Internal Spinning Forming Method of Bellows

A corrugated tube and internal spinning technology, which is applied in the field of corrugated tube internal spinning, can solve the problems of poor product forming accuracy and consistency, difficulty in ensuring the welding quality of corrugated tubes, and inability to complete corrugated tube processing, so as to achieve good product quality and save energy. Welding material costs, weld inspection costs, and the effect of reducing circumferential welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

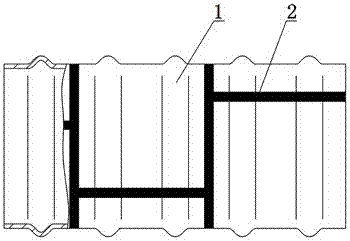

[0030] Embodiment 1: see figure 1 , figure 1 It is a schematic diagram of the product structure produced by welding among the processed products of the prior art. There is a bellows 1 in the figure, and it can be seen that the welding areas 2 are criss-crossed.

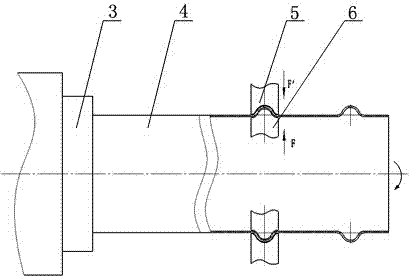

[0031] see Figure 2 to Figure 5 , a corrugated pipe 1 internal spinning forming method, comprising the following steps:

[0032] (1) Install the tube blank 4 on the main shaft 3 of the spinning machine, and the long thin-walled tube is driven by the main shaft 3 to rotate, and the rotating speed of the main shaft 3 is 60r / min~120r / min;

[0033] (2) The corrugated internal rotation wheel 6 and the external rotation wheel 5 are respectively installed inside and outside the tube blank 4. There are three inner and external rotation wheels 5, which are evenly distributed along the circumferential direction of the tube blank 4 and located in the radial direction of the tube blank 4. At the safe position, wherein, the op...

Embodiment 2

[0049] In this embodiment, the tube blank 4 is a long thin-walled tube made of 5A03 aluminum (LF3), with an inner diameter of d=380mm and a wall thickness of t=3.2mm. =386.4mm, the radius of the peak fillet of the outer wall of the finished corrugated pipe 1 is R=22mm, and the radius of the transition fillet of the root of the corrugated outer wall of the finished bellows 1 is r=10mm.

[0050] In step (1), the speed of spindle 3 is 80r / min;

[0051] In step (3), the feeding speed of the outer rotating wheel 5 is 4.5mm / r, the feeding speed of the inner rotating wheel 6 and the tube blank 4 is 4.5mm / r before contact, and 2mm / r after contact;

[0052] In step (4), the gap between the convex surface of the inner rotation wheel 6 and the concave surface of the outer rotation wheel 5 is the thickness of the tube blank 4, and the forming time for maintaining this gap is 5s.

[0053] In addition, the specific dimensions about the outer rotation wheel 5 and the inner rotation wheel 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com