Patents

Literature

533results about "Electrode accessories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

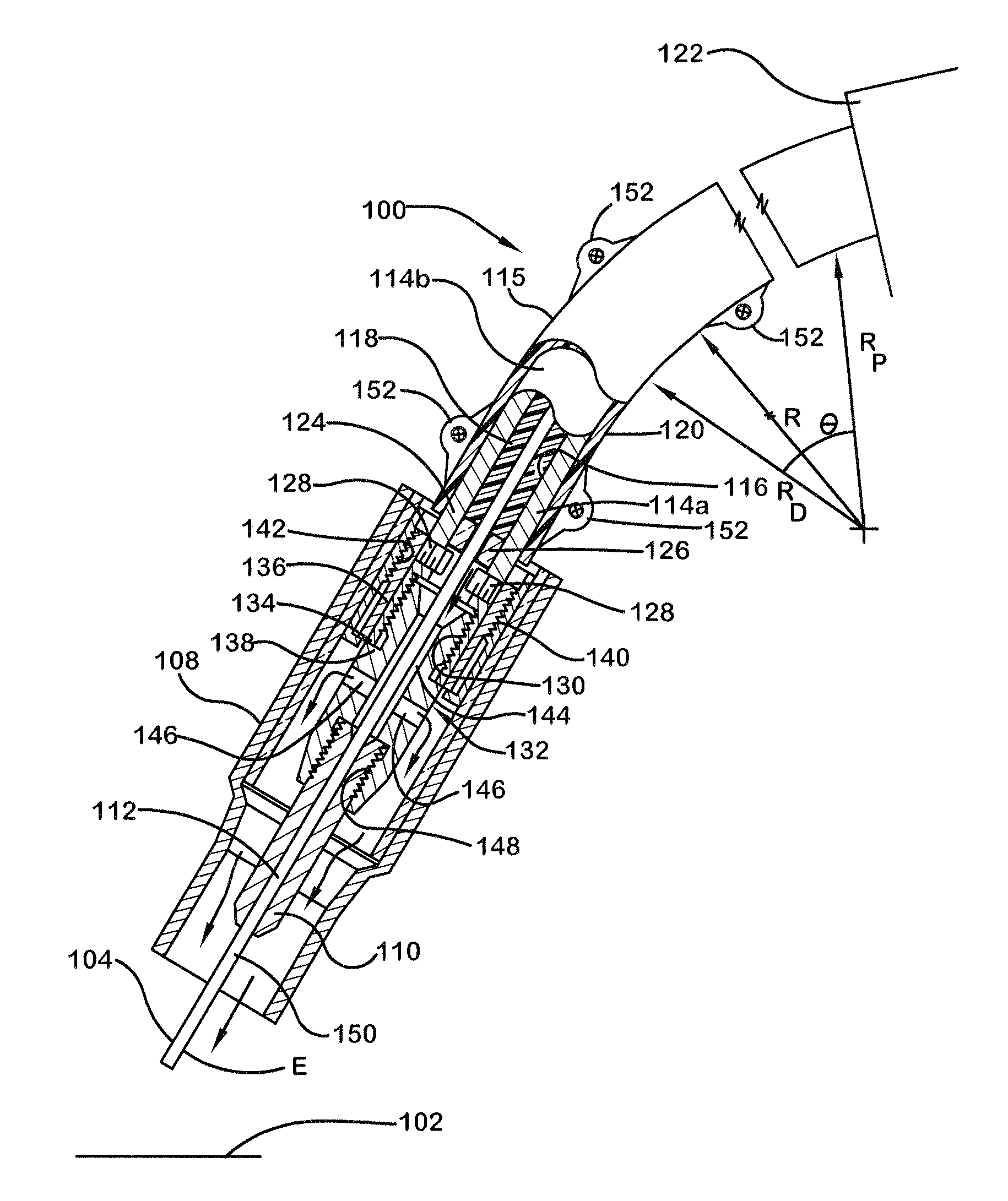

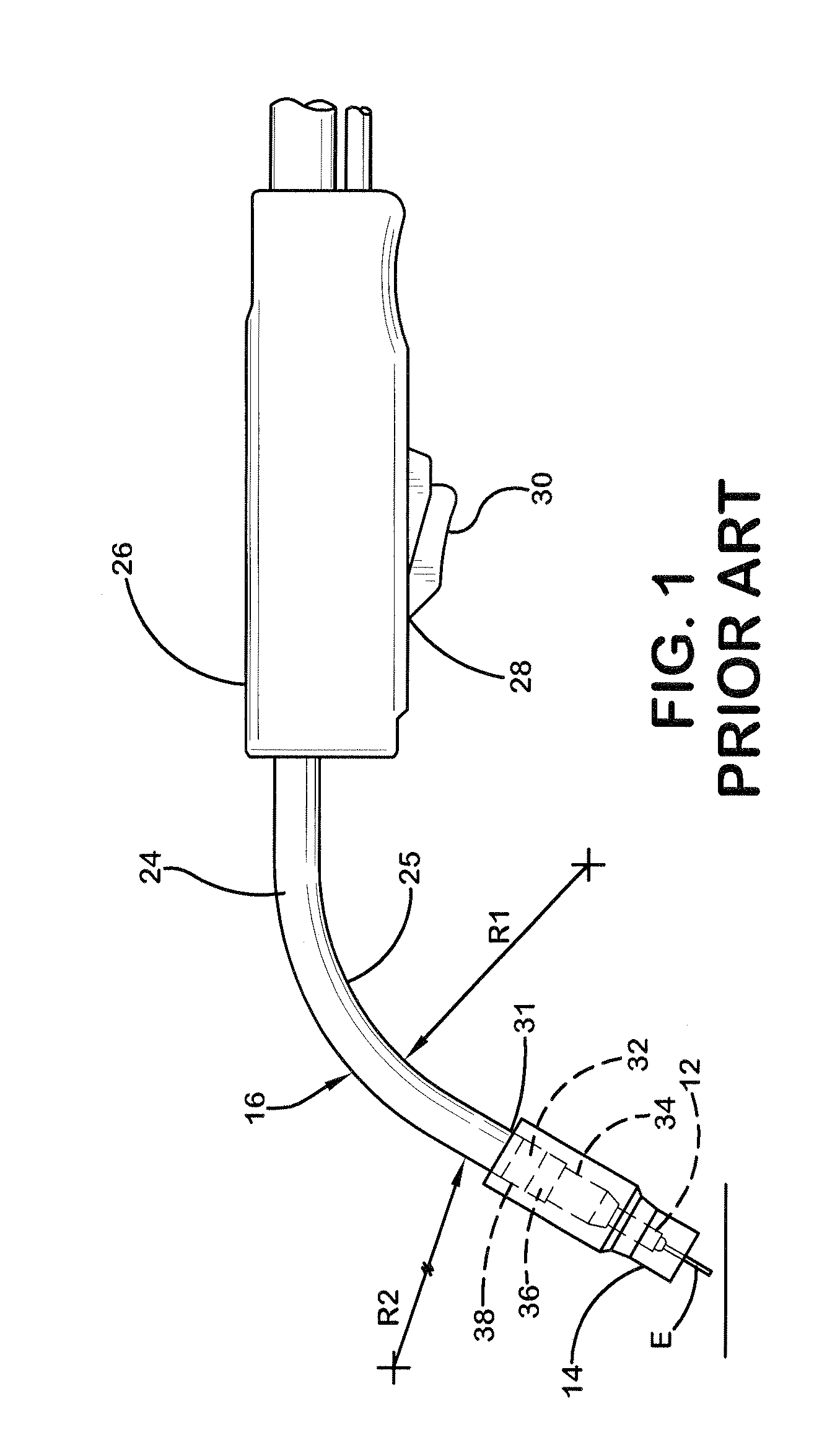

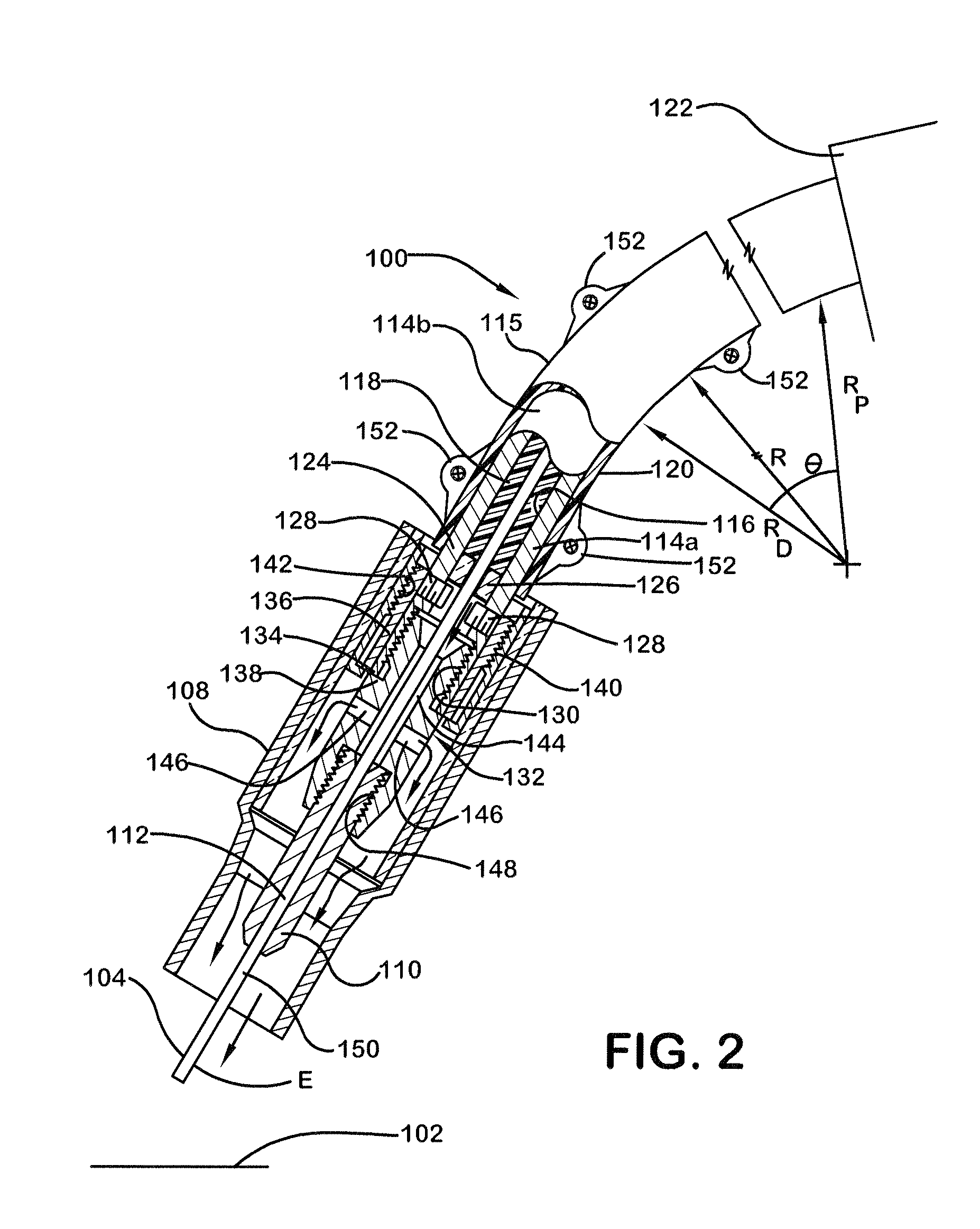

Apparatus and method for welding

InactiveUS20100276396A1Improve smoke extraction efficiencyFine-tune fume extraction efficiencyShielding gas supply/evacuation devicesDirt cleaningShielding gasCarbon Dioxide / Helium

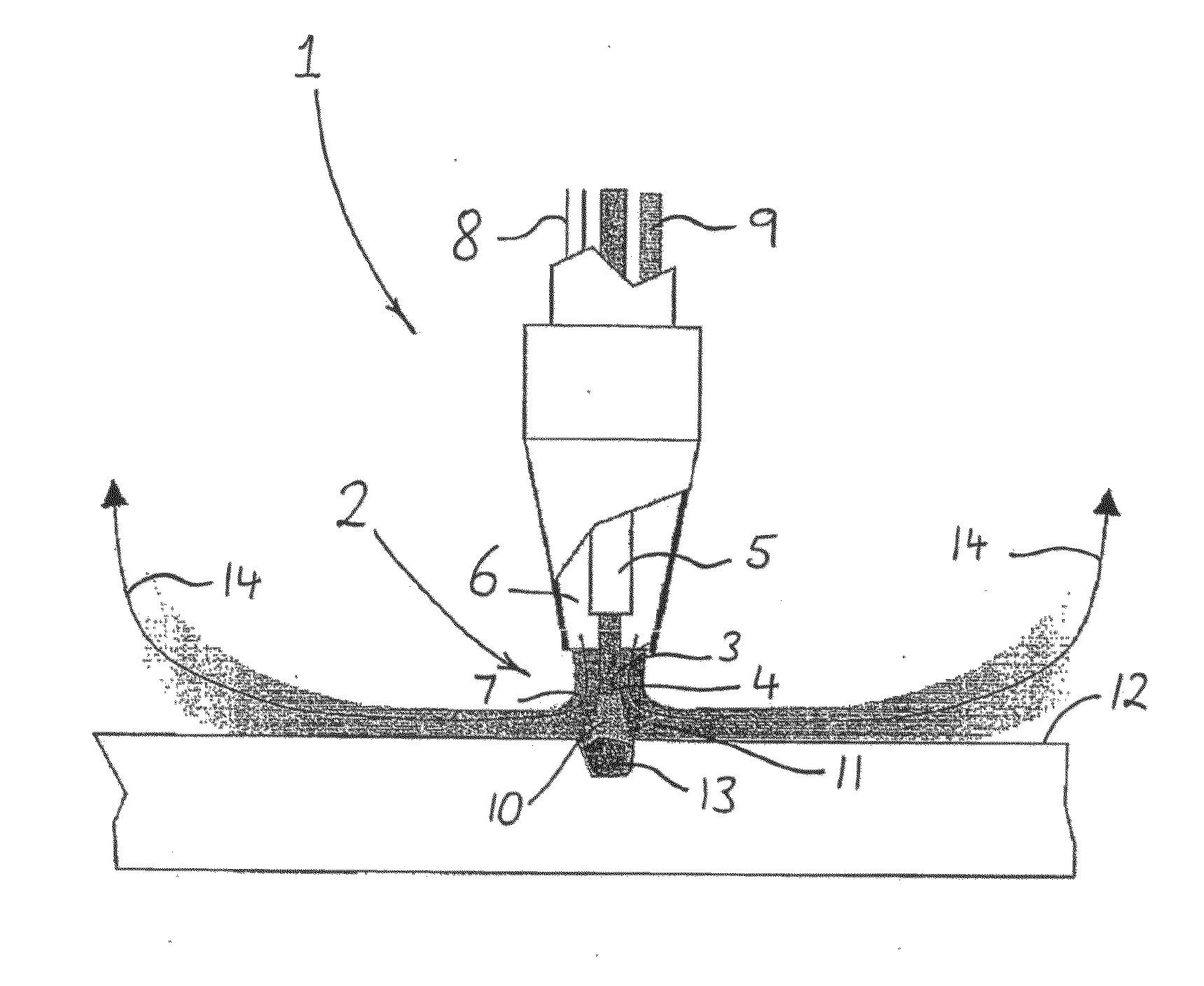

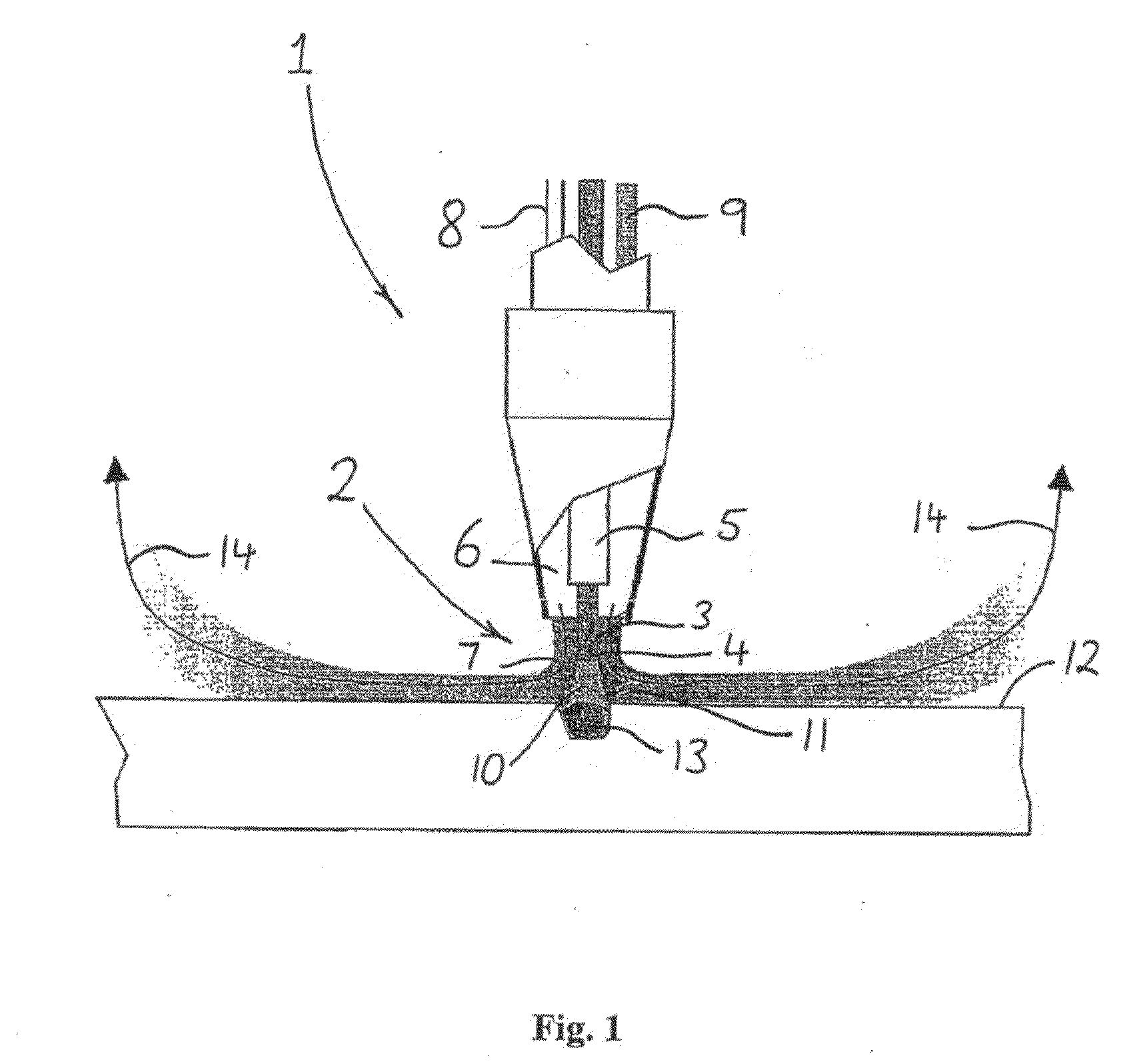

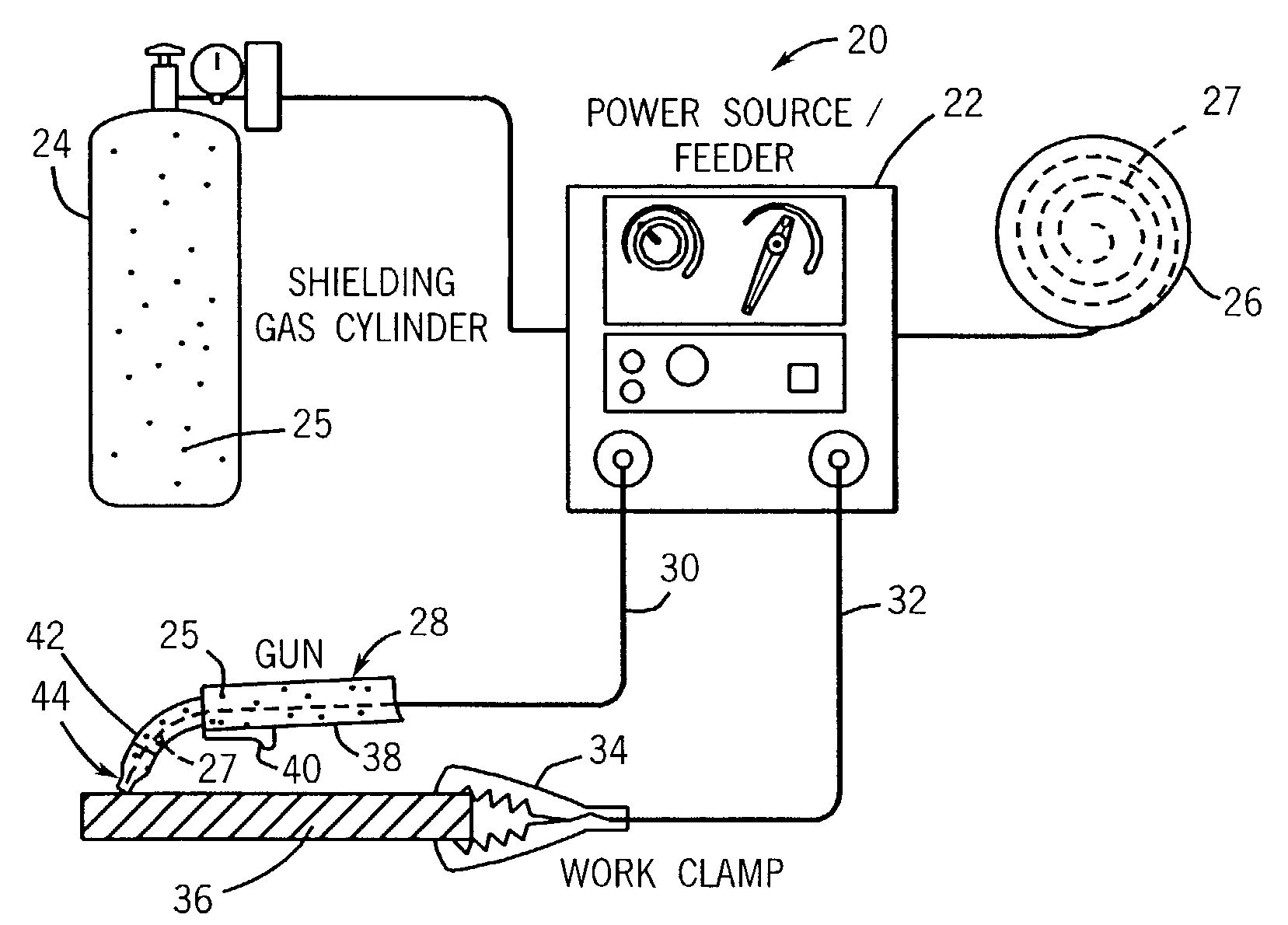

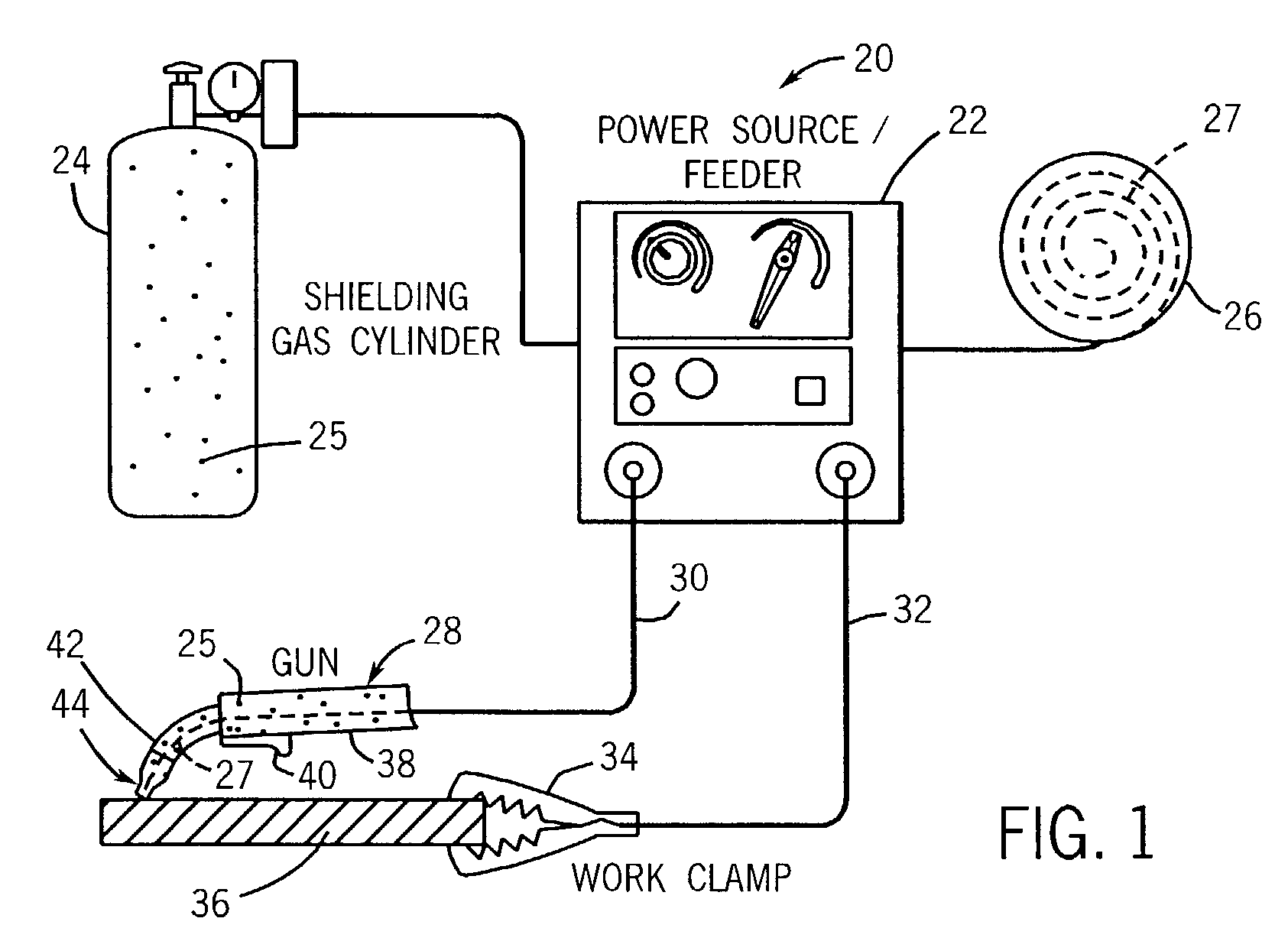

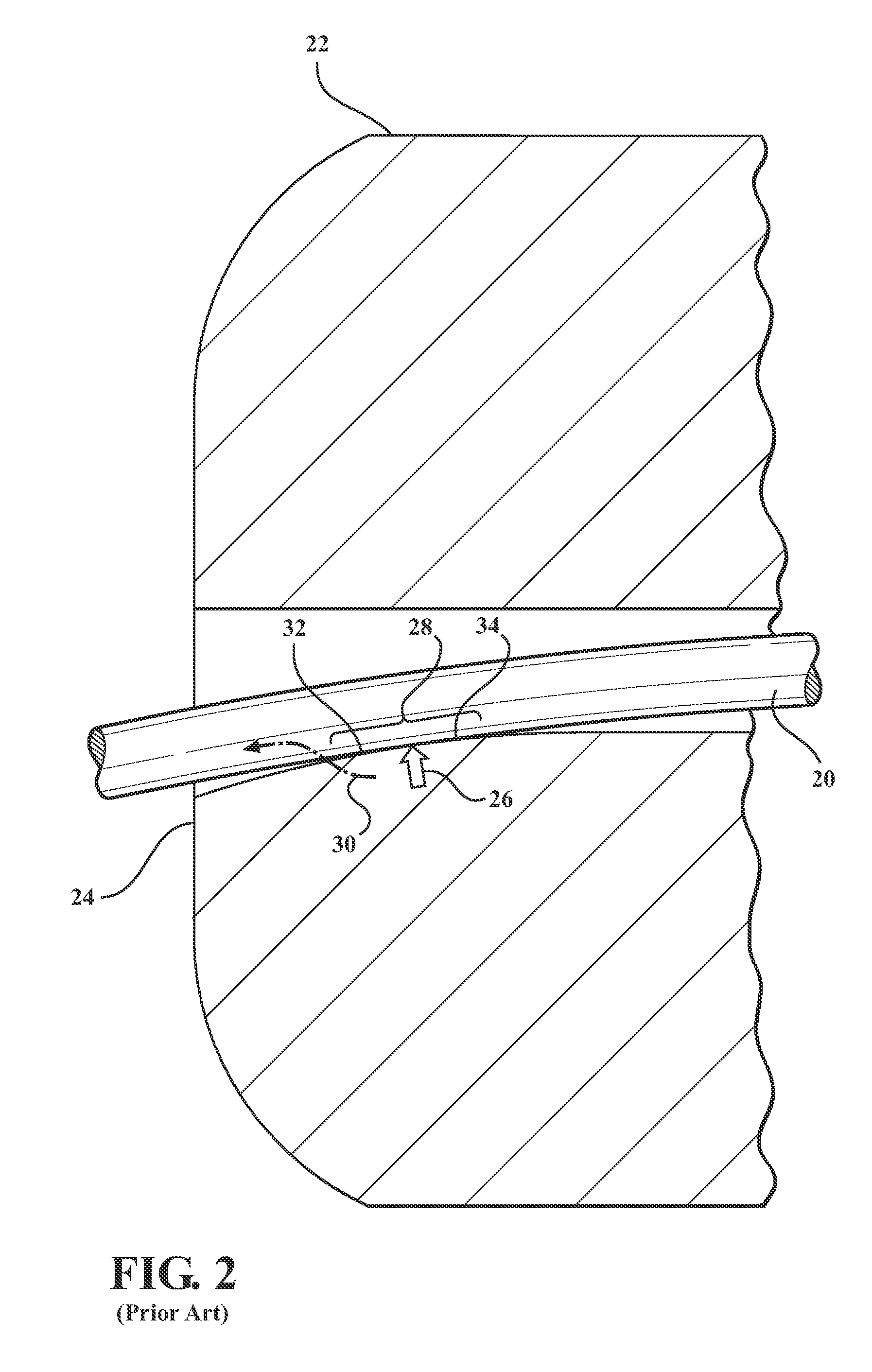

The present invention relates to arc welding torch and a method of extracting fume gas from a welding site. The torch comprises a metal electrode and at least one shield gas port adapted to direct a shield gas curtain around the metal electrode and a welding site. At least one shroud gas port is spaced radially outward from the shield gas port and adapted to impart to an exiting shroud gas a radially outward component of velocity. Fume gas is preferably extracted from a position radially intermediate the shield gas curtain and the shroud gas curtain.

Owner:COOPER PAUL +2

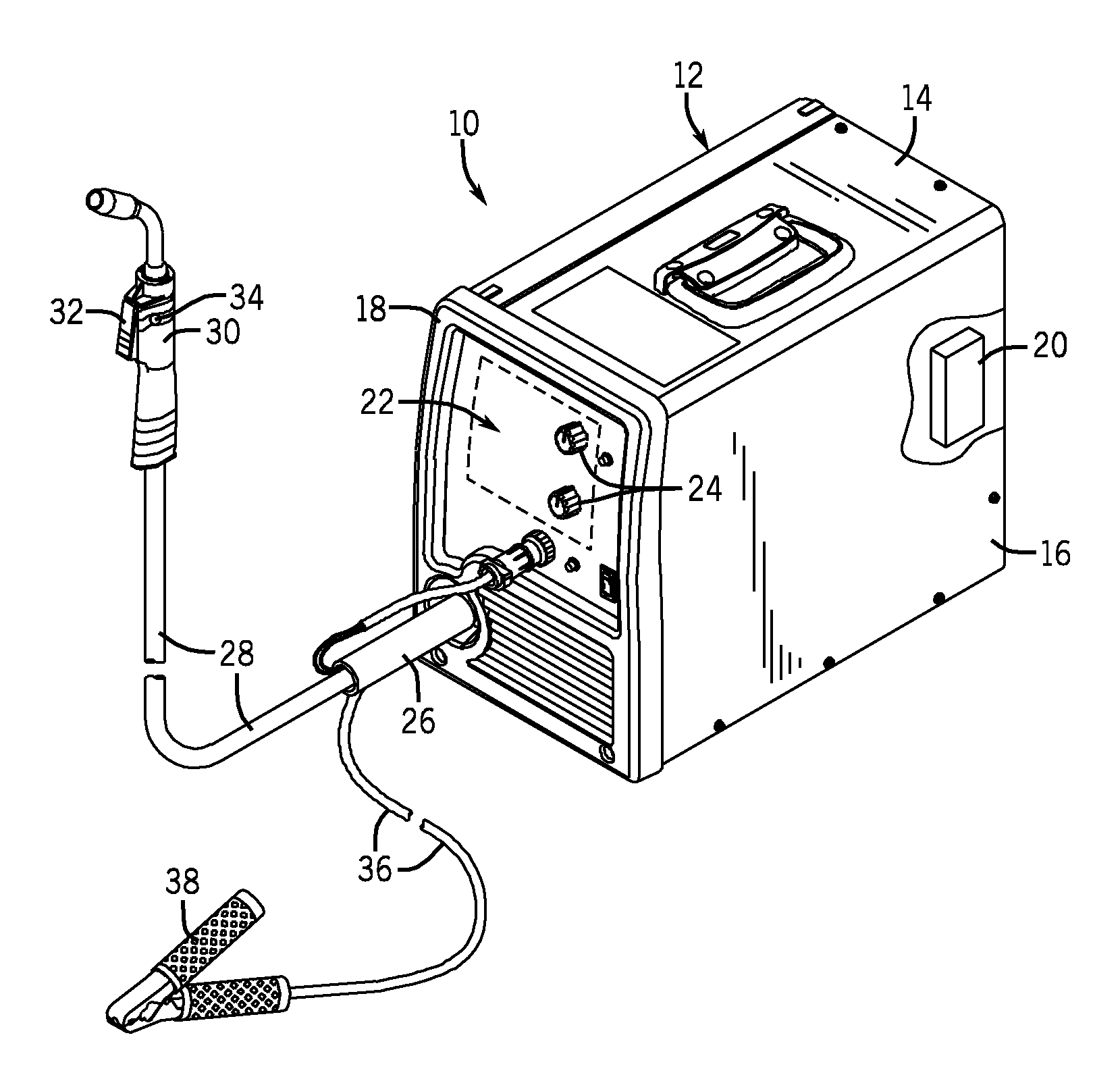

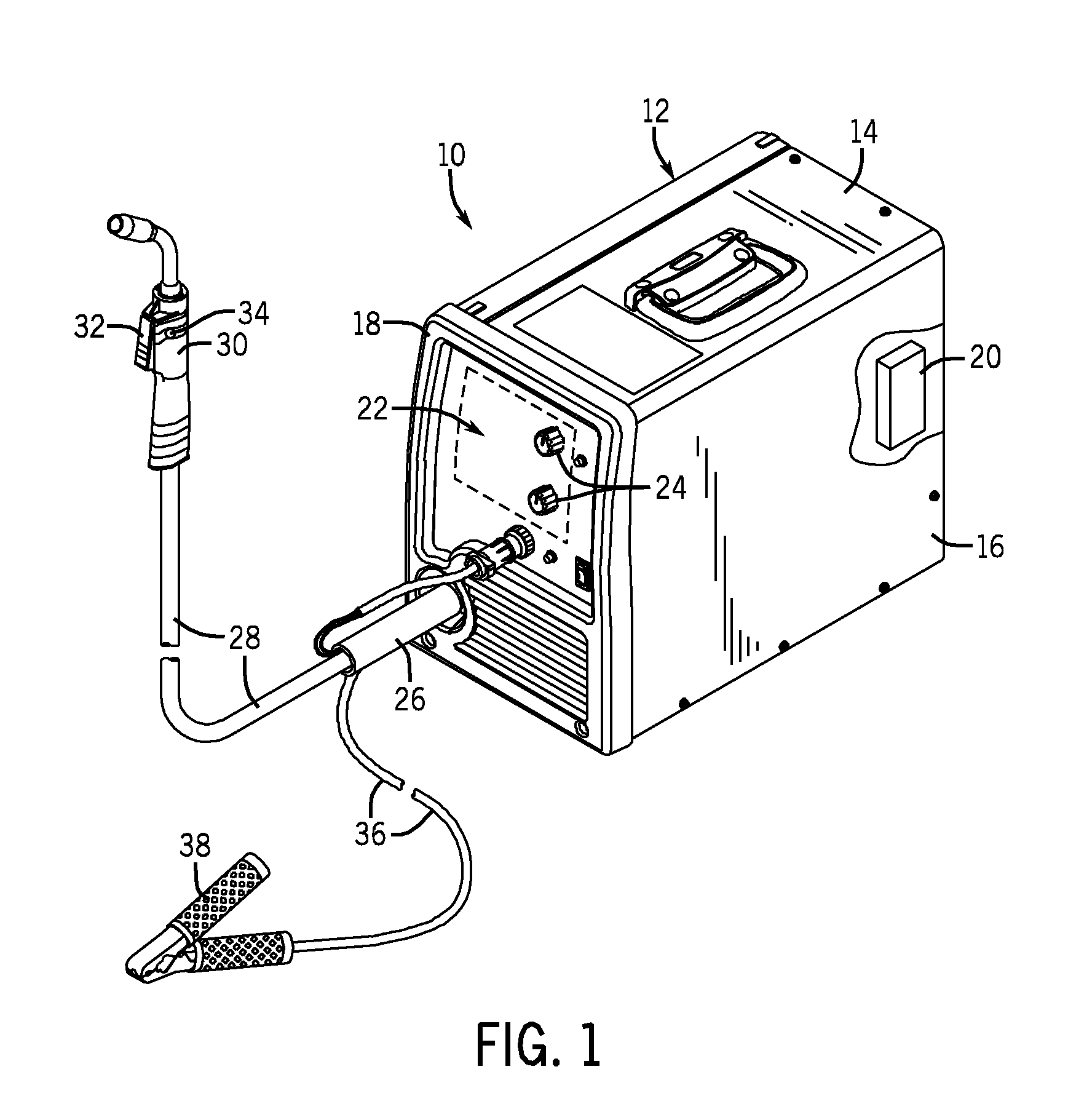

Arc welder and torch for same

InactiveUS6259059B1Increase currentStable welding processSupport devices with shieldingElectrode accessoriesElectric arcEngineering

Owner:LINCOLN GLOBAL INC

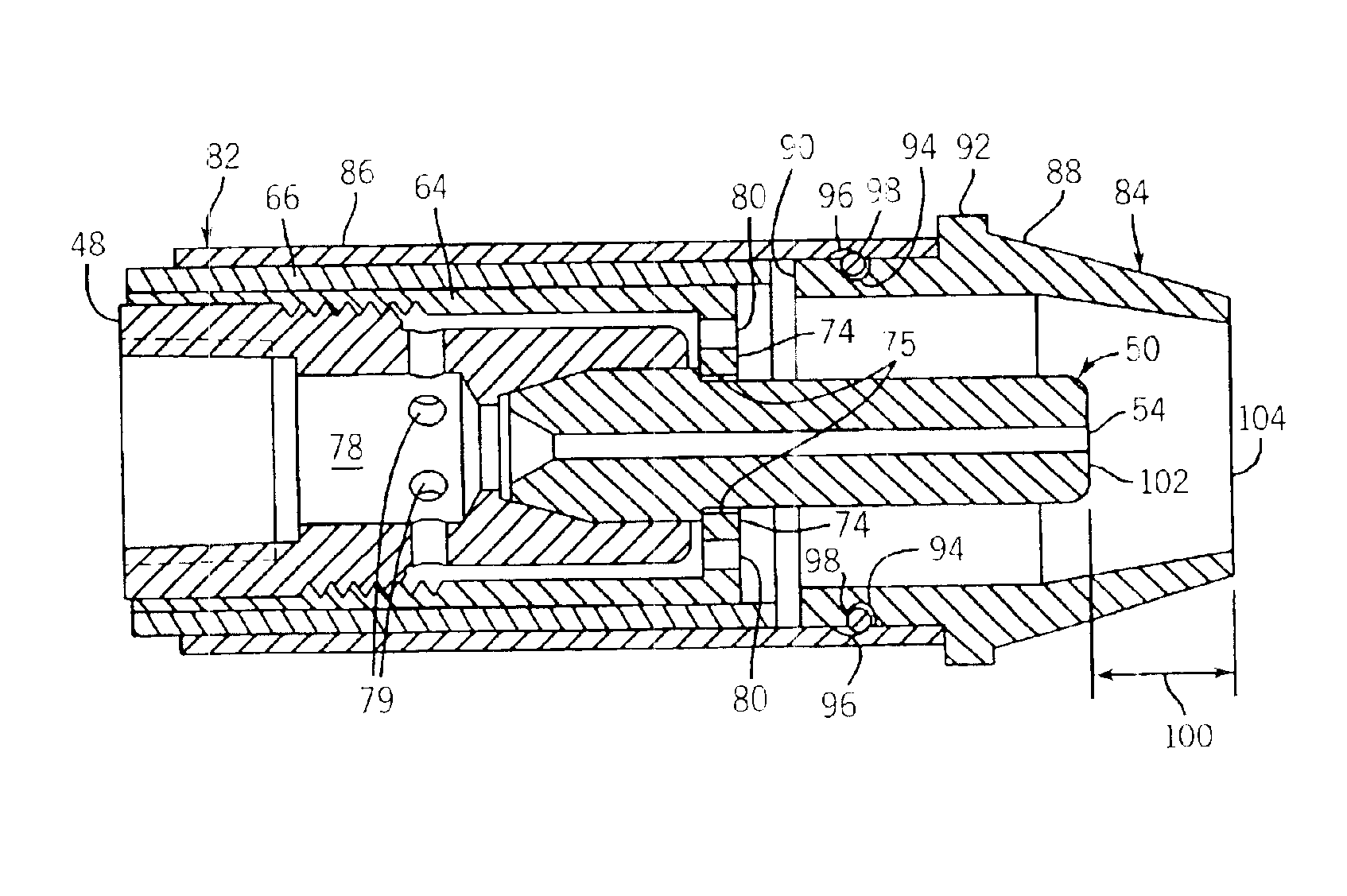

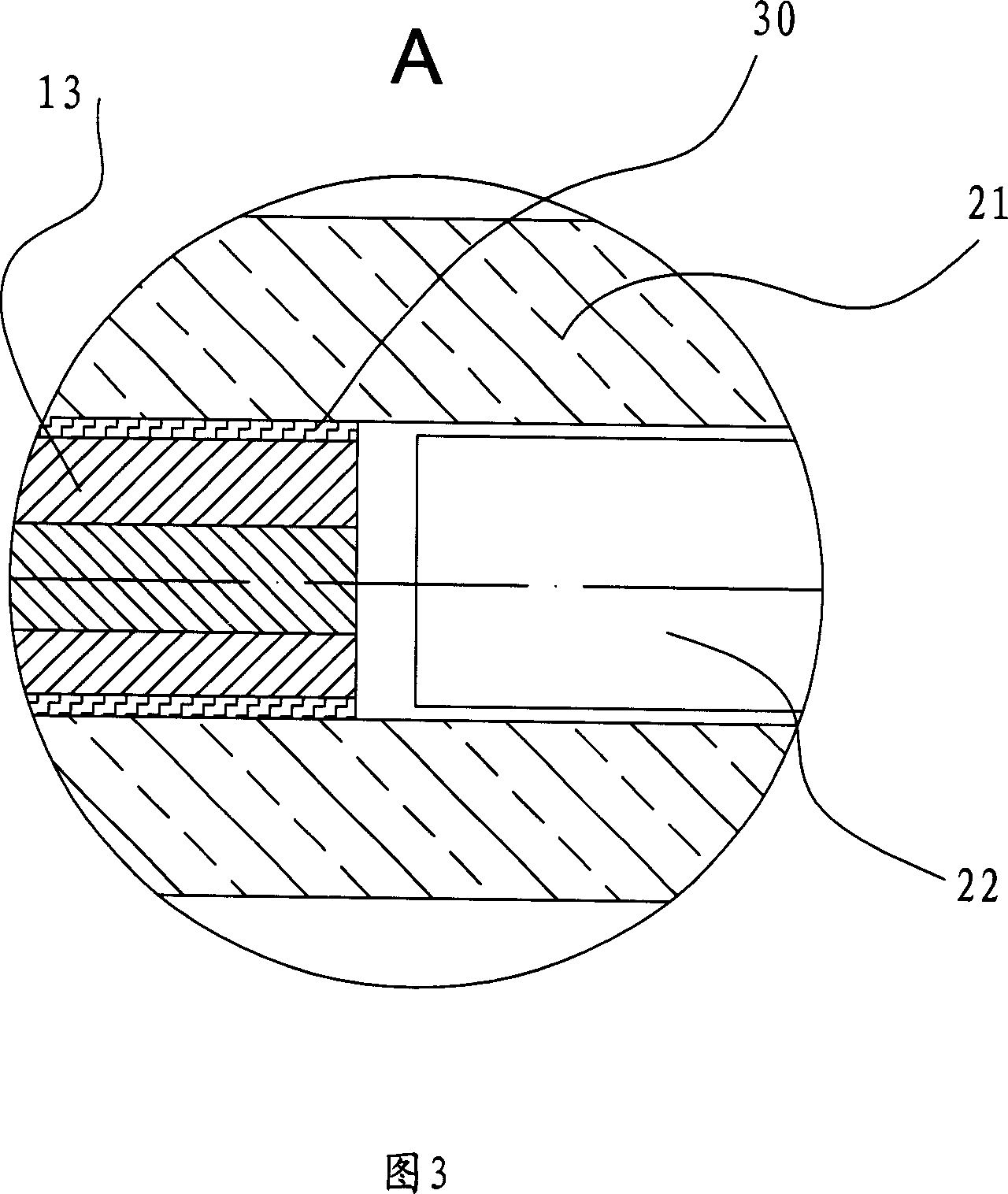

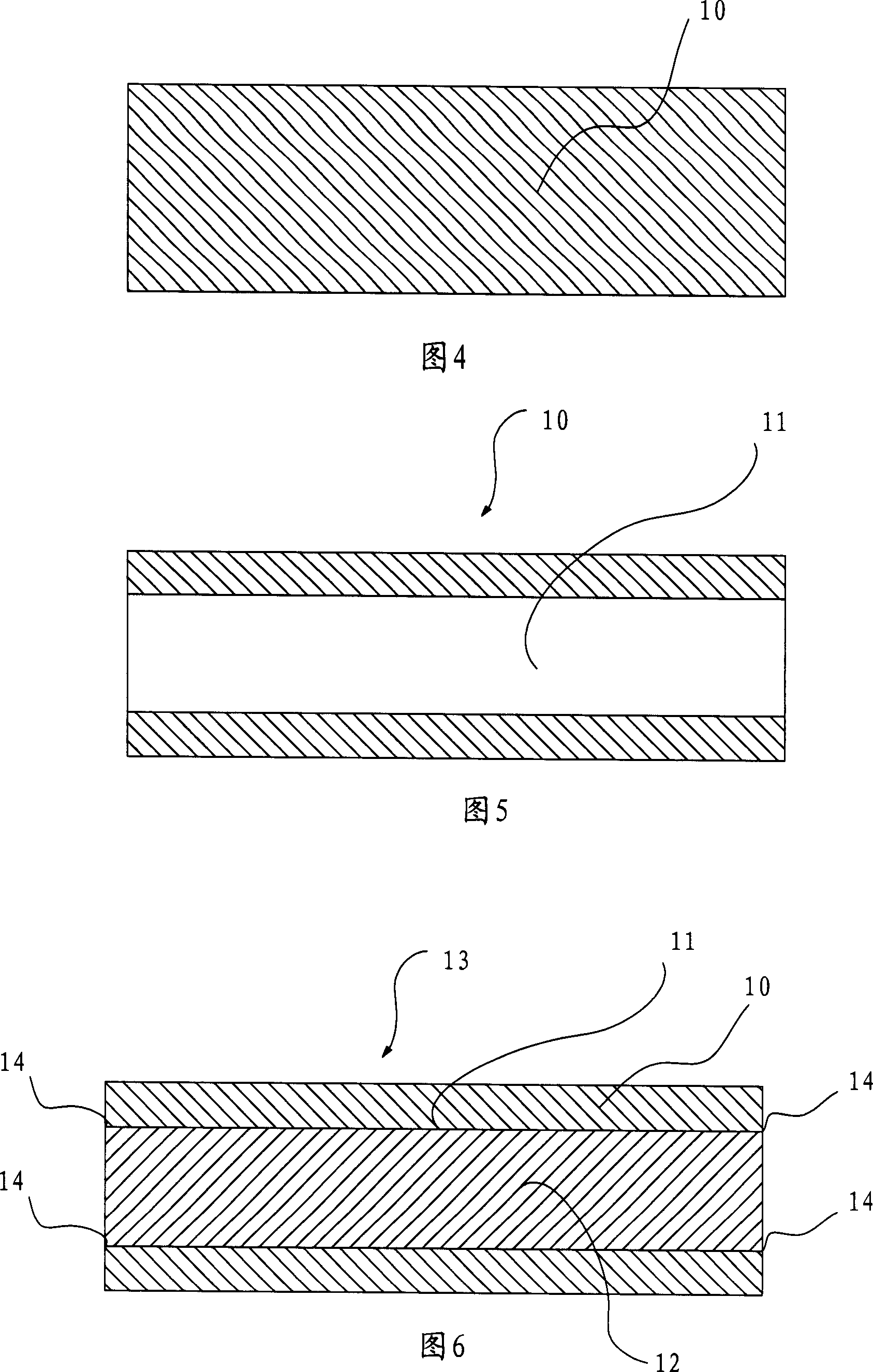

Welding contact tip and diffuser

InactiveUS6847009B2Reduce heatExtended component lifeSupport devices with shieldingElectrode accessoriesAxial forceEngineering

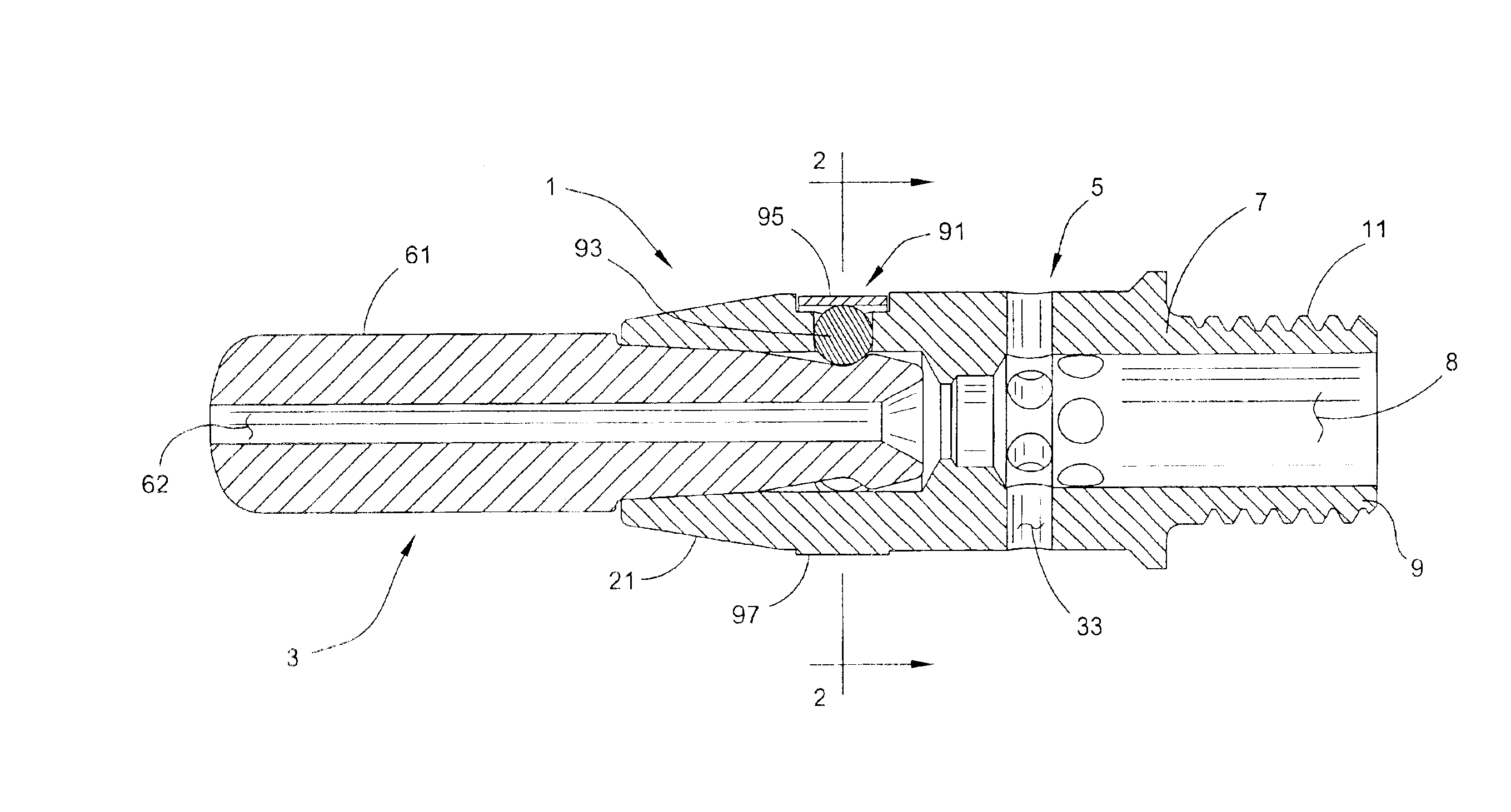

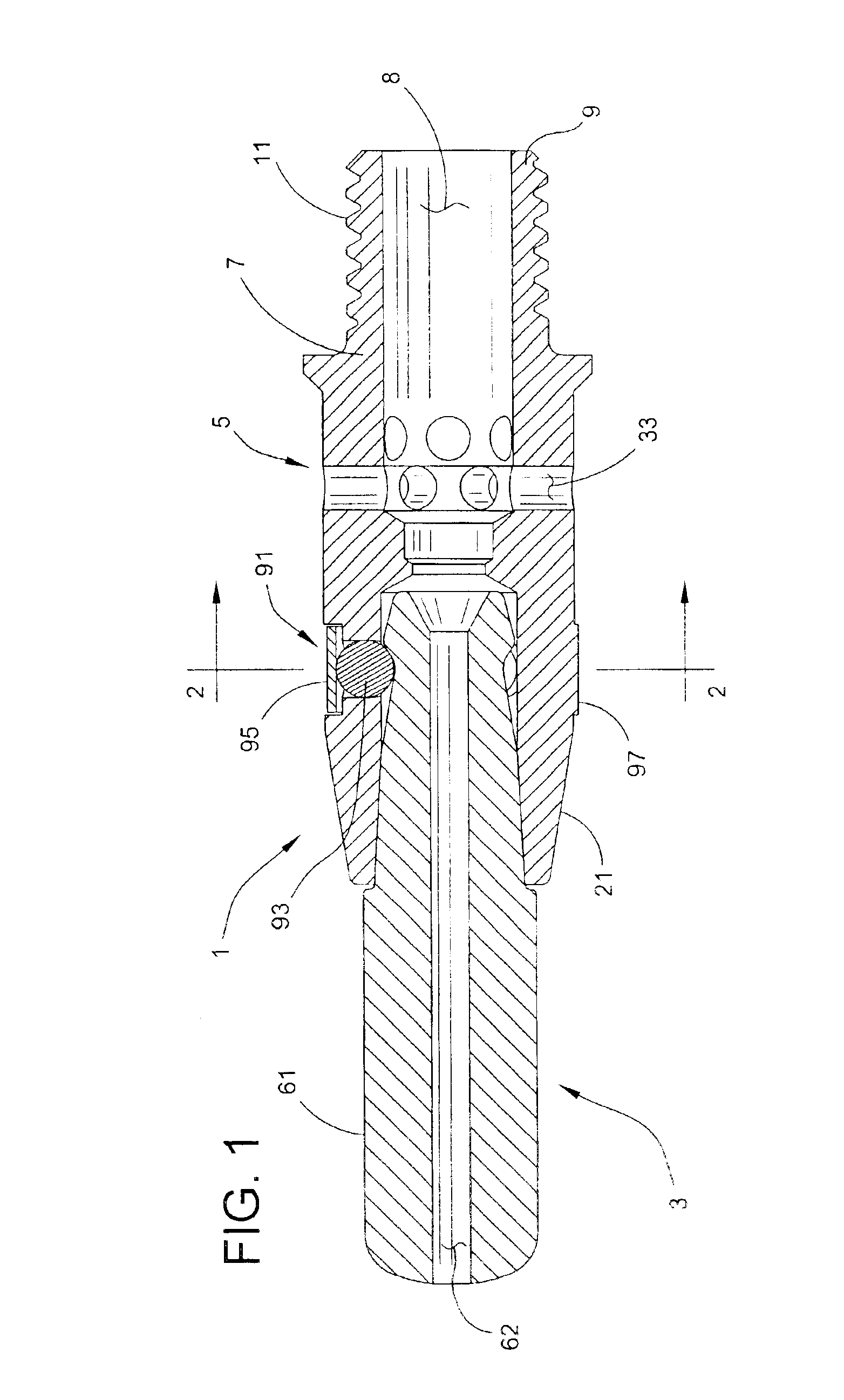

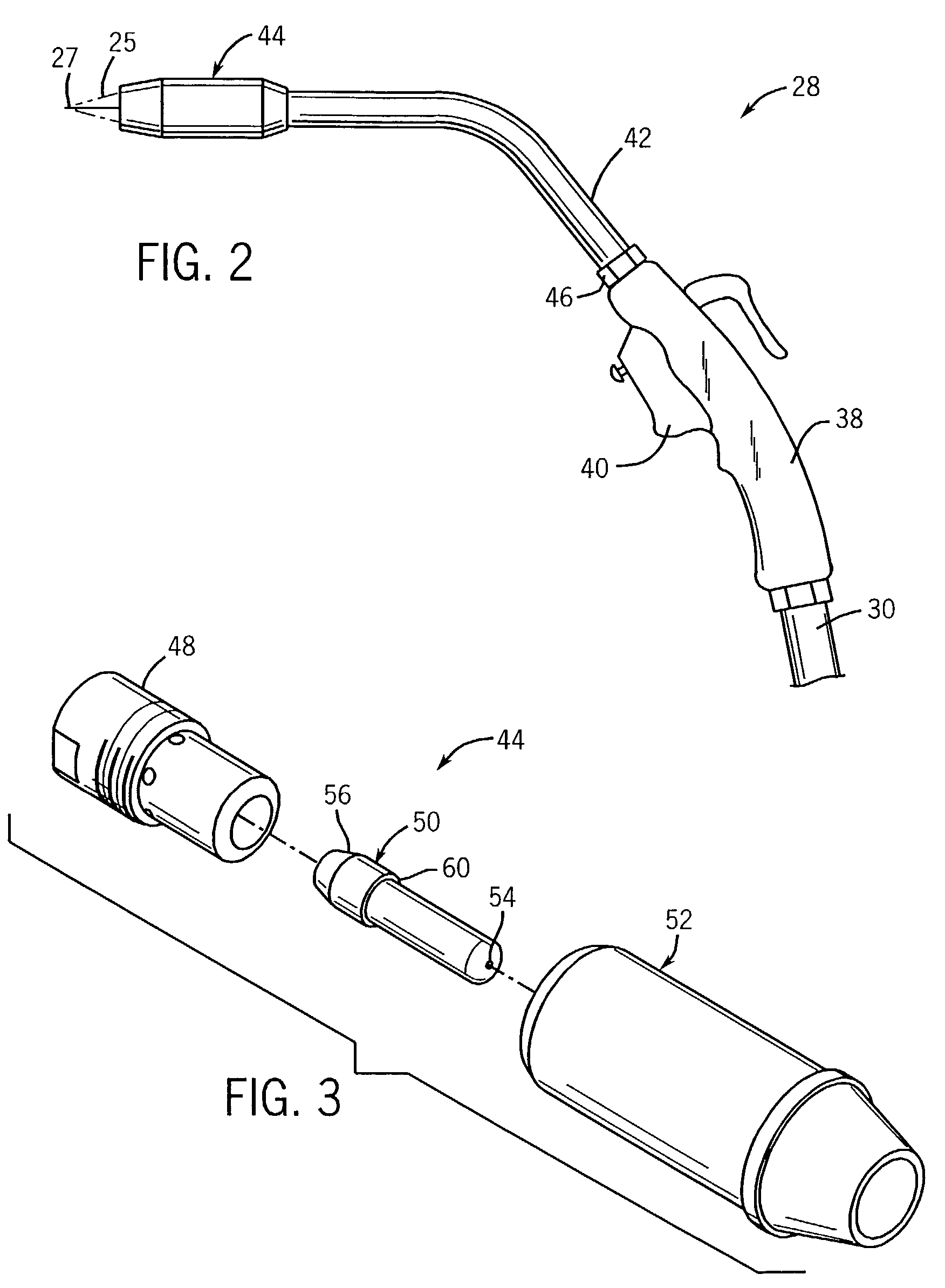

A welding contact tip and diffuser assembly for use in a welding apparatus. The assembly includes an electrically conductive contact tip having a tapered exterior surface, a diffuser having a cavity with a tapered interior surface, and a releasable connection for holding the contact tip in the diffuser. The connection includes at least one detent element in either the diffuser or the contact tip, at least one recess forming a ramp in the other of the diffuser or contact tip, and at least one spring. The spring biases the detent element into the recess and against the ramp to generate an axial force against the ramp. The axial force tends to urge the tapered surfaces of the contact tip and diffuser into contact with one another.

Owner:VICTOR EQUIP

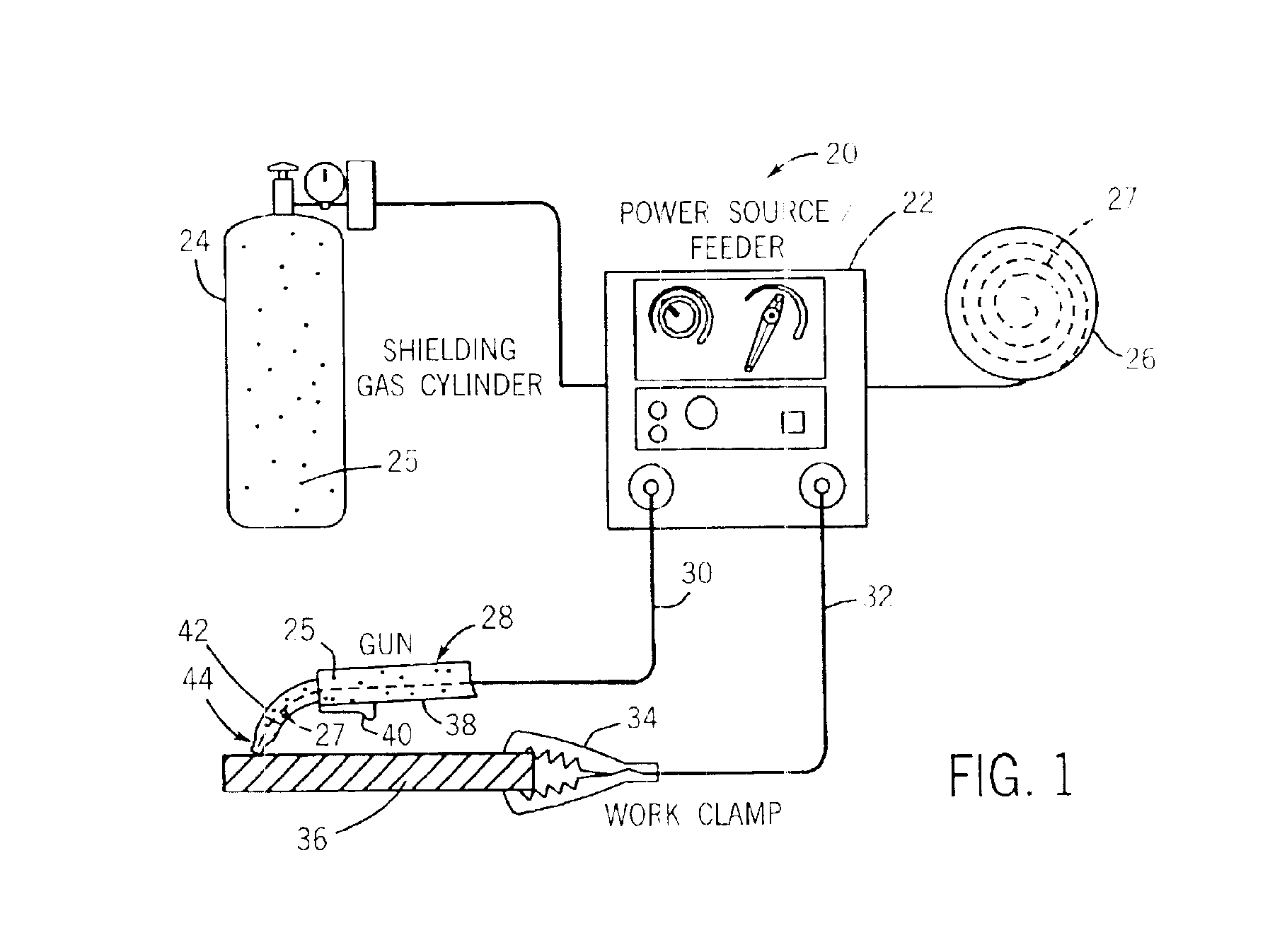

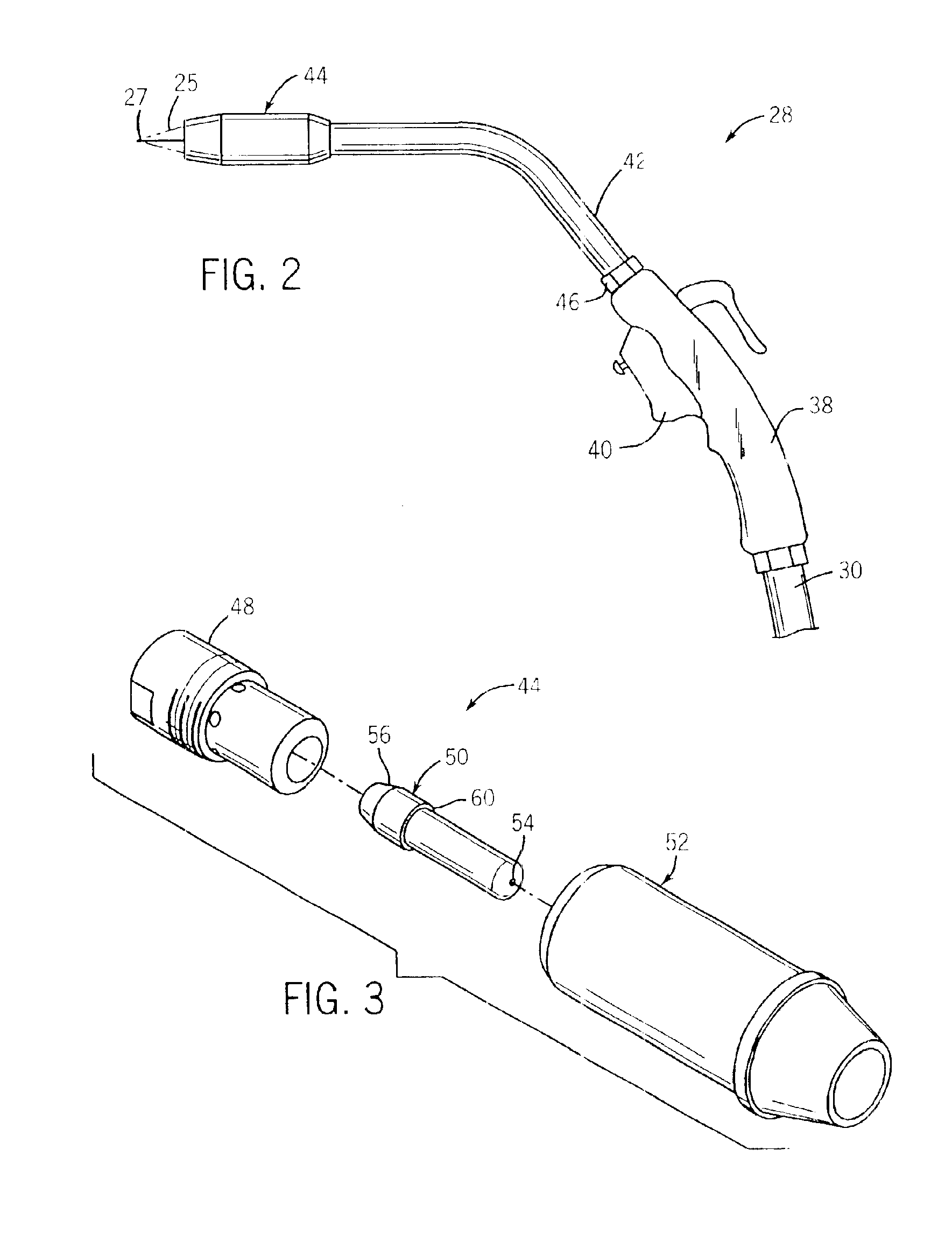

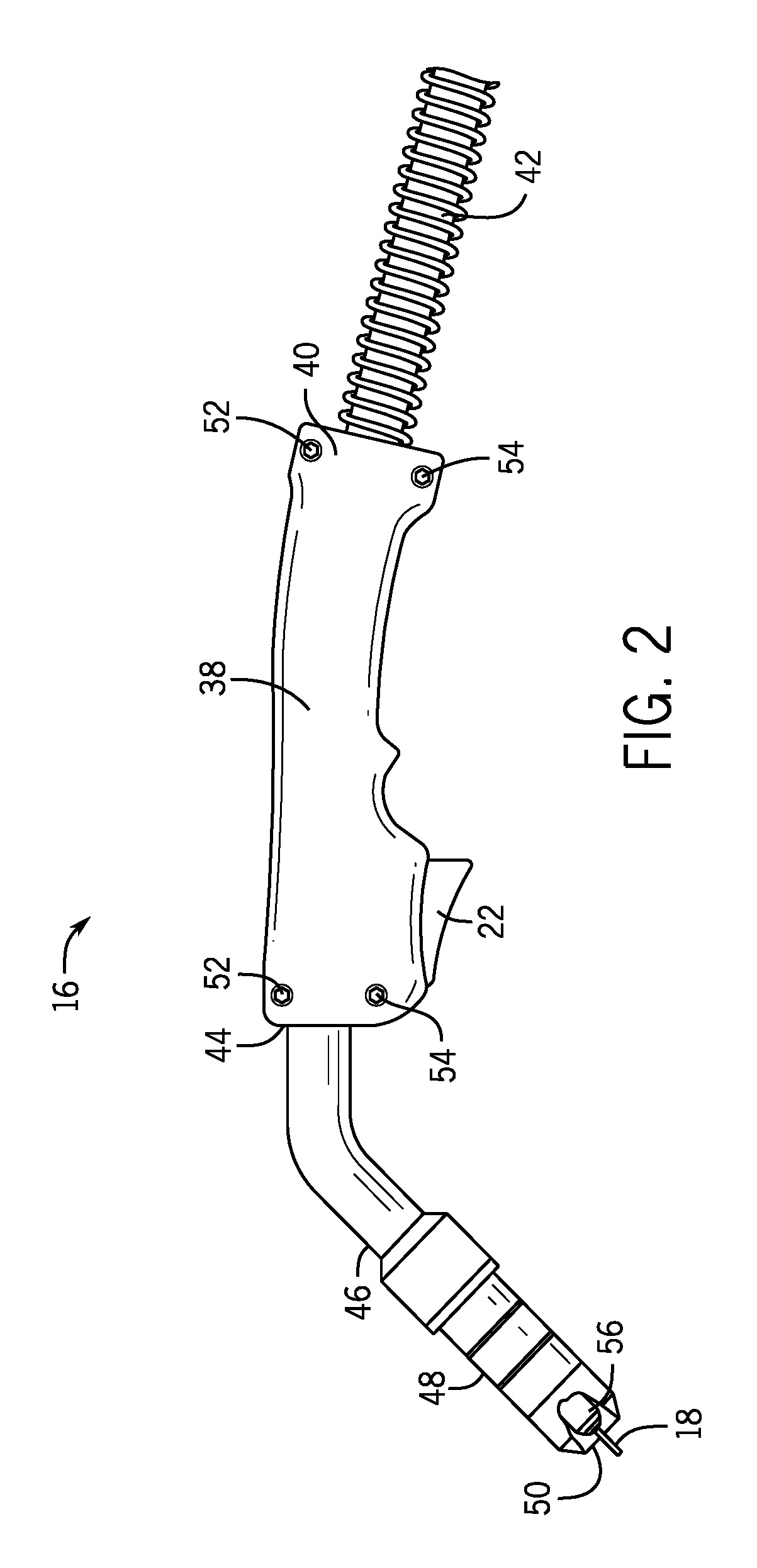

Welding gun having contact tip and method of operating same

InactiveUS7105775B2Support devices with shieldingNon-shielding electrode holdersAbutmentBiomedical engineering

A welding gun adapted to secure a contact tip within the welding gun without threading the contact tip and without the use of tools. The contact tip may be adapted to abut a surface of a first member disposed within the welding gun. The surface may be a surface of a gas diffuser. The surface may be adapted to abut the contact tip. The contact tip also may be adapted for abutment with a second member to urge the contact tip toward the first member. The second member may be a portion of a nozzle adapted to abut the contact tip to urge the contact tip toward the surface of the first member. A method of assembling a welding gun also is provided. The method may comprise disposing a contact tip between a first and a second member and capturing the contact tip between the first and second members.

Owner:ILLINOIS TOOL WORKS INC

Welding gun having a removable nozzle end portion and method for operating same

A welding gun having a removable end portion. The end portion may be adapted to direct gas from the welding gun. The end portion may be conical-shaped. The end portion may be removed without tools. The end portion also may be adapted to be secured to and / or removed from the welding gun in a linear movement. A method of assembling a welding gun. The method may comprise urging a nozzle end member and a nozzle body into engagement to secure the nozzle end member to the nozzle body.

Owner:ILLINOIS TOOL WORKS INC

Torch and contact tip for gas metal arc welding

InactiveCN101417365AElectrode supporting devicesElectrode accessoriesCarbon Dioxide / HeliumShielding gas

A torch for gas metal arc welding includes a torch housing and a contact tip mounted on the housing and having an electrode bore through which electrode wire is fed. A nozzle mounted on the housing surrounds the contact tip to define an annular gas passage between the contact tip and the inside of the nozzle. A shielding gas inlet communicates a shielding gas into the annular gas passage so that the shielding gas flows out of the nozzle. A plurality of auxiliary flow passages are provided in the contact tip, and have open ends arranged around the electrode bore. The auxiliary flow passages communicate with the gas inlet and surround the electrode wire with an auxiliary flow of shielding gas that is closer to the electrode wire than the shielding gas flow that is provided through the annular gas passage between the contact tip and the nozzle.

Owner:GM GLOBAL TECH OPERATIONS LLC

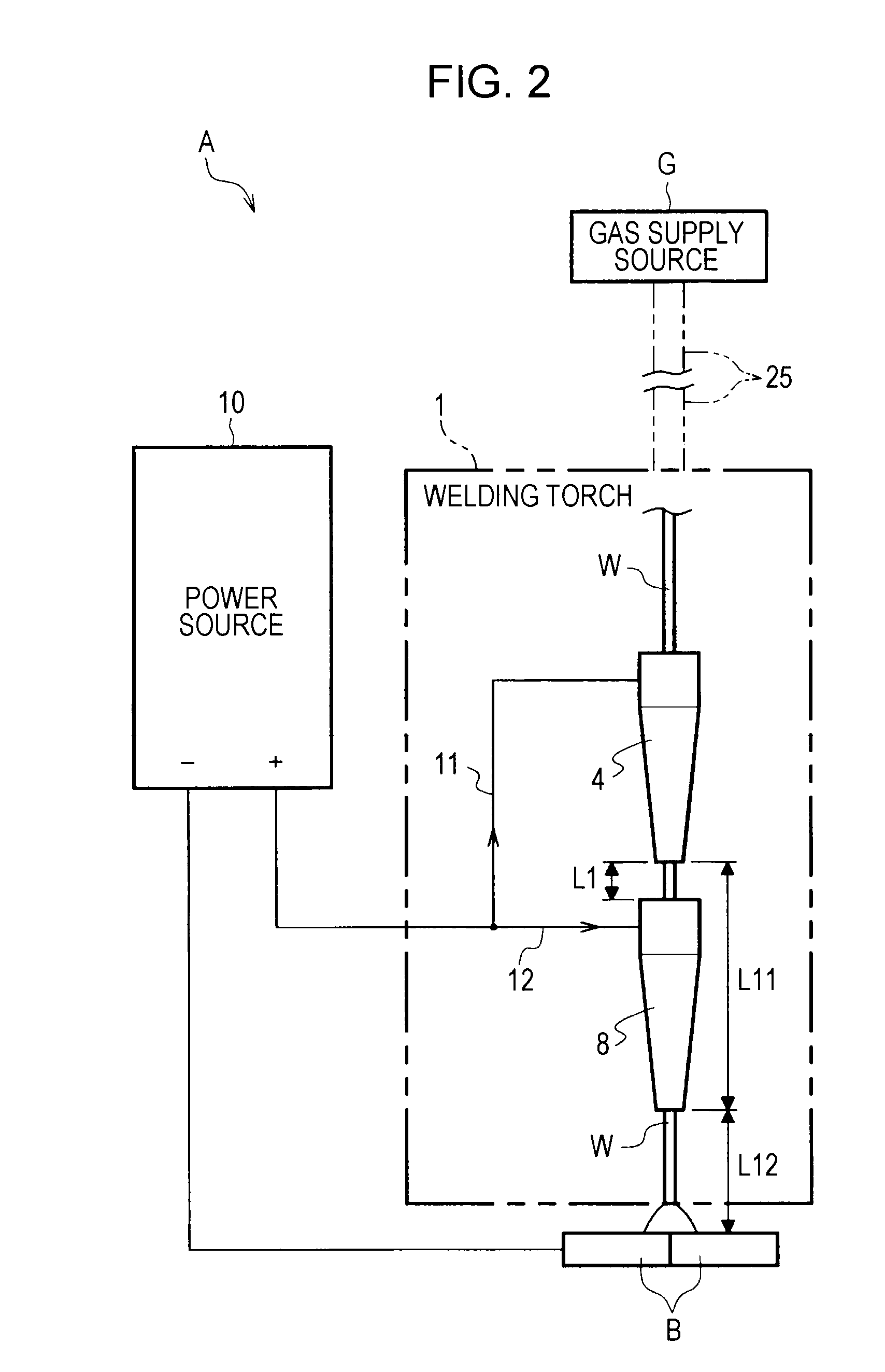

Welding torch

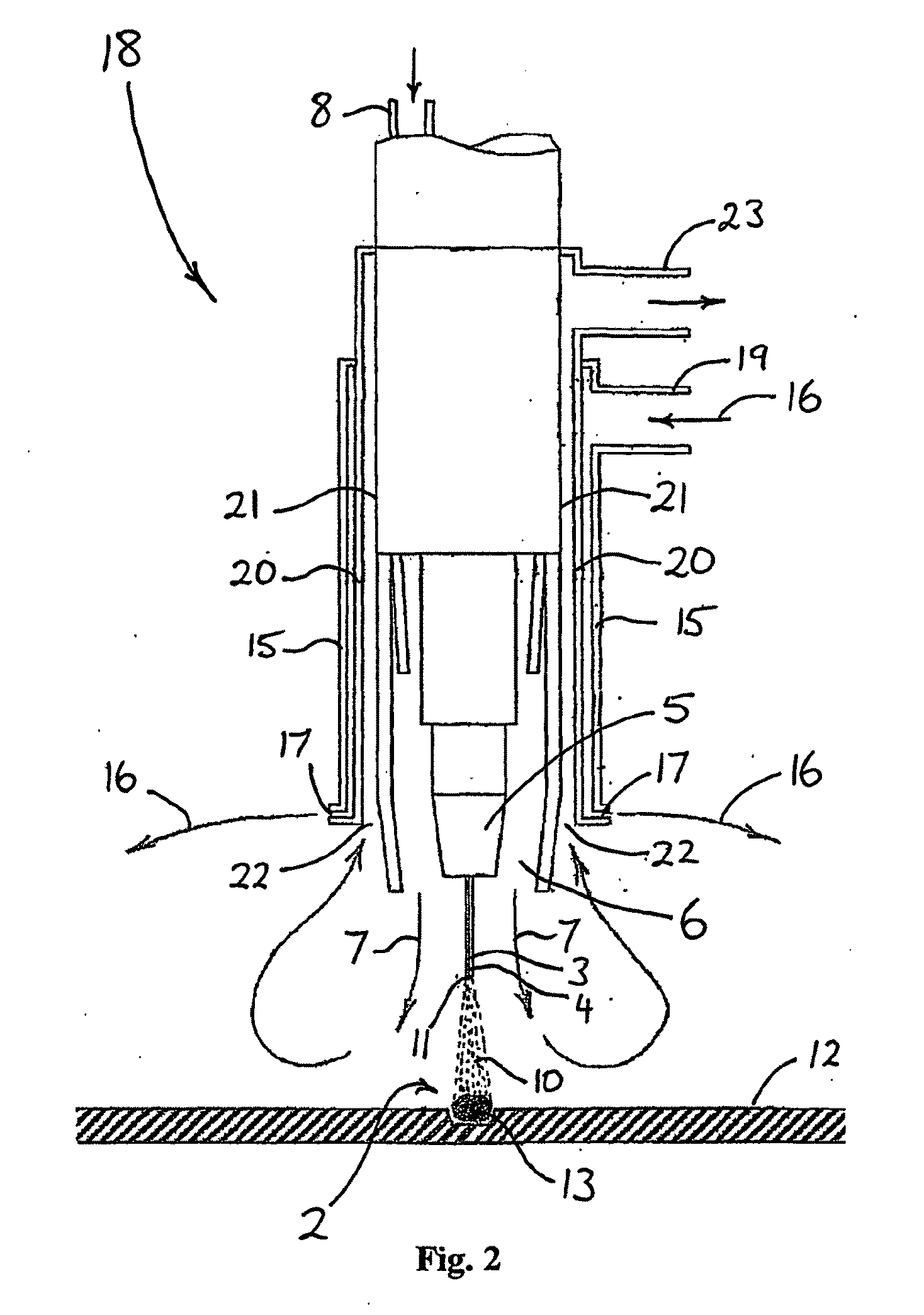

InactiveUS20120285932A1Reduce wearReduce frequencySupport devices with shieldingElectrode accessoriesPower flowWelding torch

A welding torch includes: a first tip body to which a welding wire, gas, and current having passed through a torch body is supplied; a first tip provided at a distal end of the first tip body to supply electric current having passed through the first tip body to the welding wire; an insulating bushing provided inside the nozzle, on the outer periphery of the first tip body; a second tip body to which electric current from a power source is supplied; and a second tip provided at the distal end of the second tip body to supply the current having passed through the second tip body to the welding wire. The first tip and the second tip are axially arranged at a predetermined distance and supply electric current to the welding wire.

Owner:KOBE STEEL LTD

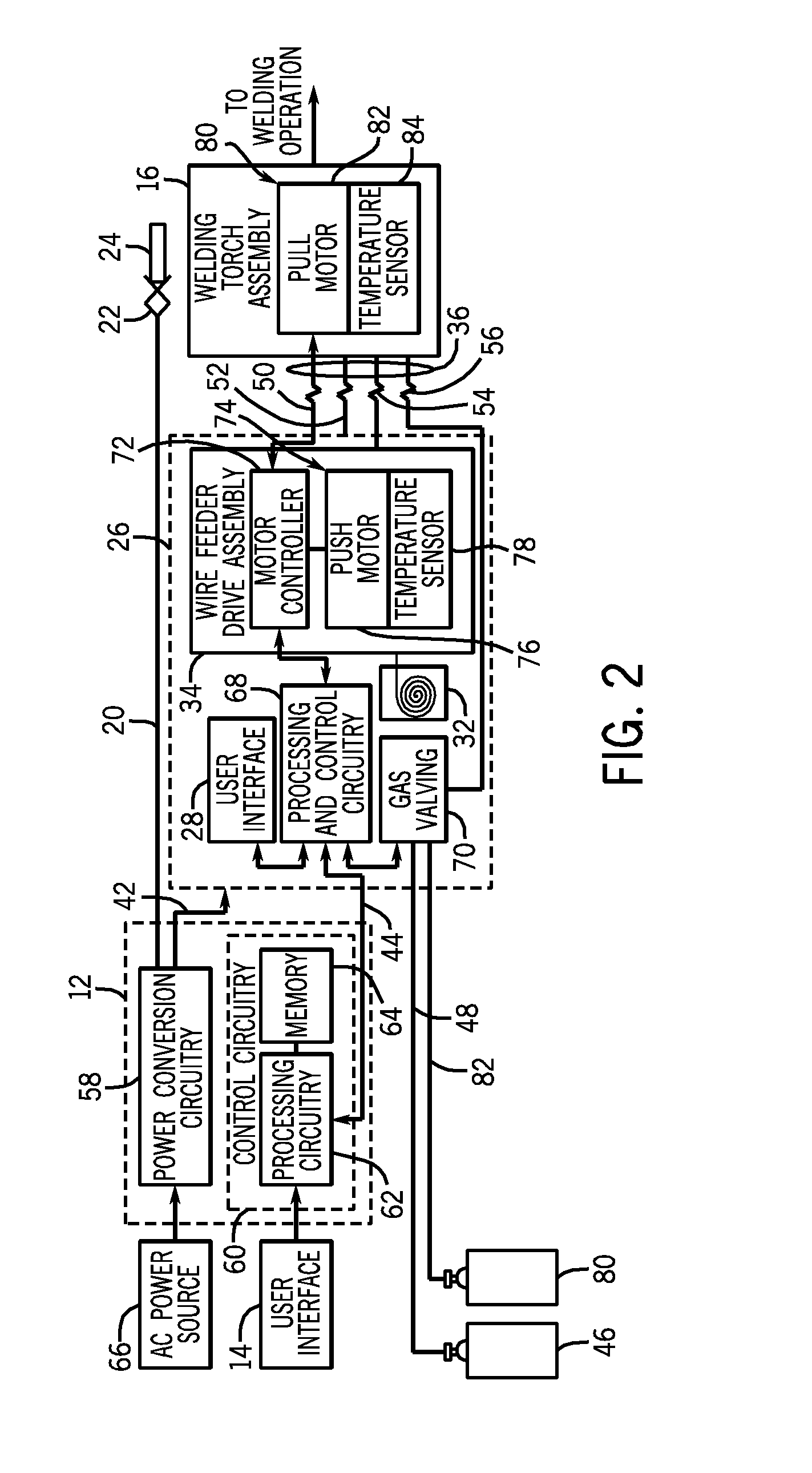

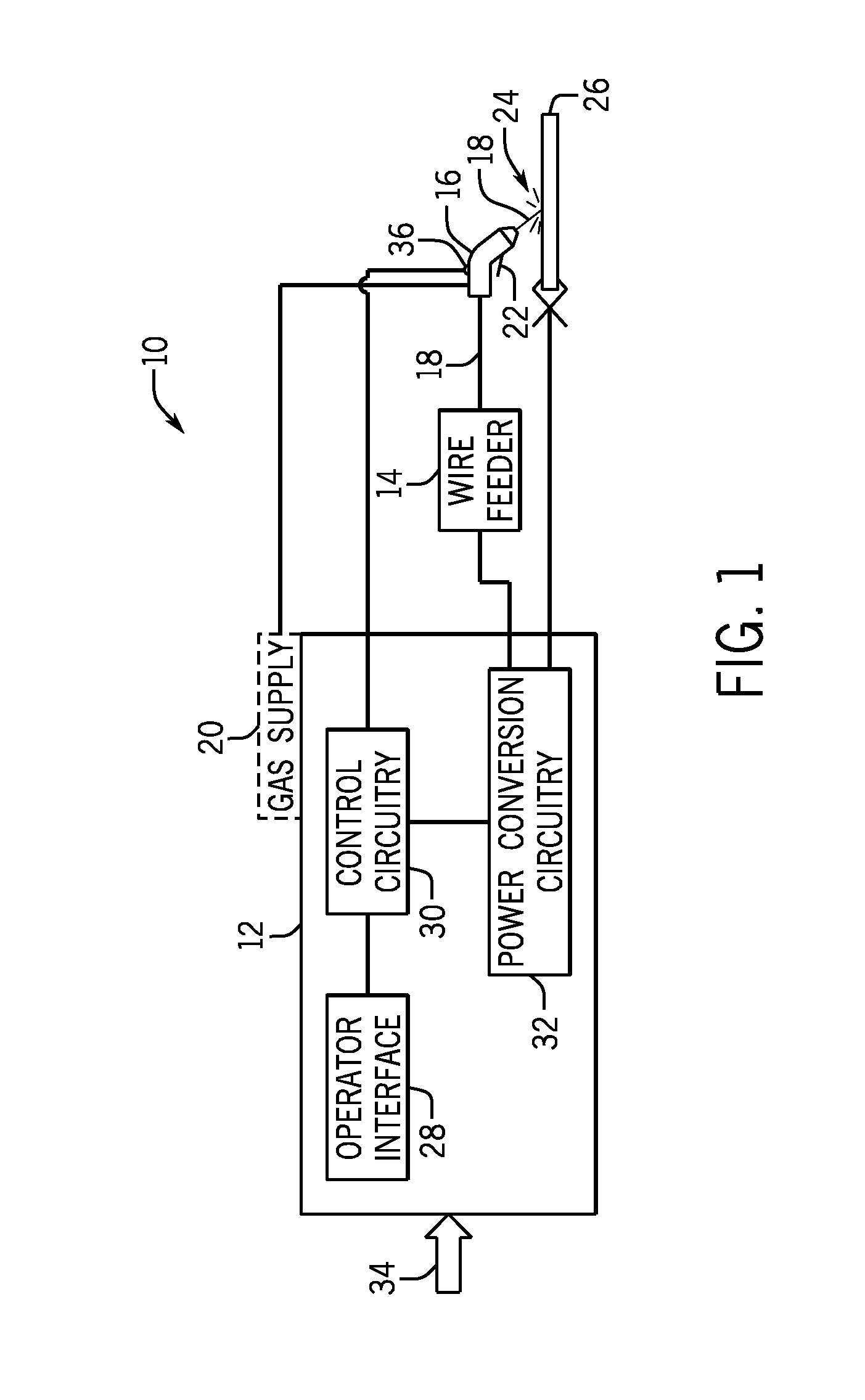

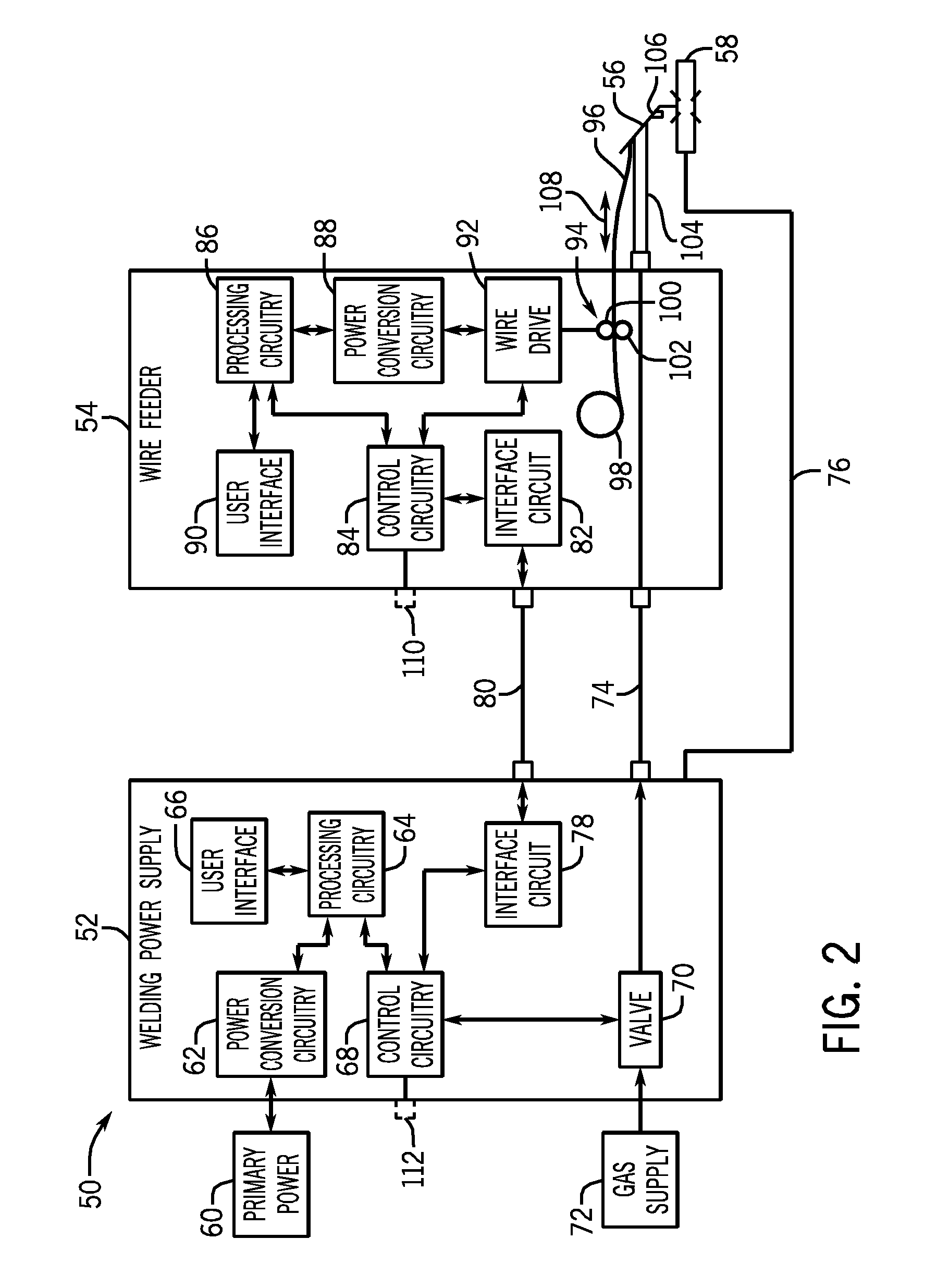

Wire feed motor control systems and methods

Wire feed drive assemblies having welding wire mounted thereon and a motor that rotates a wire feed roller to drive the weld wire toward a welding torch are provided. The wire feed drive assemblies also include a temperature sensor coupled to the motor and adapted to measure a temperature of the motor. The wire feed drive assemblies further include a motor controller coupled to the temperature sensor and the motor and adapted to receive temperature feedback from the temperature sensor and to utilize the temperature feedback to regulate a speed of the motor.

Owner:ILLINOIS TOOL WORKS INC

Automatic multifunctional narrow-clearance/super-narrow-clearance gas protection welding gun and manufacturing method thereof

ActiveCN104384683ASmall filling areaUniform fusion with high reliabilityCooled electrode holdersElectrode accessoriesCeramic coatingPipe

The invention relates to an automatic multifunctional narrow-clearance / super-narrow-clearance gas protection welding gun and a manufacturing method thereof. The welding gun comprises a plate-type welding gun body; a guide wire channel, a circulating water cooling runner and a secondary protection gas runner are integrated in the welding gun body, a primary protection gas inlet sea, a secondary protection gas inlet seat, a water inlet pipe seat, a water return pipe seat and a welding cable are fixed on the upper part of the welding gun body, the lower part of the welding gun body is fixedly connected with a gas distribution device, and the gas distribution device is fixed on the lower part of the plate-type welding gun body through the body / a spray nozzle connecting component. The method comprises the steps of preparing raw materials, machining relevant parts, embedding and soldering a runner groove cover plate, embedding a ceramic strip, spraying ceramic coating on external parts, etc. The automatic multifunctional narrow-clearance / super-narrow-clearance gas protection welding gun has the advantages of high integration, high-speed guide wire, stability and reliability in electrical conduction and gas conduction, high efficiency in heat radiation, reliability in insulation, long service life, easiness in machining, low cost, good rigidness, integration of single-wire single gun and double-wire double gun, high working efficiency, safety and reliability.

Owner:武汉纳瑞格智能设备有限公司

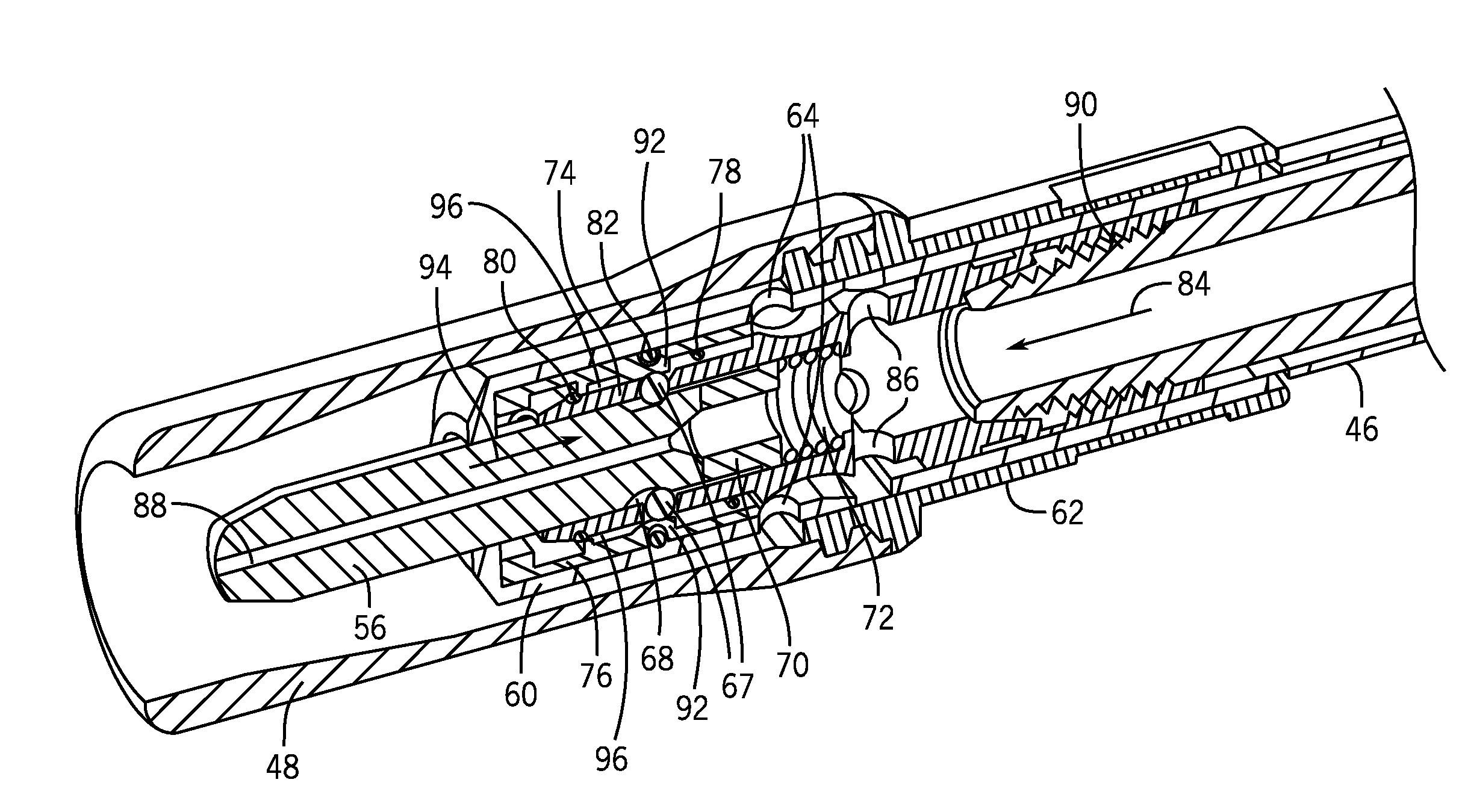

Contact tip and receiving assembly of a welding torch

InactiveUS20160144446A1Support devices with shieldingElectrode accessoriesMechanical engineeringWelding torch

A method to replace a contact tip in a welding system includes applying a first force toward a neck of a welding torch to remove the contact tip via a quick release mechanism. Additionally, the method includes inserting a new contact tip into the quick release mechanism and applying a second force on the new contact tip toward the neck of the welding torch until the new contact tip is locked in place within the quick release mechanism.

Owner:ILLINOIS TOOL WORKS INC

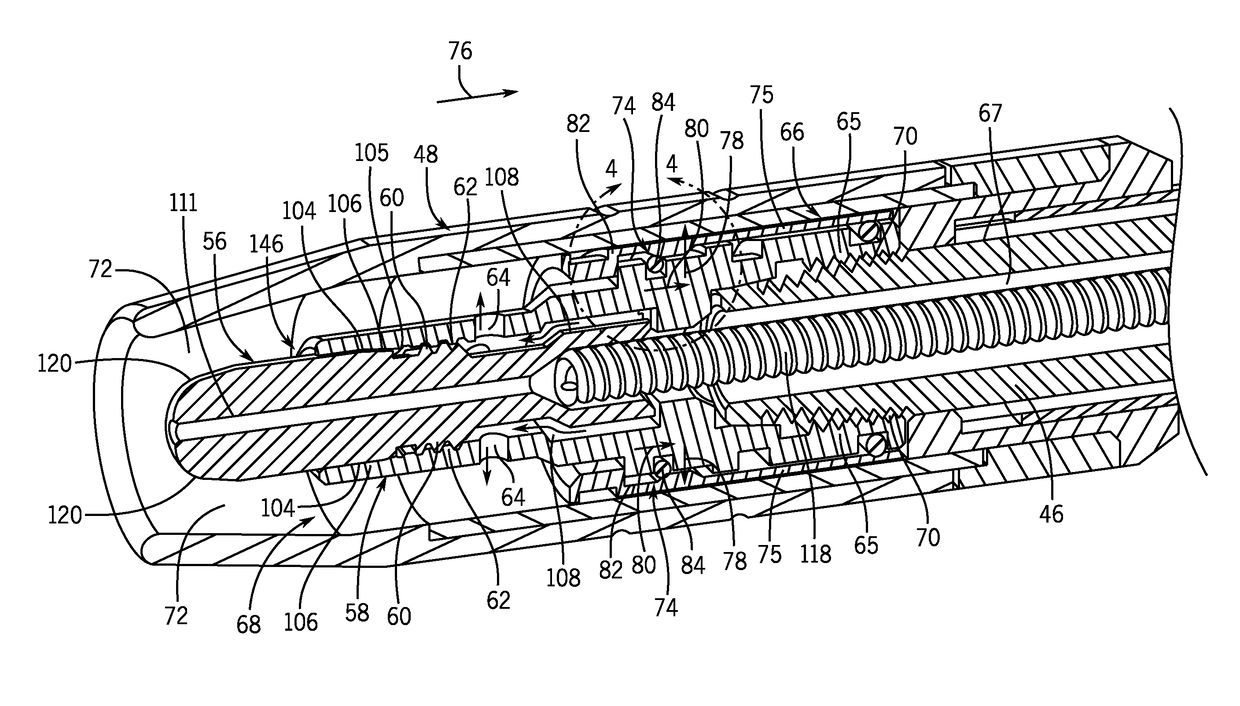

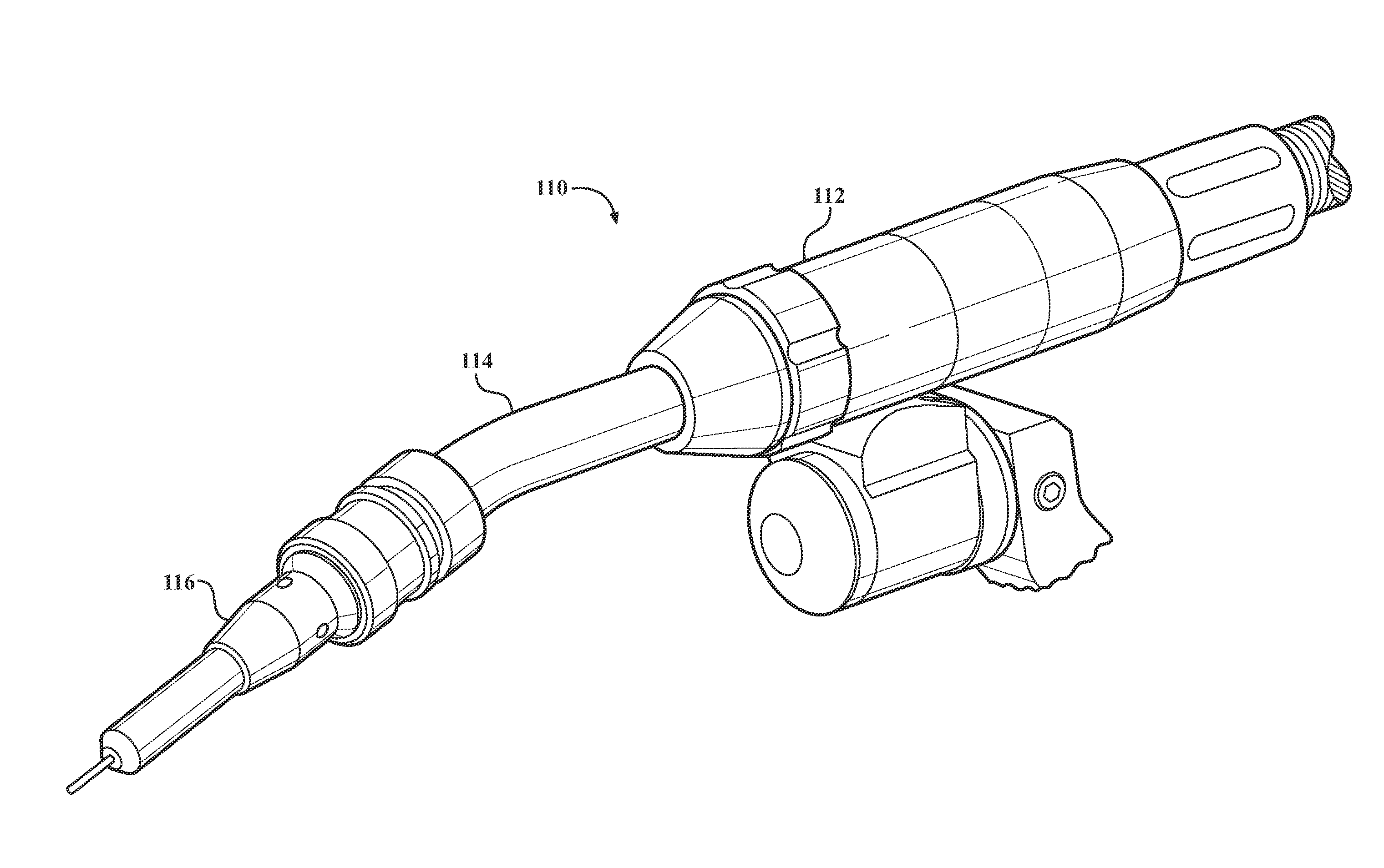

Contact tip and liner assembly for welding torch

PendingUS20170165780A1Maximizes performance of wearEasy to replaceElectrode accessoriesScrew threadWelding torch

In certain embodiments, a welding contact tip includes a first axial end portion having a welding wire outlet of an internal bore of the welding contact tip. The welding contact tip also includes a threaded middle portion adjacent the first axial end portion. The threaded middle portion includes external threads configured to mate with internal threads of a gas diffuser of a welding torch. The first axial end portion includes a tapered outer surface adjacent the threaded middle portion. The welding contact tip further includes a second axial end portion adjacent the threaded middle portion. In other embodiments, a welding torch liner assembly includes a liner stop configured to be attached to a first axial end of a welding torch liner. The welding torch liner assembly also includes a liner receiver configured to secure a second axial end of the welding torch liner. The second axial end of the welding torch liner is opposite the first axial end of the welding torch liner.

Owner:ILLINOIS TOOL WORKS INC

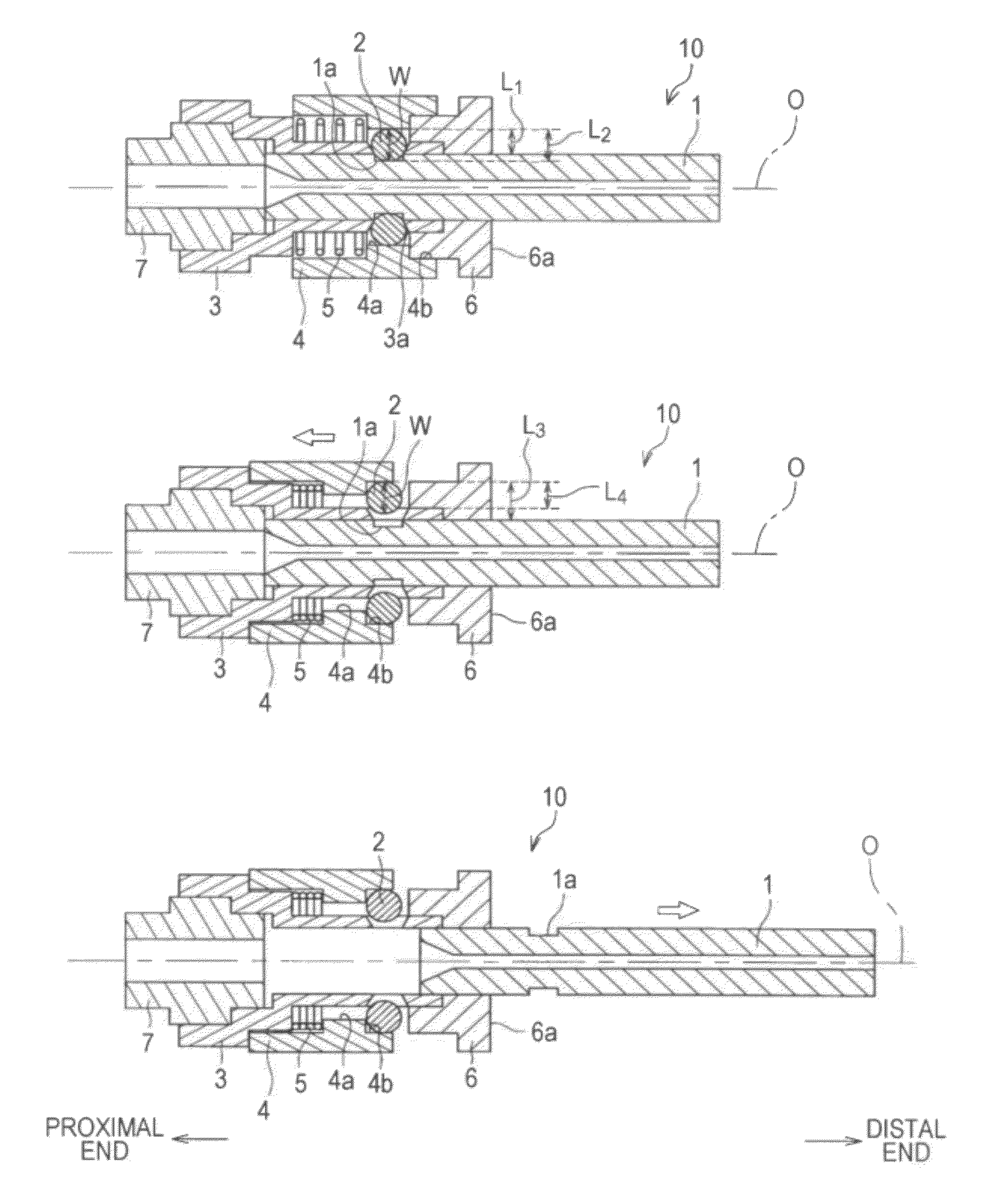

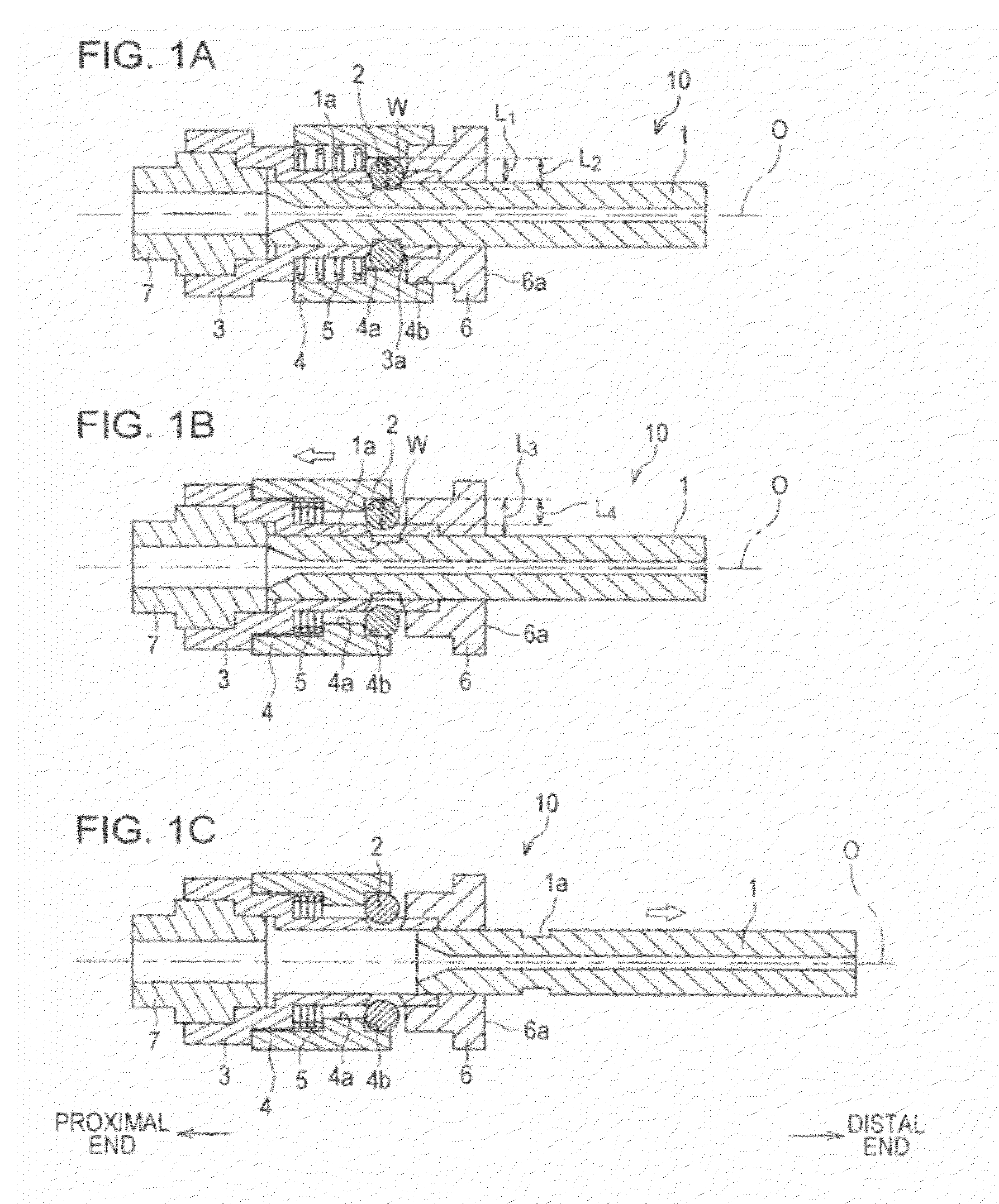

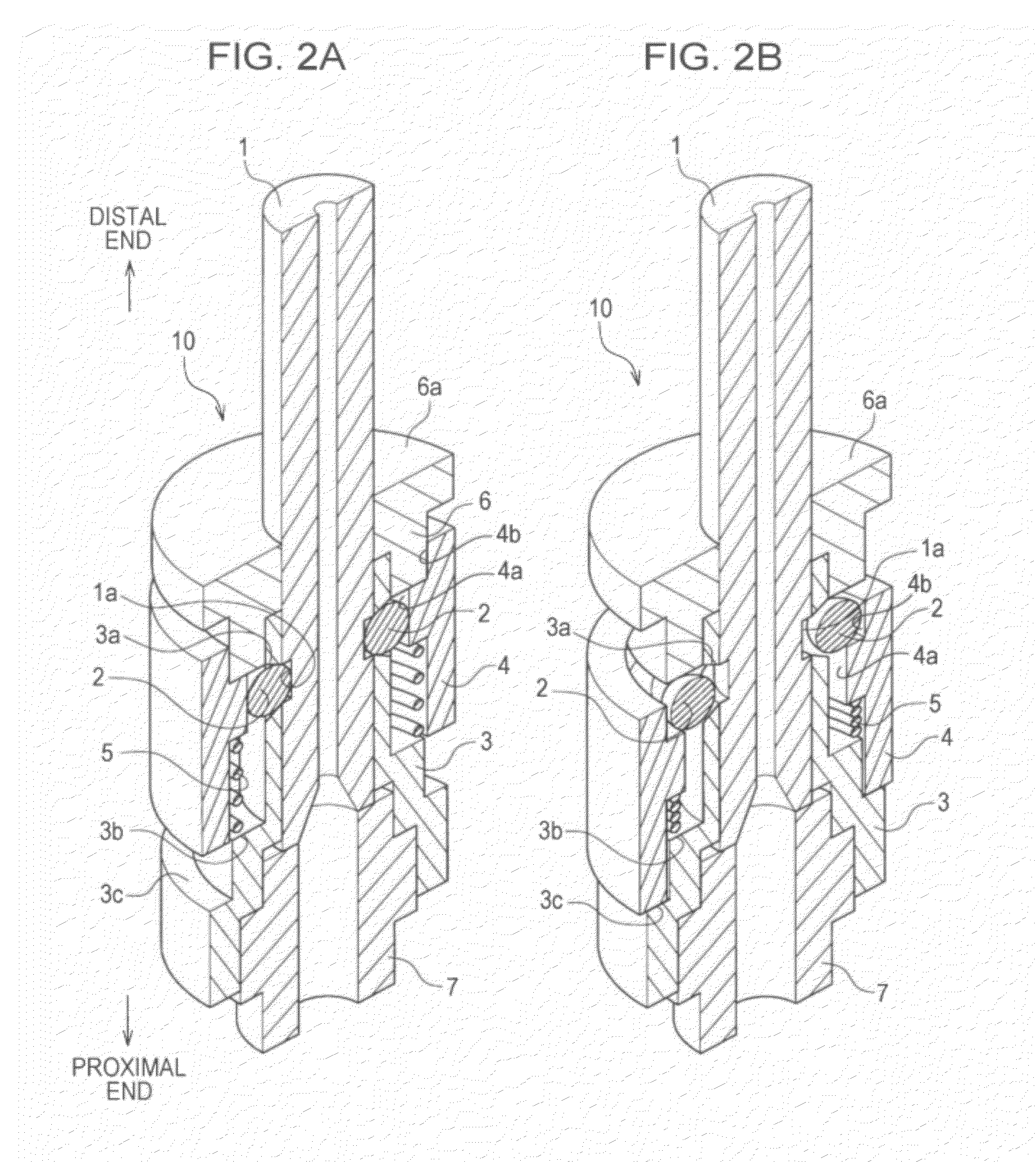

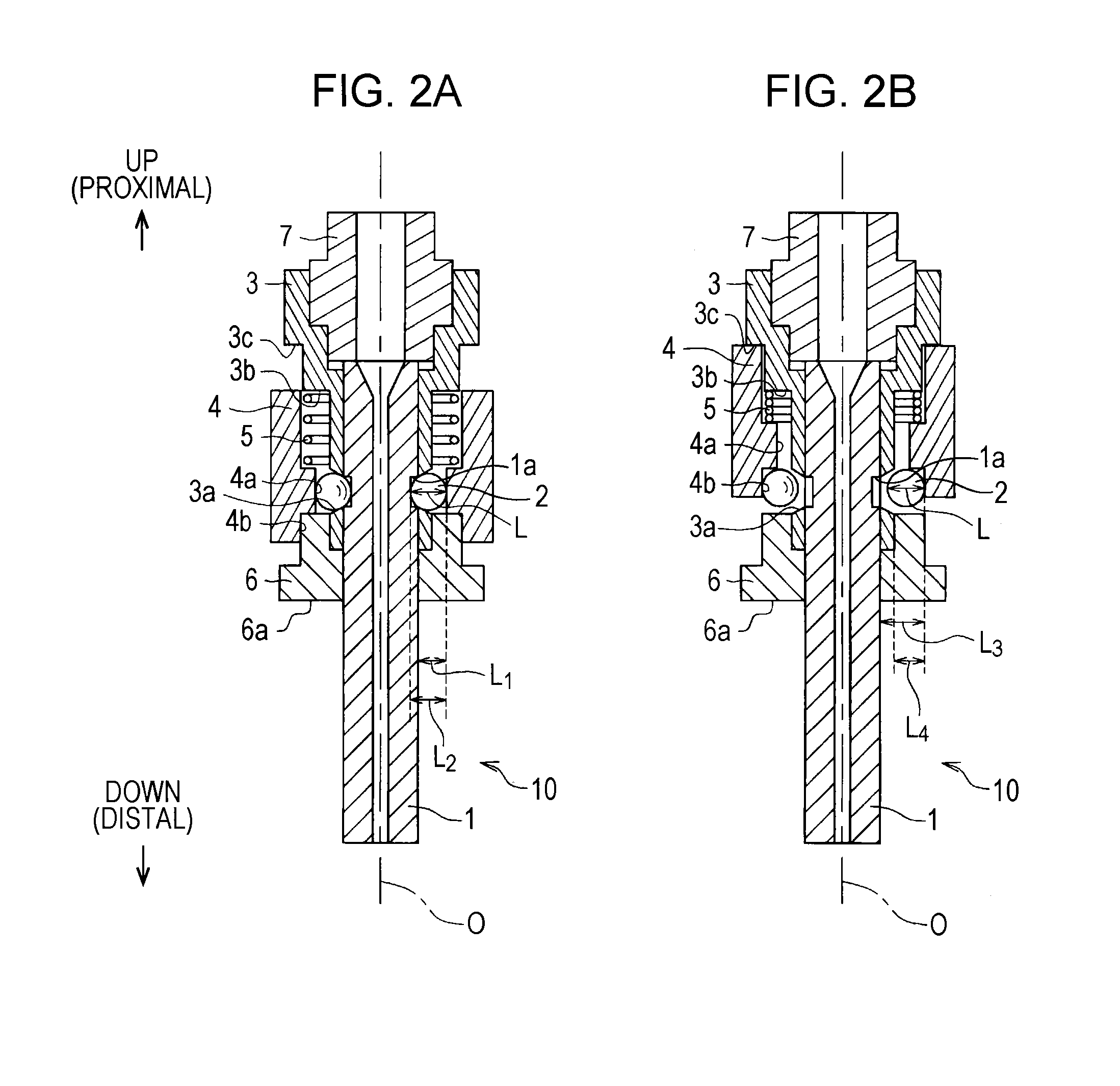

Welding torch, welding tip, and welding robot

InactiveUS20120125903A1Good adhesionEasy to removeSupport devices with shieldingElectrode accessoriesEngineeringWelding torch

A welding torch includes a tip connection body, a holding member, a fixing member, and a welding tip. The holding member is displaceable in the axial direction of the tip connection. The fixing member fixes the welding tip in place in the axial direction of the welding tip when the fixing member is in contact with a smaller diameter portion, and the fixing member releases the welding tip when the fixing member is in contact with a larger diameter portion.

Owner:KOBE STEEL LTD

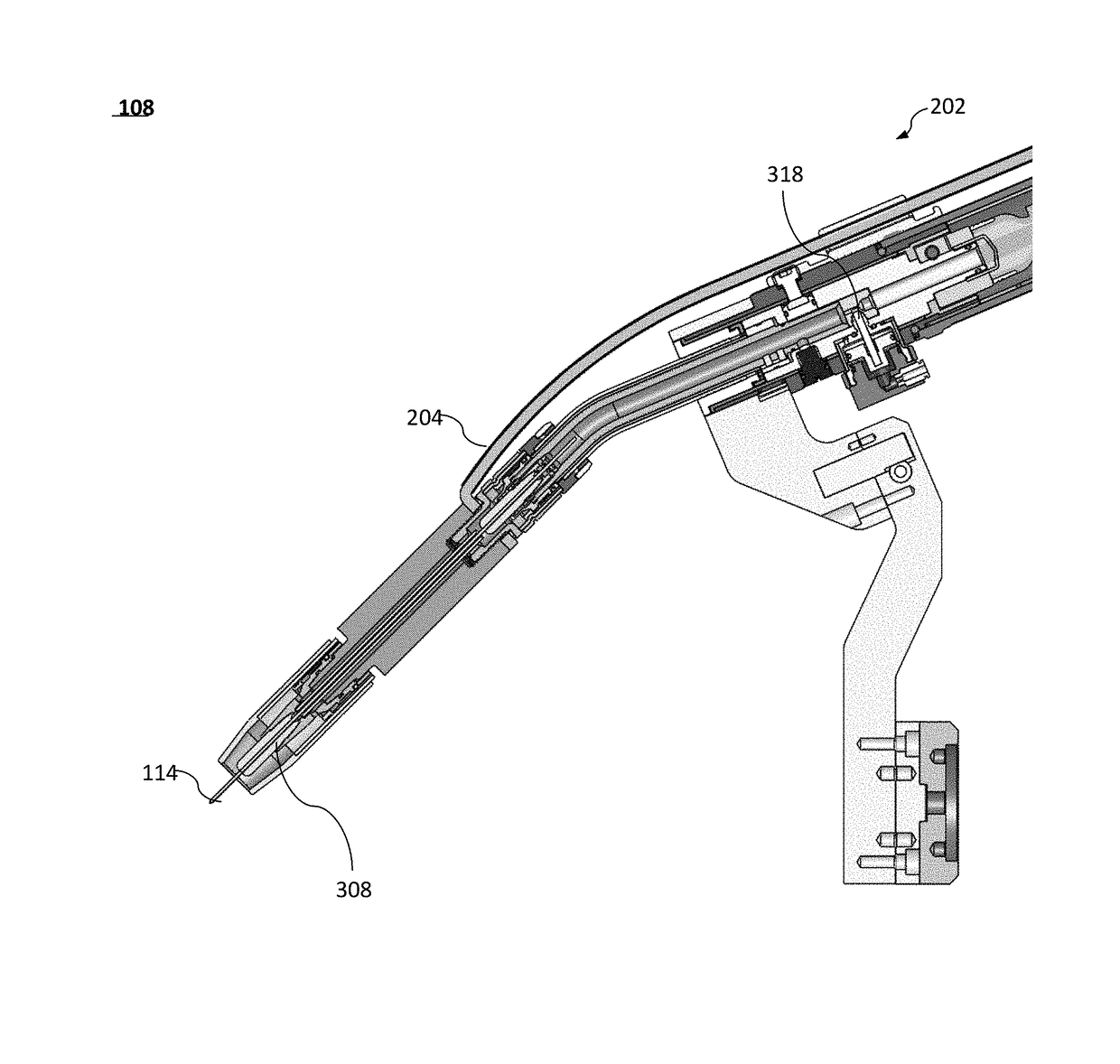

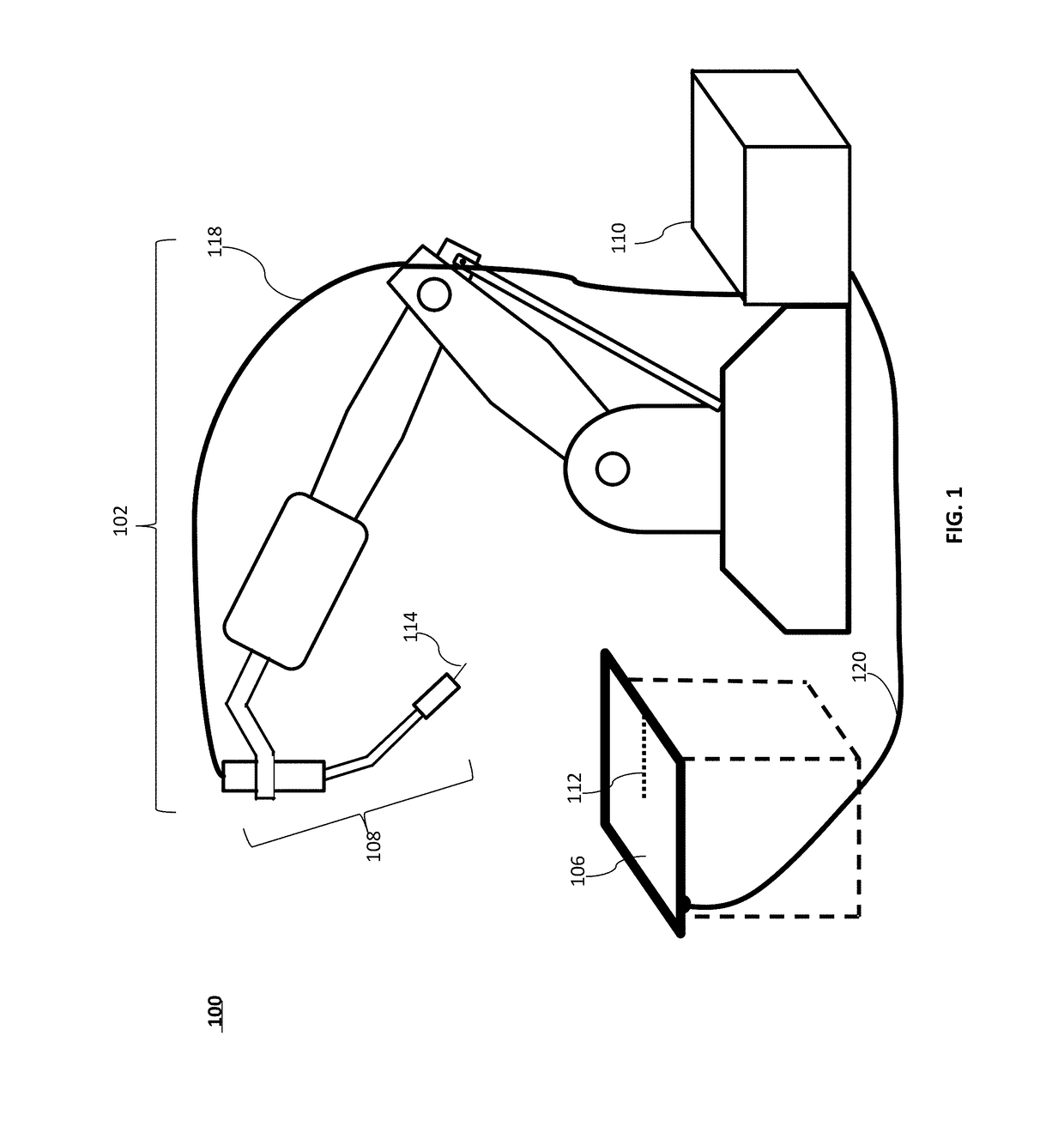

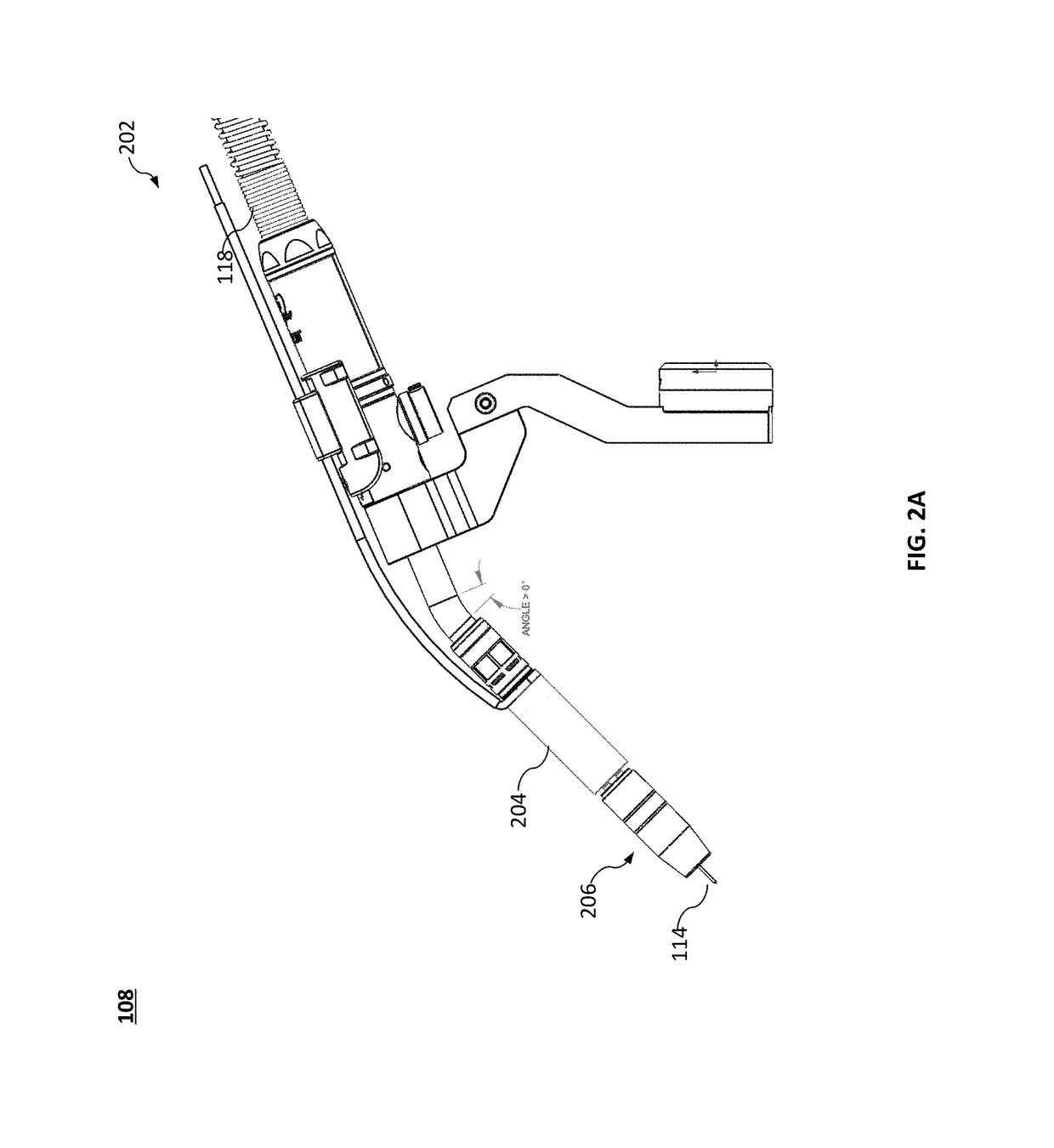

Split gooseneck for welding guns

InactiveUS20140263251A1Shielding gas supply/evacuation devicesElectrode accessoriesEngineeringWelding

Owner:LINCOLN GLOBAL INC

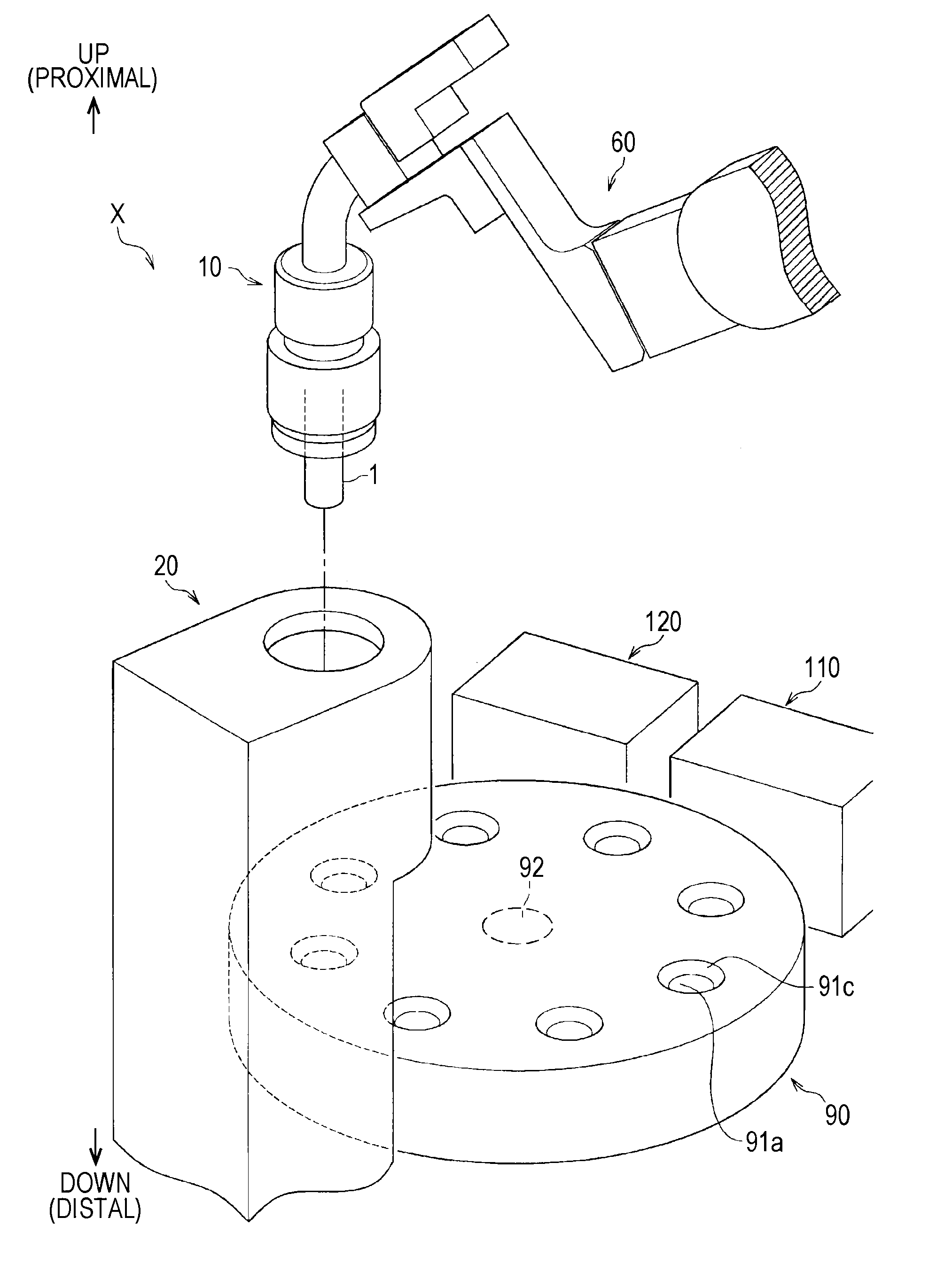

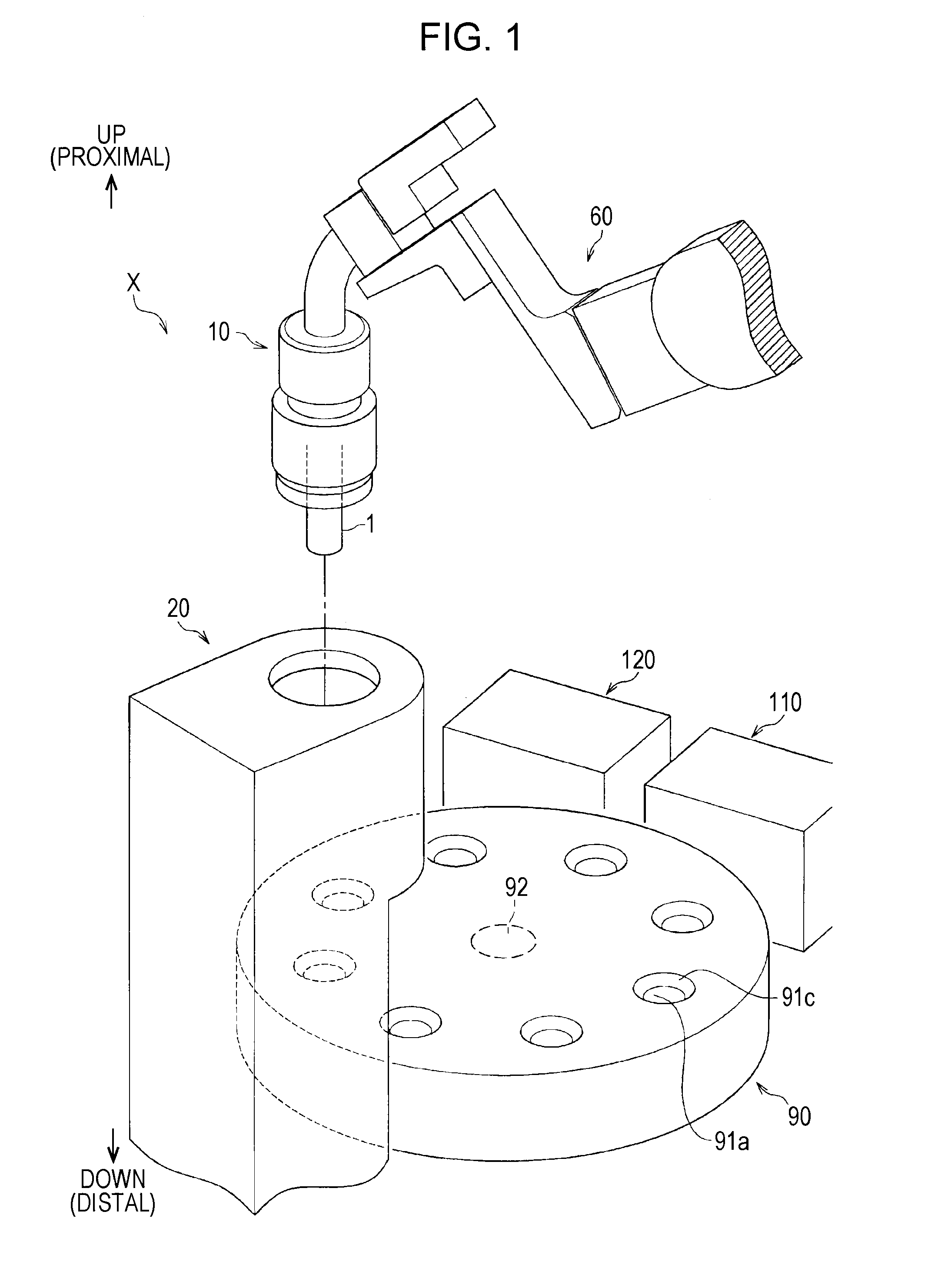

Welding tip replacement apparatus, welding tip replacement system, and method for replacing welding tip

InactiveUS20130008003A1Good adhesionEasy detachmentGripping headsTool changing apparatusEngineeringWelding torch

A welding tip replacement apparatus is used for a welding torch that includes a tubular tip connection body, a tubular retaining member fitted over the tip connection body, and a tubular welding tip fitted within the tip connection body, the welding torch being configured such that displacing the retaining member toward the proximal end of the tip connection body along the axis of the tip connection body causes the welding tip axially fastened to the tip connection body to be released. The apparatus includes a first grasping mechanism grasping the retaining member, a second grasping mechanism grasping the welding tip protruding from the retaining member in a direction away from the distal end of the tip connection body, a first driving mechanism driving the first grasping mechanism axially, and a second driving mechanism driving the second grasping mechanism axially.

Owner:KOBE STEEL LTD

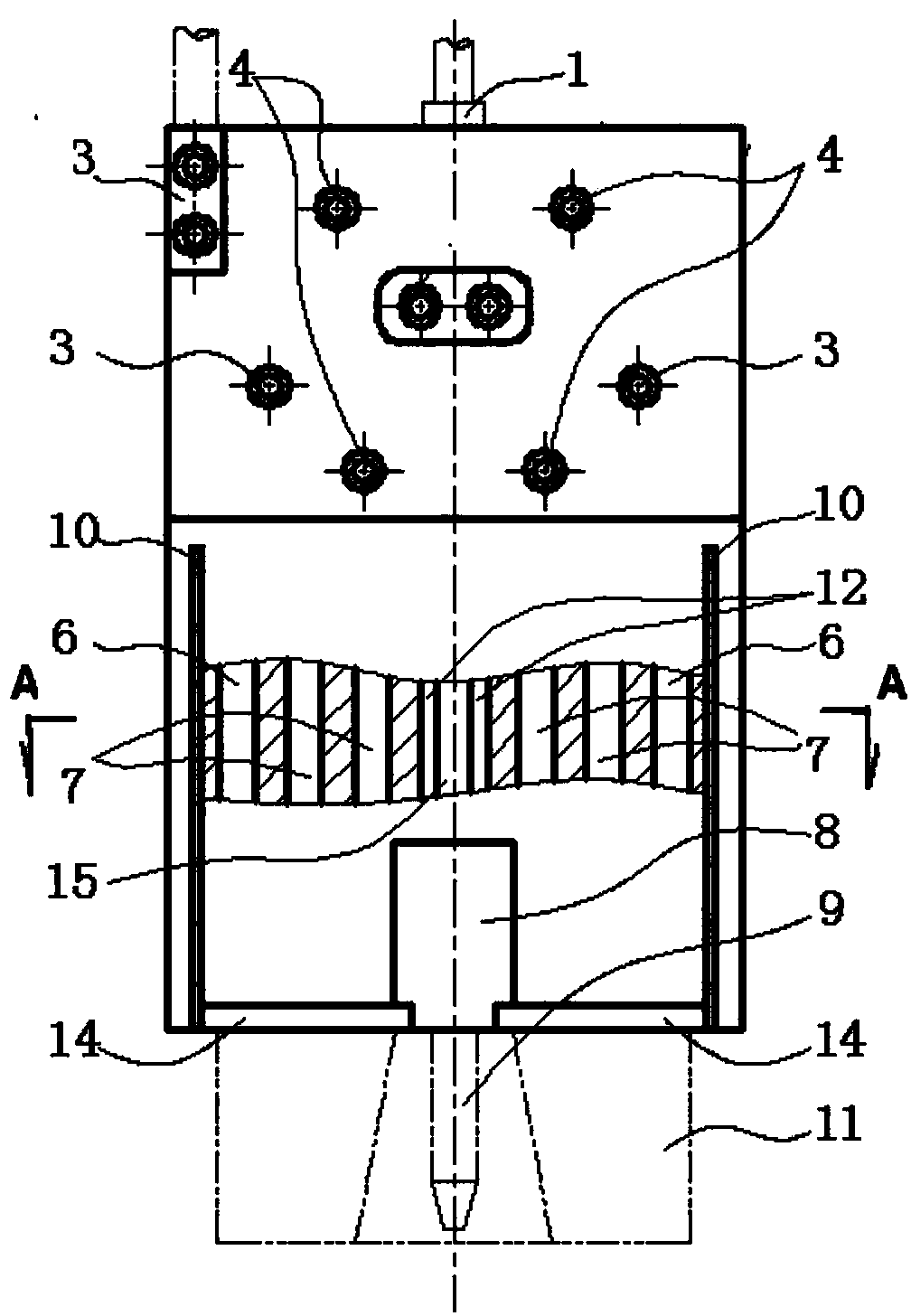

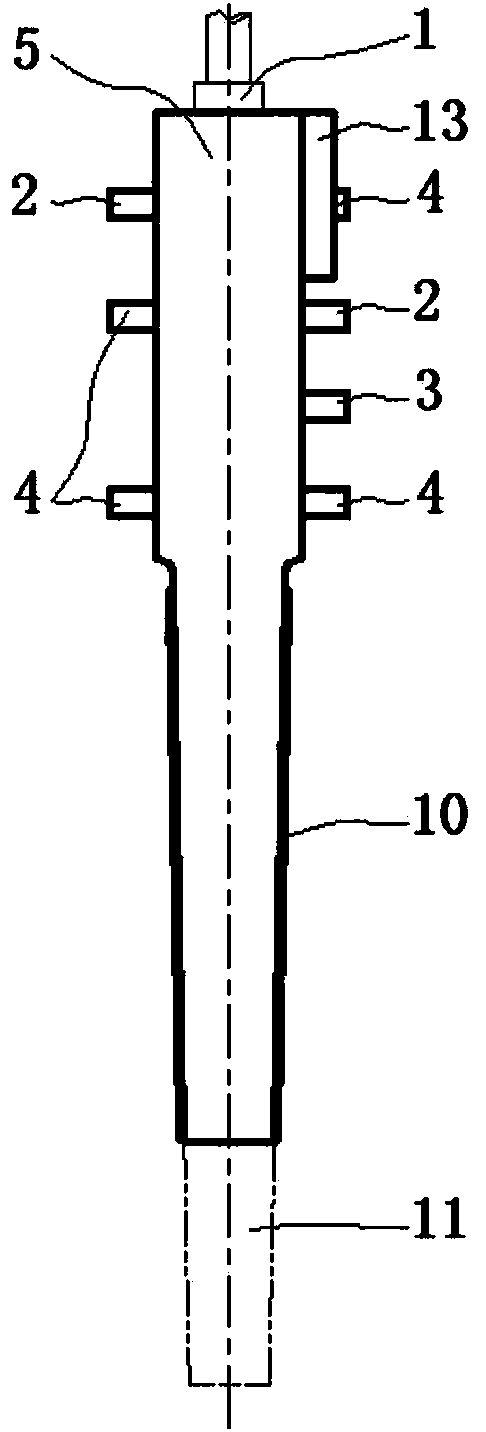

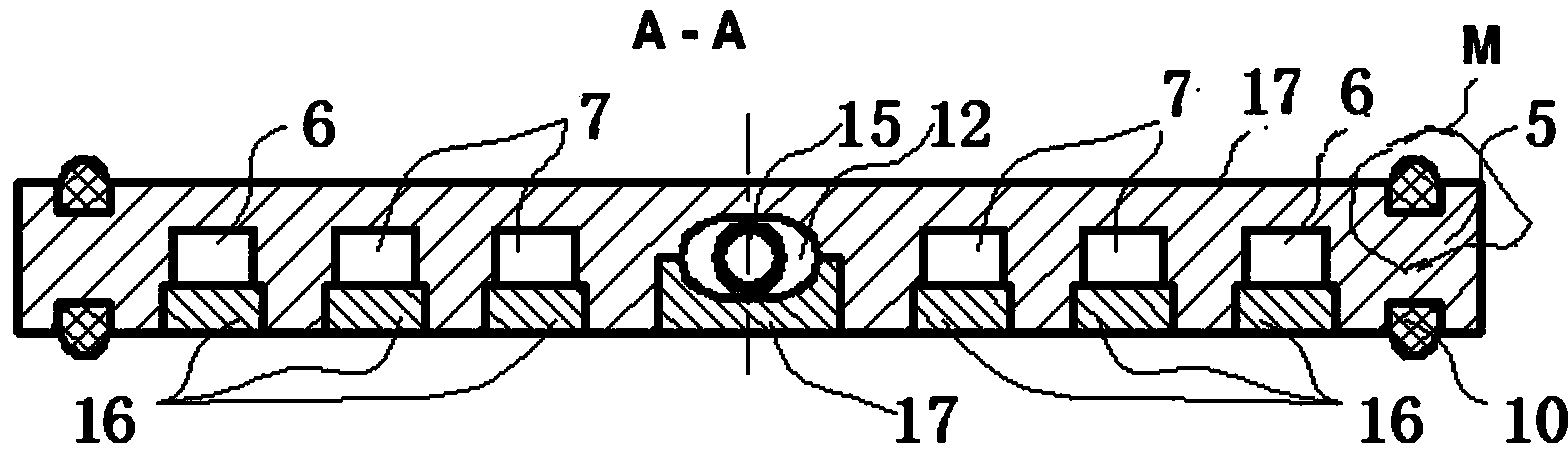

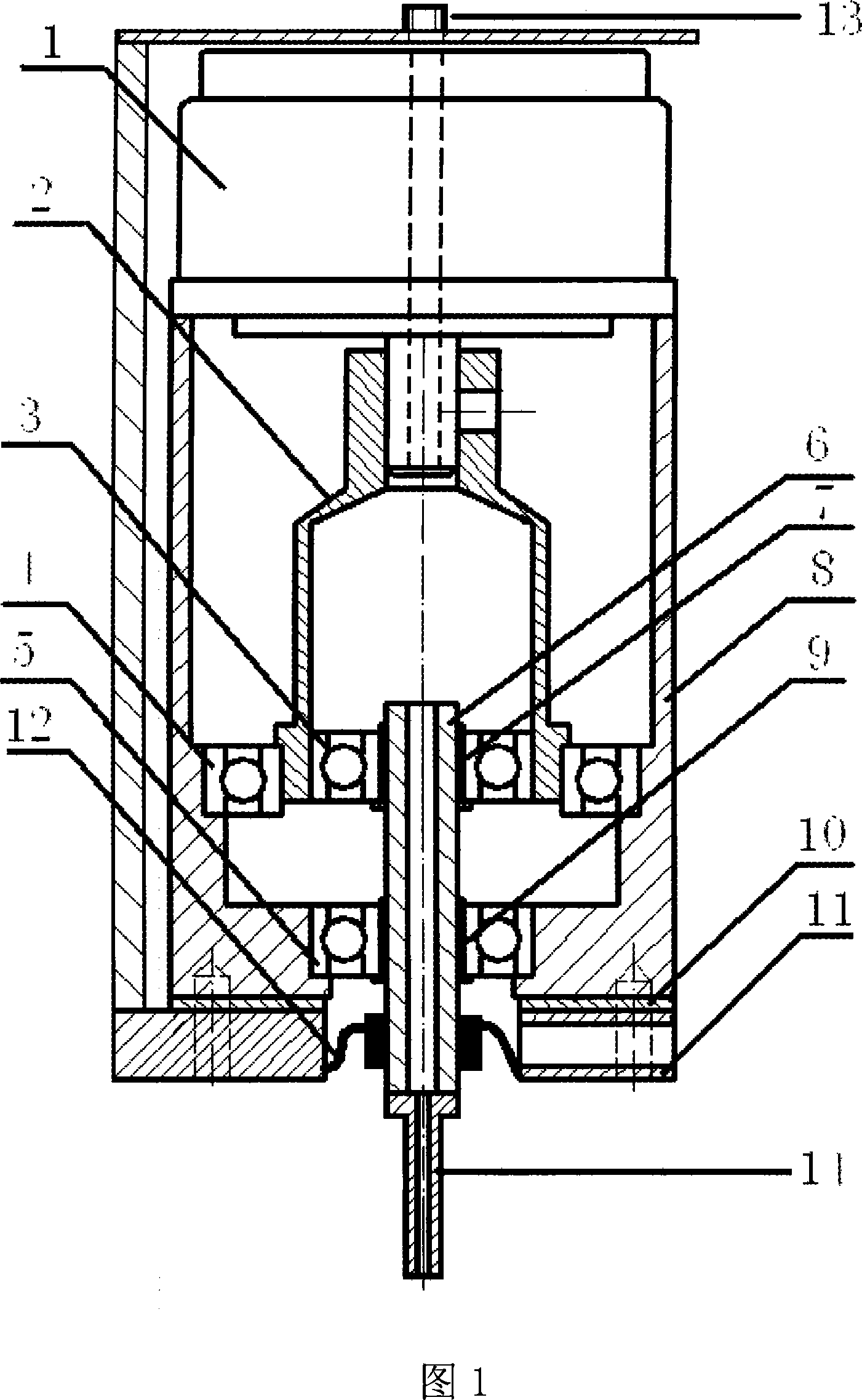

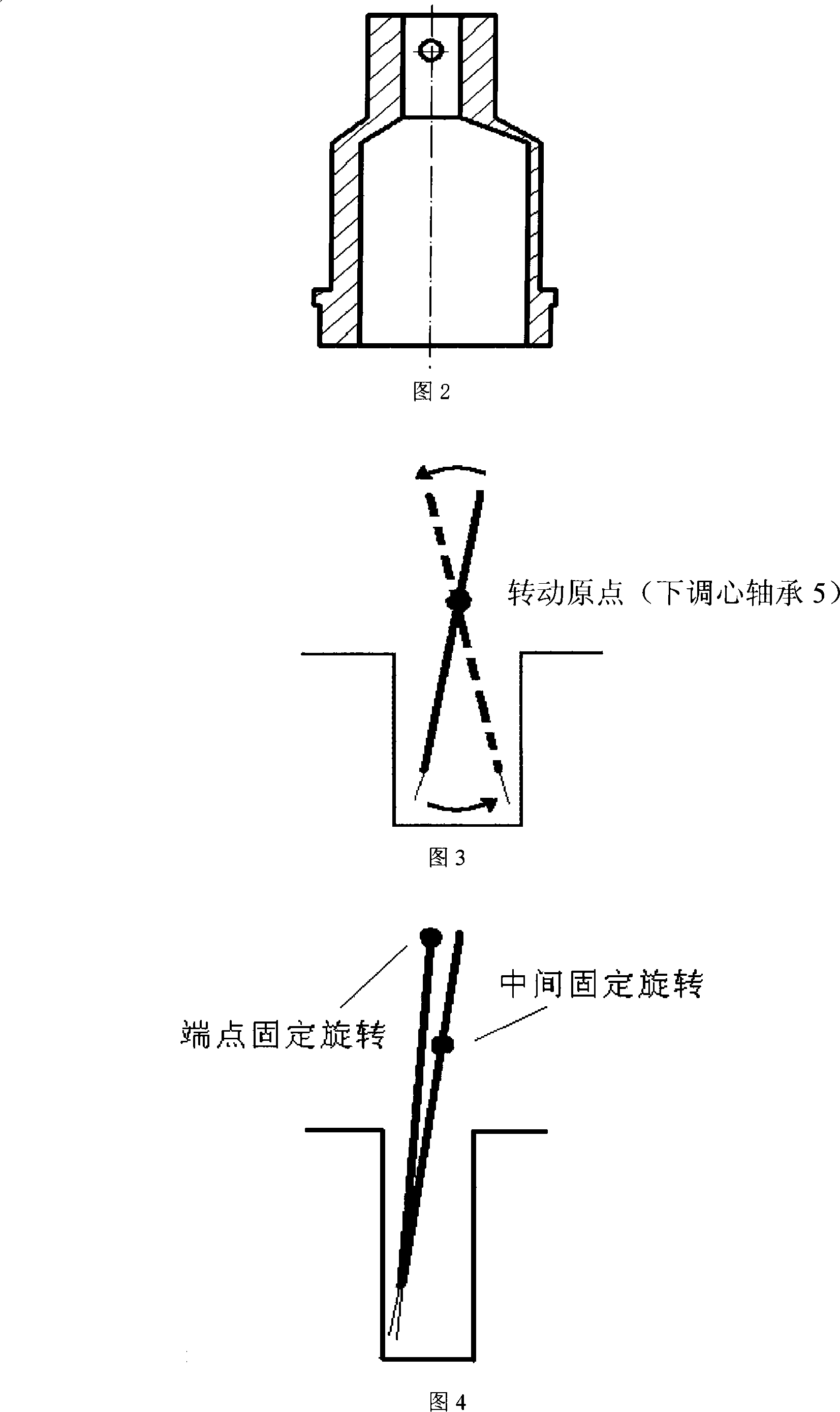

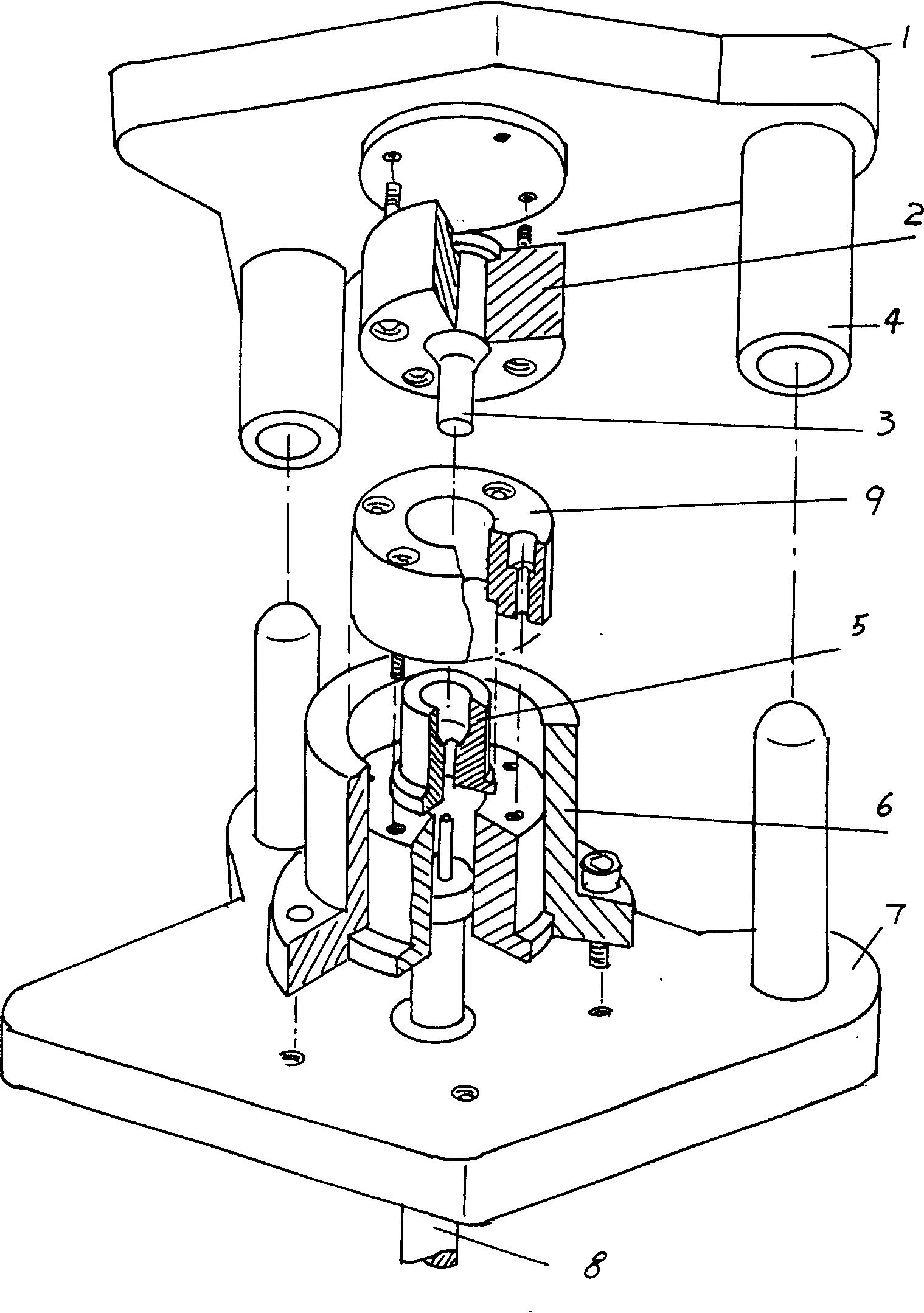

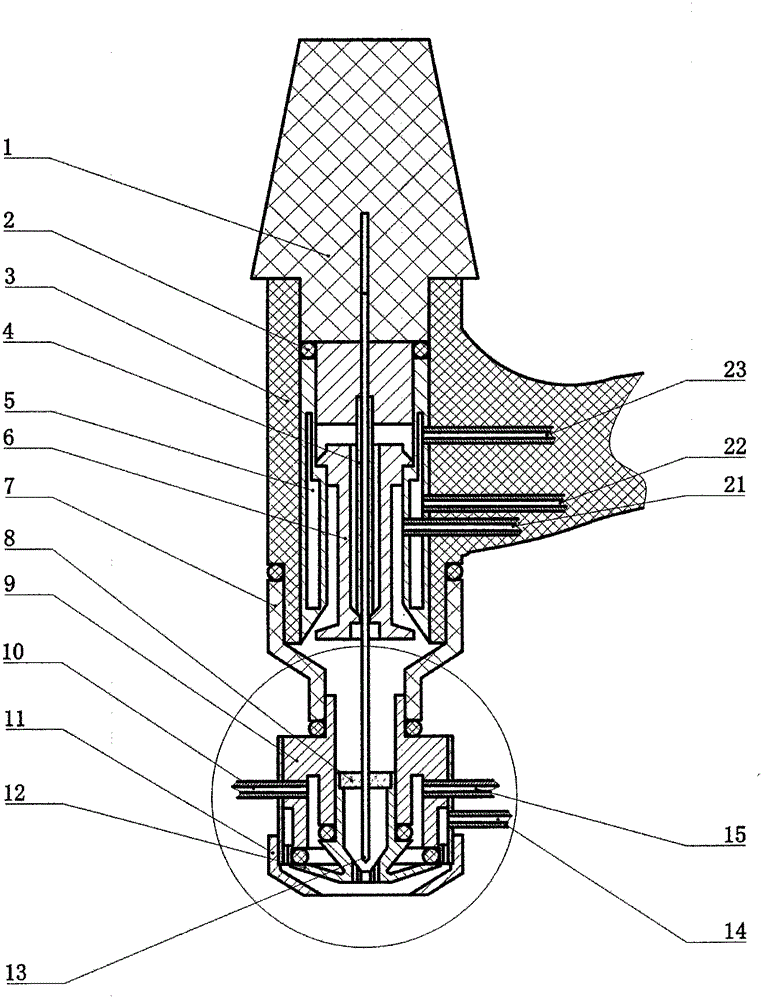

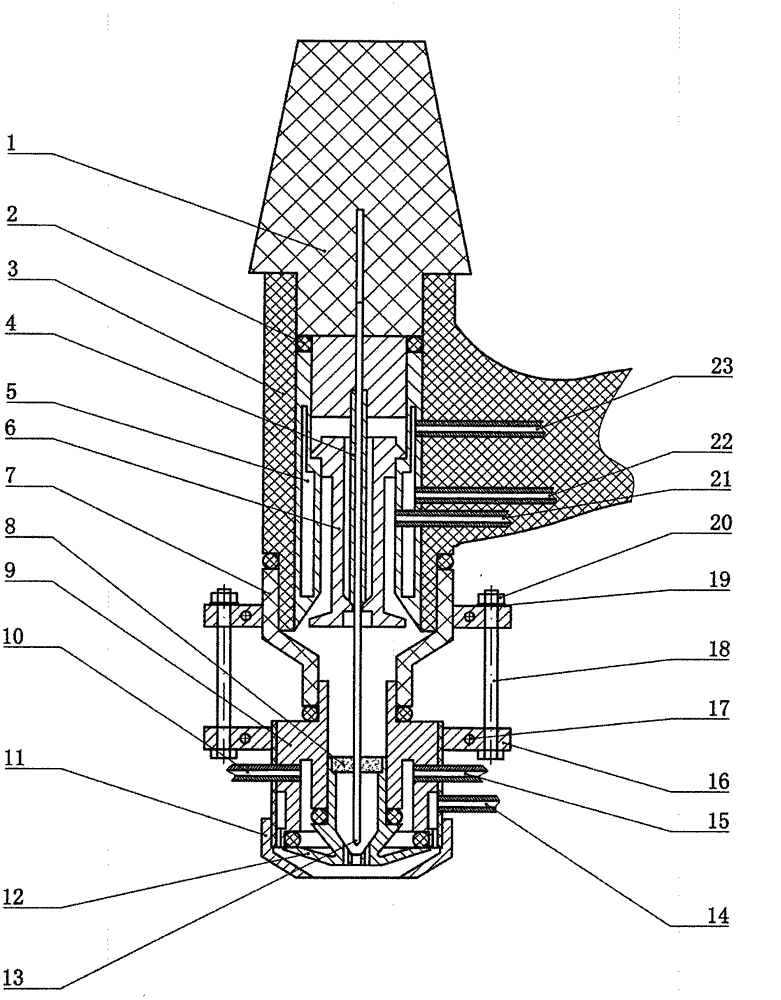

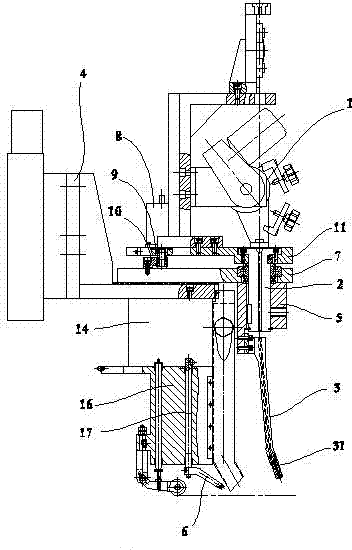

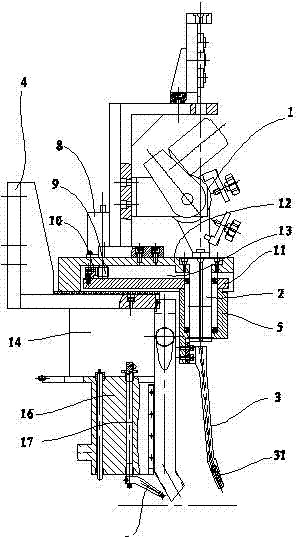

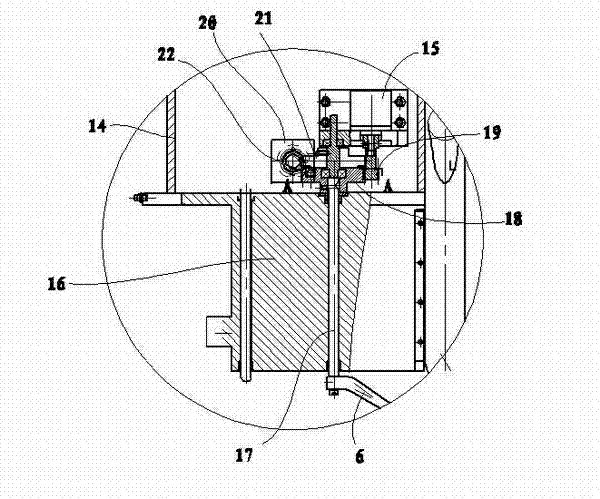

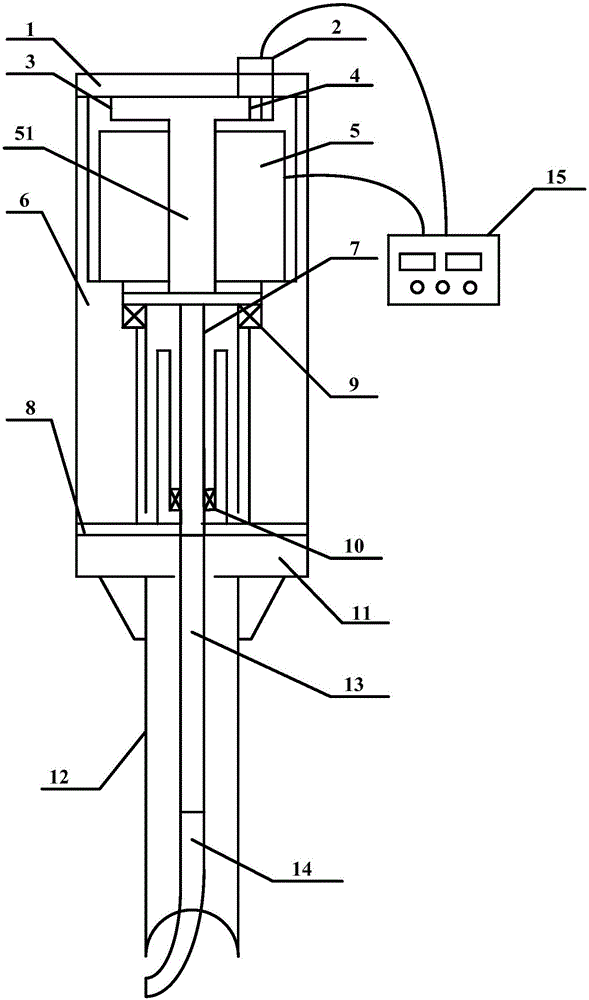

Rotating arc narrow gap welding torque

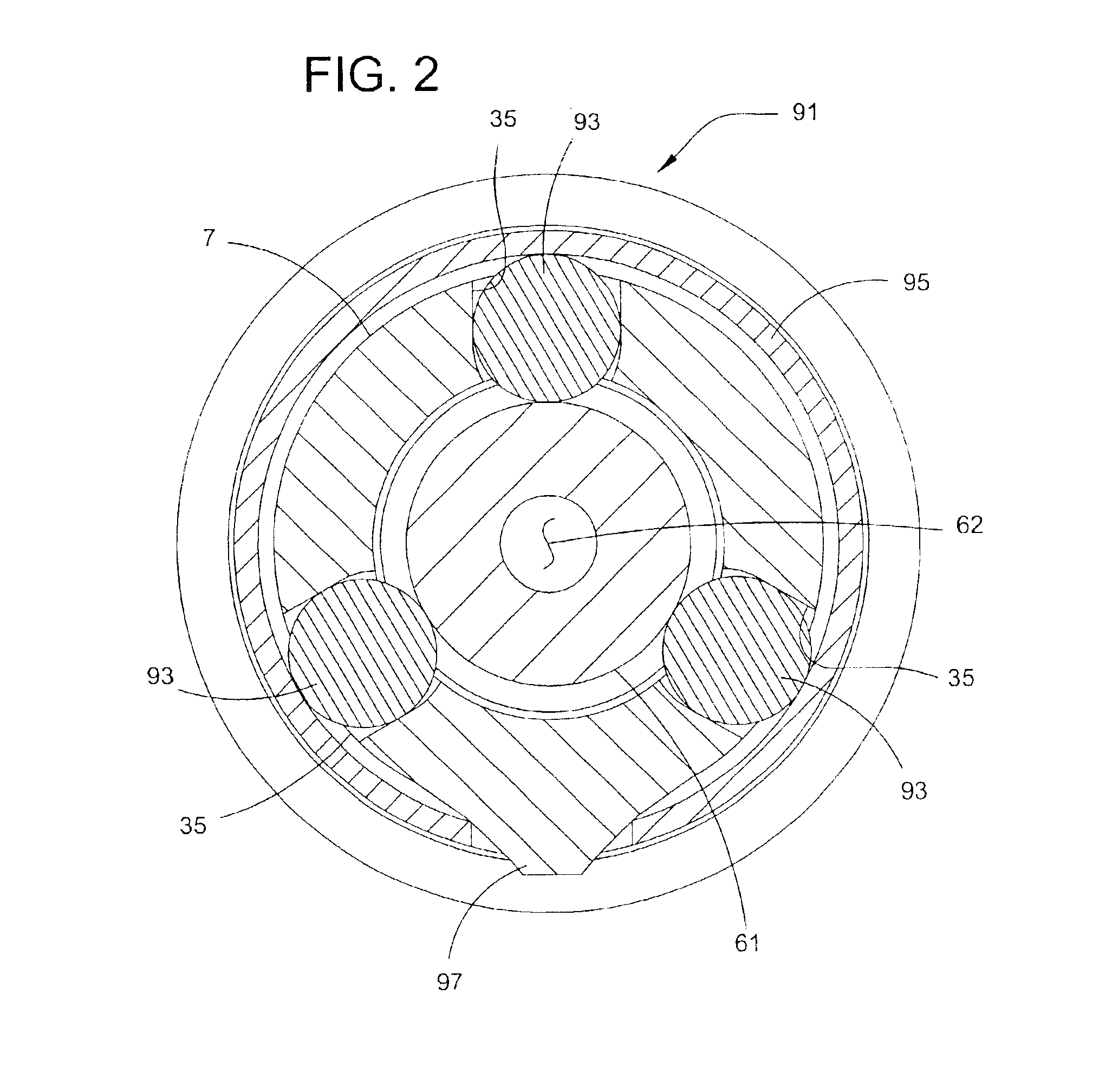

InactiveCN101200018ACompact designNice appearanceElectrode supporting devicesElectrode accessoriesWelding power supplyControl theory

The invention provides a rotating arc welding torch with narrow clearance, comprising a hollow axle high speed servo motor 1, an eccentric sleeve 2, a center-up-adjusted bearing 3, a sealed bearing4, a center-down-adjusted bearing 5, a conducting pole 6, a welding torch shell 8 and a conducting nozzle 14, etc. The invention is characterized in that the hollow axle high speed servo motor 1 and the eccentric sleeve2 which are connected together drive the conducting pole 6 and the conducting nozzle 14 to make an eccentric revolution around the axes of the welding torch; the revolution original point is close to the middle part of the conducting pole 6 which runs through the fixed center-down-adjusted bearing 5 and is fixed with the center-down-adjusted bearing 5; the revolving range is regulated jointly by the eccentric magnitude of the eccentric sleeve 2 and the position where the center-down-adjusted bearing 5 of the revolution original point exists on the conducting pole 6. The welding wire produces the rotating arc along with the revolution of the conducting pole 6 and the conducting nozzle 14. A soft wire cable 12 is connected with the loading welding power supply of the soft wire cable. The wearing components of the invention are all standard parts; thereby the implementation cost is low and the welding torch has long service life; using the soft conducting wire connection is convenient and reliable; when in operation, the welding torch can not be affected by the external disturbances.

Owner:HARBIN INST OF TECH

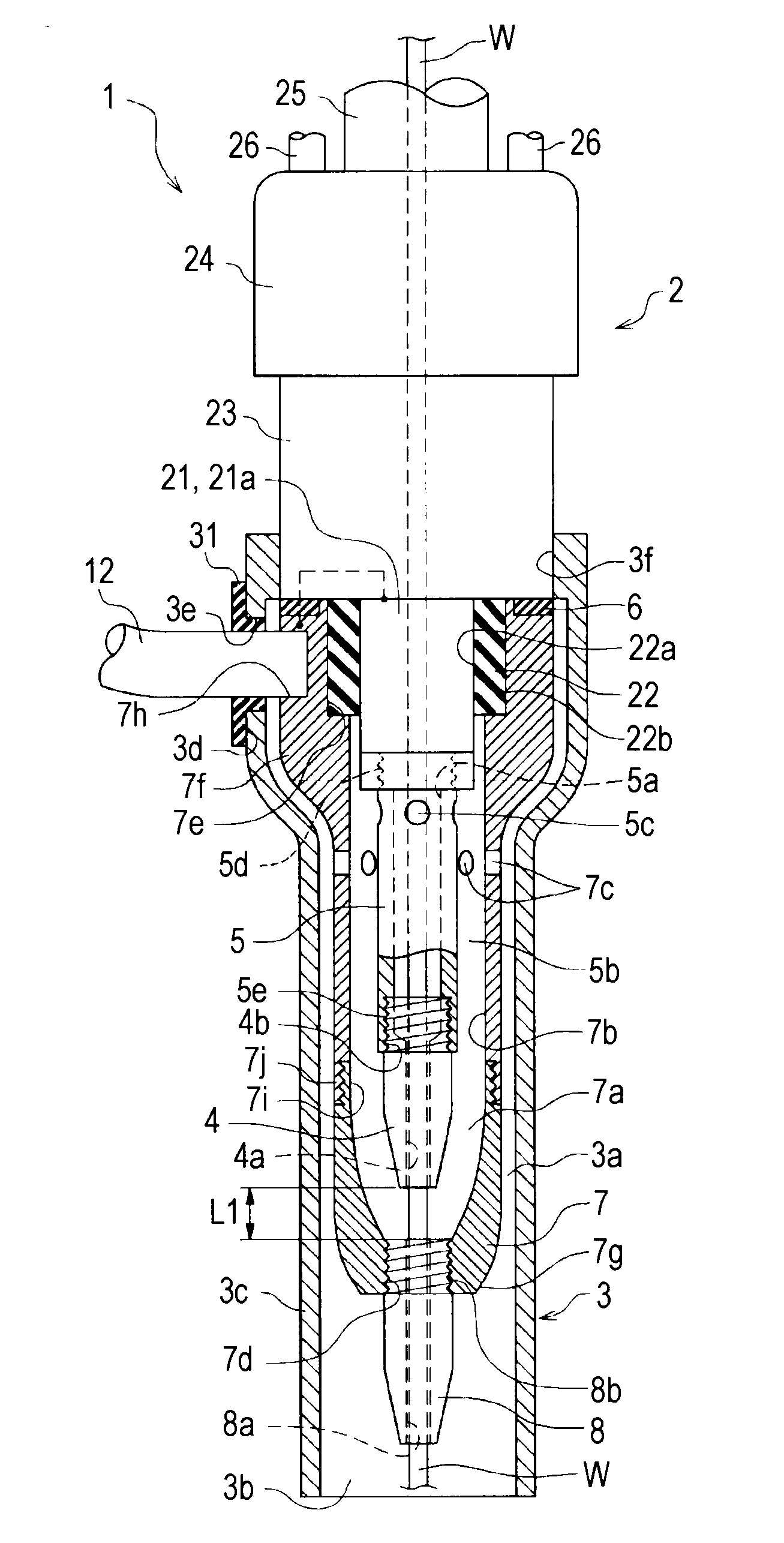

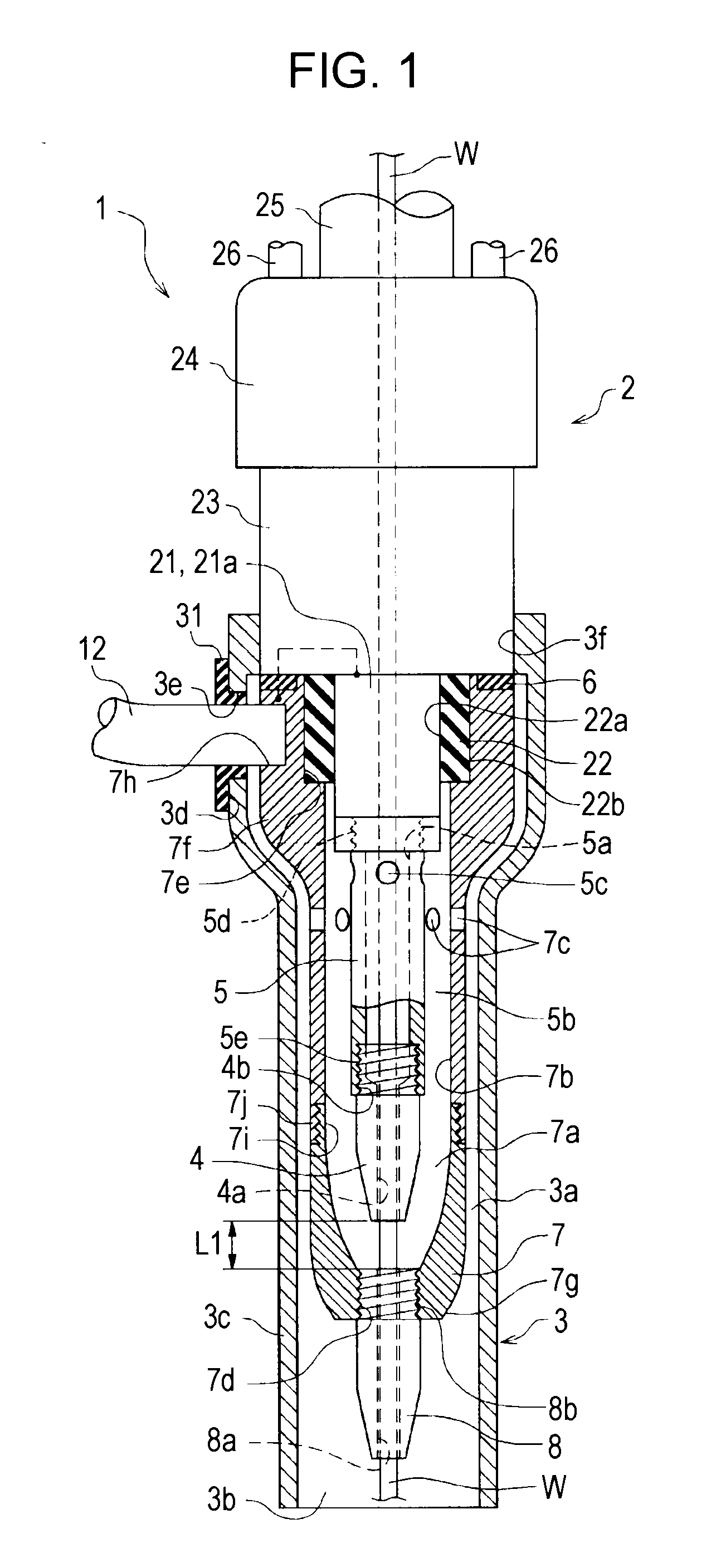

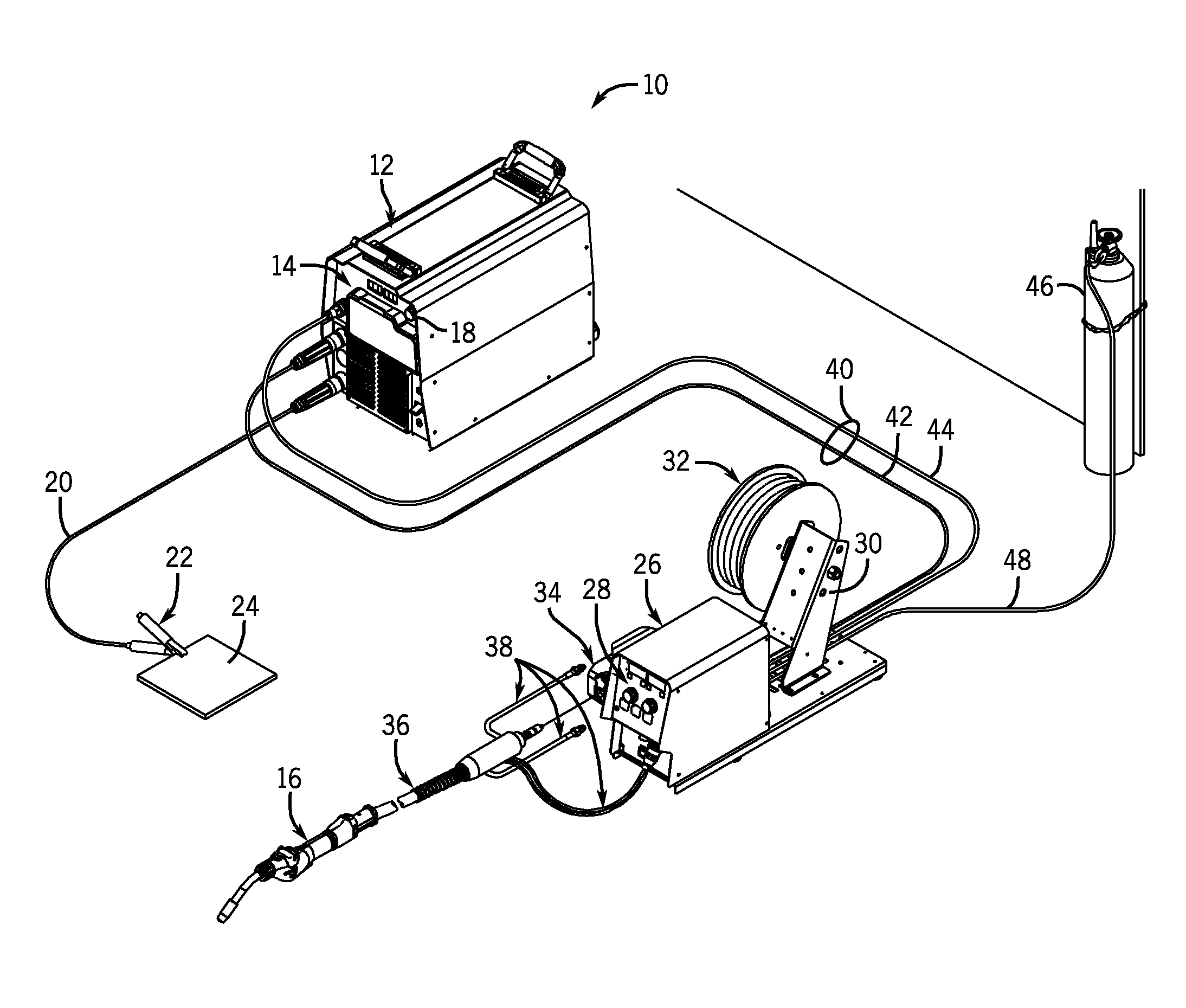

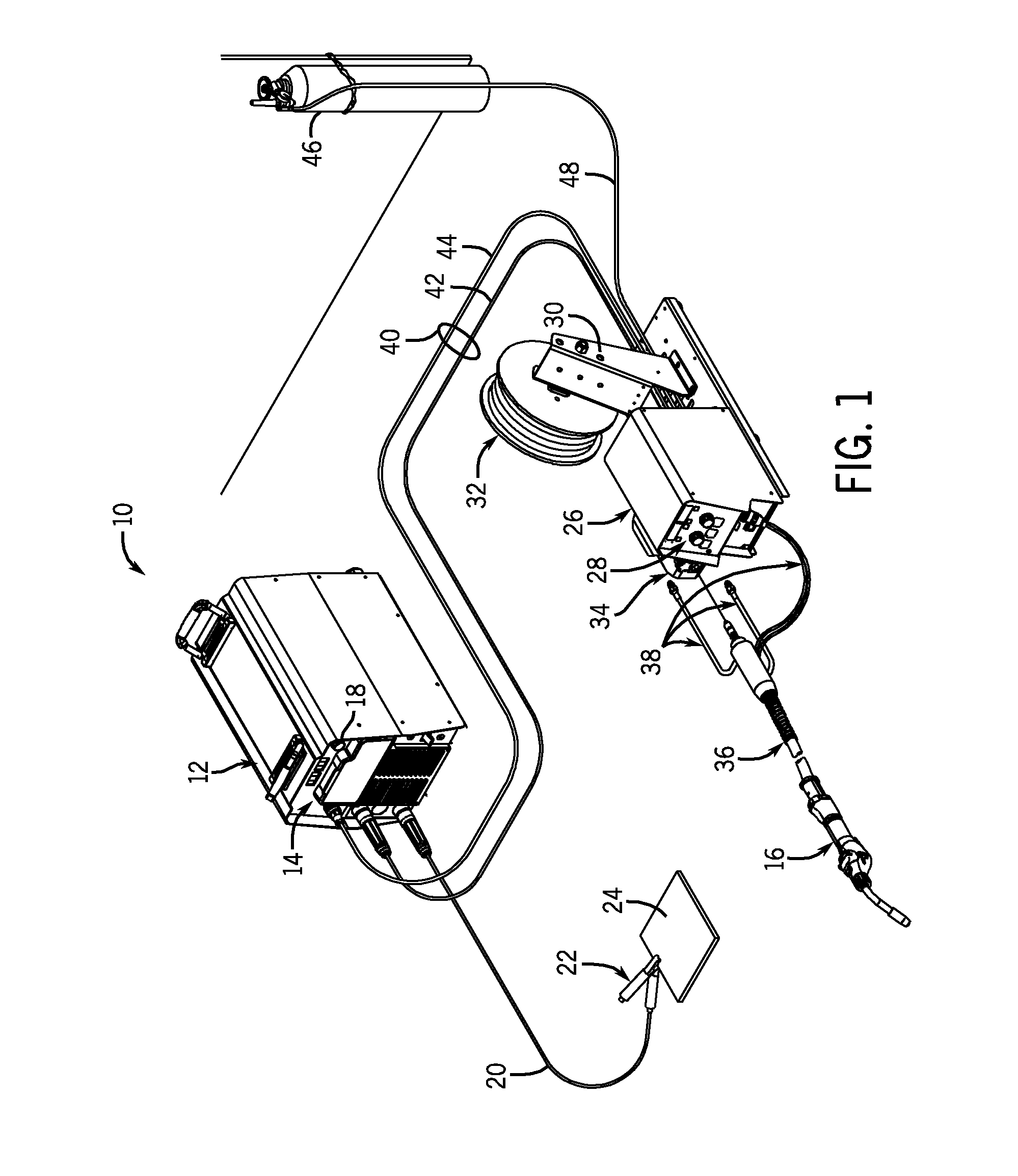

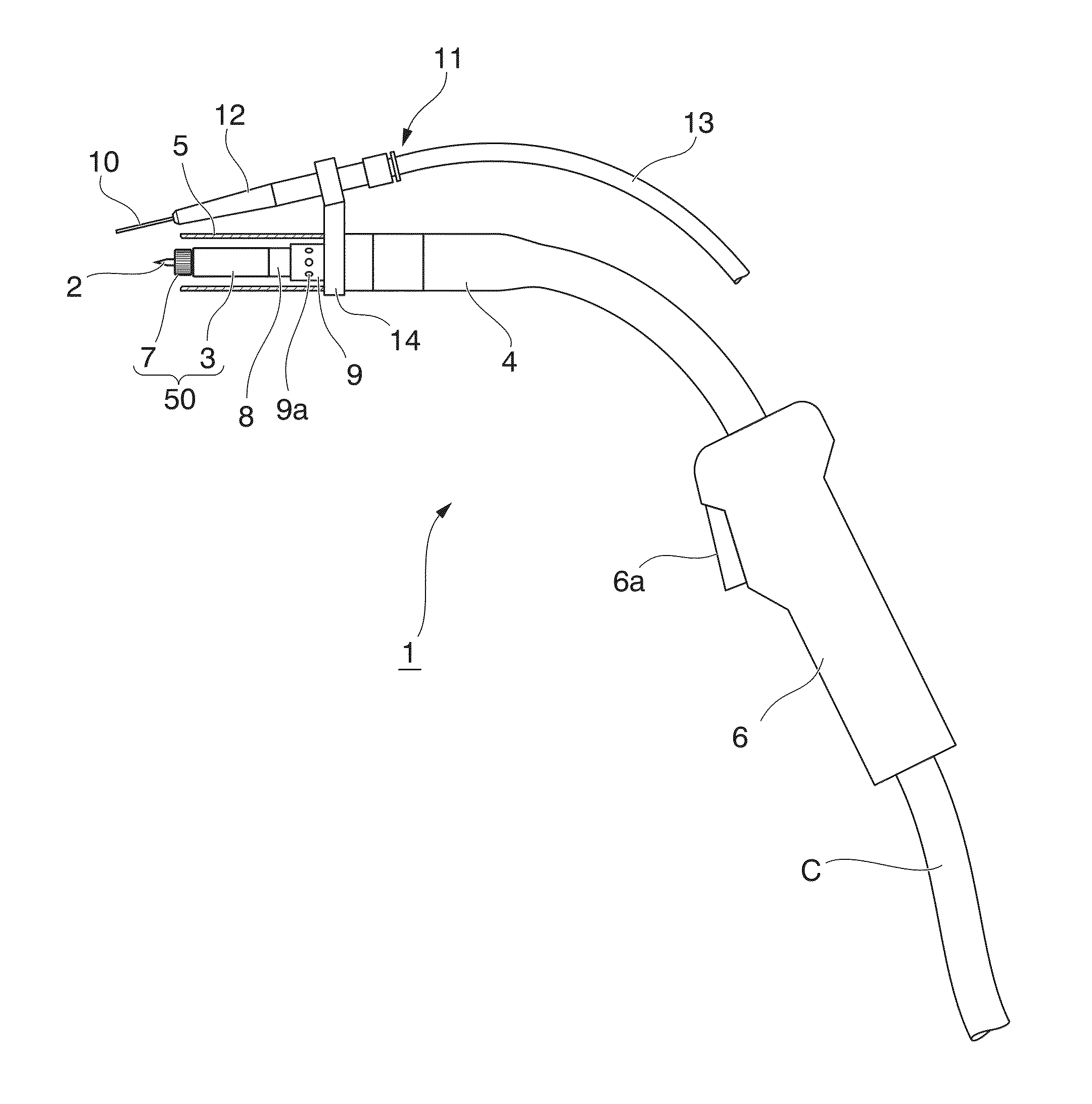

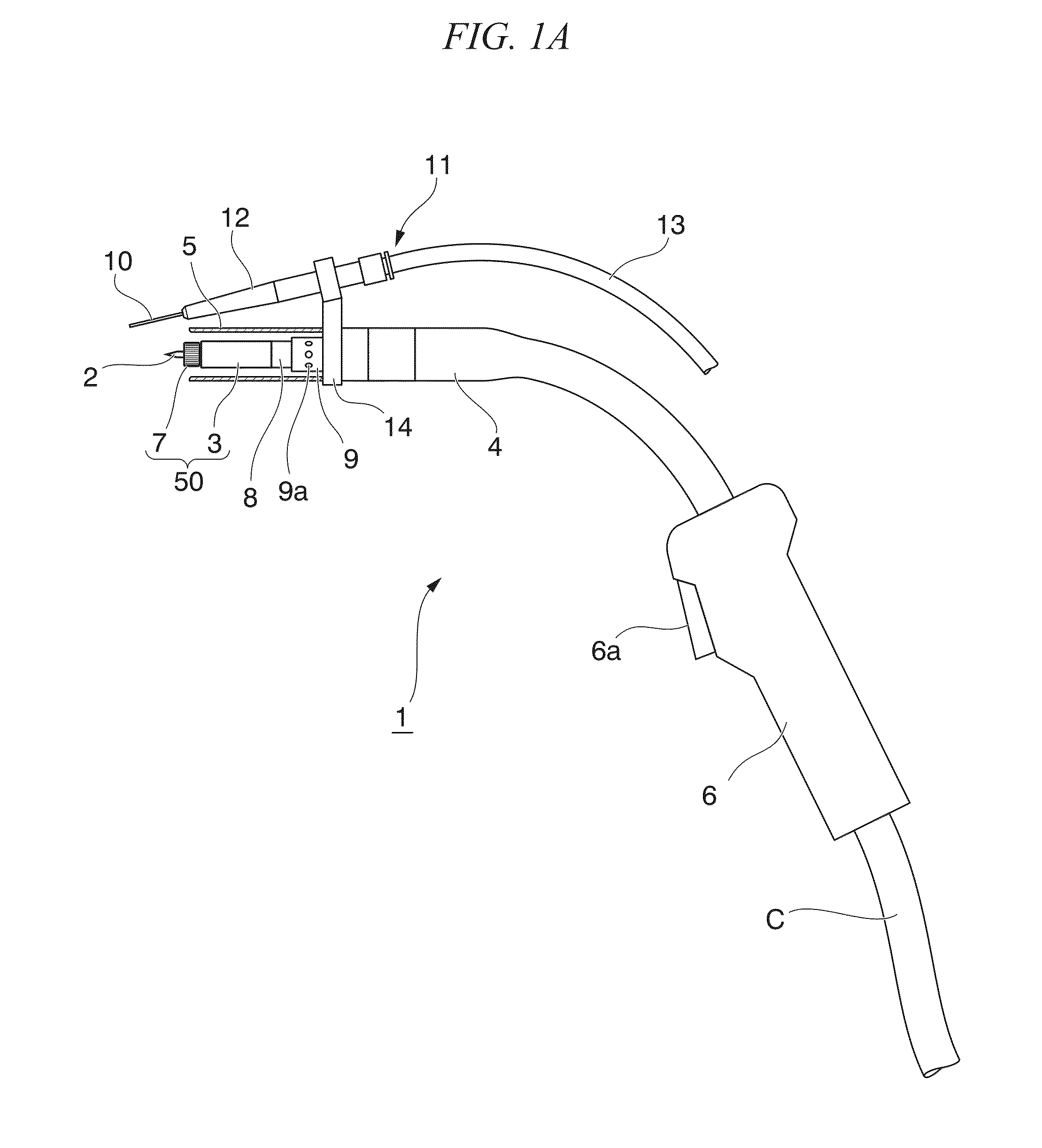

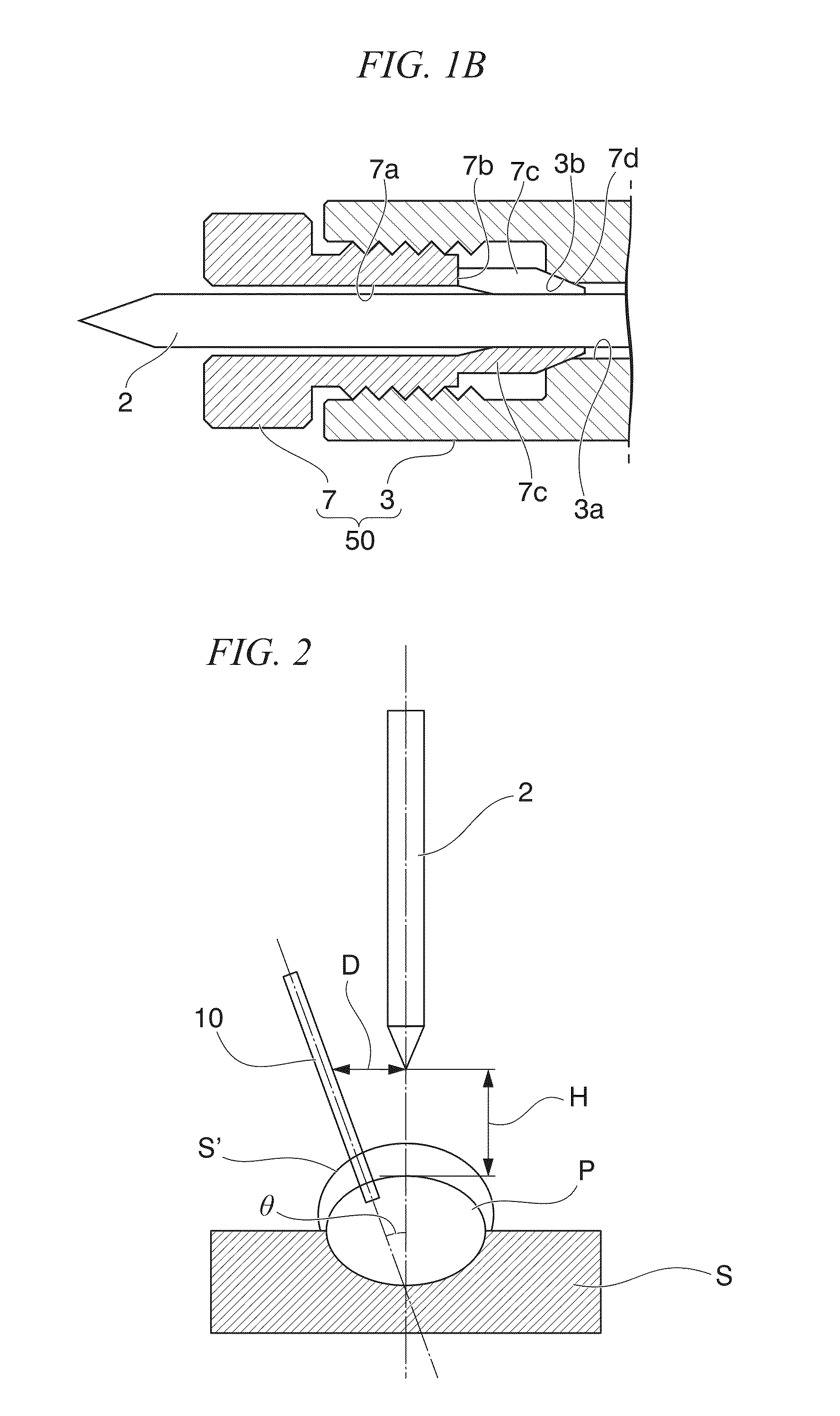

Semi-automatic welding system, conversion adapter kit, and welding torch

InactiveUS20150048057A1Support devices with shieldingElectrode accessoriesSemi automaticWelding power supply

According to the present invention, a non-consumable electrode type semi-automatic welding system which can conduct welding with high weld deposit and high speed is provided. A welding torch (1), in which a non-consumable electrode (1) generating an arc between the non-consumable electrode and an object to be welded and a torch nozzle (5) ejecting a shield gas toward a welding pool of the object to be welded generated by the arc are provided; a wire feeder (502) which delivers a welding wire (10) toward the welding pool of the object to be welded from a tip end of a feeding head, the feeding head being mounted on the welding torch (1) via an attaching jig (14); and a welding power source (501) which supplies electric power and shield gas to the welding torch (1); are provided and one or more among the welding torch (1), the wire feeder (502), and the welding power source (501) are constituted by applying at least one part of a welding torch, wire feeder, and welding power source provided in a consumable electrode type semi-automatic welding system.

Owner:NIPPON SANSO CORP

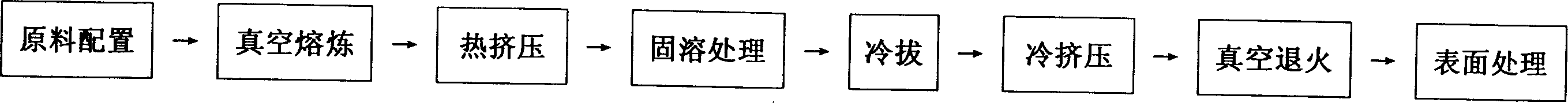

Manufacturing method of electrode cap used for welding automobile coated steel plate

InactiveCN1597223AAvoid alloying tendencyMeet the requirement of no sticking weldingElectrode featuresWelding/cutting auxillary devicesSolution treatmentSheet steel

A technology for preparing the high-performance electrode cap for welding the coated steel palte of car includes such steps as proportional mixing cathode copper, Cr powder Zr powder and Mg powder, smelting in vacuum furnace, pouring in circular mould, cleaning the surface of ingot, hot squeeznig to become rod, solutionizing, cold drawing, blanking, cold die pressing, vacuum annealing, trimming and polishing.

Owner:中外合资常熟明辉焊接器材有限公司

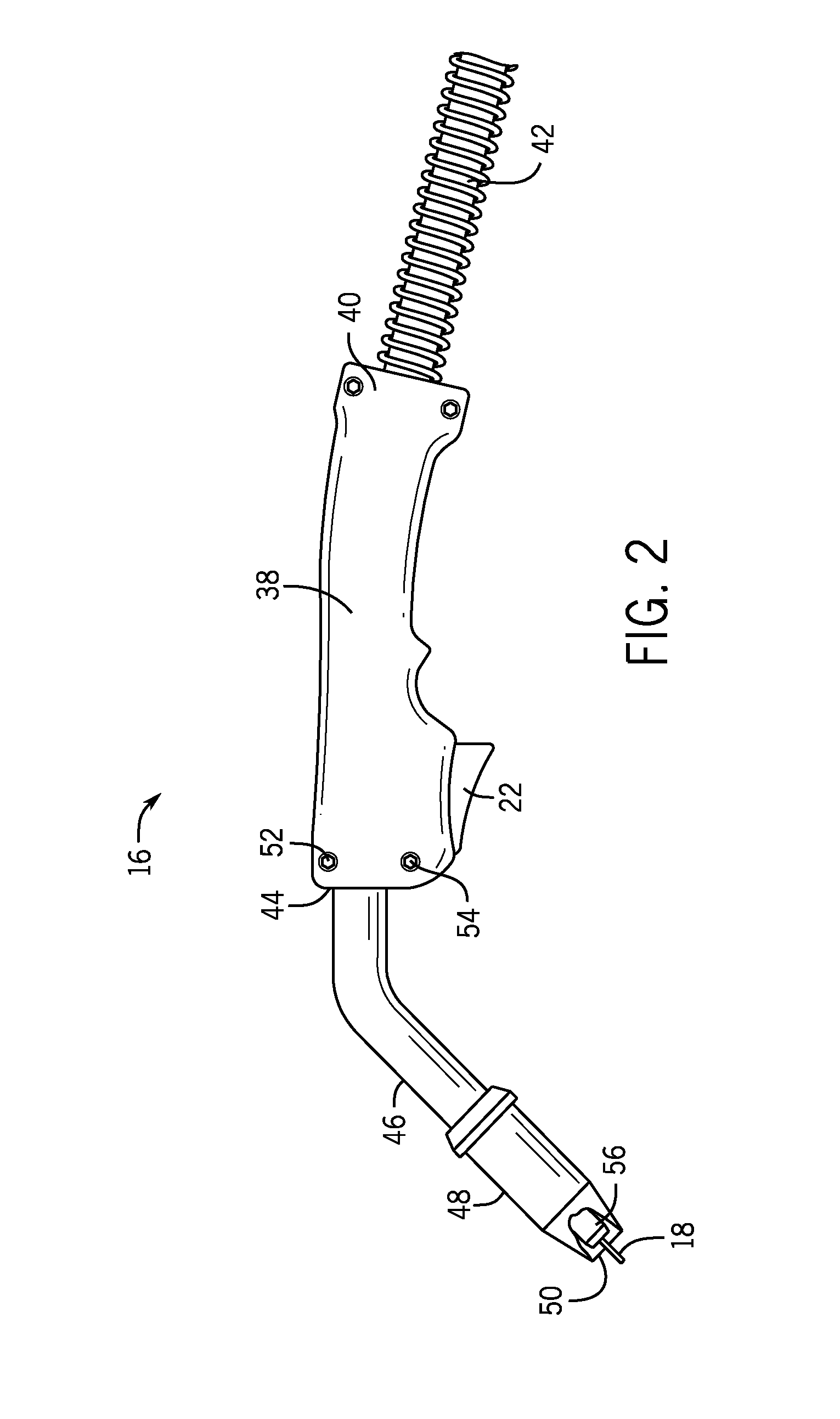

Welding wire retraction system and method

A method and system for retracting welding wire is provided. One welding torch includes a handle configured to receive welding wire from a wire source and to direct the welding wire to a torch tip. The welding torch also includes a first switch coupled to the handle and configured to cause the welding wire to extend out of the torch tip to expose more wire when the first switch is actuated. The welding torch includes a second switch coupled to the handle and configured to cause the welding wire to retract into the torch tip to expose less wire when the second switch is actuated.

Owner:ILLINOIS TOOL WORKS INC

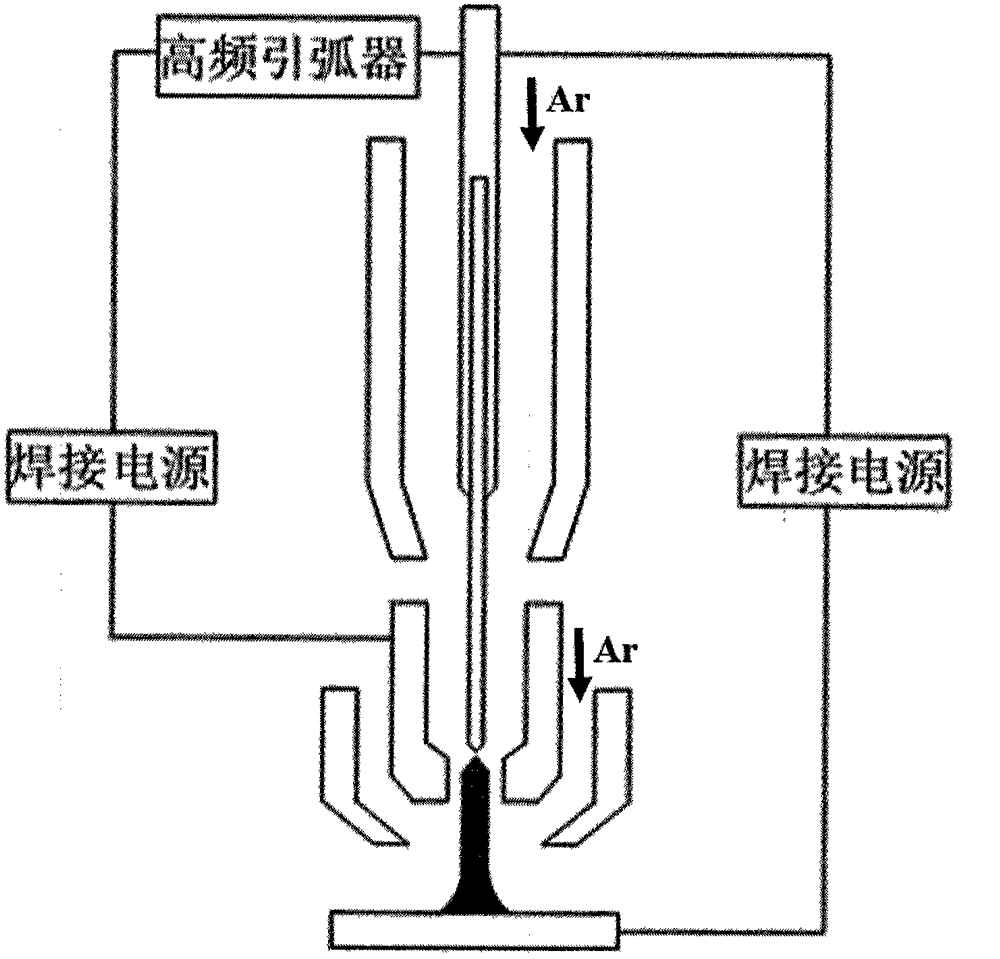

Plasma-arc welding device implemented by aid of TIG (tungsten inert gas) welding method

ActiveCN104668743AImprove welding efficiencyImprove welding qualityElectrode supporting devicesElectrode accessoriesSpray nozzleEngineering

The invention relates to a plasma-arc welding device implemented by the aid of a TIG (tungsten inert gas) welding method. The plasma-arc welding device comprises an upper gun and a lower gun. An upper spray nozzle is connected with the lower end of the upper gun and is mechanically coaxially connected with the lower gun. A water cooling groove is formed in the wall of the upper gun, an upper water inlet pipe, an upper water outlet pipe and an upper gas inlet pipe are arranged in the wall of the upper gun, a flow guide component, a tungsten electrode clamp and a tungsten electrode are coaxially arranged in the upper gun, and the tungsten electrode penetrates the tungsten electrode clamp and extends into the lower gun. A water cooling groove is formed in the wall of the lower gun, a lower water inlet pipe, a lower water outlet pipe and a lower gas inlet pipe are arranged in the wall of the lower gun, a lower spray nozzle is connected with the inner wall of the lower end of the lower gun, pore passages are arranged in the center of the lower spray nozzle, the tail end of the tungsten electrode is separated from each center pore passage of the lower spray nozzle by a certain distance, and a protective cover is connected to the outer wall of the lower end of the lower gun. The plasma-arc welding device has the advantages that plasma-arc welding can be implemented, the TIG welding efficiency and the quality of weld joints can be obviously improved, and the plasma-arc welding device is low in welding cost as compared with the traditional plasma-arc welding.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

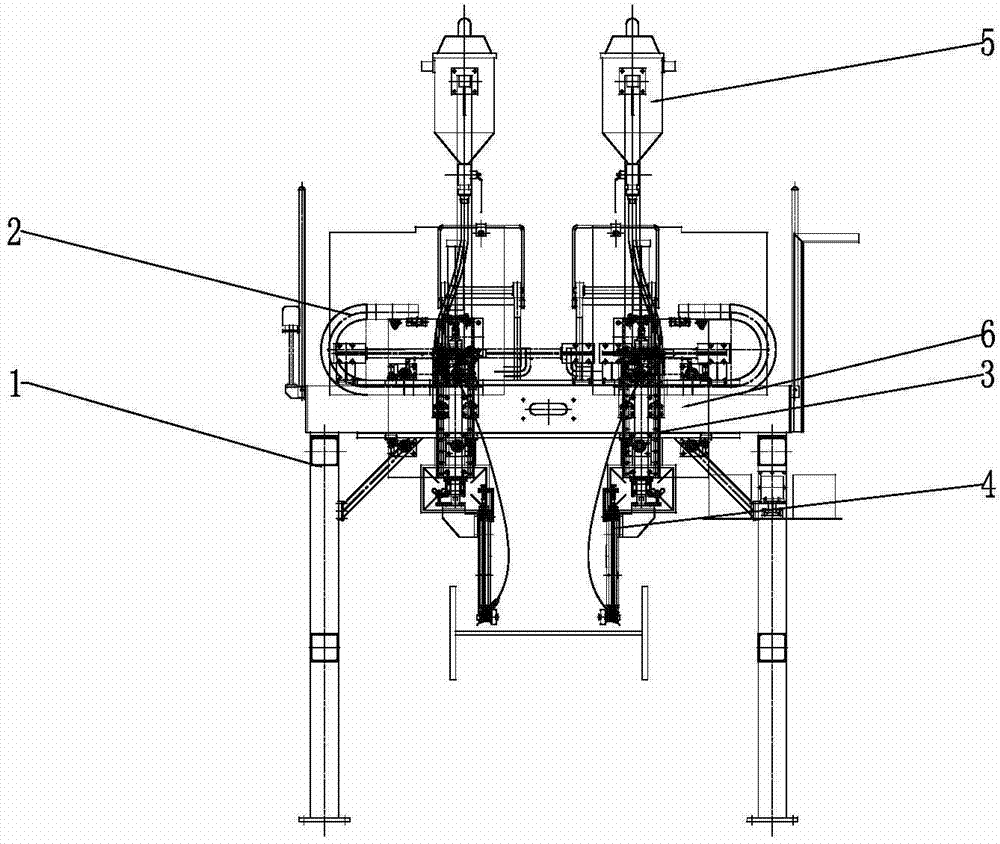

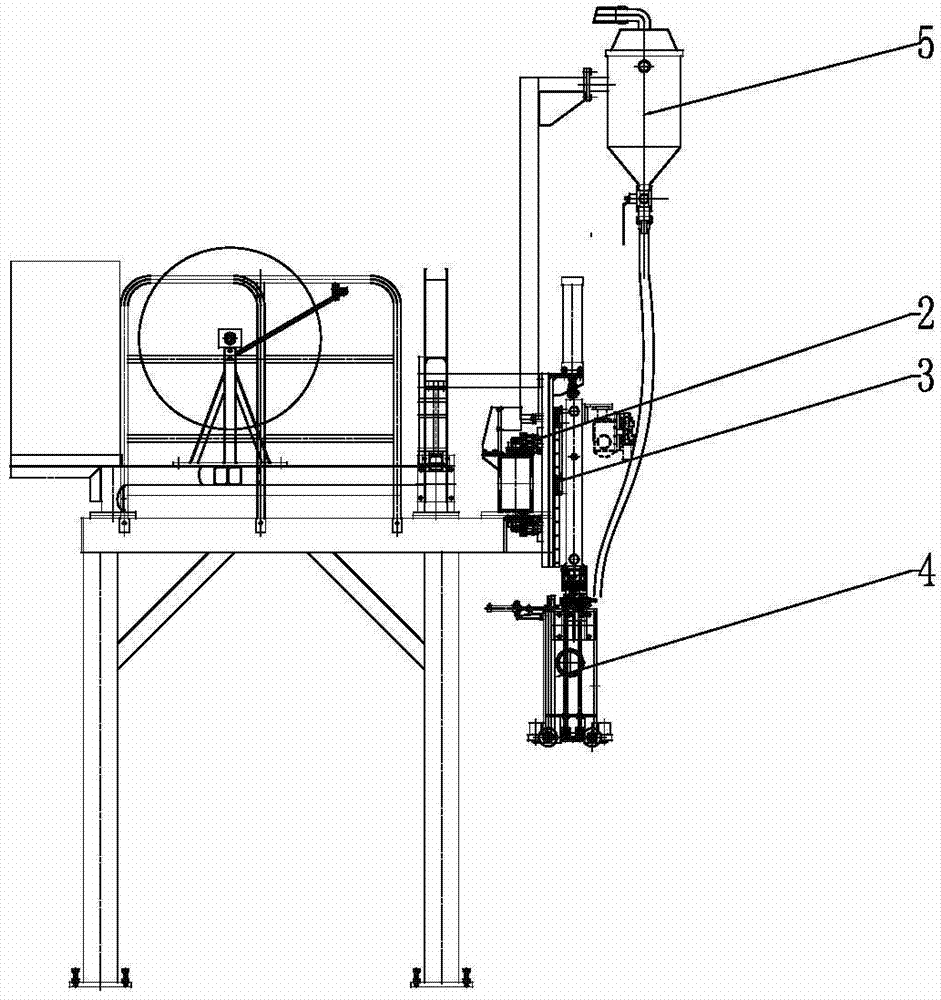

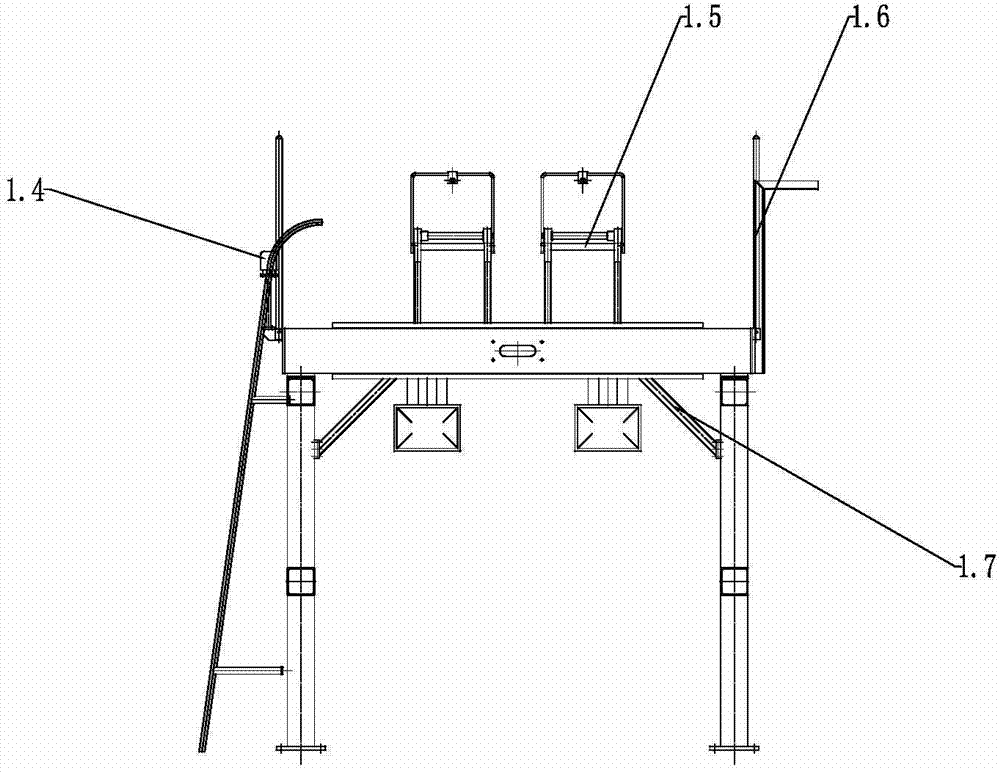

Horizontal H-shaped steel welding machine

ActiveCN103521894AImprove operational safetySimple structureElectrode accessoriesWelding accessoriesEngineeringOperation safety

The invention relates to a horizontal H-shaped steel welding machine, in particular to welding operation for horizontal H-shaped steel, and belongs to the technical field of welding machines. The horizontal H-shaped steel welding machine comprises a door frame, transverse moving mechanisms, lifting mechanisms, welding mechanisms and recovery wire conveying mechanisms. A beam is arranged on the door frame. Two transverse moving mechanisms are arranged on the beam. Each transverse mechanism is connected with a lifting mechanism. Each lifting mechanism is connected with a welding mechanism. The recovery wire conveying mechanisms are arranged at upper ends of the transverse moving mechanisms. The horizontal H-shaped steel welding machine is simple, compact and reasonable in structure, high in reliability, high in precision, convenient to operate, strong in technology adaptability, high in production efficiency, high in cost performance, and capable of welding H-shaped steel, greatly improves working efficiency, and greatly improves of operation safety of workers.

Owner:WUXI HUALIAN SCI & TECH GROUP

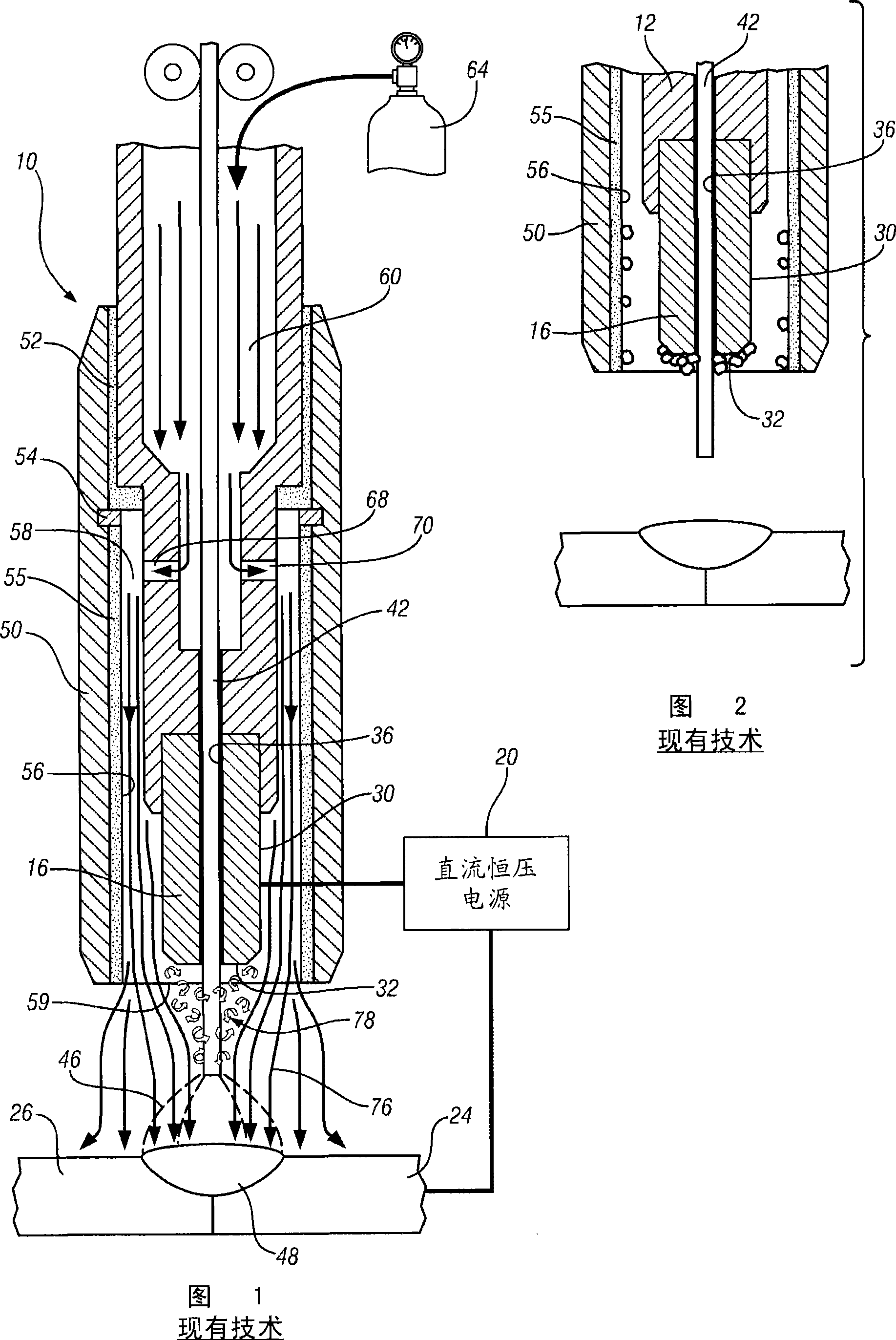

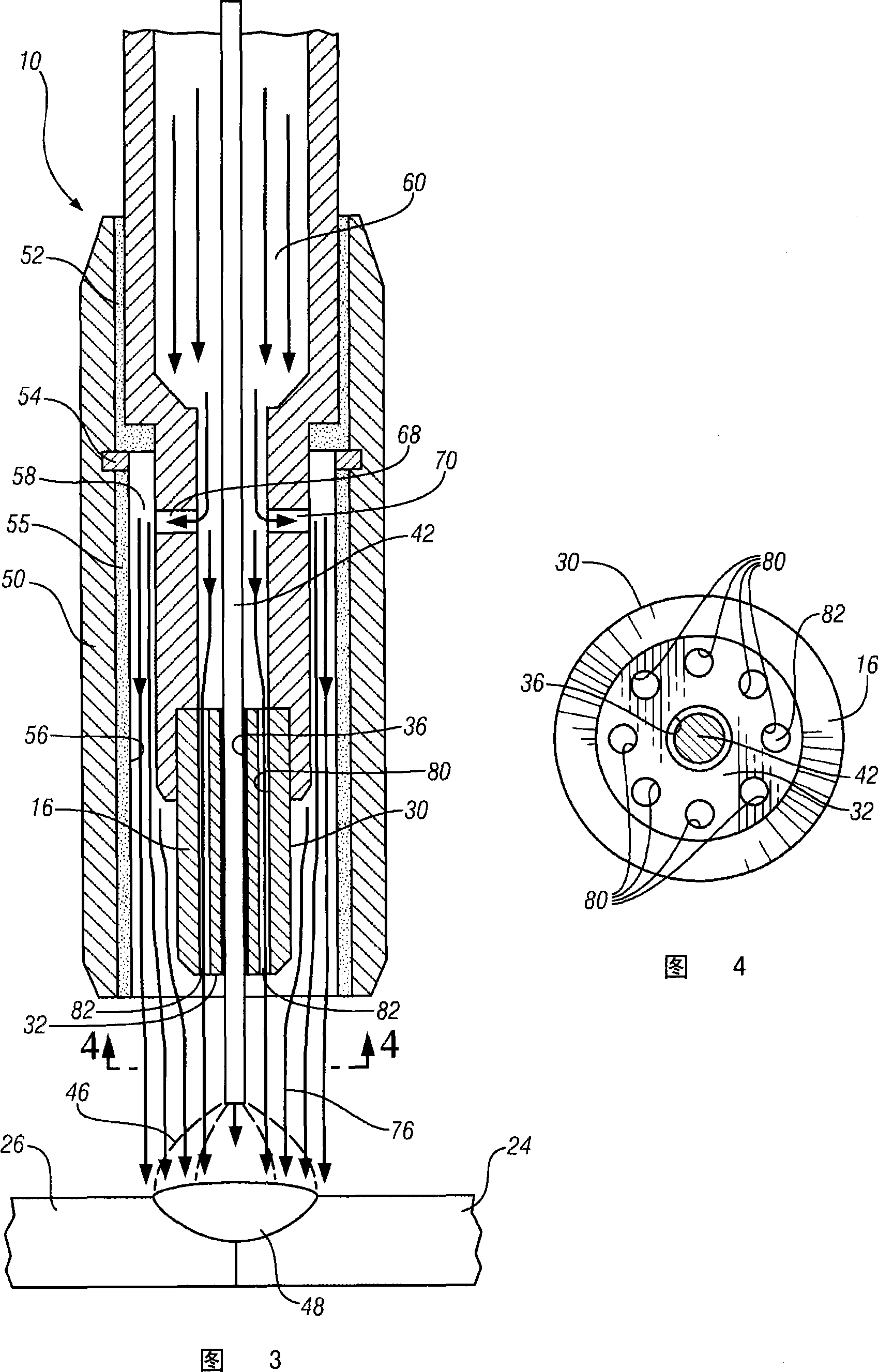

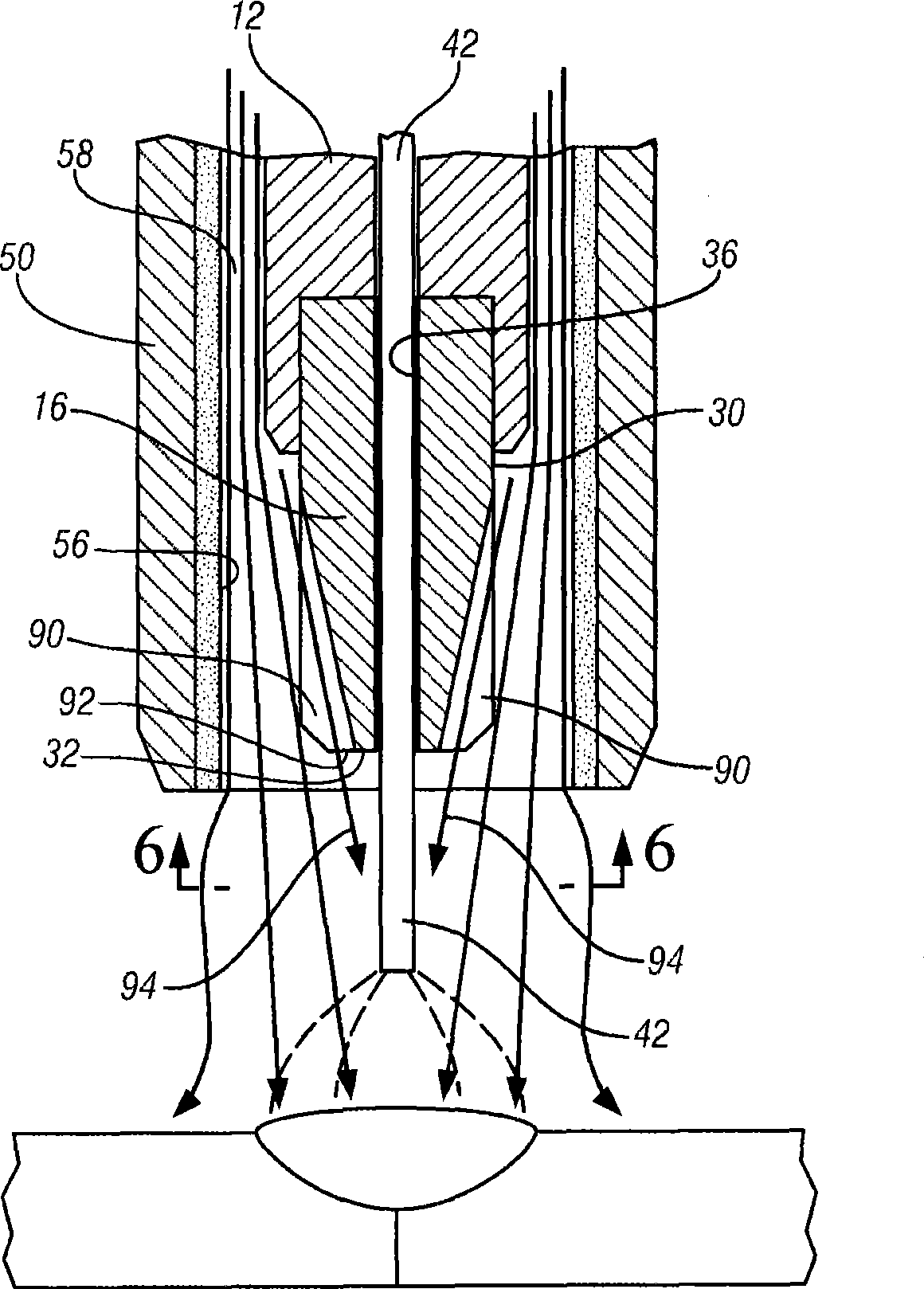

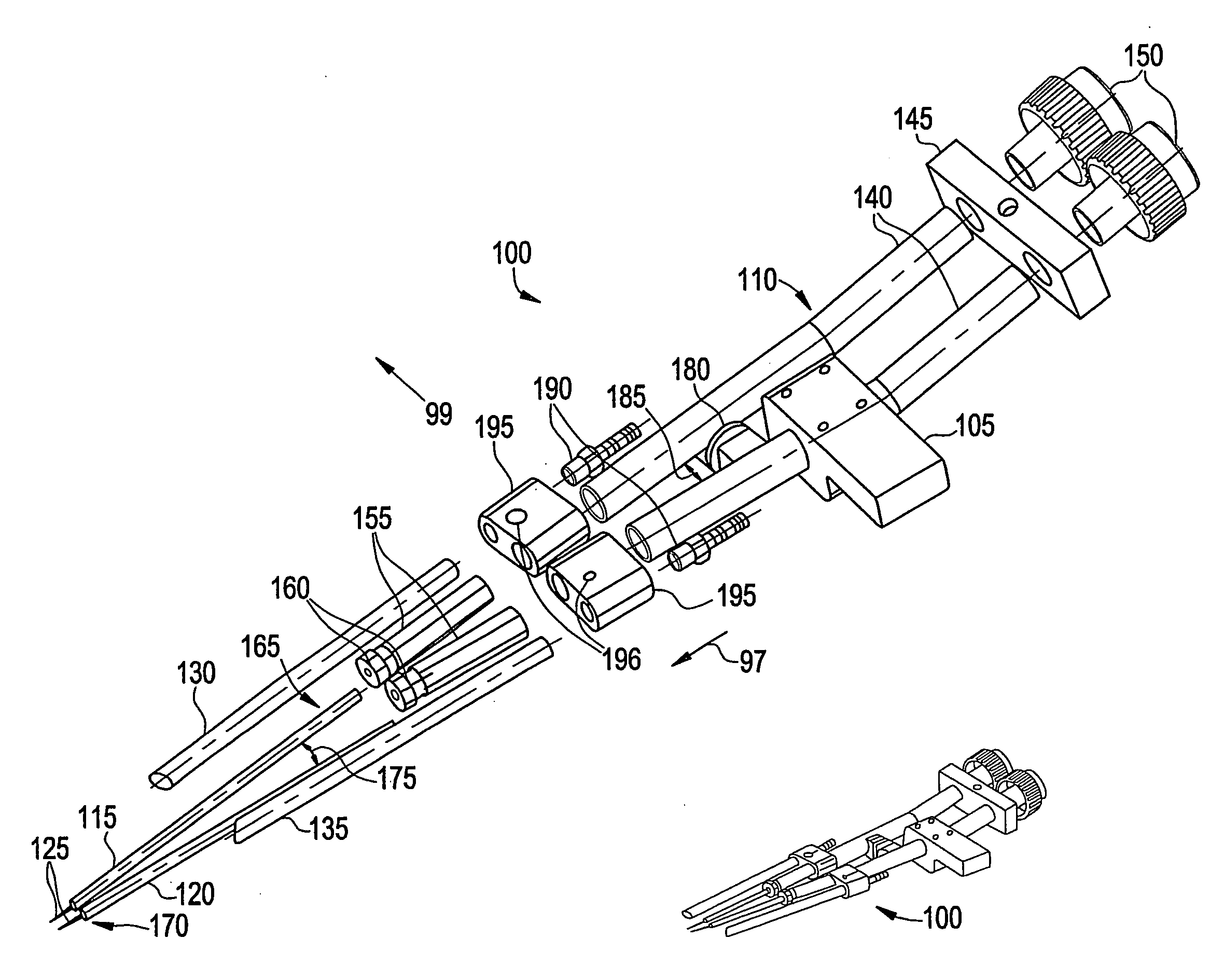

Apparatus and method for deep groove welding

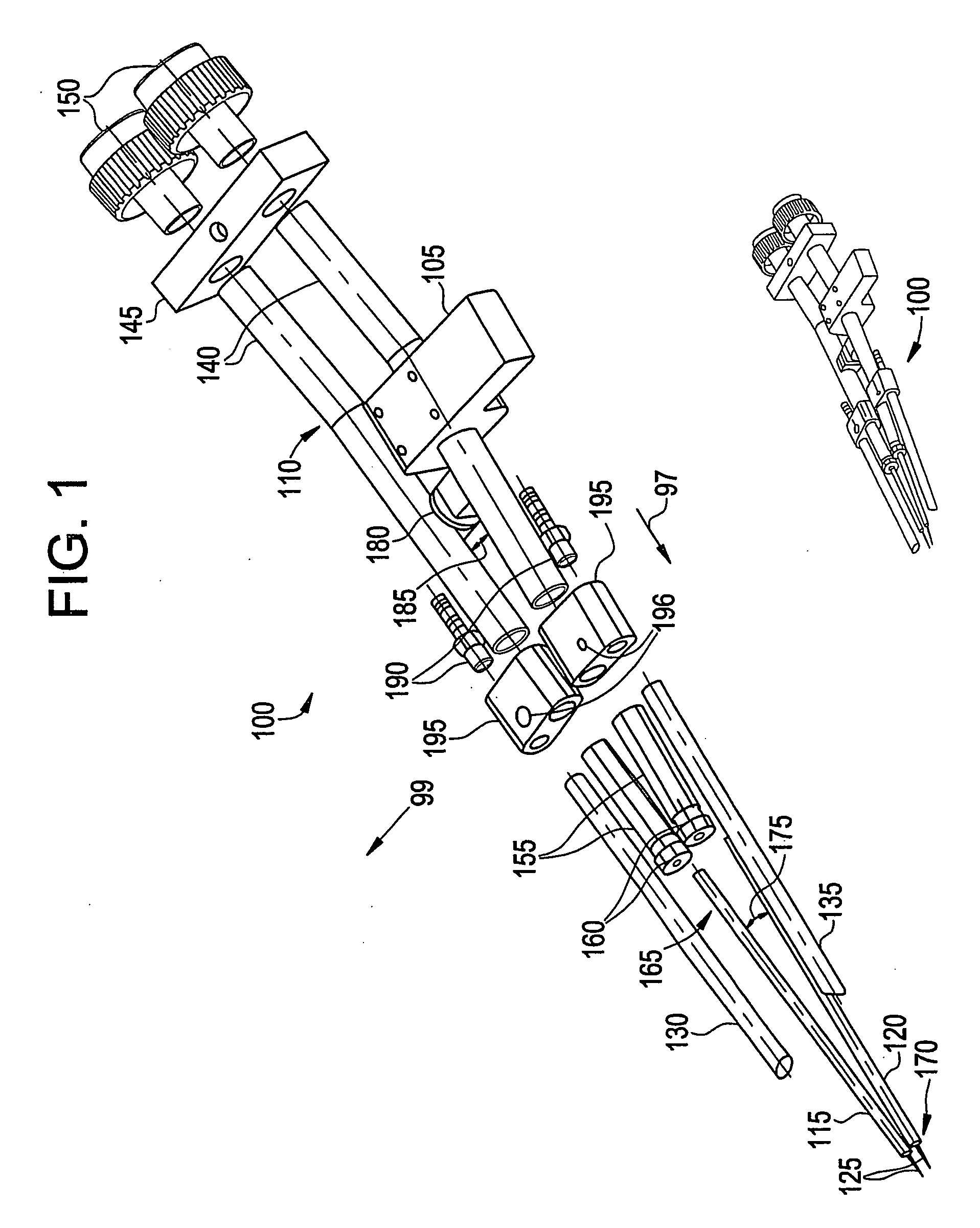

InactiveUS20080169336A1Fast welding speedPrinted circuit assemblingSoldering apparatusTorchGas supply

A welding apparatus is disclosed. The welding apparatus includes a torch body comprising at least one core, a plurality of contact tips extending in a direction from the at least one core, and a plurality of gas supply tubes disposed proximate the plurality of contact tips, the plurality of gas supply tubes extending in a substantially similar direction as the plurality of contact tips.

Owner:GENERAL ELECTRIC CO

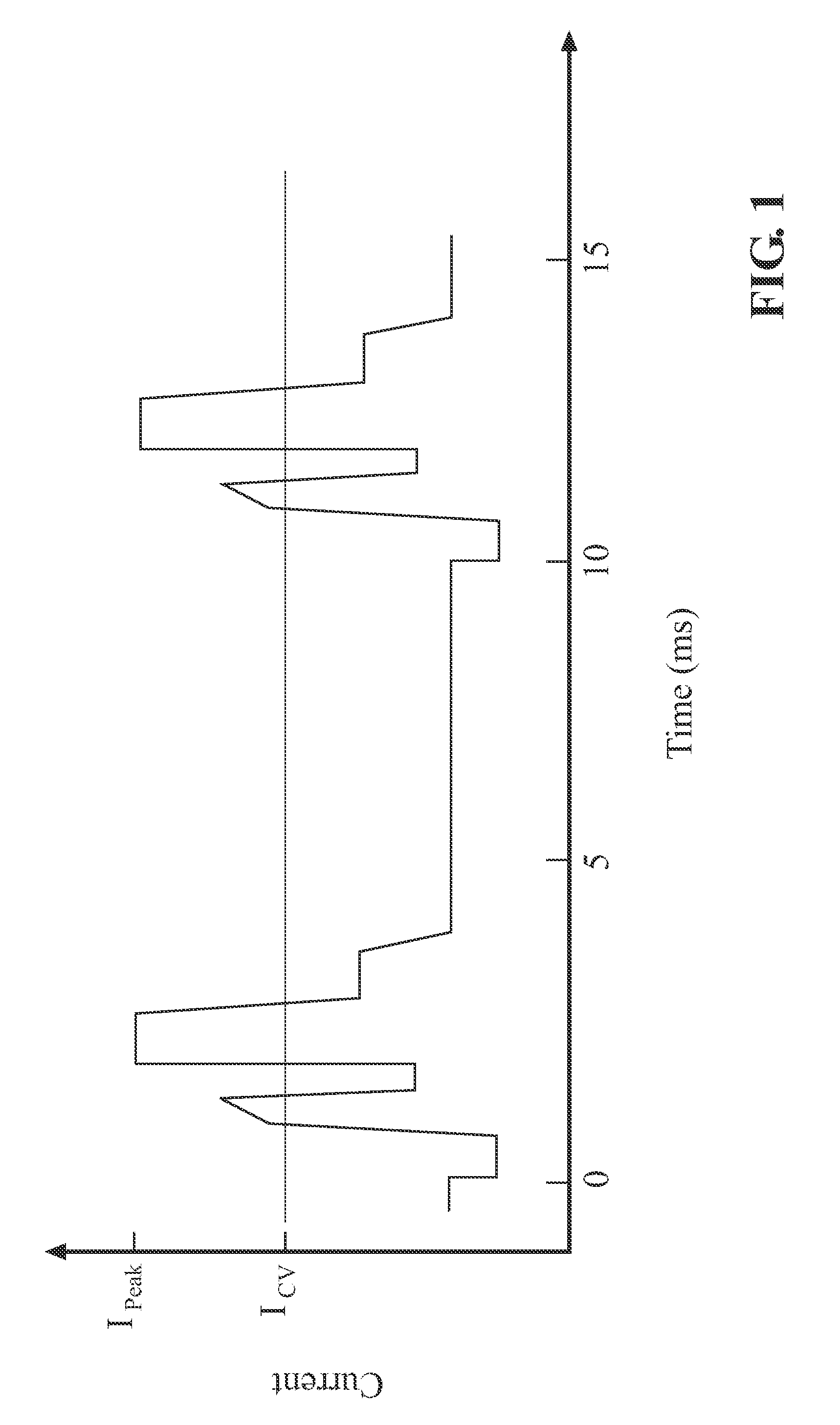

Front consumables for pulse gmaw torches

ActiveUS20100314374A1Reducing electrical resistanceReducing arc erosionElectrode supporting devicesElectrode accessoriesEngineeringMechanical engineering

Owner:ILLINOIS TOOL WORKS INC

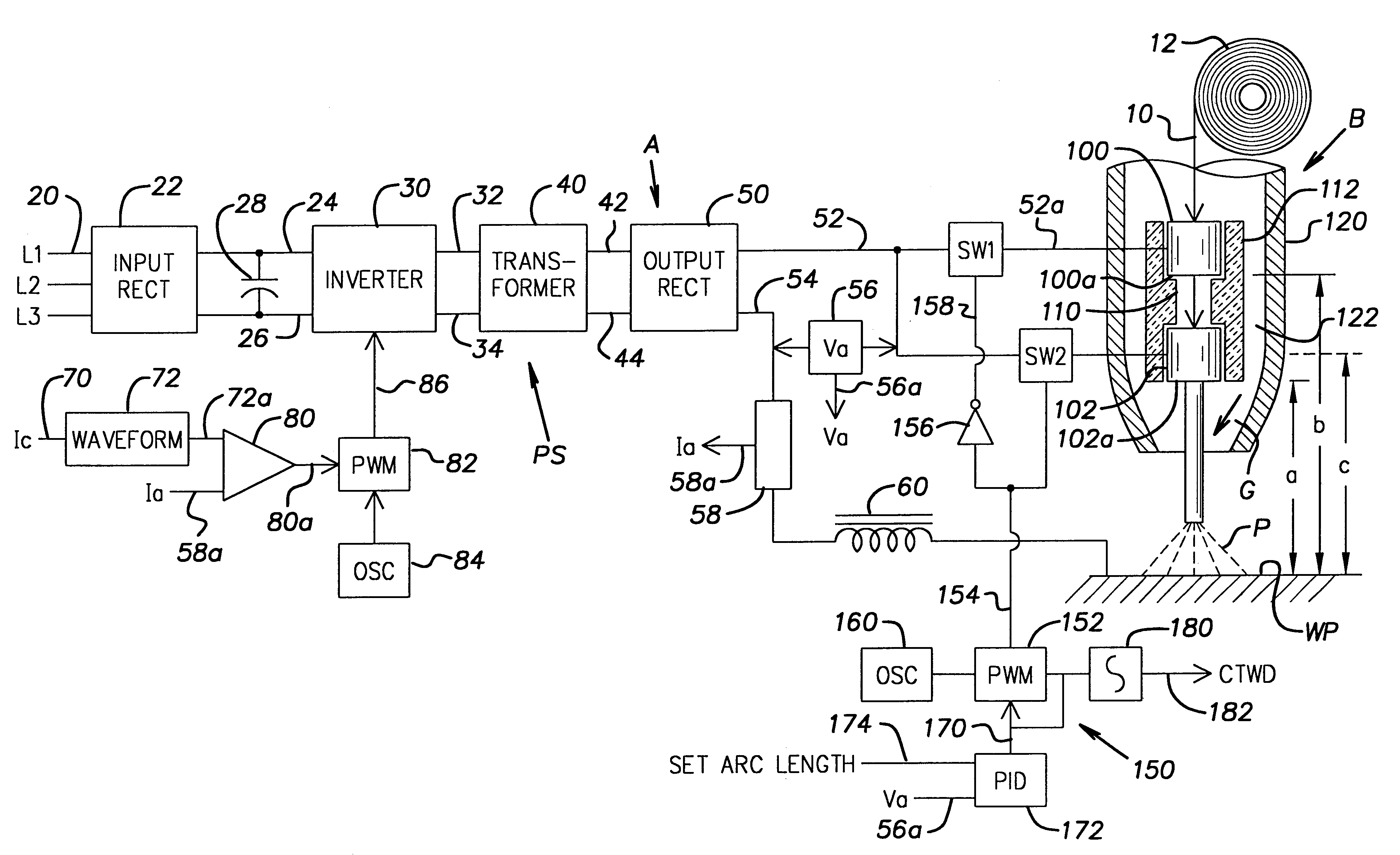

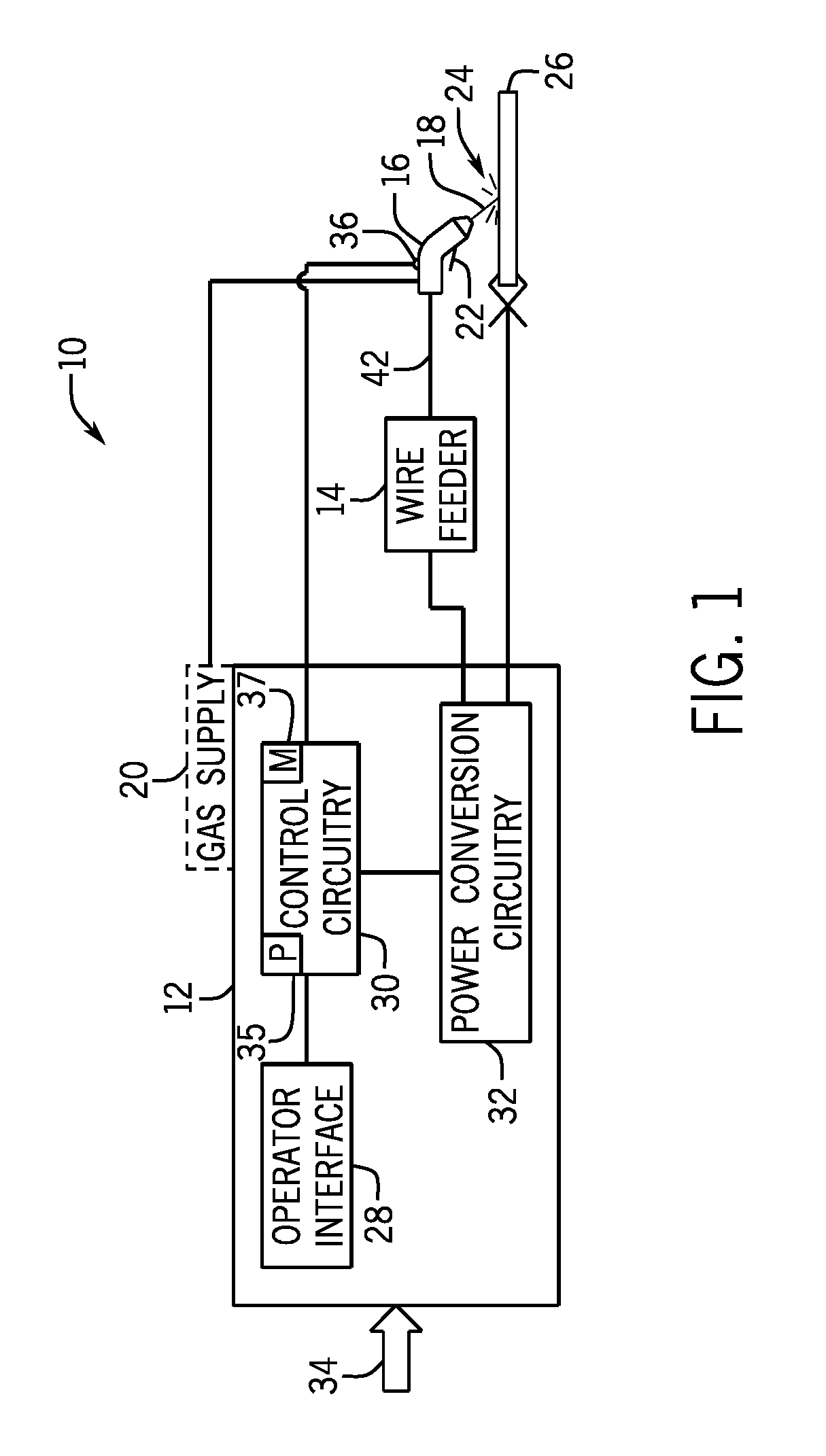

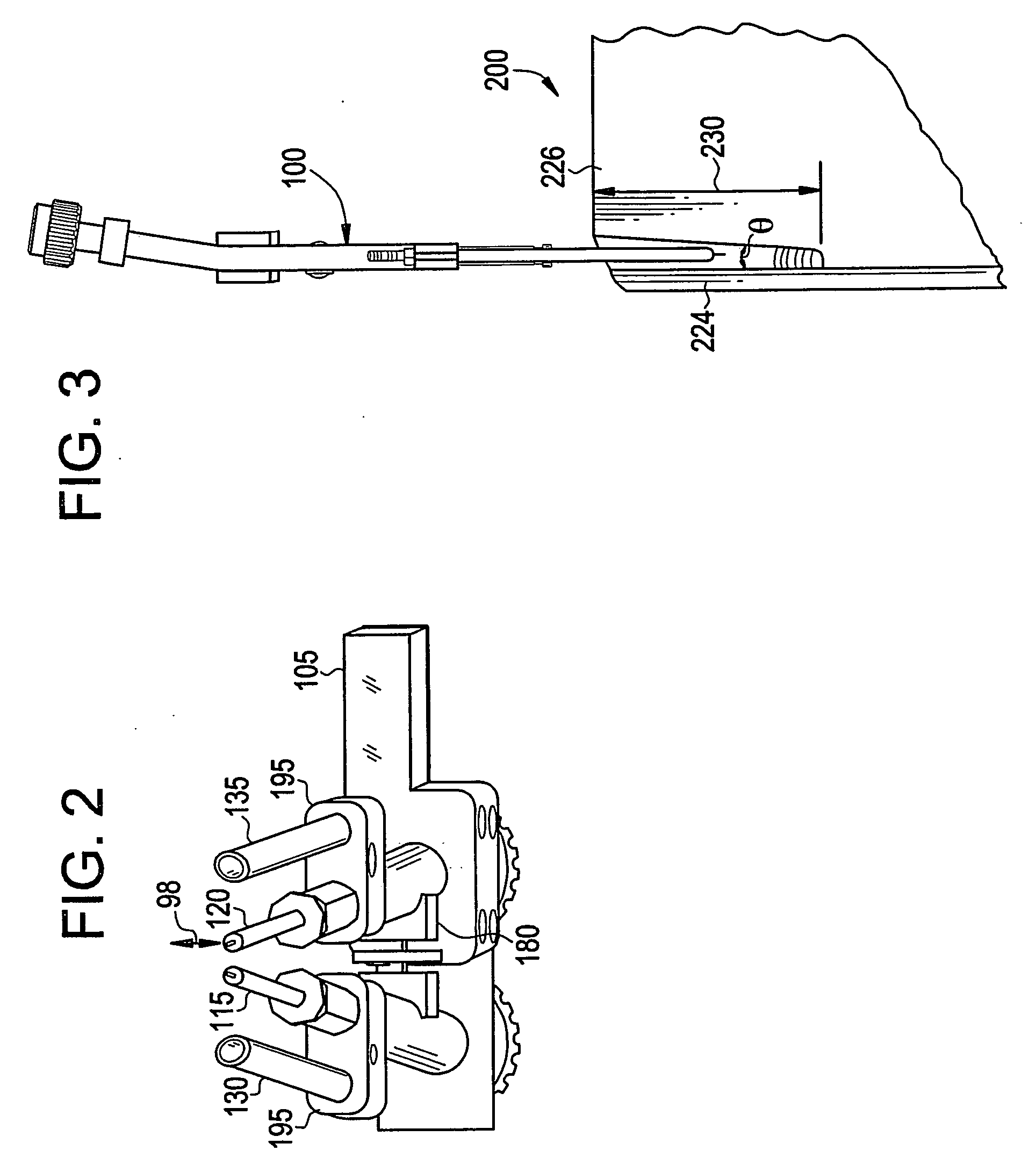

Systems, methods, and apparatus to preheat welding wire

PendingUS20180099346A1Shielding gas supply/evacuation devicesSupport devices with shieldingPower flowControl circuit

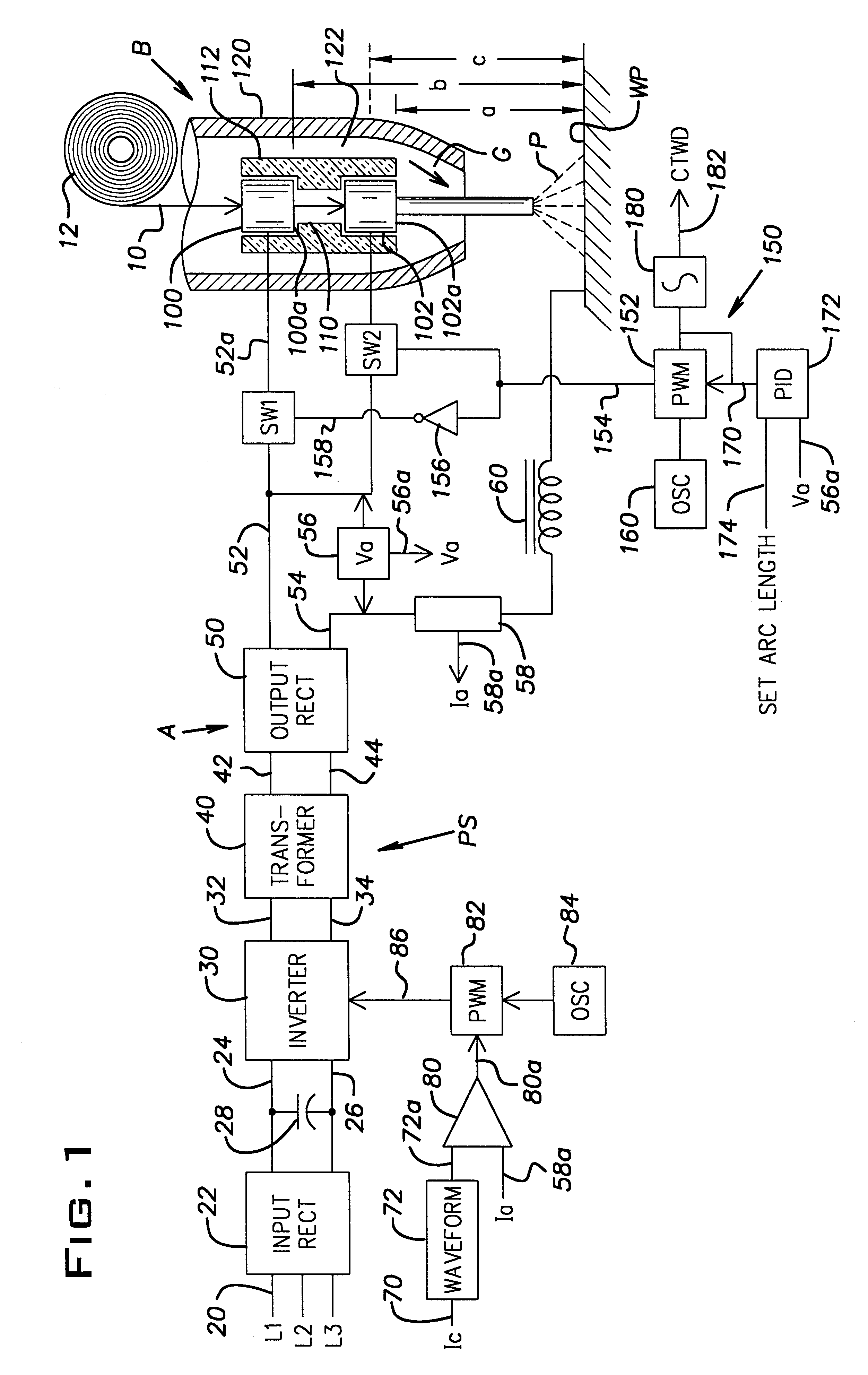

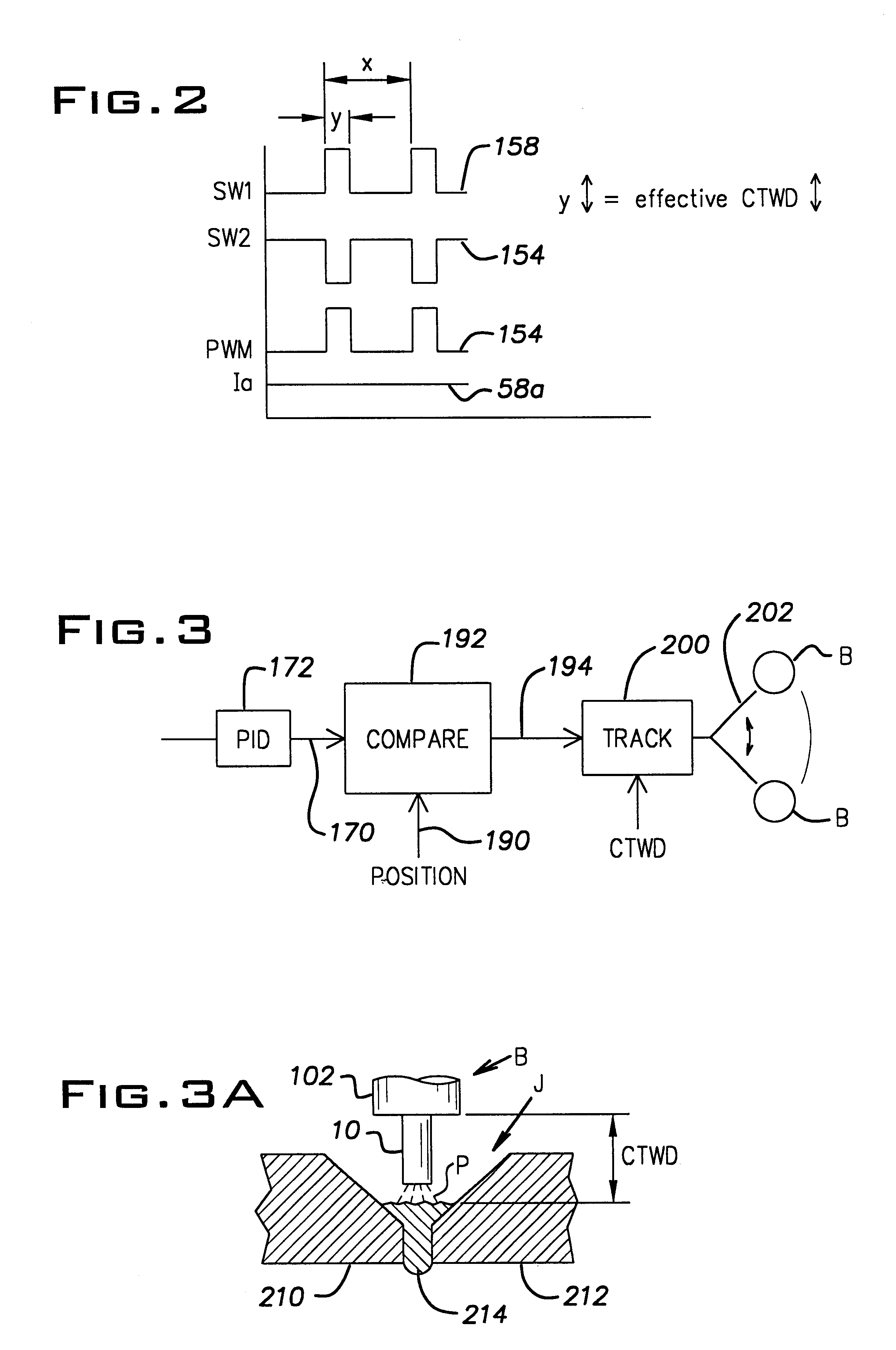

An example welding-type system includes: a welding-type power source configured to provide welding-type current to a welding-type circuit, the welding-type circuit comprising a welding-type electrode and a first contact tip of a welding torch; an electrode preheating circuit configured to provide preheating current through a first portion of the welding-type electrode via a second contact tip of the welding torch; a switching circuit configured to control a current flow between the welding-type power source and the first contact tip; and a preheat control circuit configured to control the switching circuit to: selectively direct current from the welding-type power source to the second contact tip; and selectively divert current from the electrode preheating circuit to the first contact tip

Owner:ILLINOIS TOOL WORKS INC

Sealed pipe welding gun

InactiveCN105215520AImprove stabilityImprove welding effectWelding/cutting auxillary devicesElectrode supporting devicesShielding gasEngineering

The invention discloses a sealed pipe welding gun which comprises a welding gun body and clamping devices. The welding gun body is provided with a welding chamber penetrating the two opposite sides of the welding gun body, a passageway which is communicated with the welding chamber and through which a pipe to be welded enters and exits out of the welding chamber and a gas channel through which protective gas flows into the welding chamber. At least one welding electrode capable of rotating around a rotary shaft is arranged in the welding chamber. The welding gun body is further provided with a drive device for driving the welding electrodes to rotate. The clamping devices comprise upper clamps and lower clamps. Upper semicircular grooves are formed in the end faces of the upper clamps. Lower semicircular grooves corresponding to the upper semicircular grooves are formed in the end faces of the lower clamps. When the upper clamps and the lower clamps are closed, a clamping space used for clamping the pipe to be welded is formed by the upper semicircular grooves and the lower semicircular grooves in a matched manner and the upper clamps are combined with the pipe to be welded, the lower clamps and the welding gun body to seal the welding chamber. Therefore, the stability of welding arcs and the welding effect are greatly improved.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

Narrow-gap welding nose with tilt angle device

ActiveCN103071898AUniform and stable penetrationCompact structureElectrode supporting devicesElectrode accessoriesControl systemNose

The invention relates to a narrow-gap welding nose with a tilt angle device, which carries out narrow-gap welding. The narrow-gap welding nose with the tilt angle device comprises an electric conduction nozzle of a welding gun, a connecting plate for installing the welding gun, and a tilt angle device, wherein the lower end of the electric conduction nozzle is provided with a bent part; and the bent part is coaxially and fixedly arranged on the lower end of a wire guide rod by a corner sleeve. The narrow-gap welding nose with the tilt angle device is characterized in that the tilt angle device comprises a tilt angle mechanism for driving the electric conduction nozzle to carry out deflection, and a side wall tracking mechanism for keeping the distance between the electric conduction nozzle and the side wall, wherein the tilt angle mechanism for driving the electric conduction nozzle to carry out deflection is connected with the electric conduction nozzle; the side wall tracking mechanism comprises an oscillating rod, an angle sensor and a controller, wherein the oscillating rod is used for supporting the side wall of a groove; the angle sensor is connected with the oscillating rod and is connected with the controller; the controller controls the tilt angle mechanism; and the oscillating rod and the side wall of the groove are always in elastic contact. The lateral displacement moving amount of a workpiece is measured by a high-precision sensing assembly, and the distance between the electric conduction nozzle and the workpiece is controlled to be within a tracking precision of + / -0.5mm by the lateral regulation of the control system so as to guarantee the stable and even penetration of the side wall.

Owner:北京嘉克新兴科技有限公司

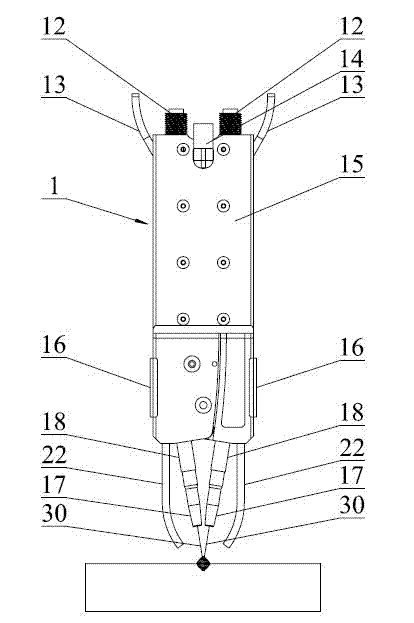

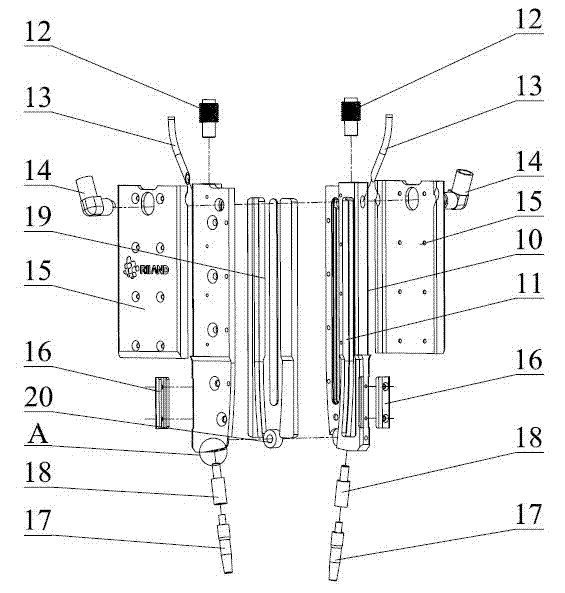

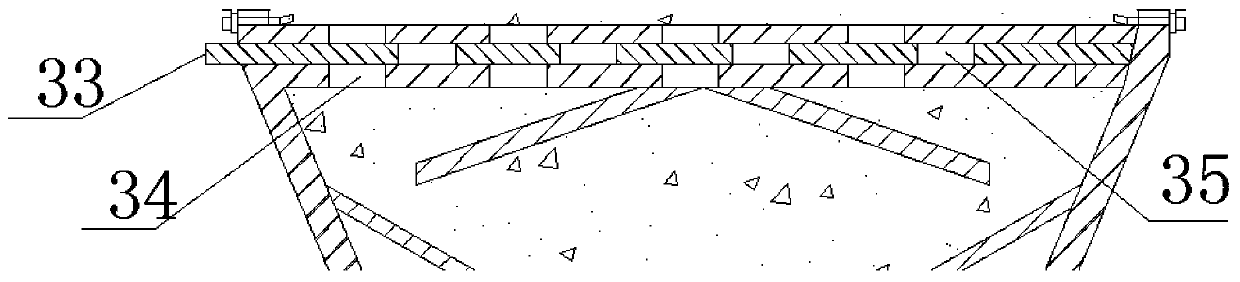

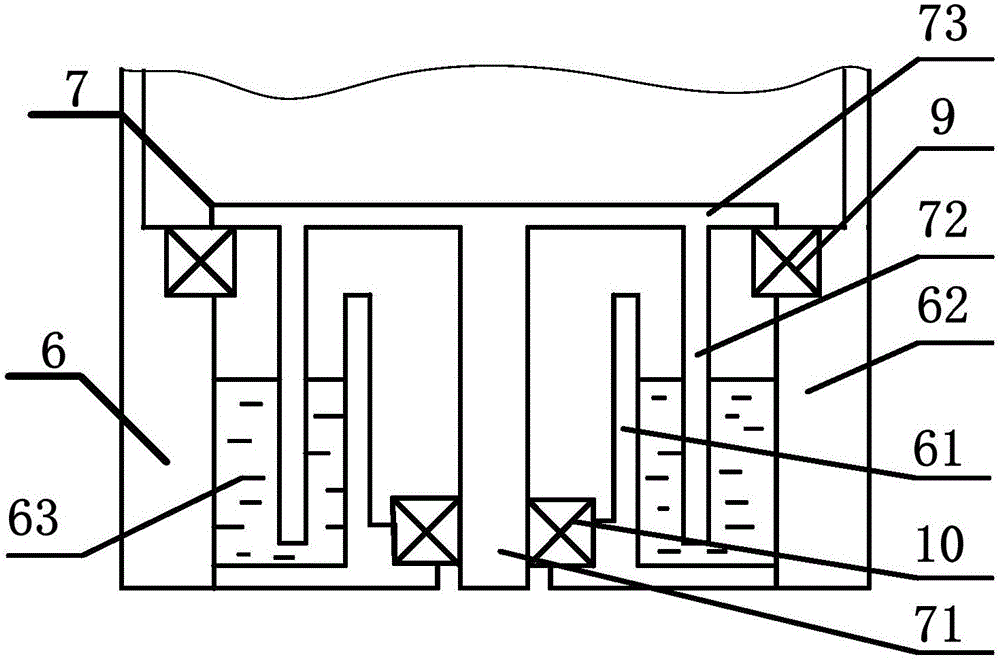

Narrow gap double-wire welding gun

InactiveCN102773596AGuaranteed melting speedReduce energy consumptionElectrode supporting devicesElectrode accessoriesEngineeringEnergy consumption

The invention relates to a narrow gap double-wire welding gun which comprises two welding gun assemblies. An insulation plate is arranged between the two welding gun assemblies, the two welding gun assemblies are fixed and assembled through the insulation plate, the two welding gun assemblies comprise gun bodies, insulation covers are arranged at the outer ends of the gun bodies, electric connectors, air inlet pipes and water connectors are arranged at the upper ends of the gun bodies in penetrating mode, the lower ends of the gun bodies are connected with contact tips which are communicated with the gun bodies, the two water connectors are communicated with each other and form cooling circulation channels in the gun bodies where the two connectors penetrate, the two contact tips are tilted inwards to form a certain angle, and the angle is at 15 degrees-30 degrees. Due to the fact that the two contact tips are tilted inwards to form a certain angle, two welding wires which are arranged in penetrating mode can be intersected. When the narrow gap double-wire welding gun is operated, the welding wires are intersected, after the welding gun is powered on, only one single electric arc is formed between the welding wires and a workpiece, welding wire melting speed is guaranteed, energy consumption is reduced virtually, only a single-channel multilayer is needed for welding seam molding. Compared with a common double-wire welding gun, the narrow gap double-wire welding gun is energy-saving and efficient.

Owner:KUSN RUILING WELDING TECH

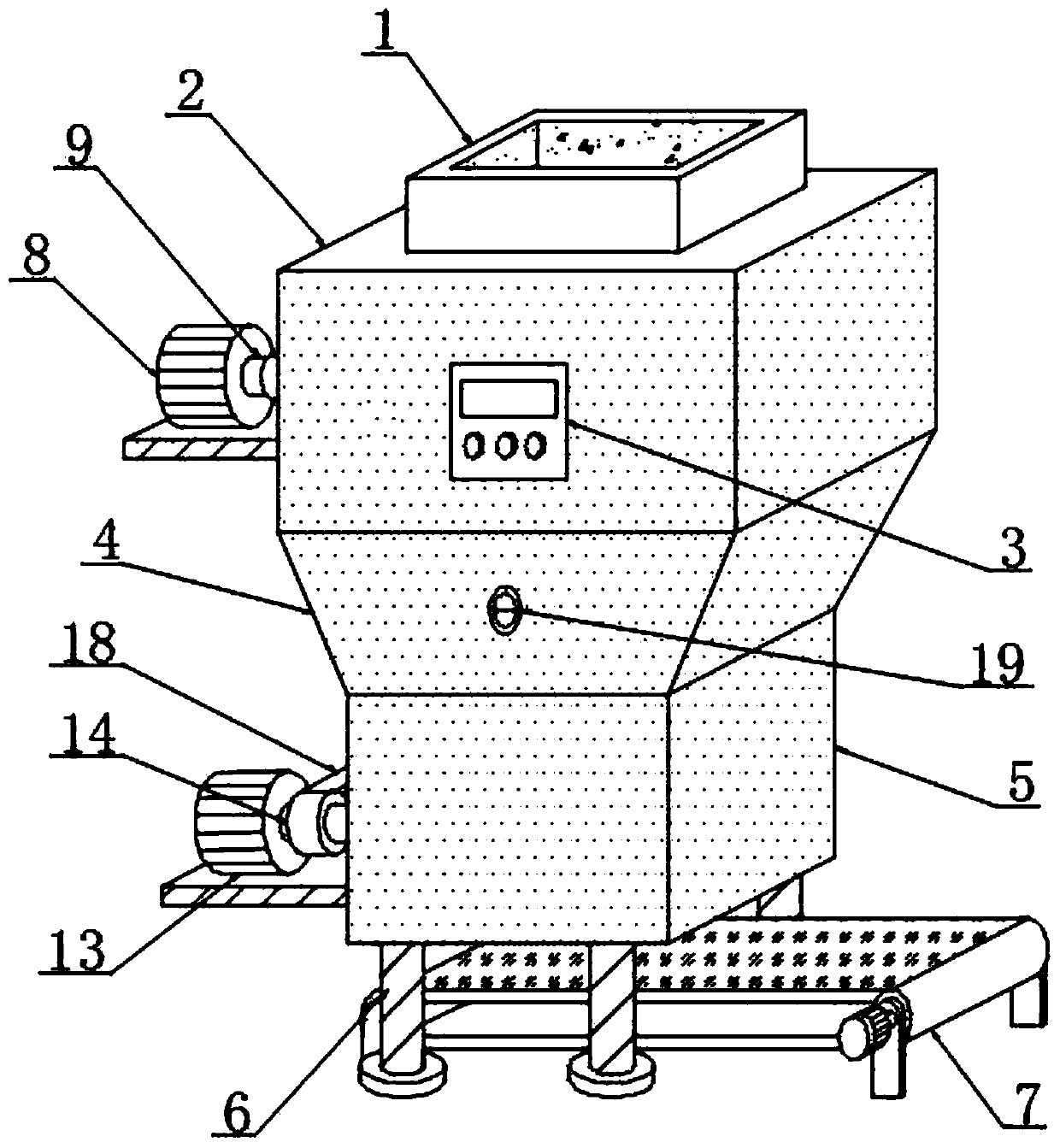

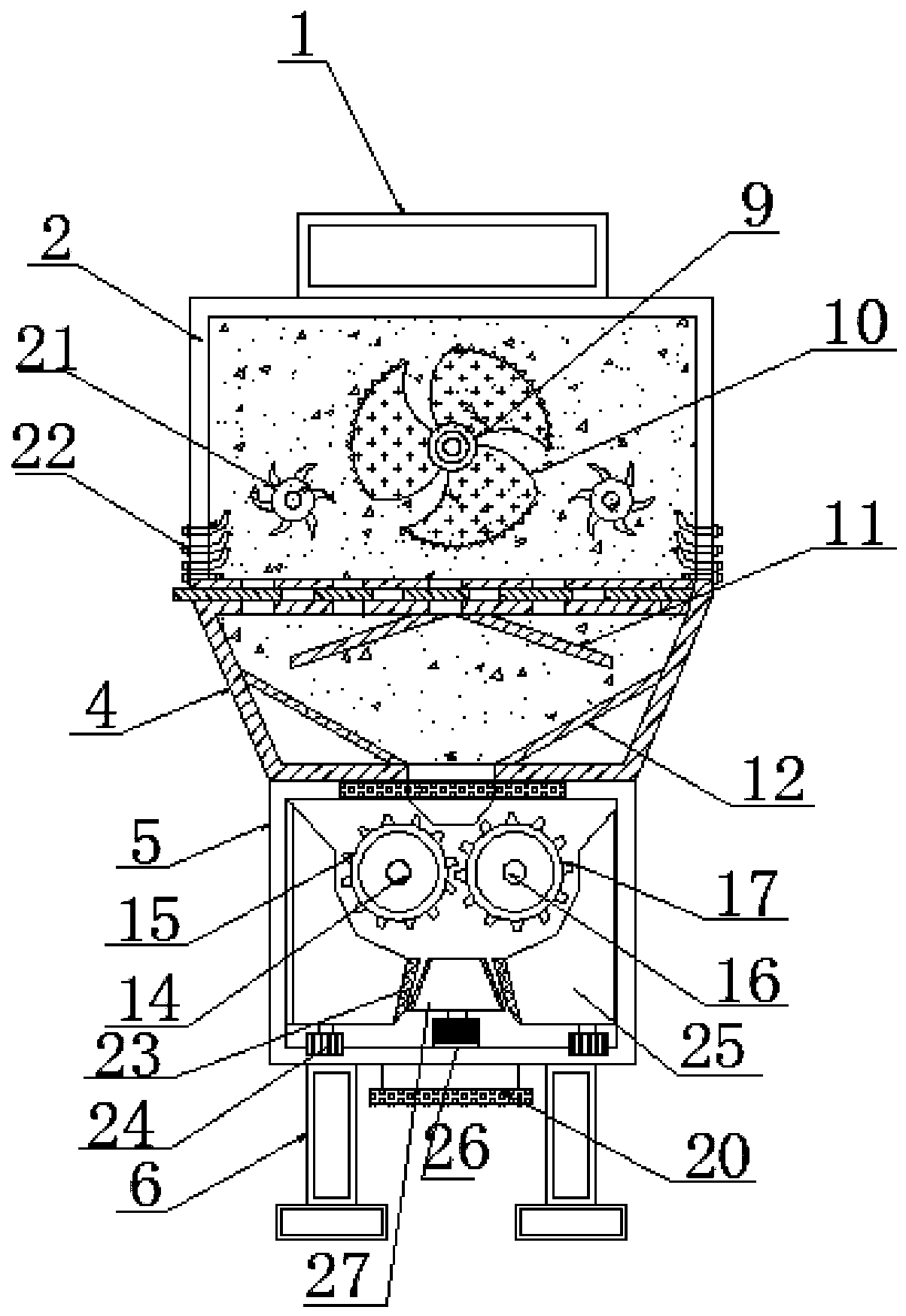

Temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products

ActiveCN109833951ARealize crushing workRealize the drying workFeeding-stuffWeld torches cleaningTemperature controlAquatic product

The invention discloses a temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products. An opening and closing control assembly is arrangedbetween a crushing box and a drying box so as to control discharging of materials in the crushing box, and the crushing box is internally provided with a flying stirring assembly enabling the to-be-crushed materials to move upwards, so that the materials can fly to the crushing assembly to be crushed; and the grinding assembly comprises a primary rough grinding assembly and a secondary fine grinding assembly, the primary rough grinding assembly is used for primary coarse grinding of the materials, the secondary fine grinding assembly is used for secondary fine grinding of the materials, the temperature of the inside of the drying box can be monitored in real time through the temperature sensors arranged at the same time, the temperature can be conveniently adjusted according to the humidity of the raw materials, and the grinding treatment of the feed raw materials is realized through the arranged grinding box; and a conveying machine is arranged, so that the automatic conveying work ofthe materials after grinding can be realized, the labor is saved, and the working efficiency is improved.

Owner:惠安先锋机械有限公司

Combined material of aluminum oxide fringing copper and chromium-copper alloy and its producing method and use

InactiveCN1988054AHigh precisionHigh yieldConductive materialElectrode accessoriesUltimate tensile strengthHigh conductivity

This invention relates to a composite material of alumina dispersion copper and chrome-copper alloy, its manufacturing method and application, in which, the composite material is composed of alumina dispersion copper at the core and chrome-copper alloy surrounding the core, the volume percentage of the copper is 10-70% and that of the alloy is 30-90%. The manufacturing method includes: shaping them up by a thermal extruding machine, in which, when squeezing, a glass lubricated composite material blank and an extruding drum are used to meet the section ratio of them after extruding, and conductive nozzles and electrode caps used in welding machine are produced at low price, high accuracy and high material rate due to the high temperature strength and high conductivity of the material, dispersion copper used at part of the electric contact points of the core and chrome-copper as the blank outside.

Owner:苏州东金机械金属有限公司 +1

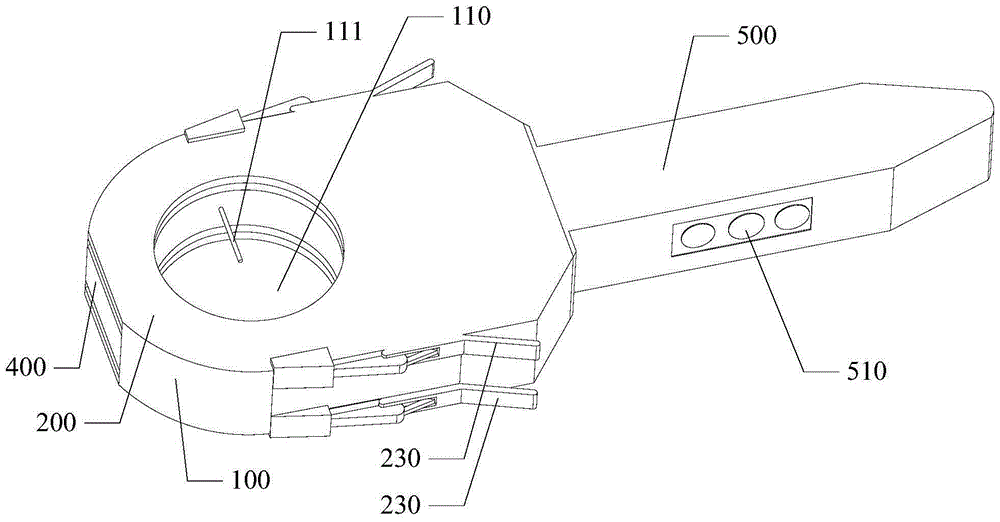

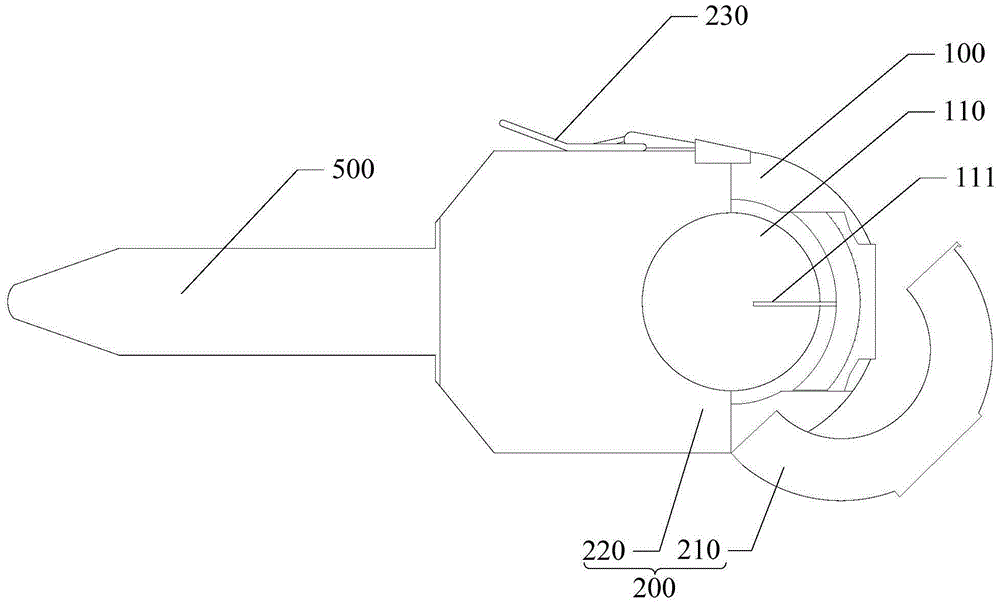

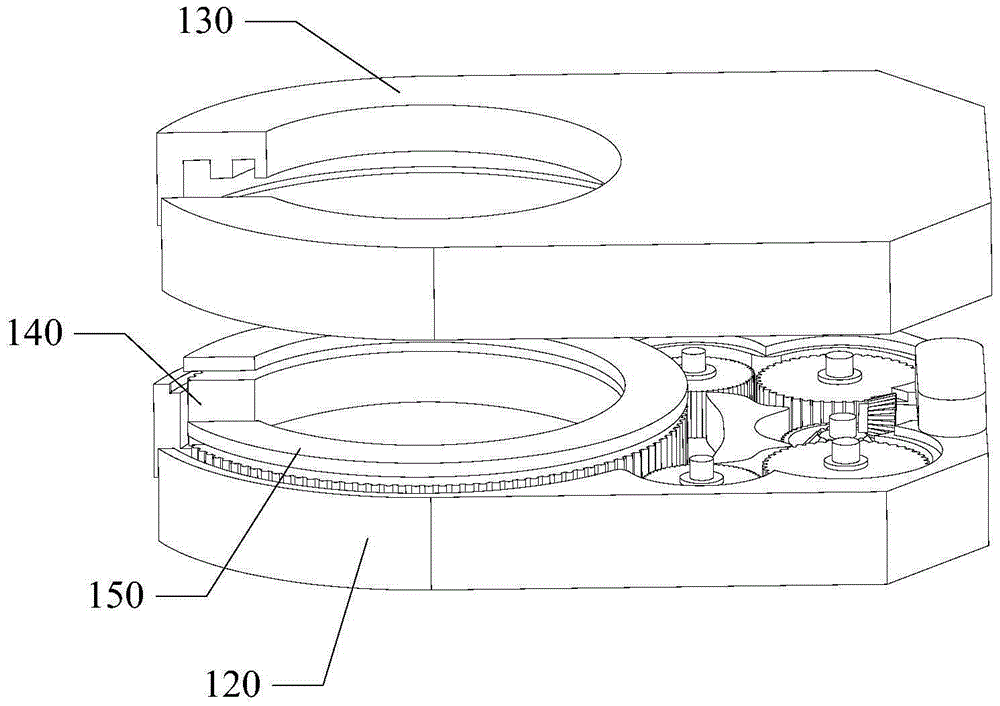

Rotary swing type welding torch and welding method

InactiveCN106180994AEasy to set upIncrease heat inputCooled electrode holdersElectrode accessoriesEngineeringWelding torch

The invention provides a rotary swing type welding torch. The rotary swing type welding torch comprises a current contact nozzle, a rotary swing driving mechanism and a control device, wherein the control device is connected with the rotary swing driving mechanism so as to control the rotary swing driving mechanism to move, and the movement output end of the rotary swing driving mechanism is connected with the current contact nozzle so as to adjust the position of the current contact nozzle and / or enable the current contact nozzle to make rotary swing movement according to preset swing parameters. According to the rotary swing type welding torch, two operating modes of swing and rotation can be realized, so that heat input to the side wall of a groove can be increased by virtue of electric arc swing, and the problem of poor fusion of the side wall and the bottom of the groove during narrow gap welding of large-thickness plates is solved. The invention further provides a welding method.

Owner:HARBIN INST OF TECH AT WEIHAI

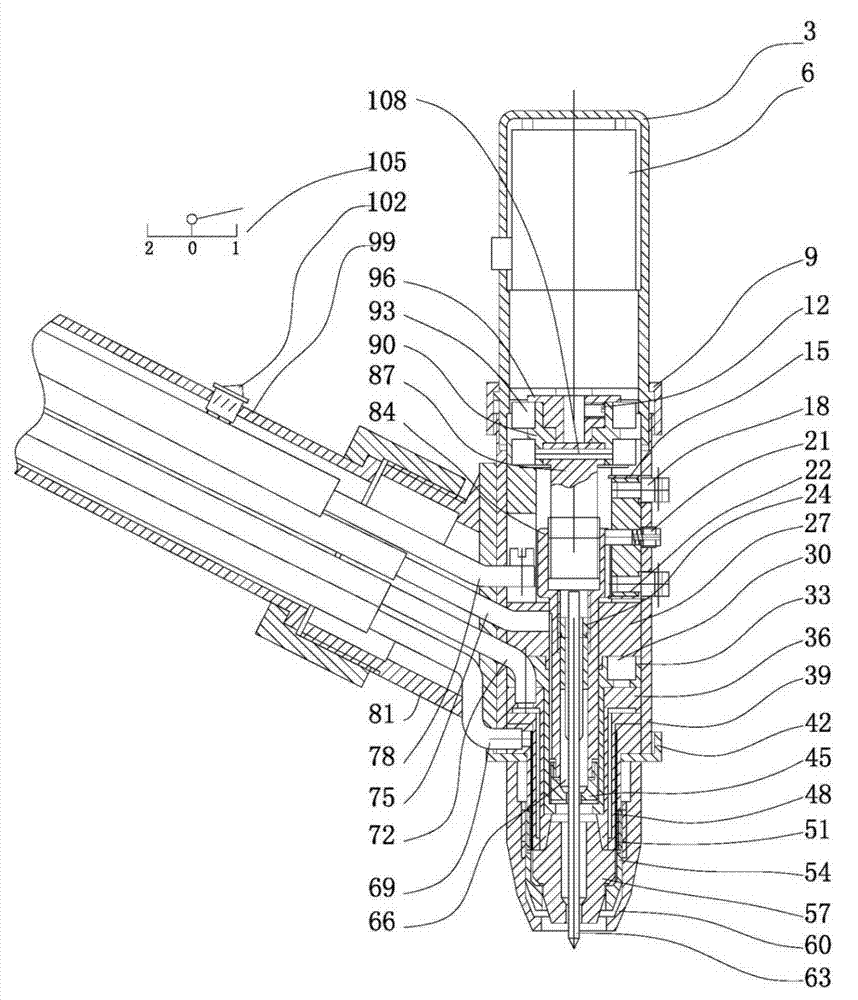

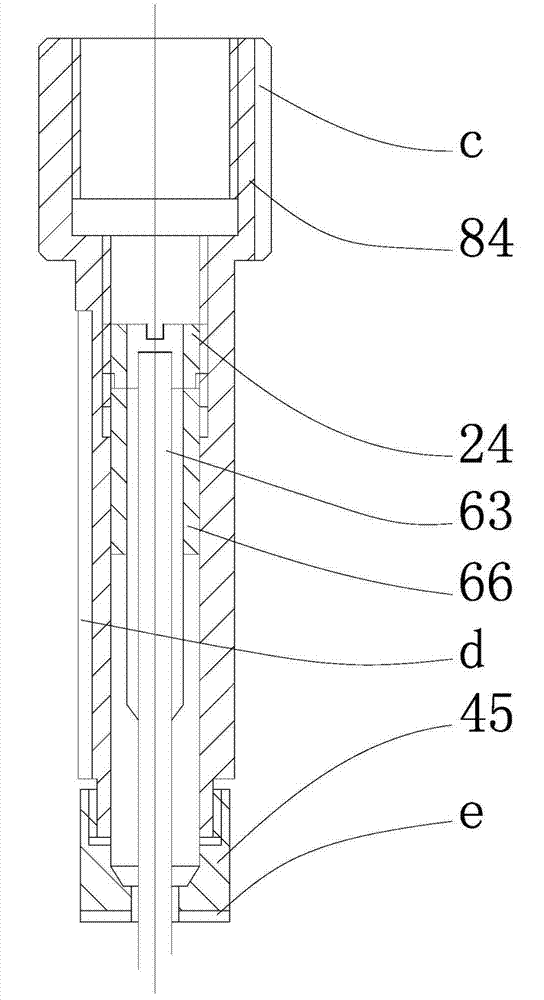

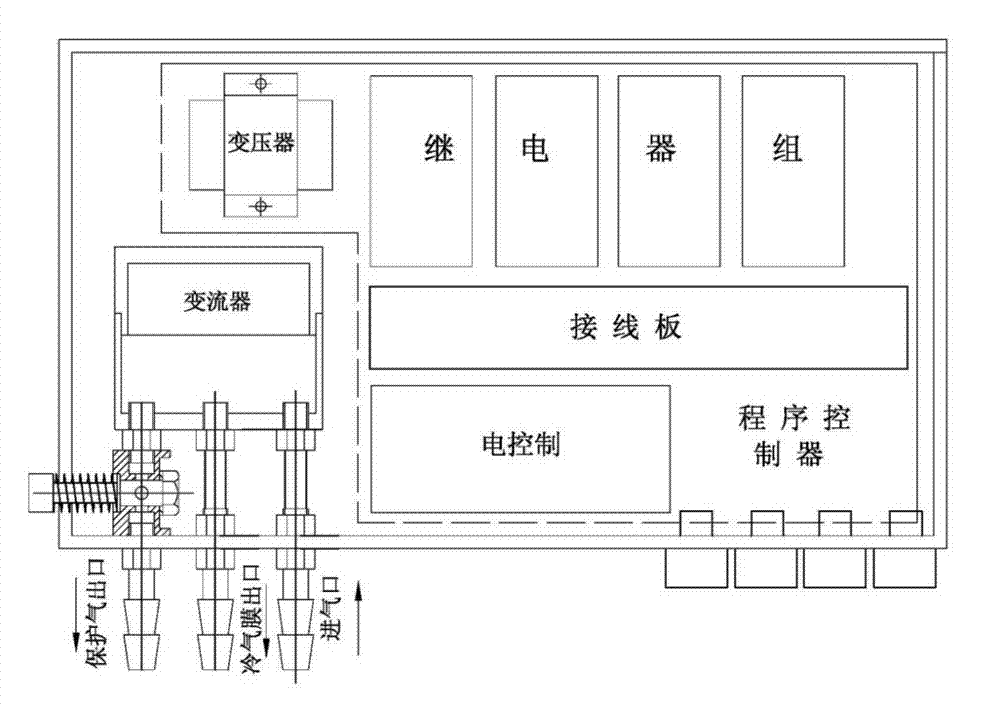

Energy-saving argon tungsten-arc welding assembly with adjustable welding torch

InactiveCN102814581ALower skill requirementsImprove efficiencyElectrode supporting devicesElectrode accessoriesReduction driveShielding gas

An energy-saving argon tungsten-arc welding assembly with adjustable welding torch comprises a welding gun and an electrical control device which is connected with the welding gun, wherein the welding gun comprises a tungsten rod clamping component, a motor reducer (6), a cooling jacket, an electric arc nozzle (57), a nozzle retainer ring and a shielding gas nozzle; the tungsten rod clamping component comprises a tungsten rod (63) and an intermediate rod (84) which drives the tungsten rod (63) to lift and descend; the cooling jacket is used for delivering cool air film and shielding argon flow; and an argon arc welding machine is adopted as a welding source, the motor reducer (6) is taken as a drive source, the tungsten rod (63) is lifted and descended through a limit ring (96), a connecting ring (90), an upper nut and a lower nut (87) and the intermediate rod (84), the electrical control device is used for controlling the rotation direction of the motor reducer (6), furthermore, a top nut contact (21) is controlled to be communicated with an upper piece contact (15) or a lower piece contact (22), so the tungsten rod (63) is freely and continuously adjusted in a stepless manner, and is reset when the arc is quenched.

Owner:上海格瀚斯机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com