Plasma-arc welding device implemented by aid of TIG (tungsten inert gas) welding method

A plasma arc and welding method technology, which is applied in the field of plasma arc welding devices, can solve problems such as unfavorable manual operation, high equipment cost, and complex structure, so as to improve welding efficiency and weld quality, reduce welding cost, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

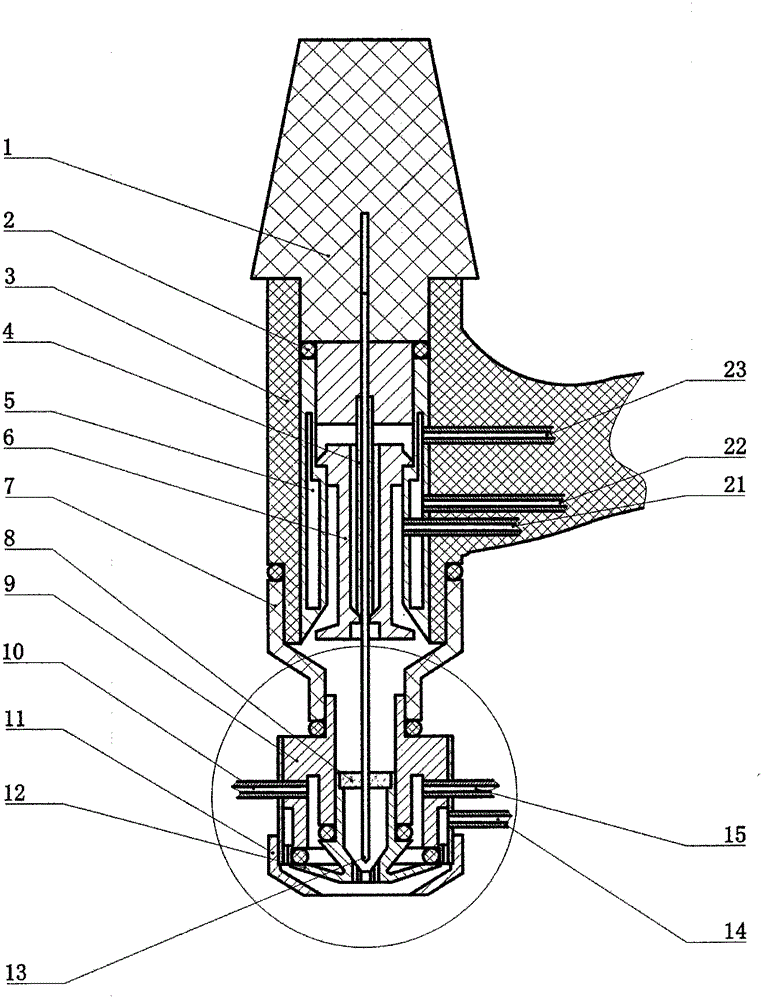

[0024] Such as figure 1 As shown, a device using TIG welding method to realize plasma arc welding, including electrode cap 1, sealing ring 2, upper gun body 3, tungsten pole clamp 4, flow guide 6, upper nozzle 7, centering ring 8, lower gun Body 9, lower water outlet pipe 10, protective cover 11, lower nozzle 12, tungsten pole 13, lower air inlet pipe 14, lower water inlet pipe 15, upper air inlet pipe 21, upper water inlet pipe 22 and upper water outlet pipe 23; electrode cap 1 and upper gun body 3 are connected by thread pairs, and the sealing ring 2 is located between the electrode cap 1 and the upper gun body 3. There is a water cooling groove 5 in the wall of the upper gun body 3, and the center of the electrode cap 1 is respectively opened with the same outer diameter as the tungsten electrode 13. The channel and the same channel as the outer diameter of the tungsten pole clip 4; the upper air inlet pipe 21, the upper water inlet pipe 22 and the upper water outlet pipe 2...

Embodiment 2

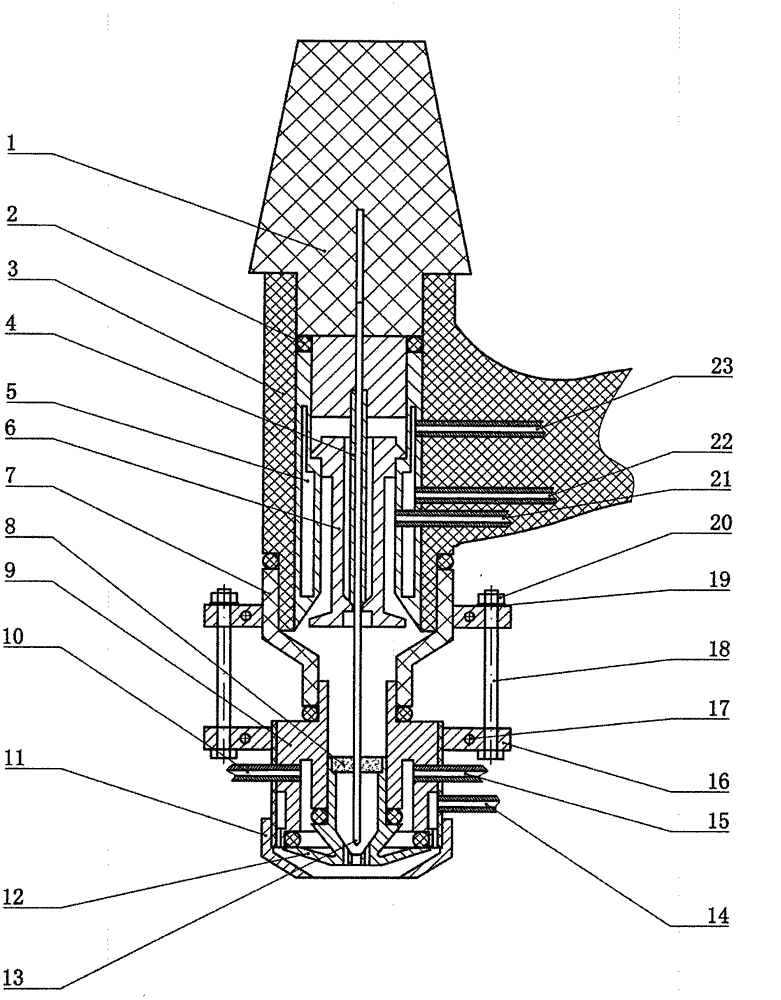

[0027] Such as image 3 As shown, the structure of this welding torch is the same as that in Embodiment 1, the difference is that the upper nozzle 7 and the outer wall of the lower torch body 9 are respectively covered with a clamp 16, which is realized by screw holes 17, bolts 18, spring washers 19 and nuts 20. The fastening and connection of the upper nozzle 7 and the lower gun body 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com