Overlap welding tool suitable for counterweight assembly of rear frame of hoisting traveling wheel type crane

A technology of counterweight assembly and crane, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of high welding technical level, unstable product quality, long welding time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

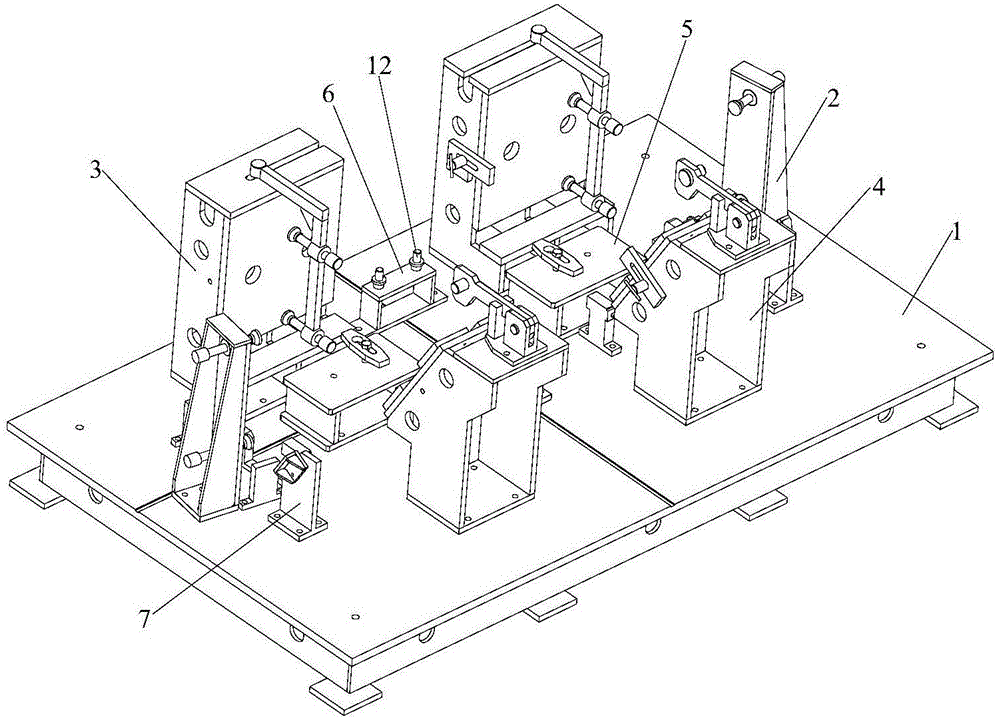

[0050] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

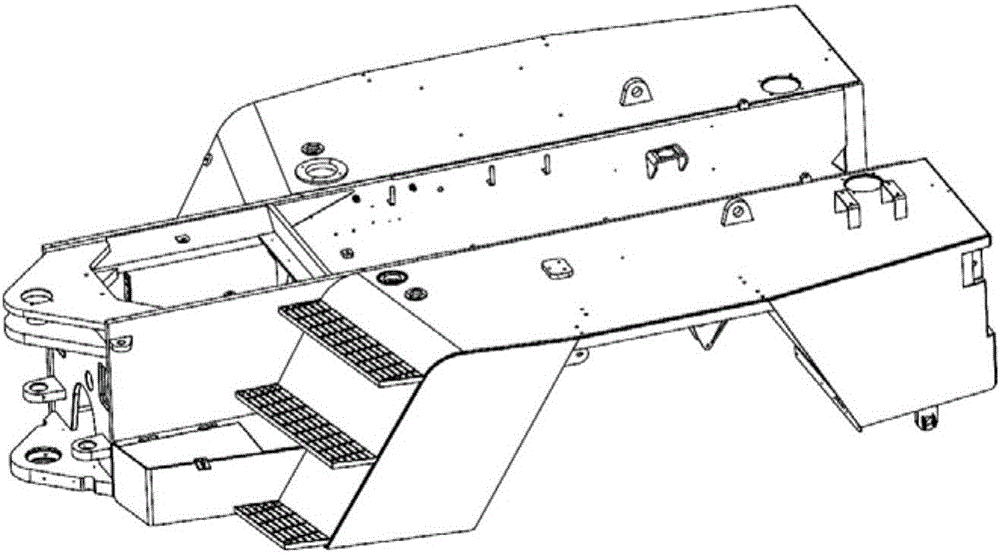

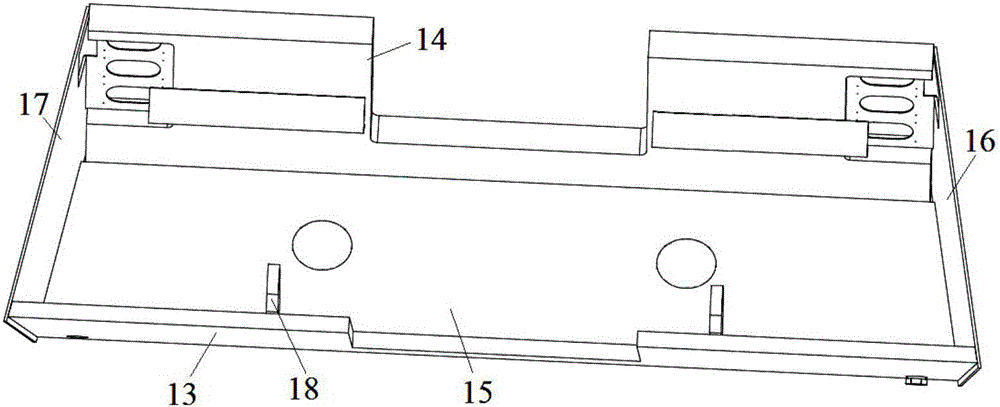

[0051] The invention provides a lap welding tool suitable for hoisting the counterweight assembly of the rear frame of a traveling wheeled crane, which is used for accurately positioning and clamping each component part of the counterweight assembly, and is convenient for welding and assembling. The hoisting traveling wheeled crane has the advantages of fast traveling speed and quick arrival at the job site, as well as strong performance and flexible maneuverability in narrow spaces. The chassis of the hoisting wheeled crane is divided into a front frame and a rear frame, and the front frame and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com