Combined material of aluminum oxide fringing copper and chromium-copper alloy and its producing method and use

A chromium-copper alloy and composite material technology, applied in conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems of poor formability of contact tips and spot welding heads, expensive materials, and complicated manufacturing processes, and achieve superiority. Effects of high temperature strength, improved wear resistance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

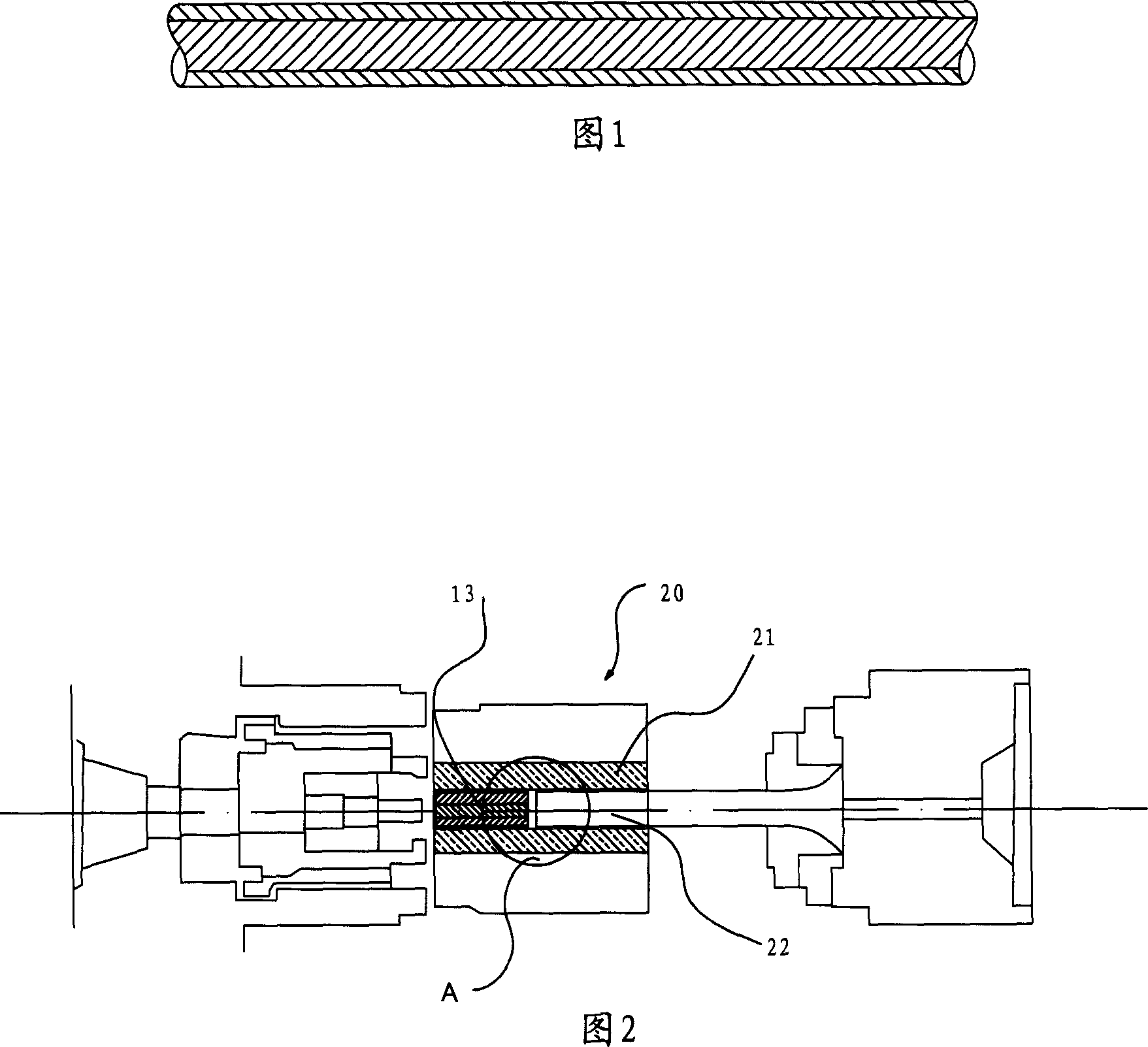

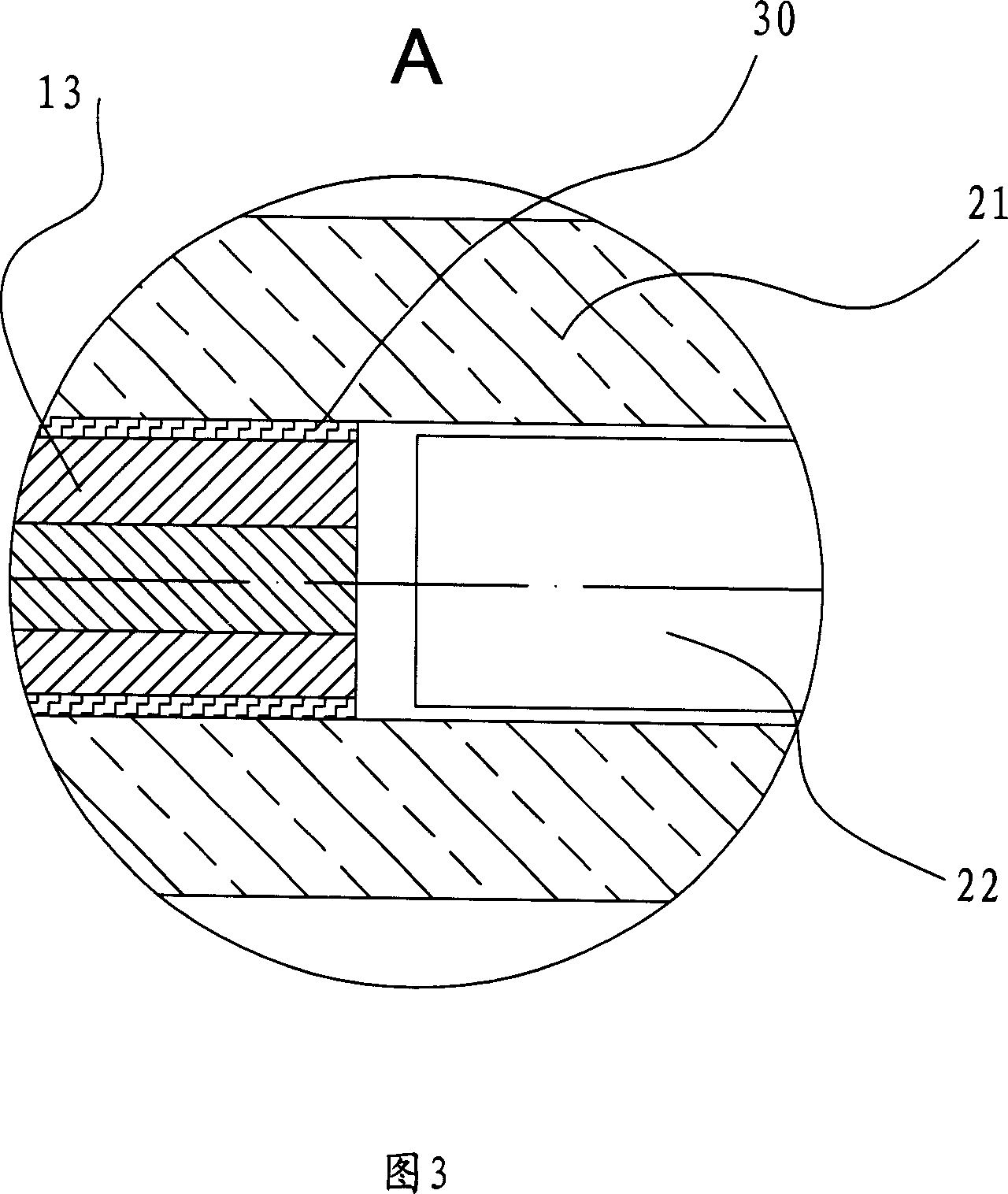

[0037] As shown in Figure 1, a composite material of aluminum oxide dispersed copper and chromium copper alloy is composed of aluminum oxide dispersed copper located in the core and a chromium copper alloy coated on the outer periphery of the core. The volume percentage of aluminum-dispersed copper is 25%, and the volume ratio of chromium-copper alloy is 75%; wherein, the weight percentage of aluminum in the alumina-dispersed copper is 0.10-0.70%, and the chromium-copper alloy contains chromium. The weight percent content of 0.4 to 1.2%.

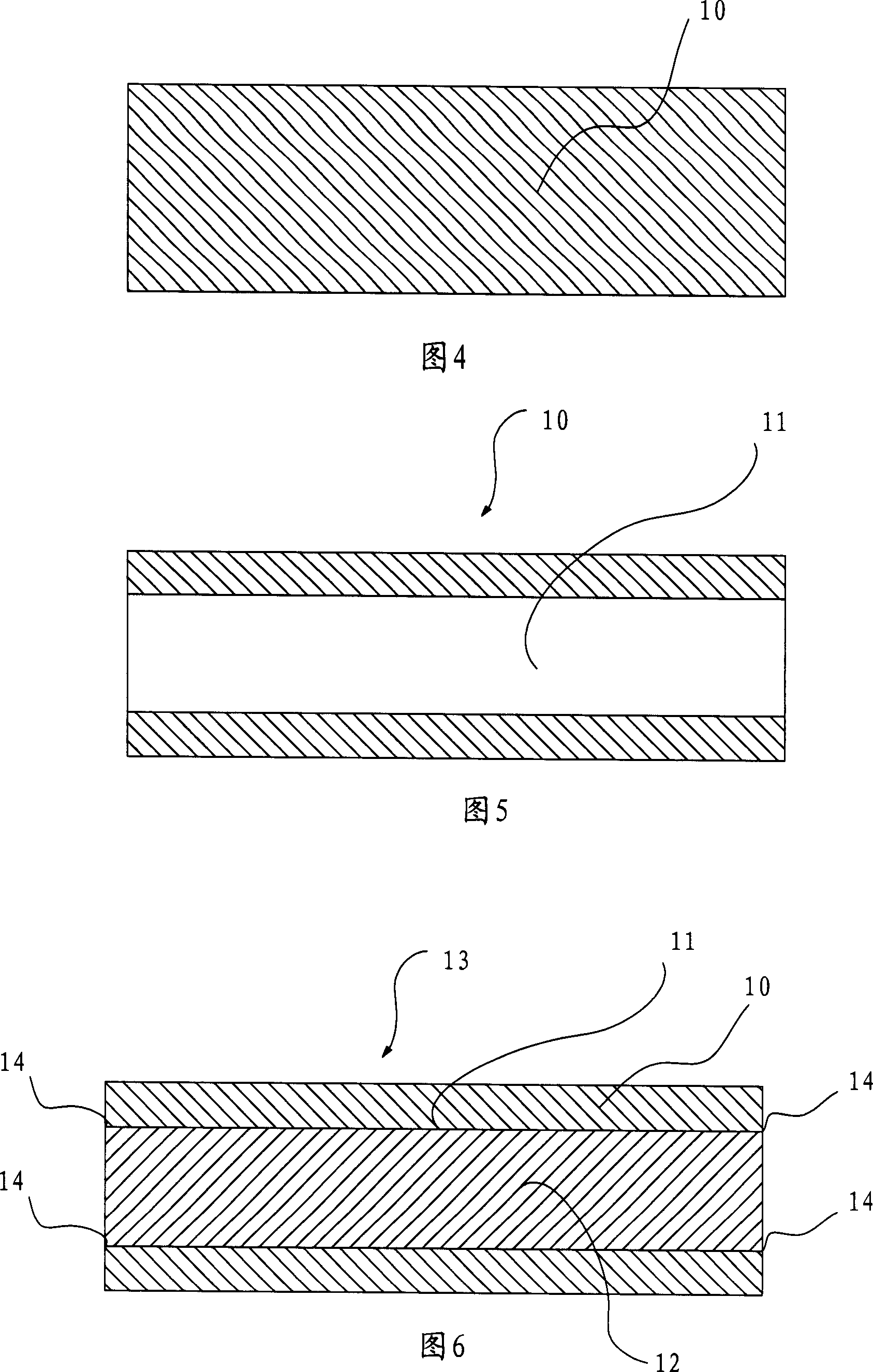

[0038] A method for manufacturing the above-mentioned composite material of alumina dispersed copper and chromium-copper alloy, as shown in Figures 4-6, includes the following process flow:

[0039] a. Take a chromium-copper alloy blank 10 and punch a core hole 11 with a volume percentage of 10 to 70% in its core;

[0040] b. Insert the dispersed copper 12 into the core hole 11 to form a composite material blank 13. In order to enhance the tight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com