Functionally gradient material forming method and functionally gradient material forming device

A technology of functionally graded materials and forming chambers, which is applied in the field of material processing, can solve the problems of complex forming process and inability to realize the forming of complex structural parts, and achieve the effect of reducing the difficulty of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

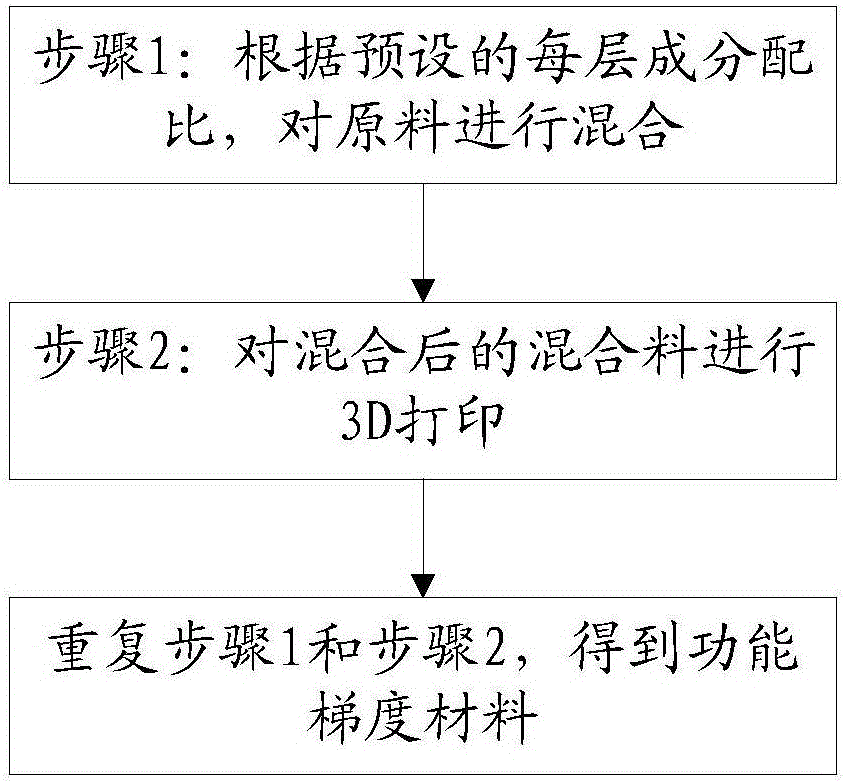

[0063] Embodiments of the present invention include the following steps:

[0064] (1) Using the ANASYS finite element analysis method to design the optimal composition distribution and structure of the gradient material, that is, the thickness of the gradient layer, the number of layers and the composition ratio of each layer;

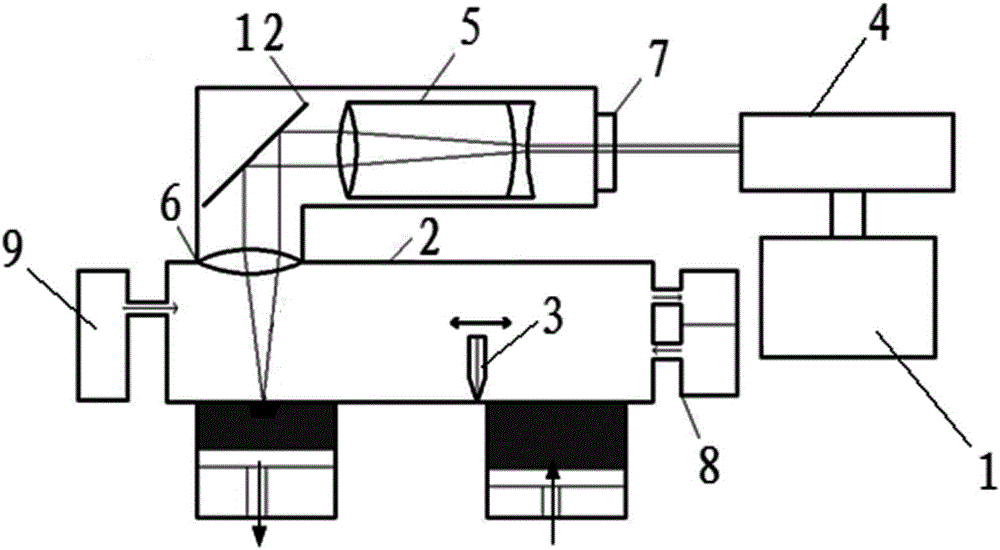

[0065] (2) Put the Inconel718 powder in the powder tank 1, and put the 316L powder in the powder tank 2. According to the optimal distribution ratio of each layer in step (1), determine the amount of powder that powder tank 1 and powder tank 2 drop to the powder mixing tank each time. Among them, Inconel718 powder and 316L powder are both spherical or nearly spherical, the average particle size of both is 20-45 μm, and the oxygen content is lower than 1000ppm.

[0066] (3) Rapidly mix the powder falling in the powder mixing cylinder, and the evenly mixed powder falls into the forming chamber 2 of the 3D printing forming device.

[0067] (4) Start the...

Embodiment 2

[0071] Embodiments of the present invention include the following steps:

[0072] (1) Using the ABAQUS finite element analysis method to design the optimal composition distribution and structure of the gradient material, that is, the thickness of the gradient layer, the number of layers and the composition ratio of each layer;

[0073] (2) Put the Ti powder in the powder tank 1, and put the TiAl powder in the powder tank 2. According to the optimal distribution ratio of each layer in step (1), determine the amount of powder that powder tank 1 and powder tank 2 drop to the powder mixing tank each time. Wherein, the Ti powder and the TiAl powder are spherical or nearly spherical, the average particle size of both is 20-45 μm, and the oxygen content is lower than 1000 ppm.

[0074] (3) Rapidly mix the powder falling in the powder mixing cylinder, and the evenly mixed powder falls into the forming chamber 2 of the 3D printing forming device.

[0075] (4) Start the 3D printing fo...

Embodiment 3

[0079] Embodiments of the present invention include the following steps:

[0080] (1) Using the MARC finite element analysis method to design the optimal composition distribution and structure of the gradient material, that is, the thickness of the gradient layer, the number of layers and the composition ratio of each layer;

[0081] (2) Put the Ti6Al4V powder in the powder tank 1, and place the TiC powder in the powder tank 2. According to the optimal distribution ratio of each layer in step (1), determine the amount of powder that powder tank 1 and powder tank 2 drop to the powder mixing tank each time. Among them, Ti6Al4V powder and TiC powder are both spherical or nearly spherical, with an average particle size of 20-45 μm and an oxygen content of less than 1000 ppm.

[0082] (3) Rapidly mix the powder falling in the powder mixing cylinder, and the evenly mixed powder falls into the forming chamber 2 of the 3D printing forming device.

[0083] (4) Start the 3D printing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com