Energy-saving argon tungsten-arc welding assembly with adjustable welding torch

A technology of argon tungsten arc welding and components, applied in the direction of electrode accessories, arc welding equipment, electrode characteristics, etc., can solve the problems of no insulation, uneven gas film protection, unreasonable structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

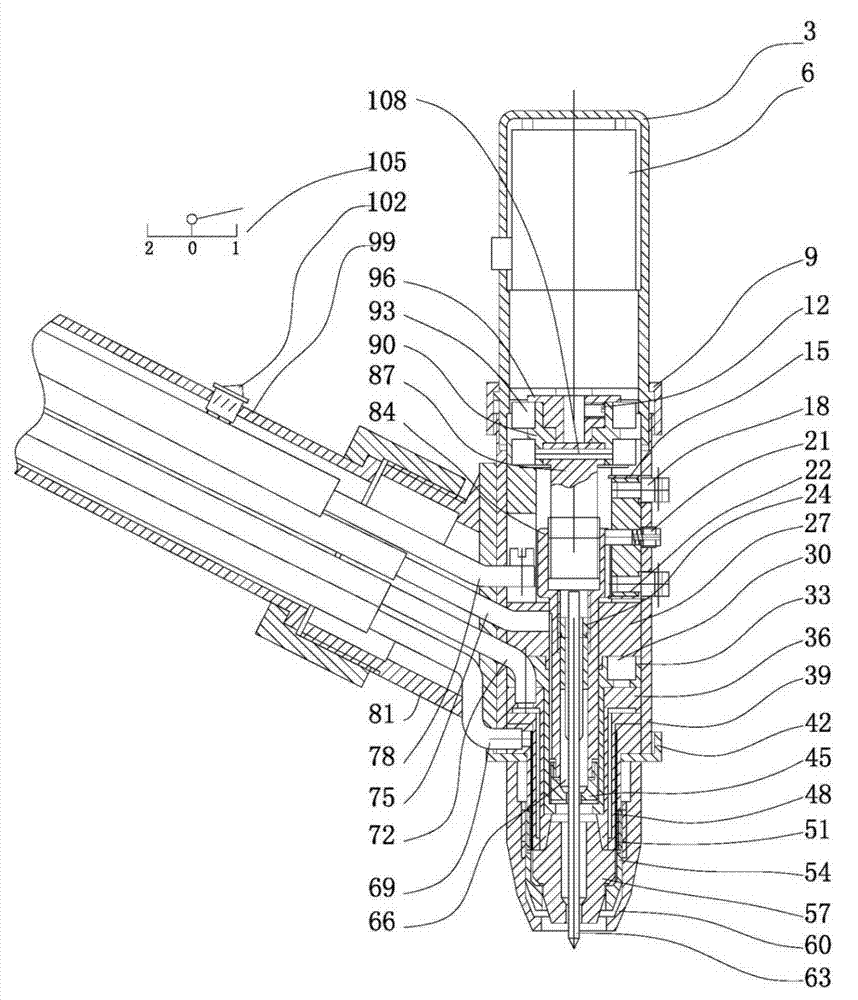

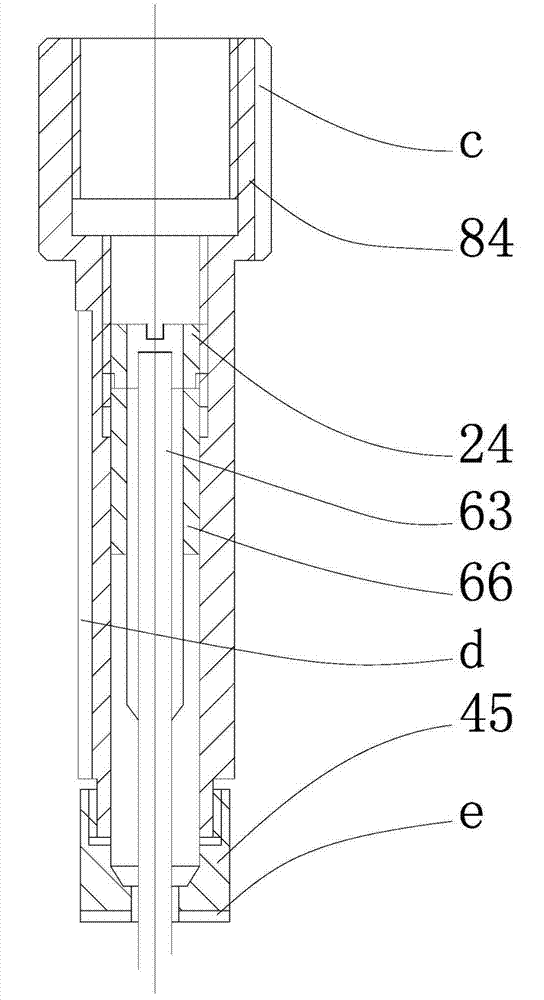

[0049] The specific implementation of the energy-saving argon tungsten arc welding adjustable welding torch assembly provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

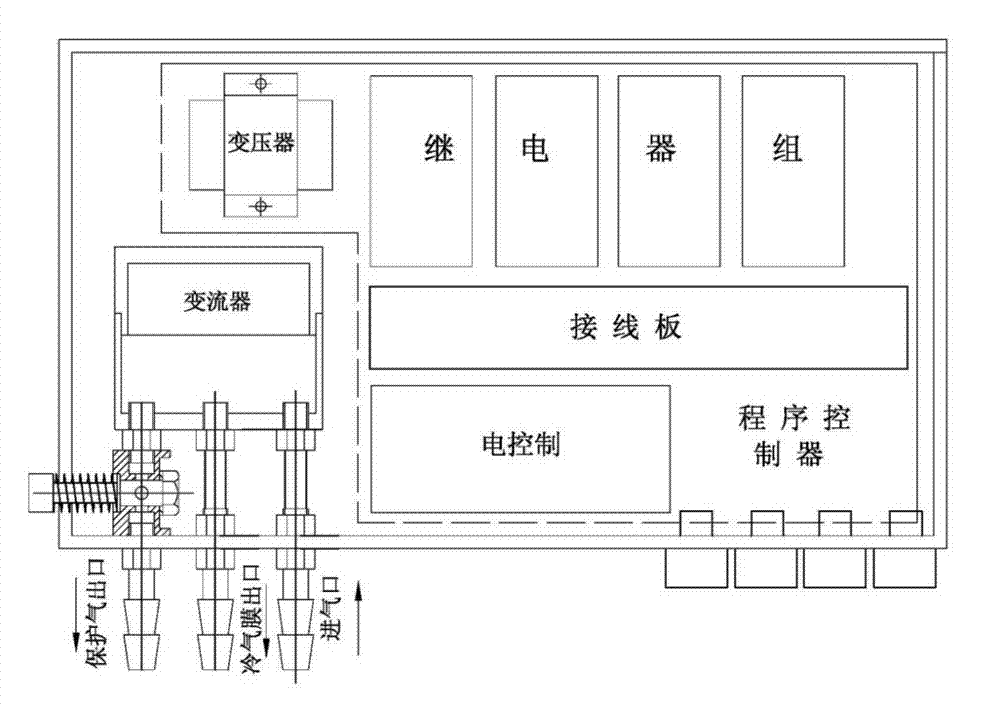

[0050] The energy-saving argon tungsten arc welding adjustable welding torch assembly involved in the present invention includes a welding torch, an electrical control device connected to the welding torch, a water, gas and electric control box, a peripheral cooling water circulation system, and an argon gas supply system. The welding torch includes a tungsten rod clamping assembly, an insulating jacket, a motor reducer, a cooling jacket, an arc nozzle, a nozzle compression ring, a shielding gas nozzle, an operating handle and an arc regulating switch arranged on the insulating jacket; The water, gas and electric circuit inside the operating handle are connected with the external water, gas and electric control box; the tungsten rod clamping assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com