Continuous extrusion method and extrusion tool for lead frame material of shallow wheel trough

A technology for lead and frame materials of shallow grooves, which is applied in the field of continuous extrusion of lead frame materials of shallow grooves and extrusion tooling, can solve the problem that the convex part of the block is easy to crack at the root, the temperature gradient of the block is large, and the damage Torque increase and other problems, to achieve the effect of increasing thickness, reducing production energy consumption, and reducing the height of the convex edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

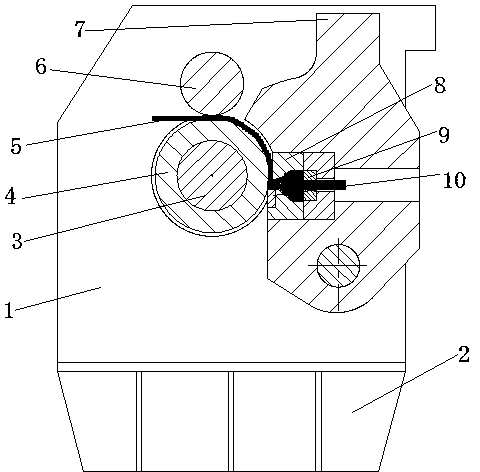

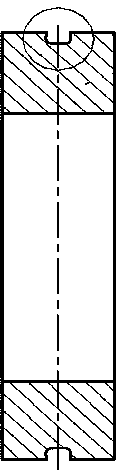

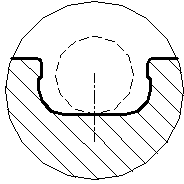

[0021] like Figure 1 to Figure 6 As shown, the shallow groove lead frame material continuous extrusion method and extrusion tooling, extrusion tooling includes frame 1, base 2, main shaft 3, shallow groove extrusion wheel 4, shallow groove compaction wheel 6, shoe seat 7. The shallow wheel groove cavity 8, the mold 9 and the shallow wheel groove block 10, the frame 1 is installed on the base 2, the main shaft 3 is installed on the frame 1 through the bearing, and the shallow wheel groove extrusion wheel 4 is installed on the main shaft 3, the shallow wheel groove compaction wheel 6 is installed on the shallow wheel groove extrusion wheel 4, the bottom of the shoe seat 7 is connected with the frame 1, the shallow wheel groove cavity 8 is set in the shoe seat 7, and the mold 9 is installed on the shallow wheel groove In the wheel groove cavity 8, the shallow wheel groove stopper 10 is arranged at the contact surface between the shallow wheel groove extrusion wheel 4 and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com