Patents

Literature

48results about How to "Reduce forming difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

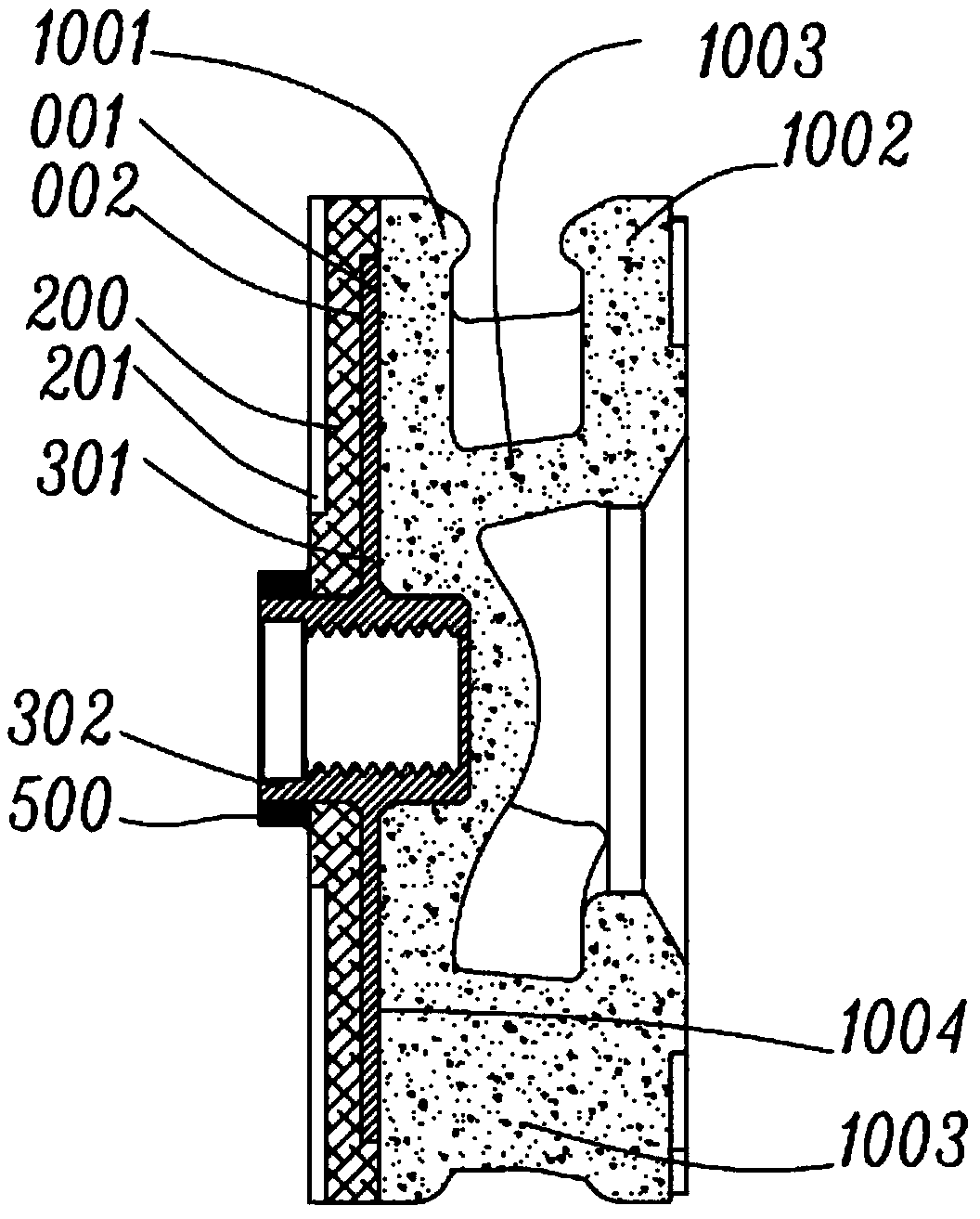

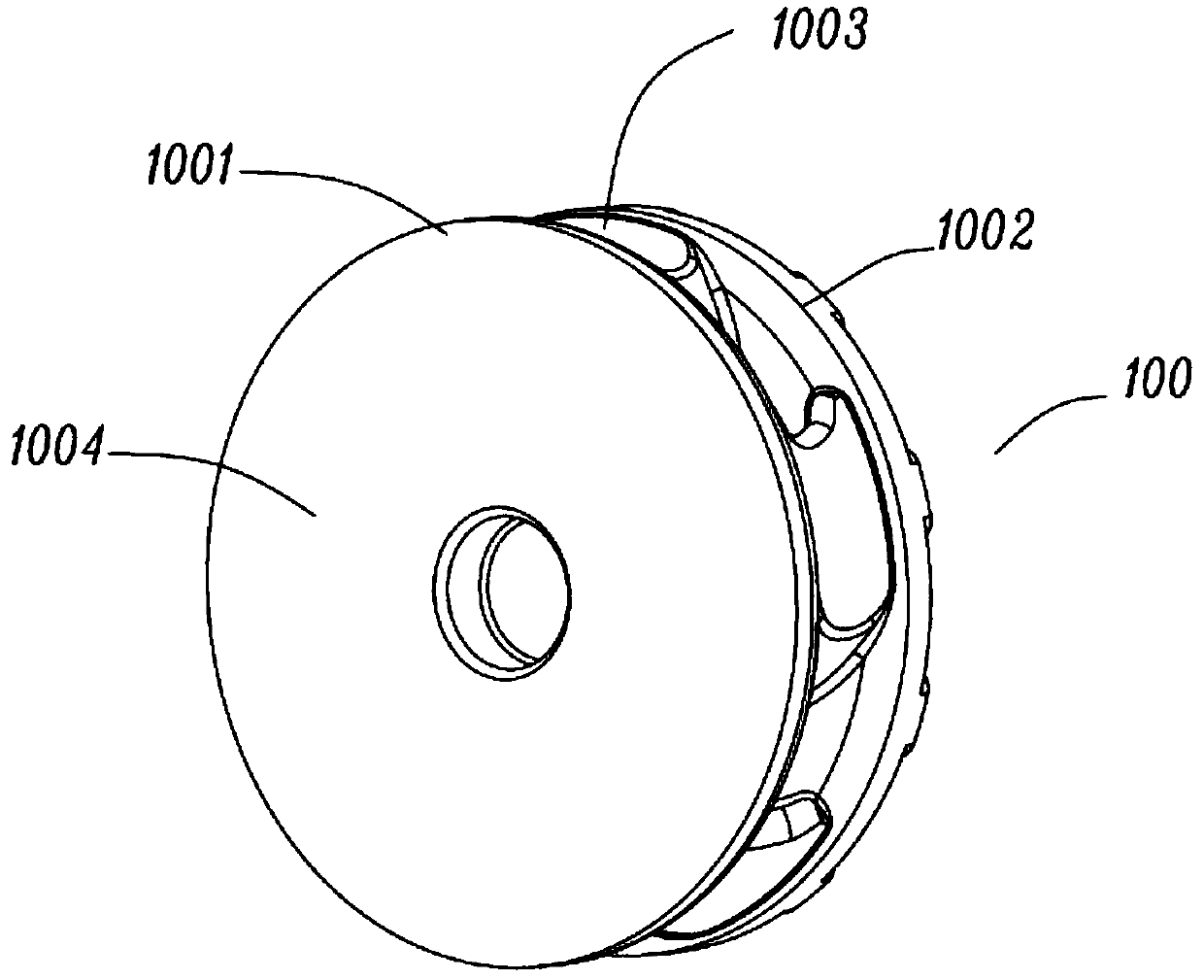

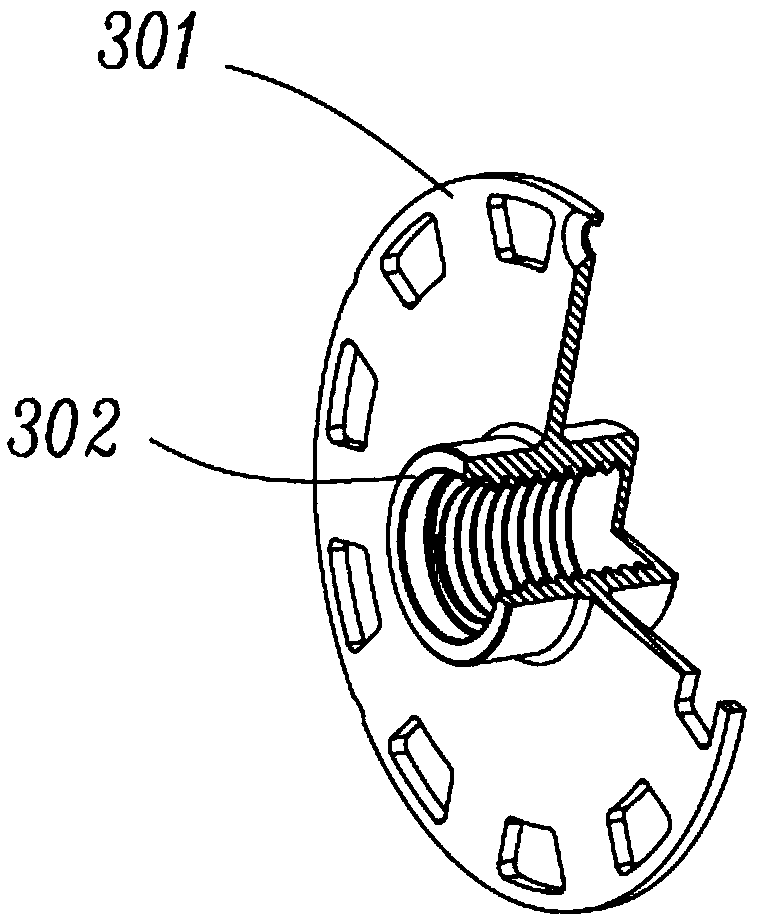

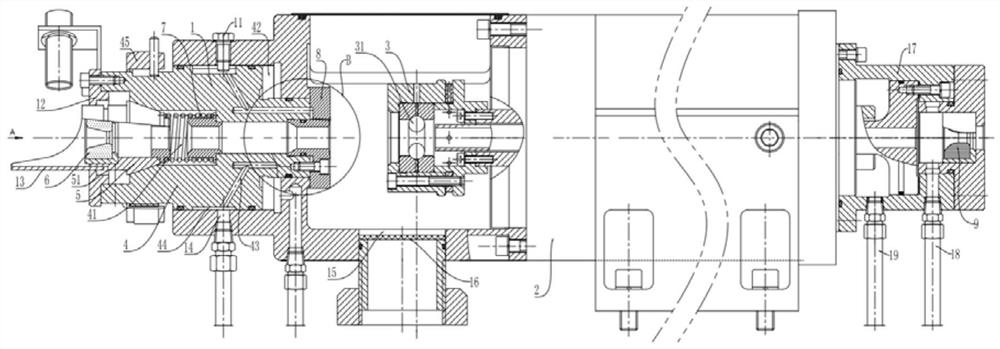

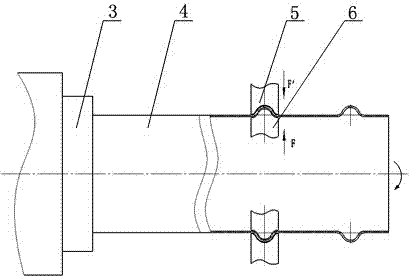

Two-stage turbocharger for aviation piston engine

InactiveCN102748121ASimple structureReduce weightInternal combustion piston enginesEngine componentsAviationTurbocharger

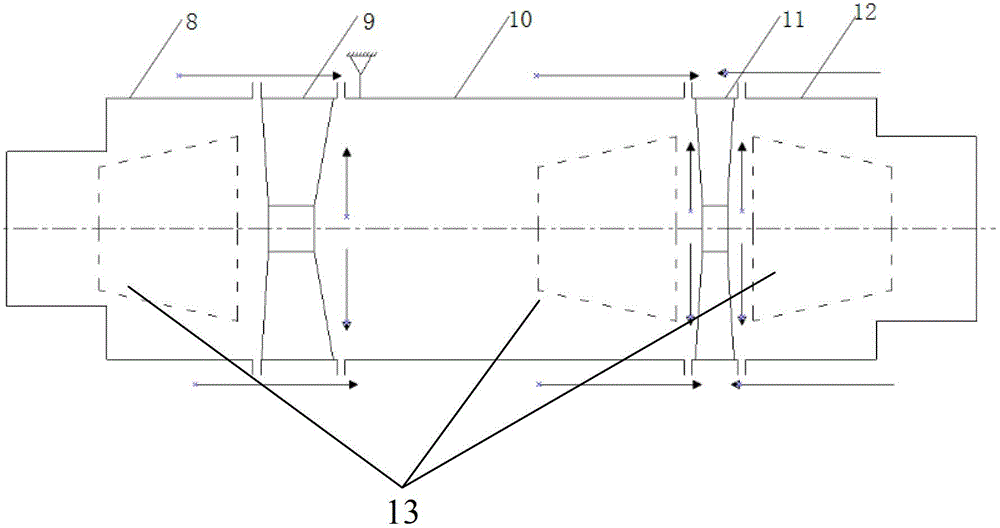

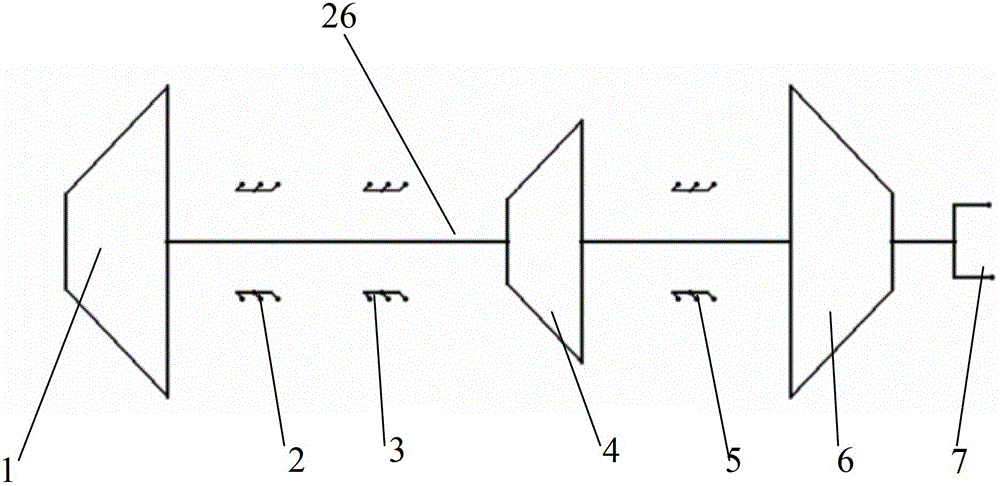

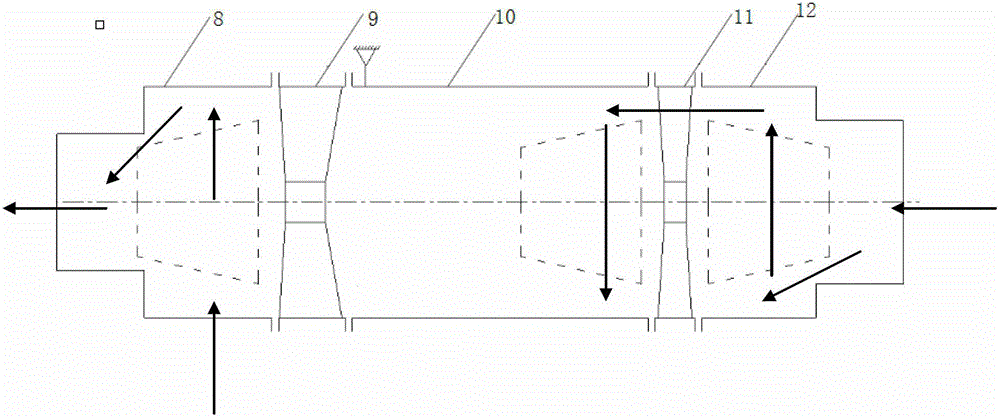

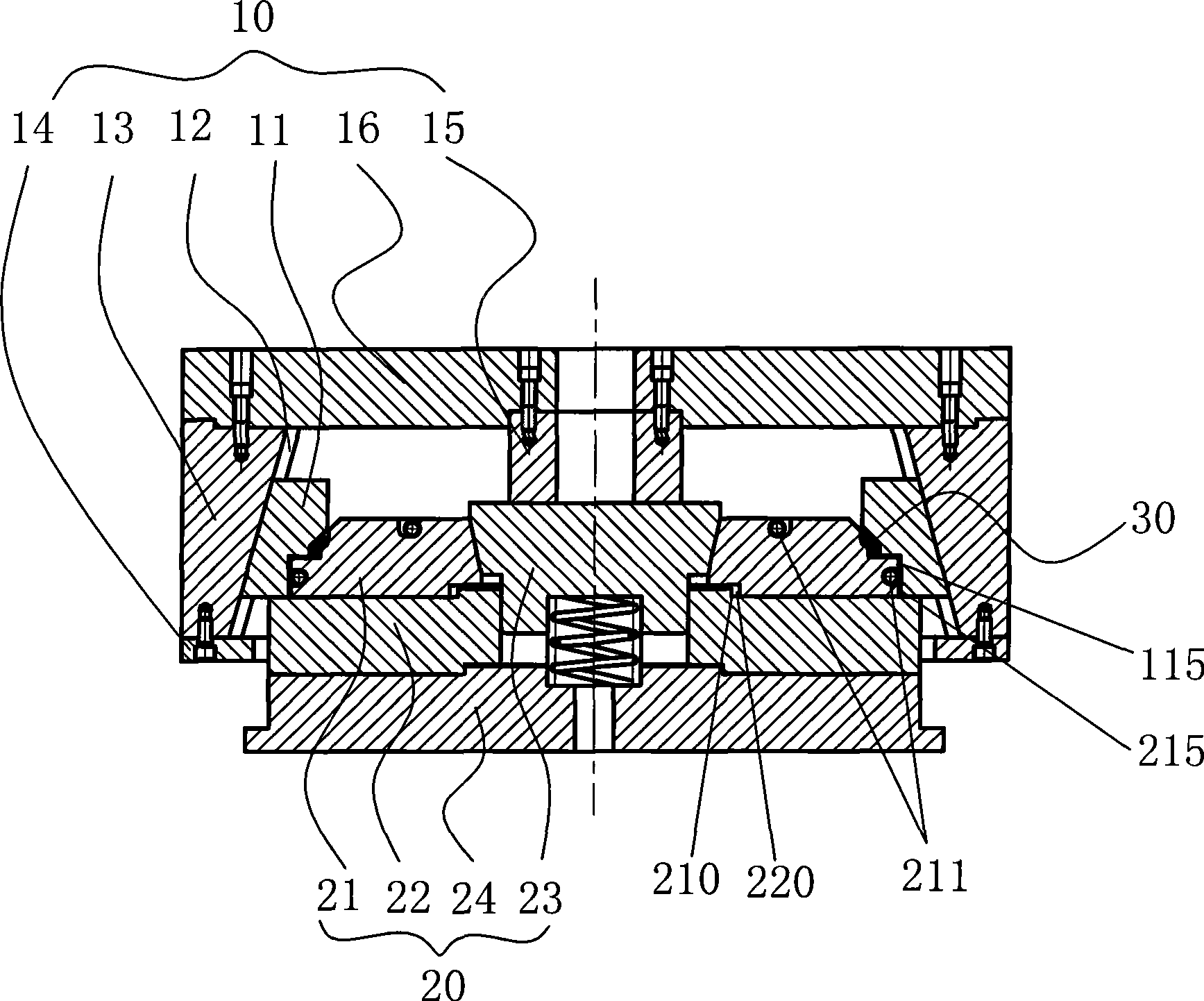

The invention discloses a two-stage turbocharger for an aviation piston engine. The two-stage turbocharger comprises a rotor assembly, a front support assembly, a rear support assembly, a turbine volute, a high-pressure compressor casing, a low-pressure compressor casing and the like, wherein each part in the rotor assembly is locked through a compression nut, and respectively connected with the turbine volute and the compressor casings through bolts; the rear support assembly is of a thin-walled stainless steel soldering structure, and bearings are distributed in a back to back mode; and the compressor casings are of a combined mode, the low-pressure compressor casing is connected with the high-pressure compressor casing through a bolt, and is connected with a regulator assembly through a bolt. The two-stage turbocharger has the advantages that: the turbocharger has simple structure and light weight, and a structure that one turbine drives two compressors is adopted, so that the requirement of an aircraft for high-altitude flight is fulfilled, and the weight of the engine is effectively reduced. The two-stage turbocharger has the characteristics of high reliability and good sealing property, and fulfills the requirement of high-altitude sealing.

Owner:BEIHANG UNIV

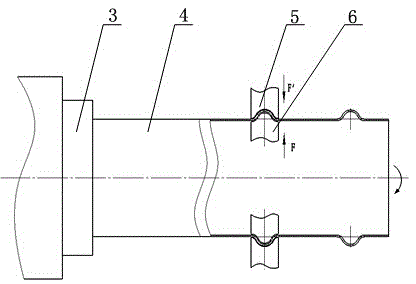

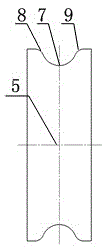

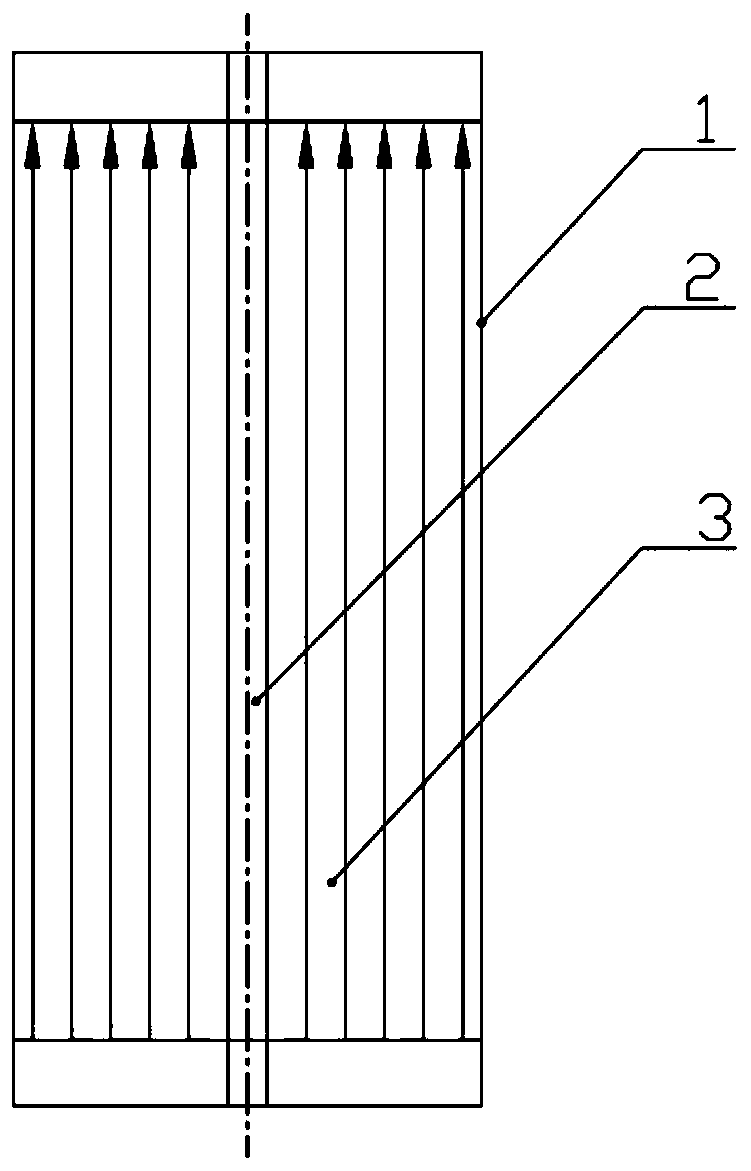

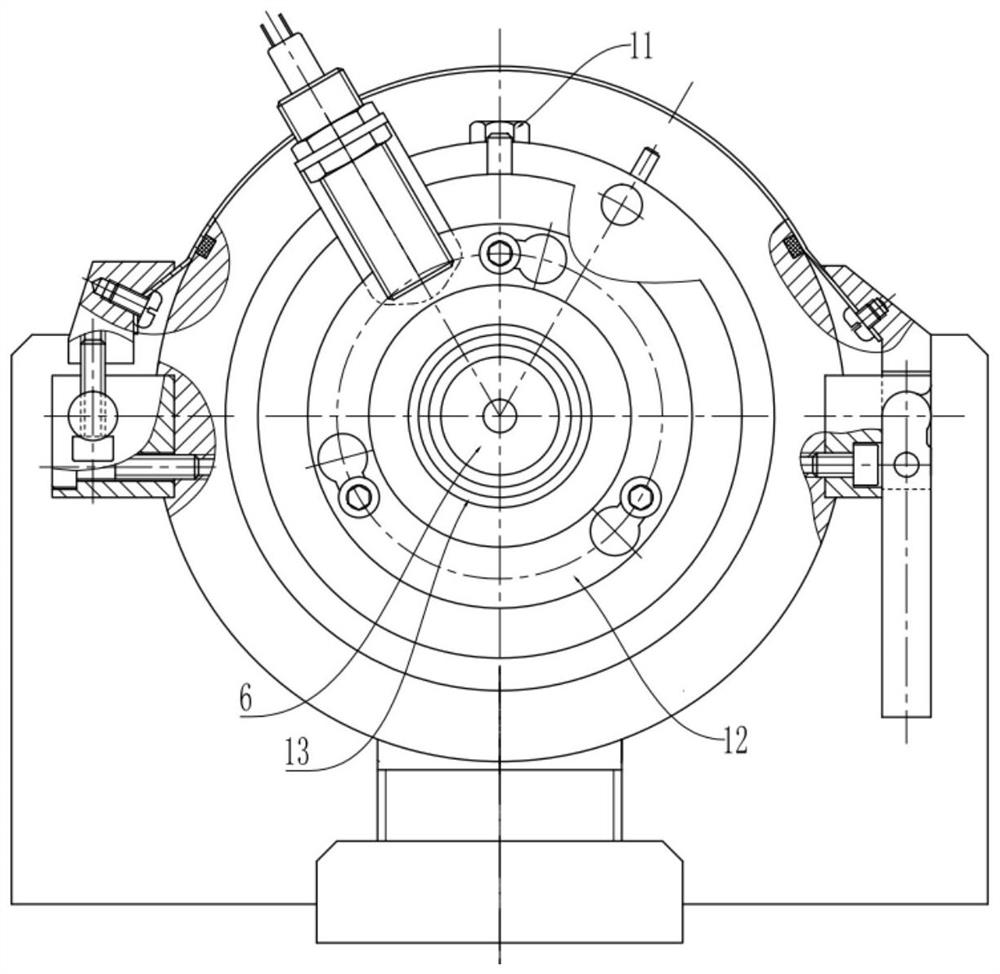

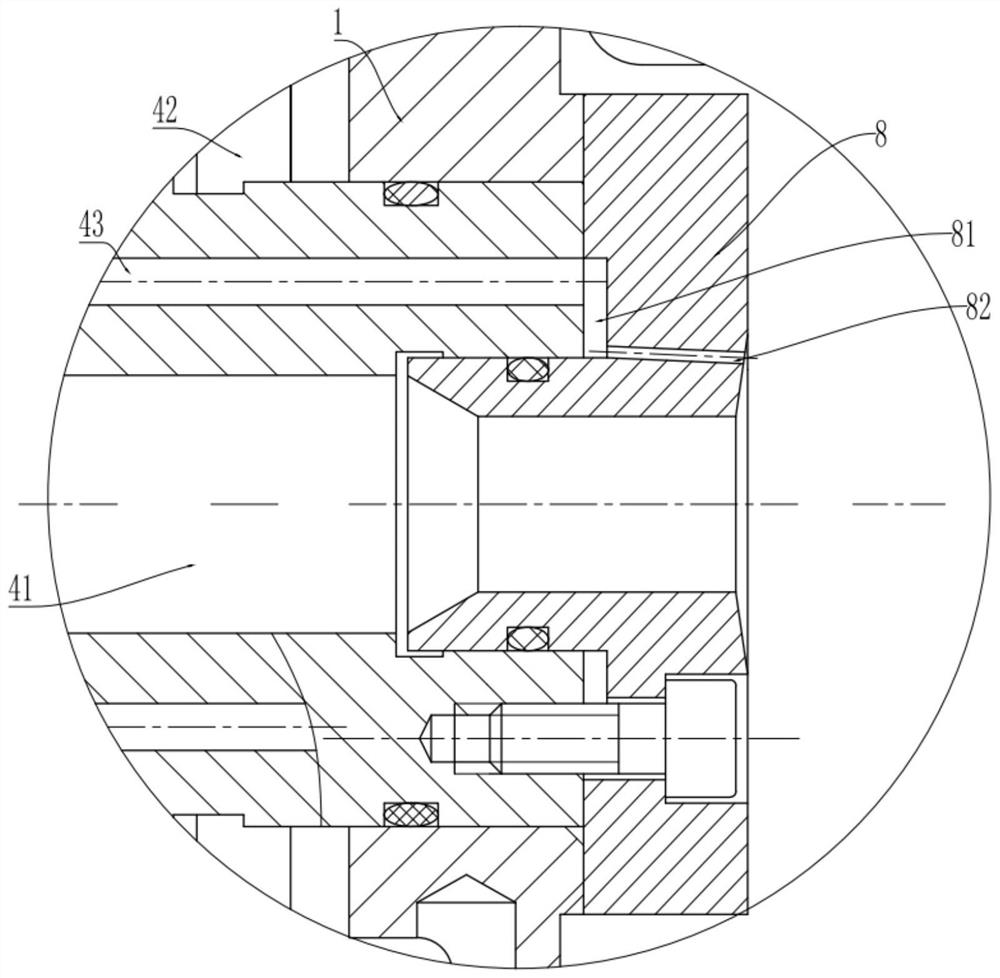

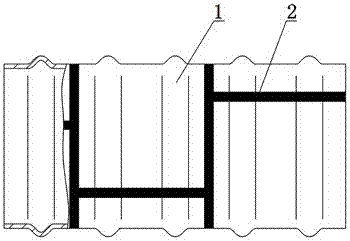

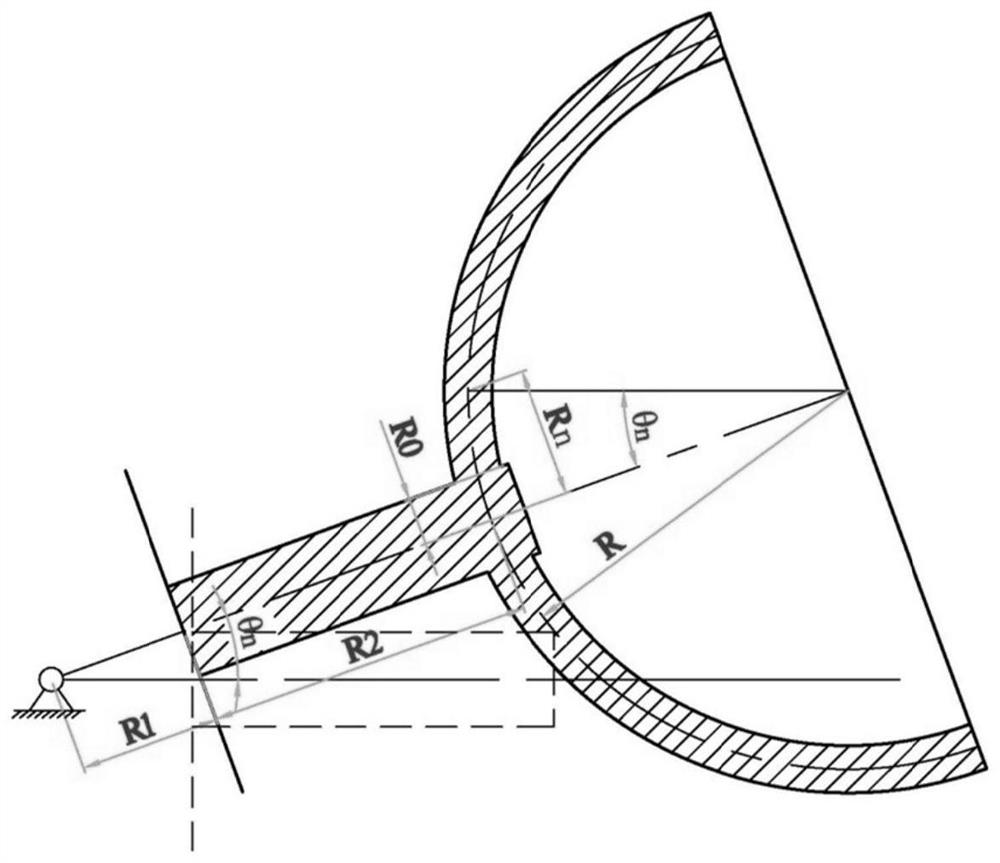

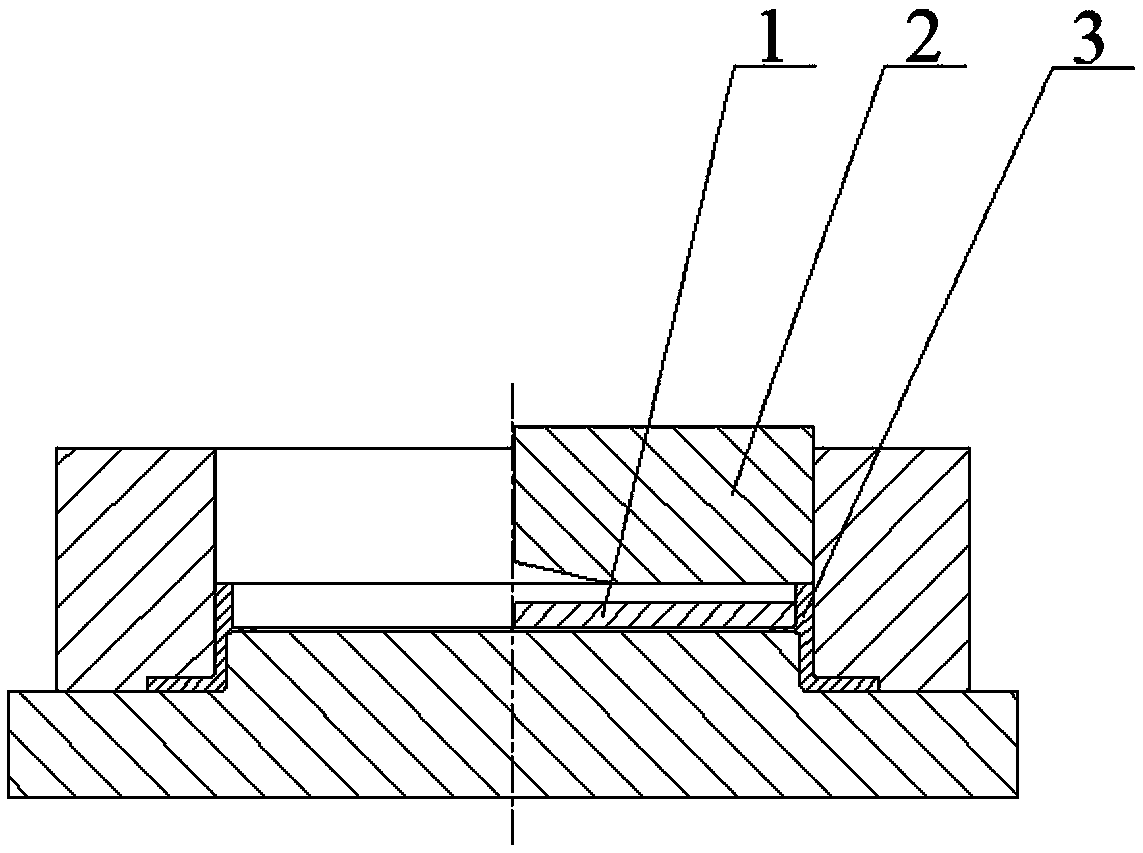

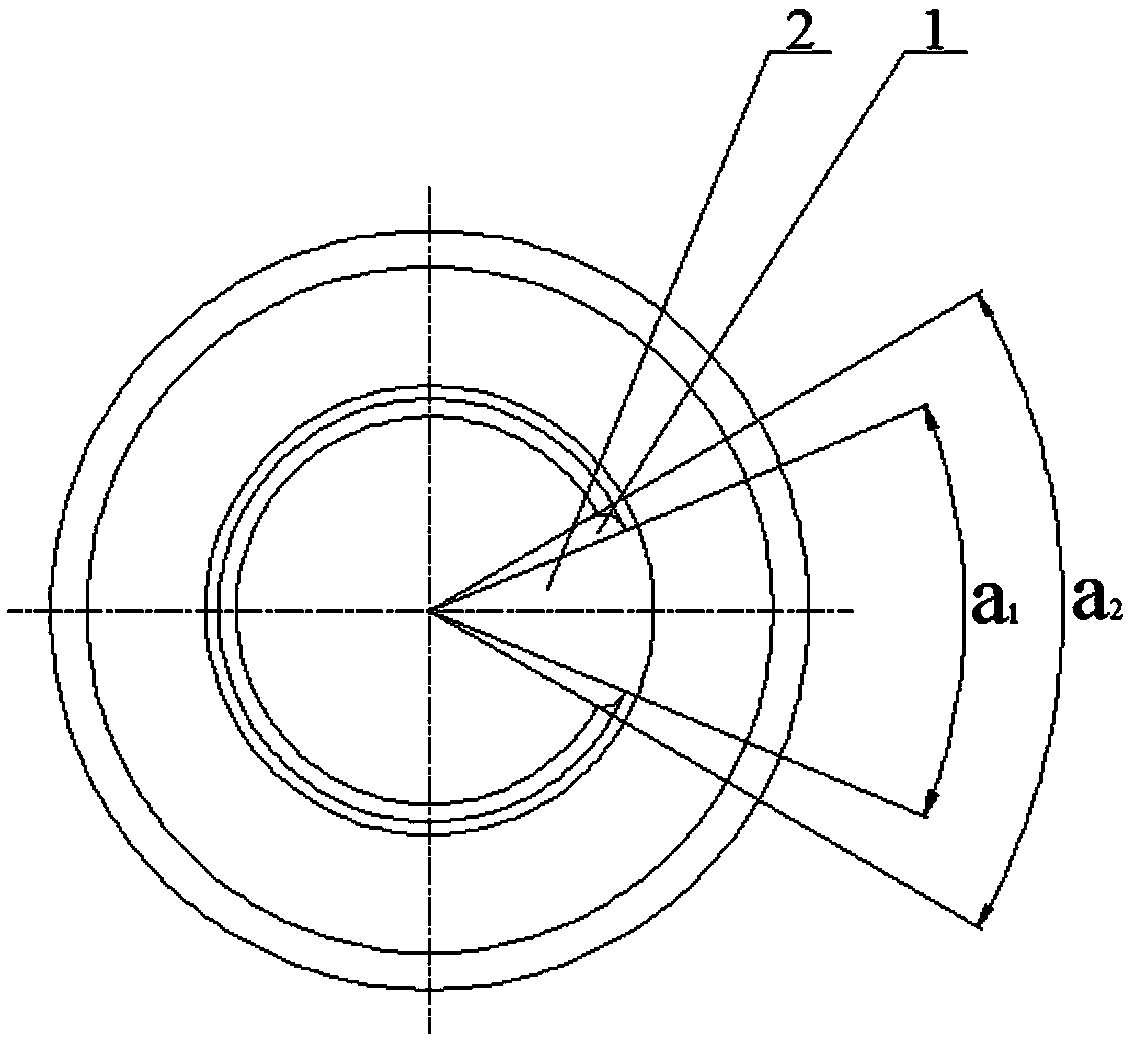

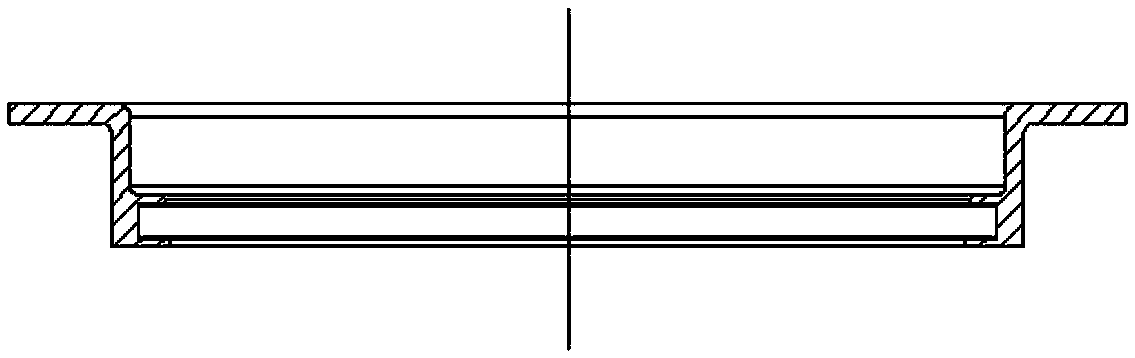

Internal spinning forming method for corrugated tube

ActiveCN105537345AImprove product qualityReduced circumferential weldsEngineeringMechanical engineering

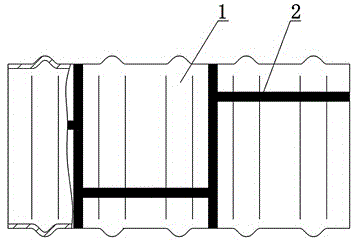

The invention discloses an internal spinning forming method for a corrugated tube. The internal spinning forming method for the corrugated tube comprises the following steps that a tube billet is installed on a main shaft of a spinning machine, and a length thin tube is driven by the main shaft to rotate; the interior and the exterior of the tube billet are respectively provided with an inner spinning roller and an outer spinning roller for forming corrugations; the inner spinning roller and the outer spinning roller synchronously work; a feed rate of the inner spinning roller is paused until a gap between a convex molded surface of the inner spinning roller and a concave molded surface of the outer spinning roller is 1.1 to 1.3 times of the thickness of the tube billet, and the gap is kept for forming for 3 to 5 seconds until one position machining is finished; the inner spinning roller and the outer spinning roller synchronously move for one pitch of waves along the axial direction of the tube billet, and the steps are repeated until the corrugated tube of a required length is formed. The internal spinning forming method disclosed by the invention is higher in forming precision and low in forming cost; moreover, a metallographic structure is even and compact due to grain refinement and spinning deformation of the corrugated tube during a spinning process; meanwhile, grains are squashed and stretched to form a fibrous tissue in a spinning direction; product quality is high, and the service life is greatly prolonged.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

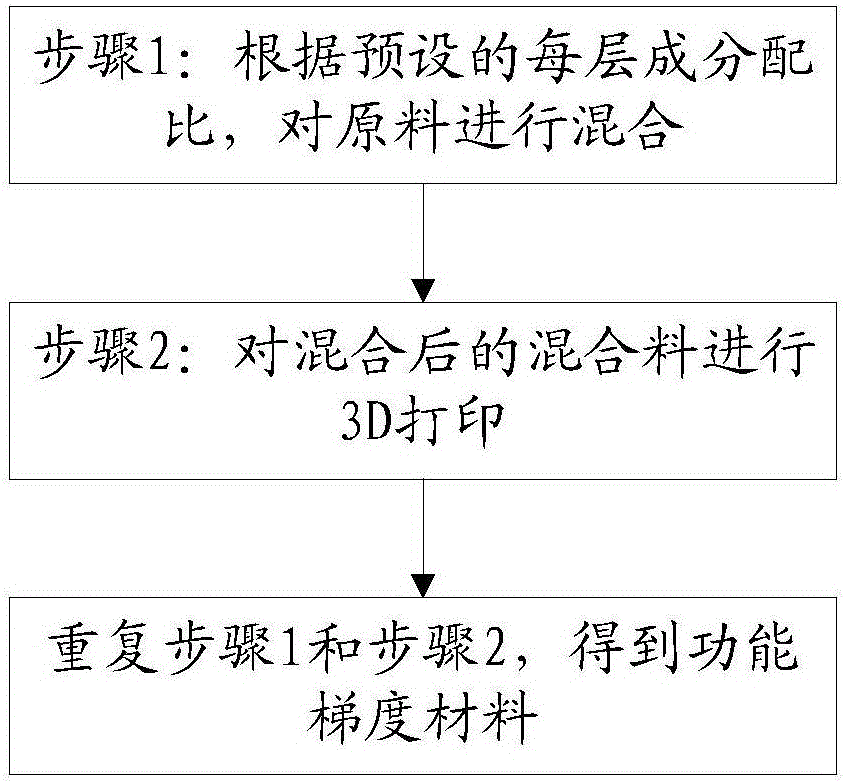

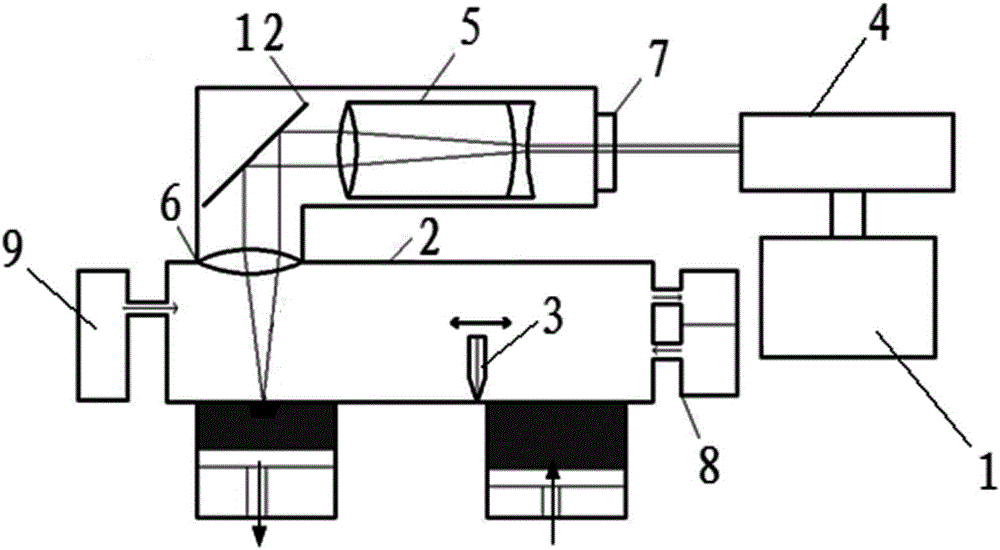

Functionally gradient material forming method and functionally gradient material forming device

InactiveCN106735211AReduce forming difficultyAdditive manufacturing apparatusIncreasing energy efficiencyFunctionally gradient materialMixed materials

The invention discloses a functionally gradient material forming method and a functionally gradient material forming device. The functionally gradient material forming method at least includes firstly, mixing raw materials according to a preset proportion of each layer of components; secondly, subjecting the mixed materials to 3D printing; thirdly, repeating the first step and the second step so as to obtain a functionally gradient material. The functionally gradient material forming method and the functionally gradient material forming device have the advantages that the raw materials are mixed firstly, the mixed materials are subjected to 3D printing, and complex three-dimensional processing is converted into simple two-dimensional processing, so that complex part forming difficulty is lowered greatly, and the functionally gradient material of a complex structure can be formed simply.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

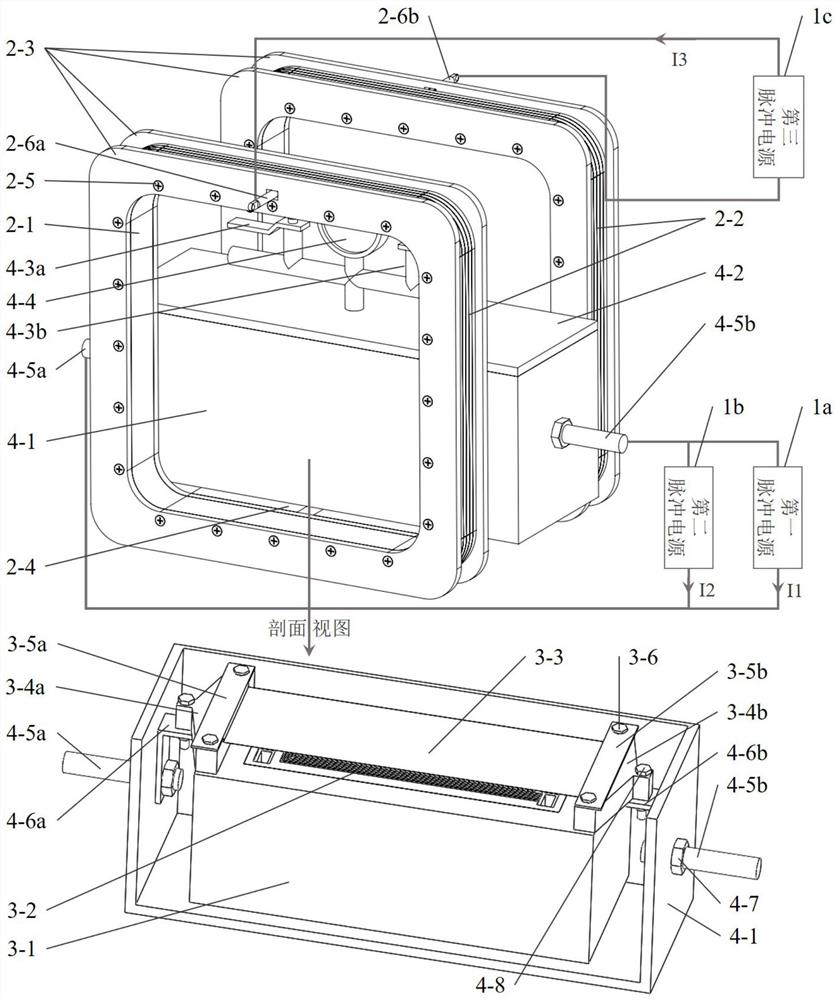

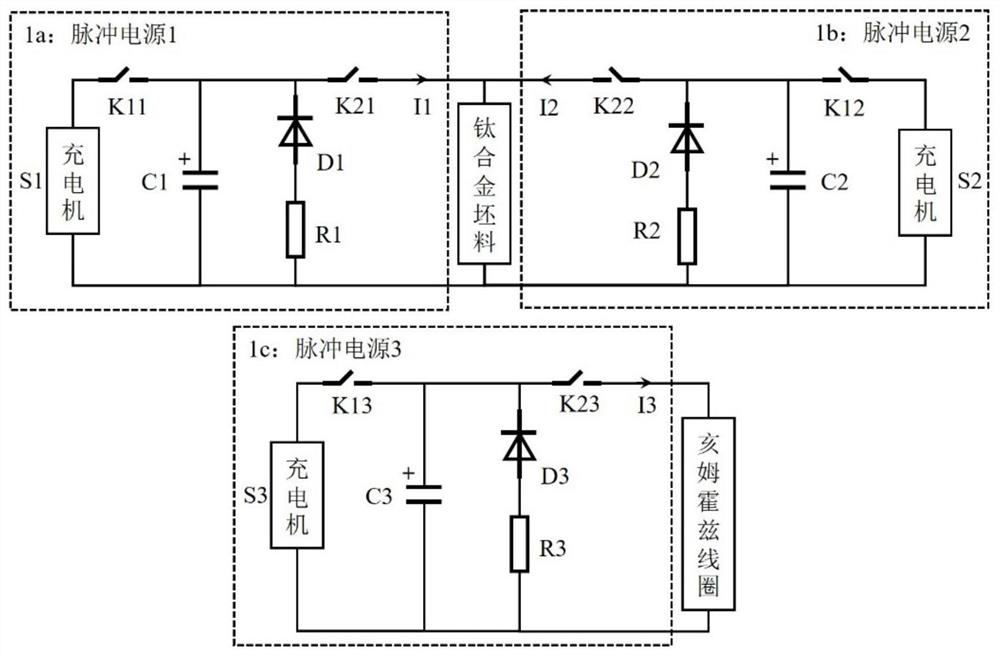

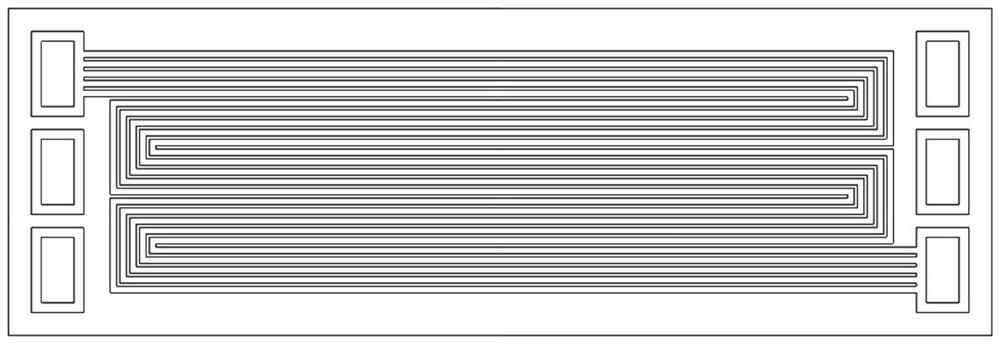

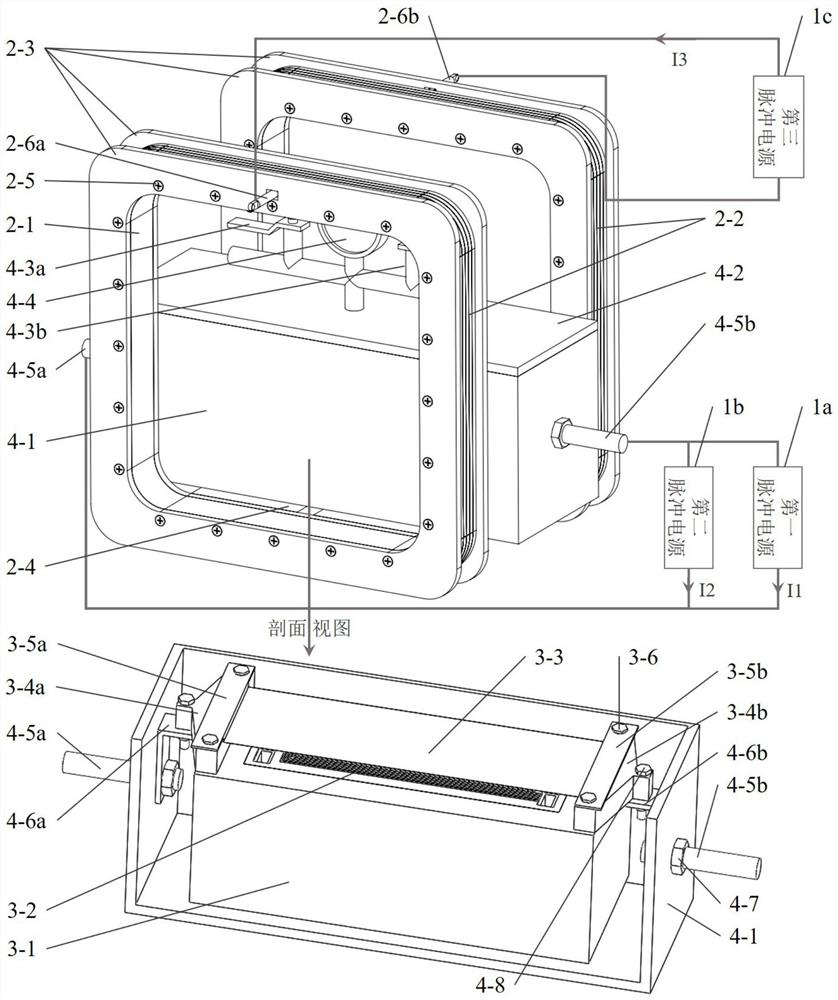

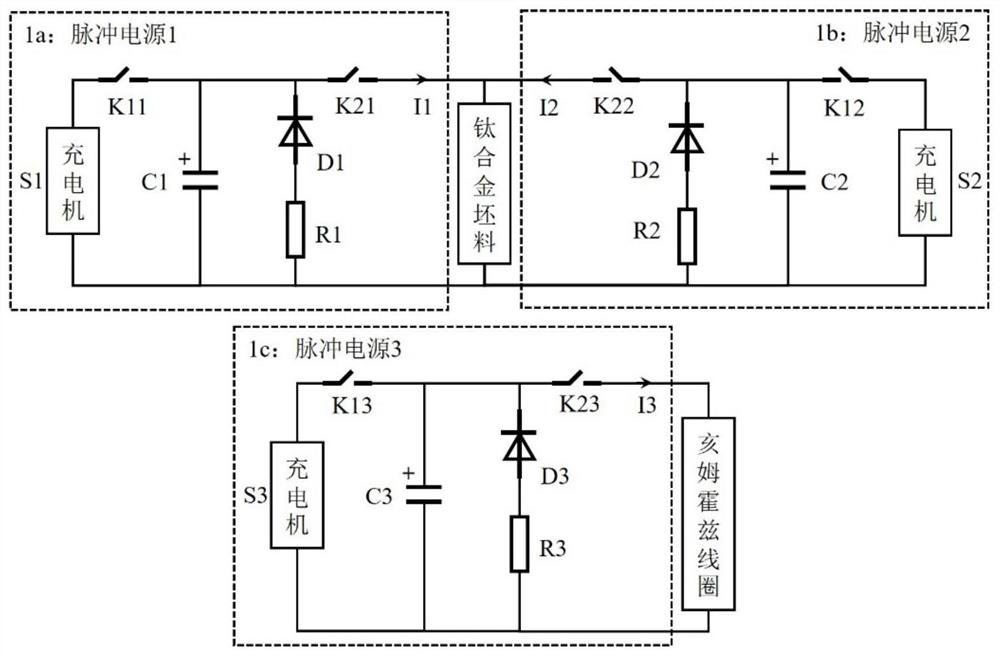

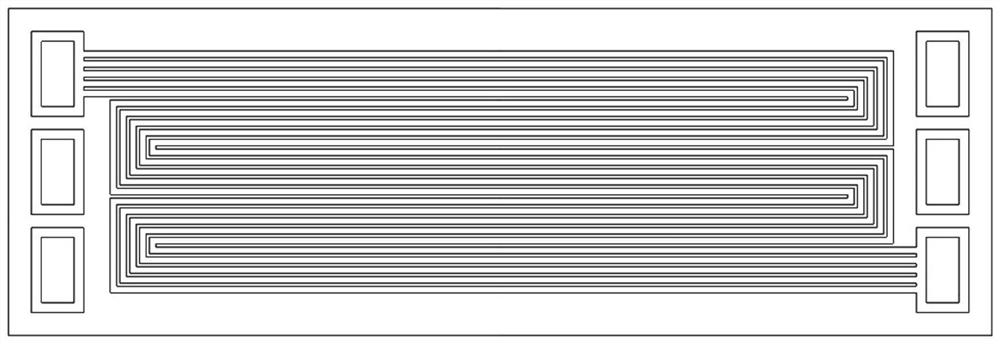

Titanium alloy bipolar plate forming device and method based on multi-time-sequence pulse current

The invention belongs to the technical field of manufacturing of metal bipolar plates for fuel cells, and particularly relates to a fuel cell titanium alloy bipolar plate electromagnetic-thermal composite forming device and method based on multi-time-sequence pulse current. A power module of the device comprises a plurality of sets of pulse power sources, the pulse power sources discharge a titanium alloy blank and a Helmholtz coil according to the time sequence, preheat the titanium alloy blank, generate pulse current in the titanium alloy blank, generate a pulse magnetic field in the Helmholtz coil, generate pulse electromagnetic force under the combined action of the pulse current and the pulse magnetic field, and drive the titanium alloy blank to rush to a mold, and forming of a titanium alloy bipolar plate is achieved. Through multi-level time sequence pulse current discharging, the plasticity and forming performance of titanium alloy are greatly improved through the thermal effect of the titanium alloy at high temperature, the electro-plastic effect of the pulse current and the high strain rate effect of the pulse electromagnetic force, and high-quality forming of the titanium alloy bipolar plate is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

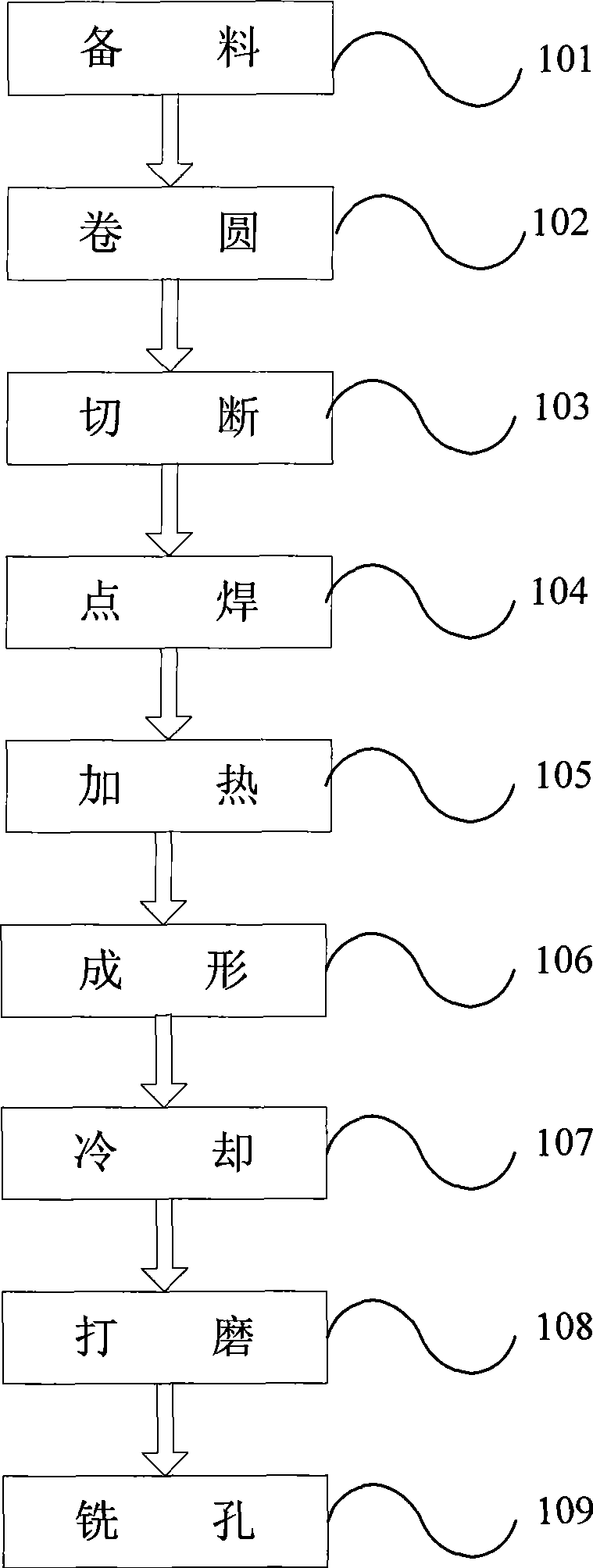

Technology for manufacturing lock ring for wheeled engineering machinery wheel and shaping mold thereof

InactiveCN101486141AReduce forming difficultyHigh shape accuracyForging/hammering/pressing machinesEngineeringSpot welding

The invention discloses a process and a forming die for manufacturing a lock ring for wheels of a wheel type construction machinery vehicle, and belongs to the technical field of construction machinery. The process comprises the following working procedures: winding into a circle, wherein long materials are wound into spiral ring materials; cutting, wherein the spiral ring materials are cut into single multiple length ring materials according to the specification of a prefabricated lock ring; performing spot welding, wherein spot welding is performed on cuts of the single multiple length ring materials to form an enclosed ring blank; heating, wherein the ring blank is heated to be between 680 and 720 DEG C to form a heating workpiece; forming, wherein dimensions and size of the heating workpiece are finished by the forming die to form the workpiece; cooling, wherein the formed workpiece is cooled directly in air; polishing, wherein welding spots of the cooled workpiece are polished to be neat, bright and clean; and milling a hole, wherein the hole on the polished workpiece is milled by a miller to manufacture a finished product lock ring. The invention is suitable for manufacturing the lock ring for the wheels of the wheel type construction machinery vehicle.

Owner:HONGYUAN JINGGONG WHEEL CO LTD

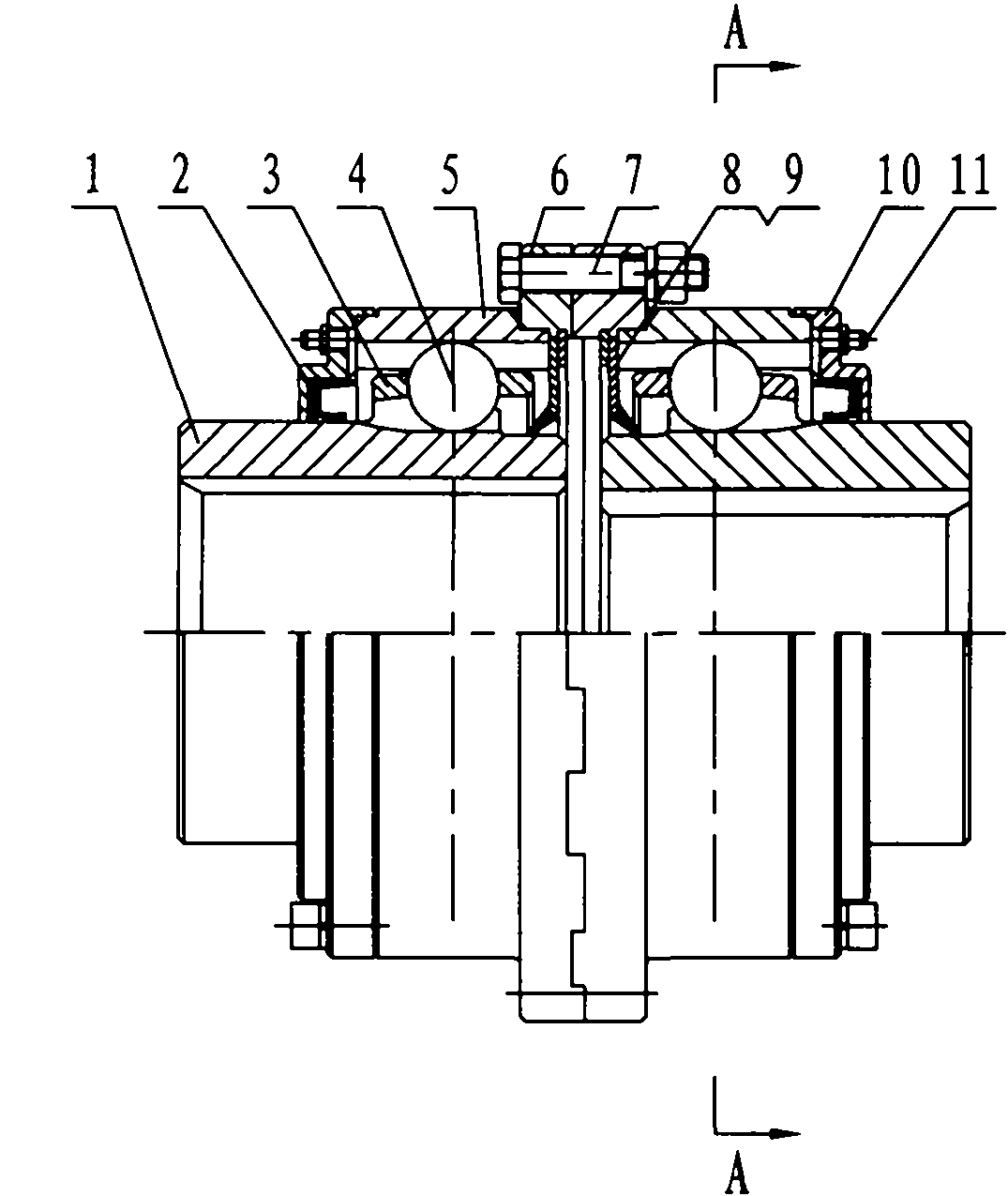

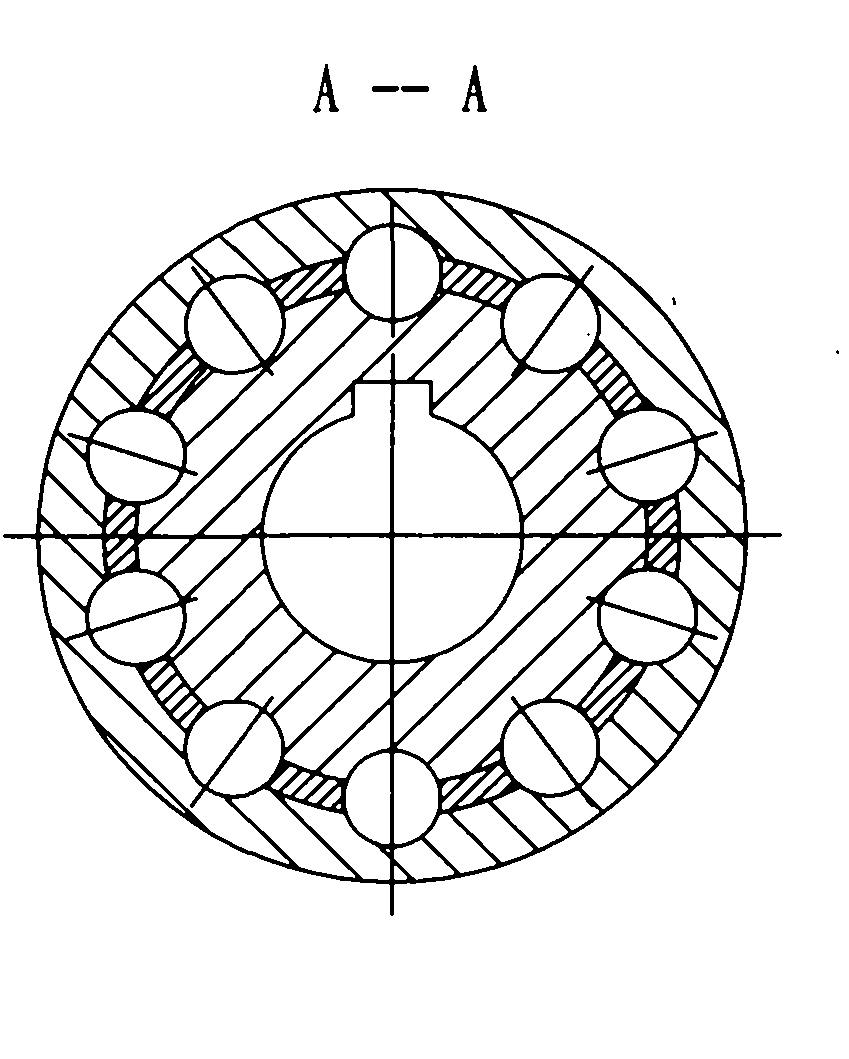

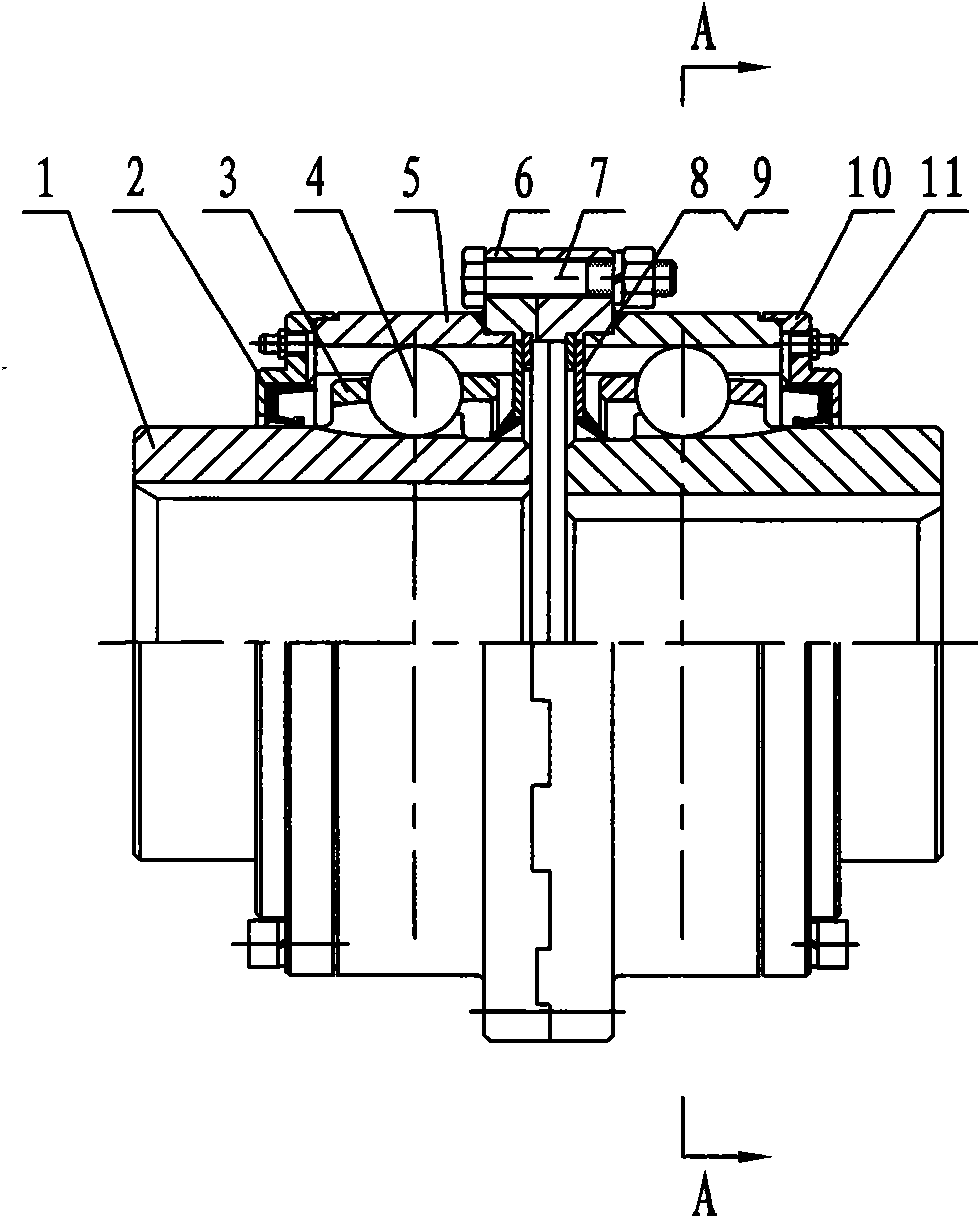

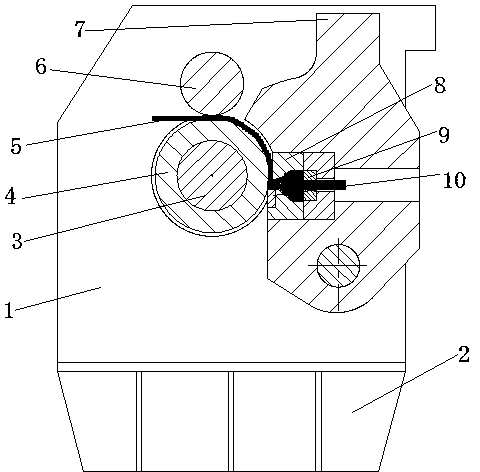

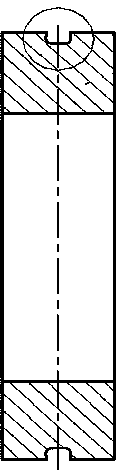

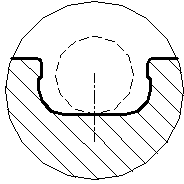

Jacket-welded short CV joint coupling

The invention relates to a jacket-welded short CV joint coupling which is mainly used for power transmission of short distance, small inclination angle and high rotation speed in metallurgical machinery, heavy-duty machinery, mining machinery, hoisting machinery, transport machinery and other industries. The coupling consists of an inner sleeve, an oil seal, a retainer, steel balls, jackets, contrate gears, bolts, a sealing baffle, hole retaining rings, a gland and an oil nozzle, wherein the two contrate gears are installed between the two jackets, the flange bosses of the contrate gears are fixed together by the bolts, and the contact surfaces of the contrate gears are of a dentiform structure and are meshed with each other to realize power transmission from a driving end and a driven end. By dividing the original jackets into the fluted jackets and the contrate gears, the invention realizes that the jackets and the contrate gears can be respectively made of more appropriate materials and made into more appropriate dimensions, thereby greatly improving the material utilization ratio, reducing the process redundancy, lowering the materials loss and the shaping difficulty, facilitating the design and the selection of the connection type of the contrite gears, enabling the organization and the arrangement of production to be more flexible, and having a shorter processing cycle. Thus, the invention meets batch and emergency requirements of modern mechanical industrial equipment.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

Preparation method for high-performance Fe-Si soft magnetic powder core

InactiveCN104668556AReduce forming difficultyImprove performanceInorganic material magnetismInductances/transformers/magnets manufactureHeat treatedSilicate

The invention relates to the technical field of powder metallurgy, in particular to a preparation method for a high-performance Fe-Si soft magnetic powder core. The preparation method includes the steps of raw material preparation, powder preprocessing, warm-pressing forming and blank heat treatment. According to the preparation method, Fe-6.5Si powder is adopted, and the Fe-Si soft magnetic powder core is prepared according to a powder metallurgy method under the condition of high content of Si. By a warm-pressing process introduced to substitute for a conventional pressing process, forming difficulty of high-Si-content Fe-Si powder is lowered; silicates and multicomponent oxides serve as a composite inorganic binder to substitute for a conventional single inorganic binder so as to improve magnetic performance of the magnetic powder core and prepare the soft magnetic powder core with good comprehensive performance.

Owner:邹和平

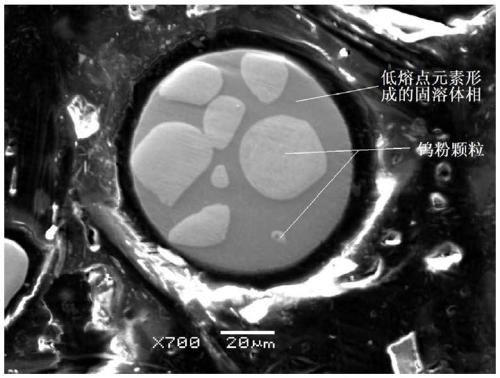

High-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder

ActiveCN110315076APromote meltingNot easy to melt and formAdditive manufacturing apparatusIncreasing energy efficiencyManufactured formSolid solution

The invention discloses a high-specific-gravity tungsten-based alloy formation method based on pre-alloyed powder. The high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder comprises the steps that firstly, according to the designed ingredients and proportion of the high-specific-gravity tungsten-based alloy, material mixing, pressing, vacuum sintering and forging machining are sequentially conducted, then a tungsten-based alloy rod is obtained, and pre-alloyed powder is obtained through a plasma-rotating electrode powder manufacturing method; secondly, athree-dimensional model of the high-specific-gravity tungsten-based alloy is established, slicing and designing are conducted, and then slice layers and scanning data are obtained; thirdly, with the pre-alloyed powder as the raw material, according to the slice layers and the scanning data, a powder bed type electron beam additive manufacturing forming device is adopted to form the high-specific-gravity tungsten-based alloy. According to the high-specific-gravity tungsten-based alloy formation method based on the pre-alloyed powder, by utilizing the different melting points between tungsten and other elements in the high-specific-gravity tungsten-based alloy, the pre-alloyed powder with tungsten powder particles being wrapped inside low-melting-point element solid solution is prepared, sothat the shells of the pre-alloyed powder are easy to melt and adhere to one another for formation, and therefore the formation difficulty of the pre-alloyed powder is lowered; and with the pre-alloyed powder as the raw material, preparation of the high-specific-gravity tungsten-based alloy is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Continuous extrusion method and extrusion tool for lead frame material of shallow wheel trough

The invention discloses a continuous extrusion method for a lead frame material of a shallow wheel trough. The continuous extrusion method comprises the following steps that (a) billets are pressed into a shallow wheel trough extrusion wheel by a shallow wheel trough compaction wheel; (b) the billets pressed into the shallow wheel trough extrusion wheel rotate with the shallow wheel trough extrusion wheel and are subjected to plastic deformation under the driving of a fraction force; (c) after forwards moving to a shallow wheel trough baffling block, the billets enter a shallow wheel trough cavity through a shallow wheel trough cavity inlet and are subjected to expansion deformation; (d) after being subjected to the expansion deformation, the billets are extruded through a mold in the shallow wheel trough cavity, so as to form a product. The continuous extrusion method and an extrusion tool for the lead frame material of the shallow wheel trough have the advantages that the service life of the mold is prolonged, and meanwhile, due to the decrease of the difficulty of the expansion deformation, deformed metal can rapidly enter the cavity and can be rapidly extruded from the mold, so that the production energy consumption of the unit product is reduced; secondly, a shallow wheel trough extrusion device with the same main shaft diameter can be used for producing products having larger widths and sections.

Owner:DALIAN JIAOTONG UNIVERSITY

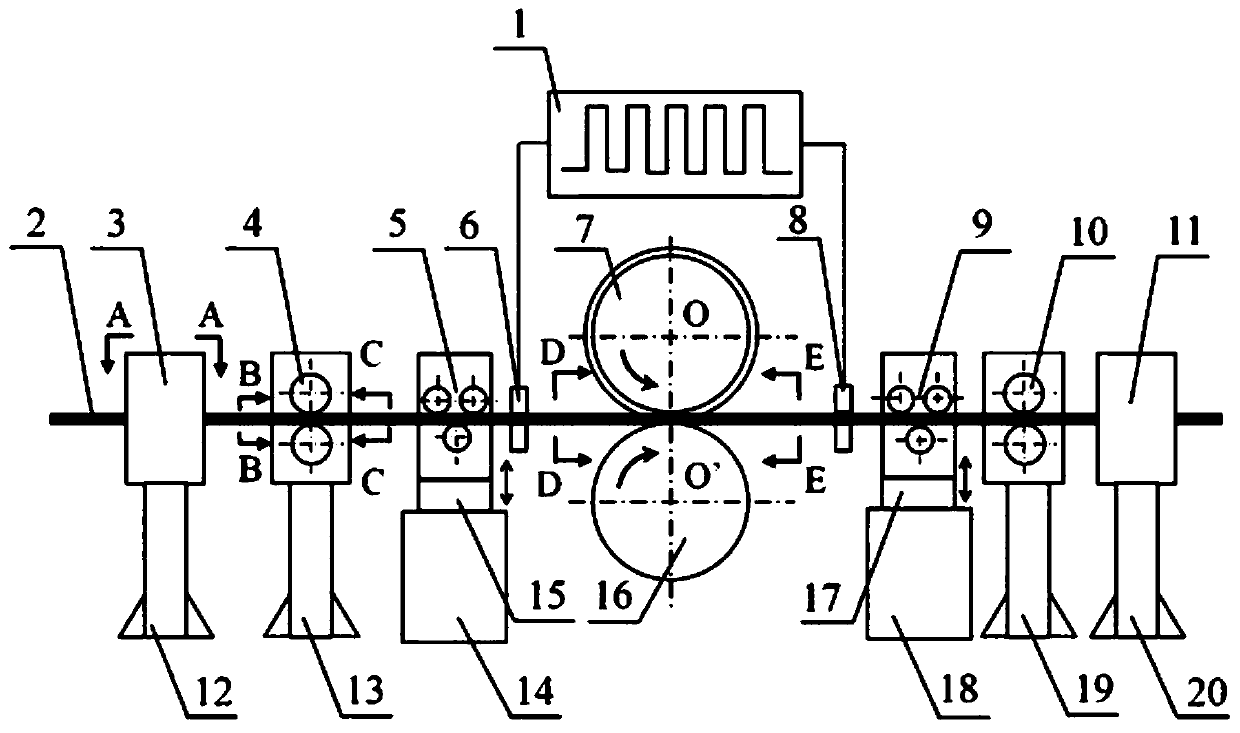

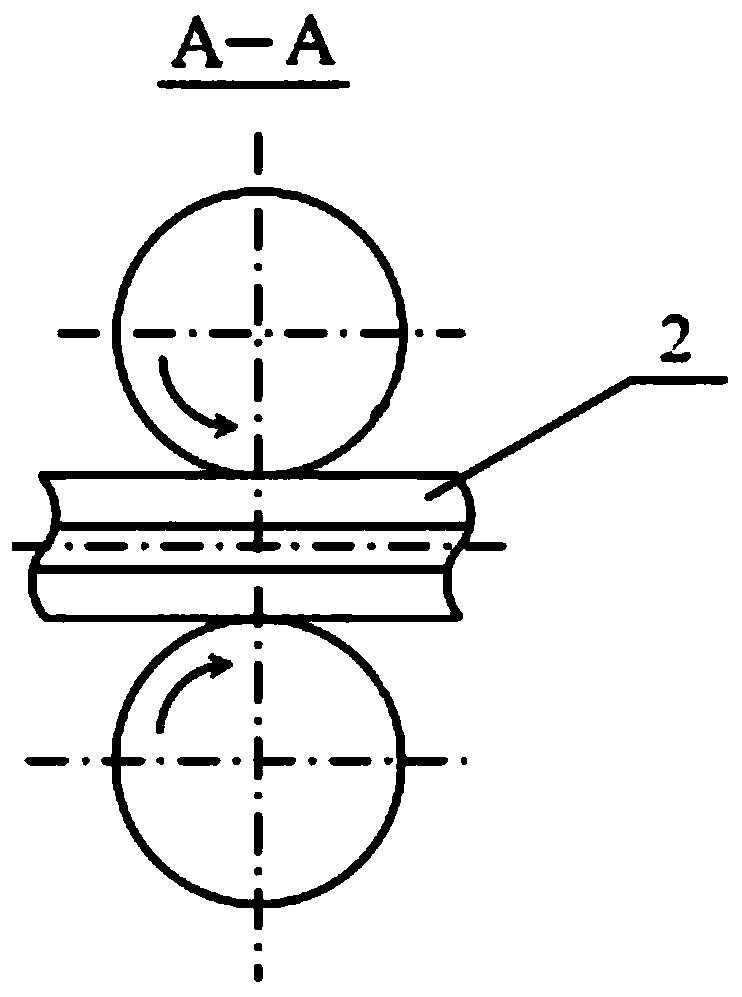

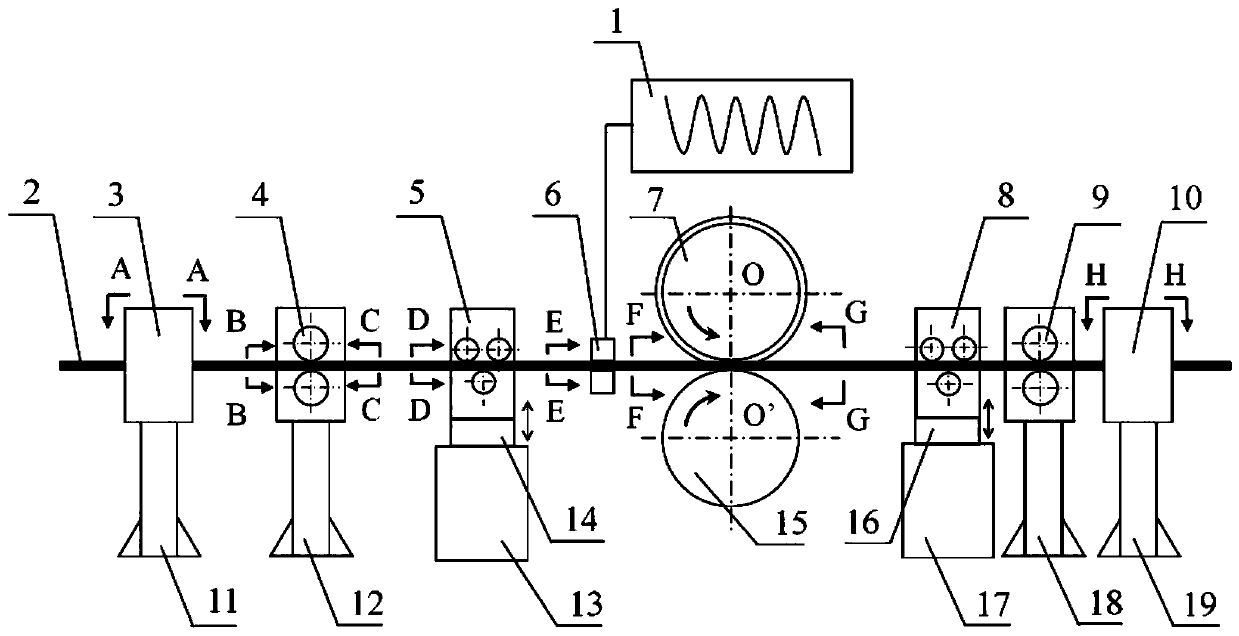

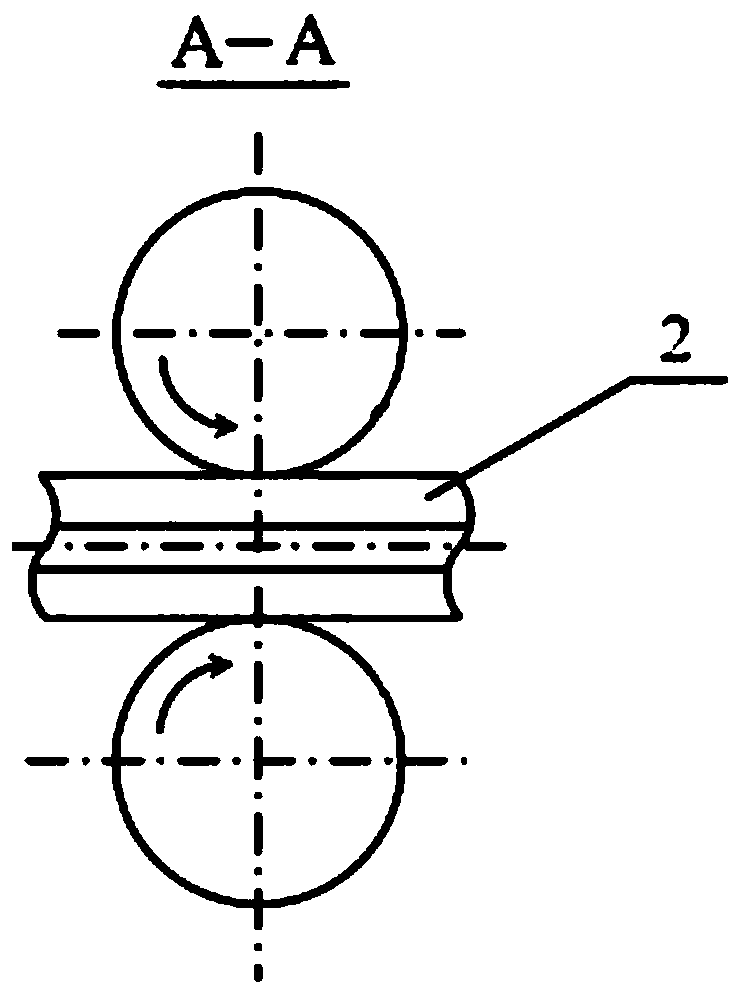

Ultrasonic and pulse current mixing auxiliary wedge-shaped cavity profile rolling line and rolling process

PendingCN111136104AAchieving Restorative HealingReduce deformation resistanceGuiding/positioning/aligning arrangementsRollsUltrasonic vibrationBrush

The invention relates to the technical field of groove profile rolling, in particular to an ultrasonic and pulse current mixing auxiliary wedge-shaped cavity profile rolling line and a rolling process. The ultrasonic and pulse current mixing auxiliary wedge-shaped cavity profile rolling line is characterized in that a left horizontal alignment roller, a pre-rolling roller, a left ultrasonic vibration roller, a left electric brush, a roller set, a right electric brush, a right ultrasonic vibration roller, a right height alignment roller and a right horizontal alignment carrier roller are sequentially arranged along the rolling line, the left horizontal alignment roller and a right horizontal alignment roller are composed of a left roller and a right roller which are horizontally arranged, the pre-rolling roller and the right height alignment roller are composed of an upper roller and a lower roller which are vertically arranged, the left ultrasonic vibration roller and a right ultrasonic vibration roller are composed of an upper roller and a lower roller which are vertically arranged, and the roller set is composed of an upper roller and a lower roller which are vertical arranged; the ultrasonic vibration module is connected with the left ultrasonic vibration roller and the right ultrasonic vibration roller, and drives the left ultrasonic vibration roller and the right ultrasonic vibration roller to vibrate ultrasonically; and the left electric brush and the right electric brush are connected with a pulse current source. The rolling difficulty of a wedge-shaped cavity profile is reduced, the rolling efficiency is improved, and the size precision and the surface finish of the wedge-shaped cavity profile are improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Forming method and forming mold of semi-closed sheet part

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

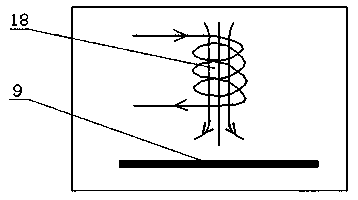

Ultrasonic wave and induced current mixed auxiliary wedge-shaped cavity sectional material rolling line and rolling process

PendingCN111136102ASoften fastGood formabilityGuiding/positioning/aligning arrangementsRollsEngineeringUltrasonic vibration

The invention relates to the technical field of wedge-shaped cavity sectional material rolling, in particular to an ultrasonic wave and induced current mixed auxiliary wedge-shaped cavity sectional material rolling line and a rolling process. A left horizontal calibration roller, a pre-rolling roller, a left ultrasonic vibration roller, a heating coil, an upper roller, a lower flat roller, a rightultrasonic vibration roller, a right height calibration roller and a right horizontal calibration carrier roller are sequentially arranged along the rolling line, the left horizontal calibration roller and the right horizontal calibration roller are composed of a left roller and a right roller which are arranged in the horizontal direction, the right height calibration roller is composed of the upper roller and a lower roller which are arranged in the vertical direction, the left ultrasonic vibration roller and the right ultrasonic vibration roller are composed of the upper roller and the lower roller which are arranged in the vertical direction, the upper roller and the lower flat roller are arranged up and down in the vertical direction, an ultrasonic vibration module is connected withthe left ultrasonic vibration roller and the right ultrasonic vibration roller and drives the left ultrasonic vibration roller and the right ultrasonic vibration roller to vibrate ultrasonically, andthe heating coil is connected with an induction current source. According to the ultrasonic wave and induced current mixed auxiliary wedge-shaped cavity sectional material rolling line and the rollingprocess, the processing forming performance is improved, the processing forming difficulty is reduced, the sectional material size precision and smoothness are improved, and the processing energy consumption is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

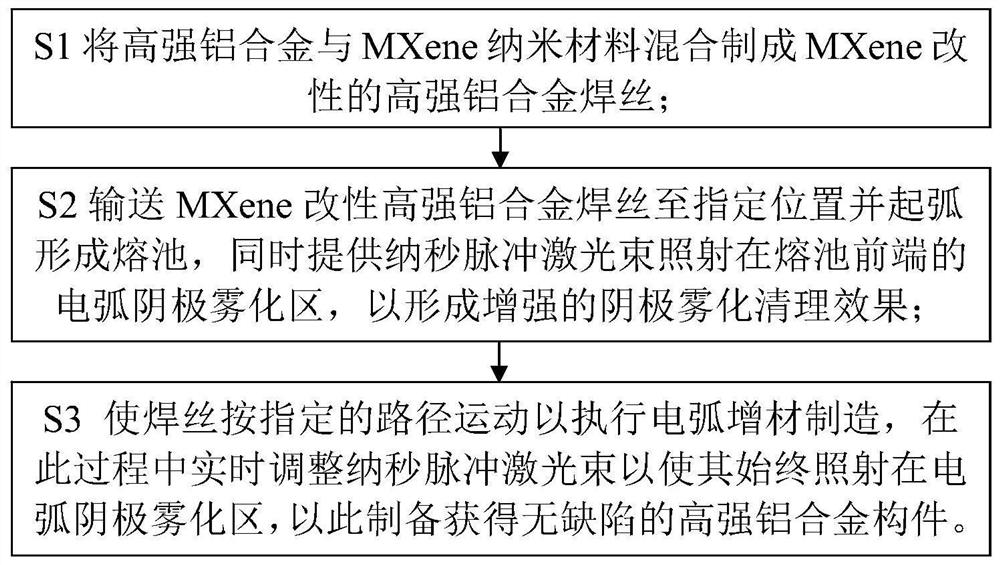

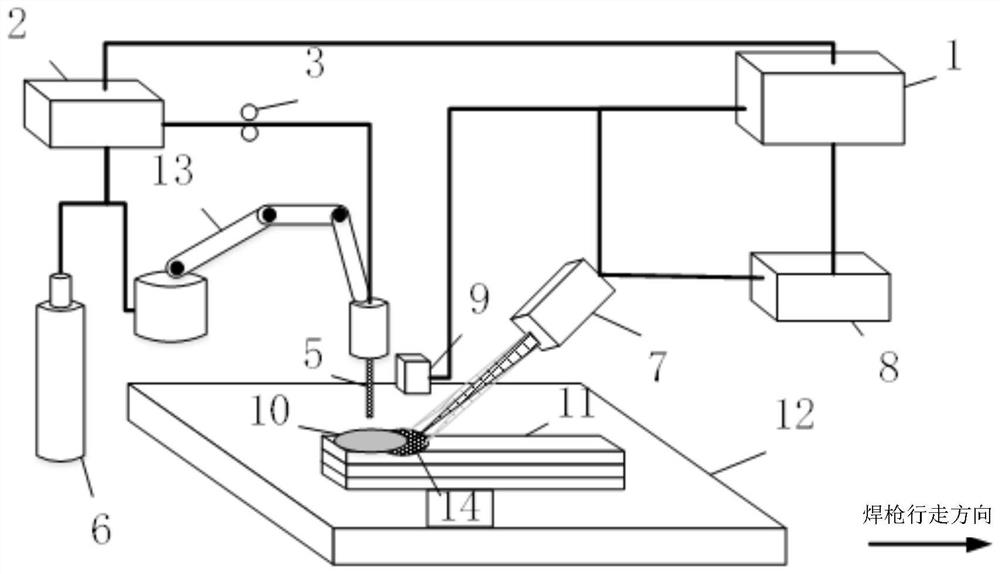

Arc additive manufacturing method, equipment and product of high-strength aluminum alloy member

ActiveCN111843215AQuality improvementReduce forming difficultyAdditive manufacturing apparatusWeld torches cleaningNanosecond laserSilumin

The invention belongs to the field of arc additive manufacturing, and particularly discloses an arc additive manufacturing method, equipment and product of a high-strength aluminum alloy member. MXenenano material is used for modifying high-strength aluminum alloy, the modified high-strength aluminum alloy is used as a raw material for arc additive manufacturing, a nanosecond laser beam is simultaneously applied in the arc additive manufacturing process to form an enhanced arc cathode atomization cleaning effect to clear impurities, and then the defect-free high-strength aluminum alloy memberis prepared. The arc additive manufacturing method, equipment and product of the high-strength aluminum alloy member can solve the problem that the forming difficulty of high-strength aluminum alloyarc additive manufacturing is high, simultaneously solves the problems of generation of many air holes, tendency to cracking and generation of many impurities in the process of high-strength aluminumalloy additive manufacturing, and can prepare the defect-free high-strength aluminum alloy member.

Owner:WUHAN UNIV

Preparation method of high-performance FeSi soft magnetic powder core

InactiveCN107910177AImprove magnetic propertiesExcellent overall performanceTransportation and packagingMetal-working apparatusPowder metallurgyMagnetic powder

The invention relates to the technical field of powder metallurgy, in particular to a preparation method of a high-performance FeSi soft magnetic powder core. The preparation method of the high-performance FeSi soft magnetic powder core comprises the following steps of raw material preparation, powder pre-processing, temperature pressure formation and blank thermal processing. Fe-6.5Si powder is employed, and the Fe-Si soft magnetic powder core is prepared by a powder metallurgy method under the condition of relatively high Si content. The formation difficulty of the Fe-Si powder with high Sicontent is reduced by introducing a temperature pressure process to substitute a traditional press process, silicate and a multi-component oxide are used as a composite inorganic binding agent to substitute a traditional and single inorganic binding agent, so that the magnetic performance of the magnetic powder core is improved, and the soft magnetic powder core with favorable comprehensive performance is prepared.

Owner:SHAANXI SHENGMAI PETROLEUM

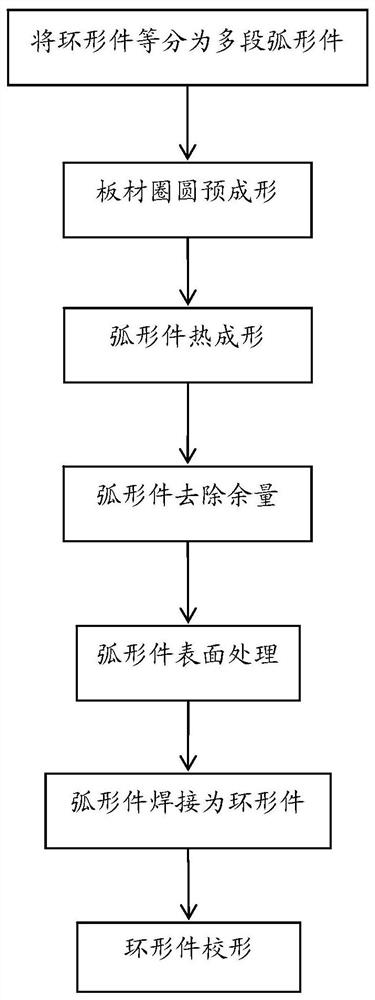

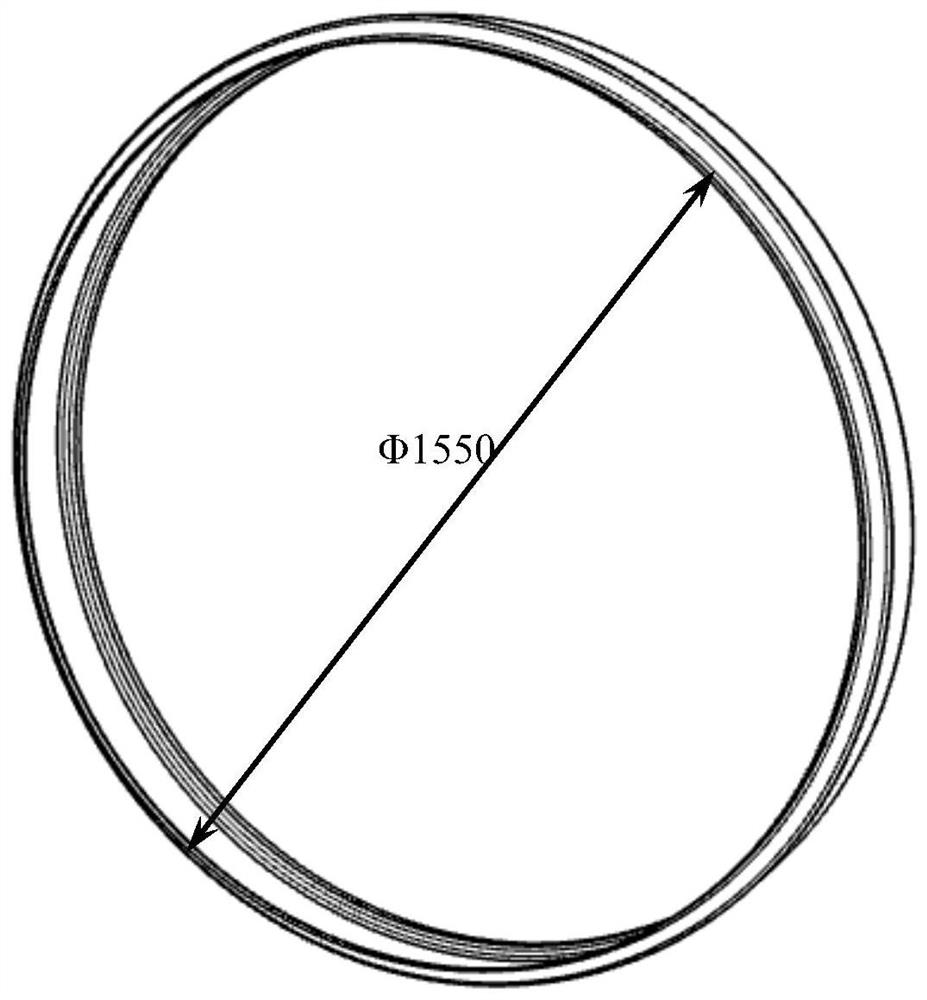

Forming method of large-size thin-wall complex curve section annular part

ActiveCN112676779AGuarantee product qualityReduce processing difficultyStructural engineeringMachining

The invention provides a forming method of a large-size thin-wall complex curve section annular part. The method comprises the following steps of dividing an annular part model into N arc-shaped part models in a circumferential direction according to a model size of the annular part; designing a hot forming process part and designing a hot forming die; determining a size of a needed blank, conducting blanking, conducting circle preforming on the blank obtained through blanking, and preparing a circle preformed part; conducting hot forming on the circle preformed part through the hot forming die to obtain the hot forming process part; removing a process allowance of the hot forming process part to prepare an arc-shaped part; conducting surface treatment on the N arc-shaped parts; assembling and welding the N arc-shaped parts subjected to surface treatment to obtain the annular part; and correcting the shape of the welded annular part. According to the method, a metal plate preforming plus hot forming plus welding composite forming technology is adopted, the most suitable forming technology is adopted for different portions, and therefore precise forming of parts is integrally achieved, the subsequent machining amount can be effectively reduced, subsequent manual shape correction is avoided, the efficiency is improved, and the cost is reduced.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

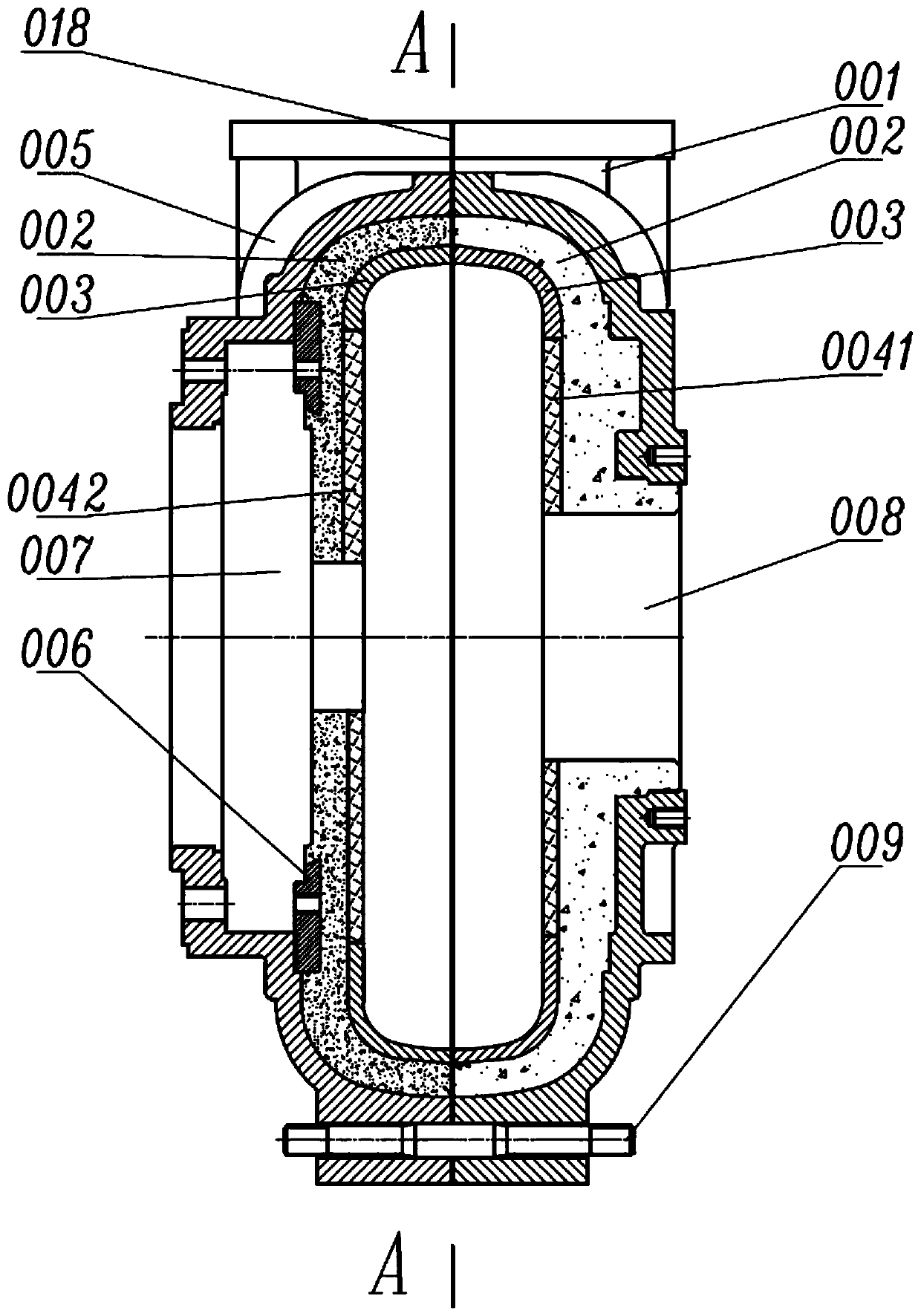

Wear-resistant pump body and manufacturing method thereof

PendingCN111456970AHigh degree of fitReduce misalignmentPump componentsCeramic shaping apparatusStructural engineeringMechanical engineering

The invention discloses a wear-resistant pump body and a manufacturing method thereof. The wear-resistant pump body comprises a shell and a lining arranged on the inner side of the shell, wherein a water inlet is formed in one side of the shell, the shell is provided with an A-A plane and a water outlet, the shell comprises a front shell and a rear shell which are detachably connected along the A-A plane, the lining comprises a plurality of curved plates which can be spliced in sequence, the lining further comprises a front annular plate arranged on one side close to the water inlet and a rearannular plate arranged on the other side, and a buffer wear-resistant layer is further arranged between the shell and the lining. The wear-resistant pump body has the advantages that the manufacturing cost of a wear-resistant pump can be remarkably reduced by selecting a reasonable splicing mode of a ceramic lining and the reasonable shape and boundary dimension of the curved plates, the coarse particle scouring resistance of the wear-resistant pump body is improved, the service life of the pump body is prolonged, the reliability of the pump body is improved, and the large-scale production iseasy to realize.

Owner:GUANGZHOU TOTALL MATERIAL TECH CO LTD

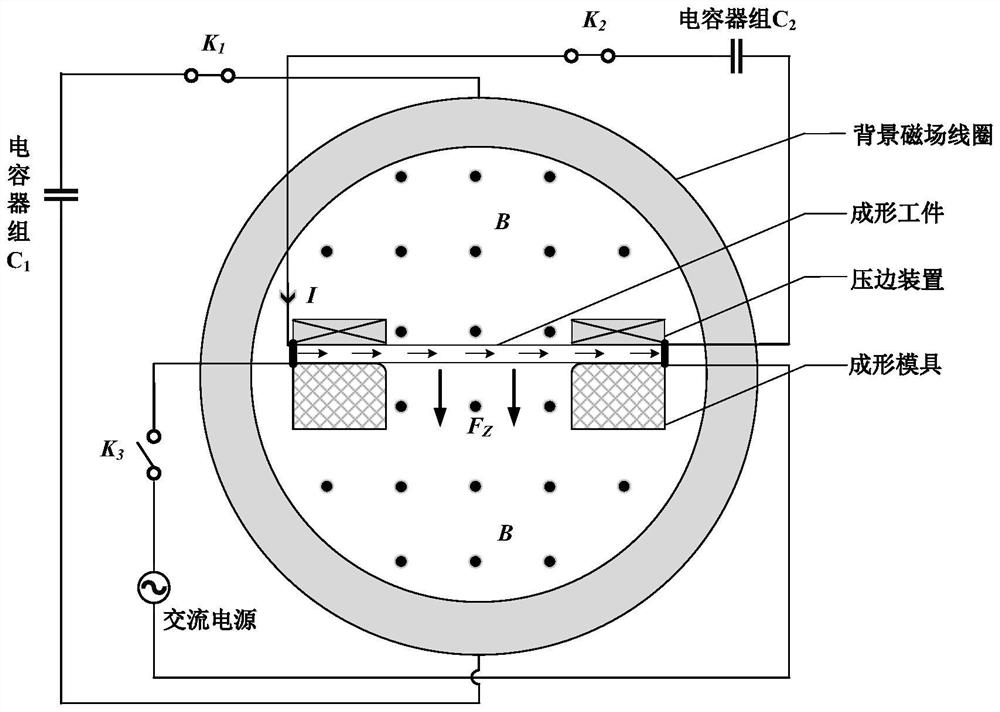

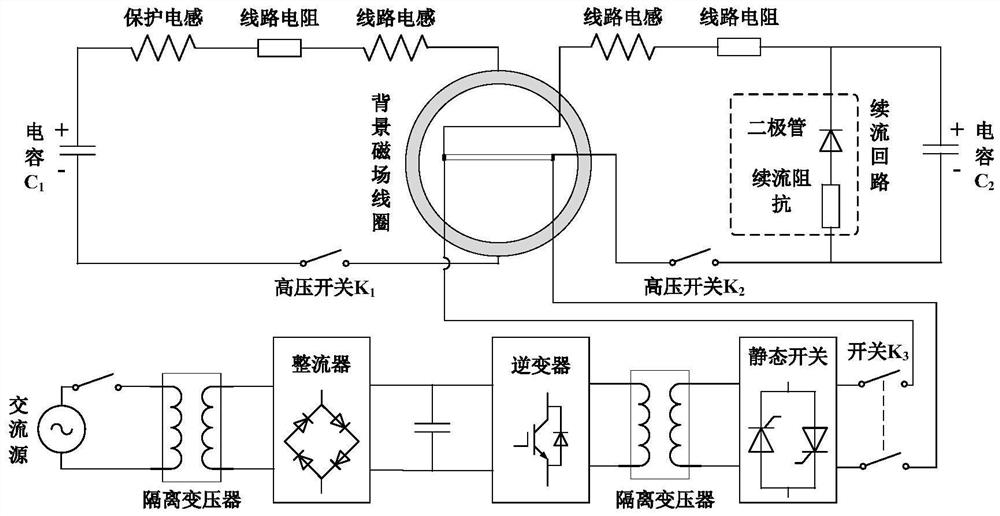

A device and method for forming titanium alloy bipolar plate based on multi-sequence pulse current

The invention belongs to the technical field of manufacturing of metal bipolar plates for fuel cells, and particularly relates to a fuel cell titanium alloy bipolar plate electromagnetic-thermal composite forming device and method based on multi-time-sequence pulse current. A power module of the device comprises a plurality of sets of pulse power sources, the pulse power sources discharge a titanium alloy blank and a Helmholtz coil according to the time sequence, preheat the titanium alloy blank, generate pulse current in the titanium alloy blank, generate a pulse magnetic field in the Helmholtz coil, generate pulse electromagnetic force under the combined action of the pulse current and the pulse magnetic field, and drive the titanium alloy blank to rush to a mold, and forming of a titanium alloy bipolar plate is achieved. Through multi-level time sequence pulse current discharging, the plasticity and forming performance of titanium alloy are greatly improved through the thermal effect of the titanium alloy at high temperature, the electro-plastic effect of the pulse current and the high strain rate effect of the pulse electromagnetic force, and high-quality forming of the titanium alloy bipolar plate is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

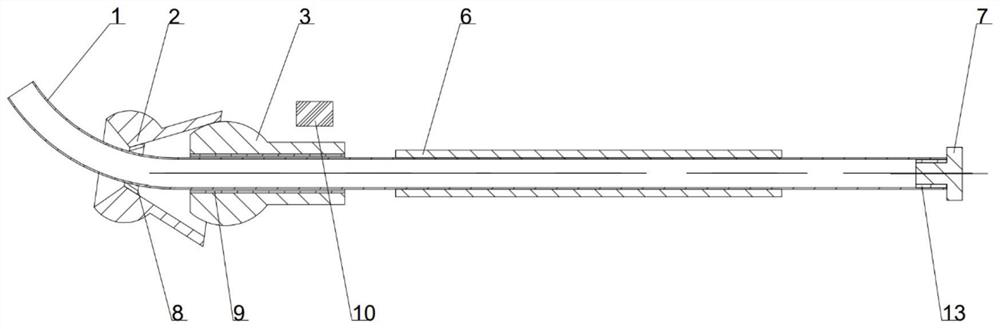

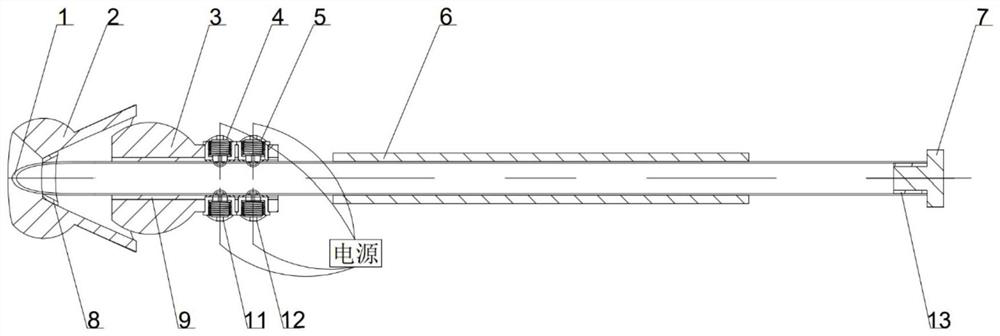

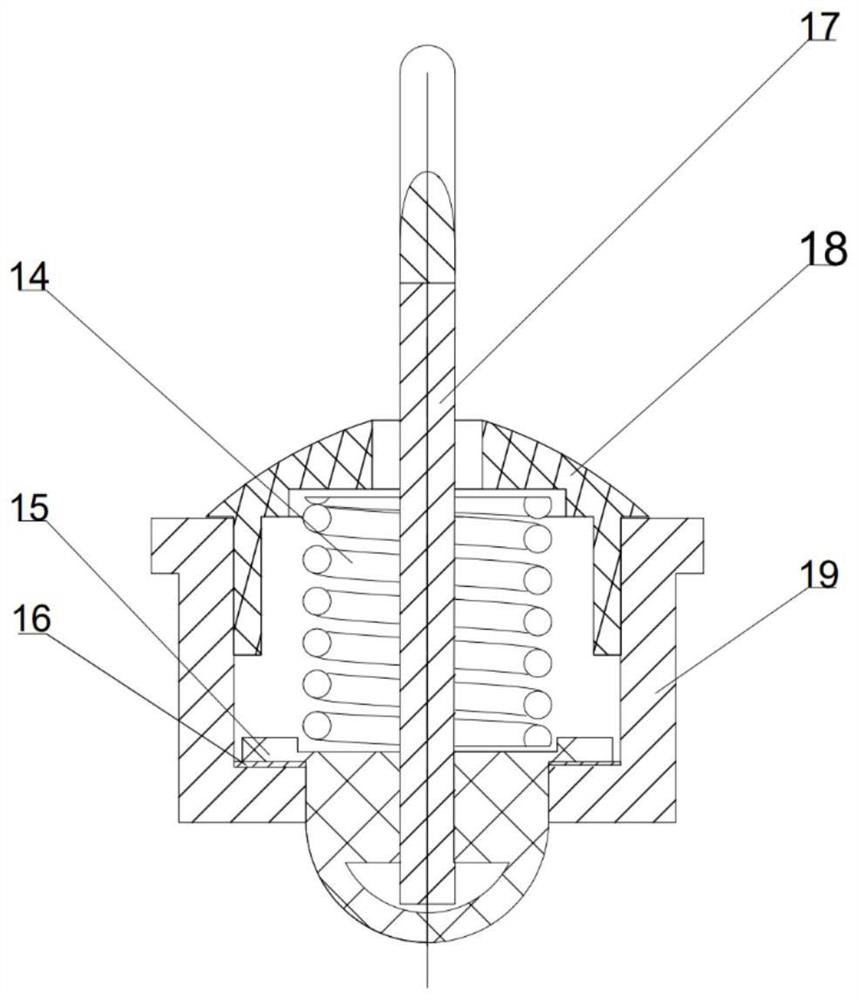

Three-dimensional free forming device and method based on current auxiliary heating

The invention discloses a three-dimensional free forming device and method based on current auxiliary heating, the three-dimensional free forming device comprises a pipe clamping mechanism for clamping a to-be-formed pipe fitting, the right end of the pipe clamping mechanism is provided with a pushing mechanism for pushing the end part of the pipe fitting, the pushing mechanism is provided with an insulating layer for being matched with the pipe fitting, and the insulating layer is arranged on the right end of the pipe clamping mechanism. A guide mechanism used for guiding a pipe fitting is arranged on the other side of the pipe clamping mechanism, and a bending die used for being matched with the pipe fitting and bending the pipe fitting is arranged at the outlet end of the guide mechanism in a matched mode. The heating power consumption is large, and the heating time is long.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

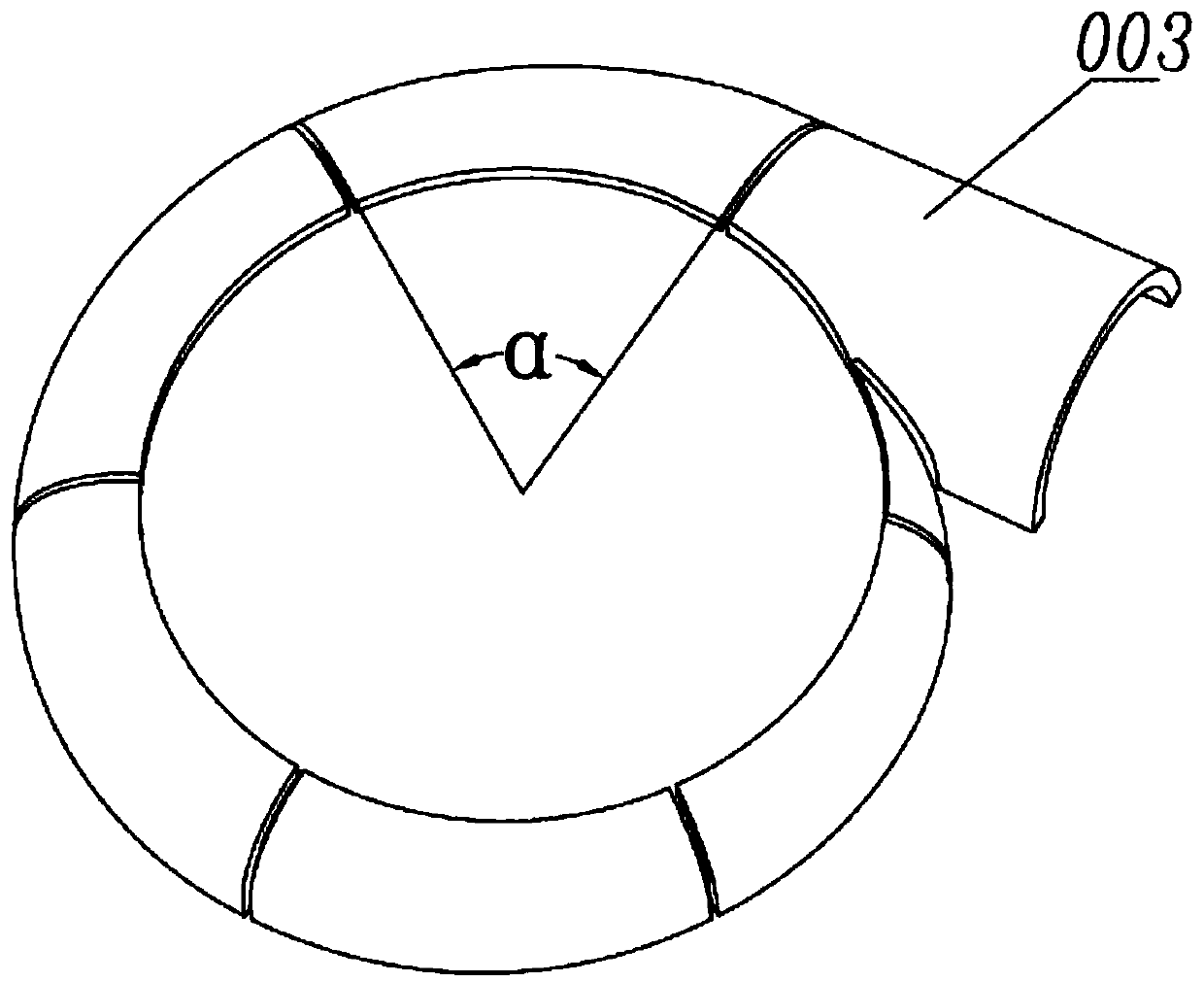

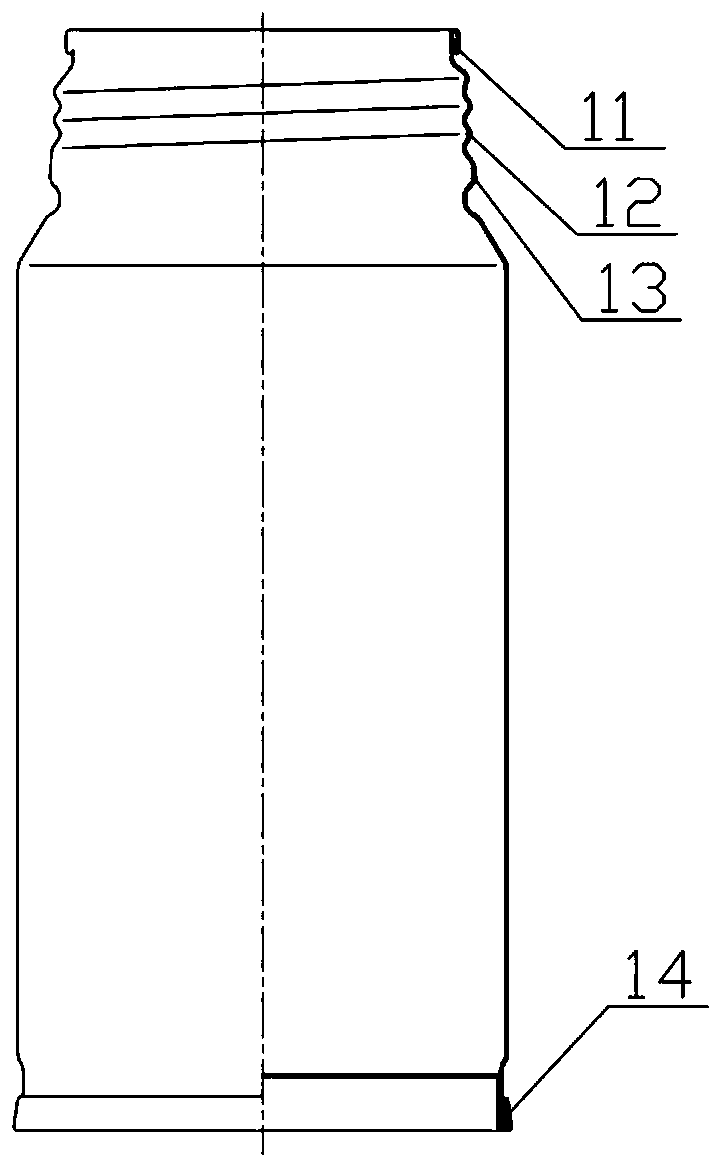

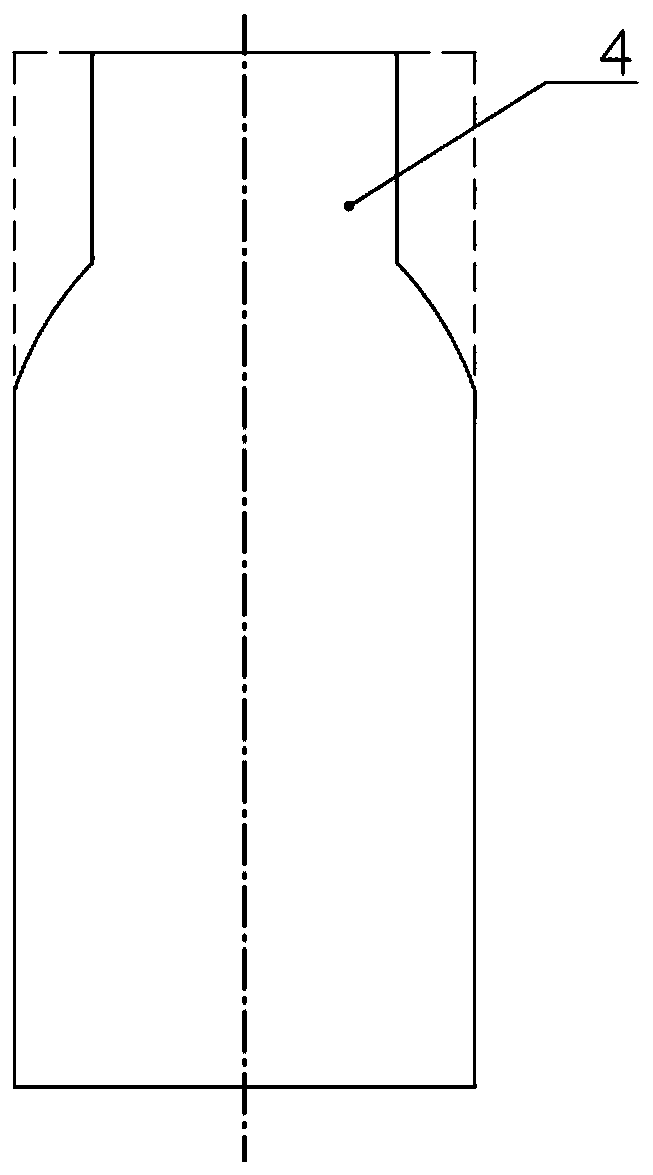

Welded metal bottle can and manufacturing method thereof

The invention discloses a welded metal bottle can and a manufacturing method thereof. The welded metal bottle can comprise a can body and a neck part on the can body, wherein the neck part comprises amiddle caliber part and a conical part arranged on the upper portion of the middle caliber part; the conical part is provided with an included angle alpha relative to a vertical plane, and the included angle alpha is 3-10 degrees; the manufacturing method comprises the steps of carrying out rolling and welding of a metal sheet after painting into a cylindrical tank body; reducing one open end ofthe can body to form the middle caliber part; and forming the middle caliber part to form the conical part on the upper portion of the middle caliber part, wherein the conical part is provided with anincluded angle alpha relative to a vertical plane, and the included angle alpha is 3-10 DEG. The welding metal bottle can and the manufacturing method have the advantages that the processing difficulty is greatly reduced; through three-layer folding process of a curling part and taper angle setting, the sealing performance of the manufactured welding metal bottle can is good, so that the coatingis not prone to peeling off; a screw cover rotates smoothly, and the sealing performance is good, so that the welding metal bottle can is not prone to rusting during containing liquid.

Owner:CHUZHOU JIAMEI PLATE PRINTING & CAN MAKING

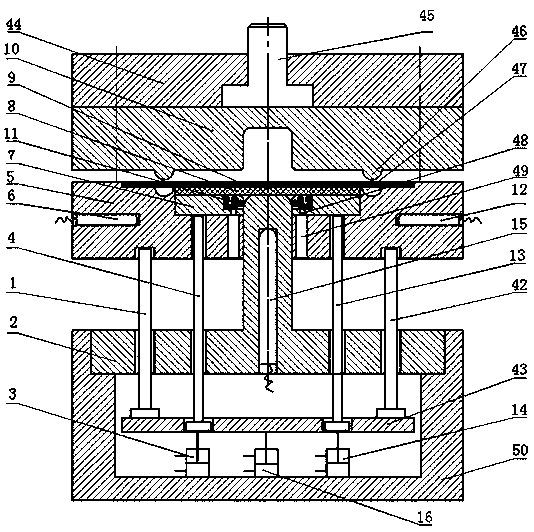

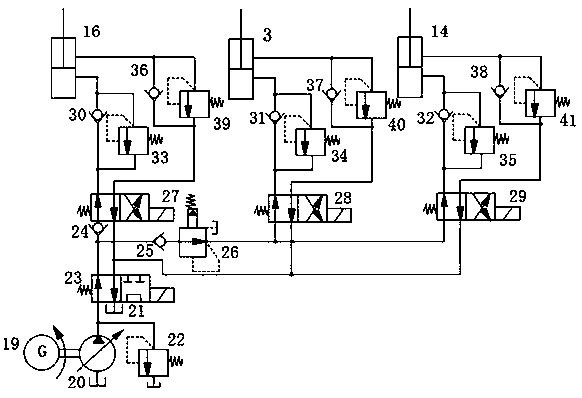

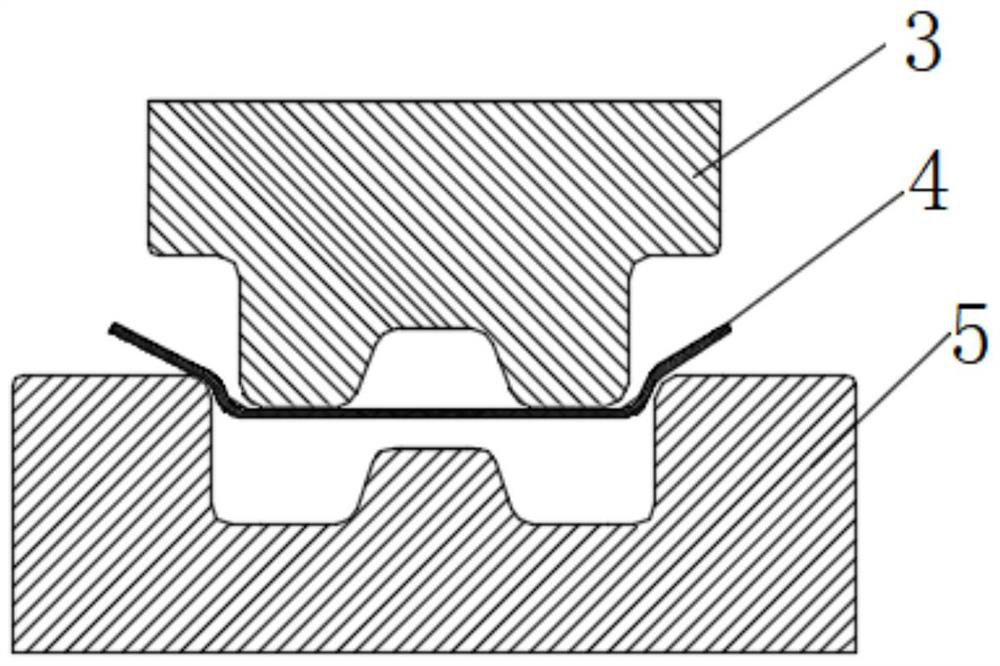

Device and method for warm forming of metal and carbon fiber prepreg composite material components

ActiveCN106891511BLarge adjustable restraint resistanceAdjustable restraint with low resistanceHydraulic cylinderFiber

The invention discloses a warm-hot forming device and method for a metal and carbon fiber prepreg composite material component in the field of lightweight composite material forming and processing. An outer blank holder is arranged between a female mold and a male mold. The middle of the outer blank holder is provided with a downwards concave step positioning groove. The top of the step positioning groove can contain a steel plate, and an inner blank holder is placed at the bottom of the step positioning groove. The upper surface of the inner blank holder can contain a carbon fiber prepreg blank. A pushing plate is arranged under the male mold. The top ends of a first outer blank holder pushing rod and a second outer blank holder pushing rod can upwards jack the outer blank holder, and the bottom ends of the first outer blank holder pushing rod and the second outer blank holder pushing rod are fixedly connected to the pushing plate. The top ends of a first inner blank holder pushing rod and a second inner blank holder pushing rod can upwards jack the inner blank holder, and the bottom ends of the first inner blank holder pushing rod and the second inner blank holder pushing rod are each connected with a hydraulic cylinder. A third hydraulic cylinder is connected under the pushing plate. Large adjustable constraint resistance is applied to the steel plate. By means of the adjustable constraint resistance with a small effect on the carbon fiber prepreg blank, two heterogeneous component materials have the mutual matching forming capacities, and warm forming and hot forming are completed in a one-time stamping stroke.

Owner:株洲西康尼克新材料有限公司

Forming method for integrally-forged multiple pipe nozzles of large-scale integrated connecting pipe section

ActiveCN114210895AReduce forming difficultyReduce resistanceNuclear energy generationMetal-working apparatusStructural engineeringManufacturing engineering

The invention provides a forming method for integrally-forged multiple nozzles of a large-scale integrated connecting pipe section, which comprises the following steps: preparing a cylindrical intermediate blank, and arranging an annular convex shoulder for forming the nozzles on the outer wall of the intermediate blank; sleeving two annular ring cutters on the blank on two sides of the annular convex shoulder, pushing the ring cutters to move towards the annular convex shoulder, and cutting edges of the ring cutters into the root of the annular convex shoulder; the annular convex shoulder is subjected to material distribution, and a plurality of pipe nozzle blanks are obtained; pre-forging the pipe nozzle blank by using a pre-forming die to obtain a pipe nozzle intermediate blank; and carrying out finish forging on the pipe nozzle intermediate blank by utilizing the finish forming die to obtain the pipe nozzle. The material utilization rate and the forging efficiency can be improved, and the pipe nozzle with uniform allowance, complete streamline and excellent performance can be obtained.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

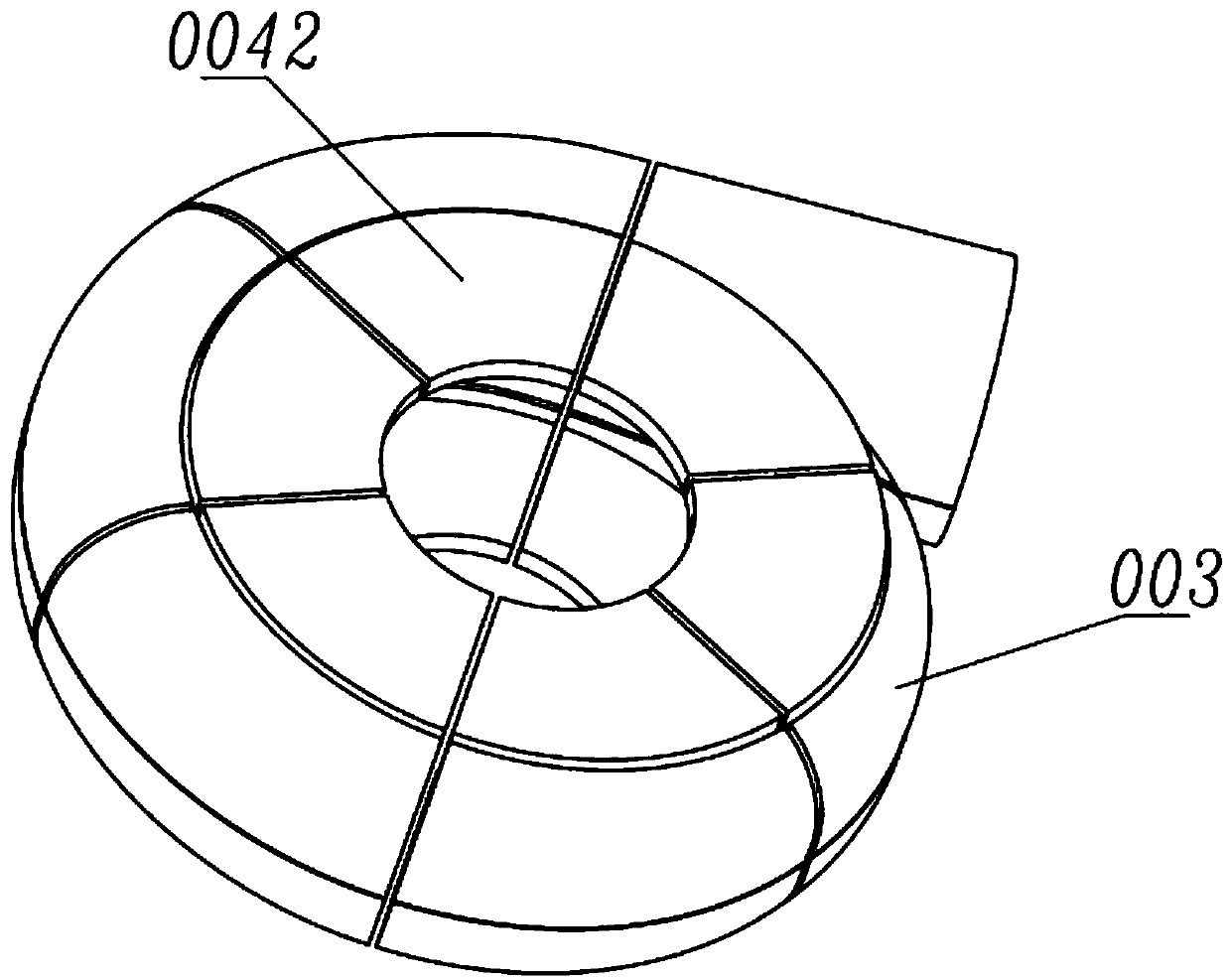

Ceramic impeller

PendingCN110848170AImprove reliabilityHigh mechanical strengthPump componentsPumpsImpellerEnergy absorption

The invention discloses a ceramic impeller and belongs to the technical field of rotary power pump equipment. According to the technical key points, an impeller body of ceramic materials is included and comprises a driving cover plate and a driven cover plate; a blade is arranged between the driving cover plate and the driven cover plate; one side of the driving cover plate is of a multilayer composite structure; and the multilayer composite structure comprises the driving cover plate, a first bonding energy absorption layer, a metal layer, a second bonding energy absorption layer and a seconddriving cover plate from inside to outside, wherein the second driving cover plate is of an independent structure and is made of ceramics or hard alloy, the metal layer is of a disc-shaped structure,a mandrel used for being connected with a spindle is connected to the radial inner side of the metal layer, and the first bonding energy absorption layer and the second bonding energy absorption layer are both filled with resin or a mixture of resin and abrasion resistant particles. The ceramic impeller has the characteristics that life is long, large torque can be borne, impact resistance is good, and large-scale production is easy to achieve.

Owner:GUANGZHOU TOTALL MATERIAL TECH CO LTD

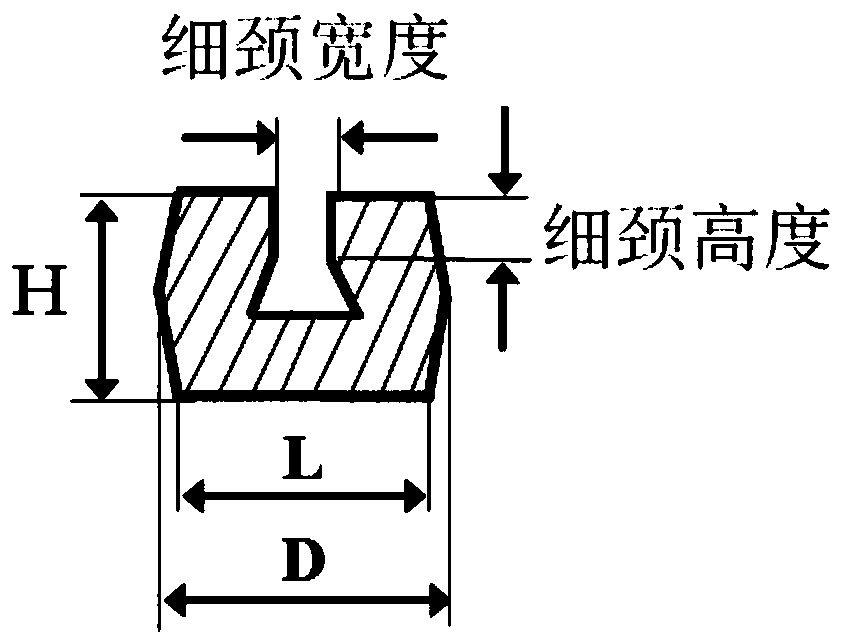

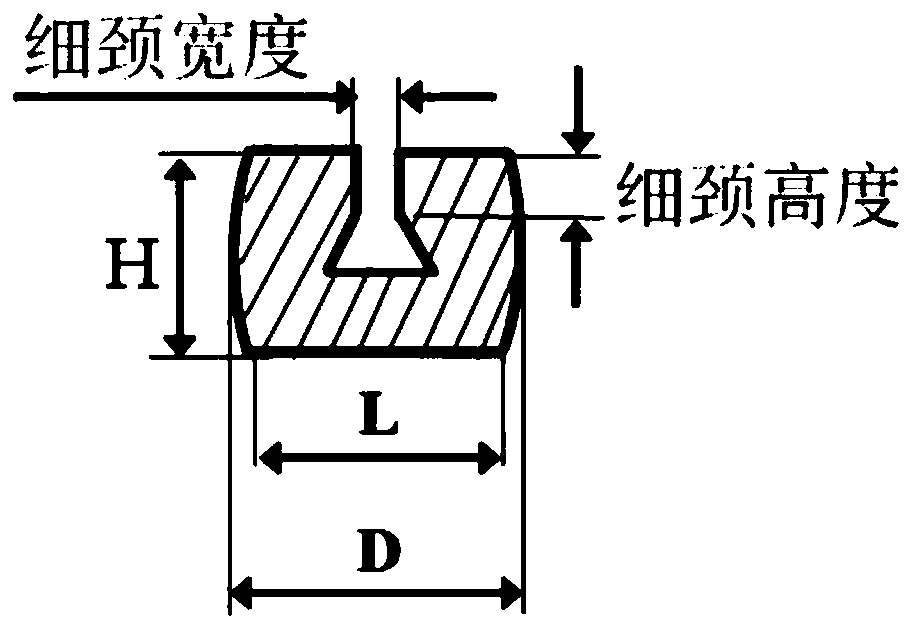

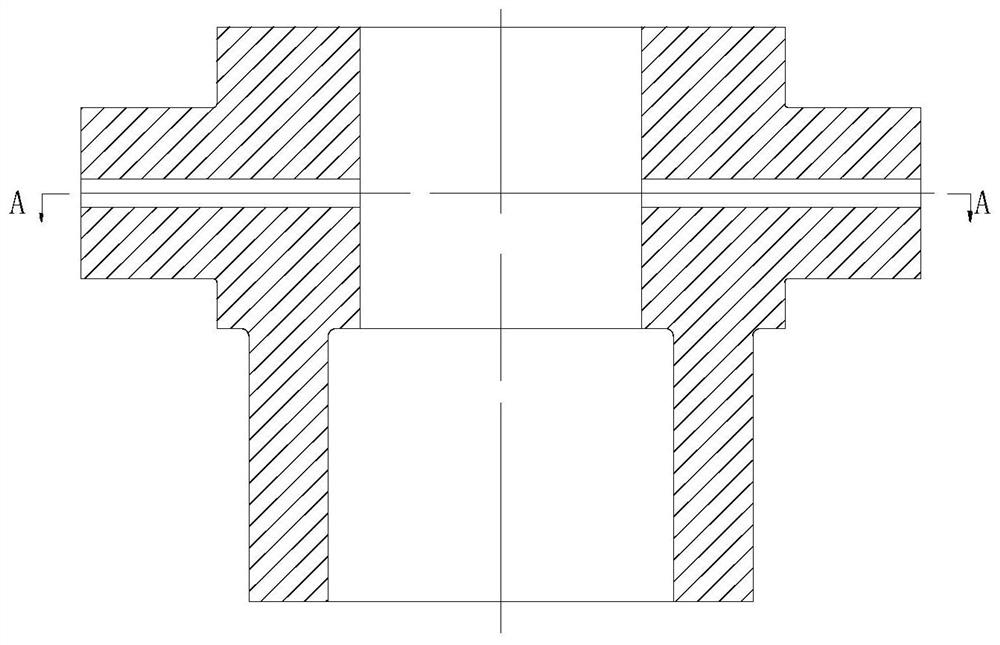

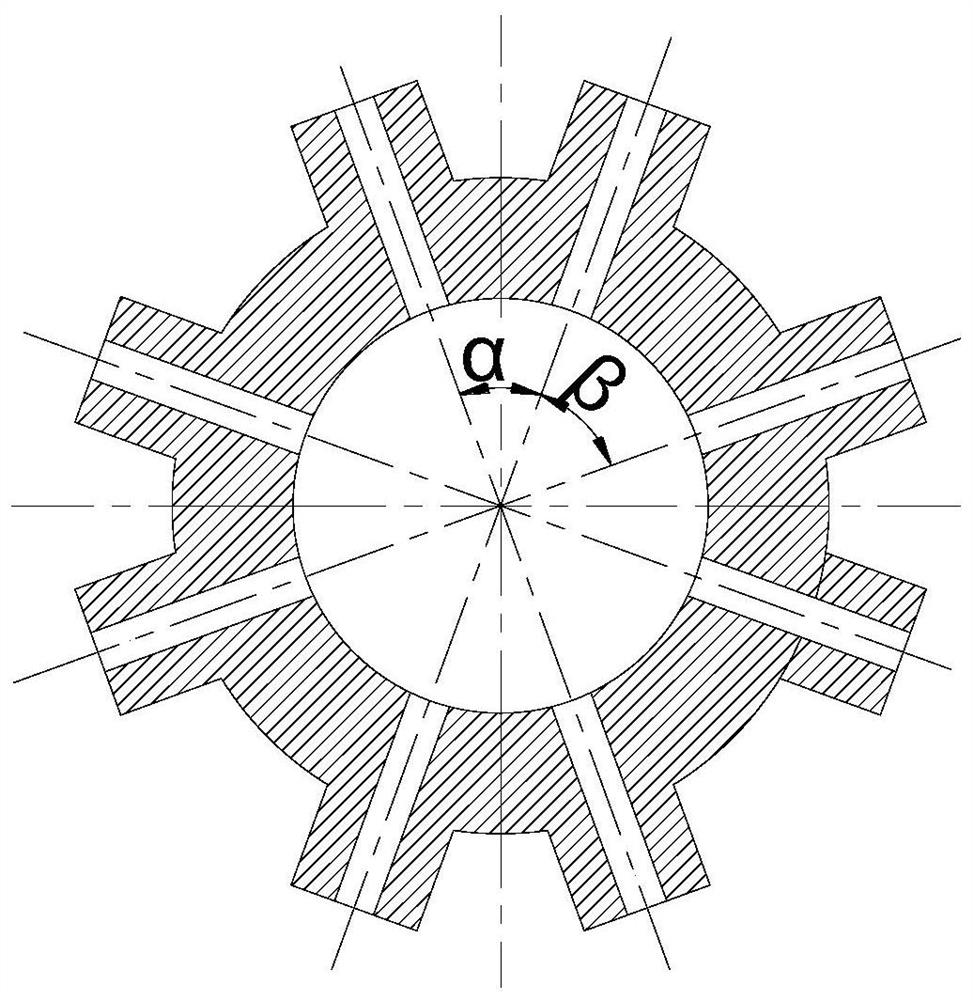

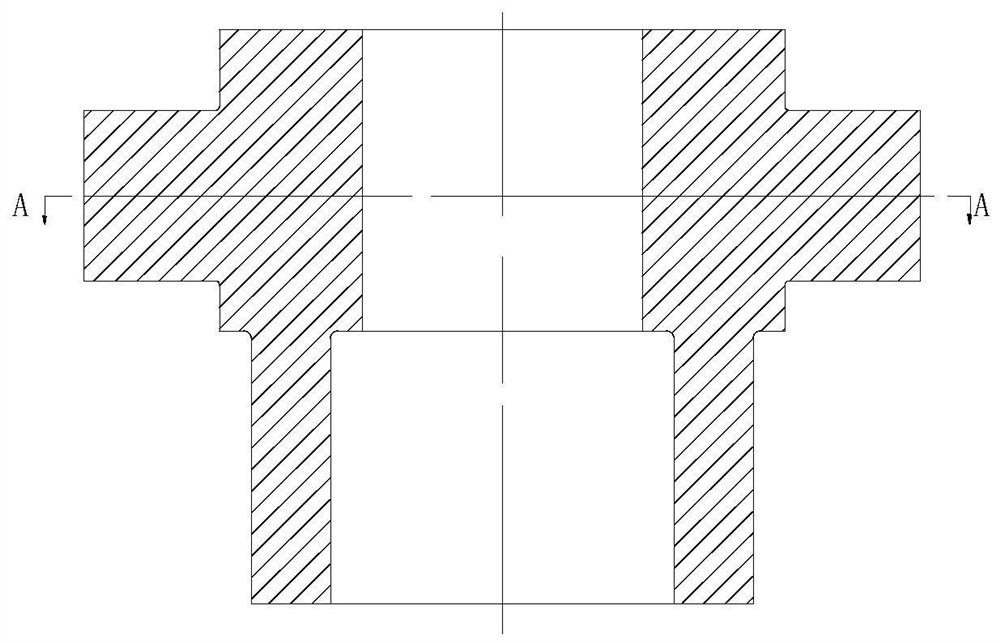

Threaded pipe production process

ActiveCN113385550AReduce forming difficultyReduce life expectancyShaping toolsDrawing diesSpinningThreaded pipe

The invention relates to the technical field of metal pipe machining, in particular to a threaded pipe production process which needs to use threaded pipe production equipment, an inner core and traction equipment for traction of a pipe. During production, the threaded pipe production process comprises the following steps of 1, reducing the diameter of the pipe, wherein the pipe is continuously subjected to traction by the traction equipment to move forwards, when the pipe moves forwards to the position between a moving drawing die and a moving core head, the moving core head rotates continuously, and the diameter of the pipe is reduced under the rotation of the moving core head and the traction of the traction equipment; 2, forming threads, wherein the pipe moves forwards to the position between a spinning ring and a threaded core head of the inner core, internal threads are formed on the inner wall of the pipe, cooling of the pipe, the spinning ring and the inner core is achieved in the pipe thread forming process, and meanwhile, lubricating of the spinning ring is achieved; and 3, sizing a threaded pipe, wherein the pipe is sized through a sizing die. The scheme is used for solving the problems that in the prior art, a large amount of heat generated in spinning forming affects the spinning forming quality, and the service life of the spinning ring and the inner core is shortened.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

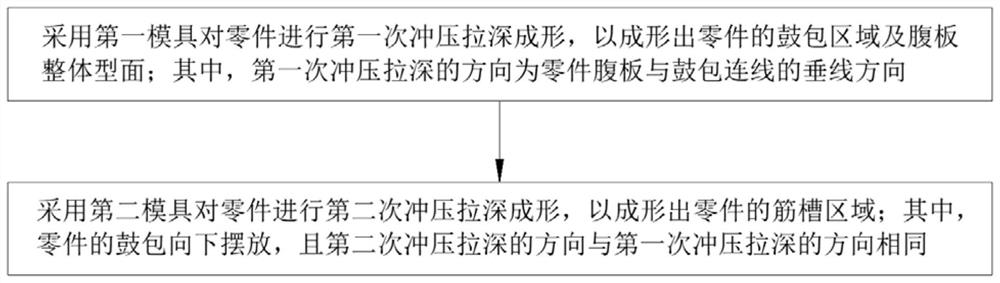

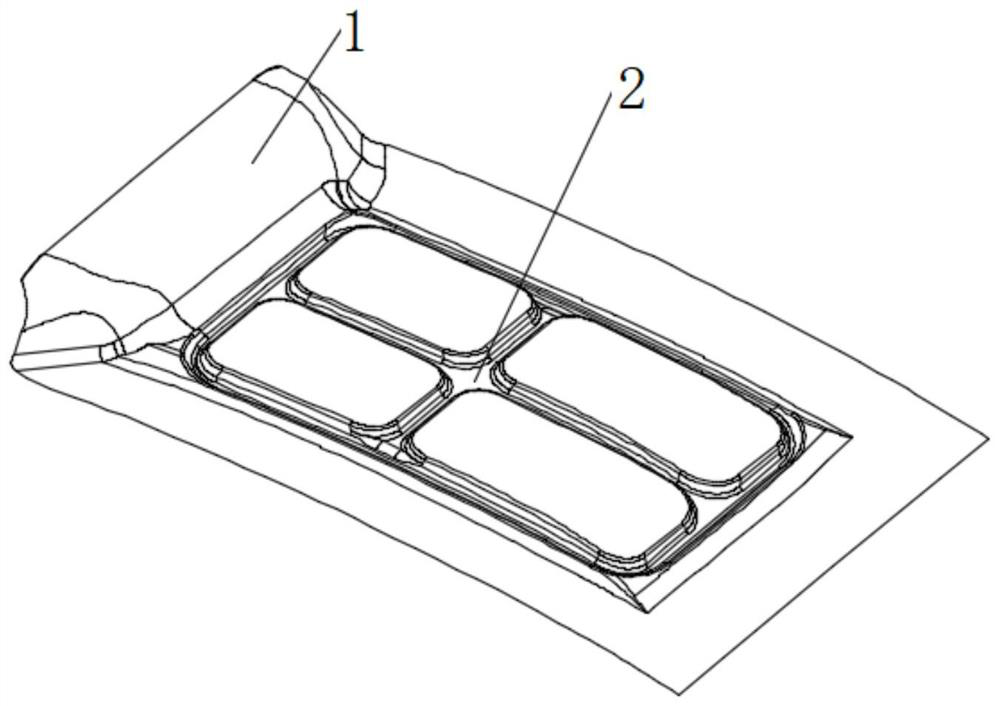

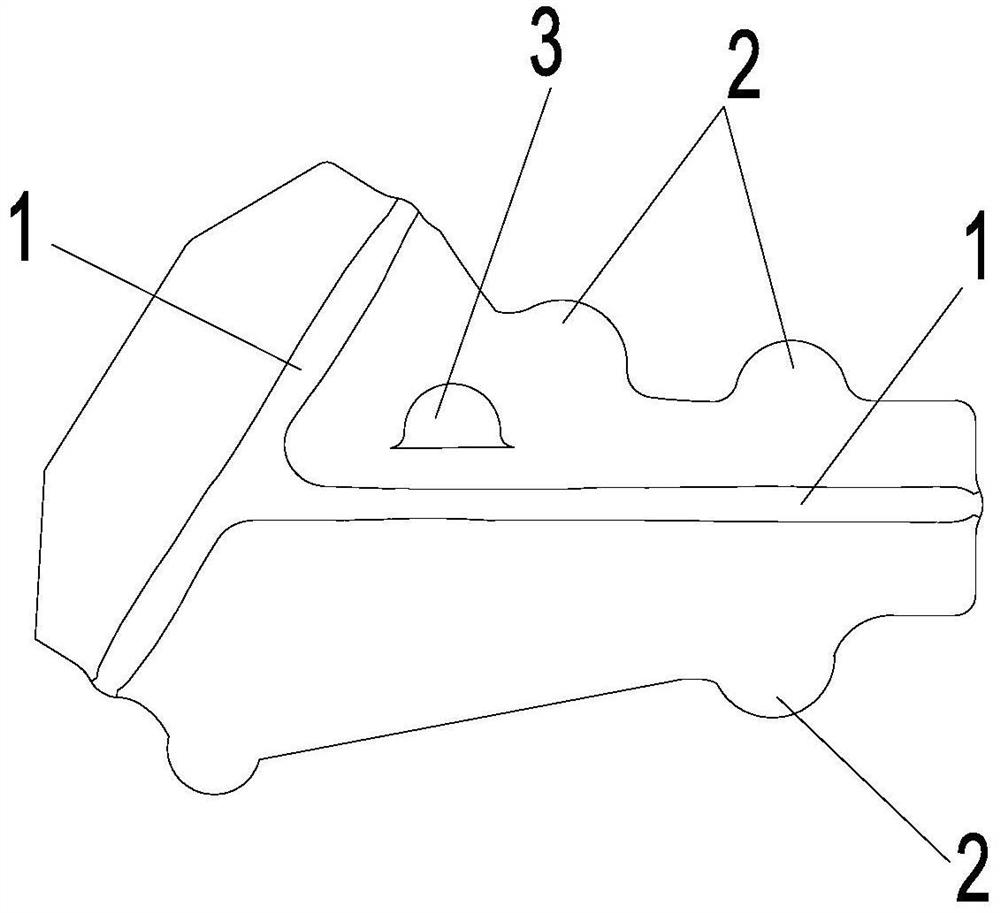

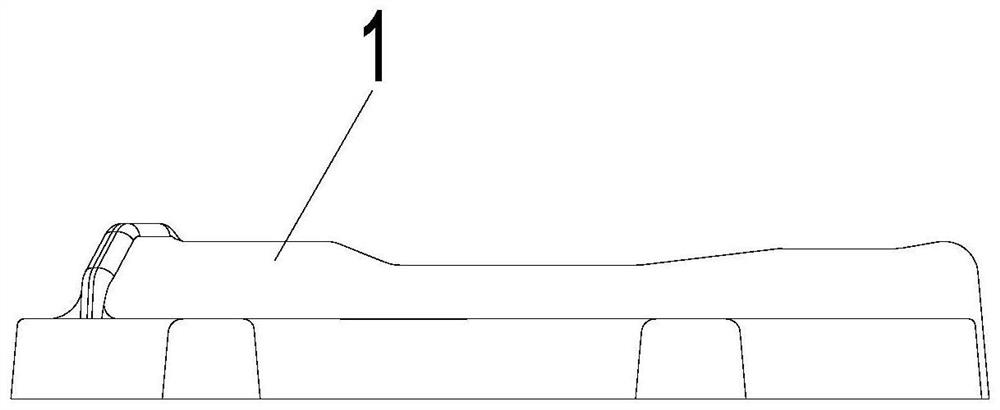

Forming method of sheet metal component with composite characteristics of bulge rib and groove

ActiveCN114798885AImprove process stabilityReduce forming difficultyShaping toolsEngineeringStamping

The invention discloses a bulging rib and groove composite characteristic sheet metal component forming method which comprises the following steps that a first die is adopted for conducting first-time stamping and deep drawing forming on a part so as to form a bulging area of the part and a web overall molded surface; wherein the direction of the first-time stamping and drawing is the direction of a vertical line of a connecting line of a part web and a bump; a second die is adopted for conducting secondary stamping and drawing forming on the part so that a rib groove area of the part can be formed; wherein a bulge of the part is placed downwards, the direction of the second time of stamping and drawing is the same as the direction of the first time of stamping and drawing, and the method has the advantages that the forming quality and the process stability of the sheet metal part with the rib groove and bulge composite characteristic are improved, and the formed part is good in performance and long in service life.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Internal Spinning Forming Method of Bellows

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

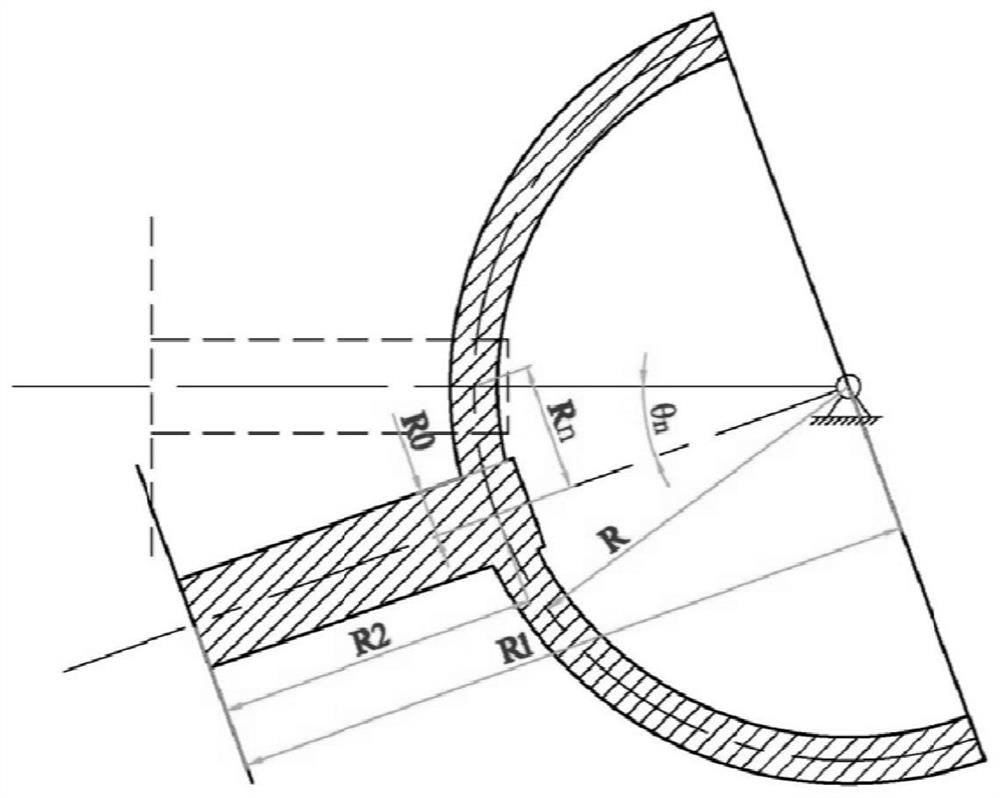

A path planning method for pressure vessel hemisphere additive manufacturing

ActiveCN109454230BReduce forming difficultyReduce manufacturing costAdditive manufacturing apparatusIncreasing energy efficiencyRotational axisEngineering

The invention discloses a path planning method for hemispherical additive manufacturing of pressure vessels. The method includes two schemes. One is to use a fixed heat source to realize the deposition path only through a two-axis positioner. The center of the hemisphere coincides with the center of the turning axis of the positioner. Every time a layer is deposited, after the positioner is turned over by the same angle, the rotation axis of the positioner rotates to achieve layer-by-layer melting and deposition to form a hemisphere. The other is to use a movable heat source, which requires a robot or other actuators to hold heat sources such as plasma arcs and electron beams. The actuators and the two-axis positioner move in coordination. Every time a layer is deposited, the positioner turns over at the same angle. The actuator drives the heat source to follow the deposited hemisphere for a certain distance, and the rotary shaft of the positioner rotates to realize layer-by-layer melting and deposition to form a hemisphere. The invention can directly and quickly form the hemisphere of the pressure vessel with complex shape, and has high forming efficiency and low cost.

Owner:CAPITAL AEROSPACE MACHINERY +1

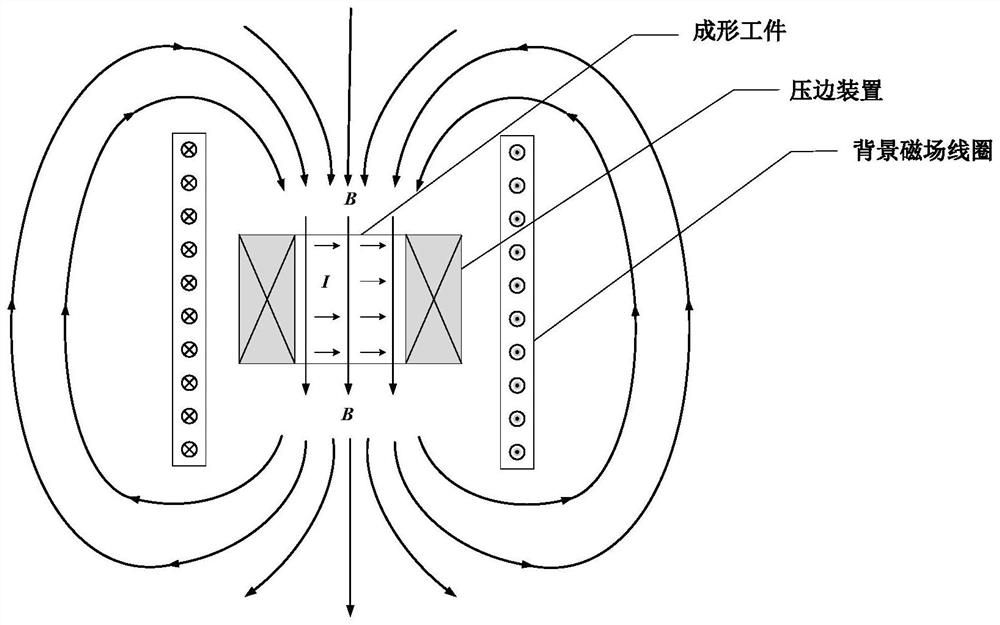

Adjustable high-frequency vibration assisted electromagnetic forming device and method

ActiveCN114733954AExtended service lifeGood formabilityIncreasing energy efficiencyMetallic materialsEngineering

The invention provides an adjustable high-frequency vibration auxiliary electromagnetic forming device. The adjustable high-frequency vibration auxiliary electromagnetic forming device comprises a background magnetic field module, a high-frequency vibration auxiliary module and an electromagnetic forming module. The background magnetic field module provides a background magnetic field for the workpiece; the high-frequency vibration auxiliary module provides alternating current for the workpiece, so that the workpiece generates high-frequency vibration; the electromagnetic forming module is used for providing pulse large current for the workpiece to generate pulse electromagnetic force, so that the workpiece is deformed; according to the method, the service life of the coil can be effectively prolonged, the forming performance of the metal material can be effectively improved, particularly, the forming difficulty of the low-conductivity metal material is reduced, and forming control is more flexible.

Owner:XIAMEN UNIV +1

The Second Radial Inner Ring Forming Process of the Inner Wall of Thin-walled Tube

ActiveCN106180507BEasy to produceSimple processForging/hammering/pressing machinesHollow articlesEngineeringWork in process

The invention discloses a process for forming a second radial inner ring on the inner wall of a thin-walled cylinder. The process includes the steps that (1) a semi-finished product with a first radial inner ring being formed in an upset-extruding mode is placed in a forming die; (2) a core die and a pressing die are mounted in an inner cavity of the thin-walled cylinder located in place, the opening of the thin-walled cylinder is subjected to upset-extruding through the pressing die to be plastically deformed, and overflowing metal is jointly limited by the core die and the pressing die to form one section of the second radial inner ring; (3) the core die and the pressing die are synchronously transferred to the next station along the inner wall of the thin-walled cylinder; (4) the pressing die conducts upset-extruding on the new station, another section of the second radial inner ring is formed, and upset-extruding is executed section by section in sequence; and (5) the core die moves inwards in the radial direction, a finished product is taken out, and another semi-finished product to be machined is placed in the forming die. According to the process, the method that upset-extruding is conducted section by section and forming is gradually achieved is adopted, upset-extruding forming of the thin-walled cylinder with the two internal radial inner rings is achieved, the upset-extruding process which breaks up the whole into parts is simple and convenient, and production can be easily organized.

Owner:JIANGSU PACIFIC PRECISION FORGING +1

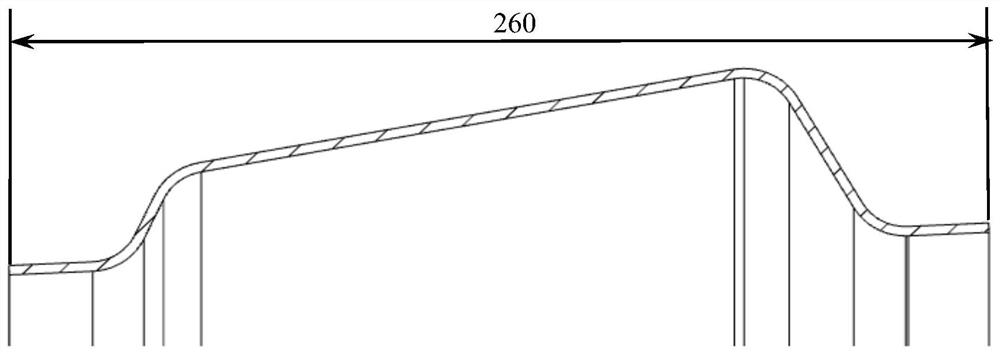

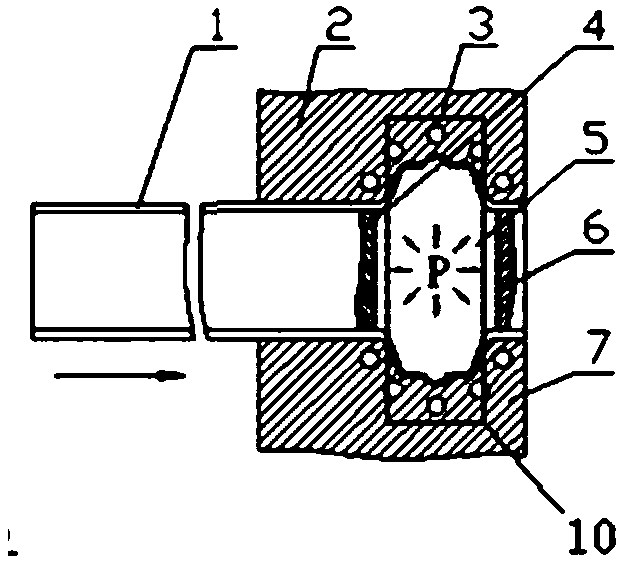

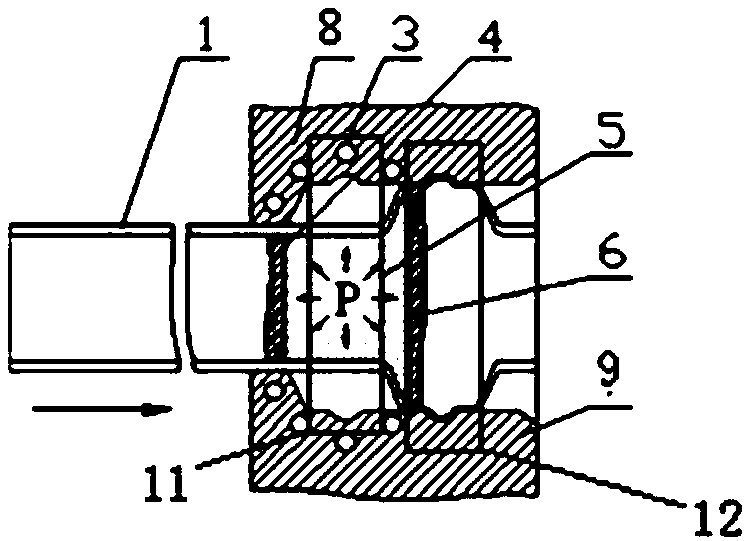

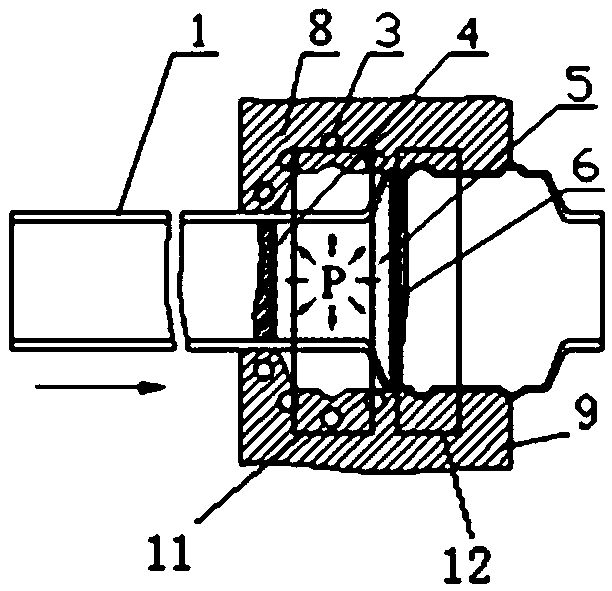

A warm forming method for seamless tunnel pipe with large diameter-thickness ratio

A warm-hot forming method of a seamless tunnel pipe with the large radius-thickness ratio comprises the following steps that S1, an original pipe is selected; S2, a heating coil is used for heating; S3, a first corrugation is formed through a pipe blank 1; S4, the pressure of a flexible medium in the pipe blank is relieved, and an upper half mold and a lower half mold are opened; S5, a second corrugation is formed through the pipe blank 1; and S6, a third corrugation continues to be formed in a cavity B, the method of the third corrugation is consistent with the forming method of the first corrugation and the forming method of the second corrugation, and an Nth corrugation is formed in the same way till all corrugations are formed.

Owner:CAPITAL AEROSPACE MACHINERY +1

Manufacturing method of titanium alloy aviation joint forge piece

PendingCN114260400ASmall forming resistanceReduce forming difficultyForging/hammering/pressing machinesForge furnacesBatch productionManufacturing engineering

The invention provides a manufacturing method of a titanium alloy aviation connector forge piece. The manufacturing method comprises the steps that a bar is blanked, and the bar is divided and drawn out; the blank is heated at the constant temperature of T beta-(30-50 DEG C) and then transferred into a die to be forged, the transferring time is smaller than or equal to 120 s, the forging time is smaller than or equal to 160 s, the pressing speed of a pre-forging press is 4-12 mm / s, the temperature of the blank at the beginning of forging is larger than or equal to 850 DEG C, the temperature of the blank at the end of forging is larger than or equal to 810 DEG C, and air cooling is conducted after forging; the blank is heated at the constant temperature of T beta + (20-40 DEG C) and then transferred into a die to be forged, the forging time is smaller than or equal to 160 s, the pressing speed of a finish forging press is 4-12 mm / s, the temperature of the blank is larger than or equal to 900 DEG C after forging is finished, the temperature of the blank is larger than or equal to 880 DEG C after forging is finished, and air cooling is conducted after forging. According to the method, the bar is adopted as the raw material, the forming difficulty is reduced, the forging process is optimized, the performance of the forge piece is guaranteed, surface treatment is not needed after blank making and pre-forging, the production process is saved, and the efficiency of batch production can be improved.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com