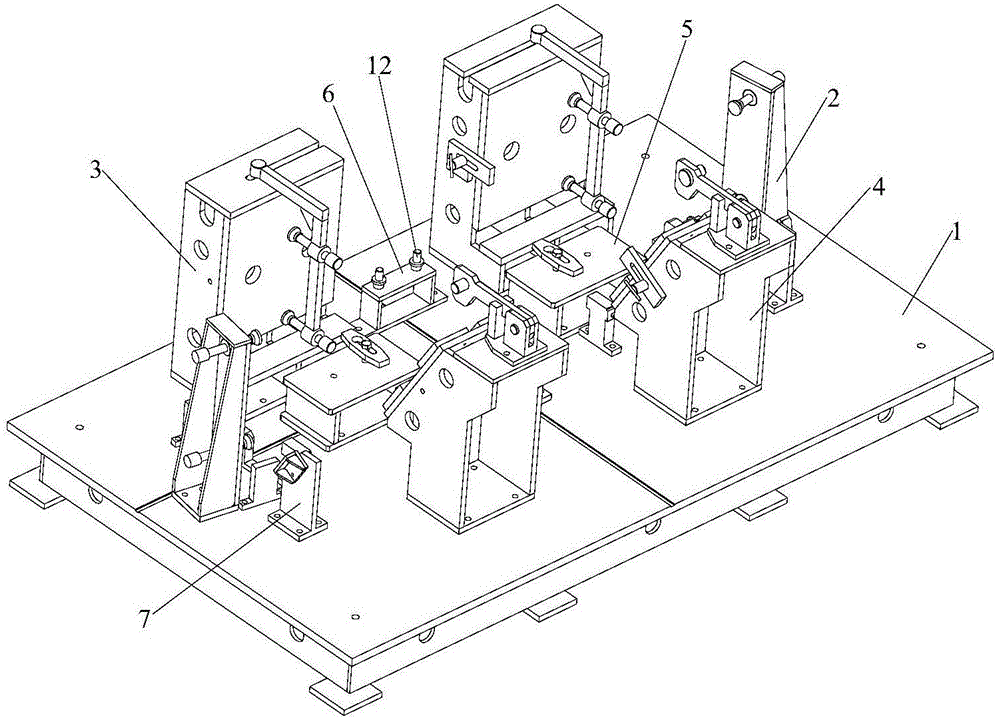

Overlap welding tool suitable for counterweight assembly of rear frame of hoisting traveling wheel type crane

ActiveCN105798519ALower skill requirementsSuitable for mass productionWelding/cutting auxillary devicesAuxillary welding devicesHigh volume manufacturingVehicle frame

The invention discloses an overlap welding tool suitable for a counterweight assembly of a rear frame of a hoisting traveling wheel type crane. The overlap welding tool comprises a base, equal-height pad assemblies arranged on the base, and cover plate positioning assemblies, side plate fastening assemblies and inclined plate positioning assemblies which are arranged on the base and distributed around the equal-height pad assemblies. According to the overlap welding tool suitable for the counterweight assembly of the rear frame of the hoisting traveling wheel type crane, all the positioning assemblies arranged on the base are used for accurately positioning and clamping all components of the counterweight assembly and performing welding assembling, so that the production efficiency is high, the product quality is stable, and the rejection rate is low; the requirement on the skill of a welding worker is reduced to a large extent, and the overlap welding tool is suitable for batch production.

Owner:ANHUI CHANG YONG DE MACHINERY

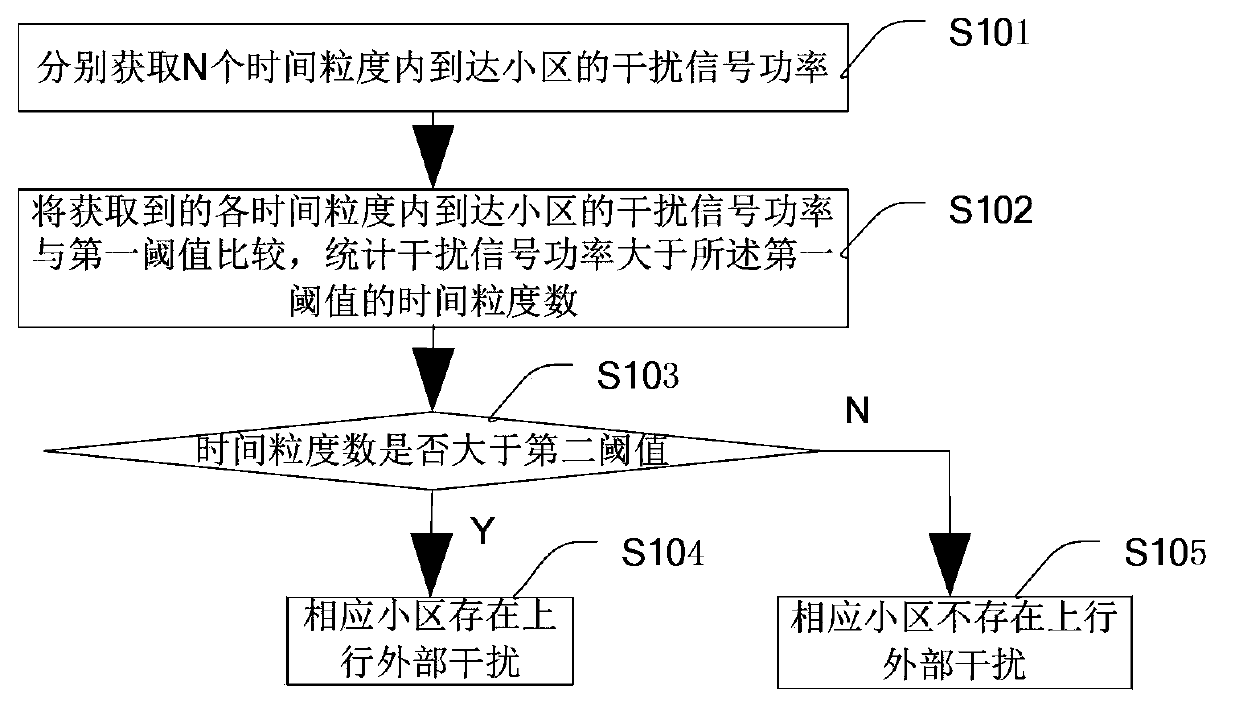

Uplink external interference detection method and device and uplink external interference source location method and device

InactiveCN103974280ALower skill requirementsReduce operation and maintenance costsWireless communicationGranularityComputer science

The invention discloses an uplink external interference detection method and device and an uplink external interference source location method and device. The uplink external interference detection method includes: acquiring powers of interference signals reaching cells in N time granularities respectively; comparing the acquired powers of the interference signals reaching the cells in each time granularity with a first threshold, and counting the number of time granularities in which the powers of the interference signals are larger than the first threshold; comparing the counted number of time granularities with a second threshold; if the counted number of time granularities is larger than the second threshold, determining that the corresponding cells have uplink external interference. The uplink external interference source location method includes: determining all interfered cells having the uplink external interference by the uplink external interference detection method; determining the interfered cells influenced by the same interference source, from all interfered cells according to preset rules; according to the interfered cells influenced by the same interference source, calculating location information of the interference source. Through the adoption of the technical scheme, the technical problem that the traditional schemes are imperfect is solved.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com