Patents

Literature

121results about "Weld torches cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

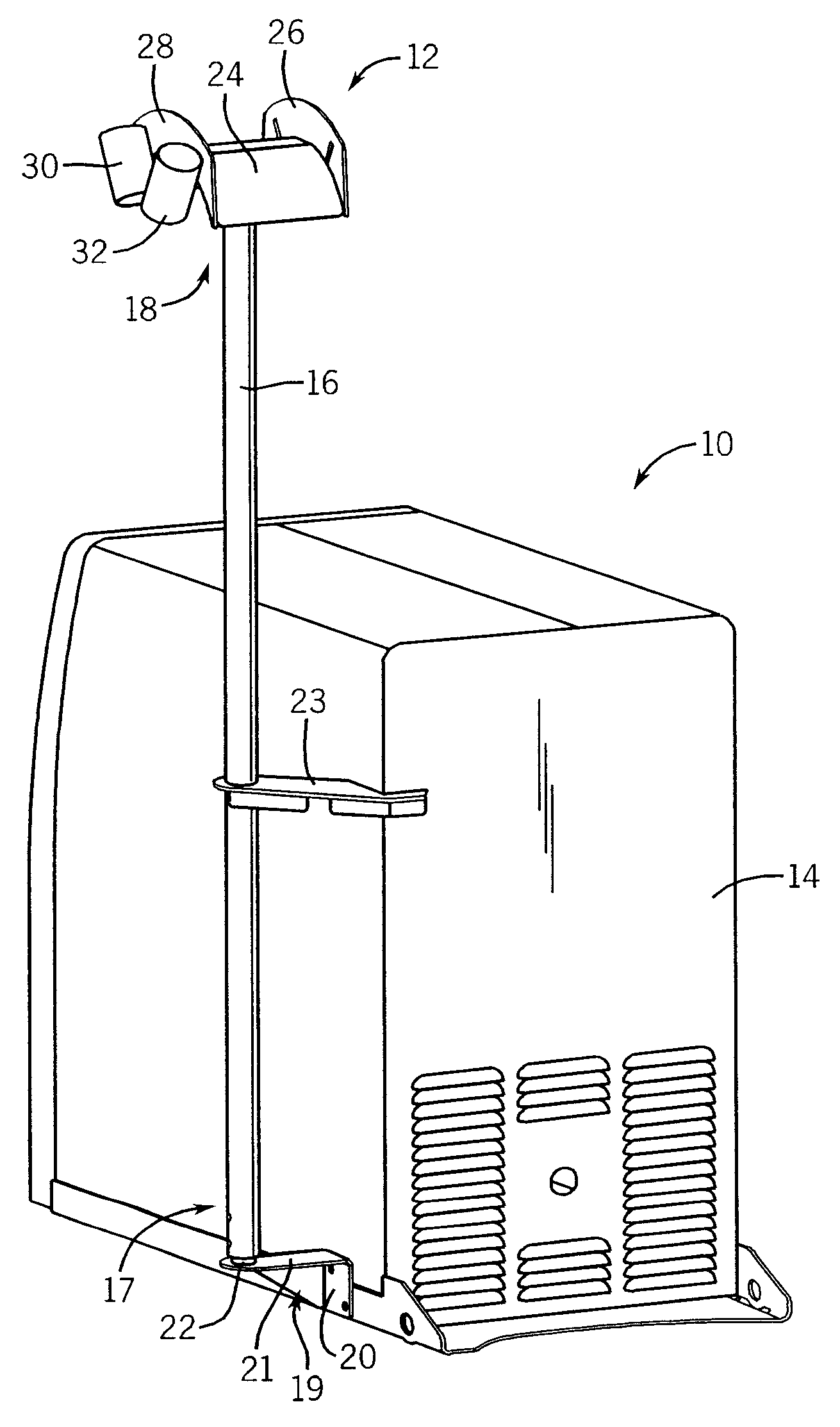

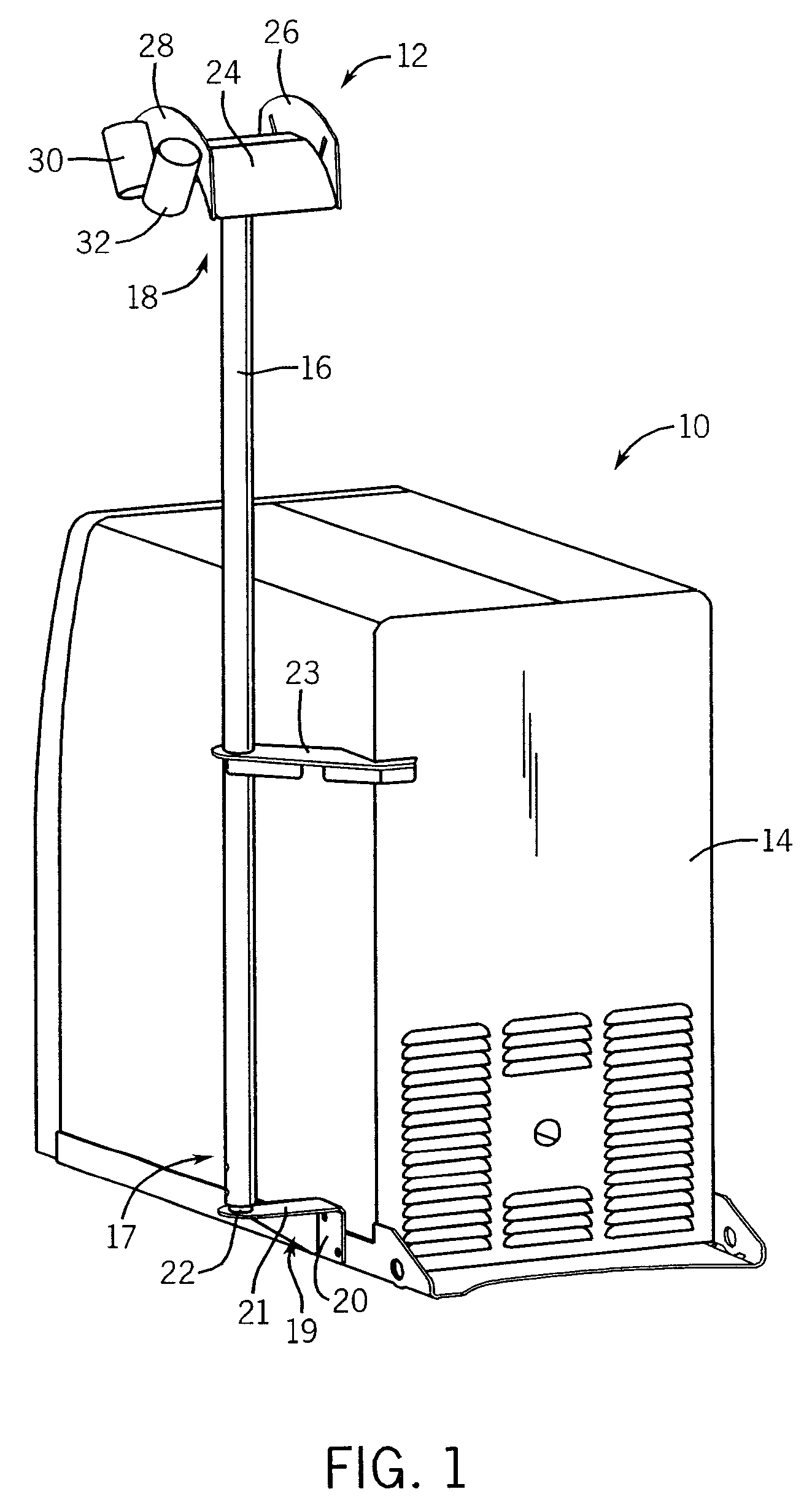

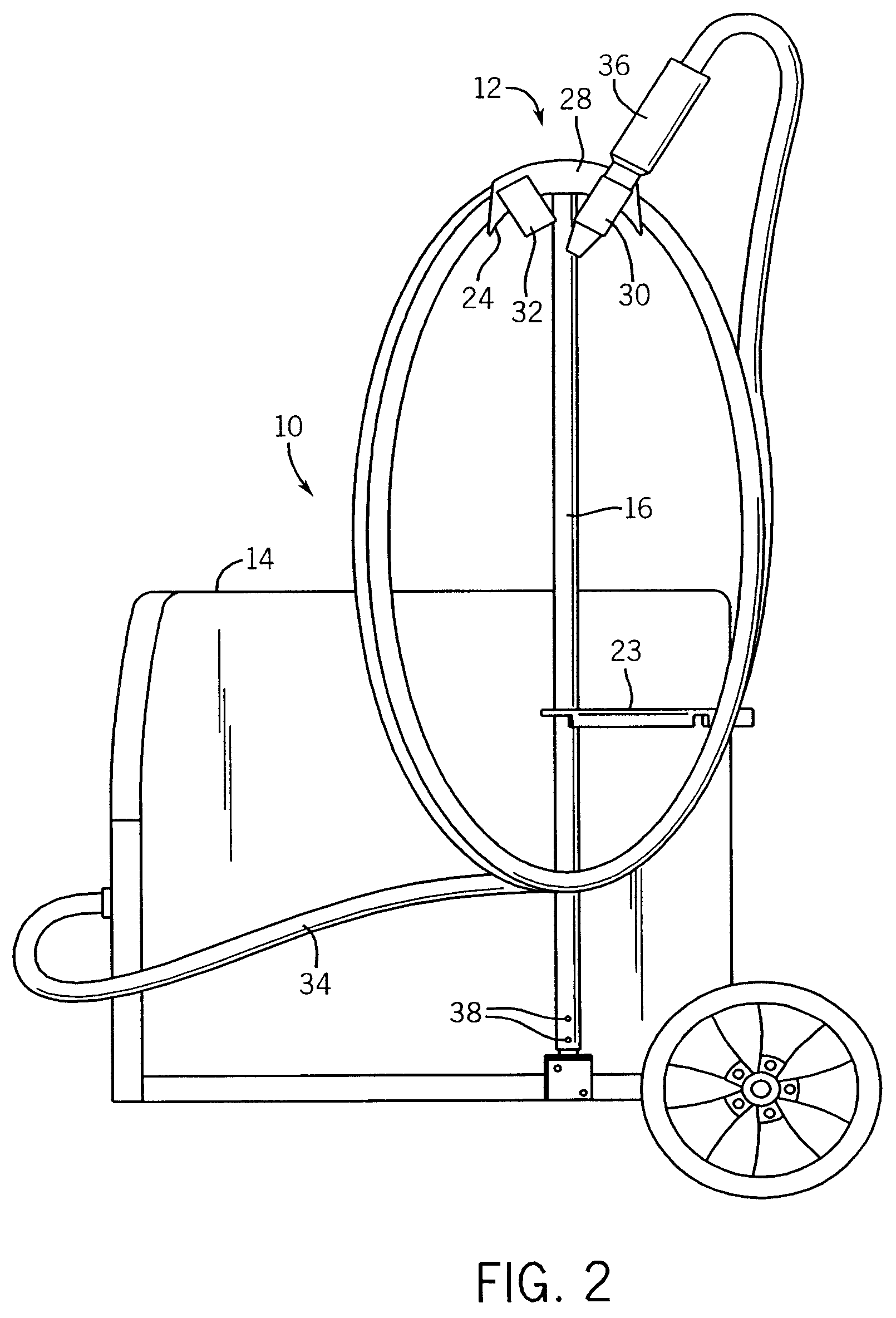

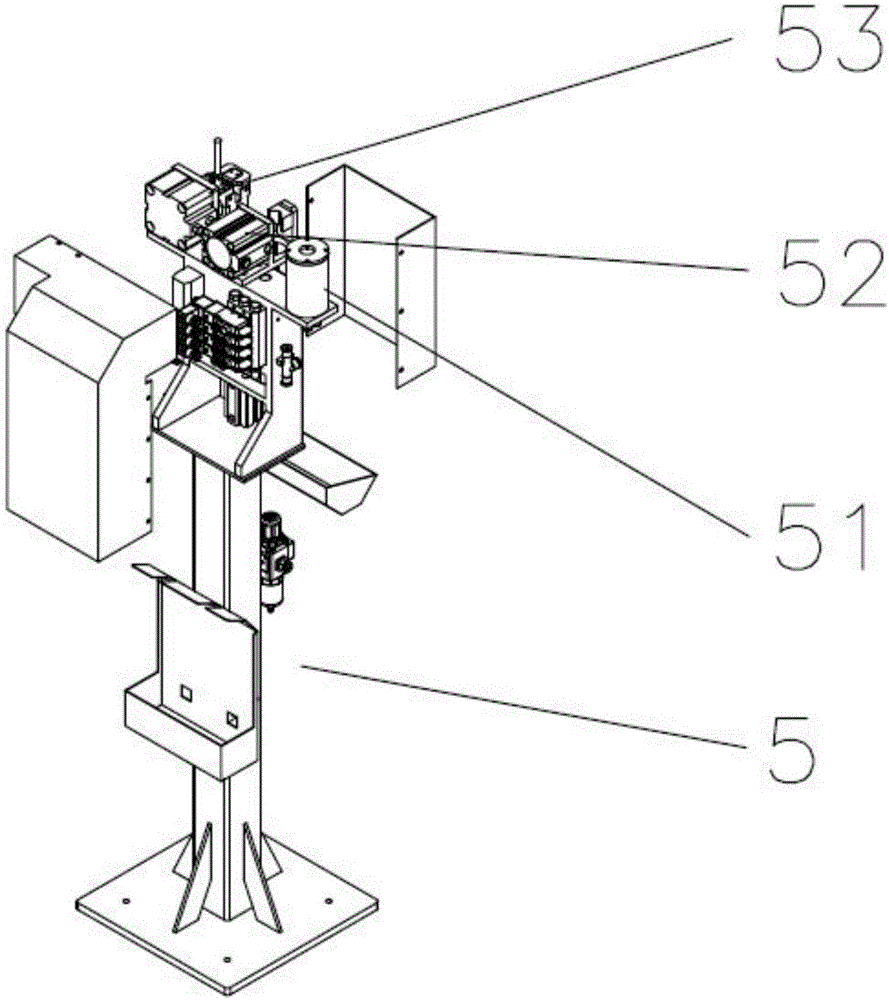

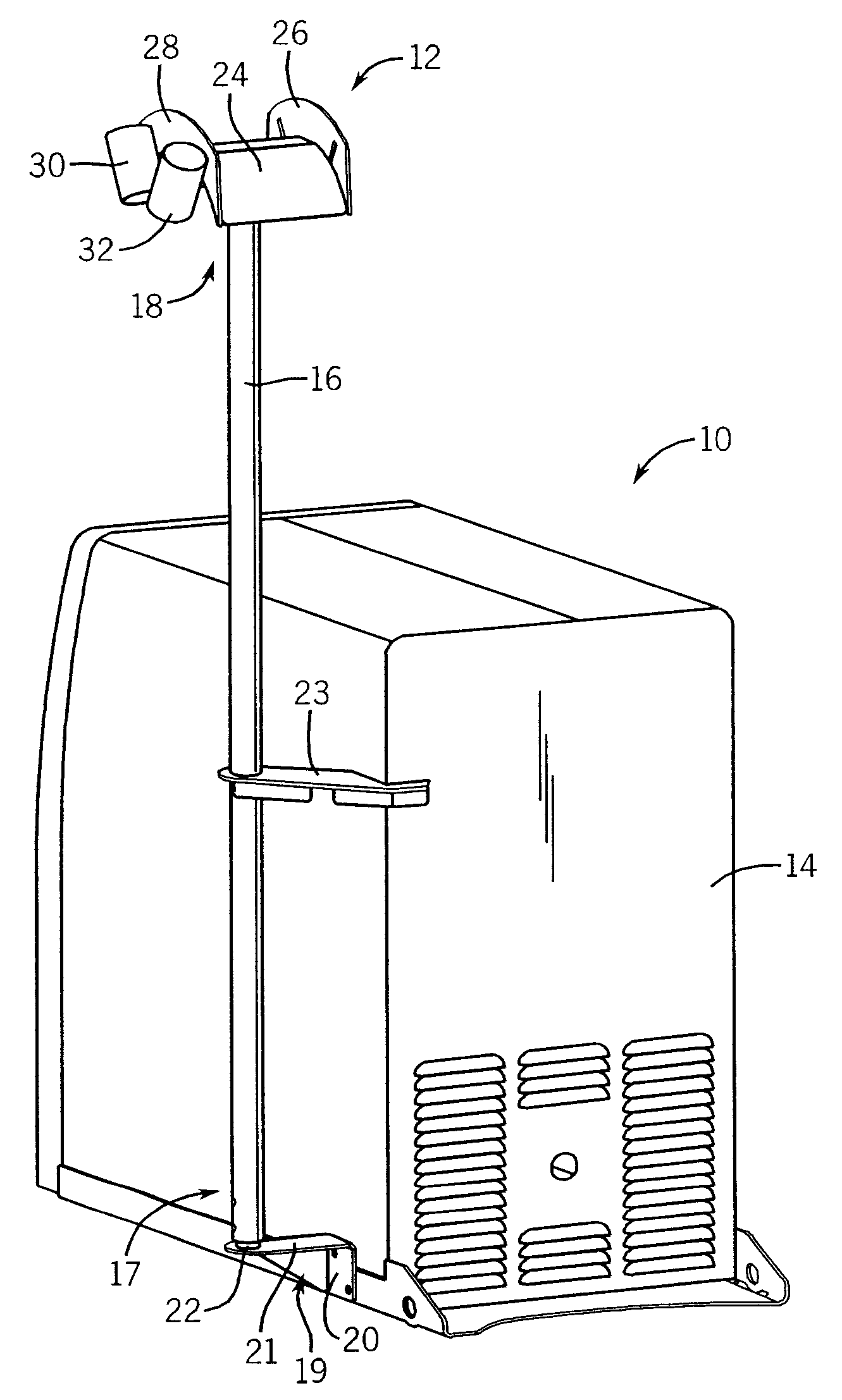

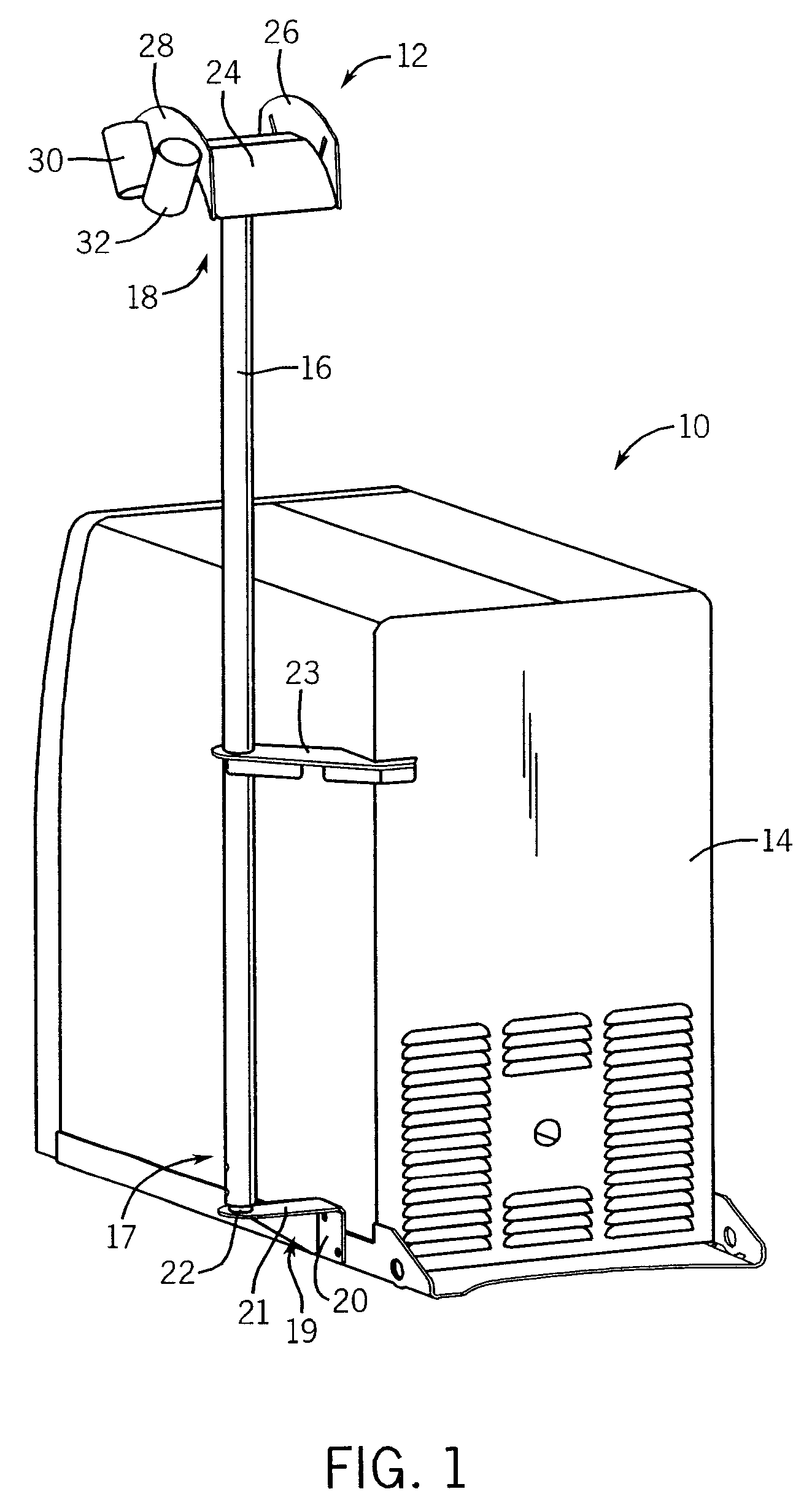

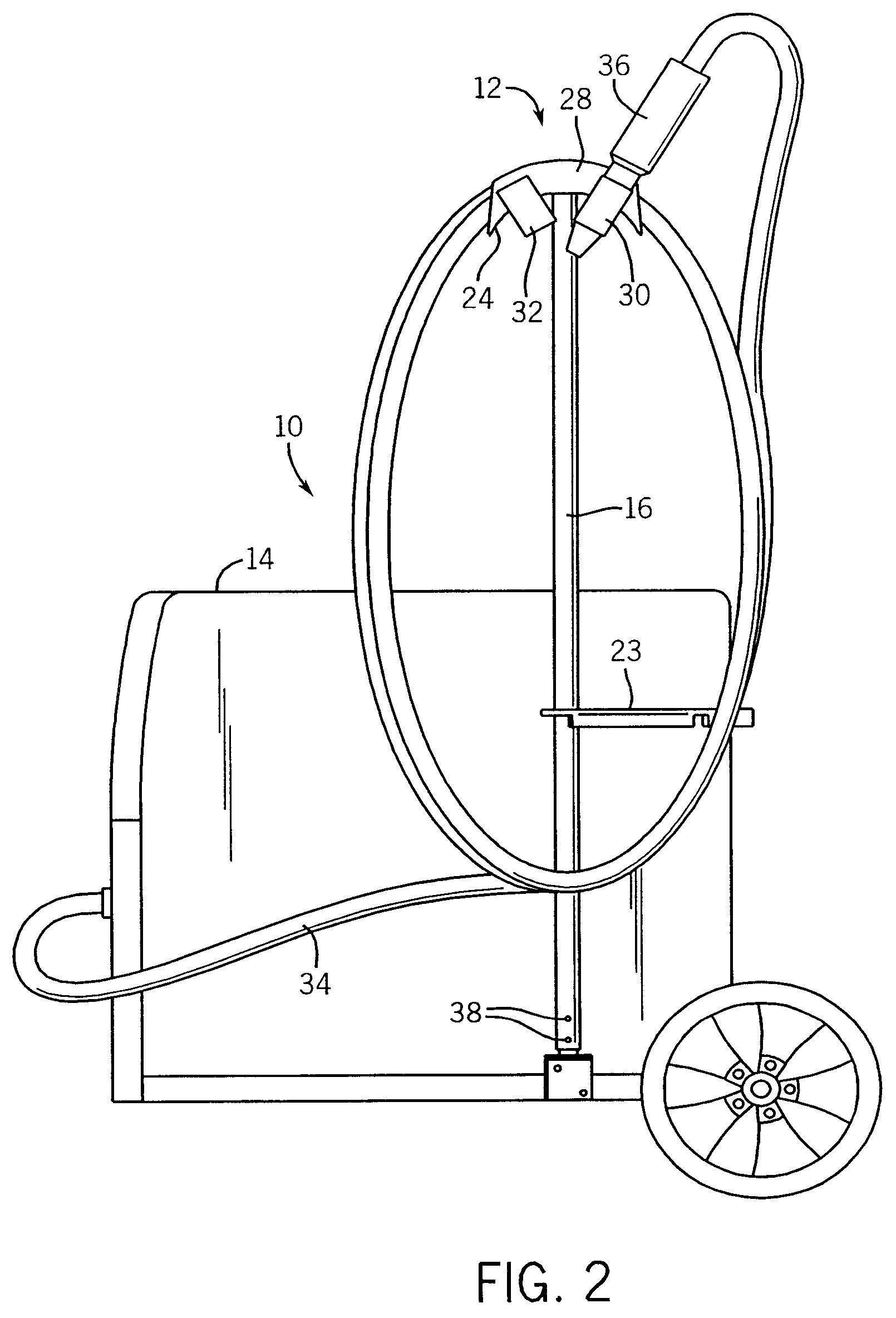

Elevated welding-type cable support system

ActiveUS20080135533A1Easy to storeWeld torches cleaningWelding/cutting auxillary devicesSupporting systemEngineering

A cable management system for a welding-type system includes a support column extending in a first direction from a first end supported by a welding-type device to a second end arranged above the welding-type device. The cable management system also includes a cable support arranged on the second end of the support column that extends in a second direction substantially transverse to the first direction. Accordingly, a portion of the cable support extends away from the welding-type device to allow a cable supported thereon to extend below the cable support and proximate to the welding-type device.

Owner:ILLINOIS TOOL WORKS INC

Protective coating and coated welding tip and nozzle assembly

InactiveUS20070090168A1Reduce the amount of noiseReduce accumulationCooking-vessel materialsWeld torches cleaningSpray nozzleTitanium dioxide

A coated welding tip and nozzle assembly is disclosed. The tip and the nozzle are coated with a coating composition comprising titanium dioxide. The coating provides resistance to adhesion and accumulation of weld spatter on the nozzle and tip and facilitates weld spatter removal. The coating also protects against thermal damage of the nozzle by providing a thermal barrier.

Owner:ND IND INC

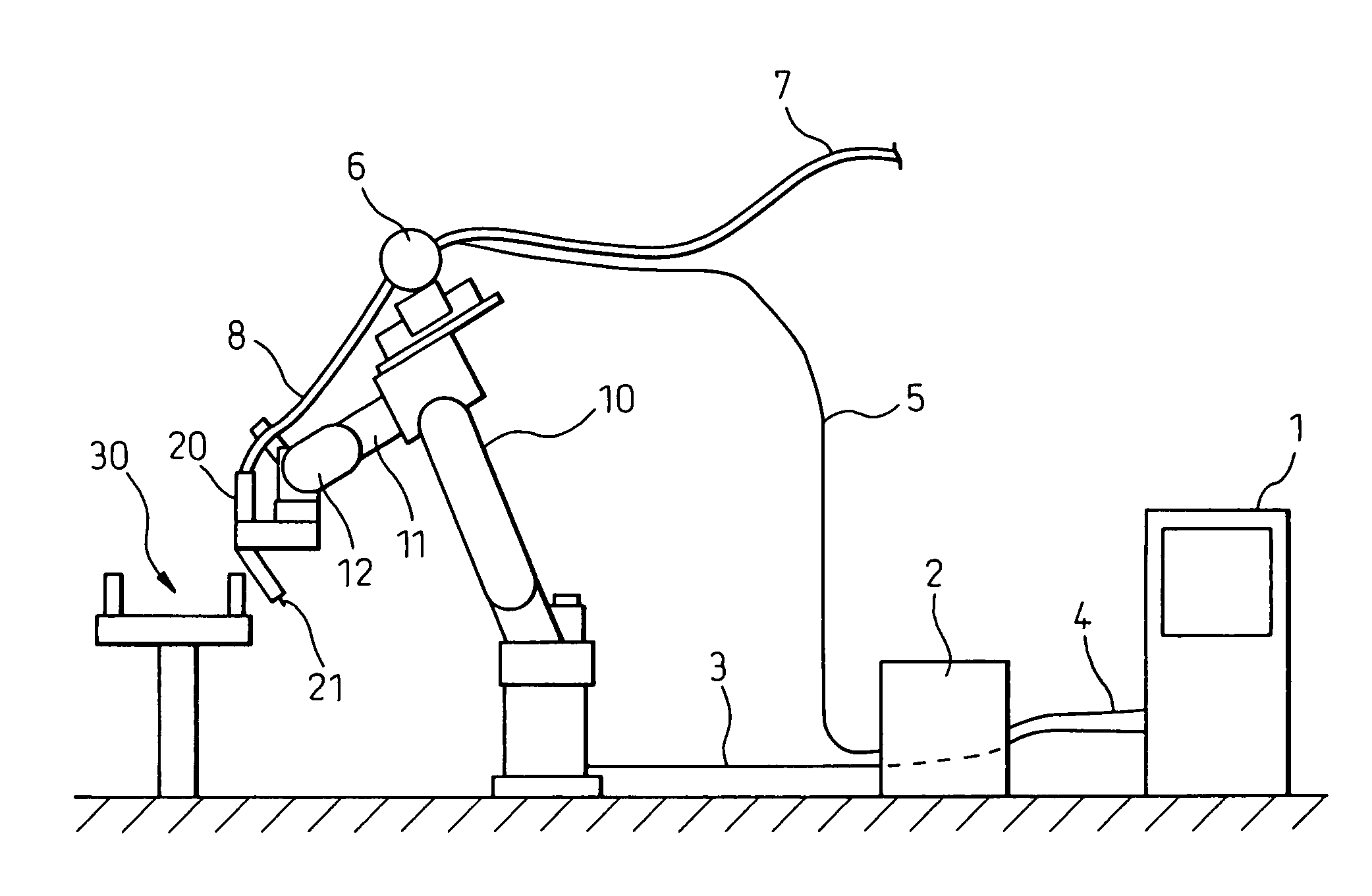

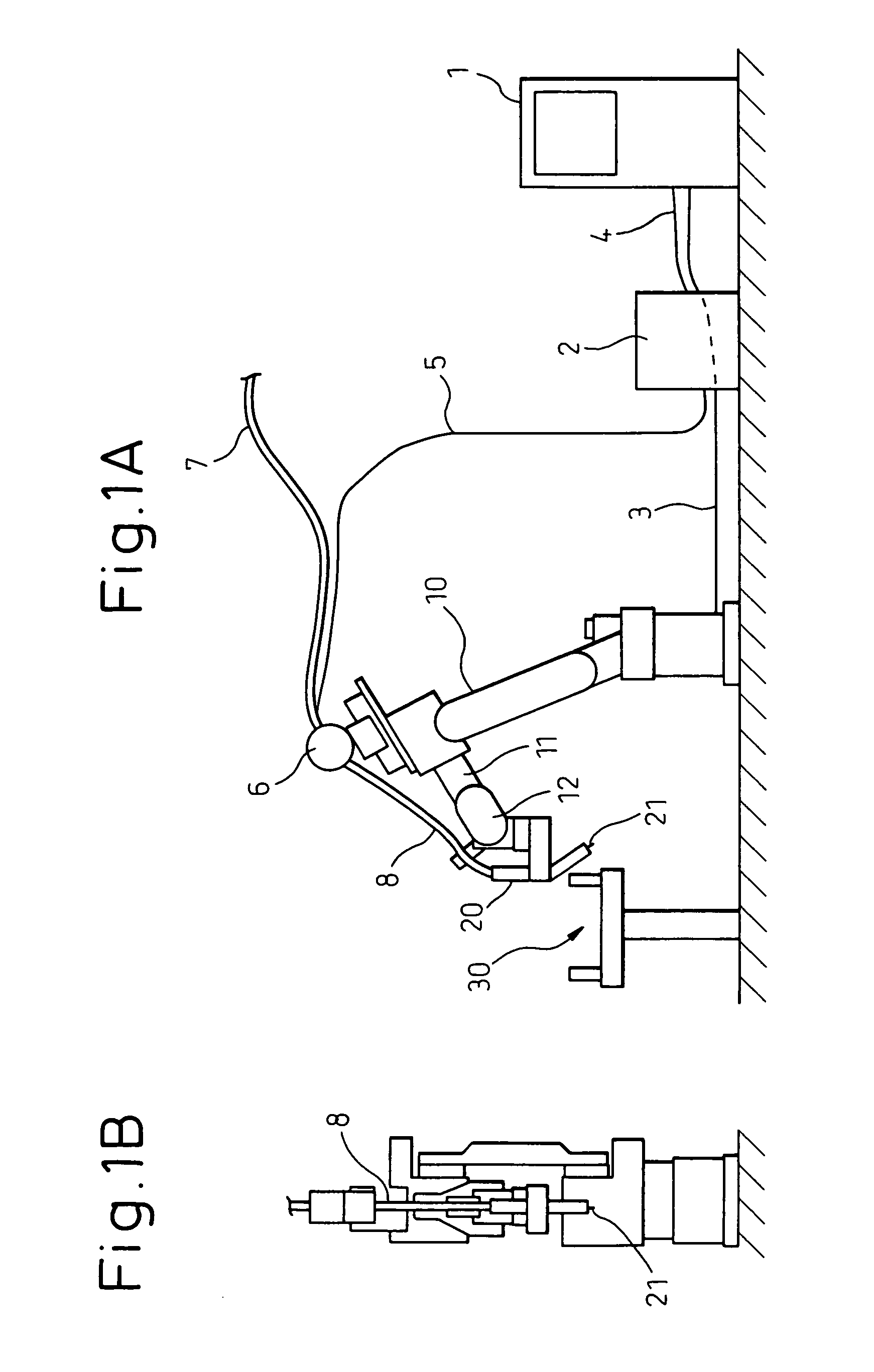

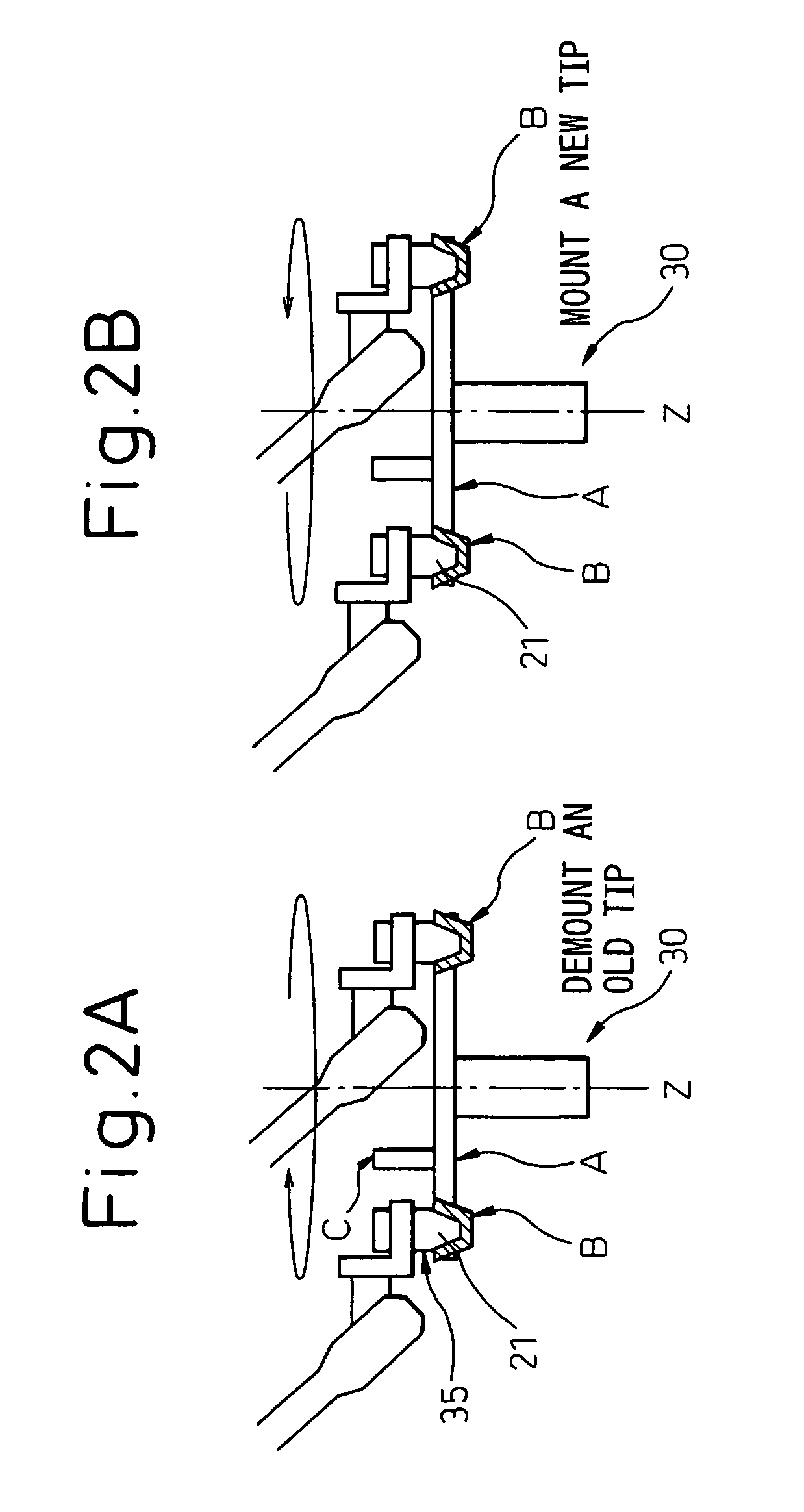

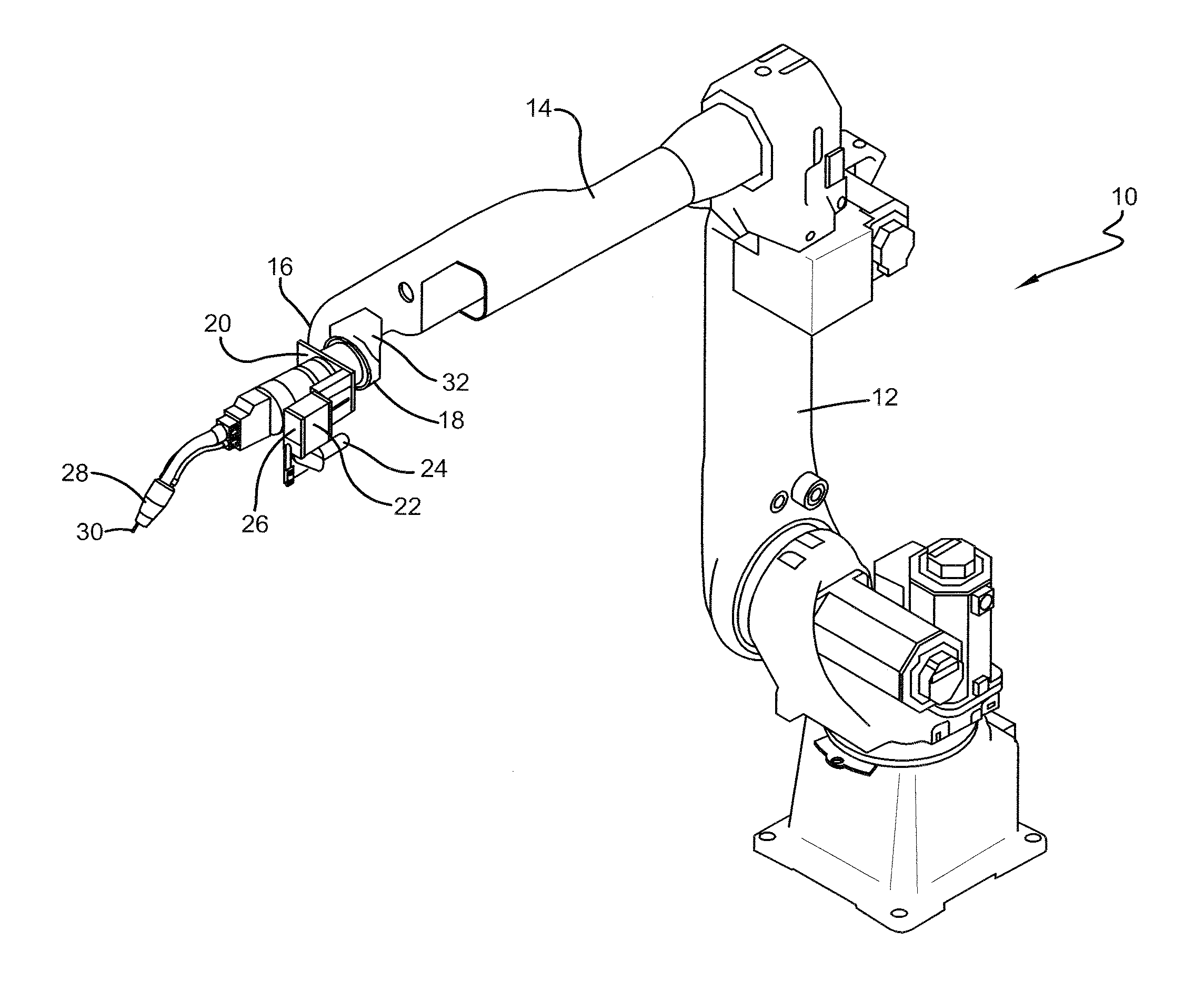

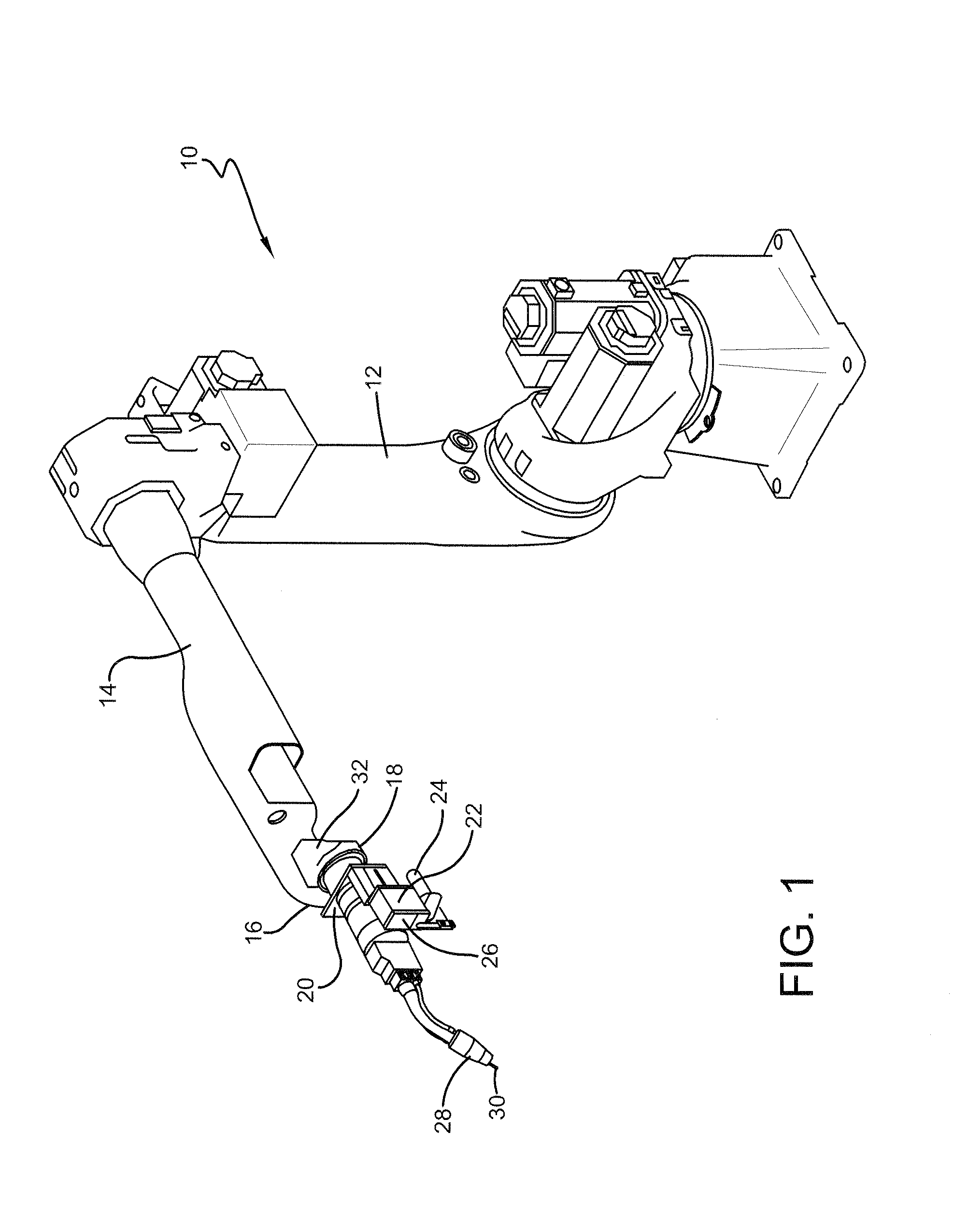

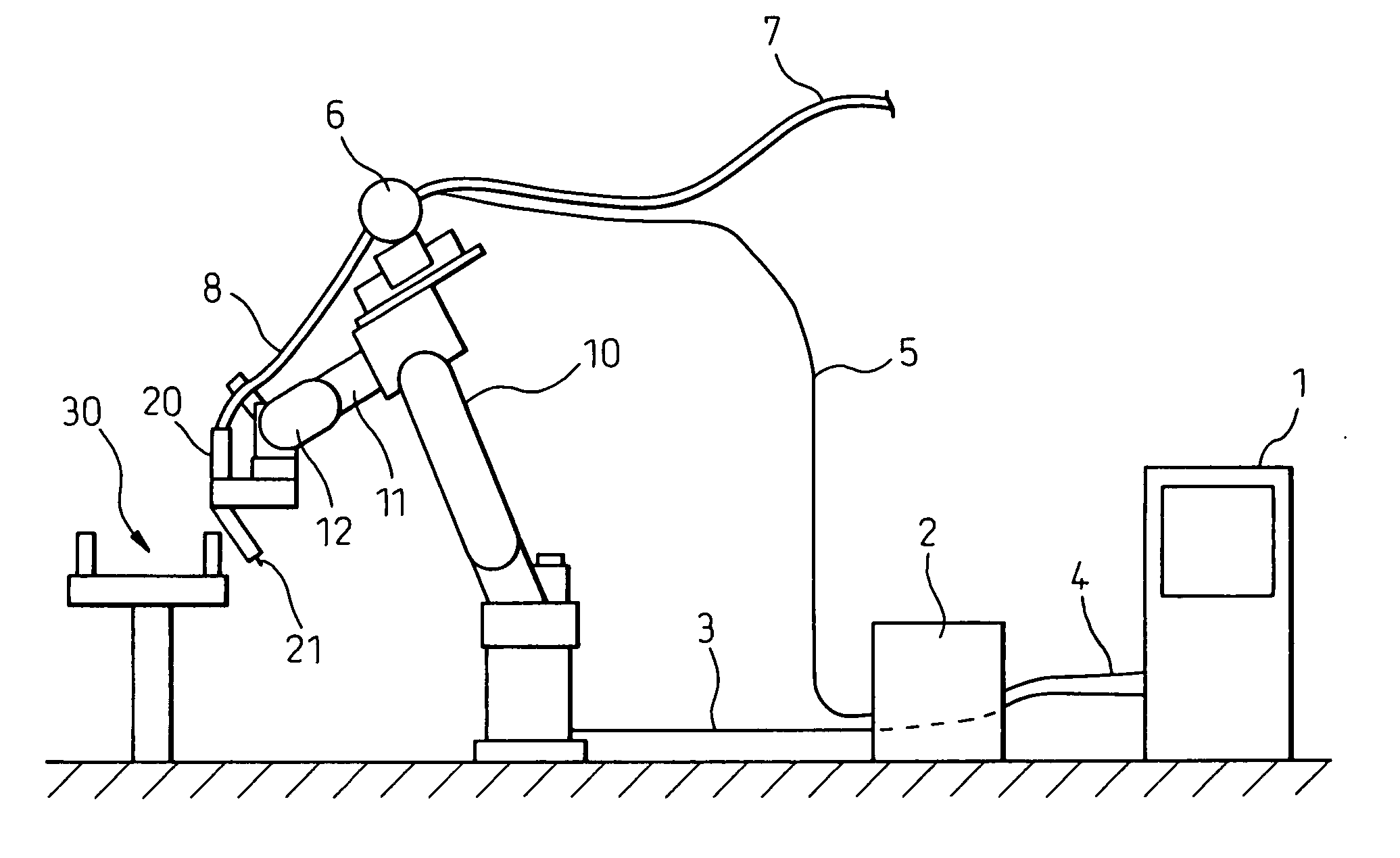

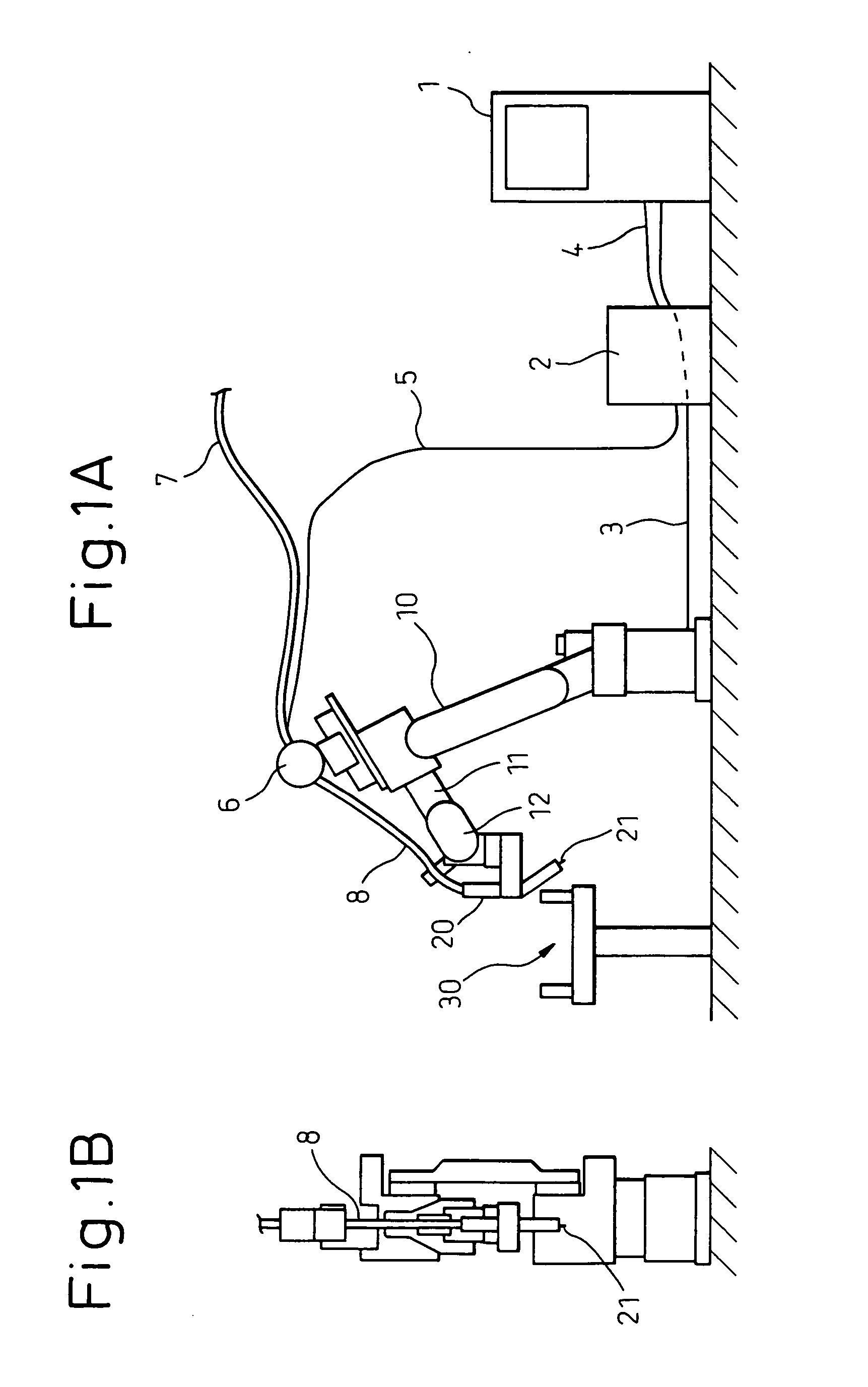

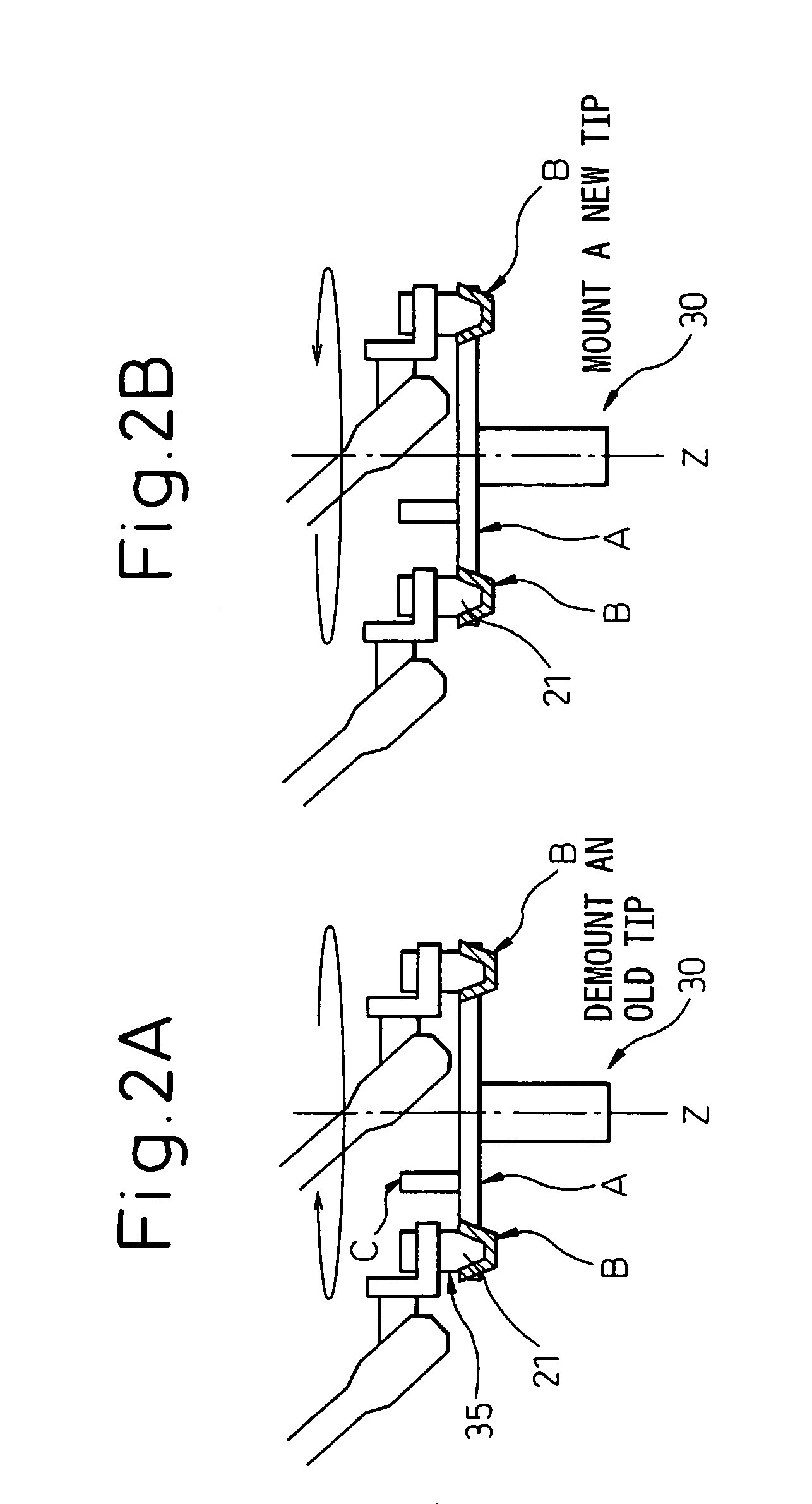

Apparatus for automatically changing a robot tool tip member

ActiveUS7204792B2Simple structureFew stepsPrecision positioning equipmentWeld torches cleaningEngineeringMechanical engineering

An apparatus for automatically changing a tool tip member for a robot includes a tip member changing jig disposed in an operational area of the robot. The tip member changing jig includes a base member, a rotating member supported by the base member so as to be rotatable about a rotation axis, and tip member holding means disposed at positions that are offset from the rotation axis of the rotating member. The tip member holding means holds the tool tip member so that a central axis of relative rotation, for threadedly mounting or demounting the tool tip member on or from the tool body, extends substantially parallel to the rotation axis of the rotating member and so that rotation of the tool tip member, with respect to the rotating member, is locked.

Owner:FANUC LTD

Coating Composition and Anti-Spatter Coating Formed Therefrom

A coating composition for forming an anti-spatter coating on a substrate is disclosed. The coating composition comprises a ceramic precursor, a curing agent, and optionally a cross-linkable resin. A coated article is also disclosed which comprises a substrate and the anti-spatter coating disposed on a surface of the substrate. The anti-spatter coating is the reaction product formed by curing the coating composition.

Owner:ND IND INC

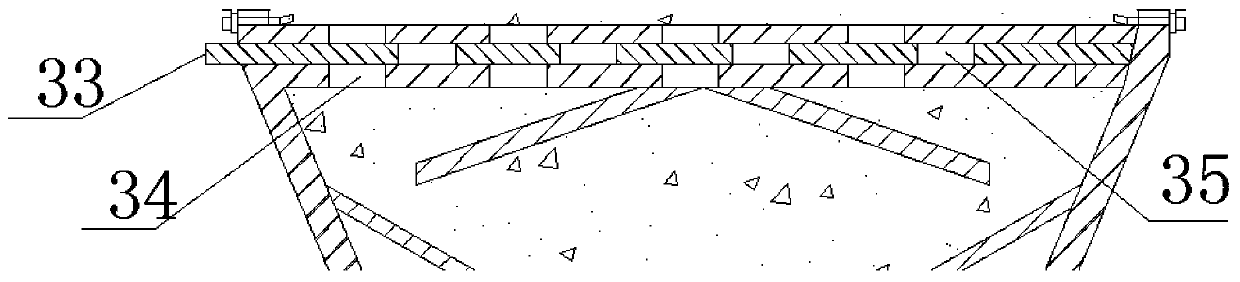

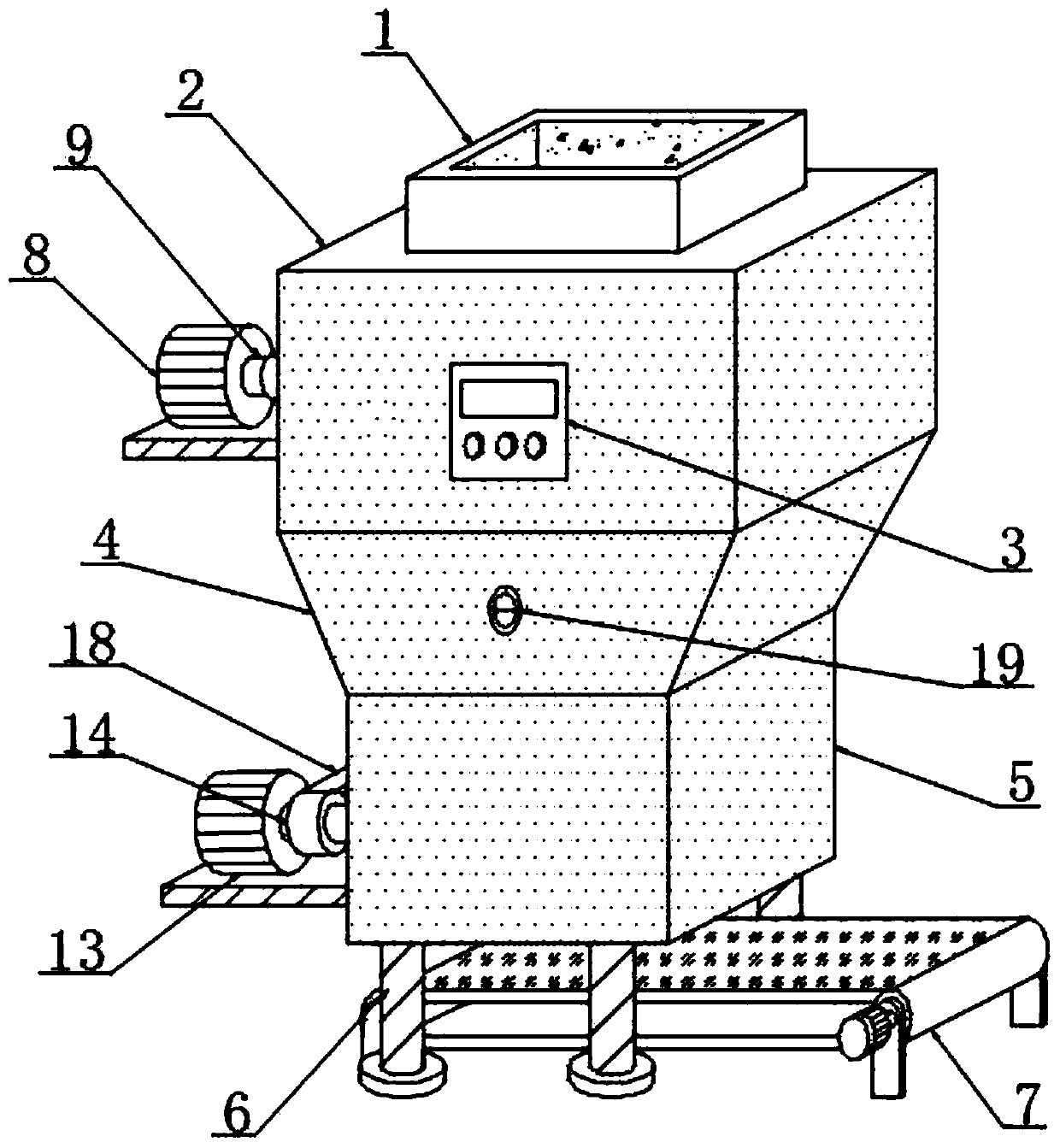

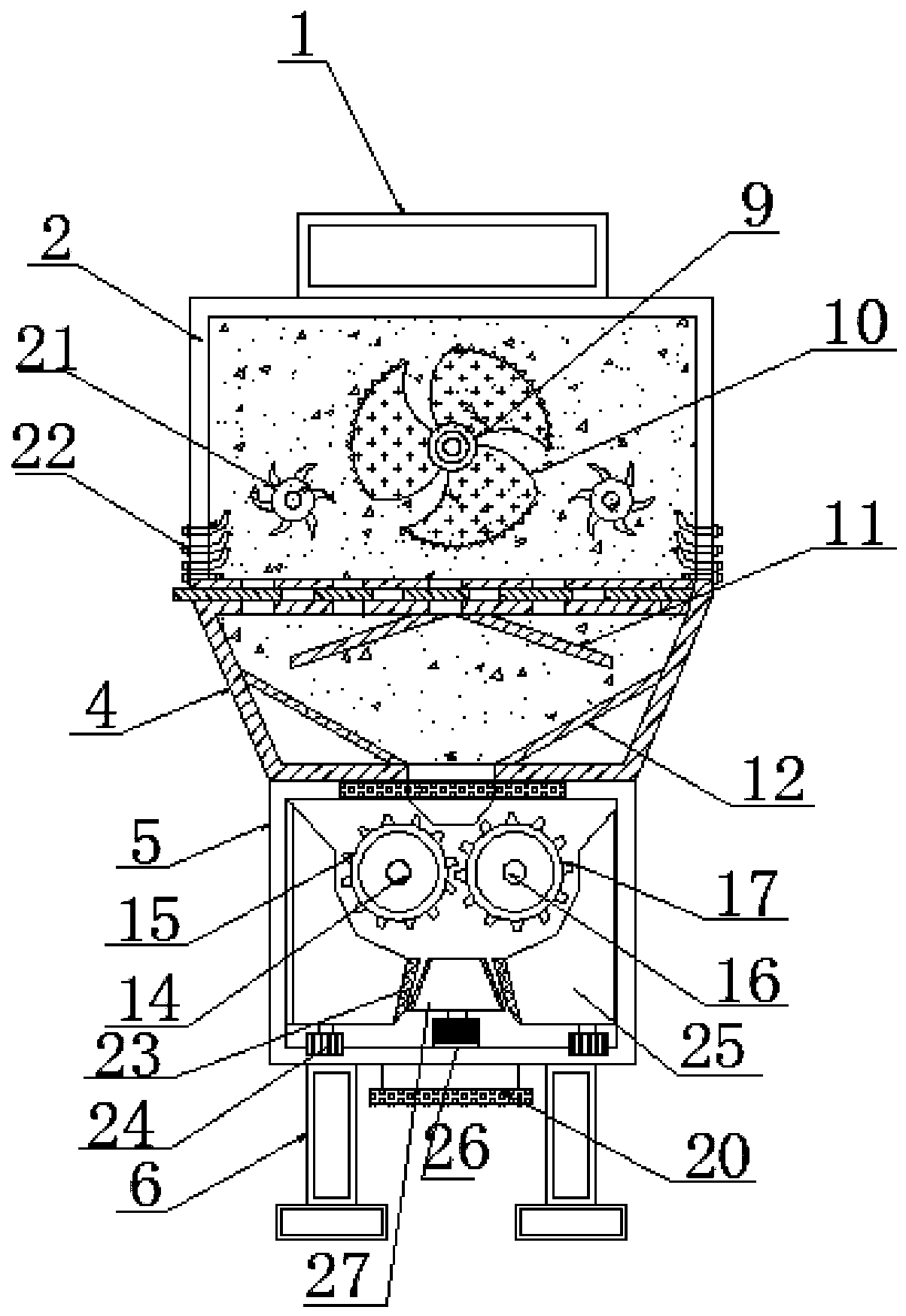

Temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products

ActiveCN109833951ARealize crushing workRealize the drying workFeeding-stuffWeld torches cleaningTemperature controlAquatic product

The invention discloses a temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products. An opening and closing control assembly is arrangedbetween a crushing box and a drying box so as to control discharging of materials in the crushing box, and the crushing box is internally provided with a flying stirring assembly enabling the to-be-crushed materials to move upwards, so that the materials can fly to the crushing assembly to be crushed; and the grinding assembly comprises a primary rough grinding assembly and a secondary fine grinding assembly, the primary rough grinding assembly is used for primary coarse grinding of the materials, the secondary fine grinding assembly is used for secondary fine grinding of the materials, the temperature of the inside of the drying box can be monitored in real time through the temperature sensors arranged at the same time, the temperature can be conveniently adjusted according to the humidity of the raw materials, and the grinding treatment of the feed raw materials is realized through the arranged grinding box; and a conveying machine is arranged, so that the automatic conveying work ofthe materials after grinding can be realized, the labor is saved, and the working efficiency is improved.

Owner:惠安先锋机械有限公司

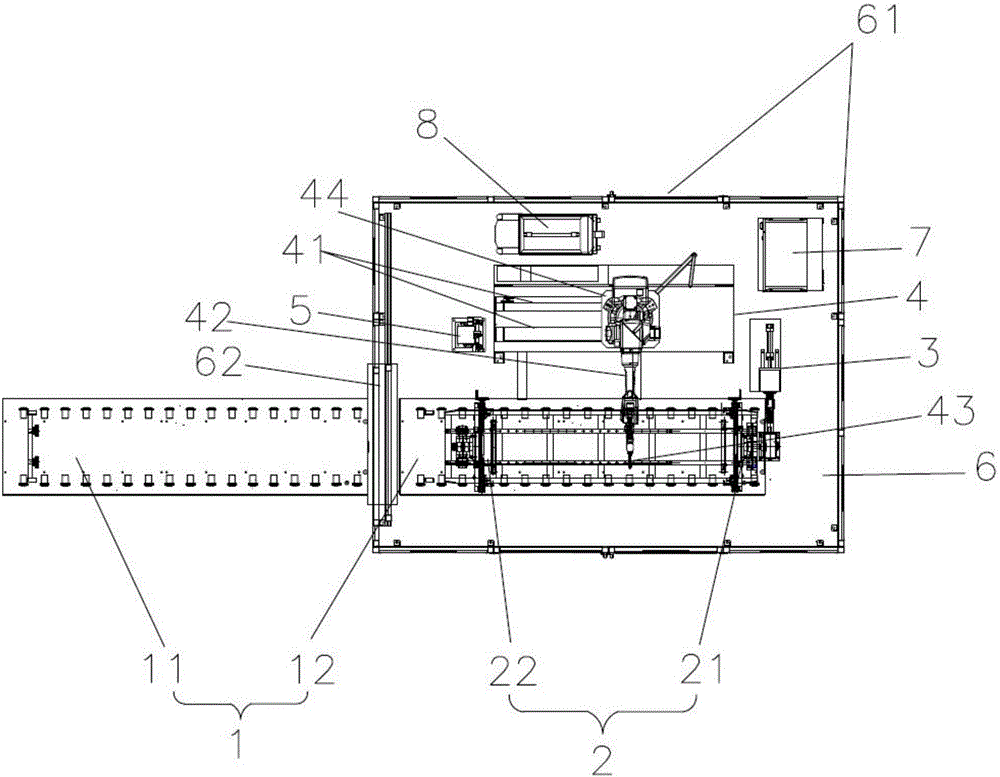

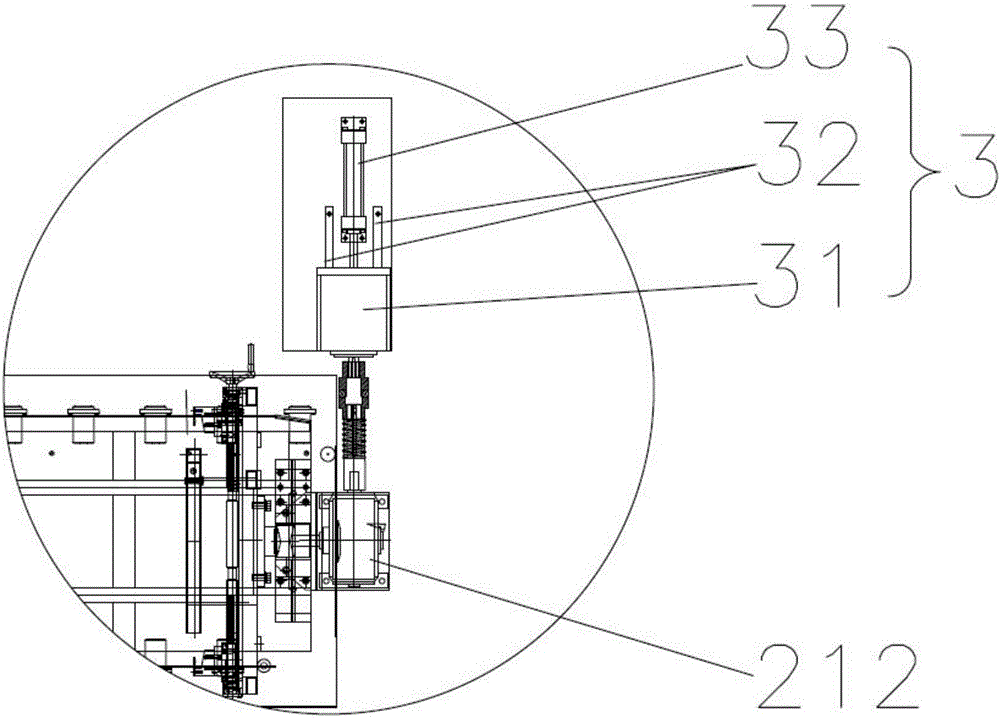

Welding system applied to cubicle gas-insulated metal-enclosed switchgear

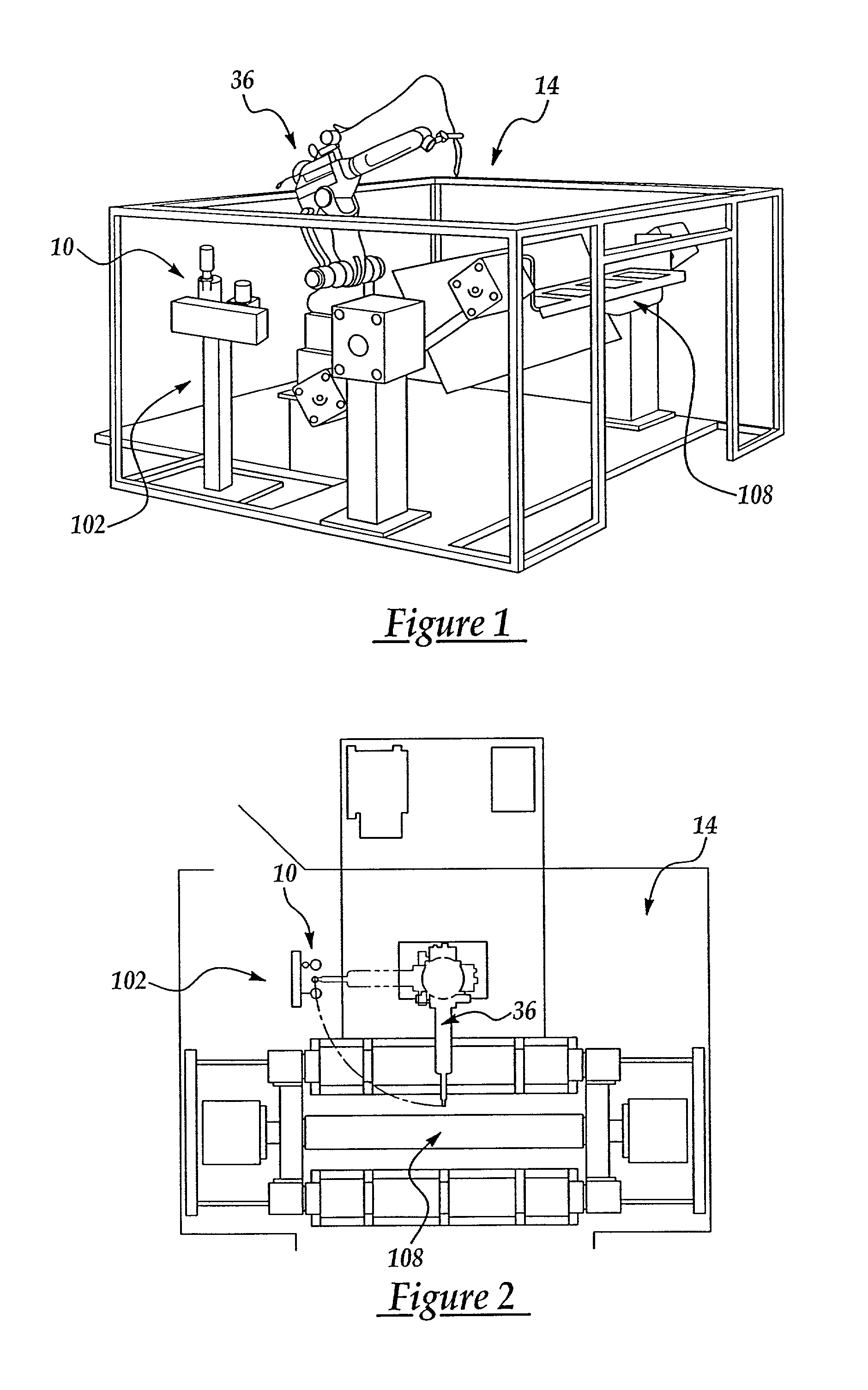

ActiveCN106001848AHigh degree of automationImprove welding efficiencyWeld torches cleaningWelding/cutting auxillary devicesWelding power supplyEngineering

The invention provides a welding system applied to a cubicle gas-insulated metal-enclosed switchgear. The welding system comprises a clamp mechanism, an automatic conveying line, a welding room, a turnover mechanism, a robot welding mechanism, a welding power supply and a robot control cabinet; the automatic conveying line comprises an assembly section and a welding section, wherein the assembly section is arranged outside the welding room, and the welding section is arranged inside the welding room; the clamp mechanism is arranged on the automatic conveying line and is used for clamping the cubicle gas-insulated metal-enclosed switchgear and then conveying the cubicle gas-insulated metal-enclosed switchgear from the assembly section o the welding section; the robot welding mechanism is arranged at one side of the welding section; a turnover mechanism is arranged at the tail end of the welding section; when the clamp mechanism reaches the tail end of the welding section, the turnover mechanism is connected with the clamp mechanism; the robot control box and the welding power supply are respectively arranged around the robot welding mechanism and are electrically connected with the robot welding mechanism. The welding system applied to the cubicle gas-insulated metal-enclosed switchgear has the advantages of high automation degree and high welding efficiency.

Owner:湖南创研智能装备有限公司

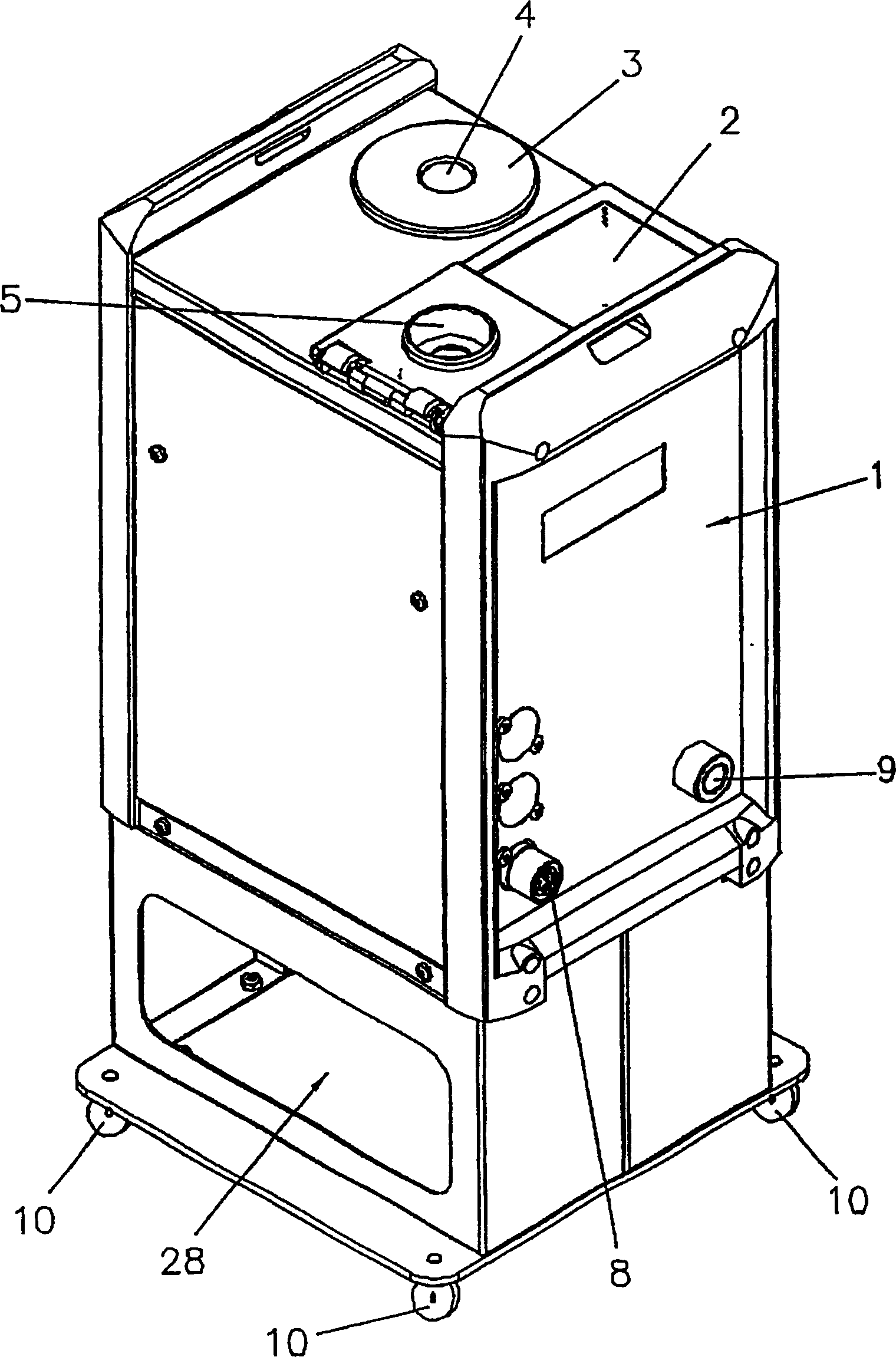

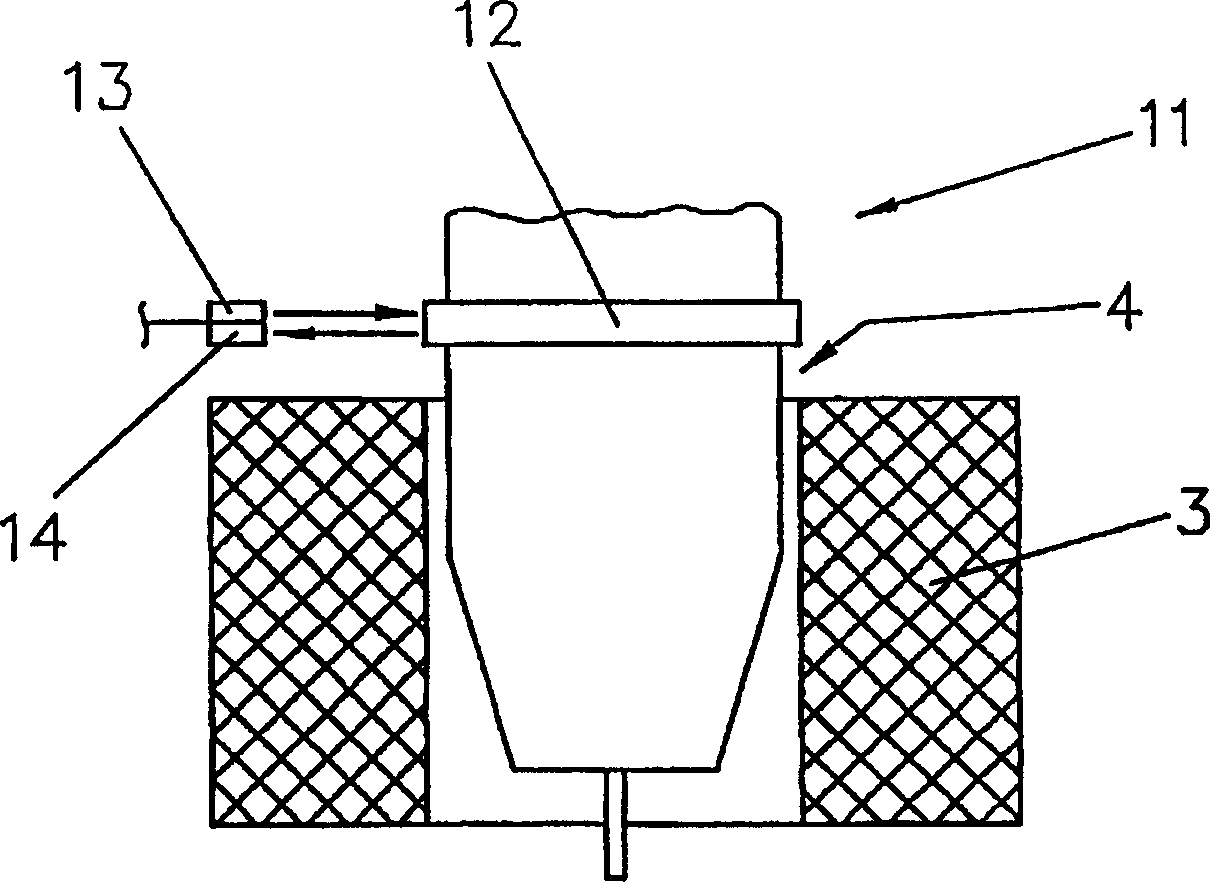

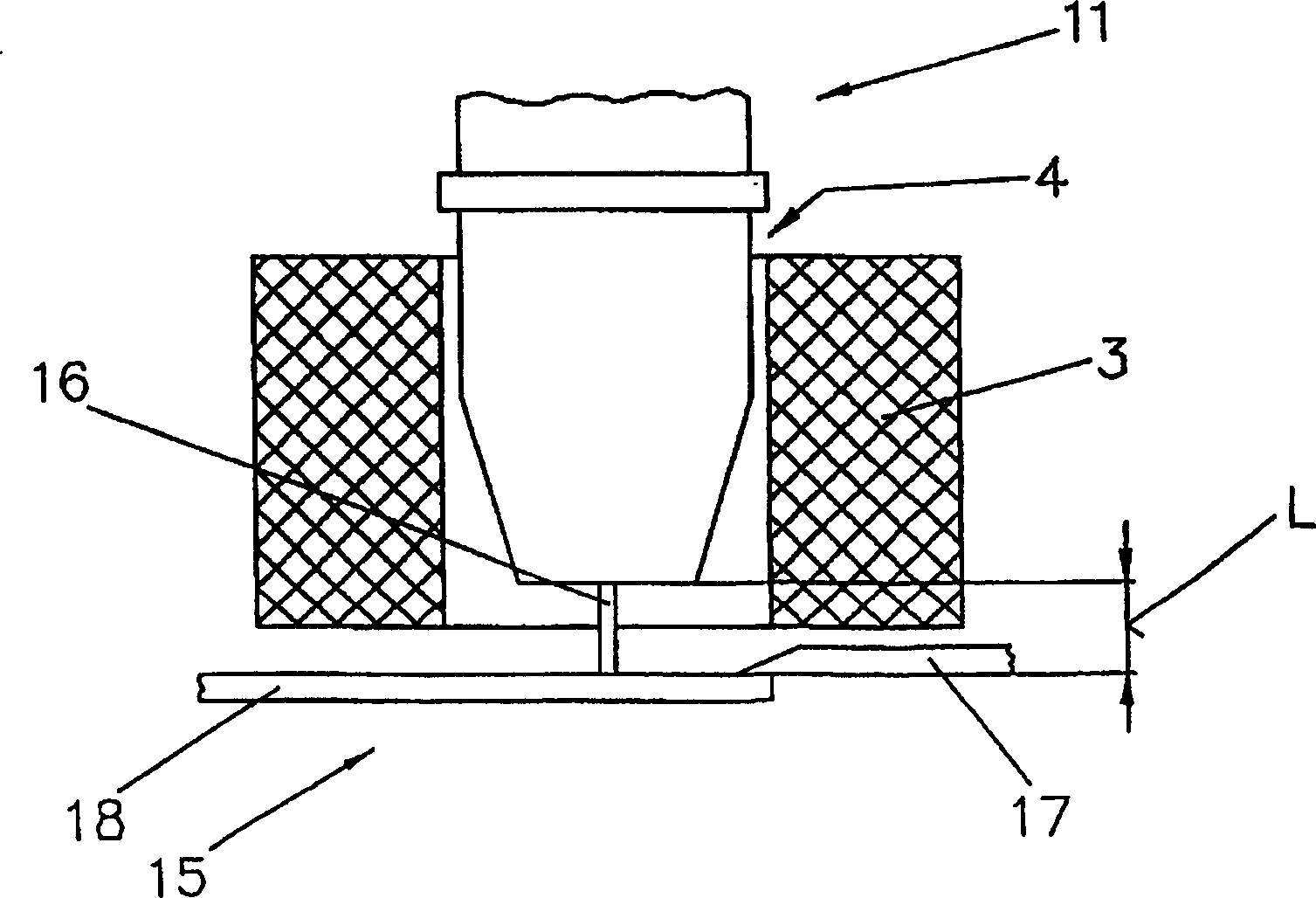

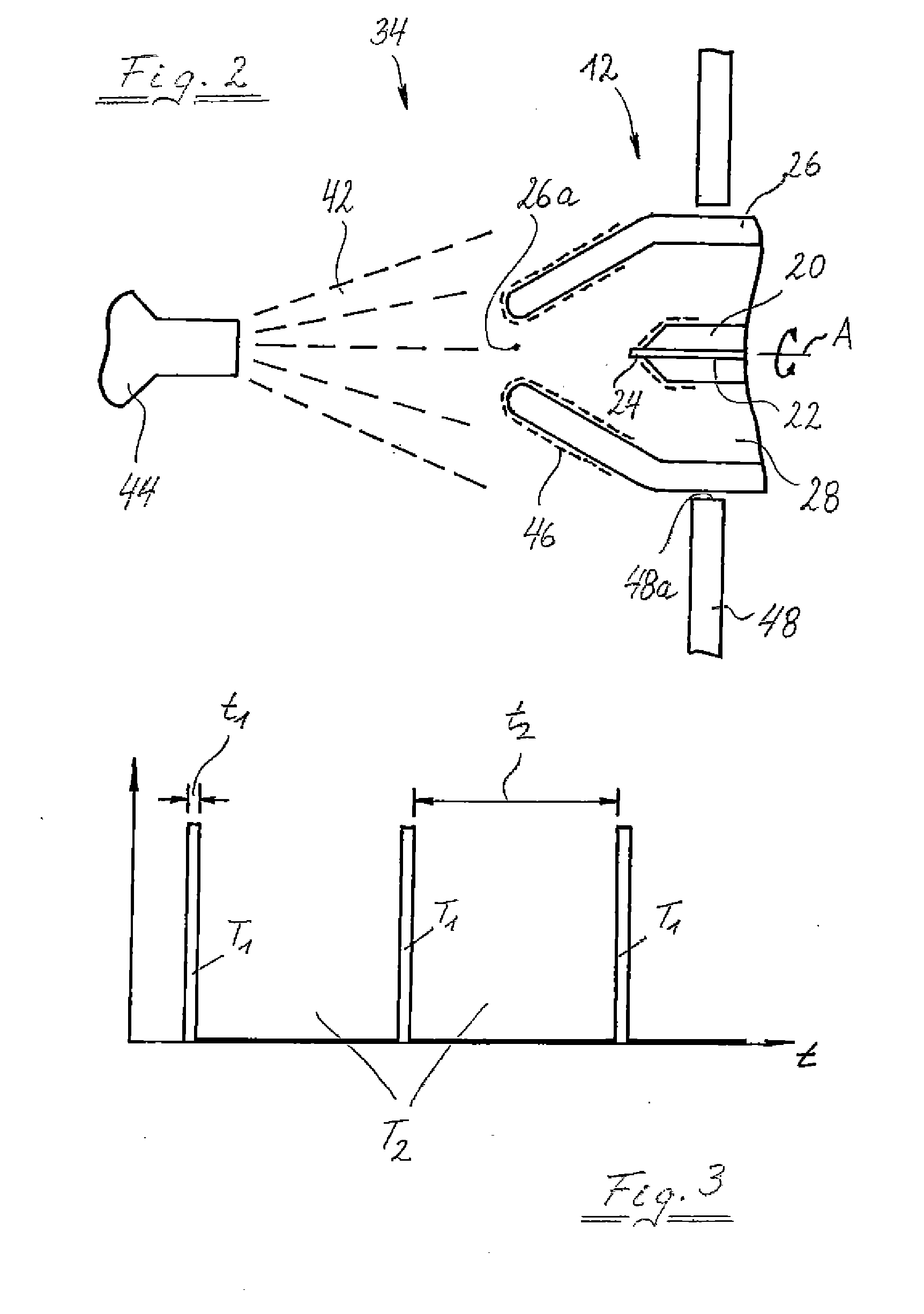

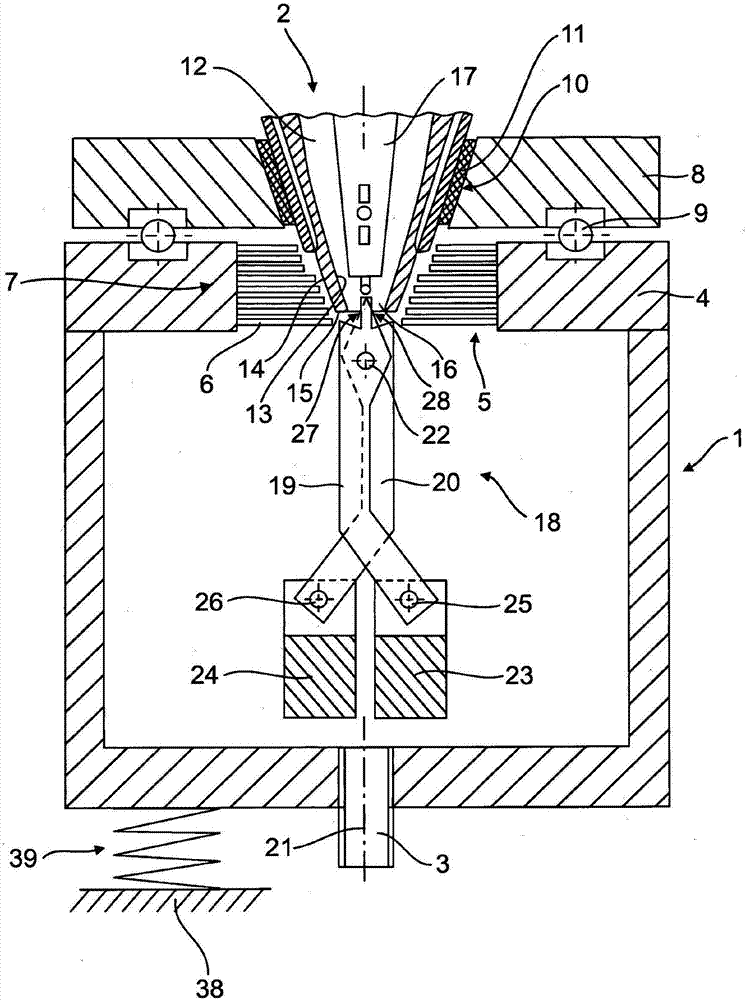

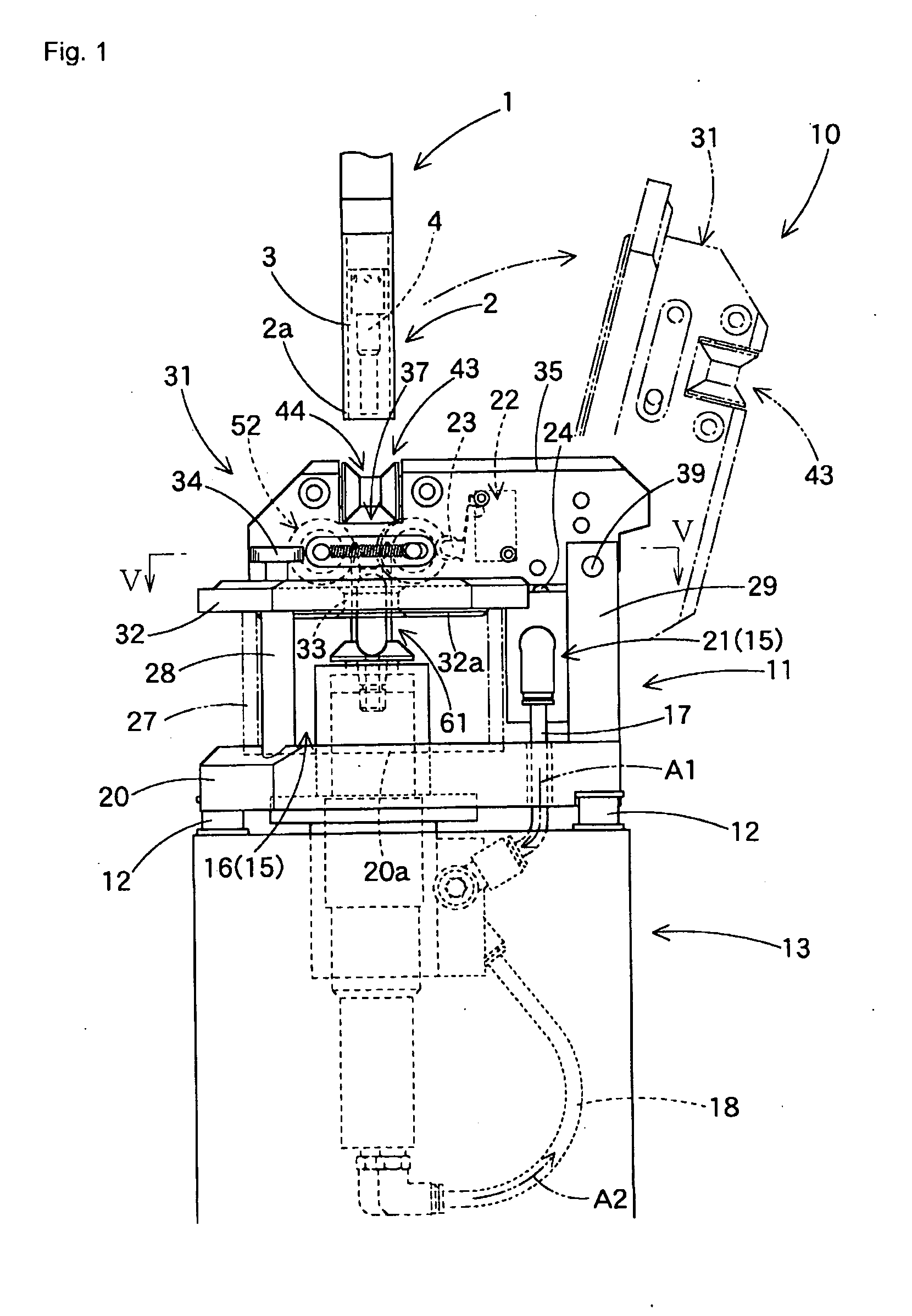

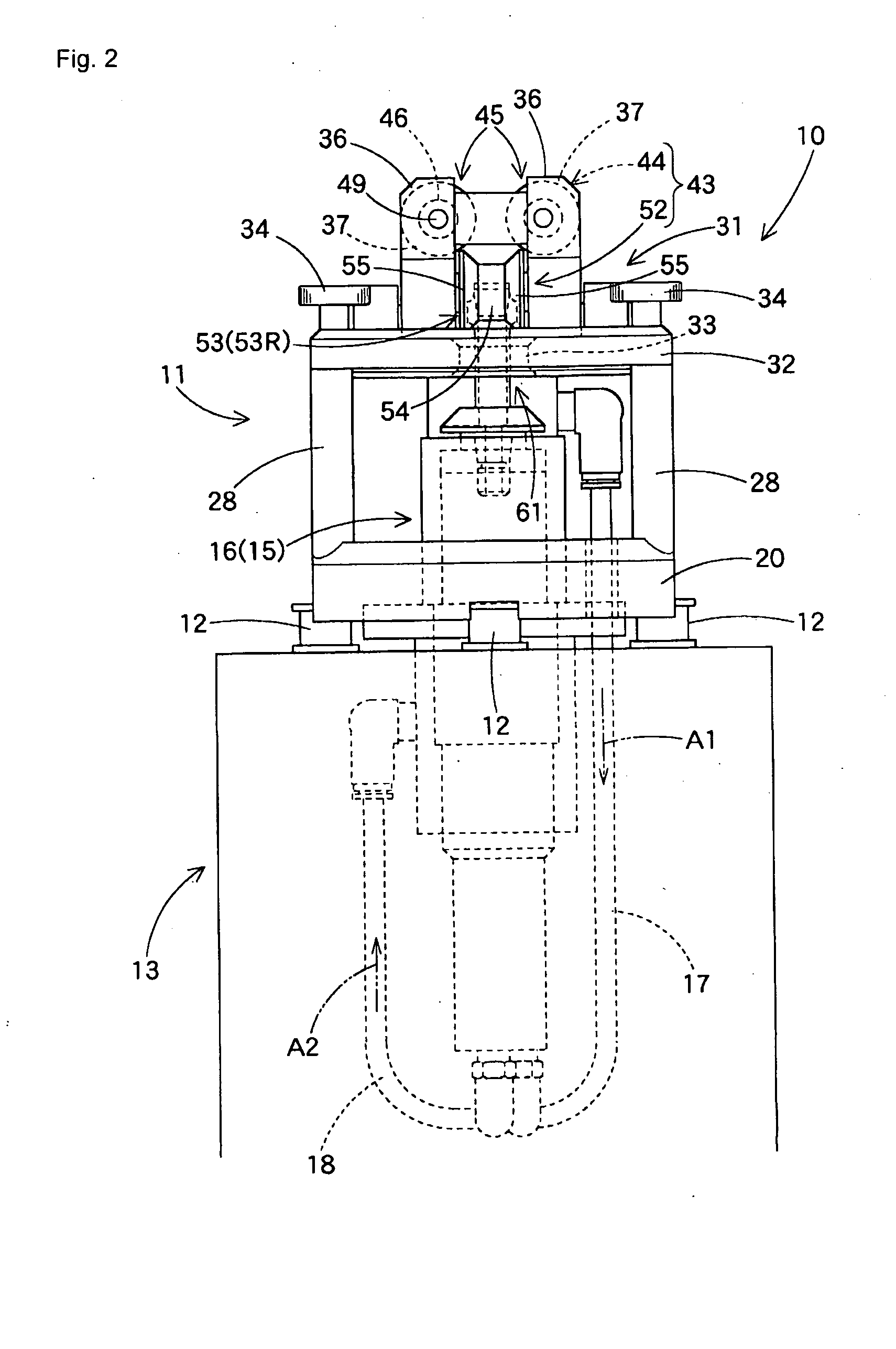

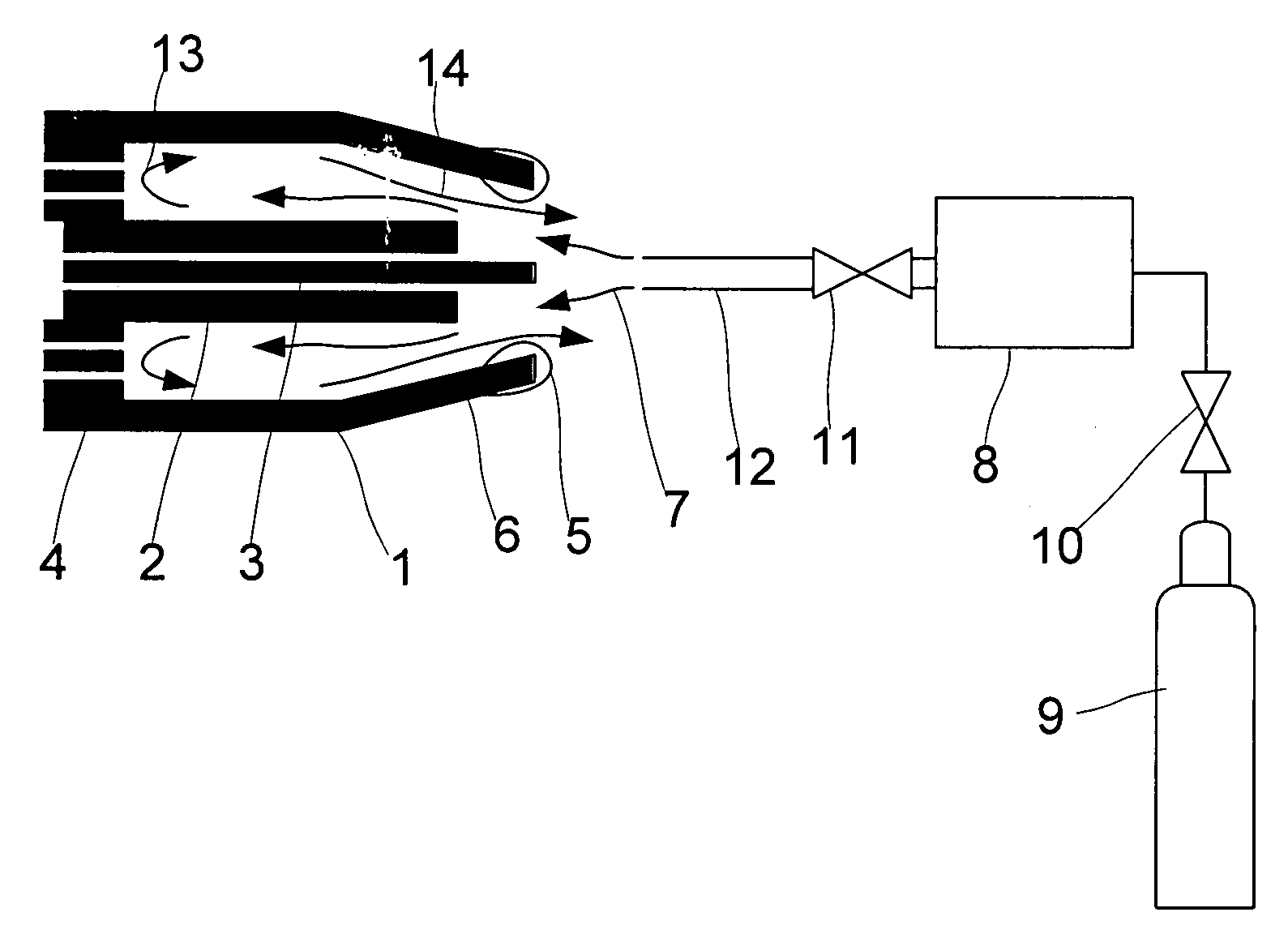

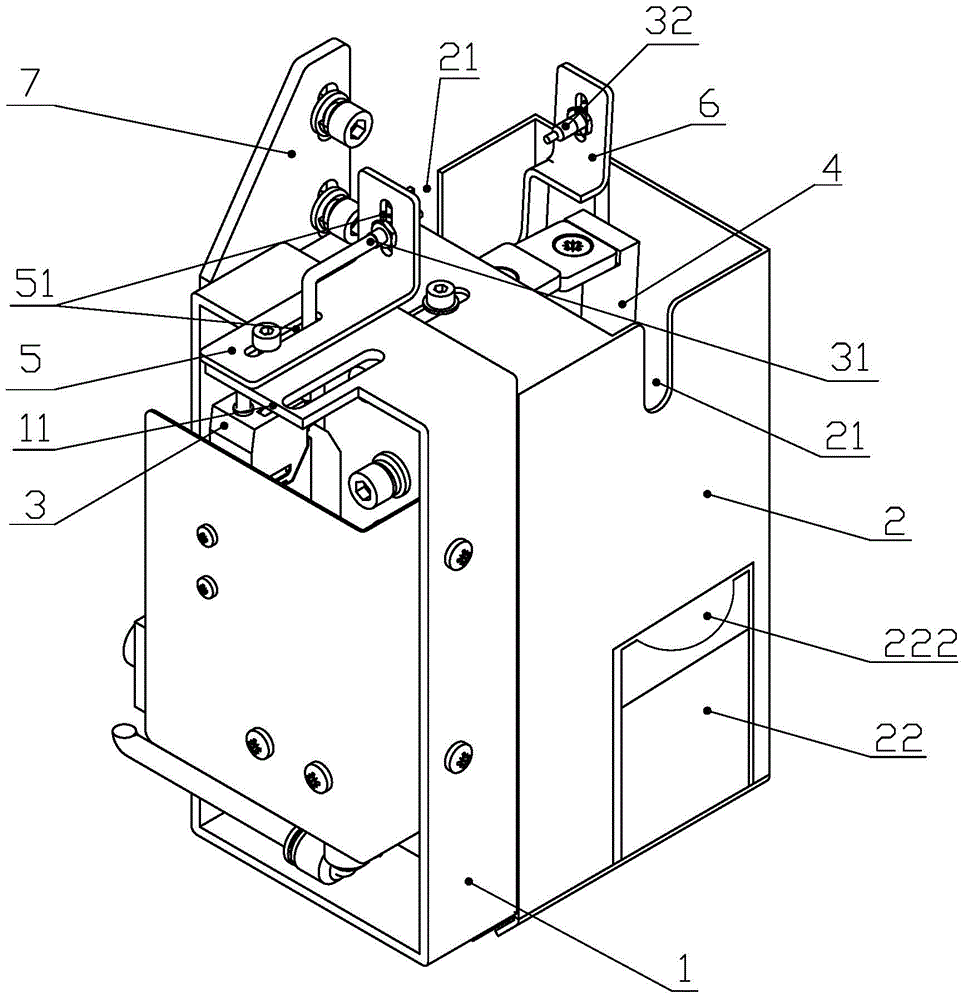

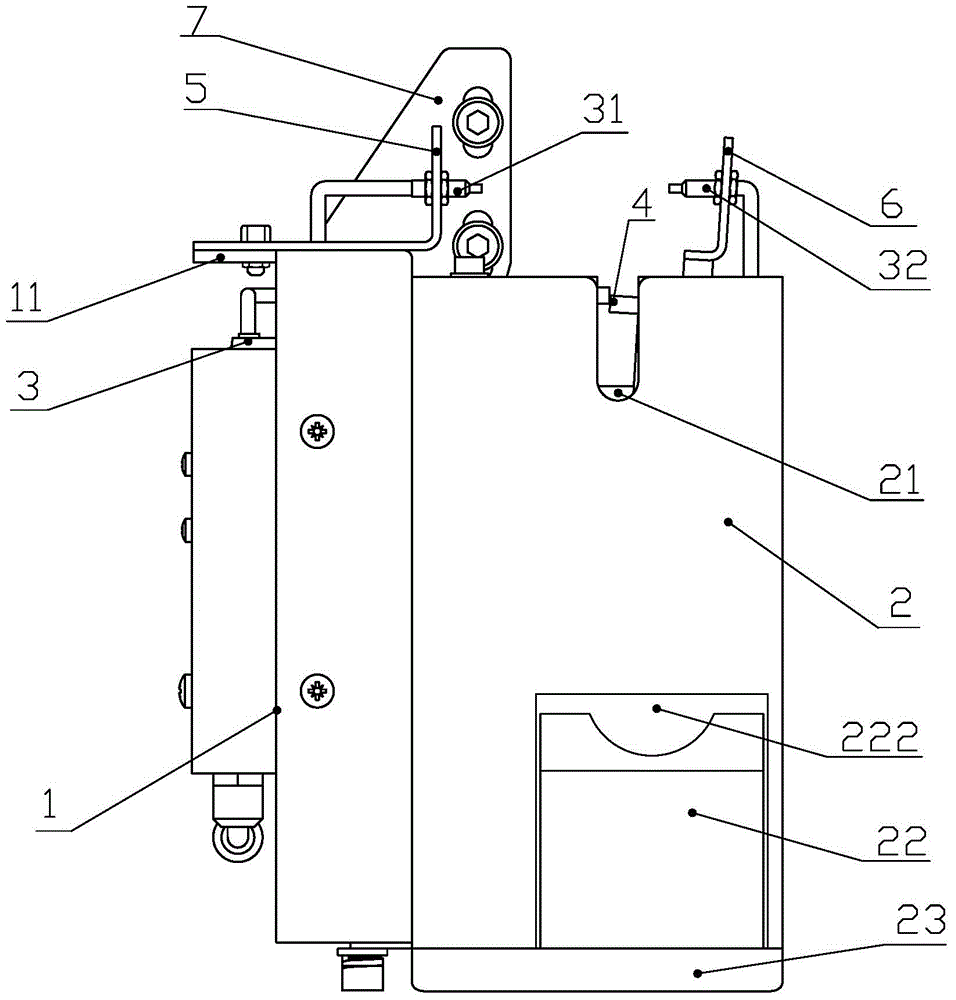

Method and equipment for cleaning welding torch

The invention relates to a method for cleaning welding torches ( 11 ) and to a device for cleaning welding torches ( 11 ), comprising a device for applying cleaning or wetting liquid to the tip of the welding torch ( 11 ) and comprising a coil ( 3 ) with an opening ( 4 ) for inserting the welding torch ( 11 ) in order to subject it to an electromagnetic cleaning. The inventive device also comprises an electric power supply device ( 7 ) that is connected to said coil ( 3 ). The aim of the invention is to provide a cleaning method that can be executed in a manner that is as rapid and automatable as possible and to create a corresponding cleaning device. To this end, the device for applying cleaning liquid, which consists of, for example, a reservoir ( 2 ) or nozzles ( 32 ), and the coil ( 3 ) are placed inside a common housing ( 1 ) together with a refuse reservoir ( 6 ), which is located underneath the coil ( 3 ) while serving to hold the electromagnetically removed foreign substances. Preferably, the device for applying cleaning liquid is placed inside or underneath the opening ( 4 ) of the coil ( 3 ) whereby enabling the welding torch ( 11 ) to be located in essentially the same position during cleaning.

Owner:FRONIUS INTERNATIONAL GMBH

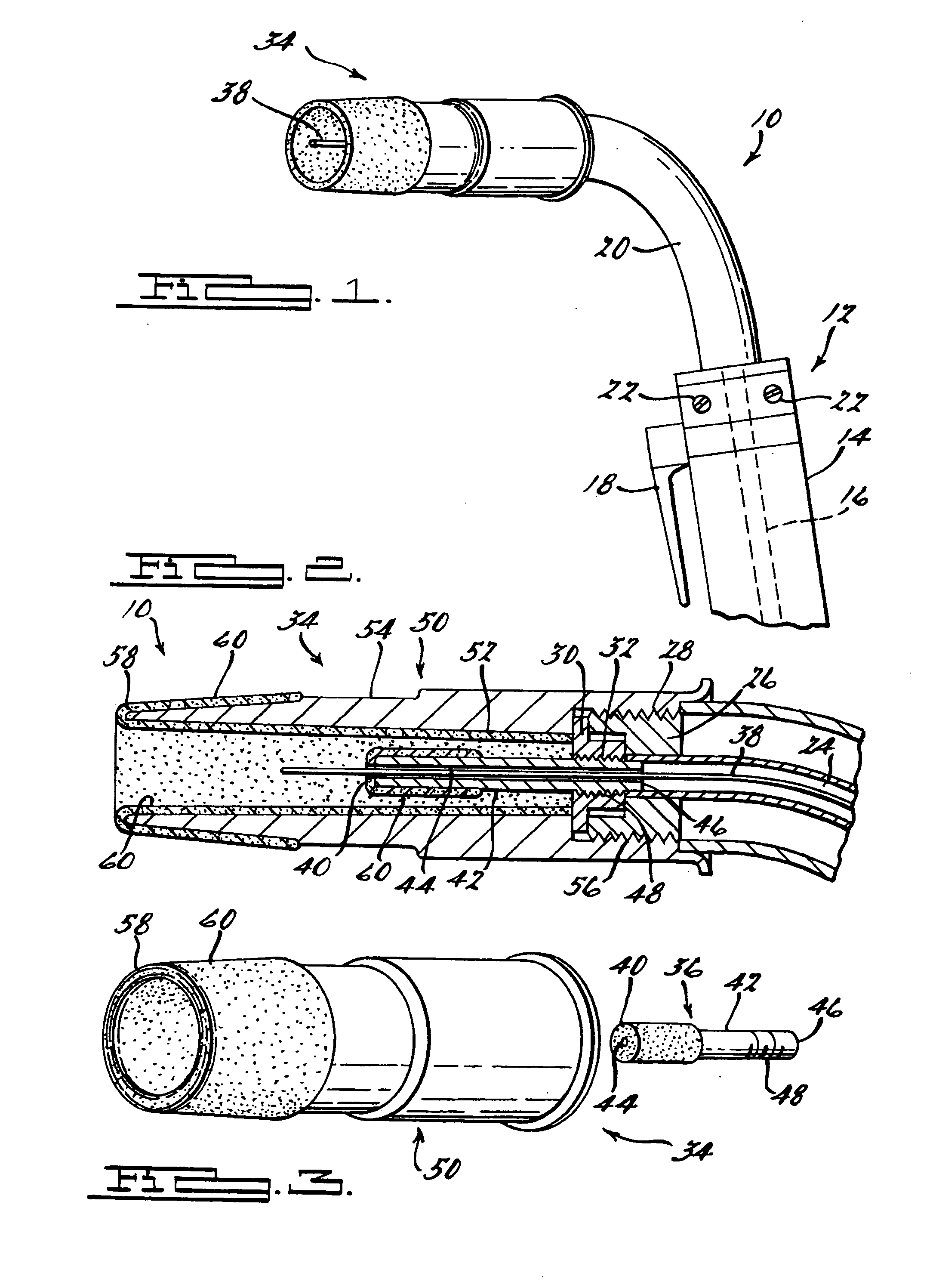

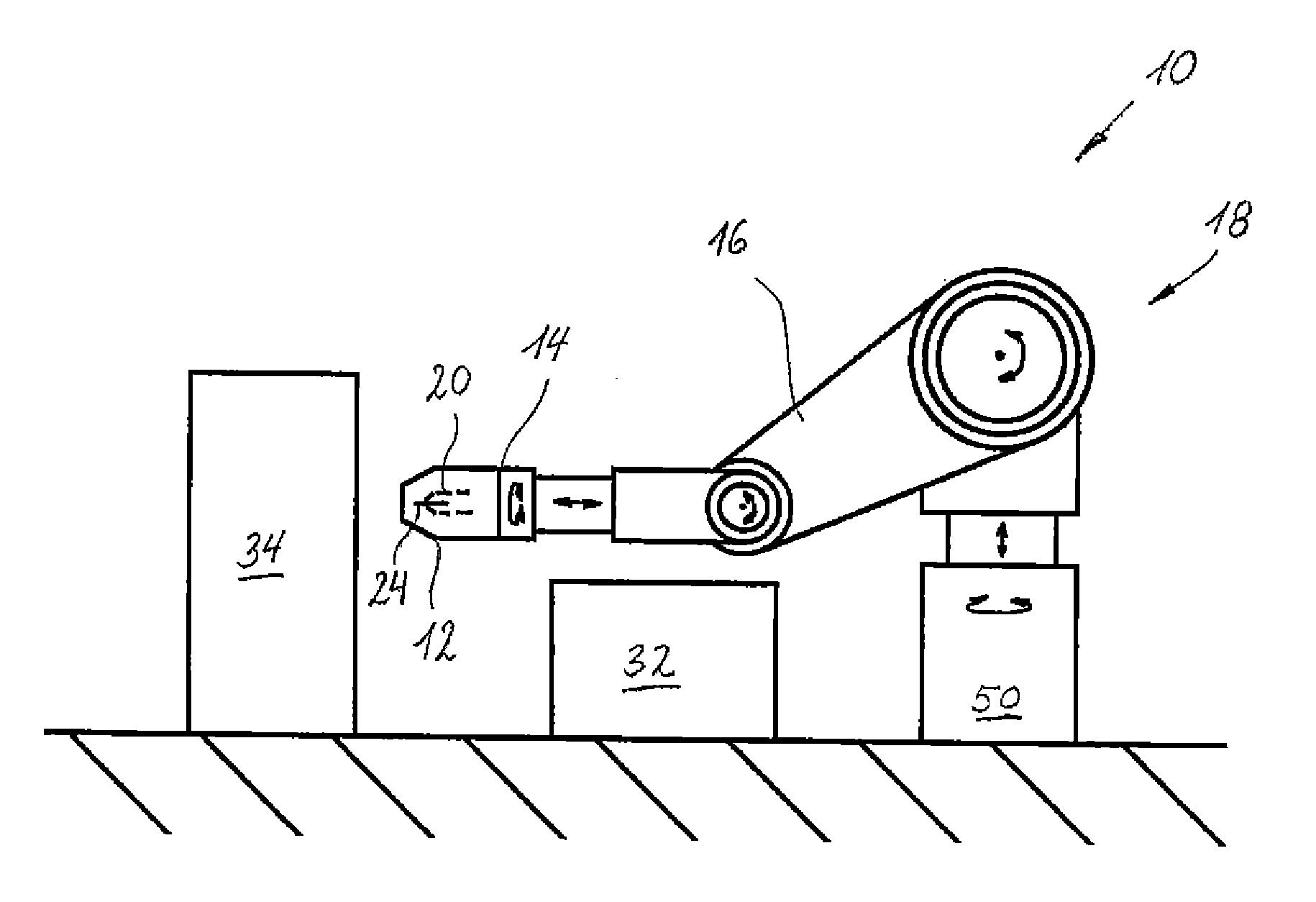

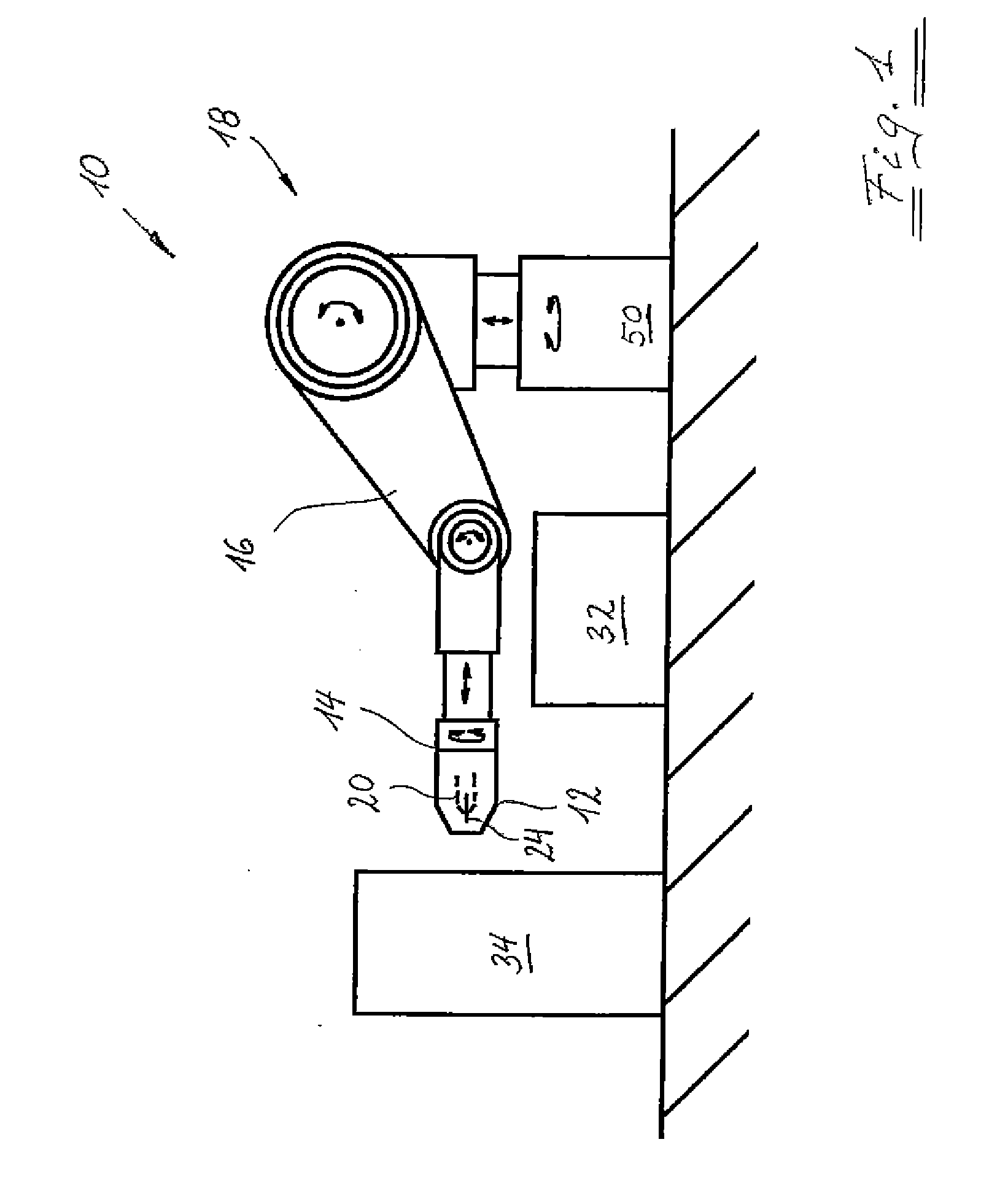

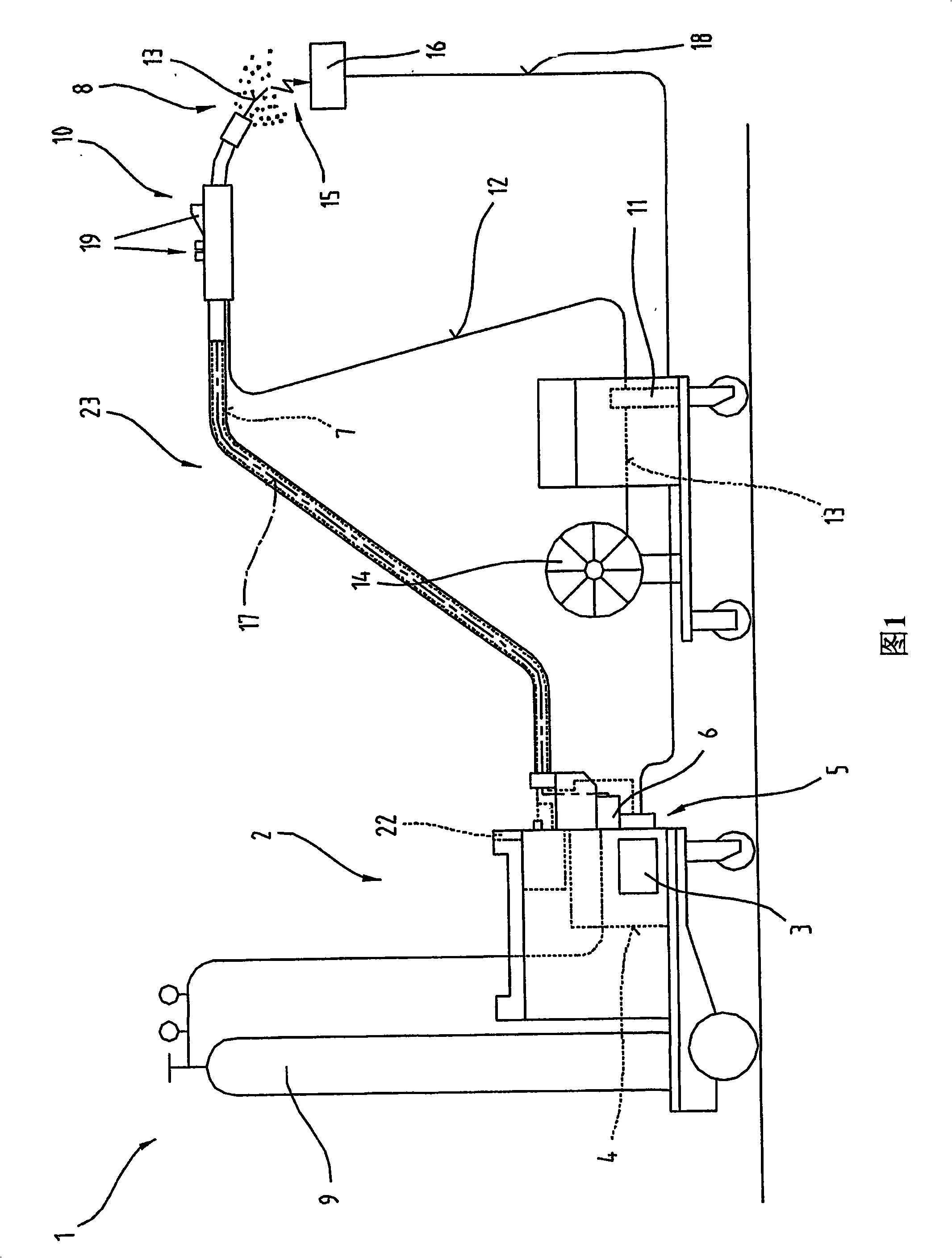

Implementation system for continuous welding, method, and products for the implementation of the system and/or method

InactiveUS6369357B1Increase the length of timeExtension of timeShielding gas supply/evacuation devicesWeld torches cleaningEngineeringElectromagnetic field

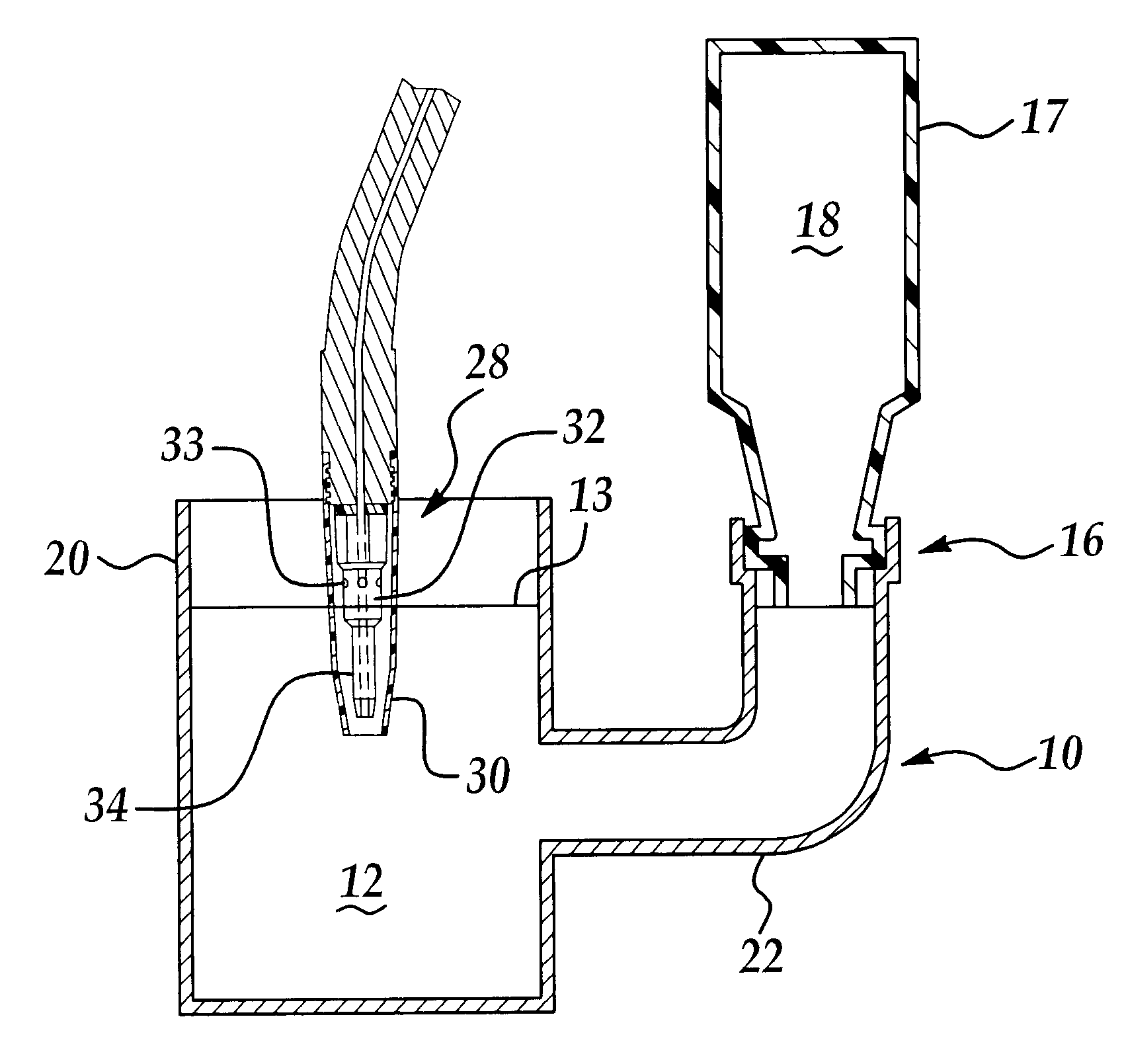

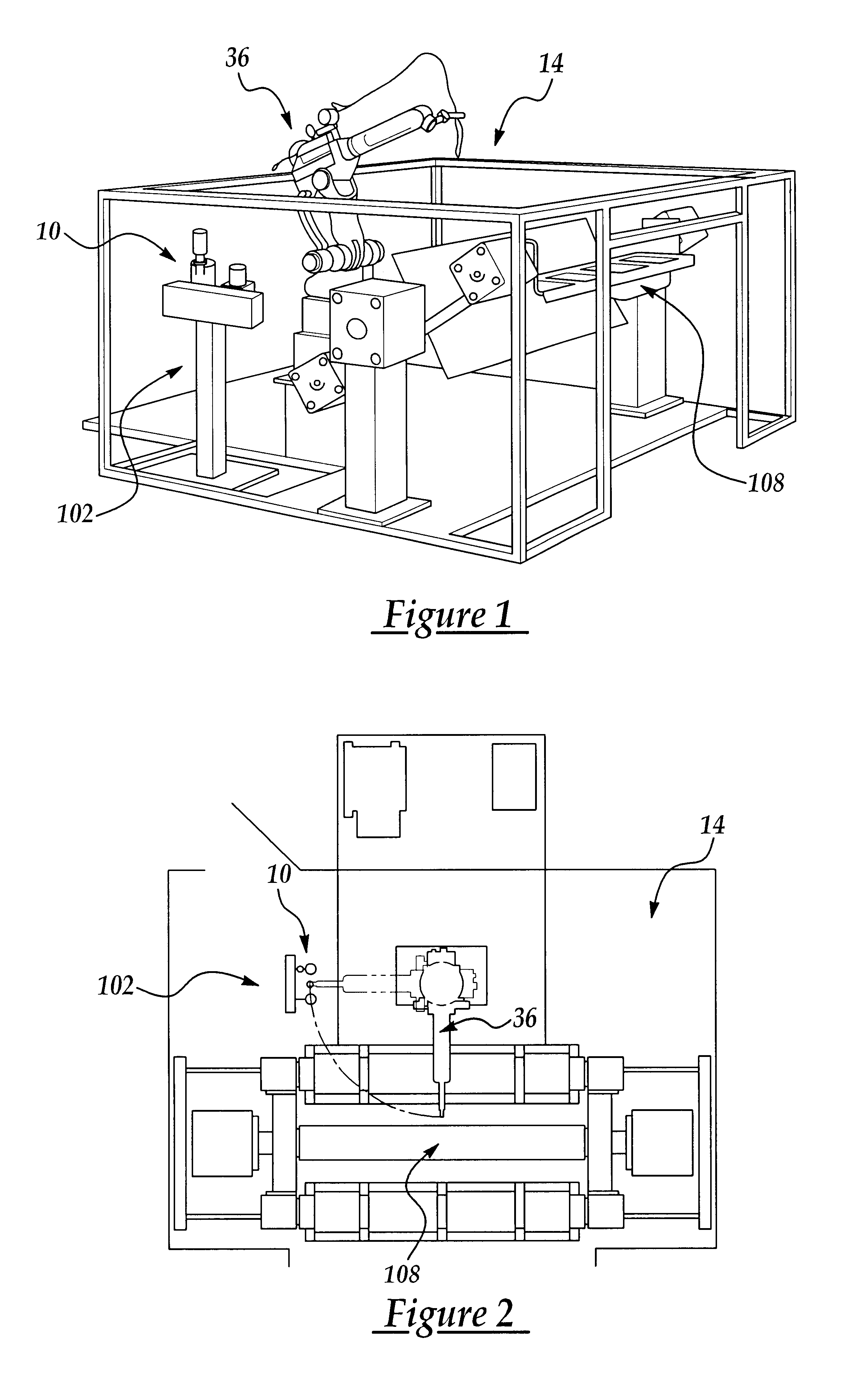

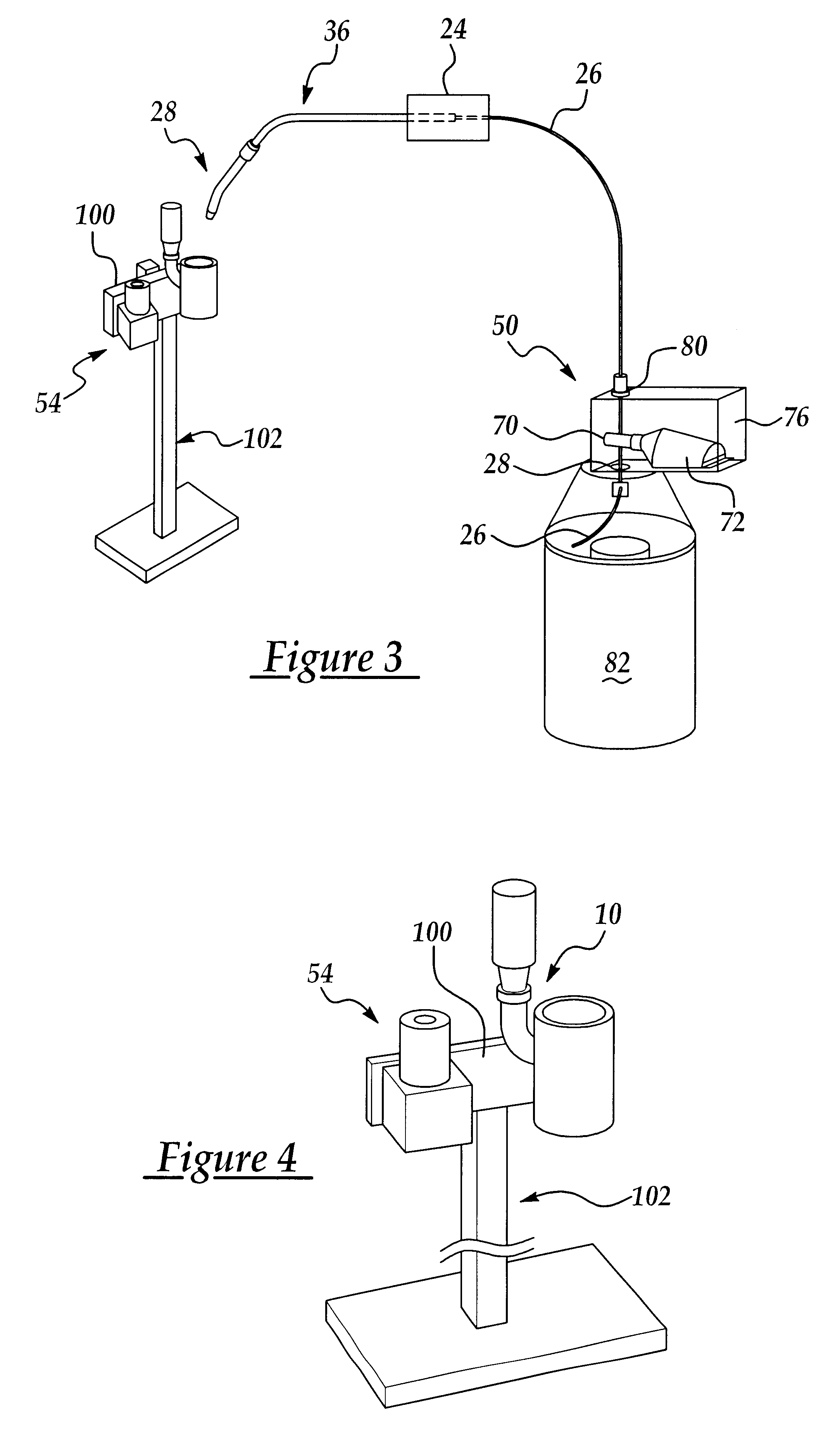

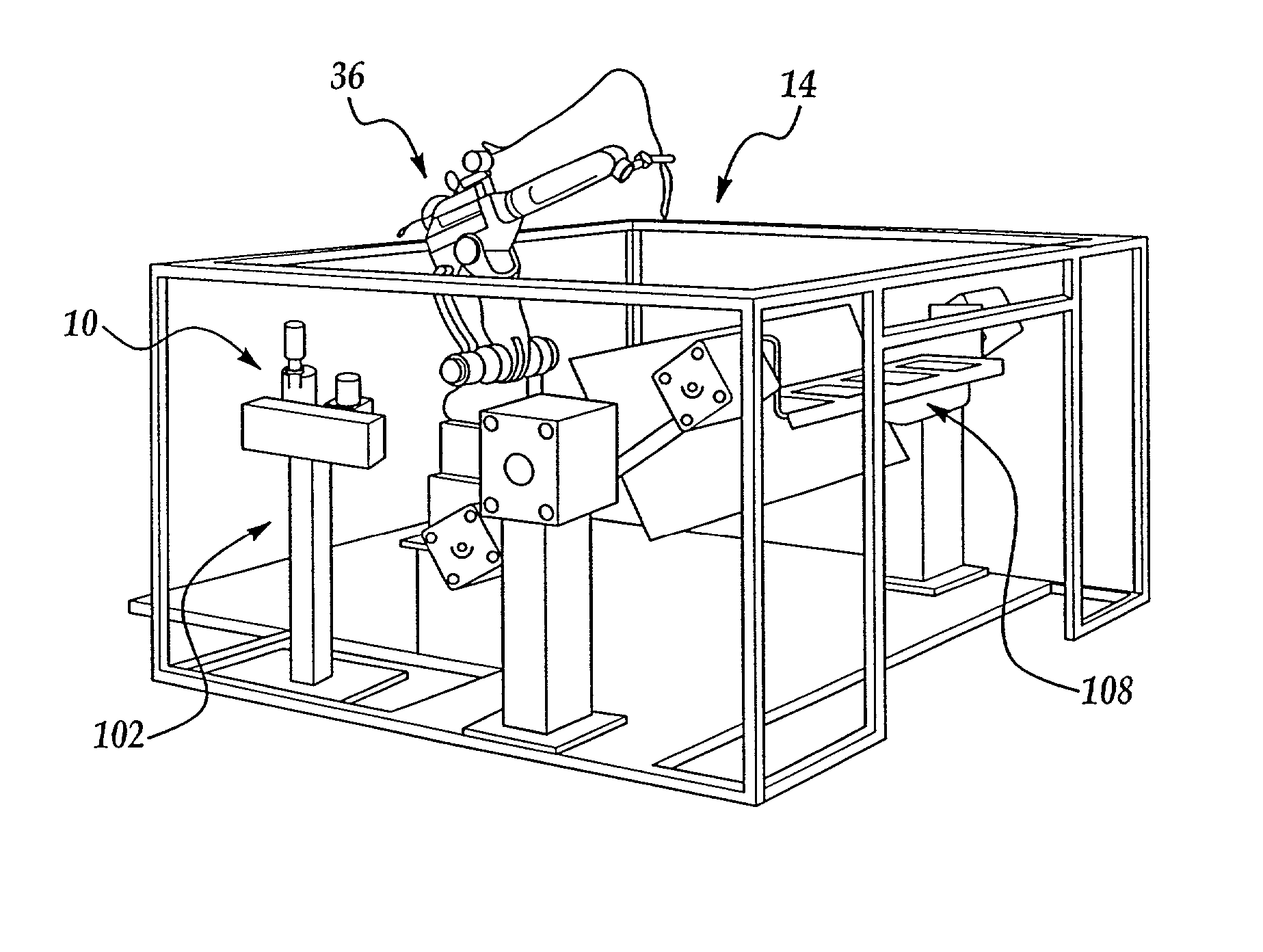

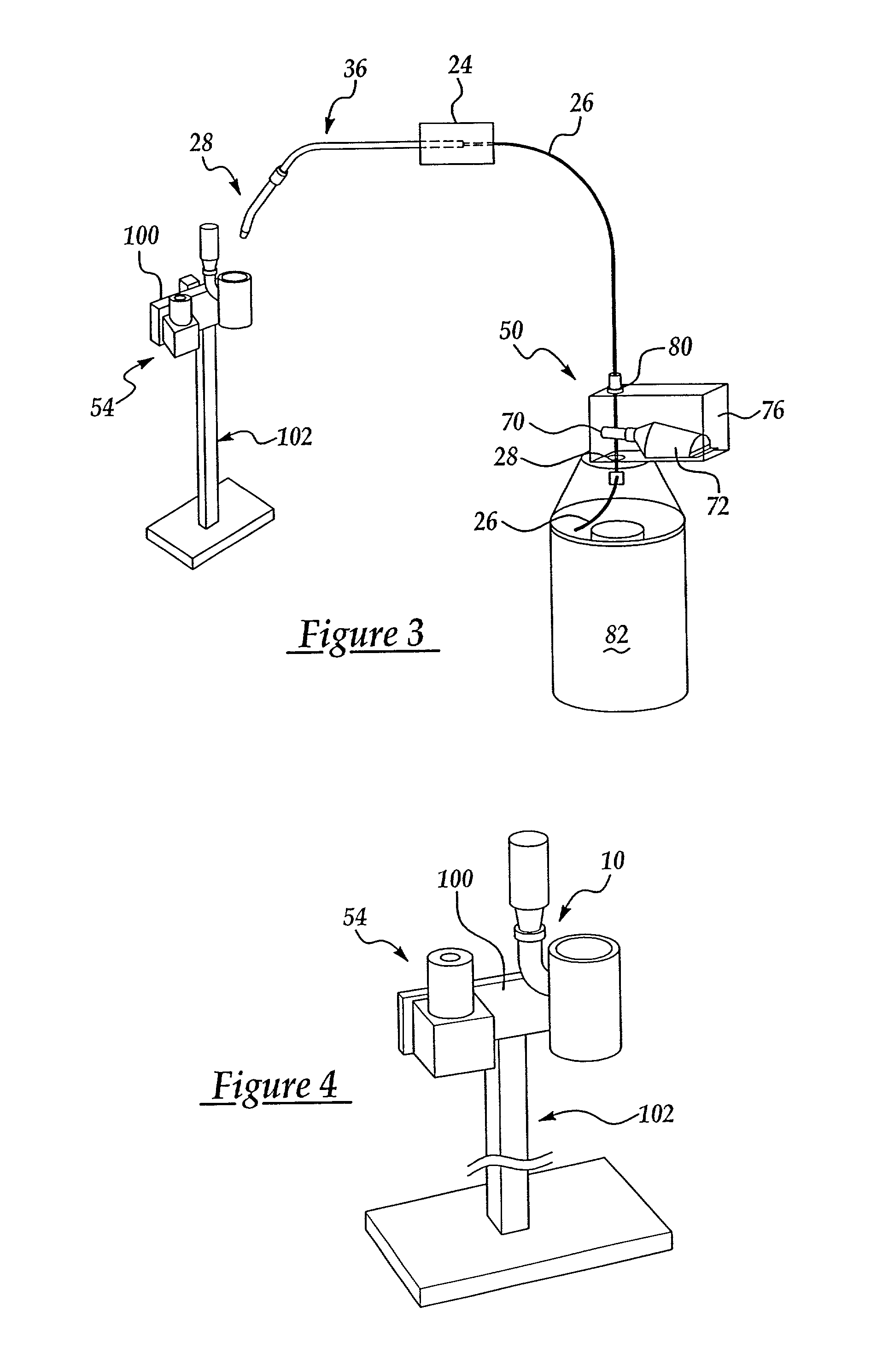

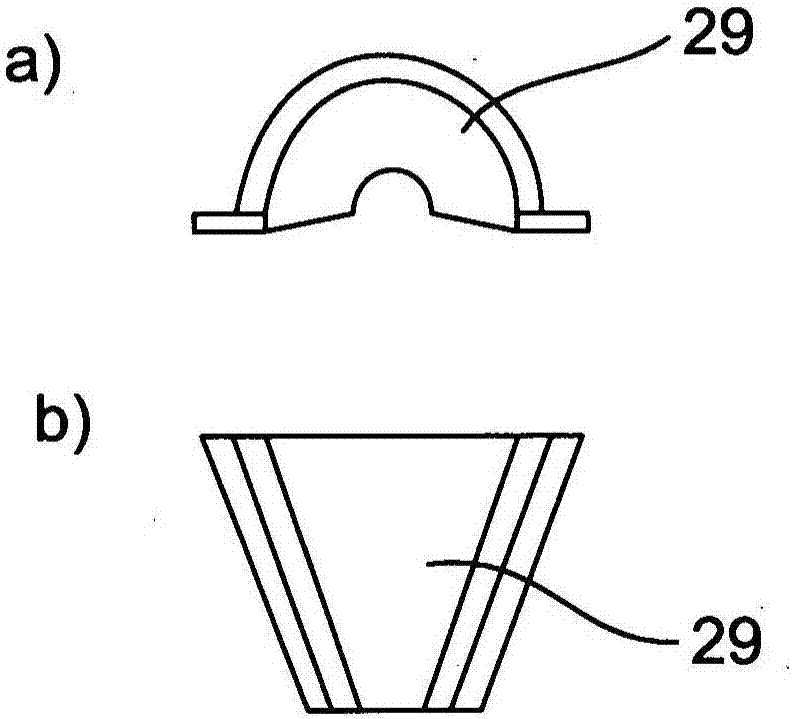

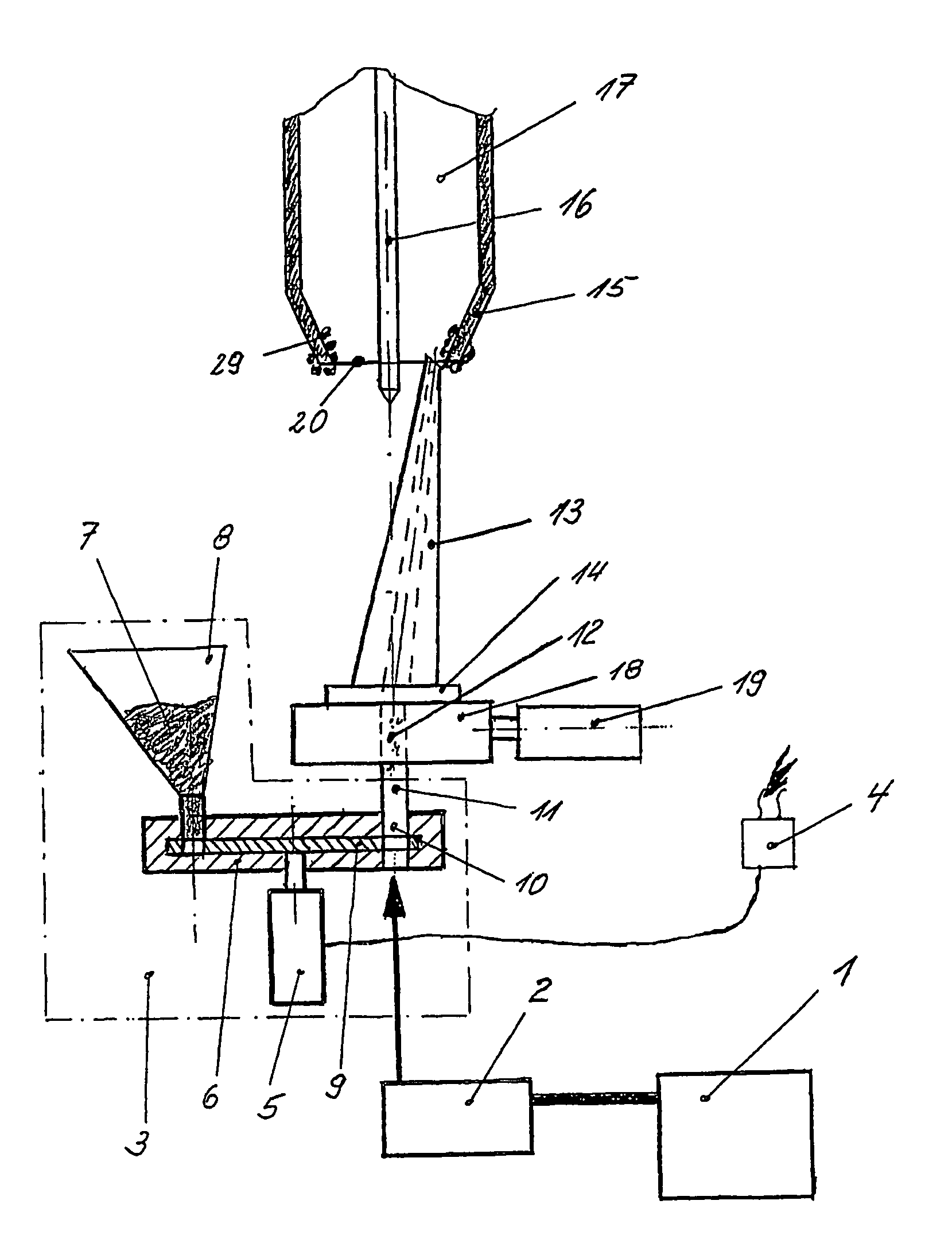

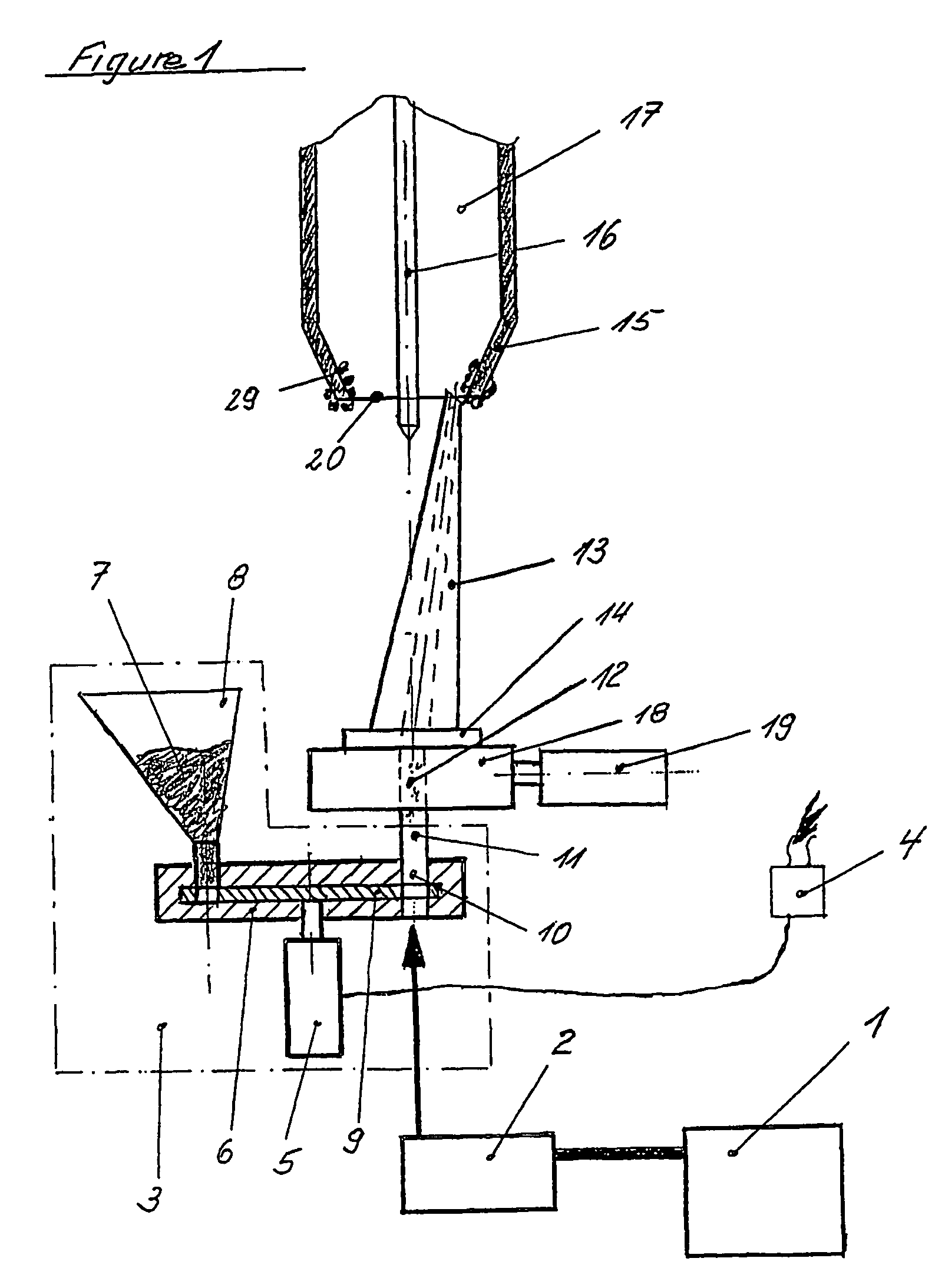

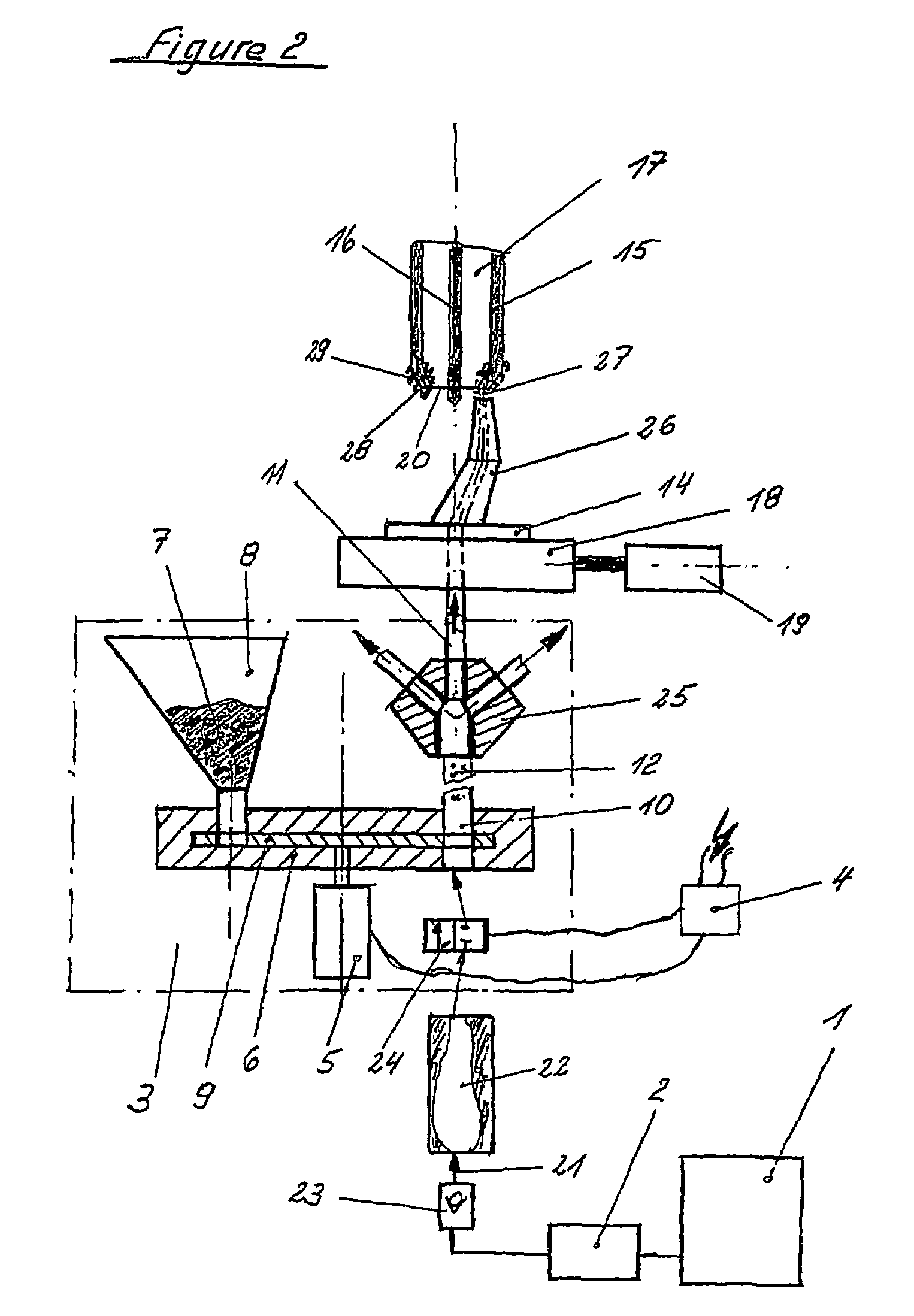

Various methods, systems and products are disclosed for providing an improved welding system which substantially improves the continuous operation of an automated welding system by increasing the amount of time between maintenance shutdowns. One of the disclosed method steps or system elements provides for dipping a welding nozzle [28 or 28a] and a portion of its related diffuser into a bath [12 or 12a] of fluid each time the automated welding system moves through a welding cycle. A product is also disclosed to best accomplish that step or element. Another method step or system element may include the removal of spatter accumulation via an electromagnetic field that magnetically pulls the spatter without direct contact with the nozzle or diffuser. A further disclosed method step or system element may include lubrication of the continuous electrode used for welding, and may also include a step or element prior to lubrication that involves cleaning the continuous electrode prior to adding lubricant. The steps or elements may vary as to whether or not they are included, or in what sequence. In each combination of method steps or system elements disclosed, however, a significant increase in time of continuous operation between maintenance shutdowns has occurred. A product is also disclosed that will hold various products as needed for the implementation of each disclosed system or method.

Owner:WELD AID PRODS

Implementation system for continuous welding, method, and products for the implementation of the system and/or method

InactiveUS20020079300A1Increase the length of timeExtension of timeShielding gas supply/evacuation devicesWeld torches cleaningEngineeringElectromagnetic field

Various methods, systems and products are disclosed for providing an improved welding system which substantially improves the continuous operation of an automated welding system by increasing the amount of time between maintenance shutdowns. One of the disclosed method steps or system elements provides for dipping a welding nozzle [28 or 28a] and a portion of its related diffuser into a bath [12 or 12a] of fluid each time the automated welding system moves through a welding cycle. A product is also disclosed to best accomplish that step or element. Another method step or system element may include the removal of spatter accumulation via an electromagnetic field that magnetically pulls the spatter without direct contact with the nozzle or diffuser. A further disclosed method step or system element may include lubrication of the continuous electrode used for welding, and may also include a step or element prior to lubrication that involves cleaning the continuous electrode prior to adding lubricant. The steps or elements may vary as to whether or not they are included, or in what sequence. In each combination of method steps or system elements disclosed, however, a significant increase in time of continuous operation between maintenance shutdowns has occurred. A product is also disclosed that will hold various products as needed for the implementation of each disclosed system or method.

Owner:WELD AID PRODS

Method, apparatus and use of a water-based dispersion for automated servicing of a welding torch head

InactiveUS20110204031A1Enhance automated servicingGood reproducibilityWeld torches cleaningHollow article cleaningWater basedBoron nitride

The invention relates to a method and an apparatus for automated servicing of a torch head comprising at least one contact tip and a nozzle surrounding the at least one contact tip. In a first servicing device the torch head is contact-freely cleaned in an assembled state of said at least one contact tip and said nozzle. A second servicing device is used for applying a torch head treatment agent to at least a portion of the surfaces of said at least one contact tip and said nozzle. The operation of the first servicing device and the second servicing device, respectively, is started by a control unit after the torch head has been transferred to a corresponding servicing position. The torch head treatment agent may include between about 5 and about 50 percent-by-weight of boron nitride as a torch head treatment agent for servicing of a welding torch head.

Owner:KOK DOUWE MARTEN +2

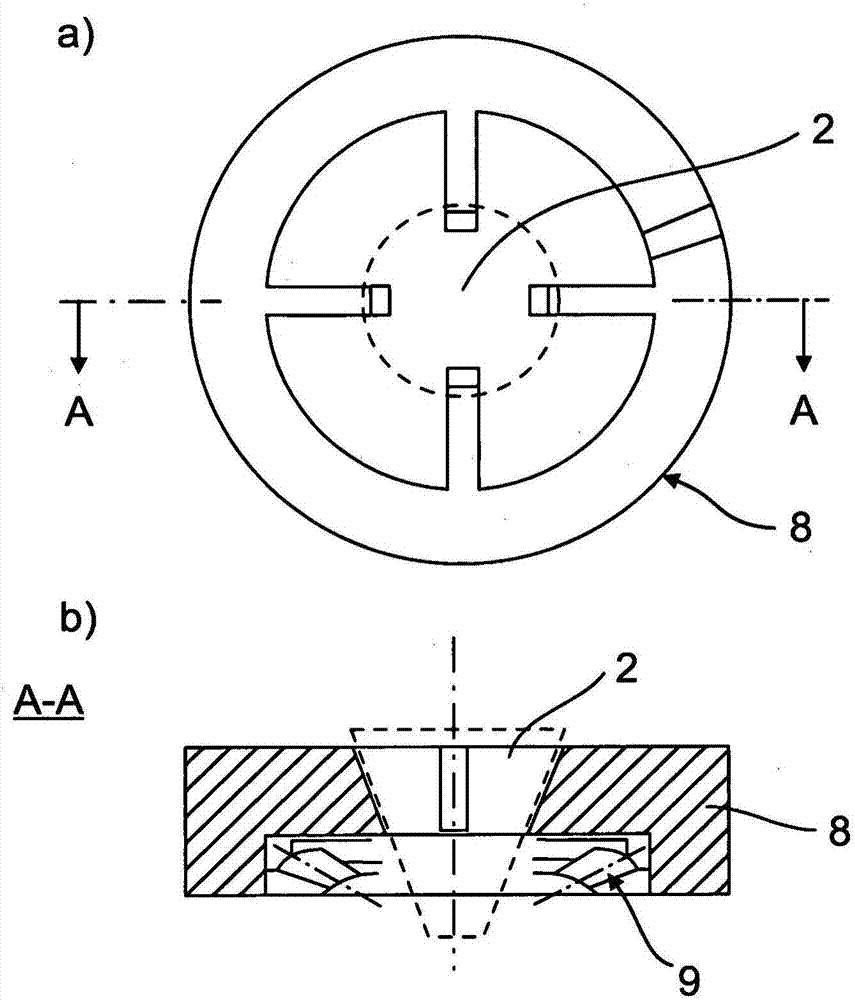

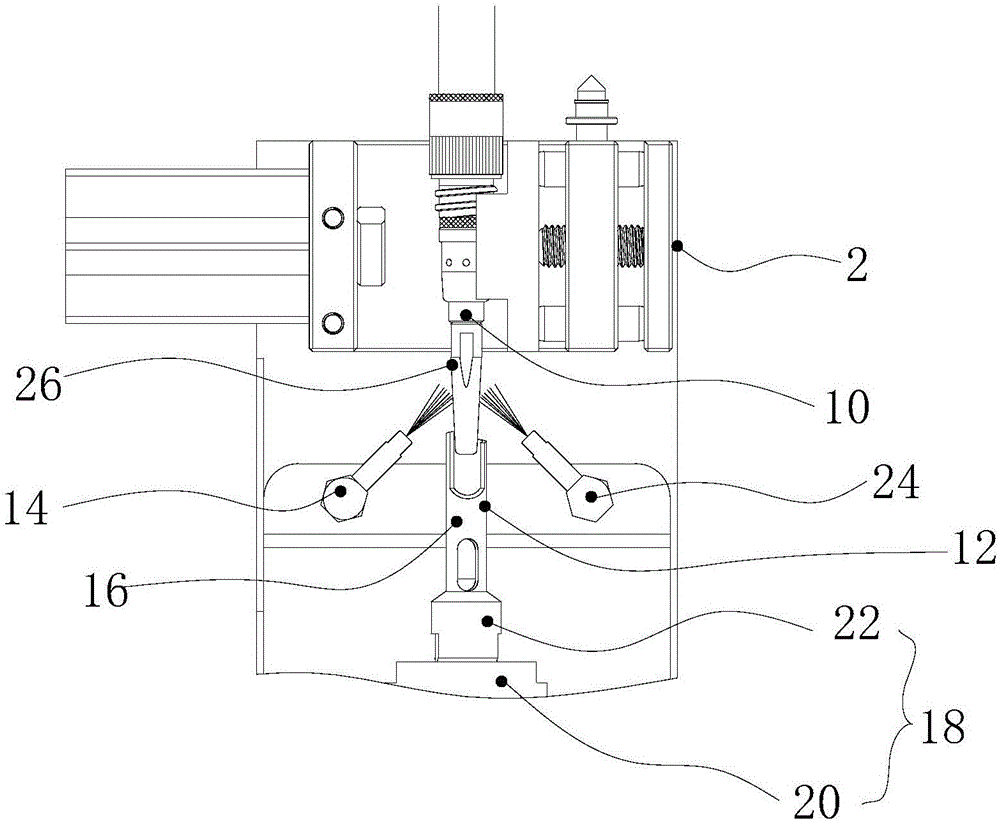

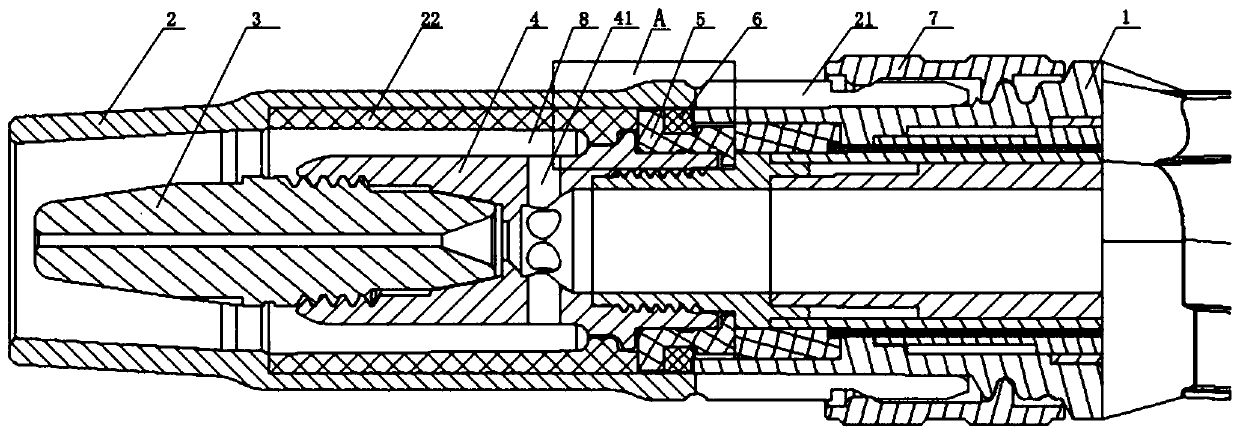

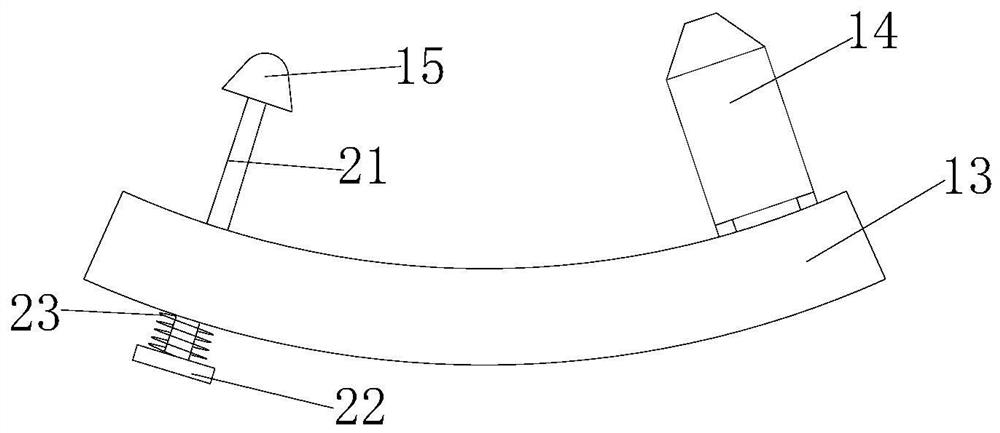

Cleaning device for mechanically cleaning gas nozzle of gas-shielded welding torch

The invention relates to a cleaning device for mechanically cleaning a gas nozzle of a gas-shielded welding torch, comprising a cleaning head (1), which is rotationally driven in a controlled manner and has at least one cleaning element that rotates therewith, and comprising a feeding and centering apparatus for positioning the gas nozzle (2) coaxially with respect to the axis of rotation (21) of the cleaning head (1) in the region of the at least one cleaning element. According to the invention, the cleaning element consists of a pair of cleaning scissors (18) having two cleaning arms (19, 20), which are suspended in the cleaning head (1) on a pivot bearing (22) arranged transversely to the axis of rotation (21) in the form of a pair of scissors, in such a way that the cleaning arms can swing freely. A centrifugal-force weight (23, 24) is arranged on each of the cleaning arms (19, 20) at the lower end region facing away from the gas nozzle such that the pair of cleaning scissors (18) is spread open when the cleaning head rotates. Each of the cleaning arms (19, 20) has a scraper structure (27, 28) at the upper end region facing the gas nozzle, which scraper structures are inserted into the gas nozzle (2) in the folded-together state of the pair of cleaning scissors without rotation of the cleaning head and are pressed against the gas-nozzle inner surface (13) of the gas nozzle (2) in a sliding and scraping manner when the pair of cleaning scissors (18) is spread open by a subsequent rotation of the cleaning head, the gas nozzle being held non-rotatably.

Owner:AUDI AG

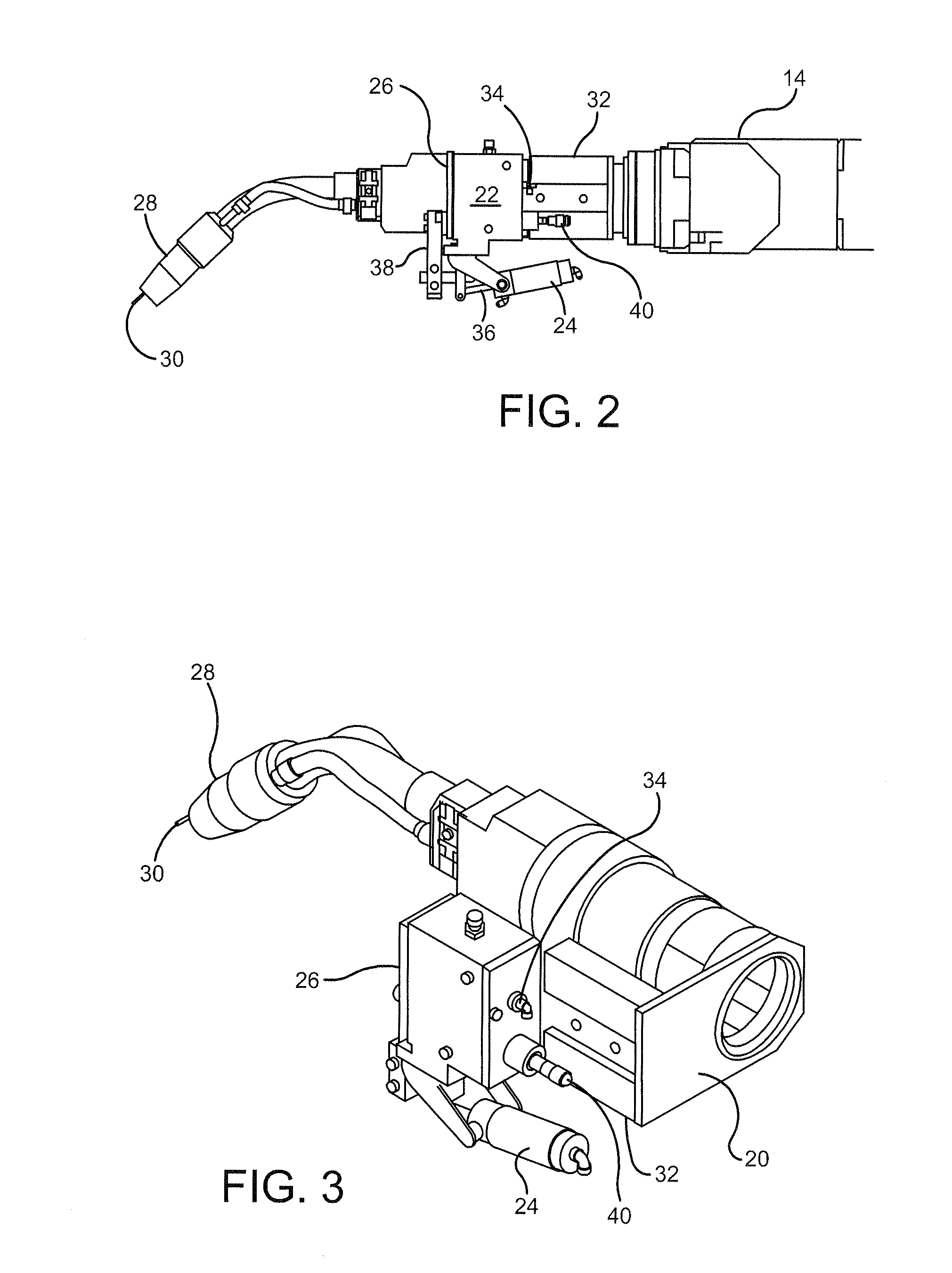

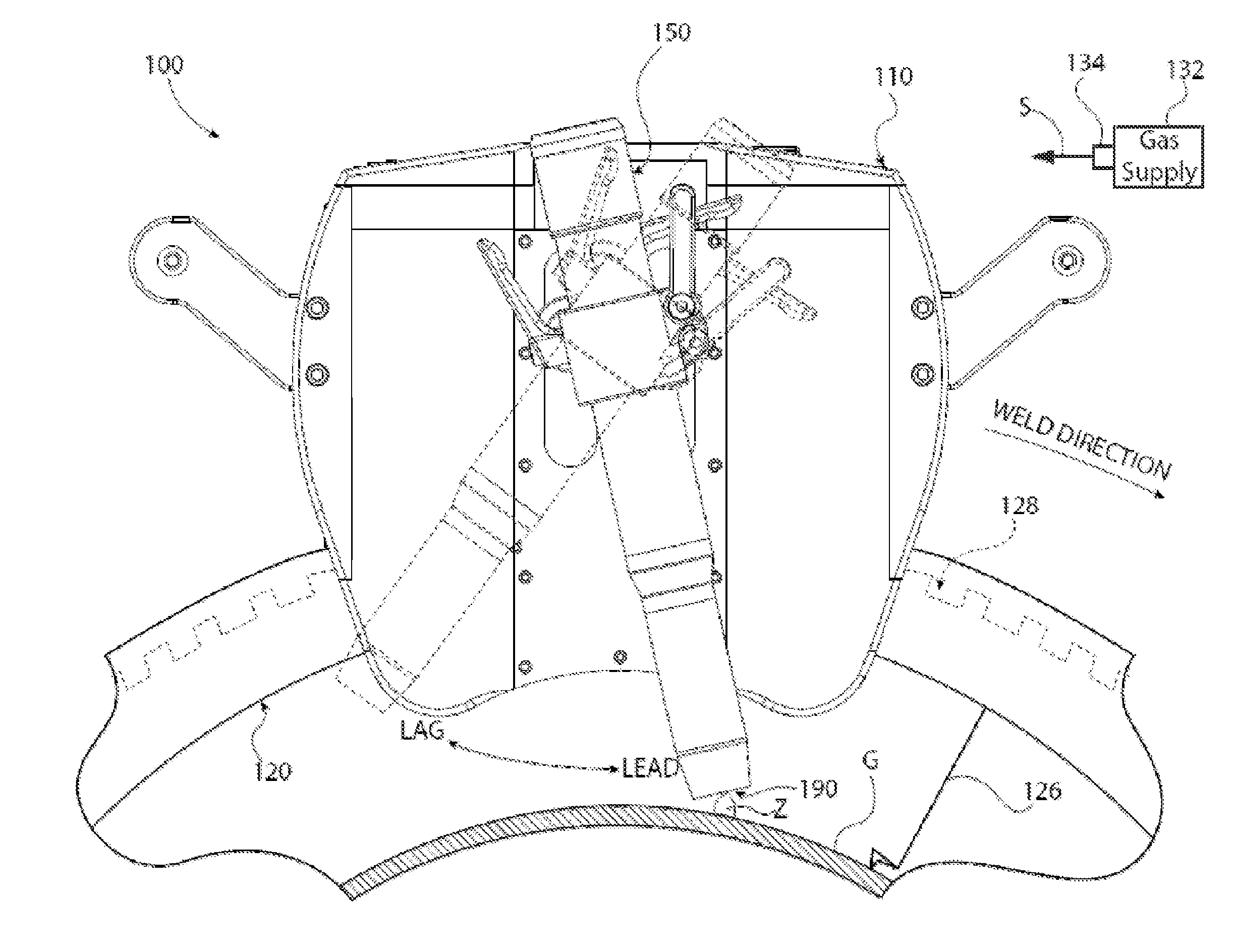

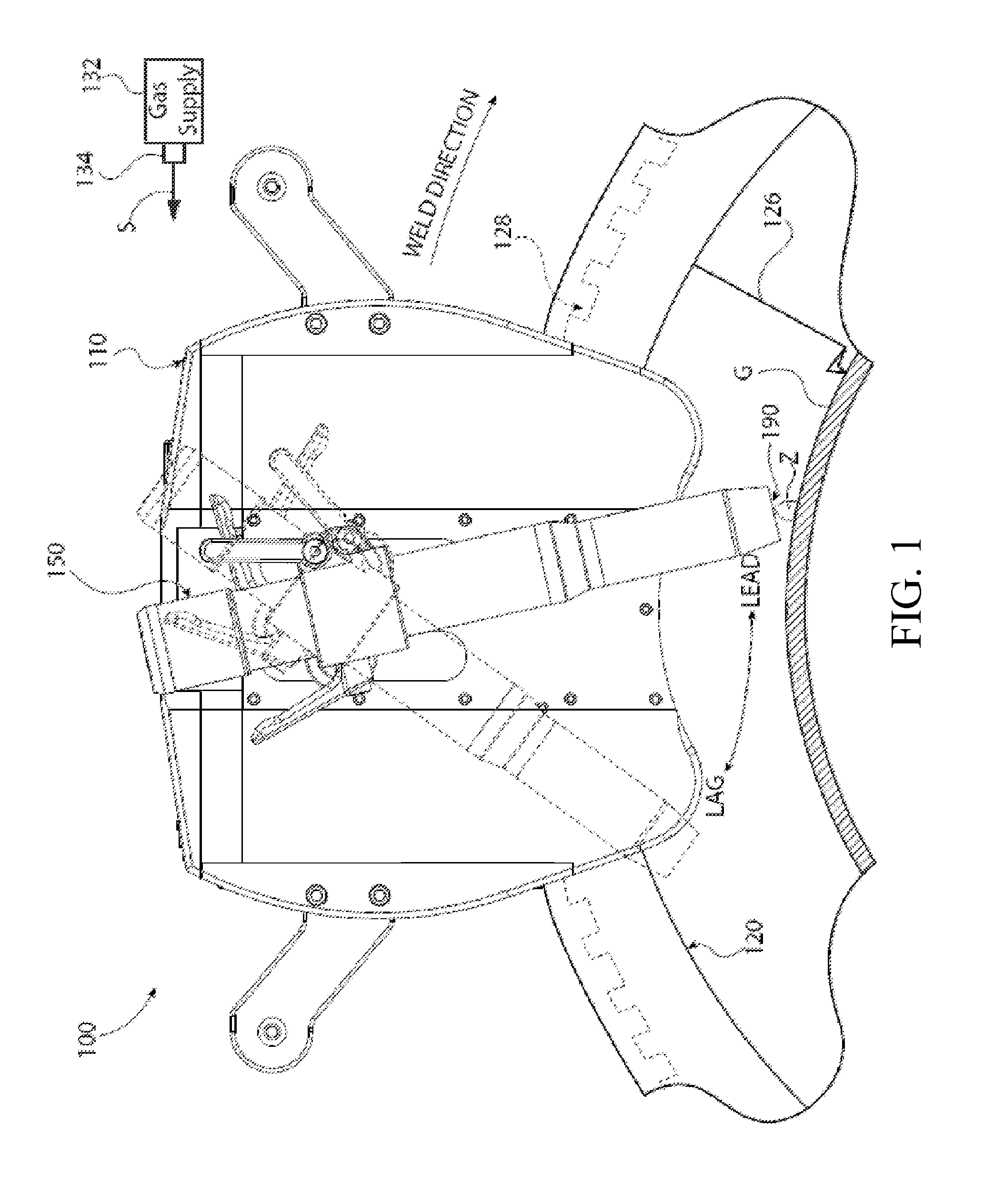

Orbital welding torch systems and methods with lead/lag angle stop

The invention described herein generally pertains to systems and methods related to repeatable and accurate setting of welding torch lead and lag positions, particularly with orbital welding systems. Specifically, a torch is coupled with a lead-lag coupler having a stop lug. A stop set with a stop pin is rotated to a desired position of lead or lag and secured. The lead-lag coupler, and torch which rotates therewith, are then unsecured and rotated until the stop lug contacts the stop pin. In this position, the torch is maintained at the desired angle. The stop pin remains in place throughout operation(s) to permit quick, accurate return to the desired angle if the torch is temporarily moved out of position.

Owner:LINCOLN GLOBAL INC

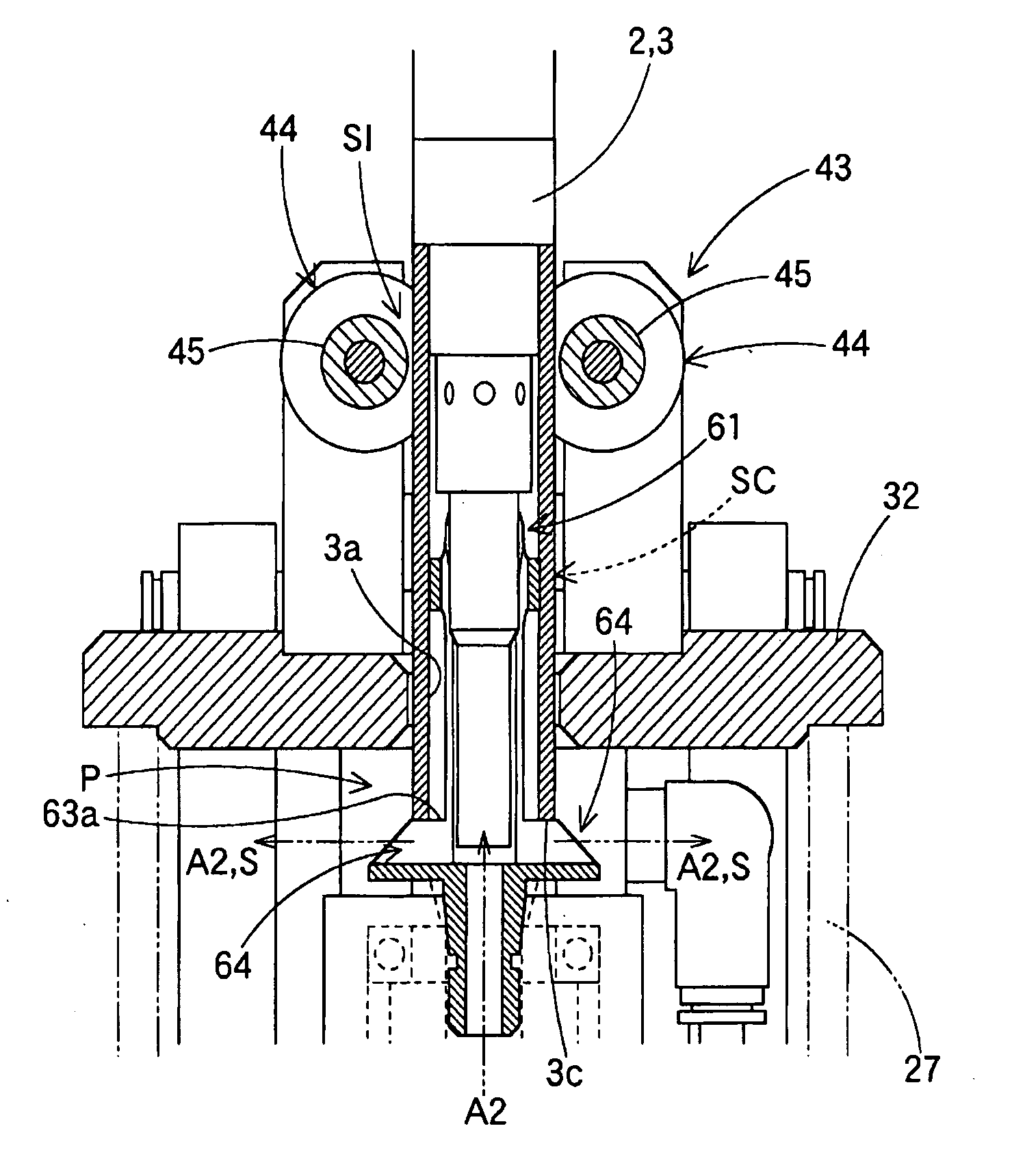

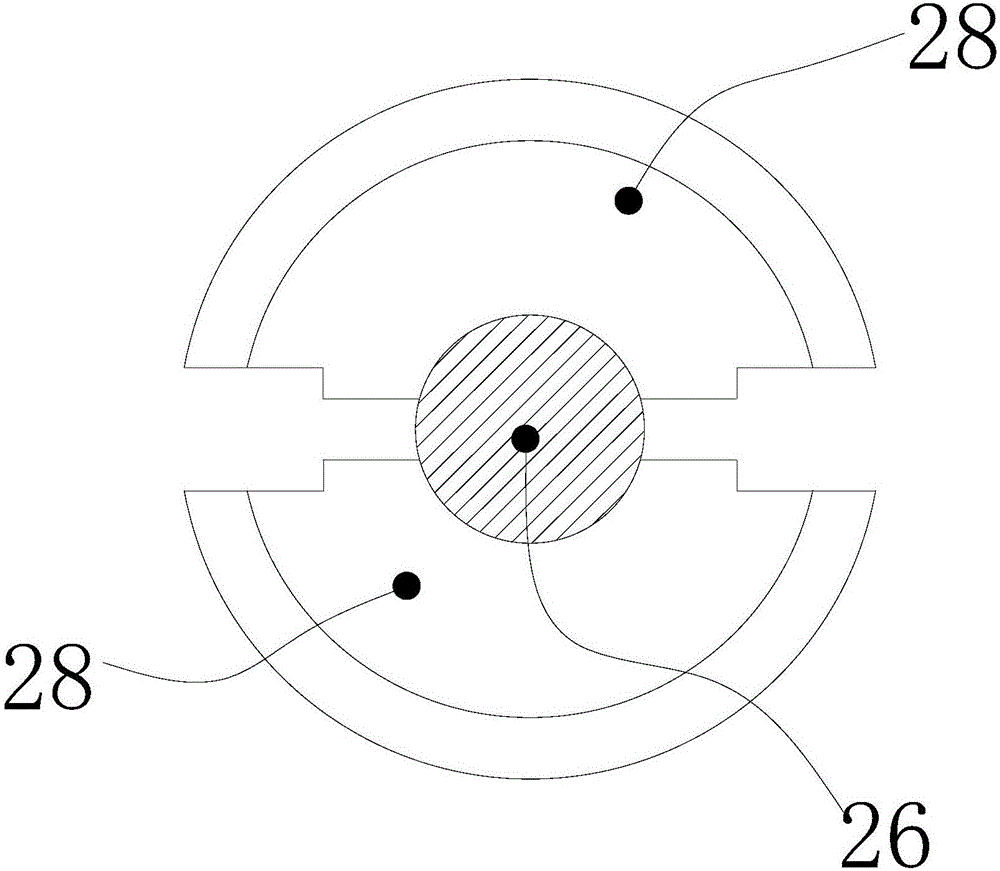

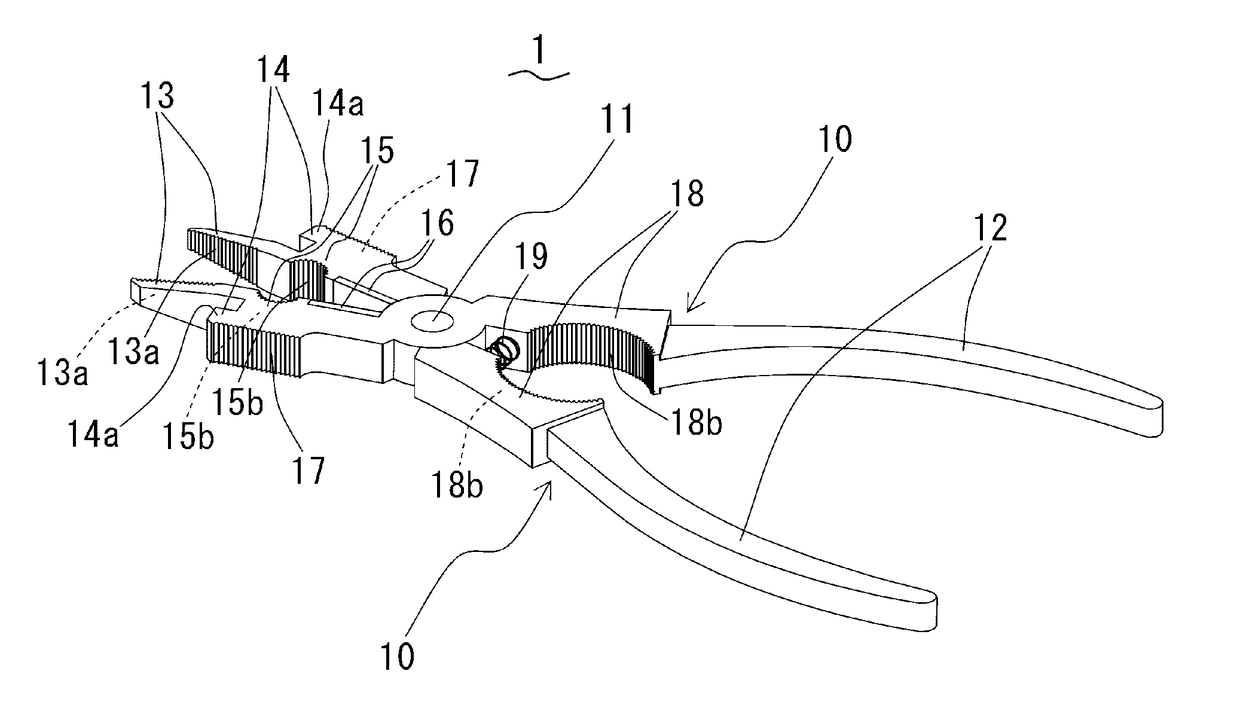

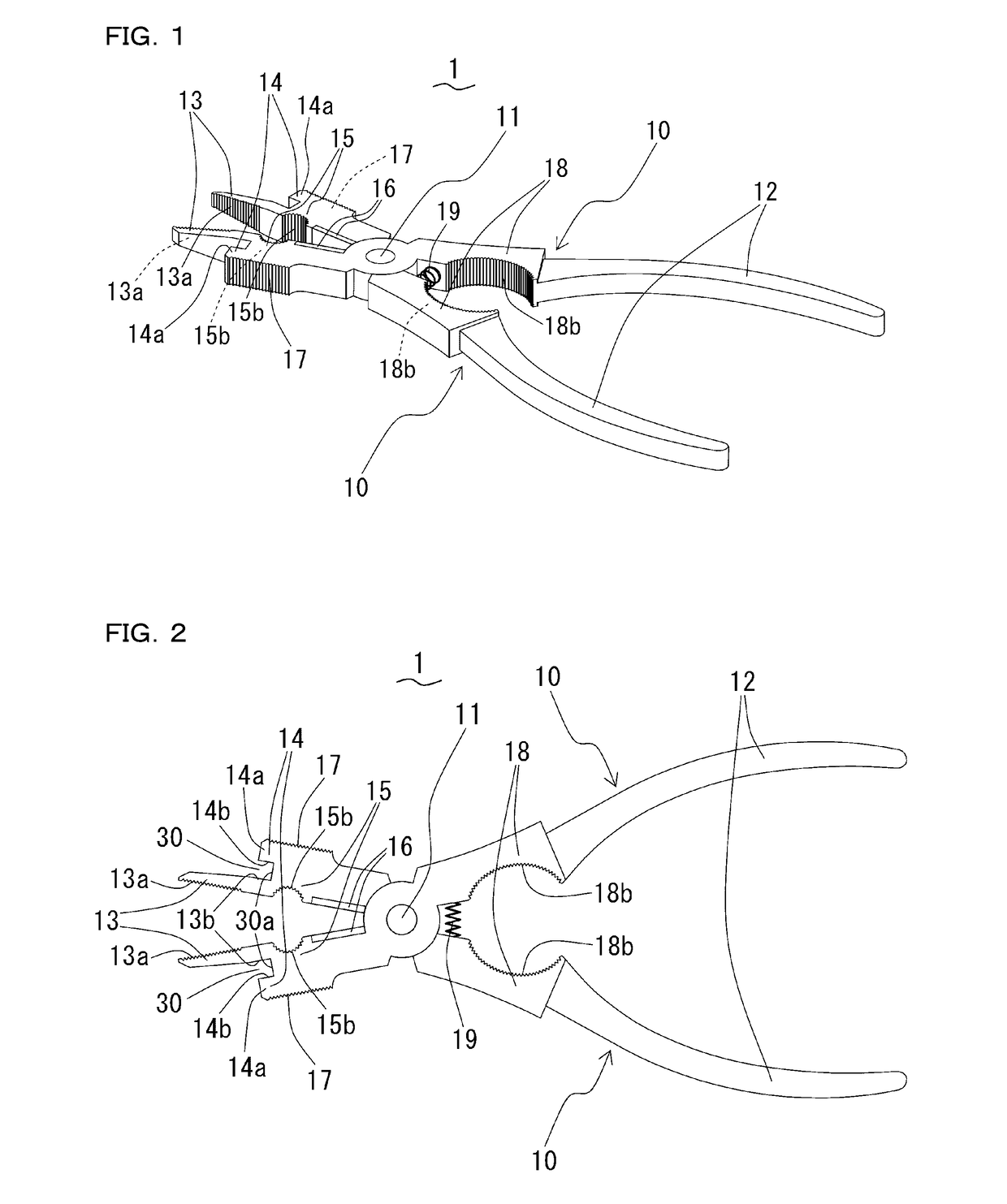

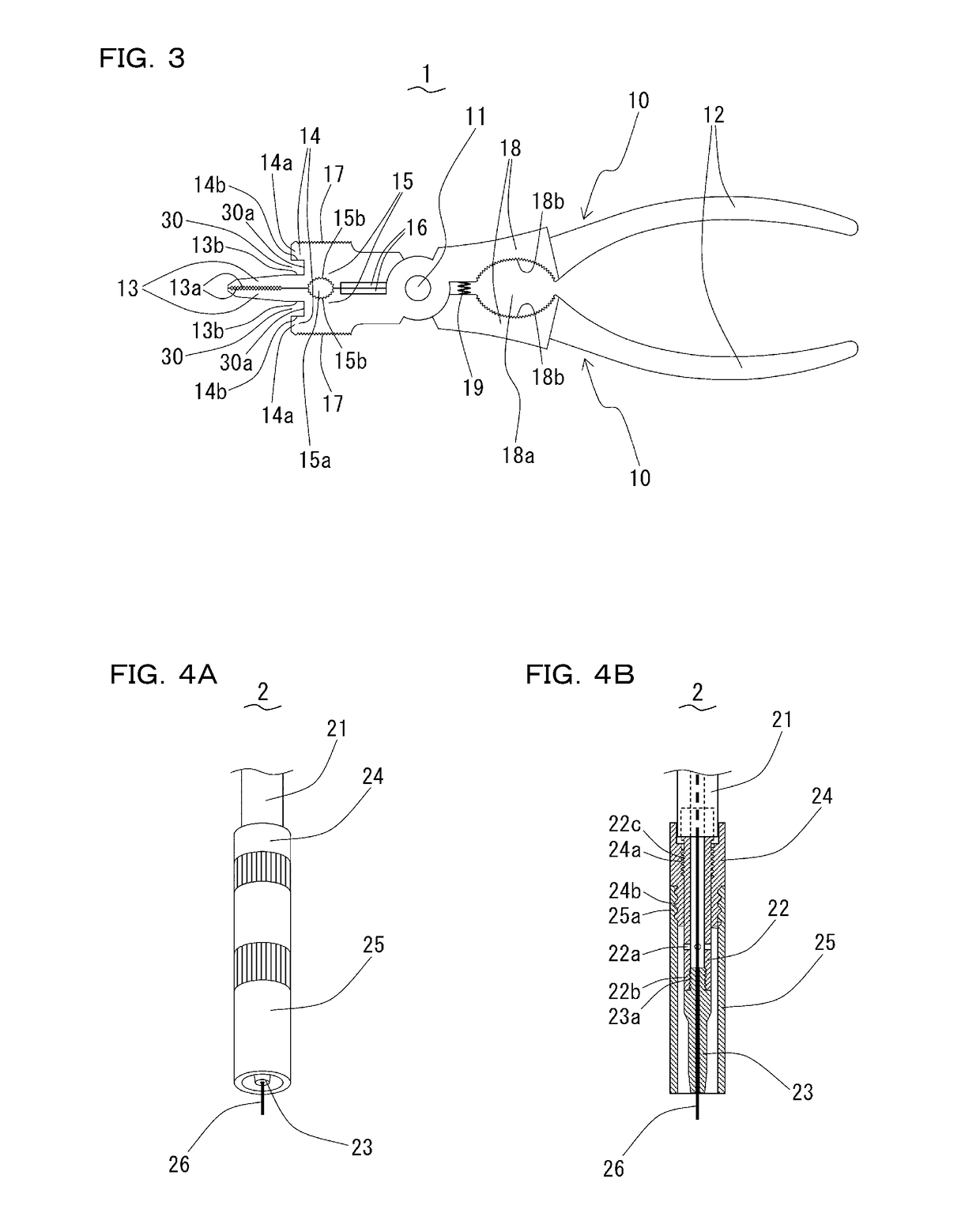

Nozzle cleaner

ActiveUS20090249567A1Smoothly inserted into weldingAvoid shakingArc welding apparatusCleaning machinesEngineeringNozzle

A nozzle cleaner having a configuration for centering a cutter thereof with respect to a welding nozzle. The nozzle cleaner peels off sputter from an inner peripheral surface of a welding nozzle by inserting the cutter toward the inner peripheral surface of the welding nozzle, and then rotating the cutter. The nozzle cleaner includes a guide mechanism to center the welding nozzle with respect to the cutter. The guide mechanism includes an insertion-side roller unit and a cutter-side roller unit, each having a pair of guide rollers having a smaller diameter portion and a pair of enlarged diameter portions. The enlarged diameter portions guide the welding nozzle to the vicinity of the central position of the corresponding smaller diameter portion. The facing guide rollers of the cutter-side roller unit and of the insertion-side roller unit are arranged in arrangement directions orthogonal to each other, respectively.

Owner:KYOKUTOH

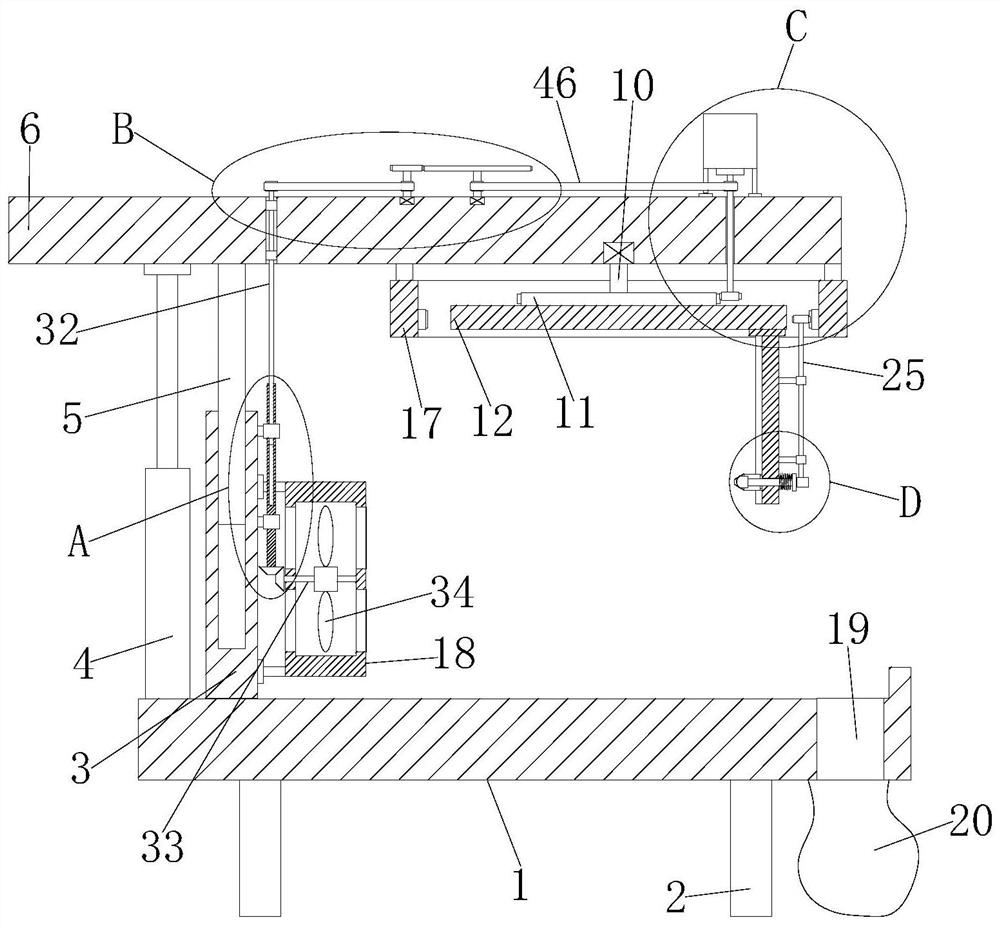

Welding gun cleaning device

InactiveCN106670632AEasy to remove slagEasy to sprayWeld torches cleaningWelding/cutting auxillary devicesSlagEngineering

The invention discloses a welding gun cleaning device which comprises a rack. A wire shearing device, a gun cleaning device and a control device are arranged on the rack. The wire shearing device, a fixing mechanism, a slag removal mechanism and an oil spraying mechanism are arranged on the welding gun cleaning device; the wire shearing device is used for cutting off unnecessary welding wires in a welding gun; the fixing mechanism is used for fixedly clamping the welding gun so as to facilitate slag removal and oil spraying subsequently; and the working process of the slag removal mechanism and the oil spraying mechanism is controlled by the control device, and it is guaranteed that anti-blocking liquid is sprayed on the welding gun through an oil injection nozzle after the welding gun is subject to deslagging.

Owner:昆山日皓焊切器材有限公司

Elevated welding-type cable support system

ActiveUS8536488B2Easy to storeWeld torches cleaningWelding/cutting auxillary devicesSupporting systemEngineering

A cable management system for a welding-type system includes a support column extending in a first direction from a first end supported by a welding-type device to a second end arranged above the welding-type device. The cable management system also includes a cable support arranged on the second end of the support column that extends in a second direction substantially transverse to the first direction. Accordingly, a portion of the cable support extends away from the welding-type device to allow a cable supported thereon to extend below the cable support and proximate to the welding-type device.

Owner:ILLINOIS TOOL WORKS INC

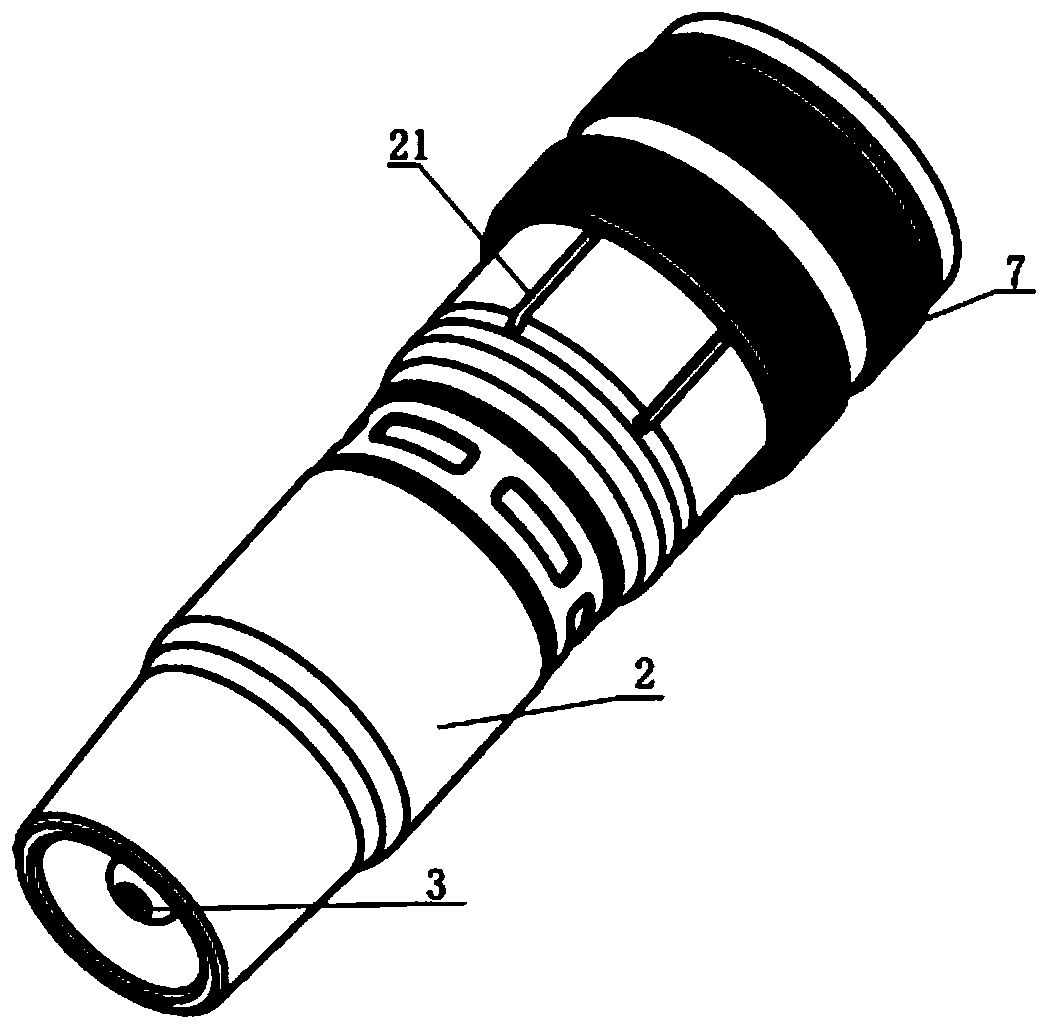

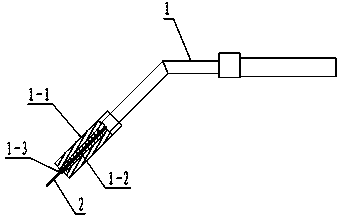

Fusion electrode gas protection welding gun

PendingCN109865922AReduce consumption costEasy to removeWeld torches cleaningElectrode holder supportersSlagSpray nozzle

The invention discloses a fusion electrode gas protection welding gun, and belongs to the technical field of welding. The welding gun structurally comprises a gun body front end, a current contact nozzle, a current contact nozzle base and a nozzle; the current contact nozzle is arranged on the front end of a gun body through the current contact nozzle base, nozzle is arranged on the current contact nozzle and the current contact nozzle base in a sleeving manner, and is connected with the gun body front end, and the welding gun is characterized in that a nozzle lining casing pipe is arranged onthe inner side of the nozzle, and the nozzle lining casing pipe and the outer contour of the current contact nozzle base form a welding slag isolation cavity. Compared with the prior art, the fusionelectrode gas protection welding gun has the advantages that welding slag is easy to clear, welding gas cannot be polluted by air, and the gun has the good popularization and application value.

Owner:济南尼克焊接技术有限公司

Welding equipment facilitating welding angle adjustment

InactiveCN112008210AAchieve weldingEasy to adjustWeld torches cleaningElectrode supporting devicesSlag (welding)Rotational axis

The invention belongs to the field of welding equipment and particularly relates to welding equipment facilitating welding angle adjustment. The welding equipment comprises a base, supporting legs areconnected to the bottom of the base, the top of the base is connected with a side plate and an electric telescopic rod, a sliding groove is formed in the top of the side plate, a supporting sliding rod is slidably mounted in the sliding groove, a top plate is connected to the top end of the supporting sliding rod, the top end of the electric telescopic rod is fixedly connected with the bottom ofthe top plate, a motor is fixedly installed at the top of the top plate, a rotating hole is formed in the top plate, a first rotating shaft is welded to an output shaft of the motor, the bottom end ofthe first rotating shaft penetrates through the rotating hole to extend to the outer side of the bottom of the top plate and is fixedly connected with a first gear, and a first rotating shaft is rotationally installed at the bottom of the top plate. The welding equipment facilitates the welding angle adjustment and comprehensive welding of a machined part, welding slag can be removed in time after welding, the welding quality can be checked in time, the collection of the welding slag is facilitated, and the situation that the machining table board is accumulated with the welding slag and is not easy to clean is avoided.

Owner:江先庆

Hand tool for welding-torch maintenance

ActiveUS20170182583A1Sufficient working efficiencyExtra workPliersWeld torches cleaningEngineeringWelding torch

A hand tool for welding-torch maintenance, which can remove sputter adhering to a nozzle with sufficient working efficiency. The hand tool has a pair of metal stays turnably supported by a pivoting axis. The metal stays comprises grips handled by a user, 1st pinchings used for pulling a welding-wire, and 2nd pinchings used for removing sputter adhering to the nozzle. The 1st pinchings are configured so as to be inserted into the nozzle when the metal stays are closed. The 2nd pinchings have projections which are extended outside from the backs of the 1st pinchings and thrown out towards heads of the 1st pinchings. The sputter adhering to the inner-and-outer circumferential surfaces and end face of the nozzle are removed by inserting the 1st pinchings into the nozzle, inserting the end of the nozzle between the 2nd pinchings and the 1st pinchings, and moving the tool to scratch the sputter off the inner-and-outer circumferential surfaces and the end face of the nozzle.

Owner:SEVENTY EIGHT CO LTD

Method for cleaning of welding torches

InactiveUS20080115809A1Avoid disadvantagesMaximize the effectShielding gas supply/evacuation devicesWeld torches cleaningEngineeringTime duration

The invention relates to a method for removing adhered particles from the contact tip of a welding torch, wherein a short-time duration stream of cleaning gas with a high speed is directed to said contact tip.

Owner:LINDE AG

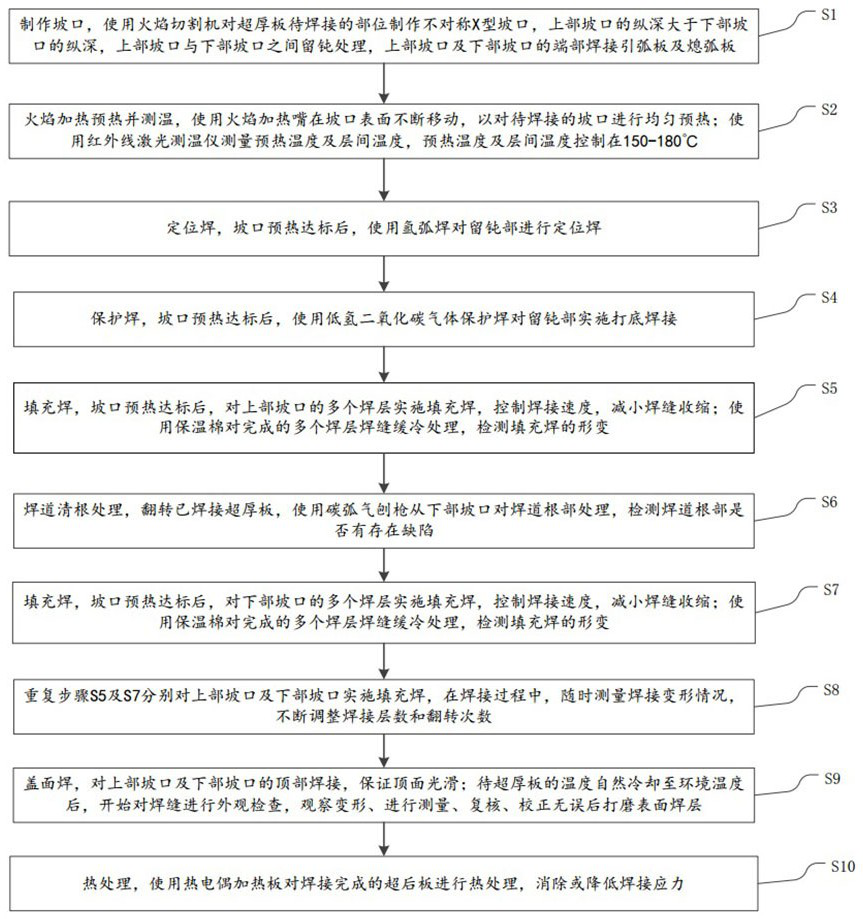

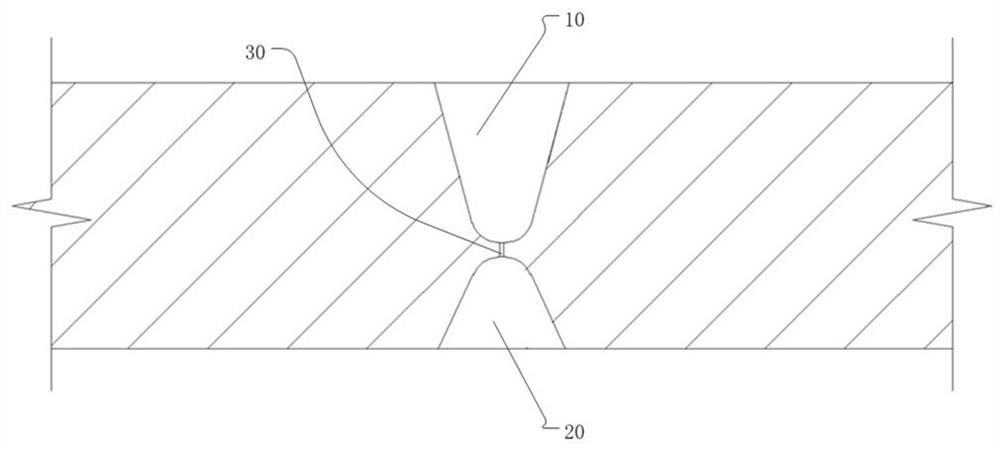

Welding construction method for super-thick plate

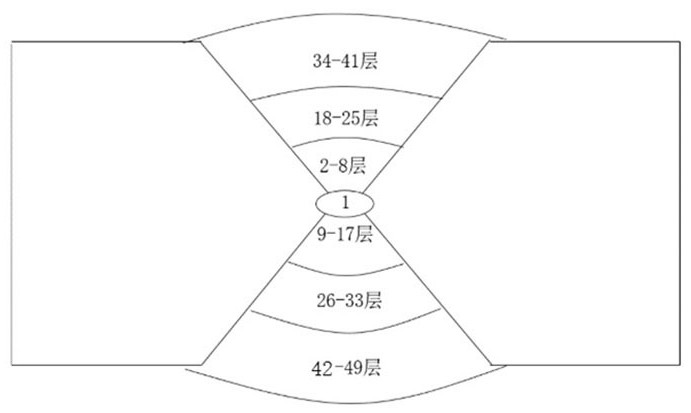

ActiveCN113319403AReasonable welding characteristicsExcellent welding characteristicsWeld torches cleaningClimate change adaptationThick plateWelding residual stress

The invention discloses a welding construction method for a super-thick plate. The method is reasonable in arrangement, an asymmetric X-shaped groove is adopted, low-hydrogen carbon dioxide gas shielded welding bottoming and submerged-arc welding filling capping are conducted, the multi-layer and multi-pass, narrow welding pass, thin welding layer and double-side symmetric filling welding is conducted, the welding characteristics of the super-thick plate is effectively improved, the defects such as weld pass root cracks and air holes are prevented from being generated, and the situation that the steel welding performance is stable is ensured. The cooling speed of a welding seam is reduced through flame heating and preheating, a hardening structure is prevented from being generated on a joint, and cracks are prevented from being generated. Heating treatment is conducted after welding is accomplished, so that the welding residual stress is effectively reduced or eliminated, and the welding quality is guaranteed.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

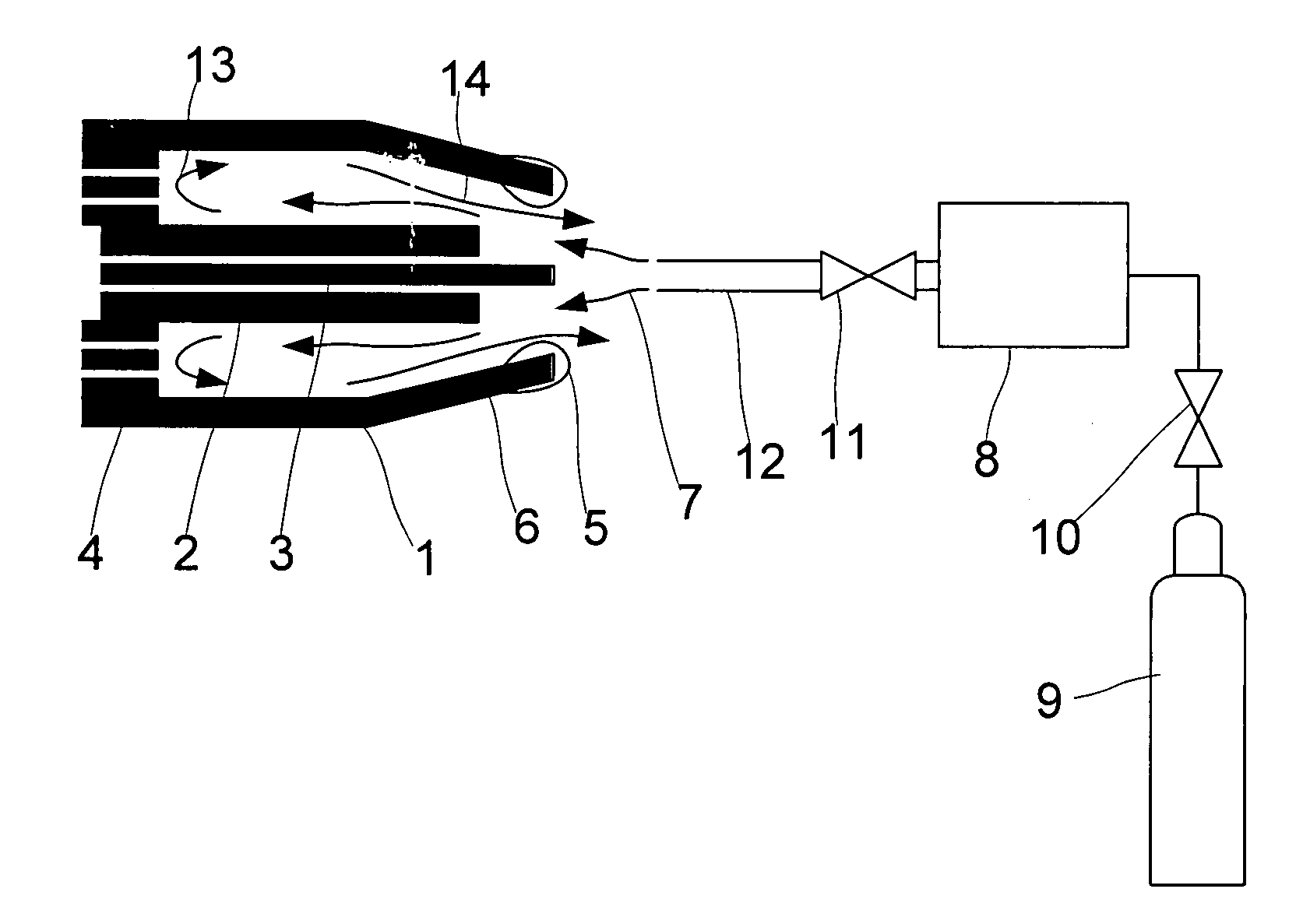

Method and device for cleaning welding torches

InactiveUS7053335B2Easy to cleanWeld torches cleaningWelding/cutting auxillary devicesOrder formDry ice

A method and a device for cleaning welding torches, for example in automated welding lines, on welding robots and in made-to-order production, by means of a cold medium, preferably CO2 dry ice. According to the method, a compressed air stream, charged with CO2 dry ice is directed constantly or at intervals by a jet nozzle onto one side of the surface to be cleaned and simultaneously describes a rotational movement.

Owner:VON DER OHE JUERGEN

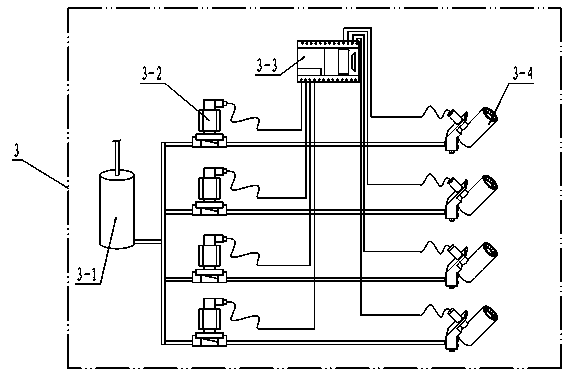

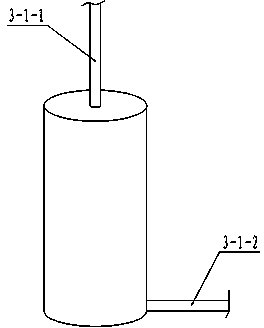

Anti-blocking processing system for welding gun nozzles for carbon dioxide arc welding

An anti-blocking processing system for welding gun nozzles for carbon dioxide arc welding is used for solving the blocking problem of the welding gun nozzles for the carbon dioxide arc welding. The anti-blocking processing system for the welding gun nozzles for the carbon dioxide arc welding comprises a liquid storage tank, a splash-proof liquid spraying device, welding gun placing supports and a PLC (Programmable Logic Controller) control mechanism; the liquid storage tank is filled with splash-proof liquid; a compressed air inlet pipe is arranged at the top of the liquid storage tank; liquid outlet pipes are arranged at the bottom of the liquid storage tank; the splash-proof liquid spraying device comprises a group of splash-proof liquid spraying units which are in series connection with the liquid outlet pipes of the liquid storage tank; the number of the splash-proof liquid spraying units is matched with that of welding guns in welding production lines; movements of the splash-proof liquid spraying units are controlled by the PLC control mechanism; the welding gun placing support is arranged at the tail end of every splash-proof liquid spraying unit. The anti-blocking processing system for the welding gun nozzles for the carbon dioxide arc welding has the advantages of reducing labor intensity of operators, improving welding production efficiency, effectively avoiding the welding gun nozzles from blocking caused by splashing of welding slags and poor electric conduction between a contact nozzle and a welding wire and caused by a processing method of dipping anti-blocking paste and satisfying a workpiece requirement for welding quality.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

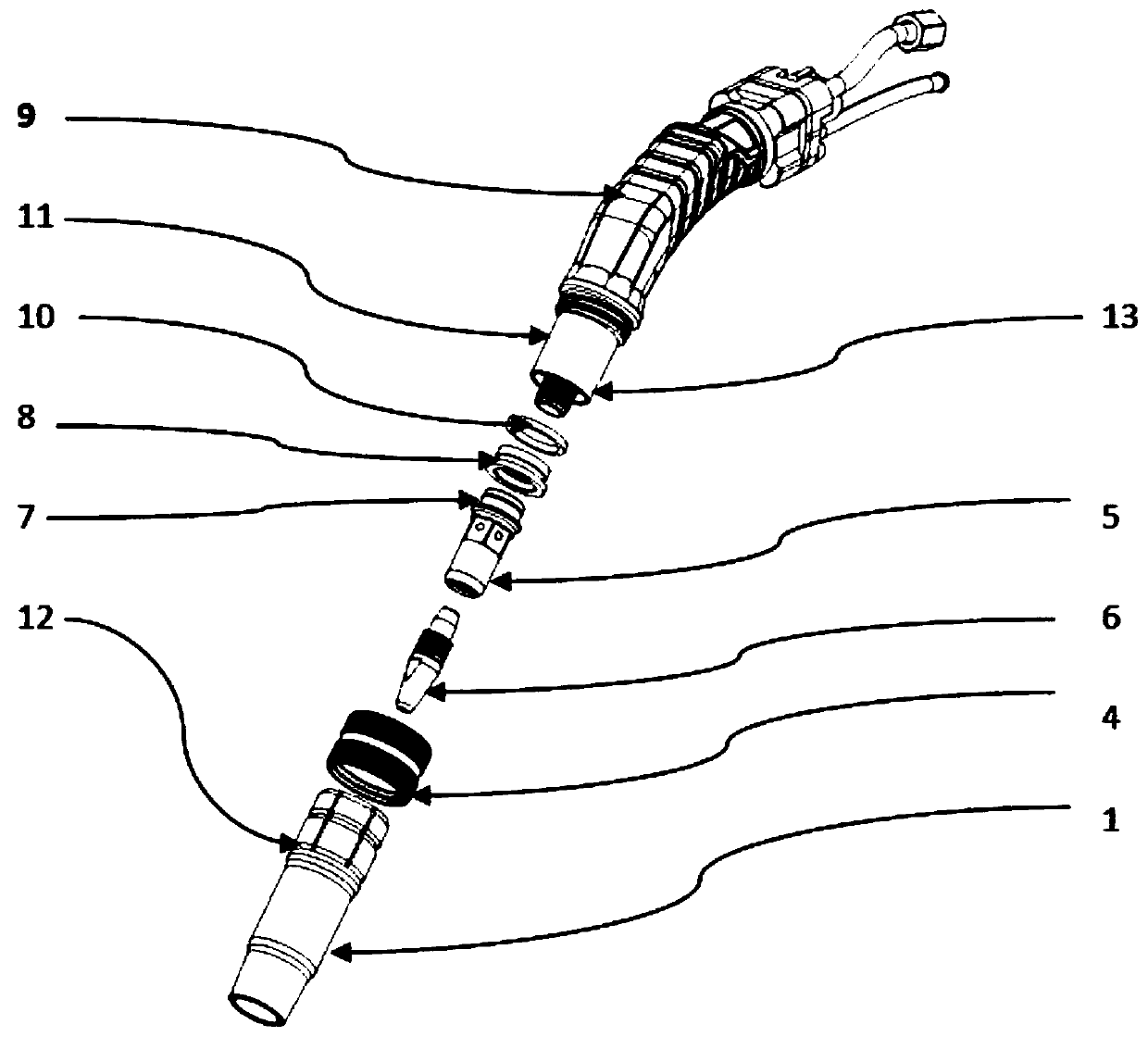

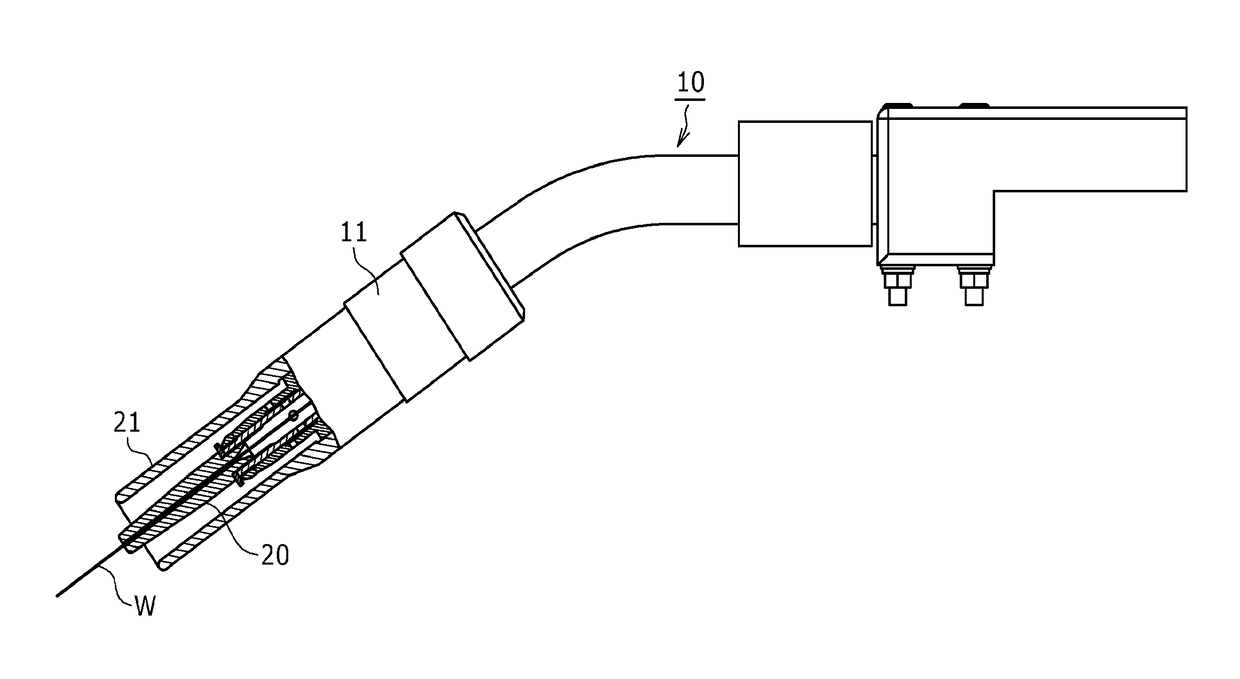

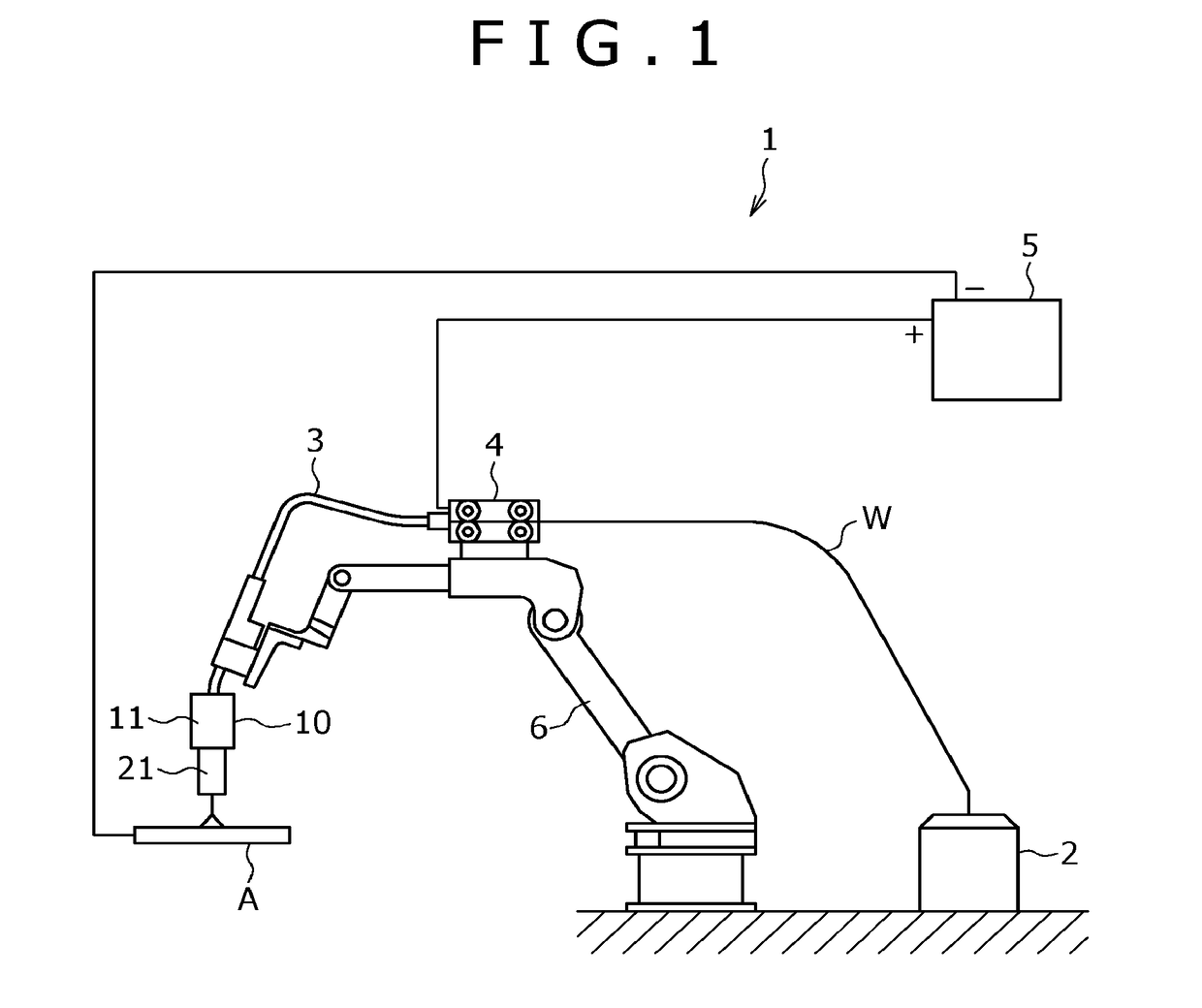

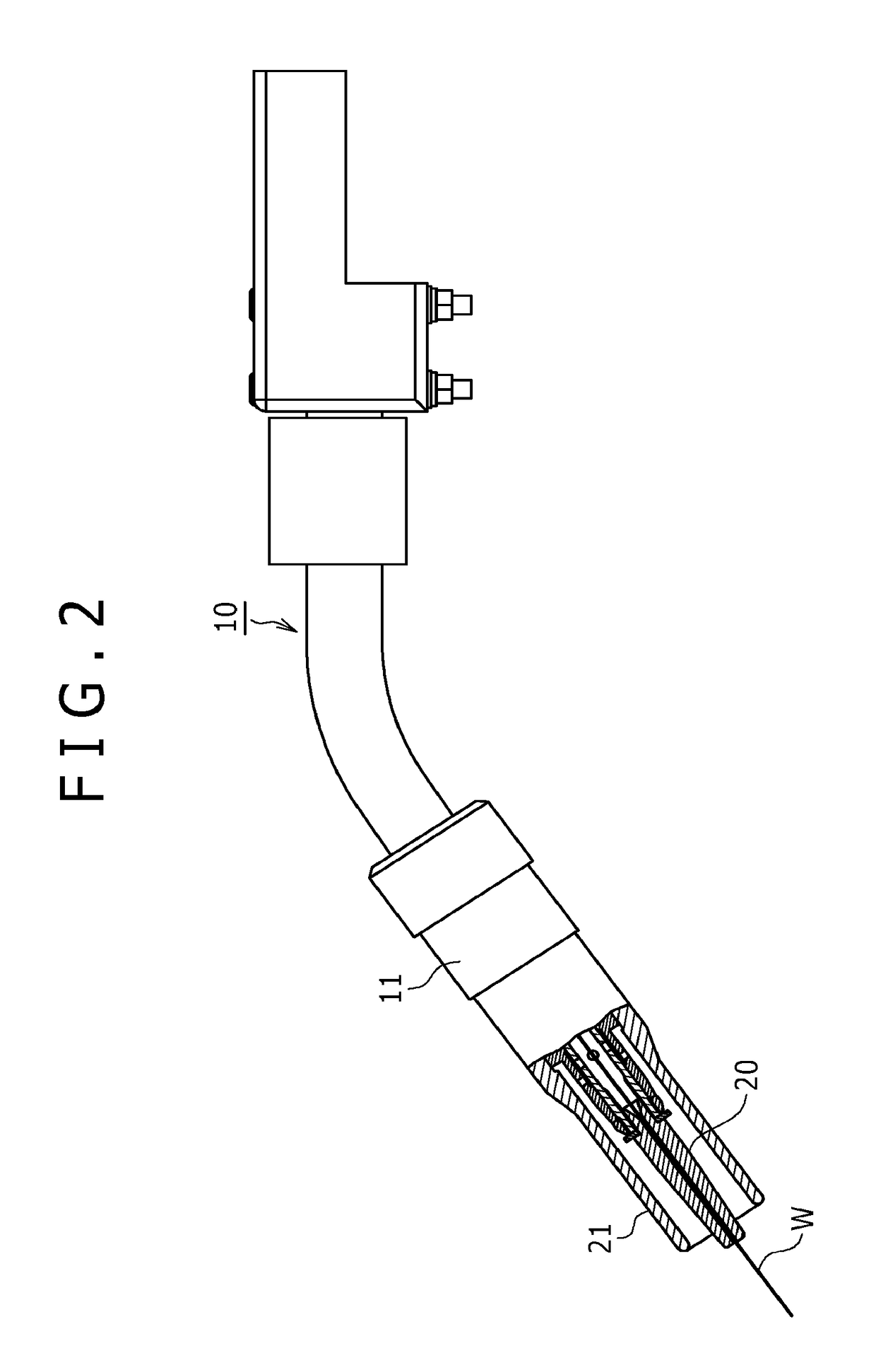

Welding torch, welding robot, and welding system

ActiveUS20170173722A1Shielding gas supply/evacuation devicesSupport devices with shieldingWelding power supplyEngineering

A tip attached to a torch barrel of a welding torch includes: a cylindrical tip body attached to the torch barrel; a cylindrical orifice member fitted on an outer circumference of the tip body; an orifice-member support nut detachably attached to a front end outer circumference of the tip body and supporting the orifice member on the outer circumference of the tip body; a cylindrical contact tip detachably attached to a front-end inner circumference of the tip body; and an annular shield member disposed between the tip body and the contact tip. The shield member has an outer diameter set no less than a front-end outer diameter of the orifice-member support nut but no more than an outer diameter of the orifice member. A welding robot including the welding torch and a welding system including the welding robot and a welding power supply are also disclosed.

Owner:KOBE STEEL LTD

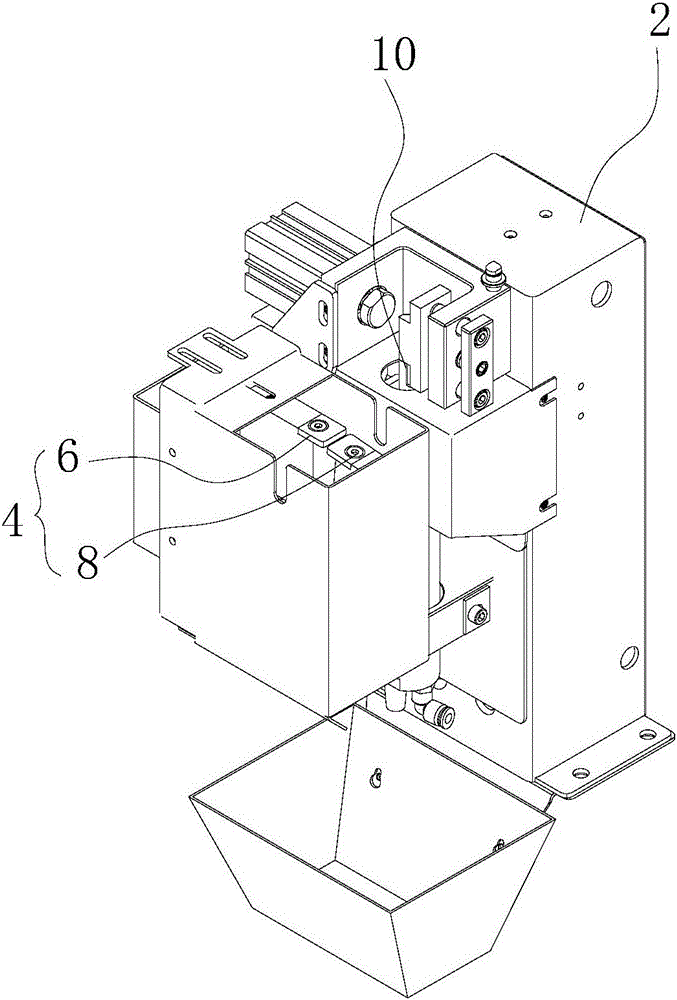

Welding gun cleaning device and welding wire cutting device

ActiveCN103949763AFlexible disassembly and installationIncrease flexibilityWeld torches cleaningElectric senseWire cutting

The invention provides a welding gun cleaning device and a welding wire cutting device. The welding wire cutting device comprises a rack, a wire cutting machine cover, a through beam type photo electric sensor, a wire cutting machine, a left support arm, a right support arm and a waste collecting box, wherein a concave arm which extends towards left is arranged on the upper end surface of the rack, a strip-shaped through groove is formed in the concave arm, the rack is connected with the wire cutting machine cover, the through beam type photo electric sensor main body and an electromagnetic valve of the wire cutting machine are fixed inside the rack, the left support arm is L-shaped, the strip-shaped through grooves are formed in both the left support arm and the right support arm, the left support arm is fixed on the upper end surface of the concave arm, a light emitter is fixed on the left support arm, the right support arm is fixed on the wire cutting machine cover, and a light receiver is fixed on the right support arm. The device can collect the cut waste, uses the photo electric sensing control way to control the cutting operation, and avoids the phenomenon of error alarm caused by that a welding robot collides; the device can be directly used for the welding robot which is few in output signal, the positions of the light emitter and the light receiver can be adjusted, and the device can be suitable for the arms of the welding robots in different appearance sizes.

Owner:TBI SHANDONG IND

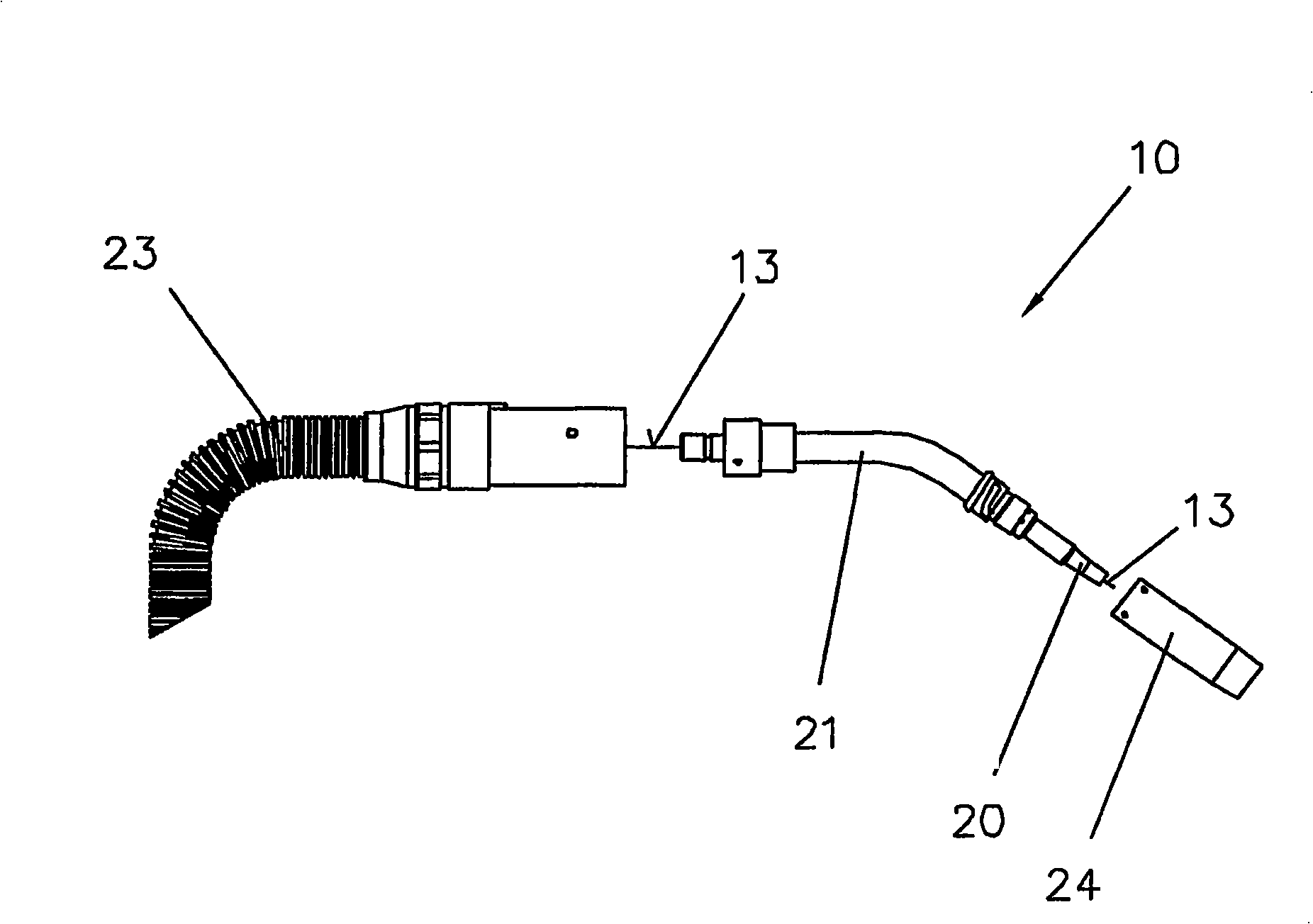

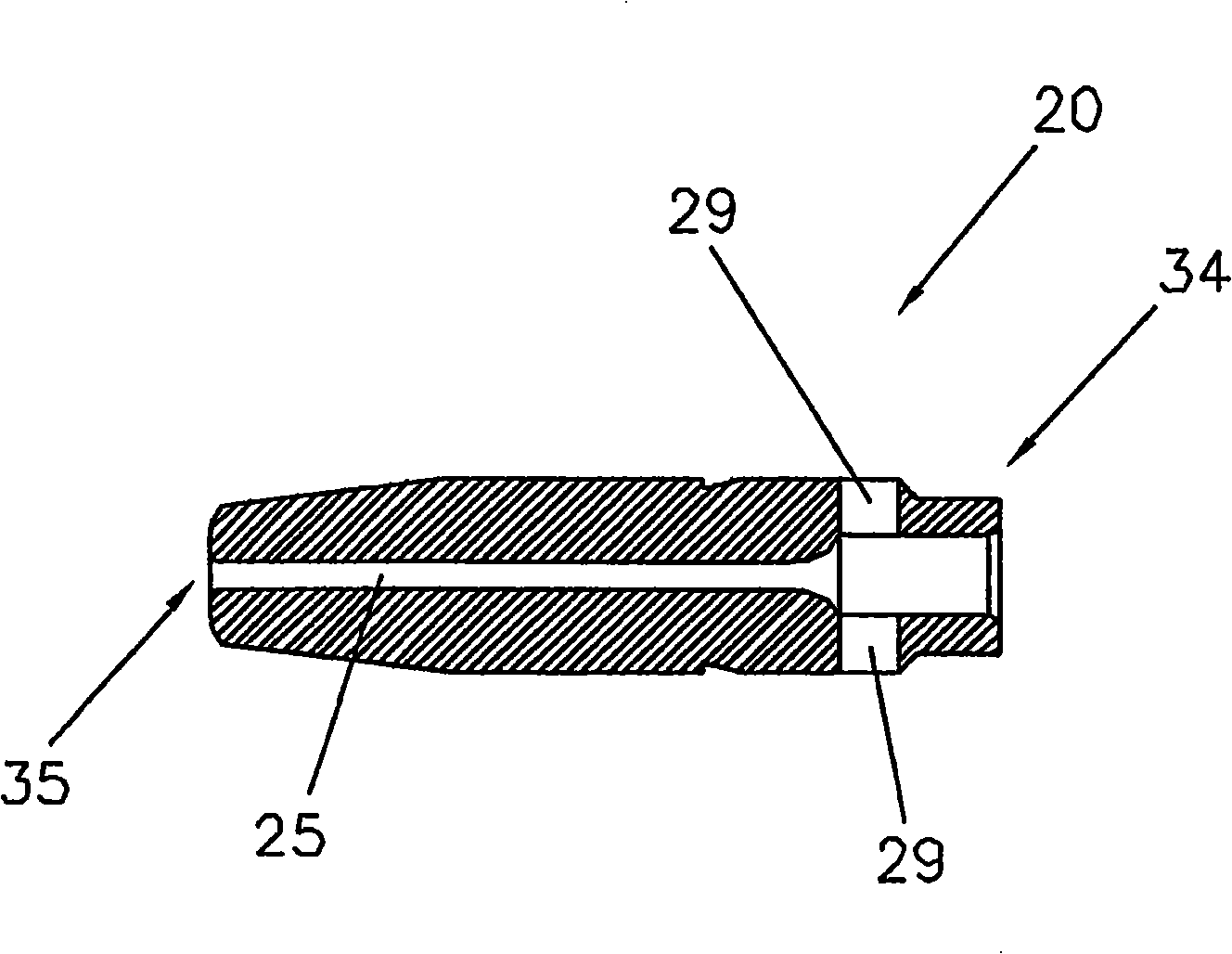

Method of cleaning a contact tube of a welding torch, and a welding torch and contact tube

ActiveCN101410216ASupport devices with shieldingWeld torches cleaningEngineeringMechanical engineering

The invention relates to a method of cleaning a contact tube (20) of a welding torch (10), via which contact tube (20) a welding wire (13) moved to the welding torch (10) from a wire reel (14) or a wire drum via a wire delivery device (11) is supplied with electrical energy, and to a welding unit (1) and a contact tube (20) for the welding torch (10) of such a welding unit (1). To prolong the service life of a contact tube (20) of a welding torch (10), provision is made according to the invention for the welding wire (13) to be moved back at least once in the direction of the wire reel (14) or wire drum until the end (27) of the welding wire (13) lies at least within the length (36) of the contact tube (20), and for the welding wire (13) to then be moved forward again, in particular into the initial position again.

Owner:FRONIUS INTERNATIONAL GMBH

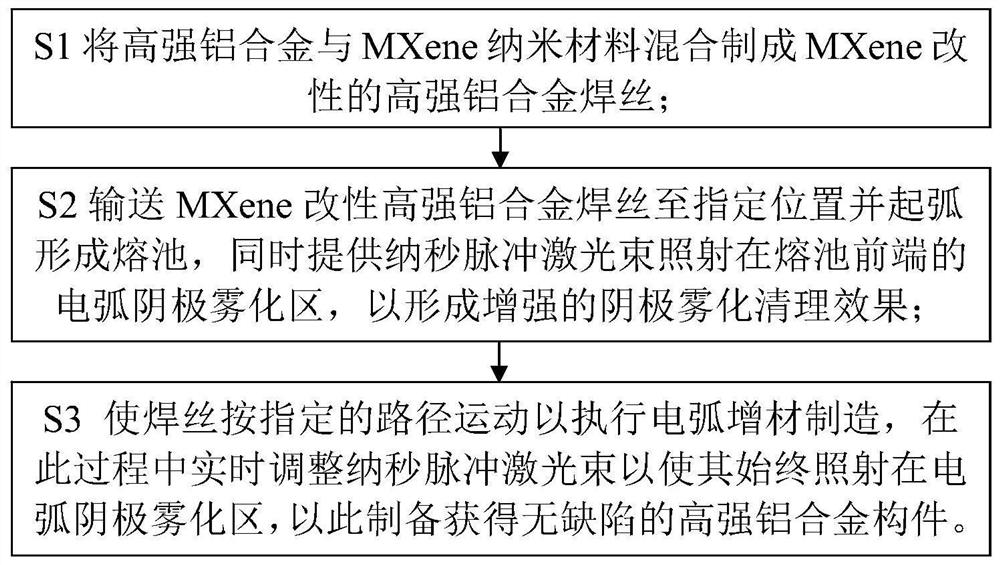

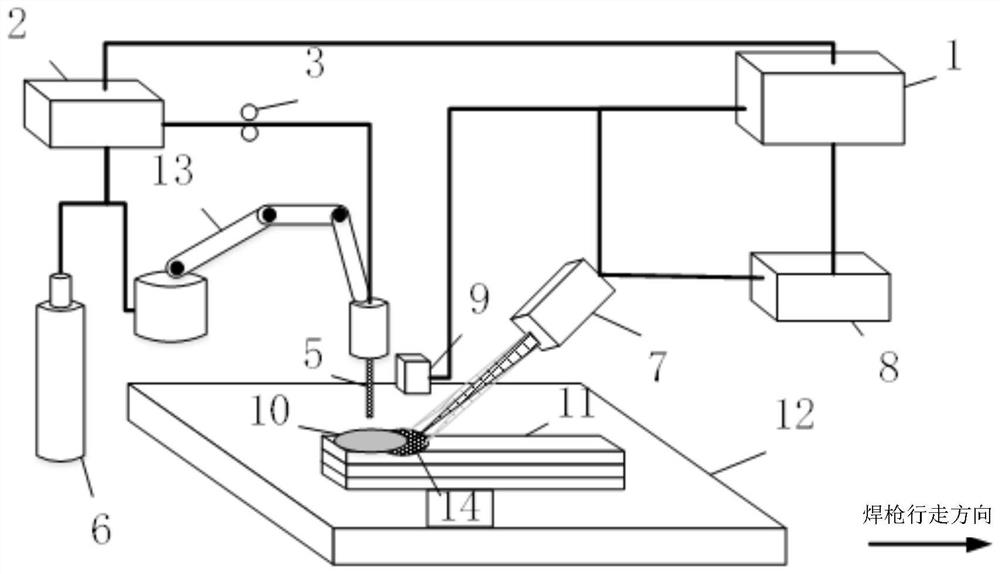

Arc additive manufacturing method, equipment and product of high-strength aluminum alloy member

ActiveCN111843215AQuality improvementReduce forming difficultyAdditive manufacturing apparatusWeld torches cleaningNanosecond laserSilumin

The invention belongs to the field of arc additive manufacturing, and particularly discloses an arc additive manufacturing method, equipment and product of a high-strength aluminum alloy member. MXenenano material is used for modifying high-strength aluminum alloy, the modified high-strength aluminum alloy is used as a raw material for arc additive manufacturing, a nanosecond laser beam is simultaneously applied in the arc additive manufacturing process to form an enhanced arc cathode atomization cleaning effect to clear impurities, and then the defect-free high-strength aluminum alloy memberis prepared. The arc additive manufacturing method, equipment and product of the high-strength aluminum alloy member can solve the problem that the forming difficulty of high-strength aluminum alloyarc additive manufacturing is high, simultaneously solves the problems of generation of many air holes, tendency to cracking and generation of many impurities in the process of high-strength aluminumalloy additive manufacturing, and can prepare the defect-free high-strength aluminum alloy member.

Owner:WUHAN UNIV

Apparatus for automatically changing a robot tool tip member

ActiveUS20060240961A1Additional running costMinimum setup stepPrecision positioning equipmentWeld torches cleaningCentre of rotationEngineering

An apparatus for automatically changing a tool tip member for a robot includes a tip member changing jig disposed in an operational area of the robot. The tip member changing jig includes a base member, a rotating member supported by the base member so as to be rotatable about a rotation axis, and tip member holding means disposed at positions that are offset from the rotation axis of the rotating member. The tip member holding means holds the tool tip member so that a central axis of relative rotation, for threadedly mounting or demounting the tool tip member on or from the tool body, extends substantially parallel to the rotation axis of the rotating member and so that rotation of the tool tip member, with respect to the rotating member, is locked.

Owner:FANUC LTD

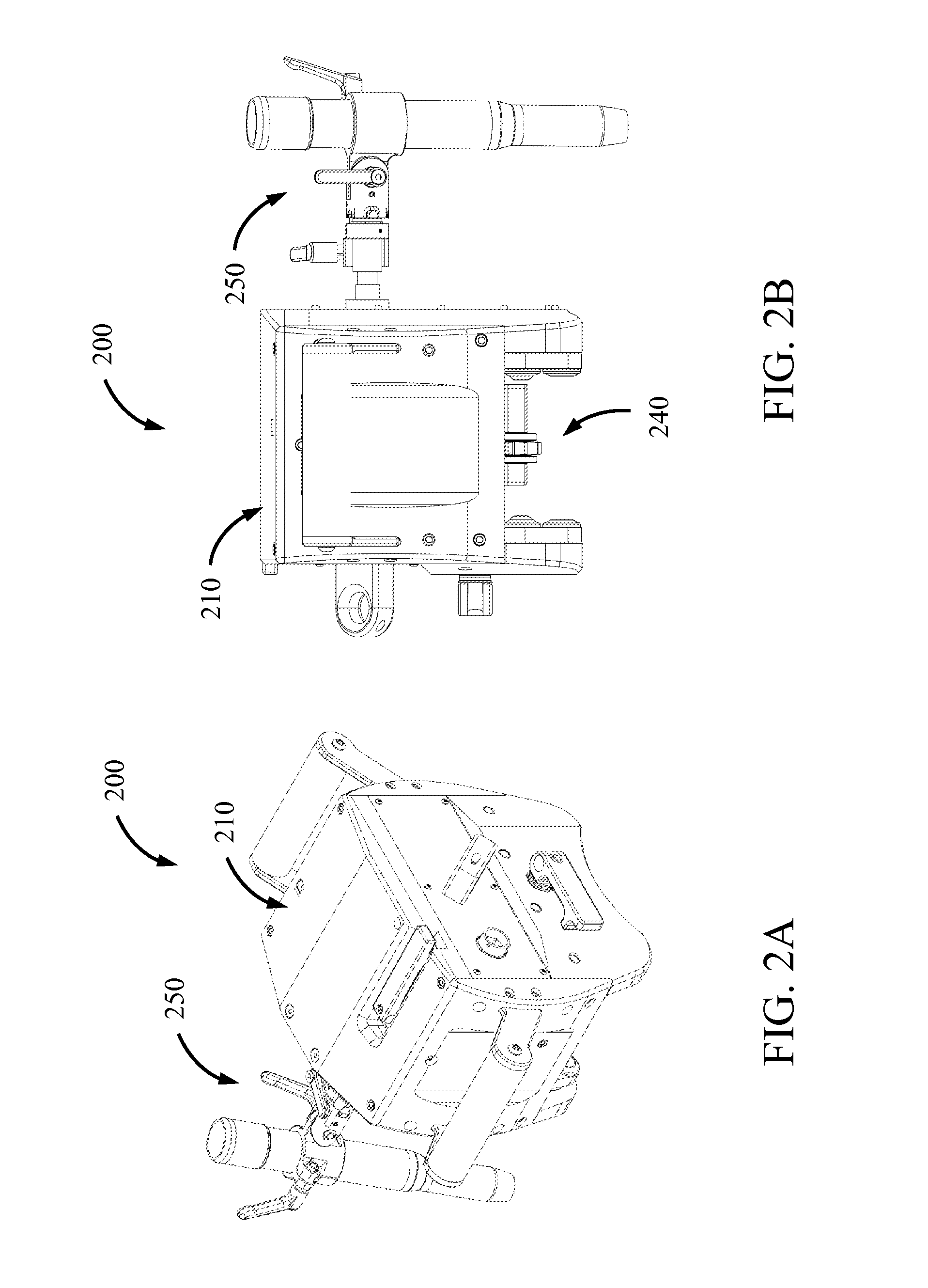

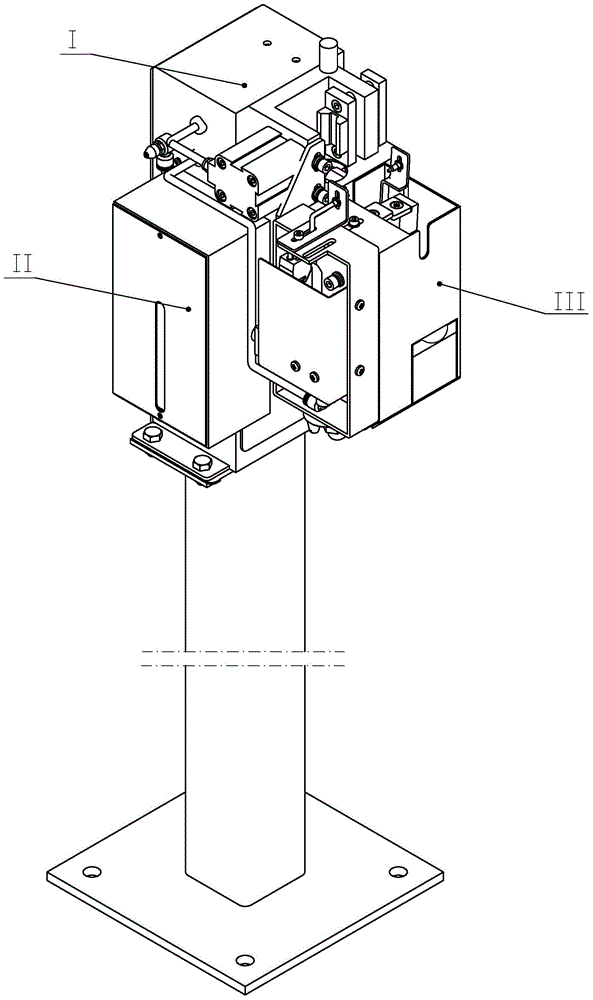

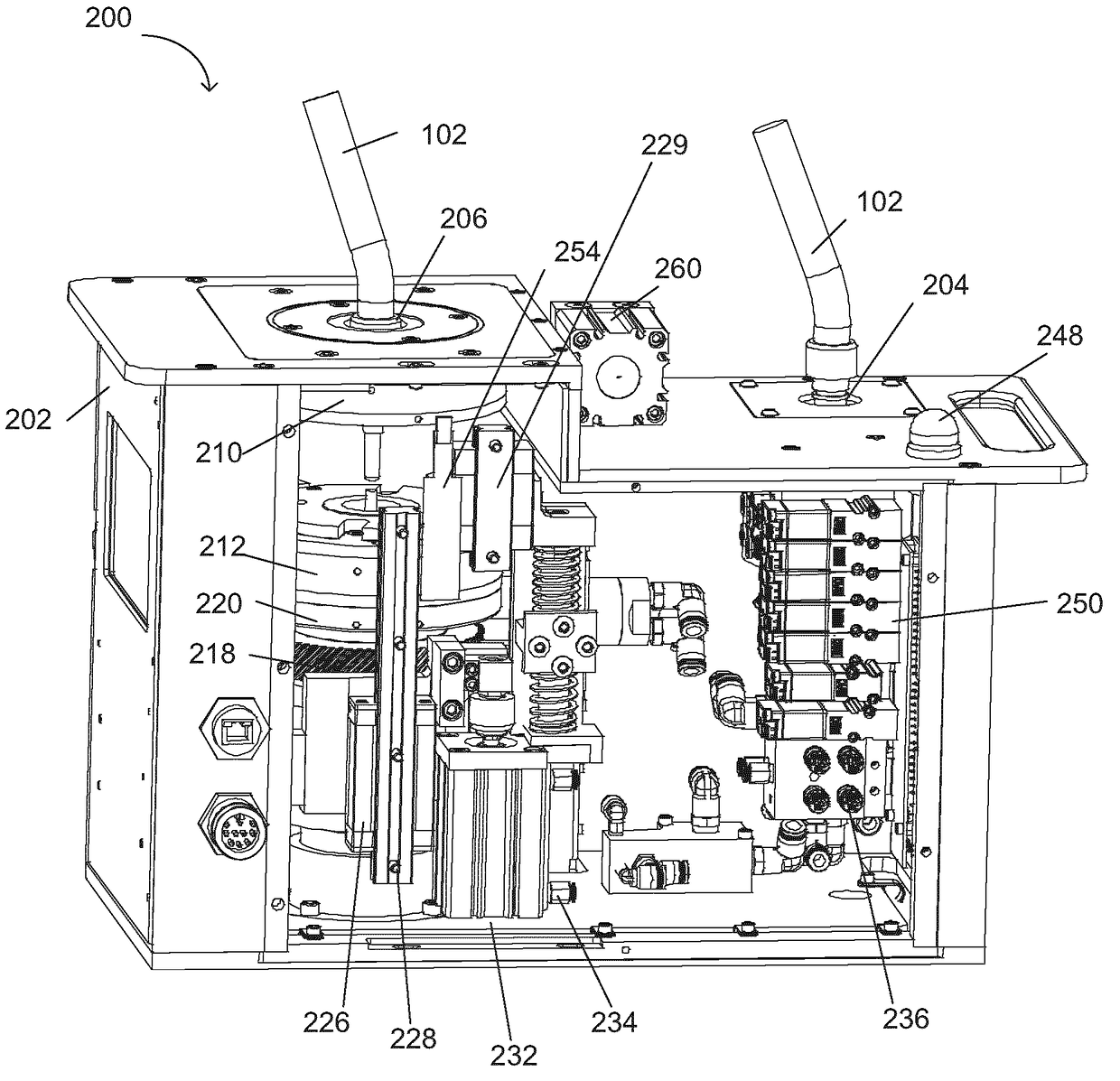

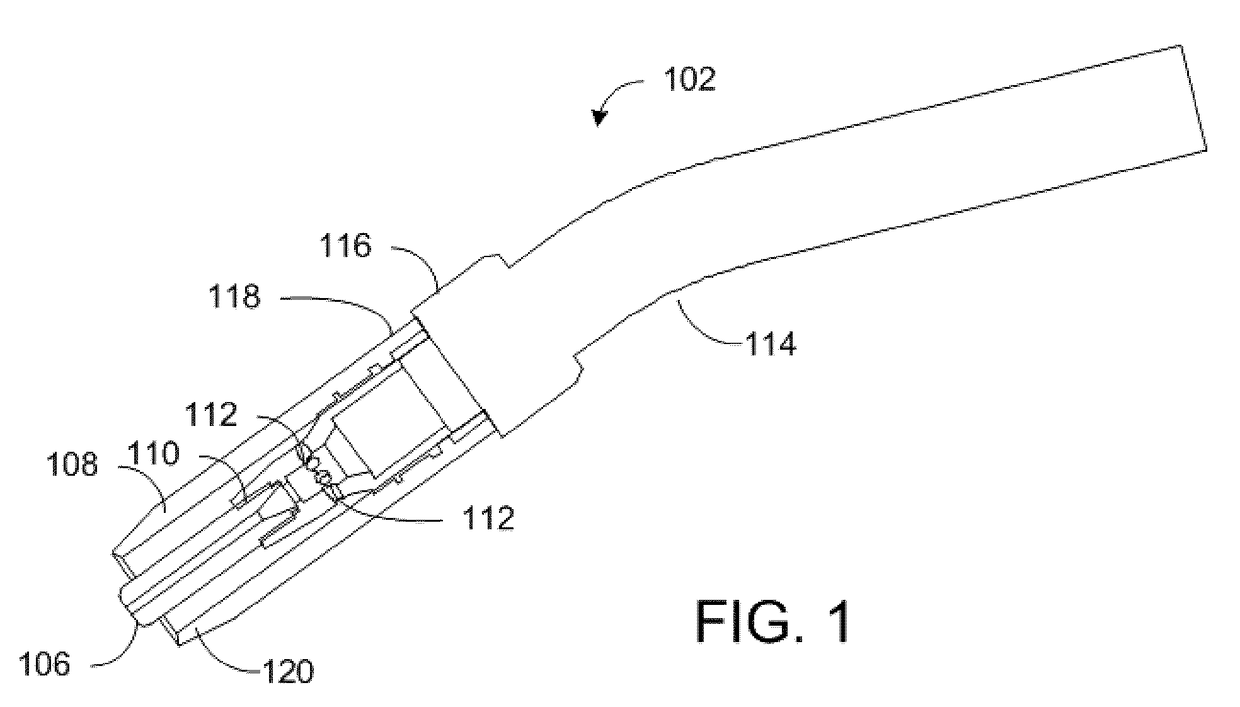

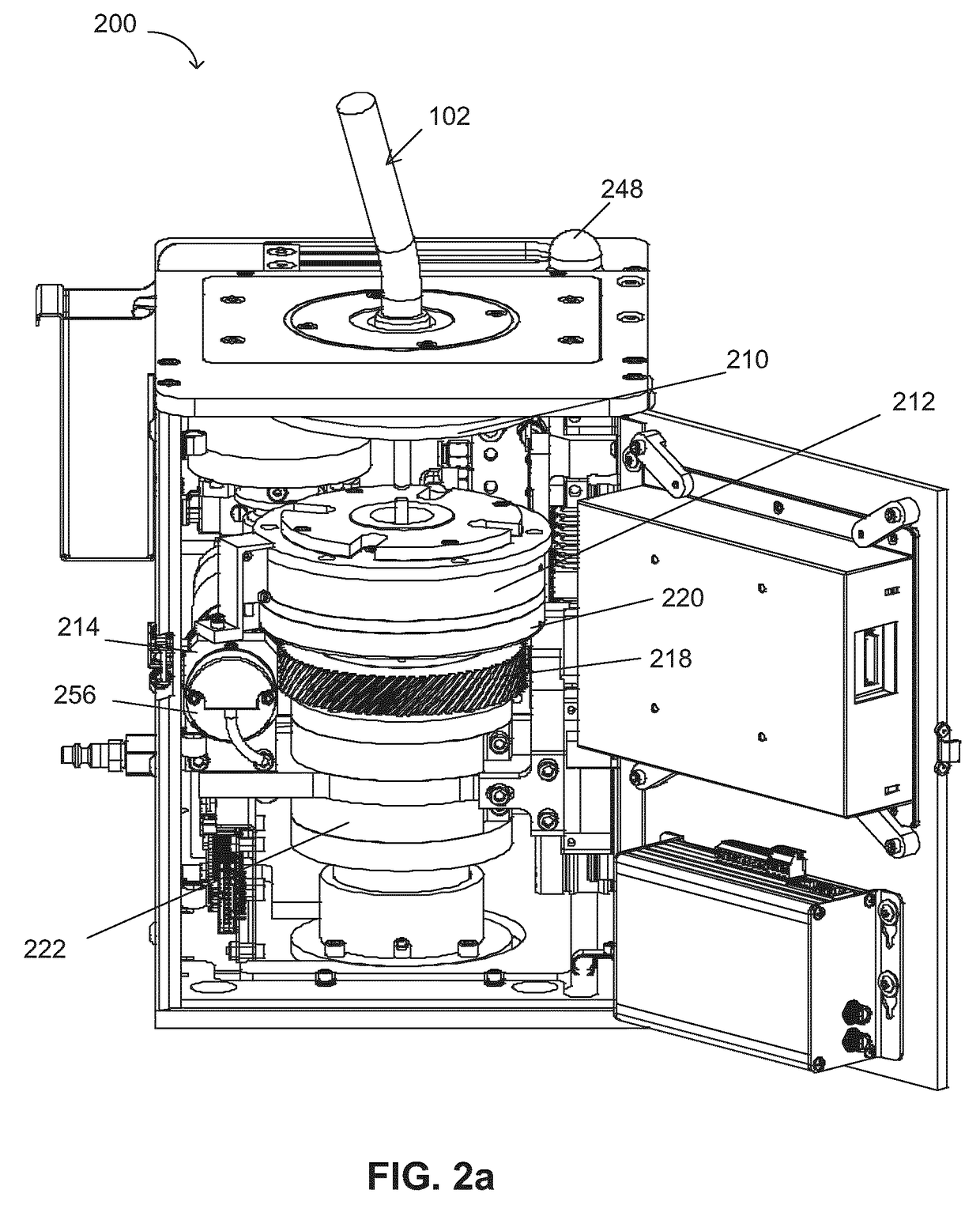

Welding torch maintenance center

A welding torch maintenance apparatus and a welding tip changer are described. The welding torch maintenance apparatus and the welding tip changing apparatus each comprise a first gripping means for fastening the welding torch / diffuser so that the nozzle / welding tip is aligned with the rotational axis, a second gripping means for holding the nozzle / welding tip, the second gripping means rotates about the rotational axis to remove the nozzle / welding tip, and moves along the rotational axis. A drive means is provided for rotating the second gripping means, and a lift system is provided for moving the second gripping along the rotational axis. The welding torch maintenance apparatus further includes a cleaning means which enters the nozzle at the distal end and cleans an interior of the nozzle.

Owner:NASARC TECH

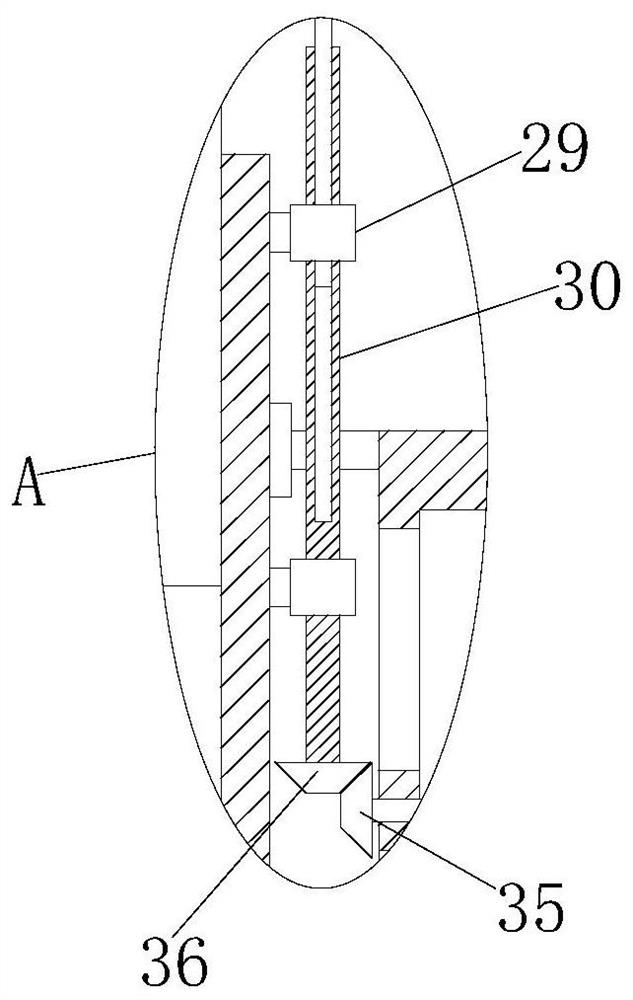

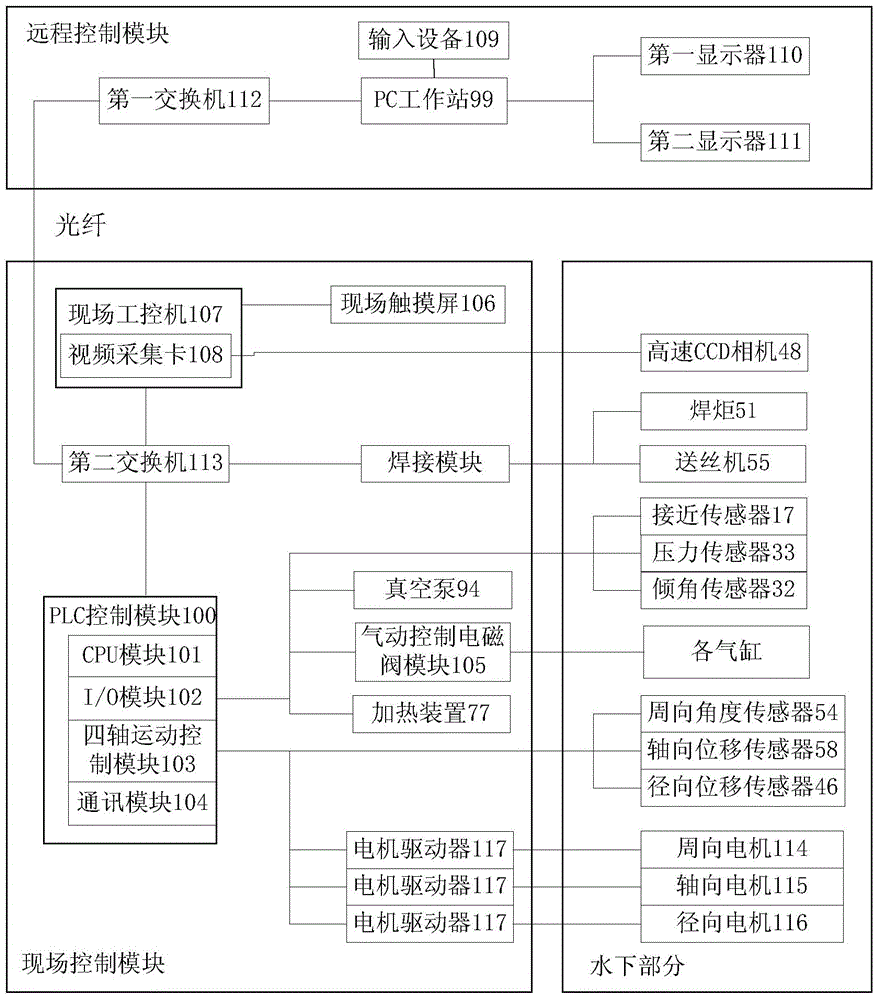

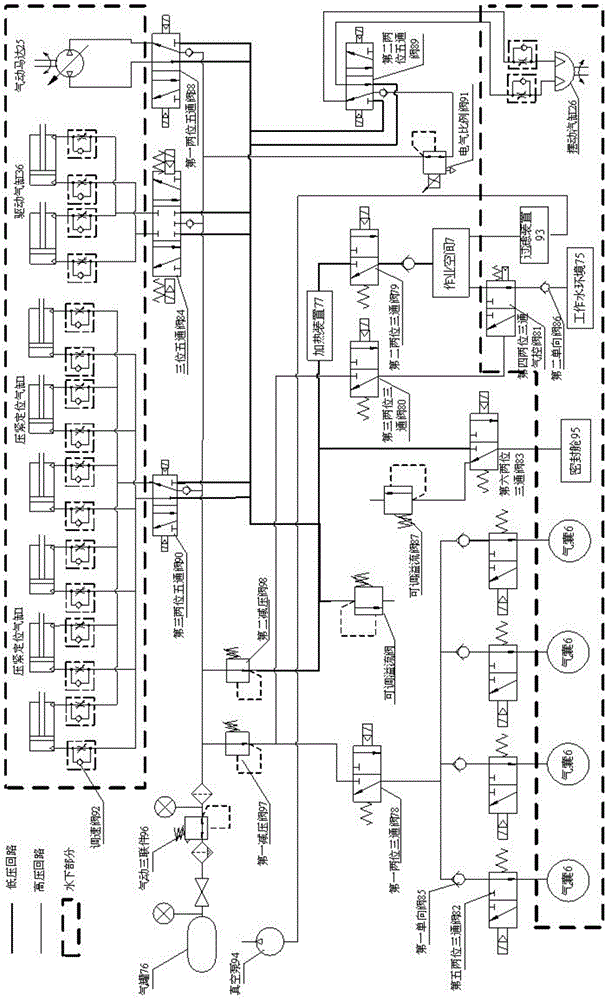

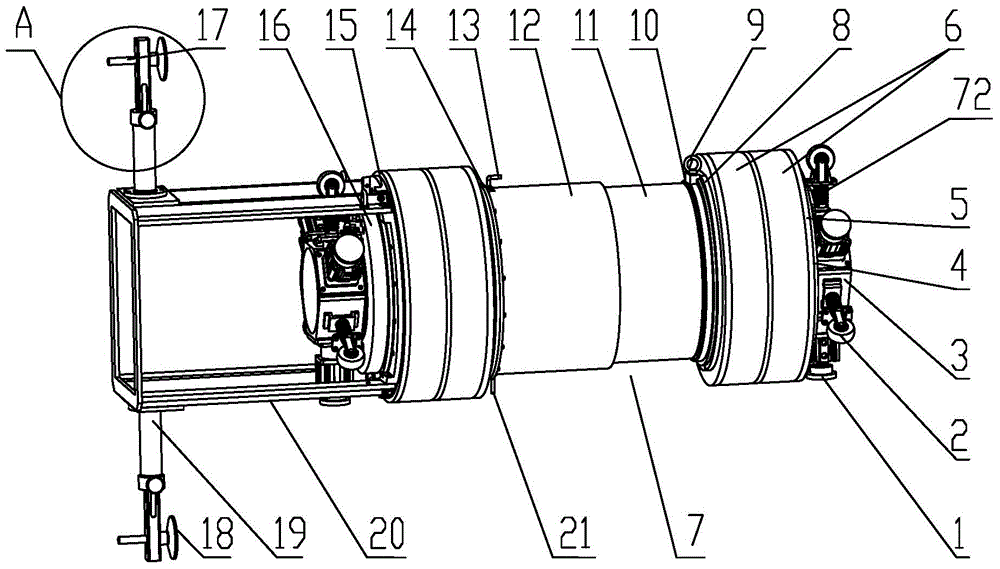

Control device for automatic underwater welding repair equipment

ActiveCN103551706AEasy to operateLow cost of on-site operationsEdge grinding machinesServomotor componentsProgrammable logic controllerEngineering

The invention provides a control device for automatic underwater welding repair equipment. The control device comprises a spindle, gasbag supports, gasbags, a working space, an axially movable cylinder, a gas inlet pipe and a drain pipe which are arranged on the cylinder, and a welding device arranged on the cylinder, and also comprises a gas tank respectively connected with first, second and third two-position three-way valves, a driving cylinder connected with the gas tank through a three-position five-through valve, and a PC (Personal Computer) workstation connected with a PLC (Programmable logic controller) control module, wherein the first two-position three-way valve is connected with the gasbags, and the second two-position three-way valve is connected with the working space through the gas inlet pipe; the third two-position three-way valve is connected with a two-position three-way gas control valve arranged on the drain pipe, and the PLC control module is respectively connected with the first, second and third two-position three-way valves and the three-position five-through valve. According to the control device, for the automatic underwater welding repair equipment, a local dry repair environment can created, and the control device is safe and reliable, is convenient to control, and is relatively lower in field operation cost.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com