Automatic multifunctional narrow-clearance/super-narrow-clearance gas protection welding gun and manufacturing method thereof

A technology of gas shielded welding and narrow gaps, which is applied in the direction of manufacturing tools, electrode characteristics, welding equipment, etc., can solve the problems of reduced welding production costs, complex welding torch systems, and difficult manufacturing, and achieves large conductive cross-sectional area and heat dissipation area, Reduced manufacturing cost and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

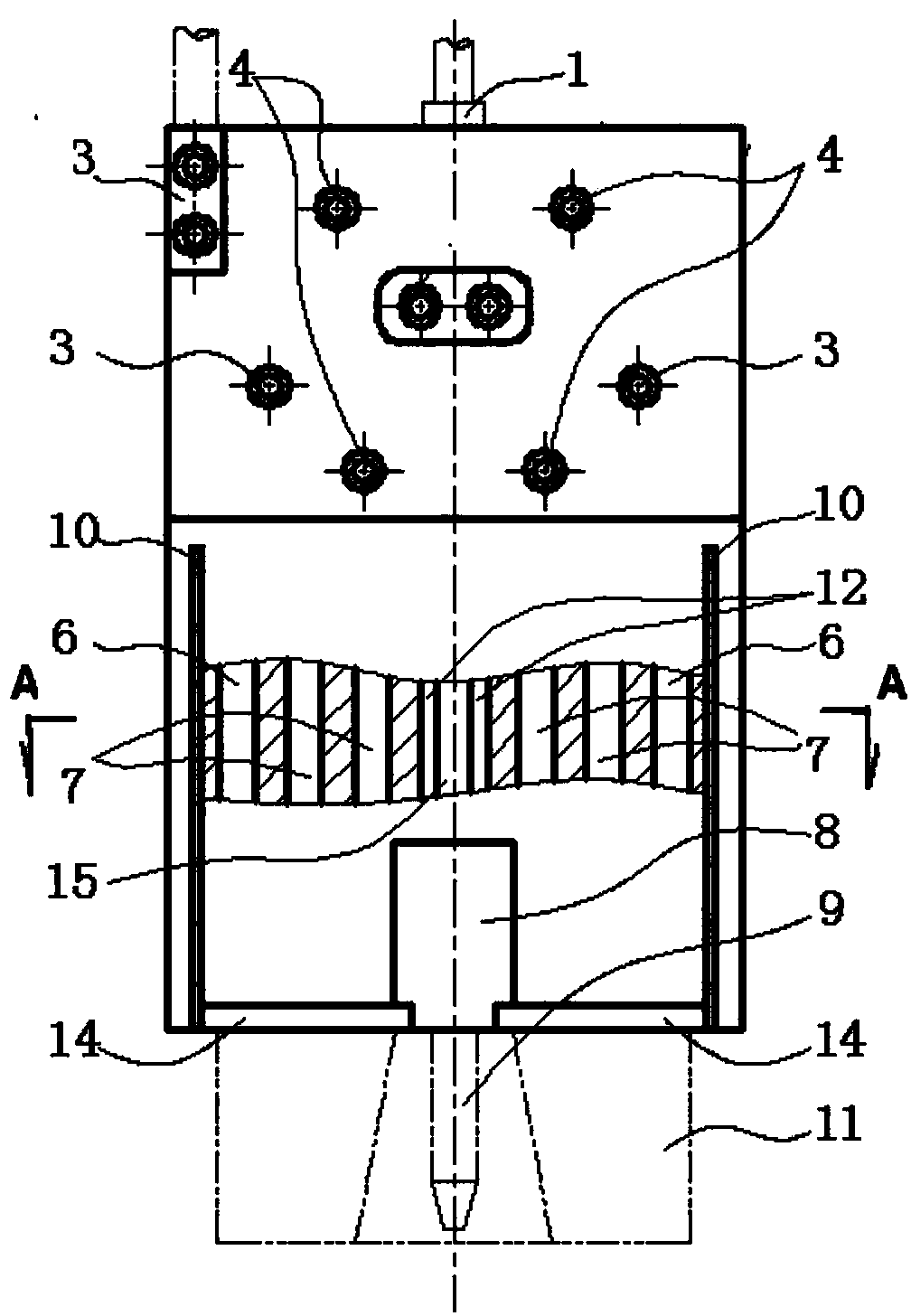

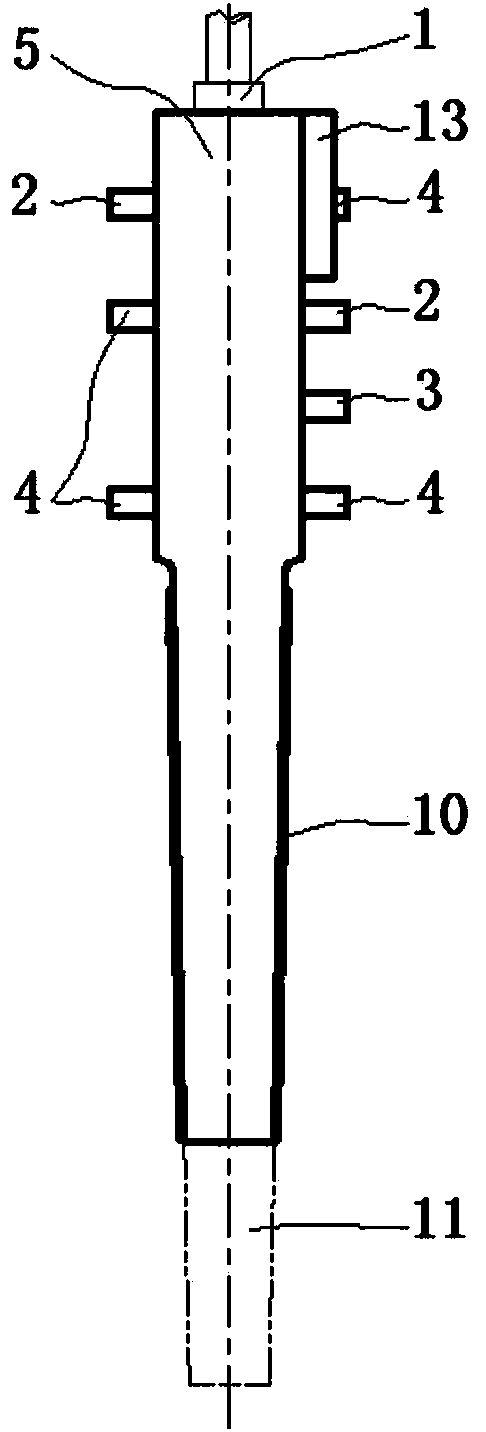

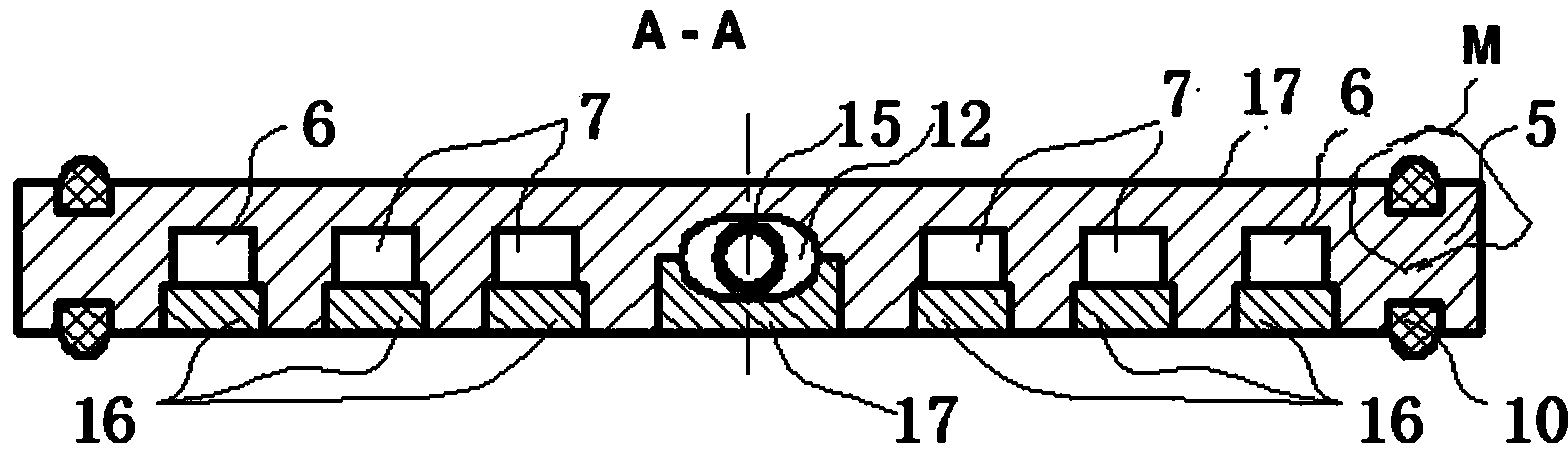

[0051] Embodiment 1: as figure 1 As shown in Fig. 7, it is a basic embodiment of the multifunctional narrow gap / ultra narrow gap gas shielded welding automatic welding torch of the present invention. It includes a plate-type welding torch body 5; the plate-type welding torch body 5 is internally integrated with a guide wire channel 12, a circulating water cooling flow channel 7 and a secondary protective air flow channel 6, and the upper part is fixedly connected with a primary protective gas inlet seat 2 and a secondary Protective gas inlet seat 3, water inlet / return pipe seat 4 and welding cable 13, the lower part is fixedly connected with a gas diversion device 8, the gas diversion device 8 is assembled with the contact nozzle seat 18 and passed through the tongue and groove on both sides of the diversion device 8 , and fixed to the lower part of the plate torch body 5 through the body / nozzle connection assembly 14; the contact tip 9 is installed at the lower end of the ...

Embodiment 2

[0052] Embodiment 2: is a further embodiment. The multifunctional narrow gap / ultra-narrow gap gas shielded welding automatic welding torch has a wire feeding hose connection assembly 1 installed on the top of the plate torch body 5; a protective gas inlet seat 2 is installed on the upper part of the wide side of the plate torch body 5 In the width direction, it communicates with the primary protective gas flow channel; the secondary protective gas intake seat 3 is installed on both sides of the primary protective gas intake seat 2 near the outer side of the plate welding torch body 5, and communicates with the secondary protective gas flow channel 6 ; The water inlet / return water pipe seat 4 is installed on both sides of the primary protective gas inlet seat 2, and communicates with the corresponding circulating cooling water flow channel 7; The guide wire channel 12 is located in the middle of the plate welding torch body 5, its upper end communicates with the wire feeding ...

Embodiment 3

[0054] Embodiment 3: as Figure 1-8 Shown is an embodiment of a combined multifunctional narrow-gap / ultra-narrow-gap gas-shielded welding automatic welding torch of the present invention. It is formed by connecting two multifunctional narrow-gap / ultra-narrow-gap gas-shielded welding automatic welding torches of the present invention; A plate-type welding torch body 5; the plate-type welding torch body 5 is internally integrated with a guide wire channel 12, a circulating water cooling flow channel 7 and a secondary protective gas flow channel 6, and the upper part is fixedly connected with a primary protective gas inlet seat 2 and a secondary protective gas The air intake seat 3, the water inlet / return pipe seat 4 and the welding cable 13 are fixedly connected to a gas distribution device 8 at the lower part. , and fixed to the lower part of the plate torch body 5 through the body / nozzle connection assembly 14; the contact tip 9 is installed at the lower end of the contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com