Sealed pipe welding gun

A technology of pipe welding and welding torch, applied in the field of nuclear power plant engineering, can solve problems such as poor welding quality, and achieve the effect of improving stability and welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

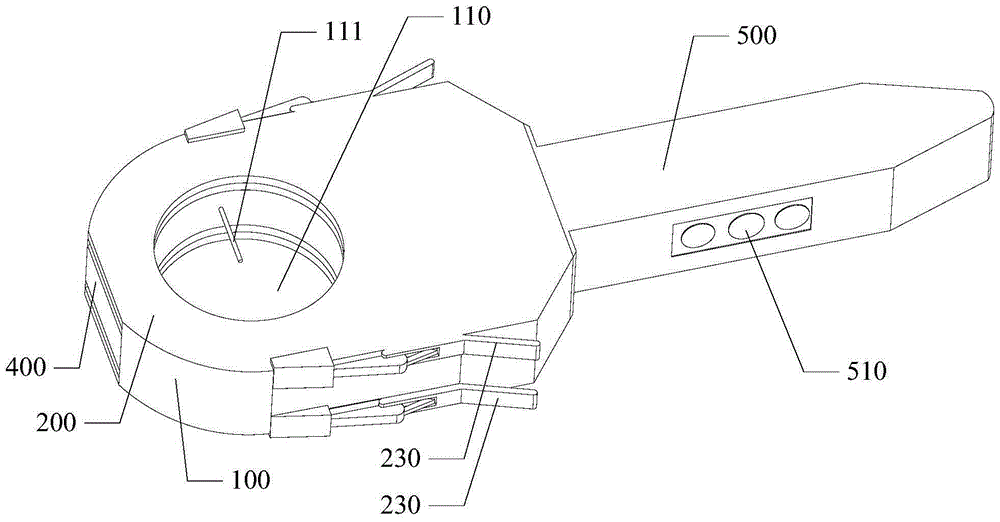

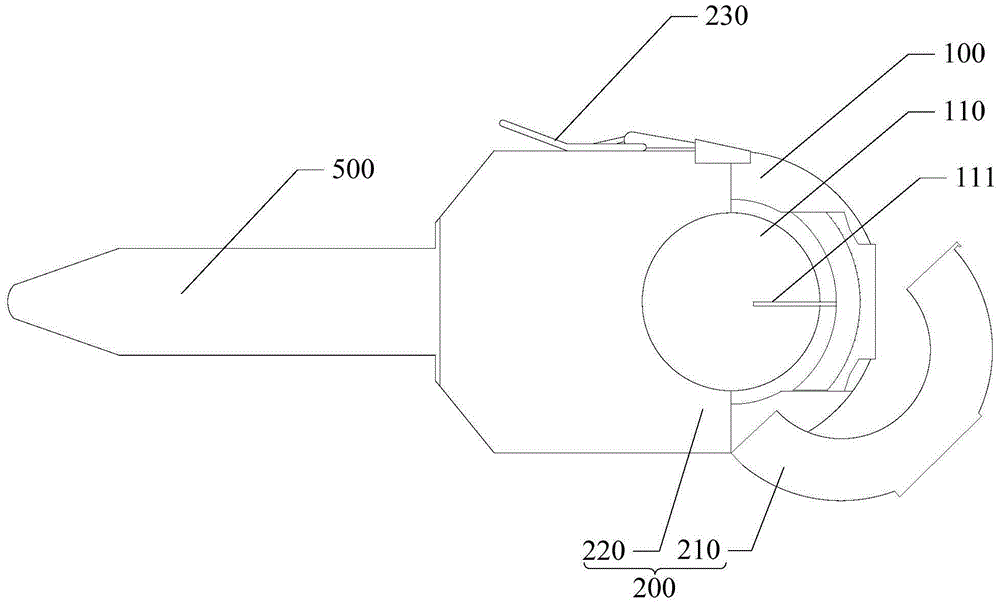

[0034] The invention provides a closed pipe welding torch, see figure 1 and figure 2 , in one embodiment, the closed tube welding torch includes a welding torch body 100 and clamping devices 200 arranged on opposite sides of the welding torch body 100, that is, the two clamping devices 200 clamp the welding torch body 100, and clamp The device 200 and the welding torch body 100 are connected and fixed by screws.

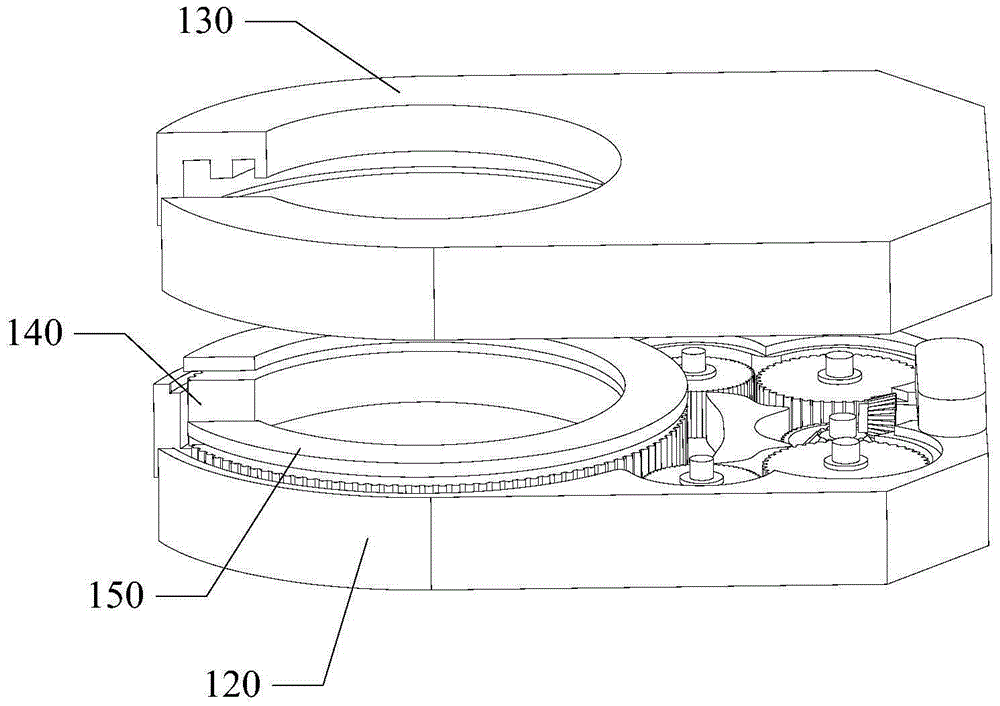

[0035] Wherein, the welding torch body 100 is provided with a welding chamber 110 that runs through its opposite sides for accommodating the pipe to be welded, communicates with the welding chamber 110 for the entrance and exit of the pipe to be welded to enter and exit the welding chamber 110, and supplies shielding gas. A gas passage into the welding chamber 110 . In actual application, the geometric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com