Narrow gap double-wire welding gun

A narrow gap and welding torch technology, applied in the direction of electrode characteristics, electrode accessories, electrode support devices, etc., can solve the problems of slow forming speed, time consumption of energy consumption, and unsatisfactory welding effect, so as to reduce energy consumption and ensure melting speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

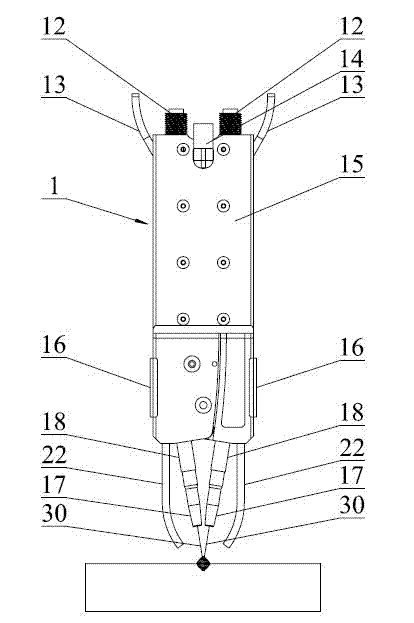

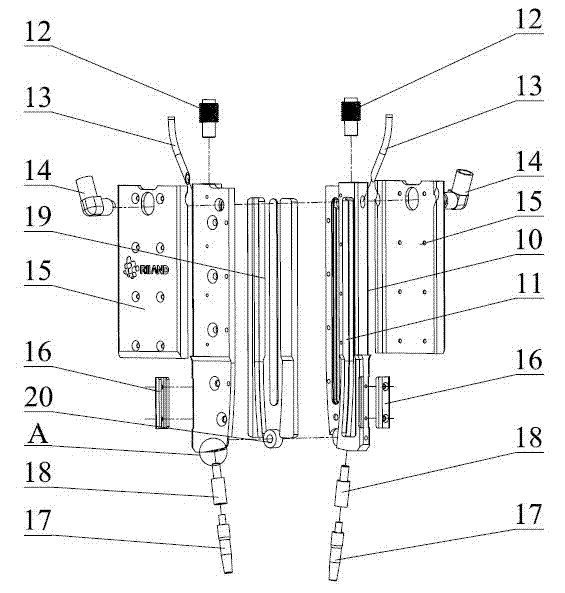

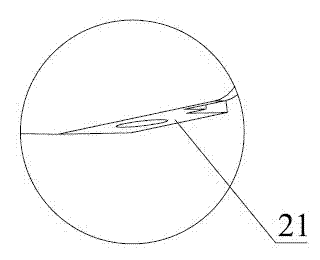

[0022] see figure 1 and figure 2 As shown, the present invention provides a narrow gap twin-wire welding torch 1, comprising two welding torch assemblies 10, an insulating plate 19 is arranged between the two welding torch assemblies 10 and fixed and assembled by the insulating plate 19, wherein the insulating plate 19 is used for The fixed connection between the two welding torch assemblies 10 also ensures that the two are electrically and thermally insulated without mutual influence. The two welding torch assemblies 10 both include a torch body 11 , and an insulating cover 15 is provided at the outer end of the torch body 11 , and the insulating cover 15 can isolate the electricity and heat carried by the torch body 11 to avoid contact by users or operators. The upper end of the gun body 11 is pierced with an electrical connector 12, an air intake ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com